Method for preparing foamed aluminium and aluminum alloy by secondary foaming with novel blowing agent

A foamed aluminum alloy and foamed aluminum technology are applied in the field of preparation of closed-cell foamed aluminum and foamed aluminum alloy, which can solve problems such as high cost, increased production cost, and unstable process, and achieve enhanced stability, increased viscosity, and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A kind of preparation of aluminum foam special-shaped parts

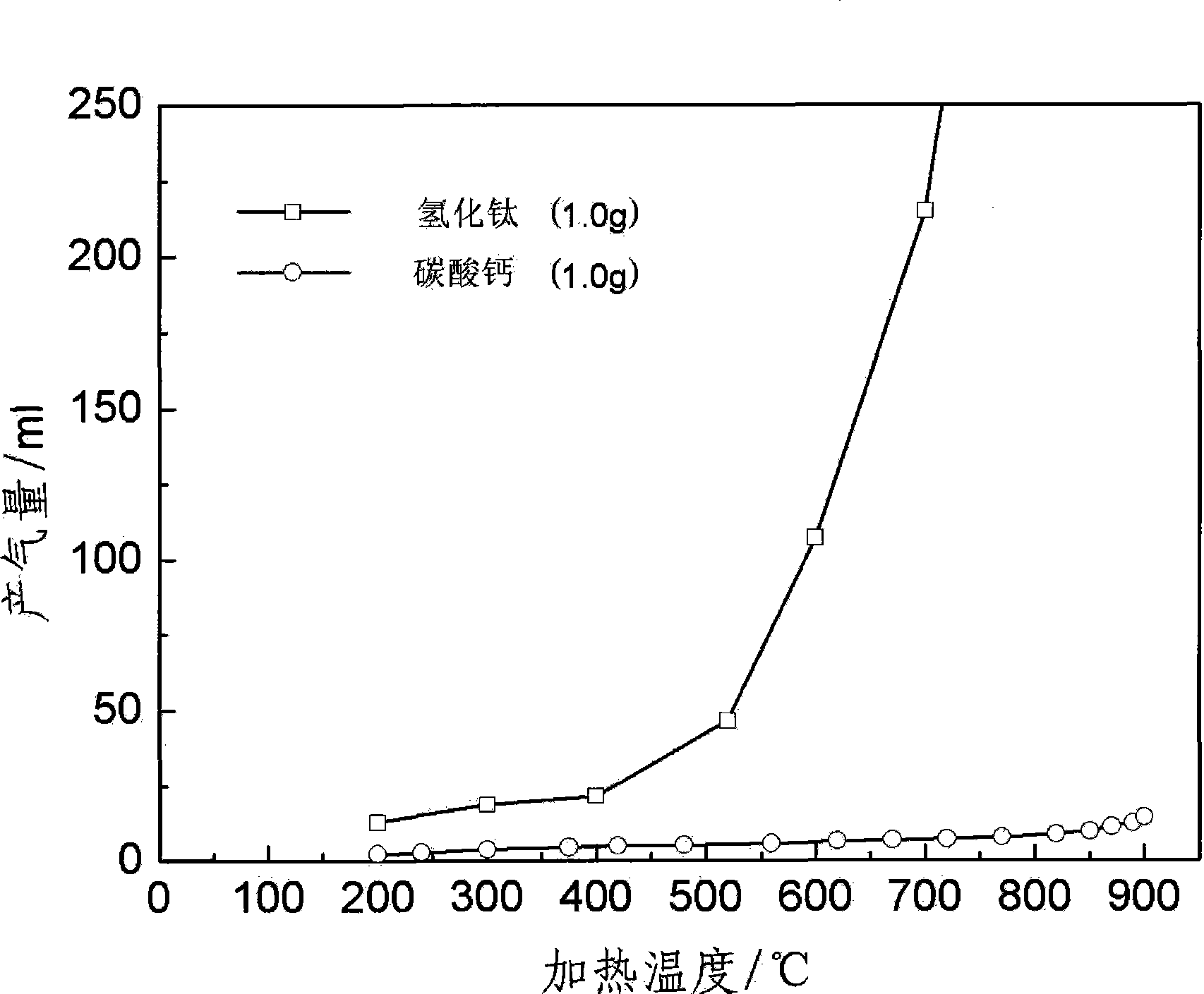

[0028] Step 1: Heat the aluminum until it melts, keep it warm at 660-720°C for 30 minutes, add calcium carbonate powder accounting for 0.5-3.0% of the mass fraction of the molten aluminum, and stir at a speed of 400-600r / min for 5-15 minutes;

[0029] The second step: add calcium carbonate powder accounting for 0.5-4.0% of the mass fraction of the aluminum liquid, the rotation speed is 700-1200r / min, the stirring time is 3.0-7.0min, and after stopping, it is cooled to room temperature by water within 40s to form a porosity of less than 65%. Aluminum foam billet with spherical holes;

[0030] Step 3: keep the above-mentioned spherical porous aluminum foam billet in the range of 300-570°C for 10-15 minutes;

[0031] Step 4: Put the above-mentioned spherical porous aluminum foam billet in the mold and make the calcium carbonate in the billet secondary thermally decompose to produce secondary foam i...

Embodiment 2

[0032] Embodiment 2 Preparation of a foamed aluminum-silicon alloy special-shaped part

[0033] Step 1: Heat the aluminum-silicon alloy until it melts, keep it at 660-720°C for 30 minutes, add calcium carbonate powder accounting for 0.5-3.0% of the mass fraction of the aluminum-silicon alloy liquid, and stir at 400-600r / min for 5-15 minutes;

[0034] The second step: add calcium carbonate powder accounting for 00.5-4.0% of the mass fraction of the aluminum-silicon alloy liquid, the speed is 700-1200r / min, the stirring time is 3.0-7.0min, and after stopping, it is cooled to room temperature by water within 40s to form a porosity lower than 65%. Al-Si Alloy billets with spherical cells;

[0035] The third step: keep the above-mentioned spherical porous aluminum-silicon alloy blank in the range of 300-570°C for 10-15 minutes;

[0036] Step 4: Put the above-mentioned spherical porous aluminum-silicon alloy billet in the mold to cause the secondary thermal decomposition of calcium...

Embodiment 3

[0037]Embodiment 3 Preparation of a foamed aluminum-copper alloy special-shaped part

[0038] Step 1: Heat the aluminum-copper alloy until it melts, keep it at 660-720°C for 30 minutes, add calcium carbonate powder accounting for 1.0-4.0% of the mass fraction of the aluminum-copper alloy liquid, and stir at a speed of 400-600r / min for 5-15 minutes;

[0039] The second step: add calcium carbonate powder accounting for 0.5-4.0% of the mass fraction of the aluminum-copper alloy liquid, the rotation speed is 700-1200r / min, the stirring time is 3.0-7.0min, and after stopping, it is cooled to room temperature by water within 40s to form a porosity of 30%. Spherical porous aluminum-copper alloy blank;

[0040] Step 3: Heat the above-mentioned aluminum-copper alloy foam with spherical holes in the range of 300-570°C for 10-15 minutes;

[0041] Step 4: Put the above-mentioned spherical cell foamed aluminum-copper alloy billet in the mold at 760-950°C to cause secondary thermal decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com