Method for preparing magnetic recording exchange coupling complex film

An exchange coupling, composite film technology, applied in magnetic recording, data recording, recording information storage, etc., can solve the problems of reducing the thermal stability of the medium film, writing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be further described below in conjunction with accompanying drawing:

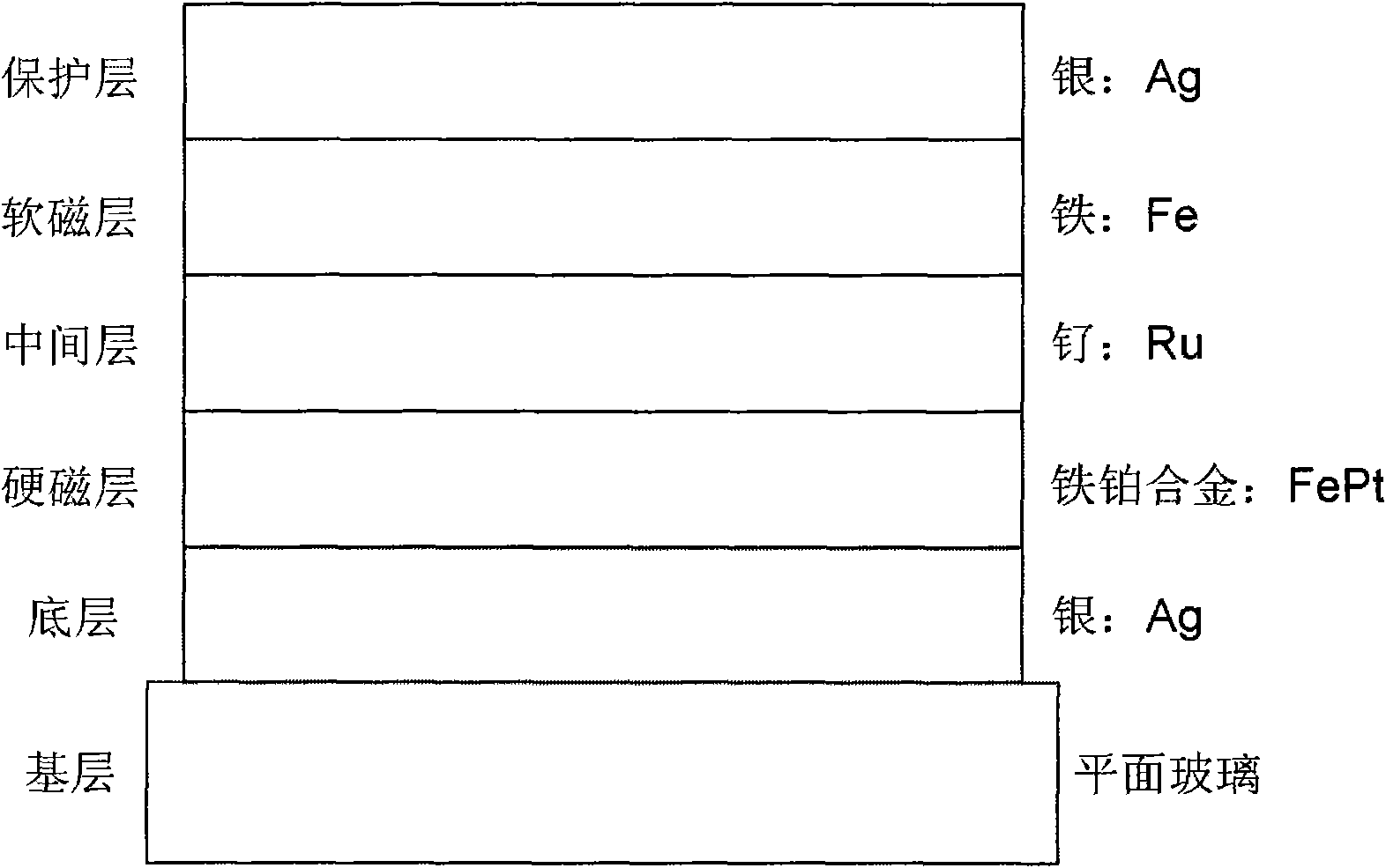

[0103] figure 1 As shown, it is the structural diagram of the exchange coupling composite dielectric membrane. The dielectric membrane has six layers in total, and each layer is tightly combined with good compactness.

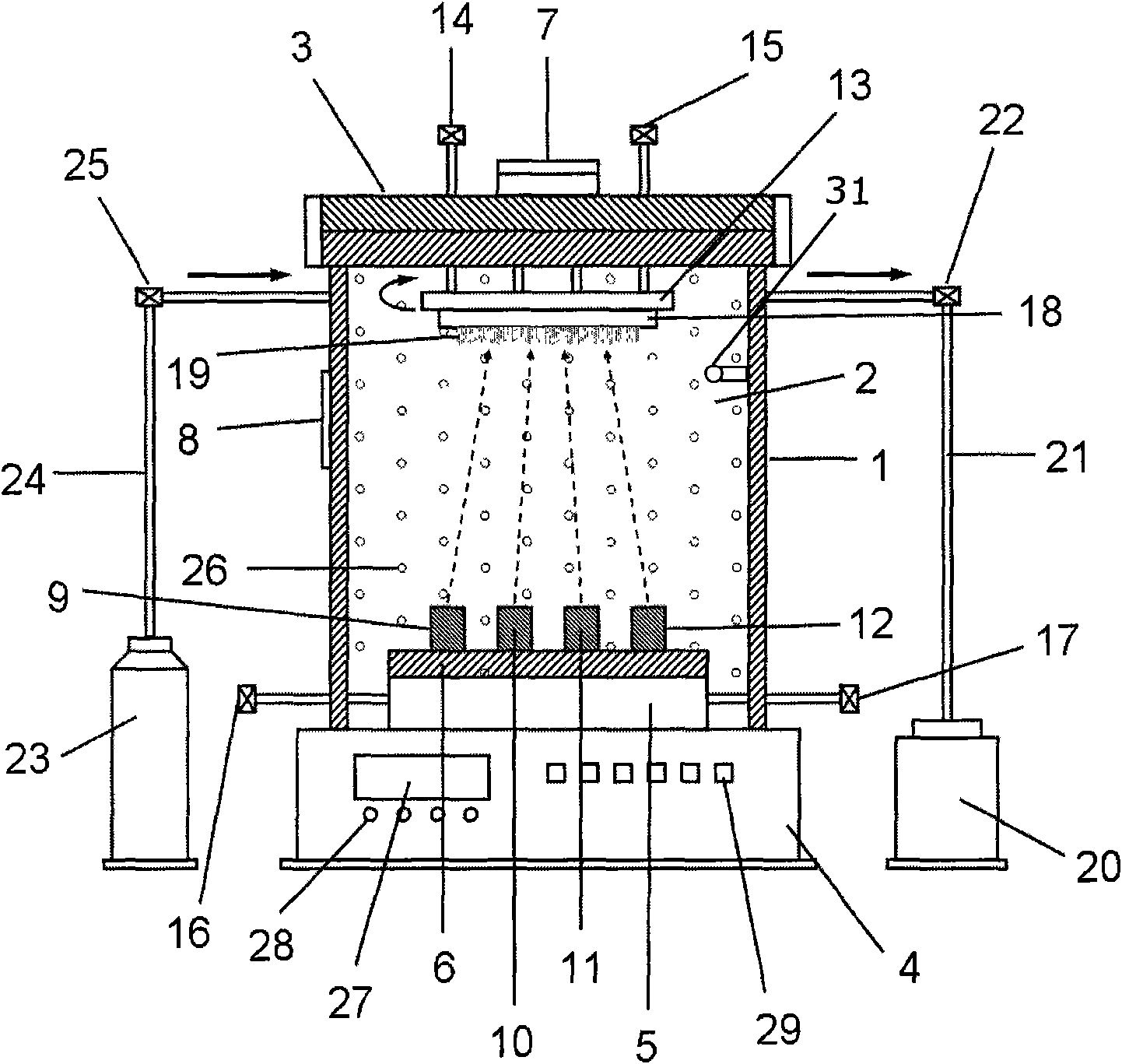

[0104] figure 2 As shown, the state diagram of the exchange coupling composite film prepared by magnetron sputtering, the position and connection relationship of each part should be correct, the installation should be firm, and the operation should be convenient.

[0105] The materials and quantities used in this preparation are determined according to the preset range, in grams, milliliters, centimeters 3 , mm is the unit of measurement.

[0106] The preparation is completed in a strictly clean state. In the furnace cavity, in an argon atmosphere, under a magnetic field, in a water-cooled state, and under a vacuum of 1.0Pa, the entire coating process mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com