Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Smooth workflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

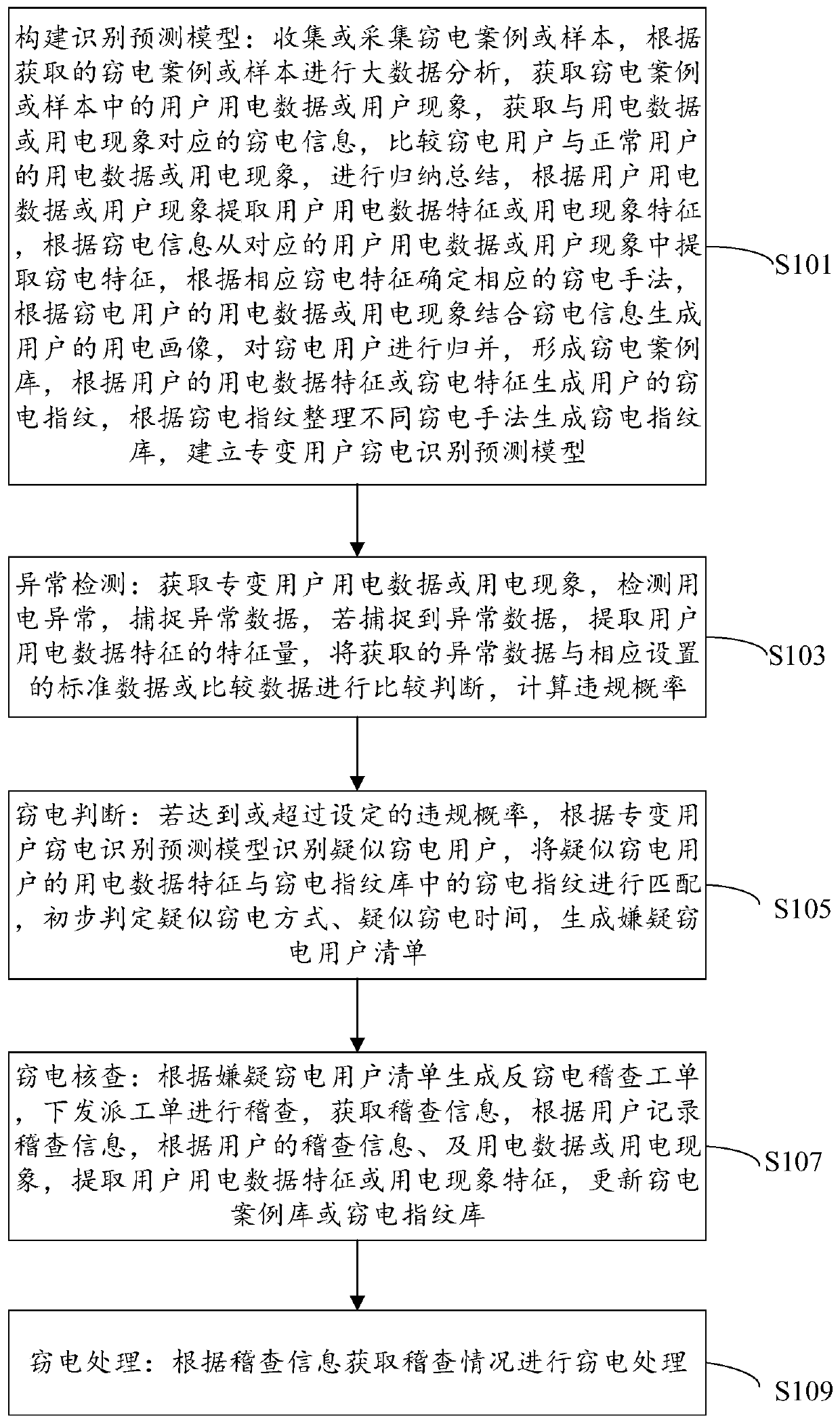

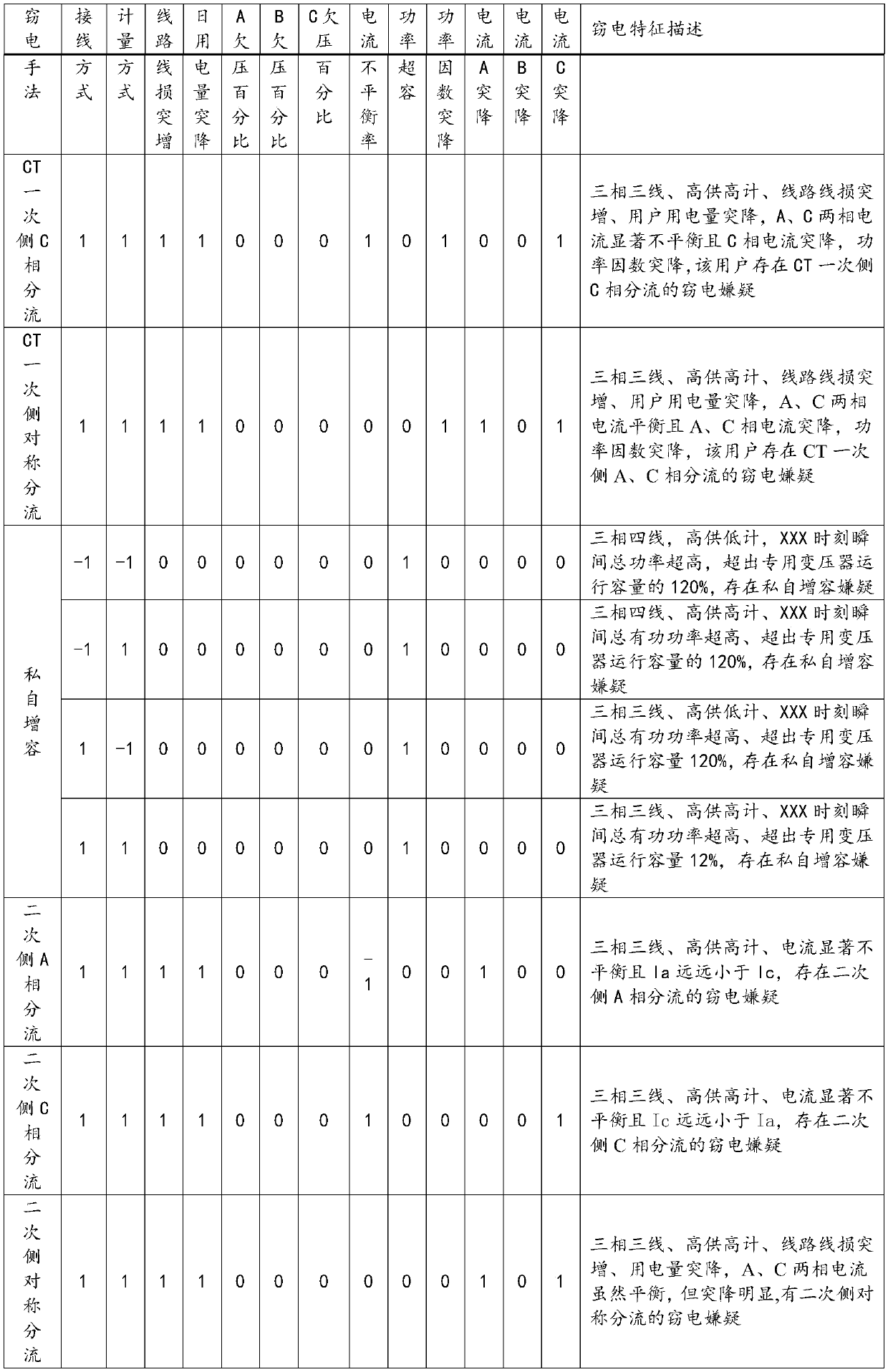

Anti-electricity-stealing inspection monitoring method and platform

PendingCN110264015APrecise positioningImprove accuracyDigital data information retrievalForecastingElectricityTransformer

The invention discloses an anti-electricity-stealing inspection monitoring method and platform. The method comprises the following steps: analyzing an electricity stealing sample, extracting user electricity utilization characteristics and electricity stealing characteristics, determining an electricity stealing technique according to the characteristics, generating a user electricity utilization portrait and an electricity stealing fingerprint, and establishing a special transformer user electricity stealing identification prediction model; detecting power consumption abnormity, capturing abnormal data, extracting characteristic quantity, comparing, and calculating violation probability; if a set probability is reached or exceeded, identifying a suspected electricity stealing user according to the special transformer user electricity stealing identification prediction model, carrying out electricity stealing fingerprint matching, judging a suspected electricity stealing mode and time, and generating a suspected electricity stealing user list; generating an anti-electricity-stealing inspection work order, dispatching inspection, obtaining inspection information and updating the inspection information; electricity stealing processing is carried out according to the inspection information. According to the anti-electricity-stealing inspection and monitoring method and platform, through big data analysis, electricity larceny fingerprints are generated according to power utilization signal characteristics of users, a special transformer user electricity larceny recognition model is established, electricity larceny users are accurately positioned, and a suspected electricity stealing technique is determined.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

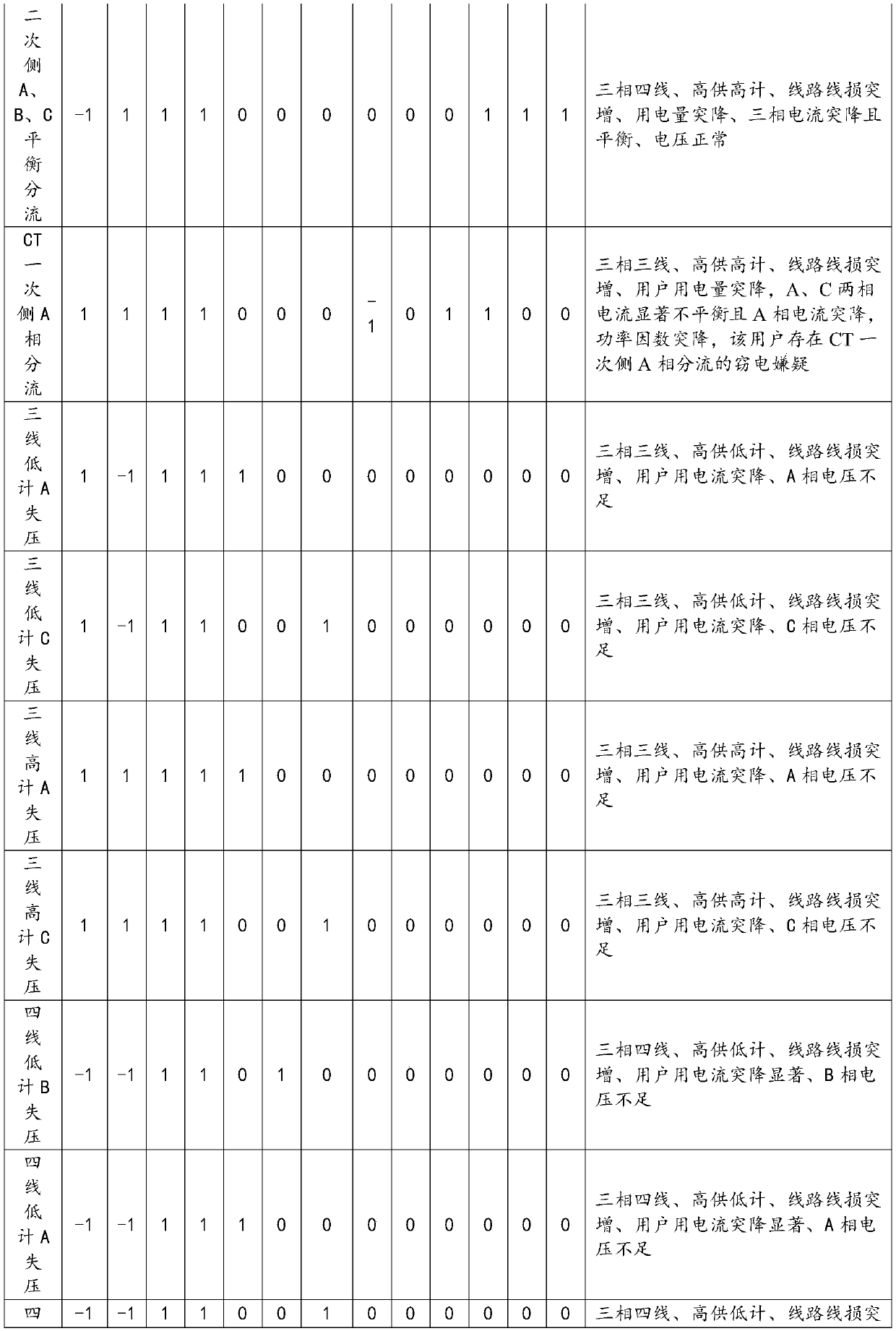

Automatic test system of electric automobile motor drive system performance

InactiveCN101408588AReduce work intensitySmooth workflowDynamo-electric machine testingMotor driveElectric machine

The invention provides a system for automatically testing the performance of a motor driving system of an electric automobile, comprising a direct current power supply used for supplying energy to a motor to be tested by a motor transducer, a power analyzer used for testing the voltage and current of the direct current power supply and testing the voltage and current of the motor transducer, a torque master which is connected with the motor to be tested and a dynamometer machine and is used for testing the rotate speed and torque of the motor to be tested, a CAN module used for transmitting the signal detected by the torque master to a master computer, and the master computer used for collecting and processing the automatic testing information of the performance of the motor driving system. The master computer is in charge of unified and cooperative control, realizes the automatic testing on the performance of the motor driving system of the electric automobile, and automatically generates a testing report and analyzes the testing report. Pre-treatment of testing data is realized by separated modules, thus relieving the working strength of the master computer and ensuring the work flow to be smooth.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

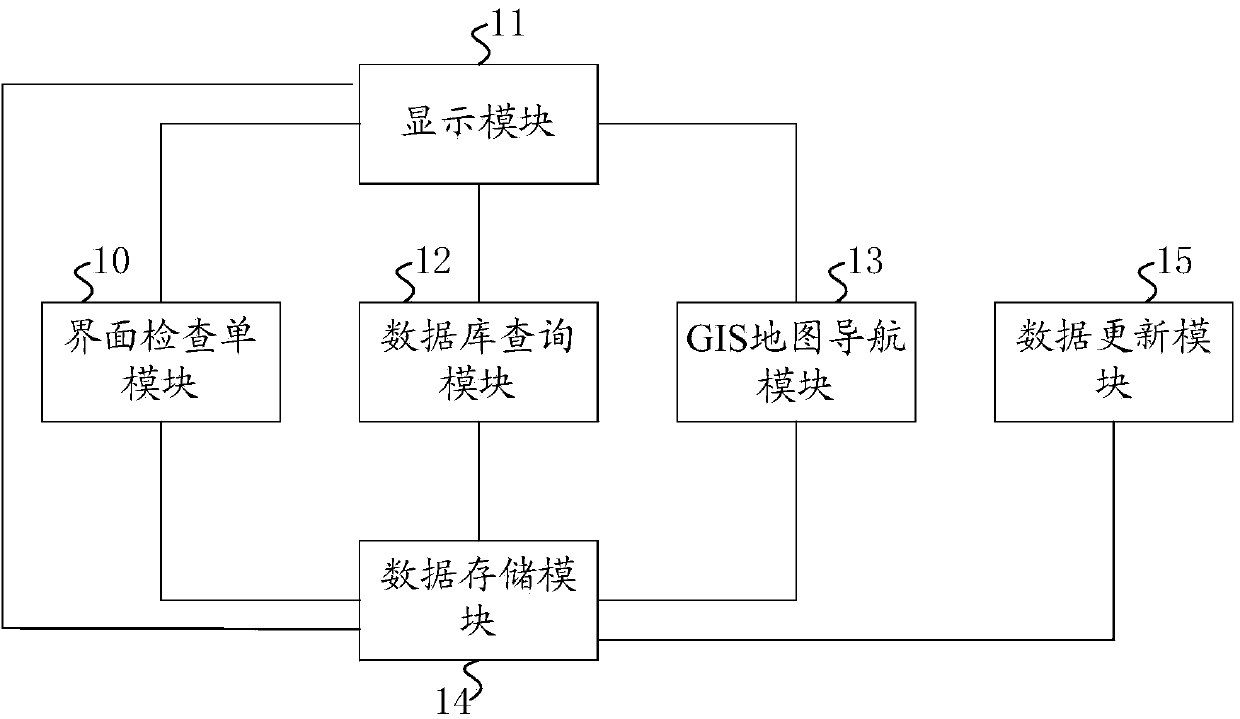

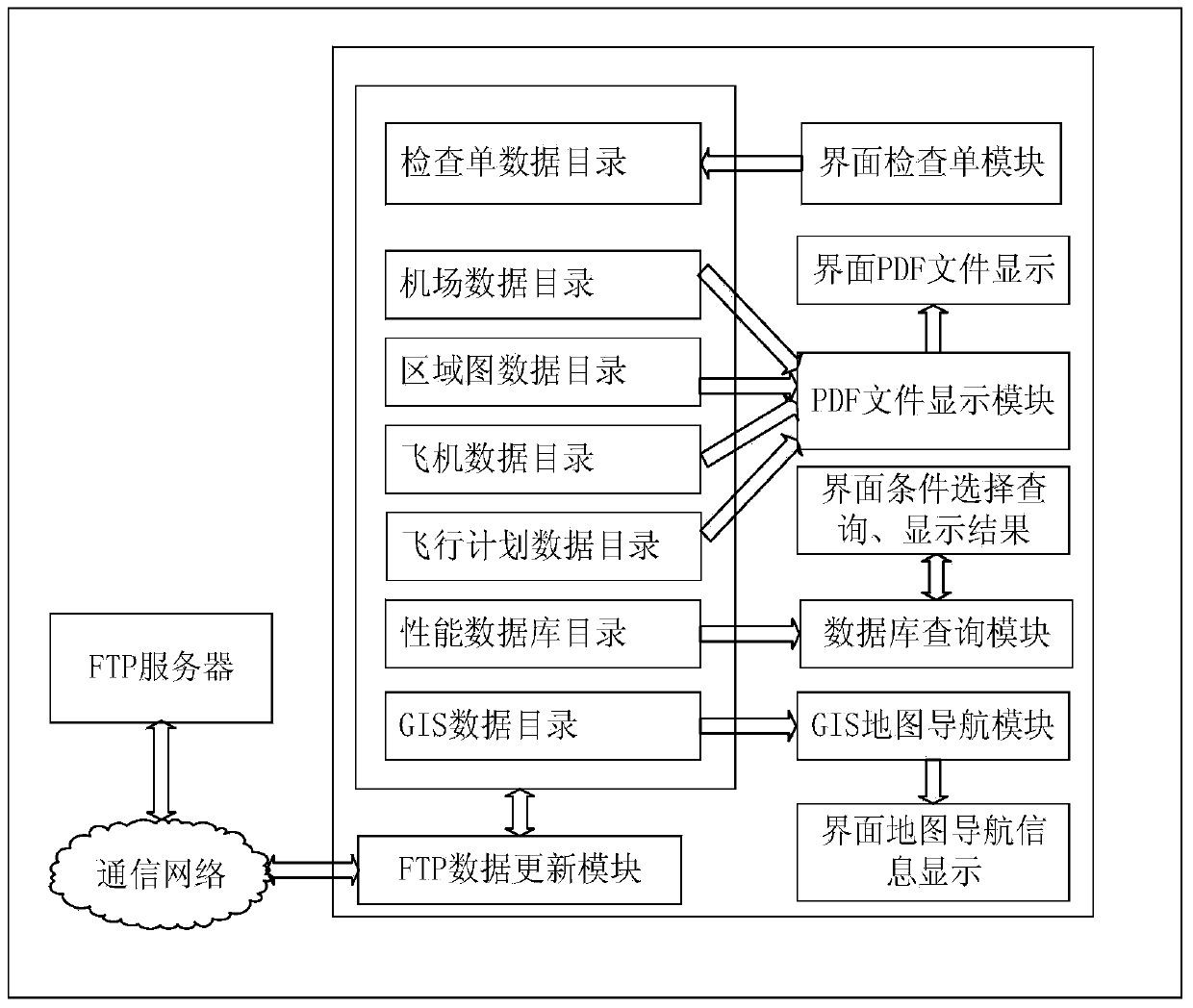

EFB system based on Windows modern UI

InactiveCN103995874AFlexible useEasy to useGeographical information databasesSpecial data processing applicationsDatabase queryOperational system

The invention provides an EFB system based on a Windows modern UI. The EFB system comprises an interface checklist module, a displaying module, a database query module and a GIS map navigation module. The interface checklist module is used for checking items which needs to be checked at the current stage one by one in various stages of flying, and checking results are stored in a data storage module. The displaying module is used for displaying the checking results of the checklist module and obtaining and displaying documents corresponding to document displaying instructions obtained from the data storage module according to the document displaying instructions of a pilot. The database query module is used for finding corresponding data which meet condition parameter instructions in a database of the data storage module according to the received condition parameter instructions of the pilot. The GIS map navigation module is used for achieving plane positioning and navigation according to the longitude and latitude information located by a GPS. According to the EFB system, an EFB application environment is enriched, a PED of a Windows operation system can use the EFB system flexibly, operation is easy, and using is very convenient.

Owner:BEIHANG UNIV

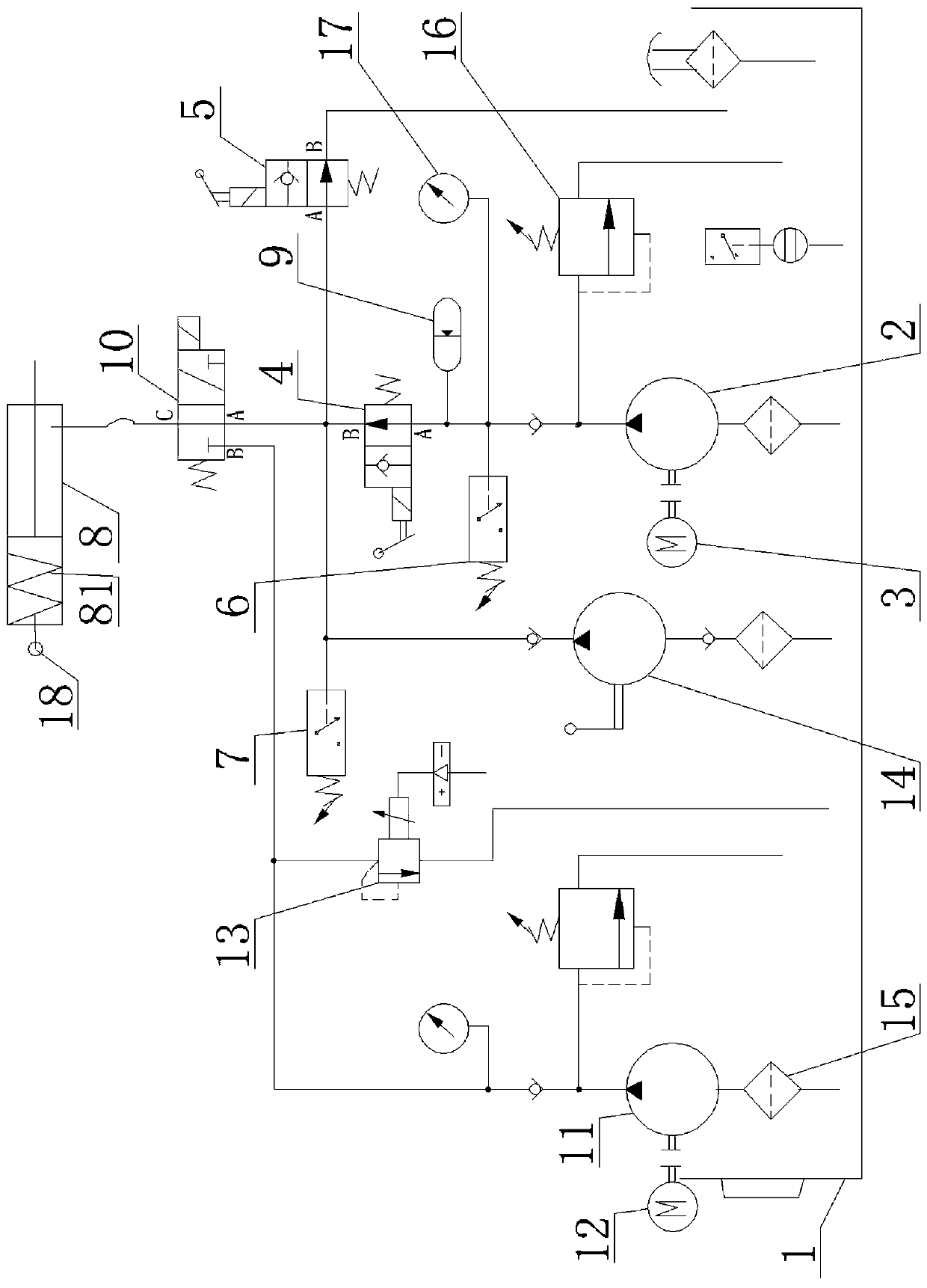

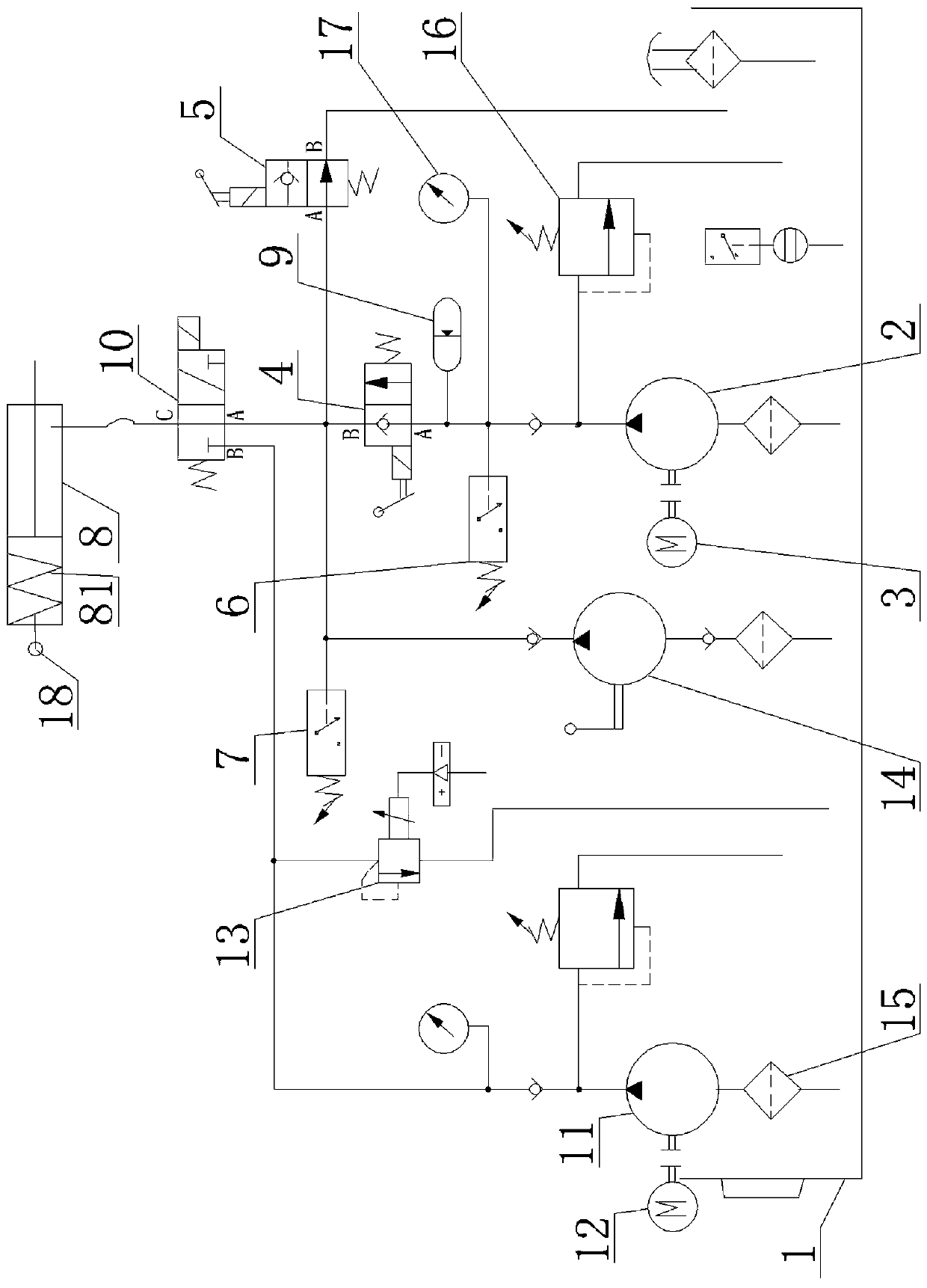

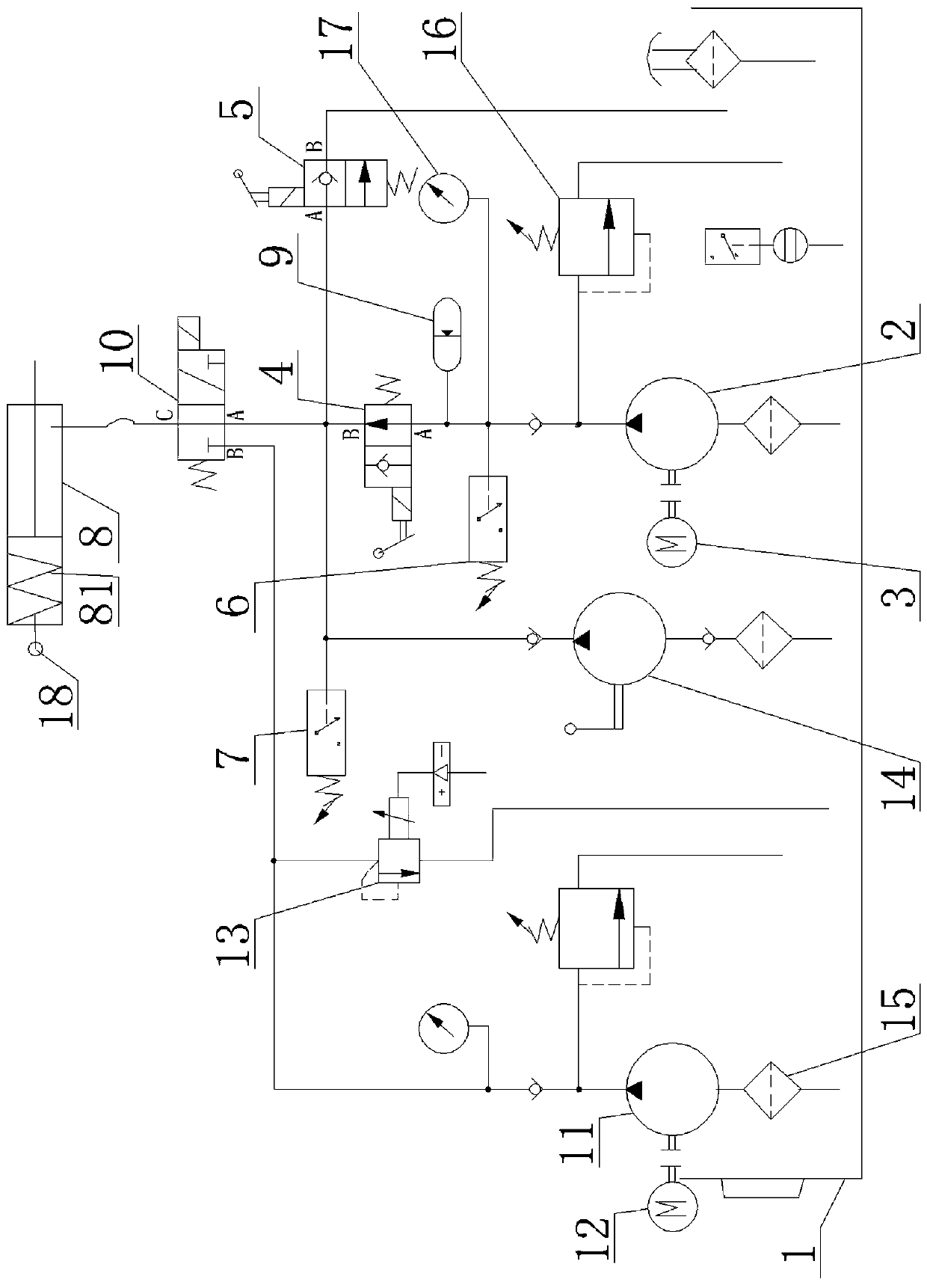

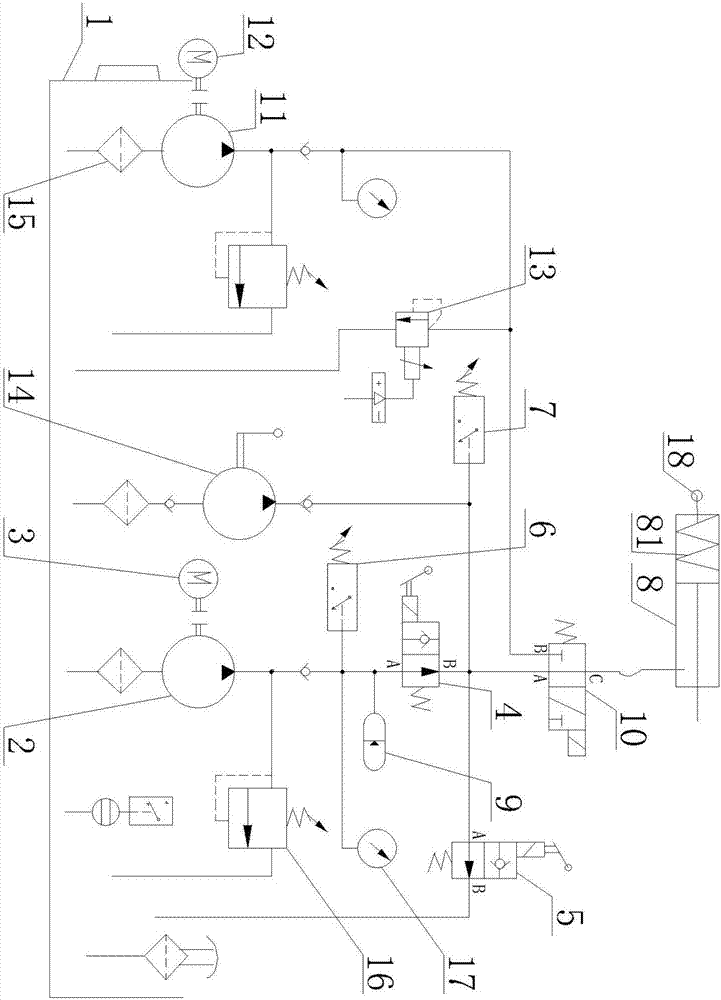

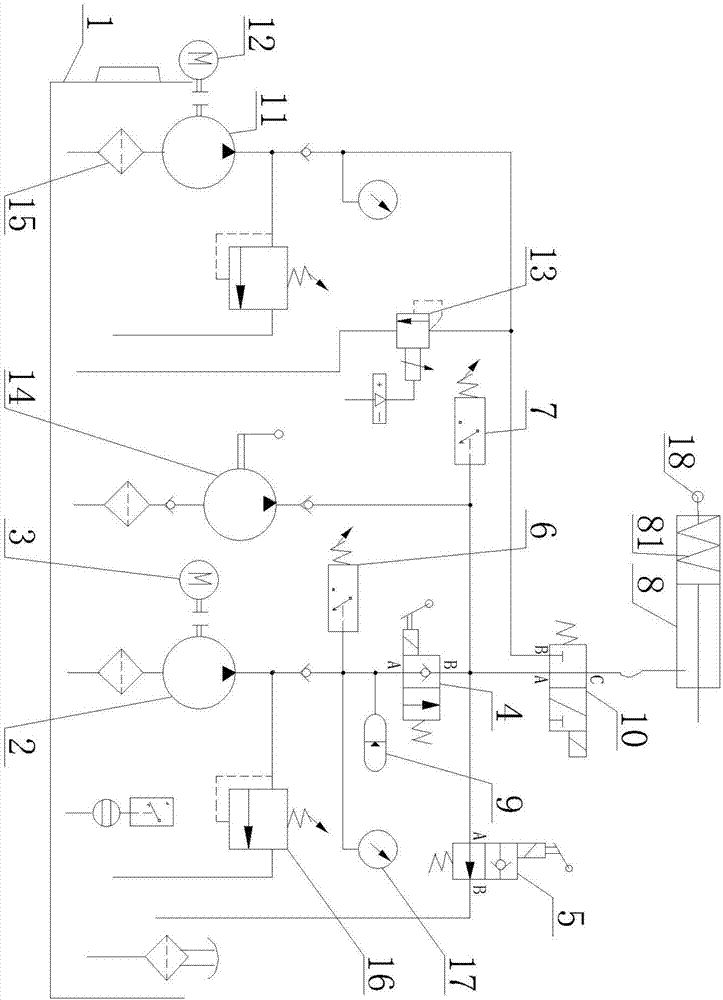

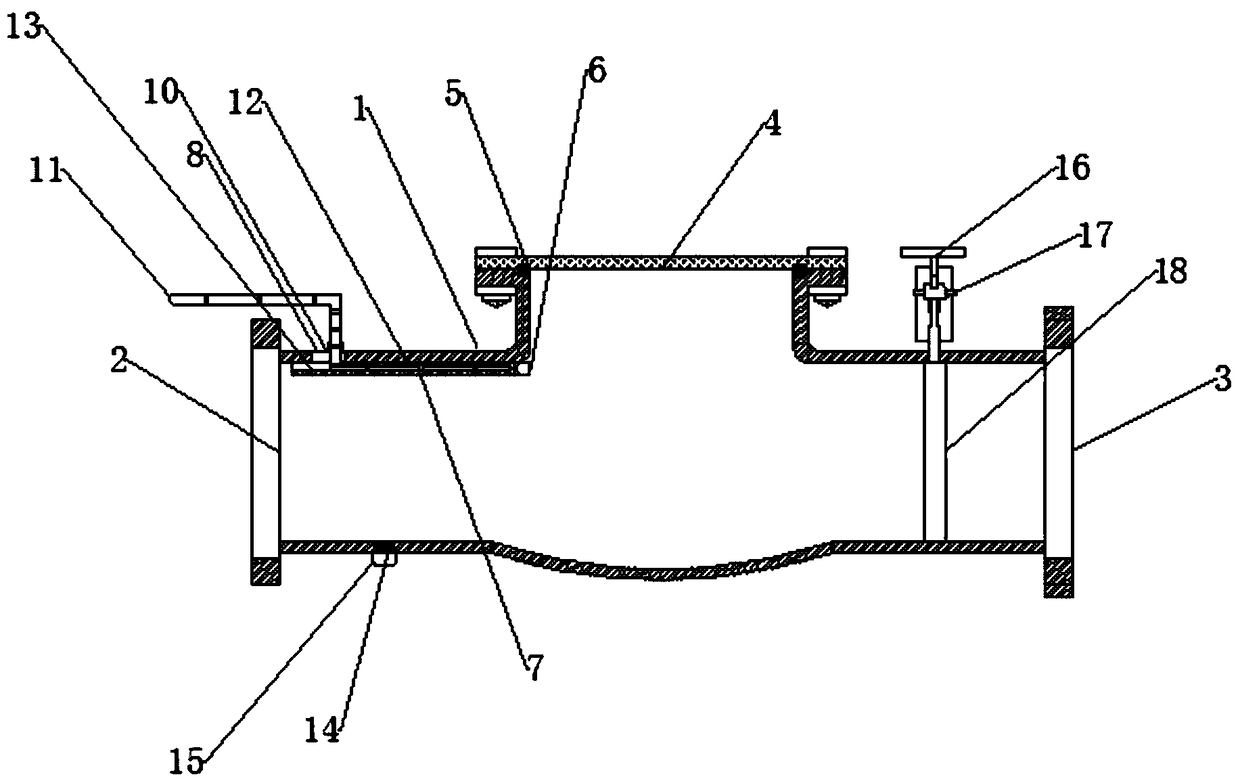

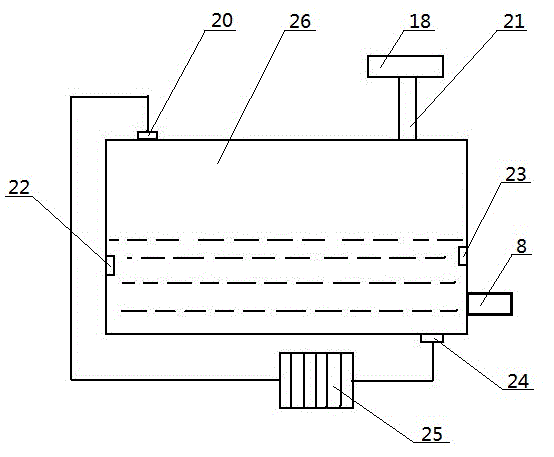

Novel safety and emergency hydraulic brake

PendingCN107739001ASmooth workflowThe release of the gate is stable and continuousServomotorsFluid-pressure actuator componentsAutomotive engineeringHydraulic brake

The invention discloses a novel safety and emergency hydraulic brake. The novel safety and emergency hydraulic brake comprises an oil tank, a main oil supplying system, a single-acting oil cylinder and a controller and also comprises a proportional overflowing valve and an emergency oil supplying system, wherein the emergency oil supplying system and the main oil supplying system are powered by different power supplies; one end of the emergency oil supplying system is connected with the oil tank and the other end of the emergency oil supplying system is connected onto an oil path between the main oil supplying system and the single-acting oil cylinder in series by a two-position three-way electromagnetic valve; the proportional overflowing valve is connected onto an oil path between the emergency oil supplying system and the two-position three-way electromagnetic valve in parallel; the emergency oil supplying system is driven by the controller and supplies oil to the single-acting oilcylinder to carry out gate-opening release action when the main oil supplying system is powered-off; the proportional overflowing valve is adjusted by the controller to control the emergency oil supplying system to supply oil to the single-acting oil cylinder stably. The novel safety and emergency hydraulic brake disclosed by the invention has the advantages that continuous and stable gate openingcan be ensured when a main motor of a normally-closed type brake is powered-off, and a hoisting mechanism can be guaranteed to release heavy objects in a safe-fast-controllable manner when the systemis powered-off, so that the probability of accidents is reduced.

Owner:JIANGXI GONGBU MACHINERY

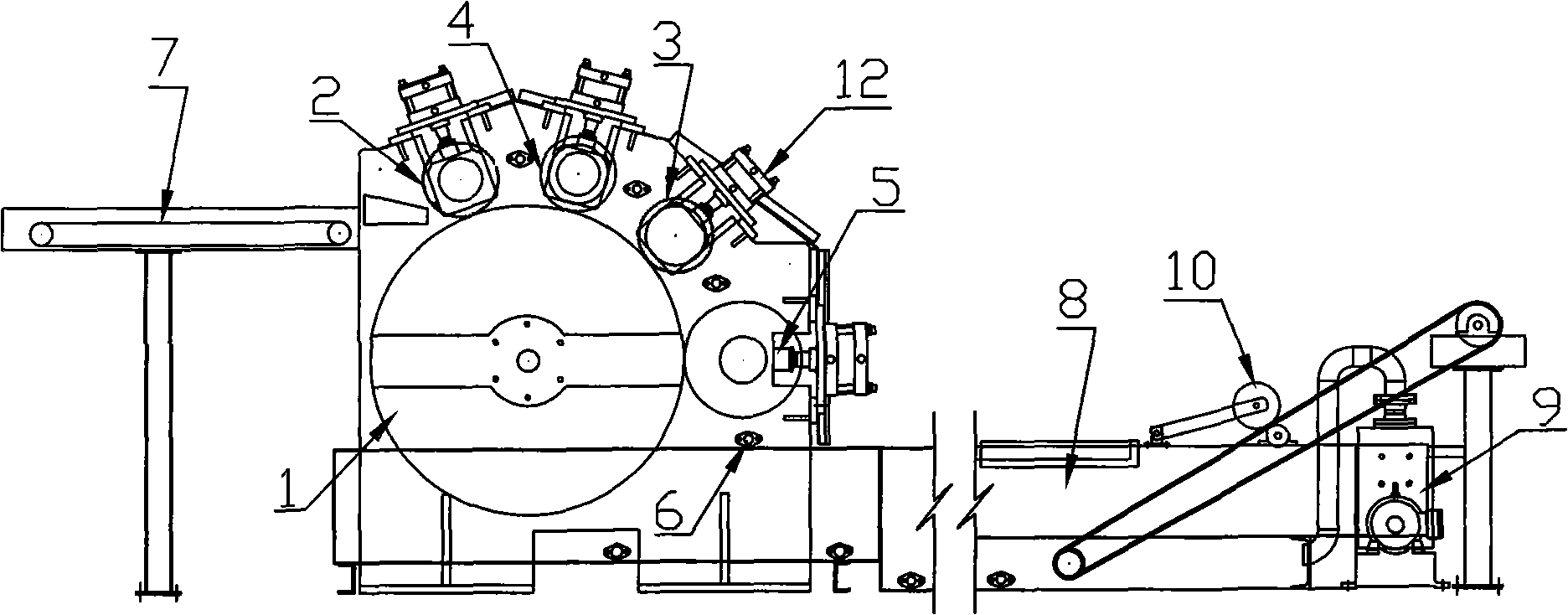

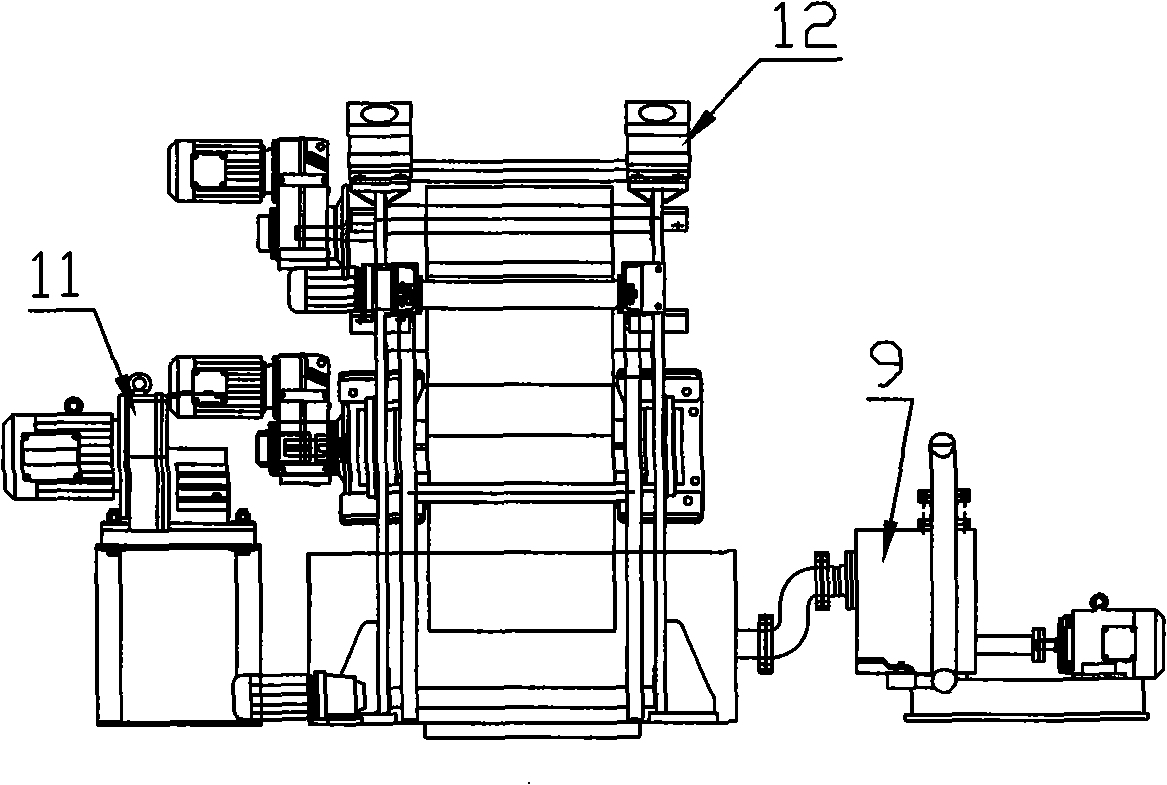

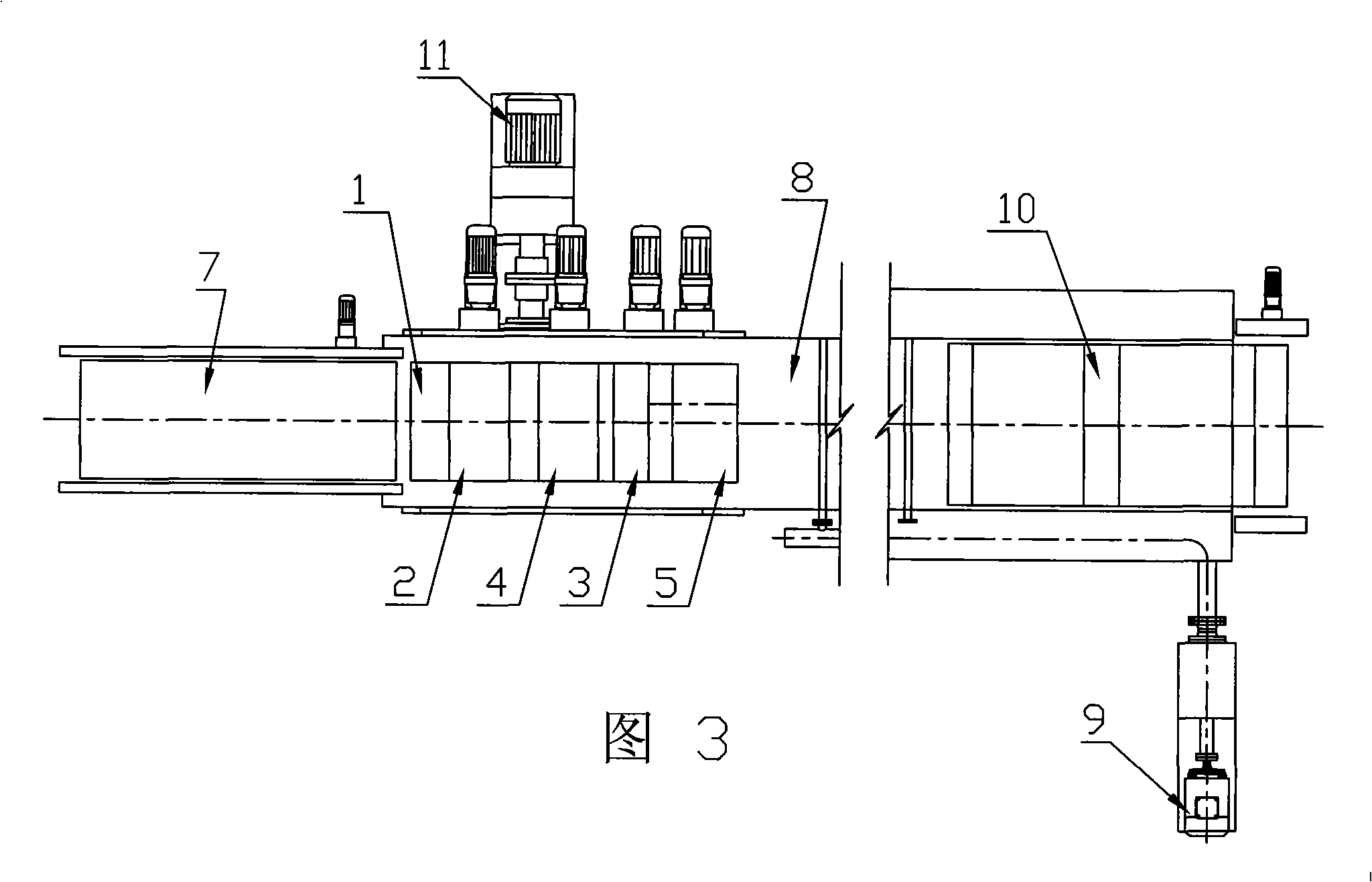

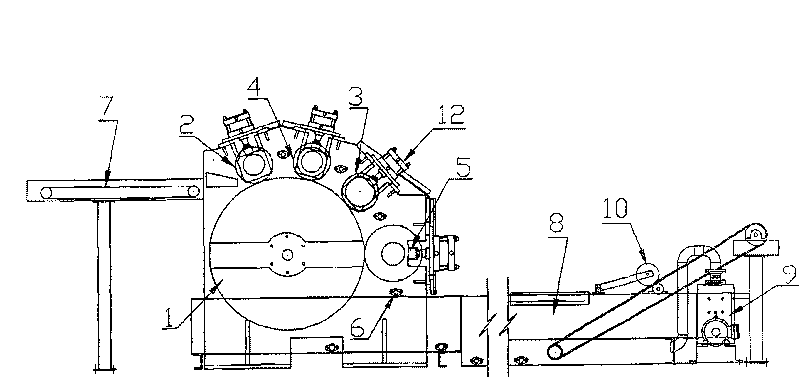

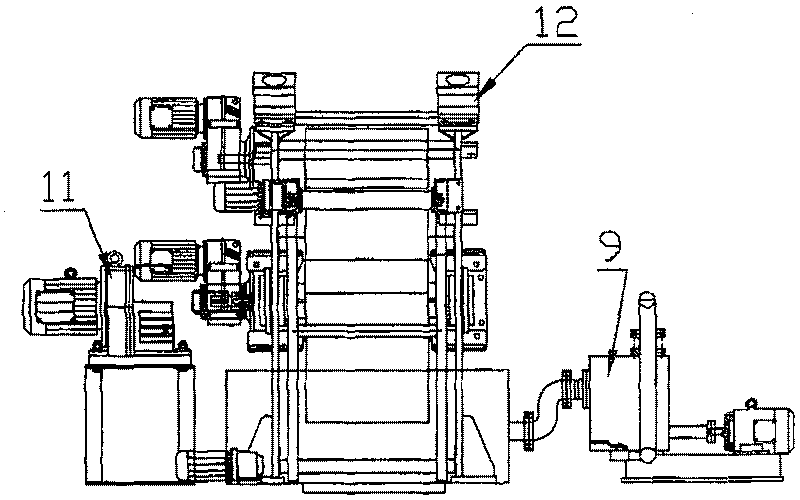

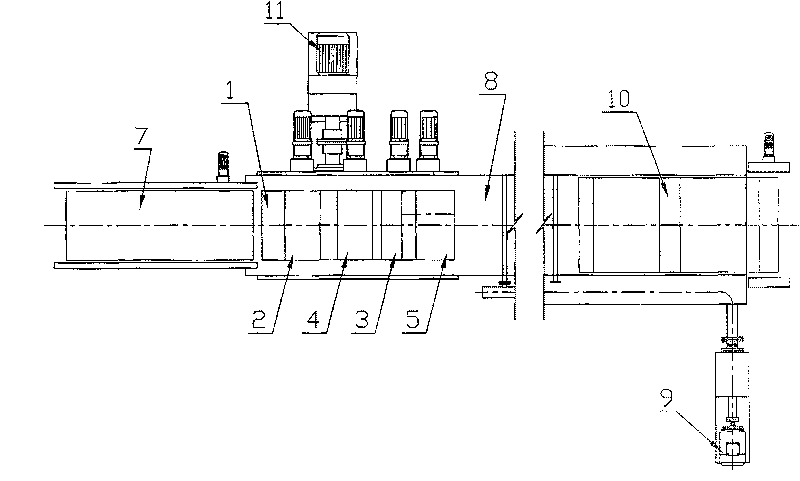

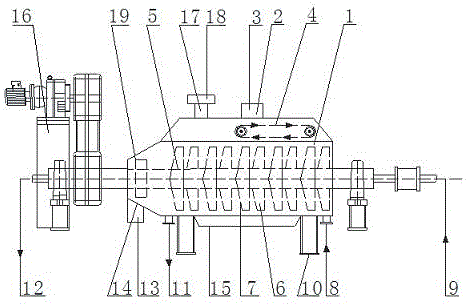

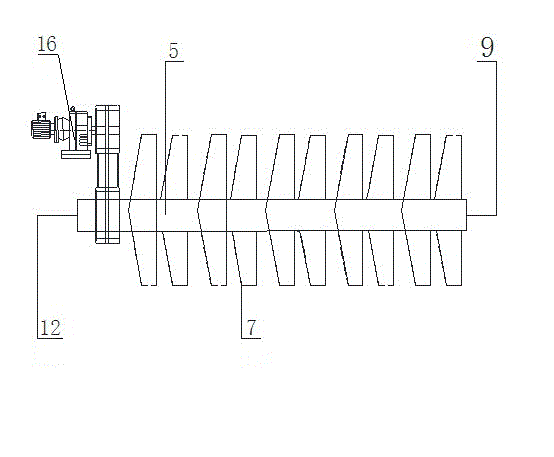

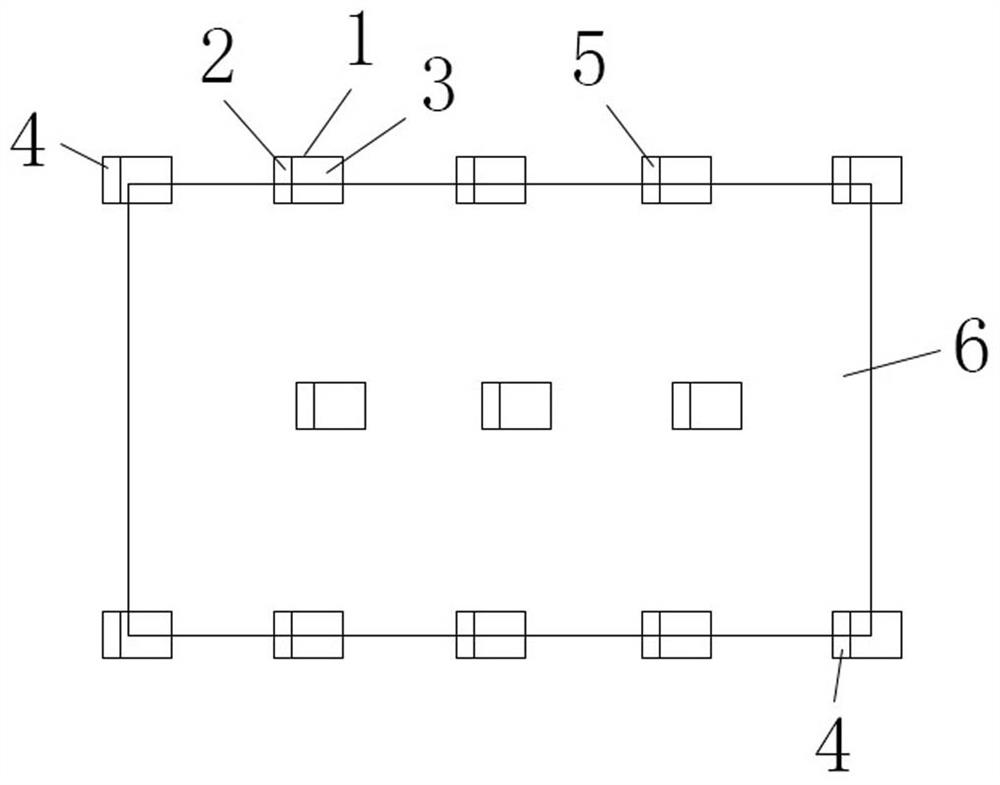

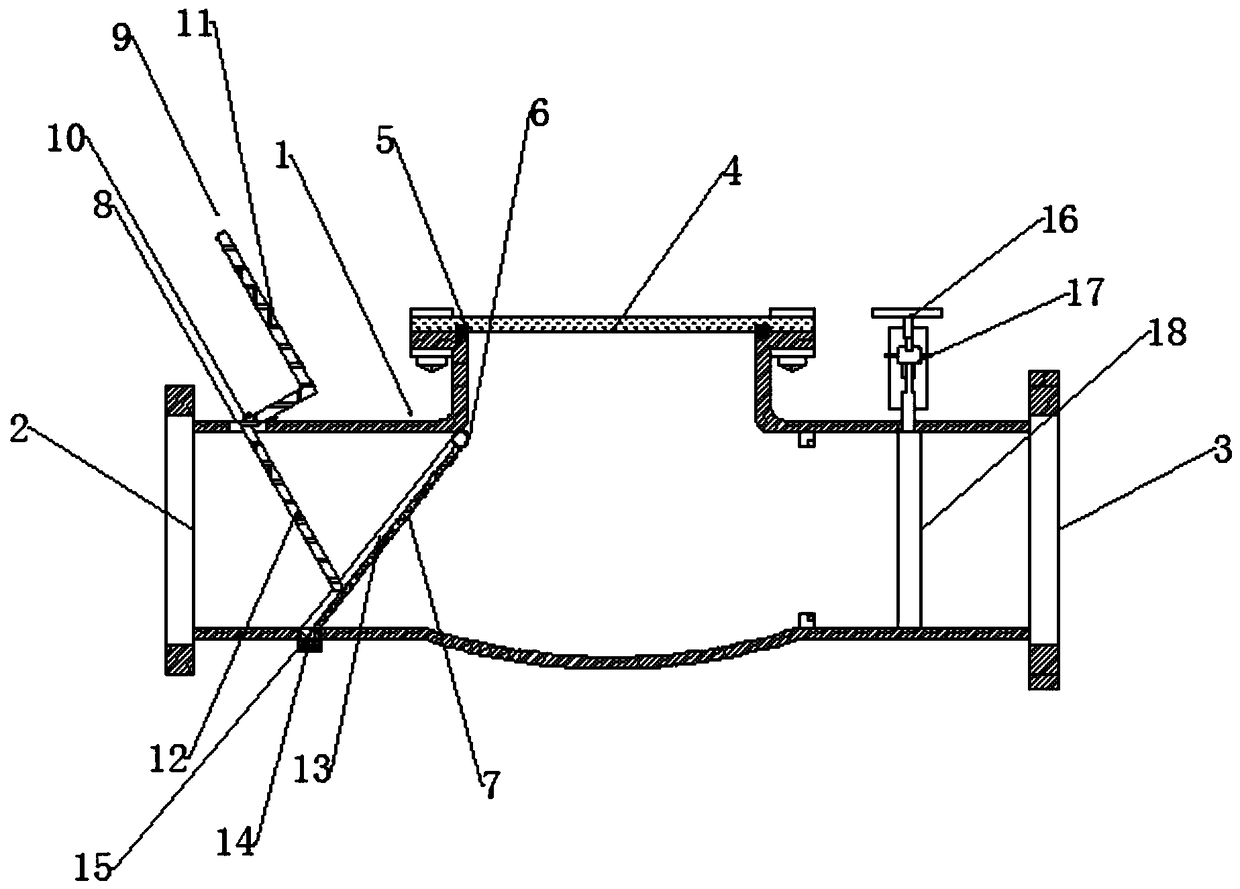

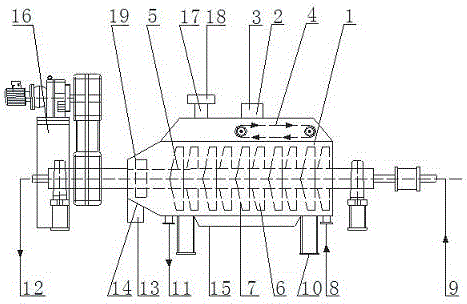

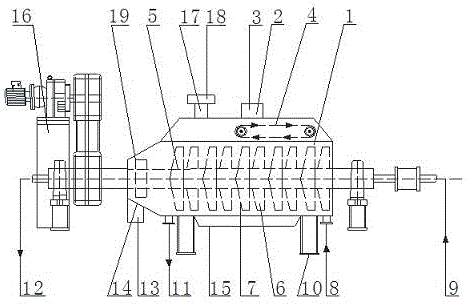

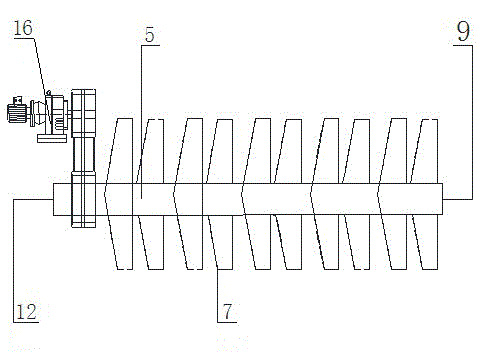

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499AHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extruding unit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

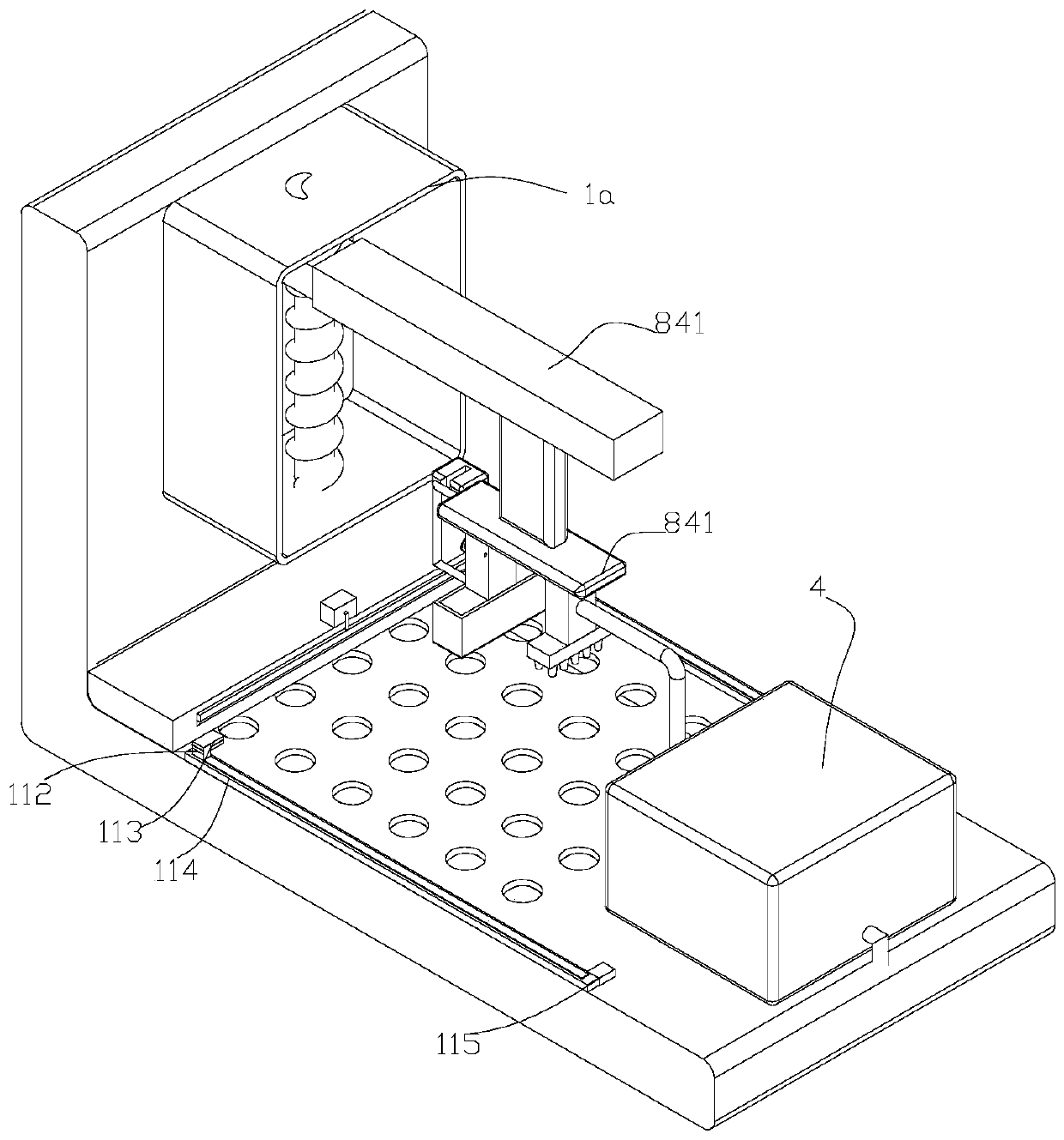

Automatic coating device

ActiveCN111515075APrecise positioningRise steadilyLiquid surface applicatorsSpraying apparatusElectric machineryEngineering

The invention discloses an automatic coating device. The automatic coating device comprises a vertical plate, a transverse plate arranged at the lower portion of the vertical plate, a material distribution box arranged on the left side of the upper portion of the transverse plate, a coating box arranged on the right side of the upper portion of the transverse plate, a coating recycling box arranged in the transverse plate, a moving box arranged on the right side of the vertical plate, a moving mechanism arranged in the moving box, a coating mechanism arranged in the coating box, and a cutting-off mechanism arranged on the material distribution box. The automatic coating device is characterized in that the moving mechanism comprises a first motor, a first screw rod arranged at the upper portion of the first motor, a first nut arranged at the outer portion of the first screw rod in a sleeving manner, and a lifting part arranged on the right side of the first nut, wherein the first nut can move vertically on the first screw rod.

Owner:吴璐纯

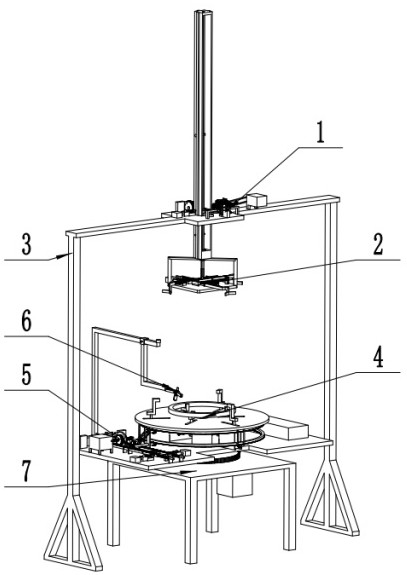

Grinding device for bearing ring of shield tunneling machine

InactiveCN113478310AAchieve grindingEasy to polishGrinding carriagesRevolution surface grinding machinesMachine partsEngineering

The invention discloses a grinding device for a bearing ring of a shield tunneling machine, and relates to the technical field of shield tunneling machine part treatment. The grinding device comprises a fixing frame and a fixing platform, wherein a lifting device and a fixing device are arranged on the fixing frame, a clamping device is arranged on the fixing platform, a clamping control device and a grinding device are arranged on the clamping device, the clamping device comprises a mounting platform which is rotationally arranged on the lifting device, the mounting platform is driven by a rotating power source arranged on the lifting device, an inner clamping jaw mechanism and an outer clamping jaw mechanism are arranged on the mounting platform, and the clamping control device is used for controlling an inner clamping jaw and an outer clamping jaw to clamp a part so as to facilitate the grinding device to carry out four-side grinding. Compared with the prior art, the grinding device has the advantage that the defects that in the prior art, grinding is not comprehensive, and the precision is not high are overcome.

Owner:江苏广联机械科技有限公司

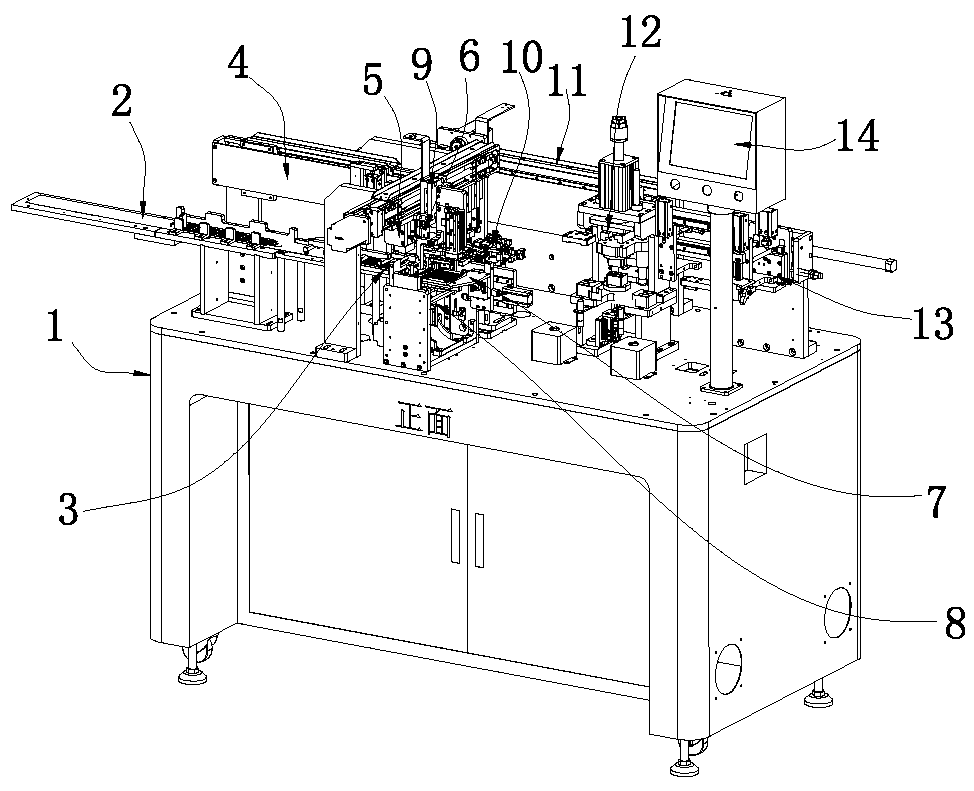

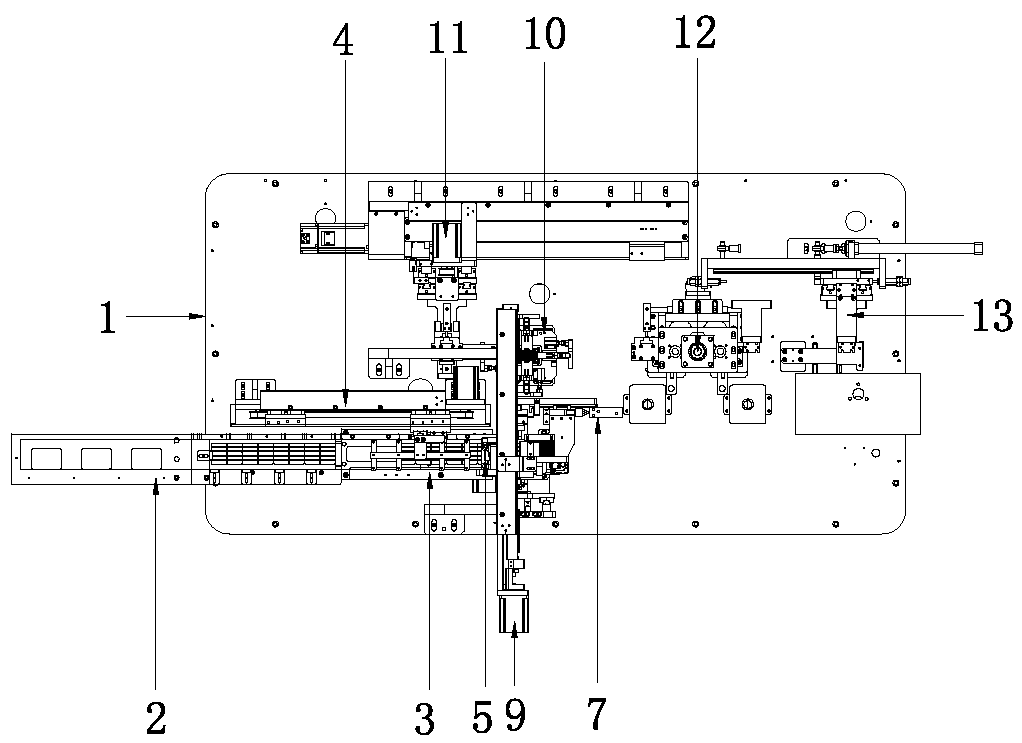

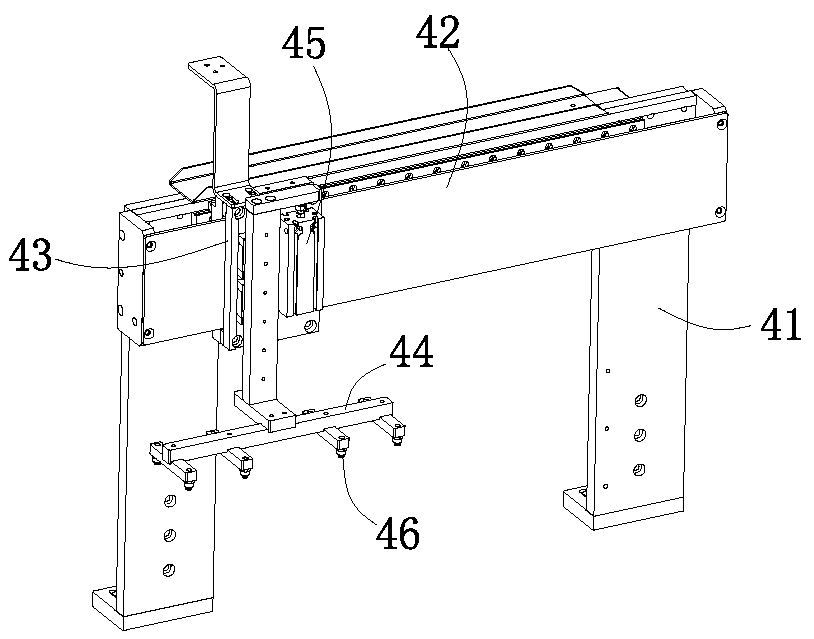

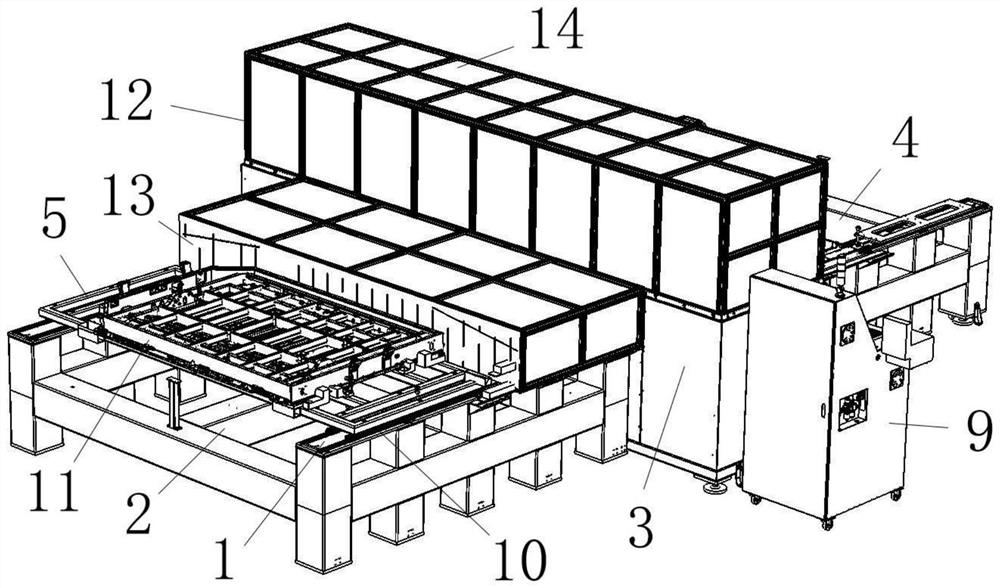

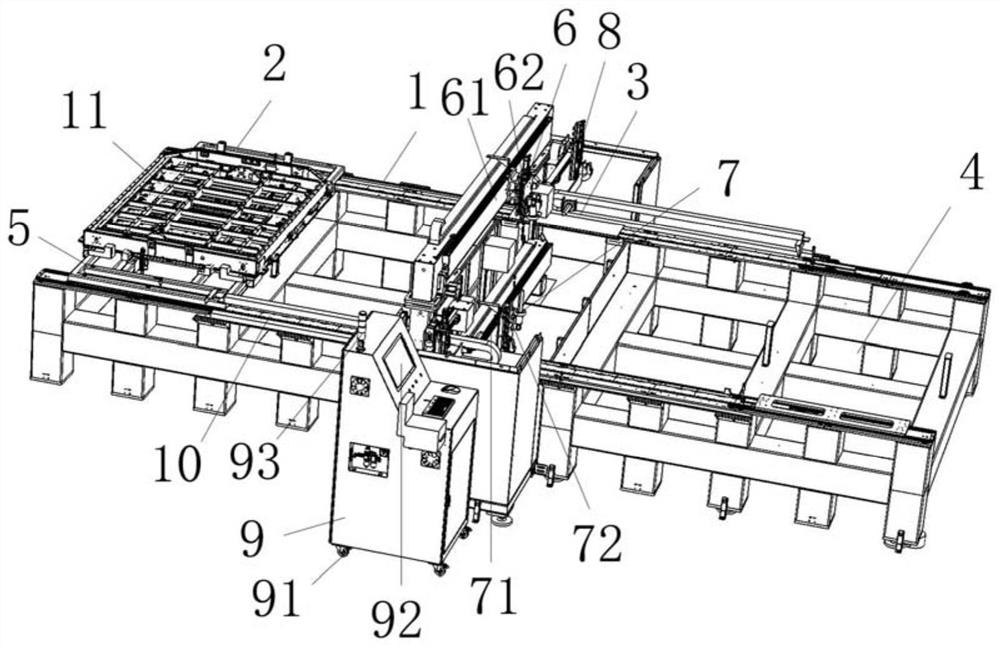

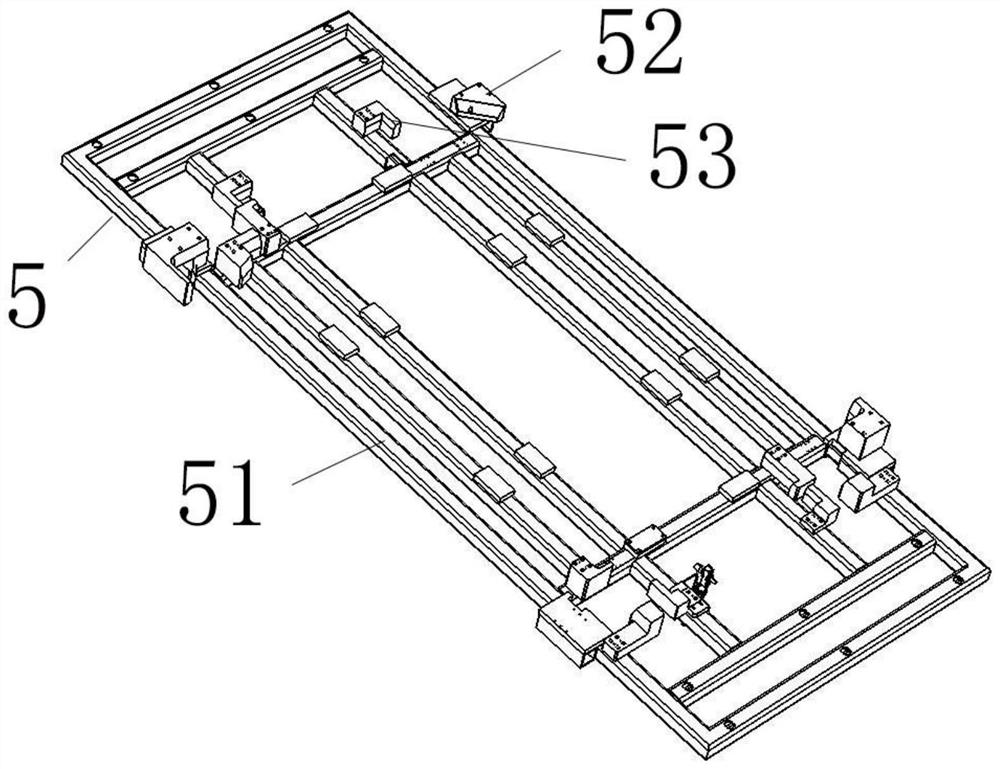

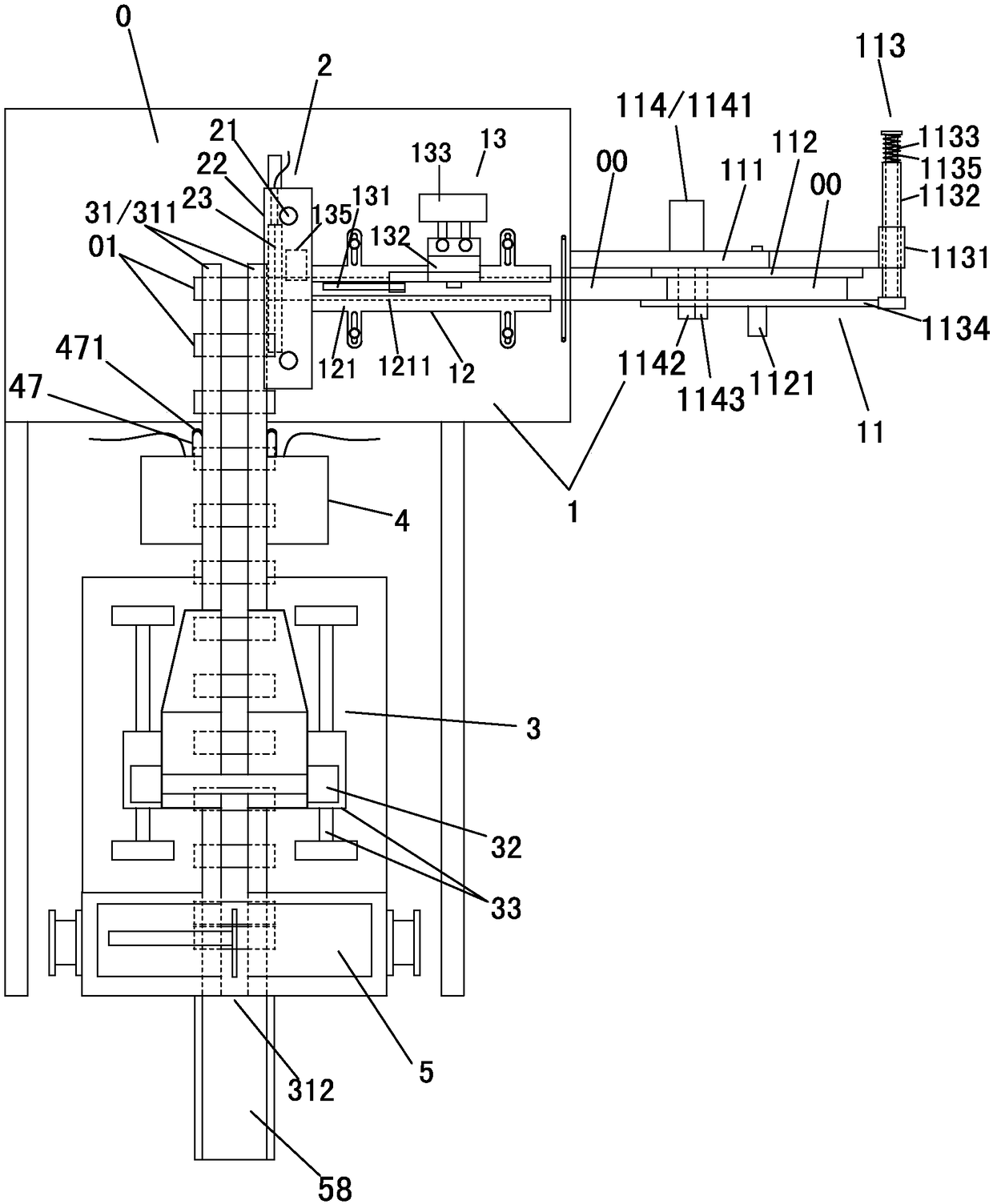

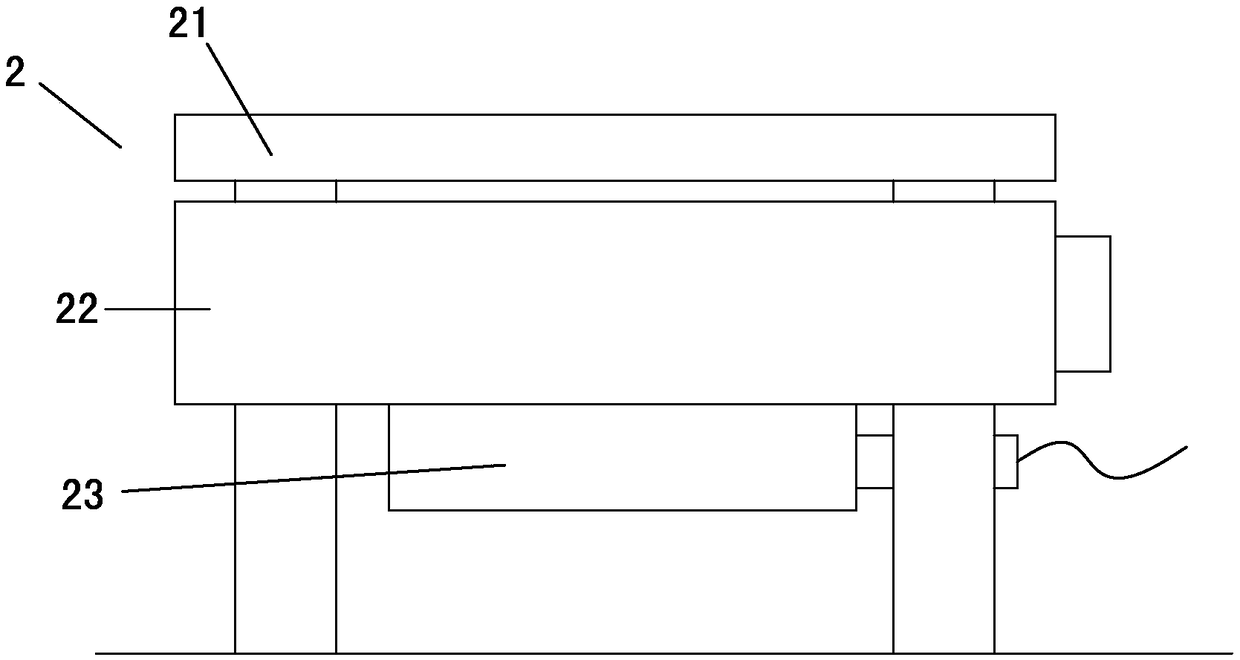

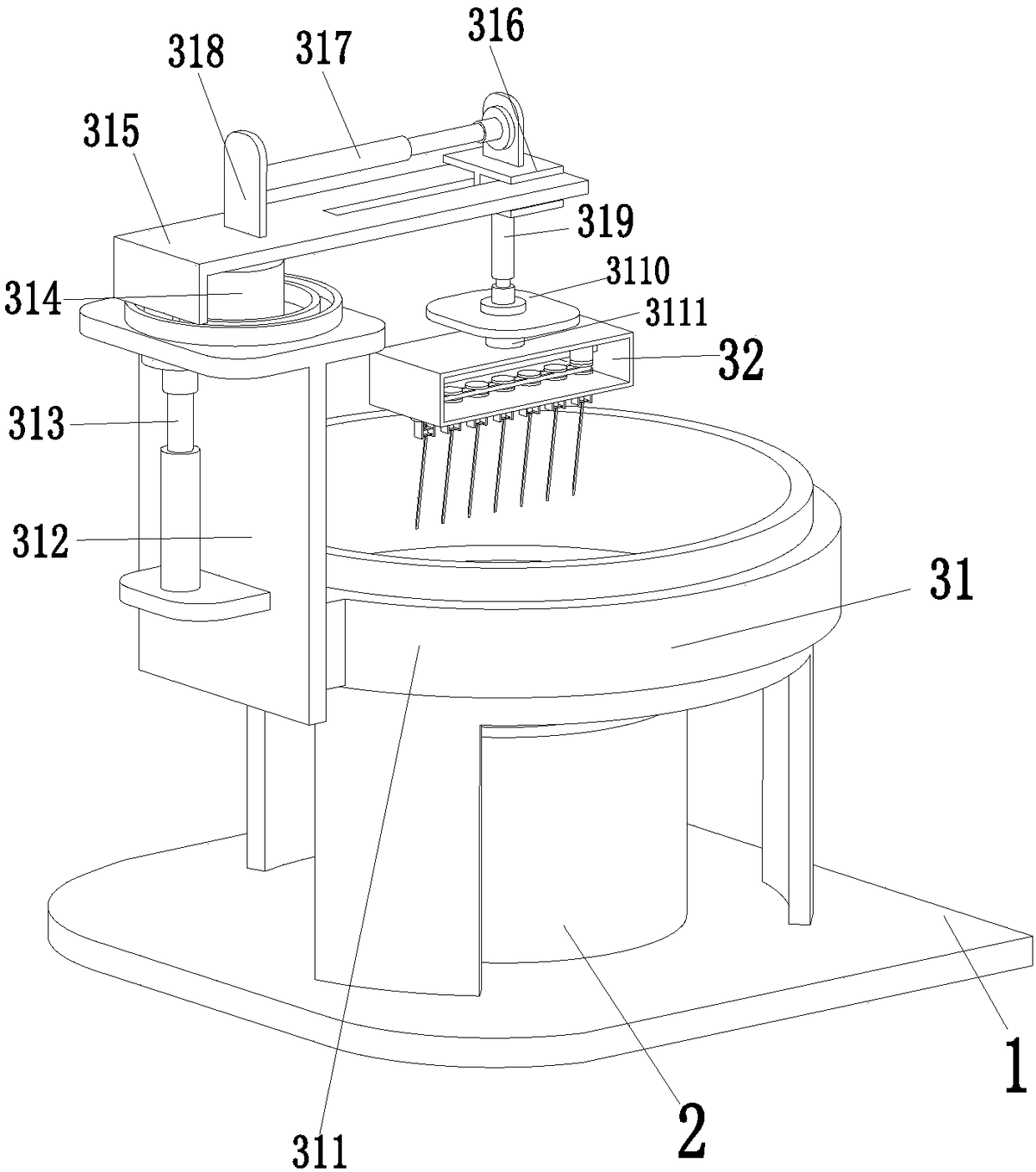

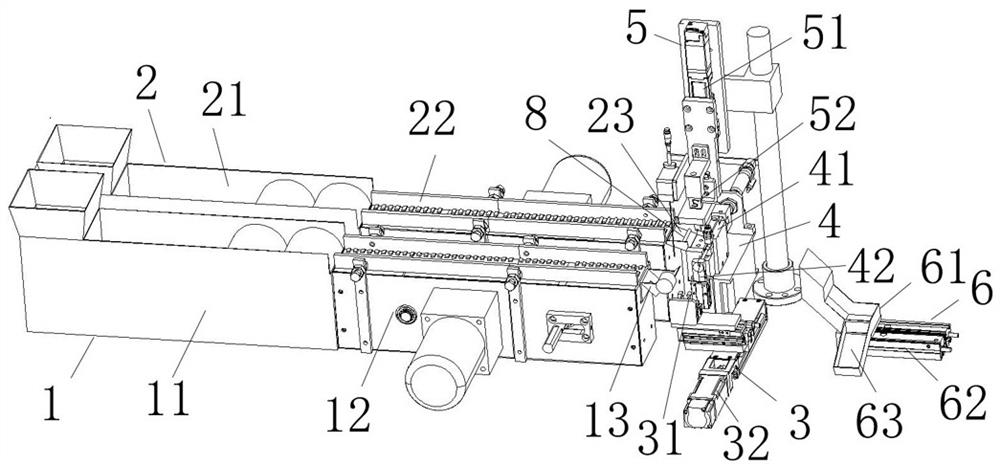

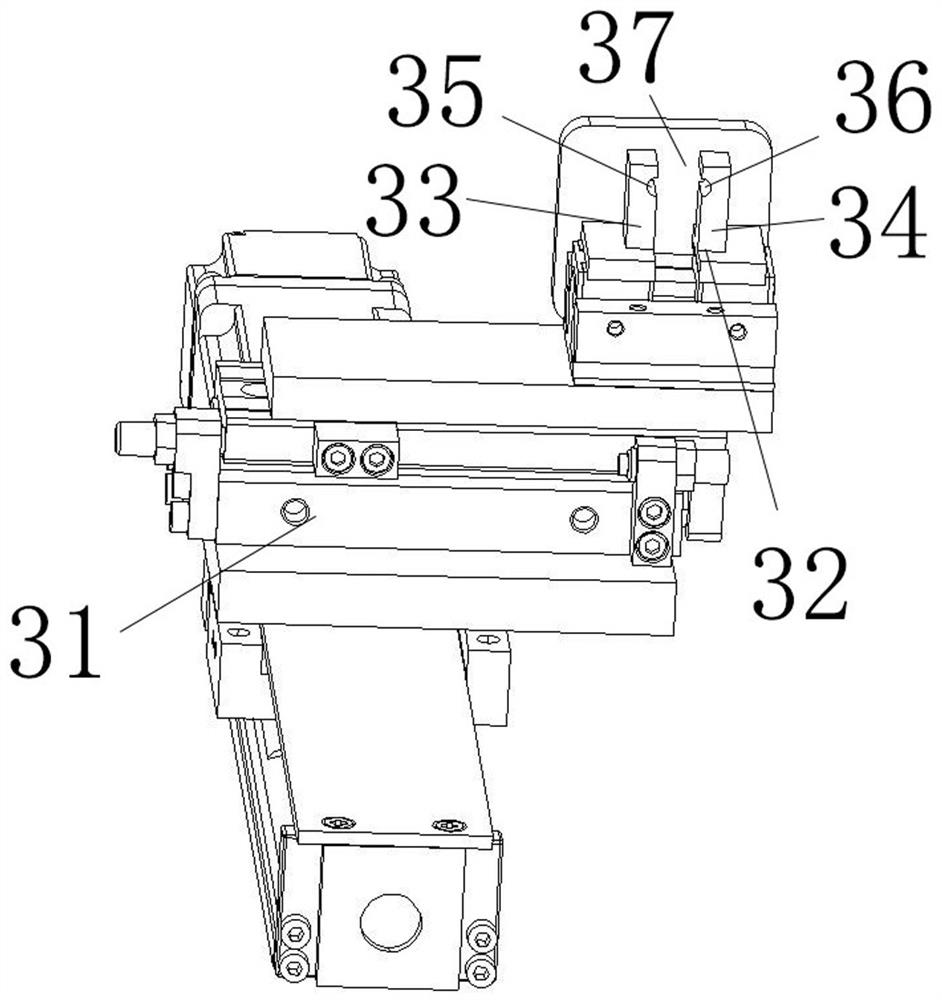

Automatic dome attaching machine and working method thereof

PendingCN109335675AReduce labor intensityIngenious structural designMaterial gluingConveyor partsTransfer mechanismBatch production

The invention discloses an automatic dome attaching machine and a working method of the automatic dome attaching machine. The automatic dome attaching machine comprises a frame, a conveying track, a feeding table, a moving and adsorbing feeding mechanism, a material belt prepressing mechanism, a material belt bending mechanism, a tray moving mechanism, a clamping downward pulling mechanism, a first moving and adsorbing transfer mechanism, a guide and alignment mechanism, a second moving and adsorbing transfer mechanism, a pressing mechanism and a moving and adsorbing discharging mechanism, wherein the conveying track, the feeding table, the moving and adsorbing feeding mechanism, the material belt prepressing mechanism, the material belt bending mechanism, the tray moving mechanism, the clamping downward pulling mechanism, the first moving and adsorbing transfer mechanism, the guide and alignment mechanism, the second moving and adsorbing transfer mechanism, the pressing mechanism andthe moving and adsorbing discharging mechanism are arranged on the frame. A PLC controller controls the working states of the conveying track, the moving and adsorbing feeding mechanism, the materialbelt prepressing mechanism, the material belt bending mechanism, the tray moving mechanism, the clamping downward pulling mechanism, the first moving and adsorbing transfer mechanism, the guide and alignment mechanism, the second moving and adsorbing transfer mechanism, the pressing mechanism and the moving and adsorbing discharging mechanism to correspondingly and automatically realize working procedures including feeding, alignment, pressing and discharging. The overall working process is smooth and fast, the quality of domes is effectively ensured, the production efficiency is greatly improved, the labor intensity of operators is reduced, the production income is increased, and the automatic dome attaching machine is suitable for batch production.

Owner:东莞市若渝电子科技有限公司

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499BHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extrudingunit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

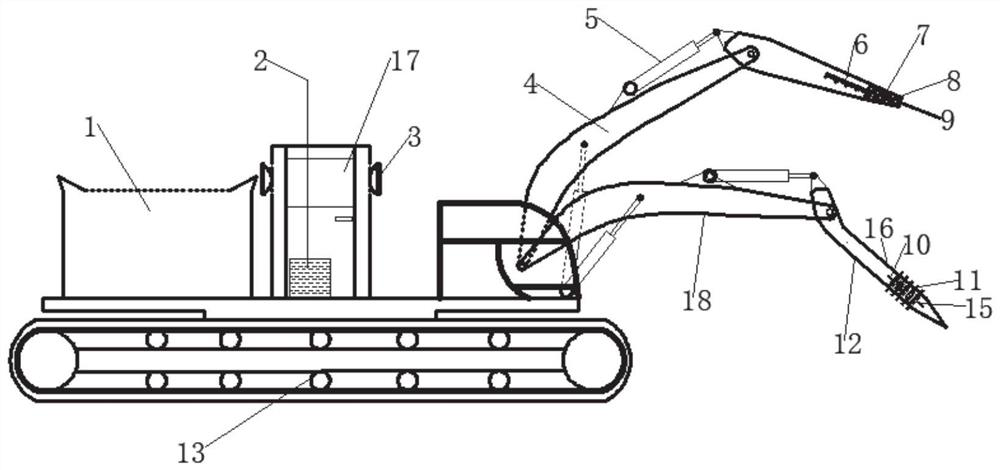

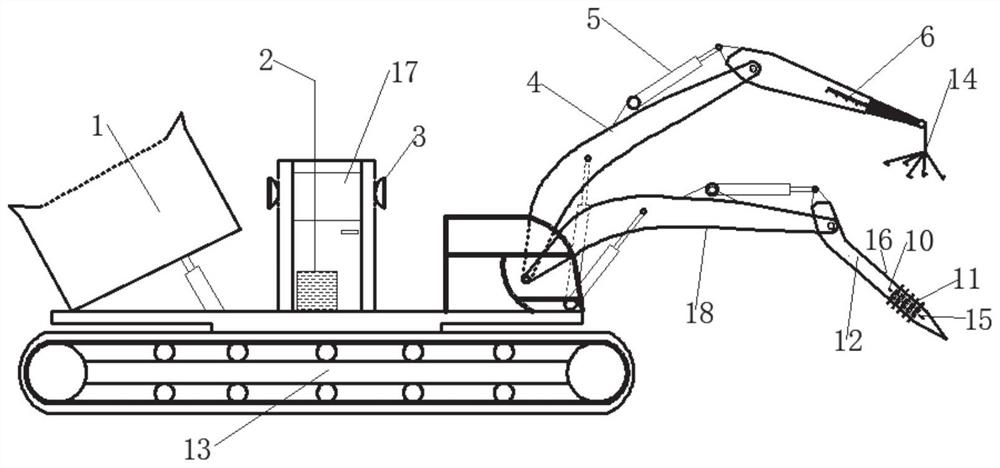

Tunnel hard rock micro-damage cutting device, system and method

ActiveCN112780293ABig market demandIncrease economic value addedMining devicesDisloding machinesReciprocating motionNatural environment

The invention discloses a tunnel hard rock micro-damage cutting device, system and method, and belongs to the technical field of underground engineering construction. The tunnel hard rock micro-damage cutting device, system and method have the advantages of being high in mechanization degree, good in rock integrity and easy to support; and while high excavation efficiency is guaranteed, damage to the natural environment can be reduced, the device comprises a columnar main body and a plurality of reciprocating motion mechanisms, wherein the reciprocating motion mechanisms are all connected to the side face of the columnar main body, the multiple reciprocating motion mechanisms can reciprocate in the radial direction of the columnar main body, the front end of the columnar main body is spine-shaped, and an image sensor is further installed at the front end of the main body.

Owner:SHANDONG JIANZHU UNIV

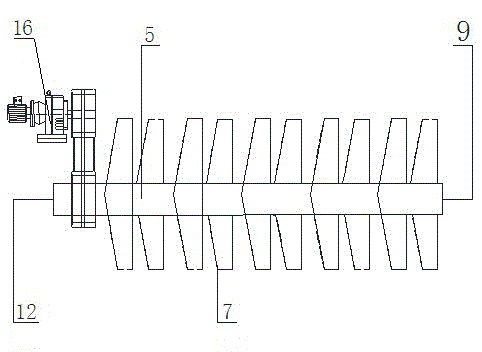

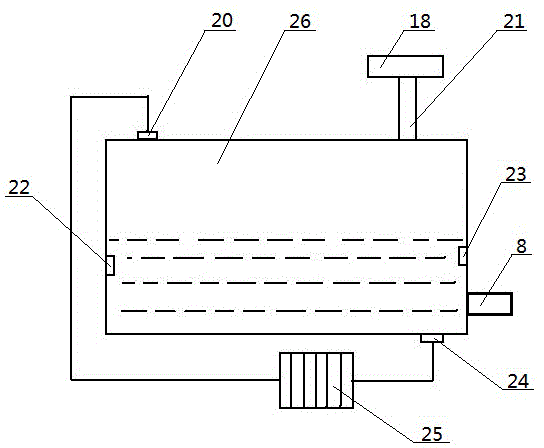

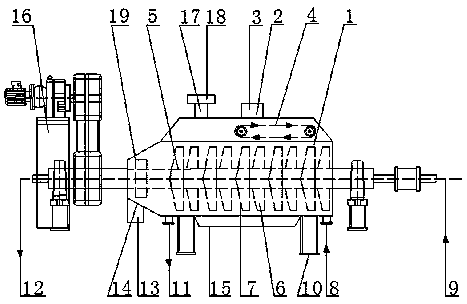

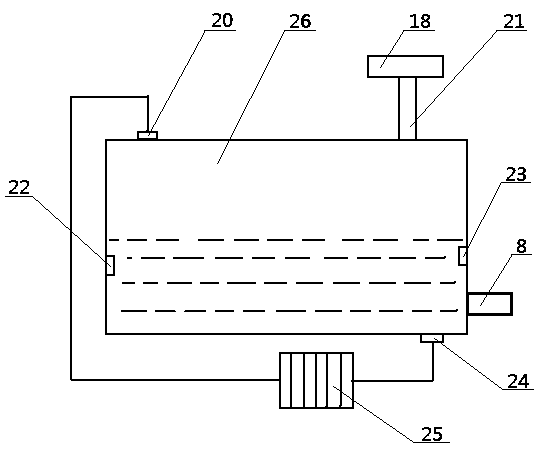

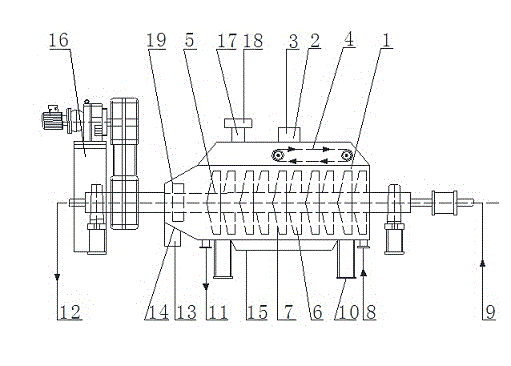

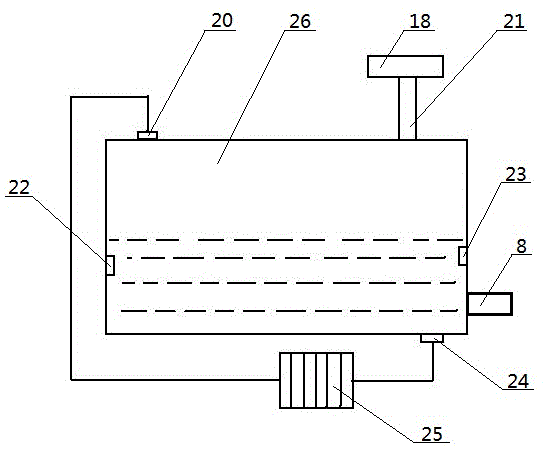

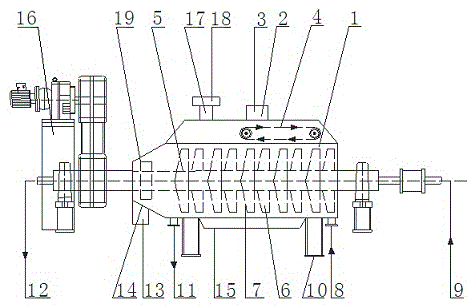

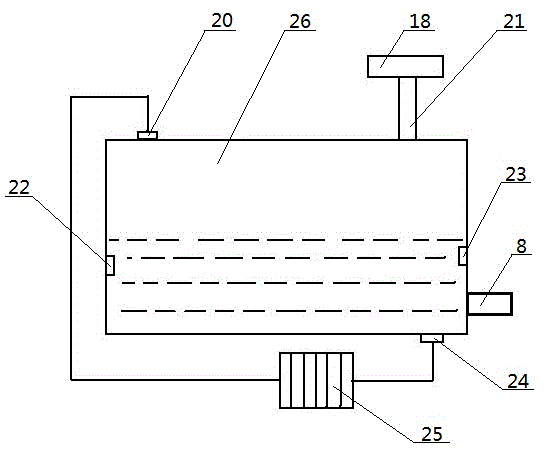

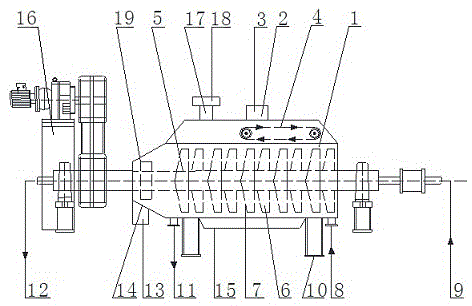

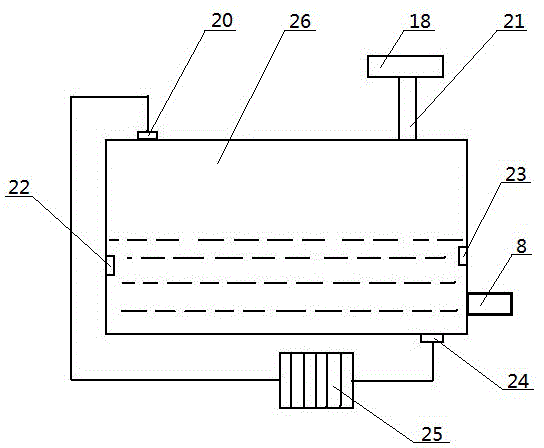

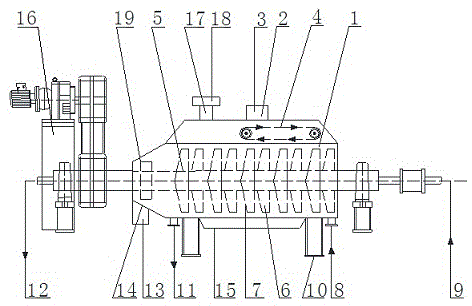

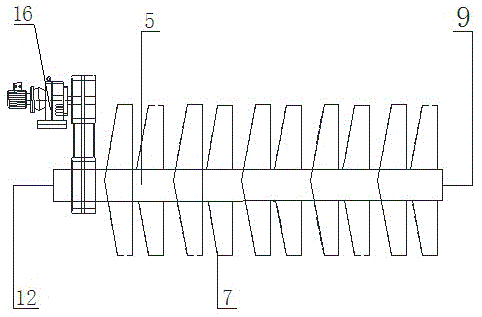

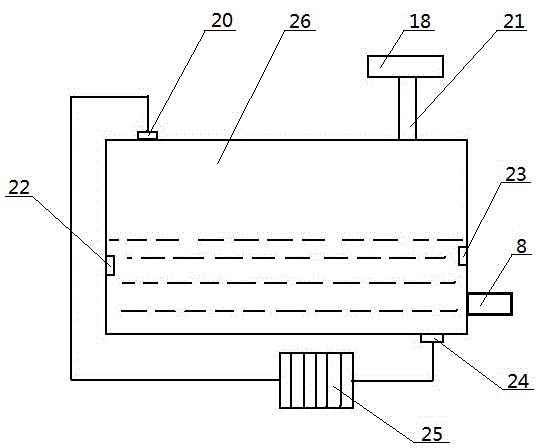

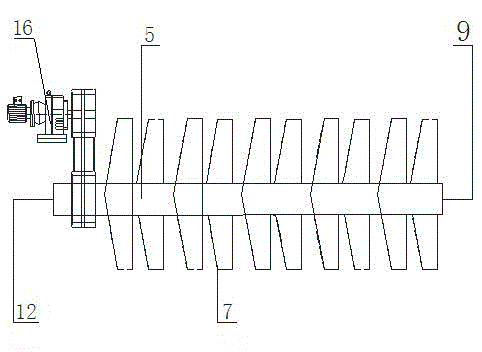

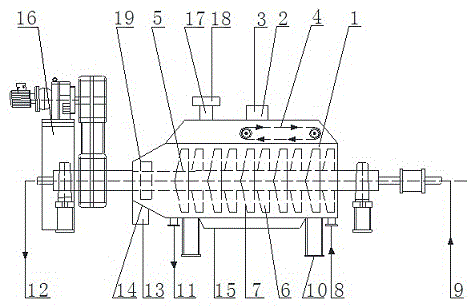

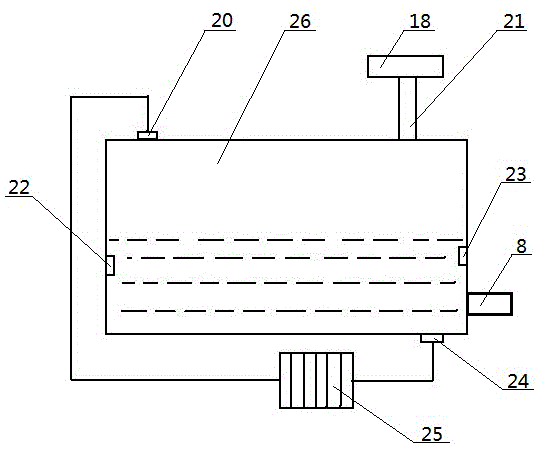

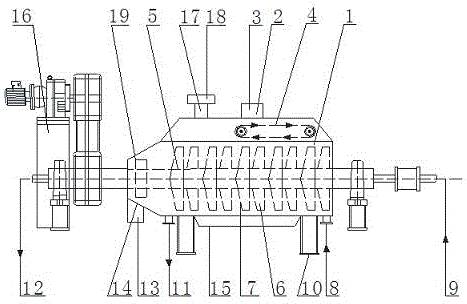

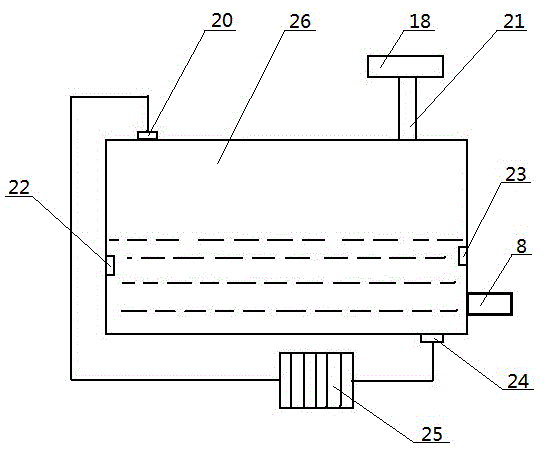

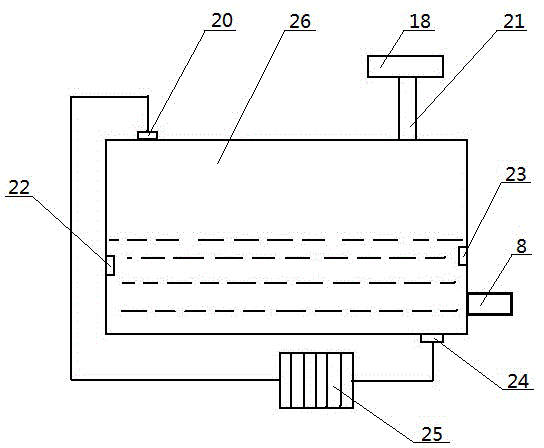

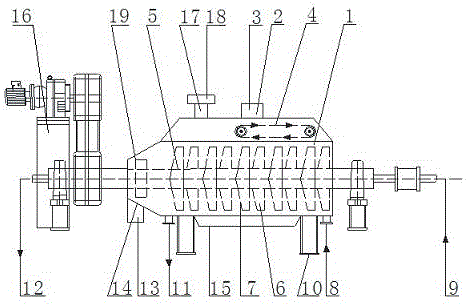

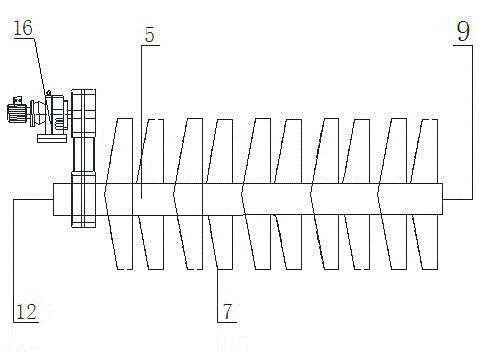

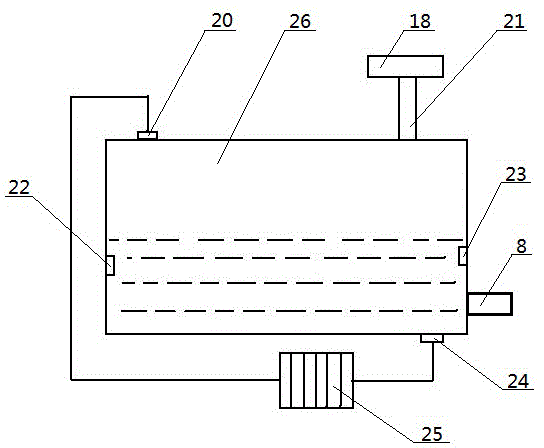

A sludge drying integrated machine

InactiveCN104649540ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a sludge drying integrated machine. The sludge drying integrated machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The sludge drying integrated machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

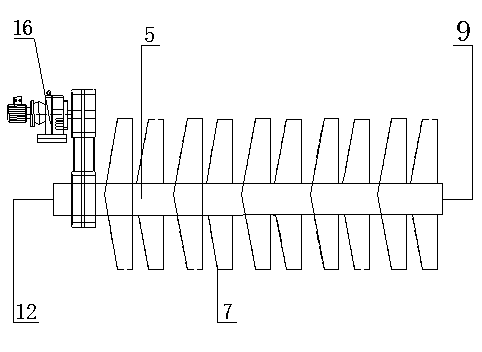

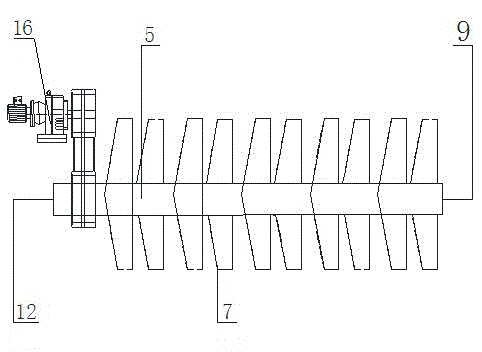

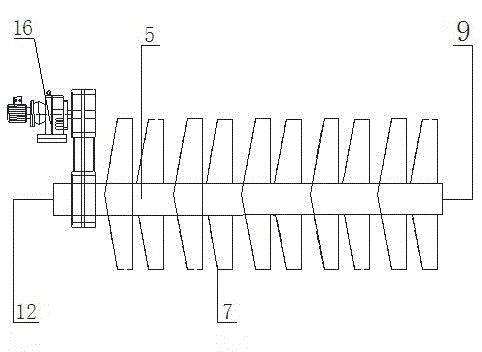

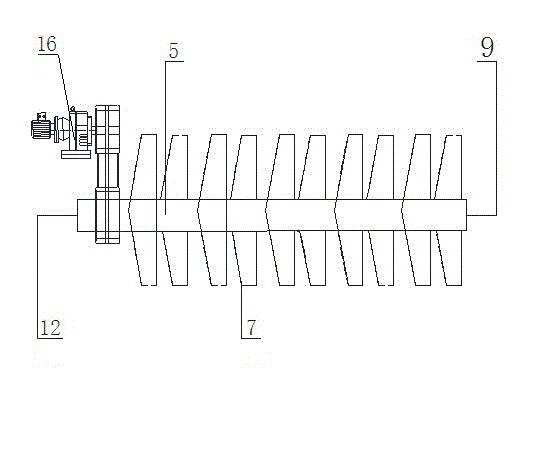

Gear type sludge dryer

InactiveCN103588376ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTemperature controlSludge

The invention relates to the field of environmental protection equipment, in particular to a gear type sludge dryer which comprises a dryer body, gear type spiral pushing shafts, a support, a condensation water circulation device, a driving system, an air purification system and an automatic temperature control system, wherein the air purification system is arranged above the dryer body; the two gear type spiral pushing shafts placed in parallel and the automatic temperature control system are arranged in the dryer body; heat conducting medium inlets and heat conducting medium outlets are formed at the two ends of the dryer body and the gear type spiral pushing shaft; the dryer placed in parallel is arranged above the support; the condensation water circulation device is arranged below the support; and the driving system is arranged at one end of the gear type spiral pushing shaft. The dryer realizes an integrated sludge drying work process, as well as low energy consumption and high efficiency during operation, and is in a full automatic unattended operation mode.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

A rotating extrusion type sludge dewatering machine

InactiveCN104649538ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesTemperature controlGear wheel

The invention relates to the field of environment protection equipment, and particularly relates to a rotating extrusion type sludge dewatering machine. The sludge dewatering machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

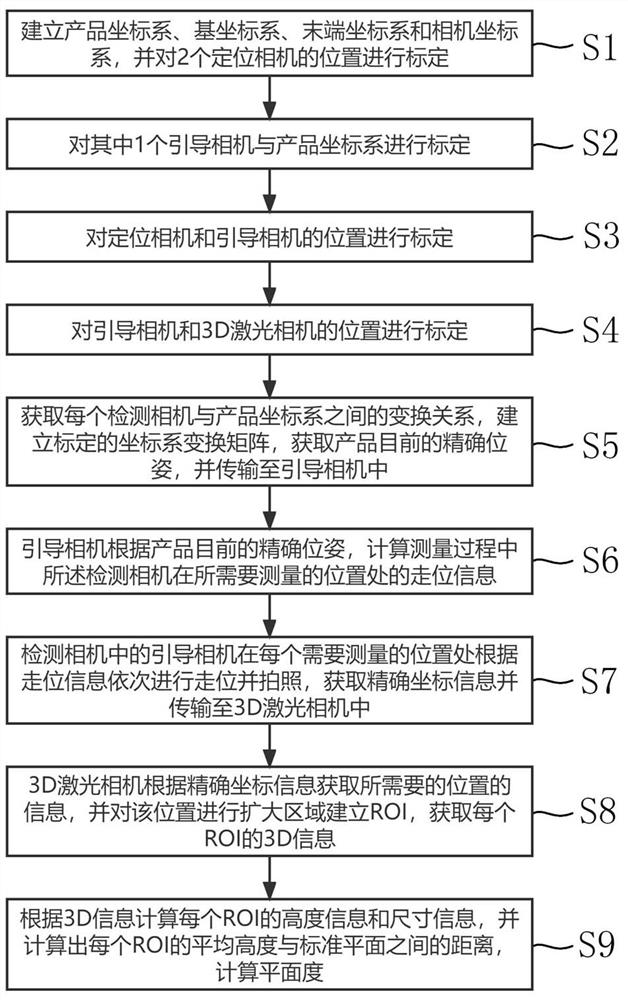

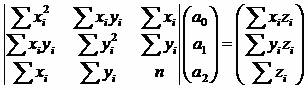

3D detection method for computer rear shell

ActiveCN114820820AHigh positioning accuracyProcessing speedImage enhancementImage analysisRadiologyComputer vision

The invention discloses a 3D detection method for a computer rear shell, which comprises a manipulator and a plurality of groups of detection cameras, and each group of detection cameras comprises a 2D camera and a 3D laser camera; calibrating the 2D camera, the 3D laser camera and the manipulator, and establishing a calibrated coordinate system transformation matrix; the 2D camera obtains accurate coordinate information, the 3D laser camera establishes ROIs according to the accurate coordinate information, and 3D information of each ROI is obtained; and calculating height information and size information of each ROI according to the 3D information, and calculating the flatness. Positioning is carried out through the 2D camera, calibration is carried out on the 2D camera, the manipulator and the 3D laser camera in three aspects, and the positioning precision is higher; the ROI is detected and compared with the fitted standard plane, so that the data volume is reduced, the detection speed is increased, and the detection precision is improved.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

New energy battery box detection equipment and detection method

PendingCN114705681AEliminate the effects ofImprove detection efficiencyMaterial analysis by optical meansNew energyEmbedded system

The invention discloses a new energy battery box detection device and method, and the device comprises a transmission line, the transmission line is sequentially provided with a feeding region, a detection region and a discharging region, and the transmission line is provided with a carrier which moves among the feeding region, the detection region and the discharging region; and the detection area comprises a top surface detection mechanism, a bottom surface detection mechanism and two side surface detection mechanisms. New energy battery boxes are moved among the feeding area, the detection area and the discharging area through the carriers on the transmission line, meanwhile, the top faces, the bottom faces and the side faces of products are automatically detected, and the detection efficiency is higher; the distance between the new energy battery box and the detection camera is compensated through the first depth compensation mechanism, the influence of product deformation on the detection result is eliminated, and the detection precision is higher.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Full-automatic sludge drier

InactiveCN104649549ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention belongs to the field of environmental protection equipment, and specifically relates to a full-automatic sludge drier. The full-automatic sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and imported medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The full-automatic sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and guardless automatic operation is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Automatic sludge drier

InactiveCN104649557AHigh degree of integrationThe overall structure is compactWater treatment parameter controlSludge treatment by de-watering/drying/thickeningAir cleaningWater circulation

The invention belongs to the field of environmental protection equipment, and specifically relates to an automatic sludge drier. The automatic sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and heat-conducting medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The automatic sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and a full-automatic guardless operation mode is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

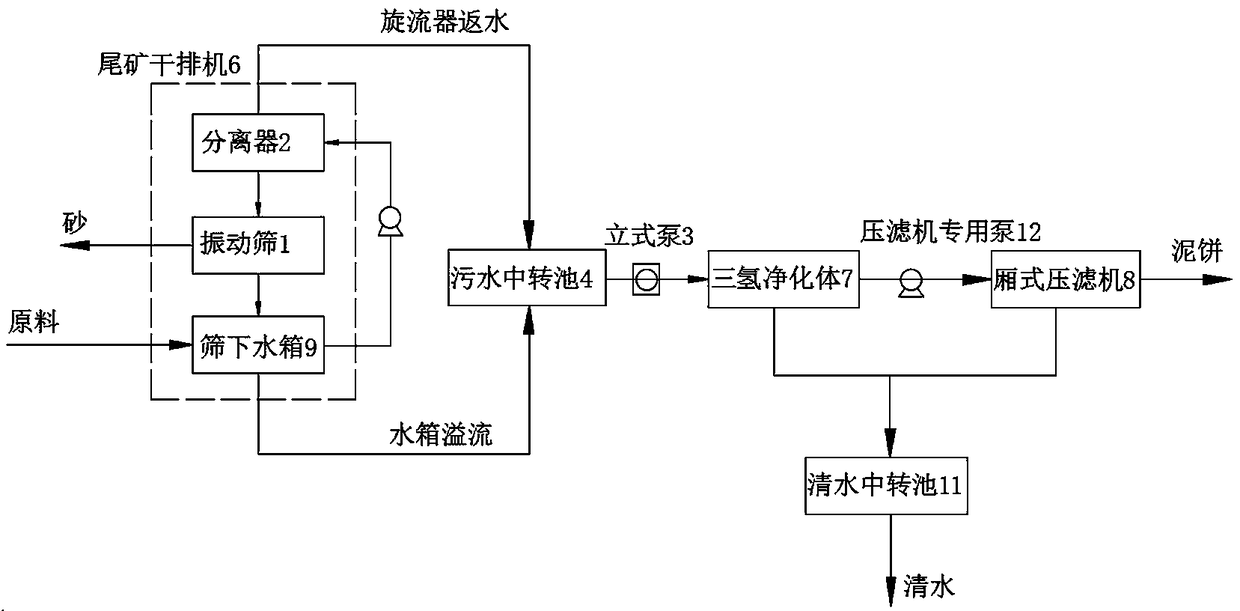

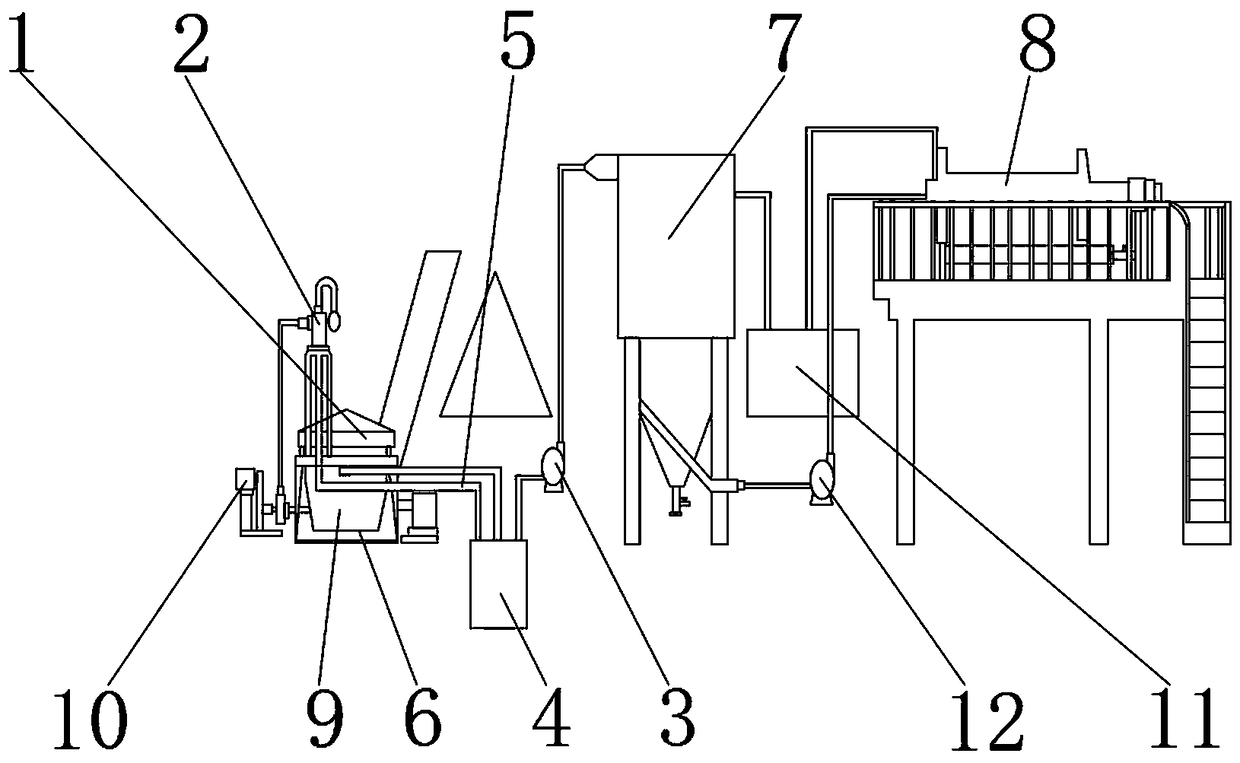

Tailing recycling zero discharge system and process

InactiveCN109091952ARealize dehydration recoveryRealize purification and reuseSludge treatment by de-watering/drying/thickeningFiltration circuitsWater dischargeEmission standard

The invention belongs to the technical field of tailing recycling and discharge, and particularly relates to a tailing recycling zero discharge system and process. The system comprises a tailing dry discharge machine, a tri-hydrogen purifying body and a chamber type filter press. Tailings are subjected to mud and sand separation through the tailing dry discharge machine, mud-water separation through the tri-hydrogen purifying body and solid waste dry discharge through the chamber type filter press to achieve dehydration and recycling of the tailings and fine sand. The purified tail water suspended solid (SS) is less than 300mg / L (excluding special materials), higher than the third-level emission standard of tail water discharge in the mining industry in GB8978 Integrated Wastewater Discharge Standard, and the fresh water reuse rate is greater than 80%, in line with national standards for reuse of water resources for industrial mining, mineral processing and the like. The dry stacking and dry discharging of the solid waste are achieved. The moisture content of a pressure-filtered mud cake is less than 60-75%, reaching the national standard for dry stacking and dry discharging or blended landfill.

Owner:LUOYANG LONGZHONG HEAVY IND MACHINERY CO LTD

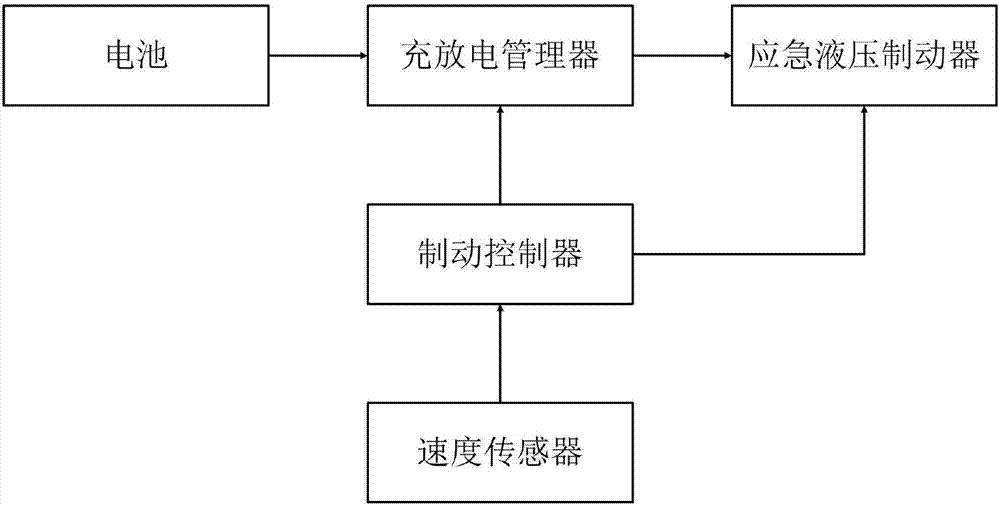

Emergency brake release system, control method and hoisting system

ActiveCN108005968AEnsure safetySafe, fast and controllable releaseFluid-pressure actuator safetyServomotor componentsControl signalHydraulic brake

The invention discloses an emergency brake release system. The emergency brake release system comprises a battery, a brake controller and an emergency hydraulic brake. The battery provides power for the emergency hydraulic brake. The brake controller issues a control signal to control the emergency hydraulic brake to work, and a hoisting mechanism releases weights during power failures. The invention further provides a control method of the emergency brake release system. The control method comprises the steps that the system is started for self-inspection; the emergency brake release system is started; an emergency oil pump is started; the brake is switched off in an emergency manner; a speed sensor detects the rotating speed of a hoisting motor and uploads the rotating speed to the brakecontroller; the brake controller controls a proportional overflow valve to guarantee the rotating speed of the hoisting motor; and if the rotating speed of the hoisting motor is larger than a threshold value, the battery and the emergency brake release system are immediately disconnected, and the brake is switched on. The invention further provides the hosting mechanism including the emergency brake release system and the control method. It can be guaranteed that the hoisting mechanism releases the weights safely, fast and controllably when the system is powered off, the structure is simple,and safety and reliability are achieved.

Owner:JIANGXI GONGBU MACHINERY

A sludge drying machine with an automatic temperature control system

InactiveCN104649542ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a sludge drying machine with an automatic temperature control system. The sludge drying machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and the automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

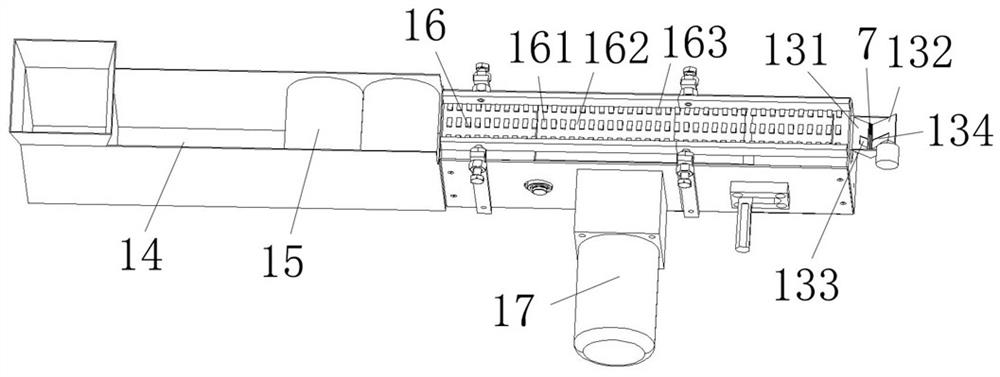

Full-automatic cutting edging machine for clothing trademarks

ActiveCN108755079AImplement sequential operationsAchieving the effect of the purposeFilament handlingSevering textilesTrademarkControl system

The invention discloses a full-automatic cutting edging machine for clothing trademarks. The machine comprises a machine base, a roll conveying device, a cutting device, a press conveying device, an edging device and a control system. The roll conveying device, the cutting device, the press conveying device, the edging device and the control system are arranged on the machine base, the roll conveying device is used for conveying rolled clothing trademark bands to the cutting device, and the cutting device is used for cutting the clothing trademark bands into segments; the press conveying device is used for conveying the clothing trademarks which are cut into segments to the edging device for press folding and formation of end edges and outputting the formed clothing trademarks; the controlsystem is used for controlling working operation of the whole machine. According to the full-automatic cutting edging machine, work of a series of steps such as roll conveying, cutting, edging can befully automatically and mechanically conducted, traditional manual operation is replaced, the working efficiency can be greatly improved, and convenience is provided for sewing.

Owner:SHISHI XINGGANG PLASTIC PACKAGING

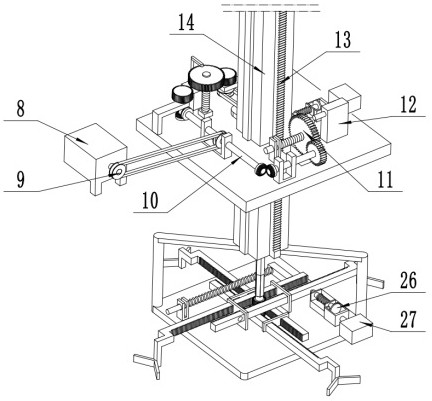

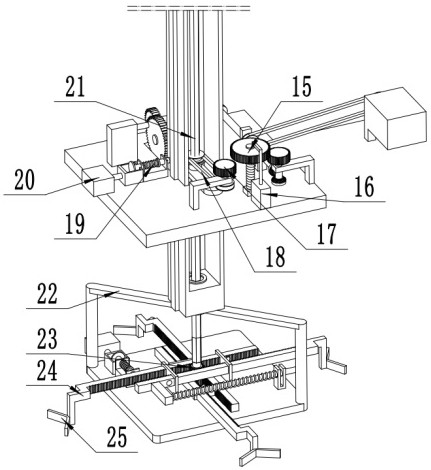

External application traditional Chinese medicine processing equipment for orthopedics department

InactiveCN108212696AReduce labor intensitySmooth workflowLiquid surface applicatorsPharmaceutical product form changeExternal applicationOrthopedic department

The invention relates to external application traditional Chinese medicine processing equipment for the orthopedics department. The external application traditional Chinese medicine processing equipment comprises a bottom plate. A heating furnace is mounted at the front end of the bottom plate. A stirring device is mounted on the outer wall of the heating furnace. A spreading device is mounted atthe rear end of the bottom plate. The stirring device comprises a stirring adjusting mechanism mounted on the outer wall of the heating furnace. A stirring execution mechanism is mounted at the lowerend of the stirring adjusting mechanism. According to the external application traditional Chinese medicine processing equipment, the problems that in the existing manual manufacturing process of external application traditional Chinese medicines, plaster pulp needs to be stirred manually, plaster raw materials need to be manually spread on plaster carriers with the help of tools, manual stirringof the plaster pulp is not uniform, the plaster pulp is thick, the plaster pulp cannot fully take effect when manually stirred, the operation of manually spreading the plaster pulp with the help of the tools is complex, the plaster carriers need to be fixed so as to be prevented from being creased, and the plaster pulp spreading effect is influenced can be solved.

Owner:李福香

Novel double-valve pneumatic stop valve

The invention relates to a novel double-valve pneumatic stop valve. The novel double-valve pneumatic stop valve comprises a valve body; the left side of the valve body is fixedly connected with an inlet, and the right side of the valve body is fixedly connected with an outlet; the top of the valve body is fixedly connected with a valve cover through a bolt, and a first sealing ring is arranged between the valve body and the valve cover; and the position, close to the inlet, of an inner cavity of the valve body is provided with an ejection type first valve assembly, and the position, close to the outlet, of the inner cavity of the valve body is provided with a second valve assembly. Through the novel double-valve pneumatic stop valve provided by the invention, the problems that an existingrotary knob type valve is difficult to control and operate, whether opening and closing of the valve are achieved or not is not prone to being determined, production accidents are prone to occurring,and the production efficiency and benefits are influenced are solved.

Owner:HENAN GUANSHI MASCH EQUIP CO LTD

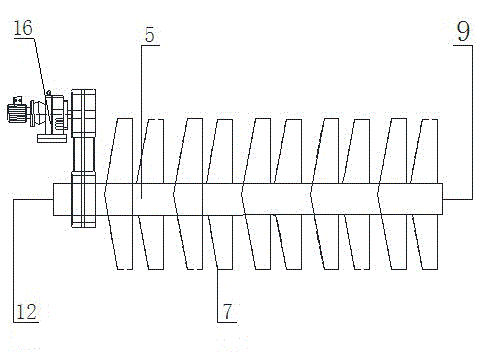

Novel sludge drier

InactiveCN104649554ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesTemperature controlSludge

The invention belongs to the field of environmental protection equipment, and specifically relates to a novel sludge drier. The novel sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and heat-conducting medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The novel sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and guardless automatic operation is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Novel sludge dewatering machine with steam discharging port

InactiveCN104649541AHigh degree of integrationThe overall structure is compactSludge treatment by de-watering/drying/thickeningAir cleaningWater circulation

The invention relates to the field of environment protection equipment, and particularly relates to a novel sludge dewatering machine with a steam discharging port. The sludge dewatering machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

A flowing type sludge drying machine

InactiveCN104649535ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a flowing type sludge drying machine. The sludge drying machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in an operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Sludge dewatering machine with air cleaning system

InactiveCN104649536ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTemperature controlGear wheel

The invention relates to the field of environment protection equipment, and particularly relates to a sludge dewatering machine with an air cleaning system. The sludge dewatering machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, the air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

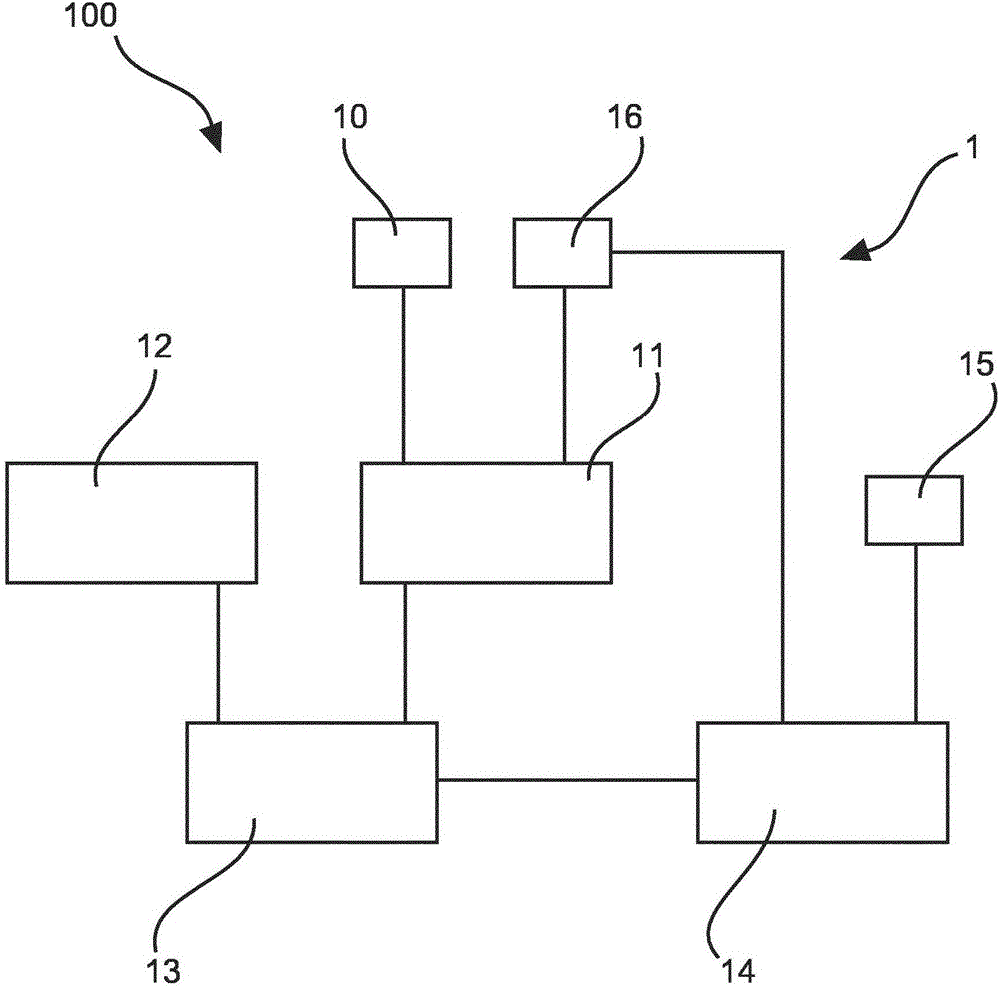

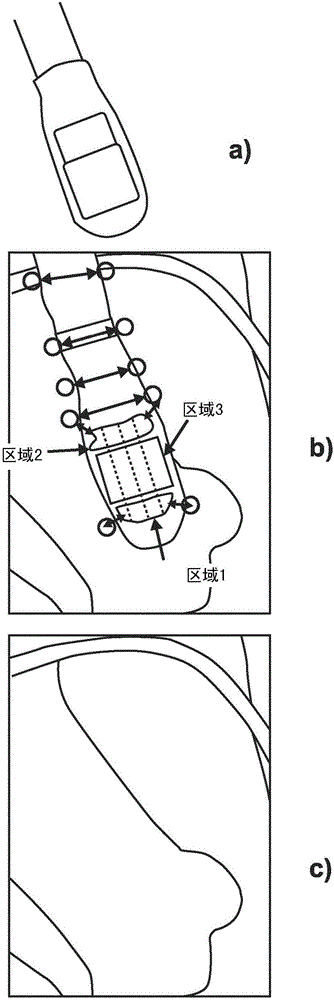

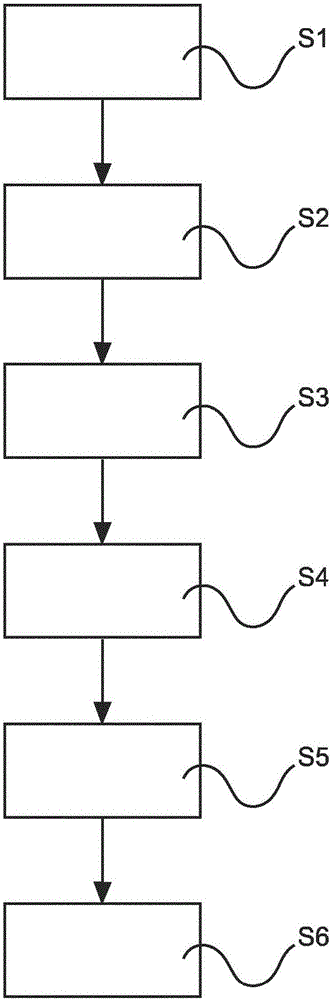

Device for modifying an imaging of a tee probe in X-ray data

ActiveCN106456080AReduce radiation doseSmooth workflowUltrasonic/sonic/infrasonic diagnosticsImage enhancementX-rayMedical imaging

The present invention relates to a device (1) for modifying an imaging of a TEE probe in X-ray data, a medical imaging system (100) for modifying an imaging of a TEE probe in X-ray data, a method for modifying an imaging of a TEE probe in X-ray data, a computer program element for controlling such device (1) and a computer readable medium having stored such computer program element. The device (1) comprises an X-ray data provision unit (11), a model provision unit (12), a position locating unit (13), and a processing unit (14). The X-ray data provision unit (11) is configured to provide X-ray data comprising image data of a TEE probe. The model provision unit (12) is configured to provide model data of the TEE probe. The position locating unit (13) is configured to locate a position of the TEE probe in the X-ray data based on the model data of the TEE probe. The processing unit (14) is configured to define a region in a predetermined range adjacent to the TEE probe as reference area. The processing unit (14) is configured to process the X-ray data of the reference area into estimated X-ray data of a region occupied by the TEE probe. The processing unit (14) is configured to modify the X-ray data in the region occupied by the TEE probe based on the estimated X-ray data.

Owner:KONINKLJIJKE PHILIPS NV

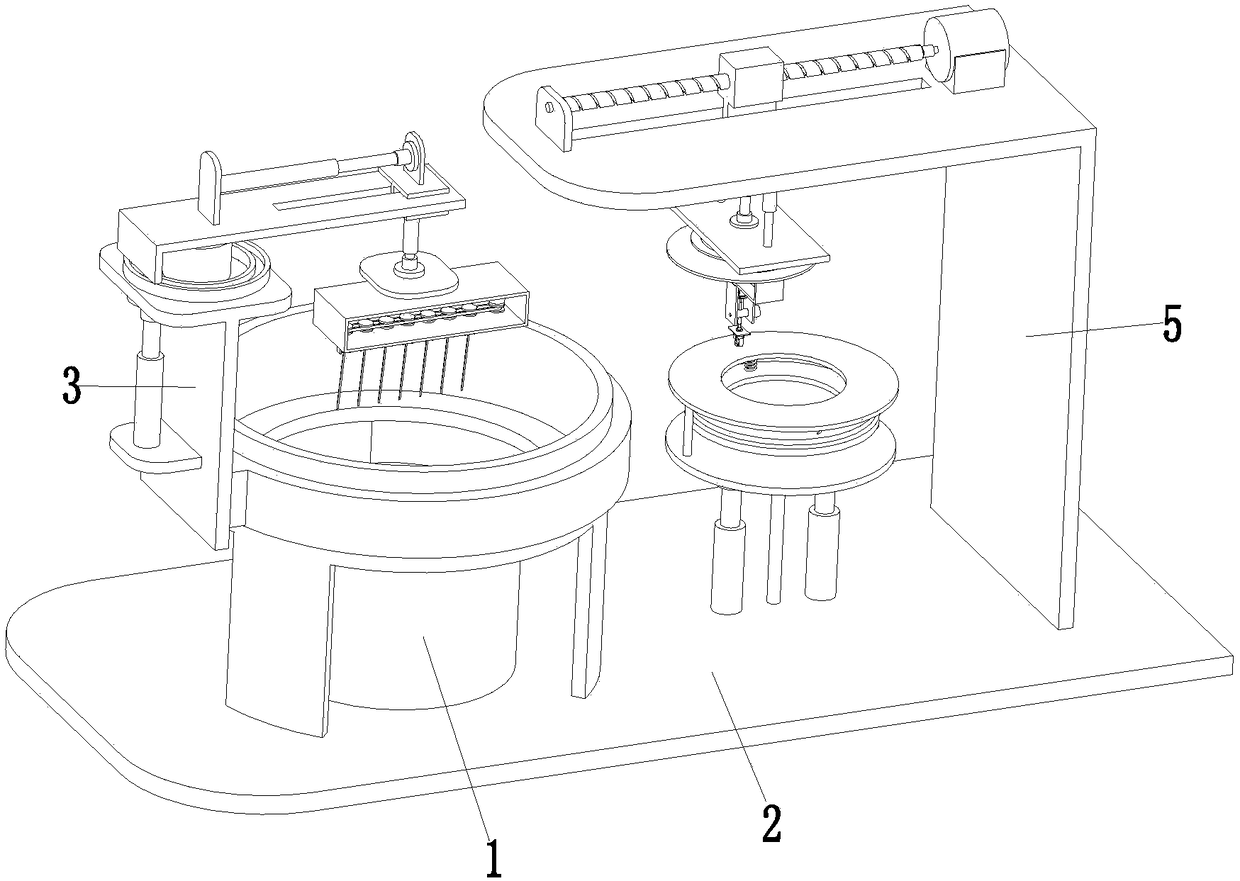

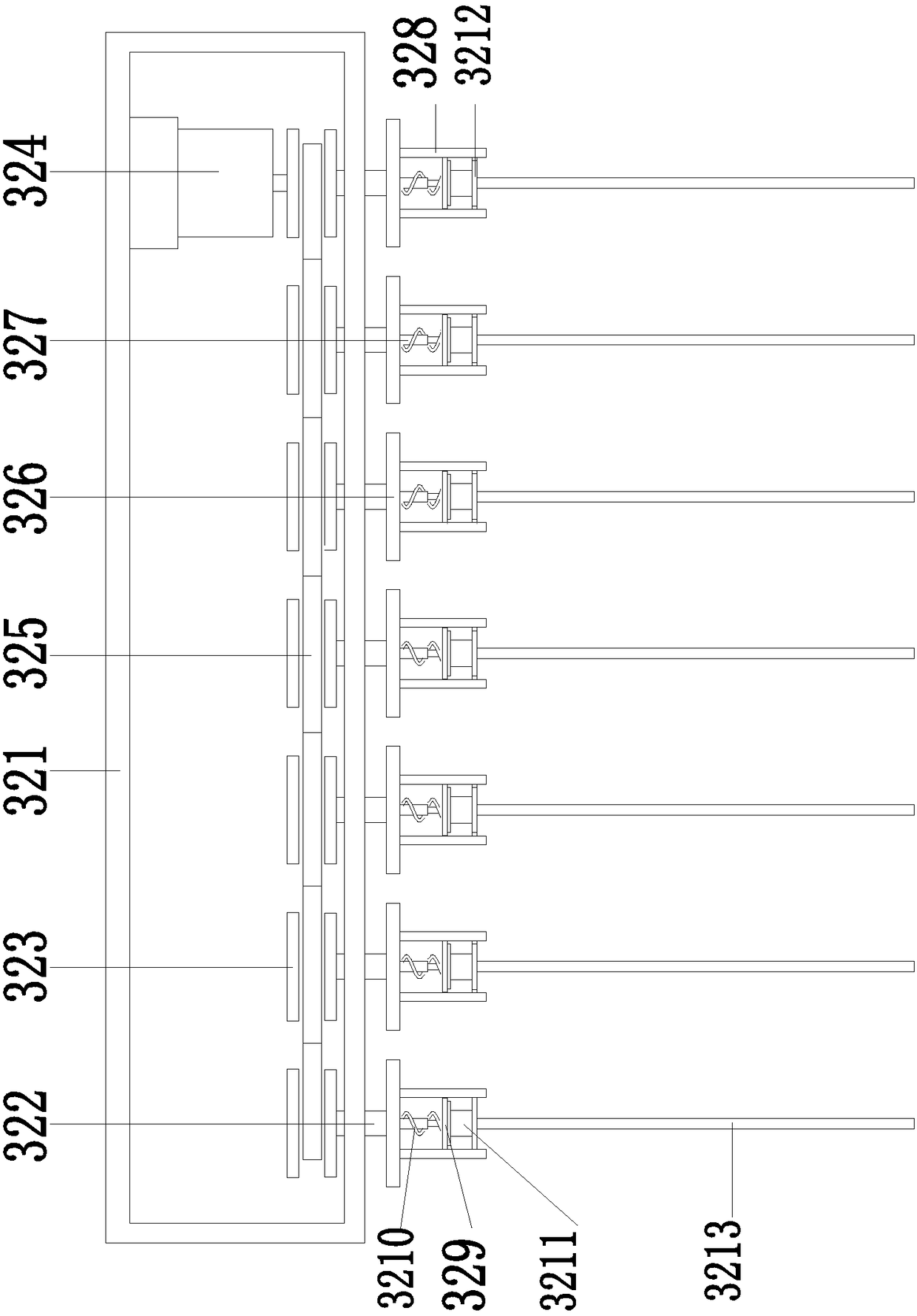

A kind of acupuncture needle automatic packaging device and packaging method

ActiveCN114572458BAvoid pollutionSave packing timePackaging automatic controlAcupuncture needlesNeedle insertion

The invention discloses an automatic packaging device for acupuncture needles and a packaging method, including a feeding device for acupuncture needles, a plastic tube feeding device, a needle insertion device, a packaging mechanism, a detection device and a blanking device. In the present invention, a plurality of acupuncture needles are simultaneously clamped by the clamping claws on the needle insertion device, gathered by the shaping mechanism in the packaging mechanism, and then sent into a plastic tube at the same time. At the same time of pollution, it can shorten the packaging time, reduce packaging consumables and reduce production costs; by controlling the number of single clips and the insertion depth, to ensure that all acupuncture needles are inserted into the plastic tube at the same depth and meet the specified depth requirements; through the detection device The packaged plastic tube is tested to determine whether its packaging accuracy meets the requirements, which improves the packaging accuracy and packaging efficiency.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Trapezoid-gear sludge drying machine

InactiveCN104649534ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a trapezoid-gear sludge drying machine. The sludge drying machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com