Power device for spraying paint

A technology of power device and movable frame, which is applied in the direction of injection device, etc., to achieve the effect of exquisite design and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

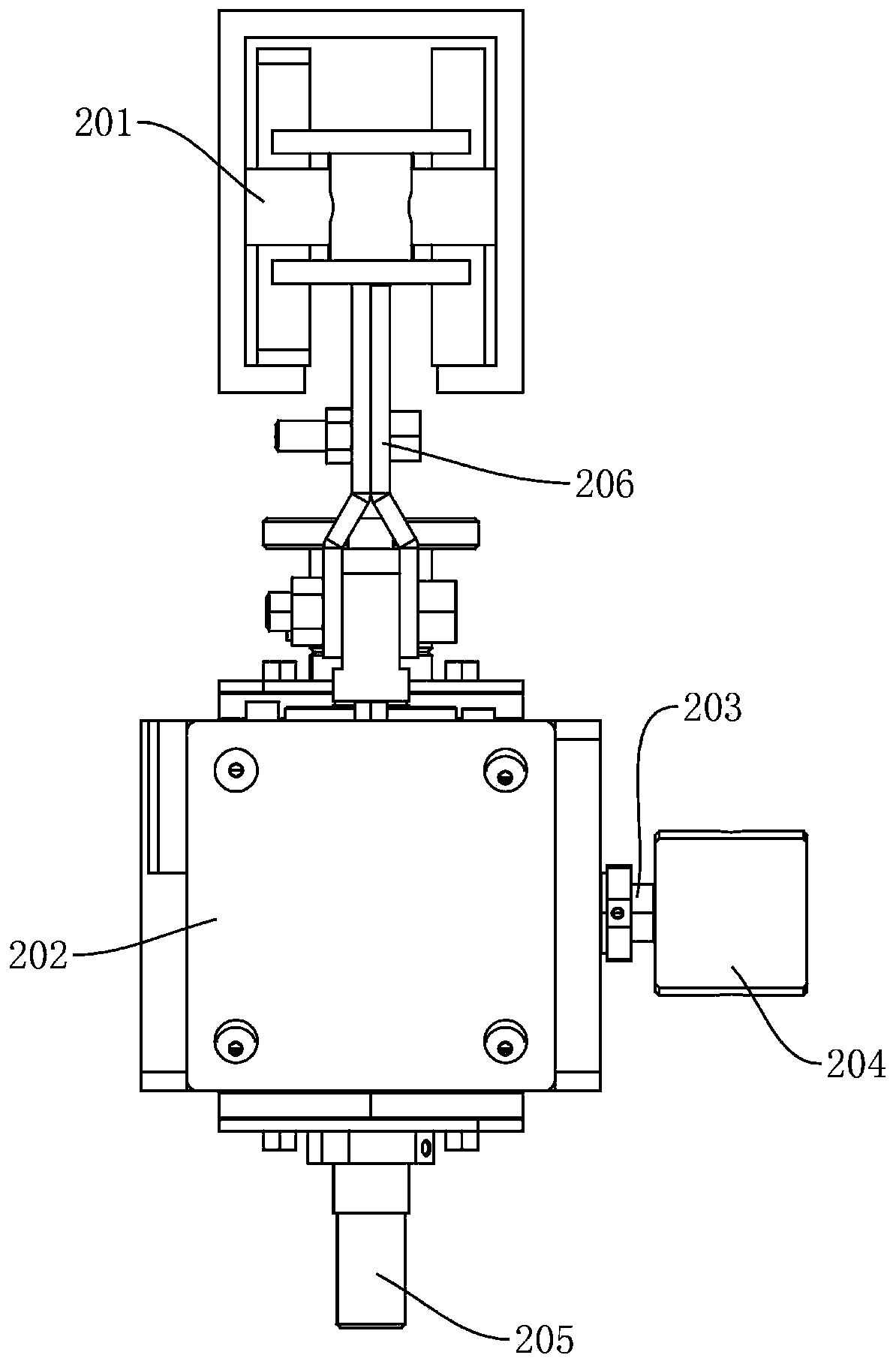

[0033] In the painting process, the workpiece that needs to be painted is usually arranged on an orientation control device 202 that can adjust the orientation of the workpiece by rotation. Conveying line 201, etc.) to be transported to the painting station that is arranged in the painting space successively; figure 1 As shown, the azimuth control device 202 is provided with a frame, one side of the frame is provided with a joint 203 for connecting the power device, and the lower end of the frame is provided with a hanger joint 205 connected to the workpiece hanger, and the joint 203 is connected to the The hanger joint 205 is connected through the power transmission mechanism arranged in the frame, and has a fixed transmission ratio. The orientation control device 202 can be moved to the painting station under the drive of the conveying line 201. , the joint 203 of the orientation control device 202 needs to be connected with the power device arranged at the painting station,...

Embodiment 2

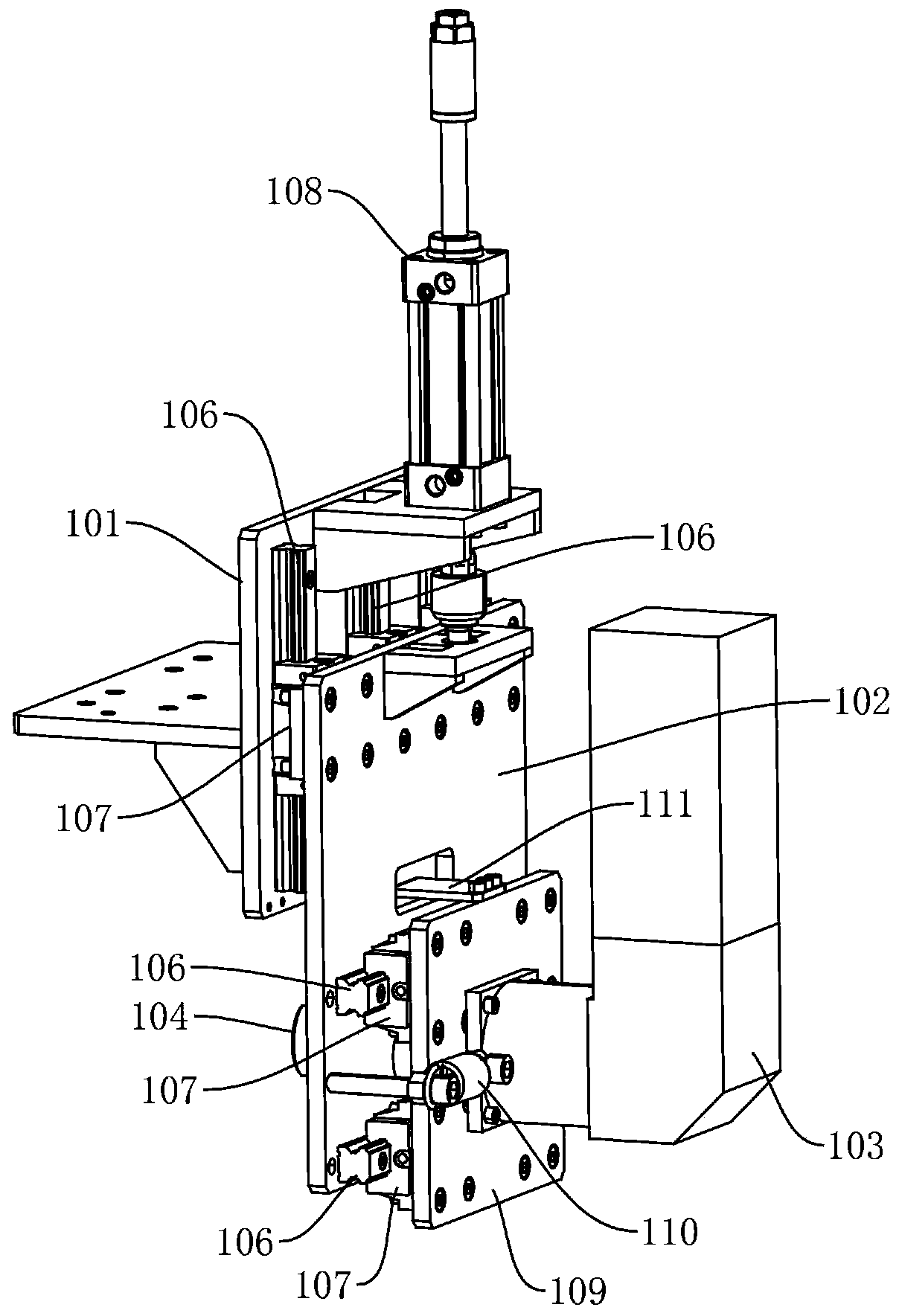

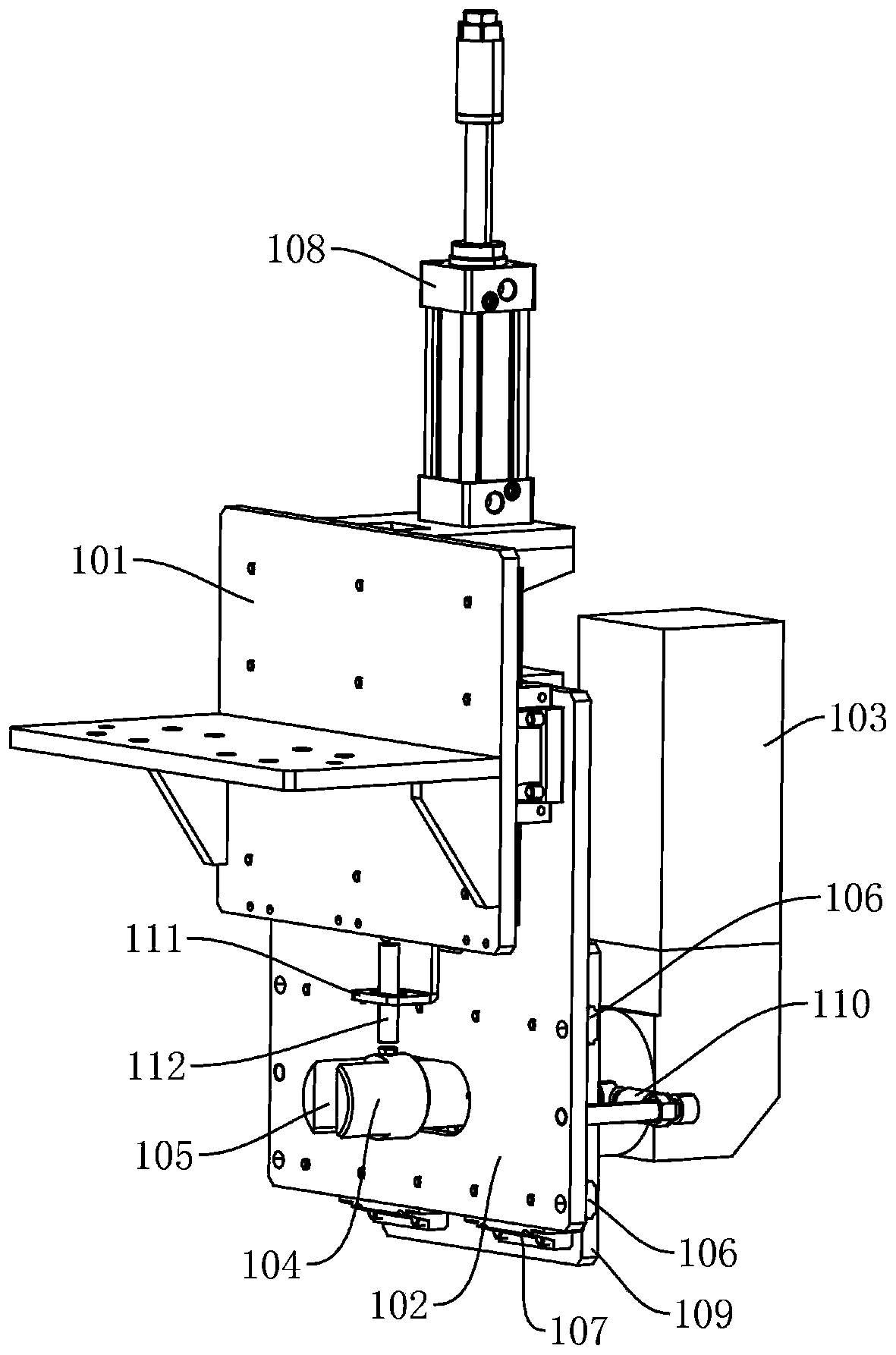

[0045] Since the connector 104 in the power unit and the joint 203 in the azimuth control device 202 are detachably connected, there must be a matching gap between the two, that is, there must be a gap between the card slot 105 and the connecting block 204; when the power unit After the connecting head 104 in the azimuth control device 202 is connected to the joint 203 in the azimuth control device 202, due to the fit gap between the connecting head 104 and the joint 203, the axes of the connecting head 104 and the joint 203 are not concentric, which is not conducive to transmission. In order to solve this problem, In the power device provided in this embodiment, it also includes a self-adjusting frame 109, such as Figure 2-Figure 5 As shown, the drive motor 103 is fixed on the self-adjusting frame 109, and the self-adjusting frame 109 is arranged on the movable frame 102 through the second linear module, and the second linear module and the first module perpendicular to each...

Embodiment 3

[0048] Because there is a matching gap between the connector 104 and the connector 203, when the connector 203 is driven by the power unit to rotate a circle and finish painting (return to the initial position), as Figure 7 As shown, at this time, the rotation angle of the connector 104 must be greater than 360 degrees, that is, the connector 104 is not at the initial position, as Figure 7 As shown, it is inconvenient for the connector 104 to cooperate with the connector 203 of the next orientation control device 202. To solve this problem, the power device provided in this embodiment also includes a sensor 112 and a controller. The connector 104 Circumferential direction is provided with detection part 113, and described sensor 112 and driving motor 103 are connected with described controller respectively, and described sensor 112 is fixed on described self-adjusting frame 109, as image 3 and Figure 8As shown, the bracket 111 is used to fix the self-adjusting frame 109 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com