Silicon resin adhesive and application method in LED packaging

A technology of silicone resin glue and application method, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low bin yield rate of finished products, achieve low bin yield rate of finished products, increase cost, and have good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

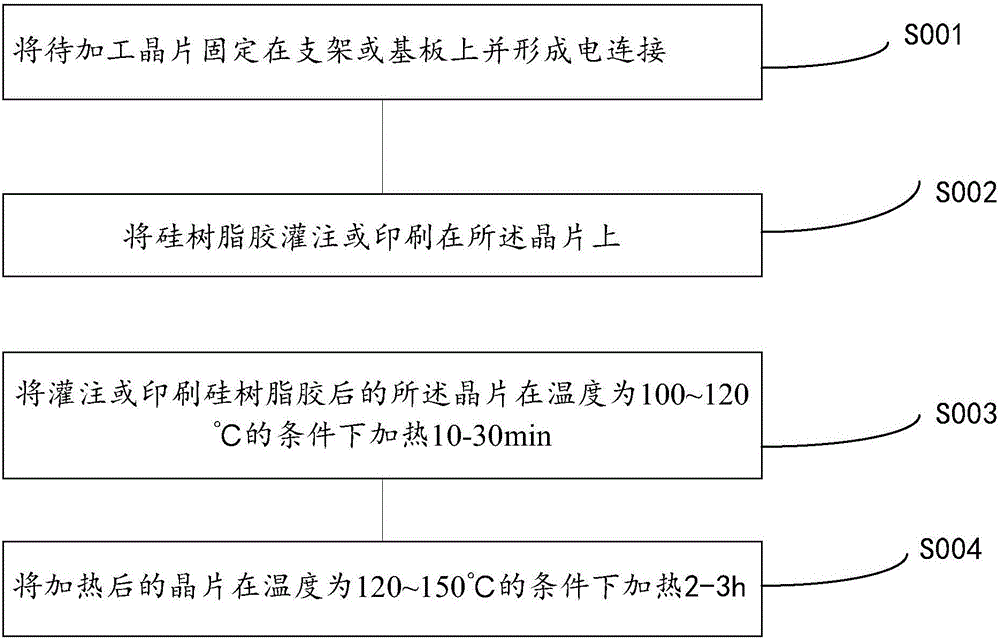

Method used

Image

Examples

Embodiment 1

[0064] Weigh 45kg of silicone resin and place it in a mixing container, weigh 5kg of amino silicone resin and add it to the mixing container and stir evenly at 2500rmp, weigh 50kg of fluorescent powder and add it to the mixing container and stir evenly at 2500rmp, and use a centrifugal defoamer to defoam. Prepare silicone resin glue A1.

[0065] Fix the front-mounted chip in the groove of the COB substrate with a cofferdam-shaped groove, and weld the chip and the substrate through the bonding wire-gold wire, so that the positive and negative poles of the positive-mounted chip and the positive and negative poles of the substrate are electrically connected; Resin glue A1 was put into the cofferdam-shaped groove on the COB substrate by dispensing, put into a 120°C oven and heated for 10 minutes, and the oven temperature was raised to 150°C and heated for 3 hours to obtain the finished packaged LED product L1.

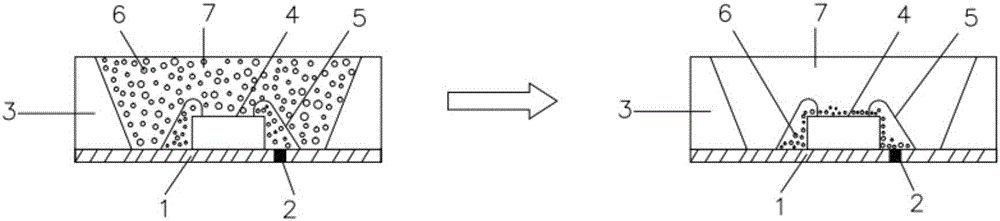

[0066] see figure 2 As shown, it is a comparison chart of phosphor ...

Embodiment 2

[0069] Weigh 78kg of silicone resin and place it in a mixing container, weigh 2kg of amino silicone resin into the mixing container and stir evenly at 2000rmp, weigh 20kg of fluorescent powder, add it to the mixing container and stir evenly at 2000rmp, and use a centrifugal defoamer to degas. A silicone resin gel A2 was prepared.

[0070] Fix the front-mount chip in the groove of the cup-shaped groove SMD bracket, and weld the front-mount chip and the SMD bracket by bonding wire-gold wire; put the silicone resin glue A2 into the bracket by dispensing Put it into the groove and heat it in an oven at 100°C for 30 minutes, then increase the temperature of the oven to 120°C and heat it for 2 hours to obtain the finished packaged LED product L2.

[0071] The obtained silicone resin glue A2 and the packaged LED finished product L2 were measured by the same method as in Example 1, and the measurement results are shown in Table 1.

Embodiment 3

[0073] Weigh 97kg of silicone resin and place it in a mixing container, weigh 3kg of amino silicone resin into the mixing container, stir evenly at 3000rmp, and use a centrifugal defoamer to defoam to obtain silicone resin A3.

[0074] Fix the front-mount chip on the flat substrate, and weld the front-mount chip with the substrate through bonding wire-aluminum alloy wire; package the front-mount chip with silicone resin glue A3 by molding, and heat it in an oven at 110°C for 20 minutes , raise the temperature of the oven to 130° C. and heat for 2.5 hours to obtain the packaged LED finished product L3.

[0075] The obtained silicone resin glue A3 and the packaged LED finished product L3 were measured by the same method as in Example 1, and the measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com