Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Strong torsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

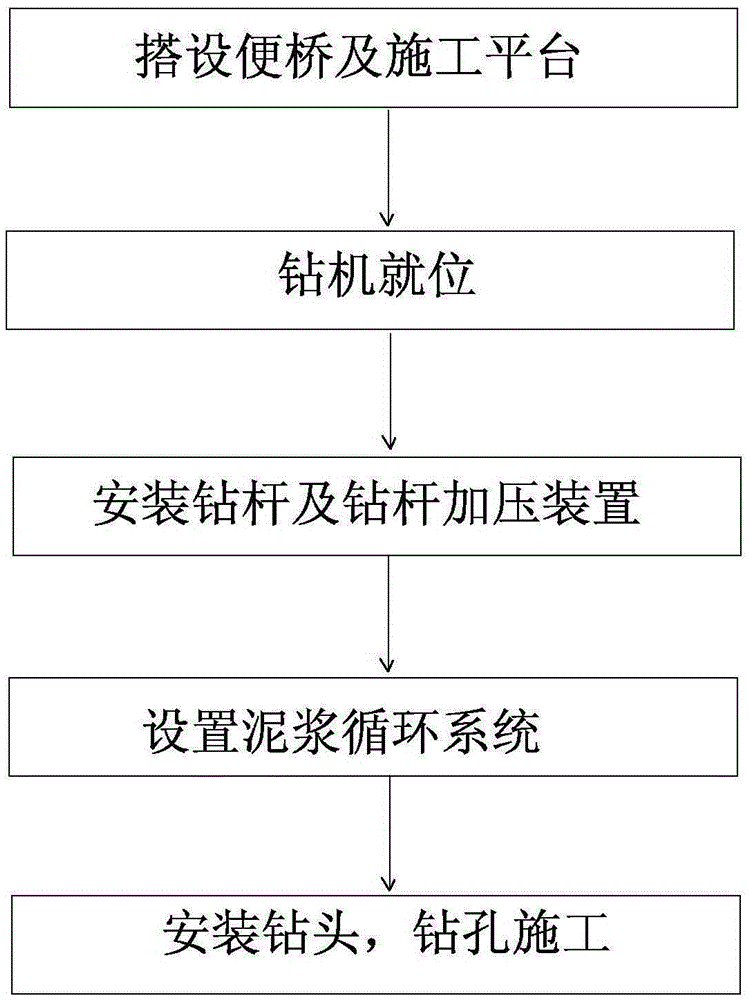

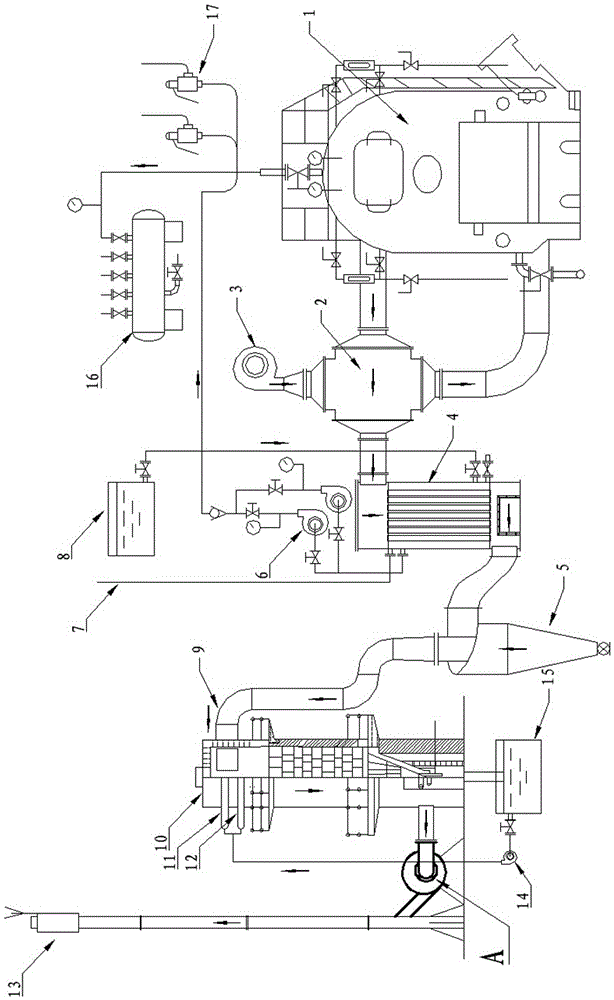

Method for performing in-water pile foundation hole drilling by large-diameter reverse circulation roller cone drilling

ActiveCN105257215ADrilling speed is fastStrong bending resistanceConstructionsDerricks/mastsSpecific gravityRiver water

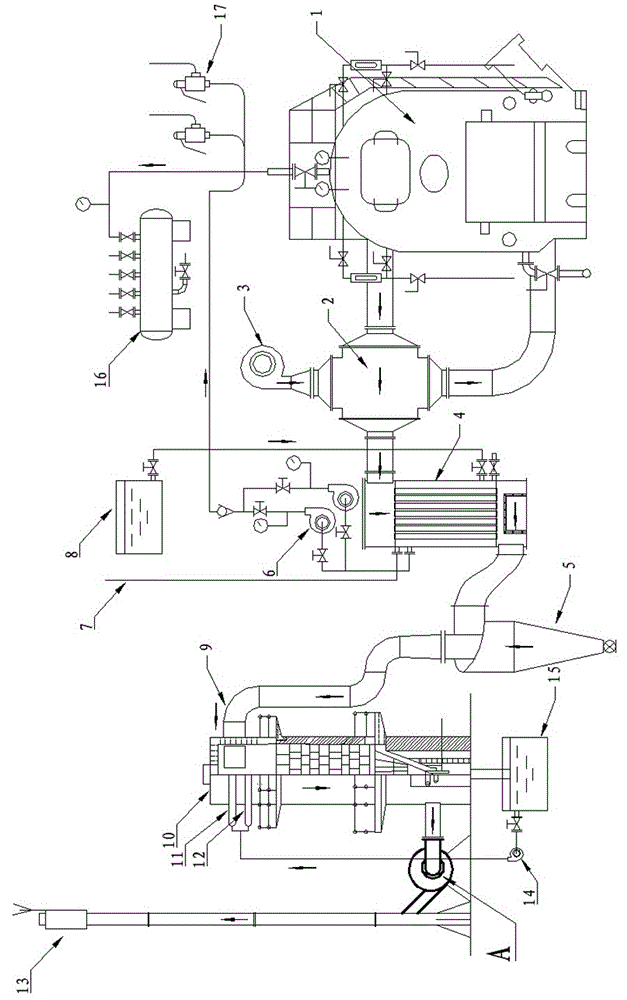

The invention relates to a method for performing in-water pile foundation hole drilling by large-diameter reverse circulation roller cone drilling. The method comprises the following steps of (1) building a temporary bridge and an on-water construction platform; (2) putting a drilling machine in place; (3) installing a drill pipe; (4) setting a slurry circulation system; and (5) performing hole drilling construction. A construction platform can bear a large-size great-self-weight large-diameter reverse circulation roller cone drilling machine; the unique drill pipe is used; good anti-folding anti-twisting and pressure-bearing performance is realized; different roller cone drill bits can be replaced when different hard rock layers are met; a drill pipe pressurizing device is used, so that when the drilling is too slow, the drill pipe can be pressurized through the drill pipe pressurizing device, and the extrusion crushing and rock cutting capability is improved; the requirement on the specific gravity of the slurry is low, river water can be used for direct water supplementation; and the drill lifting is performed before the pile pouring, and the construction step of hole cleaning can be reduced.

Owner:CCCC FOURTH HIGHWAY ENG

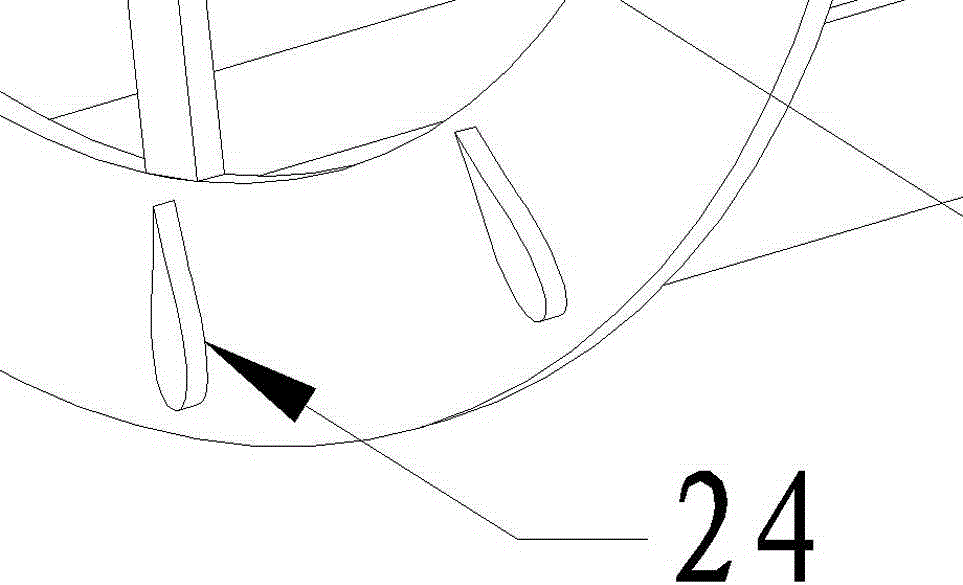

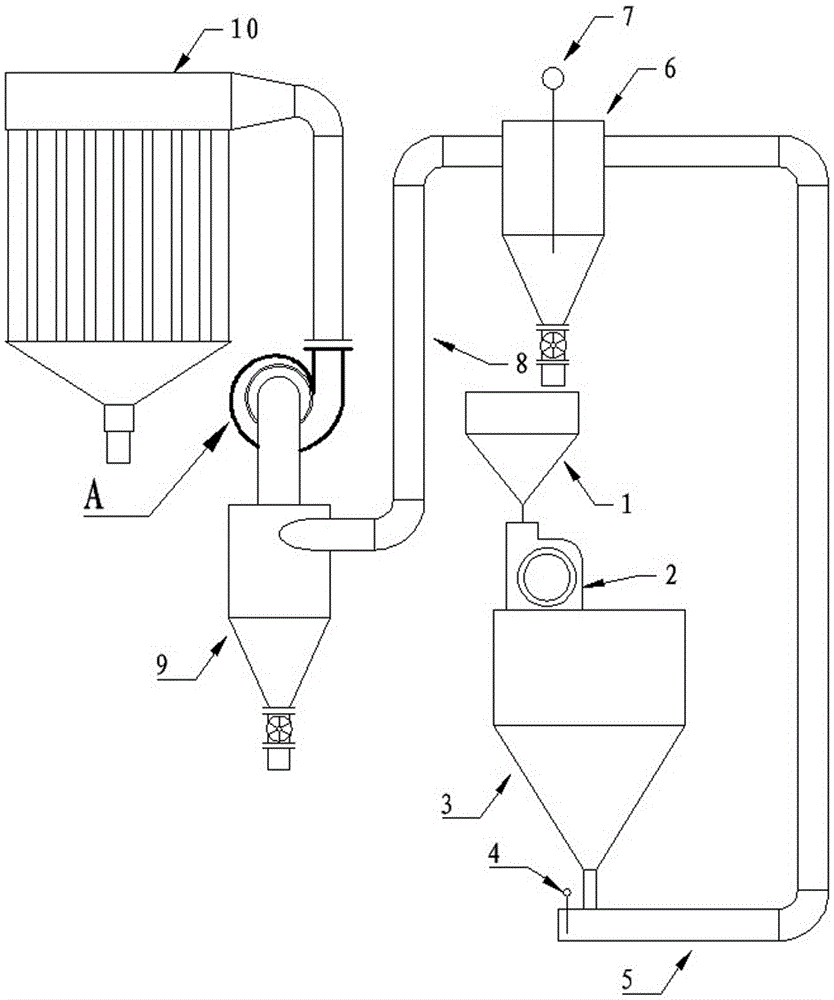

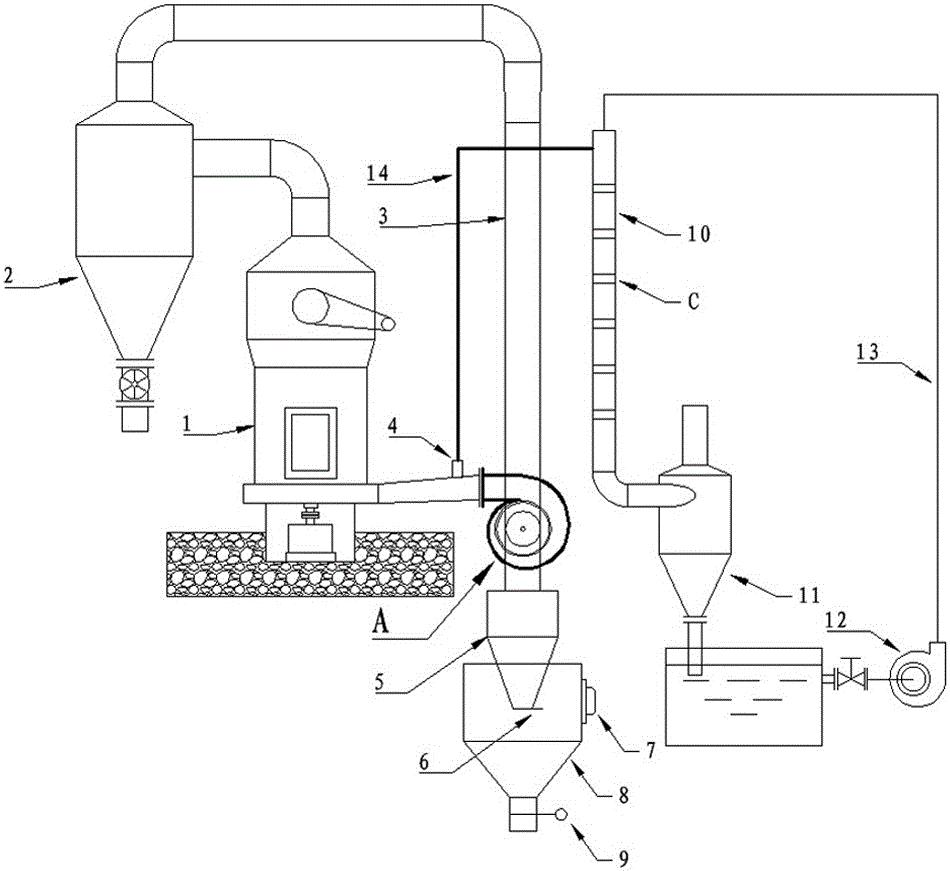

Tail gas recovery dust removal type coal-fired boiler

ActiveCN105066157ADoes not affect dynamicDoes not affect balancePump componentsCombustion processAir preheaterEngineering

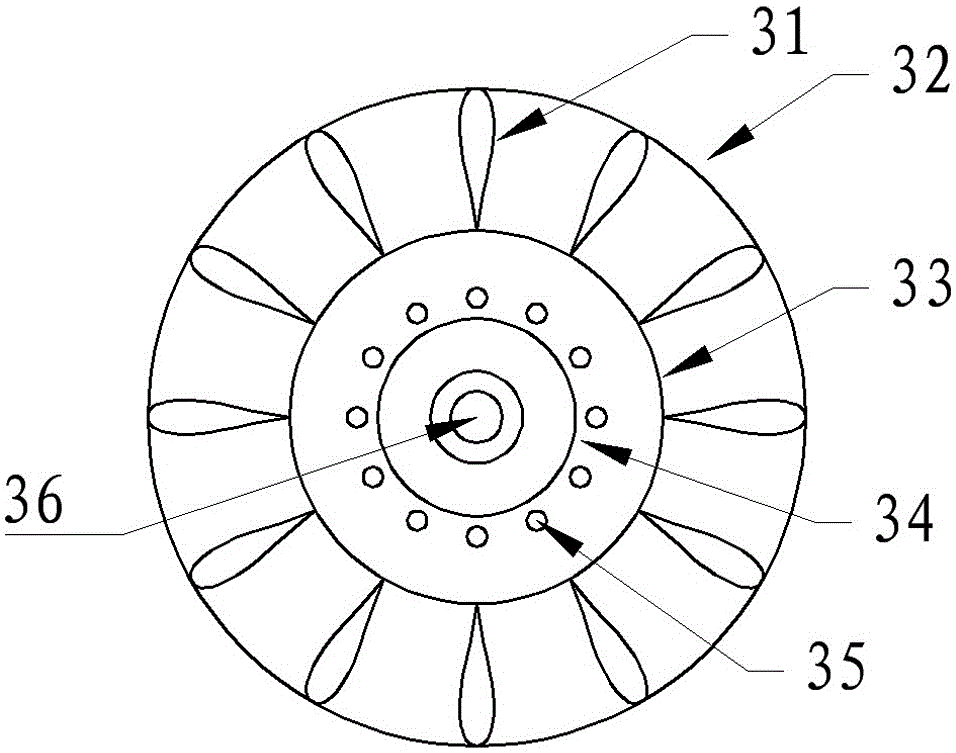

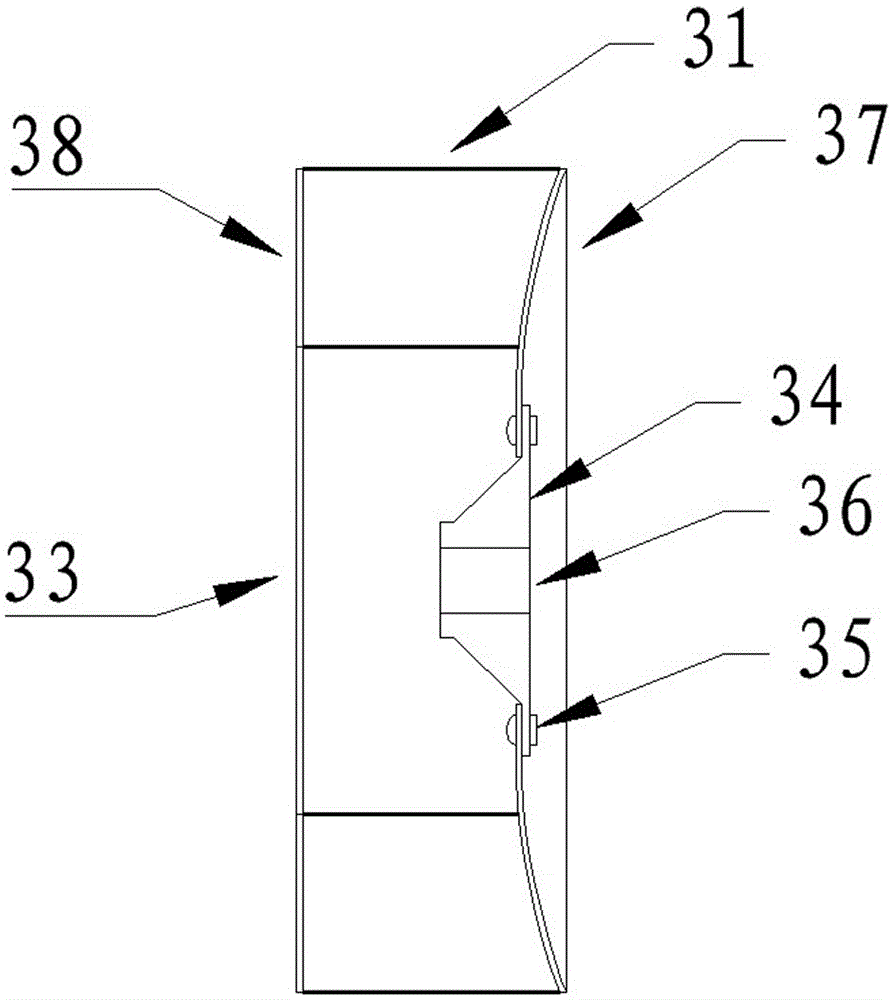

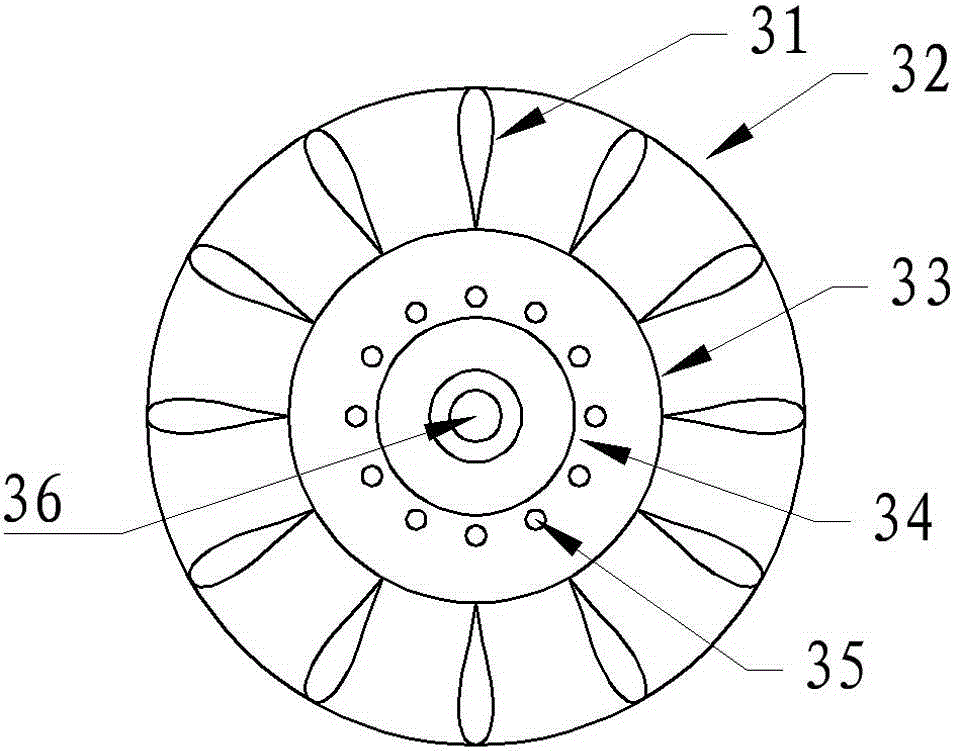

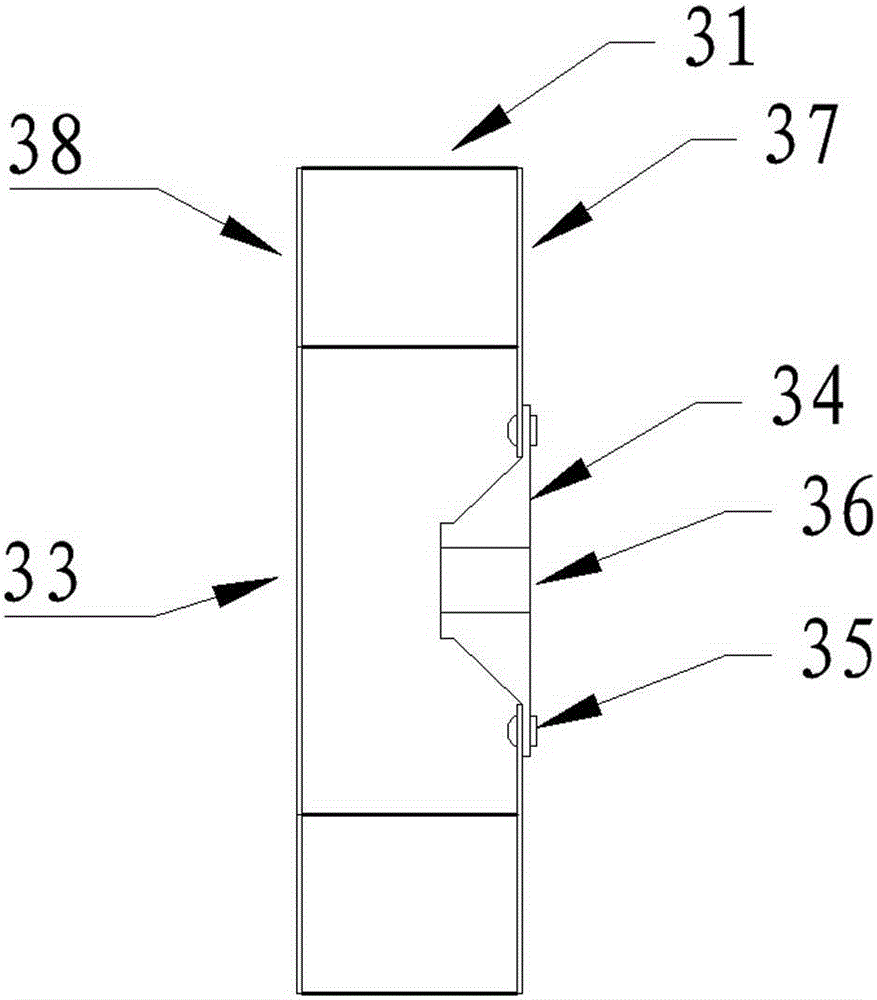

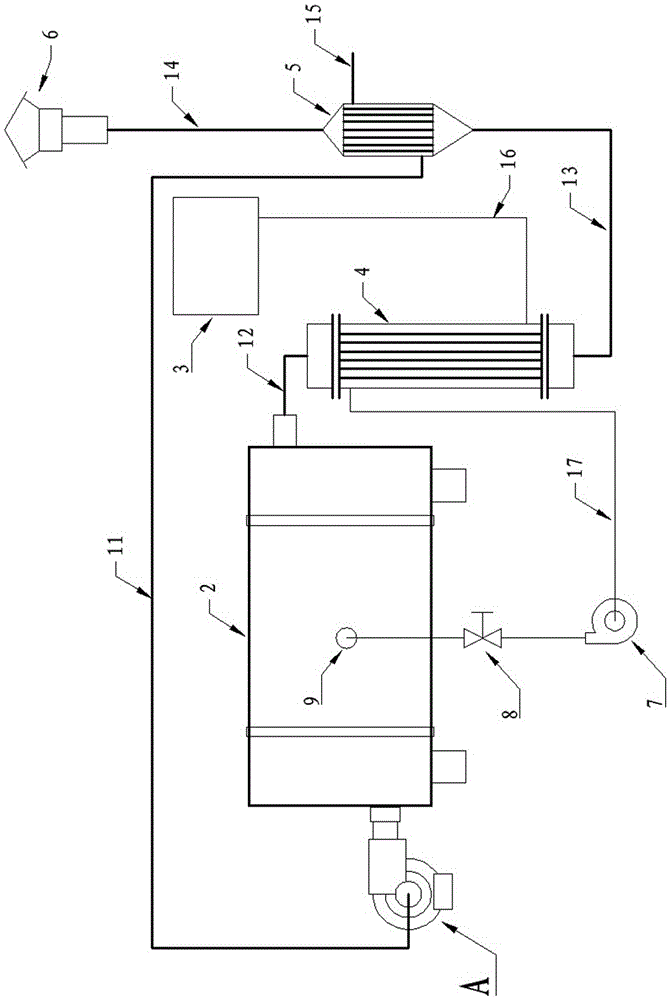

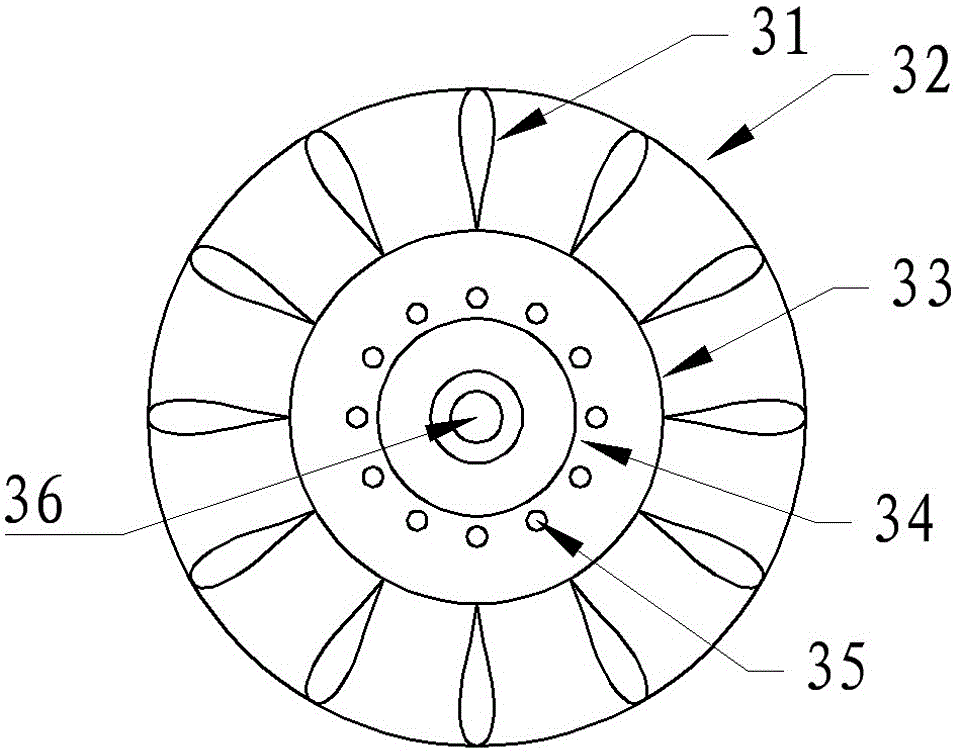

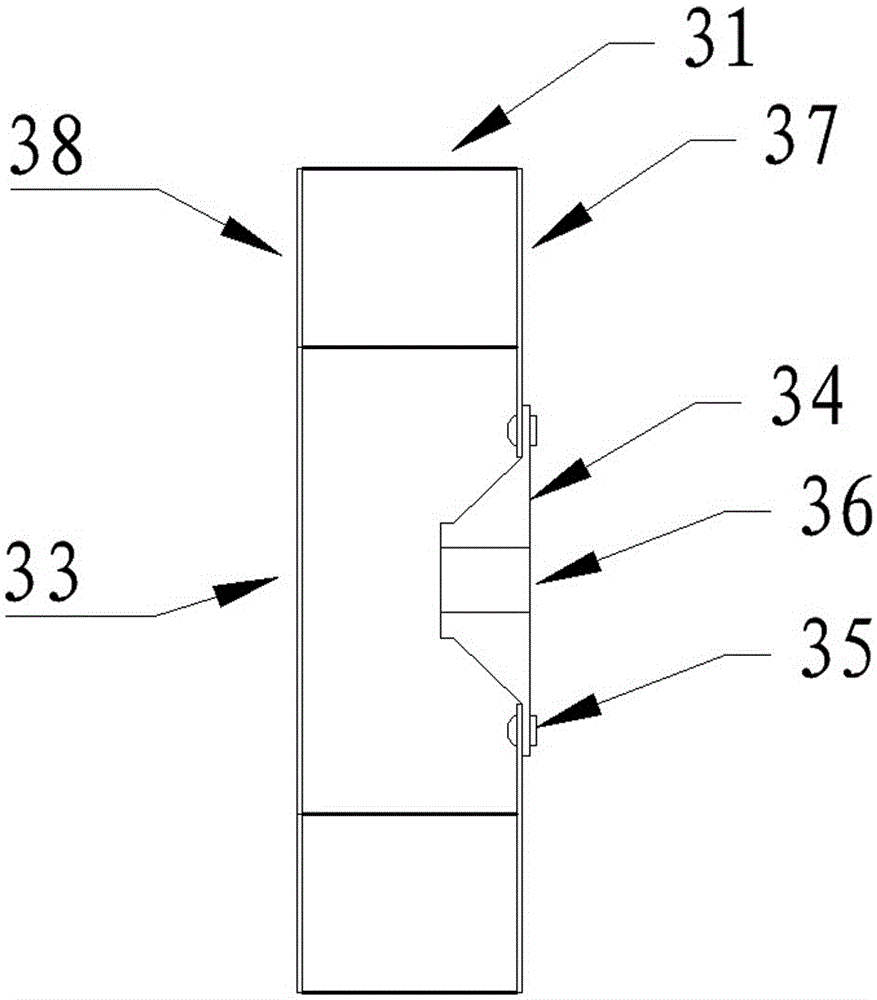

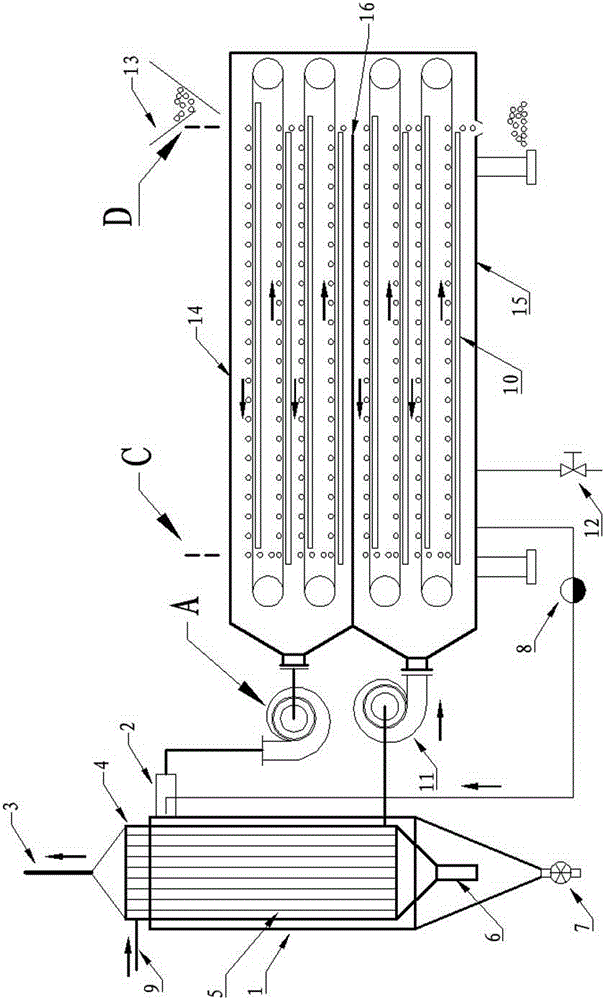

The invention discloses a tail gas recovery dust removal type coal-fired boiler. The tail gas recovery dust removal type coal-fired boiler comprises a boiler body and an induced draft fan. A tail gas tube of the boiler body is connected with the inducted draft fan through an air preheater, a water preheater, a cyclone dust collector and a granite dust collector, and then evacuation is carried out. The air inlet end of the shell side of the air preheater is connected with an air blower, and the air outlet end of the shell side of the air preheater is connected with the boiler body. A water inlet tube of the shell side of the water preheater is connected with a high-position pool, and a water outlet tube of the shell side of the water preheater is connected with a boiler water inlet pump. An impeller of the inducted draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Two-stage counterflow heat exchange and dry-wet dust removal are carried out on boiler tail gas to achieve tail heat recovery and dust removal operation, and energy saving and emission reducing are achieved. Due to the structure with the inverted-drop-shaped blades and the dish-shaped back plate, dust on the impeller of the induced draft fan is removed in real time, and meanwhile the strength of the impeller of the fan is increased; and stability is improved, potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:山东格林凯瑞精密仪器有限公司

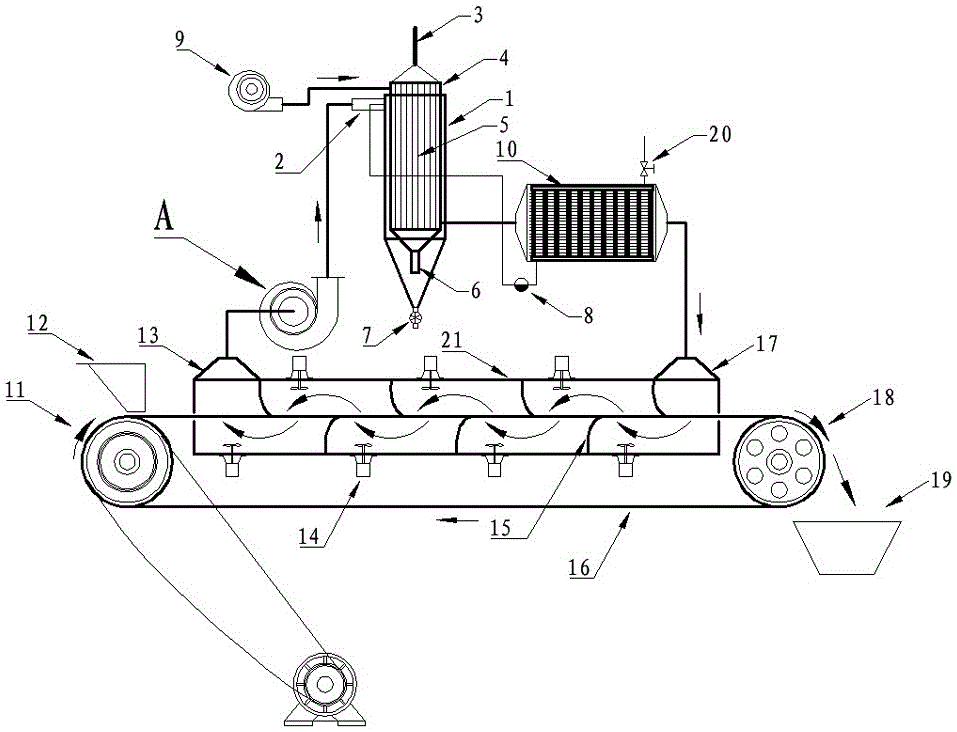

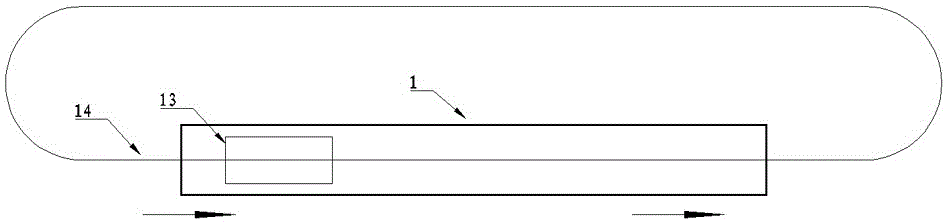

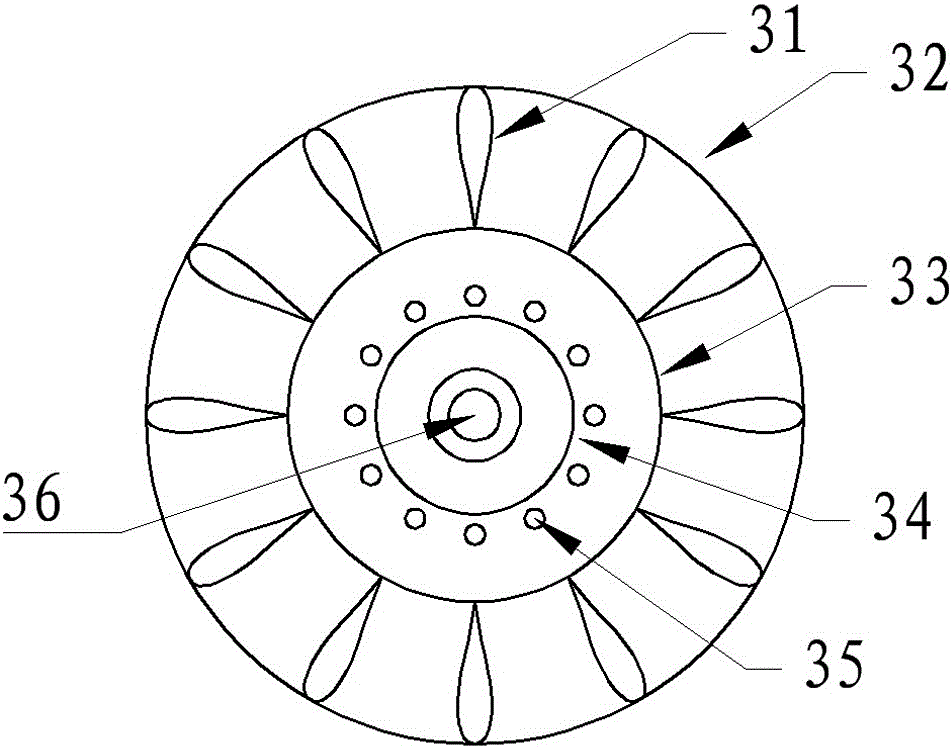

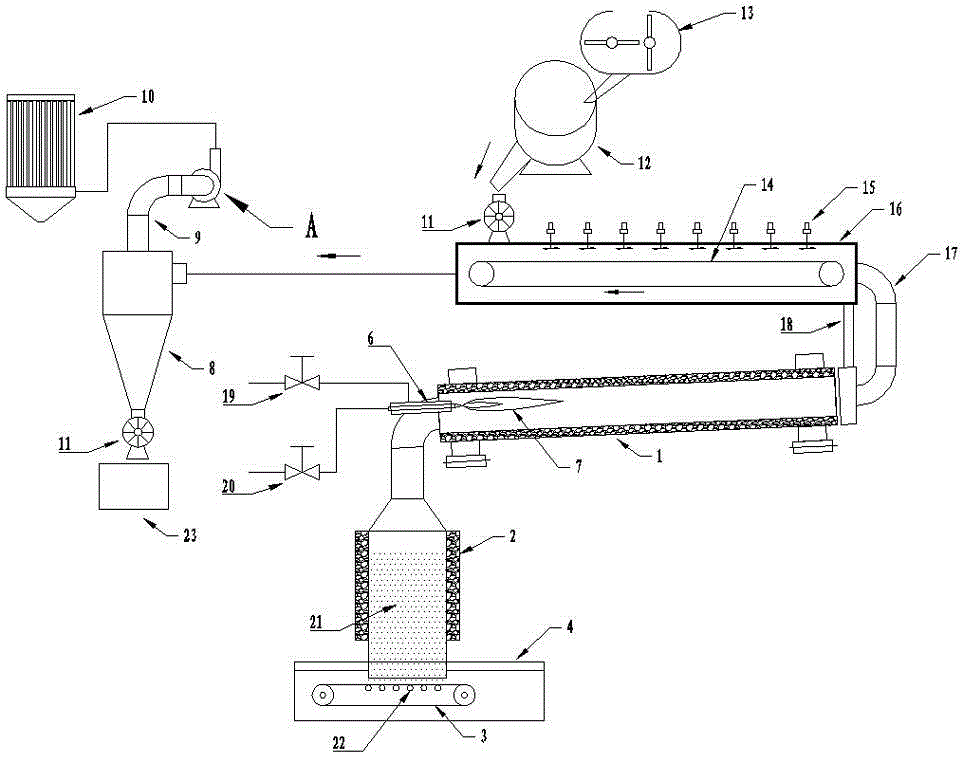

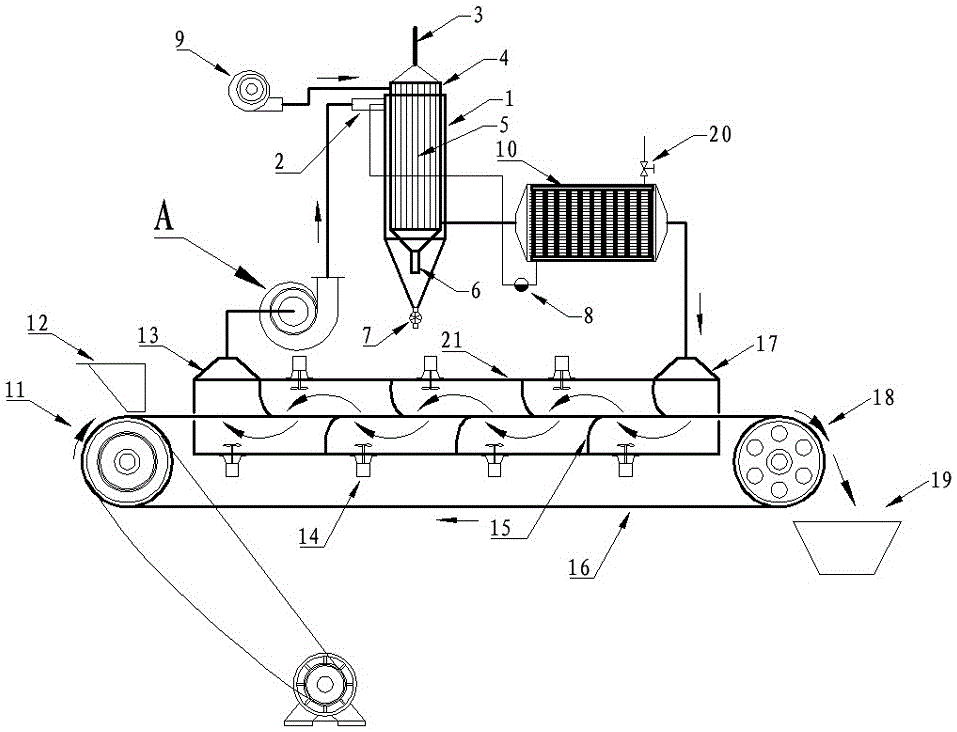

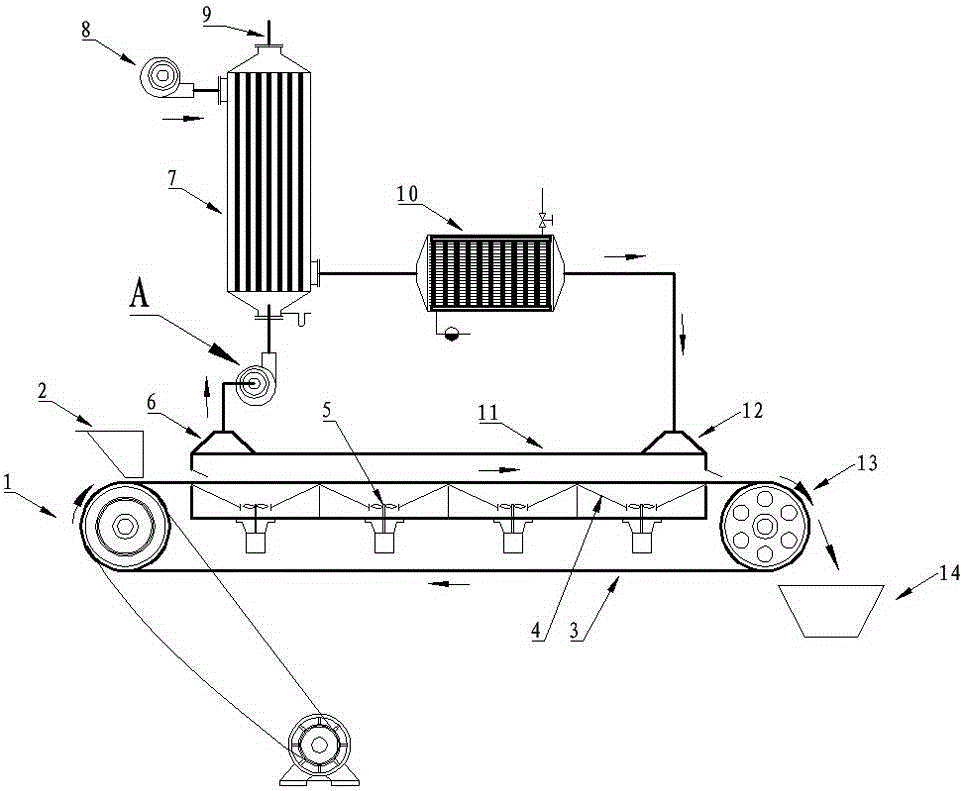

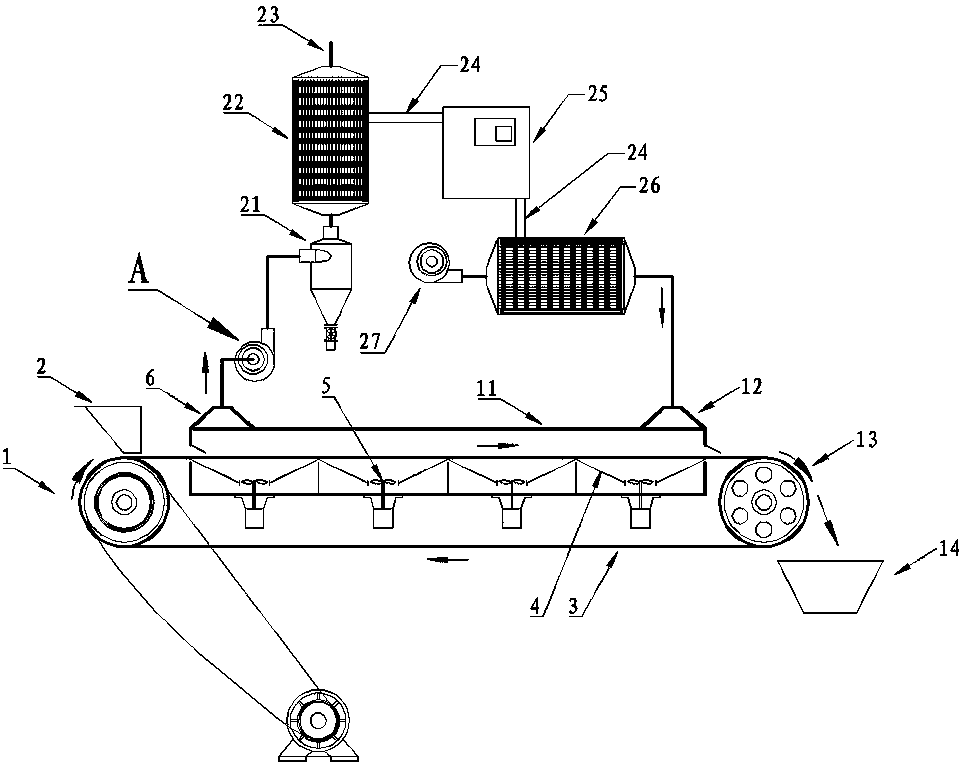

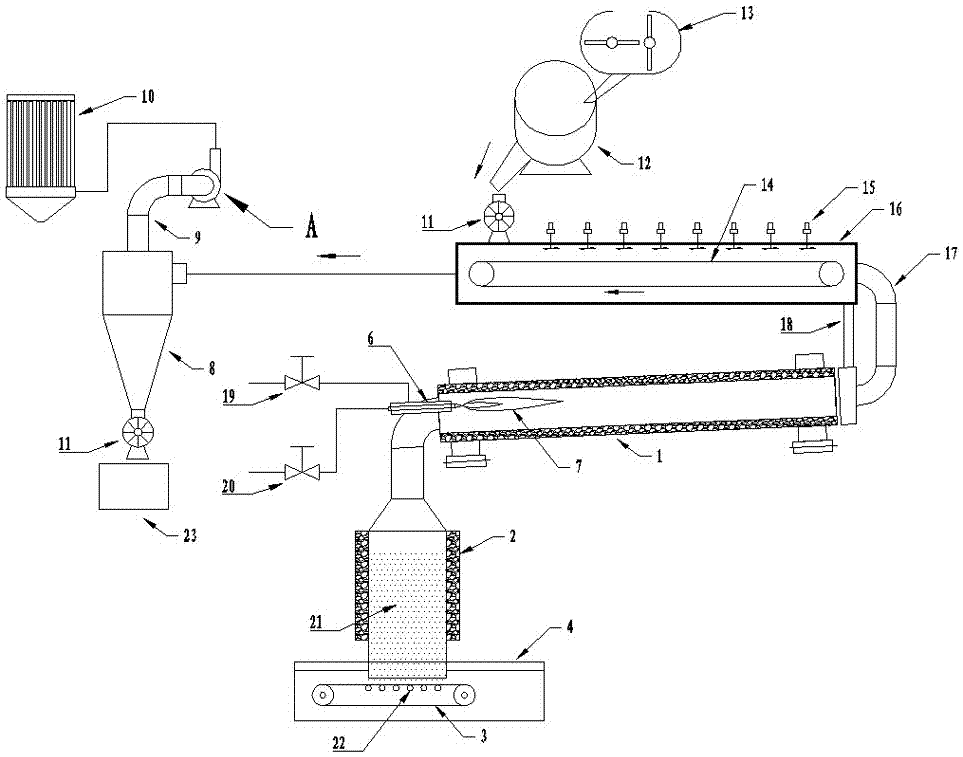

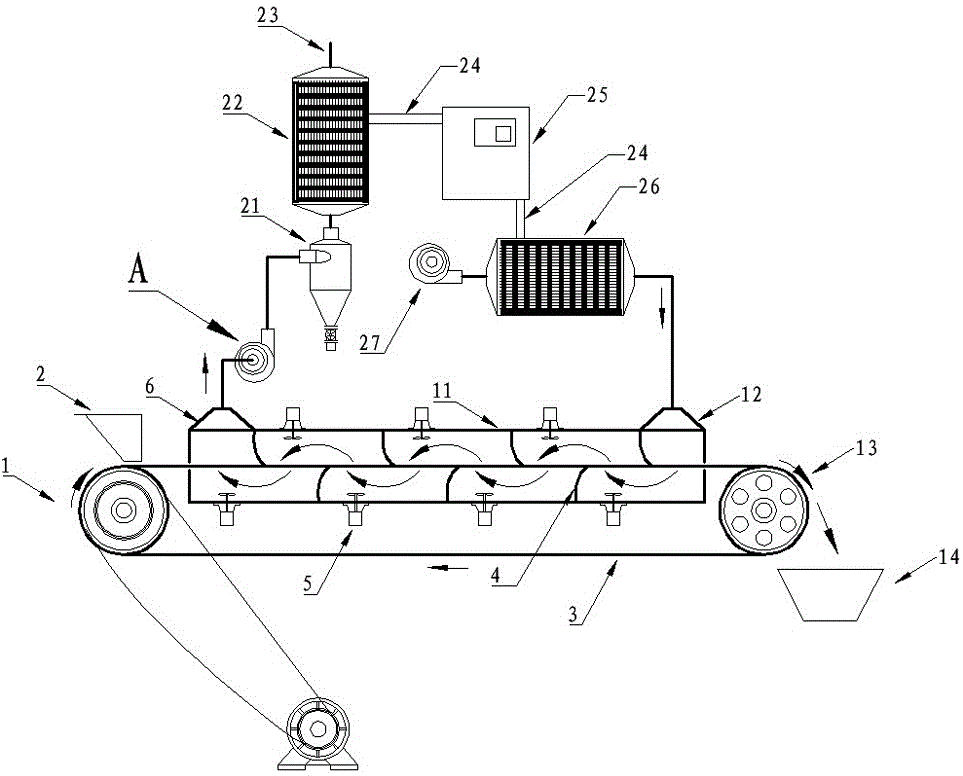

Hot wind type penetration reverse flow drying machine capable of recycling tail heat

ActiveCN105021017ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerInvolute

The invention discloses a hot wind type penetration reverse flow drying machine capable of recycling tail heat. A draught hood and a wind inlet hood are arranged at the two ends of a case body of the drying machine respectively. The draught hood is tangentially connected with a cyclone dust removing tail heat efficient recoverer through a draught fan and then evacuation is conducted. A blast blower is connected with the wind inlet hood through a tube type heat exchanger and a steam fin heater. A draught fan impeller is provided with hollow inverse-drop-shaped blades. The outline of the draught fan is an involute. According to the hot wind type penetration reverse flow drying machine capable of recycling tail heat, tail heat recovery and dust removal are creatively integrated, the cyclone dust removing tail heat efficient recoverer is designed, the equipment investment is reduced, and the working efficiency is improved. By means of the draught fan, a soft partition plate and an axial fan, penetration type reverse flow drying is ingeniously achieved, and the working efficiency is improved. The blades are in a hollow inverse drop shape, and therefore real-time cleaning of dust on the impeller is achieved, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:怀远县翰邦科技咨询有限公司

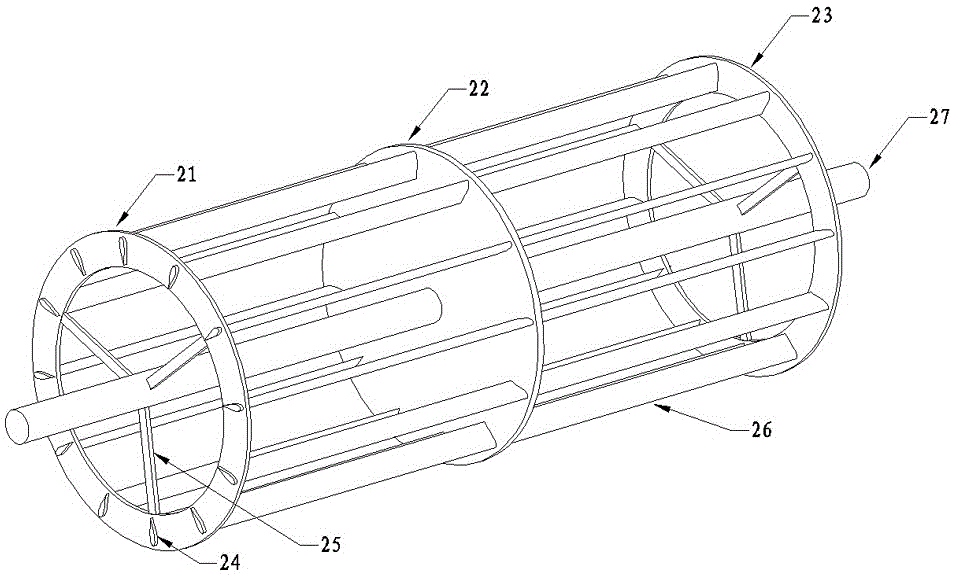

Cyclone dust removal heat pump type tunnel drying device

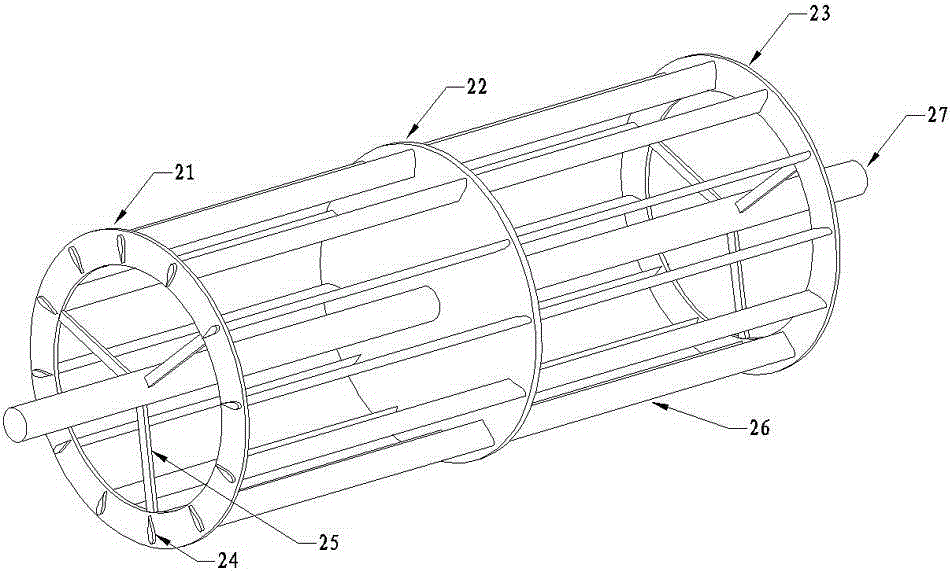

ActiveCN105066629AHigh wind resistance bendingHigh strengthDrying gas arrangementsDrying machines with progressive movementsImpellerCyclone

The invention discloses a cyclone dust removal heat pump type tunnel drying device. A trolley is arranged on a track path of a tunnel, an internal recycling long-shaft fan is arranged in the tunnel, the long-shaft fan comprises a long shaft and blades which are all shaped like a long stripe, and the cross section of each blade is a shaped like a hollow reversed water drop symmetrical to the radial direction and the center of an impeller shaft; the two ends of each blade are inserted into end plates respectively, and the long shaft is connected and fixed with the end plates through spokes; the two ends of the closed type tunnel are provided with an air draft hood and an air intake hood respectively, the air draft hood is connected with a draft fan, and the draft fan is connected with an evaporator through a cyclone dust collector for emptying; the evaporator of a heat pump system is connected with a main machine which is connected with a condenser; an air outlet end of an air blower is connected into an air hood through the condenser; the draft fan and the long-shaft fan impellers are both designed to be of a hollow symmetrical structure, dirt retention does not exist, and lightness, firmness and durability are achieved. According to the cyclone dust removal heat pump type tunnel drying device, heat pump cross flow drying and tail heat recovery are suitable for being adopted by a low-temperature drying system, destroy to heat sensitive components can be prevented, and the system can complete drying, dust removing and heat recovery efficiently with low energy.

Owner:倡创(上海)咨询管理事务所

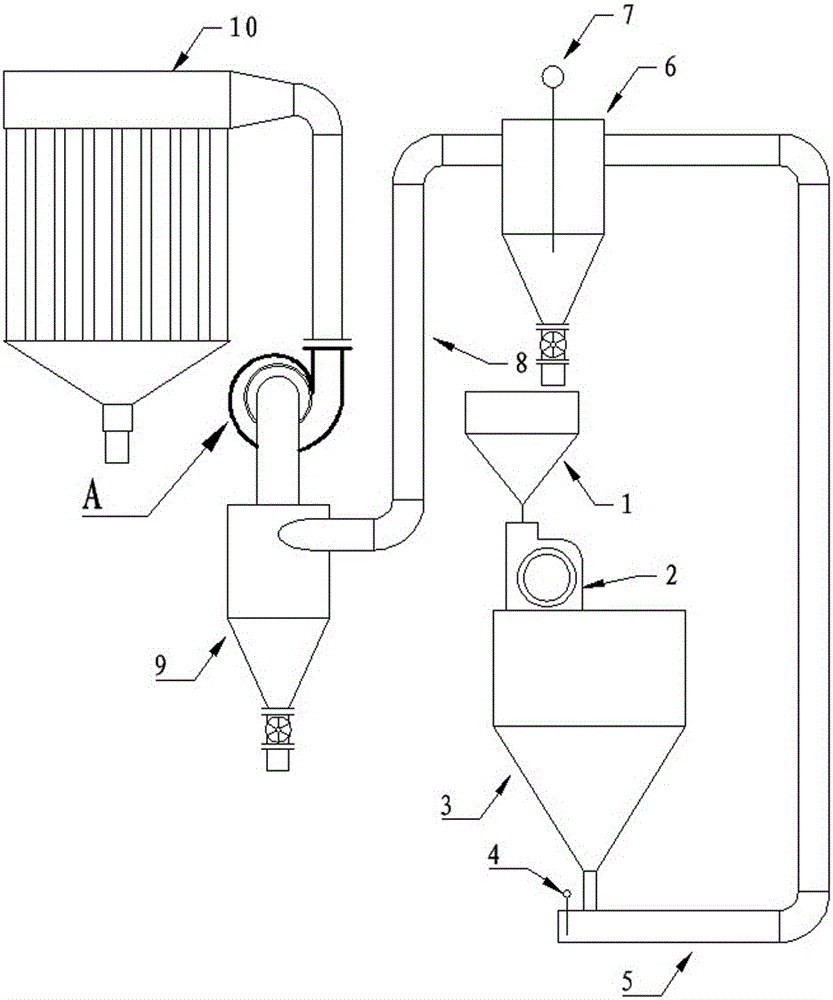

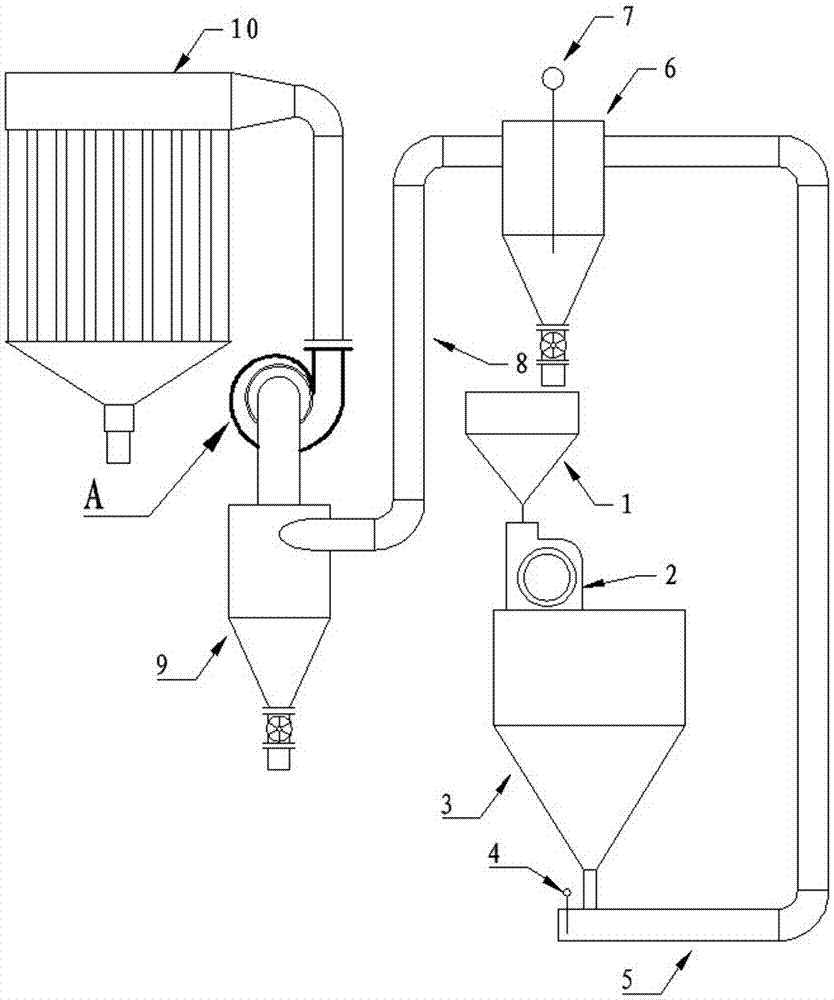

Air suction type grinder for pseudo-ginseng

InactiveCN105013593ADoes not affect dynamicDoes not affect balancePump componentsPumpsAir volumeInvolute

The invention discloses an air suction type grinder for pseudo-ginseng. The air suction type grinder for the pseudo-ginseng comprises a grinder body and an induced draft fan, wherein the discharging end of the grinder body is connected with the induced draft fan through a material storage case, air suction pipes and a cyclone separator; a ventilation door used for adjusting the air volume is arranged on one of the air suction pipes; and an impeller of the induced draft fan is of a structure with blades in a hollow reverse drop shape, and the shape contour line of the induced draft fan is an involute. By means of the air suction type grinder for the pseudo-ginseng, sorting of particles and cooling and temperature drop of the material are achieved in the pneumatic transmission process; the return and secondary grinding of the coarse particles are completed in one step, the qualified output of the material is achieved, and meanwhile dust capture is achieved; the timely and smooth discharging of the grinder is guaranteed by an air suction system, the material is prevented from being excessively ground, and electric power is saved; by means of the structure with the blades in the hollow reverse drop shape, the real-time cleaning of dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved, the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:JISHOU UNIVERSITY

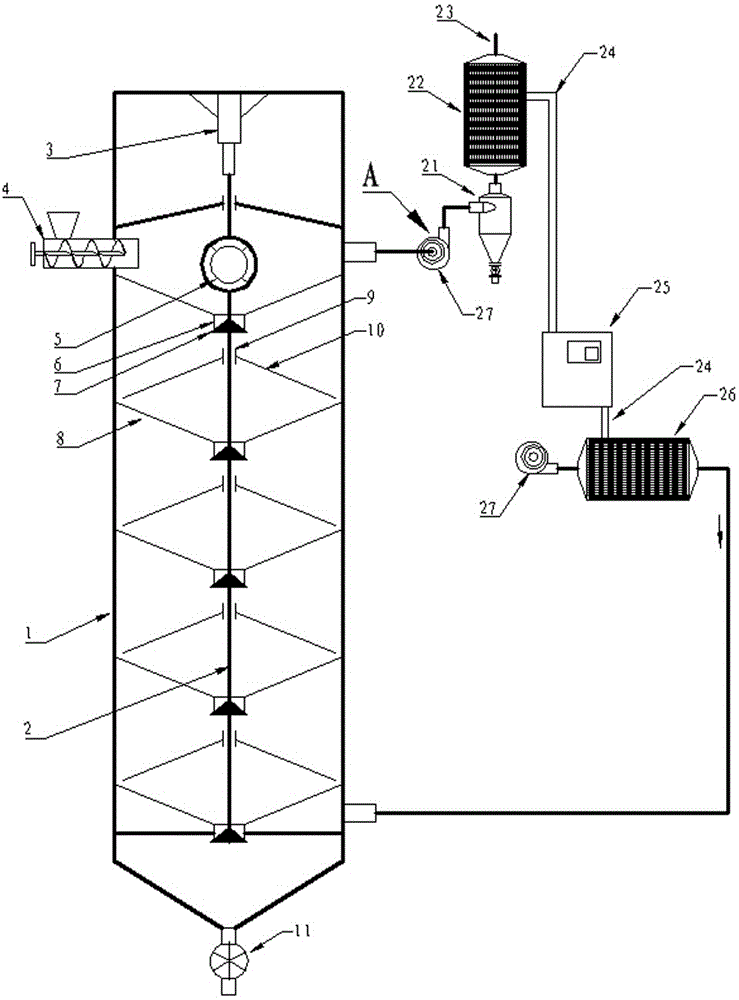

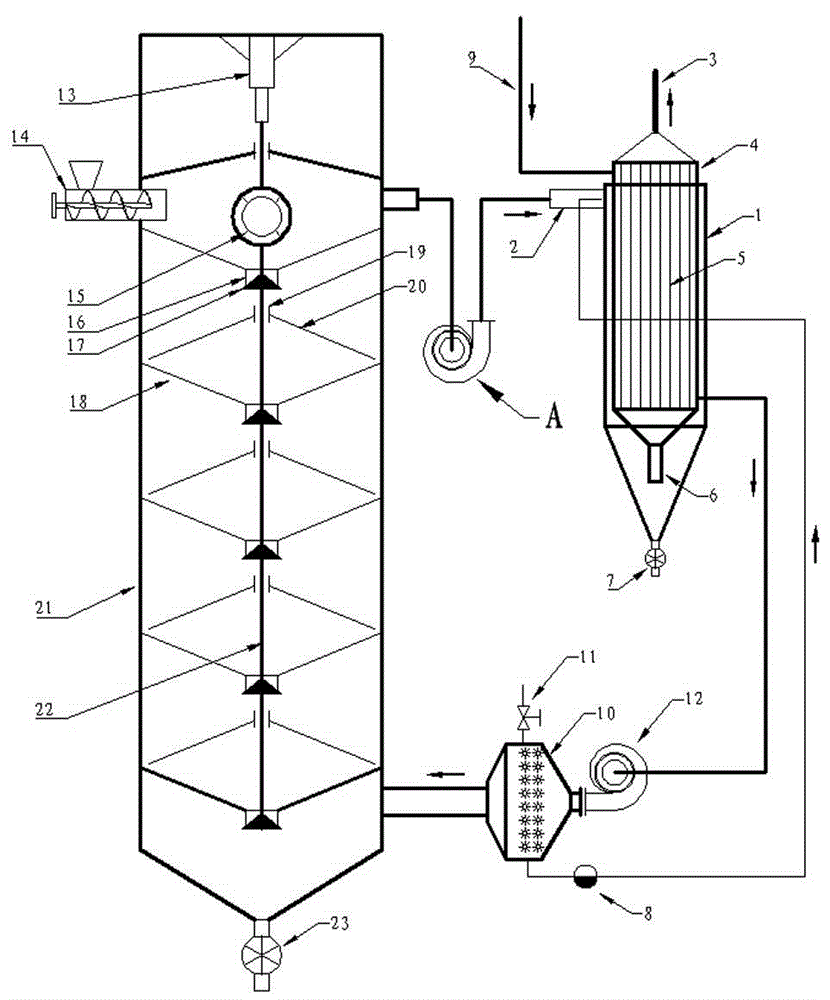

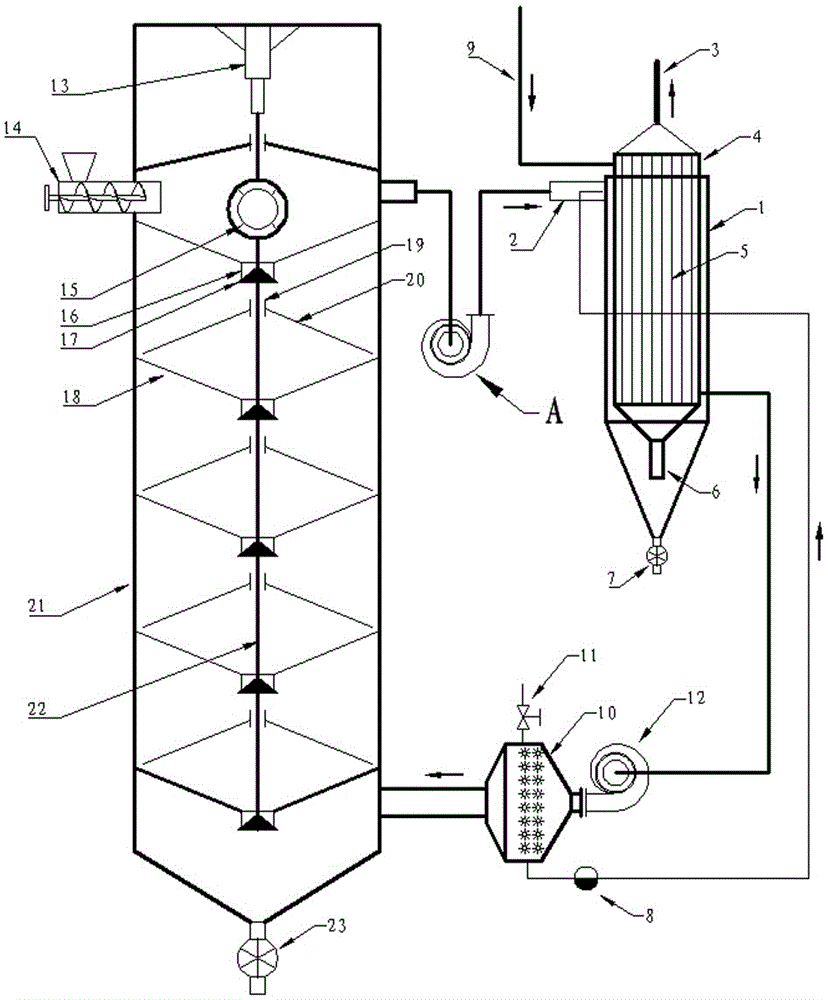

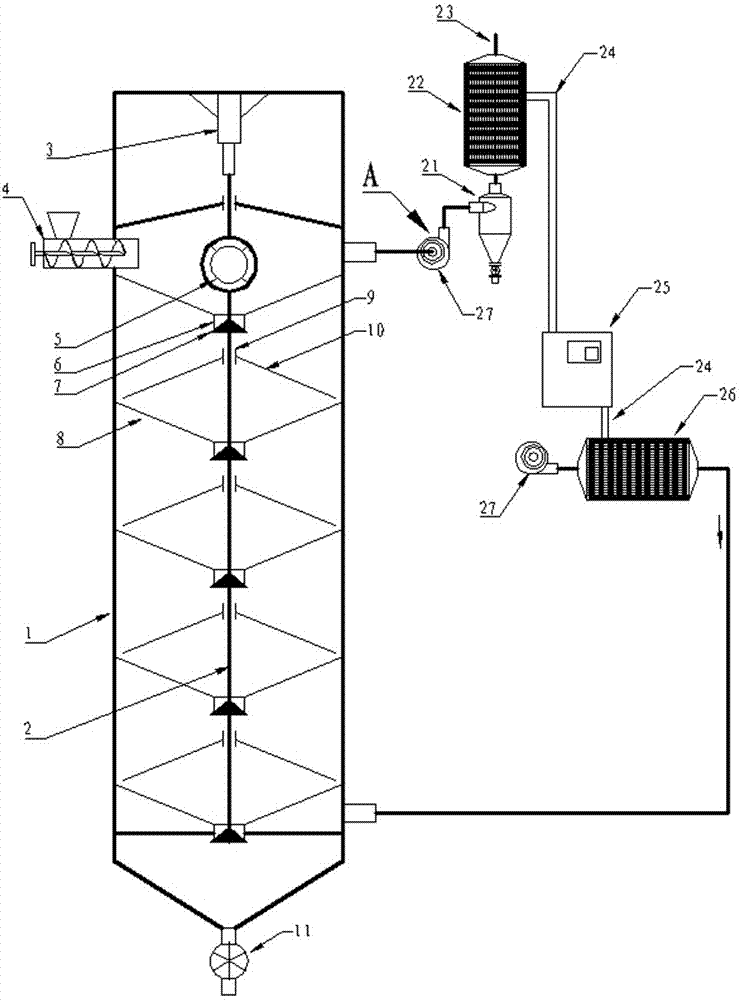

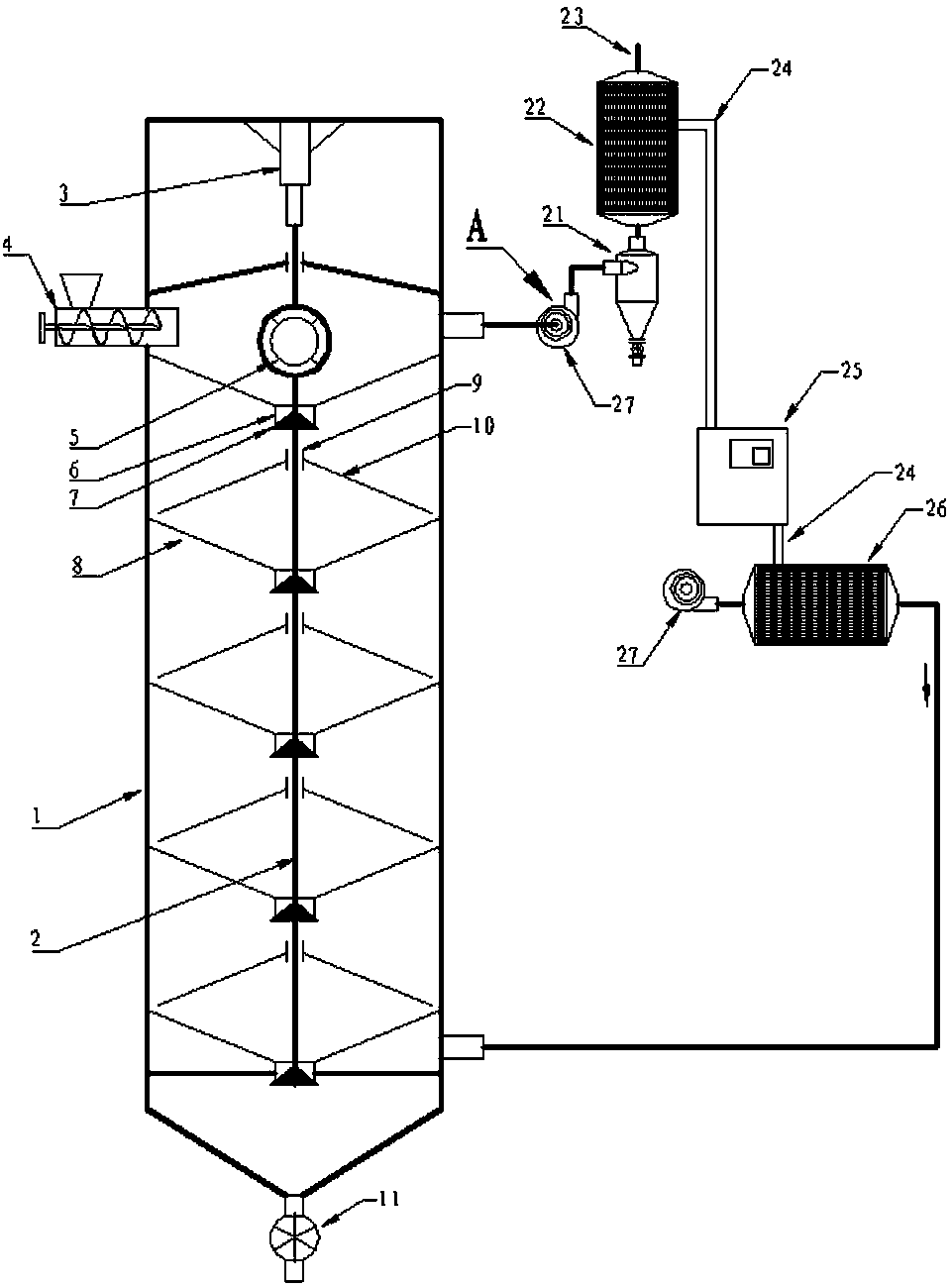

Heat pump type tail heat recovery and penetrating counterflow fluidized drying machine

ActiveCN105066653AImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsDrop-shapedAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

Cyclone dust removal heat pump type drying room

ActiveCN105180597ADoes not affect dynamicDoes not affect balancePump componentsDrying gas arrangementsCycloneImpeller

The invention discloses a cyclone dust removal heat pump type drying room. An internal recycle long-shaft draught fan is arranged in the drying room and comprises a long shaft and blades; the blades are long-strip-shaped; the cross section of each blade is centrosymmetric hollow reverse drop-shaped in the radial direction of an impeller shaft; two ends of the blades are inserted in end discs; the long shaft is connected with and fixed with the end discs through spokes; a draught hood and an air inlet hood are arranged at two ends of the drying room; the draught hood is connected with an induced draft fan; the induced draft fan is connected with the evaporator of a heat pump system via a cyclone dust collector for evacuation; the evaporator of the heat pump system is connected with a host machine; the host machine is connected with a condenser via a refrigerant pipe; the air outlet end of an air blower is connected with the air inlet hood via the condenser; the induced draft fan and the impeller of the long-shaft draught fan are arranged into hollow symmetrical structures, do not accumulate dust, and are firm and durable. The heat pump dries in a cross flow manner, recycles residual heat, is particularly suitable for being adopted by a lower drying temperature system, prevents nutritional ingredients of thermosensitive substances from being destroyed, and completes drying, dust removal and heat recovery in an efficient and low energy consumption manner.

Owner:湖南美林住宅工业有限公司

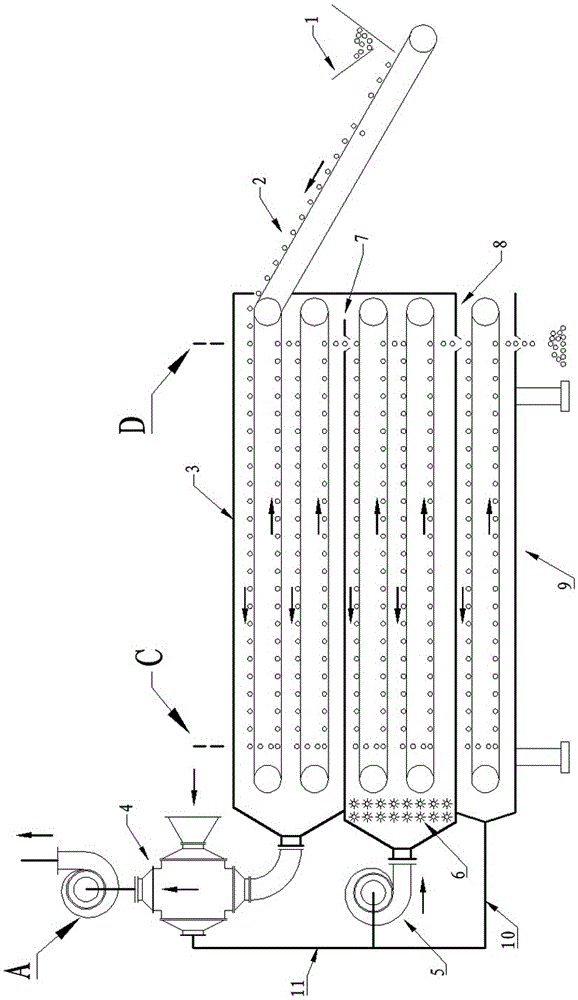

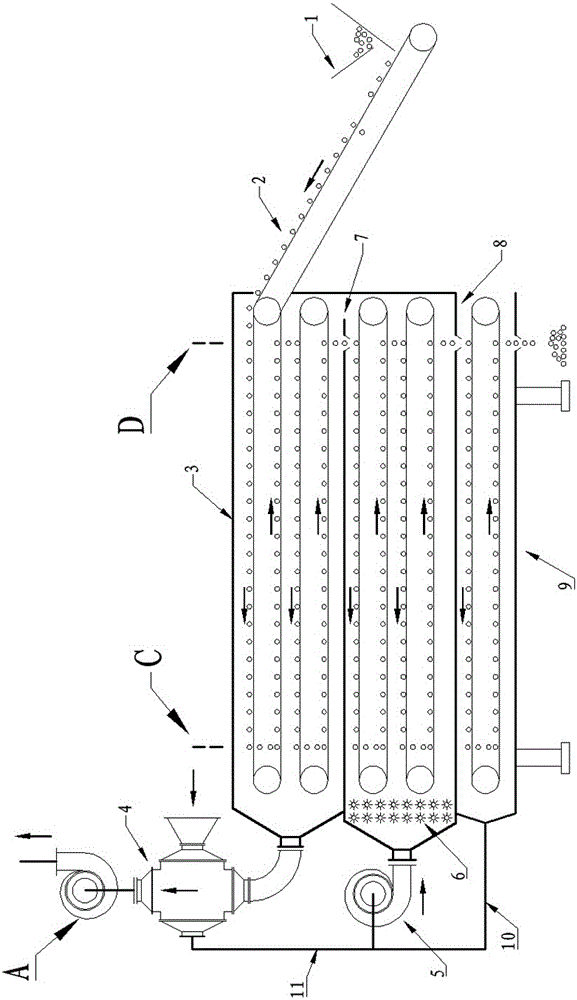

Tail heat recovery and dust removal integrated coal-fired boiler

ActiveCN105003927AHigh strengthReliable usePump componentsLighting and heating apparatusExhaust gasImpeller

The invention discloses a tail heat recovery and dust removal integrated coal-fired boiler. A boiler exhaust pipe is in tangential connection with a cyclone dust collector, dust is exhausted from a cone bottom through an air-lock valve after cyclone de-dusting, and exhaust enters a cone through a cyclone riser, passes through a tube nest after being uniformly dispersed, and is discharged by an exhaust pipe through an induced draft fan after being centralized by an upper tapered hopper; an impeller of the induced draft fan adopts the structure that blades are shaped like hollow reversed water droplets and a back plate is dish-shaped; the contour line of the induced draft fan is an involute. The tail heat recovery and dust removal integrated coal-fired boiler creatively integrates boiler tail heat recovery and dust removal, and a cyclone dust removal efficient tail heat recoverer is designed to complete tail heat recovery and dust removal in one step, so that the equipment investment is reduced and the working efficiency is improved; as the structure that the blades are shaped like hollow reversed water droplets and the back plate is dish-shaped is adopted, dust on the impeller of the induced draft fan can be cleaned in real time, the impeller strength of the induced draft fan is improved, the stability is enhanced, safety accidents caused by dust accumulation are effectively prevented, and the application prospect is wide.

Owner:YANGZHOU SUNLIGHT MACHINERY

Tail heat recovery hot wind type penetration countercurrent fluidized dryer

ActiveCN105135826ADoes not affect dynamicDoes not affect balanceDrying solid materials with heatDrying gas arrangementsCycloneDrop-shaped

The invention discloses a tail heat recovery hot wind type penetration countercurrent fluidized dryer. The upper part of a drying tower is connected with an induced draft fan; the induced draft fan is tangentially connected with a cyclone dust removal tail heat efficient recoverer formed by superposing a shell and tube heat exchanger and a cyclone dust remover for evacuation; a shell pass intake end of the shell and tube heat exchanger is communicated with atmosphere, and an exhaust end is connected with the lower part of the drying tower by an air blower and a steam fin heater; an impeller of the induced draft fan has a structure with hollow reverse water drop-shaped blades and a disc-shaped back plate; and the outline of the induced draft fan is an involute. The cyclone dust removal tail heat efficient recoverer is designed through creatively integrating the tail heat recovery with the dust removal, so that the equipment investment is reduced, and the working efficiency is improved; and as a screen hole conical cover, a screen hole conical disc, a blanking pipe, an extension vibration transmission shaft and a conical plug are arranged, the penetration, the backflow, the boiling and the fluidized drying of materials are skillfully and perfectly realized, more energies are saved, the drying quality is higher, the fan power consumption is lower, and the application prospect is broader.

Owner:邳州陆压汽车配件有限公司

Aconitum brachypodum ventilation type crusher

The invention discloses an aconitum brachypodum ventilation type crusher. The aconitum brachypodum ventilation type crusher comprises a crusher body and an induced draught fan. The discharging end of the crusher body is connected with the induced draught fan through a storage tank, exhaust pipes and a cyclone separator. The exhaust pipes are provided with an air door adjusting the air volume. An impeller of the induced draught fan is provided with a structure that blades are in a hollow inverted water drop shape, and a back plate is in a dish shape. The contour line of the appearance of the induced draft fan is an involute. In the pneumatic conveying process, particle sorting and material cooling are achieved. Rough particle returning and secondary crushing are finished by one step, qualified material output is achieved, and meanwhile dust capturing is achieved. Good-time smooth discharging of the crusher body is guaranteed through a ventilation system, materials are prevented from being excessively crushed, and electric power is saved. Through the structure that the blades are in the hollow inverted water drop shape, and the back plate is in the dish shape, dust on the impeller of the induced draft fan is cleaned away in real time, the impeller strength of the draught fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:JISHOU UNIVERSITY

Tail heat recovery hot air type penetrating counterflow fluidized drying machine

InactiveCN105066652ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying solid materialsCycloneAtmospheric air

The invention discloses a tail heat recovery hot air type penetrating counterflow fluidized drying machine. The upper portion of a drying tower is connected with an induced draft fan, the induced draft fan is tangentially connected with a cyclone dust removal tail heat efficient recoverer formed by overlapping a tube type heat exchanger and a cyclone dust collector, and then evacuation is carried out. The shell side air inlet end of the tube type heat exchanger is communicated with the air, and the air outlet end of the tube type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam fin heater. An impeller of the induced draft fan is provided with the structure with hollow inverted-drop-shaped blades. The contour line of the appearance of the induced draft fan is an involute. According to the tail heat recovery hot air type penetrating counterflow fluidized drying machine, tail heat recovery and dust removal are creatively integrated, the cyclone dust removal tail heat efficient recoverer is designed, equipment investment is reduced, and work efficiency is improved. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, more energy is achieved, and the drying quality is higher; and the power consumption of the fan is lower, and wider application prospects are achieved.

Owner:JISHOU UNIVERSITY

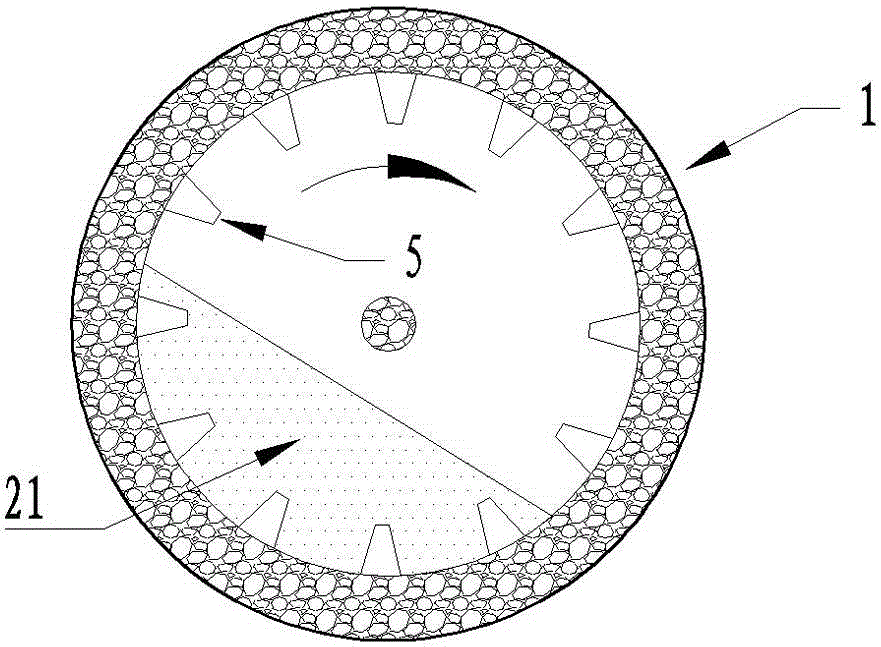

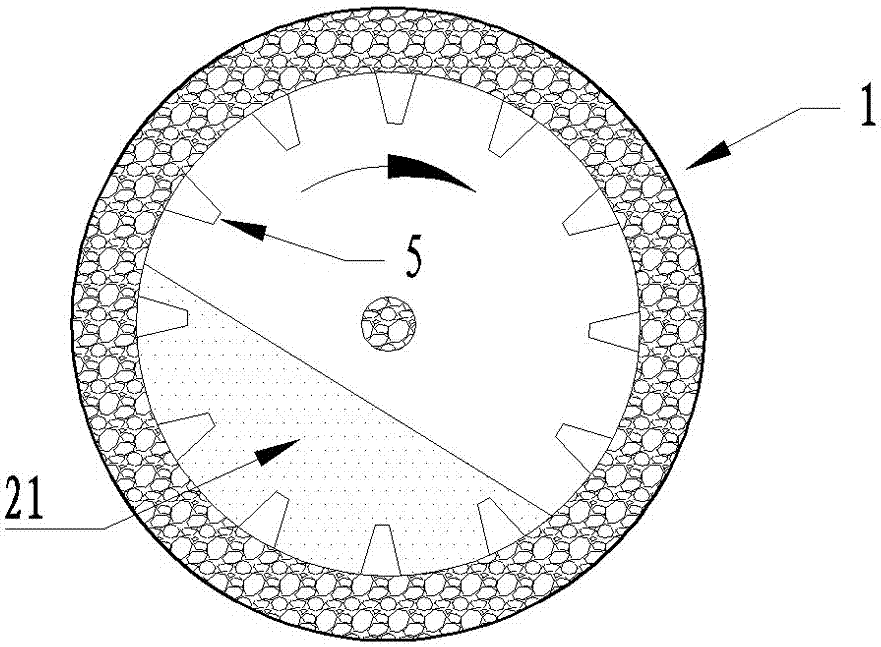

Rotary kiln system capable of utilizing residual heat for stoving and with no dirt retention on induced draft fan

ActiveCN105180645AEasy flipIncrease the heating areaPump componentsRotary drum furnacesEngineeringThermal efficiency

The invention discloses a rotary kiln system capable of utilizing residual heat for stoving and with no dirt retention on an induced draft fan. A rotary kiln is arranged in an inclined manner; a burner is arranged in the rotary kiln; the high end of the rotary kiln and one end of a dryer are connected with an air hose in a bidirectional manner through a discharging pipe; a conveyer belt is arranged in the dryer and is connected with the discharging pipe; a star discharger is arranged at the other end of the dryer; a bulged refractory slab is arranged in the rotary kiln; the induced draft fan for dust removal has the structure of wedge-shaped blades and a dished backboard. According to the invention, the bulged refractory slab increases the heat transfer area of the rotary kiln, promotes stirring of a material, and facilitates improvement of thermal efficiency; the dryer utilizes residual heat to facilitate forming and drying of a globular material; residual heat utilization and heat preservation consequent reaction of hot material have the remarkable energy-saving characteristic; a quenching liquid pool rapidly cools a pellet material, and plenty of water is evaporated through reaction, so that the environmental protection pressure caused by expansion of producing fluid is effectively relieved; the induced draft fan does not accumulate dirt to completely eradicate a safety accident; the rotary kiln system is particularly suitable for burning processing of vanadium ore and is broad in application prospect.

Owner:NANTONG HENGDA MACHINERY MFG

Hot wind type penetration reverse flow drying machine capable of recycling tail heat

ActiveCN105021008AImprove rigidityImprove carrying capacityDrying gas arrangementsDrying machines with progressive movementsDish structureImpeller

The invention discloses a hot wind type penetration reverse flow drying machine capable of recycling tail heat. A draught hood and a wind inlet hood are arranged at the two ends of a case body of the drying machine respectively. The draught hood is tangentially connected with a cyclone dust removing tail heat efficient recoverer through a draught fan and then evacuation is conducted. A blast blower is connected with the wind inlet hood through a tube type heat exchanger and a steam fin heater. A draught fan impeller is provided with hollow inverse-drop-shaped blades, and a back plate is of a dishing structure. The outline of the draught fan is an involute. According to the hot wind type penetration reverse flow drying machine capable of recycling tail heat, tail heat recovery and dust removal are creatively integrated, the cyclone dust removing tail heat efficient recoverer is designed, the equipment investment is reduced, and the working efficiency is improved. By means of the draught fan, a soft partition plate and an axial fan, penetration type reverse flow drying is ingeniously achieved, and the working efficiency is improved. The blades are in the hollow inverse drop shape, the back plate is of the dishing structure, and therefore real-time cleaning of dust on the impeller is achieved, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:湖北楚佳茶业有限公司

Raymond mill device with non-dust-accumulation draught fan

The invention discloses a Raymond mill device with a non-dust-accumulation draught fan. An air flow circulation abrasive powder discharge system is formed by the draught fan, a Raymond mill, a cyclone separation discharge device and an air return air pipe. A pressure equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe. A plurality of cyclones are arranged in the cyclone pipe. The lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction. A lower pipe opening of the cyclone separator is soaked in a circulation pool which is connected with the upper end of the cyclone pipe. An impeller of the draught fan is of a structure that blades are in hollow reverse water drop shapes and a back plate is in a dish shape. The appearance contour line of the draught fan is an involute. According to the Raymond mill device, low-resistance pressure-equalized exhausting is achieved through the cyclone pipe and the cyclones, and therefore dust overflow caused by system positive pressure is eradicated. Wet-method efficient dust removal and mineral powder recycle are achieved through the circulation pool. By means of the structure that the blades are in the hollow reverse water drop shape and the back plate is in the dish shape, dust on the impeller of the induced draught fan is removed in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and application prospects are wide.

Owner:JISHOU UNIVERSITY

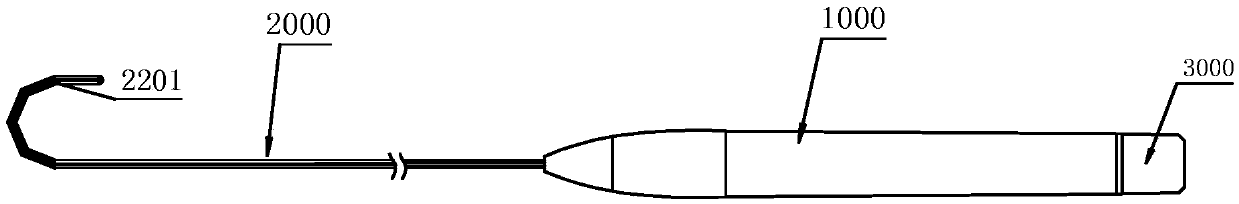

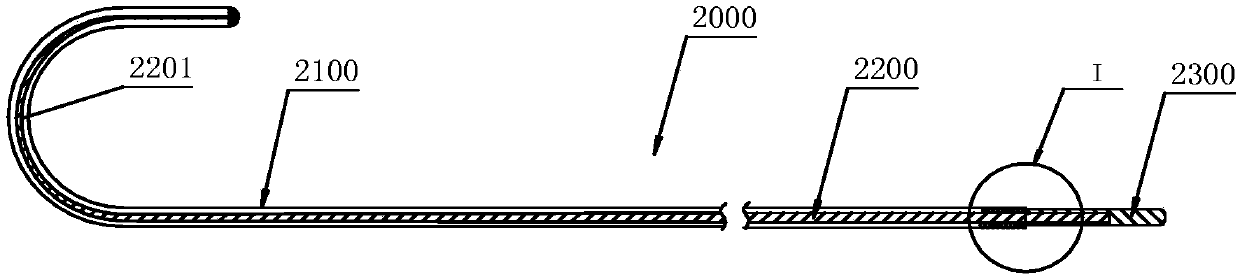

Guide wire device capable of adjusting bending

The invention discloses a guide wire device capable of adjusting bending. The device includes a guide wire main body. The guide wire main body includes a hollow outer guide wire and a core wire passing through the cavity of the outer guide wire. An end head of the far-end of the outer guide wire is fixedly connected to an end head of the far-end of the core wire. A far-end part which is shaped into a curved shape is arranged on the far-end of the core wire. The far-end of the guide wire main body is curved in a free state. The device also includes a bending adjusting mechanism used for adjusting a bending degree of the far-end of the guide wire main body and a guide wire locking mechanism used for locking the near-end of the core wire. The near-end of the core wire extends out of the outerguide wire and is detachably and fixedly connected to the guide wire locking mechanism. The bending adjusting mechanism is movably connected to the near-end of the guide wire main body and drives thenear-end of the outer guide wire to move axially relative to the near-end of the core wire. The guide wire locking mechanism is detachably fixed to the near-end of the bending adjusting mechanism. The invention provides the guide wire device capable of adjusting bending which can detach a handle from the guide wire main body, is rapid in separation and simple in operation.

Owner:HANGZHOU WEIQIANG MEDICAL TECH CO LTD

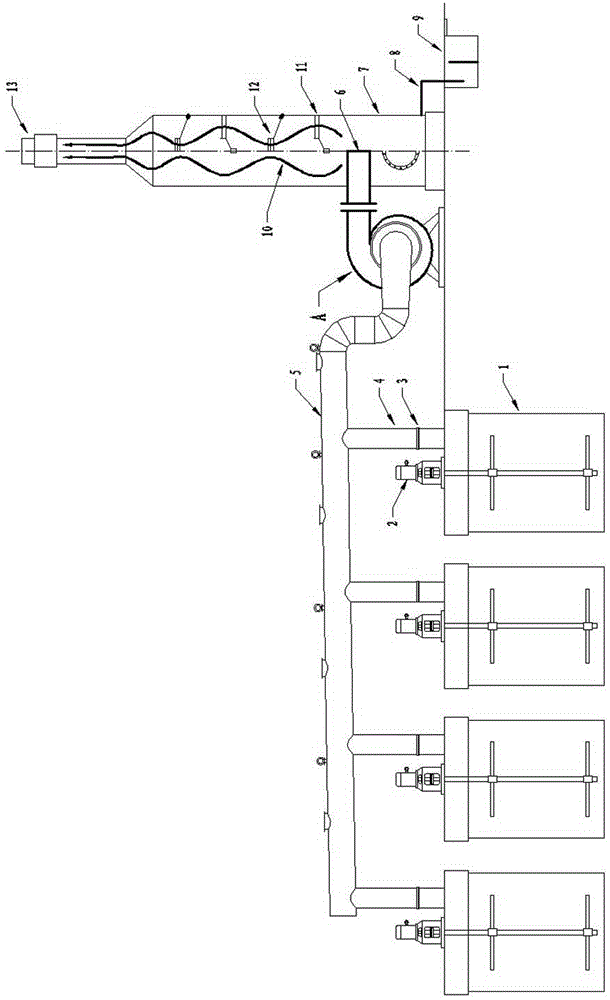

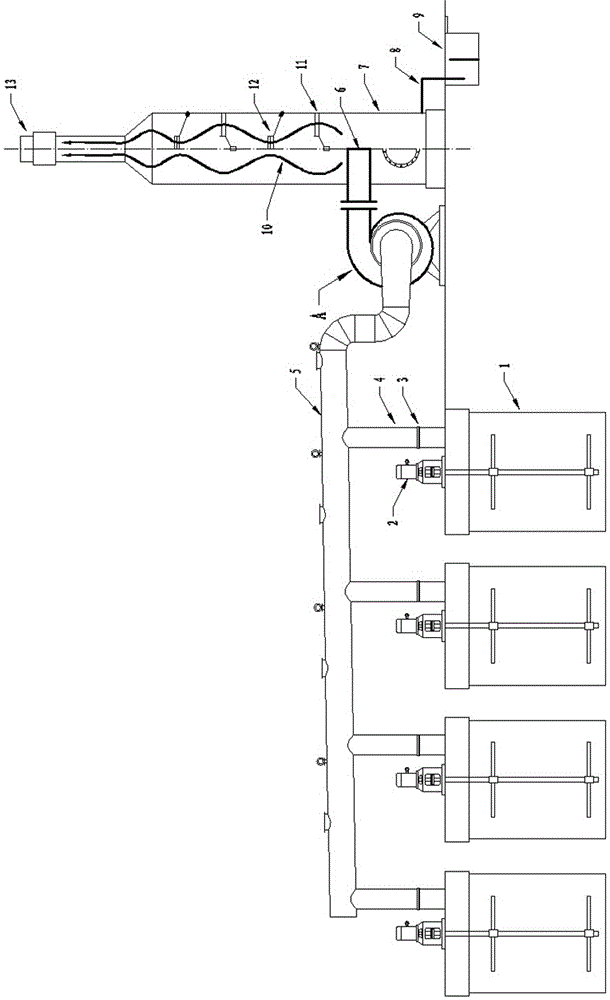

Combination exhausting device for manganese ore powder and sulfuric acid reaction

ActiveCN105110333AHigh strengthEnsure stabilityCarbon compoundsChemical industryImpellerCarbon dioxide

The invention discloses a combination exhausting device for manganese ore powder and sulfuric acid reaction. Stirring systems are arranged in combination barrels, the combination barrels are connected with a draught fan through exhaust pipes, the draught fan is tangentially connected with a swirl tower and then is exhausted, and air valves are arranged in the exhaust pipes; multiple groups of swirlers, which consist of large swirl plates, small swirl plates and conical hopper plates, are vertically arranged in the swirl tower; an impeller of the draught fan has hollow and inverted-droplet-shaped vanes; and the appearance contour line of the draught fan is involute. According to the combination exhausting device, the real-time exhaust of carbon dioxide gas produced from the reaction between the manganese ore powder and the sulfuric acid is realized through the draught fan and the swirlers, the proceeding of the reaction is facilitated, carrying powdered ore is effectively recovered through gas swirling, and energy saving and emission reduction are realized; and the vanes are of hollow and inverted-droplet-shaped structures, thus dust on the impeller of the draught fan can be cleaned in real time, the strength of the impeller of the fan is improved, the stability is enhanced, and safety accidents caused by dust accumulation are effectively avoided, so that the application prospect is broad.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

Tail heat recycling and dust removing type coal-fired boiler

InactiveCN105135414ADoes not affect dynamicDoes not affect balancePump componentsPumpsAir preheaterImpeller

The invention discloses a tail heat recycling and dust removing type coal-fired boiler. The tail heat recycling and dust removing type coal-fired boiler comprises a boiler main body and an induced draft fan. An exhaust gas pipe of the boiler main body is connected with the induced draft fan sequentially through an air preheater, a water preheater, a cyclone dust remover and a granite dust remover and then is emptied. The air inlet end of the shell pass of the air preheater is connected with an air blower, and the air outlet end of the shell pass of the air preheater is connected with the boiler main body. A water inlet pipe of the shell pass of the water preheater is connected with a high-position water tank, and a water outlet pipe of the shell pass of the water preheater is connected with a boiler water inlet pump. An impeller of the induced draft fan is provided with vanes adopting a structure in a shape of a hollow reverse water droplet. The external contour line of the induced draft fan is an involute. The tail heat recycling and dust removing type coal-fired boiler carries out two-stage counterflow heat exchange and dry and wet two-stage dust removal on boiler exhaust gas so as to realize tail heat recycling and dust removing operation and realize energy conservation and emission reduction. As the vanes adopt the structure in the shape of the hollow reverse water droplet, dust on the impeller of the induced draft fan is cleared in real time, the impeller strength of the fan is increased, the stability is enhanced, and safety accidents caused by dust accumulation are effectively avoided. The application prospect is wide.

Owner:JISHOU UNIVERSITY

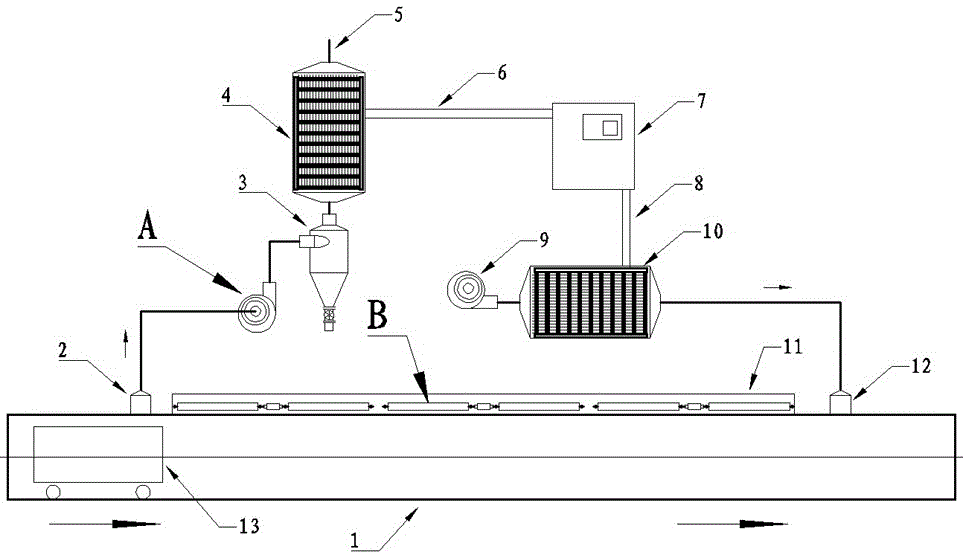

Tail heat recovery screen mesh plate turning type drying machine

ActiveCN105066627ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerPulp and paper industry

The invention discloses a tail heat recovery screen mesh plate turning type drying machine. A box of the drying machine is provided with a screen mesh plate turning plate type conveying device from top to bottom. The box of the drying machine is divided into an upper drying area, a middle drying area and a lower drying area. The upper drying area is connected with an induced draft fan through an air heat exchanger, and then evacuation is carried out. A fresh air outlet of the air heat exchanger is connected with an air inlet of an air blower, and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. The tail heat recovery screen mesh plate turning type drying machine is simple and reasonable in tail heat recovery, damp and hot tail gas obtained after heat recovery is exhausted through the induced draft fan, effective cooling and further tail heat recovery are carried out on dried materials, and energy saving and emission reducing are promoted. Due to the structure that the blades are in a hollow inverted drop shape and the back plate is in a dish shape, dust is removed in real time, and the strength of the impeller of the fan is increased; and stability is improved, potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Hot-air through counter flow dryer for panax notoginseng

InactiveCN105180629ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying solid materialsImpellerPANAX NOTOGINSENG ROOT

The invention discloses a hot-air through counter flow dryer for panax notoginseng. The two ends of the dryer are provided with a draught hood and an air intake hood respectively. The draught hood is connected with a draught fan. The draught fan is connected with a tube pass of a tubular heat exchanger and then emptied. The air inlet end of a shell pass of the tubular heat exchanger is connected with an air blower. The air outlet end of the shell pass of the tubular heat exchanger is connected with the air intake hood through a steam finned heater. An impeller of the draught fan is provided with blades which are of a hollow inverted-water-drop-shaped structure. The hot-air through counter flow dryer is provided with the draught fan, the heat exchanger and closed conical hoppers arranged below a sieve plate steel strip, and axial-flow fans are arranged in the conical hoppers, so that through type counter flow drying of the panax notoginseng is achieved, the drying efficiency is improved, the drying speed is increased, and energy consumption is also reduced; since the blades are of the hollow inverted-water-drop-shaped structure, dust on the impeller of the draught fan is cleaned away in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, safety accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:JISHOU UNIVERSITY

Waste heat recovery-type dirt retention-prevention oil burning boiler

ActiveCN105066086ADoes not affect dynamicDoes not affect balanceSteam generation using pressureSteam boilersAir preheaterImpeller

The invention discloses a waste heat recovery-type dirt retention-prevention oil burning boiler. The oil burning boiler comprises a burner and a boiler body, wherein a waste gas pipe of the boiler body is sequentially connected with tube passes of a water preheater and an air preheater and then is exhausted; a water inlet pipe of the shell pass of the water preheater is connected with a head tank, and the water outlet pipe of the shell pass of the water preheater is connected with a water inlet connector of the boiler through a water pump and a valve; the air inlet pipe of the shell pass of the air preheater is communicated with the atmosphere, and the air outlet pipe of the shell pass of the air preheater is connected with the burner; each blade of a centrifugal fan impeller of the burner is of a hollow inverted-drop shape. According to the waste heat recovery-type dirt retention-prevention oil burning boiler disclosed by the invention, heat in the waste gas of the boiler is effectively recycled for twice, so that consumption of diesel fuel of the burner is lowered; each blade is of a hollow inverted-drop shape, so that dirt on the centrifugal fan impeller of the burner is cleaned in real time; besides, the strength of the fan impeller is increased, so that the service life of the equipment is prolonged, and safety accidents caused by dirt retention can be effectively eradicated; and the application prospect of the waste heat recovery-type dirt retention-prevention oil burning boiler is wide.

Owner:徐州华睿炭材料科技有限公司

Heat pump tail heat recovery countercurrent dryer

ActiveCN105066643BRealize penetrating countercurrent low temperature dryingRecycling fitDrying solid materials with heatHeat recovery systemsInvoluteAir blower

The invention discloses a heat pump type tail heat recovery counterflow drying machine. A draught hood of the drying machine is connected with an induced draft fan, the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant tube, and the main engine is connected with a condenser through a refrigerant tube. The air outlet end of an air blower is connected with an air inlet hood through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades. The contour line of the appearance of the induced draft fan is an involute. The induced draft fan, a heat exchanger and a closed cone hopper below a screen plate steel rip are arranged, an axial fan is arranged in the cone hopper, so that penetrating type counterflow low-temperature drying of materials is achieved, and the heat pump system is especially suitable for recovery of heat of low-temperature tail gas. The blades are of a hollow inverted drop shape, so that dust on the impeller of the induced draft fan is removed in real time, the strength of the impeller of the fan is increased, and stability is improved; and potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:安徽上元家居材料股份有限公司

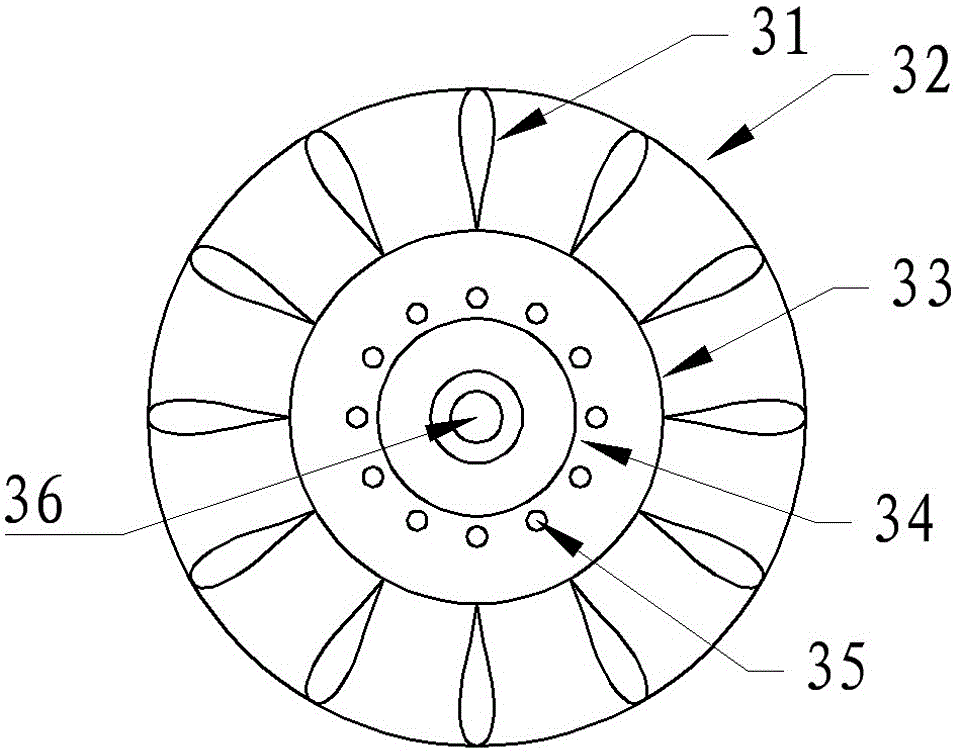

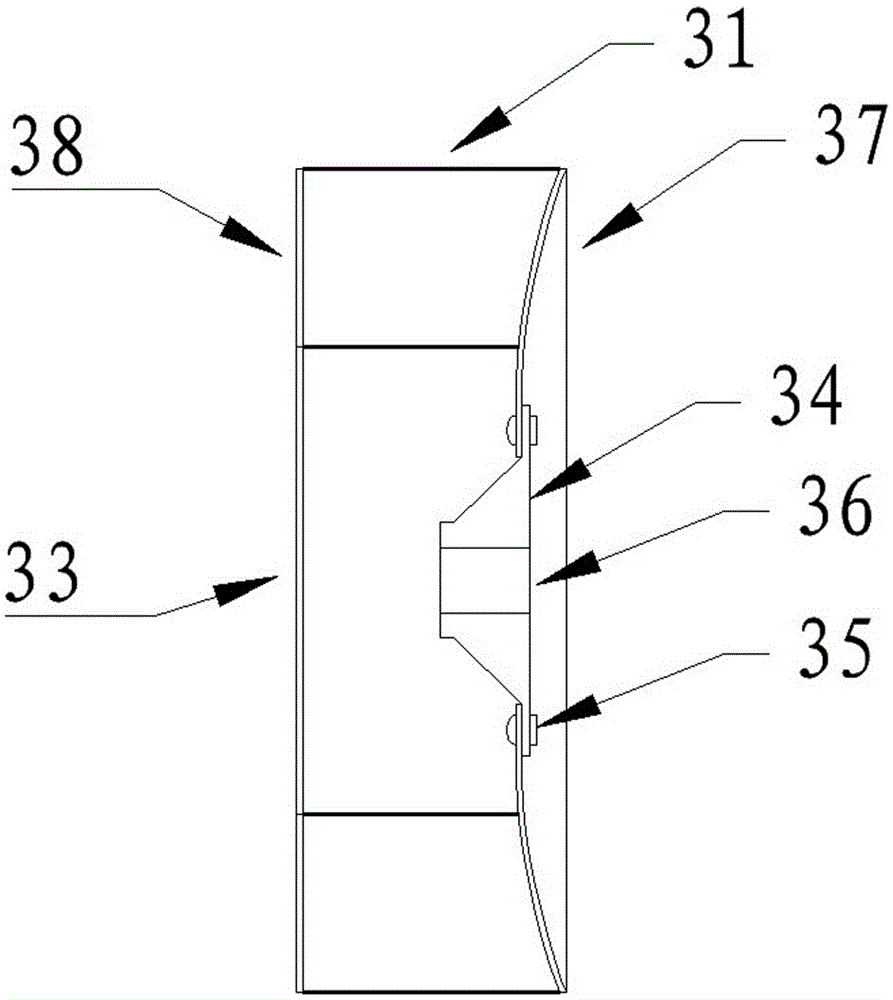

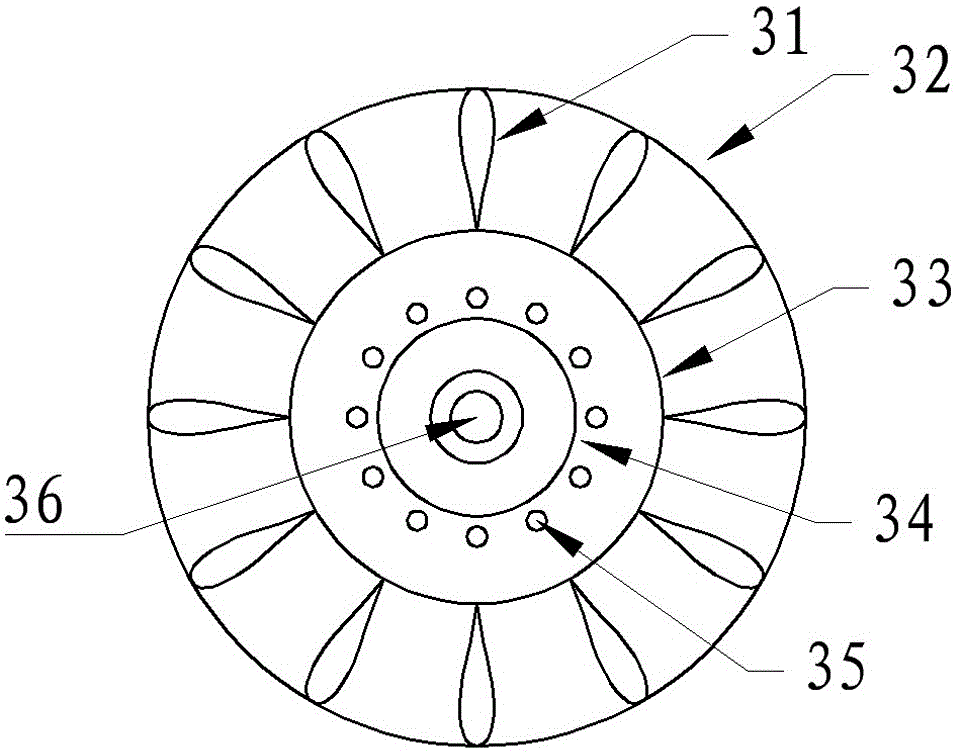

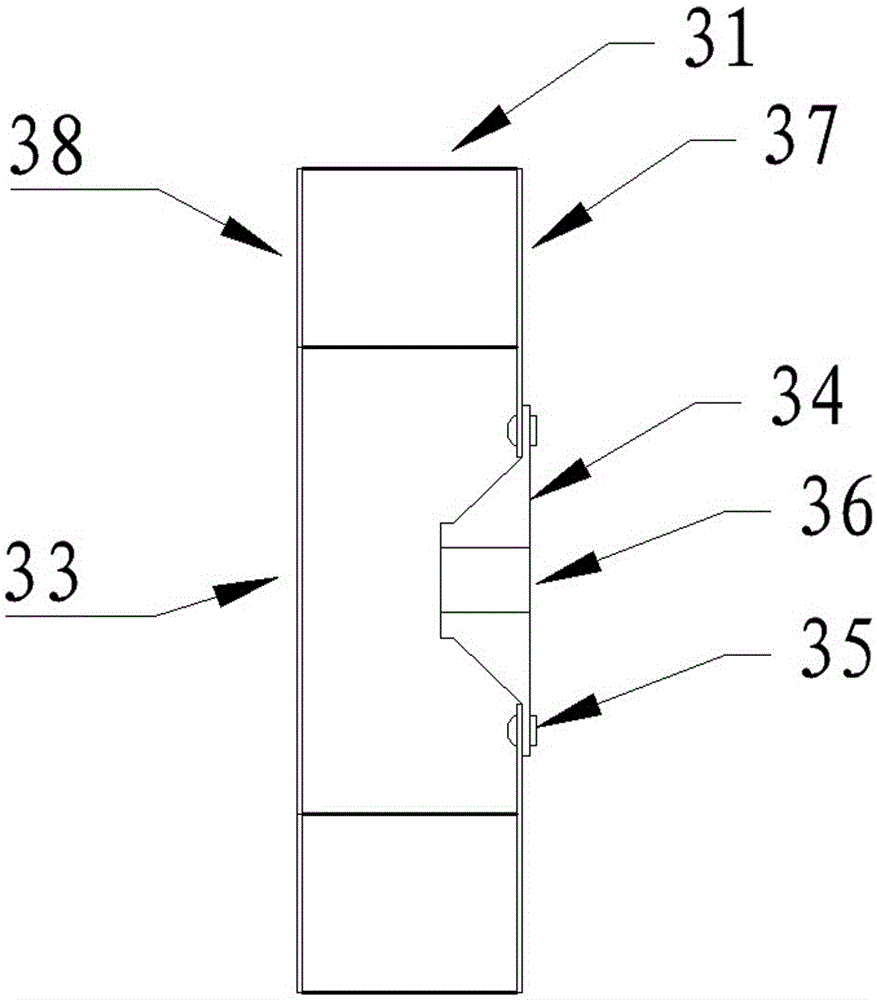

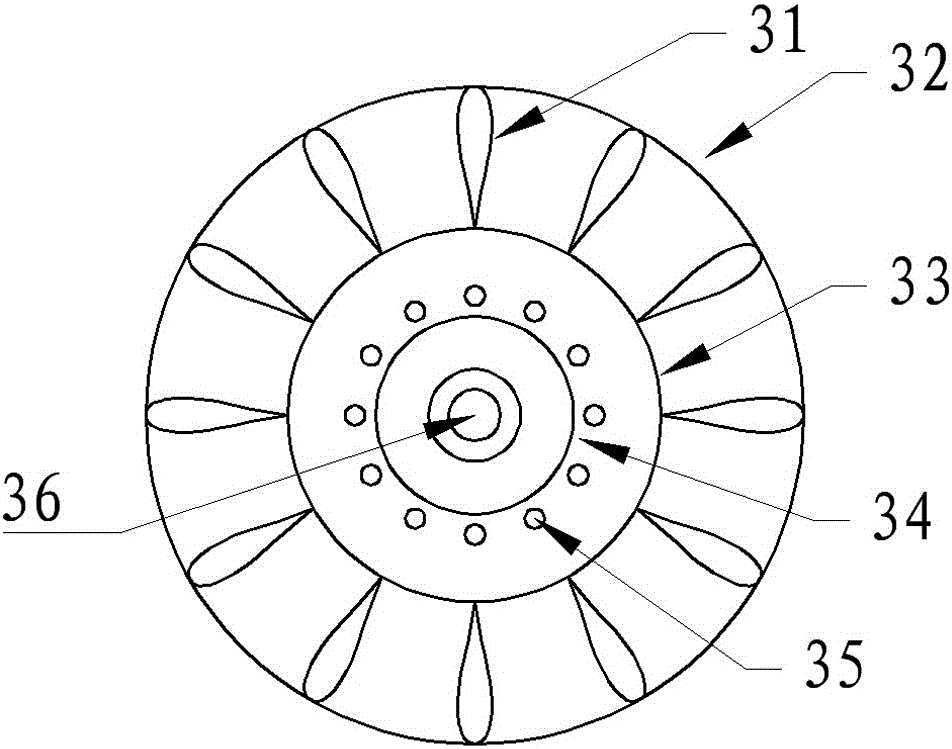

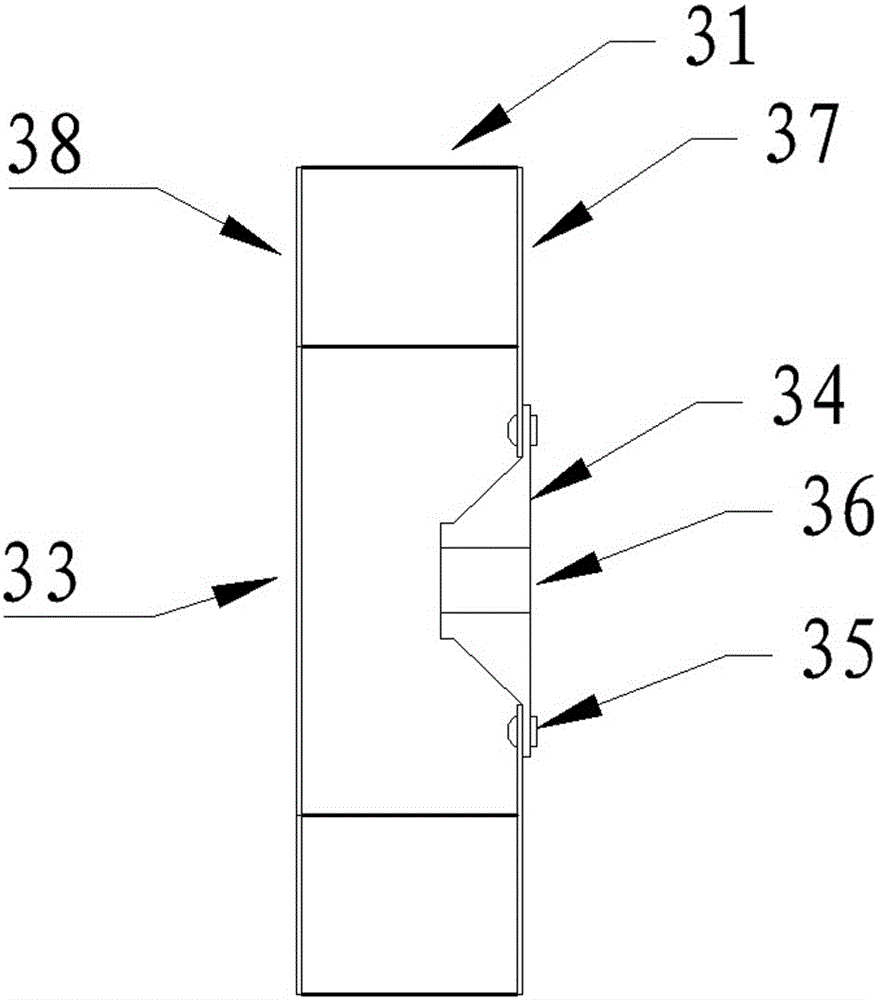

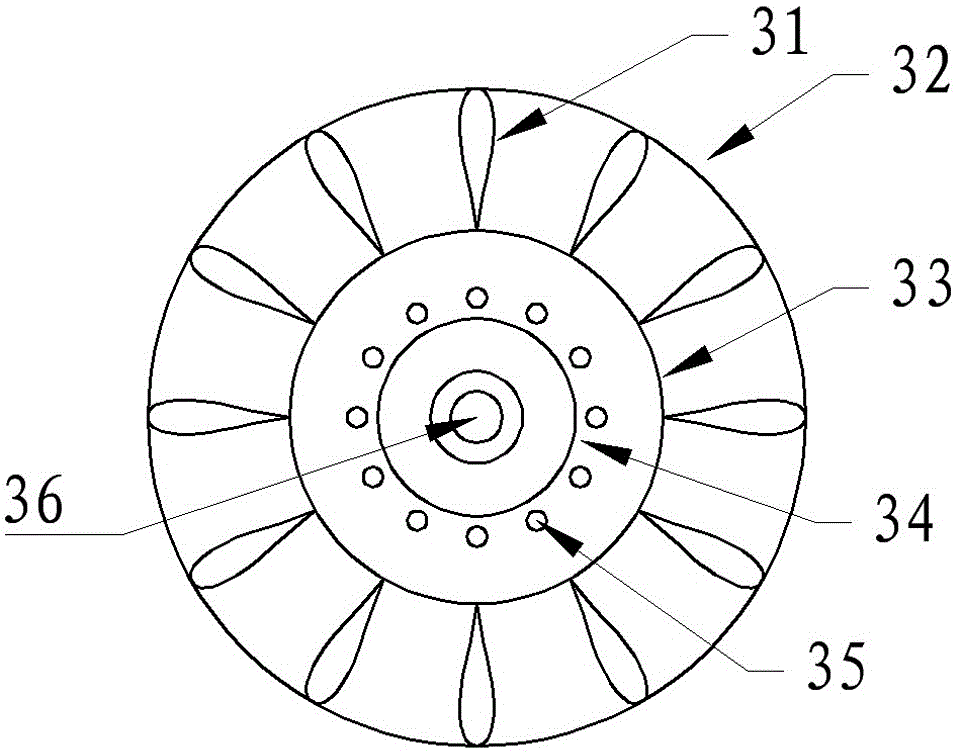

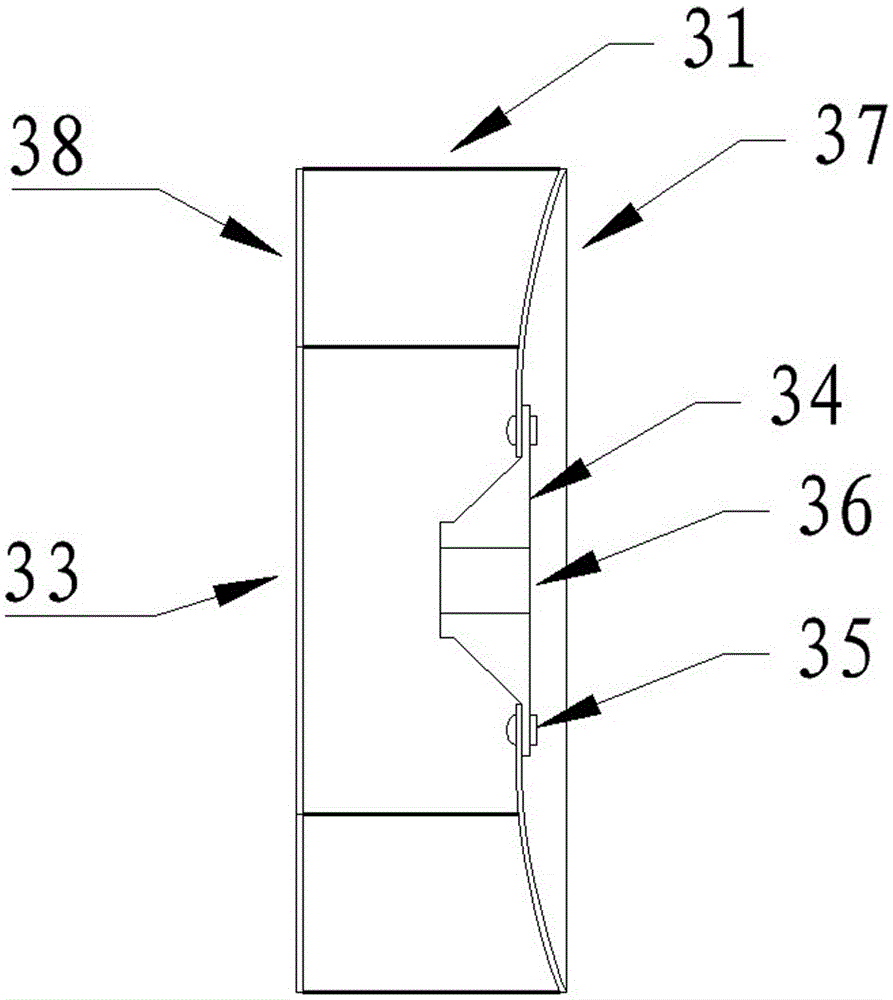

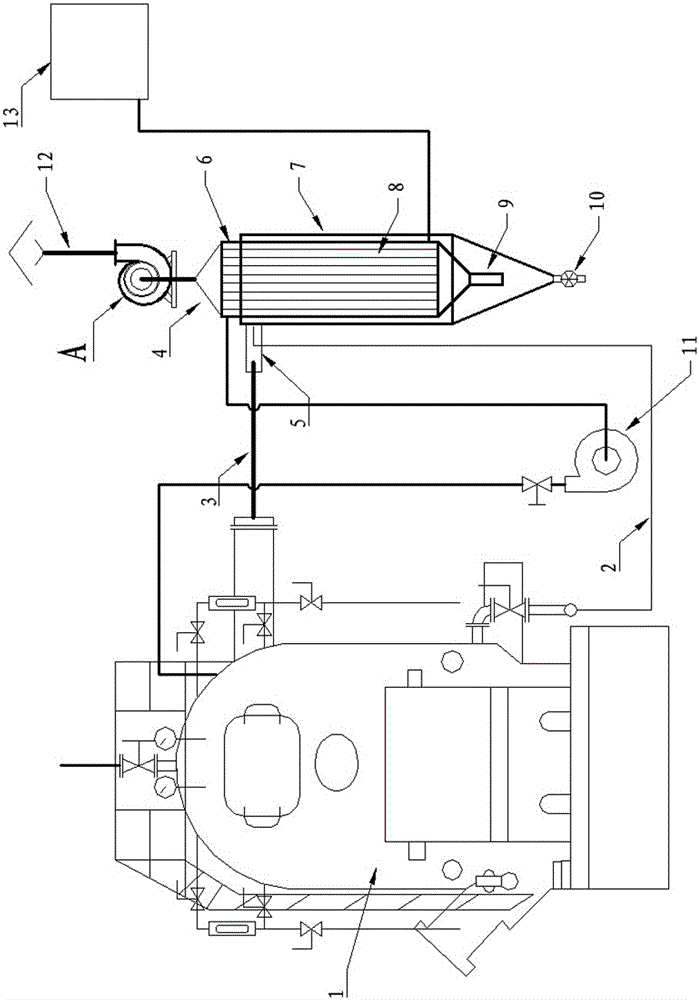

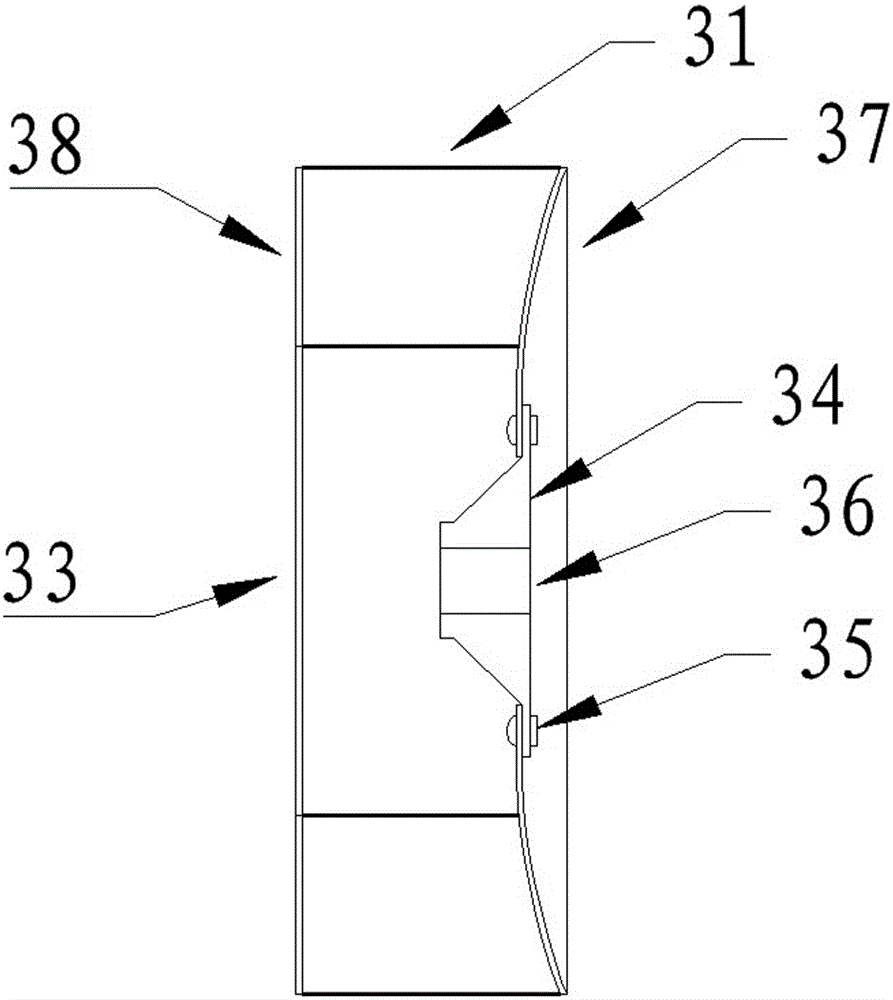

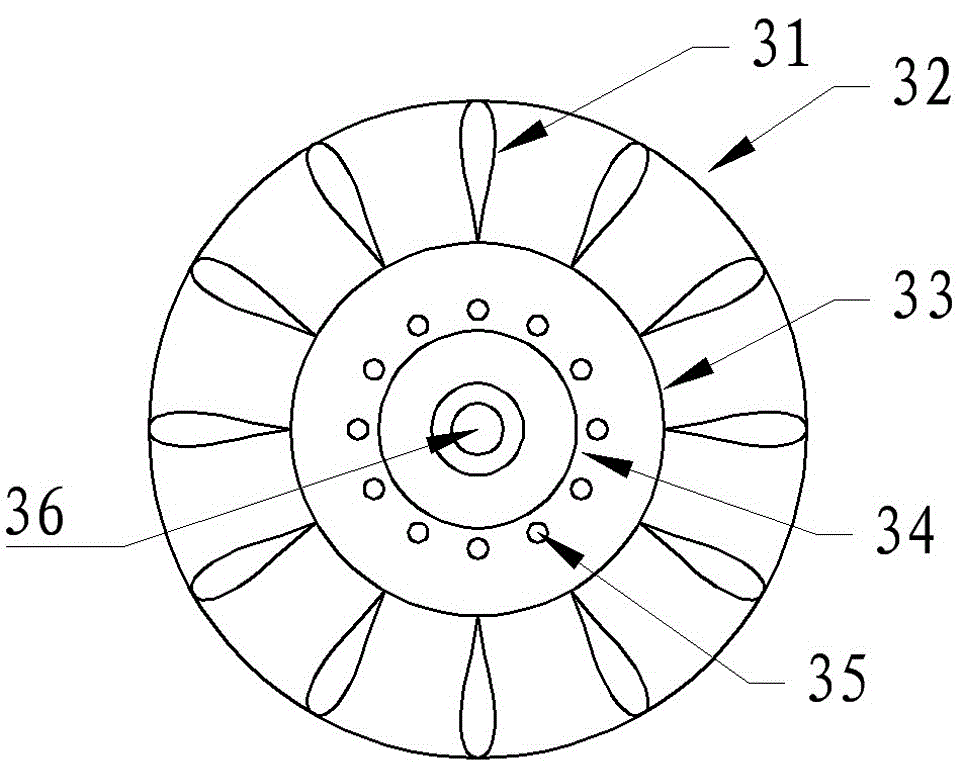

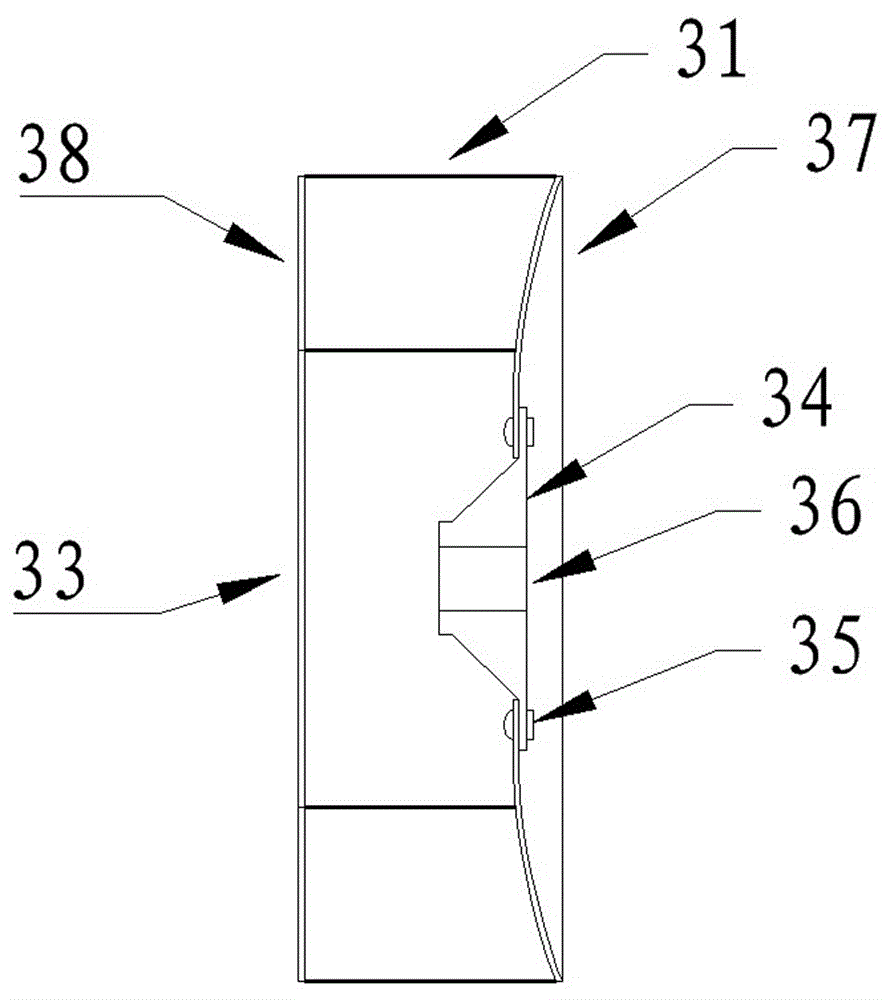

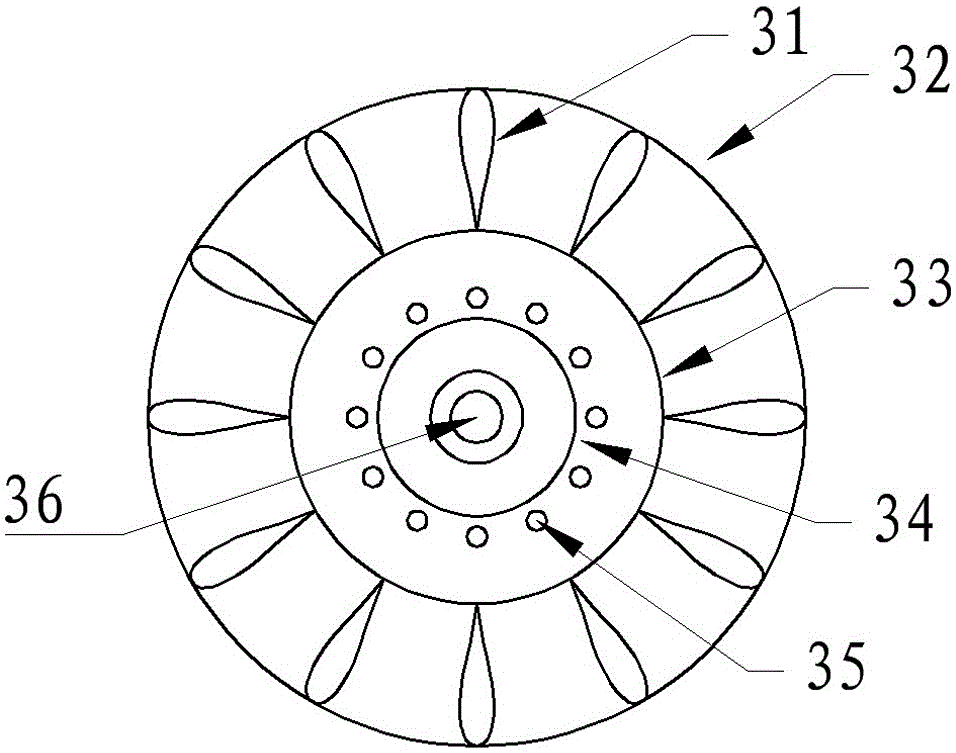

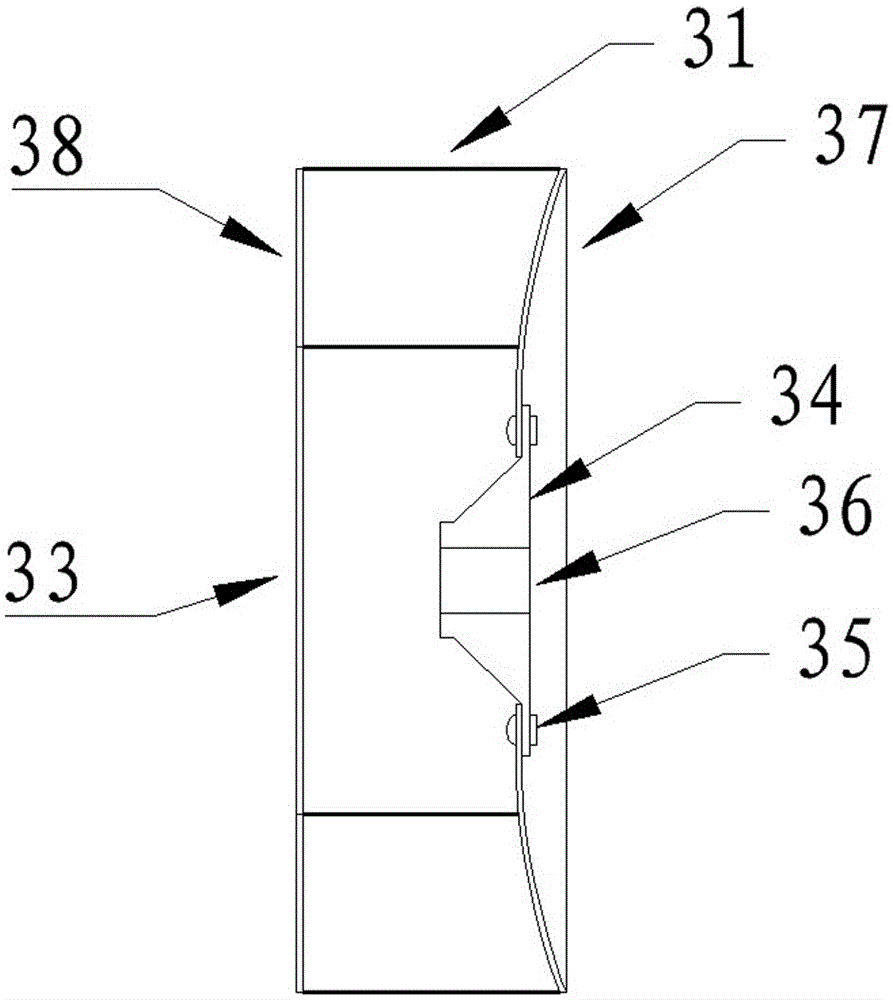

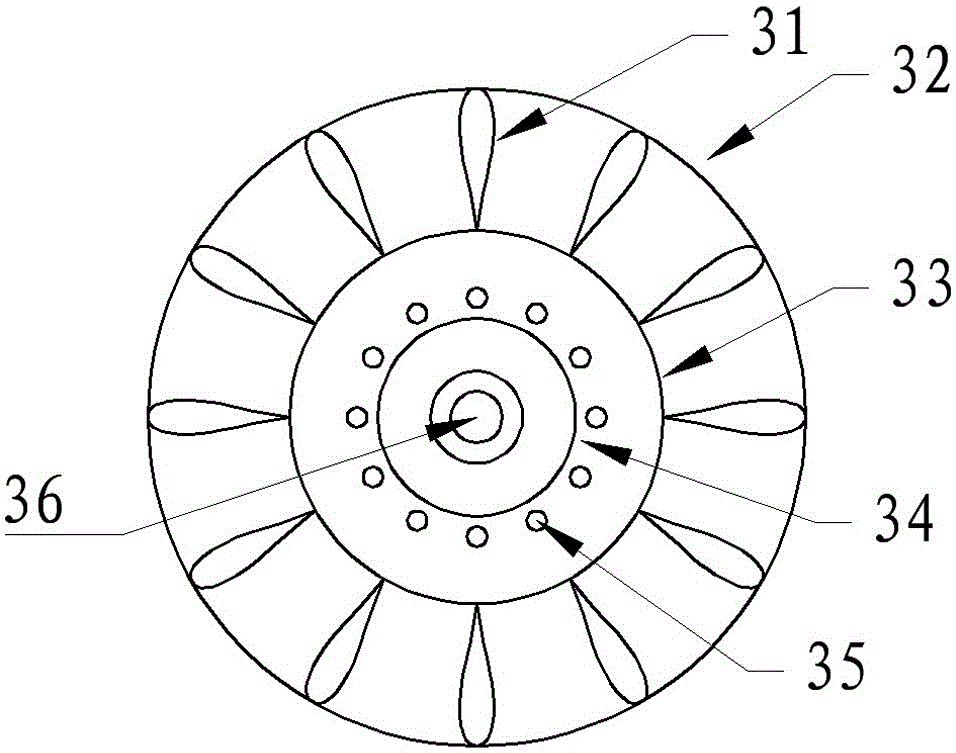

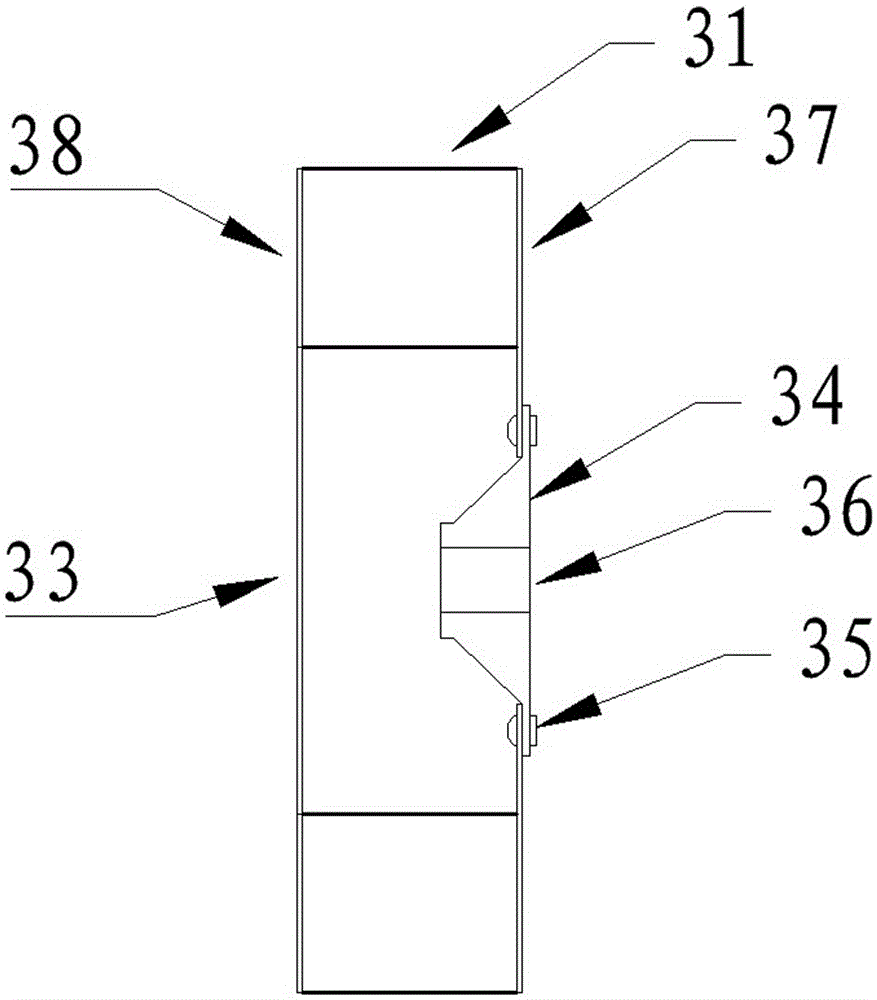

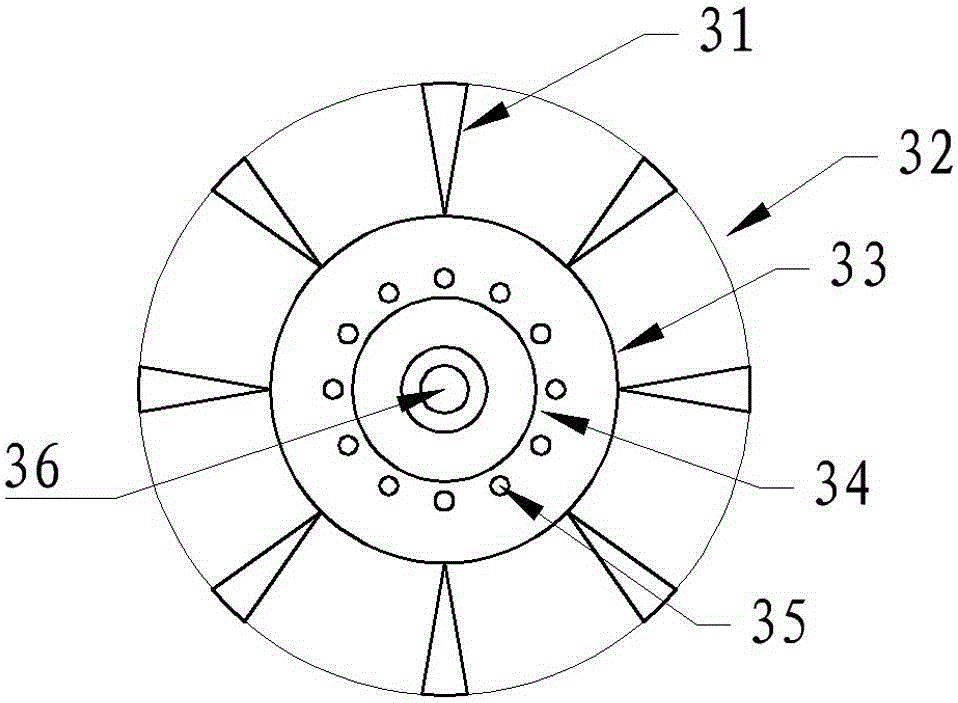

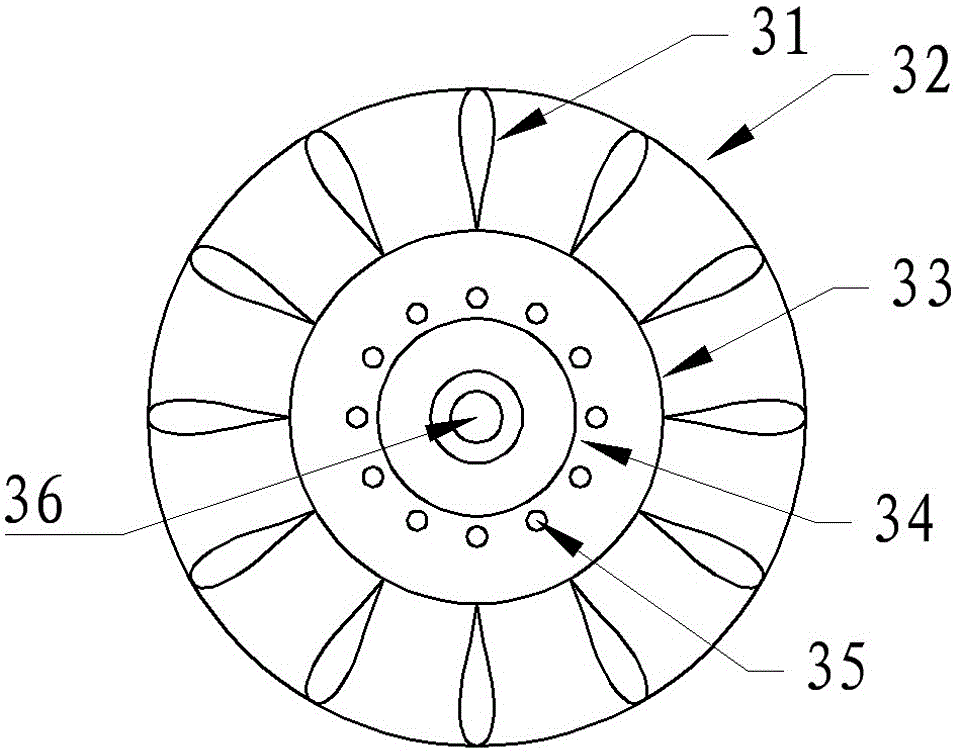

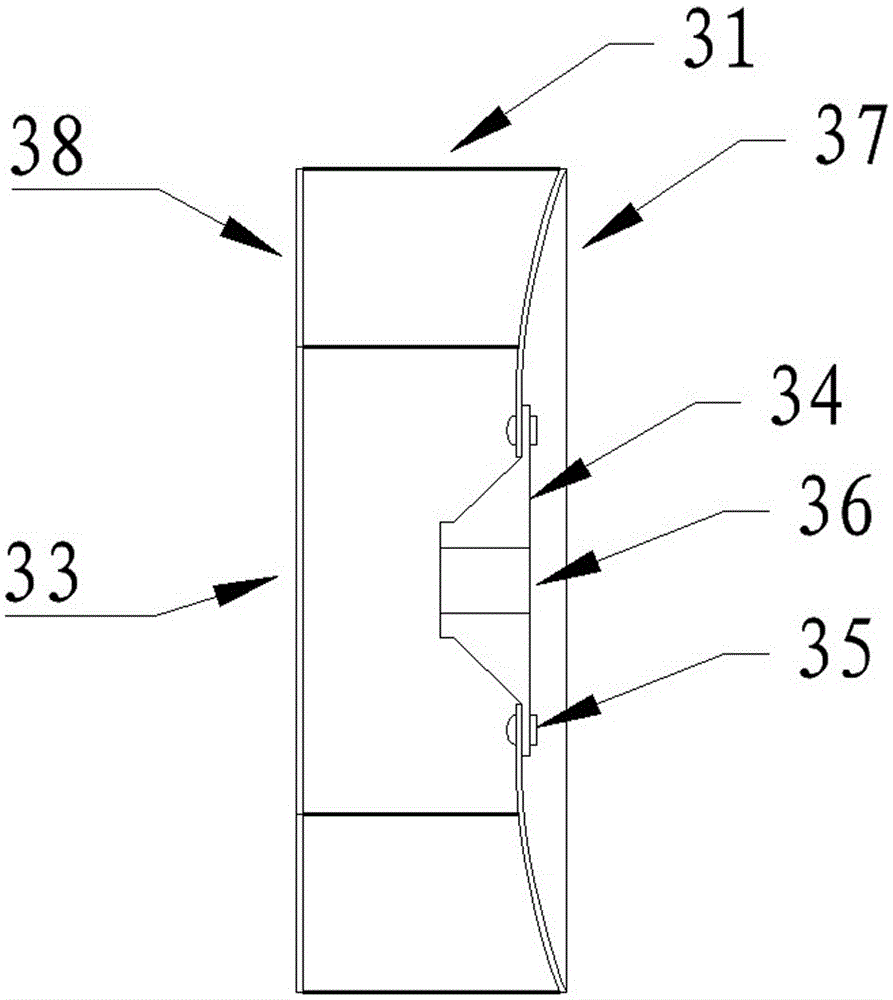

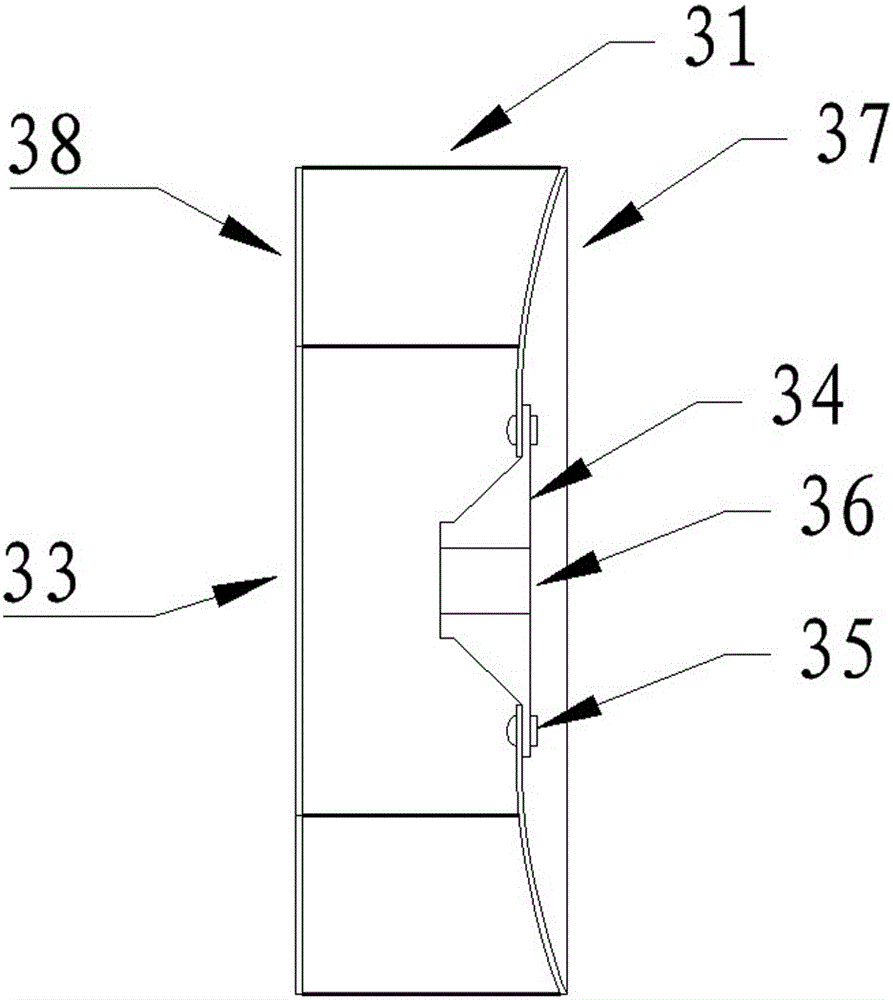

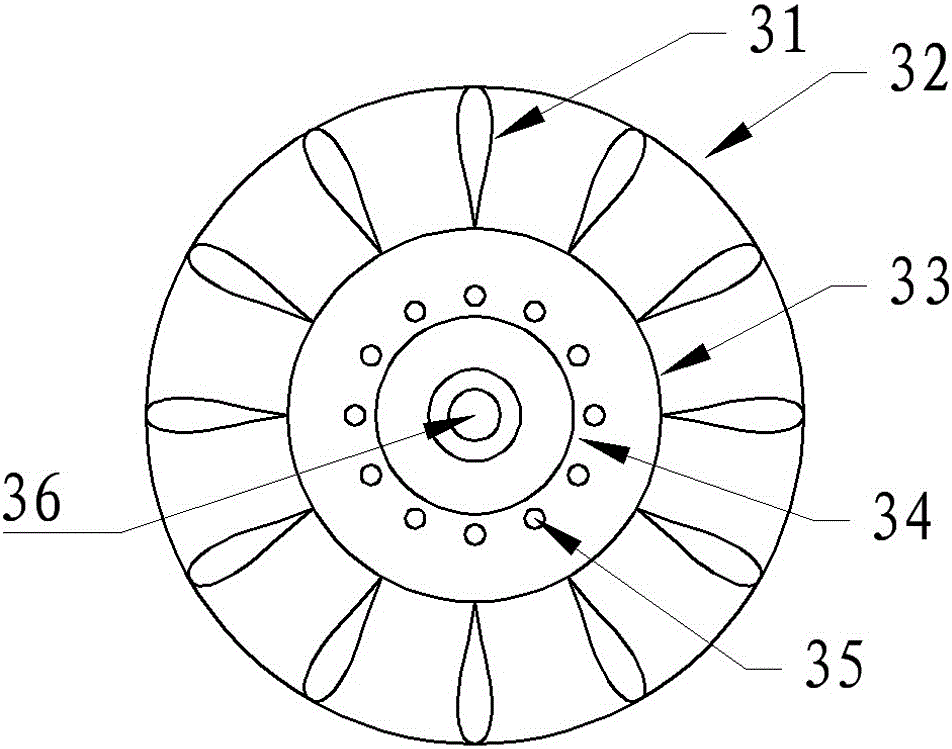

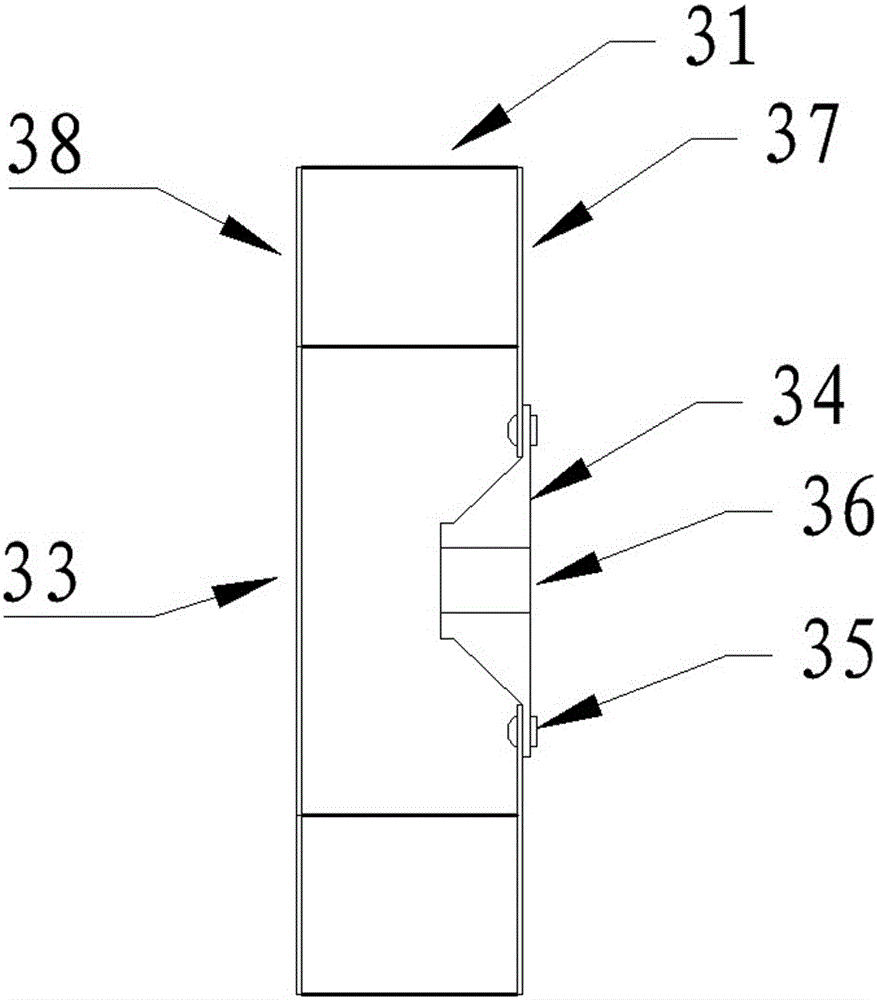

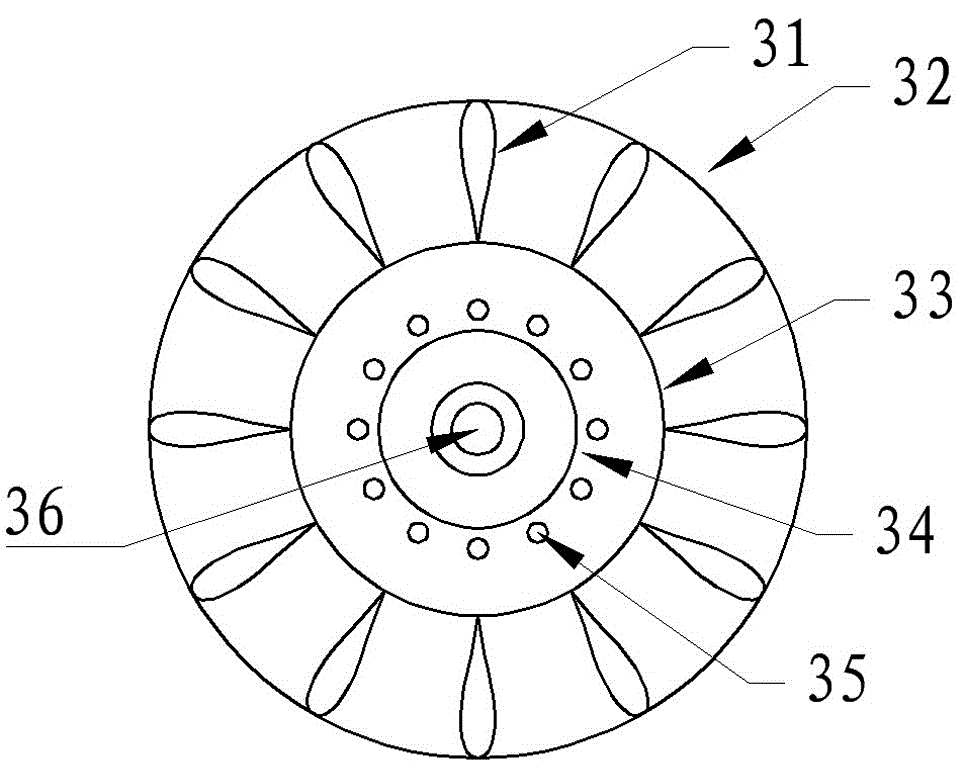

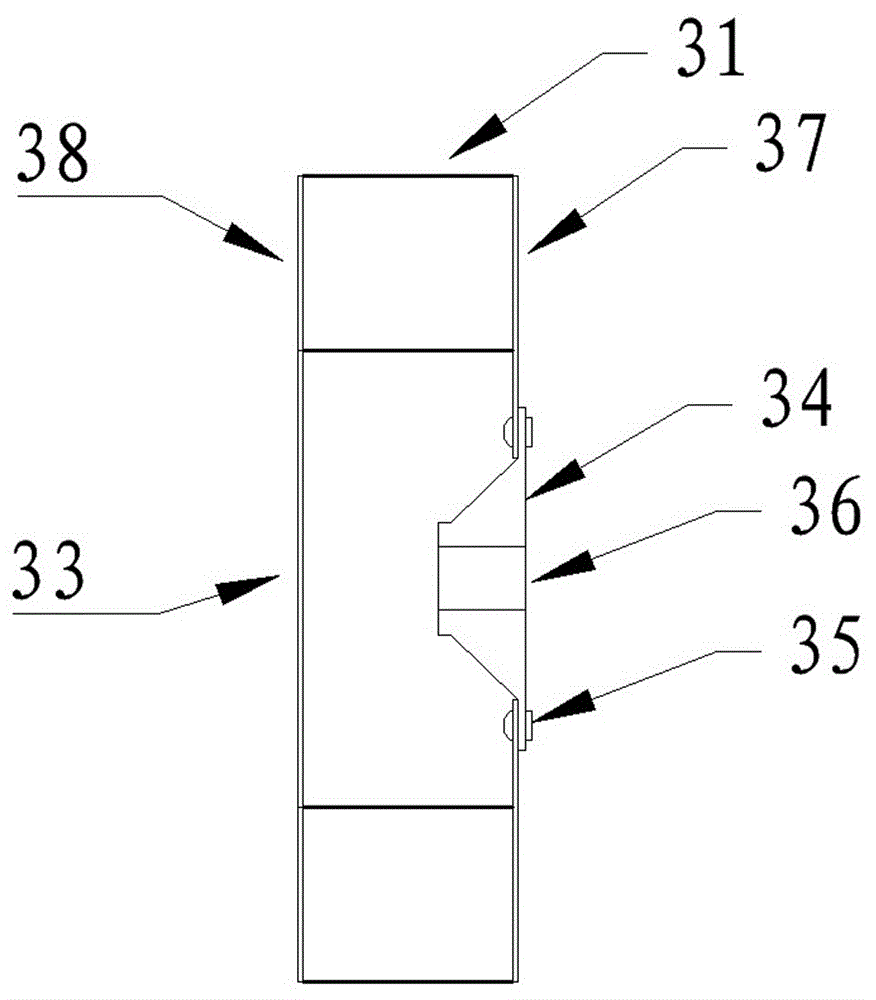

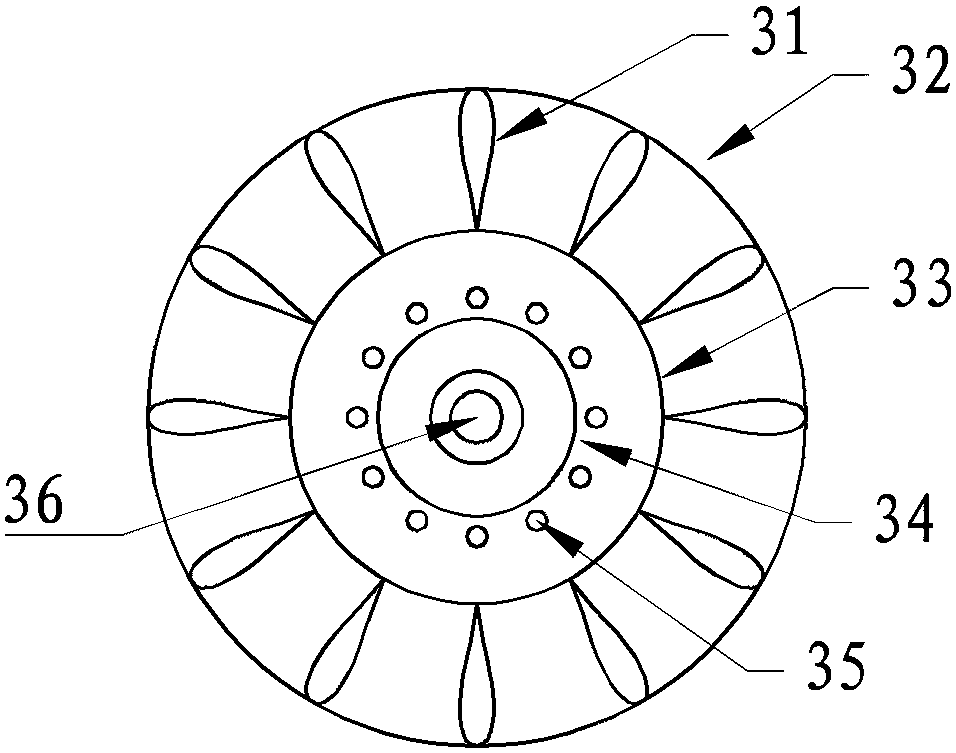

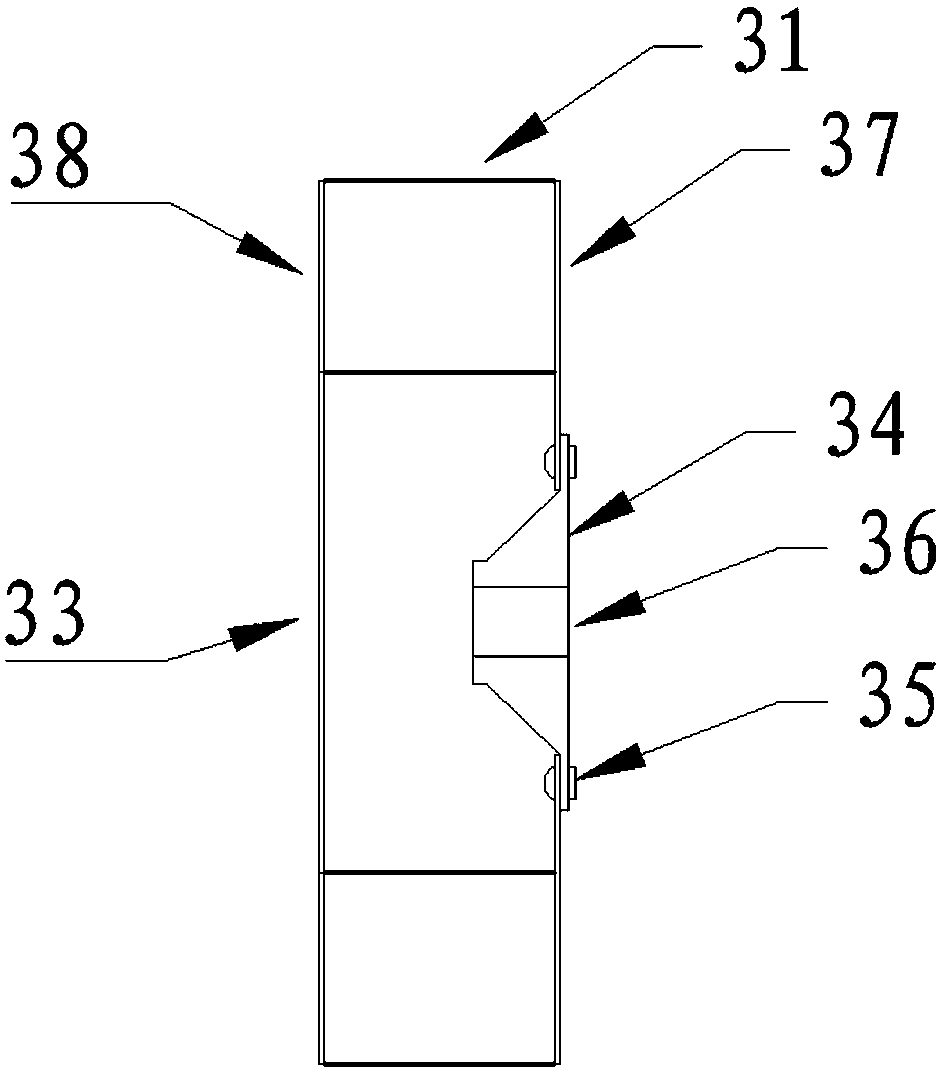

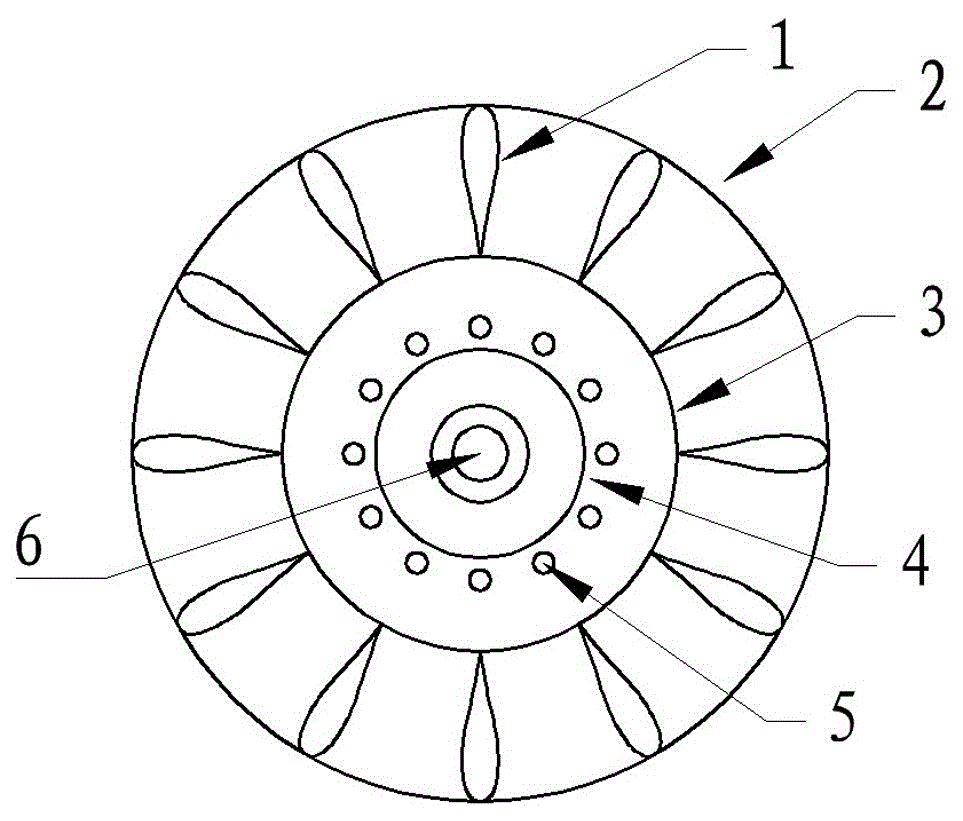

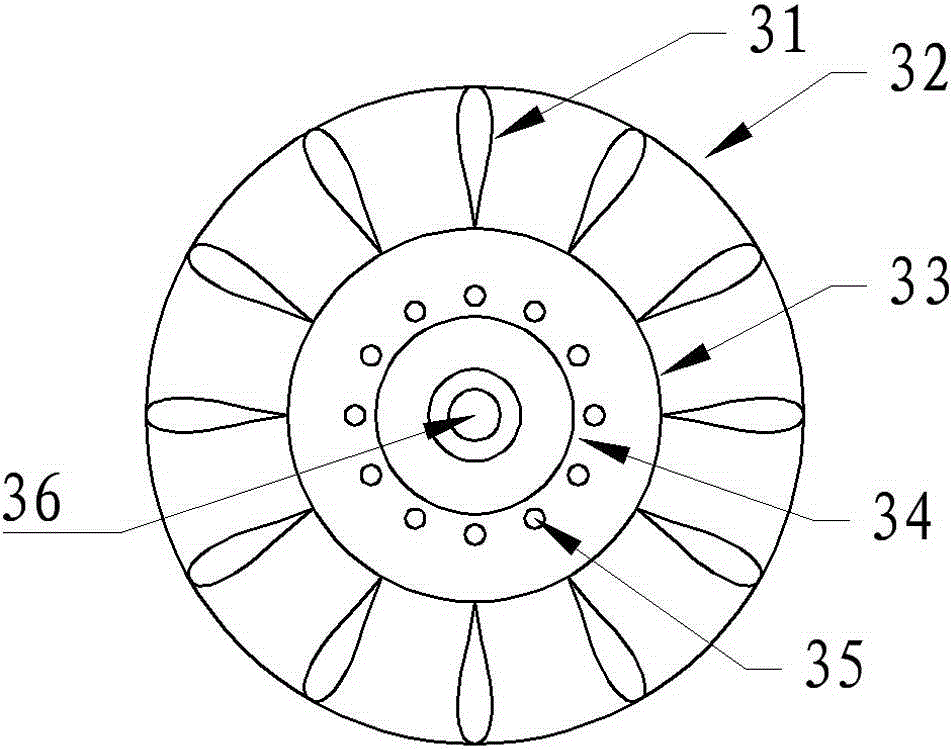

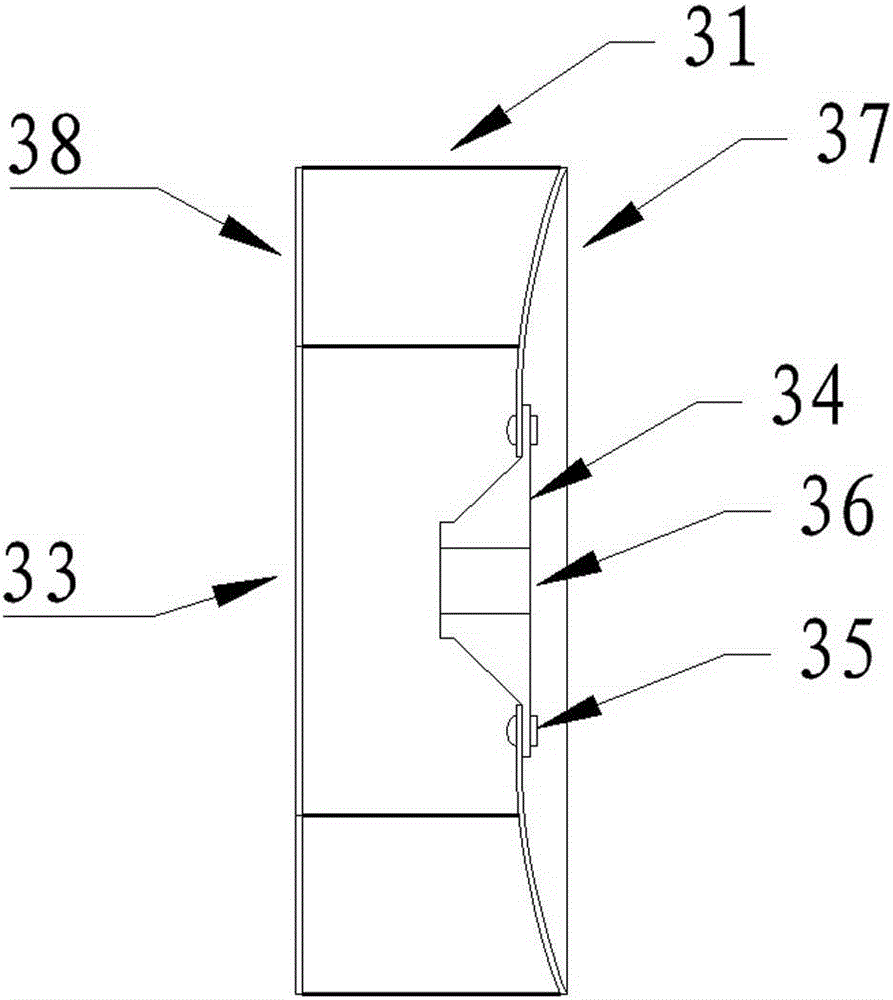

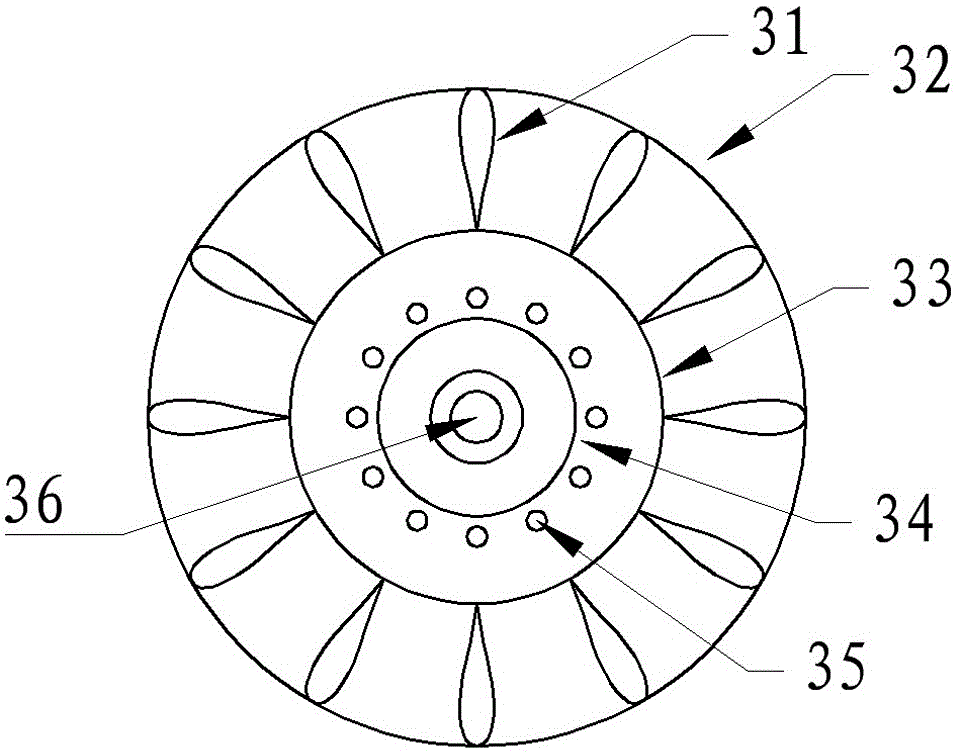

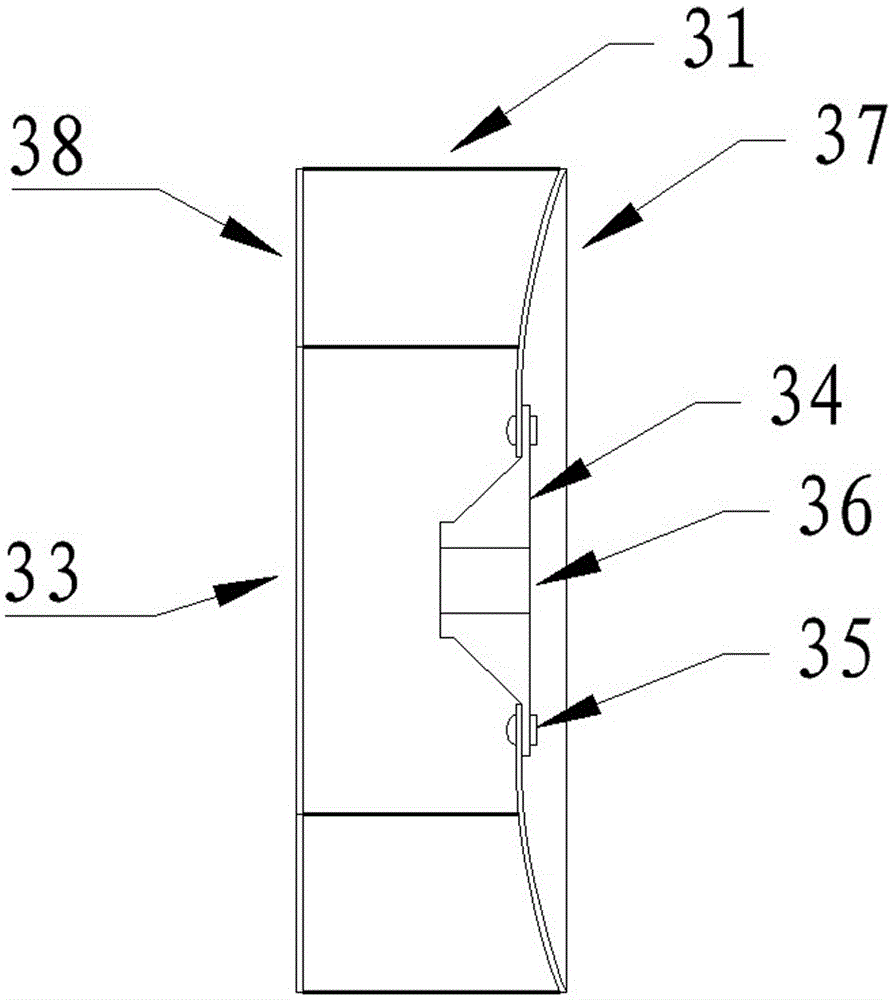

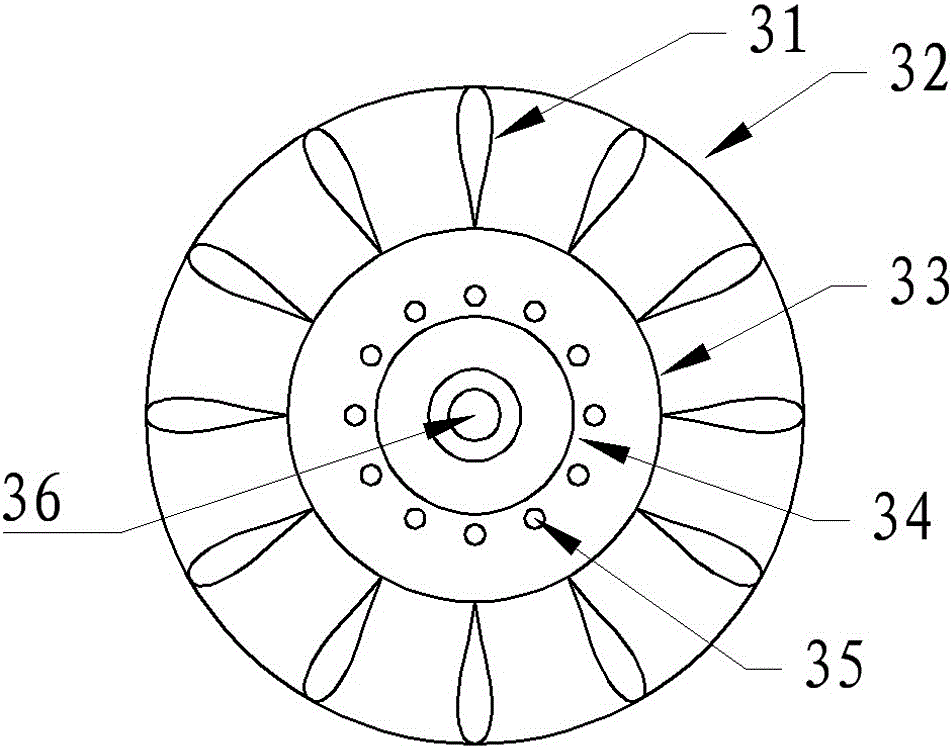

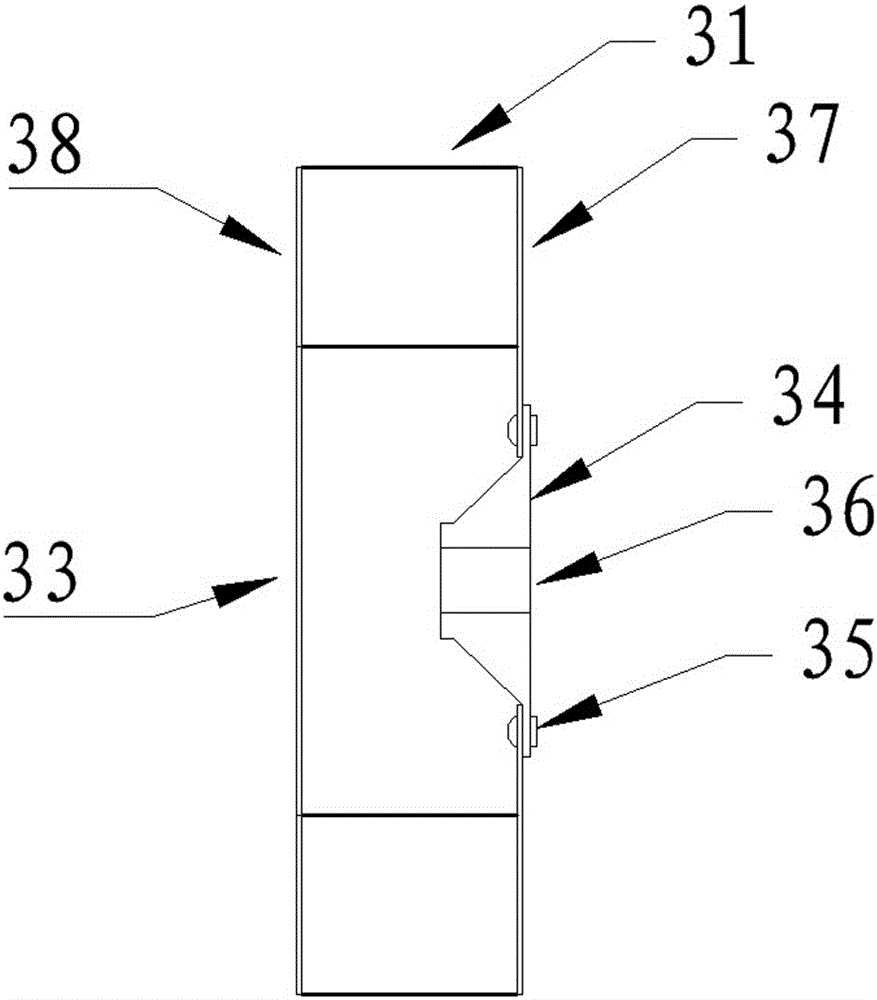

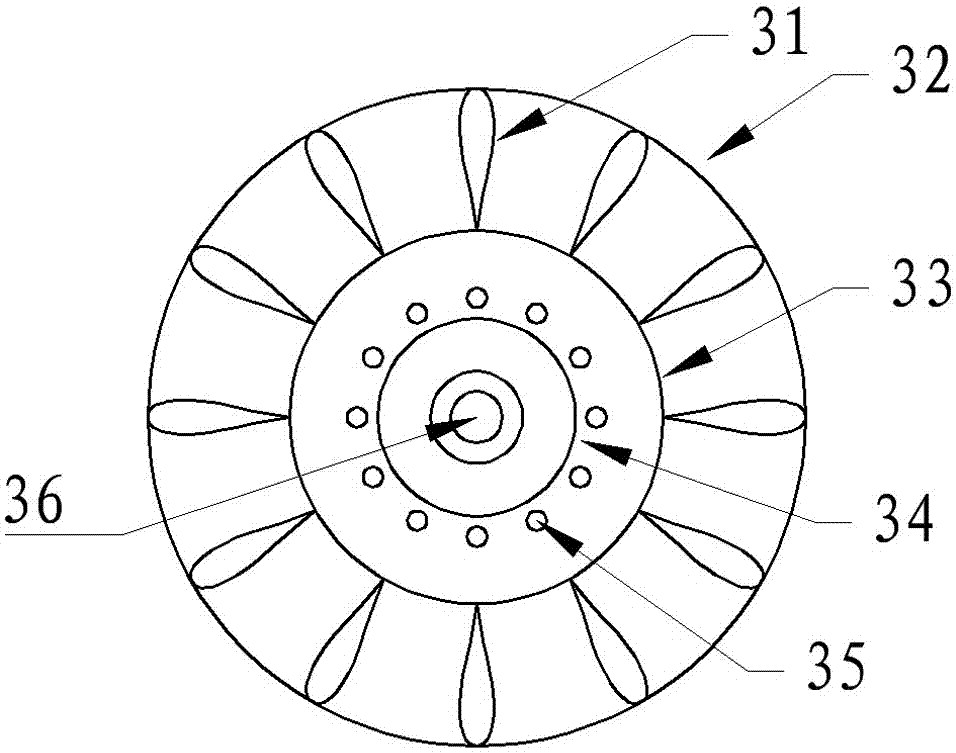

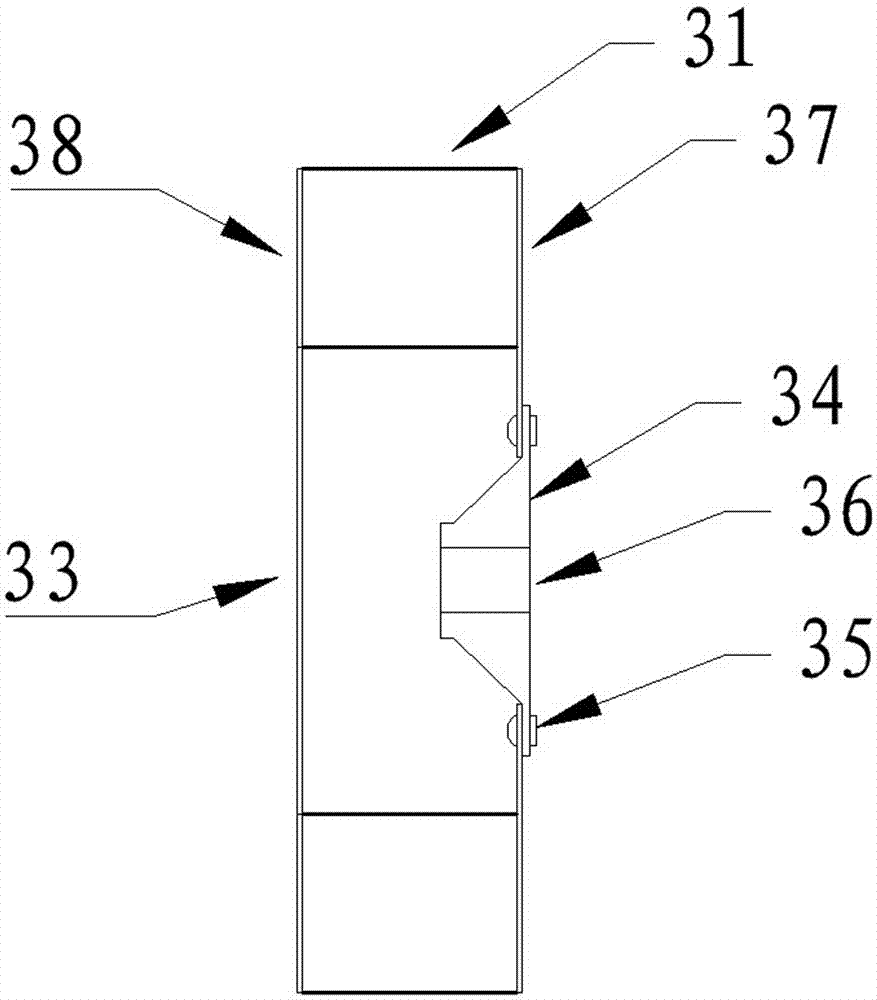

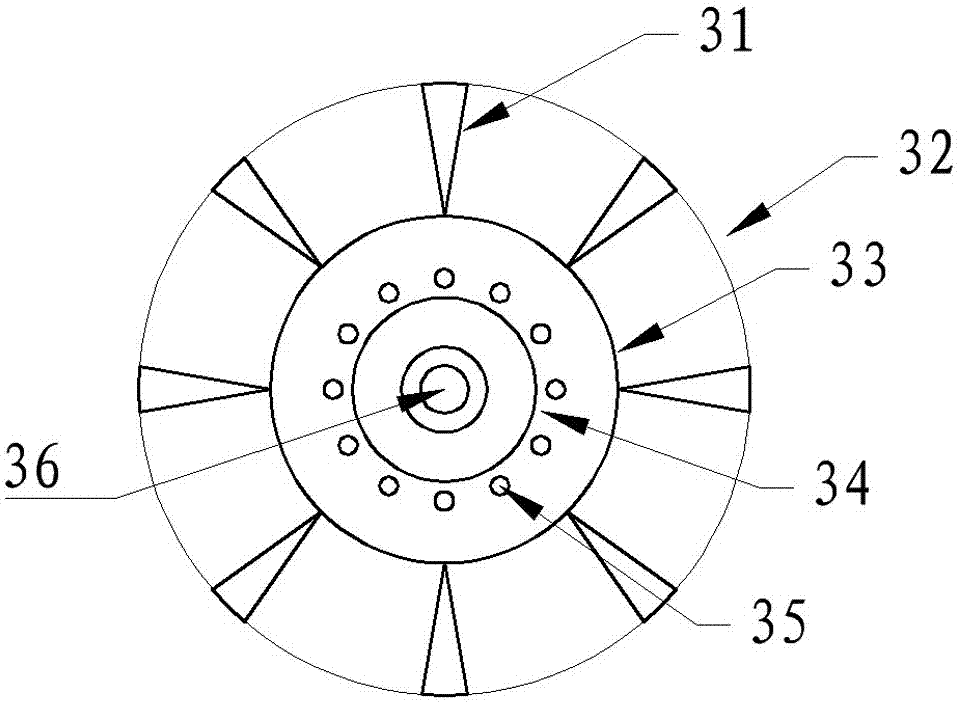

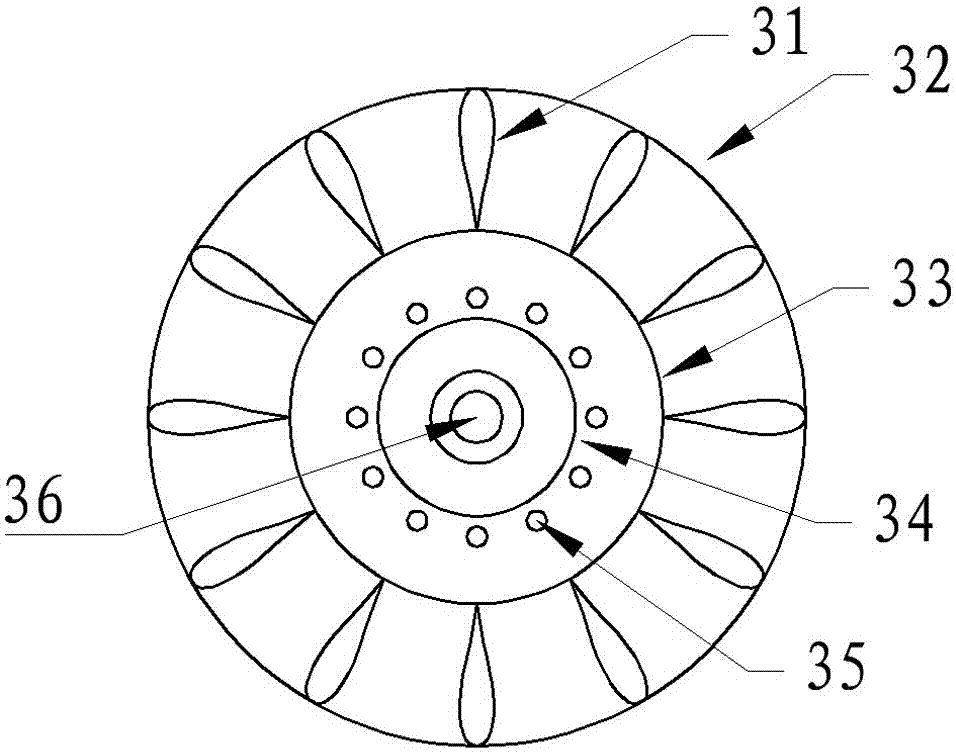

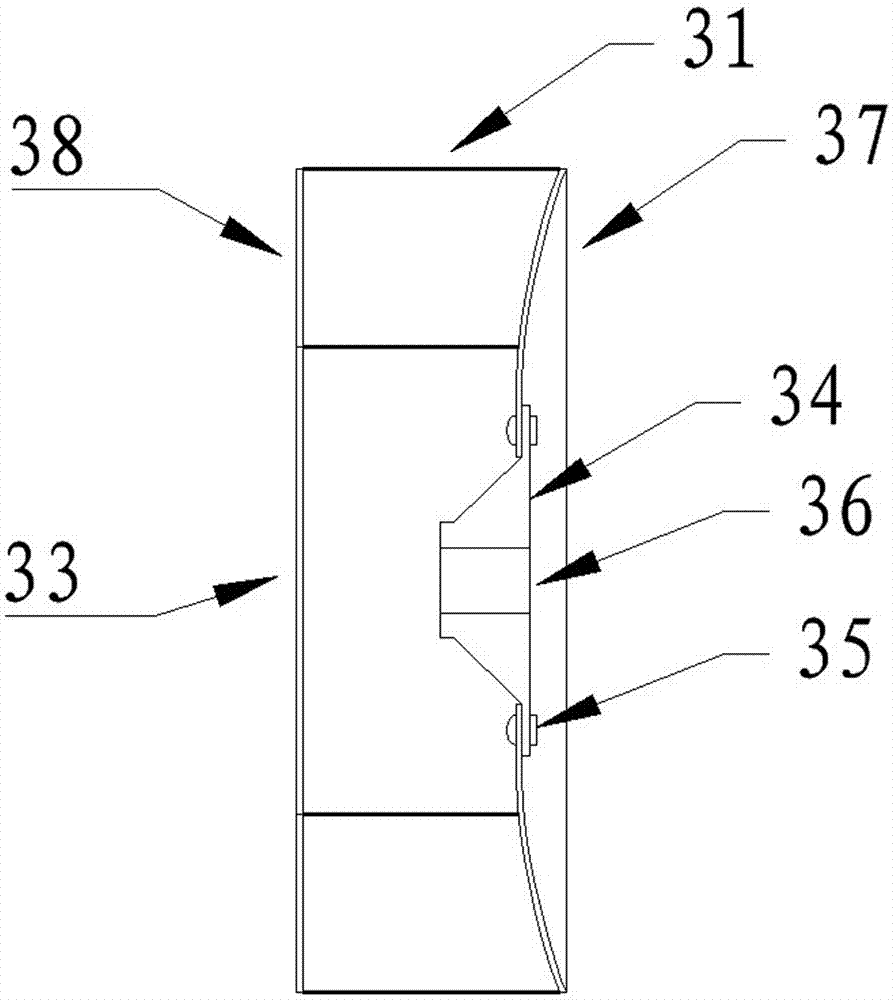

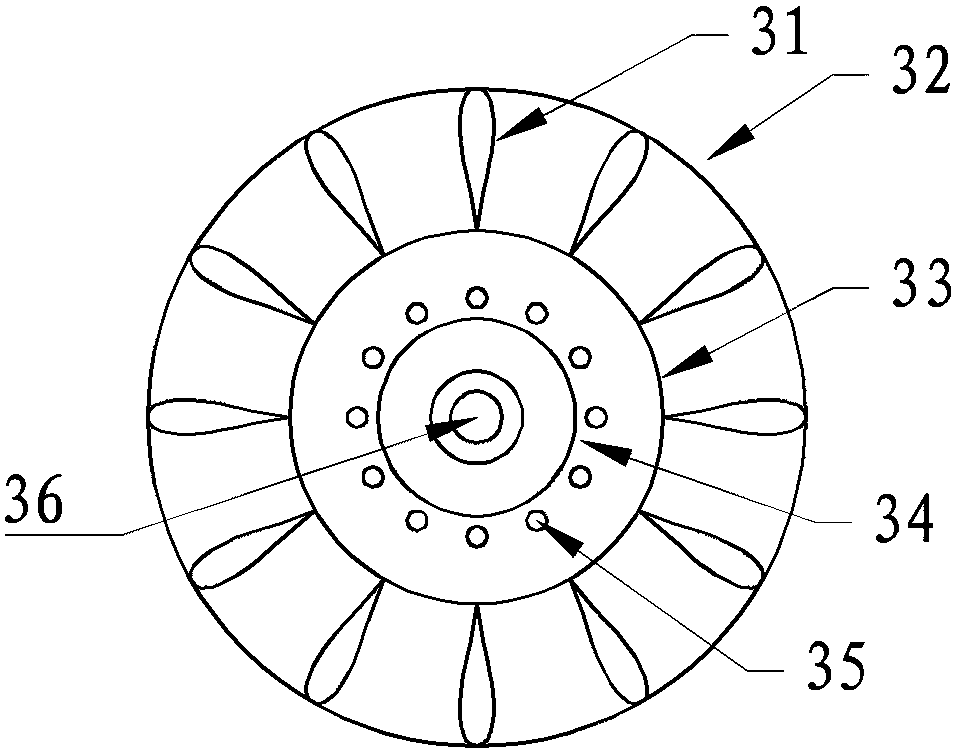

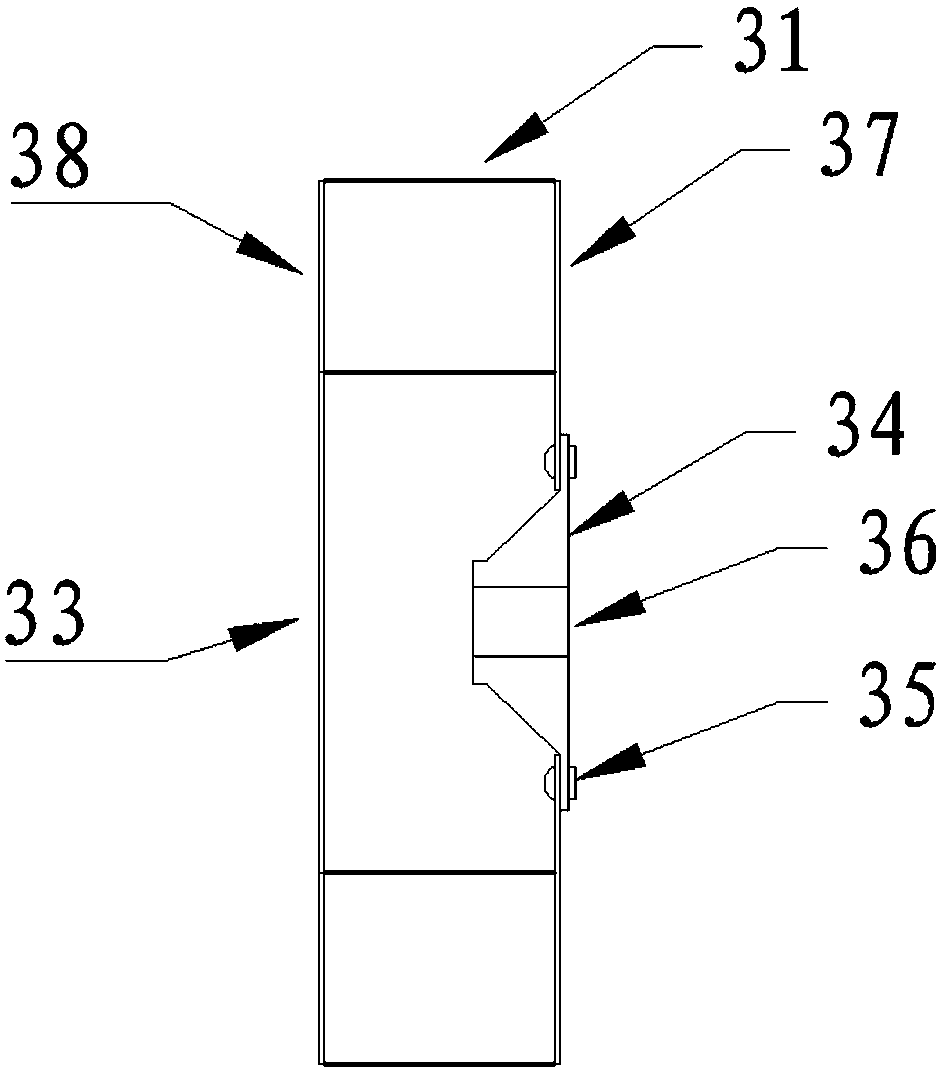

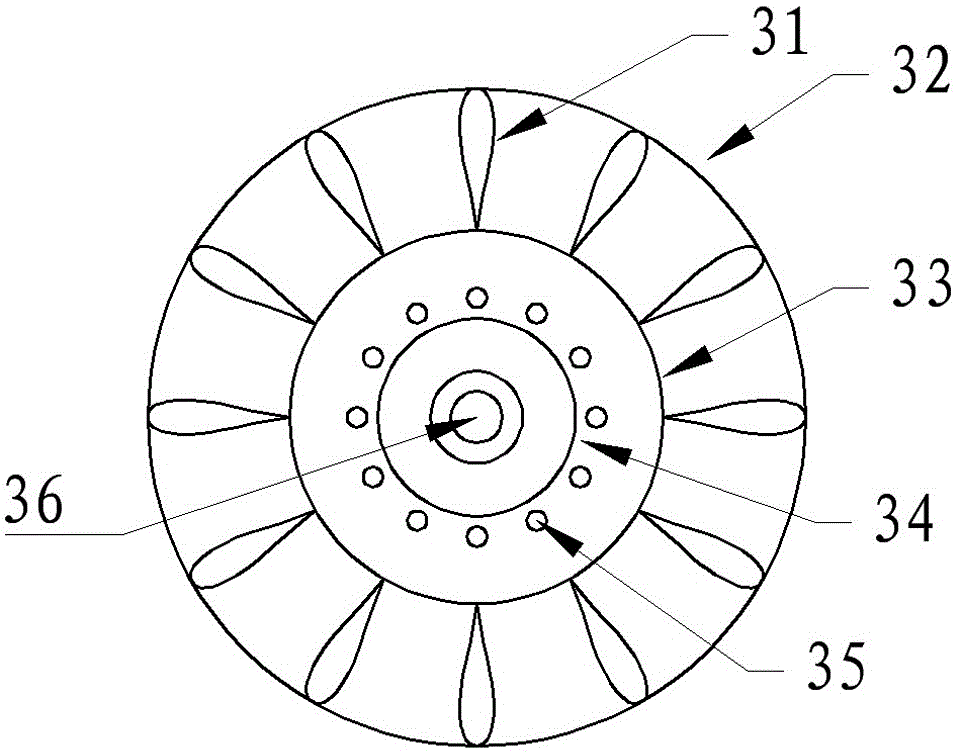

Dust-accumulation-proof fan propeller with reverse-droplet-shaped blades and disk-shaped back plate

InactiveCN105065325ADoes not affect dynamicDoes not affect balancePump componentsPumpsImpellerPropeller

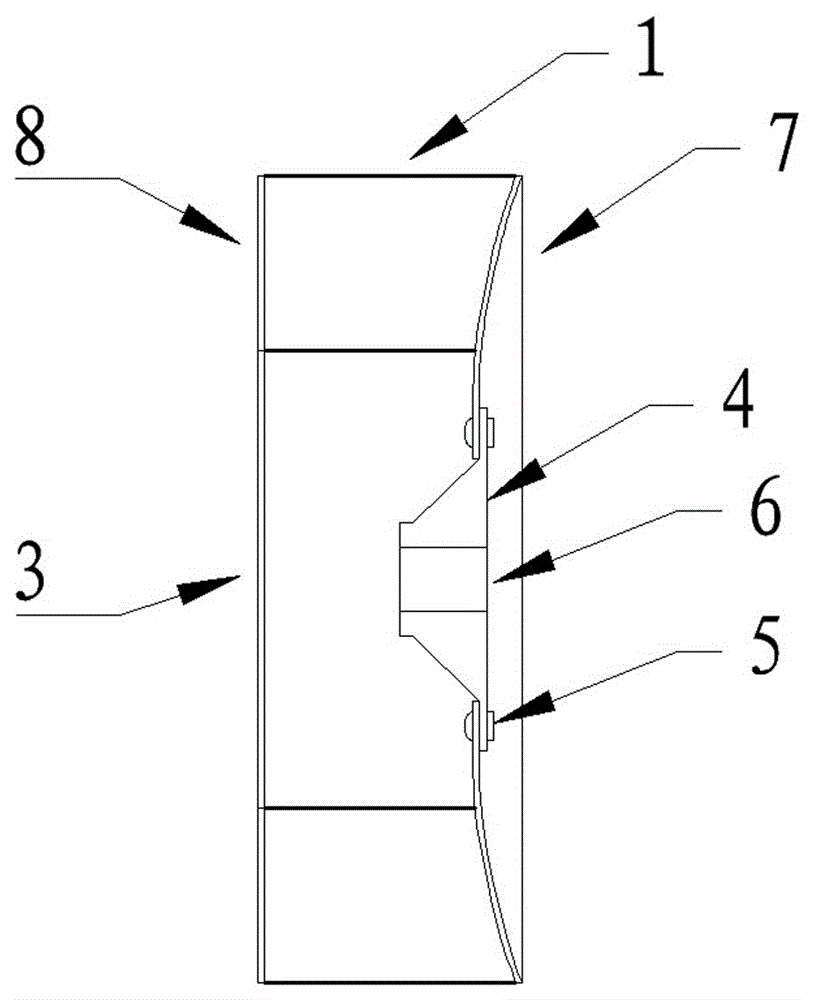

The invention discloses a dust-accumulation-proof fan propeller with reverse-droplet-shaped blades and a disk-shaped back plate. The fan propeller comprises the propeller back plate, a propeller panel and the blades, wherein the blades are in the shape of a reverse droplet, arranged in the radial direction of a propeller shaft and are in central symmetry; the propeller back plate is in the shape of a disk; the hollow reverse-droplet-shaped blades are connected with the propeller panel and welded to the disk-shaped propeller back plate, so that a propeller body is formed; the propeller panel is provided with an air inlet; the disk-shaped propeller back plate is fixed through rivets and connected with a shaft base; and the shaft base is in matched connection with a fan shaft through a shaft hole. When the fan propeller is in use, because the blades are hollow and in the shape of the reverse droplet, and blade shafts are in radial central symmetry; when the blades rotate at a high speed, the surfaces of the blades have a self-cleaning effect under the action of centrifugal force, dust cannot adhere to the blades due to centrifugal force and does not accumulate, and the dust-accumulation-proof fan propeller is particularly applicable to a wide-impeller large fan which has the large distance between a front end plate and a rear end plate of an impeller, and is particularly high in quantity of needed conveyed air; and due to the disk-shaped back plate, the compressive strength of the fan is improved, and the service life of the fan is prolonged.

Owner:JISHOU UNIVERSITY

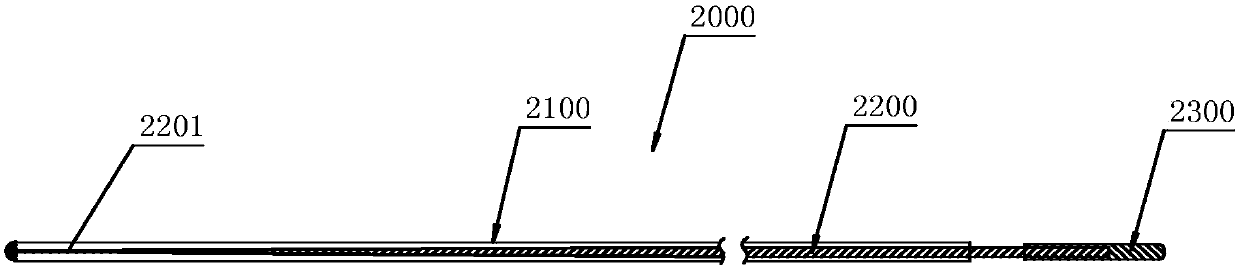

Tail heat recovery type steam flat-plate dryer

ActiveCN105180620ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsDrive wheelInvolute

The invention discloses a tail heat recovery type steam flat-plate dryer. Driving wheels, driven wheels and scraping plates are arranged on the dryer and used for driving materials to be conveyed on steam flat-plates. An upper drying zone is connected with a cyclone dust collection and tail heat high-efficiency recoverer through a draught fan in the tangential direction, and the cyclone dust collection and tail heat high-efficiency recoverer is formed by overlapping a tubular heat exchanger and a cyclone dust collector. The upper end of a shell pass of the tubular heat exchanger is connected with an air inlet pipe. The lower end of the shell pass of the tubular heat exchanger is connected with a lower drying zone through an air blower. An impeller of the draught fan is provided with blades which are in a hollow inverted water drop shape, and a back plate of the impeller is of a dish-shaped structure. The contour line of the draught fan is an involute. According to the tail heat recovery type steam flat-plate dryer, tail heat recovery and dust collection are creatively integrated, and the cyclone dust collection and tail heat high-efficiency recoverer is designed, so that tail heat recovery and dust collection are completed in one step, equipment investment is reduced, and the working efficiency is improved; the blades are in the hollow inverted water drop shape, and the back plate is of the dish-shaped structure, so dust is cleaned away in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, safety accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:临沂新科绿色建材有限公司

Chemical combination exhausting device for reaction of manganese mineral powder with sulfuric acid

ActiveCN105056838AHigh strengthEnsure stabilityPump componentsDispersed particle separationChemical combinationImpeller

The invention discloses a chemical combination exhausting device for a reaction of manganese mineral powder with sulfuric acid. Stirring systems are arranged in chemical combination barrels connected with a draught fan through exhaust pipes, the draught fan is tangentially connected with a rotational flow tower and then emptied, and air doors are arranged in the exhaust pipes; multiple rotational flow devices comprising large rotational flow plates, small rotational flow plates and conical hopper plates are vertically arranged in the rotational flow tower; an impeller of the draught fan adopts such a structure that blades are in a hollow reversed water droplet shape and a back plate is in a dish shape; the contour line of the draught fan is an involute. Carbon dioxide gas produced due to the reaction of the manganese mineral powder with the sulfuric acid is exhausted in real time by the aid of the draught fan and the rotational flow devices, the reaction is facilitated, carried mineral powder is effectively recovered through rotational gas flows, and energy saving and emission reduction are realized; with the adoption of the structure that the blades are in the hollow reversed water droplet shape and the back plate is in the dish shape, dust on the impeller of the draught fan is cleaned in real time, the strength of the impeller of the draught fan is enhanced, the stability is enhanced, accidents caused by accumulation of the dust are effectively eliminated, and the device has the broad application prospect.

Owner:JISHOU UNIVERSITY

Tail heat recovery screen hole plate turnover type dryer

ActiveCN105066628ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerInvolute

The invention discloses a tail heat recovery screen hole plate turnover type dryer. Screen hole plate turnover type conveying from top to bottom is adopted in a box of the dryer, and the box of the dryer is divided into an upper drying area, a middle drying area and a lower drying area. The upper drying area is connected with an inducted draft fan through an air heat exchanger and then emptied. A fresh air outlet of the air heat exchanger is connected with an air inlet of an air blower, and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. An impeller of the induced draft fan is of the structure that blades are in a hollow inverted drop shape, and the contour line of the appearance of the induced draft fan is an involute. Tail heat recovery is simple and reasonable, damp and hot tail gas obtained through heat recovery is exhausted out of the induced draft fan, dried materials are effectively cooled, tail heat recovery is further conducted, and energy saving and emission reduction are promoted. Through the structure that the blades are in the hollow inverted drop shape, dust is cleaned away in real time, the impeller strength of the fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:湖州优研知识产权服务有限公司

A notoginseng ventilated pulverizer

InactiveCN105013593BAchieve qualified outputAvoid over crushingPump componentsPumpsAir volumeInvolute

Owner:JISHOU UNIVERSITY

A rotary kiln system with tail heat drying and induced draft fan without dust accumulation

ActiveCN105180645BImprove rigidityImprove carrying capacityPump componentsRotary drum furnacesEngineeringThermal efficiency

The invention discloses a rotary kiln system capable of utilizing residual heat for stoving and with no dirt retention on an induced draft fan. A rotary kiln is arranged in an inclined manner; a burner is arranged in the rotary kiln; the high end of the rotary kiln and one end of a dryer are connected with an air hose in a bidirectional manner through a discharging pipe; a conveyer belt is arranged in the dryer and is connected with the discharging pipe; a star discharger is arranged at the other end of the dryer; a bulged refractory slab is arranged in the rotary kiln; the induced draft fan for dust removal has the structure of wedge-shaped blades and a dished backboard. According to the invention, the bulged refractory slab increases the heat transfer area of the rotary kiln, promotes stirring of a material, and facilitates improvement of thermal efficiency; the dryer utilizes residual heat to facilitate forming and drying of a globular material; residual heat utilization and heat preservation consequent reaction of hot material have the remarkable energy-saving characteristic; a quenching liquid pool rapidly cools a pellet material, and plenty of water is evaporated through reaction, so that the environmental protection pressure caused by expansion of producing fluid is effectively relieved; the induced draft fan does not accumulate dirt to completely eradicate a safety accident; the rotary kiln system is particularly suitable for burning processing of vanadium ore and is broad in application prospect.

Owner:NANTONG HENGDA MACHINERY MFG

A heat pump type tail heat recovery penetration countercurrent fluidized dryer

ActiveCN105066653BImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsHeat penetrationAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

Heat pump tail heat recovery penetrating countercurrent fluidized dryer

ActiveCN105020986BAchieve penetrationAchieve countercurrentDrying solid materials with heatHearth type furnacesInvoluteDrop-shaped

The invention discloses a thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, a material seal screw feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower; the upper portion of the drying tower is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a thermal pump system through a cyclone dust collector, and then carries out evacuation; the evaporator of the thermal pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe; the air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser; an impeller of the induced draft fan is provided with a structure with blades in a hollow reverse drop shape; and the shape contour line of the induced draft fan is an involute. According to the thermal pump type tail heat recycling reverse flowing penetrating fluidized drying machine, through the arrangement of sieve mesh cone covers, sieve mesh cone disks, discharging pipes, a telescopic vibration transmission shaft and cone stoppers, penetration, reverse flowing, boiling and fluidized drying are tactfully and perfectly conducted on materials; the classic boiling reverse flowing drying mode is completely surpassed, the energy saving effect is better, the drying quality is higher, and power consumption of the draught fan is lower; and the thermal pump type tail heat recycle is particularly suitable for recycling heat of tail gas at a low temperature.

Owner:湖北沄禾泽生态农业开发有限公司

Heat pump type tail heat recovery penetration counter flow dryer

InactiveCN105066636ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerCounter flow

The invention discloses a heat pump type tail heat recovery penetration counter flow dryer. A draught hood and an air inlet cover are arranged at the two ends of a box of the dryer respectively, the draught hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then emptied. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the air inlet cover through the condenser. A plurality of vertically-arranged flexible separation plates are arranged in the box of the dryer and divide an upper case body and a lower case body into a plurality of units. Through the induced draft fan, the flexible separation plates and axial fans, penetration type counter flow drying is ingeniously achieved, and work efficiency is improved. Heat pump type tail heat recovery is suitable for heat recovery of low-temperature tail gas, and is particularly efficient and convenient. Through the structure that blades are in a hollow inverted drop shape, dust on impellers is cleaned away in real time, the impeller strength of the fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:贵州九鼎新能源科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com