Wind power blade main beam sheet pultrusion impregnation device, die, equipment and method

A technology of pultrusion and wind power blades, which is applied in the field of wind power blade main girder sheet pultrusion dipping devices, can solve problems such as weak bearing capacity, poor performance, uneven impregnation of fibers, etc., to reduce physical damage, No harmful gas volatilization, the effect of improving the impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

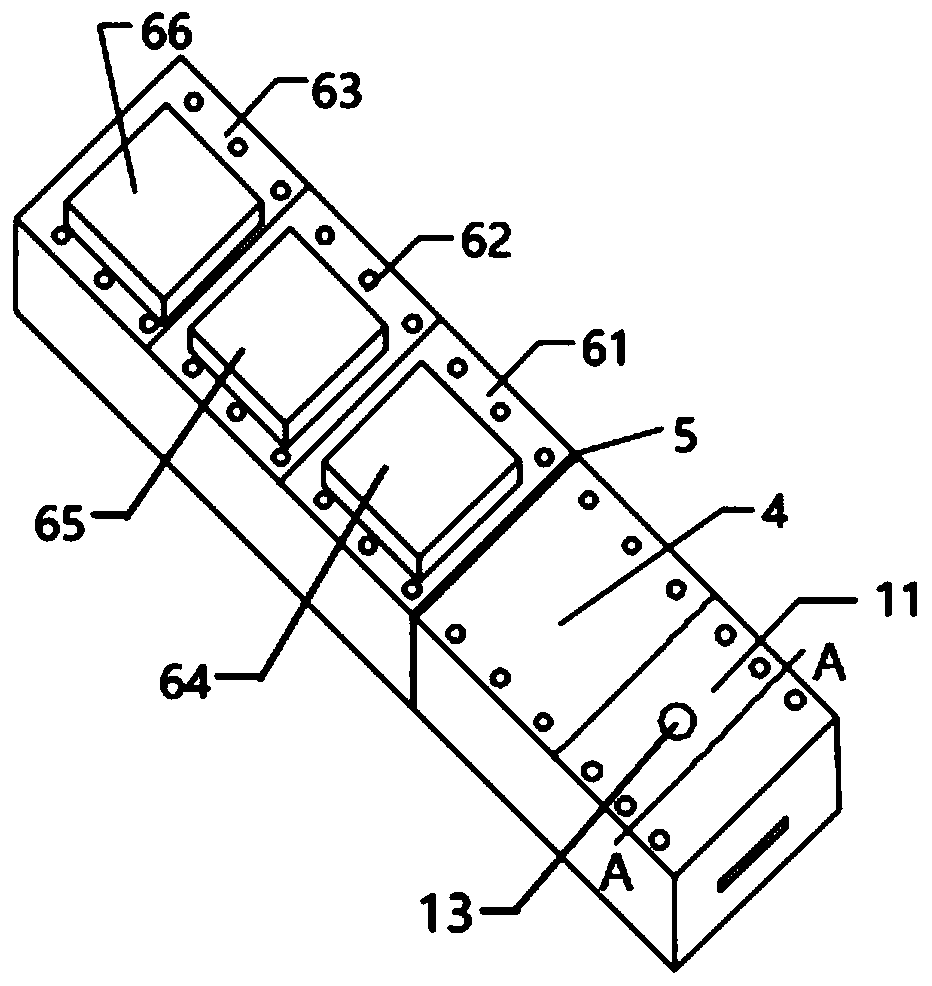

[0055] Such as figure 1 , figure 2 As shown, a closed dipping device for pultrusion forming of a main beam sheet of a wind power blade described in this embodiment includes: a dipping mold 1 and a plurality of glue injection devices 2; the dipping mold 1 includes a closed first The mold cavity 11 and the first heating device located outside the first mold cavity 11; the first mold cavity 11 is provided with an inlet and a discharge port, and the first mold cavity 11 is also provided with a glue injection holes 13; the glue outlets of multiple glue injection devices 2 are connected to the glue injection holes 13, suitable for injecting glue into the first mold cavity 11.

[0056] Wherein, the closed first mold cavity has the same cross-sectional shape as that of the product to be formed, only the feed inlet and the discharge port are open, and the rest of the walls are closed mold cavities.

[0057] The working process of the closed rubber dipping device of the pultrusion mo...

Embodiment 2

[0076] The wind power blade main girder sheet pultrusion molding equipment structure adopted in this embodiment is the same as that in Embodiment 1, the difference is that: the length of the first cavity is 20 cm; the length of the heating section in the curing molding mold is 30 cm; the length of the gel section is 40cm; the length of the curing section is 30cm.

[0077] The pultrusion forming method of the wind power blade main beam sheet in this embodiment is specifically as follows:

[0078] S1. The fiber material is led out from the creel, separated by the sand plate, arranged by the preformed plate, then penetrated into the dipping mold, passed through other molds in the pultrusion mold, and then reaches the traction device through the curing oven, and is drawn by Machine traction production, the traction speed is 0.35m / min;

[0079] S2. Add the first resin glue solution to a precision glue injection machine and preheat it at 65°C for 10 minutes. Add the second resin gl...

Embodiment 3

[0082] The wind power blade main girder sheet pultrusion molding equipment structure adopted in this embodiment is the same as that in Embodiment 1, the difference is that: the length of the first cavity is 40 cm; the length of the heating section in the curing molding mold is 35 cm; the length of the gel section is 30cm; the length of the curing section is 35cm.

[0083] The pultrusion forming method of the wind power blade main beam sheet in this embodiment is specifically as follows:

[0084] S1. The fiber material is led out from the creel, separated by the sand plate, arranged by the preformed plate, then penetrated into the dipping mold, passed through other molds in the pultrusion mold, and then reaches the traction device through the curing oven, and is drawn by Machine traction production, the traction speed is 0.8m / min;

[0085] S2. Add the first resin glue solution to a precision glue injection machine and preheat it at 50°C for 10 minutes. Add the second resin glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com