A modular box and assembly method for scr denitrification catalyst

The technology of a denitration catalyst and an assembly method, which is applied in the field of thermal power generation denitration system, can solve the problems of small flue gas flow area, uneven force on the catalyst unit, large material loss, etc., to prevent corrosion, prevent dislocation and drop, increase buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

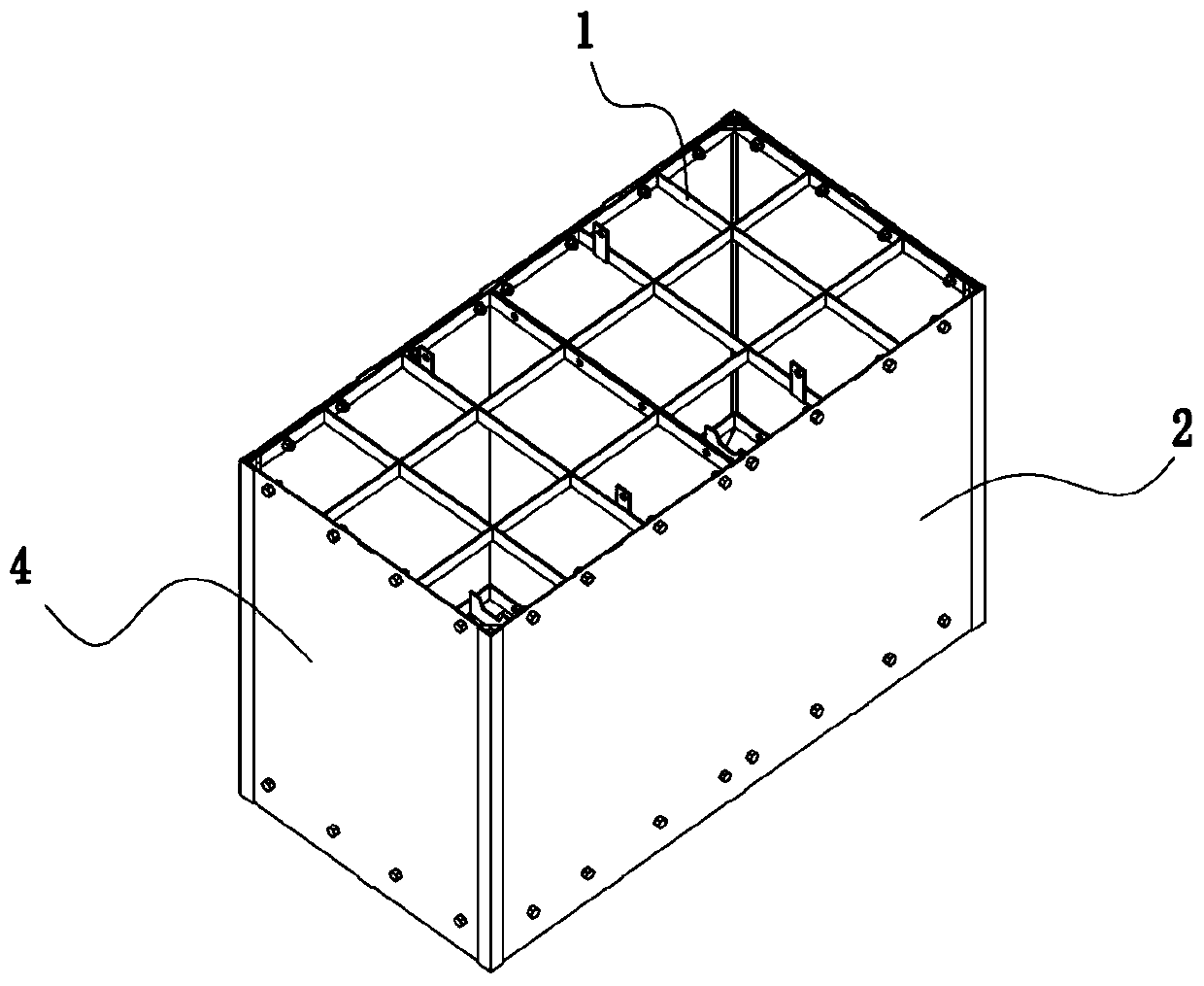

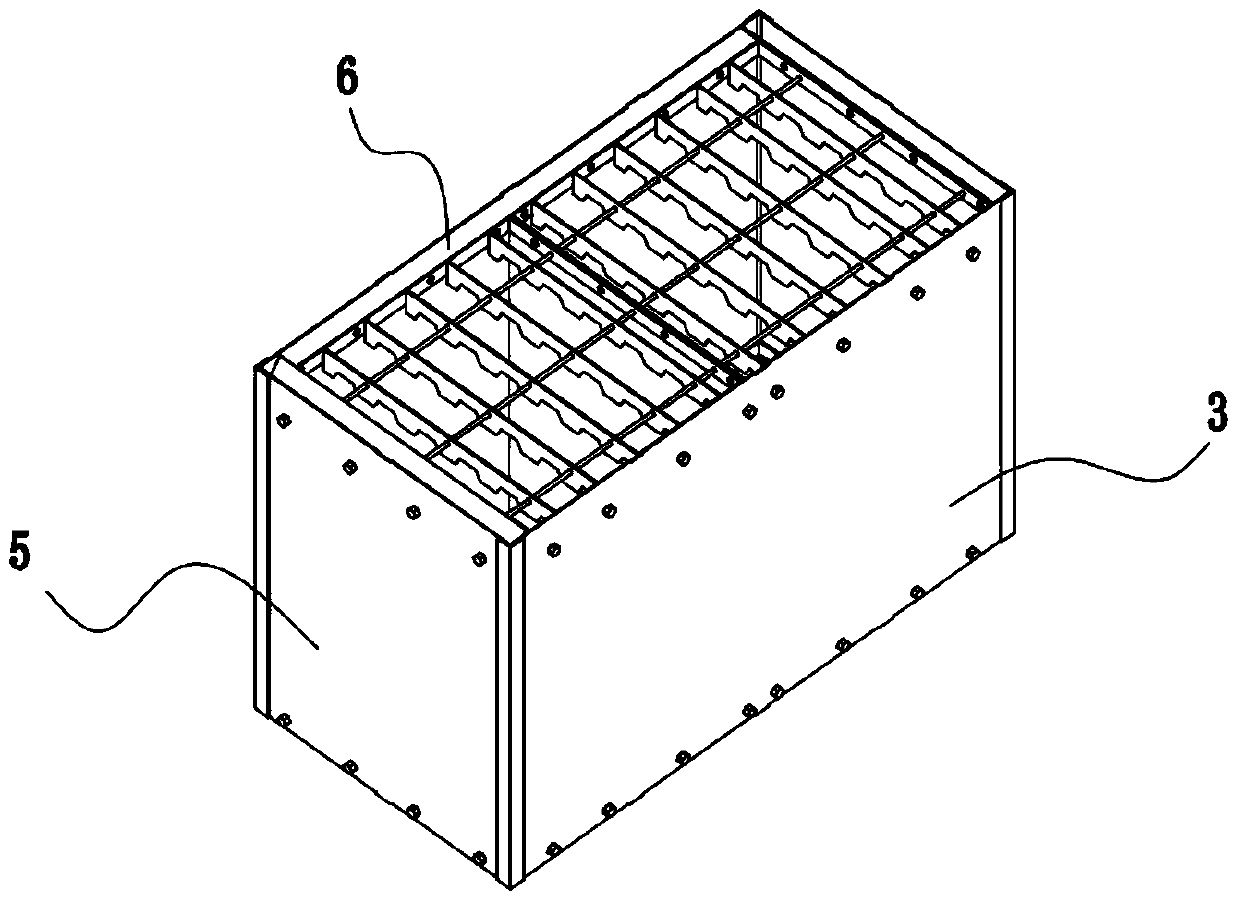

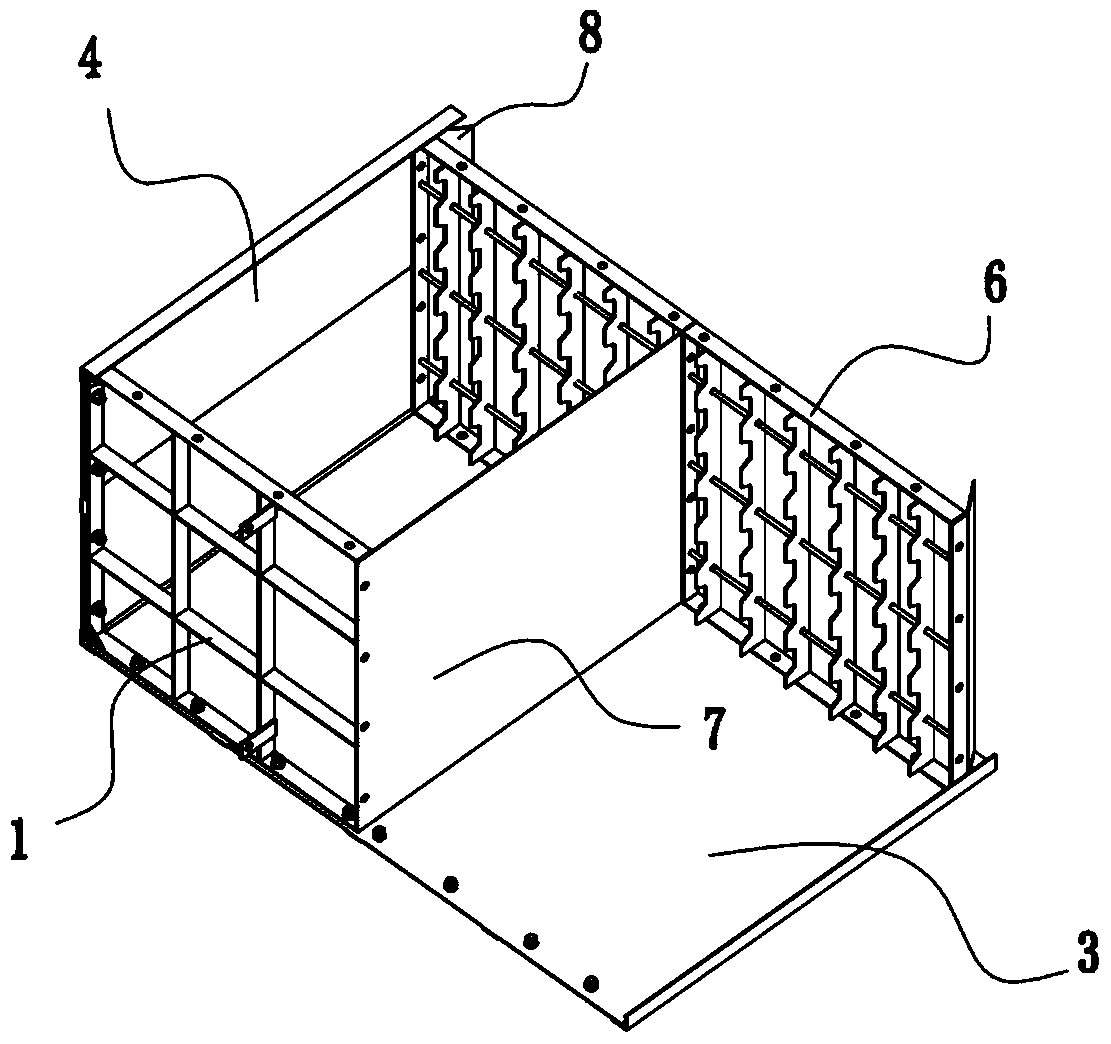

[0029] Referring to the accompanying drawings, a modular box for SCR denitrification catalyst, the box body of the modular box is mainly composed of a top plate 1, a front side plate 2, a rear side plate 3, a left side plate 4, a right side plate 5 and a bottom plate 6; The top plate 1 is a grid plate welded by steel plates, and the thickness direction of all steel plates in the top plate is kept perpendicular to the height direction of the box body. The bottom plate 6 is composed of a bottom frame 61 and a support plate 62, and the bottom frame is welded by steel plates. , the thickness direction of the same steel plate is perpendicular to the height direction of the box body; a plurality of support plates 62 are welded at intervals along the length direction on the bottom frame, and the support plates 62 are also steel plates, wherein one long side of the support plate 62 is tooth-shaped, The sides are vertically upward in the box body, and the tooth-shaped tooth grooves are ...

Embodiment 2

[0035] A method for assembling an SCR denitration catalyst module, comprising the module box in embodiment 1 and the cuboid catalyst unit installed in the module box, its specific assembly steps are as follows:

[0036] A) Place the rear side board horizontally on the assembly platform, install the left and right bottom boards first, and fix them on the rear side board through bolts passing through the left and right bottom boards and the bolt holes around the bottom board, and install the left and right bottom boards Install the middle partition at the same time, and clamp the two ends of the middle partition in the middle of the left and right bottom plates;

[0037] B) Fix the top plate on the rear side plate in the same way as step A);

[0038] C) Paste strip-shaped ceramic fiber gaskets on the left and right side walls of the intermediate partition; then arrange the cuboid catalyst units one by one in the box until the box is filled, wherein ceramic fiber gaskets are set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com