High temperature resistant silver oxide contact tip material manufacturing method

A contact material, silver oxide technology, applied in electrical components, electrical switches, circuits, etc., to achieve the effect of good high temperature resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Silver-Sn-Bismuth Alloy Strips Obtained by I Rapid Quenching Method

[0023] 90% silver, 9% tin, and 1% bismuth are melted into a silver alloy in a molten state in an intermediate frequency furnace. The melting temperature is 1050-1500°C. After the metal is melted, keep it warm for 30 minutes.

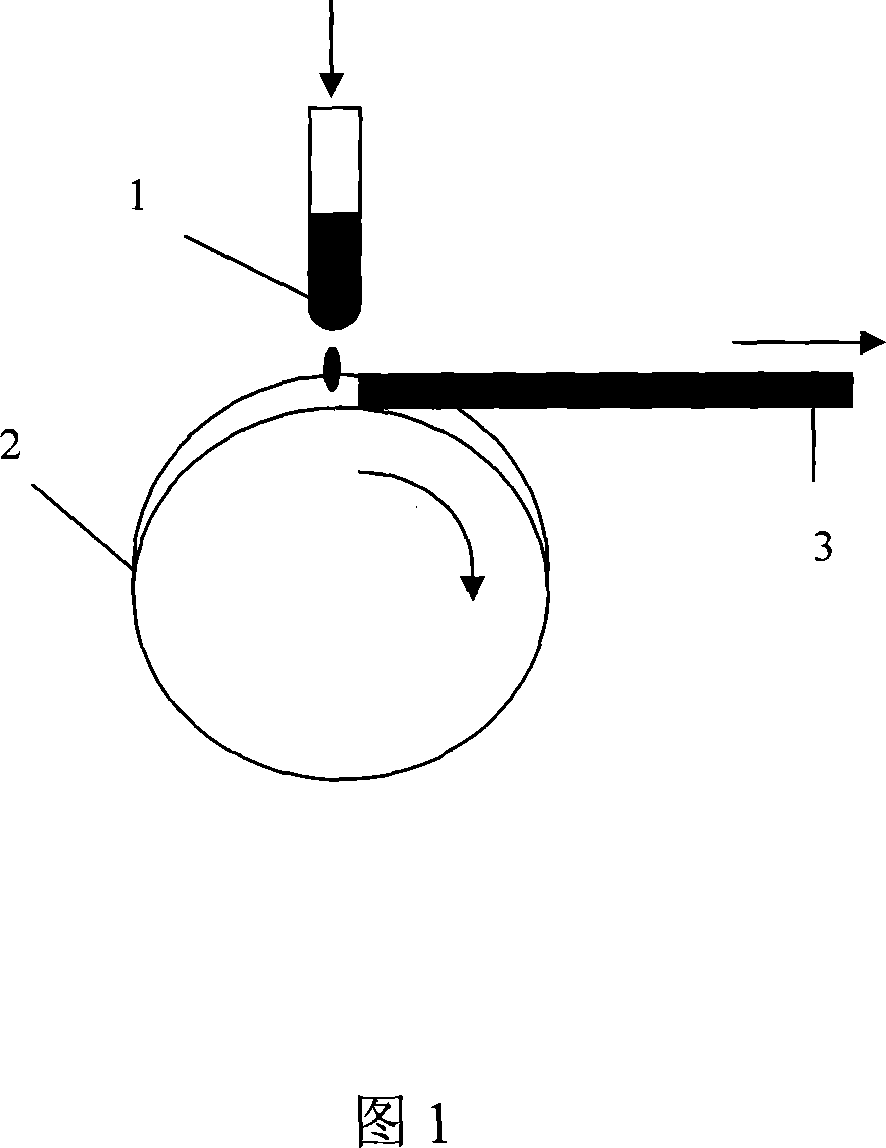

[0024] As shown in FIG. 1 , a silver alloy strip 2 is obtained by using a single-roller quick quenching strip machine to obtain a silver alloy 1 in a molten state. The nozzle of the belt throwing machine is elliptical, with a short axis of 3 mm and a long axis of 10 mm; during the rapid quenching process, the gas with 80% of the weight of argon and 20% of the weight of air is used to pressurize 0.05MPa, and the speed of the cooling roller 2 is 16m / s, the resulting silver alloy strip 3 has a thickness of 0.2 mm.

[0025] II Silver alloy strips are oxidized into strips mixed with silver, tin oxide and bismuth oxide

[0026] Oxidize the silver alloy strips at 500°C and 10Mpa ox...

Embodiment 2

[0029] I Rapid Quenching Method to Obtain Silver-Zinc Alloy Strips

[0030] 92% silver and 8% zinc are melted into a molten silver alloy in an intermediate frequency furnace. The melting temperature is 1050-1500°C. After the metal is melted, keep it warm for another 20 minutes.

[0031] Silver alloy strips 3 are obtained by using the molten silver alloy 1 with a single-roller quick quenching strip machine. The nozzle of the belt throwing machine is an ellipse with a short axis of 5mm and a long axis of 15mm; in the rapid quenching process, pressurize 0.08MPa with a mixture of 65% by weight of argon and 35% by weight of air, and the speed of the cooling roller 2 is 3m / s, the thickness of the obtained silver alloy strip is 0.5mm.

[0032] II Silver alloy strips are oxidized into strips mixed with silver and zinc oxide

[0033] Oxidize the silver alloy strips at 750°C and 0.2Mpa oxygen pressure for 18 hours, the zinc oxide is evenly distributed in the silver matrix, and the zi...

Embodiment 3

[0036] I Rapid Quenching Method to Obtain Silver-cadmium Alloy Strips

[0037] 89% silver and 11% cadmium are melted into molten silver alloy in an intermediate frequency furnace. The melting temperature is 1050-1500°C. After the metal is melted, keep it warm for another 10 minutes.

[0038] Silver alloy strips are obtained by using a single-roller quick quenching strip machine to melt the silver alloy. The nozzle of the belt throwing machine is elliptical with a minor axis of 2mm and a major axis of 7mm; during the rapid quenching process, the gas with argon weight accounting for 95% and air weight accounting for 5% is used to pressurize 0.02MPa, and the speed of the quenching roller is 30m / s , the thickness of the obtained silver alloy strip is 0.1mm.

[0039] II Silver alloy strips are oxidized into mixed strips of silver and cadmium oxide

[0040] Oxidize the silver alloy strips at 600°C and 0.1Mpa oxygen pressure for 12 hours, the cadmium oxide is uniformly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com