Manufacturing method of low-voltage transient voltage suppression diode chip

A technology of transient voltage suppression and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increasing costs, and achieve the effect of increasing P/N junction depth and reducing surface leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

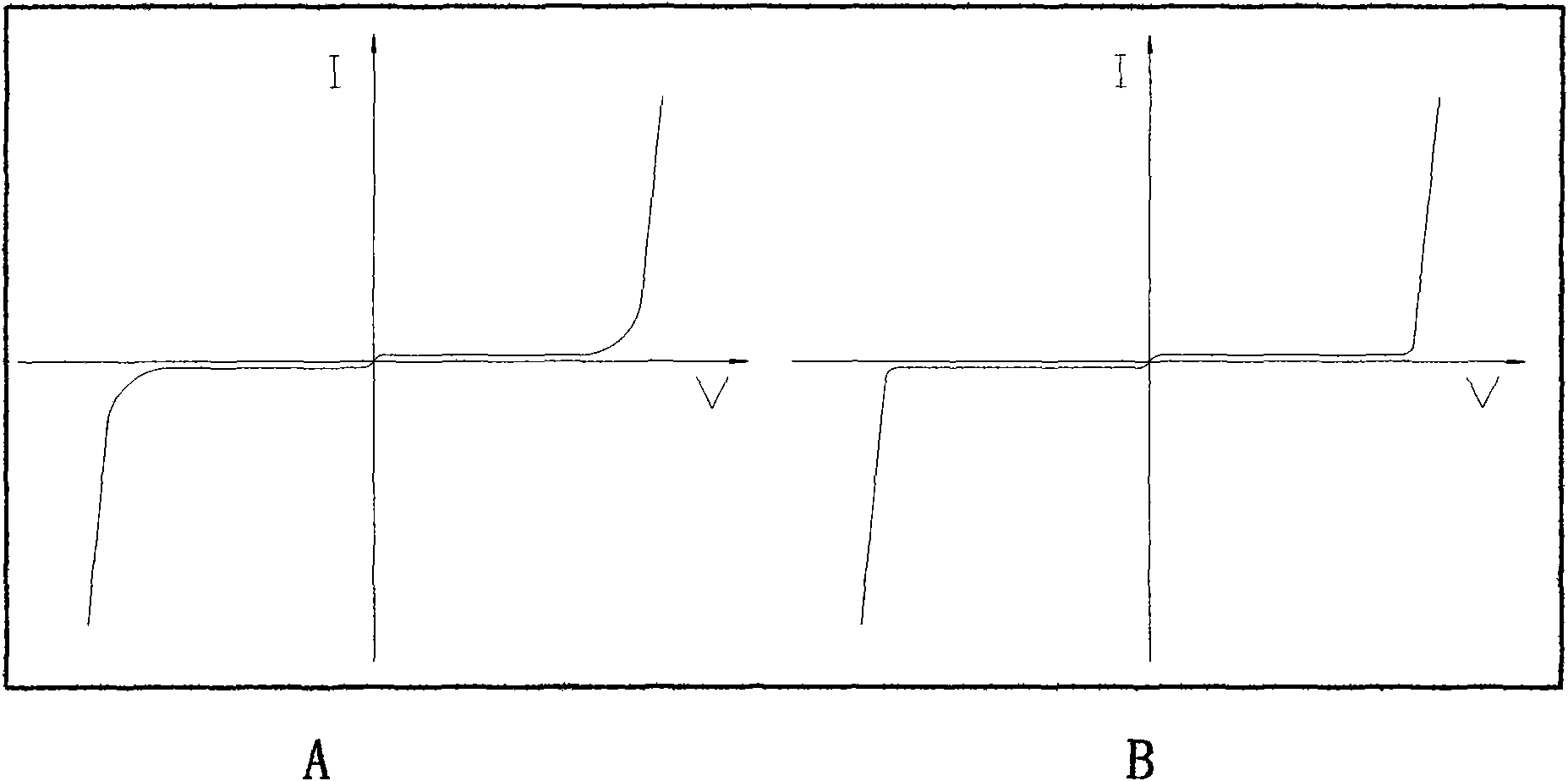

[0023] The manufacturing method of the low-voltage transient voltage suppression diode chip of the invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 and figure 2 As shown, the present invention uses a single-crystal silicon grinding disc with a resistivity of 0.001-0.02 Ω·cm in the P-type crystal orientation, and first performs chemical polishing treatment to remove the surface defect layer of the ground silicon wafer. Use nitric acid, hydrofluoric acid, and glacial acetic acid mixed acid according to the ratio of polishing to carry out polishing treatment on the silicon wafer at low temperature, and the thickness of single-side etching is 5-30um.

[0025] The polished silicon wafers are heat treated with a high-low-high temperature curve. First, perform one-step high-temperature annealing, and then continue the multi-step temperature-increasing heat treatment process at 750-900°C. Annealing is carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com