Assembling mechanism of guide sleeve of column of hydraulic support

A hydraulic support column and assembly mechanism technology, which is applied in the directions of columns/supports, mining equipment, earth-moving drilling, etc. The effect of avoiding axial wear, strong practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

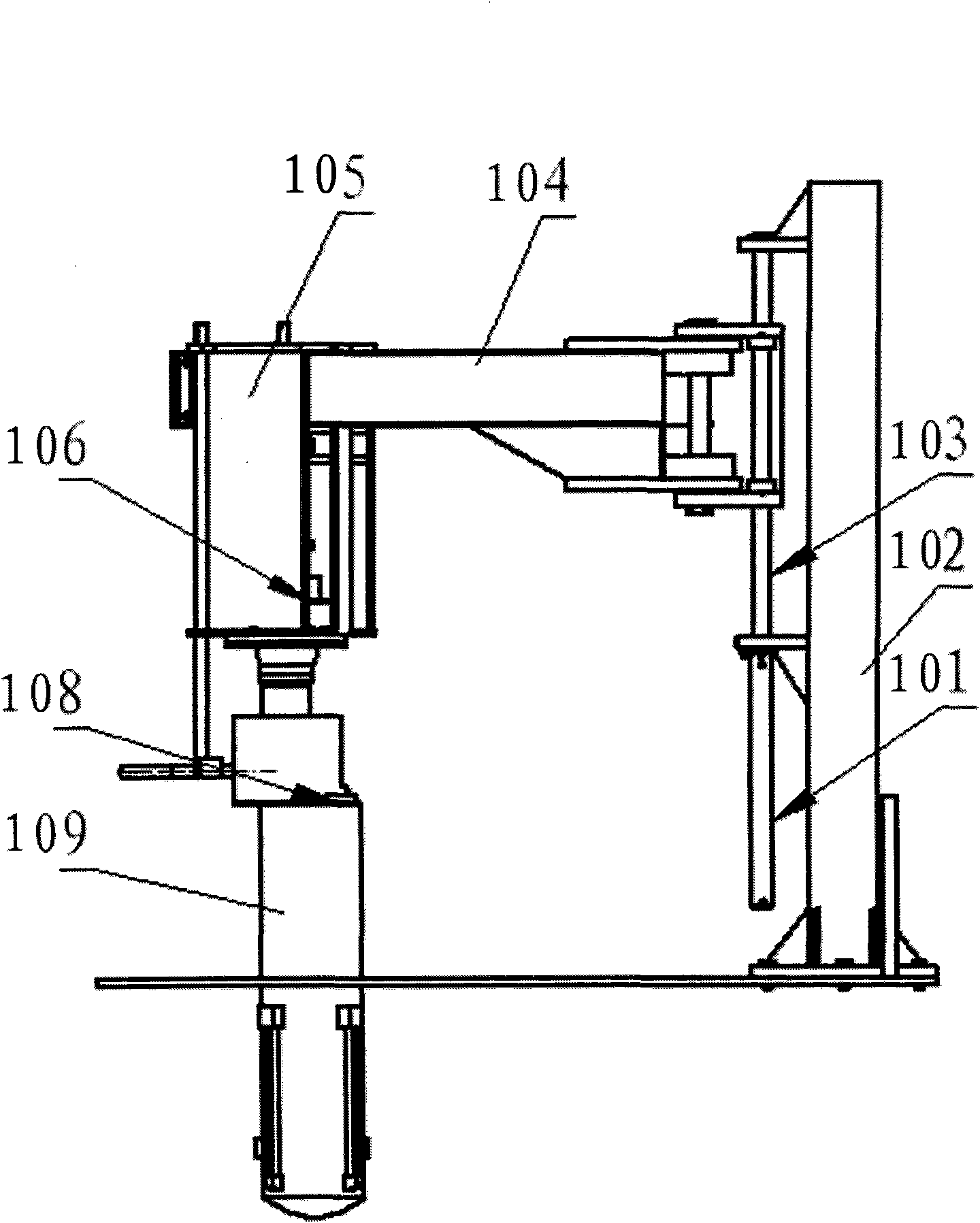

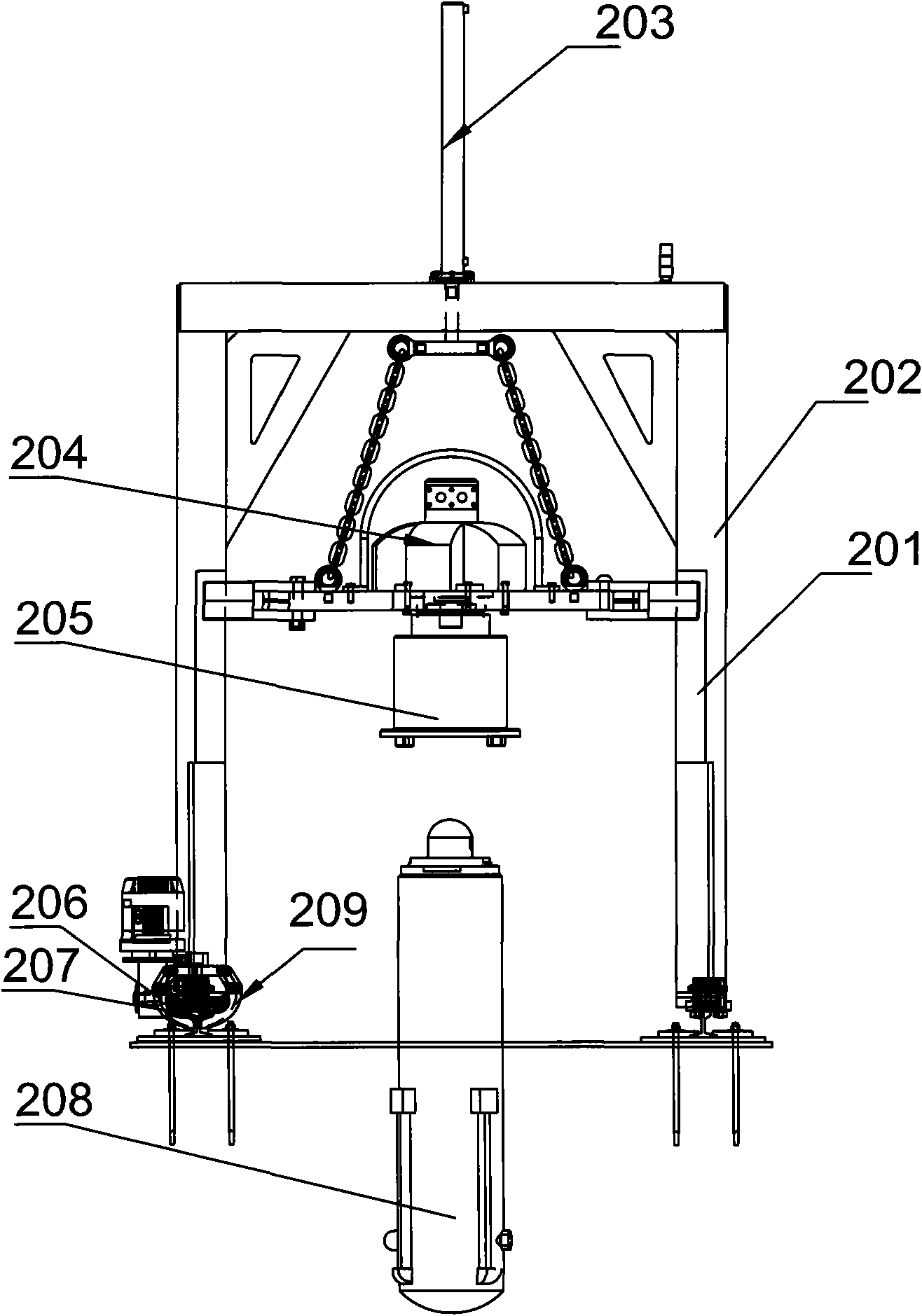

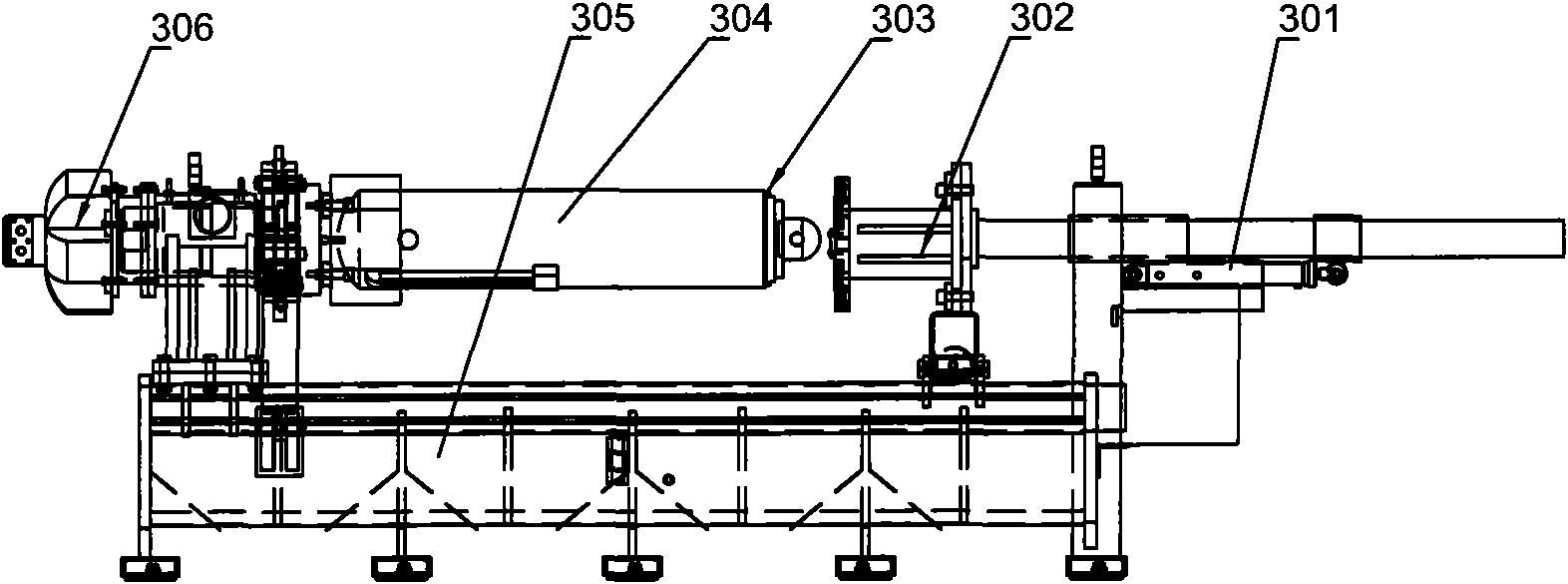

[0029] see Figure 4 and Figure 5 , which shows a preferred embodiment of a hydraulic support column guide sleeve assembly mechanism of the present invention, including a base 13 and a frame 10 vertically arranged on the base 13 and connected to the base 13 through a hinge structure 14, an inclined The provided swing arm cylinder 12 is connected to the frame 10, and the frame 10 can be inclined to one side of the swing arm cylinder 12 through the hinge structure 14 under the drive of the swing arm cylinder 12, preferably , the base 13 is fixed on the ground or other working surfaces, such as figure 1 As shown, the swing arm cylinder 12 is fixedly connected with the frame 10 through the upper hinge 121, and the swing arm cylinder 12 is fixedly connected with the working surface through the lower hinge 122. When working, the swing arm cylinder 12 The lifting or retracting can make the frame 10 swing between the vertical position and the tilted position, and the frame 10 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com