Production method for formaldehyde-free bamboo chip plate

A production method and technology of bamboo chips, which are applied in the field of plate manufacturing, can solve problems such as low bonding strength and poor water resistance, and achieve good bonding effect, improved waterproof performance, and good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

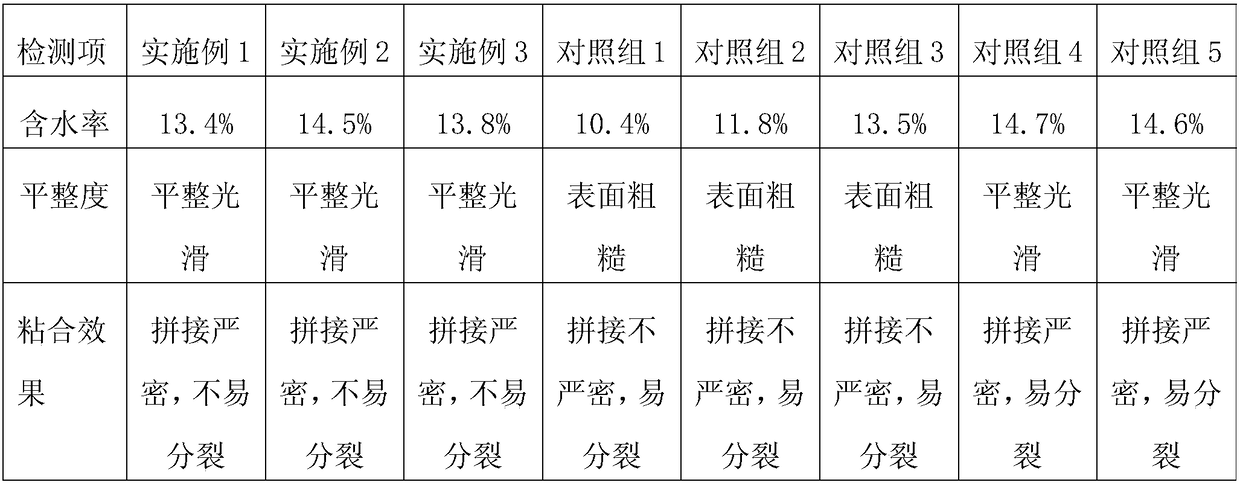

Examples

Embodiment 1

[0028] A method for making a formaldehyde-free bamboo chip board comprises the steps:

[0029] (1) heat treatment: bamboo is placed in hot steam and kept warm for 5h;

[0030] (2) making bamboo chips;

[0031] (3) Drying: the wood is placed in a drier with a relative air humidity of 10%, and the temperature is 50°C, and the wind speed is 10m / s to dry the wood to a moisture content of 23%;

[0032] (4) Repair: Repair and arrange the badly shaped planks;

[0033] (5) One-time gluing: apply the A adhesive to the surface of the wood to form a glue layer, and the coating amount of the A adhesive is 100g / m 2 ; The A adhesive is made up of the following raw materials in parts by mass: 30 parts of chitosan, 10 parts of konjac chitosan, 4 parts of lysozyme, 40 parts of fish gelatin, 10 parts of montmorillonite, 1 part of salicylic acid 6 parts, 6 parts of potassium dichromate;

[0034] (6) Tissue culture: the fiber angle of two bamboo planks is 90 degrees, and the number of layers ...

Embodiment 2

[0042] A method for making a formaldehyde-free bamboo chip board comprises the steps:

[0043] (1) heat treatment: place bamboo in hot steam for 3 hours;

[0044] (2) making bamboo chips;

[0045] (3) drying: the wood is placed in a drier with a relative air humidity of 20%, and the temperature is 40°C, and the wind speed is 20m / s, and the moisture percentage of the wood is dried to 15%;

[0046] (4) Repair: Repair and arrange the badly shaped planks;

[0047] (5) One-time gluing: apply the A adhesive to the surface of the wood to form a glue layer, and the coating amount of the A adhesive is 200g / m 2 ; The A adhesive is made up of the following raw materials in parts by mass: 20 parts of chitosan, 30 parts of konjac chitosan, 1 part of lysozyme, 50 parts of fish gelatin, 5 parts of montmorillonite, 5 parts of salicylic acid 1 part, 1 part of potassium dichromate;

[0048] (6) Tissue culture: the angle between the fibers of the two bamboo planks is 90 degrees, and the number...

Embodiment 3

[0056] A method for making a formaldehyde-free bamboo chip board comprises the steps:

[0057] (1) heat treatment: place bamboo in hot steam for 4 hours;

[0058] (2) making bamboo chips;

[0059] (3) drying: the wood is placed in a drier with a relative air humidity of 15%, and the temperature is 45°C, and the wind speed is 15m / s to dry the wood until the moisture percentage of the wood is 20%;

[0060] (4) Repair: Repair and arrange the badly shaped planks;

[0061] (5) One-time gluing: A glue is coated on the wood surface to form a glue layer, and the coating amount of the A glue is 150g / m2; the A glue is composed of the following raw materials in parts by mass : 25 parts of chitosan, 20 parts of konjac chitosan, 3 parts of lysozyme, 45 parts of fish gelatin, 8 parts of montmorillonite, 3 parts of salicylic acid, 5 parts of potassium dichromate;

[0062] (6) Tissue culture: the angle between the fibers of the two bamboo planks is 90 degrees, and the number of layers is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com