Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Solve disagreement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

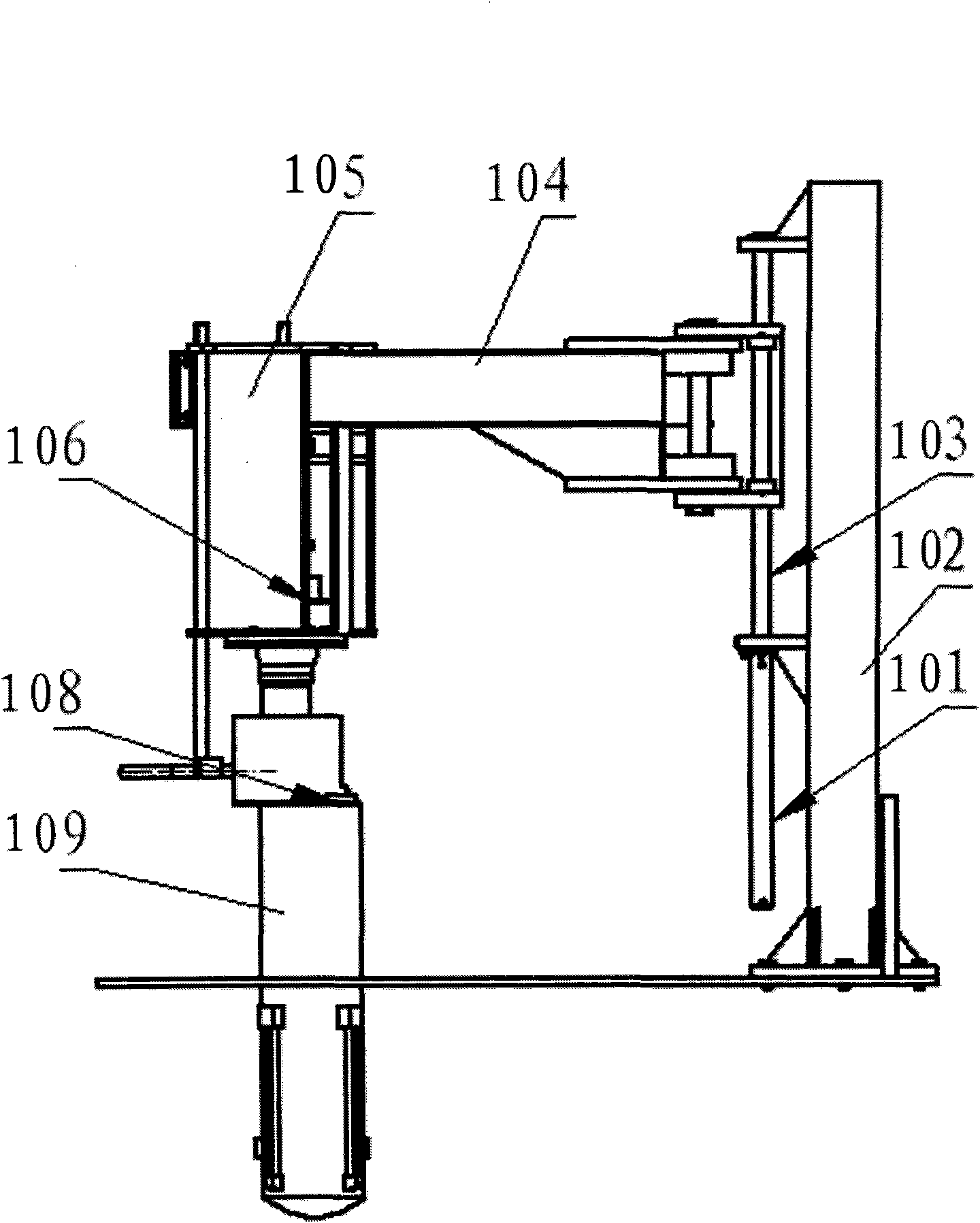

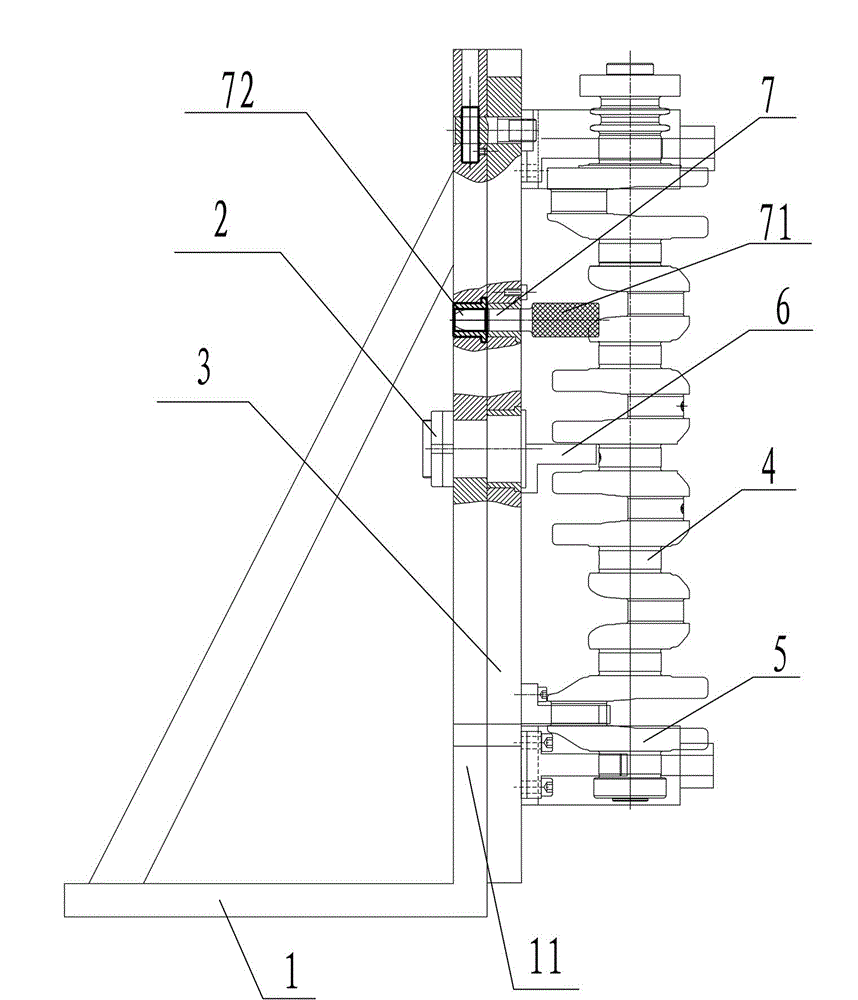

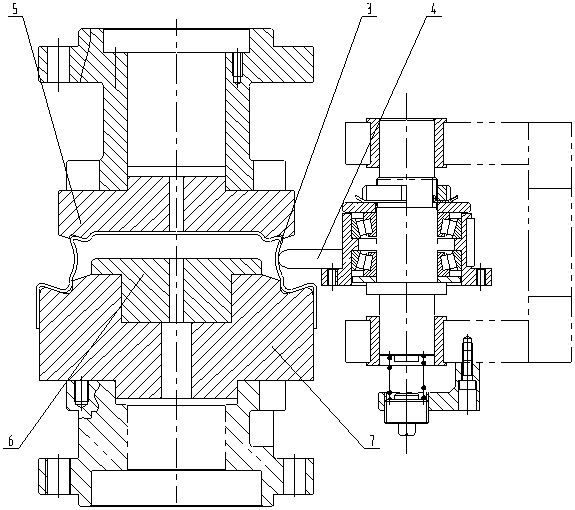

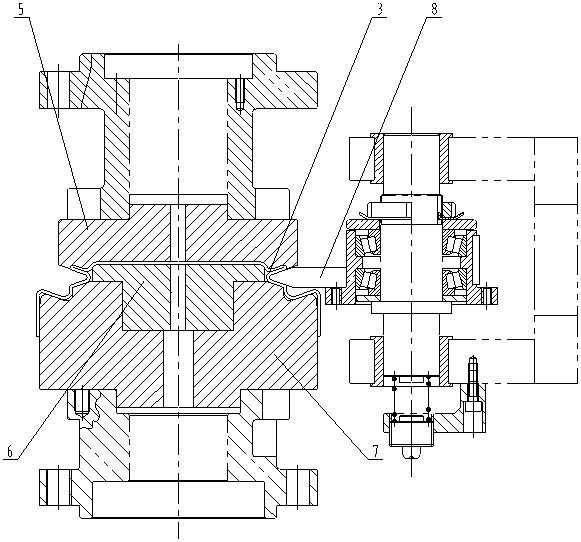

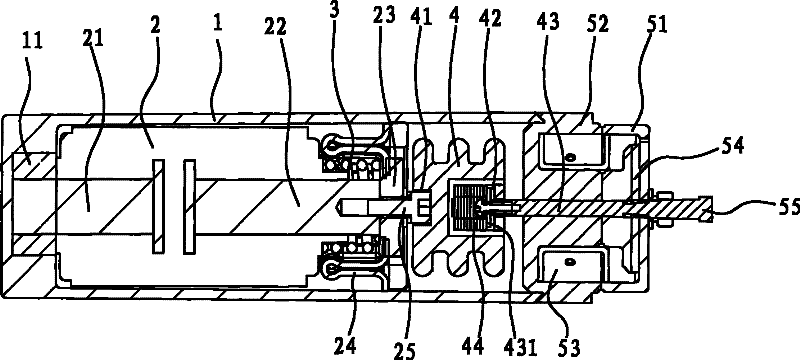

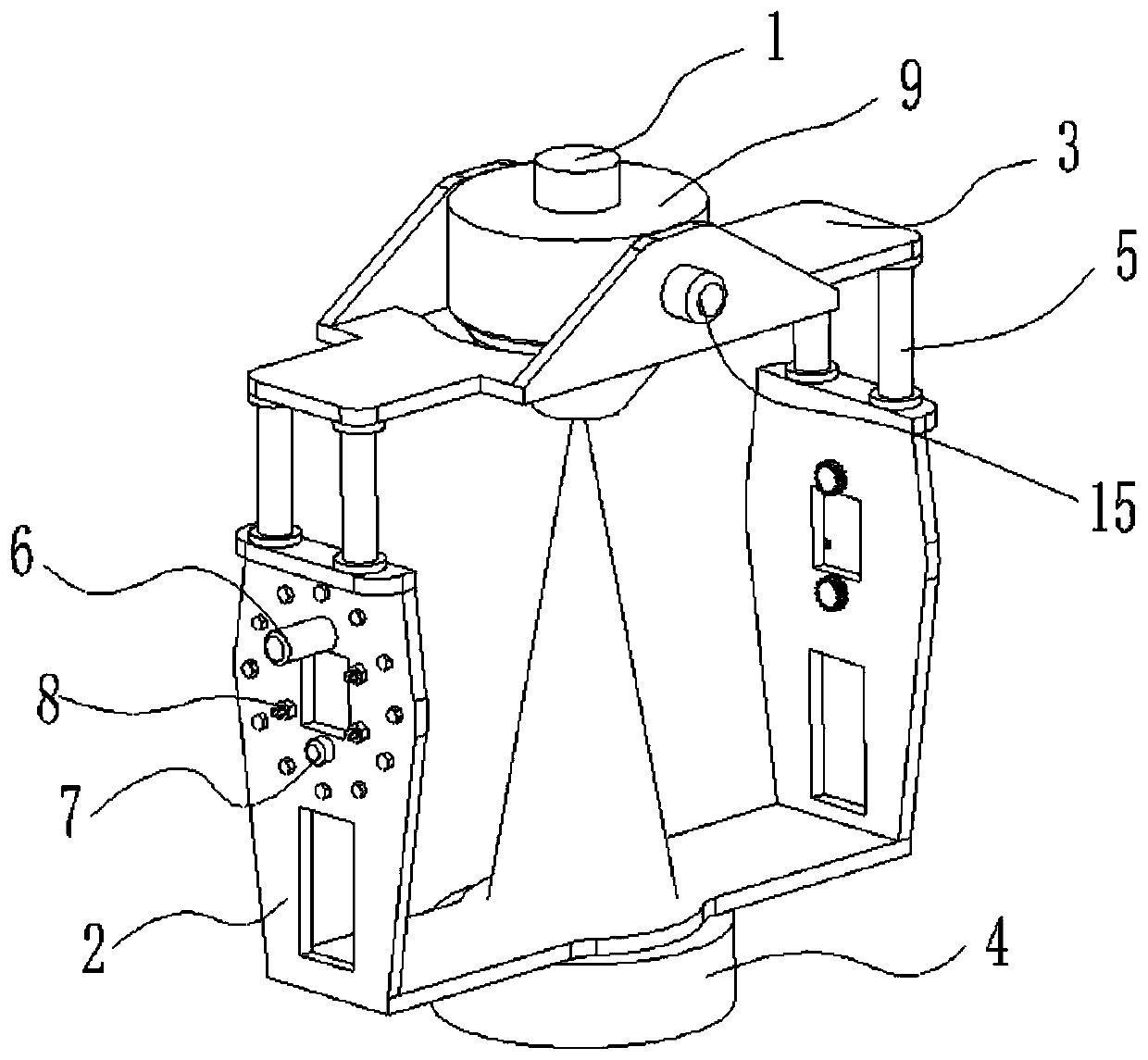

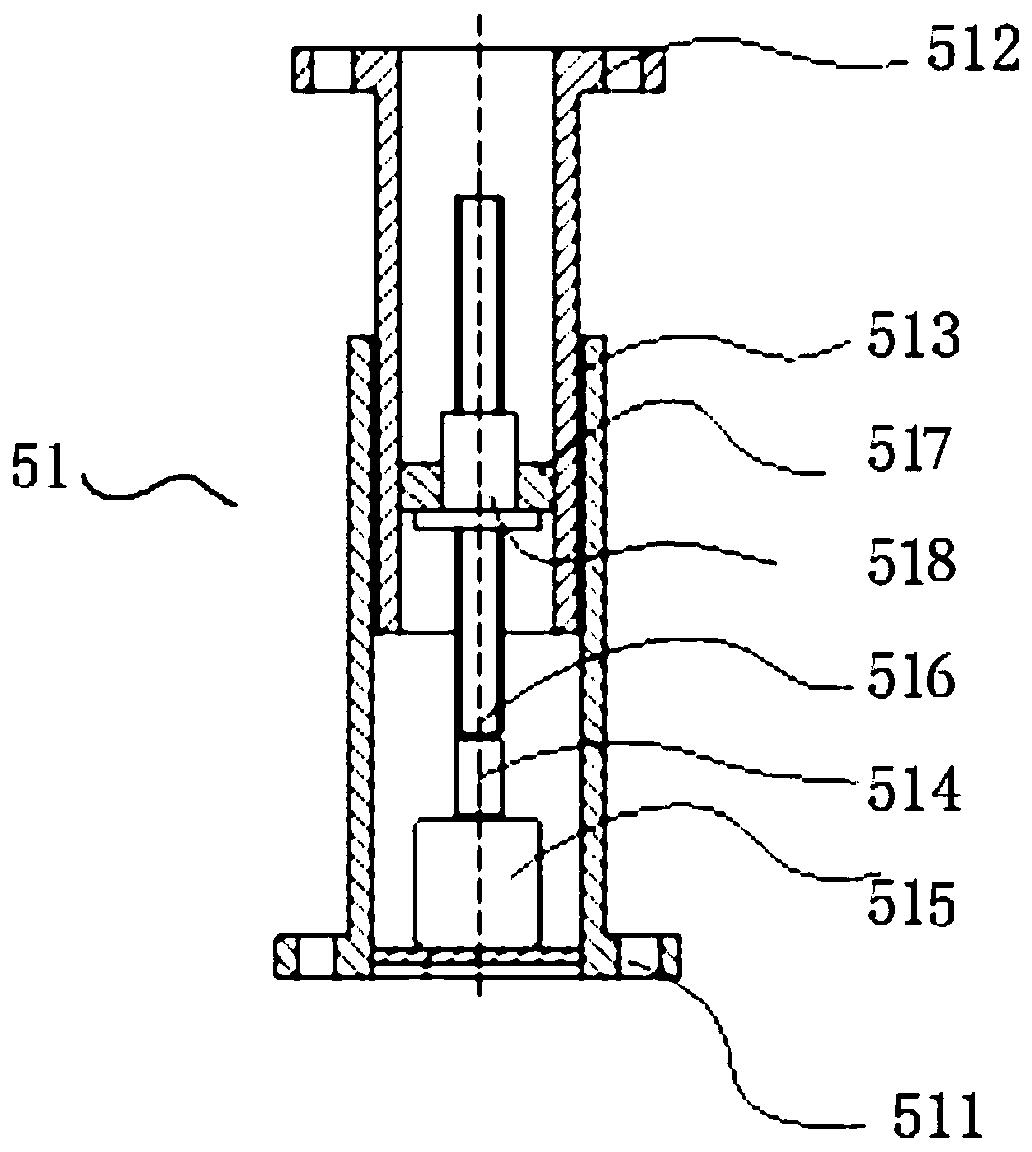

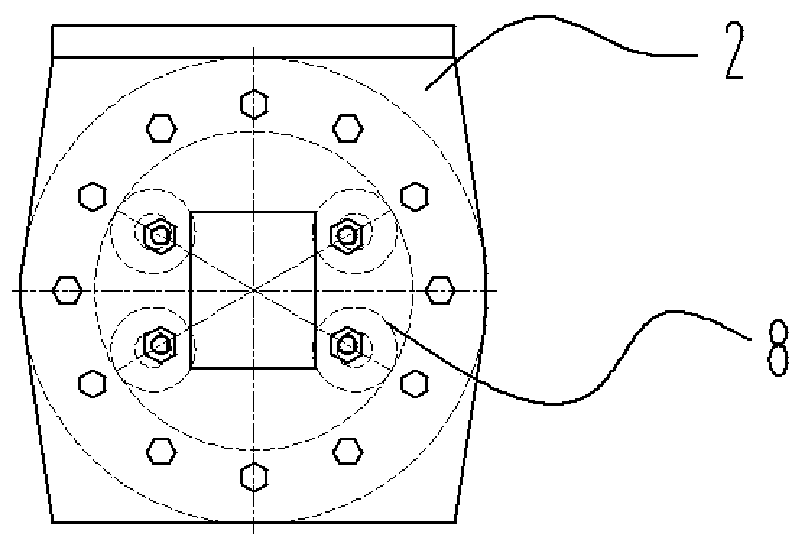

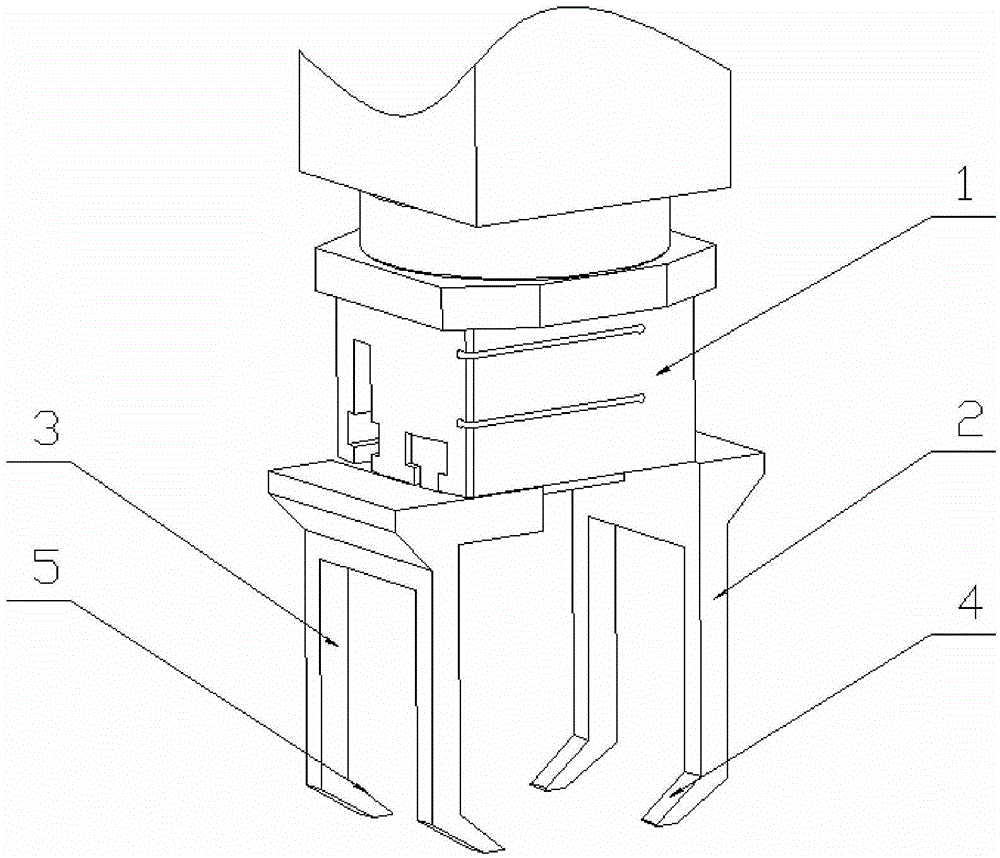

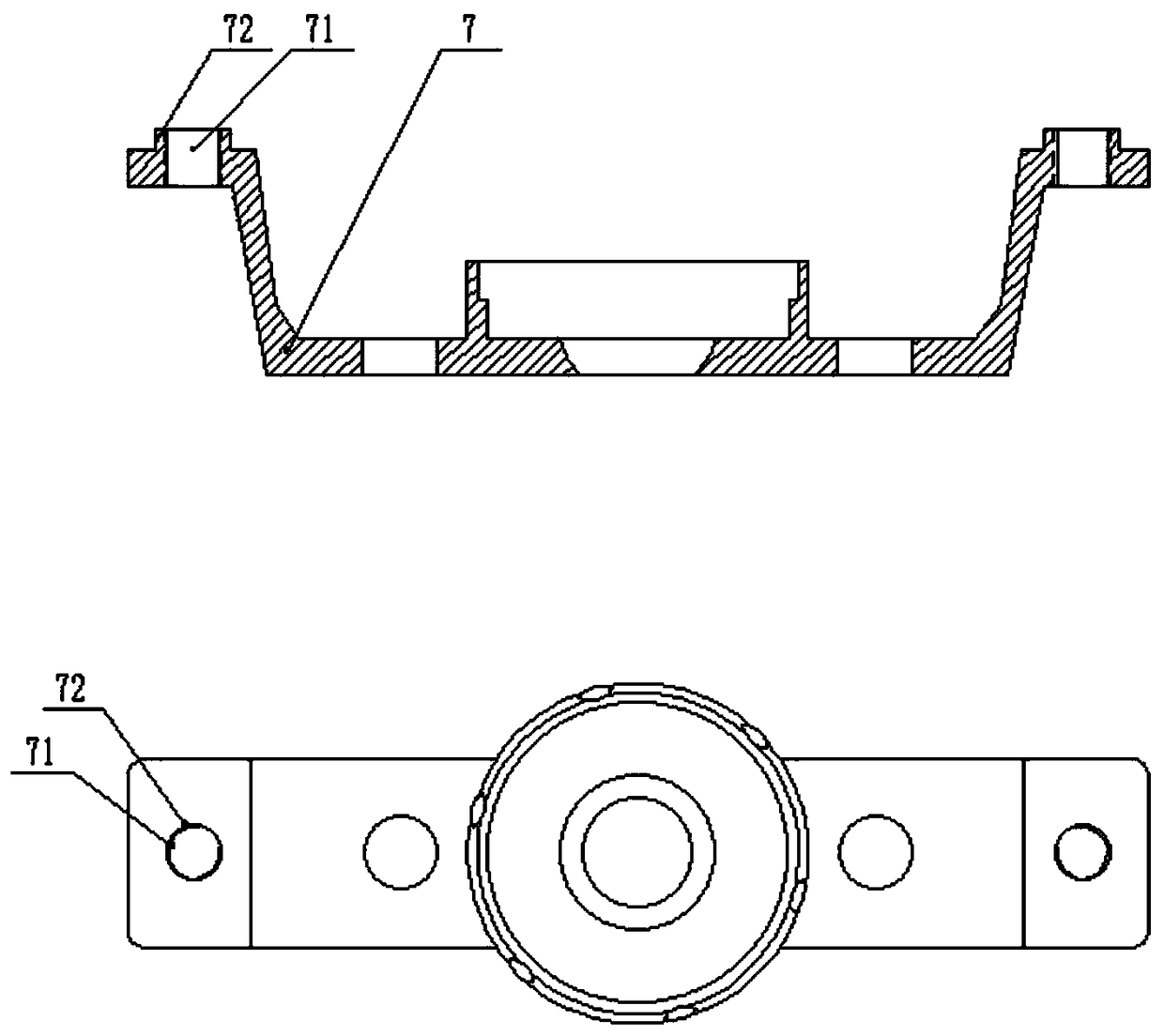

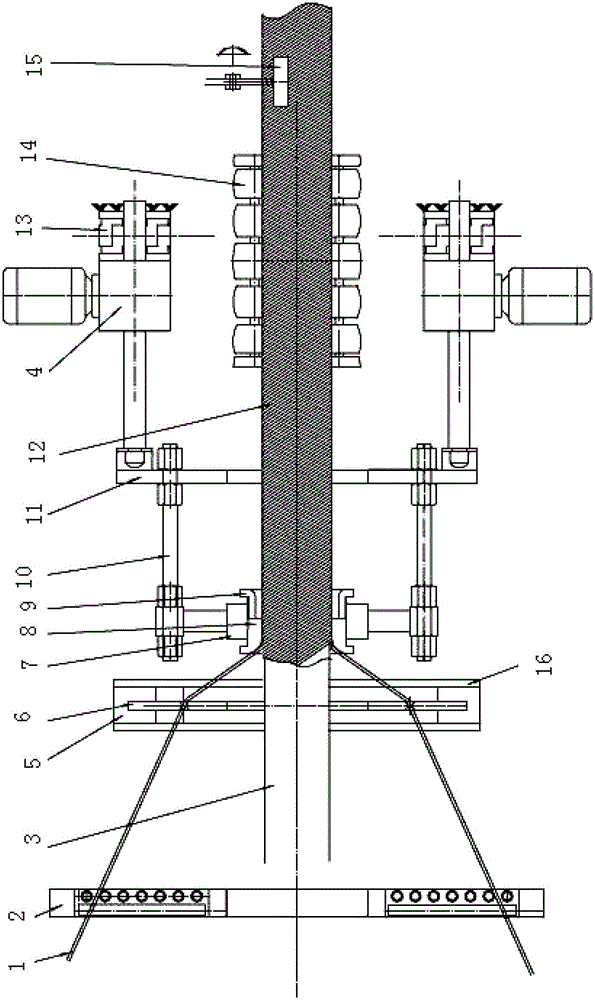

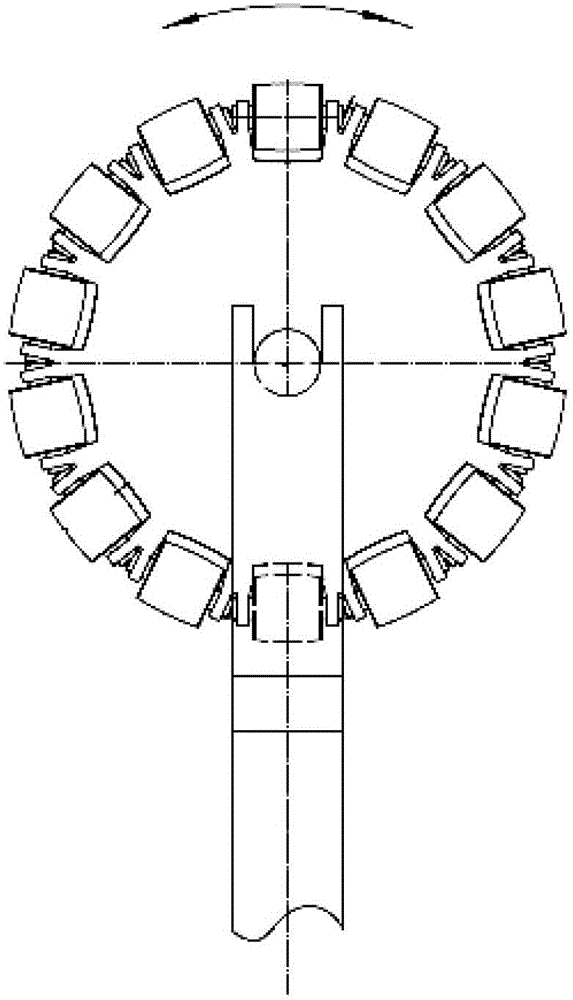

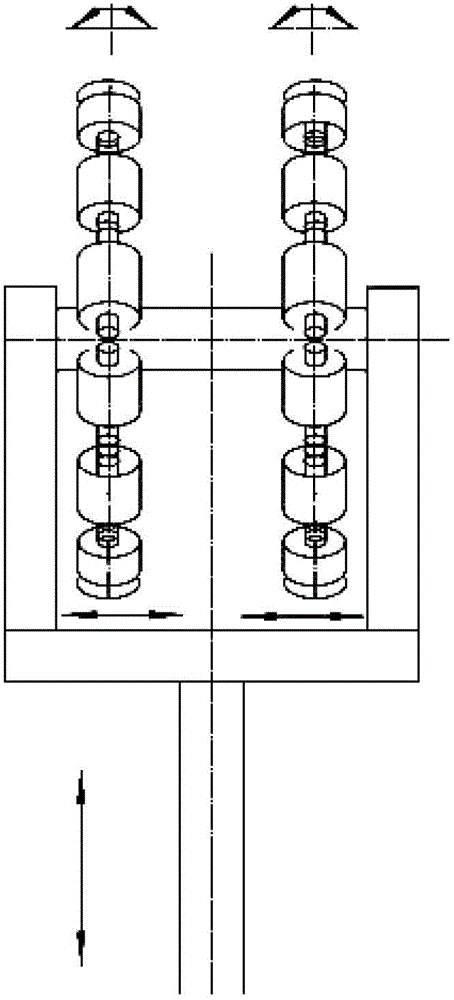

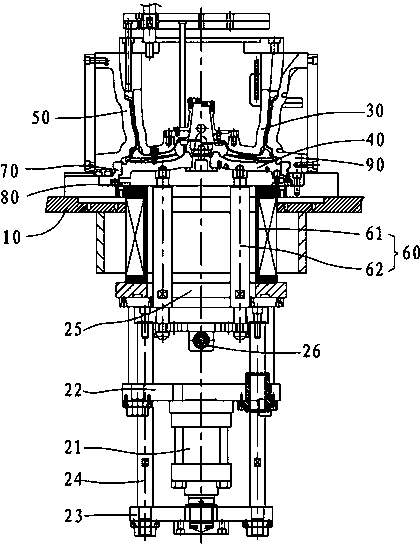

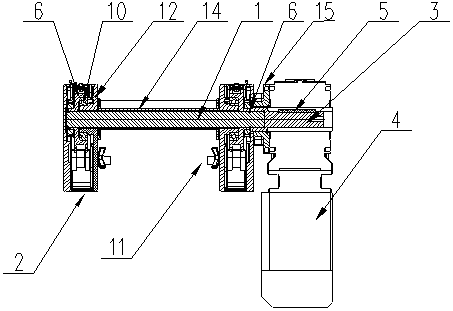

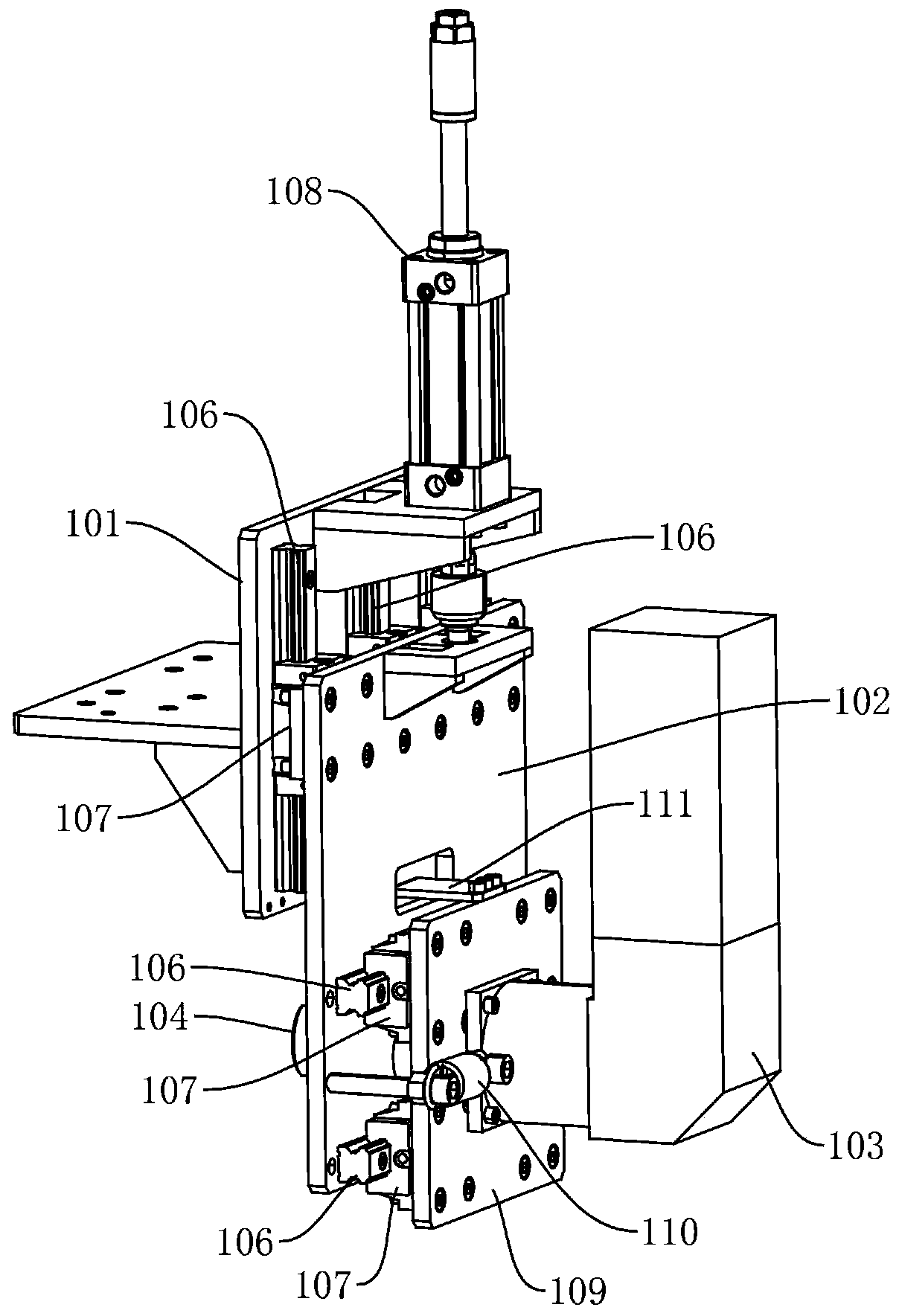

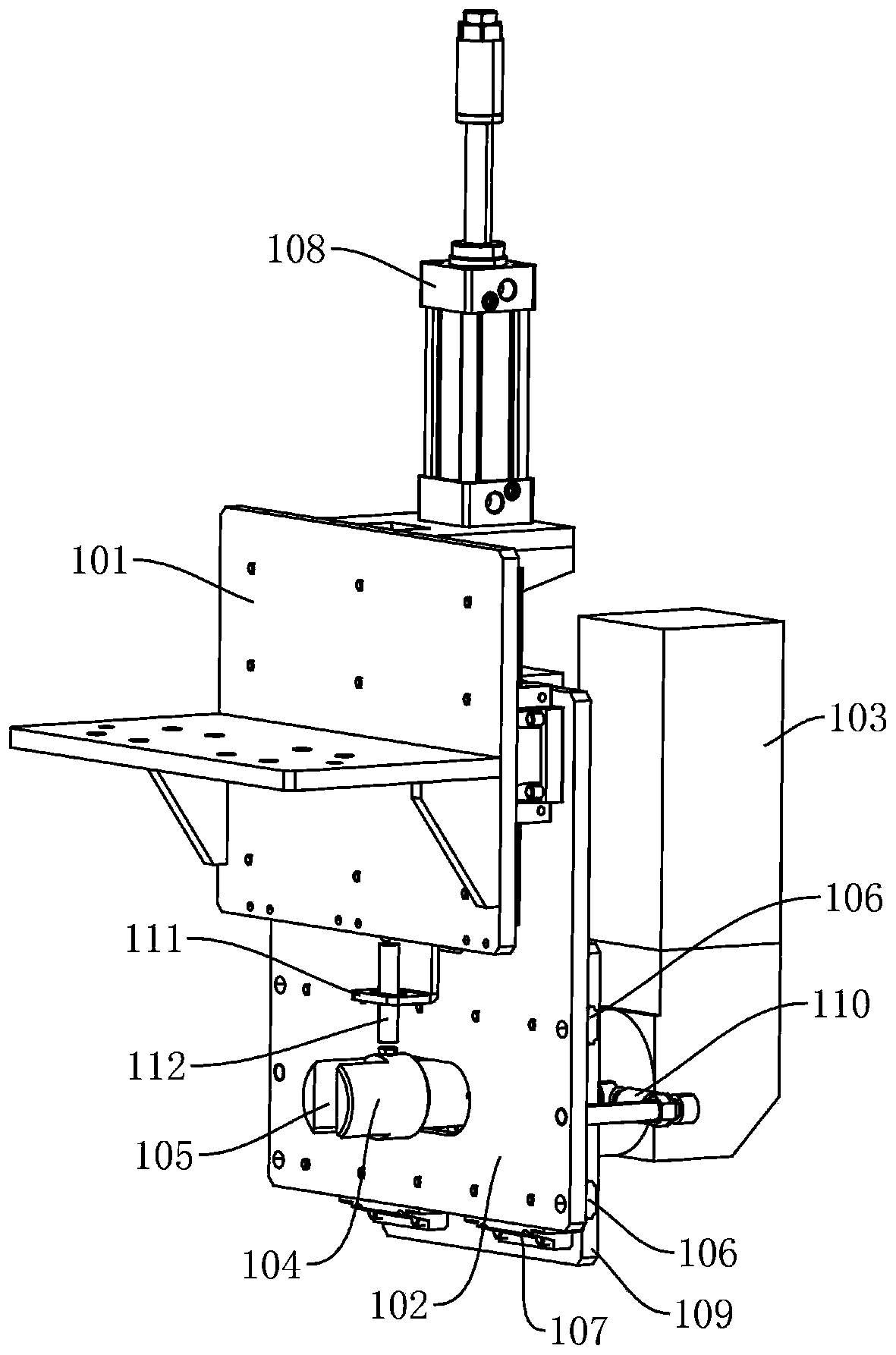

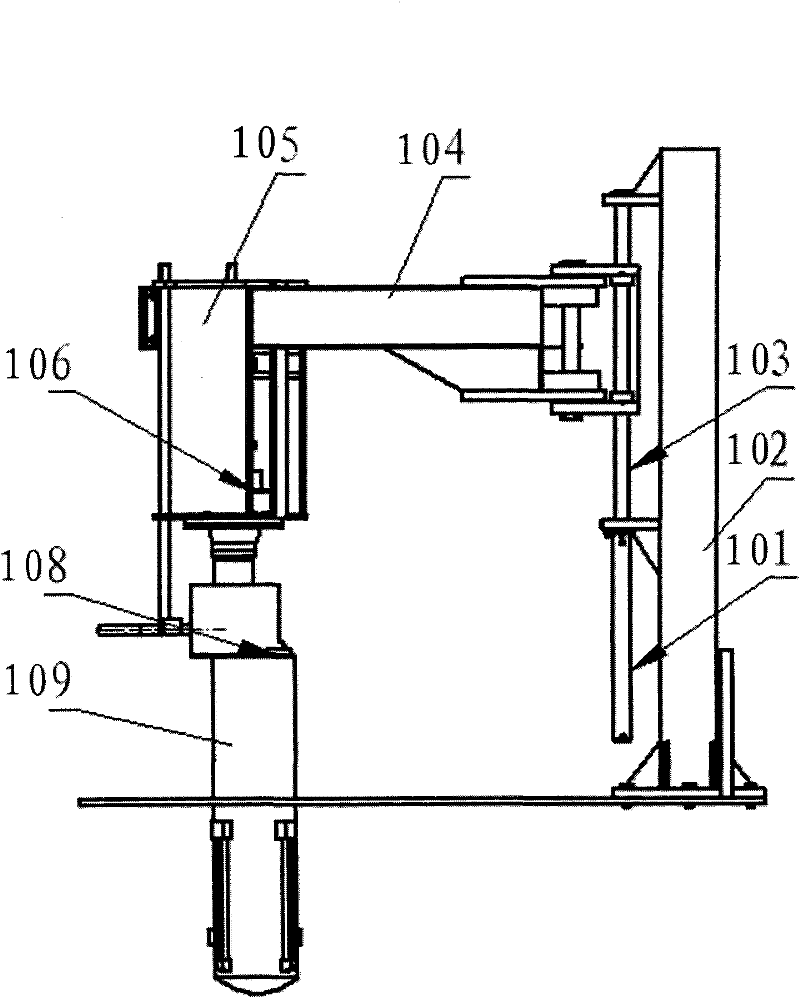

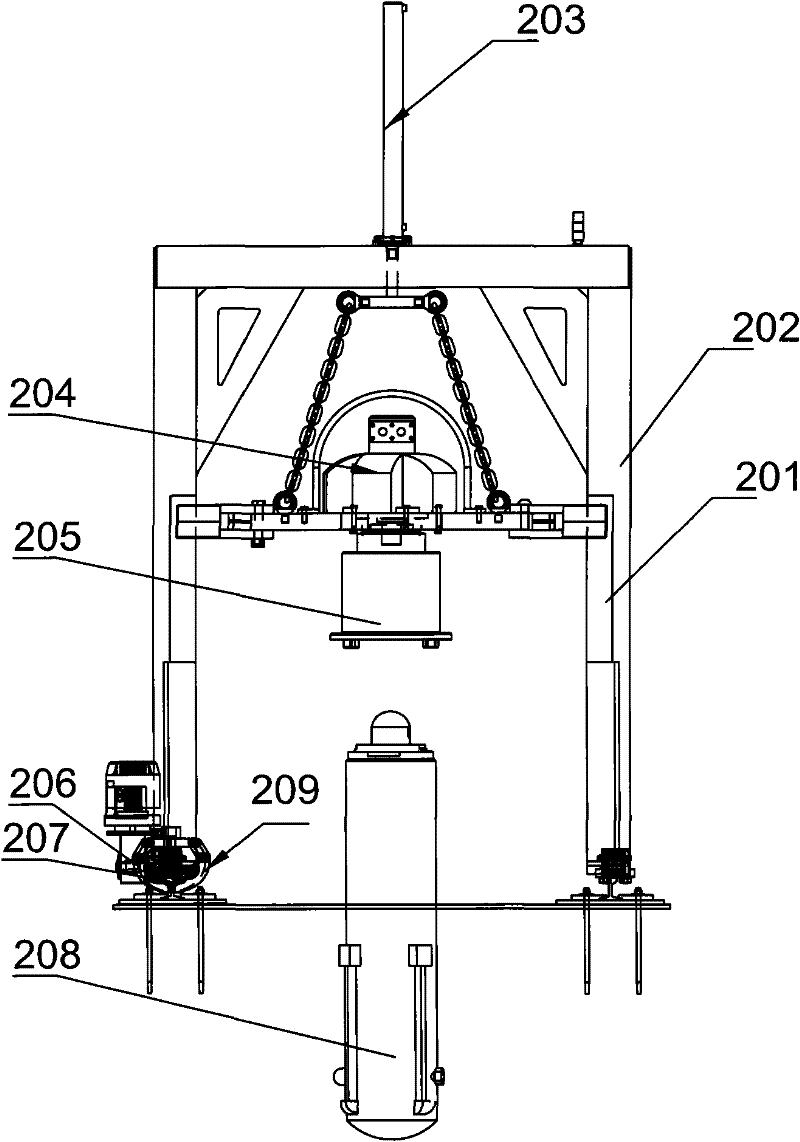

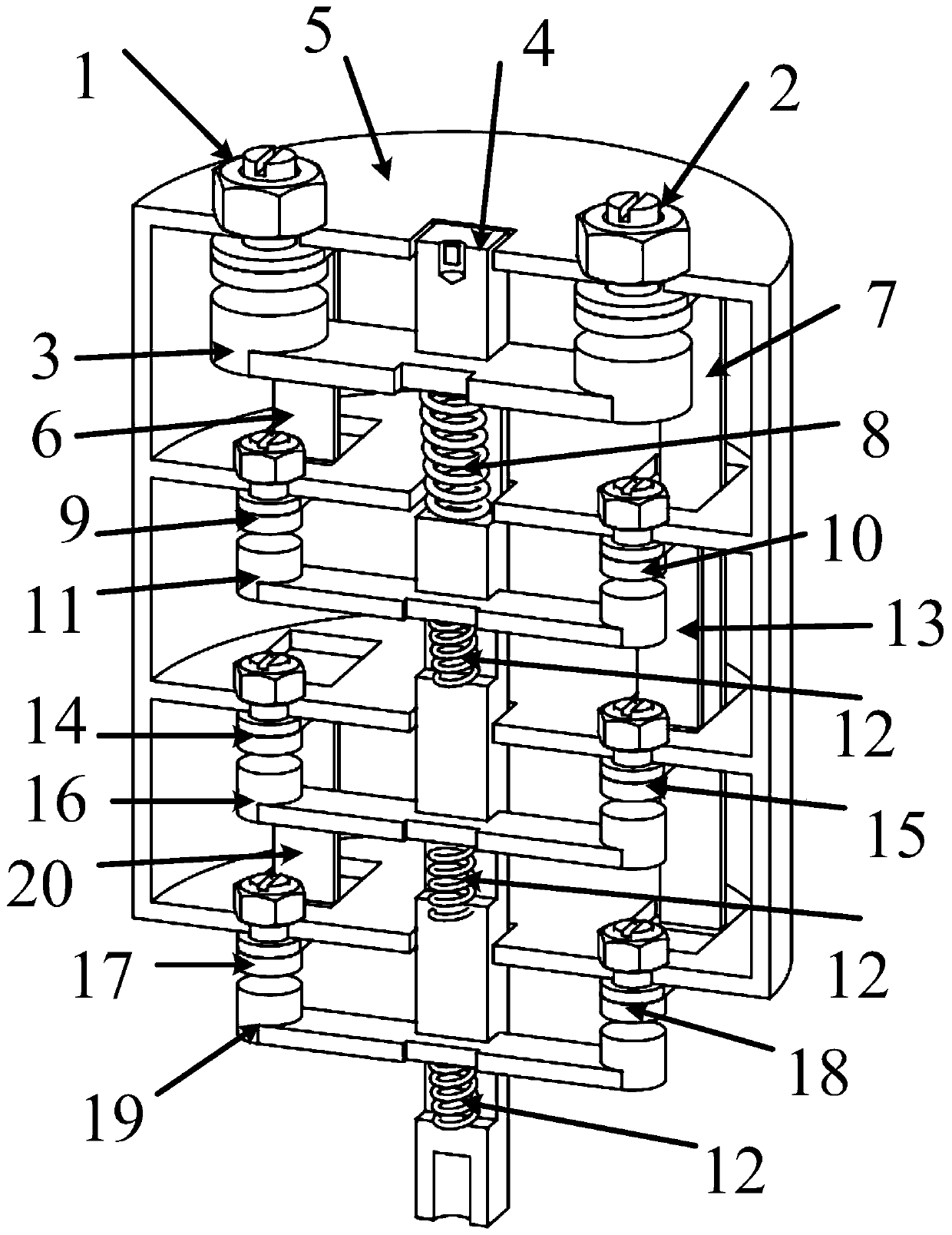

Assembling mechanism of guide sleeve of column of hydraulic support

ActiveCN102031979AControl the size of the preloadPrevent crushingProps/chocksAxial displacementEngineering

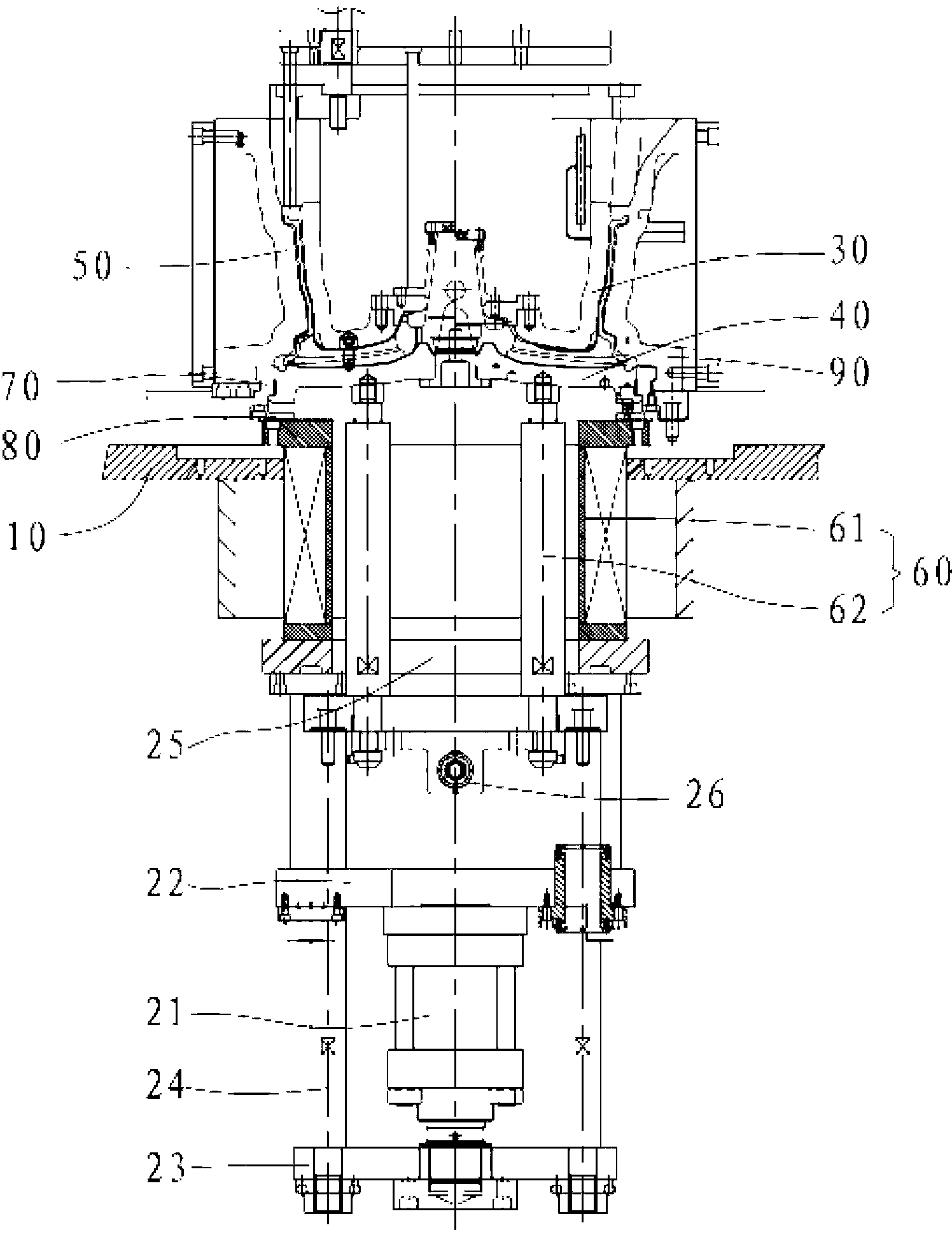

The invention relates to an assembling mechanism of a guide sleeve of a column of a hydraulic support, which comprises a base and a rack arranged vertically on the based and connected with the base via a hinge structure. An obliquely arranged swinging arm oil cylinder is connected with the rack which can be inclined to one side of the swinging arm oil cylinder via the hinge structure under the driving of the swinging arm oil cylinder. The rack is further provided with a vertically lifting oil cylinder and a motor used for installation of the guide sleeve of the column and matched and connected with the lifting oil cylinder. The invention, by using the swinging arm structure and the vertically installed guide sleeve, can prevent the seal ring from being damaged due to dead load of the column. The motor has a floating structure, solves the problem that the motor and the column are not concentric. The invention, by using a structure of two springs, not only solves the problem of axial displacement compensation of the screw thread of the guide sleeve, but also avoids axial abrasion. Therefore, the invention not only controls the pre-pressure of the guide sleeve, but also protects the guide sleeve from being damaged effectively.

Owner:CHINA SHENHUA ENERGY CO LTD

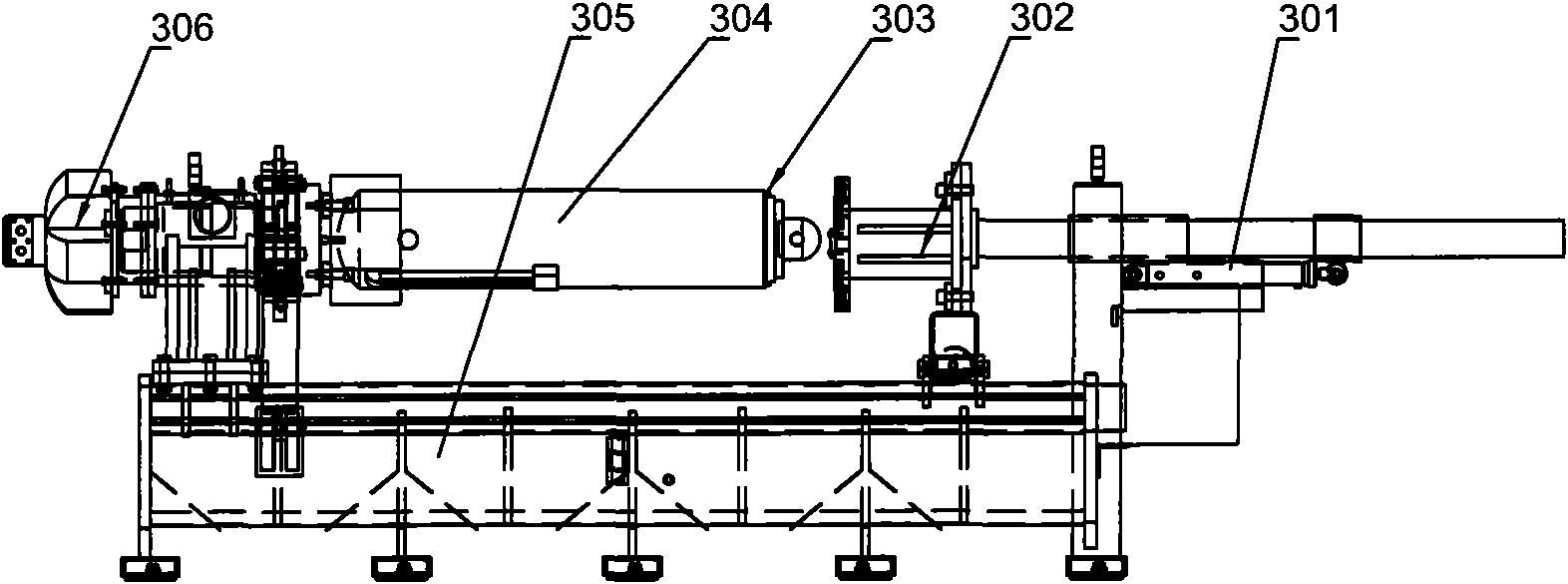

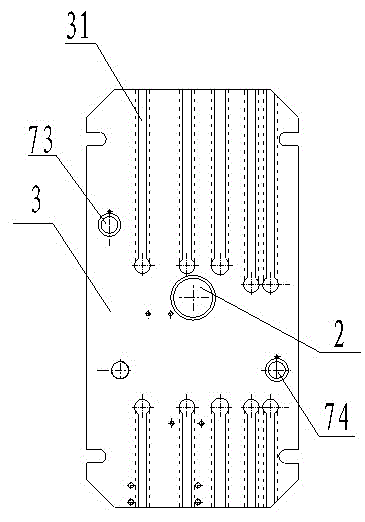

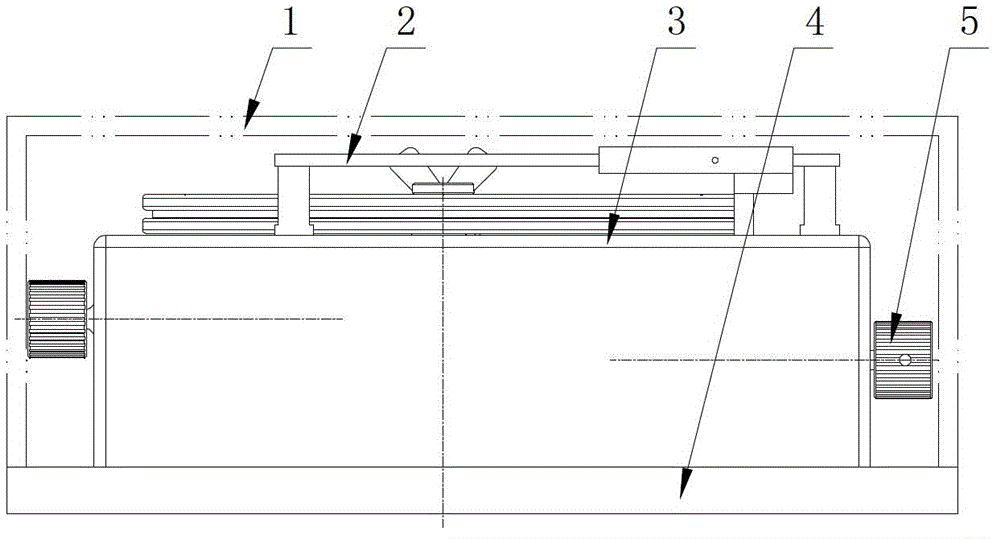

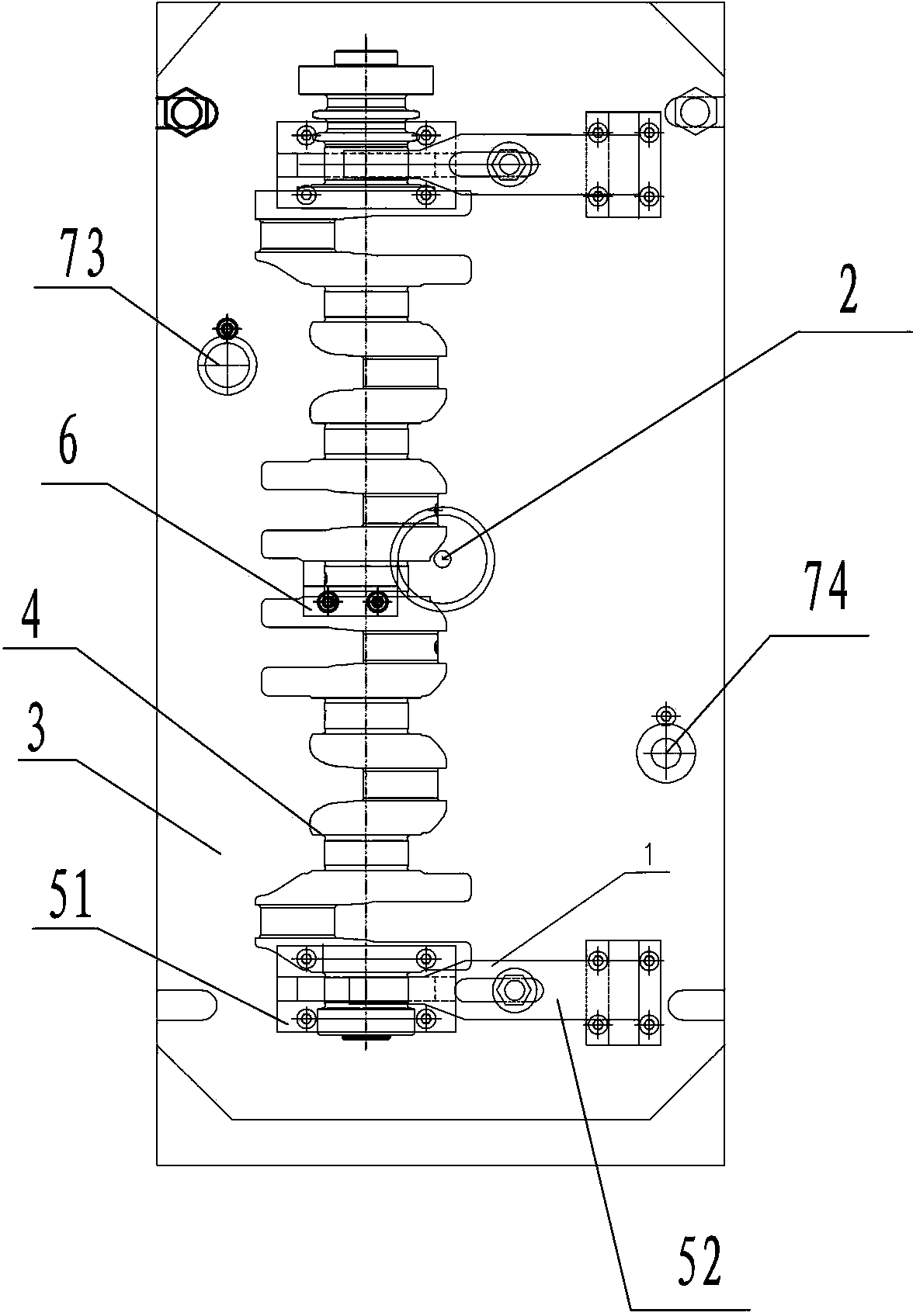

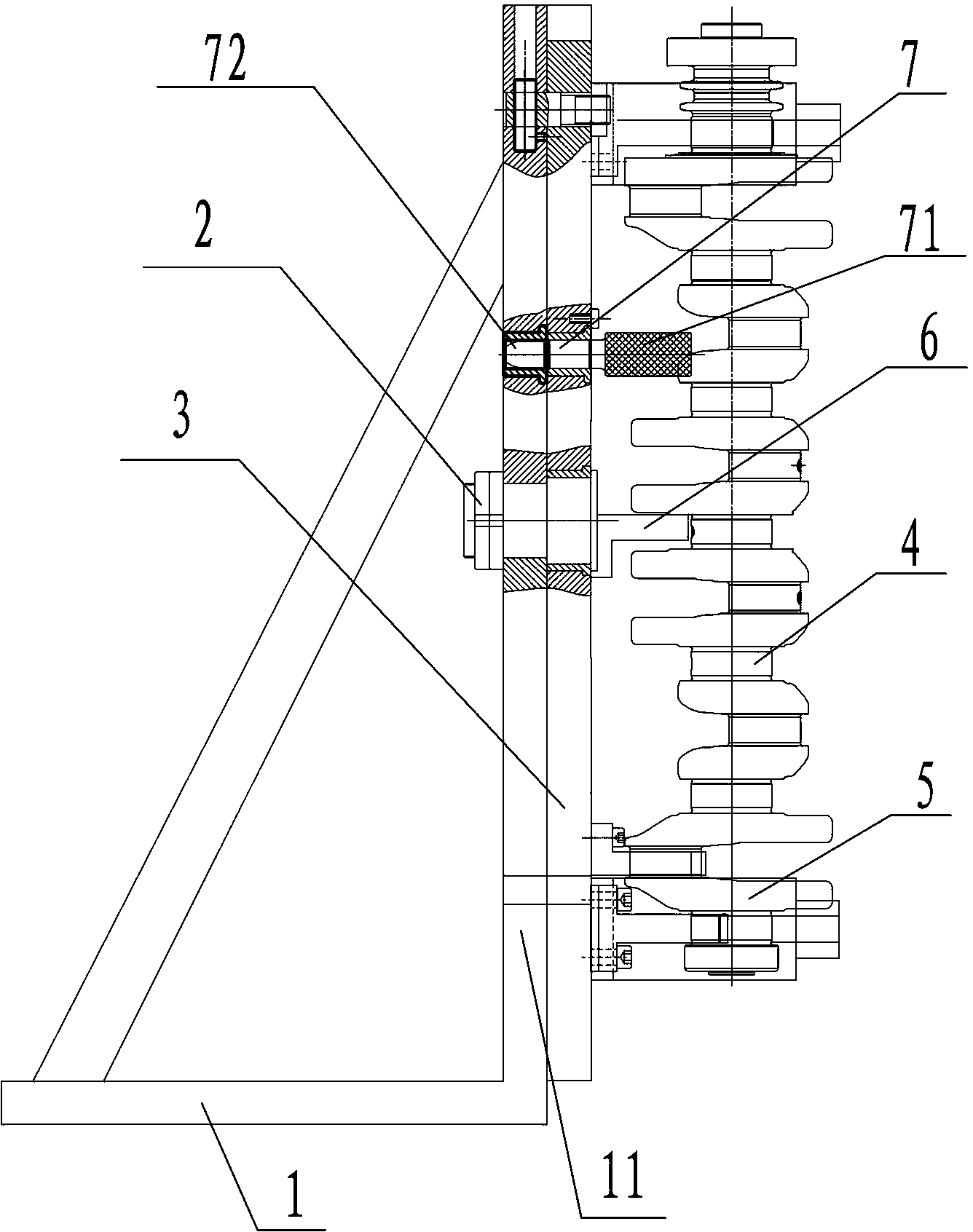

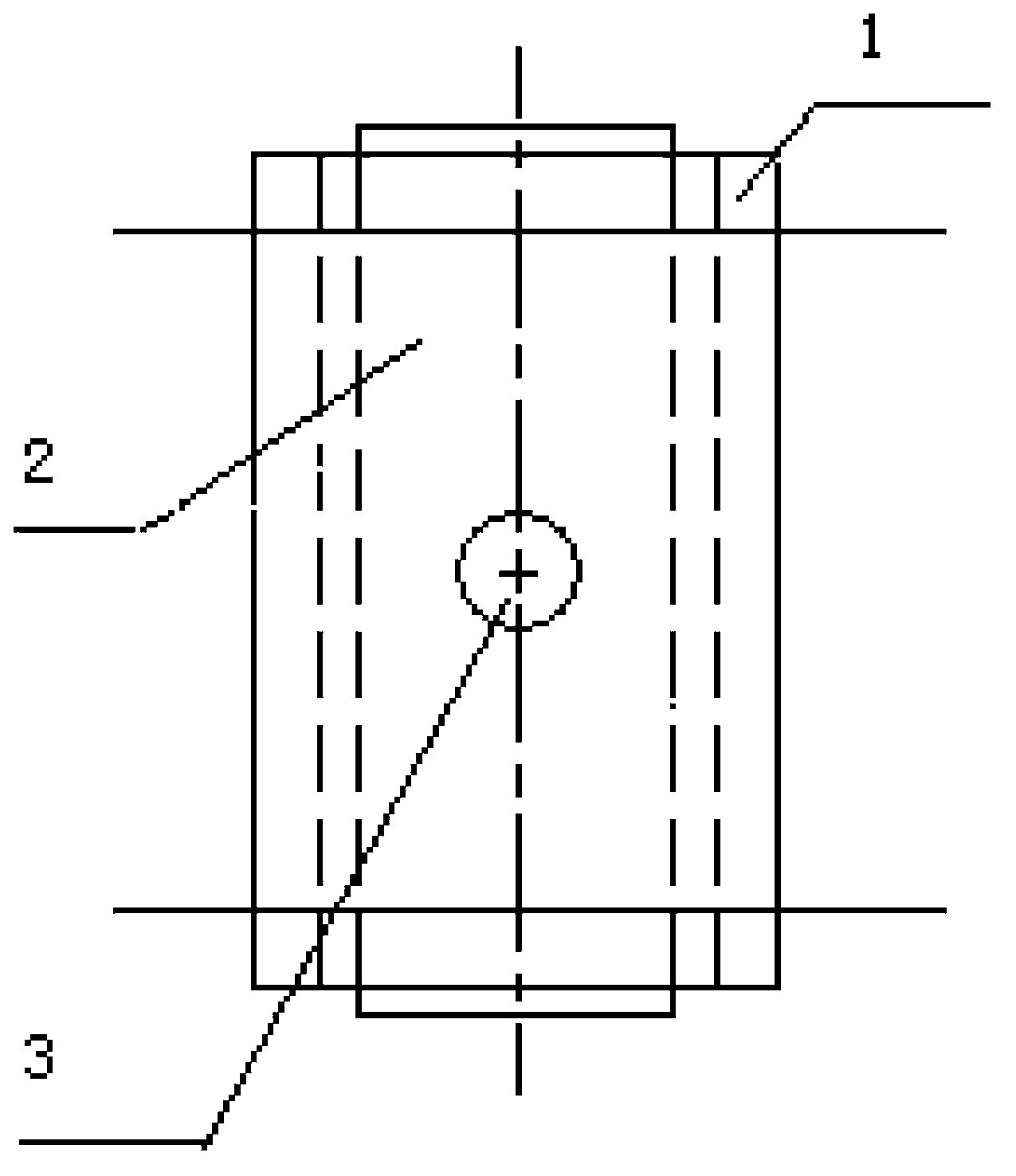

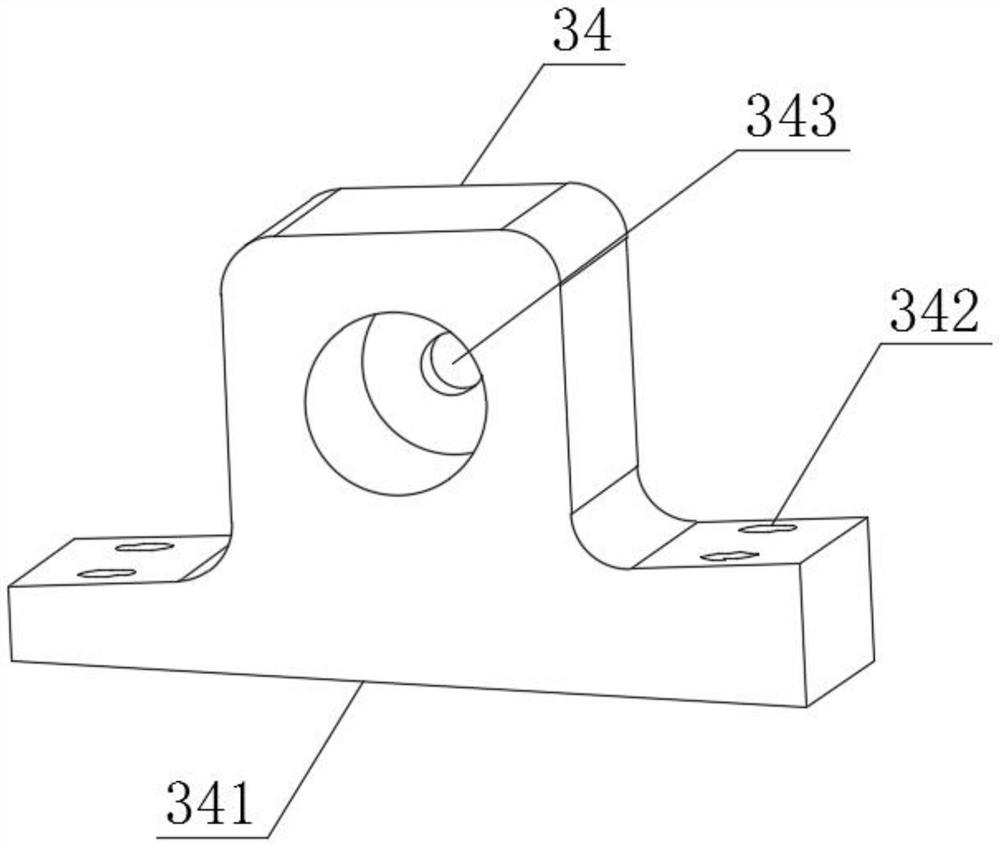

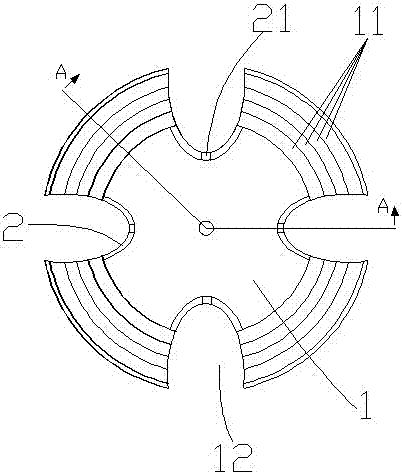

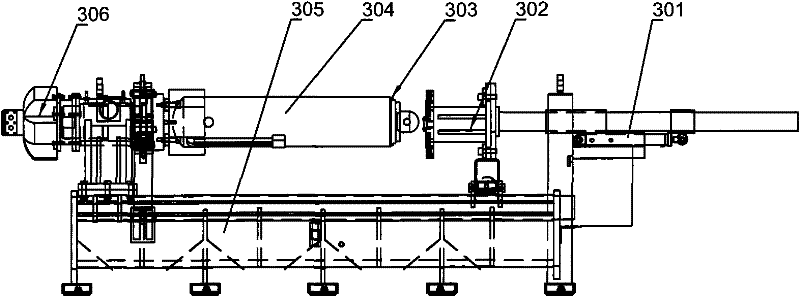

Locating mechanism for machining two ends of crank shaft

ActiveCN102717275ASimple structureEasy to operatePositioning apparatusMetal-working holdersRotational axisEngineering

The invention discloses a locating mechanism for machining the two ends of a crank shaft, comprising a support frame, a rotating shaft, a driven plate and a crank shaft fixing device, wherein the support frame is fixed on ground and is provided with a vertical working surface; the rotating shaft is horizontally arranged at the middle part of the working surface of the support frame; the driven plate is vertically arranged, is fixed on the rotating shaft and is close to the working surface of the support frame; the driven plate is fixedly provided with a fixing mechanism and an axial locating piece; a driven plate limit mechanism used for fixing the driven plate after the driven plate rotates along with the rotating shaft is arranged between the driven plate and the support frame; and the driven plate is respectively horizontally provided with height regulating slots which extend vertically at the upper side and the lower side of the rotating shaft, and the fixing mechanism and the axial locating piece are both fixed in the height regulating slots. The locating mechanism disclosed by the invention is used for locating in the machining of the two ends of the crank shaft, holes at the two ends can be machined while the crank shaft is clamped once, and therefore positional accuracy of the holes at the two ends is guaranteed and labour intensity of operating personnel is reduced.

Owner:长城汽车股份有限公司平湖分公司

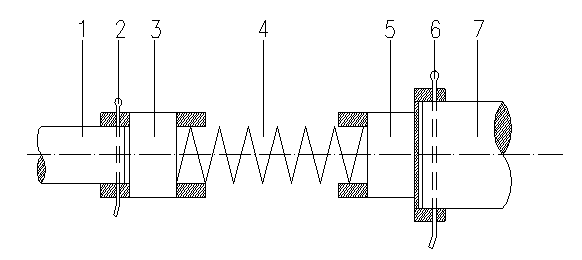

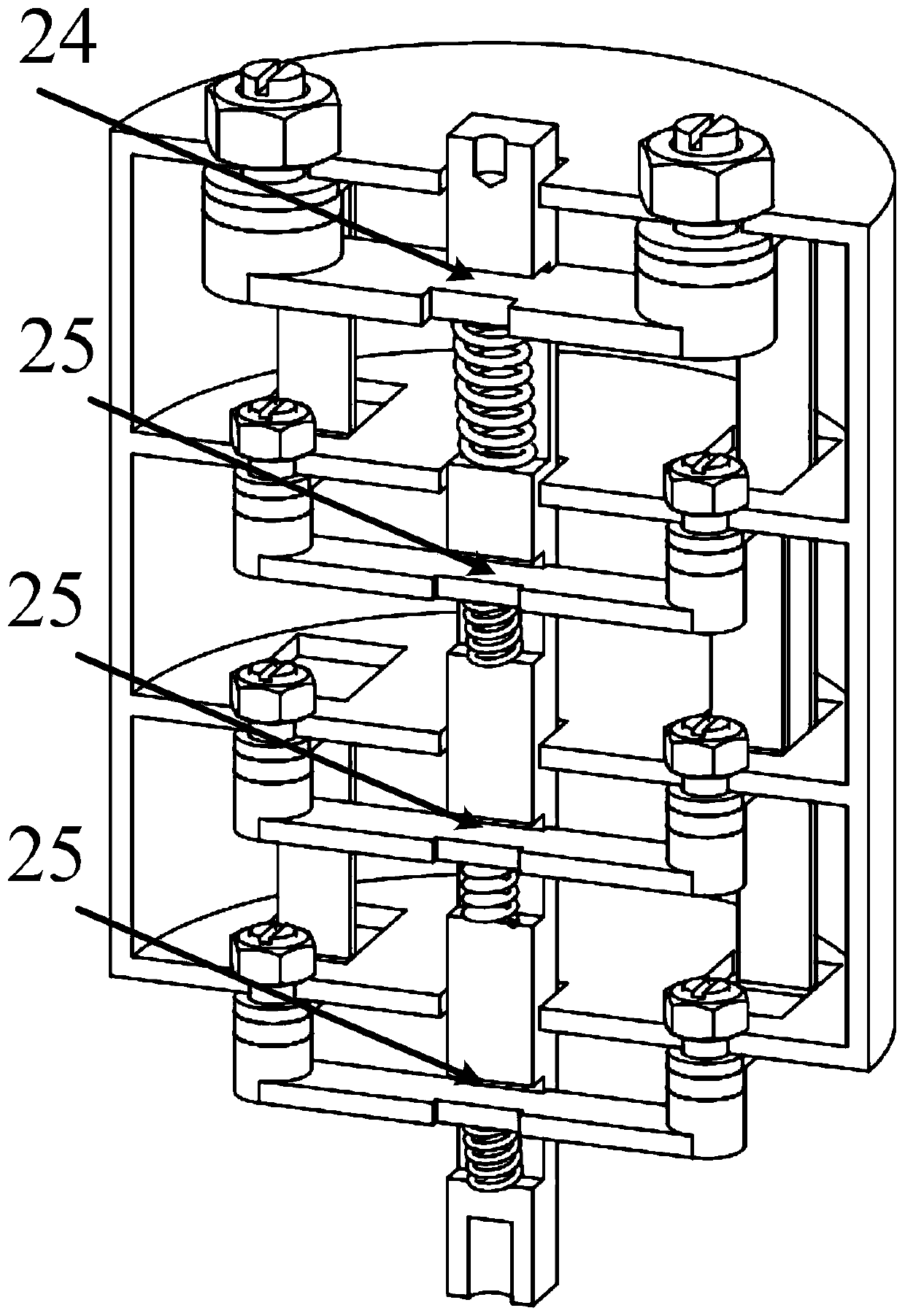

Flexible connection device for multifunctional limiting stopper

The invention relates to a flexible connection device for a multifunctional limiting stopper. The flexible connection device comprises the multifunctional limiting stopper, wherein the multifunctional limiting stopper is provided with a transmission shaft; and the transmission shaft is connected with a multifunctional limiting stopper connection shaft sleeve through a fixing shaft pin II. The flexible connection device is characterized in that the multifunctional limiting stopper connection shaft sleeve is connected with a speed reducer through a flexible spring. By the characteristic of soft transmission of the spring, the problem that an output transition shaft of a speed reducer and the transmission shaft of the multifunctional limiting stopper are not concentric due to secondary machining is effectively solved. By the flexible connection device, the multifunctional limiting stopper is easily arranged on the speed reducer without an output interface.

Owner:LANZHOU NO 2 CONSTR GRP JIANXIN ENG

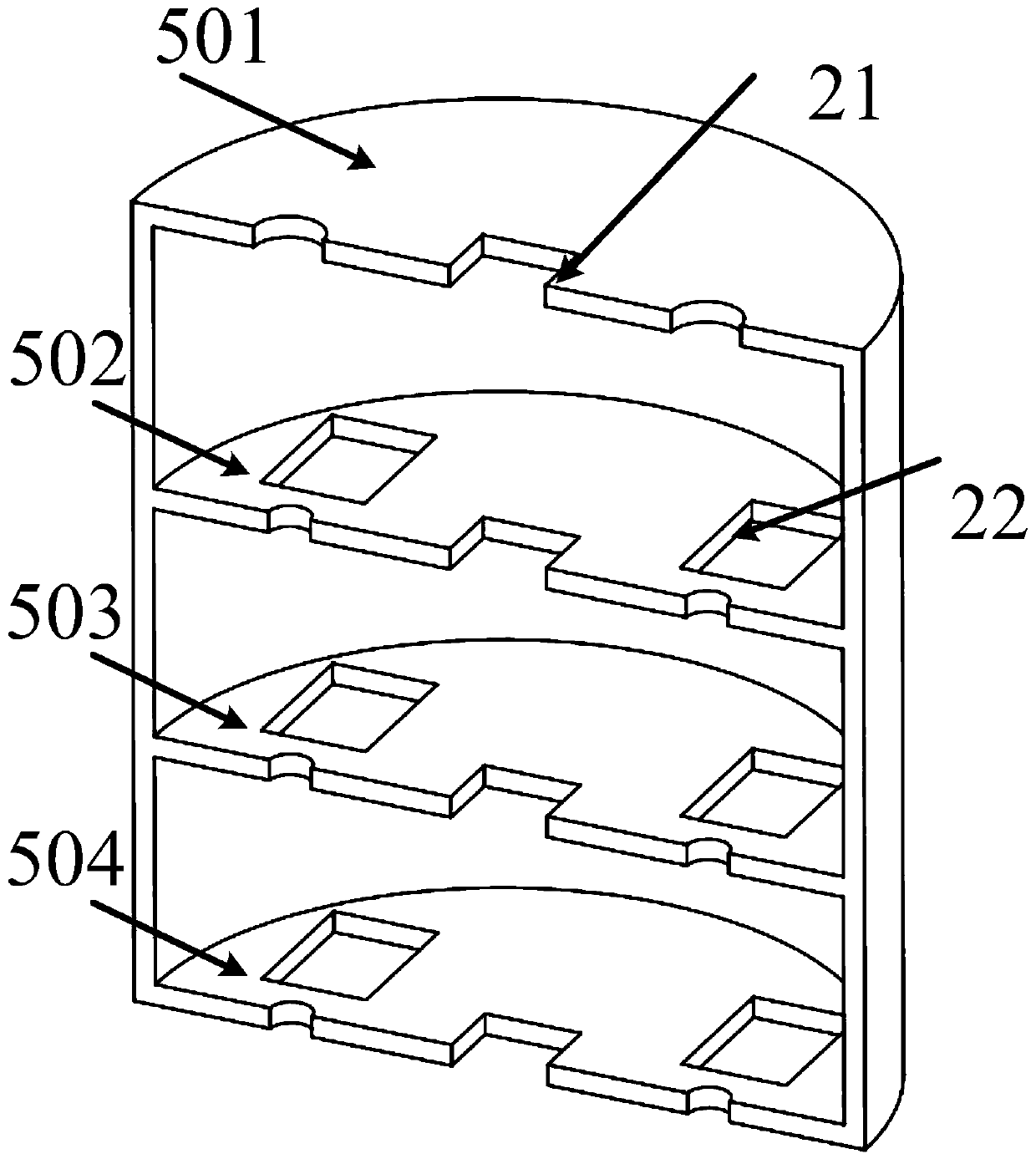

Spinning process for manufacturing step type spinning belt wheels with different diameters and special tool thereof

PendingCN108213162ASolve the problem of inconsistent upper and lower alveolarStable spinning productionMetal-working apparatusTextile/flexible product manufactureEngineeringLower tooth

The invention discloses a spinning process for manufacturing step type spinning belt wheels with different diameters and a special tool thereof. The spinning process comprises twice spinning, and adopts two steps to mold by spinning. In primary spinning, the inner diameter of a second-grade large end surface is used for positioning on a mold; after molding by spinning, and when materials are totally filled in upper and lower core molds, the roundness of a first-grade tooth groove is guaranteed by the upper and lower core molds; then, a spun first tooth groove is used as reference; a center hole is formed in the bottom plane, so that the first-grade tooth groove is better in jumping relative to the reference hole; then, the center hole is used for positioning; a second-grade tooth groove isspun, and is better in jumping relative to the center hole; and the coaxiality of tooth grooves of upper and lower steps can be guaranteed. The spinning process has the following beneficial effects:the problems of staggered installation of upper and lower tooth grooves of the step type spinning belt wheels with different diameters and instable mounting size are solved; stable spinning productionis realized; the product quality is effectively guaranteed; and qualified step type plate spinning belt wheels with different diameters are provided.

Owner:东风襄阳旋压技术有限公司

Permanent-magnetic vacuum one-way switch

InactiveCN102194601APrevent rejectionSolve disagreementHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

Owner:张凯

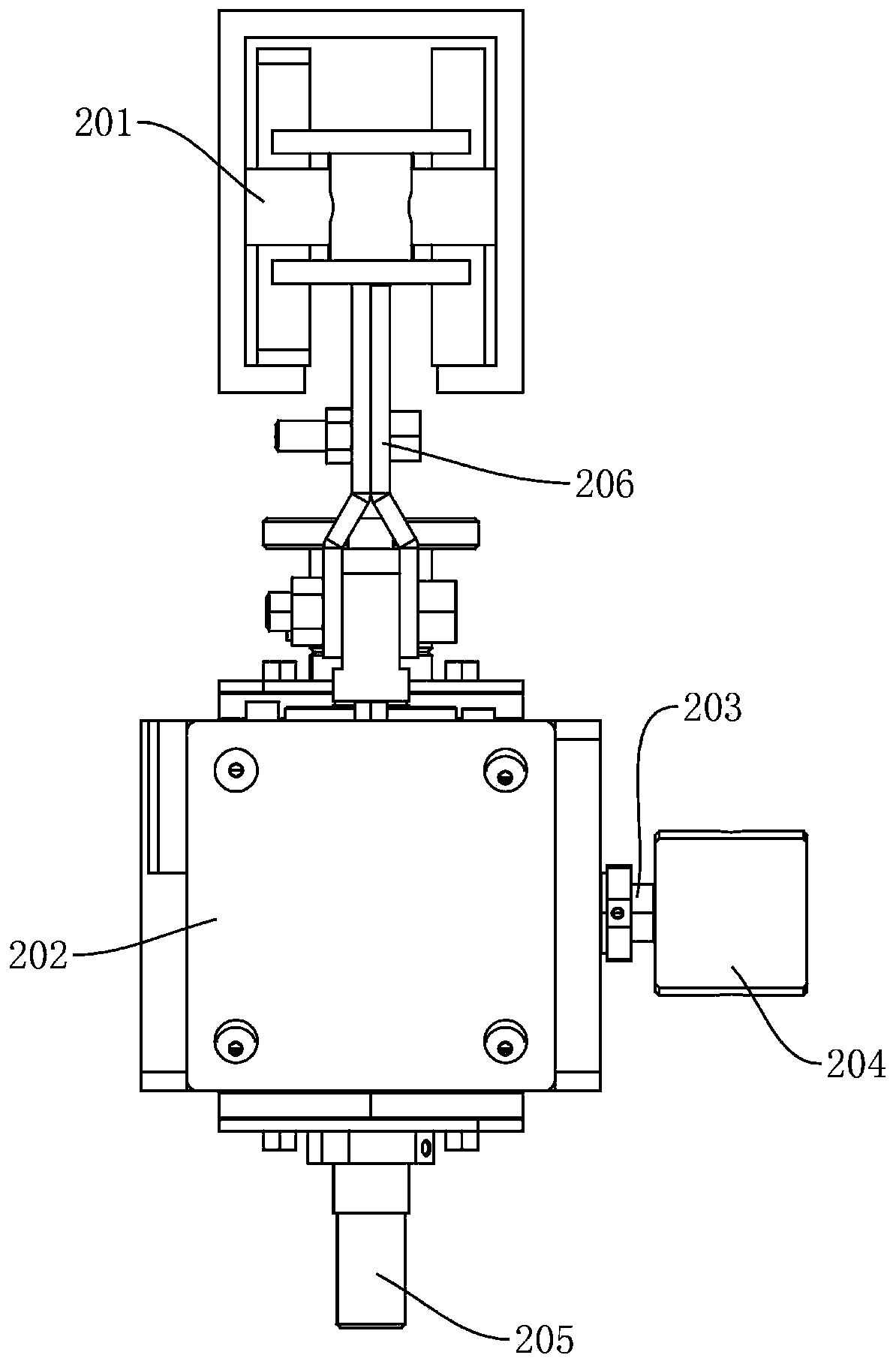

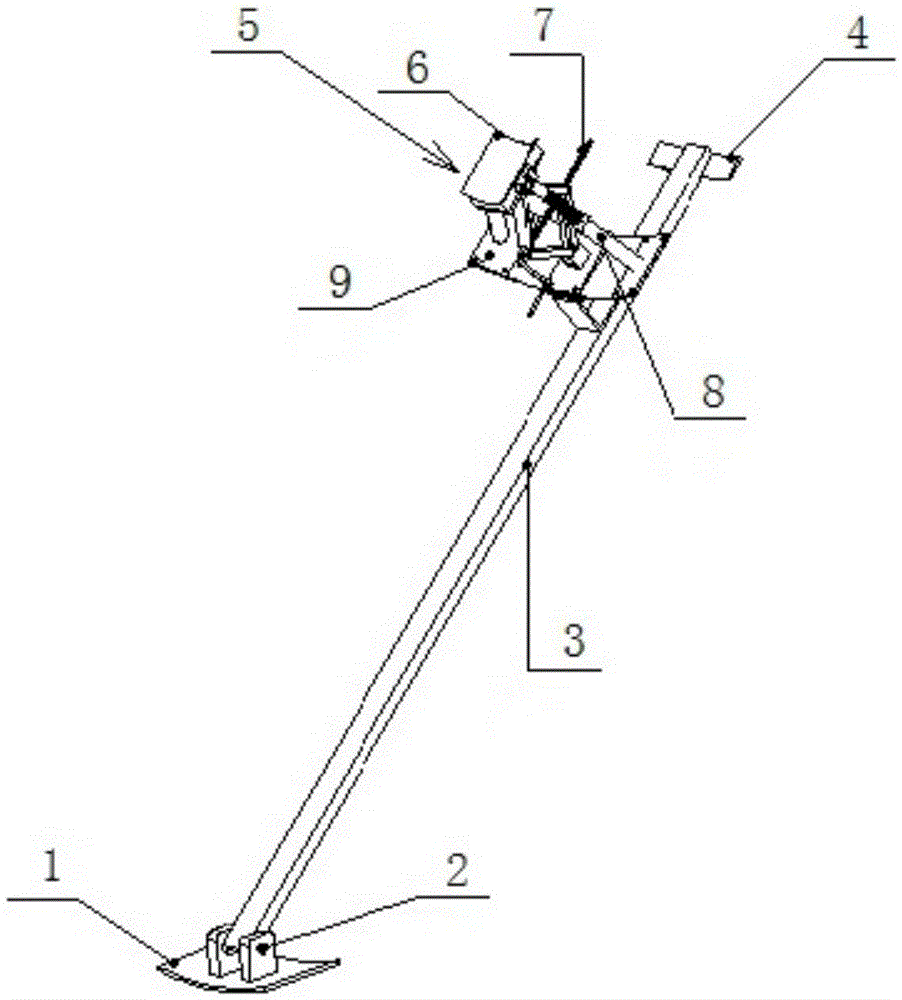

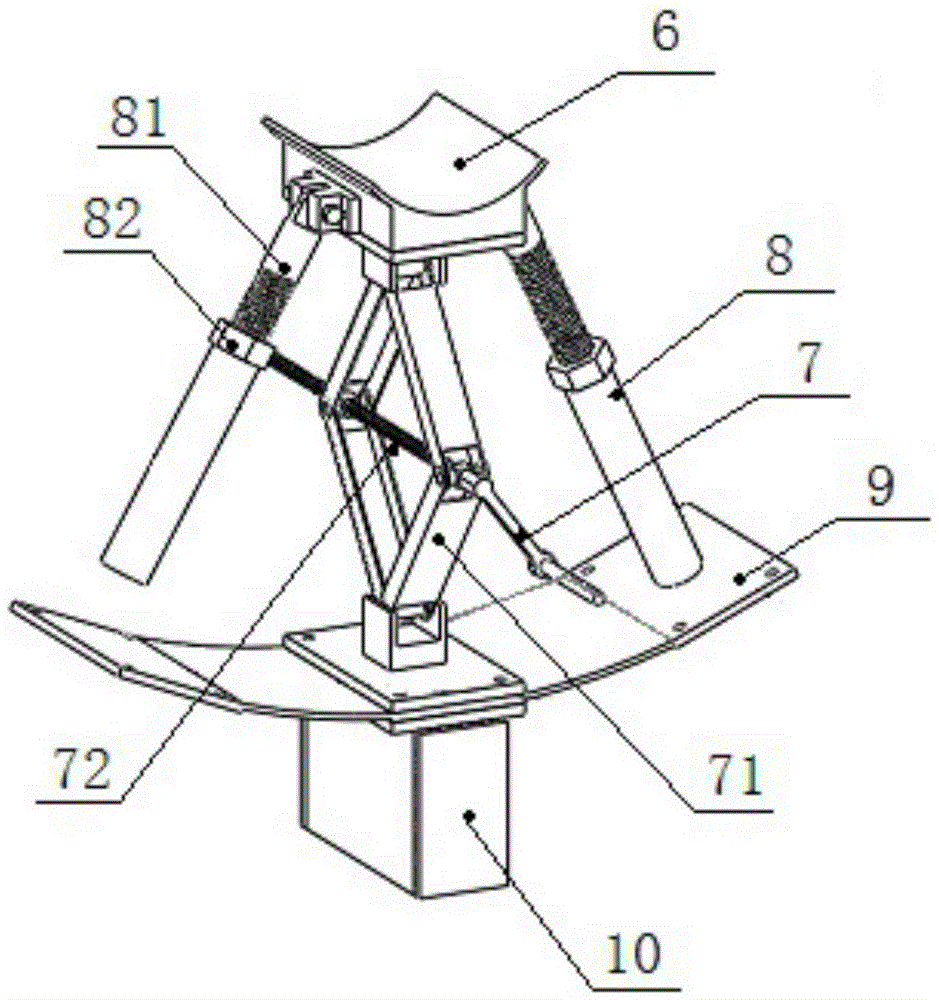

Accelerator adjusting device

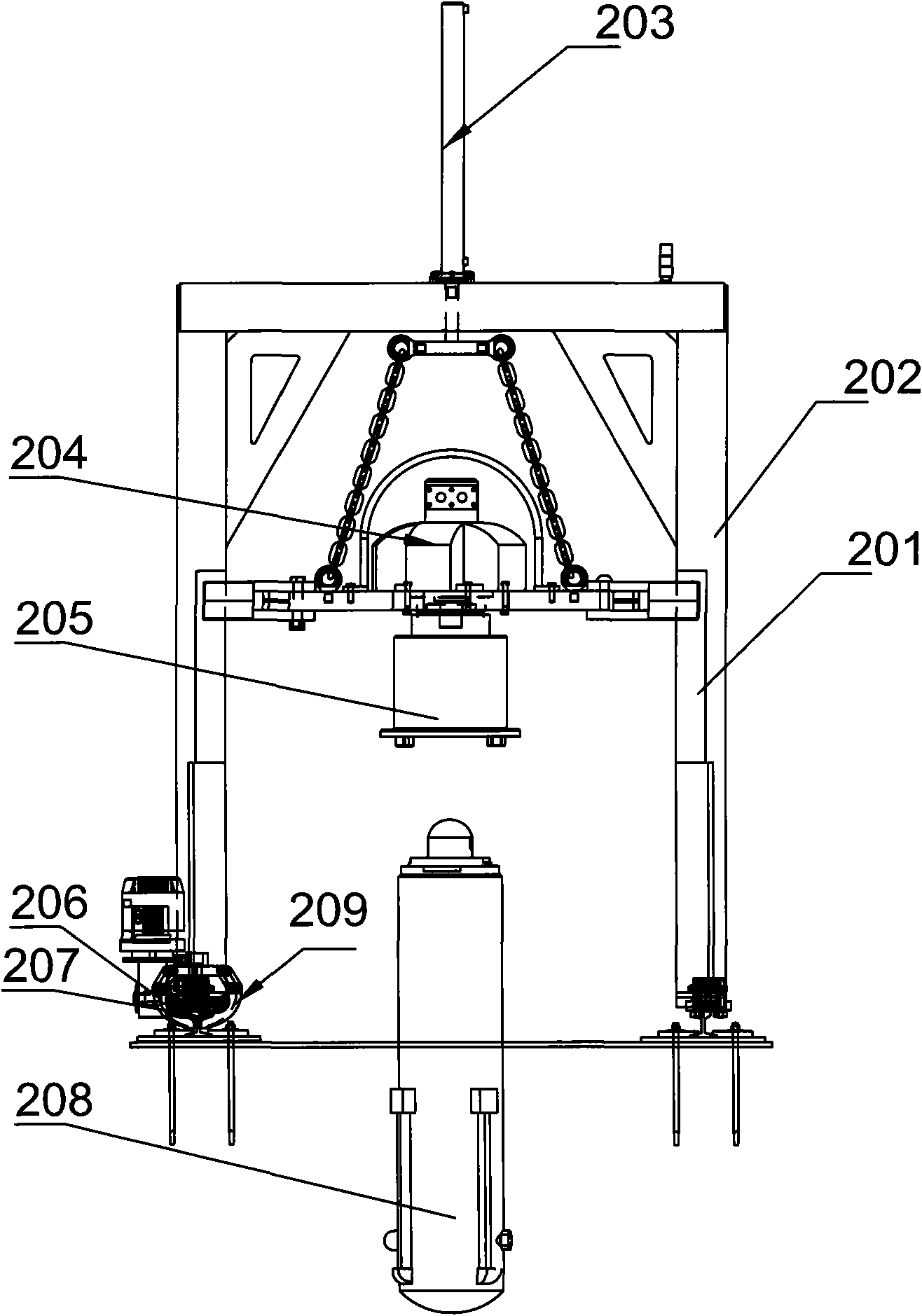

PendingCN109847198ASolve disagreementShorten radiation therapy timeX-ray/gamma-ray/particle-irradiation therapyHuman bodyEngineering

The invention provides an accelerator adjusting device. The adjusting device comprises a machine head bearing frame, a machine head lifting adjusting device and a deflection bracket. The accelerator adjusting device can respectively adjust the up and down height of a machine head and left and right deflection displacement, and solves the problems that the tumor and the entire rotary treatment center of equipment are in non-concentricity caused by structure limitation of image radiography equipment. Besides, when normal human body tissue can be used for shielding tumors, radioactive source deflection can be performed to prevent illumination on normal human body tissue, the radiation treatment time of patients can be shortened, and the radiotherapy effect is increased. The accelerator adjusting device is used for radiotherapy equipment introduced by the image radiography equipment, and is used for solving the problems that a conventional product can only perform single dimensionality radiation treatment.

Owner:RAY PLUS MEDICAL TECH CO LTD

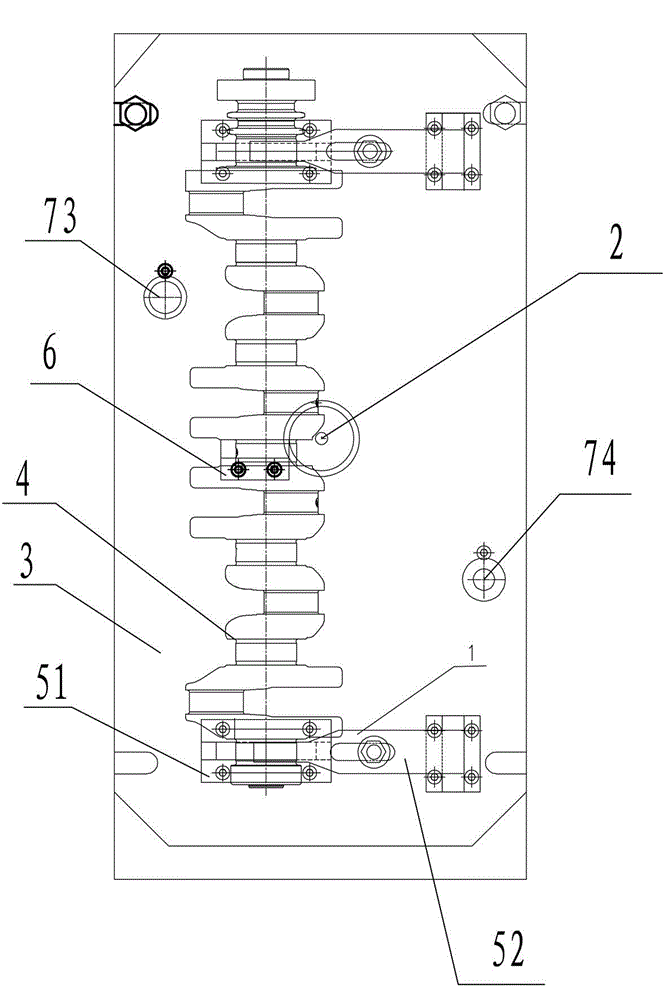

Method for positioning carrier roller shaft and carrier roller drum in grabbing fingers

InactiveCN104308854ASolve the problem of inconsistency in positioningSolve disagreementGripping headsProduction lineWorkstation

The invention discloses a method for positioning a carrier roller shaft and a carrier roller drum in grabbing fingers, belongs to the technical field of manufacturing equipment for belt transport equipment, and is applied to a carrying manipulator in a belt conveyor carrier roller production line. The grabbing forms of the carrying manipulator in the belt conveyor carrier roller production line comprise automatic centering clamping, magnetic clamping and the like, those devices are not concentric with a clamp positioning mechanism in the processes of grabbing and releasing a part, and the positioning relationship of the grabbed part on fingers of the manipulator and the stability of the part in the carrying process are also related to positioning of two workstations before and after moving. By the method, decentraction of the manipulator and the clamp positioning mechanism in the carrying process is solved; according to the scheme, the grabbing process adopts two groups of fingers in opposite movement; after being closed, the fingers form two groups of V shapes in the same straight line; the part is fixed on a V-shaped positioning surface by virtue of self weight, so that the grabbed part can be taken down when the part is clamped by a clamp and is positioned; by the method provided by the invention, the positioning decentraction of the manipulator and the clamp is effectively solved.

Owner:SHENYANG JINGRUI CNC MACHINE TOOL

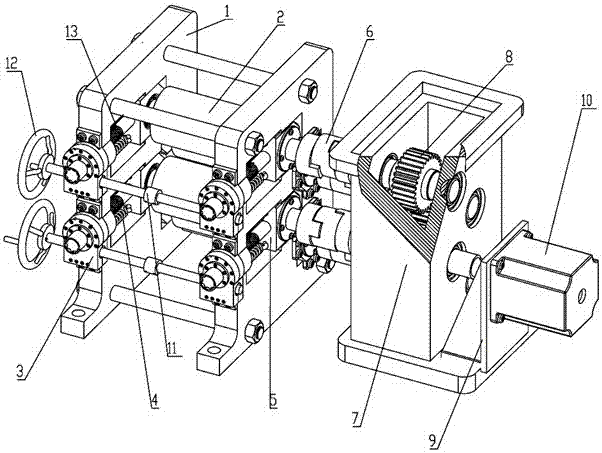

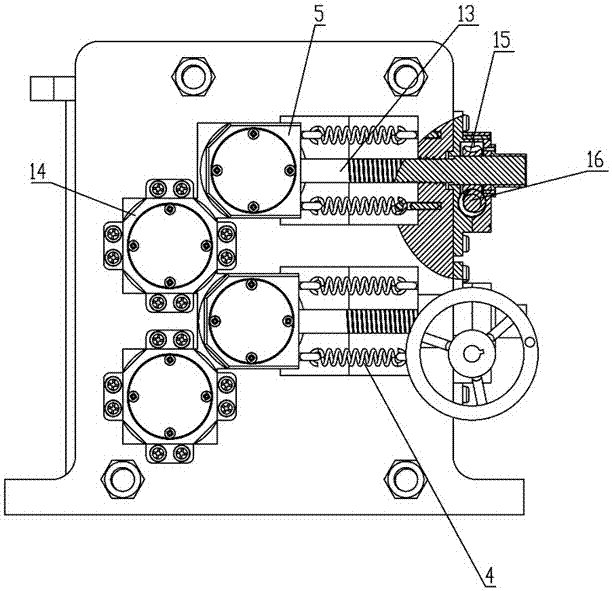

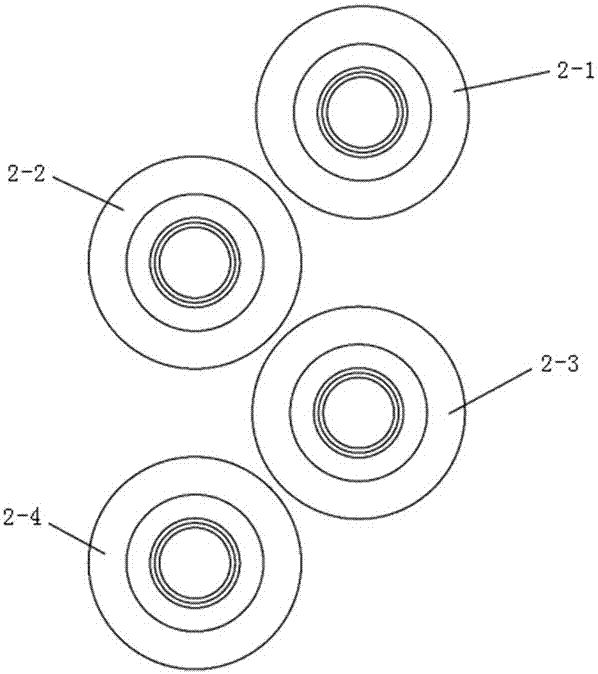

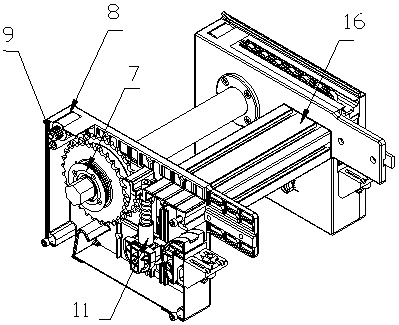

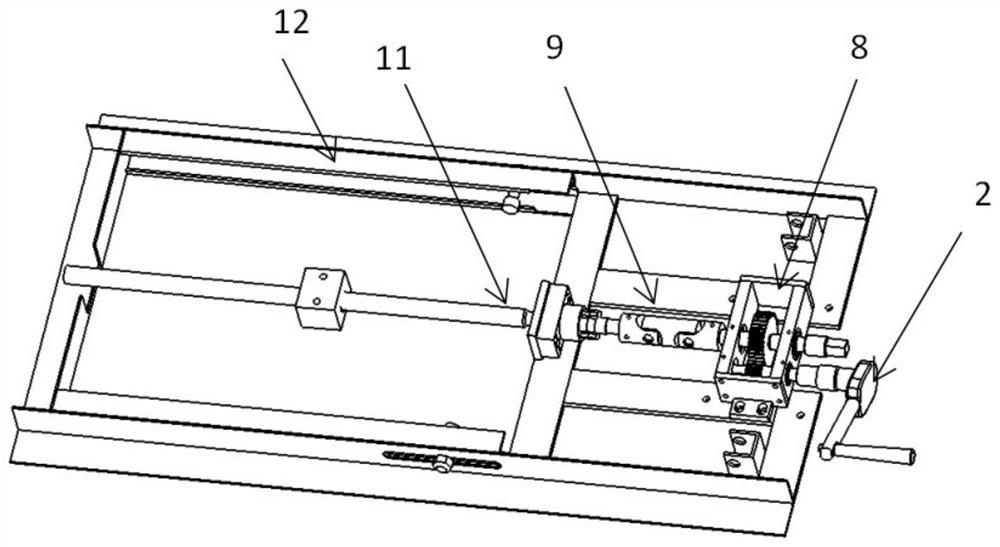

Small calendaring device for producing special sealing adhesive tape for full-automatic dyed film sealing machine

InactiveCN107984667AHigh transmission precisionLarge transmission torquePreparing sample for investigationRoller bearingEngineering

The invention discloses a small calendaring device for producing a special sealing adhesive tape for a full-automatic dyed film sealing machine. The calendaring device comprises a rack, a roller, a roller bearing seat, a worm-gear roller space adjusting device, a balance spring, a roller temperature adjusting device and a synchronous gear box. The precise small calendaring device provided by the invention is mainly used for producing the high-precision sealing adhesive tape applied to the full-automatic dyed film sealing machine, the size of the calendaring device is greatly reduced, the problem of roller space adjustment is solved, the problem of power transmission after roller space changing is solved, a production process is simplified, meanwhile, the flexibility and the processing precision in processing the special sealing adhesive tape for the film sealing machine are ensured, and the small calendaring device is adapted to producing the special sealing adhesive tape for the filmsealing machine.

Owner:HARBIN INST OF TECH +2

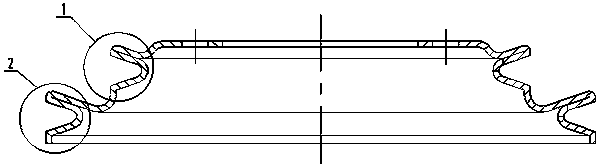

Resilient disc type coupling

InactiveCN102072263APrevent bolts from looseningSimple structureYielding couplingSynchronismEngineering

The present invention relates to a resilient disc type coupling comprising a driving shaft connecting piece and a driven shaft connecting piece, wherein both the driving shaft connecting piece and the driven shaft connecting piece are composed of shaft sleeves and connecting discs. The shaft sleeve and the shaft are coaxially fixed at the outboard end face of the connecting disc; a plurality of projections are uniformly distributed radially on the external circumference of the connecting disc; the connecting discs of the driven shaft connecting piece and the driving shaft connecting piece are symmetrically buckle-connected, and are fixed through radial connecting sheets arranged among the spacing projections. The resilient disc type coupling provided by the present invention is simple in structure and low in cost. As the torque between the driving shaft and the driven shaft is transmitted, and the non-concentricity between the driving shaft and the driving shaft is compensated through the radial connecting sheets, and the bolts arranged on the two sides of the radial connecting sheets are prevented from loosening through cushion blocks, the resilient disc type coupling is convenient in maintainance, large in transmission moment, excellent in angular synchronism, and safe and stable in torque transmission.

Owner:CHINA PACKAGING RES & TEST CENT

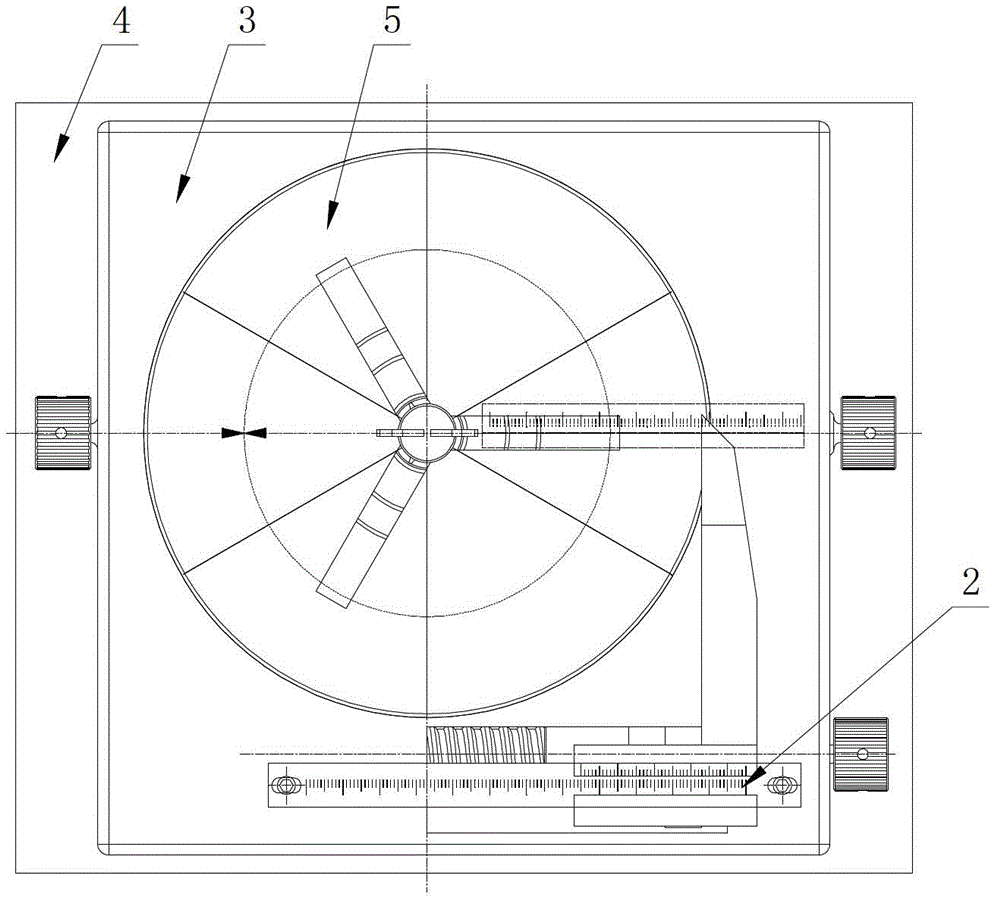

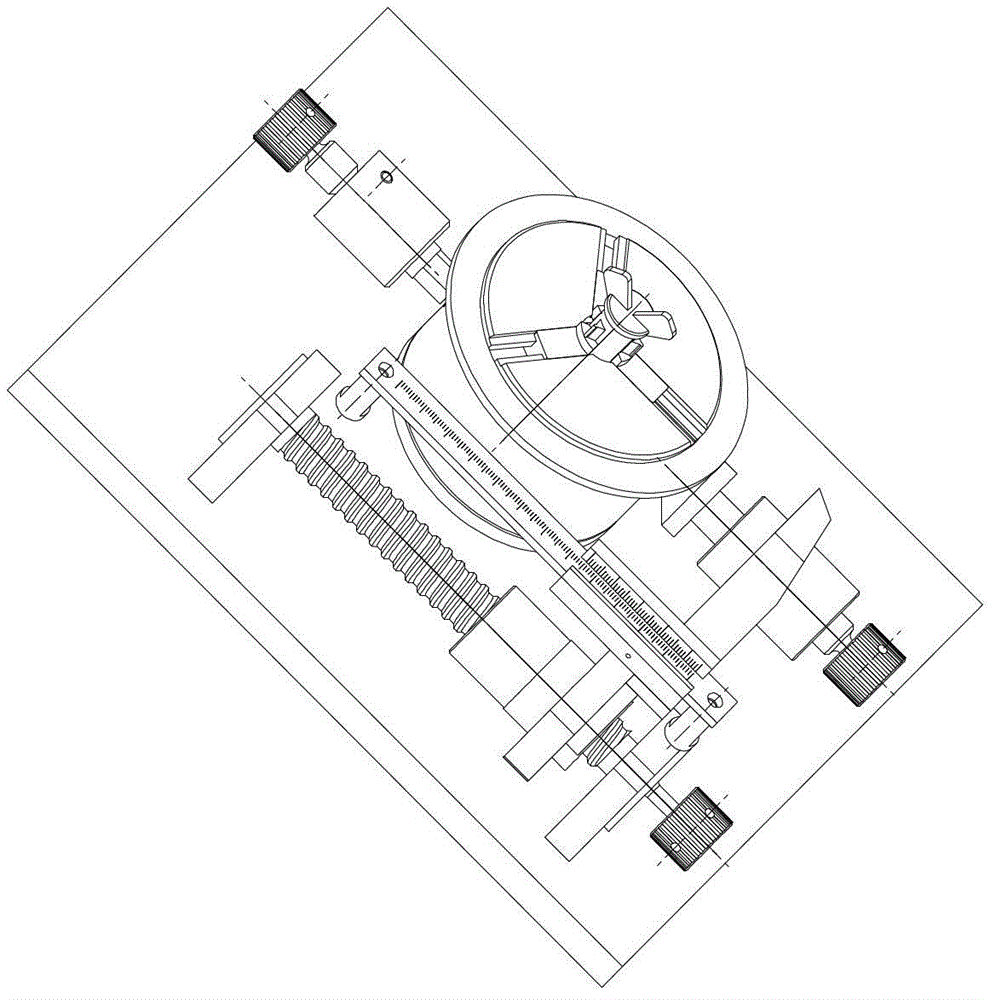

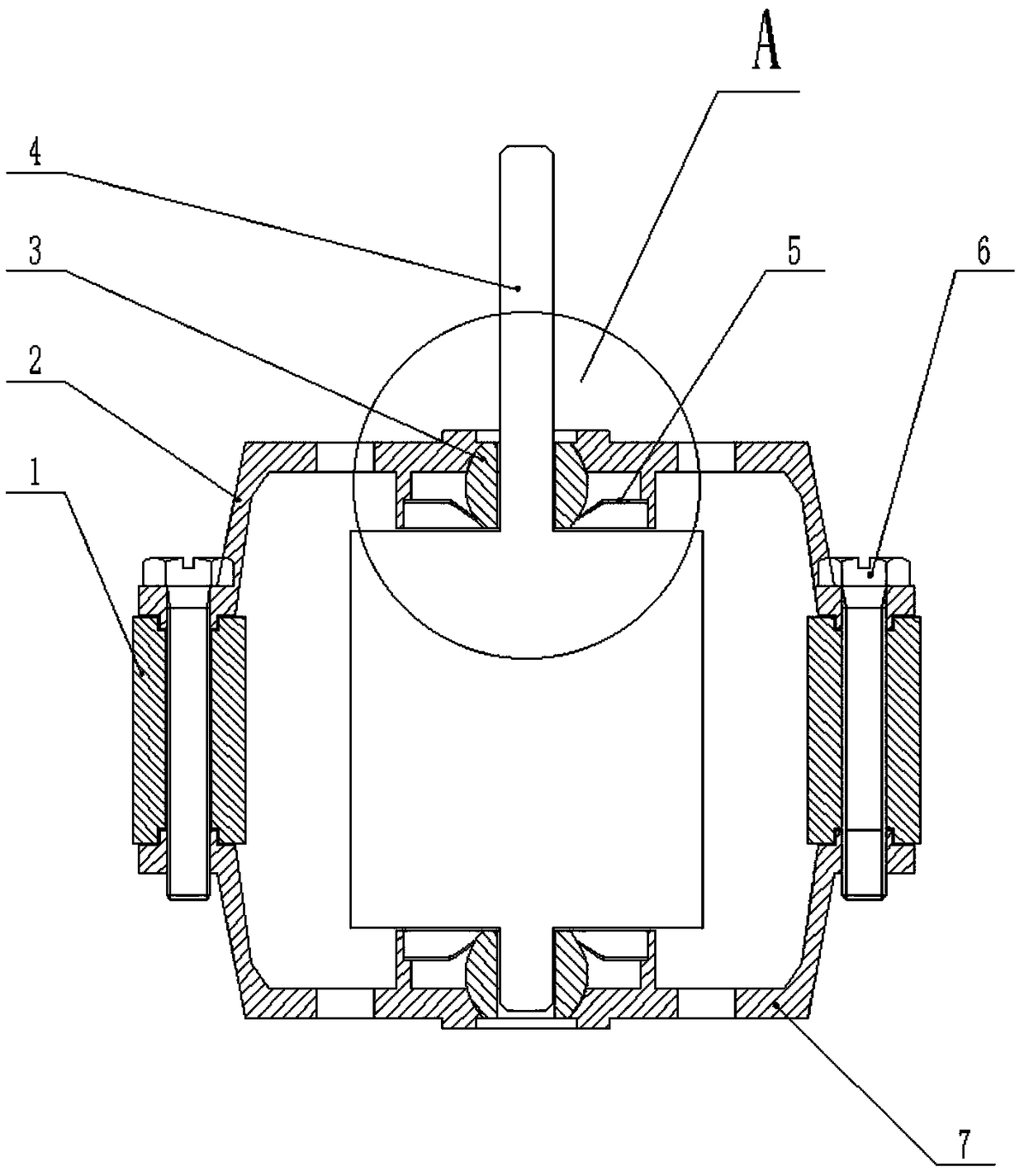

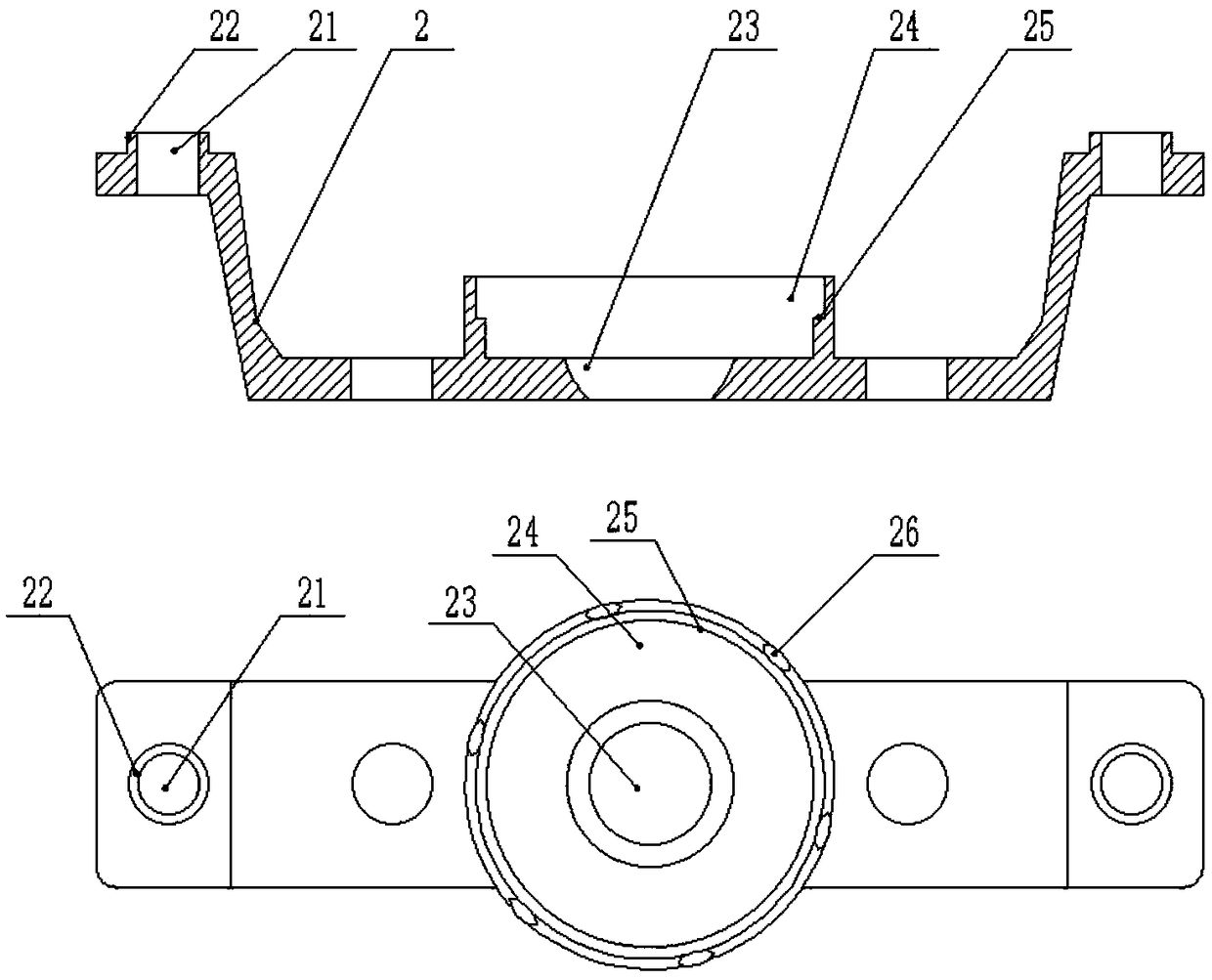

A method for measuring cable insulation thickness and eccentricity and corresponding measuring device

ActiveCN103292665BGuaranteed accuracyFast measurementMechanical thickness measurementsInsulation layerMeasurement point

The invention relates to a method and a corresponding device for measuring the cable insulation thickness and eccentricity. The method includes the following steps: (1) selecting and manufacturing a testing piece of a cable to be measured; (2) placing the manufactured testing piece on a portable cable measuring device, determining the circle center and fixing the testing piece; (3) rotating the testing piece to determine the thinnest point and recording the smallest thickness values of an insulation layer, an inner semi-conductive layer and an outer semi-conductive layer; (4) rotating the testing piece to determine any other N locating measuring points, and recording four values of the insulation layer, the inner semi-conductive layer and the outer semi-conductive layer of each locating measuring point; and (5) calculating three eccentricity values and three deviation degree values of the insulation layer, the inner semi-conductive layer and the outer semi-conductive layer of the testing piece of the cable according to a formula. The method and the corresponding device can remove manual errors and improve measuring efficiency and measuring result accuracy. By means of the method, the problem in a traditional method that the cable with the insulation layer, the inner semi-conductive layer and the outer semi-conductive layer even in thickness but deviated in circle centers can not be detected is solved, and a gap in the field of cable detecting is filled.

Owner:STATE GRID CORP OF CHINA +1

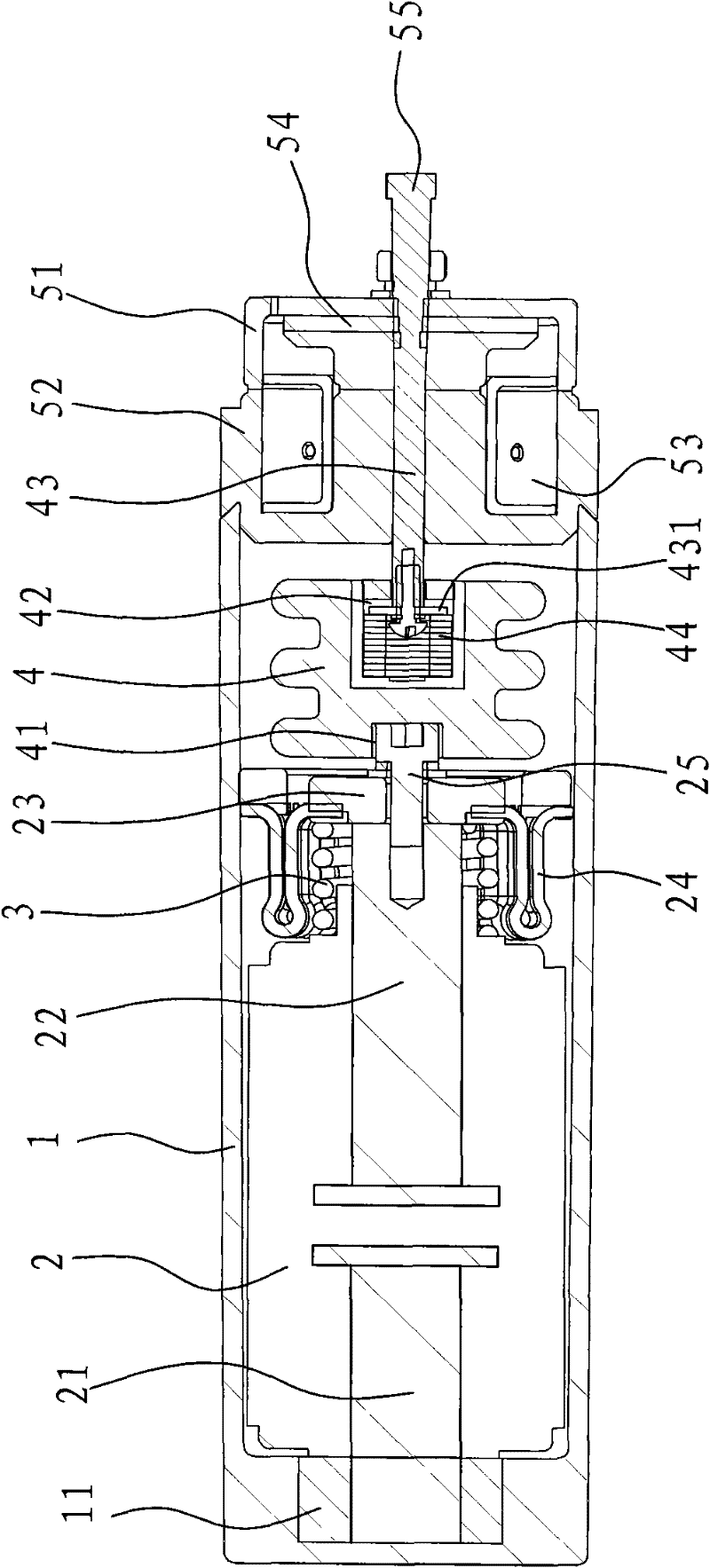

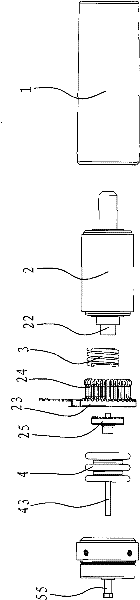

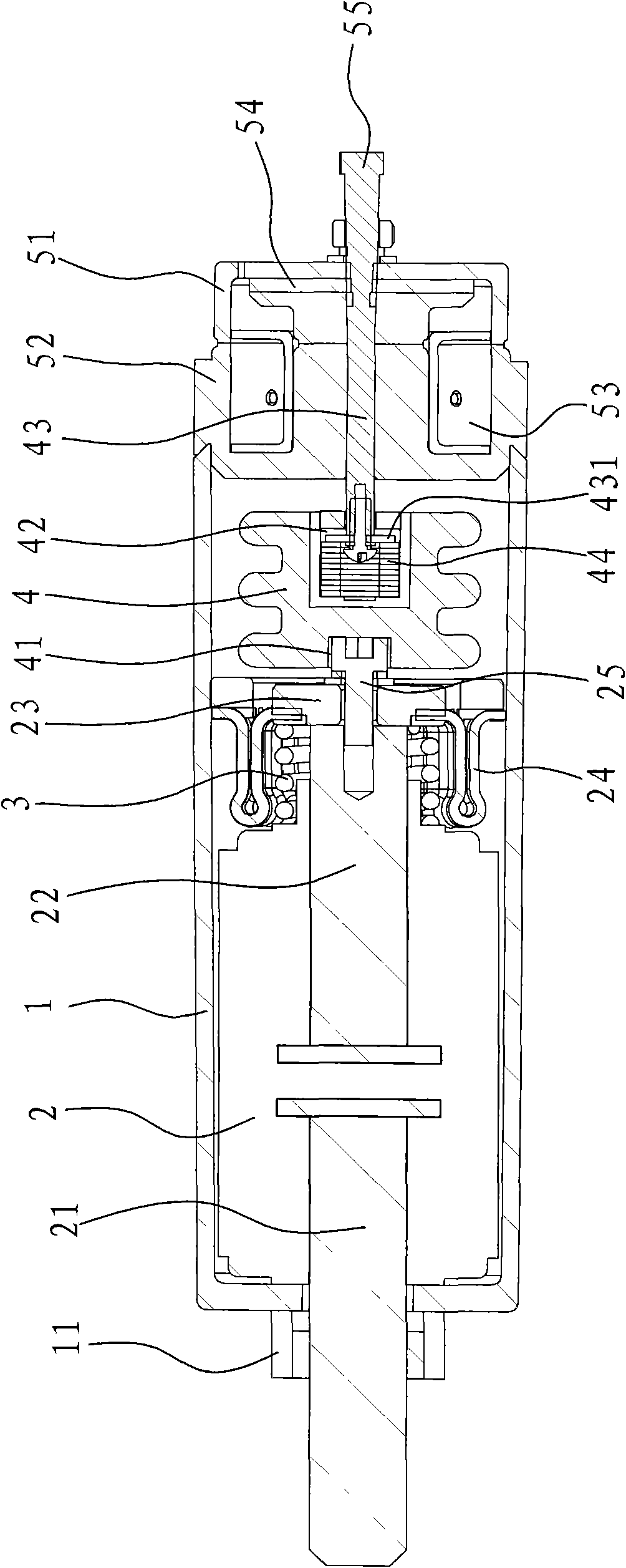

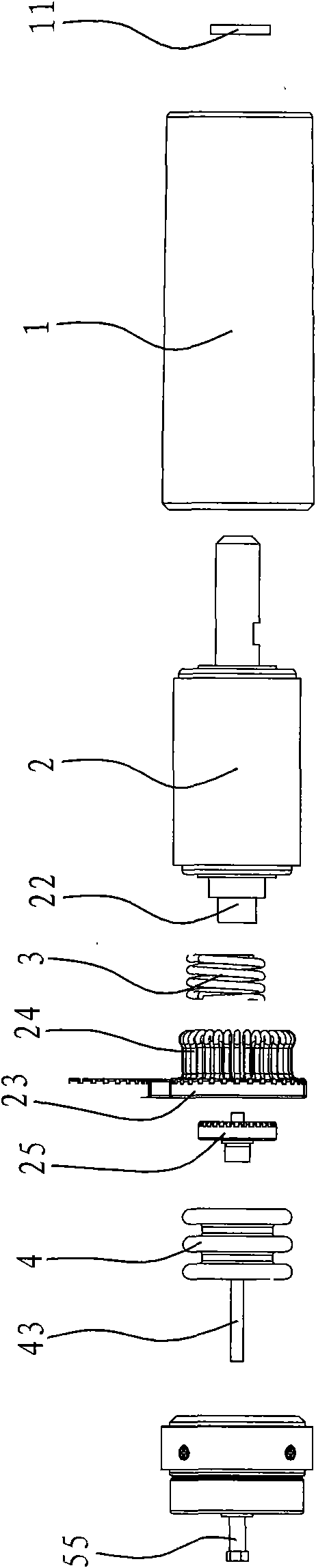

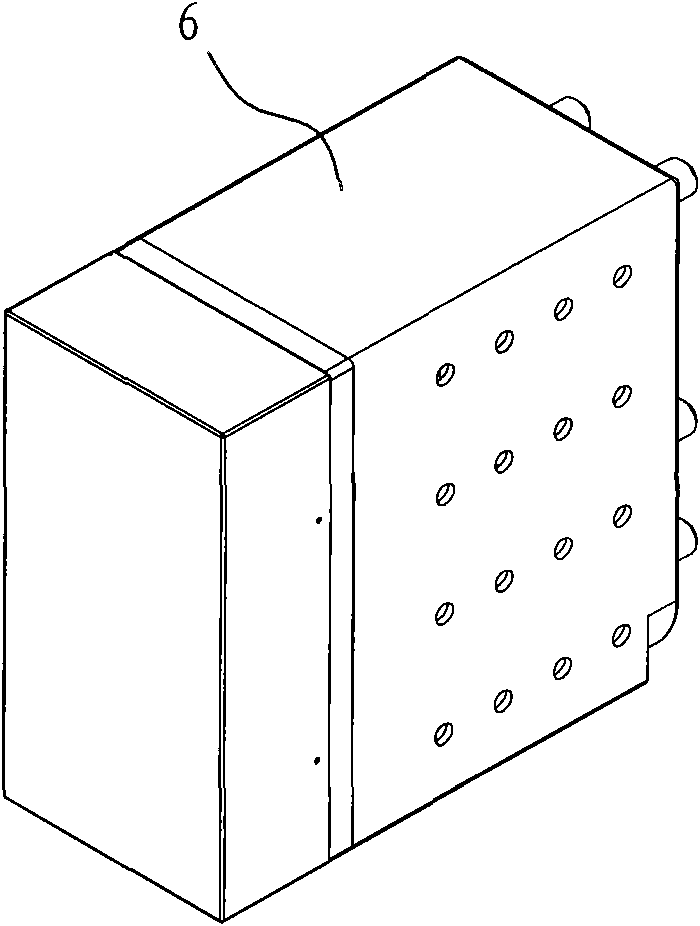

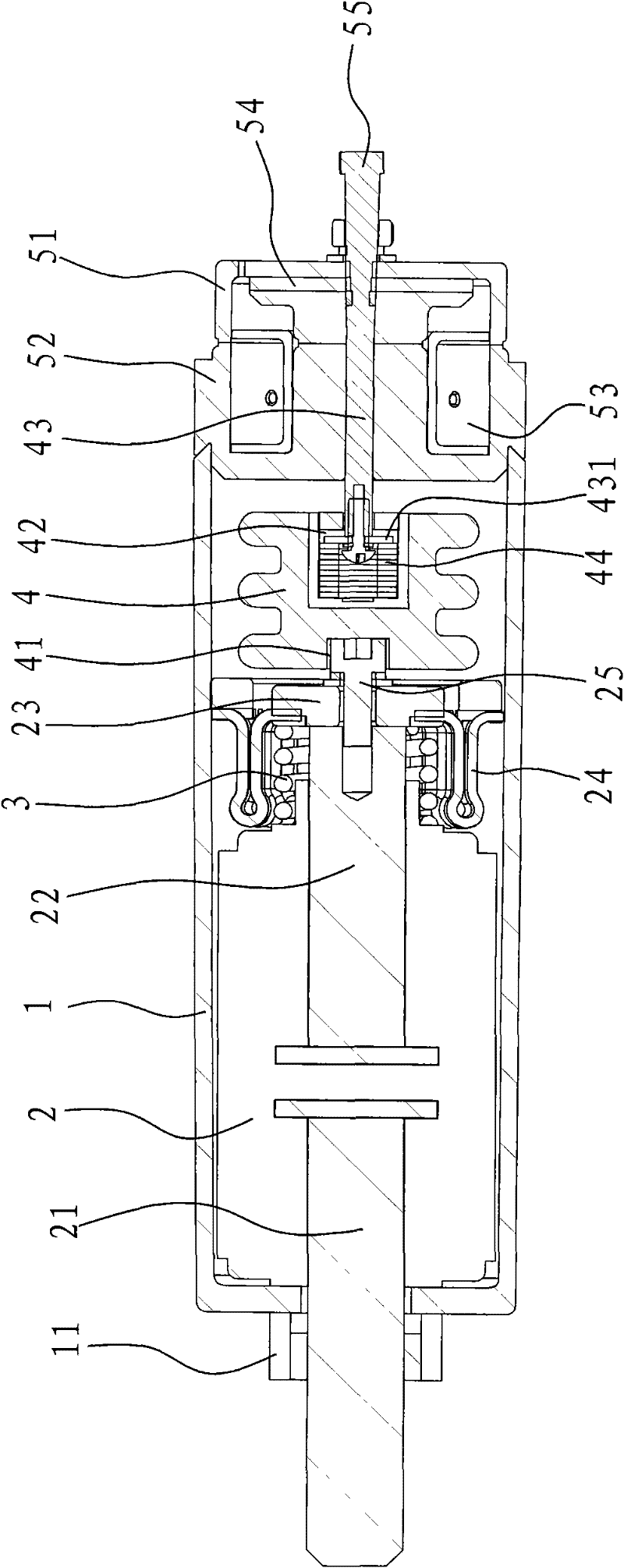

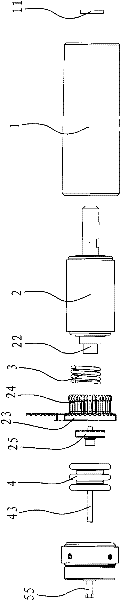

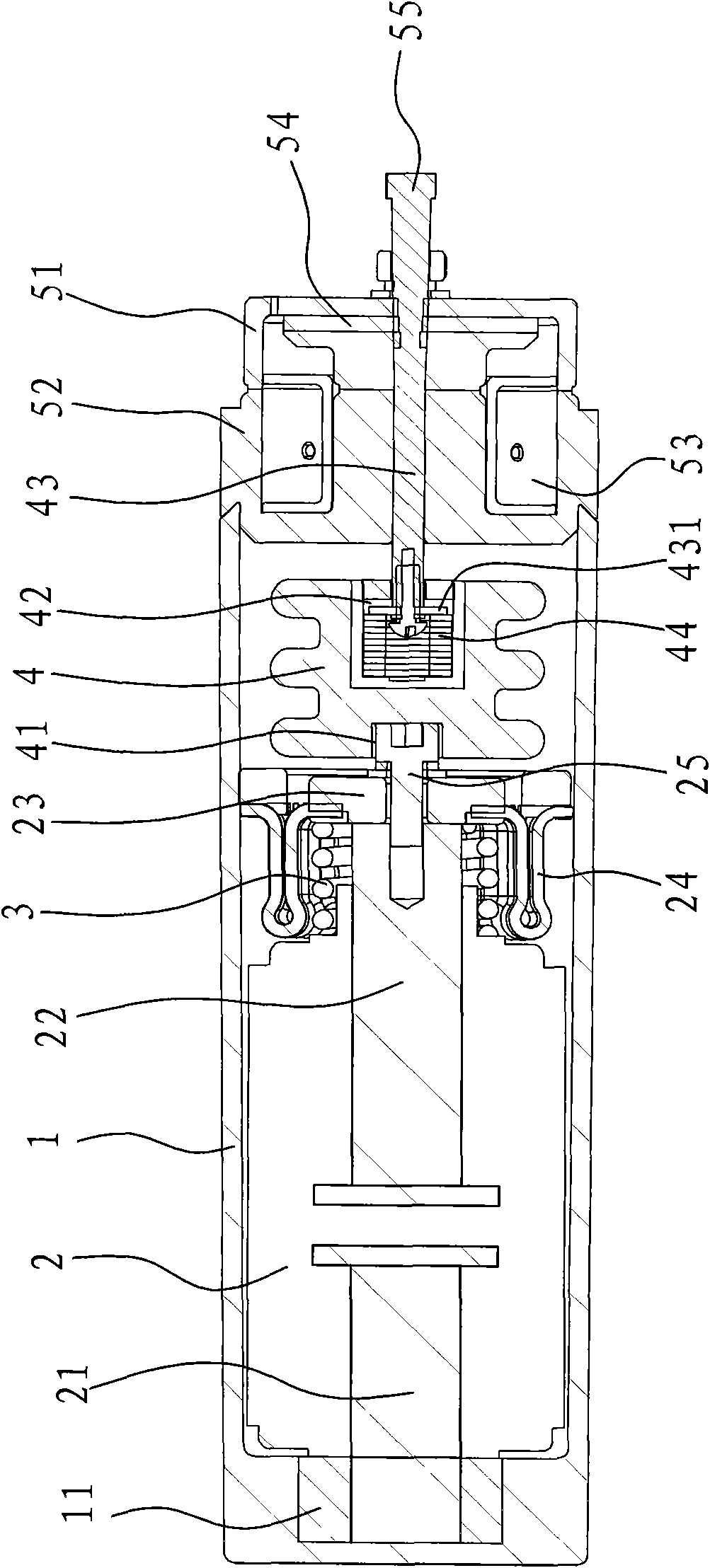

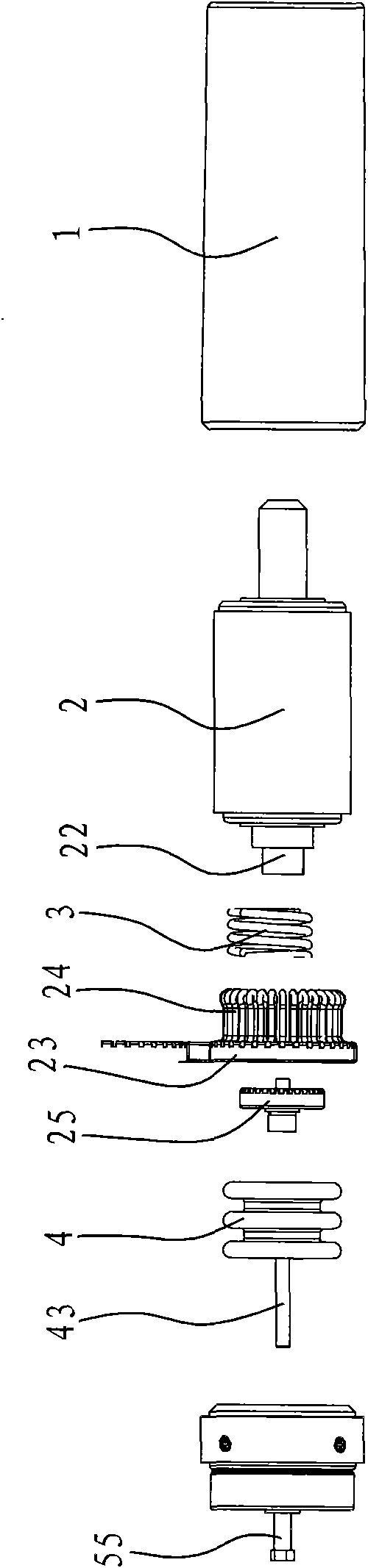

Small-power motor

InactiveCN108667190ASolve disagreementReduce noiseMagnetic circuit rotating partsSupports/enclosures/casingsLow noiseEngineering

A small-power motor comprises a rotor, wherein a rotor is movably arranged between an upper cover and a lower cover, through holes and upper positioning convex shoulders are processed in two ends of the upper cover, threaded holes and lower positioning convex shoulders are correspondingly processed in the lower cover, the upper cover and the lower cover are fixed on a support by bolts, spherical-surface shaft sleeve positioning holes and counter holes are formed in middle parts of the upper cover and the lower cover, counter shoulders are arranged in the counter holes, spherical-surface shaftsleeves are arranged in the shaft sleeve positioning holes and are provided with elastic baffle sheets in a matching way, the elastic baffle sheets are limited by the counter shoulders and riveting grooves, and the riveting grooves are processed in the circumferences of the counter holes. The spherical-surface shaft sleeves are used for installing a rotor, and the problem that the spherical-surface shaft sleeve positioning holes of the upper cover and the lower cover are not concentric after actual processing can be solved; and meanwhile, the motor has the advantages of safety, reliability, low noise, good starting performance, long service lifetime and the like.

Owner:舟山市敏瑞科技咨询有限公司

A floating winding device and winding method thereof

Owner:烟台泰悦流体科技有限公司

Permanent magnet vacuum unidirectional switch and multifunctional composition switch provided with same

ActiveCN102194602BAvoid short circuitPrevent rejectionHigh-tension/heavy-dress switchesAir-break switchesElectricityVacuum circuit breakers

The invention relates to a permanent magnet vacuum unidirectional switch and a multifunctional composition switch provided with the same. The permanent magnet vacuum unidirectional switch comprises a shell, a vacuum circuit breaker and a permanent magnet driving mechanism, wherein, the vacuum circuit breaker comprises a stationary contact end and a dynamitic contact end; the permanent magnet driving mechanism drives the stationary contact end and the dynamitic contact end to be closed, and comprises an insulator; a counter-force spring which drives the dynamitic contact end to move is sheathed on the dynamitic contact end; the dynamitic contact end is in clearance fit with the insulator, and is not directly connected with the insulator, the permanent magnet driving mechanism drives the stationary contact end and the dynamitic contact end to be closed through the insulator, and when in closing, the dynamitic contact end and the insulator can automatically find a concentricity, thus avoiding the problems such as abrasion, unequal contact surfaces and the like. By utilizing the composition switch, the closing and openness of a plurality of permanent magnet vacuum unidirectional switches can be combined and controlled, thus the composition switch has a breaker function, a contactor function, a contactor reversing function, a breaker and contactor function and a breaker and contactor reversing function, thus satisfying the requirements of electricity utilization of different equipment; and the adaptability is more comprehensive.

Owner:YANGQUAN HUASHENG MINING EQUIP FACTORY

Improved pouring type casting production device

The invention discloses an improved pouring type casting production device which comprises a frame, a program control assembly, an oil cylinder assembly, an upper mould, a bottom mould and side moulds, wherein the program control assembly, the oil cylinder assembly, the upper mould, the bottom mould and the side moulds are arranged on the frame. The program control assembly controls the movement of the oil cylinder, the oil cylinder is connected with the bottom mould, the bottom mould is arranged under the upper mould, and the side moulds are arranged on the periphery of the upper mould. The improved pouring type casting production device further comprises a demoulding mechanism, the upper end of the demoulding mechanism is fixedly connected with the bottom mould, the lower end of the demoulding mechanism is connected with the oil cylinder assembly, and the oil cylinder assembly drives the demoulding mechanism to drive the bottom mould to move downwards. The improved pouring type casting production device only utilizes one power cylinder in the demoulding operation to enable a casting to be separated from the bottom mould smoothly, and meanwhile, solves the problem of decentraction caused by an overlong stroke in demoulding, so that the casting quality is improved.

Owner:厦门民兴工业有限公司

Improved pouring type casting production equipment

The invention discloses an improved pouring casting production equipment, which includes a machine frame and a program control assembly located on it, an oil cylinder assembly, an upper mold, a bottom mold, and a side mold. The program control assembly controls the movement of the oil cylinder assembly, and the oil cylinder assembly and the bottom mold Die connection, the bottom mold is located under the upper mold, the side mold is located around the upper mold, and also includes a lower release mechanism, the upper end of which is fixedly connected with the bottom mold, and its lower end is connected with the oil cylinder assembly, and the oil cylinder assembly drives the lower release mechanism to drive the bottom mold Downward movement. The improved equipment only uses one power cylinder for the demoulding action, which makes the parting of the casting and the bottom mold more smooth, and at the same time solves the problem of non-concentricity caused by the long stroke during the demoulding, and improves the quality of the casting.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

Permanent magnetic vacuum unidirectional switch and circuit breaker and contactor combined switch

InactiveCN102194603APrevent rejectionSolve disagreementHigh-tension/heavy-dress switchesAir-break switchesVacuum circuit breakersContactor

The invention relates to a permanent magnetic vacuum unidirectional switch and a circuit breaker and contactor combined switch. The permanent magnetic vacuum unidirectional switch comprises a shell, a vacuum circuit breaker and a permanent magnetic driving mechanism, wherein the vacuum circuit breaker comprises a static contact and a moving contact; the permanent magnetic driving mechanism is used for driving the moving contact and the static contact to be closed and comprises an insulator; and a reaction spring for driving the moving contact to move is sleeved on the moving contact, the moving contact is movably matched to the insulator, and the permanent magnetic driving mechanism drives the moving contact and the static contact to be closed through the insulator. The moving contact and the insulator are movably matched and not directly connected, and therefore automatic centering can be realized in closing, and the problems of wearing, uneven contact surface and the like can be avoided. The combined switch is used for carrying out combined control on the closing and opening of a plurality of permanent magnetic vacuum unidirectional switches through a controller, so that the combined switch has the functions of a circuit breaker, the functions of a contactor and the functions of both the circuit breaker and the contactor. The power utilization needs on unused equipment are satisfied, and the adaptability is more comprehensive.

Owner:张琪

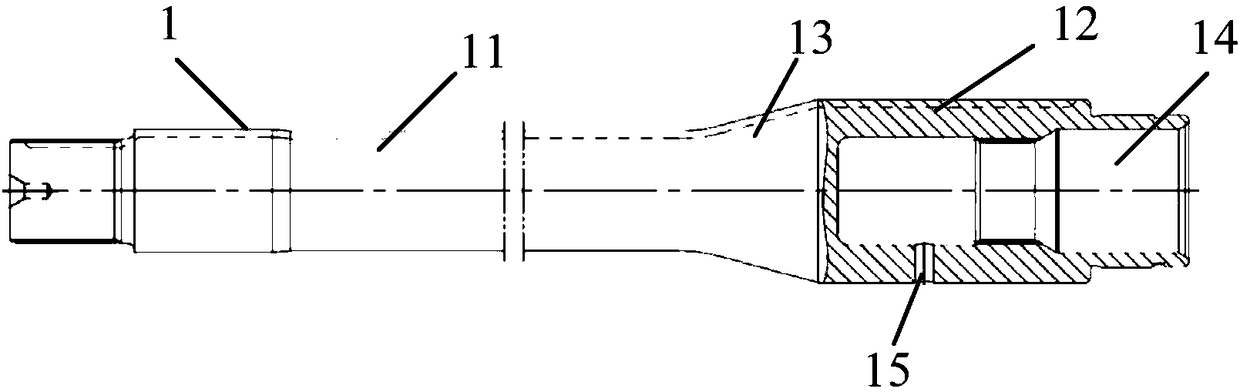

Automobile and front axle inner half shaft thereof

PendingCN108248292AAvoid the problem of weak solder jointsCompact designShaftsAxle unitsAutomotive engineering

The invention provides an automobile and a front axle inner half shaft thereof. The automobile front axle inner half shaft comprises an integrated shaft structure, the shaft structure comprises a shaft rod portion, a gear sleeve portion and a transition portion, the diameter of the shaft rod portion is a first number value, the diameter of the gear sleeve portion is a second number value, the first number value is smaller than the second number value, the transition portion is connected with the shaft rod portion and the gear sleeve portion, an outer spline is arranged at the tail end of the shaft rod, and an inner spline is arranged at the tail end of the gear sleeve portion. The automobile front axle inner half shaft is integrated and avoids a fact than a plurality of components are welded to form a traditional automobile front axle inner half shaft, and the firmness of the automobile front axle inner half shaft is improved.

Owner:BAIC GRP ORV CO LTD

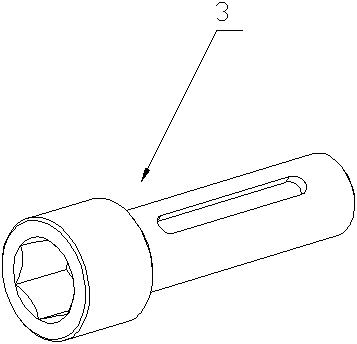

Conveyor drive mechanism provided with hexagonal through shaft and motor adapter sleeve shaft

Owner:DALIAN MODULAR ASSEMBLY TECH

Power device for spraying paint

The invention relates to a power device for spraying paint. The power device comprises a fixed frame, a movable frame, a driving motor and a connector. The movable frame is arranged on the fixed frameand can move relative to the fixed frame. The driving motor is arranged on the movable frame, and the driving motor is used for driving the connector to rotate. The connector is matched with a jointin a direction control device. The power device for spraying the paint is compact in structure and ingenious in design, and is matched with the direction control device in a paint spraying process ina detachable connection manner, so that a workpiece arranged in the direction control device is driven to rotate; and in addition, the problem that the axis of the connector and the axis of the jointare not concentric and the problem that the connector cannot restore an initial position conveniently can be effectively solved, and therefore paint spraying work is completed precisely and efficiently at low cost.

Owner:SICHUAN GUORUAN SCI & TECH DEV CO LTD

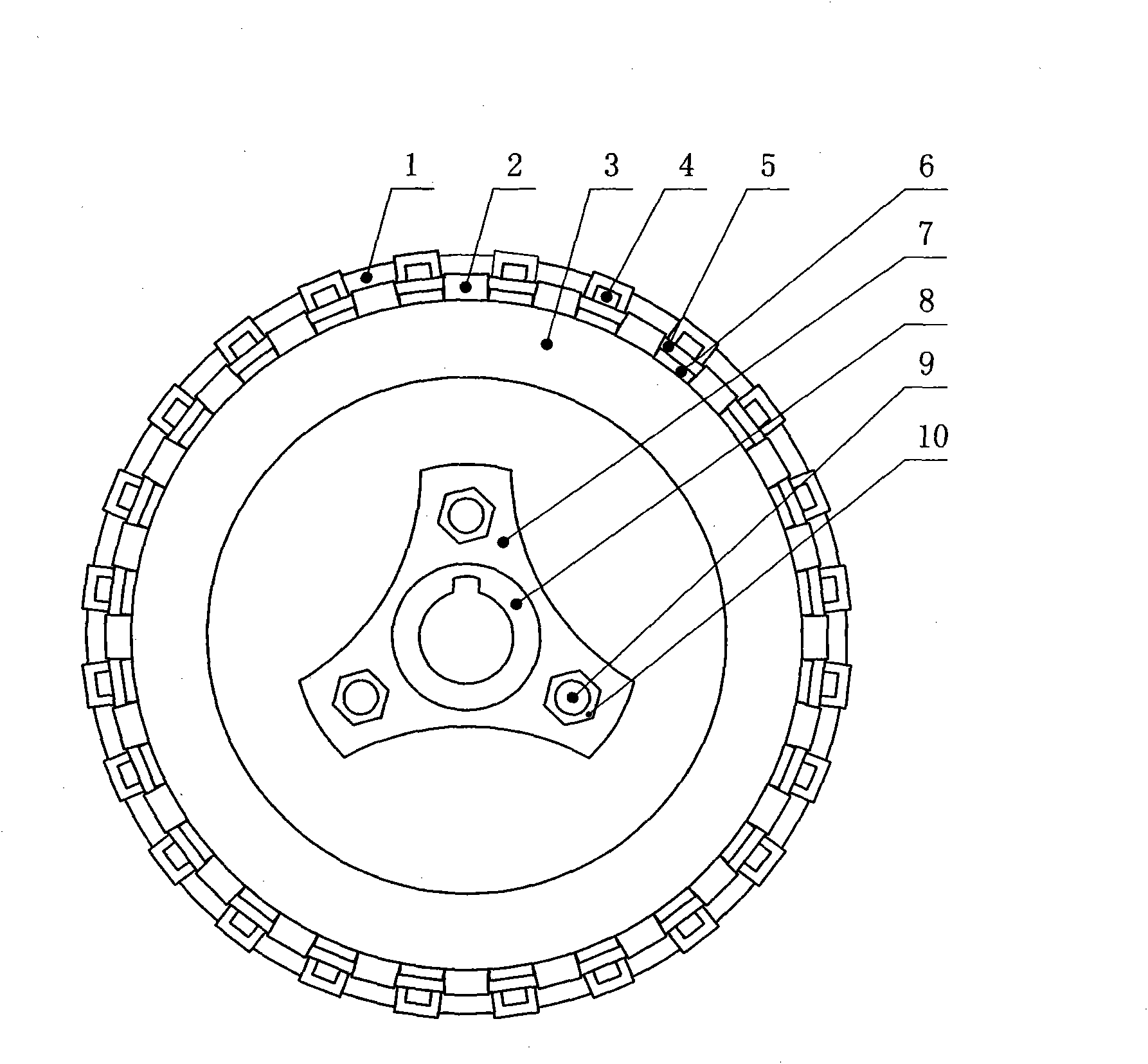

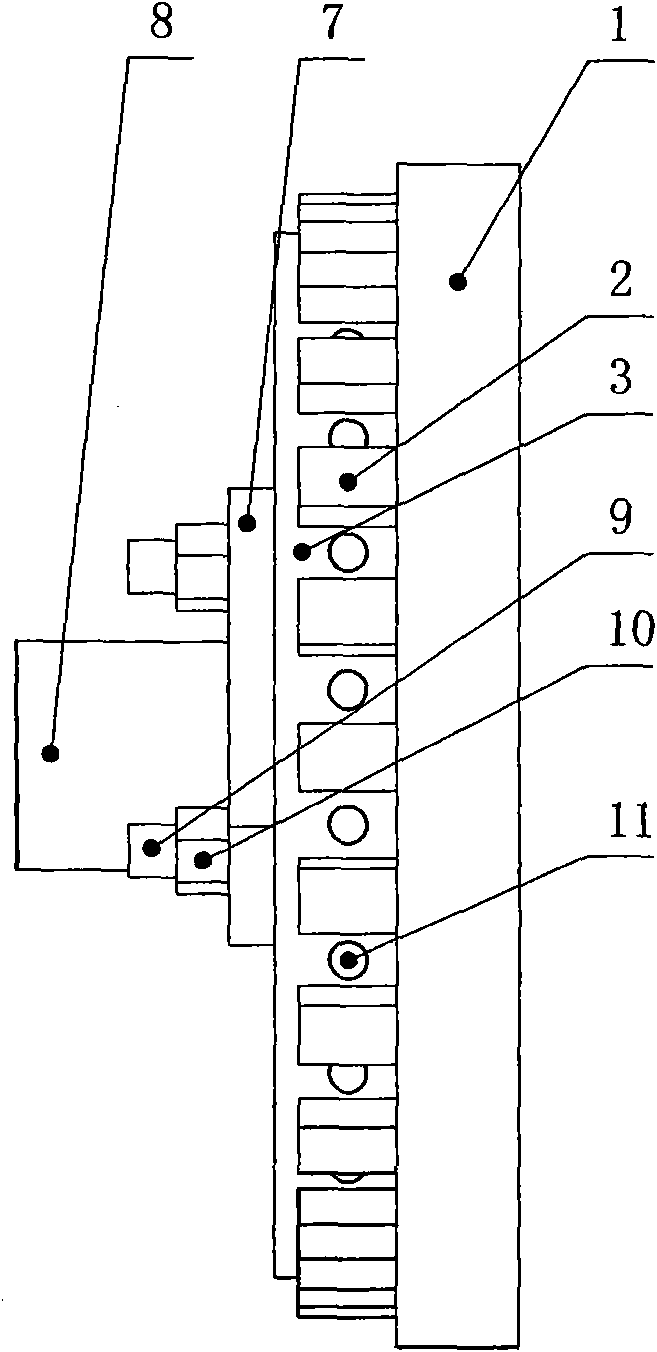

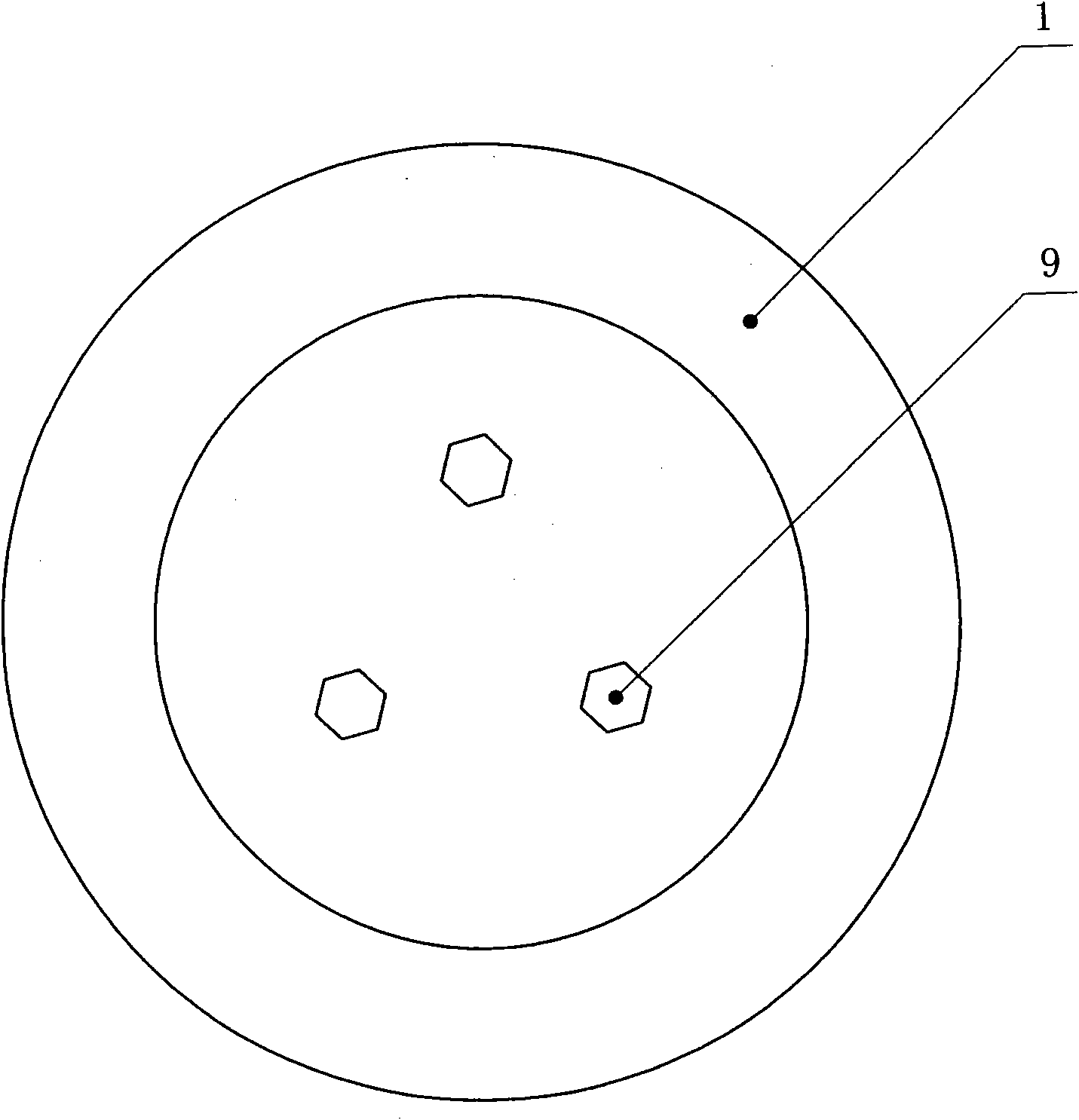

Abrasion-free abrasive disc type solid-liquid separator

The invention discloses an abrasion-free abrasive disc type solid-liquid separator which comprises a rack (17), a driving mechanism and a solid-liquid separating mechanism. The driving mechanism is connected with the solid-liquid separating mechanism, the rack (17) is arranged on the lower portions of the driving mechanism and the solid-liquid separating mechanism, the solid-liquid separating mechanism comprises a box, a feeding port (3) is formed in the front portion of the box, a solid discharging port (10) is arranged on the rear portion of the box, a water collector (18) is arranged on the lower portion of the box and provided with a water outlet, and a separating component is arranged inside the box. The abrasion-free abrasive disc type solid-liquid separator has grinding effect, hard particles or fibers entering a piece gap of the separating component are cut and ground through relative rotation of movable and fixed pieces, self-cleaning is realized through effect of water flow in the piece gap, and blockage or unsmooth drainage is avoided. Parameters like depth and angle of a spiral groove can be changed according to inter-face materials.

Owner:HENAN INST OF ENG

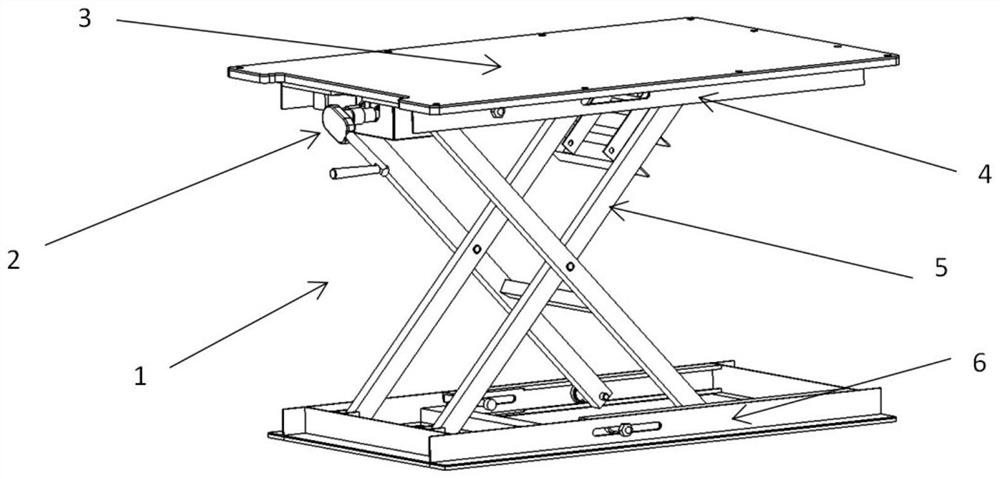

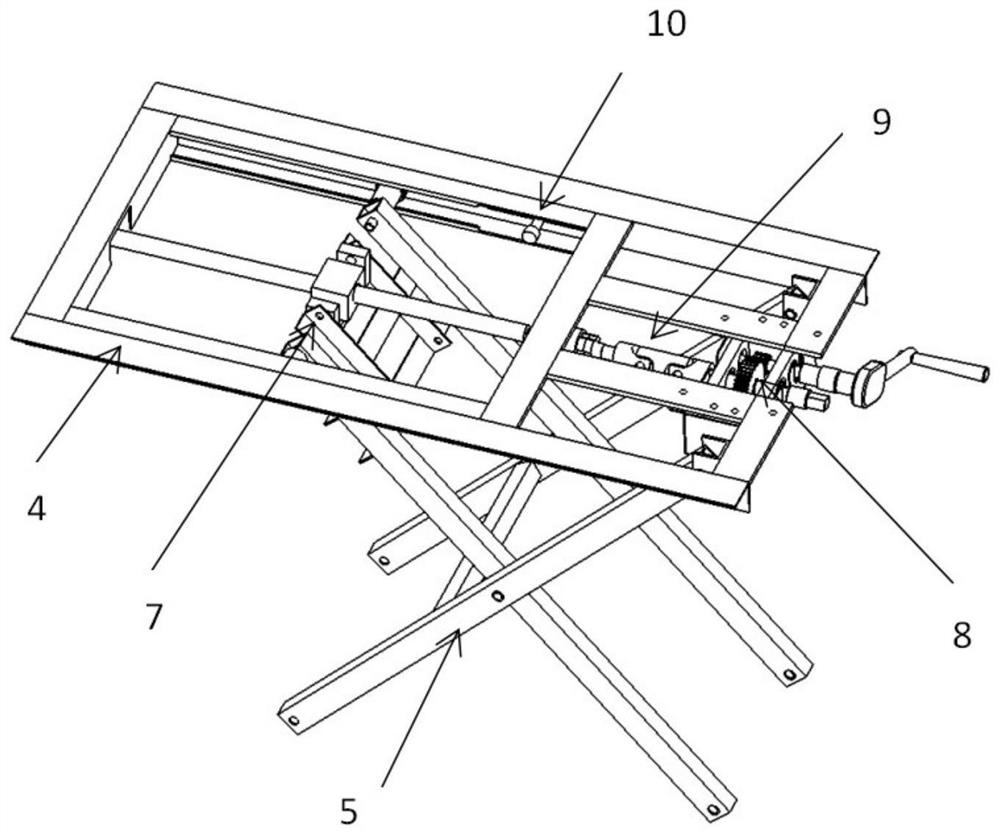

Manual lifting platform and assembling method thereof

The invention provides a manual lifting platform. The manual lifting platform comprises a ratchet hand crank, a product placing panel, a platform upper frame, platform lifting arms and a platform lower frame; the platform upper frame and the platform lower frame are directly connected and matched with the platform lifting arms for use; the platform lifting arms comprise a first lifting arm and a second lifting arm, and the first lifting arm and the second lifting arm are arranged in a scissor type; one end of the first lifting arm is fixedly connected to the platform upper frame, and the otherend of the first lifting arm is connected to the platform lower frame in a sliding mode; one end of the second lifting arm is connected to the platform upper frame in a sliding mode, and the other end of the second lifting arm is fixedly connected to the platform lower frame; and the ratchet hand crank drives a gear module mechanism to rotate, and the platform lifting arms can enable the productplacing panel to ascend or descend. According to the manual lifting platform, by adopting the technology that the lifting arms are directly connected with the platform upper frame and the platform lower frame, connecting holes on two sides are parallel and concentric in a two-head connection mode, the good synchronism is achieved, and the lifting process is smoother and more stable.

Owner:芝纶自动化科技(上海)有限公司

Locating mechanism for machining two ends of crank shaft

ActiveCN102717275BPlay the role of vertical fixationWon't shakePositioning apparatusMetal-working holdersRotational axisCrankshaft

The invention discloses a locating mechanism for machining the two ends of a crank shaft, comprising a support frame, a rotating shaft, a driven plate and a crank shaft fixing device, wherein the support frame is fixed on ground and is provided with a vertical working surface; the rotating shaft is horizontally arranged at the middle part of the working surface of the support frame; the driven plate is vertically arranged, is fixed on the rotating shaft and is close to the working surface of the support frame; the driven plate is fixedly provided with a fixing mechanism and an axial locating piece; a driven plate limit mechanism used for fixing the driven plate after the driven plate rotates along with the rotating shaft is arranged between the driven plate and the support frame; and the driven plate is respectively horizontally provided with height regulating slots which extend vertically at the upper side and the lower side of the rotating shaft, and the fixing mechanism and the axial locating piece are both fixed in the height regulating slots. The locating mechanism disclosed by the invention is used for locating in the machining of the two ends of the crank shaft, holes at the two ends can be machined while the crank shaft is clamped once, and therefore positional accuracy of the holes at the two ends is guaranteed and labour intensity of operating personnel is reduced.

Owner:长城汽车股份有限公司平湖分公司

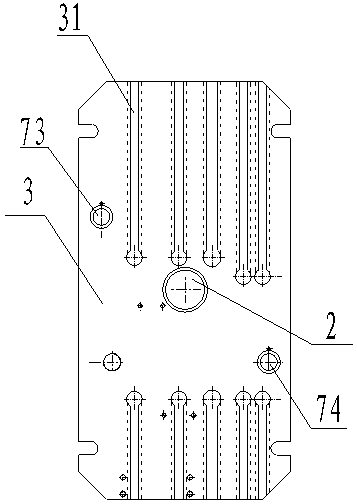

Ring plate positioning and reinforcing device applied to DTM169 spinning frame

InactiveCN103849960ADoes not affect concentricityPrecise positioningTextiles and paperYarnEngineering

The invention relates to a ring plate positioning and reinforcing device applied to a DTM169 spinning frame. A fixing board is mounted on a ring plate lifting beam of the DTM169 spinning frame and longitudinally provided with reinforcing cavities, and lifting belts are mounted inside the reinforcing cavities; the fixing board is transversely provided with positioning pin holes corresponding to the small holes of the beam and the lifting belts, and bolts penetrate the positioning pin holes and the small holes to fix the fixing board onto the beam. According to the ring plate positioning and reinforcing device applied to the DTM169 spinning frame, the fixing board is mounted on the ring plate lifting beam of the DTM169 spinning frame, and the lifting belts are mounted inside the reinforcing cavities of the fixing board, so that by controlling the matching space of the lifting belts between the two side plates of the ring plate lifting beam, the problems of displacement of the lifting beam and decentraction of a ring plate, a spindle and a leafage plate can be solved. The ring plate positioning and reinforcing device applied to the DTM169 spinning frame ensures positioning stability of the ring plate during production, does not affect the concentricity of the ring plate, the spindle and the leafage plate, can reduce broken ends of spun yarns and improve the product quality and is easy to operate and safe in usage.

Owner:JIHUA 3509 TEXTILE

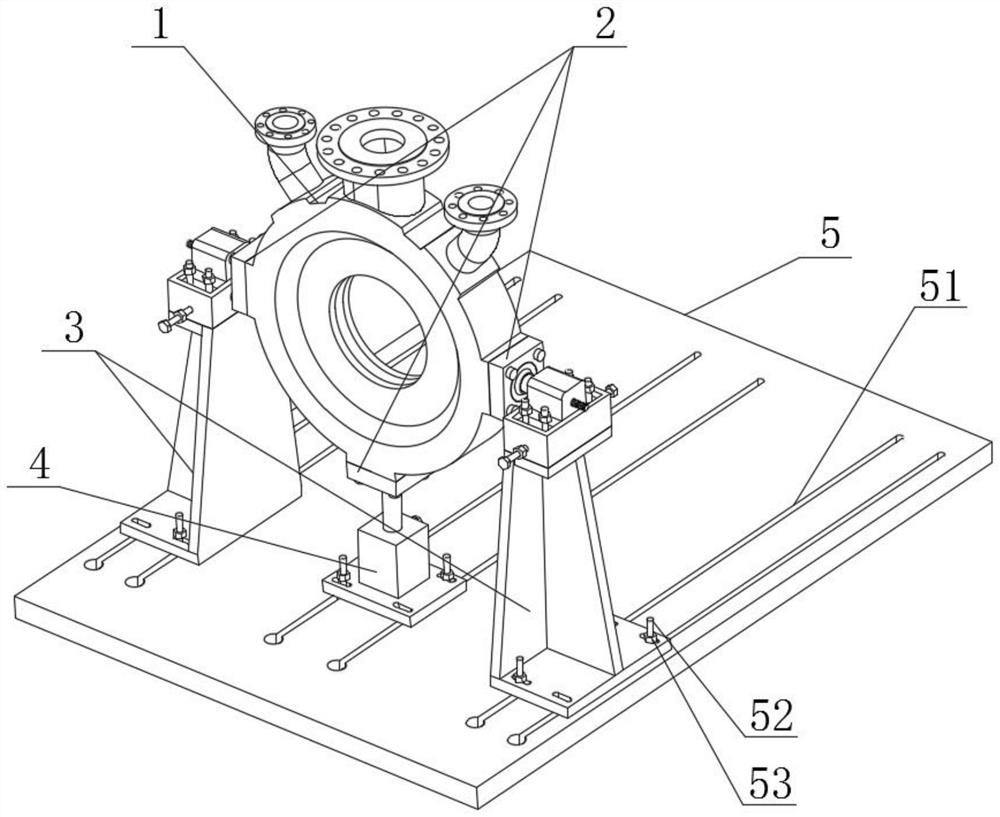

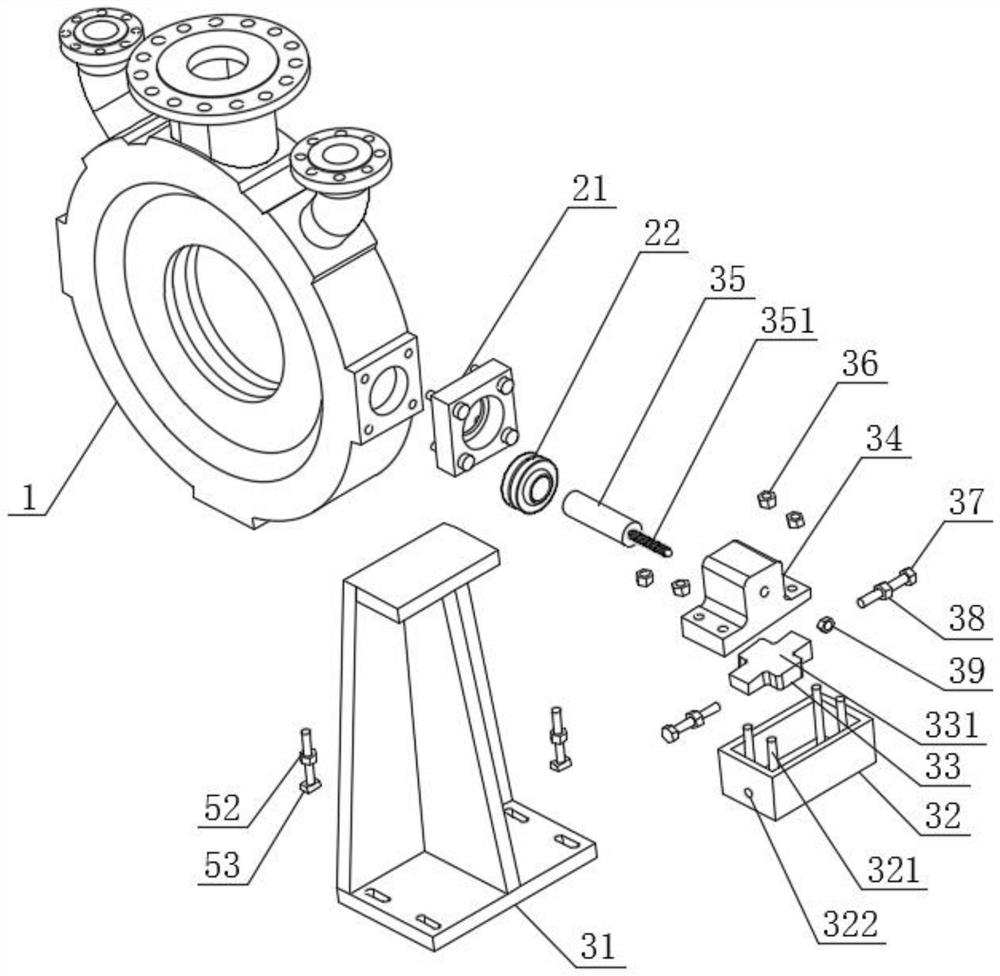

Exhaust volute with aligning function

PendingCN114320502ASolve disagreementMachines/enginesEngine componentsStructural engineeringMechanical engineering

The invention discloses an exhaust volute with an aligning function, and relates to the technical field of exhaust volutes. Comprising a volute main body, two groups of aligning mechanisms, a bottom fixing mechanism and a bottom plate, universal mechanisms are arranged on the two sides and the bottom of the volute body. The two groups of aligning mechanisms are respectively connected with the universal mechanisms on the two sides of the volute main body; the bottom fixing mechanism is connected with a universal mechanism at the bottom of the volute main body; the aligning mechanism and the bottom fixing mechanism are both connected with the bottom plate. Through adjustment of the aligning mechanism and the bottom fixing mechanism, the volute body is subjected to horizontal and vertical height adjustment in a small range, even the volute body rotates by a certain angle around the axis, and the problem of non-concentricity in the assembling process is effectively solved.

Owner:上海蓝铸特种合金材料有限公司

Permanent-magnetic vacuum one-way switch

InactiveCN102194601BPrevent rejectionSolve disagreementHigh-tension/heavy-dress switchesAir-break switchesMechanical engineeringVacuum interrupter

Owner:张凯

Improved pouring type casting production device

The invention discloses an improved pouring type casting production device which comprises a frame, a program control assembly, an oil cylinder assembly, an upper mould, a bottom mould and side moulds, wherein the program control assembly, the oil cylinder assembly, the upper mould, the bottom mould and the side moulds are arranged on the frame. The program control assembly controls the movement of the oil cylinder, the oil cylinder is connected with the bottom mould, the bottom mould is arranged under the upper mould, and the side moulds are arranged on the periphery of the upper mould. The improved pouring type casting production device further comprises a demoulding mechanism, the upper end of the demoulding mechanism is fixedly connected with the bottom mould, the lower end of the demoulding mechanism is connected with the oil cylinder assembly, and the oil cylinder assembly drives the demoulding mechanism to drive the bottom mould to move downwards. The improved pouring type casting production device only utilizes one power cylinder in the demoulding operation to enable a casting to be separated from the bottom mould smoothly, and meanwhile, solves the problem of decentraction caused by an overlong stroke in demoulding, so that the casting quality is improved.

Owner:厦门民兴工业有限公司

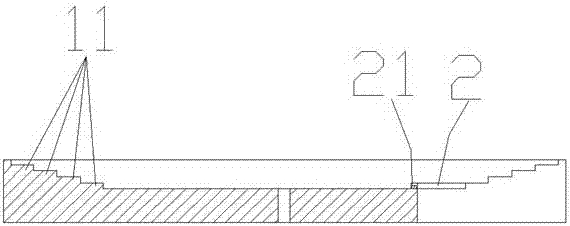

Adsorption Silicon Wafer Coating Rotary Table

An absorption type wafer coating rotating table comprises a table board and is characterized in that radially arranged ring tables in a stepped shape are arranged on the table board and concentric with the table board, and openings extending toward the circle center are formed in the edge of the table board; a baffle plate as high as the ring table on the innermost side is arranged at the tail end of each opening, two ends of the baffle plate are connected with the ring table on the innermost side, and a gap is formed in the baffle plate. By means of the ring tables arranged on the table board, the problem that wafers are not concentric with the table board when an operator places the wafers is solved, and the openings formed in the edge of the table board facilitate taking of the wafers; and the rotating table is simple in structure, different diameters of wafers can be placed, the cost is lower than that of clamping type rotating equipment, and the rotating table is not prone to damage.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Tooling for assembling conductor

InactiveCN105552691ASolve disagreementSolve the difficulty of hoisting and alignmentCoupling device engaging/disengagingElectrical conductorEngineering

The invention discloses a tooling for assembling a conductor. The tooling comprises a main support body and a butting device, wherein the butting device is arranged at the upper part of the main support body; an elevation tank body butting plate is arranged at the top end of the main support body to be butted with an elevation tank body; a bottom tank body butting plate is arranged at the bottom end of the main support body to be butted with a bottom tank body; an angle adjusting device is arranged between the bottom end of the main support body and the bottom tank body butting plate; the butting device comprises a plate for the conductor, a height adjusting device, a left and right support adjusting device and an adjusting support plate; the height adjusting device is arranged between the plate for the conductor and the adjusting support plate and can adjust the height of the plate for the conductor; the left and right support adjusting device comprises a telescopic support bar and a nut; the upper end of the telescopic support bar is hinged with the plate for the conductor; and the telescopic support bar stretches to be in contact with the adjusting support plate by adjusting the nut, so that the plate for the conductor can be stabilized. The tooling disclosed by the invention solves the problems that an existing high-voltage and extra-high voltage product conductor is difficult to hoist and align, not easy to assemble, low in butting efficiency and the like when butted and installed, and is high in butting efficiency.

Owner:CHINA ELECTRIC POWER RES INST +3

Assembling mechanism of guide sleeve of column of hydraulic support

ActiveCN102031979BControl the size of the preloadPrevent crushingProps/chocksAxial displacementEngineering

Owner:CHINA SHENHUA ENERGY CO LTD

A contact structure of a commutation-type high-voltage DC contactor

ActiveCN109637887BSolve disagreementSolve fever problemHigh-tension/heavy-dress switchesAir-break switchesPower flowEngineering

The invention discloses a contact structure of a converter-type high-voltage DC contactor, and belongs to the field of switching devices. The contact structure comprises a through-current branch composed of a main static contact A1, a main static contact A2 and an active contact M, and also comprises an arc extinguishing branch composed of six arc static contacts and three arc moving contacts. Thethrough-current branch and the arc extinguishing branch are connected in parallel through a copper conductive bridge A1B1 and a copper conductive bridge A2D2. A rectangular insulating pull rod drivesthe four groups of moving contacts to move up and down simultaneously to complete the switching operation. According to the invention, the structure can achieve the two-way rated current bearing andshort-circuit current breaking, solves a problem that the moving contact and the static contact are not concentric due to offset movement in the moving process of the switching moving contact, solvesthe problem of contact heat under a large-current-level rated state through the through-current branch circuit, and solves the problem of high-voltage-level direct-current arc breaking through the three groups of contacts connected in series of the arc extinguishing branch circuit; meanwhile, the structure reduces ablation of the main contact, and prolongs the service life of the contactor effectively.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com