Assembling mechanism of guide sleeve of column of hydraulic support

A technology of hydraulic support column and assembly mechanism, which is applied in the direction of support/support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of column strain, column sealing ring is easy to be crushed, scratched, etc., so as to achieve convenient operation and avoid Axial wear, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

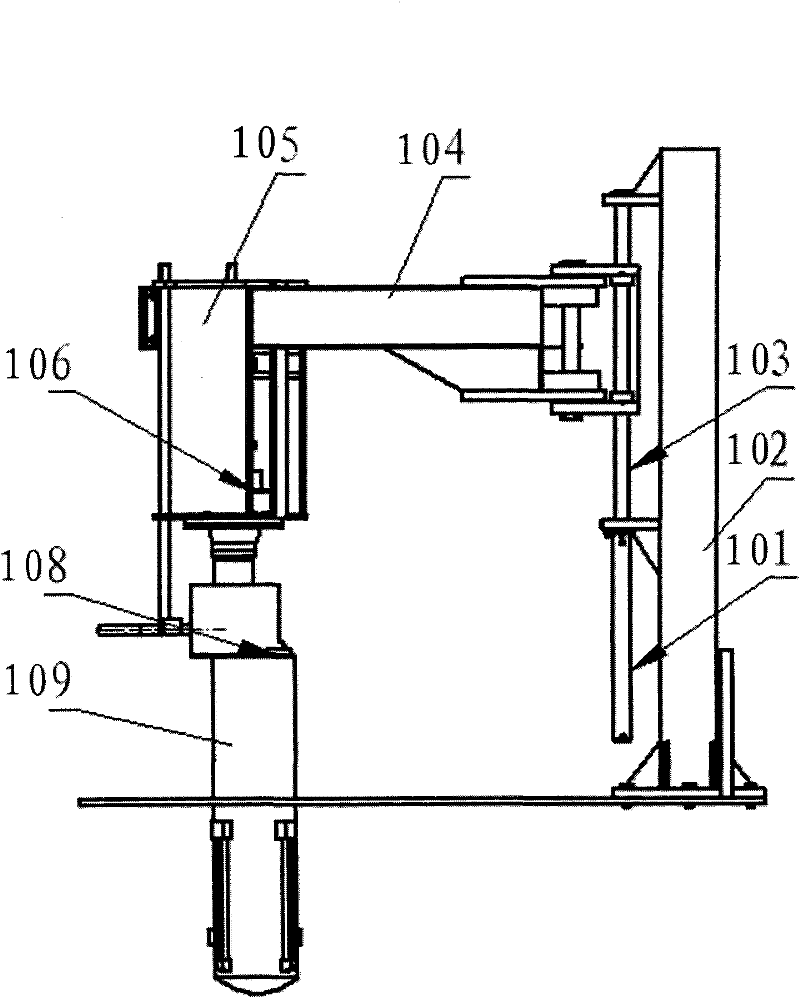

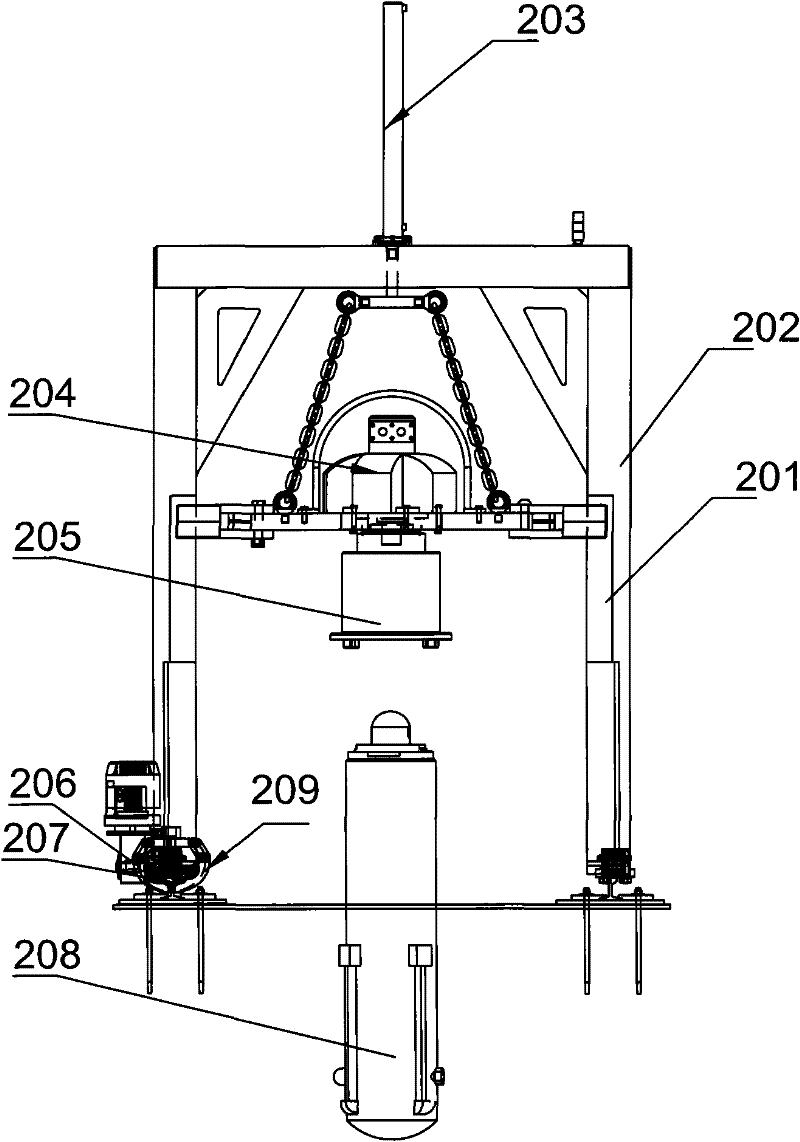

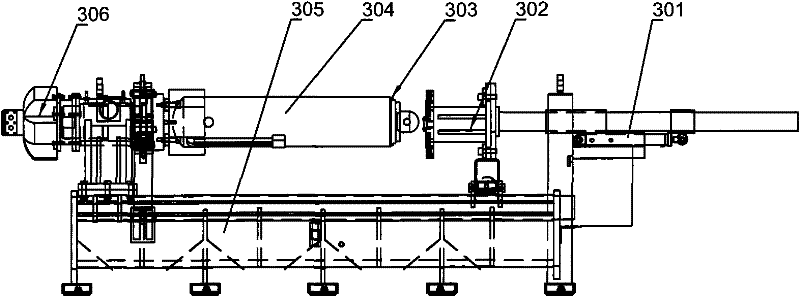

[0030] Preferably, the frame 10 is further provided with a motor guide rail, and the motor 8 is slidably arranged on the motor guide rail. And further, the motor guide rail also includes a vertical guide rail 9 parallel to the frame 10 and a horizontal guide rail 7 perpendicular to the frame 10 . In this embodiment, the vertical guide rail 9 is matched with the lifting cylinder 11, and the horizontal guide rail 7 is fixed on the vertical guide rail 9, so that the motor 8 of the present invention can move vertically Move in both vertical and horizontal directions.

[0031] Preferably, a chuck 5 is disposed below the motor 8 , and at least one set of springs 6 is disposed between the motor 8 and the chuck 5 . In this embodiment, the set of springs includes two springs 6, such as figure 1 As shown, the guide sleeve 3 of the hydraulic support column guide sleeve assembly mechanism is connected to the chuck 5 through the tooling 4 .

[0032] Further, the present invention also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com