Heat pump tail heat recovery countercurrent dryer

A tail heat recovery and dryer technology, applied in dryers, heat recovery systems, drying and other directions, can solve problems such as personnel and equipment safety accidents, strong vibrations, etc., and achieve extended service life, high strength, and improved drying. The effect of drying efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with accompanying drawing, the present invention is described in further detail.

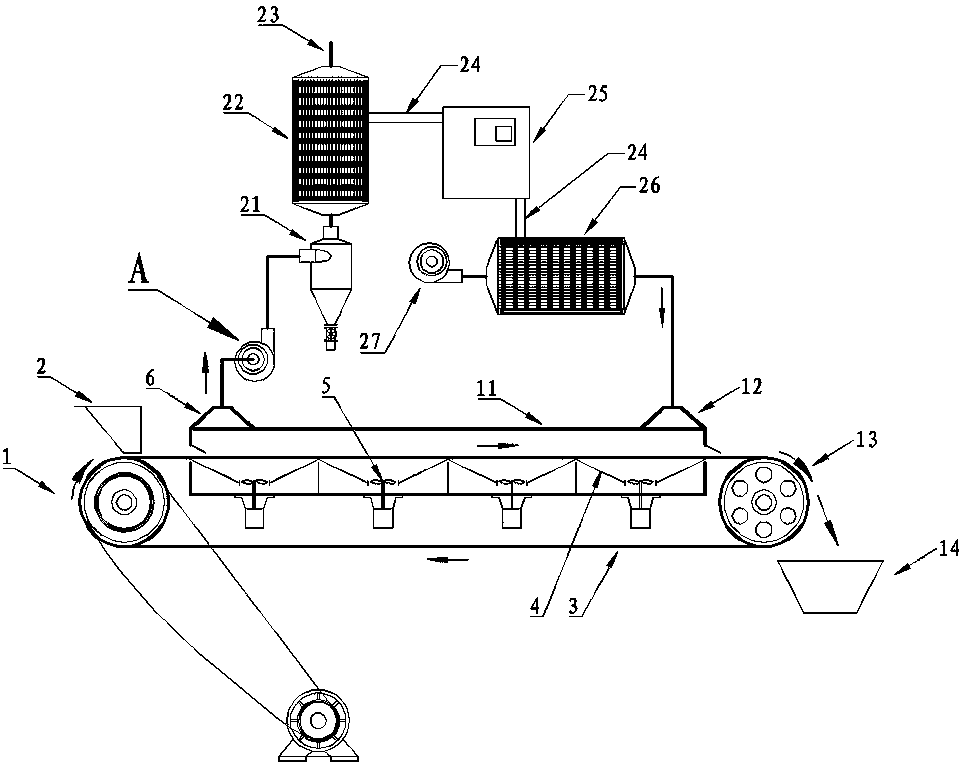

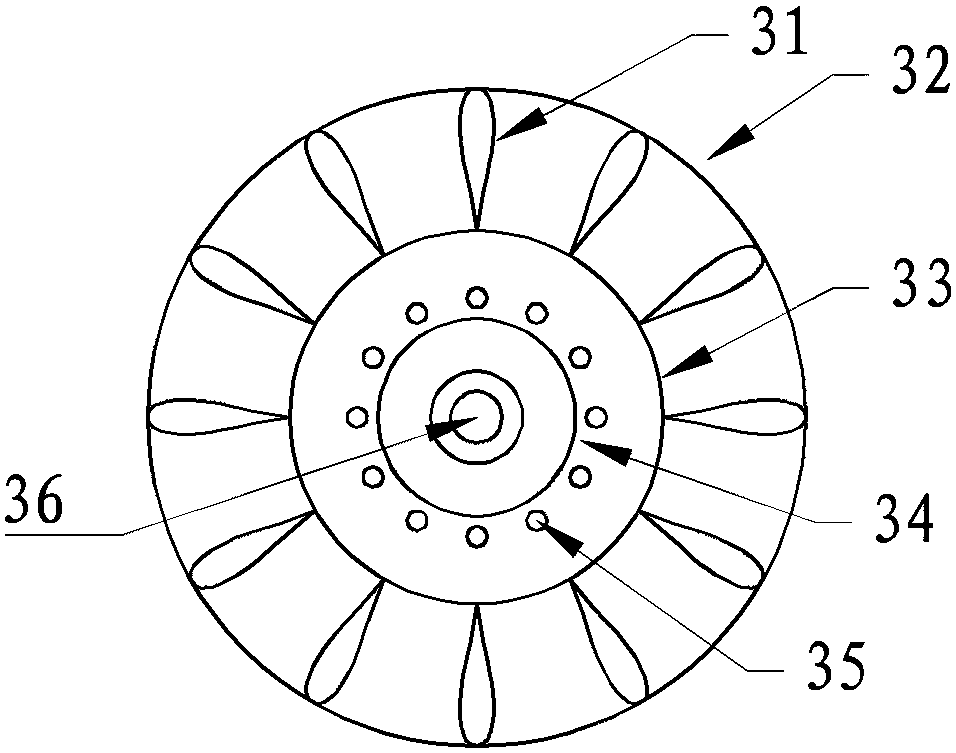

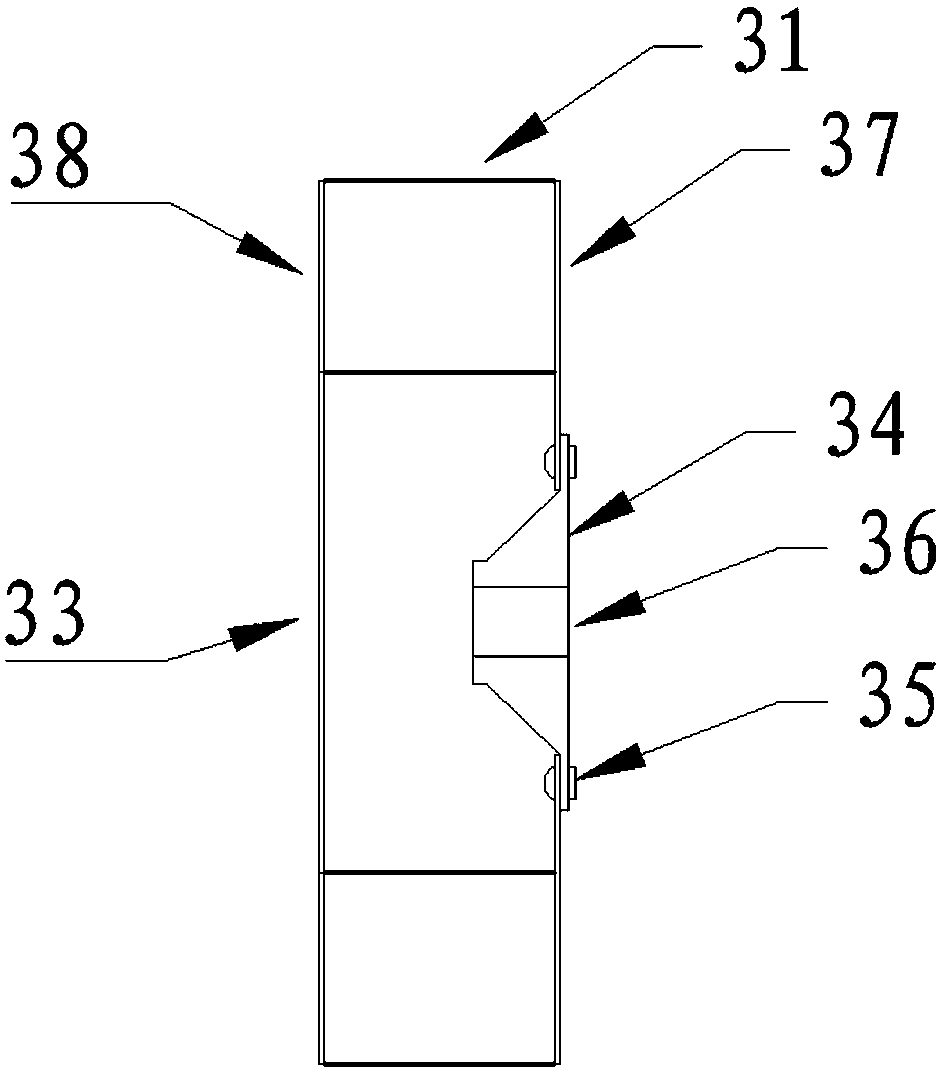

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown heat pump tail heat recovery countercurrent dryer includes a dryer 11 and an induced draft fan A. The two ends of the dryer 11 are respectively provided with an exhaust hood 6 and an air intake hood 12. The exhaust hood 6 is connected to the induced draft fan A, and the induced draft fan A is emptied after being connected to the evaporator 22 of the heat pump system through the cyclone dust collector 21; the evaporator 22 of the heat pump system is connected to the main engine 25 through the refrigerant pipe 24, and the main engine 25 is connected to the condenser 26 through the refrigerant pipe 24; the air outlet end of the blower 27 is passed through the condenser 26 is connected to the air inlet cover 12; the induced draft fan includes a fan impeller 41 and a casing 45, and the fan impeller 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com