Exhaust volute with aligning function

An exhaust volute and centering technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of misalignment, increase cost investment, reduce product qualification rate, etc., and achieve the effect of solving misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to achieve the above objectives and efficacy, the technical means and configurations used in the present invention will be described in detail with reference to the preferred embodiments of the present invention.

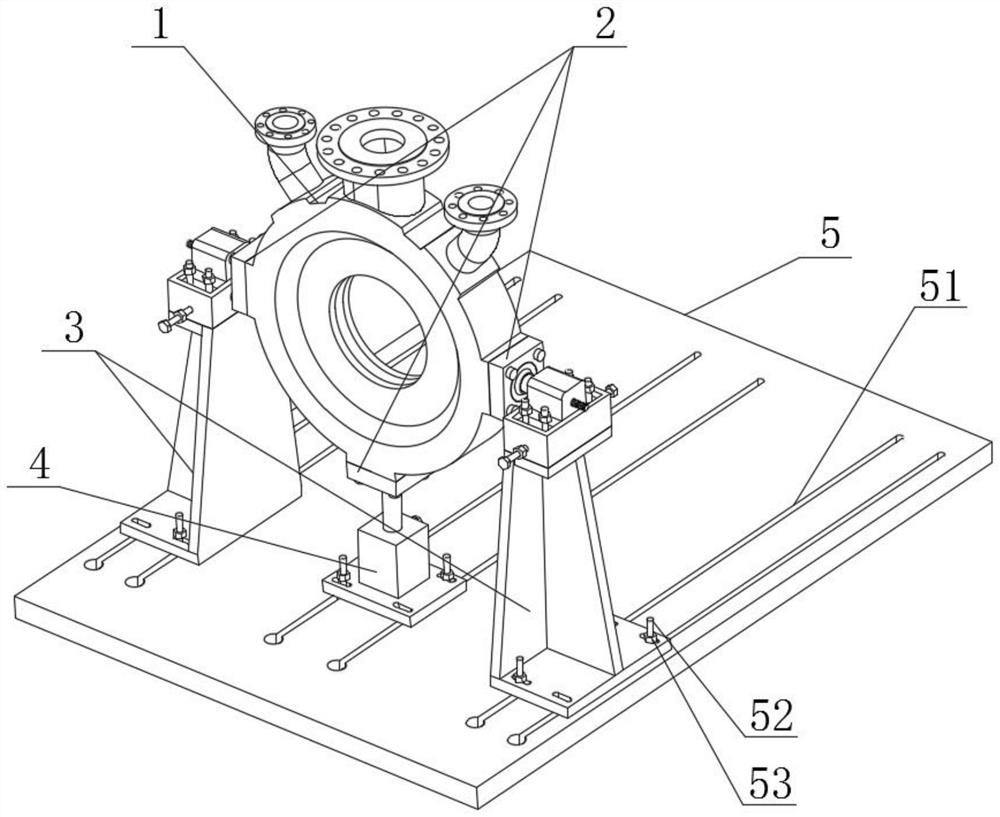

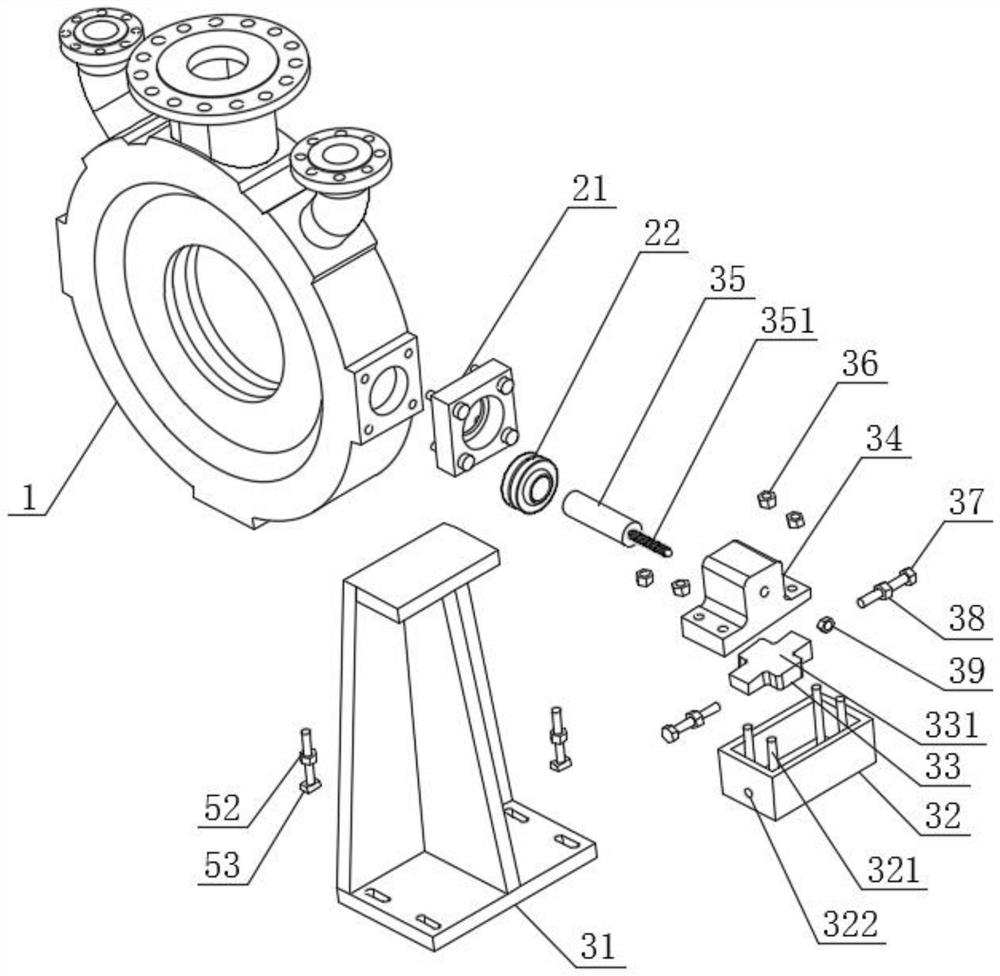

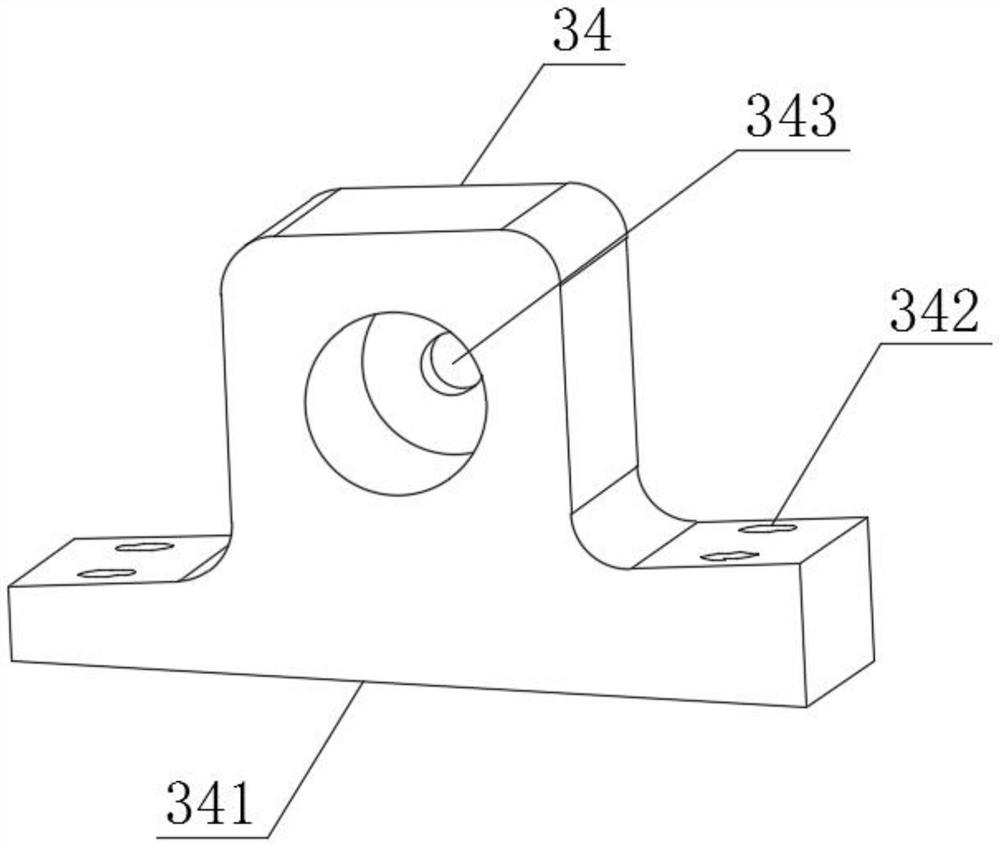

[0018] Such as Figure 1-4 As shown, the present invention provides an exhaust volute having a calorie function, including a volute body 1, two sets of adjustment mechanism 3, a bottom fixing mechanism 4, and a bottom plate 5; the volute body 1 side and There is a universal mechanism 2 at the bottom; the two sets of adjustment mechanisms 3 are connected to the universal mechanism 2 on both sides of the volute body 1; the bottom fixing mechanism 4 is connected to the universal mechanism 2 at the bottom of the volute; The adjustment mechanism 3 and the bottom fixing mechanism 4 are connected to the bottom plate 5. By adjusting the adjustment mechanism 3 and the bottom fixing mechanism 4, the resolve body 1 performs a small range of horizontal and vertical h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com