Aluminum/aluminum oxide/Ni-base superalloy composite coating for titanium-aluminum alloy and preparation method thereof

A composite coating and alloy technology, applied in the direction of metal material coating process, coating, metal layered products, etc., can solve problems such as chemical mismatch, to avoid interface reaction, good high temperature stability, high ionization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is Al / Al 2 o 3 Application of / MCrAlY composite coating on γ-TiAl alloy. The substrate composition is Ti-48Al-2Cr-2Nb (at.%), and the sample size is 15×10×2mm 3 . The substrate is ground with metallographic sandpaper, cleaned and sandblasted (220 mesh glass shot, wet sprayed). Deposition of Al and Al on domestic MIP-8-800 arc ion plating equipment 2 o 3 and NiCoCrAlY coating, the cathode target material is metal aluminum (99%, wt.%) and Ni32Co20Cr8Al0.5Y (wt.%) alloy, the background vacuum degree of the vacuum chamber is 7×10 -3 Pa, target base distance is about 240mm, substrate temperature is 300-400°C; first deposit 2-3μm thick Al film, then deposit 2-3μm thick Al 2 o 3 thin film, and finally deposit a 20-30 μm NiCoCrAlY coating. Before depositing the NiCoCrAlY coating, apply a high bias voltage of -800--1000V, and clean the surface of the sample by sputtering for 2-5 minutes; the deposition process parameters are shown in Table 1 . After coat...

Embodiment 2

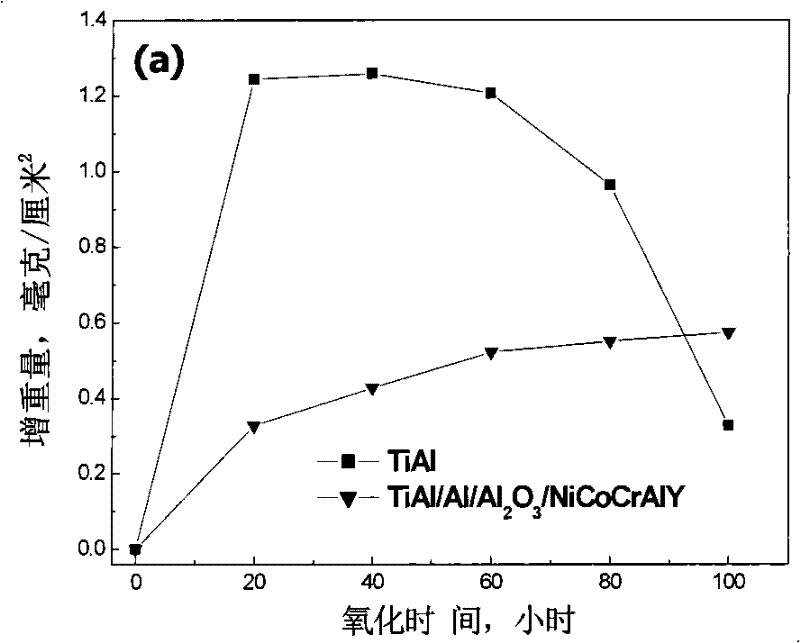

[0034] This embodiment is Al / Al 2 o 3 / NiCoCrAlY composite coating on O-Ti under isothermal and cyclic oxidation conditions at 800 °C 2 High temperature protection of AlNb alloys. The substrate composition is Ti-22Al-26Nb (at.%), and the sample size is 15×10×2mm 3 . The substrate is ground with metallographic sandpaper, cleaned and sandblasted (220 mesh glass shot, wet sprayed). The coating deposition parameters are the same as in Example 1. After coating, the sample is subjected to vacuum heat treatment, and the temperature is raised at a rate of -1 Pa.

[0035] Prepared Al / Al 2 o 3 / NiCoCrAlY composite coating can treat O-Ti under both isothermal and cyclic oxidation conditions at 800 °C 2 AlNb alloys provide good high temperature protection, as shown in Figure 3(a)-(b) for isothermal and cyclic oxidation at 800 °C. O-Ti 2 The surface of AlNb alloy is easy to peel off during the high temperature oxidation process, and TiO 2 The mixed oxide film mainly cannot provid...

Embodiment 3

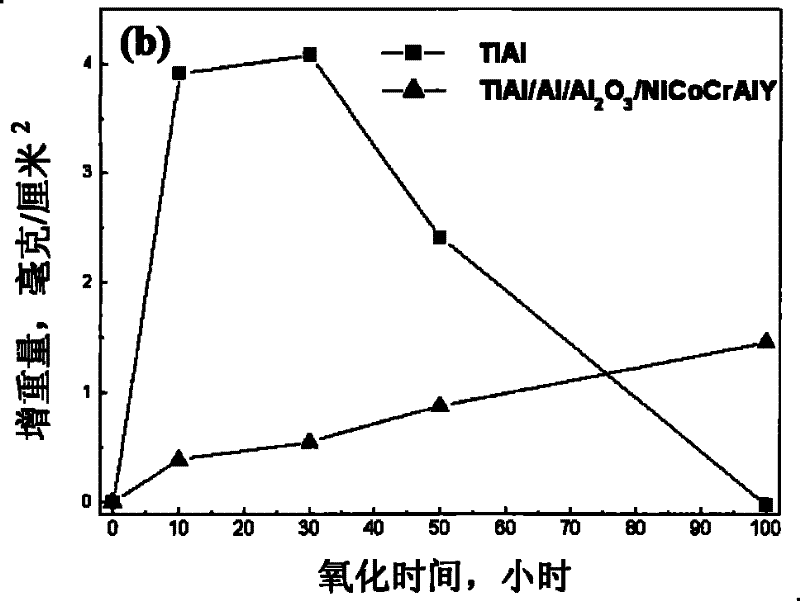

[0037] This embodiment is Al / Al 2 o 3 / NiCoCrAlY composite coating on O-Ti under cyclic oxidation conditions at 900 °C 2 High temperature protection of AlNb alloys and their high temperature stability. The substrate composition, coating process and heat treatment system are the same as in Example 2.

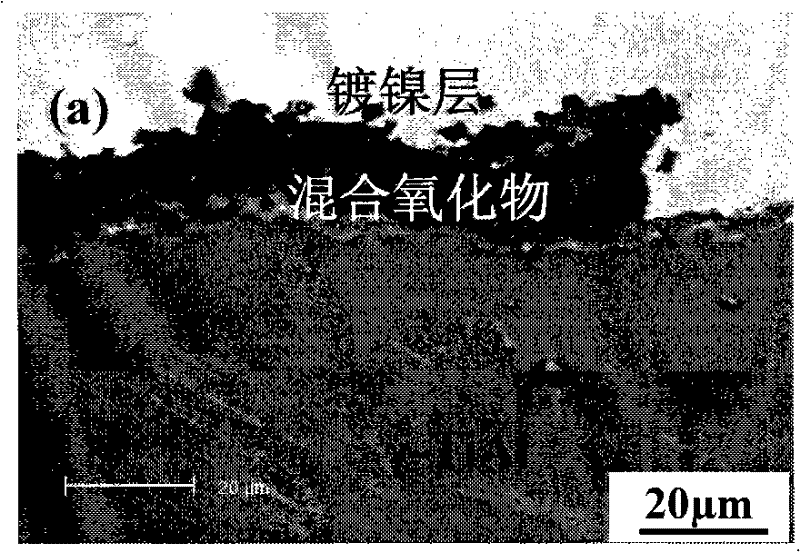

[0038] Prepared Al / Al 2 o 3 / NiCoCrAlY composite coating can treat O-Ti under cyclic oxidation conditions at 900 °C 2 AlNb alloys provide good high temperature protection, such as Figure 5 is the cyclic oxidation weight gain curve at 900°C. The NiCoCrAlY coating is almost completely consumed, and the O-Ti 2 The microstructure of AlNb is also significantly changed due to the serious interdiffusion between the coating and the substrate at high temperature, so it is difficult for NiCoCrAlY coatings to be directly applied to O-Ti without a diffusion barrier layer. 2 On AlNb, see Figure 6(a). And Al / Al 2 o 3 Formation of continuous and dense α-Al on the surface of / NiCoCrAl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com