Application of laser weld in ultra-high tensile steel welding and welding method

An ultra-high-strength steel and laser welding technology, applied in the metallurgical field, can solve the problems of limiting laser welding and the thickness of laser manufacturing level welding materials, and achieve the effect of low welding equipment cost, excellent polarization performance, and continuous production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

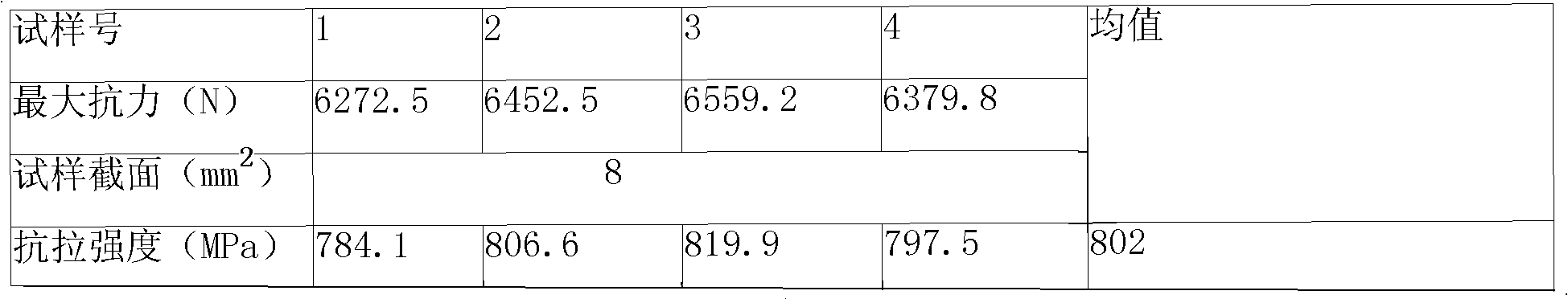

Embodiment 1

[0059] Embodiment 1 of the present invention: laser welding of 30CrMnSiNi2A ultra-high-strength steel: the 30CrMnSiNi2A ultra-high-strength steel welding sample is cut by molybdenum wire, and the welded joint of the sample is polished with metallographic sandpaper before welding, derusted and deburred, and used Wash with acetone, and then use narrow-band TJ-HL-T5000 continuous CO 2 Laser, the mixed low-order mode is selected in the cavity, the copper mirror is focused by transmission, the focal length is 310mm, and the laser welding is performed under the conditions of laser output power P = 2.8KW, scanning speed V = 180mm / min, and spot diameter d = 1.0mm. Thickness 1mm. The results of microstructure analysis and tensile fracture analysis show that the welded joint has no welding defects, no inclusions, no pores, and good fusion.

Embodiment 2

[0060] Embodiment 2 of the present invention: laser welding of 30CrMnSiNi2A ultra-high-strength steel: the 30CrMnSiNi2A ultra-high-strength steel welding sample is cut by molybdenum wire, and the welded joint of the sample is polished with metallographic sandpaper before welding, derusted and deburred, and used Wash with acetone, followed by narrow-band continuous CO 2 Laser, the mixed low-order mode is selected in the cavity, the copper mirror is focused by transmission, the focal length is 315mm, and the laser welding is performed under the conditions of laser output power P = 2.6KW, scanning speed V = 240mm / min, and spot diameter d = 0.7mm. Thickness 1mm. The results of microstructure analysis and tensile fracture analysis show that the welded joint has no welding defects, no inclusions, no pores, and good fusion.

Embodiment 3

[0061] Embodiment 3 of the present invention: laser welding of 300M ultra-high-strength steel: the 300M ultra-high-strength steel welding sample is cut by molybdenum wire, and the welding joint of the sample is polished with metallographic sandpaper before welding, derusted and deburred, and used Wash with acetone, followed by narrow-band continuous CO 2 Laser, select mixed low-order modes in the cavity, copper mirror transmission focus, focal length 300mm, laser welding under the conditions of laser output power P=3.2KW, scanning speed V=60mm / min, spot diameter d=0.5mm, welding Thickness 1mm. The results of microstructure analysis and tensile fracture analysis show that the welded joint has no welding defects, no inclusions, no pores, and good fusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com