Assembly type indoor sound insulation wall auxiliary assembly

An auxiliary component and sound insulation wall technology, which is applied in the direction of sound insulation, walls, and insulation layers, etc., can solve the problems that the wall and the top surface of the building cannot be closely bonded, rapid linkage expansion installation cannot be realized, and the sound insulation of the building is affected. Prevent wall paint from cracking, avoid grouting and glue filling, and reduce the amount of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

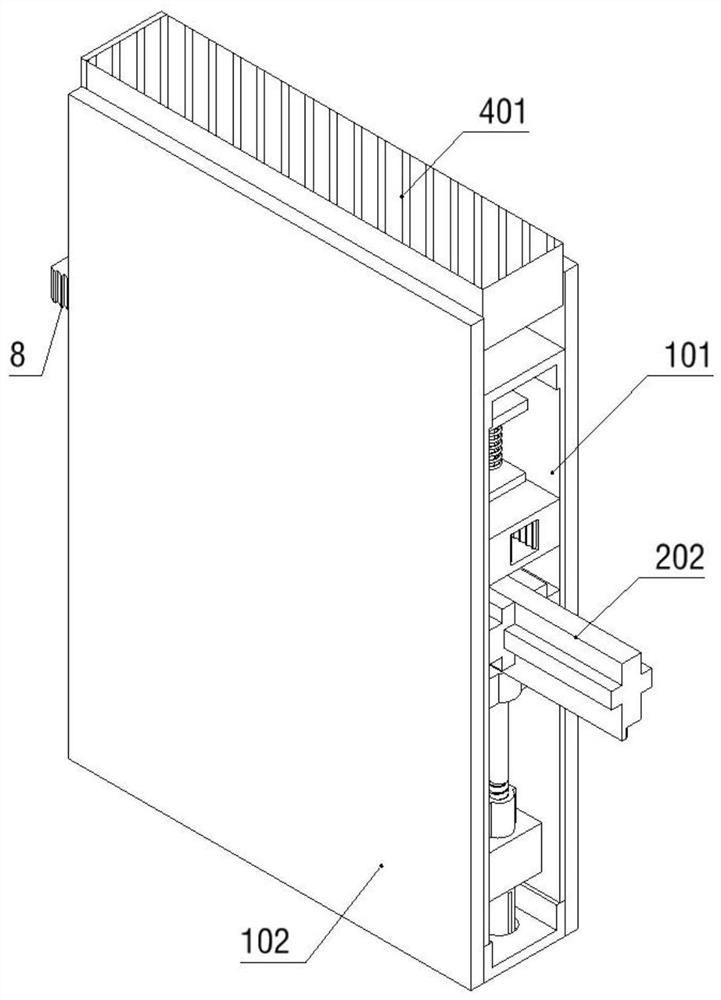

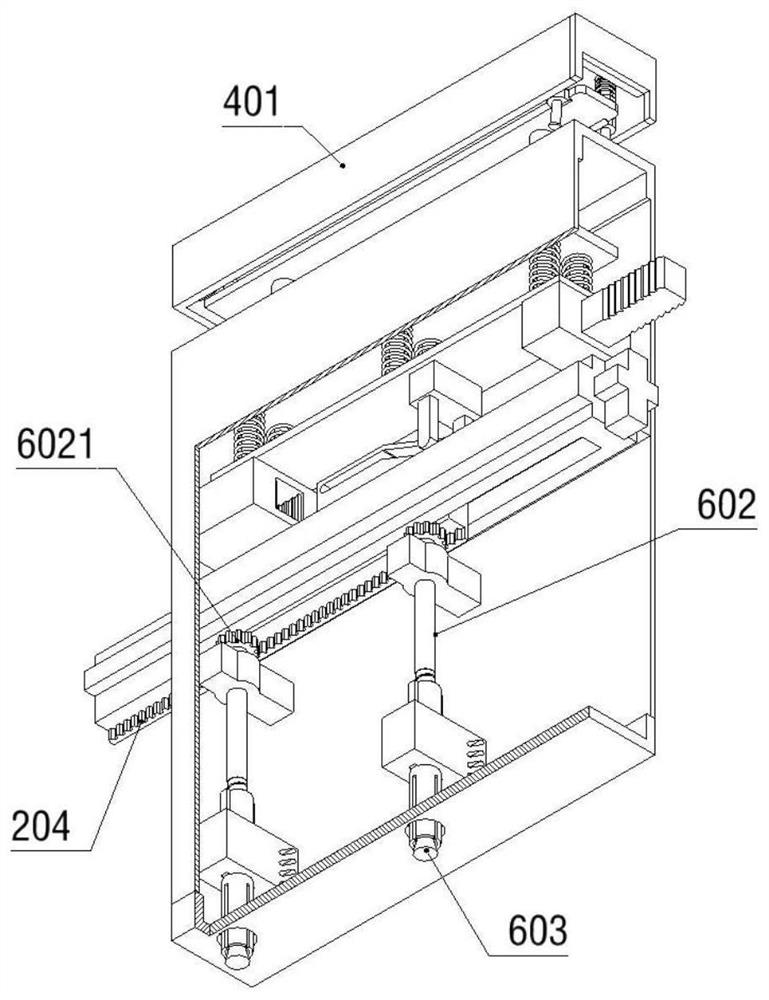

[0067] Example: Please refer to Figure 1 to Figure 14 :

[0068] The present invention proposes a prefabricated indoor sound insulation wall auxiliary assembly, including: a frame part 1: a linkage part 2 is installed on the frame part 1; a tightening device 3 is slidably connected to the frame part 1, and the tightening device 3 rotates The bonding part 4 is connected; the edge sealing device 5 is fixedly connected inside the frame part 1; two floating drive parts 6 are installed inside the frame part 1; two linkage expansion parts 7 are installed inside the frame part 1; the frame part 1 is fixed inside Connected with a ratchet tooth block 8; the fitting part 4 includes: a fitting soundproof box 401, which is rotatably connected to the drive plate 304; an arc-shaped sliding shaft 402, and there are two arc-shaped sliding shafts 402, two Two arc-shaped sliding shafts 402 are respectively fixedly connected to the sound-insulating box 401, two arc-shaped sliding shafts 402 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com