Multi-wheel scutching integrated machine of degumming and rinshing

A multi-wheel train and integrated machine technology, which is applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of unsatisfactory stripping quality, time-consuming back pulling, and difficult removal of impurities, etc., and achieves easy operation Maintenance, long service life, and less fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

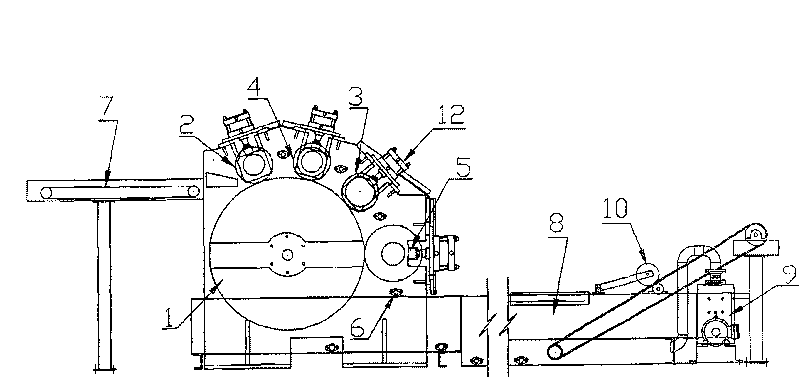

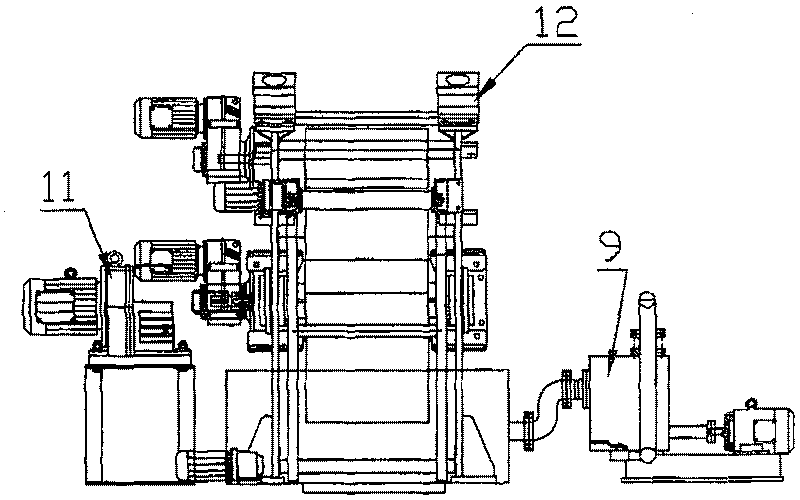

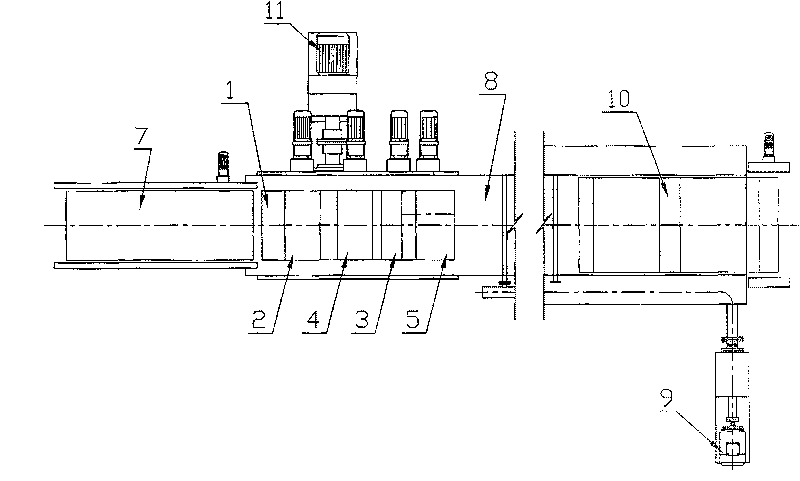

[0027] The multi-wheel train degumming and washing all-in-one machine provided by the invention has the following structure: Figure 1 to Figure 3 Shown: It includes feeding hemp, bone cutting and skin scraping, bone crushing and extrusion unit. specifically is:

[0028] Bone cutting and skin scraping unit: mainly composed of large round roller 1, first roller roller 2, and second roller roller 3. Among them, the large round roller 1 is fixed on the frame through the bearing seat; the two rollers are installed on the respective slide rails through the bearing seat respectively, and are distributed around the large round roller 1 . The first roller 2 is responsible for the initial skin scraping and bone crushing, and the second roller 3 is responsible for scraping the skin and bone crushing again.

[0029] Crushed bone extruding unit: mainly composed of the first small round roller 4 and the second small round roller 5. Wherein, the two small round rollers are installed on r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com