Ultra-hard composite sheet with hard alloy interlayer

A technology of cemented carbide and composite sheets, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of low toughness, easy cracking, and high production costs, and achieve improved bending strength and impact Toughness, expanded application range, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

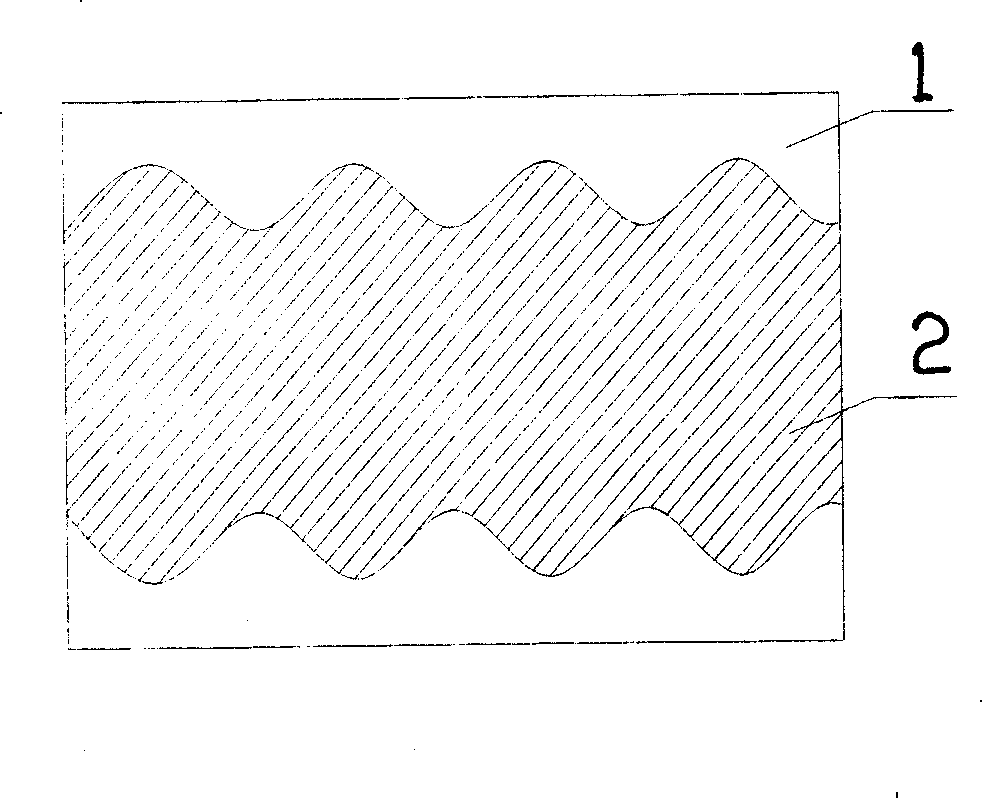

[0012] As shown in the figure, the present invention includes double-sided superhard material layer (1) and cemented carbide interlayer (2), and its superhard material layer (1) is made up of artificial diamond or cubic boron nitride and bonding agent, combined The agent is selected from aluminum nitride, titanium nitride, molybdenum nitride, magnesium nitride, zirconium nitride, chromium nitride, tungsten nitride, aluminum oxide, cobalt, molybdenum, titanium, iron, aluminum, nickel, copper, Any one or several of tungsten and chromium; the surface of the cemented carbide interlayer (2) is a convex-concave surface, and the cemented carbide interlayer (2) and the superhard material layer (1) are combined through the convex-concave contact surface .

Embodiment 2

[0014] As shown in the figure, the present invention includes double-sided superhard material layer (1) and cemented carbide interlayer (2), and its superhard material layer (1) is made up of artificial diamond or cubic boron nitride and bonding agent, combined The agent is selected from aluminum nitride, titanium nitride, molybdenum nitride, magnesium nitride, zirconium nitride, chromium nitride, tungsten nitride, aluminum oxide, cobalt, molybdenum, titanium, iron, aluminum, nickel, copper, Any one or several of tungsten and chromium; the surface of the cemented carbide interlayer (2) is a convex-concave surface, and the cemented carbide interlayer (2) and the superhard material layer (1) are combined through the convex-concave contact surface . The concave-convex surface on the surface of the cemented carbide interlayer (2) is a concave-convex plane or a concave-convex curved surface.

Embodiment 3

[0016] As shown in the figure, the present invention includes double-sided superhard material layer (1) and cemented carbide interlayer (2), and its superhard material layer (1) is made up of artificial diamond or cubic boron nitride and bonding agent, combined The agent is selected from aluminum nitride, titanium nitride, molybdenum nitride, magnesium nitride, zirconium nitride, chromium nitride, tungsten nitride, aluminum oxide, cobalt, molybdenum, titanium, iron, aluminum, nickel, copper, Any one or several of tungsten and chromium; the surface of the cemented carbide interlayer (2) is a convex-concave surface, and the cemented carbide interlayer (2) and the superhard material layer (1) are combined through the convex-concave contact surface . The surface of the cemented carbide interlayer (2) is in the shape of a convex platform or a concave platform or a concave-convex platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com