Room temperature curing epoxy adhesive and preparation method thereof

An epoxy resin, room temperature curing technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the physical and chemical properties of epoxy resin adhesive fire resistance, acid resistance, insulation, melting point and flexibility and The luster is not enough to meet the expected requirements, the tensile strength and shear strength are low, the preparation process is complicated, etc., and the curing effect is ideal, the preparation method is concise, and the formula selection is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

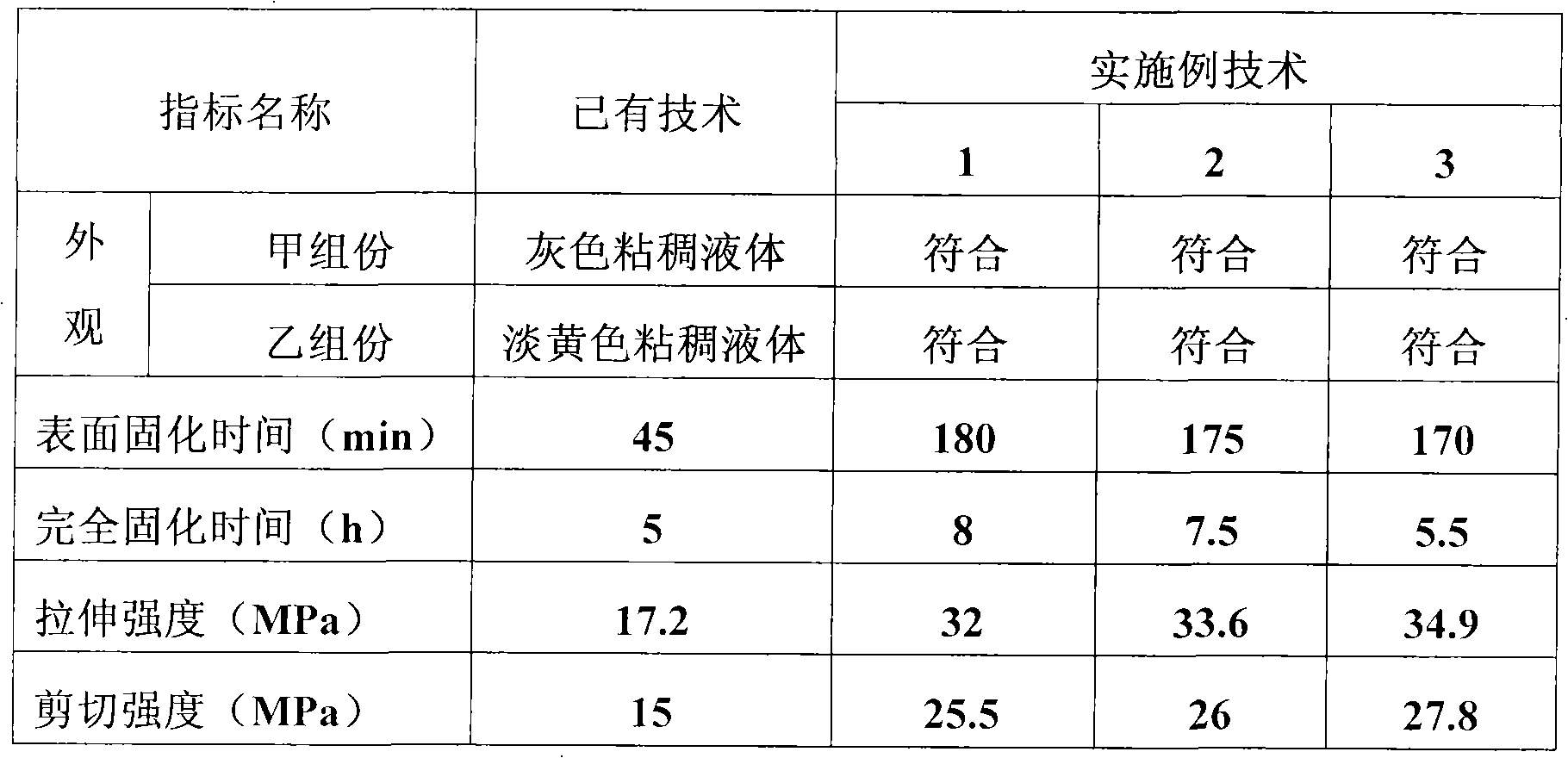

Examples

Embodiment 1

[0022] A) Preparation of component A: first weigh 80 parts of E-44 epoxy resin (also known as 6101 epoxy resin), 28 parts of talcum powder, 3.5 parts of fumed white carbon black and 10 parts of dibutyl phthalate by weight. Parts, put the aforementioned E-44 epoxy resin, talcum powder, fumed silica and dibutyl phthalate into a mixing device with a stirrer and mix, and the speed of the stirrer of the mixing device is controlled It is 90n / min, after mixing for 25min, the mixture is obtained, then the mixture is dropped into a three-roller grinder for grinding, and the belt transfer of the grinding roller of the three-roller grinder is controlled to be 35n / min, after 70min grinding, component A is obtained, Pack component A according to the required packaging specification;

[0023] B) Preparation of component B: First weigh 25 parts of T30 long-chain fatty amine modified curing agent, 35 parts of kaolin, 1.5 parts of fumed silica, 2 parts of dibutyl phthalate and KH-550 silane by...

Embodiment 2

[0026] A) Preparation of component A: First weigh 100 parts of E-44 epoxy resin (also known as 6101 epoxy resin), 12 parts of talcum powder, 1.2 parts of fumed white carbon black and 3 parts of dibutyl phthalate by weight. Parts, put the aforementioned E-44 epoxy resin, talcum powder, fumed silica and dibutyl phthalate into a mixing device with a stirrer and mix, and the speed of the stirrer of the mixing device is controlled It is 70n / min, after mixing 35min, obtain compound, then compound is put into three-roll mill grinding, and the belt transfer control of the grinding roller of three-roll mill is 140n / min, obtains component A after 50min grinding, Pack component A according to the required packaging specification;

[0027] B) Preparation of component B: first weigh 45 parts of T30 long-chain fatty amine modified curing agent, 20 parts of talcum powder, 2 parts of fumed white carbon black, 3 parts of dibutyl phthalate and KH-550 4 parts of silane coupling agent, put the a...

Embodiment 3

[0029] A) Preparation of component A: first weigh 92 parts of E-44 epoxy resin (also known as 6101 epoxy resin), 16 parts of talcum powder, 5 parts of fumed white carbon black and 6 parts of dibutyl phthalate by weight. Parts, put the aforementioned E-44 epoxy resin, talcum powder, fumed silica and dibutyl phthalate into a mixing device with a stirrer and mix, and the speed of the stirrer of the mixing device is controlled It is 80n / min, after mixing for 30min, the mixture is obtained, and then the mixture is dropped into a three-roller grinder for grinding, and the belt transfer of the grinding roller of the three-roller grinder is controlled to be 100n / min, and component A is obtained after grinding for 60min. Pack component A according to the required packaging specification;

[0030]B) Preparation of component B: first weigh 35 parts of T30 long-chain fatty amine modified curing agent, 28 parts of titanium dioxide, 1 part of fumed white carbon black, 1 part of dibutyl phth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com