Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Socket firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

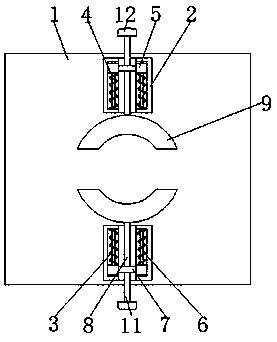

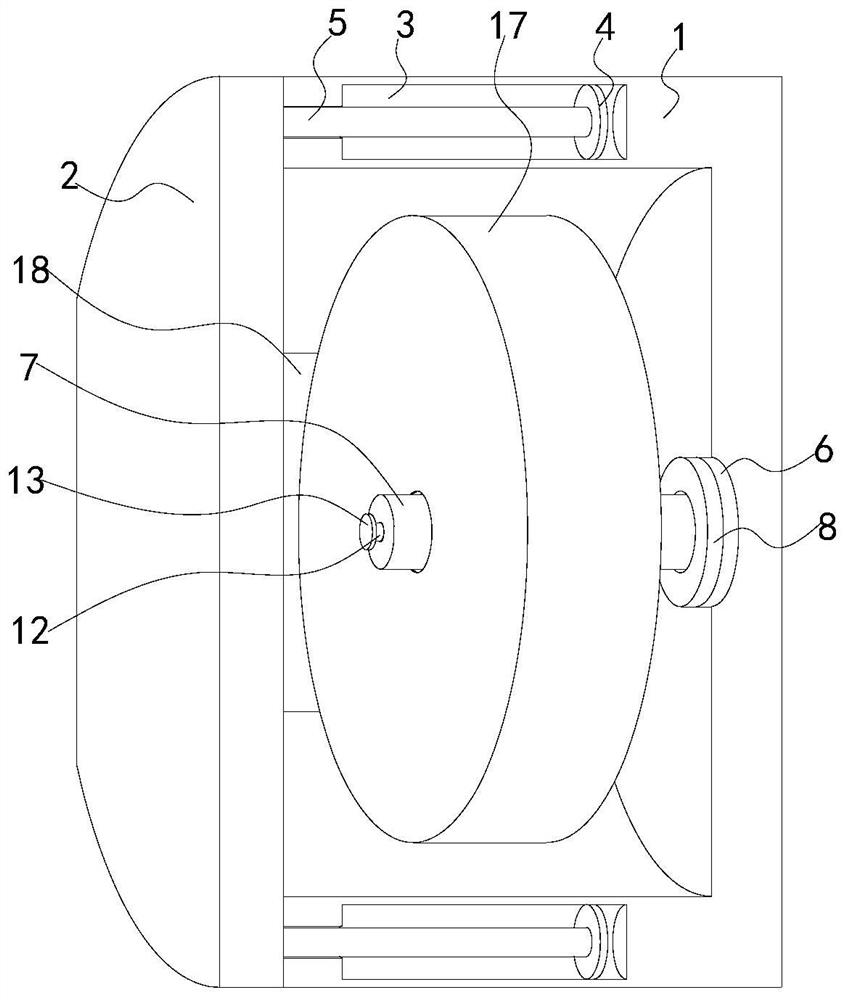

Ammeter convenient to install

InactiveCN109959808AEasy to installSocket firmlyTime integral measurementComputer engineeringAmmeter

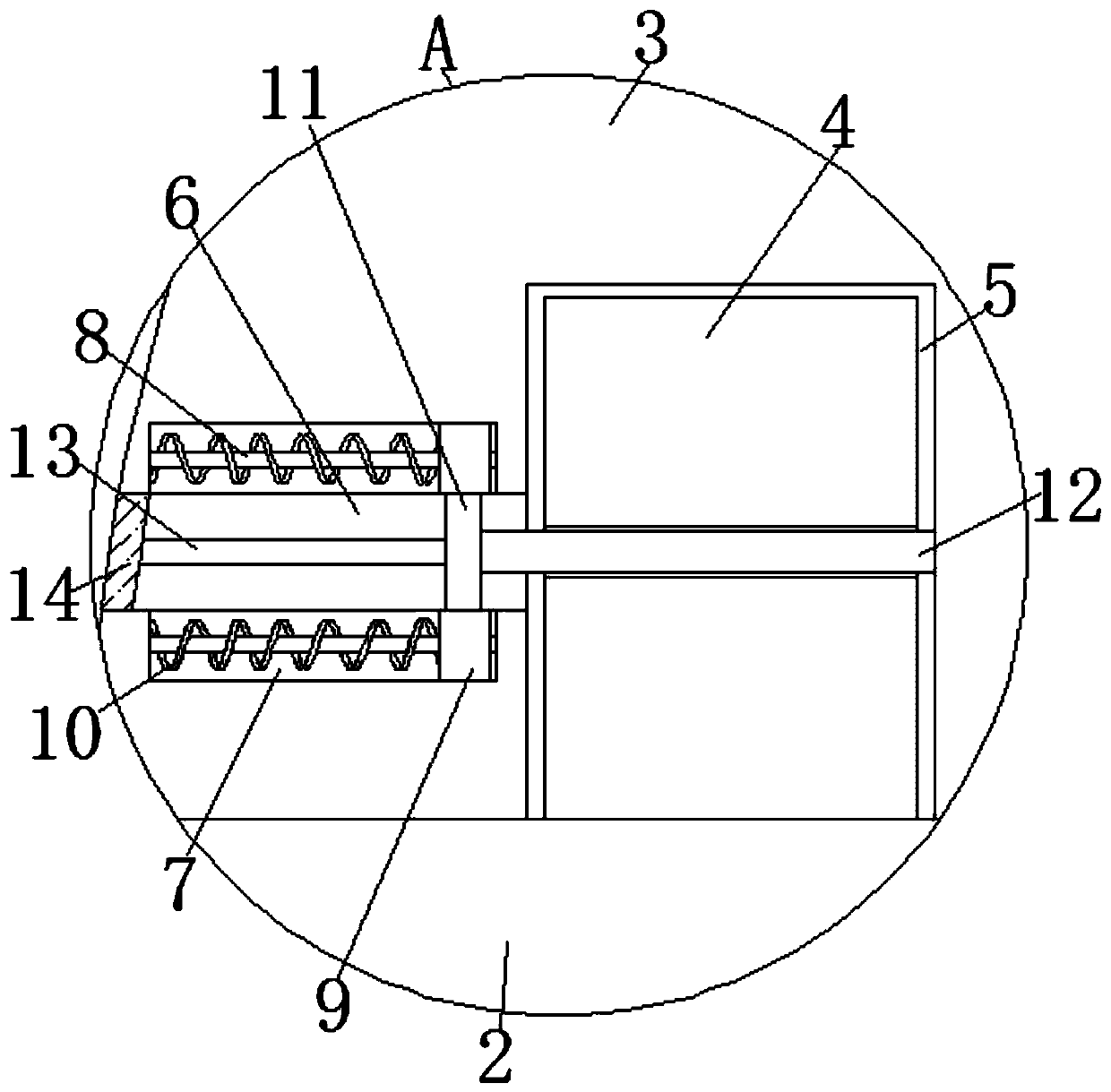

The invention discloses an ammeter convenient to install. The ammeter convenient to install comprises an ammeter. The upper and lower two ends of the back surface of the ammeter are respectively and fixedly connected with a limit sleeve; the two sides of the inner wall of each limit sleeve are respectively provided with a slide groove; the top and bottom of the inner wall of the slide groove are connected by a slide rod; a sliding block sleeving the slide rod is slidbly connected in the slide groove; the slide rod is sleeved by a compressed spring; the two ends of the compressed spring are fixedly connected with one side of the inner wall of the slide groove and one side of the sliding block respectively; and the opposite sides of the two sliding block are connected through a sliding plate. Through improvement of arc clamp plates, when two press plates are pushed oppositely, press rods drive the two arc clamp plates to close to each other through the sliding plates and push rods; then,the press plates are released, the sliding blocks drive the arc clamp plates to return through the sliding plates under the action of rebound force of the compressed springs; through cooperatively use of clamp rods, the arc clamp plates are allowed to be stably clamped in a through slot; and thus, the ammeter can be installed quickly.

Owner:桑祖春

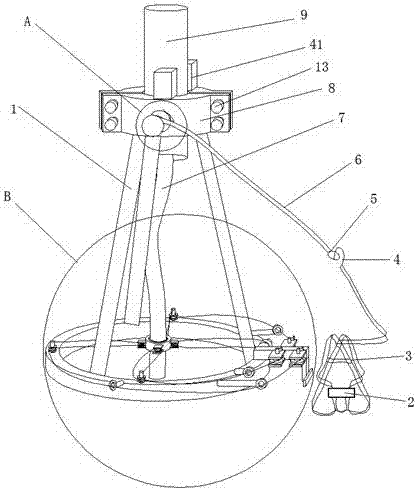

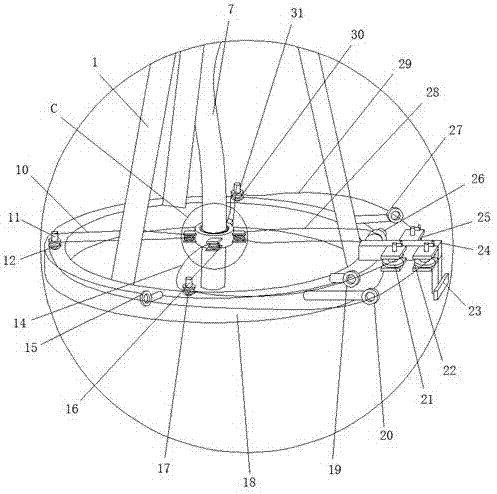

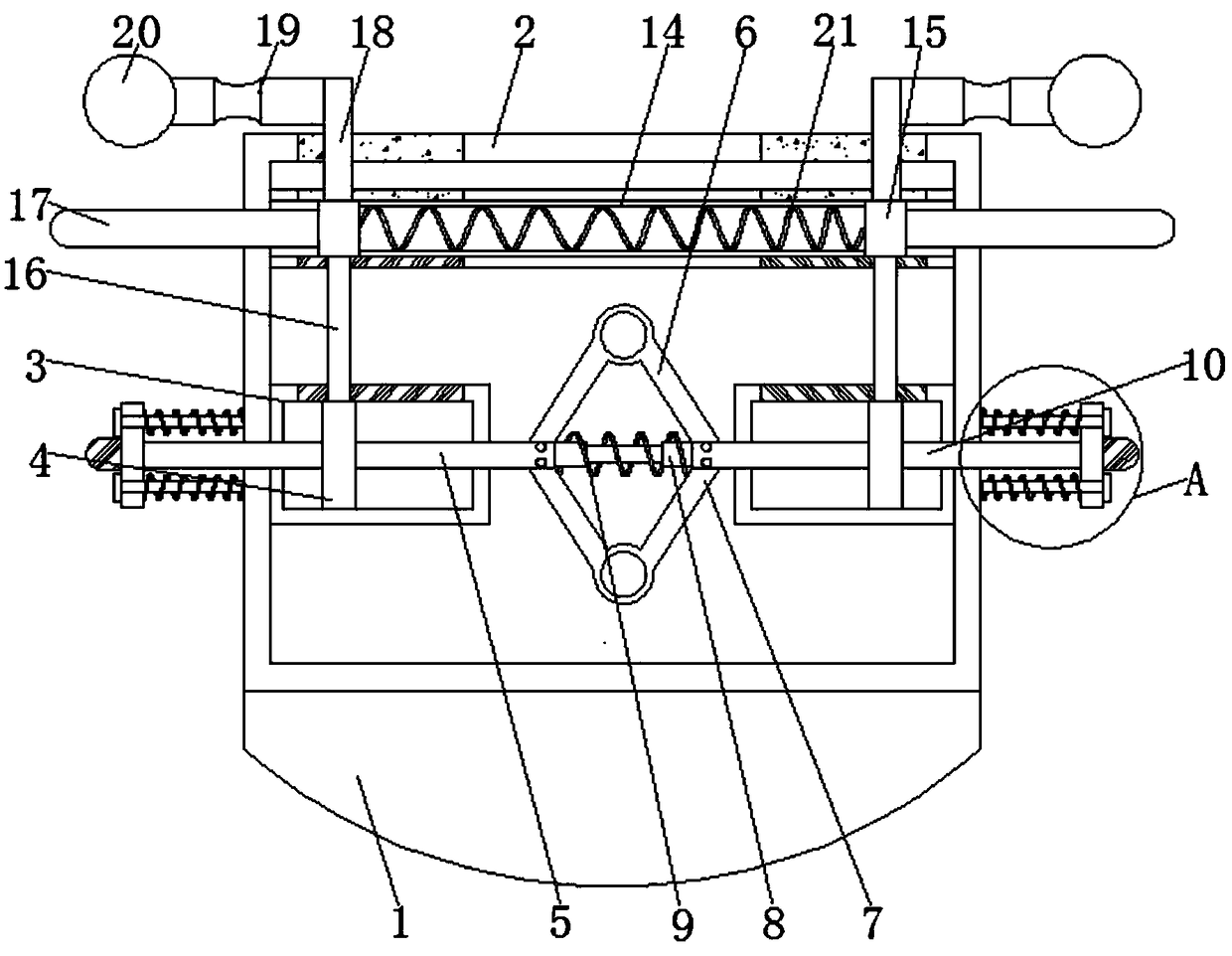

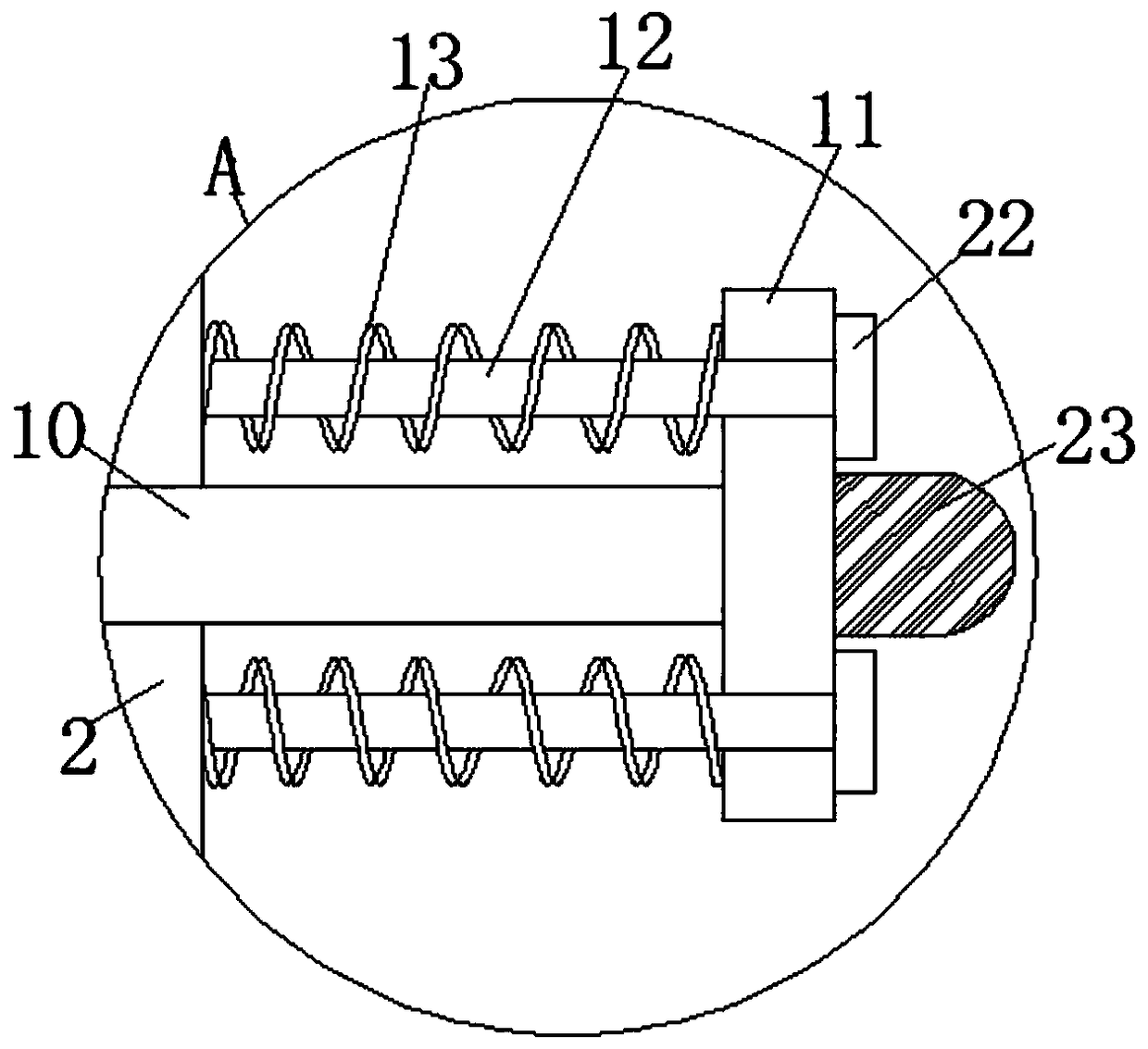

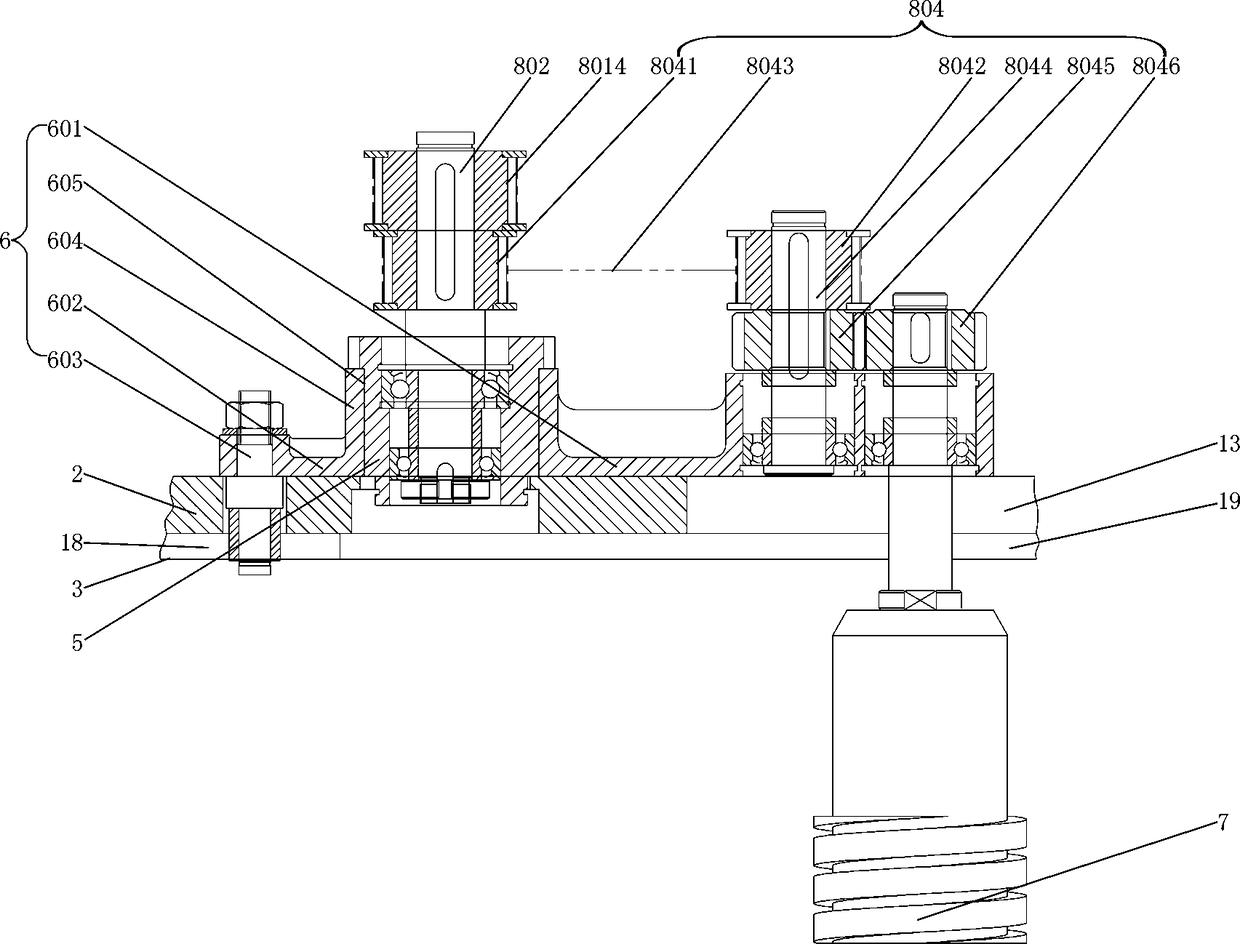

Safe positioning and adjustment device used for concrete pouring vehicle hose

ActiveCN107060342AEnsure personnel safetyPhysical stabilityBuilding material handlingEngineeringBelt safety

The invention discloses a safe positioning and adjustment device used for a concrete pouring vehicle hose and belongs to the field of safe positioning and adjustment. The safe positioning and adjustment device used for the concrete pouring vehicle hose comprises a fixing locking ring, a positioning operation ring, a hose lantern ring and an all-directional safety belt. According to the safe positioning and adjustment device, the positioning operation ring can be located around the hose through the fixing locking ring and a connecting rod, an operator controls a winding wheel to pull the hose lantern ring through a corresponding traction line, a corresponding movable pulley and a corresponding fixed pulley, the fixed pulley is fixed to the positioning operation ring, the hose lantern ring drives the hose to move, labor is saved during operation, the misoperation and misstep situations are effectively prevented, personal safety of the operator is ensured, accidents are effectively prevented from occurring to the operator through the all-directional safety belt and a safety rope mounted on the fixing locking ring, meanwhile, the body of the operator can be conveniently stabilized under the effects of a first magnet on an operation rod and a second magnet on the all-directional safety belt, and the accidents are further prevented.

Owner:武汉盛大长青建材有限公司

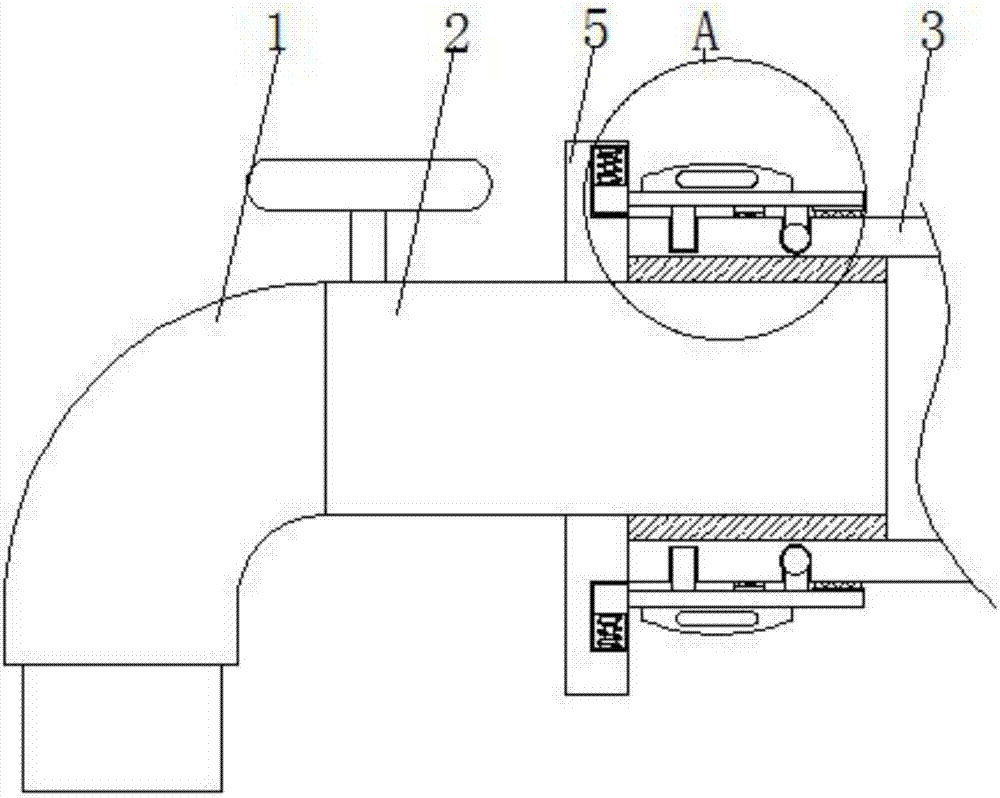

Intelligent water faucet convenient to mount and stable in butt-joint

InactiveCN107387912ASolve the inconvenience of installationEasy to installCouplingsEngineeringPiping

The invention discloses an intelligent water faucet convenient to mount and stable in butt-joint. The intelligent water faucet convenient to mount and stable in butt-joint comprises a water faucet, wherein one end of the water faucet is fixedly connected with a water inlet tube; the water faucet communicates with the water inlet tube; a water conveying tube sleeves the water inlet tube; a sealing sleeve sleeves the water inlet tube; the outer side wall of the sealing sleeve is in lap joint on the inner wall of the water conveying tube; the water inlet tube is sleeved by a hollow tube; slide rails are embedded into the upper end and the lower end of one side of the hollow block; slide blocks are in sliding connection in the slide rails; and back sides of the two slide blocks are movably connected with inner walls of the two slide rails through telescopic poles separately. According to the intelligent water faucet convenient to mount and stable in butt-joint disclosed by the invention, a limiting rod is improved, and a limiting ejector rod can be separated from a limiting slot when two slide blocks are reversely pulled; after the slide blocks are loosened, and the limiting rod is re-blocked into the limiting slot under action of resilience force of an extrusion spring, so that the connecting rods and soft balls are in stable sleeve connection in through slots and circular slots, and therefore, the water inlet tube is stably connected with the water conveying tube.

Owner:宁波鄞州竹创信息科技有限公司

Wrapping type dust easily-cleaned device based on Internet-of-Thing control

The invention relates to the technical field of Internet of Things, in particular to a wrapping type dust easily-cleaned device based on Internet-of-Thing control. The wrapping type dust easily-cleaned device solves the technical problems that an existing camera cleaning mechanism is limited in cleaning zone, the view is easily shielded, and stable cleaning is not facilitated. In order to solve the above technical problems, the wrapping type dust easily-cleaned device based on Internet-of-Thing control comprises an installing base inclined supporting rod, a fixed sheet inclined supporting rodis welded to the top of the installing base inclined supporting rod, the two sides of the top of the fixed sheet inclined supporting rod are fixedly connected with the two sides of the bottom of the side surface of a U-shaped rod inclined supporting rod through strut inclined supporting rods, and one end of the U-shaped rod inclined supporting rod is fixedly connected with a camera inclined supporting rod. According to the wrapping type dust easily-cleaned device based on Internet-of-Thing control, an inclined movable wrapping mechanism can conveniently cover a camera, or the inclined movablewrapping mechanism can conveniently move to the position far away from the camera, cleanliness of the camera can be conveniently completed, and the monitoring view of the camera is not influenced.

Owner:ZHENGZHOU INST OF TECH

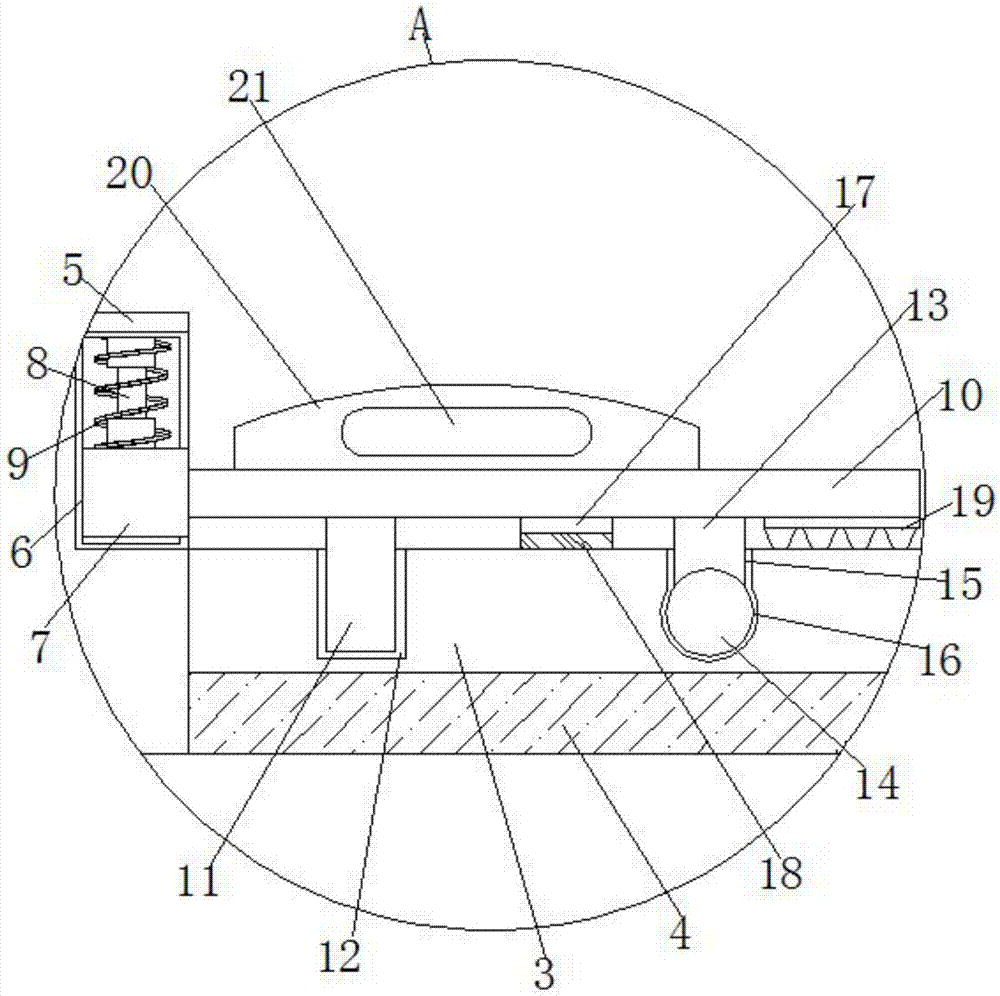

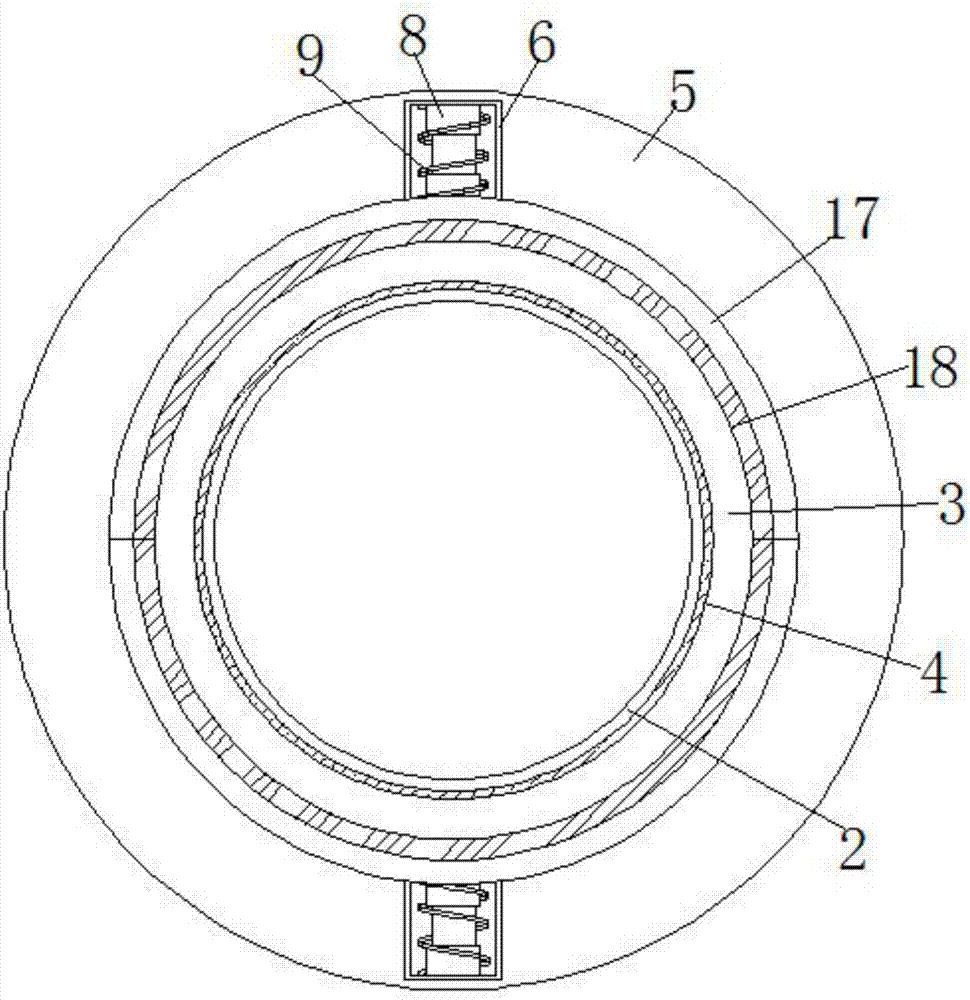

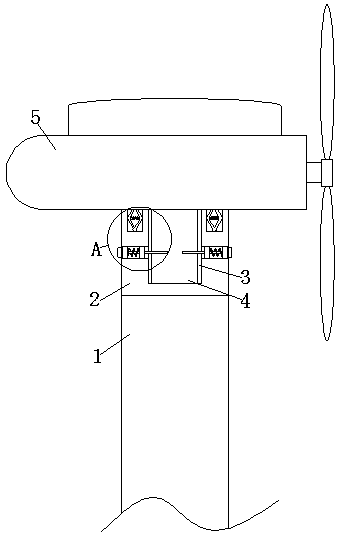

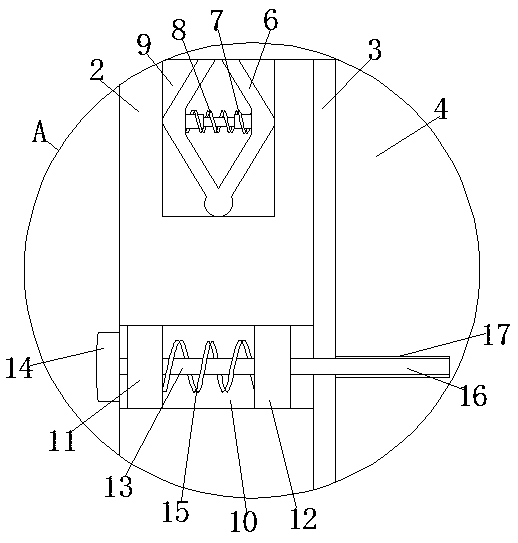

Wind power generation device for new energy

InactiveCN107829882AQuick connectionSocket firmlyWind motor supports/mountsWind energy generationButt jointNew energy

The invention discloses a wind power generation device for new energy. The wind power generation device comprises a strut. An installing column is fixedly connected to the top end of the strut. The top of the installing column is provided with a butt-joint groove. A butt-joint rod is sleeved with the butt-joint groove. A wind power generator is fixedly connected to the top end of the butt-joint rod. The bottom of the wind power generator is connected to the top of the installing column in an overlapped mode. Rhombic soft plates are fixedly connected to both the two sides of the bottom of the wind power generator. The two sides of the inner walls of the rhombic soft plates are movably connected through telescopic rods. The telescopic rods are sleeved with extrusion springs. According to thewind power generation device, clamping rods are improved, thus when two pull plates are pulled oppositely, pull rods can drive two pistons to move oppositely in two round grooves correspondingly, thepistons can drive the clamping rods to leave clamping holes, the butt-joint rod can be taken out of the butt-joint groove conveniently, the pull plates are loosened, and under the action of clampingsprings, the pistons can push the clamping rods to be inserted in the clamping holes so that the wind power generator can be installed fast.

Owner:王丽

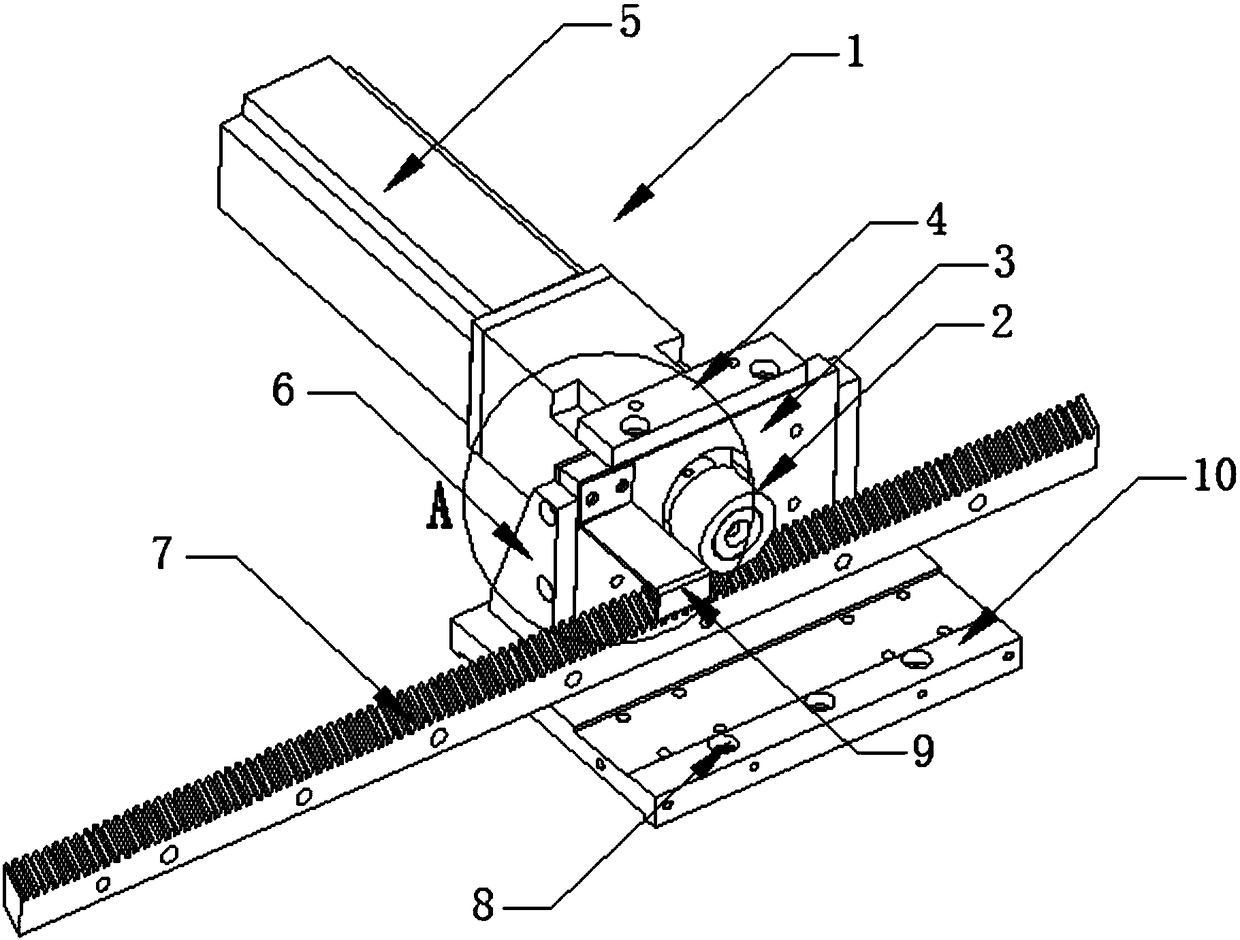

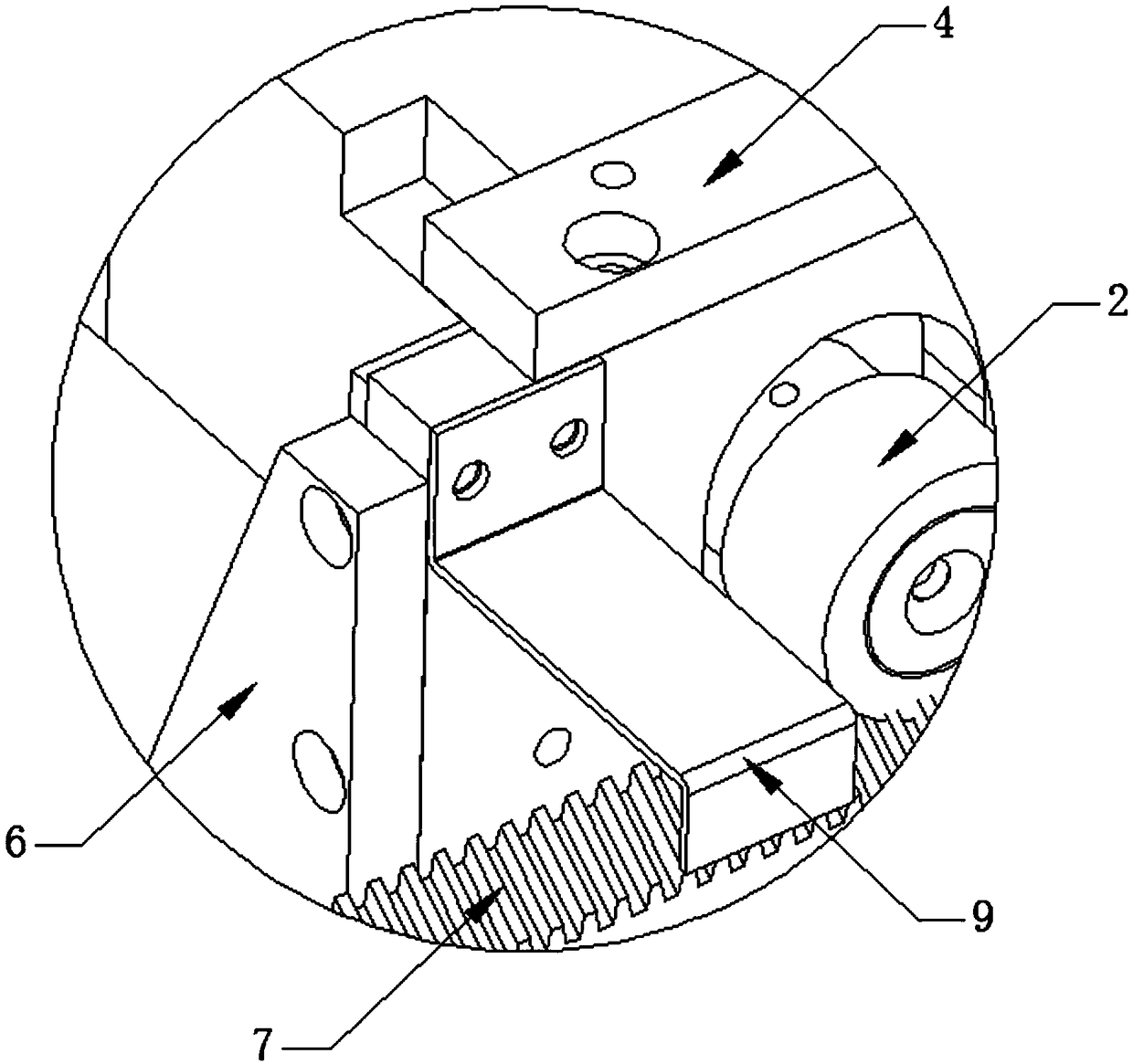

Transmission device for gear guide rail

InactiveCN108374871ASimple structurePracticalCouplings for rigid shaftsGearing detailsMotor driveFixed frame

The invention discloses a transmission device for a gear guide rail. The transmission device comprises a transmission cap which is longitudinally arranged, wherein a concave opening is embedded in theinner wall of the transmission cap; a rotating shaft is clamped by the transmission cap through the concave opening; a convex block is welded on the outer wall of the rotating shaft; a round hole penetrates through the middle part of the transmission cap; a clamping piece is clamped on one end of the transmission cap; a fixed frame is sleeved at the outer part of the rotating shaft; two supporting plates are respectively arranged at two sides of the fixed frame; a fixed plate is arranged at the top part of the fixed frame; a motor is arranged on one end of the rotating shaft; a baffle plate is arranged on the outer wall of the fixed frame; a base is arranged under the fixed frame; a plurality of screw holes which are uniformly distributed are formed in one end of the base; the gear guiderail is arranged above the base; the motor drives the rotating shaft to rotate, the rotating shaft drives the transmission cap to rotate, and the transmission cap drives the gear guide rail to slide through a gear.

Owner:曹国平

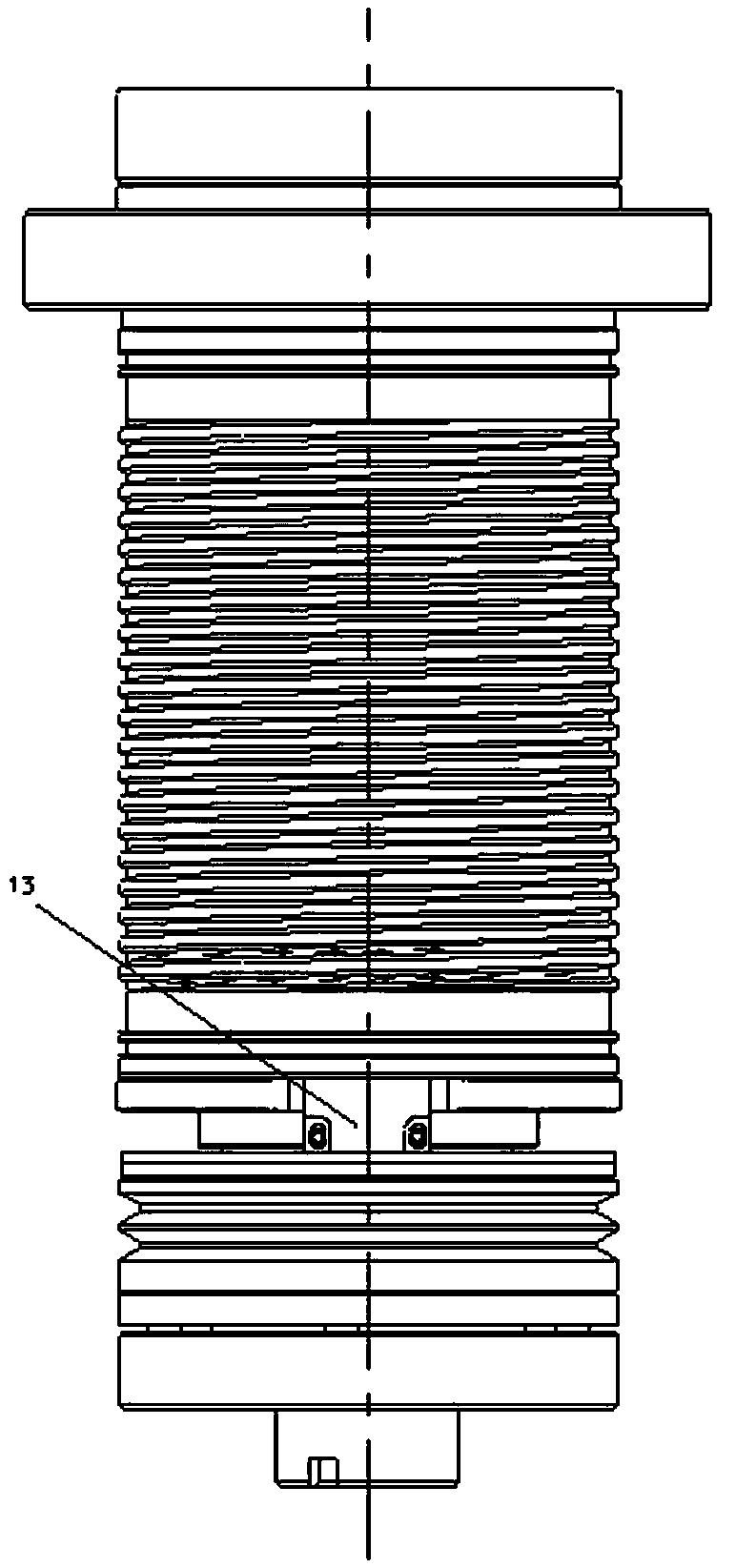

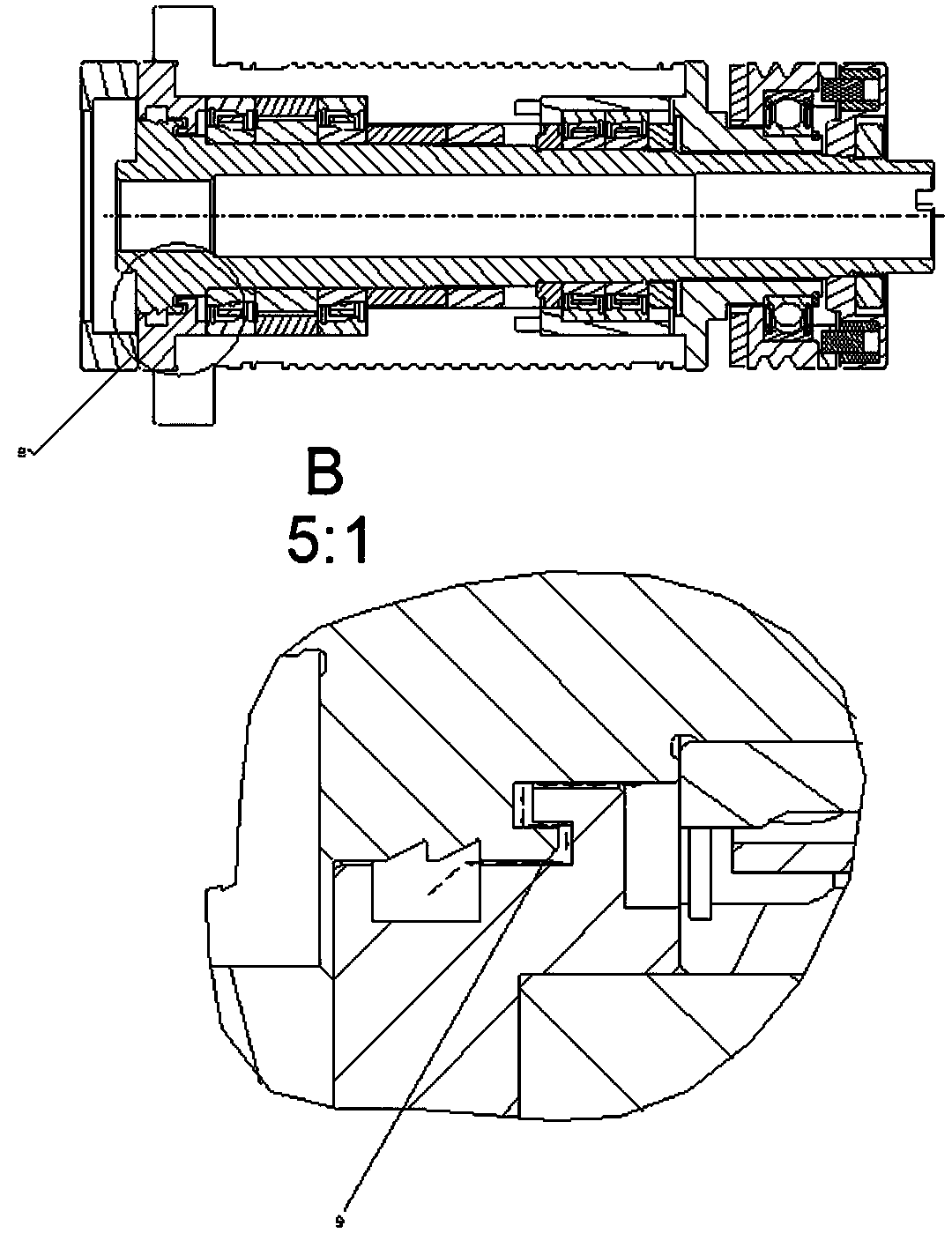

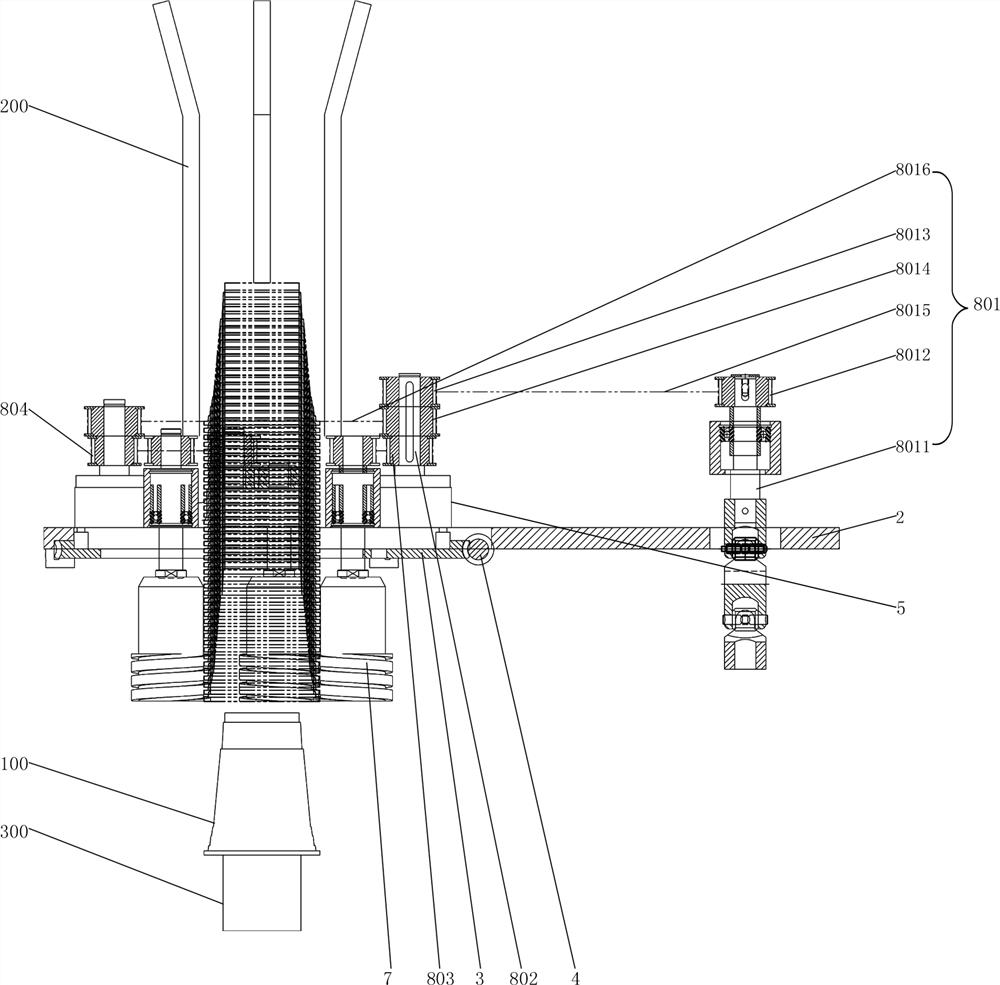

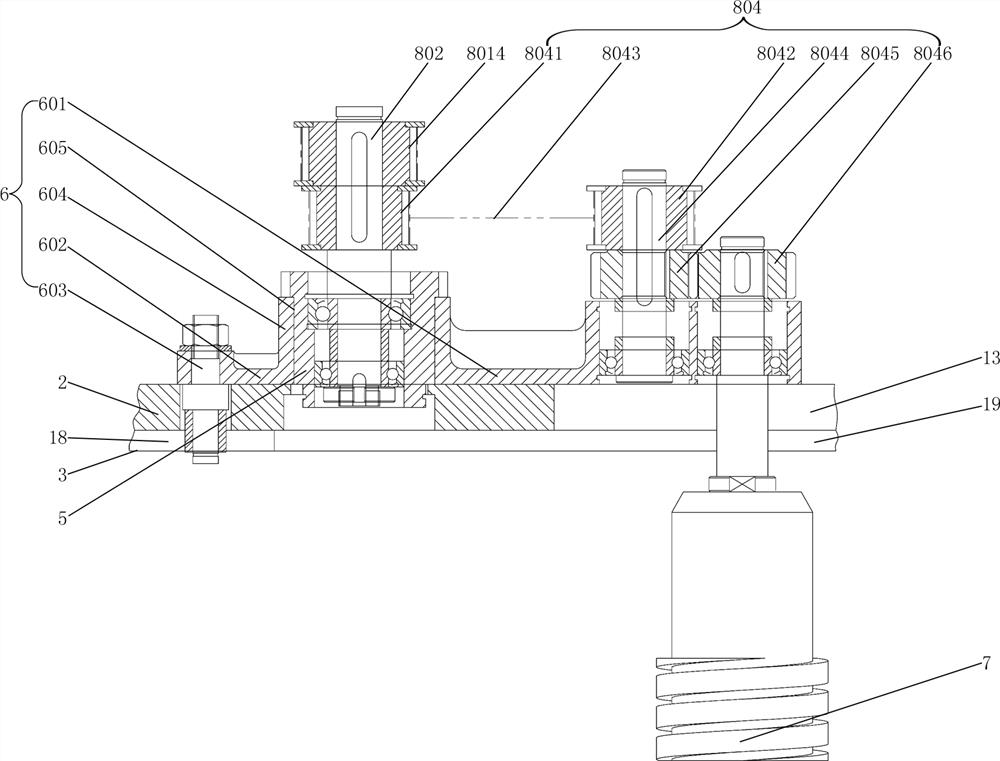

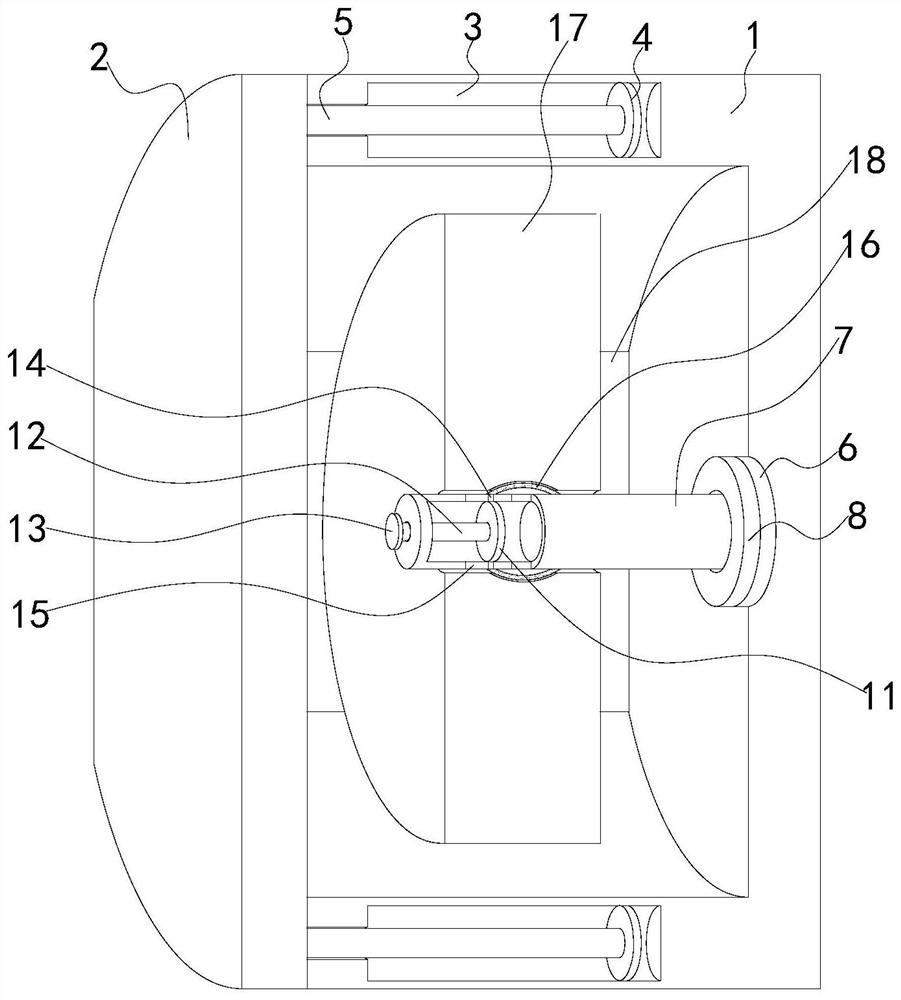

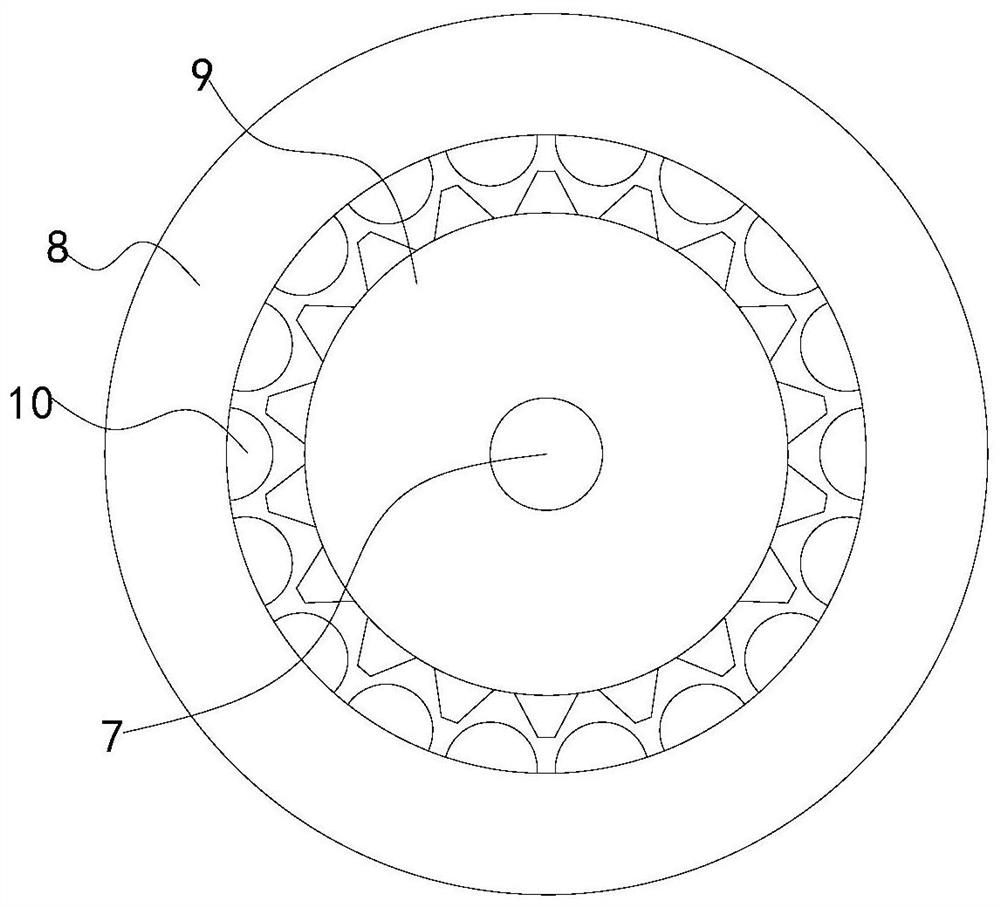

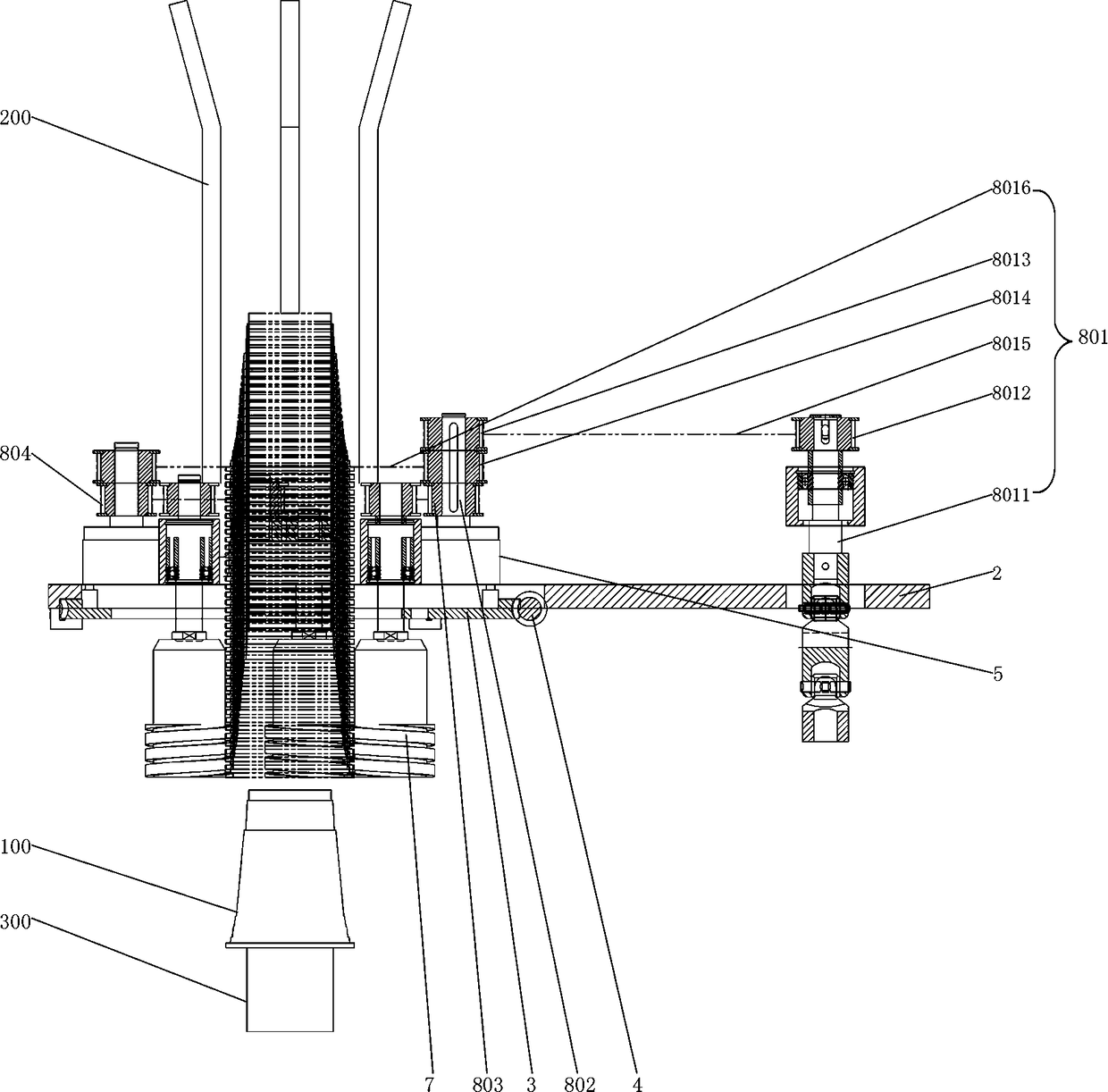

Lathe spindle

InactiveCN110238415ASocket firmlyGuaranteed stabilityLarge fixed membersMaintainance and safety accessoriesEngineeringMachine parts

The invention provides a lathe spindle. The lathe spindle comprises a spindle core and a body sleeved on the spindle core, a belt wheel assembly used for driving the spindle core to rotate is arranged on the spindle core in a sleeved mode, the belt wheel assembly comprises a belt wheel arranged on the spindle core in a sleeved mode and a driving ring arranged on the spindle core in a sleeving mode and fixedly connected with the belt wheel and used for driving the spindle core to rotate, a first damping part is arranged between the belt wheel and the spindle core in a sleeved mode, and a second damping part is arranged at the fixed connection part between the belt wheel and the driving ring. According to the lathe spindle, the first damping part is arranged between the belt wheel and the spindle core in a sleeved mode, the second damping part is arranged at the joint between the driving ring and the belt wheel, the vibration generated by the belt wheel is greatly weakened by the first damping part and the second damping part, so that the spindle core can be prevented from being in radial linkage with the sleeving position of the belt wheel in the rotating process of the spindle core, the spindle core is prevented from being in radial linkage with the sleeving position of the driving ring in the rotating process of the spindle core, the stability of the spindle core in the rotating process is ensured, and the precision of a machined part machined by the lathe spindle is higher.

Owner:深圳市兴旺达科技有限公司

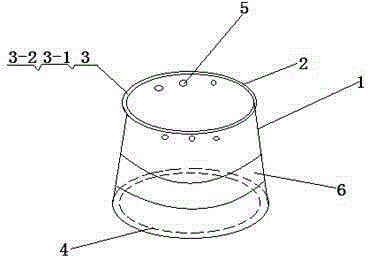

Dustbin

The invention relates to a dustbin, which comprises a dustbin body. The dustbin is characterized in that the interior of the dustbin body is provided with an inner bracket, the inner bracket consists of a plurality of elastic vertical rods and a plurality of transverse press strips, the elastic vertical rods are fixedly connected with the bottom end of the inner bracket, the transverse press strips are respectively and fixedly arranged at the upper ends of the elastic vertical rods, the shape of each transverse press strip corresponds to the shape of the inner cavity of the dustbin body, and the transverse press strips are attached on the inner wall of the dustbin body. The dustbin has the beneficial effects that after a large plastic bag coats all the transverse press strips, the excessive part of the plastic bag is extruded into the dustbin through elastic force, a small plastic bag only coats one part of transverse press strips, and an opening or a lift handle of the plastic bag can also be pressed into the dustbin, so a plurality of plastic bags different in sizes can coat the dustbin; the plastic bags can more stably coat the dustbin, so the falling of the plastic bags loaded with garbage is avoided; by adopting the inner bracket structure, the plastic bag cannot be exposed out of the dustbin, so the appearance is attractive.

Owner:雷海平

Convenient-to-install intelligent alarm for fire protection

InactiveCN108091097AEasy to installEasy to disassembleCasings/cabinets/drawers detailsFire alarm smoke/gas actuationFire protectionWear resistant

The invention discloses a convenient-to-install intelligent alarm for fire protection. The intelligent alarm comprises an alarm; the top of the alarm is fixedly connected with an installation sleeve;two sides of the inner side of the installation sleeve are fixedly connected with two sliding sleeves respectively; one piston is connected slidingly inside each sliding sleeve; opposite sides of thetwo pistons are fixedly connected with one end of one push rod and one end of the other push rod respectively; the other ends of the push rods penetrate the sliding sleeves and extend out form the sliding sleeves; and the tops and bottoms of the surfaces of the push rods are movably connected with upper inclined plates and lower inclined plates outside the sliding sleeves. According to the convenient-to-install intelligent alarm for fire protection of the invention, clamping rods are improved; when two pressing plates are pressed relative to each other, two sliding blocks can be driven to moverelative to each other through the pistons and connecting rods, at this moment, the clamping rods can be disengaged from pre-formed clamping slots in a ceiling, and therefore, the alarm can be disassembled conveniently; and after the pressing plates are released, wear-resistant balls can be in lap joint with the interiors of through slots formed in the ceiling under the action of the resilience of clamping springs, so that the alarm can be easily installed.

Owner:宁波鄞州竹创信息科技有限公司

Sealing method for container

The invention provides a sealing method for a container. The sealing method comprises the following steps: manufacturing a ring-shaped sealing sleeve adaptive to the periphery of a bottle body by adopting a rubber material which expands with heat and contracts with cold; arranging a ring of ring-shaped stripes capable of being torn in the middle of a ring-shaped outer sleeve; heating the ring-shaped sealing sleeve, and then arranging the heated ring-shaped sealing sleeve at the periphery of the bottle body and at the periphery of a bottle cover in a sleeving mode; and arranging the ring-shaped stripes at an intersection position of the bottle body and the bottle cover. According to the sealing method, an outer cover re-sealing mode is adopted, so that the outer cover is very easy to open, and therefore, anti-theft and anti-fake purposes can be achieved, and quality guarantee time of products in a bottle can be prolonged. After the ring-shaped stripes are torn, the ring-shaped sealing sleeve is changed into two sections which are respectively arranged on the bottle body and the bottle cover in the sleeving mode, so that the container is protected; and meanwhile, the container, which is made of a plastic or elastic material, is convenient for a consumer to hold.

Owner:SHANGHAI YUQIAN CONTAINER CO LTD

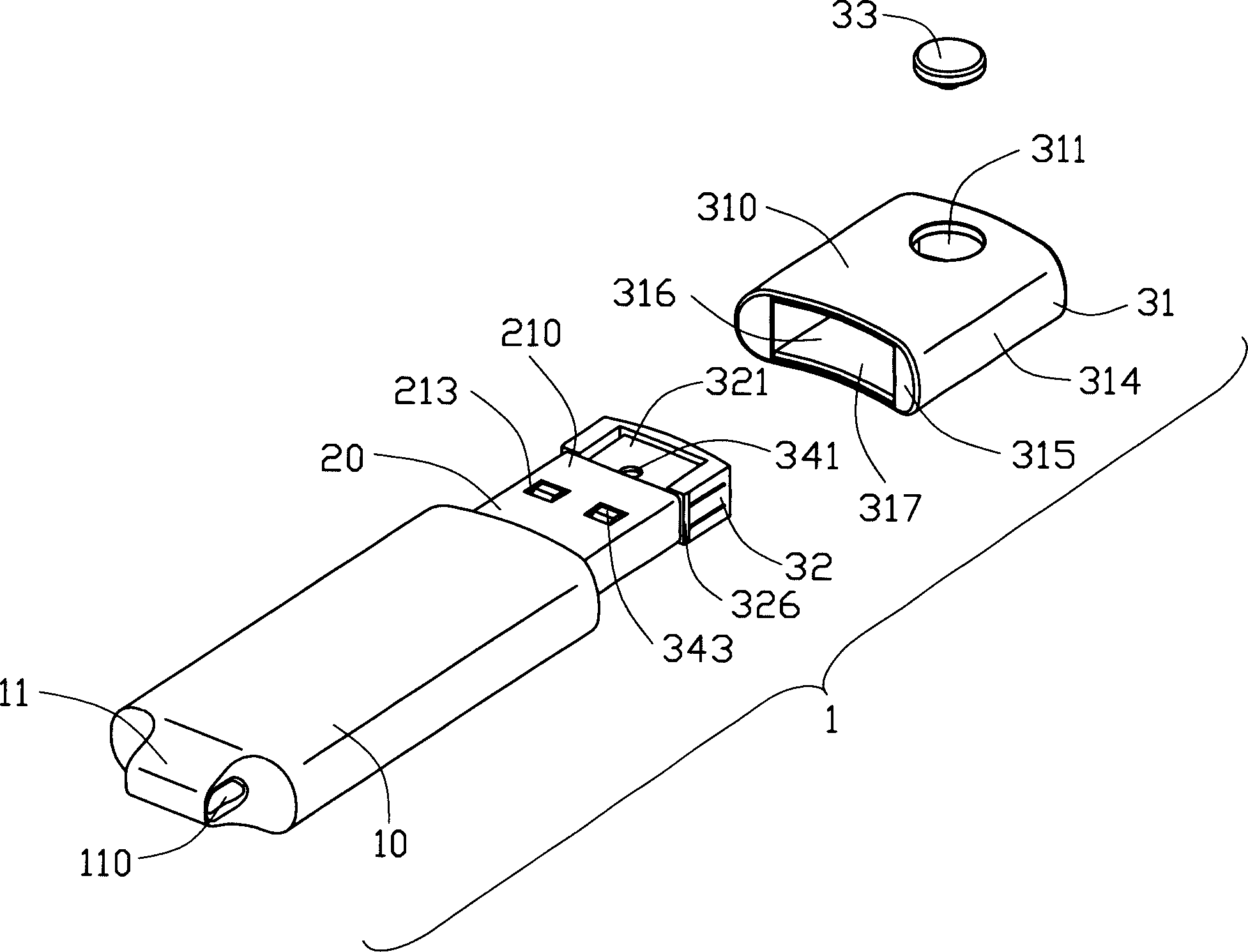

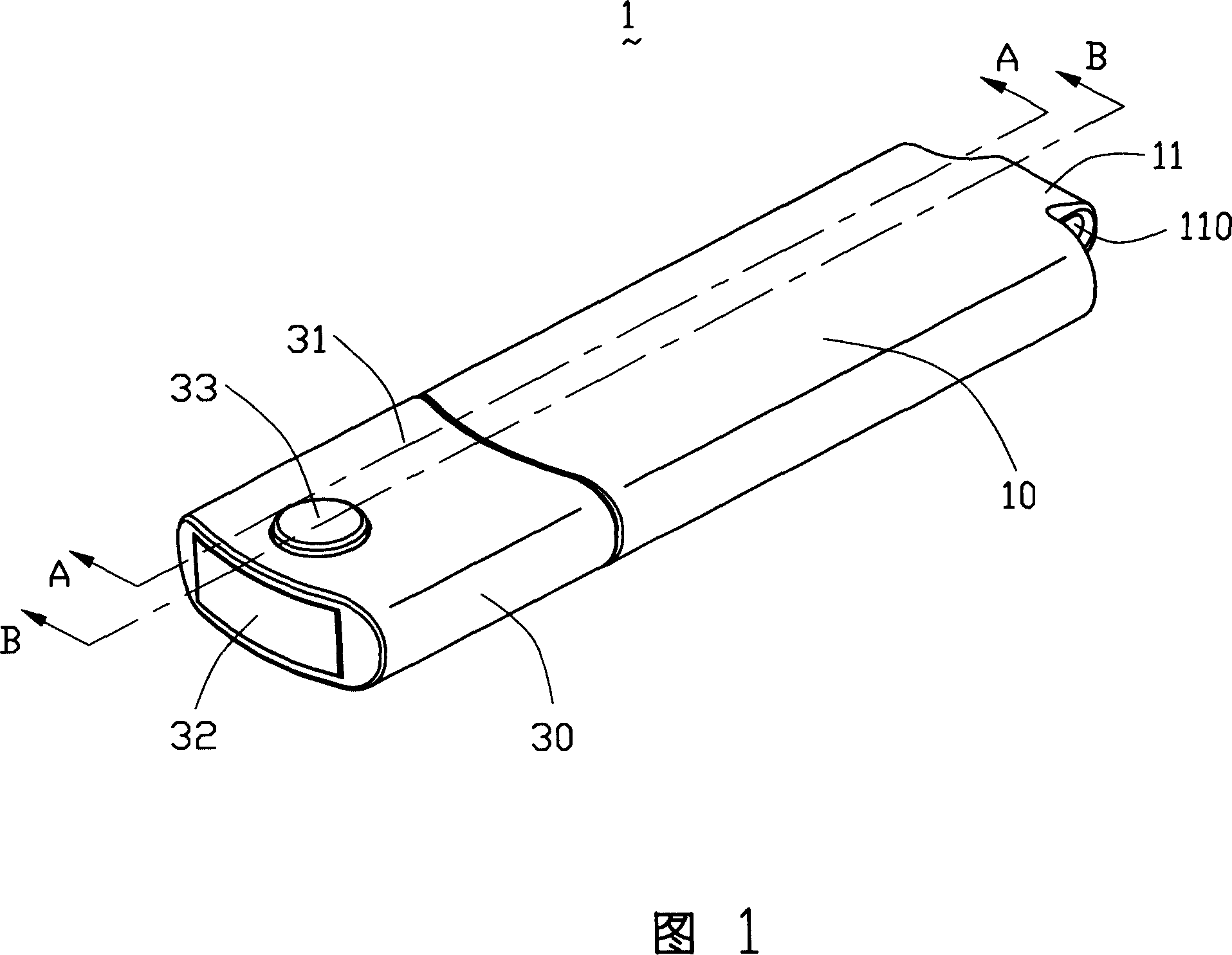

Fast flasher memory and USB interface protective cover

InactiveCN1835663ASocket firmlyAvoid sheddingDigital data processing detailsCasings/cabinets/drawers detailsPush outEngineering

The invention comprises: a case, a control circuit board located in the case and a USB port connected to the control circuit board. Wherein, the USB port has a metal shell whose top wall has an acceptance hole. The USB port protective cover houses the elastic component in the metal shell and the button located on the shell and the elastic component. There is an extruding portion on the elastic component, which can extend to the acceptance hole of the USB port when the protective cover sleeves the USB port. When the USB protective cover needs to be removed, the button can be pressed to push out the protruding portion from the acceptance portion of the USB port.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

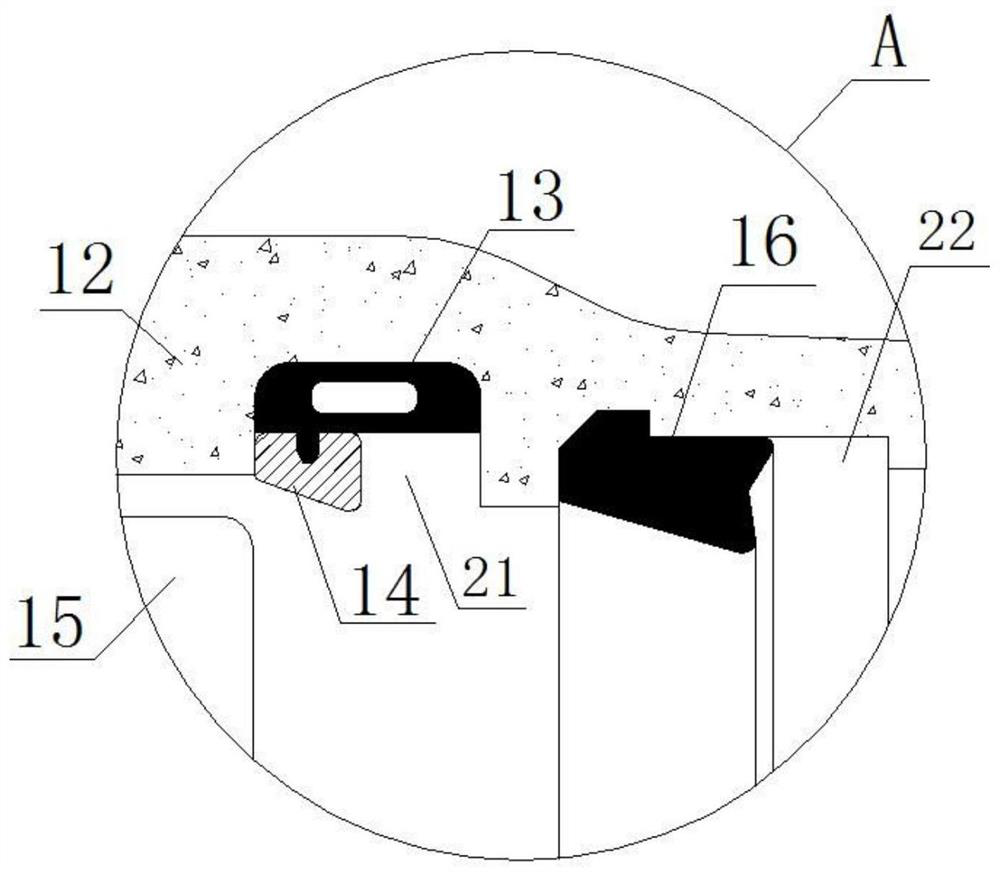

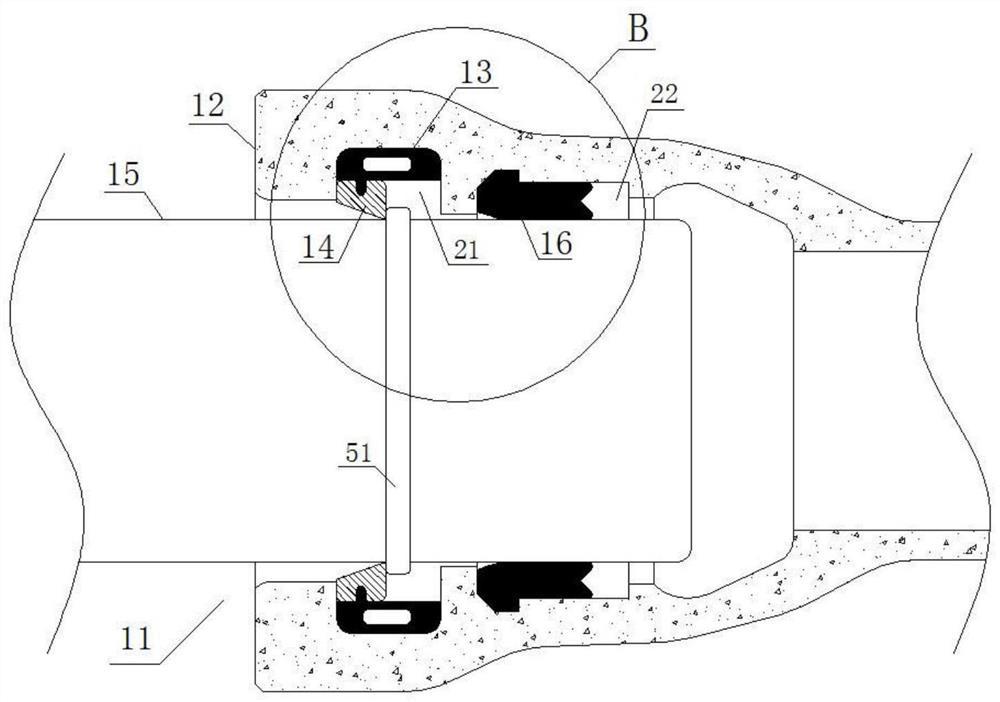

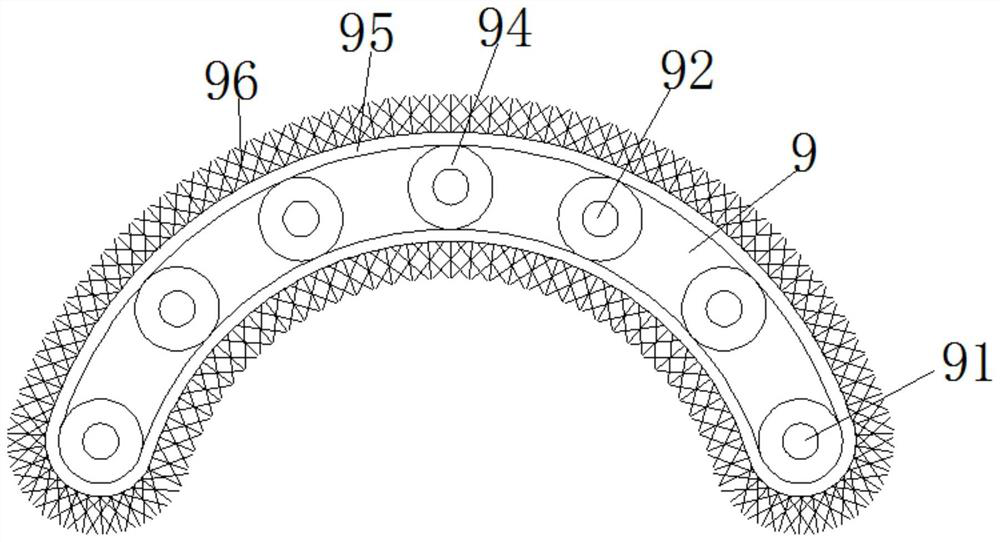

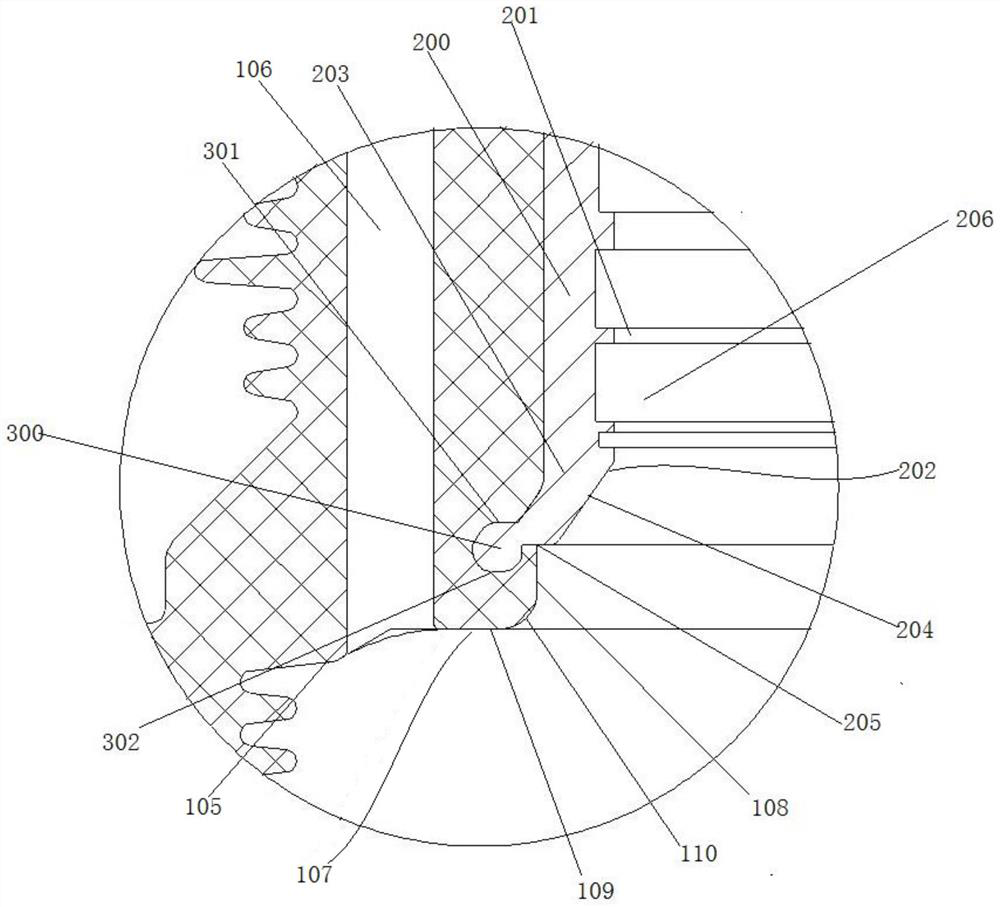

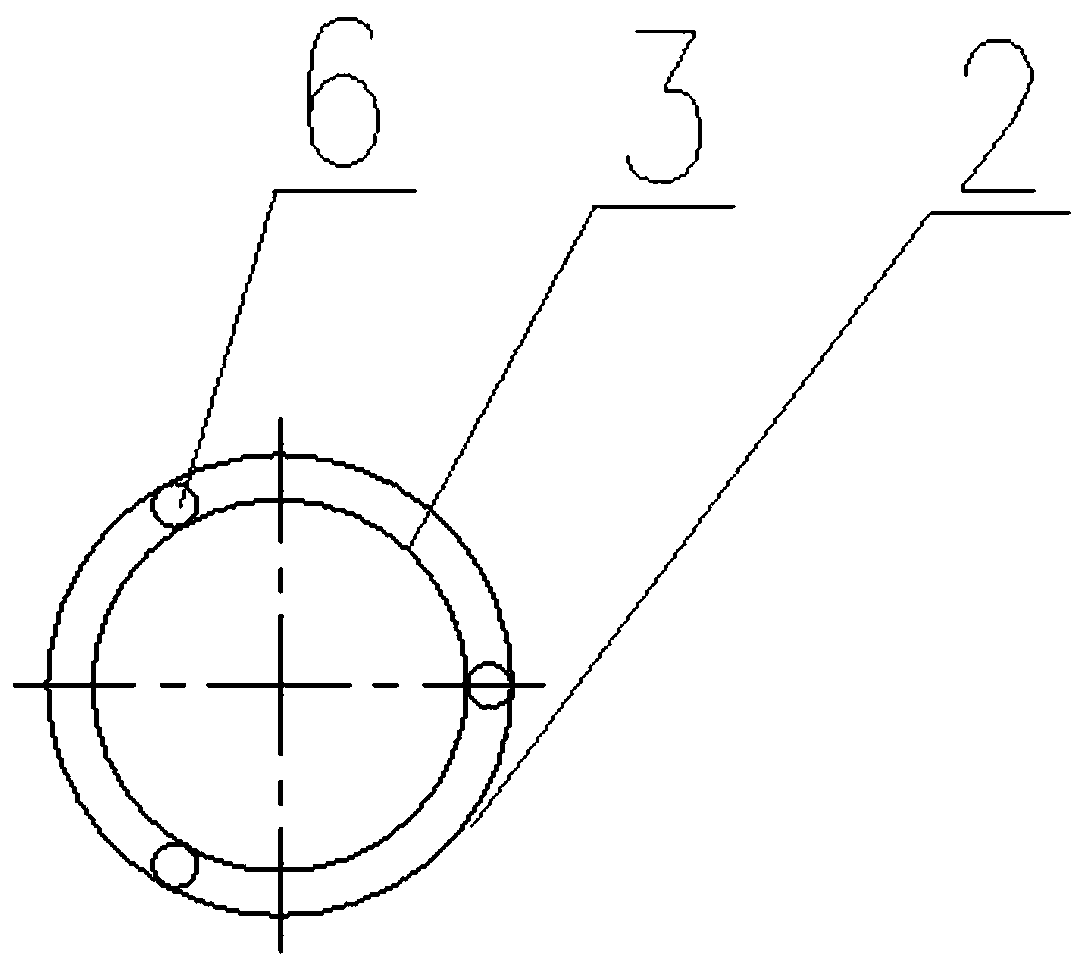

Compound rubber sealing ring of ultra-large water supply spigot and socket pipe

ActiveCN112240391AEasy to installSocket firmlySleeve/socket jointsEngine sealsRubber ringStructural engineering

The invention discloses a compound rubber sealing ring of an ultra-large water supply spigot and socket pipe. The compound rubber sealing ring comprises anti-falling annular grooves formed close to the end in a socket of the spigot and socket pipe, wherein an anti-falling rubber ring is arranged in each anti-falling annular groove; a cavity annular groove is formed in each anti-falling rubber ringin an annular direction; a plurality of fixing tongues are arranged on each anti-falling rubber ring; the plurality of fixing tongues are sleeved with arc-shaped anti-falling strips; an anti-fallingconvex ring is integrally arranged on the outer wall of the spigot of the spigot and socket pipe; a rubber ring groove is formed in one side of each anti-falling annular groove in the socket; and a rubber sealing ring is arranged in each rubber ring groove. The compound rubber sealing ring of the ultra-large water supply spigot and socket pipe is convenient to mount, good in connecting effect andnot easy to slip; the construction period is shortened; the construction cost is reduced; and the sealing effect is good.

Owner:天津市际华橡胶制品有限公司

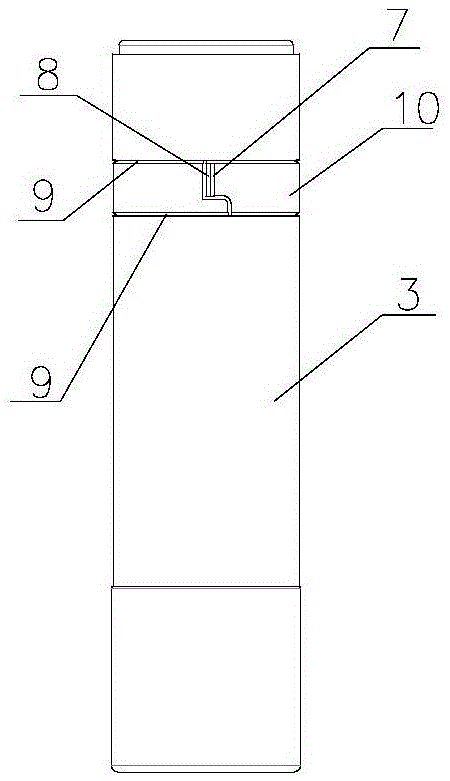

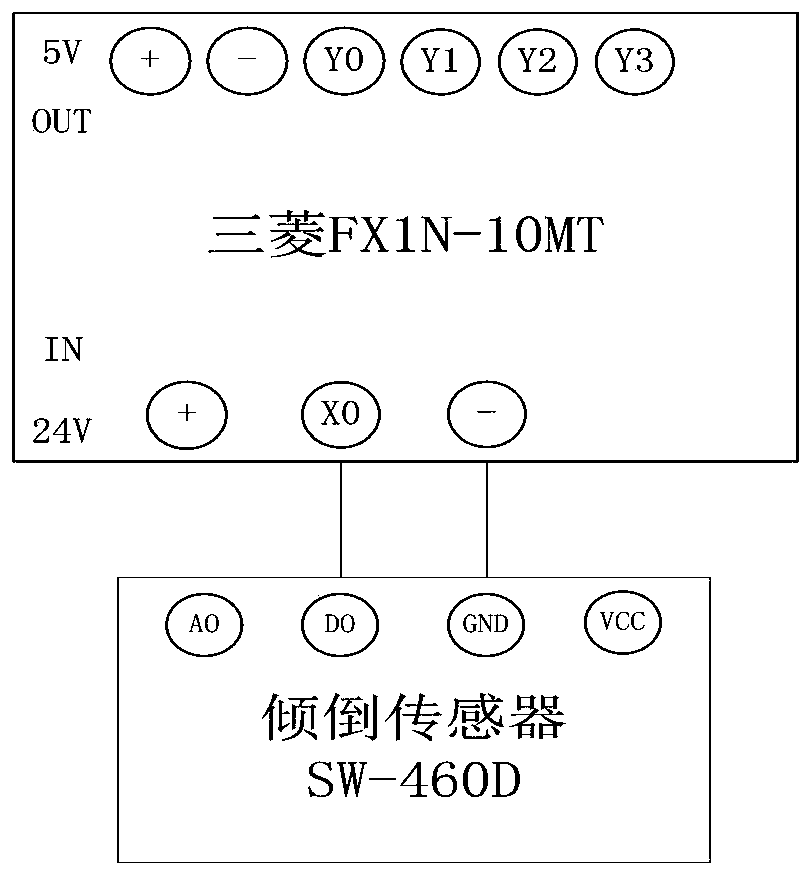

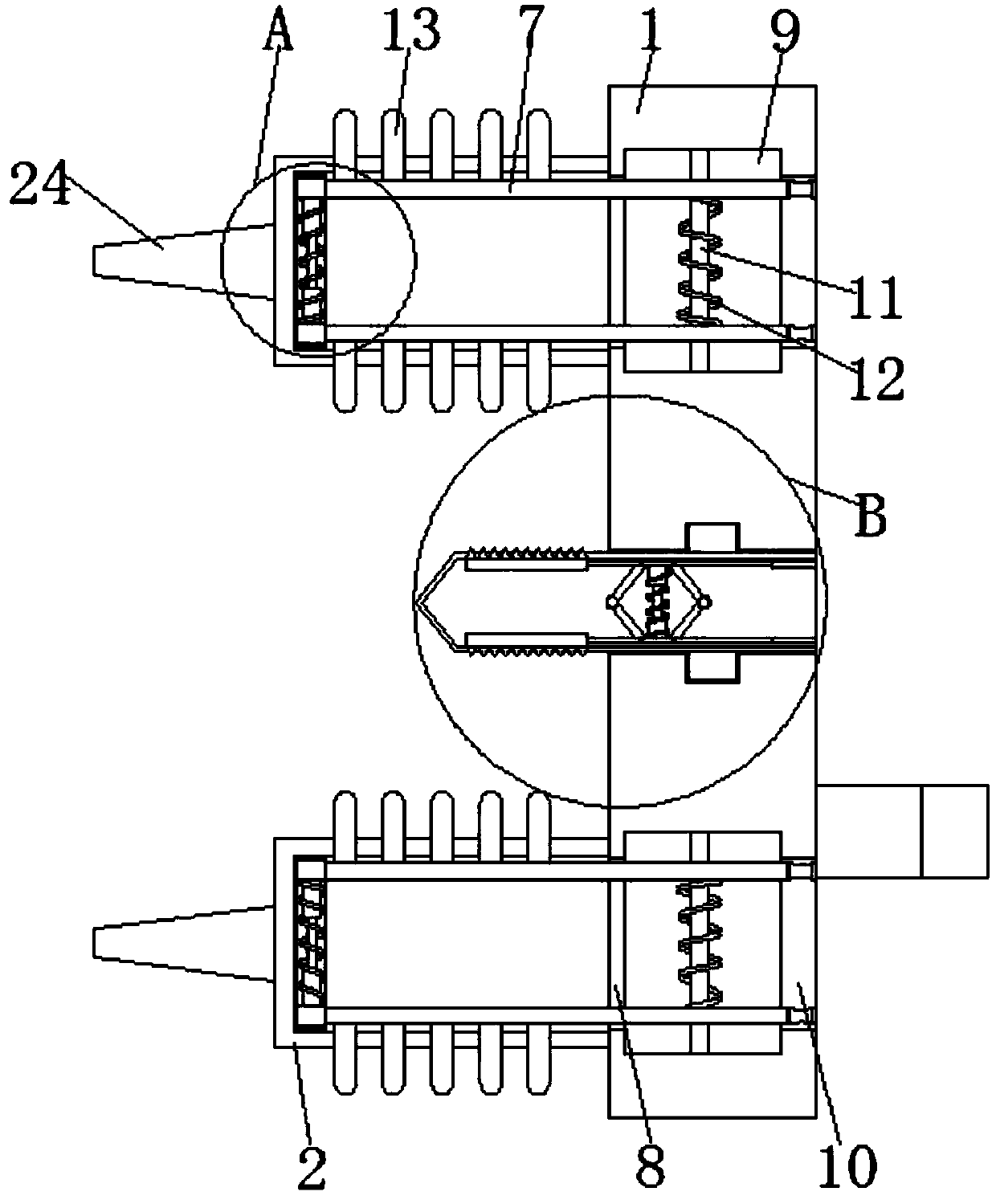

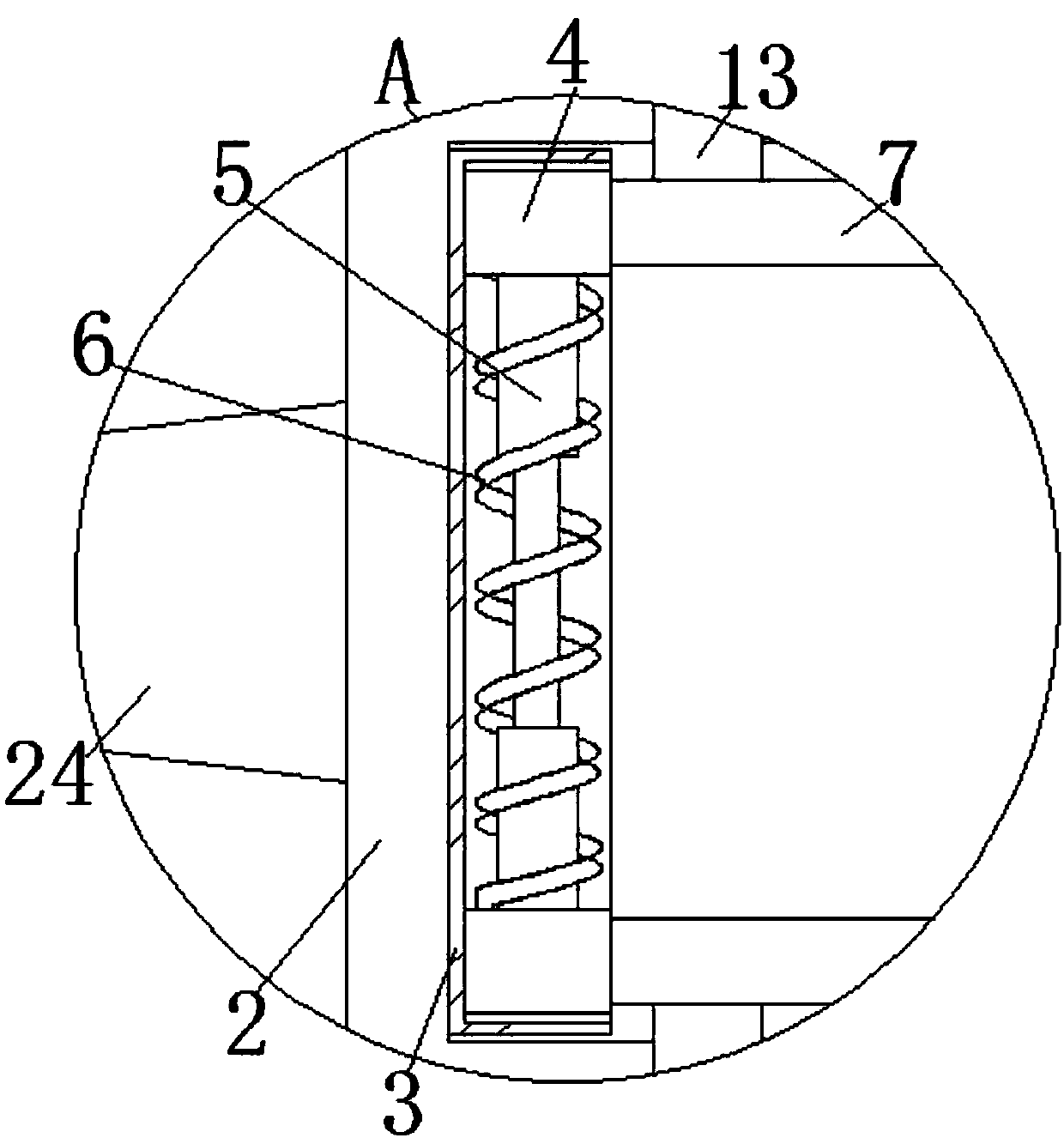

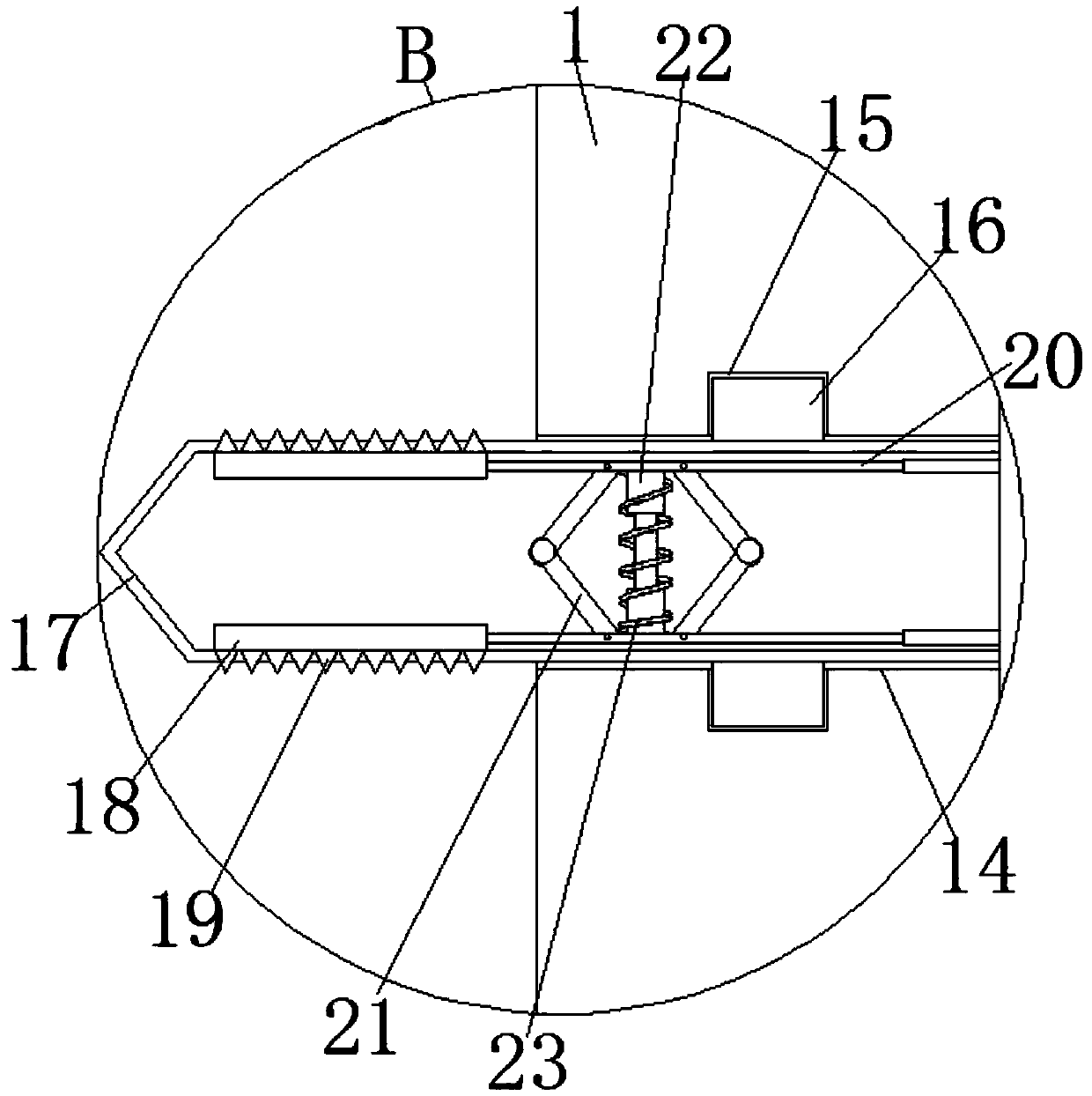

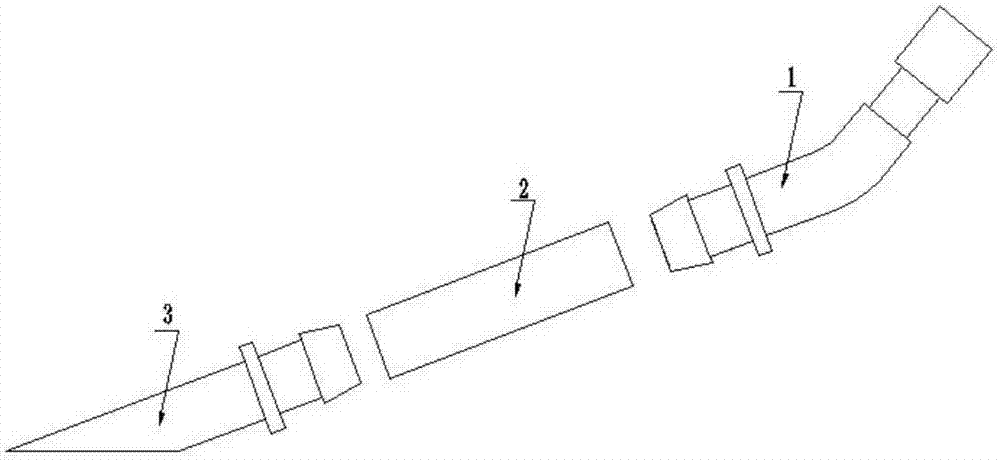

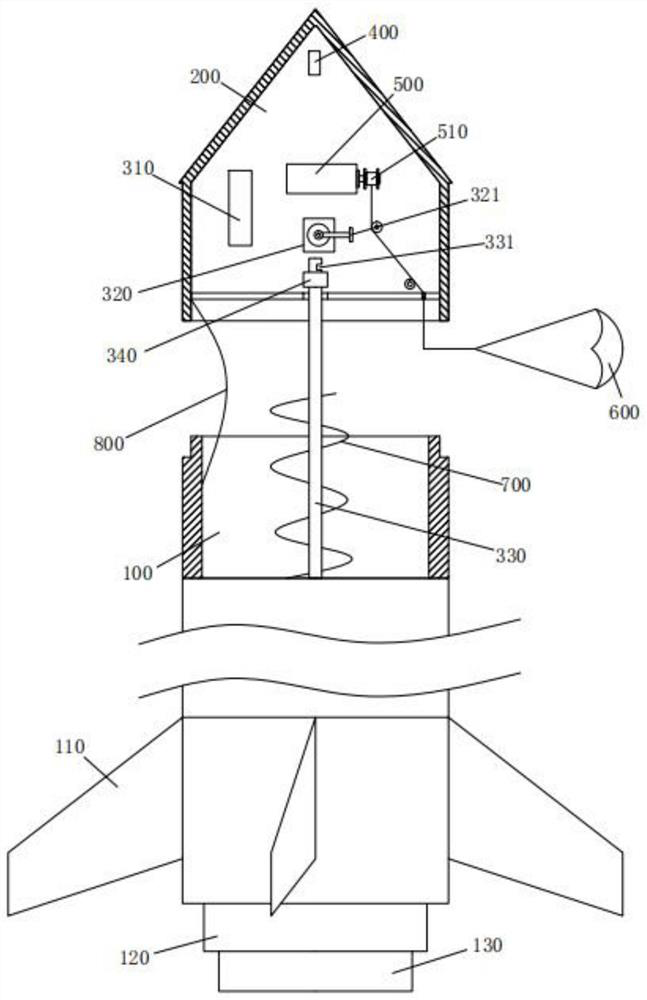

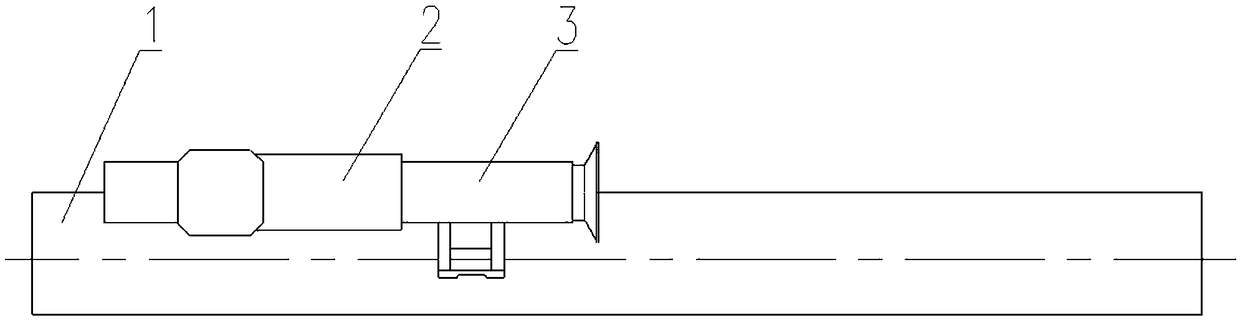

Model rocket convenient to recycle

The invention relates to a model rocket convenient to recycle. The model roket comprises a rocket head and a rocket body, and a sensor and a parachute are arranged in the rocket, and the sensor is connected to an adjusting mechanism. In the operation process of the rocket, the adjusting mechanism adjusts the rocket head to be in two states, wherein one state is that the rocket is in an upright posture during lift-off, and when the sensor does not detect the change of the rocket attitude, the adjusting mechanism adjusts the rocket head to be in the working state of being assembled on the rocketbody; the second state is that the posture of the rocket is changed when the rocket falls down; the sensor detects the attitude change of the rocket, the adjusting mechanism adjusts the rocket head to be in a separation state of separating from the rocket body to release the parachute according to a signal detected by the sensor. The model rocket is stable in structure and reasonable in layout, the rocket head and the rocket body can be separated in time and the parachute can be released when the falling posture of the rocket is changed after the rocket lifts off, parachute ropes of the parachute can be wound when the rocket is about to fall to the ground, resistance is increased, landing impact force is reduced, and the risk that the rocket is damaged by falling is effectively reduced.

Owner:CHAOHU UNIV

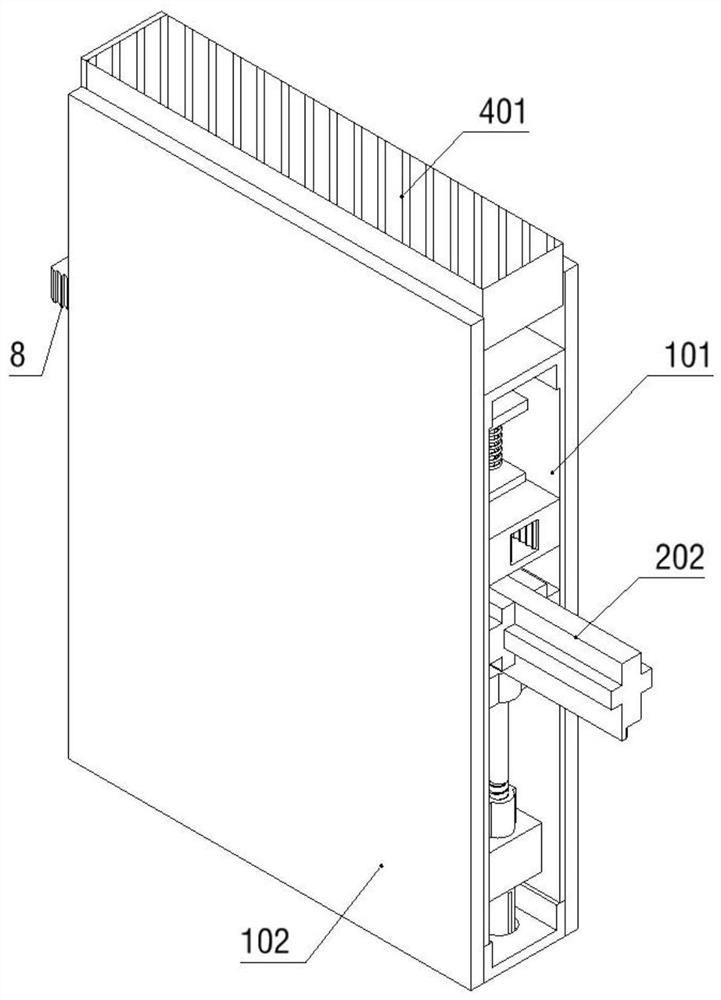

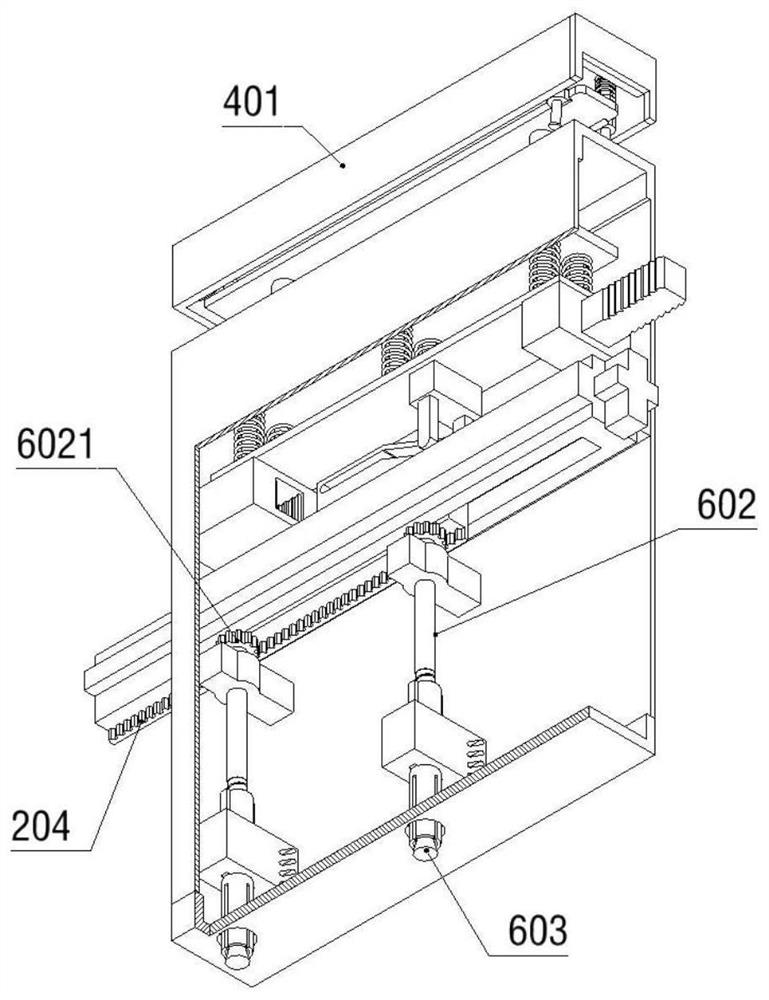

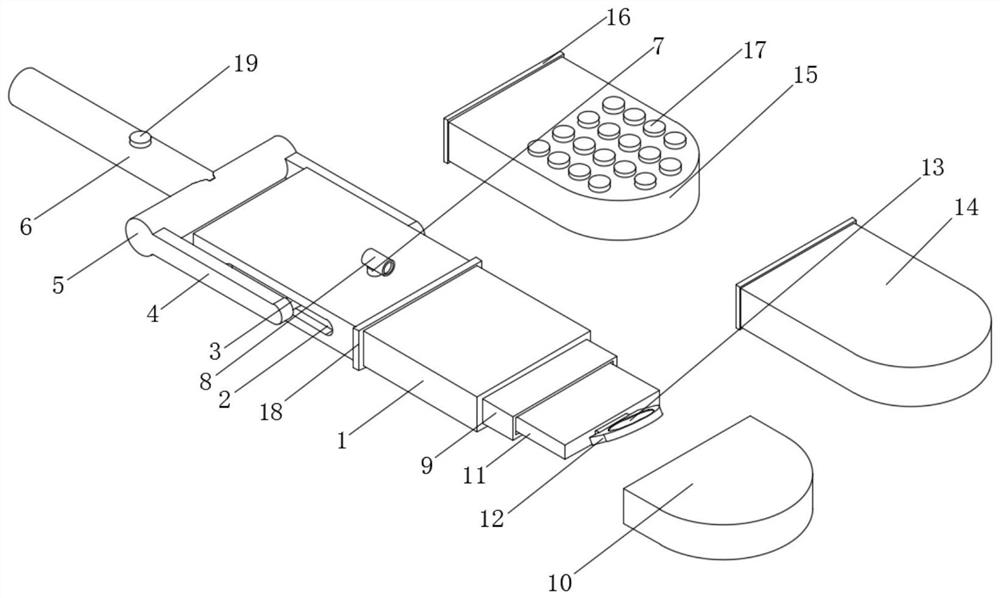

Intelligent lock capable of being mounted stably

ActiveCN107905627AEasy to assemble and disassembleSolve the inconvenience of disassemblyLock casingsComputer engineeringExtrusion

The invention discloses an intelligent lock capable of being mounted stably. The intelligent lock comprises an intelligent control panel; the upper side and the lower side of one side of the intelligent control panel are fixedly connected with hollow sleeves; sliding rails are fixedly connected with the inner walls of one sides, departing from the intelligent control panel, of the hollow sleeves;two sliding blocks are connected with the interior of each sliding rail; the opposite sides of every two sliding blocks are movably connected through first expansion rods; the first expansion rods aresleeved and connected with extrusion springs; the two ends of each extrusion spring are fixedly connected with the opposite sides of the two sliding blocks correspondingly; and one side, departing form the corresponding sliding rail, of each sliding block is fixedly connected with one end of a pressing plate. According to the intelligent lock capable of being mounted stably, through improvement on clamping rods, firstly two groups of pressing plates are extruded relatively and the hollow sleeves are inserted into and connected with plugholes formed in the door sheet in advance, and then the pressing plates are released and by the action of resilience force of the extrusion springs, the clamping rods can be inserted into and connected with clamping holes formed in the inner walls of the plugholes in the door sheet, by this time, the intelligent lock can be quickly mounted.

Owner:GUANGZHOU SNIMAY HOME FURNITURE CO LTD

Assembly type indoor sound insulation wall auxiliary assembly

The invention provides an assembly type indoor sound insulation wall auxiliary assembly, and relates to the technical field of sound insulation wall bodies. A linkage part is mounted on the frame part; a tightening device is slidably connected to the frame part, and a fitting part is rotatably connected to the tightening device; an edge sealing device is fixedly connected into the frame part; two floating driving parts are mounted in the frame part; two linkage expansion parts are mounted in the frame part; a ratchet-shaped tooth block is fixedly connected into the frame part, the frame part is provided with a linkage part in a matched mode; fitting driving on the top surface of a building and tight fitting between walls can be achieved; the structure is simple; the linkage is efficient; the wall installation is more stable; meanwhile, glue pollution is effectively reduced; and the sound insulation effect is effectively improved. The problems that the sound insulation performance of a building is affected, the environmental protection performance is poor and the installation is not stable enough since joints between walls are large and later grouting and glue supplementing are needed are solved.

Owner:长春恒发房地产开发有限公司

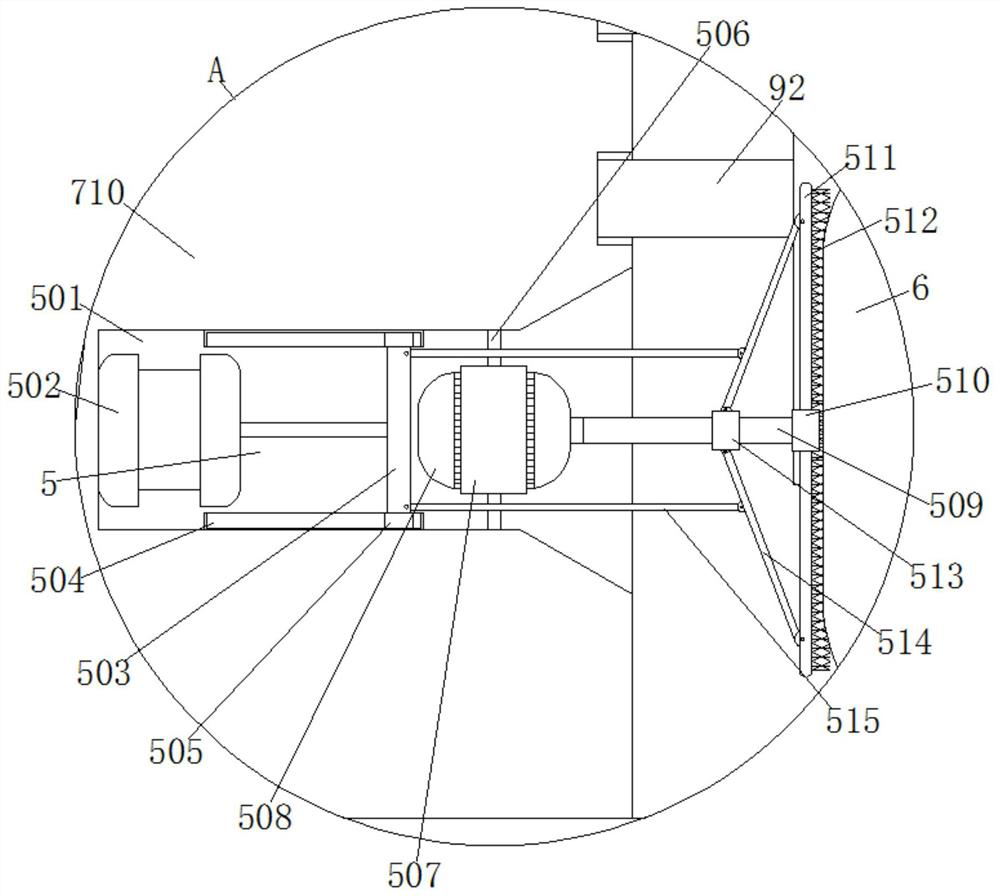

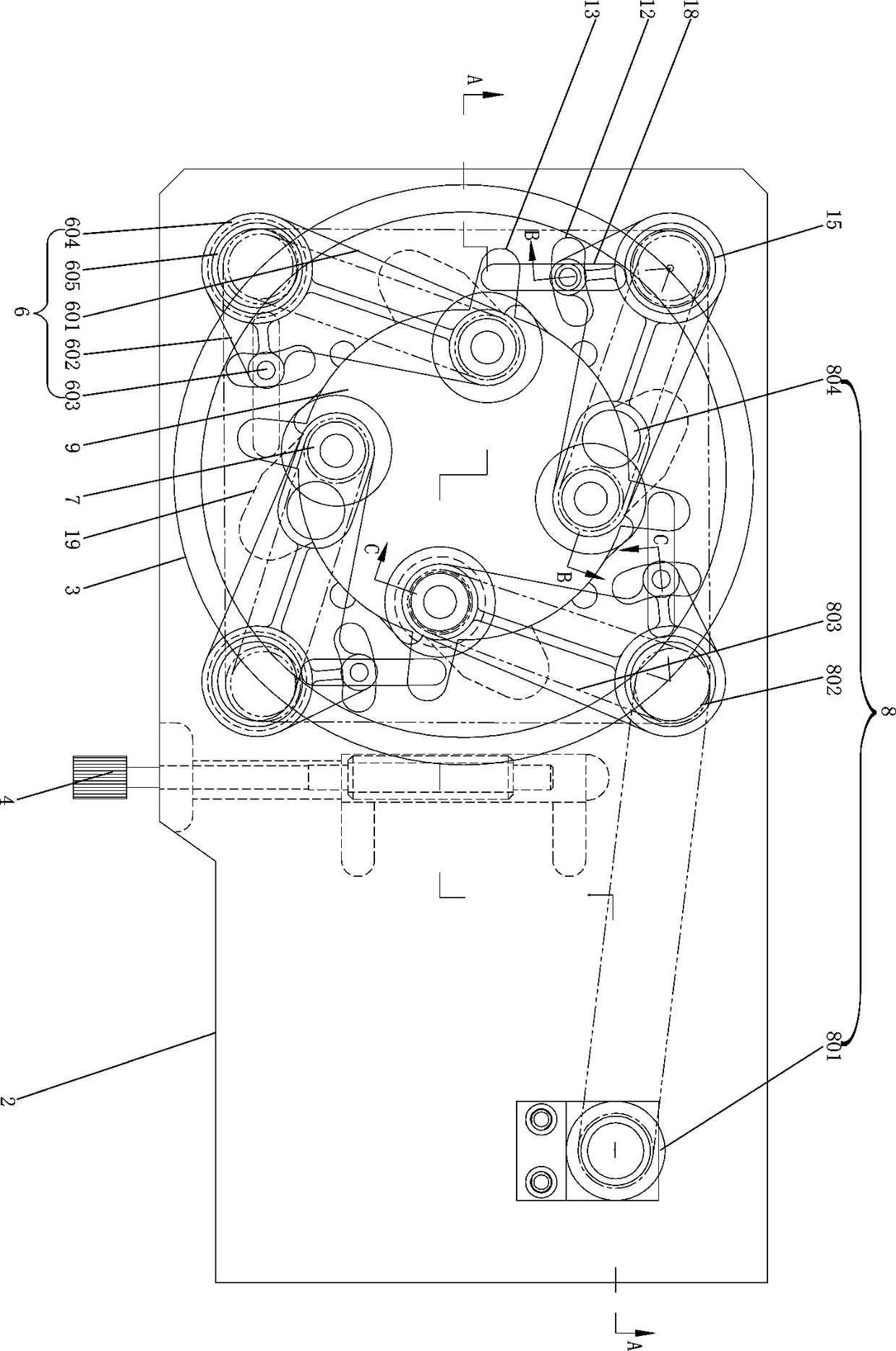

A cup feeding mechanism of a cup printing machine

A cup feeding mechanism of a cup printing machine, comprising a frame, a pallet, a turbine, a worm, four fixed shafts, four swing arms, four screw rods, and a drive mechanism capable of driving two adjacent screw rods to rotate in opposite directions; through the four screw rods The screw grooves on the cups are synchronously transported to four points on the opening edge of the cup, and the cup can be more stably and accurately socketed on the cup mold, making the alignment between the cup and the printing device more accurate; The linear guide groove and the arc-shaped guide groove can position the movement track of the roller shaft. Through the adjustment of the worm, the turbine can push the swing arm to swing inside and outside through the roller shaft, thereby adjusting the diameter of the circle surrounded by the four screws. It is suitable for different Specification cup; Since the screw is installed at the end of the long arm of the swing arm, the distance between the screw and the fixed shaft is fixed, and part of the transmission connection on the long arm follows the movement of the long arm. When adjusting the diameter of the circle surrounded by the four screws , without changing any structure of the drive mechanism.

Owner:广东金兴机械股份有限公司

A wrapped easy-to-clean dust device based on Internet of Things control

Owner:ZHENGZHOU INST OF TECH

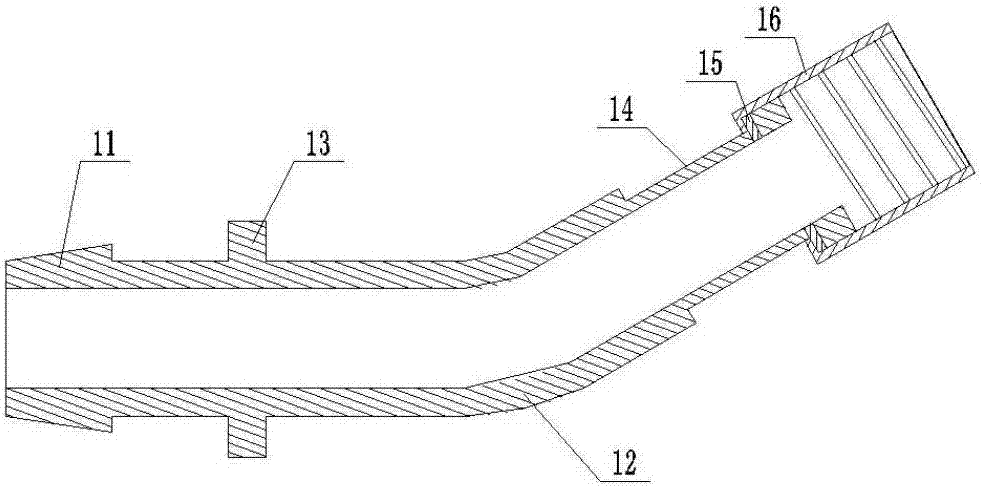

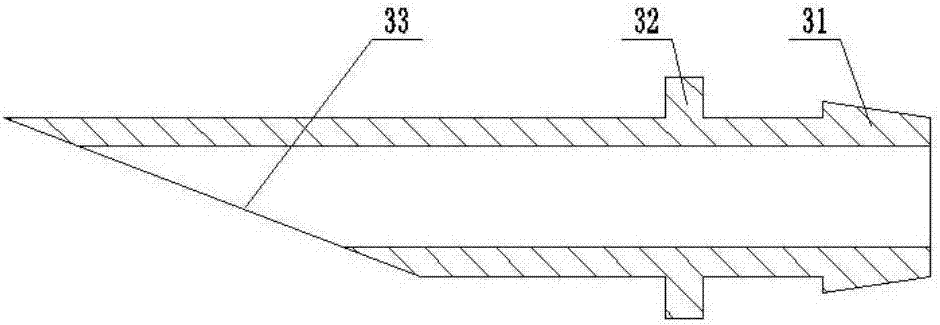

Sand spraying pipe for locomotive sand sprayer

The invention provides a sand spreading pipe for a locomotive sand spreader, which includes a connecting piece, a connecting hose and a sand outlet steel pipe. Sand steel pipe. The connector is a hollow tube with a trapezoidal boss at one end and a limited boss near the trapezoidal boss; an annular groove is arranged near the other end of the connector, and a card slot is provided at the end of the annular groove. The circlip is slidingly sleeved on the annular groove with a connecting sleeve, and the connecting sleeve is provided with an internal thread, one end is bent inward, and is sleeved on the annular groove, and the other end is threadedly connected with the locomotive sand spreader; the connecting piece is provided with a folding The bending part, the bending angle of the bending part is 130-140 degrees. The sand spreading pipe for the locomotive sand spreading device provided by the invention has the advantages of simple and compact structure, convenient disassembly and good waterproof effect.

Owner:XIANGYANG QIJINGTE MECHANICAL & ELECTRICAL MFG CO LTD

Locking structure used for sleeving inner pipe with outer pipe

InactiveCN103836038ASocket firmlySafe and reliable lockingCyclesRod connectionsEngineeringScrew thread

A locking structure used for sleeving an inner pipe with an outer pipe comprises an outer ring, locking bolts and nuts, wherein the outer ring is provided with a hollow through hole. The outer ring is provided with a notch communicated with the through hole. The two sides of the notch are respectively provided with a transverse hole, wherein the locking bolts penetrate through the transverse holes to be in threaded connection with the nuts. The outer wall of the outer pipe is sleeved with the outer ring through the through hole in the outer ring. The locking structure further comprises an inner sleeve. A sleeve hole is formed in the inner sleeve, wherein the outer wall of one end of the inner pipe can be sleeved with the sleeve hole. The inner sleeve is provided with a notch, wherein the notch is communicated with the sleeve hole in the vertical direction and communicated with the middle of the upper end of the sleeve hole in the horizontal direction. The outer pipe is inserted into the space between the outer wall of the inner sleeve and the inner wall of the outer ring. The locking bolts or the nuts are provided with partition parts used for controlling locking force. The locking structure is reasonable, the locking force is consistent, and locking is safer and more reliable.

Owner:陈开明

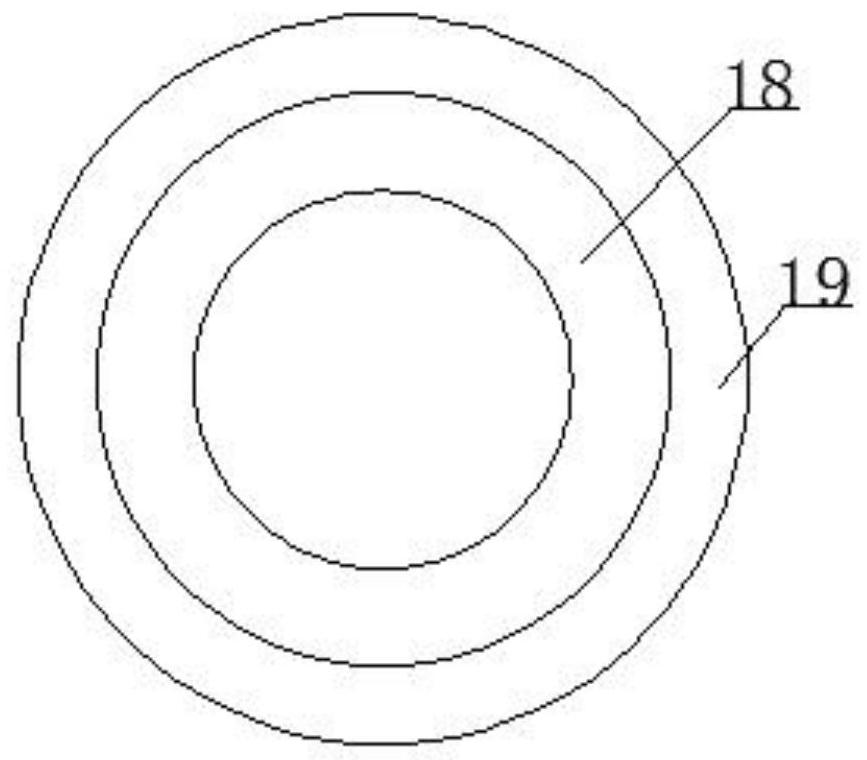

A detection system for intelligent DC tubular busbar

ActiveCN107546691BEasy to removeEasy to disengageMeasurement apparatus componentsBus-bar installationButt jointTubes types

The invention discloses an intelligent detection system for a direct-current tubular bus. The intelligent detection system comprises a tubular bus, the tubular bus is sleeved with a first arc sleeve and a second arc sleeve, and the two opposite sides of the first arc sleeve and the second arc sleeve butt joint; clamping blocks are fixedly connected to the two sides of the top of the first arc sleeve and connected into clamping grooves formed in the two sides of the bottom of the second arc sleeve in a sleeved mode respectively, through grooves are formed in the inner walls of one sides of theclamping grooves, sliding grooves are formed in the tops and the bottoms of the inner walls of the through grooves, and the two sides of the inner walls of the sliding grooves are connected through first sliding rods. According to the intelligent detection system for the direct-current tubular bus, a detector is improved, and when two shifting rods are oppositely pushed, the shifting rods can drive two pressing plates to oppositely move through installing blocks, and therefore the two pressing plates can be separated; at this moment, the detector is conveniently taken out of installing grooves, and is put into the installing grooves, then the shifting rods are loosened, and under the effect of resilience force of clamping springs, the pressing plates can clamp the detector through rubber blankets.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

Isolation sleeve

PendingCN114360821ANot easy to gatherEvenly distributedContact surface shape/structureInsulating bodiesStructural engineeringIndustrial engineering

The invention provides an isolating sleeve which comprises an insulating jacket and a static contact, the lower end of the static contact is provided with a trumpet-shaped turned edge and an outer ring connected to the tail end of the turned edge, the outer wall surface of the turned edge is an outer conical surface, and the inner wall surface of the turned edge comprises a conical section and a horizontal section. The horizontal section is connected to the lower end of the conical section and extends in the direction away from the central axis. The lower end face of the outer ring is lower than that of the horizontal section. The hole wall of the upper section of the insulating jacket is provided with an annular wrapping section used for wrapping the outer ring and the turned edge, the horizontal section is flush with the lower end opening and partially extends into the annular wrapping section, the annular wrapping section comprises a hole wall face facing the central axis and a hole opening end face, and the hole opening end face is formed by the central portion of the step face. A set distance is formed between the orifice end face of the annular wrapping section and the lower end face of the horizontal section, so that the annular wrapping section has a set thickness. The isolating sleeve provided by the invention can effectively solve the technical problems that the centering is difficult when the moving contact and the static contact are plugged and the electrical insulation performance of the insulating jacket is insufficient.

Owner:PINGGAO GRP

A Model Rocket That's Easy to Recycle

ActiveCN111354256BRealize the recycling functionSocket firmlyEducational modelsClassical mechanicsRocket

The invention relates to a model rocket which is easy to recover, which includes an arrow and a rocket body. The arrow is equipped with a sensor and a parachute, and the sensor is connected with an adjustment mechanism. When the attitude of the rocket is upright when the sensor does not detect a change in the attitude of the rocket, the adjustment mechanism adjusts the arrow to be in the working state of being assembled on the rocket body. The detected signal adjusts that the arrow is in the disengagement state of releasing the parachute from the rocket body. The structure of the present invention is stable and the layout is reasonable, and it can realize that after the rocket is lifted into the air, when the falling attitude of the rocket changes, the arrow and the rocket body can be separated in time, and the parachute can be released, so that the rocket can be released. When it is about to fall to the ground, the parachute cord is retracted to increase the resistance and reduce the landing impact, effectively reducing the risk of the rocket crashing.

Owner:CHAOHU UNIV

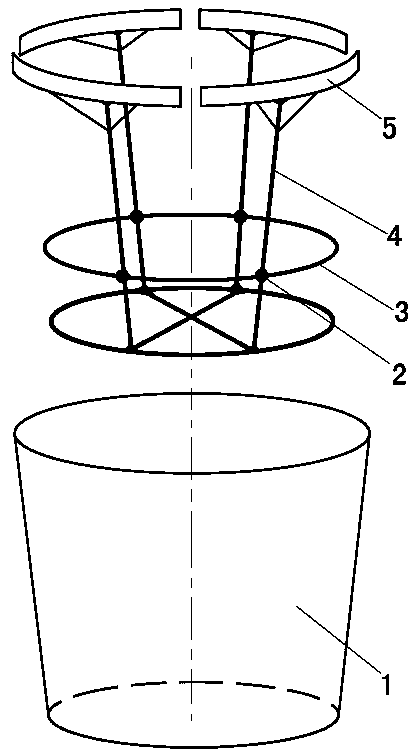

Transplantation bag for landscaping

InactiveCN105766421AGuaranteed circulationNo pollution in the processReceptacle cultivationLandscapingEngineering

The invention provides a transplantation bag for landscaping. The bag comprises a bag body, wherein the bag body comprises an upper port, the upper port is equipped with an outer edge, and the outer edge is internally equipped with a fastening ring; a ring of water-absorbent cotton is disposed circumferentially on the inner wall of the bag body; and the bottom of the bag body is connected to peripheries by a transition ring. In conclusion, the bag provided by the preferential scheme of the invention is characterized in that the outer edge is disposed on the upper port; the fastening ring is internally disposed on the outer ring; the water-absorbent cotton is disposed circumferentially on the inner wall of the bag body; and the bottom of the bag body is connected to the peripheries by the transition ring. In this way, the transplantation bag can be cup-jointed stably; moisture can be maintained; and a transplantation survival rate is greatly increased. Equivalently, an infusion bottle is provided for a transplanted plant. According to the preference, the transition detachable edge can be directly detached from the bottom during cluster planting. The bag has the advantages that the overall structure is simple and highly practical; the cost is low; and the bag can be widely applied to landscaping operations and governmental projects.

Owner:SHAANXI TANGYUAN GARDEN LANDSCAPE CONSTR CO LTD

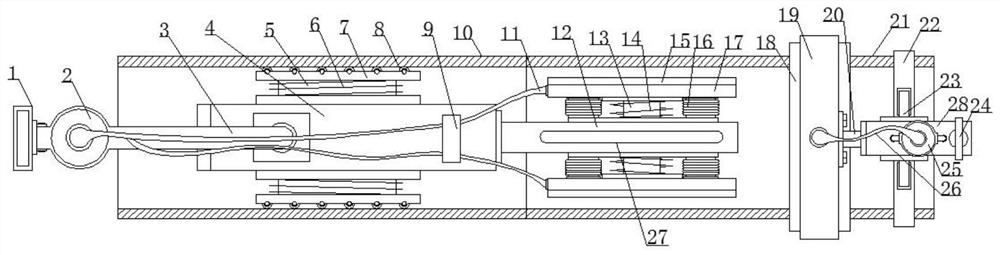

Individual rocket launching tube with night vision function

The invention discloses an individual rocket launching tube with a night vision function. The individual rocket launching tube can be used at night when a night vision sight and a white light sight are matched and installed on a launcher. When the night vision sight is disassembled, only the white light sight is used, so that the individual rocket launching tube can be used in the daytime, and thenight vision sight can be reused. An elastic material sheet is simple in structure and stable to install and conforms to the characteristics of multiple uses. When the white light sight is inserted into a barrel body of the night vision sight, the outer wall of a barrel body of the white light sight extrudes the elastic material sheet to deform, and the elastic extrusion of the elastic material sheet acts on the barrel body of the white light sight, so that the sleeve joint of the white light sight and the night vision sight is more stable; and the white light sight can be more smoothly pulled out from the night vision sight.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Splicing device for PE pipes

ActiveCN113290867AEasy to moveEasy splicingGeneral water supply conservationTubular articlesHydraulic cylinderAir pump

The invention aims to solve the splicing problem of PE pipes, and discloses a splicing device for the PE pipes. The splicing device comprises a first pipe body and a second pipe body, a first hydraulic cylinder is sleeved with the first pipe body, a holding rod is fixedly mounted at the left side of the surface of the first hydraulic cylinder, a handle is fixedly mounted at the left end of the holding rod, a first air pump is fixedly installed at the left side of the surface of the holding rod, a guide ring is fixedly installed at the right side of the surface of the first hydraulic cylinder, first spiral springs are symmetrically connected to the two side faces of the first hydraulic cylinder, first sliding rods are sleeved with the first spiral springs, and a top plate is installed at the outer ends of the first sliding rods; and guide wheels are evenly installed on the outer surface of the top plate, a first piston rod is installed at the right side of the first hydraulic cylinder, and a heating strip is fixedly installed in the middle of the side face of the first piston rod. By means of the splicing device, tension is provided for the inner walls of the PE pipes through an adhesion layer, and then extrusion force is provided for the PE pipes through an air bag ring, so that splicing of the PE pipes is conveniently achieved so as to meet different requirements.

Owner:山东中科欧普管道有限公司

Fast flasher memory and USB interface protective cover

InactiveCN1835663BSocket firmlyAvoid sheddingDigital data processing detailsCasings/cabinets/drawers detailsEngineeringUSB

The invention comprises: a case, a control circuit board located in the case and a USB port connected to the control circuit board. Wherein, the USB port has a metal shell whose top wall has an acceptance hole. The USB port protective cover houses the elastic component in the metal shell and the button located on the shell and the elastic component. There is an extruding portion on the elastic component, which can extend to the acceptance hole of the USB port when the protective cover sleeves the USB port. When the USB protective cover needs to be removed, the button can be pressed to push out the protruding portion from the acceptance portion of the USB port.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Cup feeding mechanism of cup printing machine

The invention discloses a cup feeding mechanism of a cup printing machine. The cup feeding mechanism of the cup printing machine comprises a machine frame, a supporting plate, a turbine, a worm, fourfixed shafts, four swing arms, four screws and a driving mechanism capable of driving every two adjacent screws to rotate in the opposite direction. The four points on the edge of an opening of a cupare subjected to synchronous transmission though screw grooves of the four screws, and the cup can be more stably and accurately connected on a cup mold in a sleeving mode, so that the alignment of the cup with a printing device is more accurate; linear wire guiding grooves and curved guiding grooves which cross each other are arranged on the turbine and supporting plate to locate the movement track of a roller shaft, the turbine pushes the swing arms to swing inside and outside through the roller shaft through the adjustment of the worm, and the diameter of a circle enclosed by the four screws is adjusted and the circle is applicable to cups of different specifications; since the screws are installed at the tail ends of long arms of the swing arms, the distance between the screws and a fixed shaft is fixed and unchanged, part of the transmission connection on the long arms follows the movement of the long arms, and when the diameter of the circle enclosed by the four screws is adjusted, any structure of the driving mechanism does not need to be changed.

Owner:广东金兴机械股份有限公司

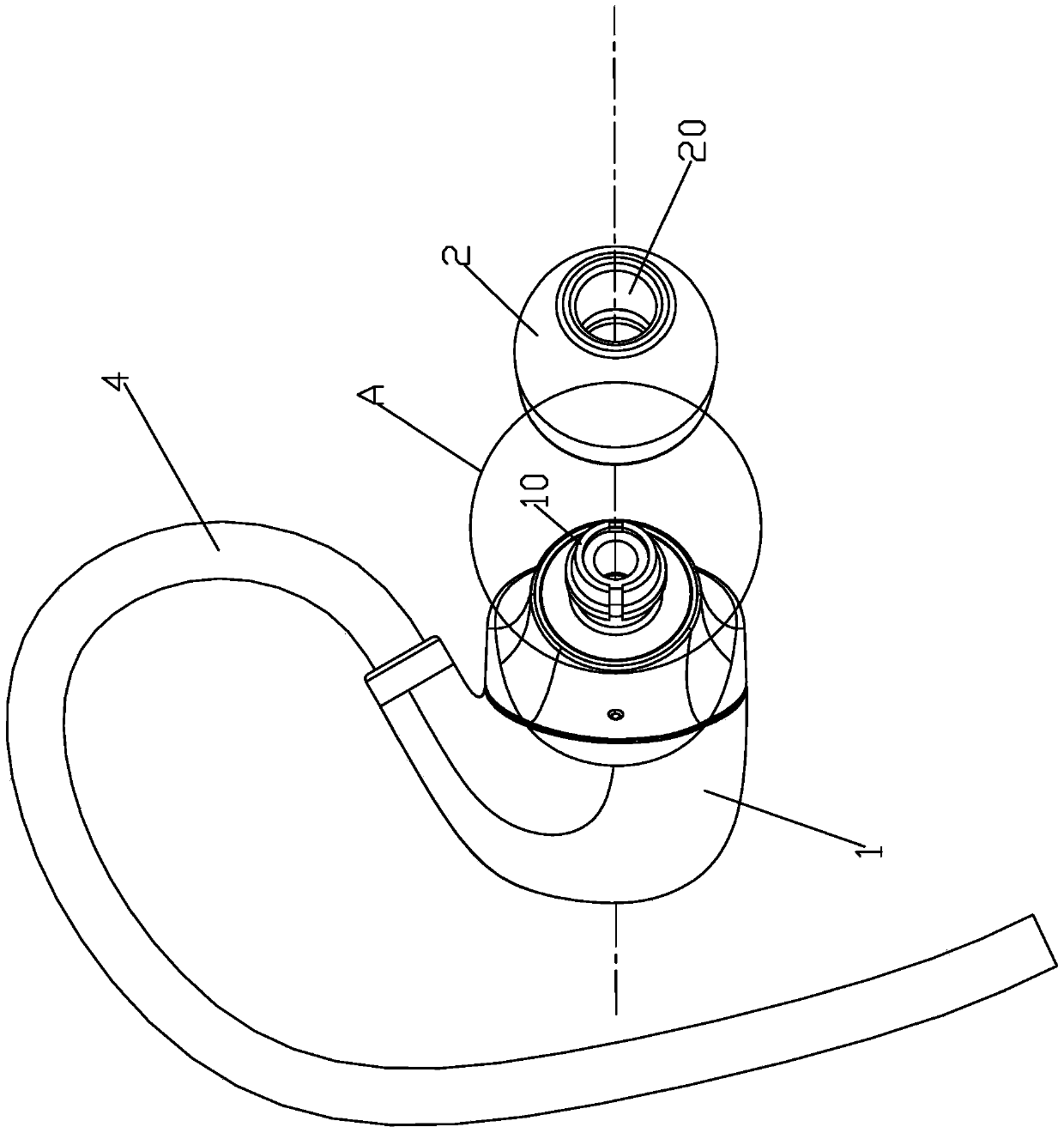

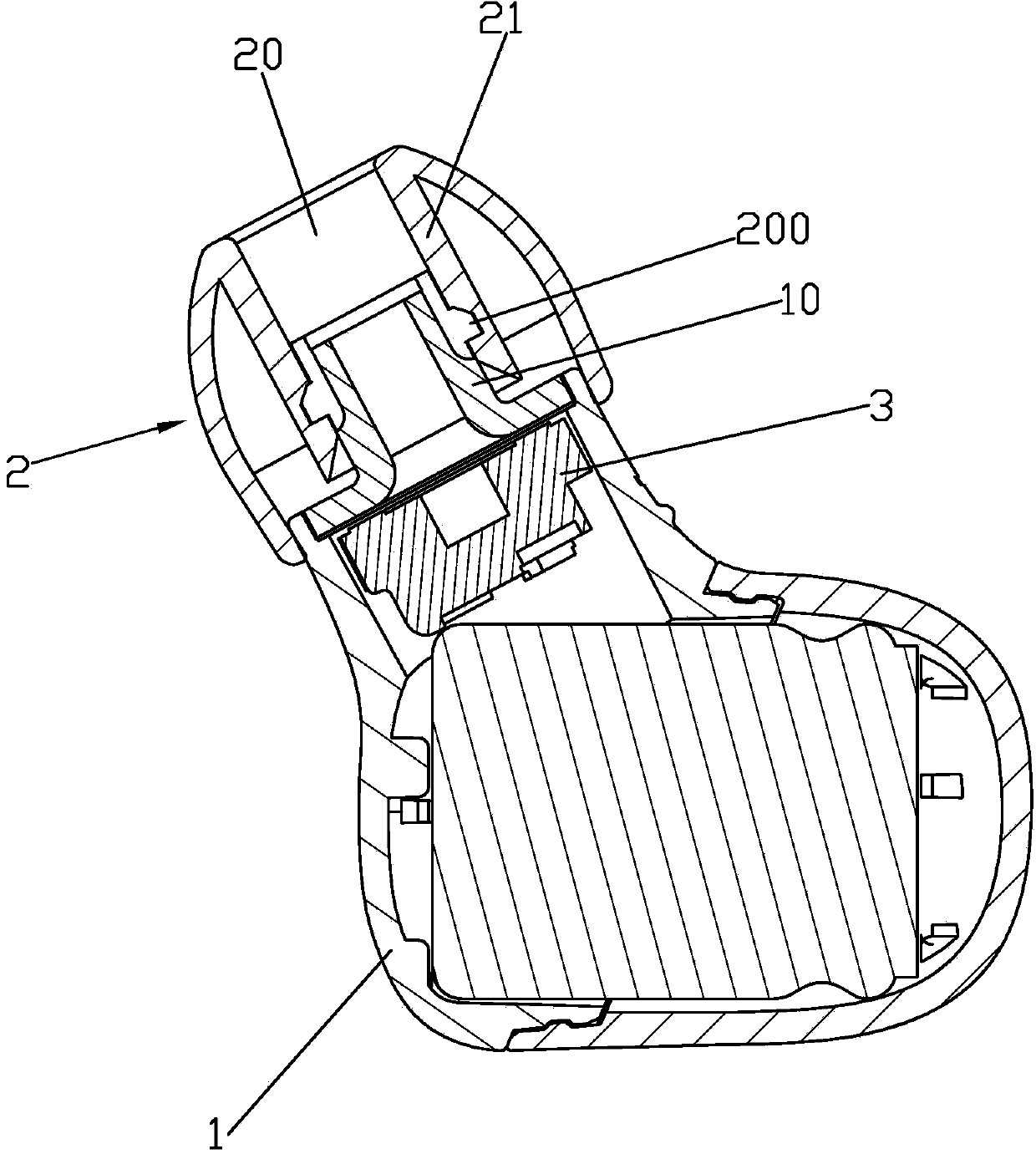

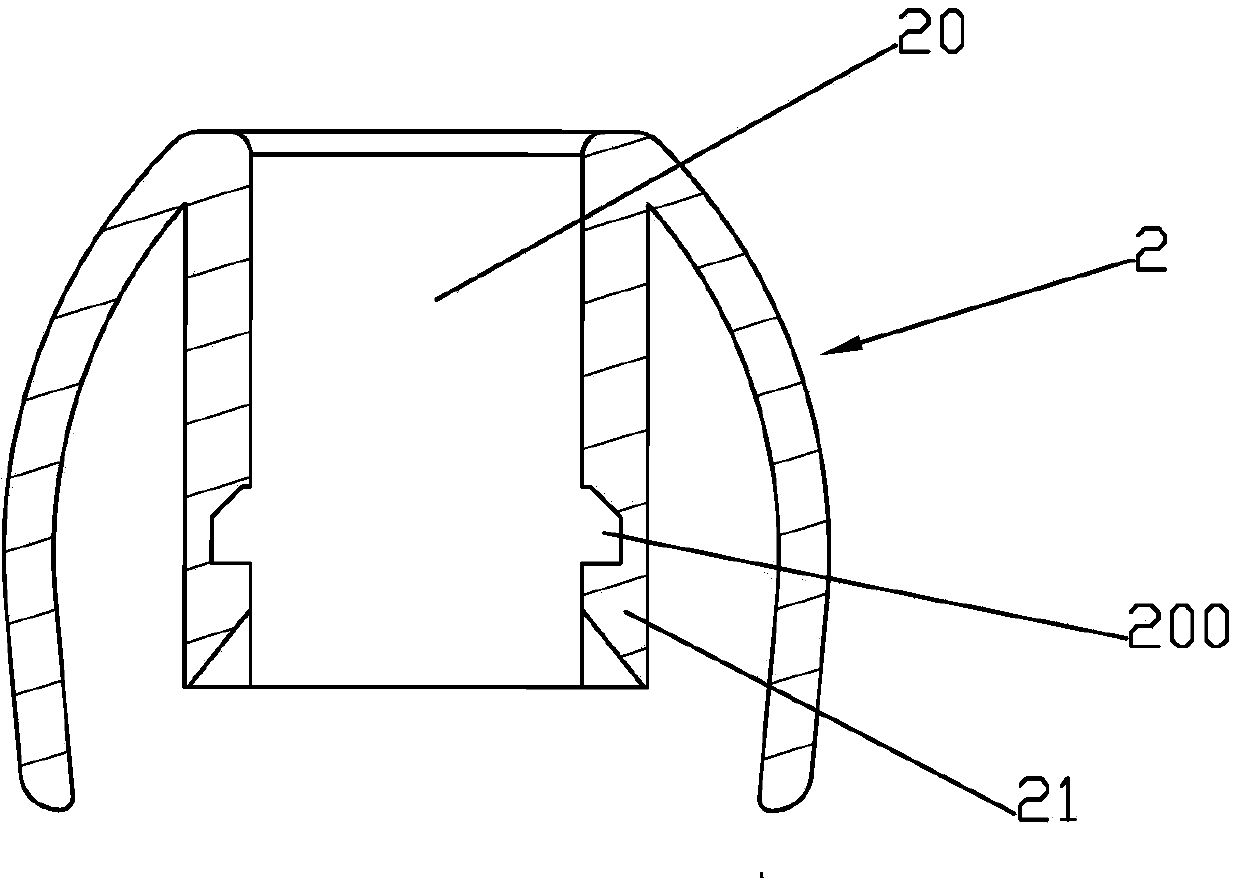

Earphone

InactiveCN104202690ANo loss of qualityPrevent fallingEarpiece/earphone attachmentsEngineeringHeadphones

The invention discloses an earphone. The earphone comprises an earphone main body into which a loudspeaker is embedded, and an ear cap, wherein the earphone main body is provided with a hollow extension portion which is communicated with the inside of the earphone main body; the hollow extension portion is sleeved with the ear cap; meanwhile the ear cap is further provided with a small hole which is communicated with the inside of the hollow extension portion; a voice diaphragm of the loudspeaker faces a channel which is communicated with the small hole of the hollow extension portion; the peripheral wall of the hollow extension portion is provided with more than one exhaust groove. The peripheral wall of the hollow extension portion is provided with the exhaust groove, and air in the small hole of the ear cap can be exhausted from the exhaust groove when the small hole of the ear cap is blocked and the ear cap is connected to the hollow extension portion in a sleeved way due to error operation of a user, so that deformation of the voice diaphragm of the loudspeaker due to extrusion of the air in the small hole into the earphone main body is effectively avoided, and the quality of the earphone is ensured.

Owner:ZHONGSHAN K MATE GENERAL ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com