Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Shorten production preparation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

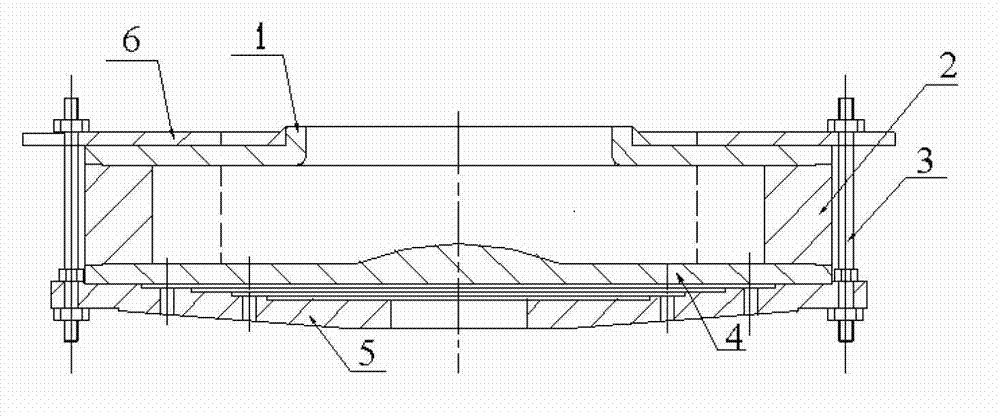

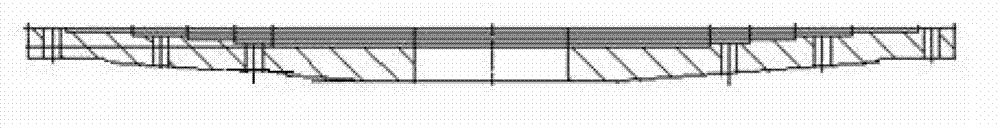

Combined skin-covering face measuring flexible multi-point support device

InactiveCN101221032AReduce in quantityEasy to assembleMechanical counters/curvatures measurementsEngineeringMechanical engineering

The invention relates to a combined skin face measuring flexible multi-point support device, adopting a modularization design idea. The whole device is composed of a plurality of positioning plates and shape-regulating components. The positioning plate appears as a flat T-shape, and screw holes and matching faces are arranged on the plate. The shape-regulating component consists of a basic pillow and a nail-height regulating unit. The shape-regulating component is horizontally arranged along X direction, and the central distances are all fixed. The positioning plates are divided into two symmetrical lines along Y direction, and each positioning plate is connected with the same end of two neighboring shape-regulating components. The shape-regulating components and positioning plates of different quantities are connected and combined to form the support devices of different sizes and specifications. The quantity of the shape-regulating components and positioning plates can be determined according to the size of the skin parts. The device of the invention realizes the flexible clamping and greatly reduces the quantity of special clamps and work pieces so as to reduce cost and coordination links and to shorten preparation period, with distinct economical and time benefits.

Owner:BEIHANG UNIV

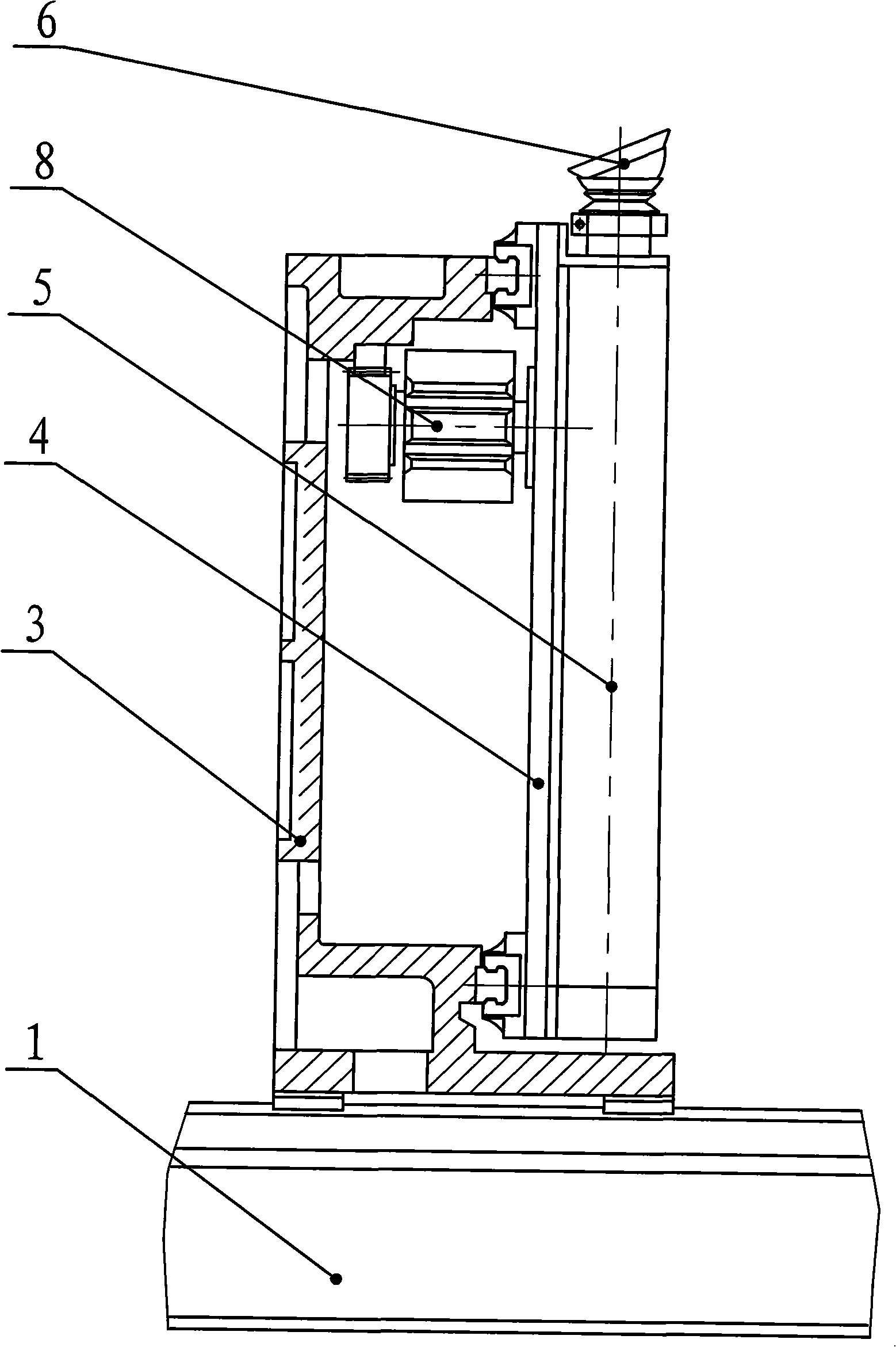

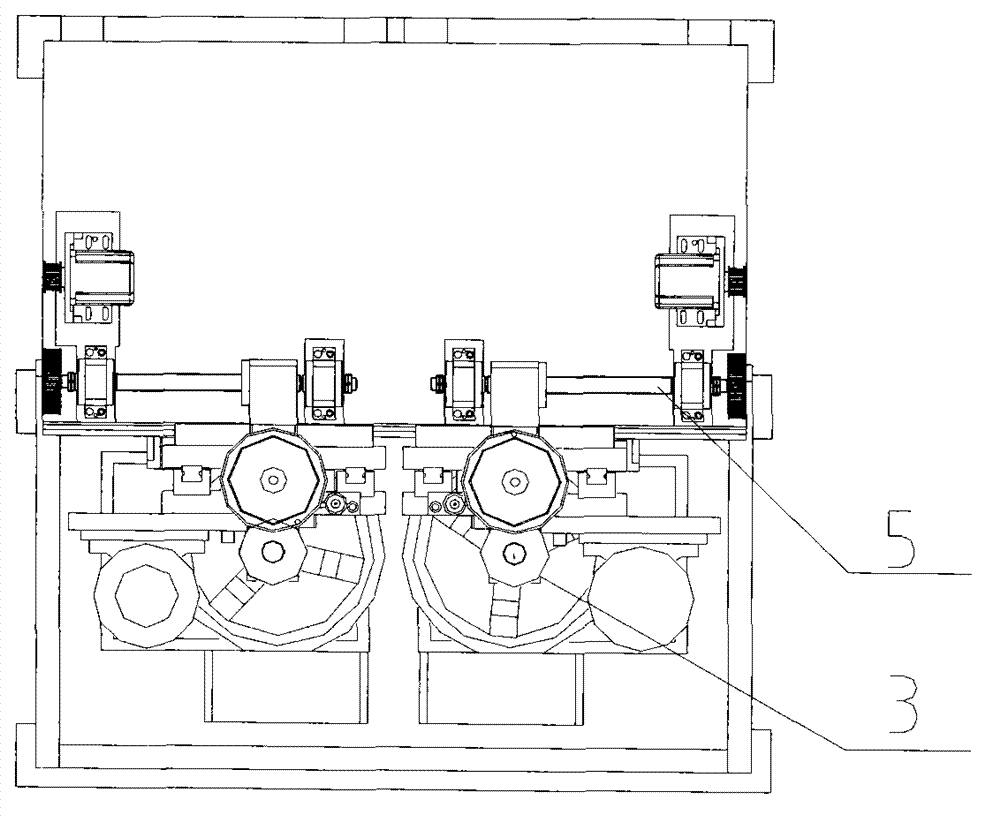

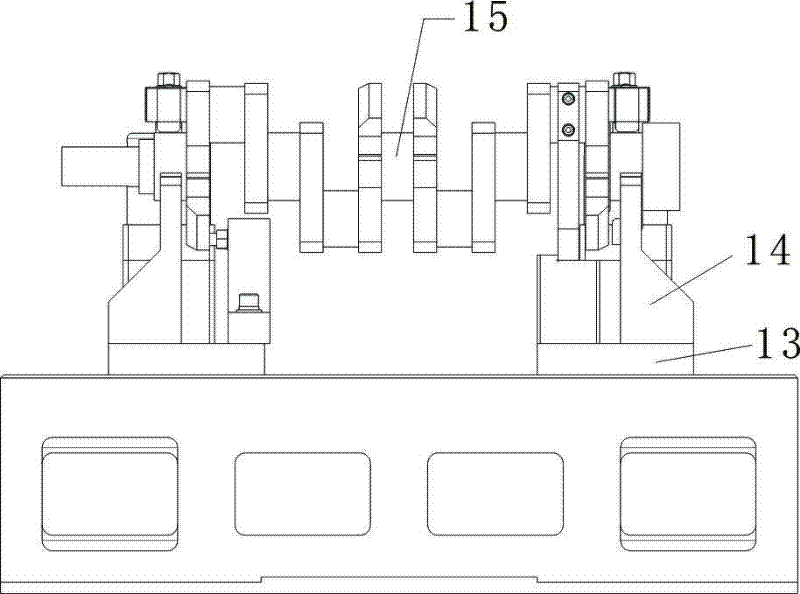

Flexible retaining fixture for metal plate series part

InactiveCN101327565AReduce manufacturing costShorten production preparation cyclePositioning apparatusMetal-working holdersGear wheelEngineering

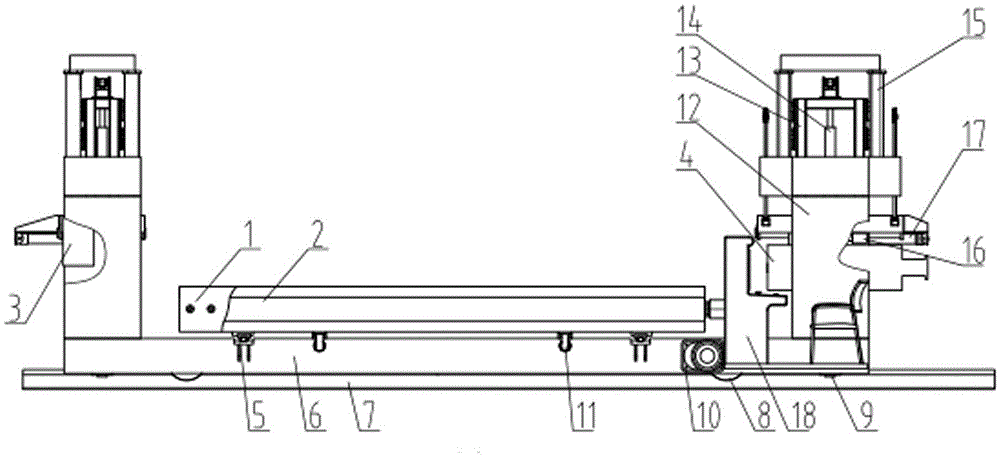

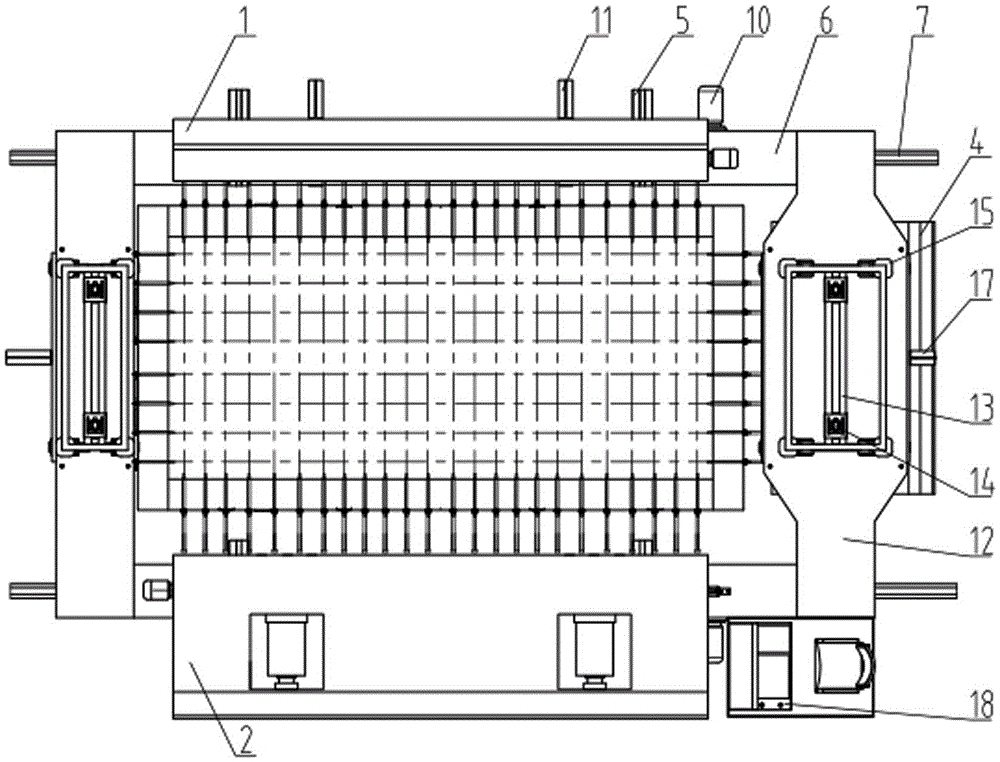

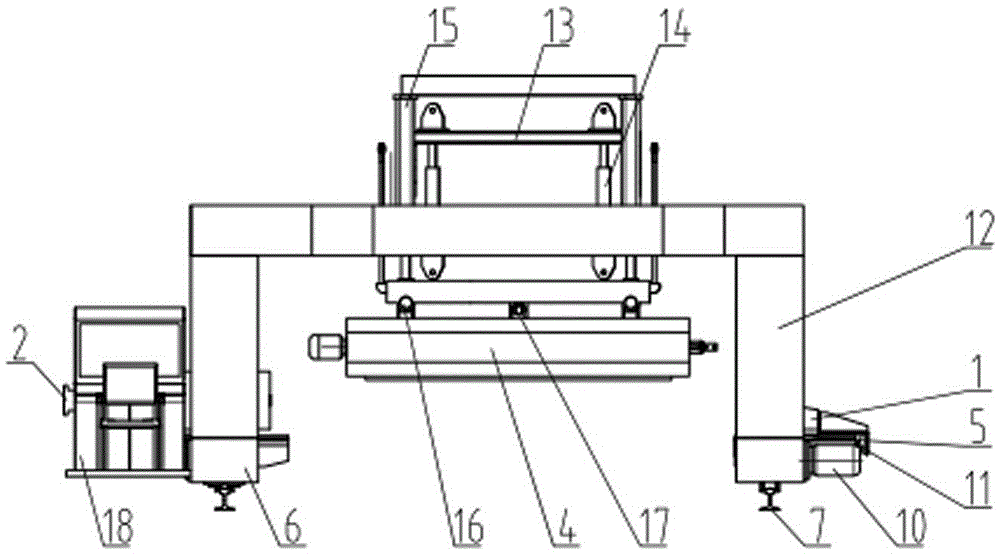

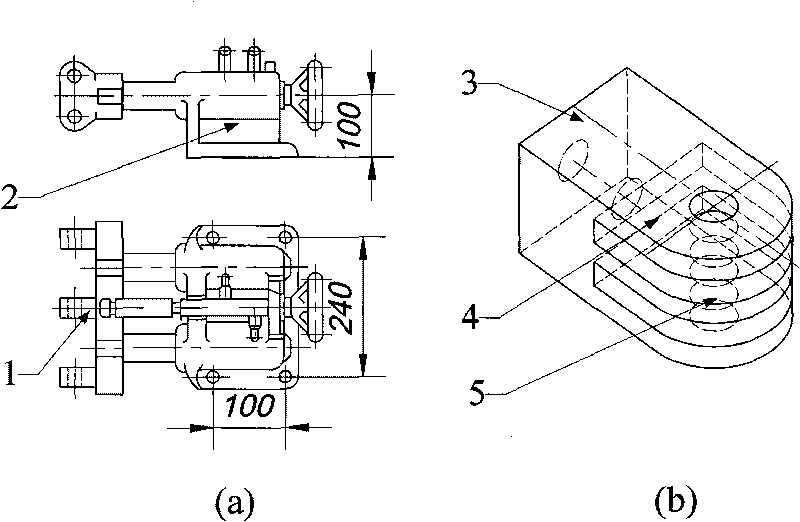

The present invention relates to a flexible clamping tooling of sheet metal parts, which is a tooling used to flexibly clamp a sheet metal part. The flexible clamping tooling resolves the defects of the prior special tooling, including large quantity and high cost. A crossbeam slide way assembly is mounted respectively on the left of a bed body, the right of the bed body and crossbeams; the crossbeams are mounted on the left of the bed body and the right of the bed body; a bed body rack is mounted on the bed body; crossbeam-travelling decelerating motors are mounted on the crossbeams; the output gear of each crossbeam-travelling decelerating motor is engaged with the bed body rack; a crossbeam rack is mounted on the crossbeams; a slide plate device slide way assembly is mounted respectively on each crossbeam and slide plate devices; a slide plate-decelerating motor is mounted on each slide plate device; the output gear of the slide plate-decelerating motor is engaged with the crossbeam rack; a servo-cylinder is mounted on each slide plate device; a universal suction cup is connected with the servo-cylinder. The flexible clamping tooling can suitably clamp various curved sheet metal parts and reduce the number of the special tooling in the production of sheet metal parts, thus reducing production cost.

Owner:SHENYANG AIRCRAFT CORP

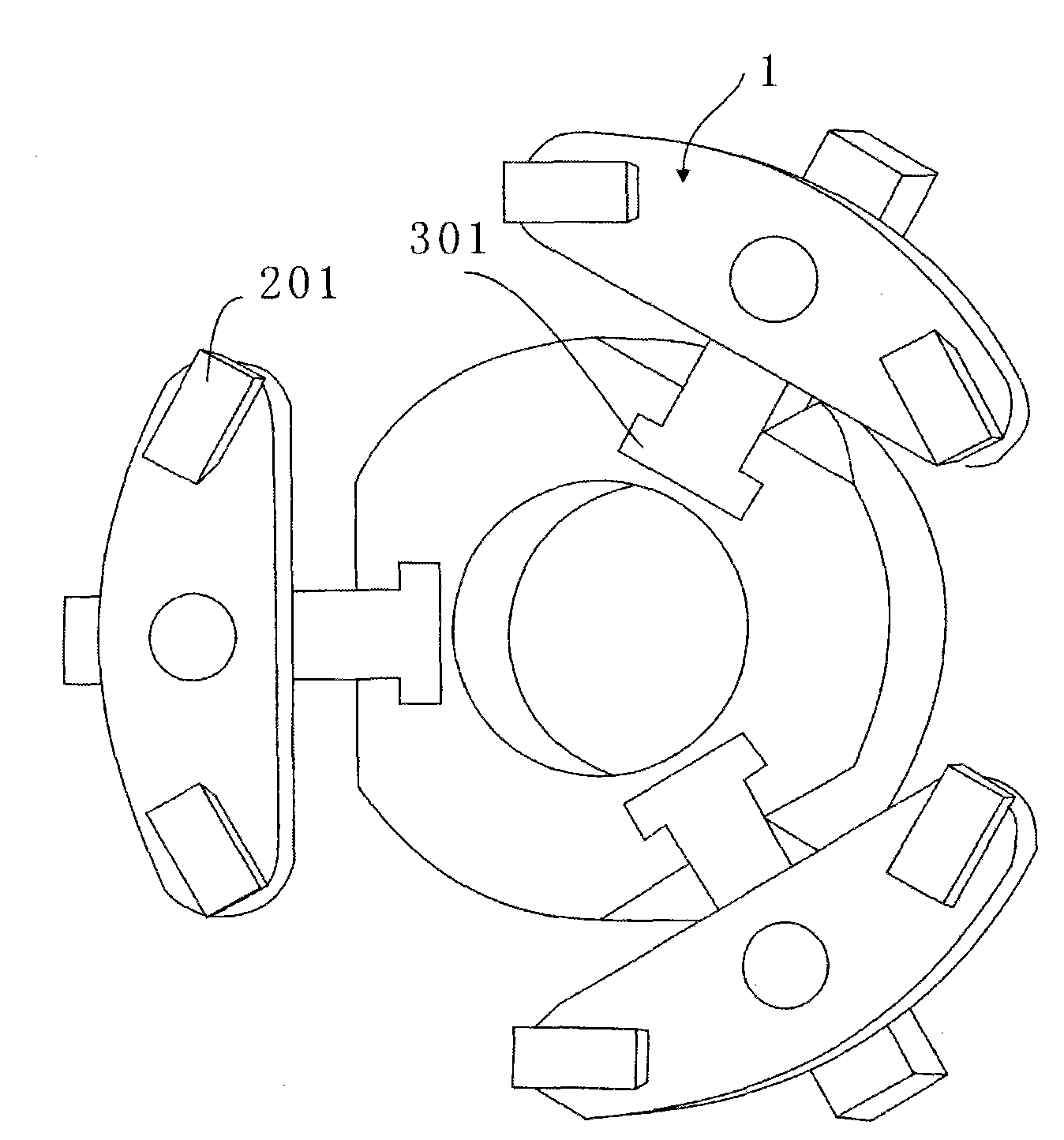

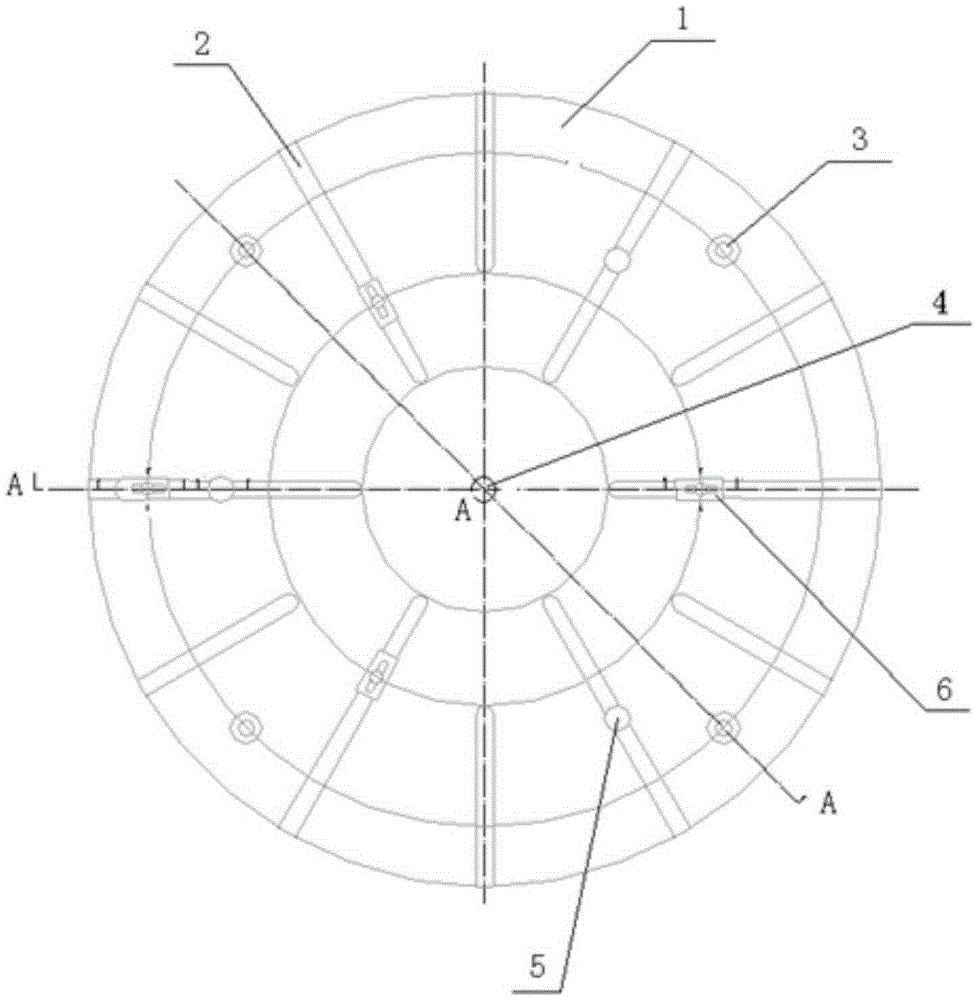

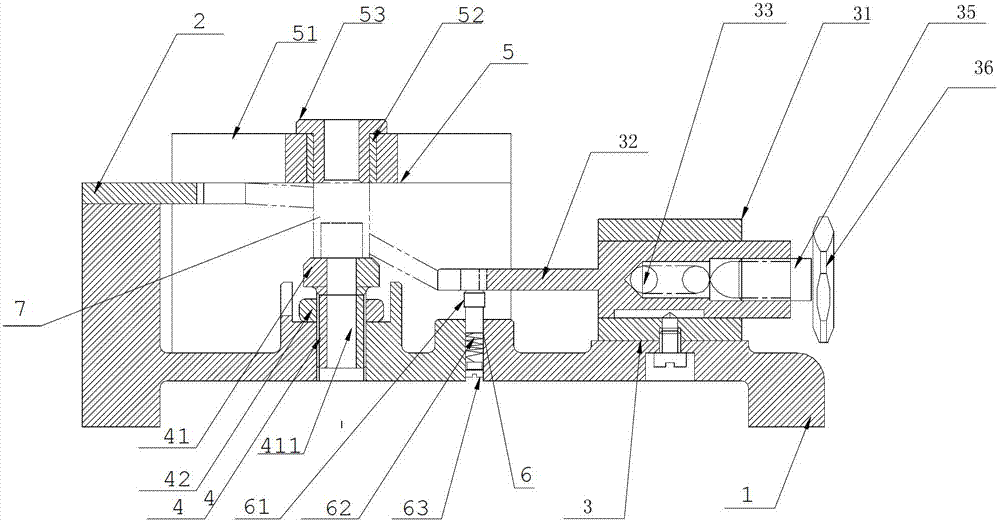

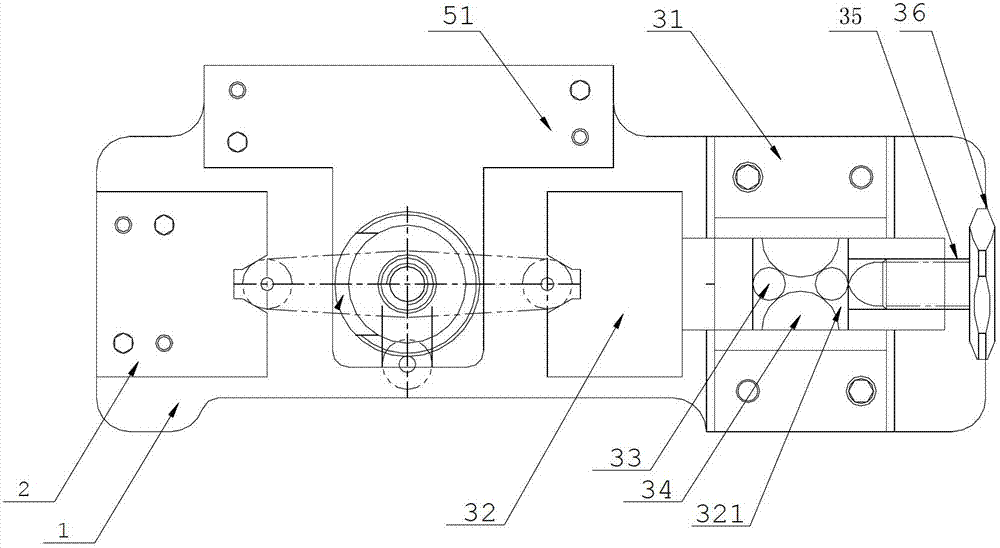

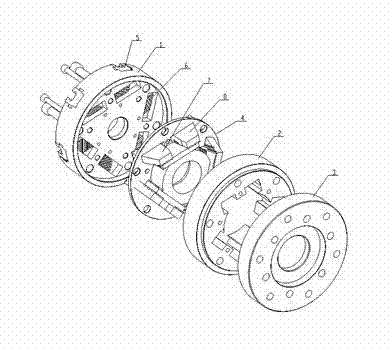

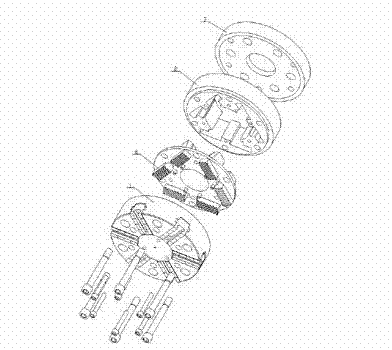

Six-claw double-linkage self-centering chuck

InactiveCN101829794AGood centering clampingEasy to install the card at easeChucksEngineeringStandardization

The invention discloses a six-claw double-linkage self-centering chuck. The chuck comprises a transmission assembly installed between a front end cover and a back end cover, wherein the transmission assembly is formed in a way that a floating lever rod is hinged with a first sliding block and a second sliding block; one end of the first sliding block is a cylindrical pin, the other end of the first sliding block is a rectangular sliding block, the lower end of the second sliding block is an oblique T-shaped boss, the rectangular sliding block of the first sliding block is embedded in straight groove behind bottom claws to be meshed with the bottom claw, the oblique T-shaped boss at the lower end of the second sliding block is embedded in three oblique T-shaped grooves uniformly distributed in a round wedge in the circumferential direction to be meshed with the round wedge, and simultaneously an upper rectangular end is embedded in three radial straight grooves of the back end cover to be matched with the back end cover; the round wedge is assembled in the inner hole of the back end cover to slide freely in the axial direction; and the six bottom claws are respectively inserted in six radial T-shaped grooves uniformly distributed in the circumferential direction of the front end cover, and are subject to mesh type transmission by the transmission assembly. The chuck can realize favorable centering and clamping effects on rotational parts, and can effectively reduce the chucking deformation of low-rigidity thin-wall parts, thereby playing active roles in promoting and implementing process standardization.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

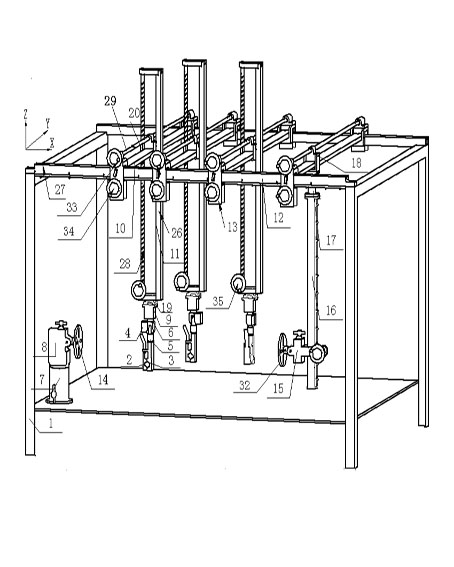

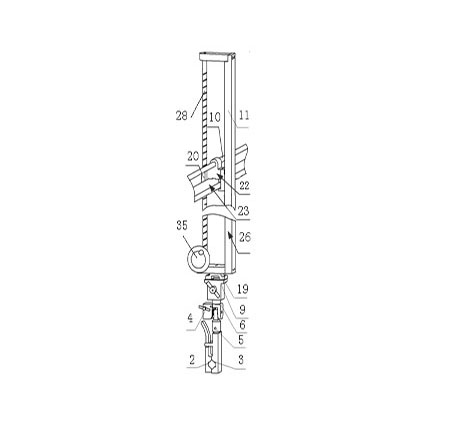

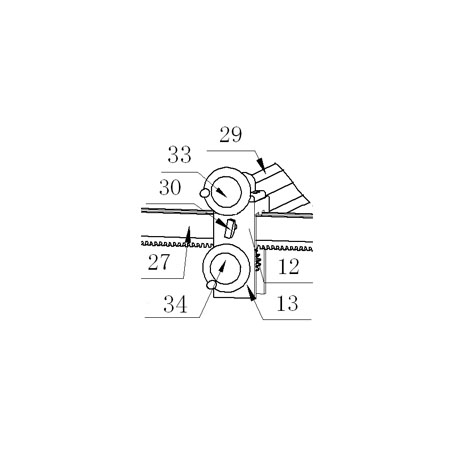

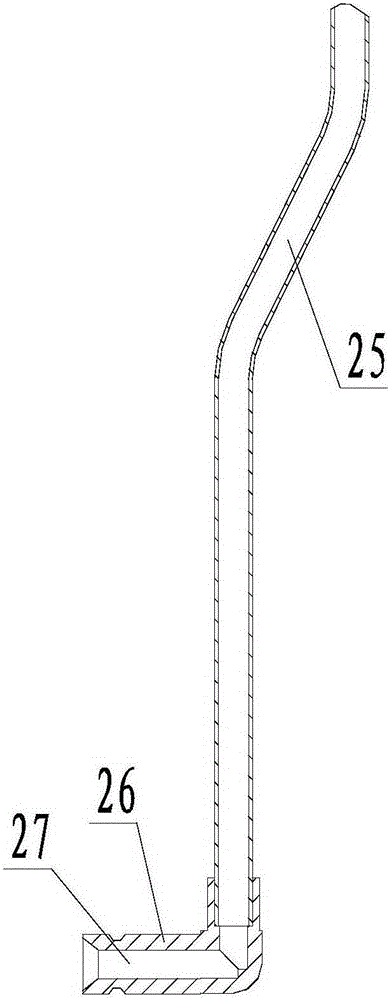

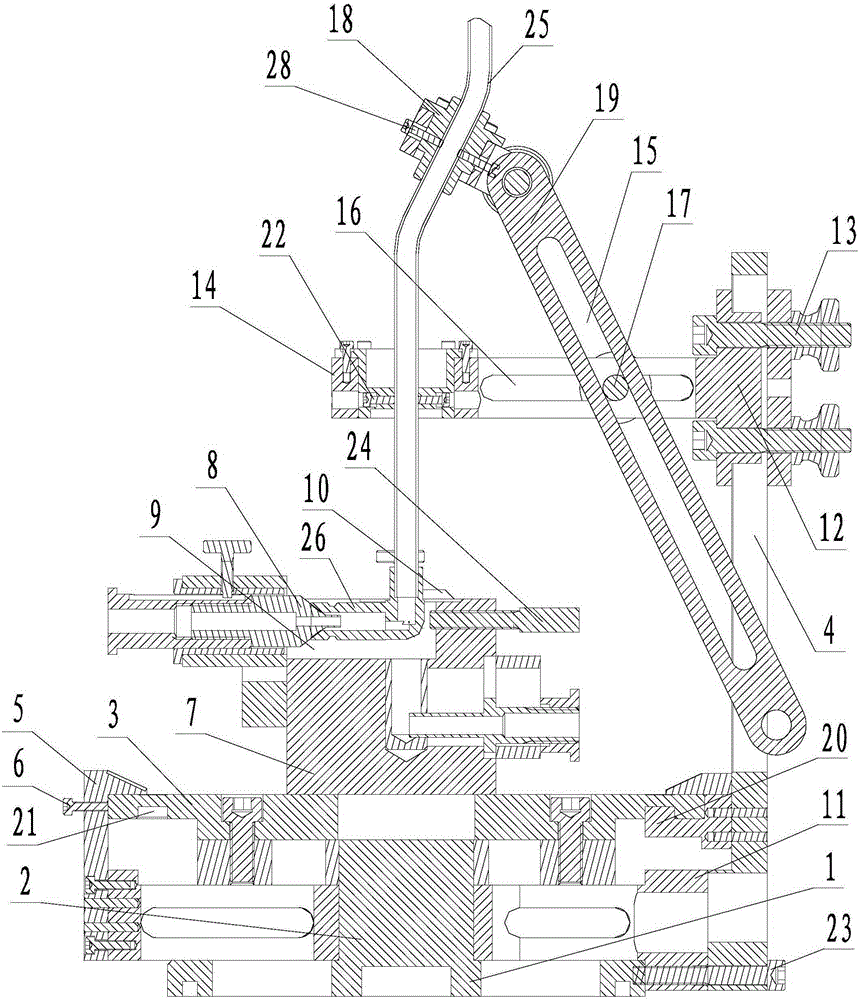

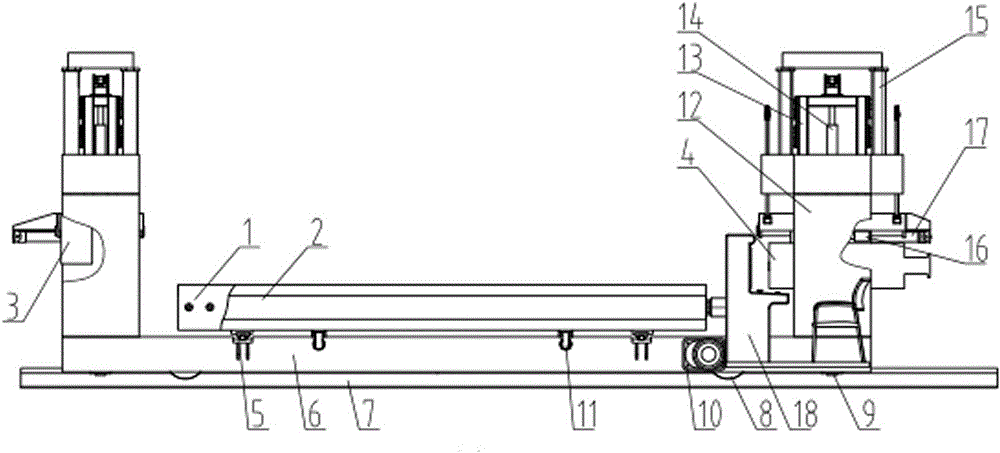

Flexible clamp for pipe fitting welding and adjusting method thereof

InactiveCN102000935AAvoid misalignmentExpand the scope of useWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

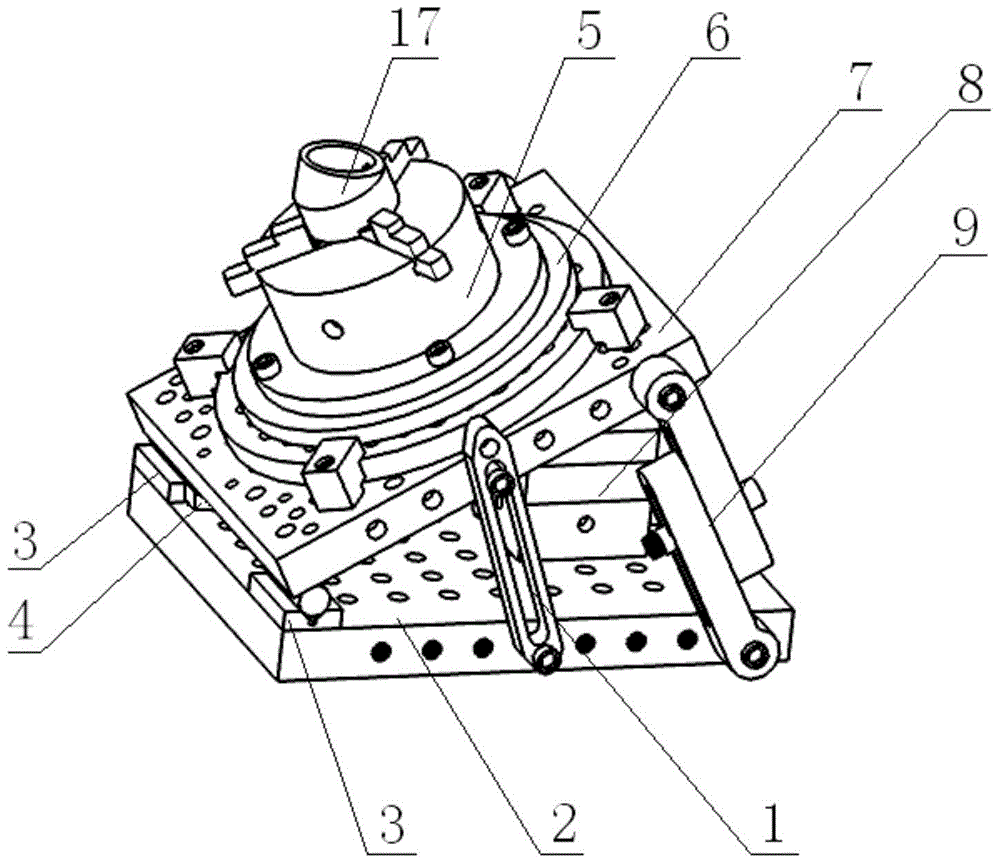

The invention discloses a flexible clamp for pipe fitting welding between multi-section pipe fittings and between a pipe fitting and a flange, and an adjusting method thereof. The bottom of a base bracket is provided with a fixed end flange around Z-axis angle adjusting mechanism and a fixed end flange around Y-axis angle adjusting mechanism connected with an equant chute flange plate rotating mechanism; a top Y-direction displacement regulating mechanism, a vertical Z-direction displacement regulating mechanism and a top X-direction displacement regulating mechanism for regulating the pipe fittings and a flange Y-direction displacement regulating mechanism for regulating the flange are arranged on the upper part of the base bracket; and each mechanism is adjusted to make a positioning mechanism rotate around the X, Y and Z directions. The invention can be rapidly and accurately adjusted and positioned so as to clamp the pipe fittings according to diversified space trends of different pipe fittings, and a set of clamp can adapt to welding a series of pipe fitting sections in different specifications.

Owner:JIANGSU UNIV OF SCI & TECH

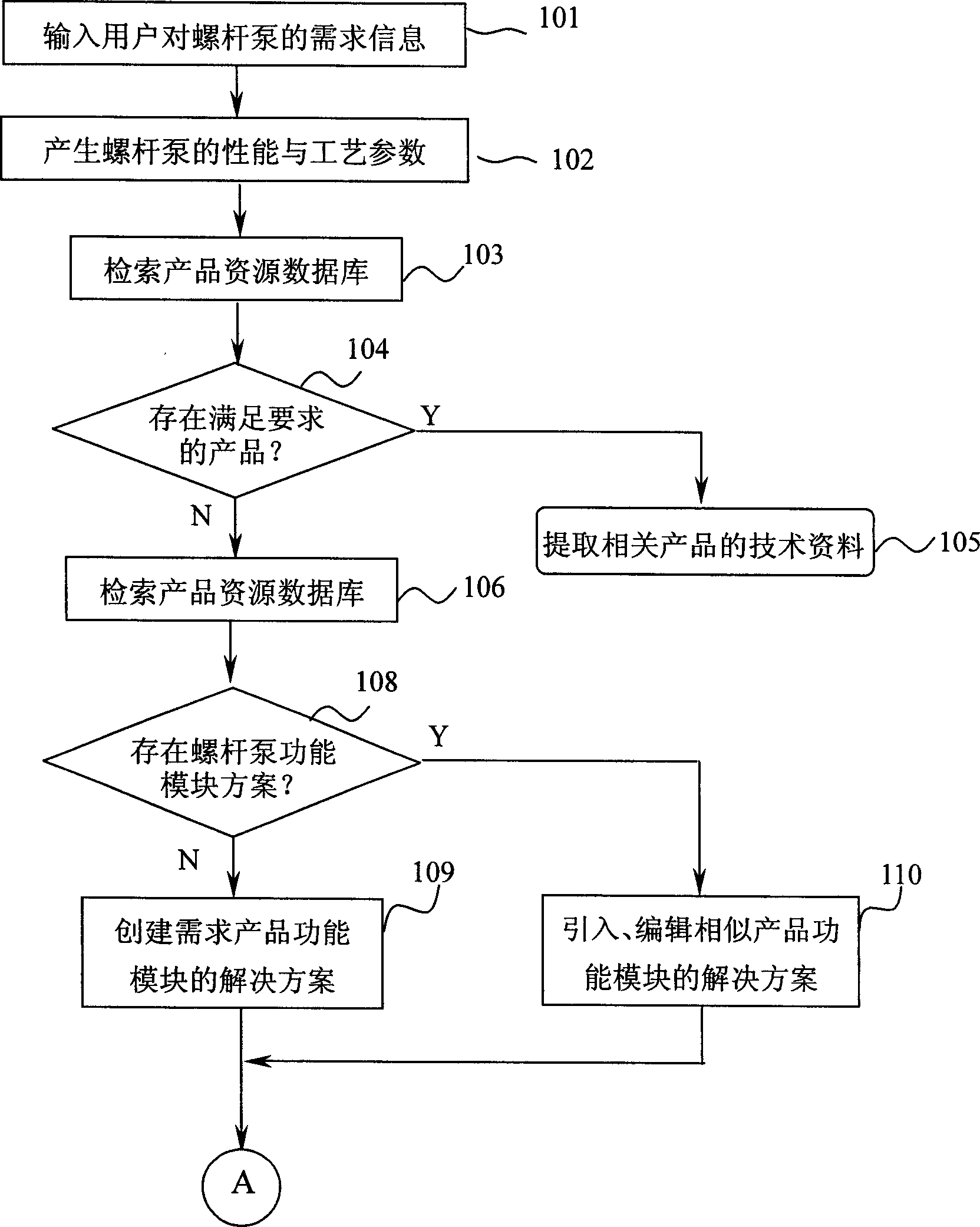

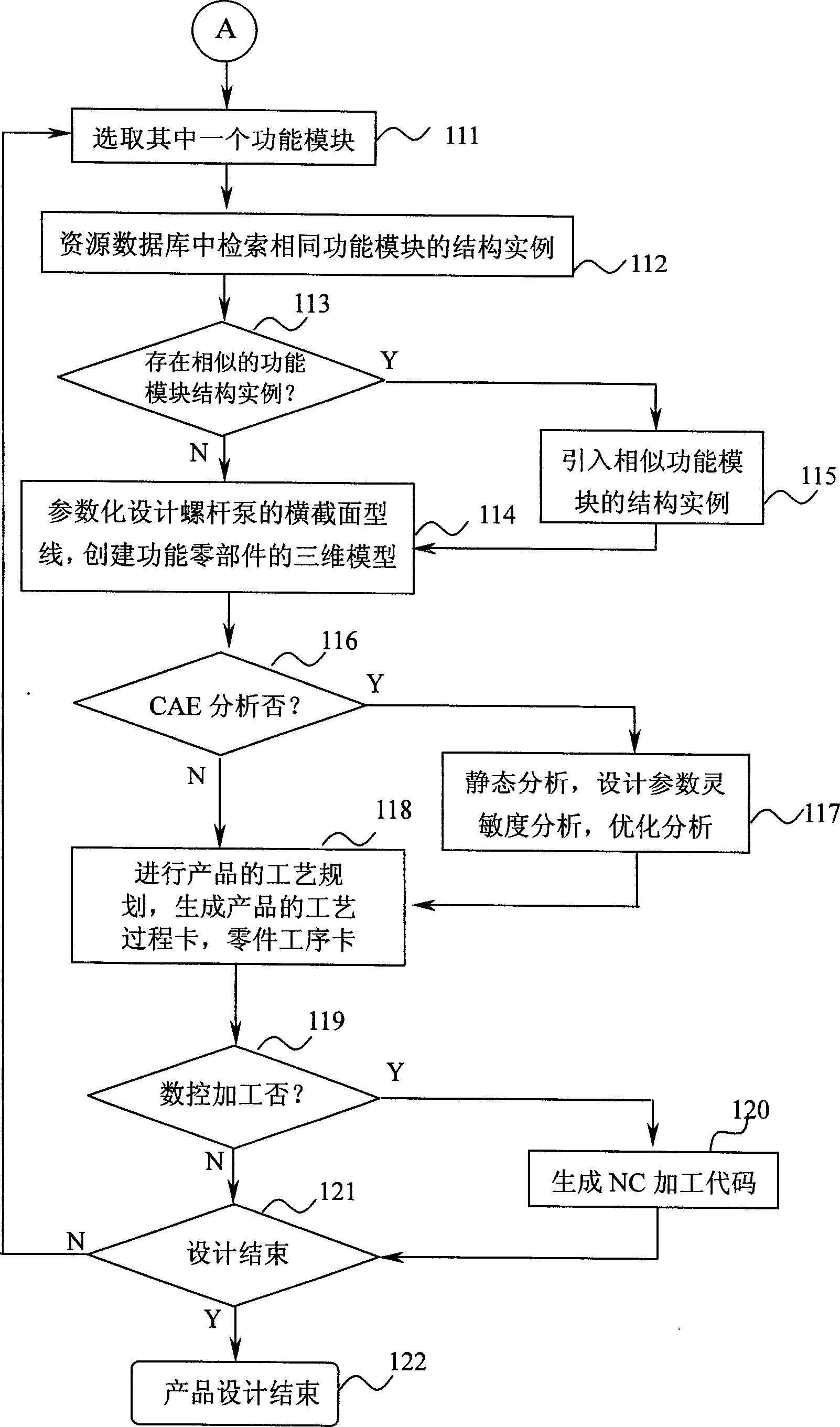

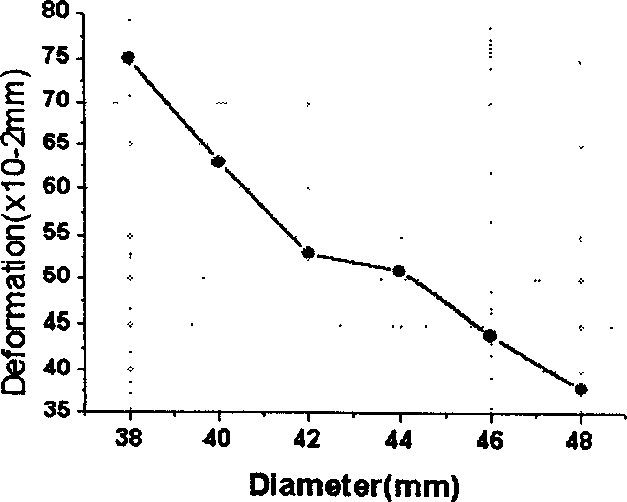

Method for integrated designing screw pump

InactiveCN1760876AImprove manufacturing levelRealize unified managementProgramme controlComputer controlNumerical controlElement analysis

Applying KBE, CBR etc. knowledge design, modularized and variable techniques, the method is built based on 3D CAD platform. The method includes following steps: (1) based on userí»s need, creating main parameters for preliminary design; (2) based on the said parameters, searching database to see whether there are products to meet userí»s need; (3) based on design scheme of functional module in the said products, searching structure instance of functional module in the said products to determine whether there is similar structure instance of functional module in the said products; (4) whether ANSYS finite element analysis is carried out for the said functional module; (5) based on structure of functional module, carrying out process planning, generating technological process sheet and operation sheet; using CAM subsystem generates NC machining codes for making module structure needed of using digital control machine-tool.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

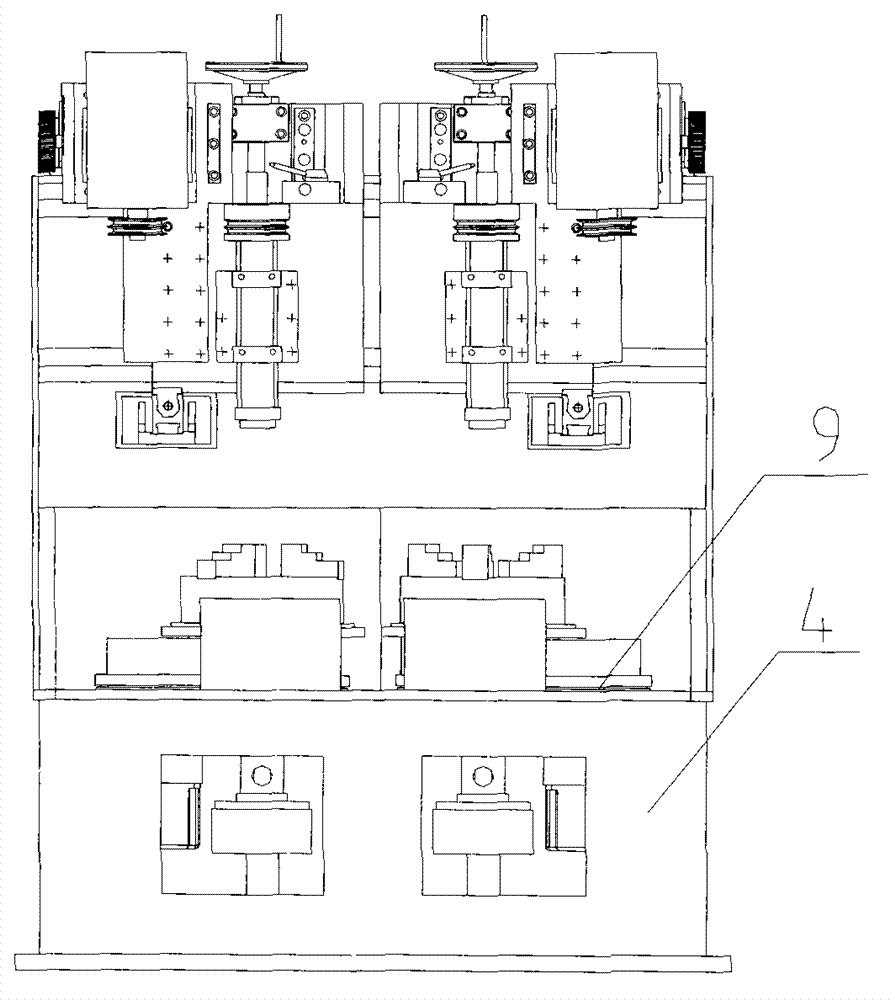

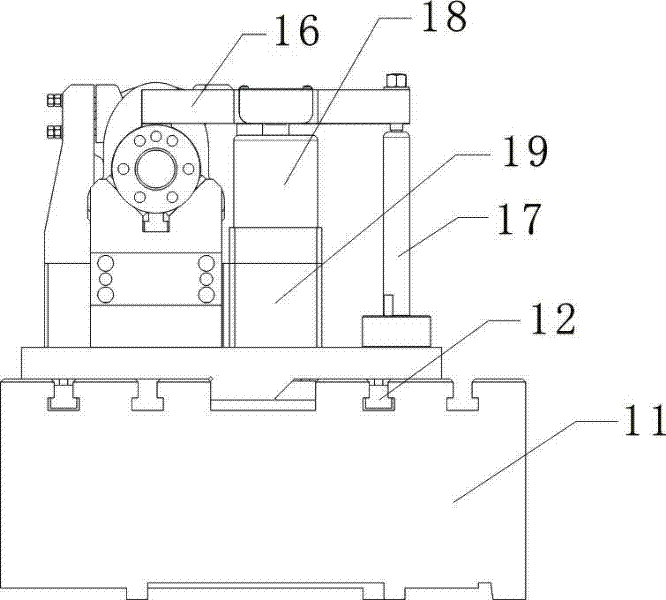

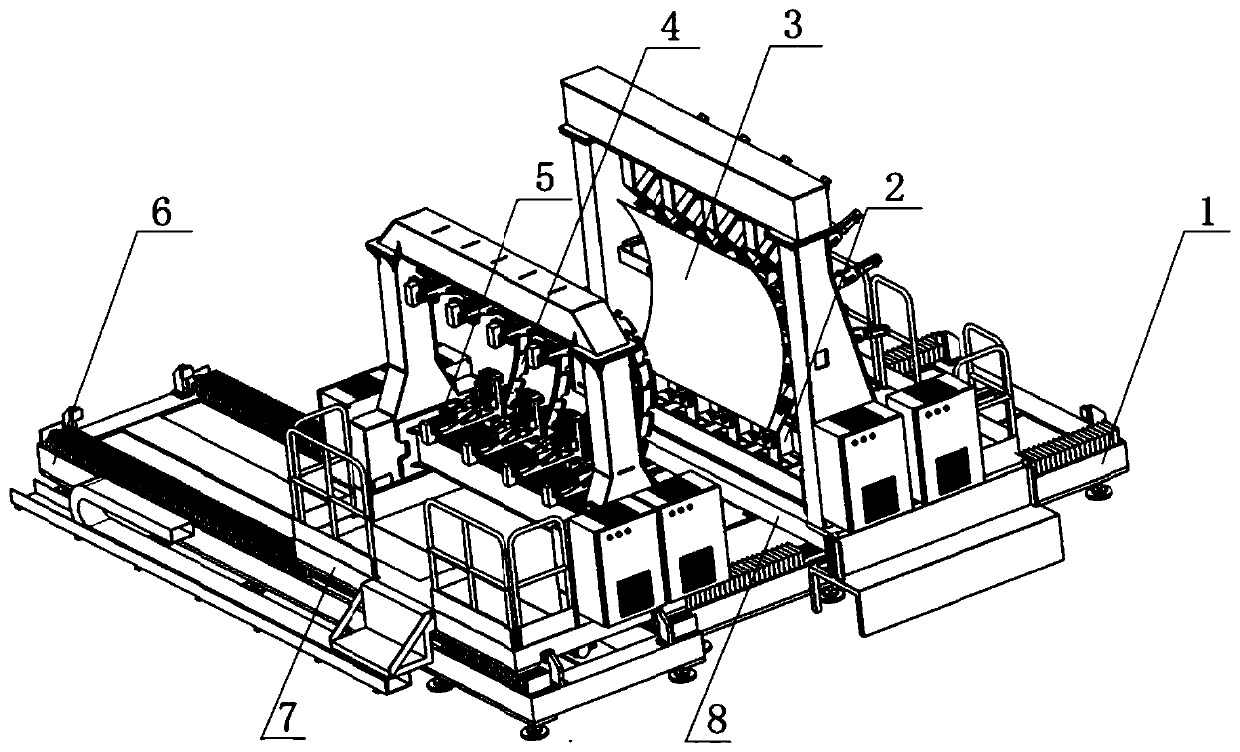

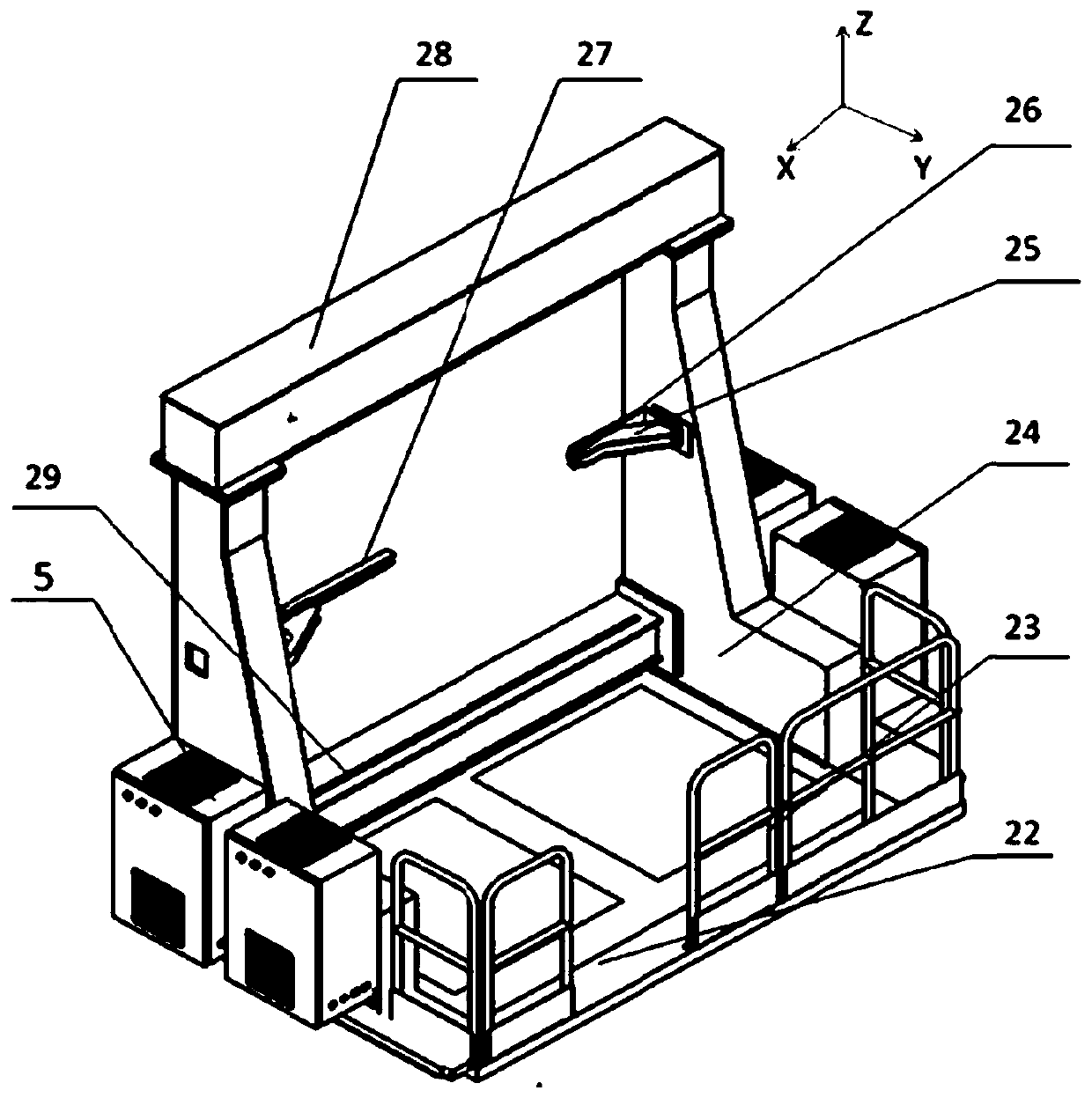

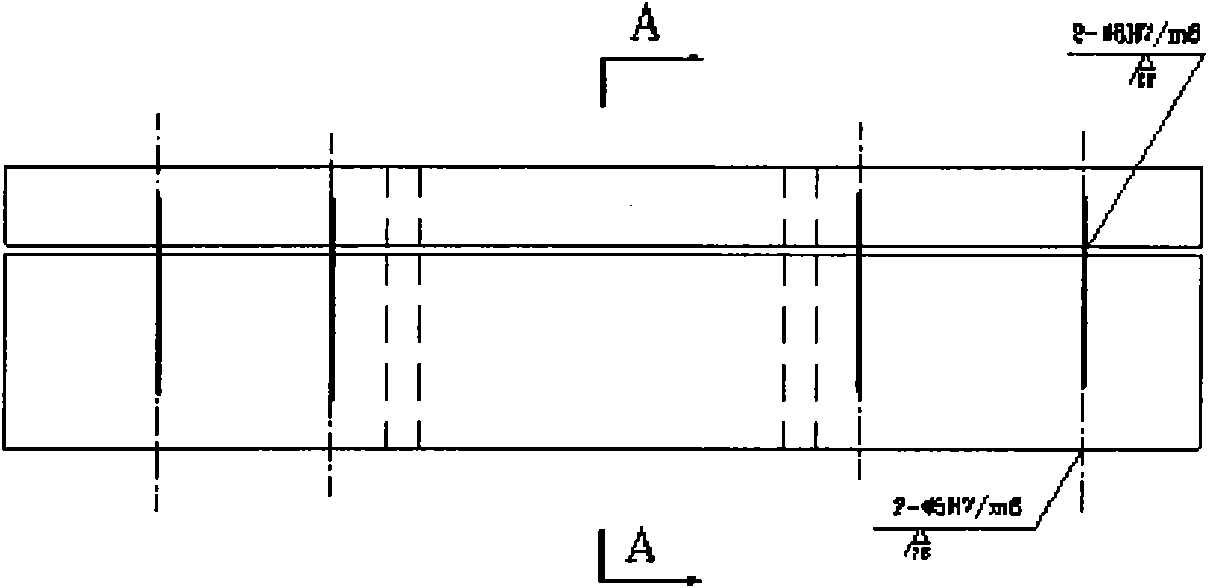

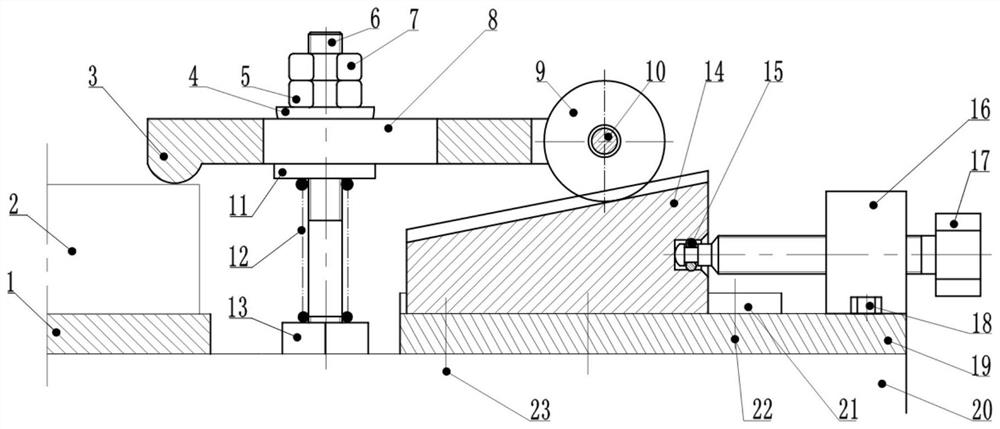

Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment

ActiveCN105643792ASimple structureIncrease stiffnessCeramic shaping apparatusPre stressElectric machinery

Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment comprises a side pre-locking beam, a side tensioning beam, an end pre-locking beam and an end tensioning beam; the side pre-locking beam and the side tensioning beam are assembled on two walking beams through a pair of side beam linear guide rails, and each walking beam is provided with wheels matched with a running rail, walking guide wheel sets, a wheel speed reduction motor and side beam advancing and retreating oil cylinders; portal frames are arranged at the two ends of the walking beams, and a lifting frame, a lifting frame lifting oil cylinder and a lifting frame lifting guide device are assembled on each portal frame; and the end pre-locking beam and the end tensioning beam are assembled on the lower faces of the lifting frames through a pair of end beam linear guide rails, and end beam advancing and retreating oil cylinders are arranged on the lifting frames. According to the equipment, the production preparation period can be effectively shortened, the engineering construction cost is reduced, industrial pollutions are avoided, and meanwhile a steel mold fixed mounting production manner facilitates simplifying of a mold structure, reduction of cost, improvement of precision and reduction of occupied areas and working energy consumption of production equipment.

Owner:秦皇岛老虎重工有限公司

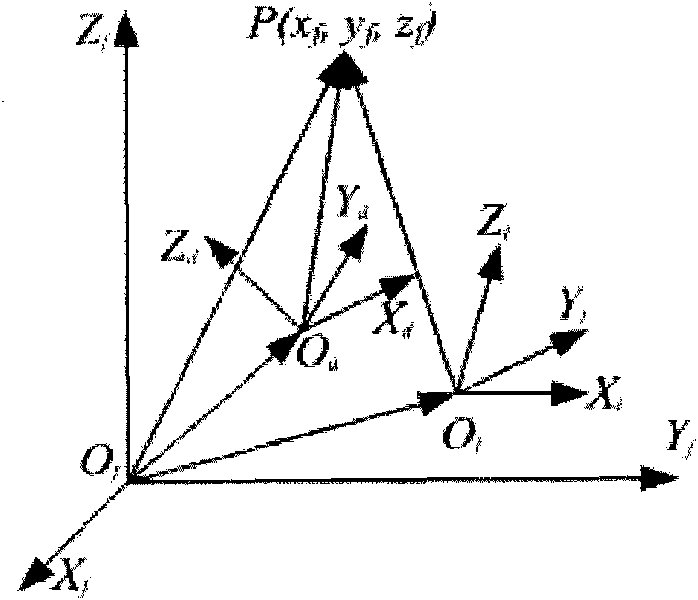

Angle-adjusting numerical control machine tool combined clamp

ActiveCN104668991AHigh precisionReduce production man-hoursChucksPositioning apparatusEngineeringMachine tool

The invention discloses an angle-adjusting numerical control machine tool combined clamp which comprises a lower base plate, an upper base plate, a connecting plate, a support part and a three-jaw chuck. The support part is vertically fixed on the lower base plate. The lower base plate is provided with two identical low-position V-shaped support blocks close to one side. The central lines of the two V-shaped support blocks coincide. The support part comprises a rectangular support element and a high-position V-shaped support block. The high-position V-shaped support block and the low-position V-shaped support blocks are identical in structure. One downward face of the upper base plate is provided with three trimming shafts forming a triangle. The trimming shafts are identical in structure and integrally connected with the upper base plate. The three trimming shafts are respectively located on the two low-position V-shaped support blocks and the high-position V-shaped support block. By the structure, the angle-adjusting numerical control machine tool combined clamp has the advantages that the precision of the clamp is increased greatly, clamp manufacturing time can be reduced, production preparation cycle can be shortened, machining efficiency is increased, and manufacturing cost is lowered.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

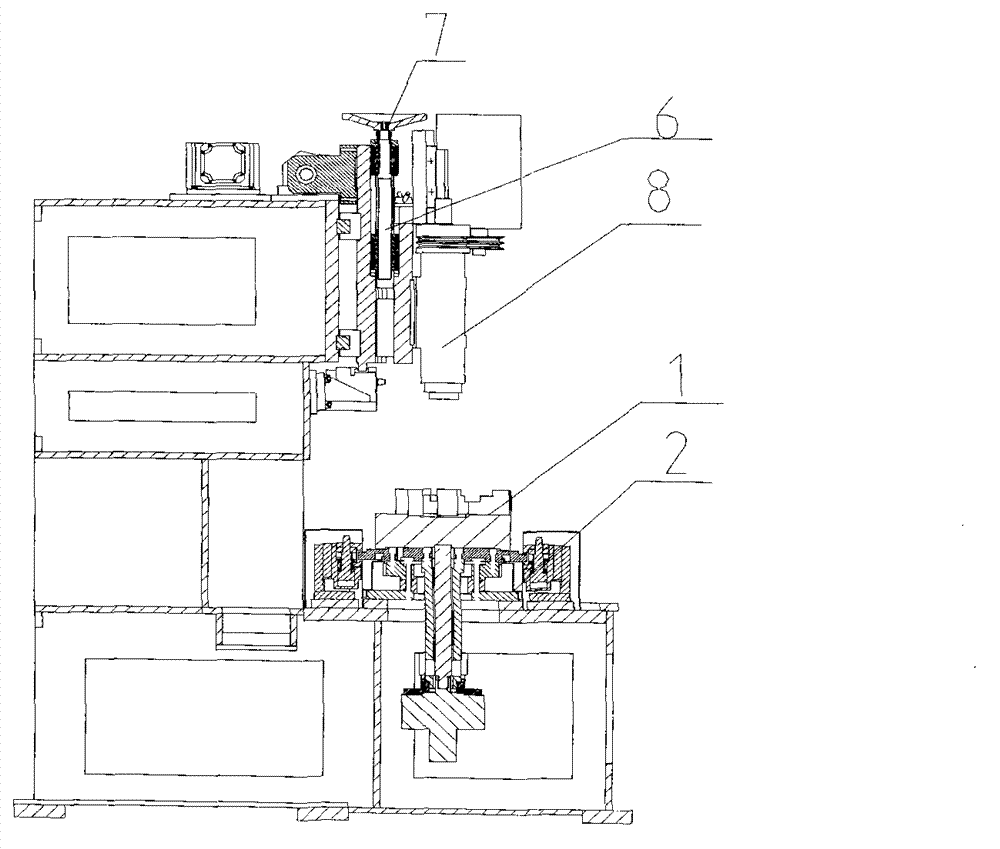

Digital controlled drill

ActiveCN102962488AImprove efficiencyHigh strengthBoring/drilling machinesElectrical controlEngineering

The invention discloses a digital controlled drill, which mainly comprises a host machine, a cooling system, a hydraulic system, an electrical control system and the like. The drill can be used for processing multiple pore diameters, can adapt to a variety of specifications of workpieces, and is double-power head high pressure cooling high speed drilling equipment. The electrical digital control system adopts centralized control; two power heads are not mutually subordinated, are independently separated, and are independent working units in a working process, so that the efficiency is enhanced, and the strength and the stability are increased; an X shaft and a W shaft are digitally controlled, a Z shaft is manually controlled, a workpiece can be accurately located in a central line in a working region, the drilling operation is completed, the feeding speed can be adjusted, when being far away from the workpiece, a drill bit is fed quickly, and when being close to the workpiece, the drill bit is fed slowly; and a lubricating system adopts a dispersion lubricating manner, has a simple structure, and is convenient to use and maintain.

Owner:SHANDONG TARGUS PRECISION MACHINE

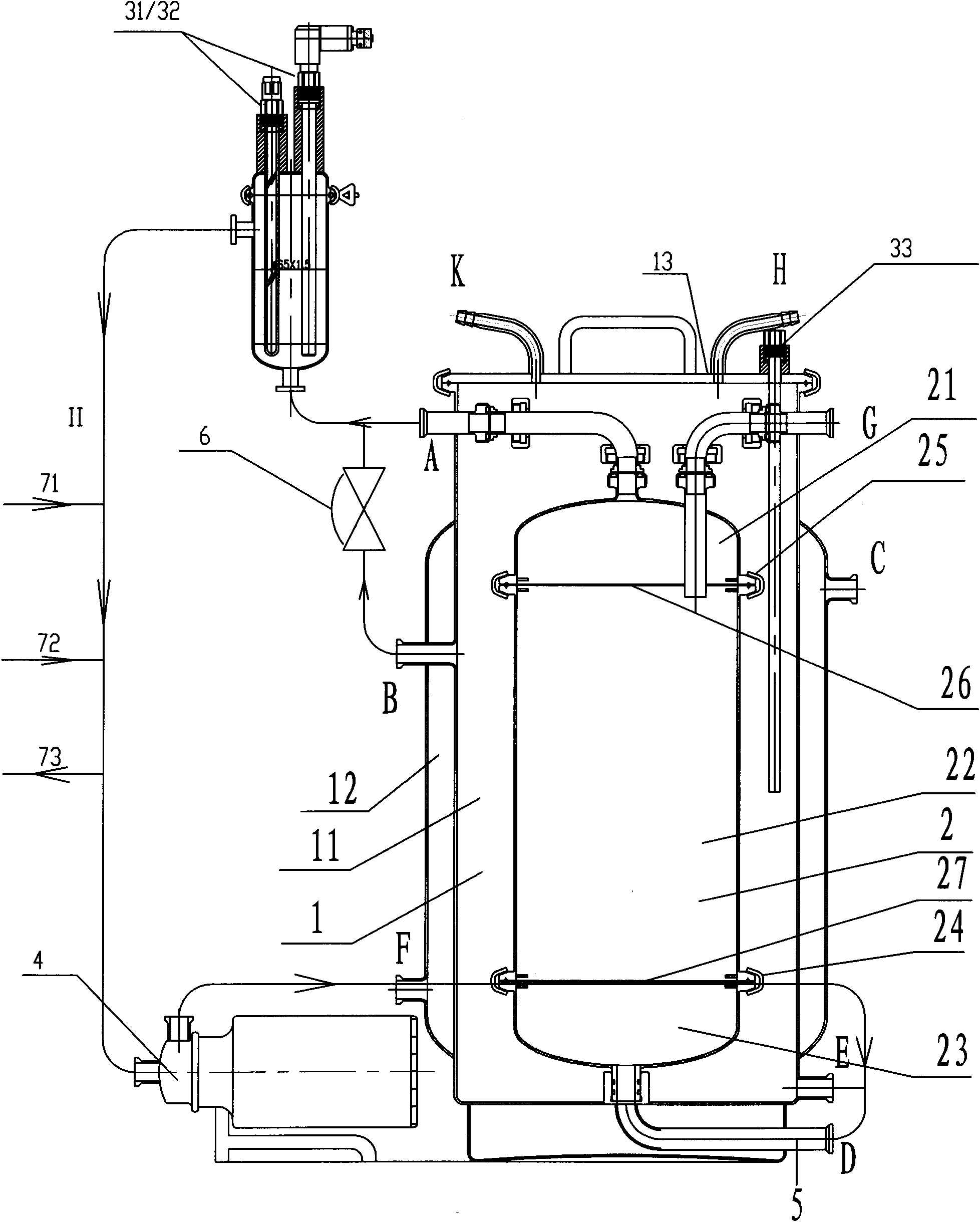

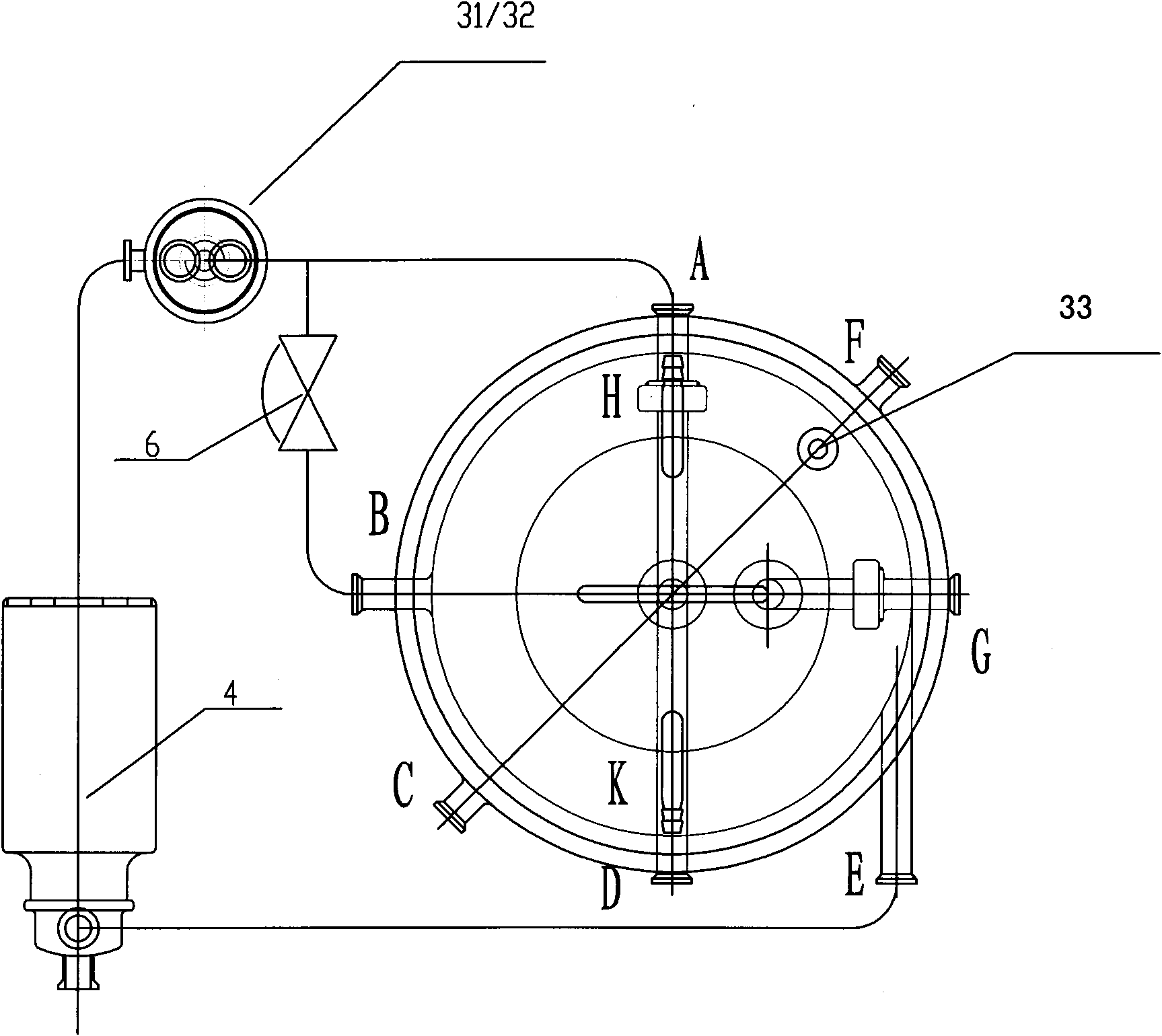

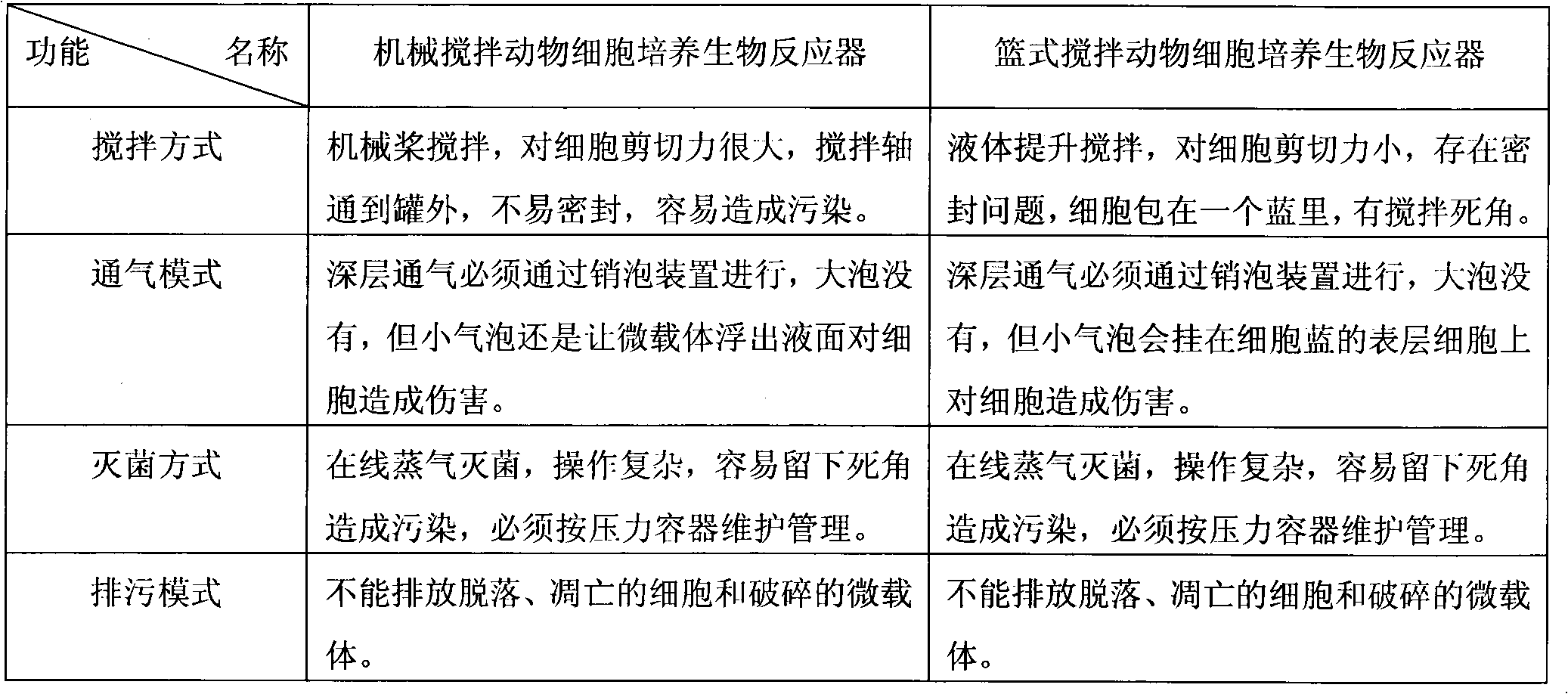

External circulation animal cell culture bioreactor

ActiveCN101899394AOptimize layoutFunctionalBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpControl system

The invention relates to an external circulation animal cell culture bioreactor which comprises a tank body, an external circulation pipeline, a heater, a peristaltic pump and a control system, wherein the tank body comprises a large tank and a small tank; the small tank is sheathed in the large tank and is clamped and fixed with the large tank respectively through ducts D, A and G; the external circulation pipeline comprises a tank external circulation pipeline and ducts A, B, E and D; on the upper part of the outside of the tank body, the ducts A and B are connected with the tank external circulation pipeline through a tee joint; on the lower part of the outside of the tank body, the ducts E and D are connected with the tank external circulation pipeline through a tee joint; the tank external circulation pipeline penetrates through the peristaltic pump; and the lowest position of the duct D is connected with a drainage pipe. The invention fully displays the characteristics of the animal cell large-scale culture technique, has the characteristics of thorough sterilization, simple operation, low pollution rate of cell culture, good quality and high yield, has favorable functionality and economical efficiency, and can be widely used for animal cell microcarrier suspension culture and animal cell suspension culture.

Owner:罗火生

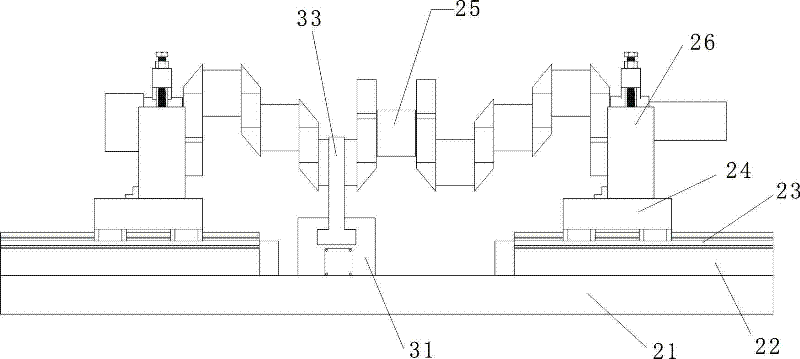

Flexible and rapid clamp device

InactiveCN102371495AImprove flexibilityAdjust and reducePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a flexible and rapid clamp device which comprises a baseplate, wherein guide rail supports are respectively arranged at the left and the right of the baseplate, carriages are respectively mounted on the guide rail supports through guide rails, a V-shaped block for positioning a revolving support shaft neck of a crankshaft is respectively arranged on each carriage, the revolving support shaft neck of the crankshaft is clamped through a revolving oil cylinder pressure plate mechanism, an automatic centering mechanism is arranged on the side edge of a crank at the middle of the crankshaft and the two sides of the crank are clamped for realizing auxiliary positioning; the revolving oil cylinder pressure plate mechanism comprises a pressure plate which is compressed on the revolving support shaft neck of the crankshaft, one end part of the pressure plate is fixed on an oil cylinder base through an adjustable screw rod, and an oil cylinder connected with the middle part of the pressure plate is mounted on the oil cylinder base; and the automatic centering mechanism comprises a middle guide rail mounted on the baseplate, and a middle support for performing auxiliary positioning on one pair of the side edges of the crank is connected on the middle guide rail through a crank oil cylinder. The flexible and rapid clamp device has the characteristics of being simple in structure, being convenient to use and having good stability in positing during the clamping process, high positioning precision, high working efficiency and the like.

Owner:杭州杭机数控机床有限公司

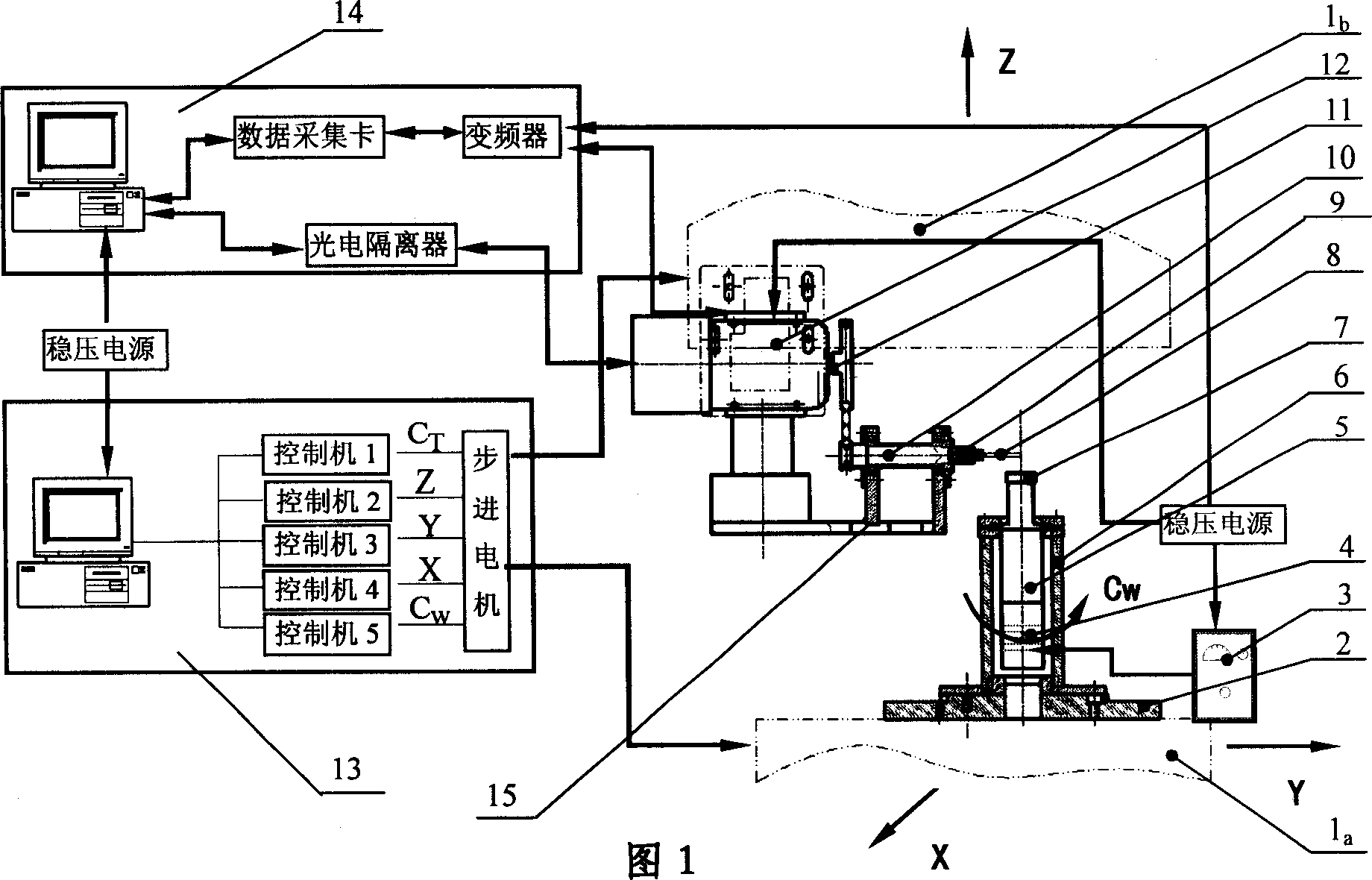

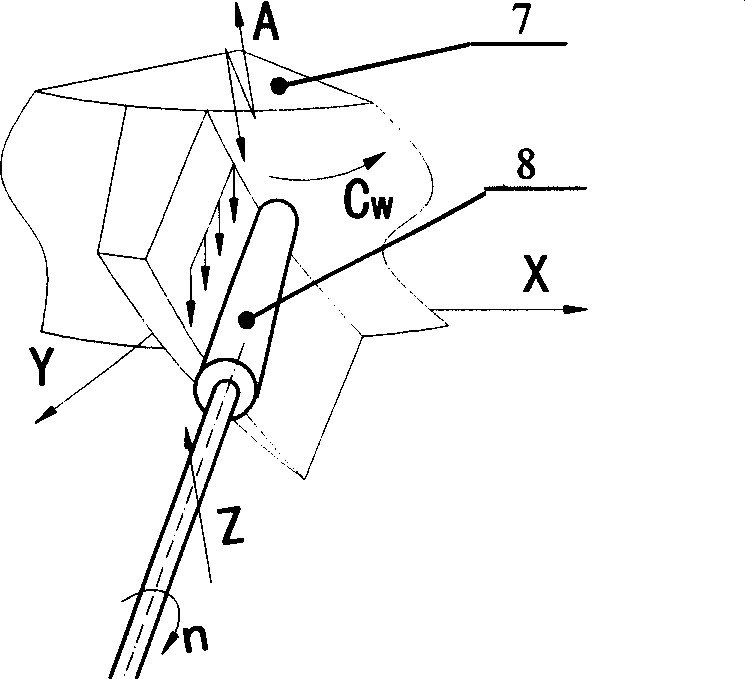

Digital controlled development and creep ultrasonic grinding process and apparatus for engineer ceramic blade profiles

InactiveCN1745966AHigh processing flexibilityImprove surface qualityControl systemUltrasonic vibration

A technology for machining the shaped surface of engineered ceramic blade by numerally controlled developing, creep advance and ultrasonic grinding features that the ceramic work piece is ultrasonically vibrating in Z axis, the grinding disc is rotating around main shaft perpendicular-to Z axis at high speed, and under the control of numeral control system, the grinding disc and work piece are relatively moving in X, Y, Z directions and rotating around Z axis. Its apparatus is composed of a numerally controlled 5-axle machine tool, numeral control system, grinding disc and its main shaft, frequency-regulatable motor and its control system and ultrasonic vibrating system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

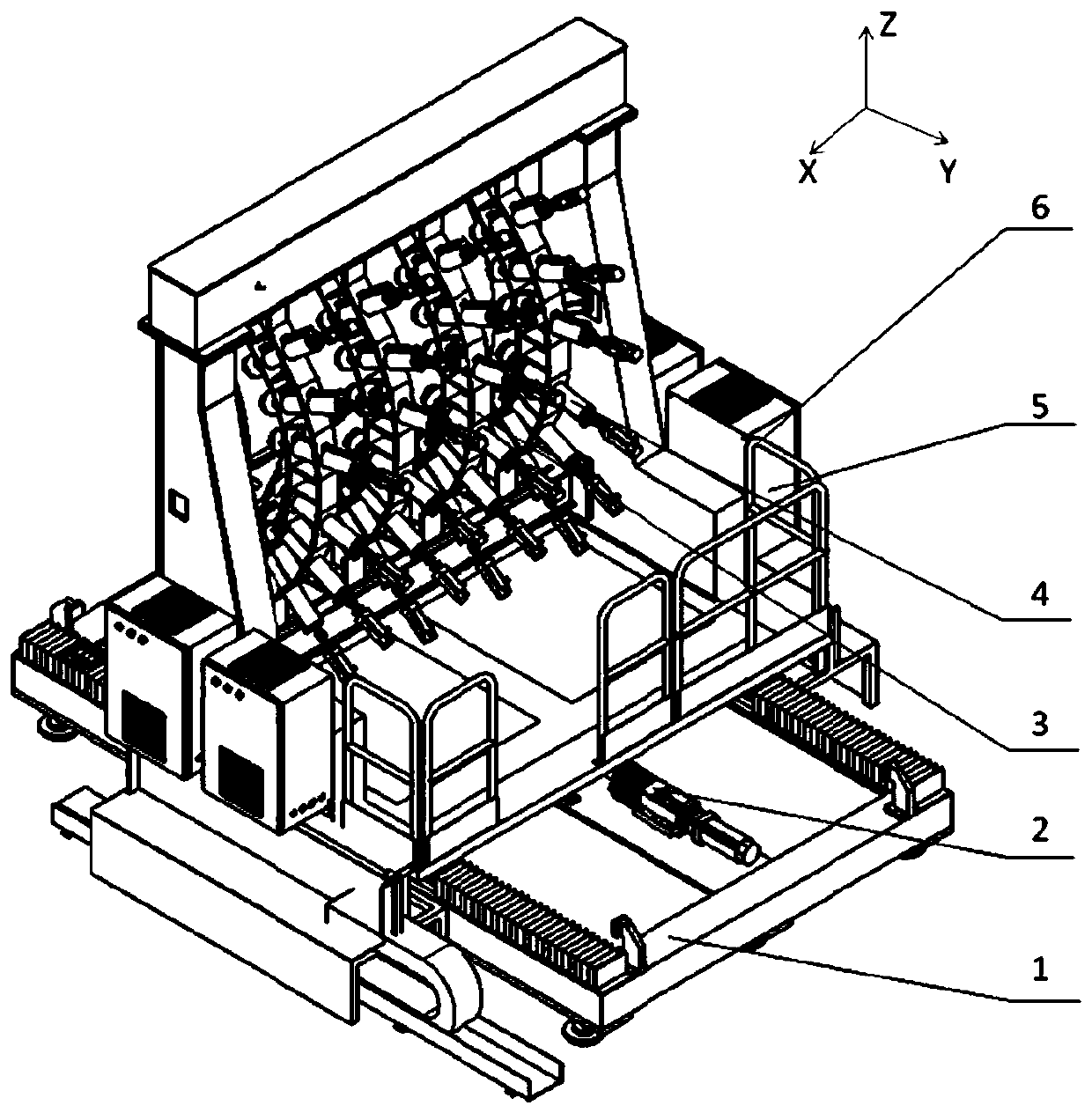

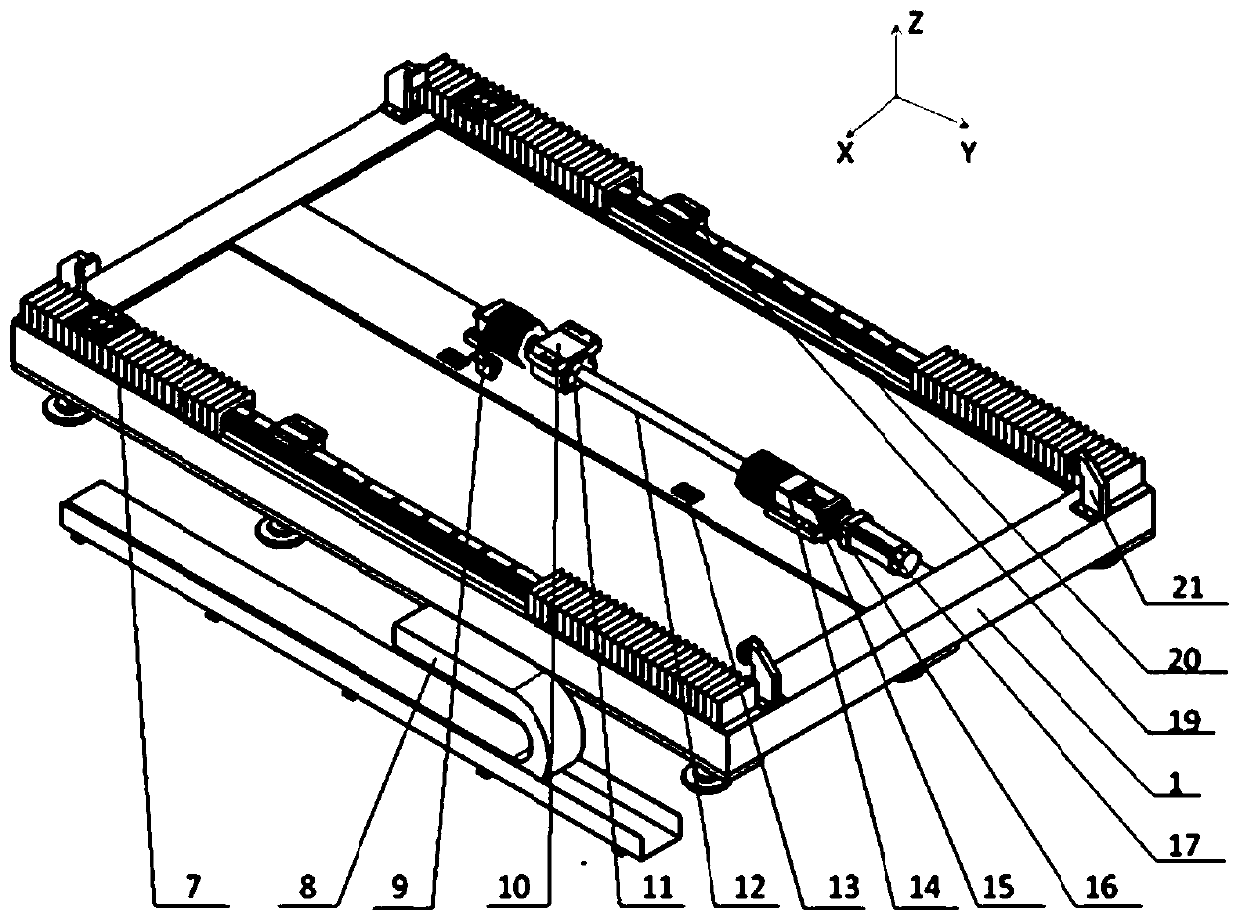

Flexible wallboard assembling tool

InactiveCN110920927AReduce the number of toolingShorten production preparation cycleAircraft assemblyAirplaneWall plate

The invention discloses a flexible wall plate assembling tool e, which belongs to the technical field of aircraft digital assembly. The tool comprises a base provided with a processing station, an assembly station and a drilling station, and an X-direction sliding table which is arranged on the base, slides between the processing station and the assembly station, is movably arranged on the base along the X direction, and is provided with a skin adsorption unit for fixing a skin; a Y-direction sliding table which slides between the assembly station and the drilling station; a base which is movably mounted on the base along the Y direction; wherein the Y-direction sliding table is provided with a wall plate frame positioning assembly for fixing the wall plate frame. The wallboard frame positioning assembly comprises a plurality of positioners which are oppositely arranged, each positioner comprises a fixing frame which is connected with the wallboard frame and has three-axis freedom degrees, an X-direction driving mechanism, a Y-direction driving mechanism and a Z-direction driving mechanism, and the X-direction driving mechanism, the Y-direction driving mechanism and the Z-directiondriving mechanism are used for driving the fixing frames and used for adjusting the position of the wallboard frame. Based on digital control technology, compared with a positioning mode of a traditional rigid tool, the digital positioning precision is greatly improved.

Owner:ZHEJIANG UNIV +1

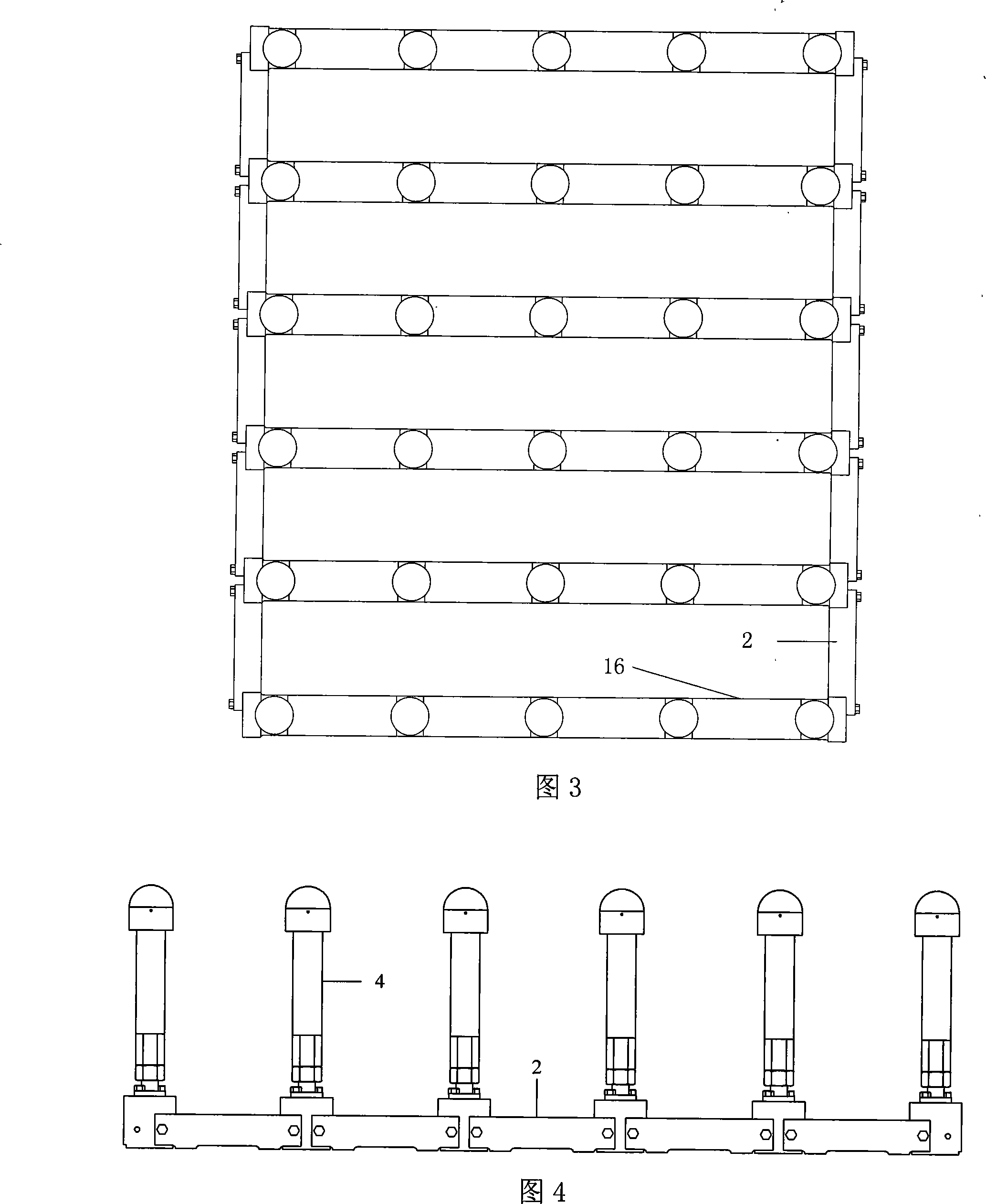

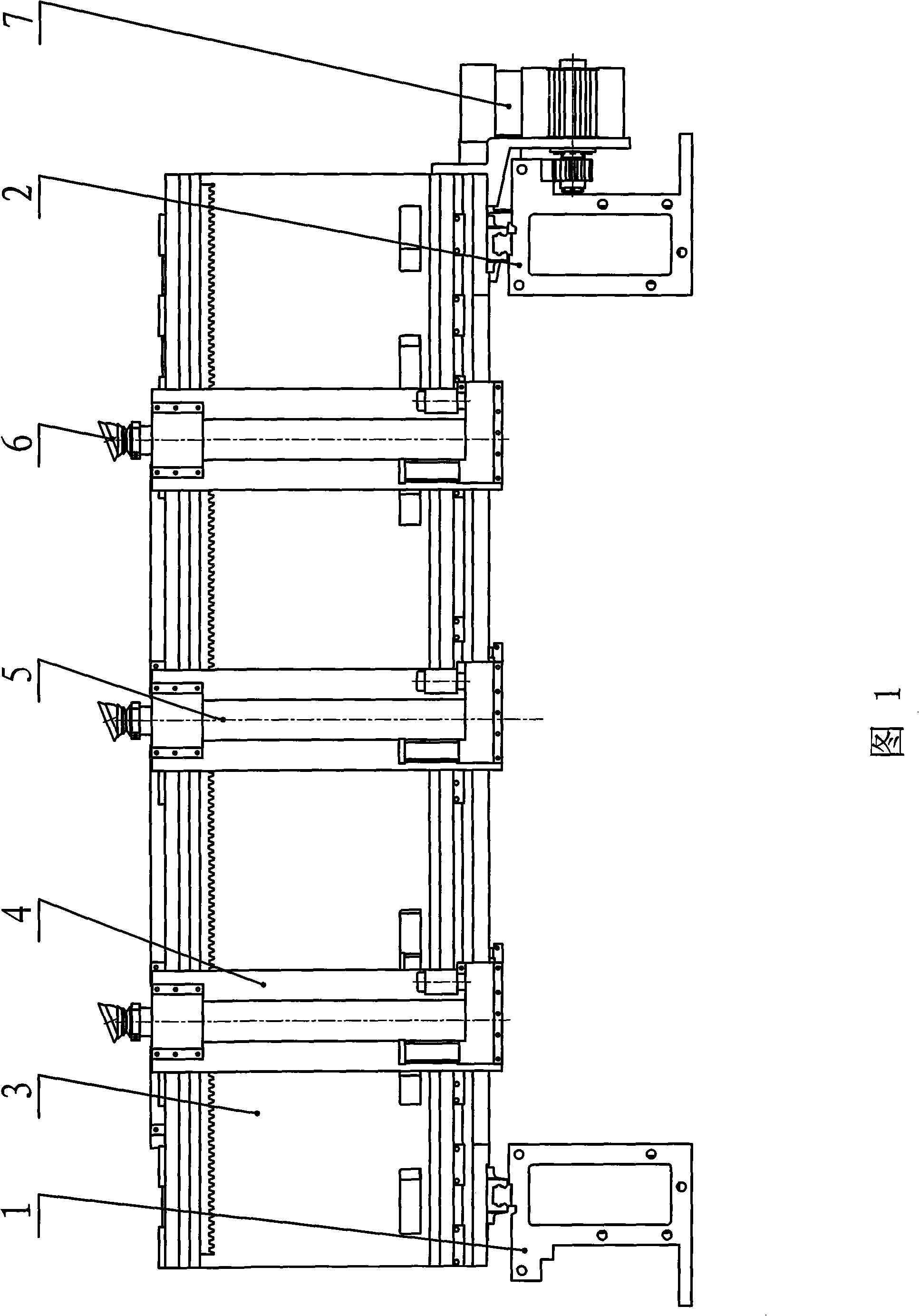

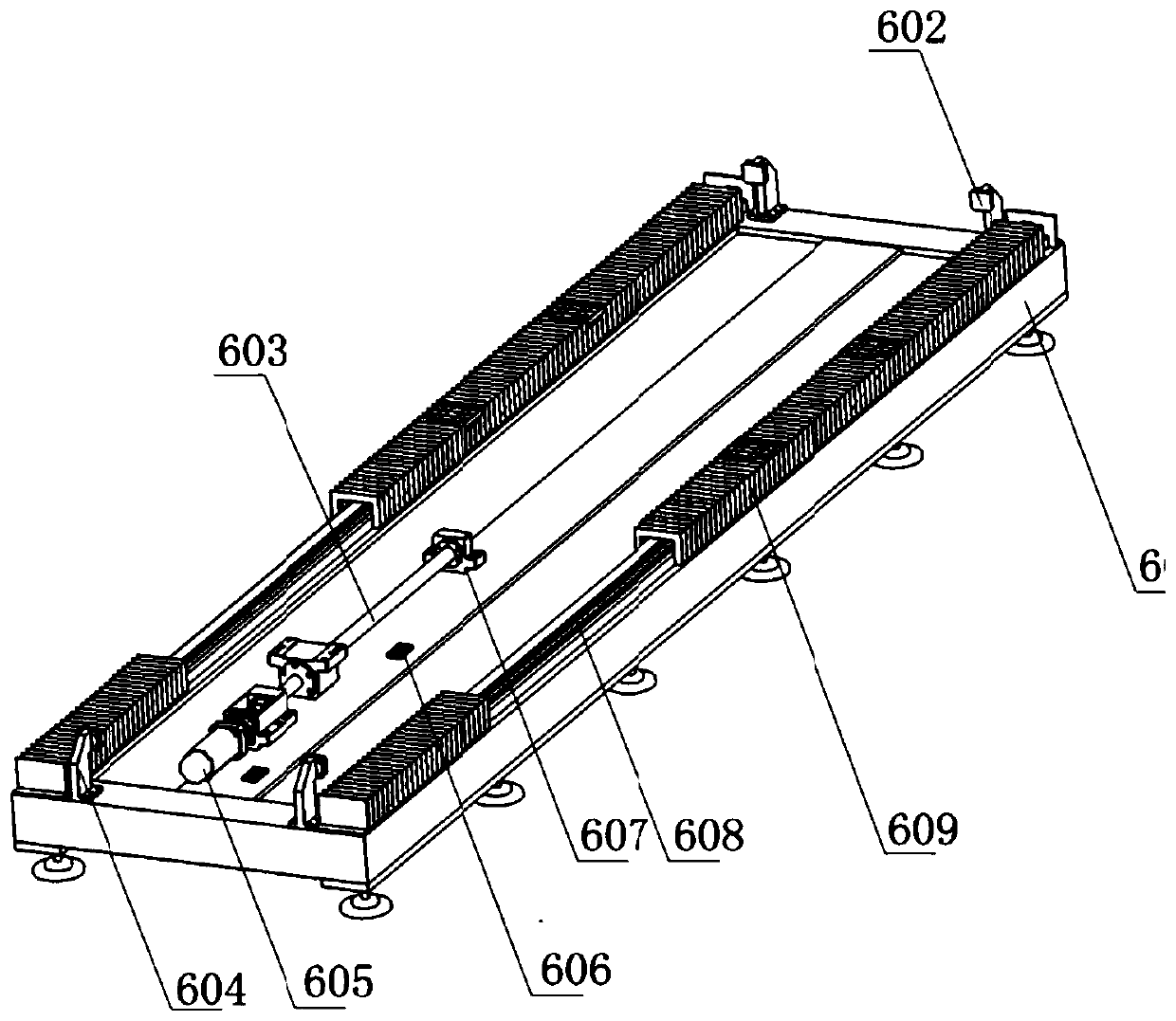

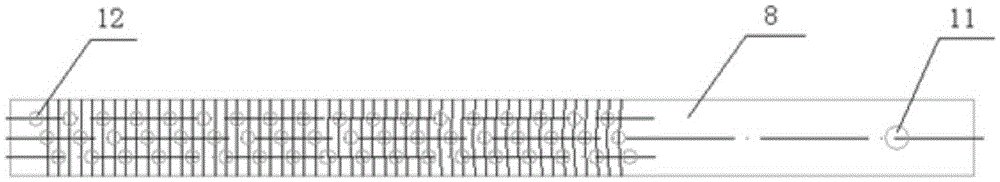

Flexible array type aircraft skin adsorption tool

InactiveCN110900481AImprove flexibilityMeet the requirements of different assembly positionsWork holdersWork benchesEngineeringStructural engineering

The invention discloses a flexible array type aircraft skin adsorption tool, which belongs to the technical field of aircraft assembly. The flexible array type aircraft skin adsorption tool comprisesa base, a movable platform and a driving mechanism, wherein the movable platform and the driving mechanism are arranged on the base. The movable platform is installed on the base, and the movable platform is equipped with a frame; the frame is internally provided with a stand column matched with the aircraft skin in shape; the stand column is provided with a plurality of vacuum adsorption units; the driving mechanism drives the movable platform to slide on the base in the Y direction, wherein the Y direction is perpendicular to the position plane where the aircraft skin is located; a Z-direction adjustable positioning stop block is arranged at the bottom end of the stand column and used for positioning the placing height of the skin in the Z direction; connecting blocks are arranged at thetwo sides of the frame, wherein the connecting block at one side is provided with a movable block capable of moving in the X direction, and the movable block and the connecting block at the other side are provided with positioning pin holes matched with positioning holes in skin lugs. A corresponding workpiece is positioned and clamped through rapid reconstruction of the vacuum adsorption units.

Owner:ZHEJIANG UNIV +1

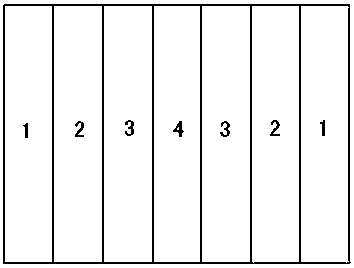

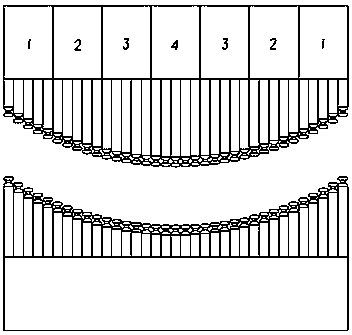

Plate multipoint divisional forming method and divisional pressing type multipoint forming device

PendingCN107597940AReduce designSaving manufacturingShaping toolsMultiple formsMechanical engineering technology

The invention discloses a plate multipoint divisional forming method and a divisional pressing type multipoint forming device, and belongs to the technical field of mechanical engineering. The plate multipoint divisional forming method and the divisional pressing type multipoint forming device aim to change the current situation that a blank pressing mechanism and a trimming process are needed when a plate is formed by utilizing an integer mould, overcome the detect that a workpiece is prone to wrinkling or the material utilization rate is low when the plate is formed by utilizing a multipointtype digitized mould, and has an anti-wrinkling function. The upper portion and the lower portion of the multipoint forming device are each composed of a plurality of basic body units, the upper portion or the lower portion of the multipoint forming device is divided into a plurality of forming areas, and the multiple basic body units are arranged on the multiple forming areas correspondingly; and when the plate is formed, the multiple forming areas are divided into two sets or a plurality of sets, each set comprises one or more forming areas, and the formed plate is pressed step by step in sets. According to the plate multipoint divisional forming method and the divisional pressing type multipoint forming device, compared with integer mould forming, mould-free forming without blank pressing of the plate three-dimensional curved surface can be achieved, and the processes of designing, manufacturing, debugging and workpiece outline cutting after plate forming of the mould are saved.

Owner:吉林省柔创机电科技有限公司

Rapid and universal positioning clamp and application method thereof

ActiveCN105290814APart lean production leapThe fixture is simple and convenientWork clamping meansPositioning apparatusMachine partsEngineering

The invention relates to a clamp, in particular to a rapid and universal positioning clamp and an application method thereof. According to the technical scheme, the rapid and universal positioning clamp comprises a base, T-shaped slide blocks, bulb point positioning slide blocks, ejecting blocks, a pressing plate, supporting blocks, pressing screws and an alignment device; the base is provided with a central hole, T-shaped grooves, installation holes and an alignment belt; T-shaped blocks are arranged on the lower portions of the bulb point positioning slide blocks, and spherical segment bodies are arranged on the upper portions of the bulb point positioning slide blocks; the alignment device comprises an alignment plate, positioning pins and alignment pins; positioning holes and a plurality of distance showing holes are formed in the alignment plate; the positioning pins are inserted in the positioning holes and the central hole; and the alignment pins are inserted in the distance showing holes with the sizes matched with the sizes of to-be-machined parts so as to show the installation positions of the ejecting blocks and the pressing plate. By means of the clamp, machined parts can be classified and grouped according to the process similarity and the size similarity, standardization, serialization, specialization and universalization are achieved for the complete set of tool, and a qualitative leap is achieved for the part lean production of factories.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Adjustable lever drilling die clamp

ActiveCN102729064ALow technical requirementsReduce labor intensityDrilling/boring measurement devicesPositioning apparatusEngineering

Owner:SUZHOU VOCATIONAL UNIV

Rapid design method of tyre mould

The invention provides a rapid design method of a tyre mould, which comprises the following steps of: 1) simplifying the expressed mould design pattern, classifying the shape related characteristics of the tyre mould, and drawing and establishing a CAD (computer-aided design) pattern library of the typical structure of various types of tyres; 2) compiling a special tyre designing and manufacturing specification, attaching tyre typical structure legends corresponding to the tyre typical structure pattern library and the pattern of the simplified drawing work order, and classifying and numbering the typical structure legends; and 3) correspondingly selecting a legend number from the typical structure specification according to the product shape, calling the CAD pattern from the typical structure pattern library and filling the CAD pattern into the simplified drawing work order according to the number, and finally filling an order number, a fixture pattern number and other simple information into the work order to finish the design. As the tyre typical structures in the invention are strictly classified, the classes nearly include all tyre structure types and the compiling idea is novel, the tyre mould is convenient and quick to use by designers, the design speed is increased by 6-10 times than that before, and the manual labor and material resources are saved. The invention can greatly shorten the production preparation period, and provides solid technical storage for the development of new products.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

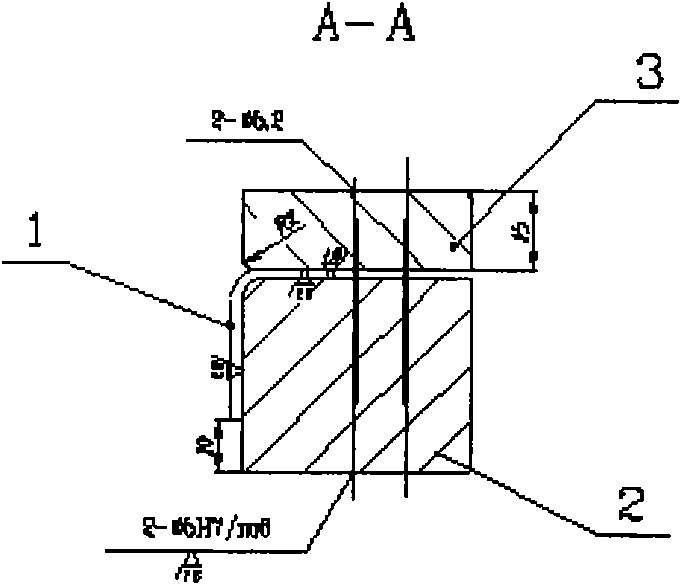

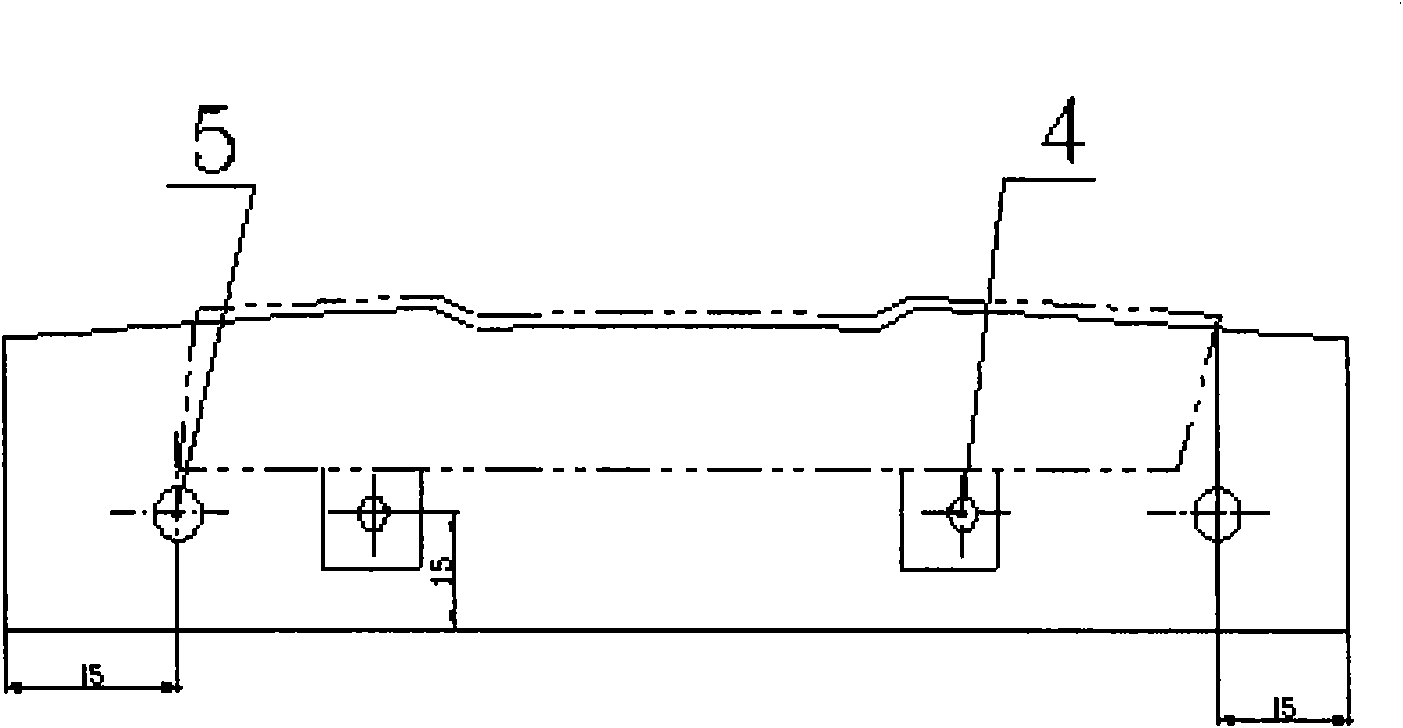

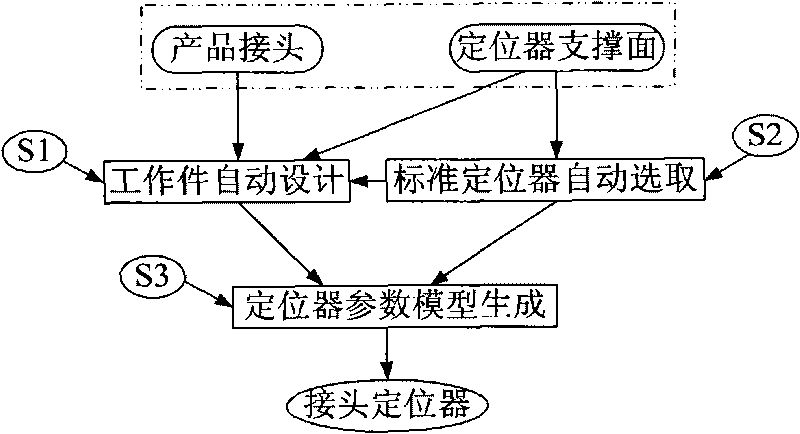

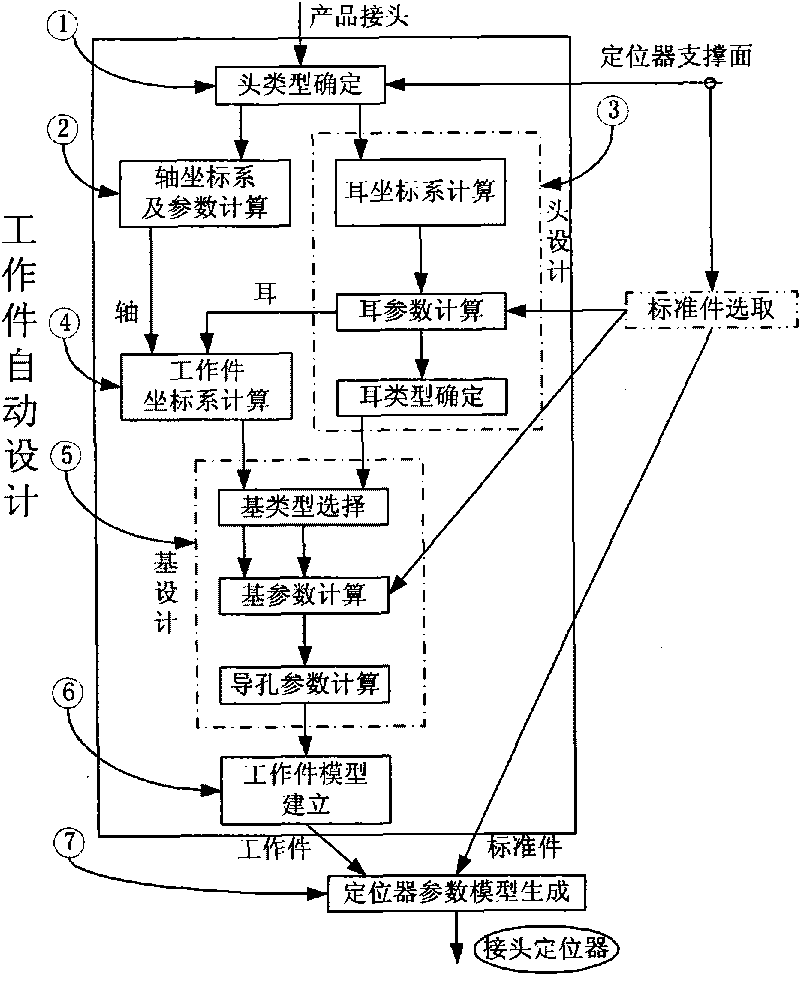

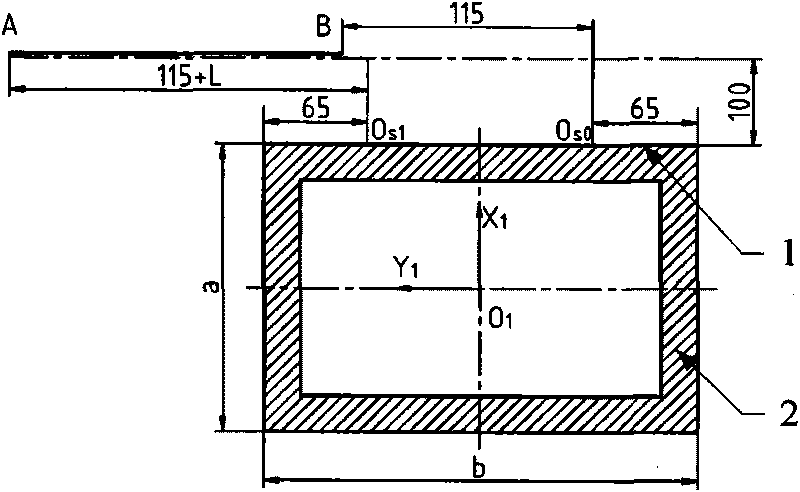

Automatic design method of numerical control machining tool positioner of complex parts of airplane

InactiveCN101763065AImprove assembly development cycleShorten assembly development cycleProgramme controlComputer controlAirplaneManufacturing engineering

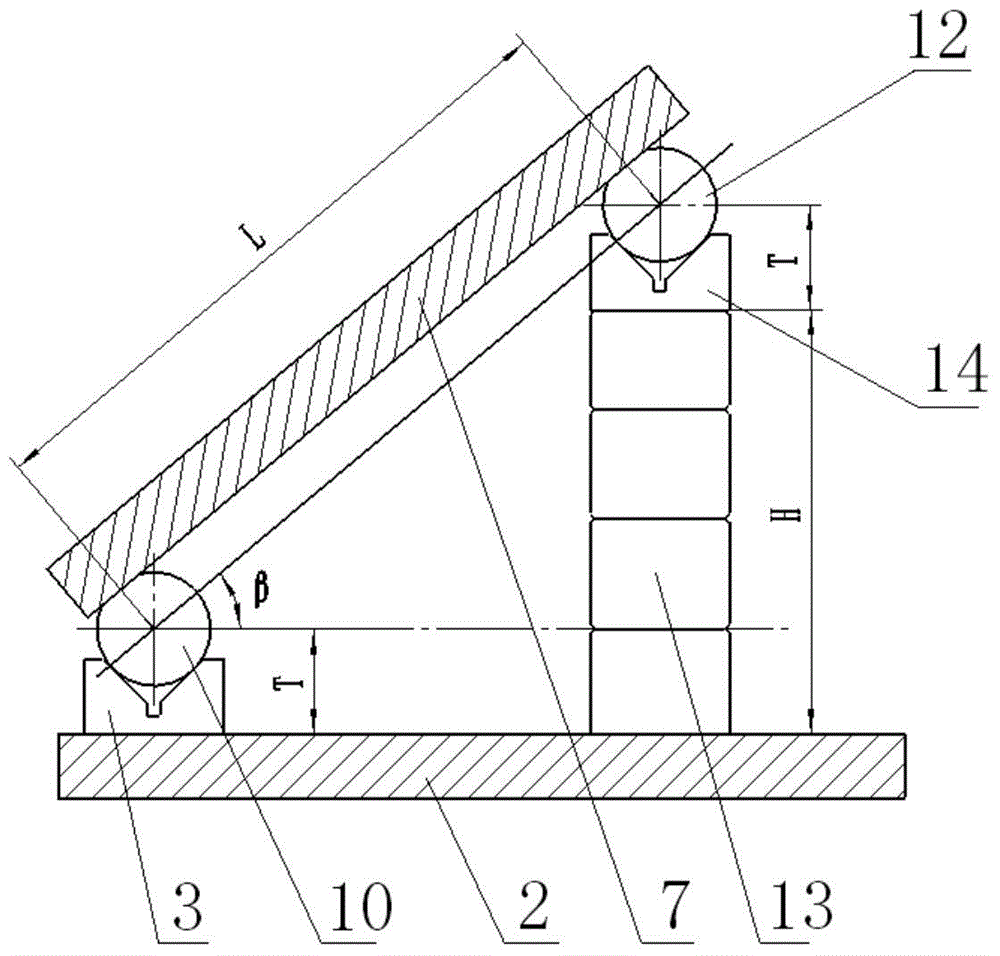

The invention discloses an automatic design method of a numerical control machining tool positioner of complex parts of an airplane, which comprises the steps of: automatically designing a work piece, automatically selecting a slandered positioner and automatically modeling positioner parameter. The method can be used for developing an automatic selection procedure of the slandered positioner for a 'tool quick generation subsystem' in a 'quick numerical control machining preparation system of complex parts of airplane (PrtRMP)'. The module can be applied to designing the numerical control machining tool of the complex parts of various type airplanes, improves the designing efficiency of the tool, shortens a tool-developing period and even a whole tool-producing and preparing period, and obtains good application benefit. The method can simplify the designing process of the positioner, realizes the automatic and quick design of the positioner, and improves the designing efficiency and the designing quality of the tool, thereby shortening the assembling and developing period of the airplane.

Owner:SHENYANG AIRCRAFT CORP +1

Airplane complex construction member numerical control processing tool standard locator automatically selecting method

InactiveCN101738983AImprove development cycleShorten the development cycleProgramme controlComputer controlAirplaneTool design

The invention provides an airplane complex construction member numerical control processing tool standard locator automatically selecting method. Domain definition system and product joint position can be defined by calculation, and a candidate locator and an optimal locator are determined, so as to determine the type and specification of the standard locator meeting the locating requirement. The method can be applied to development of 'tool rapid generating sub system' standard locator automatically selecting program in the 'airplane complex construction member rapid numerical control processing ready system'. Tool design efficiency is improved, tool development and even the whole production ready period is shortened, and application benefit is favourable. Besides, the invention can be applied to automatic calling of airplane manufacturing tool and other special standard component. When applying the method, only manual selection of product joint and locator supporting surface is required, the standard locator can be automatically selected, automation, intellectualization and rapid design of locator can be realized, and design efficiency and quality of complex construction member numeric control processing tool is improved, thus shortening airplane development period.

Owner:SHENYANG AIRCRAFT CORP +1

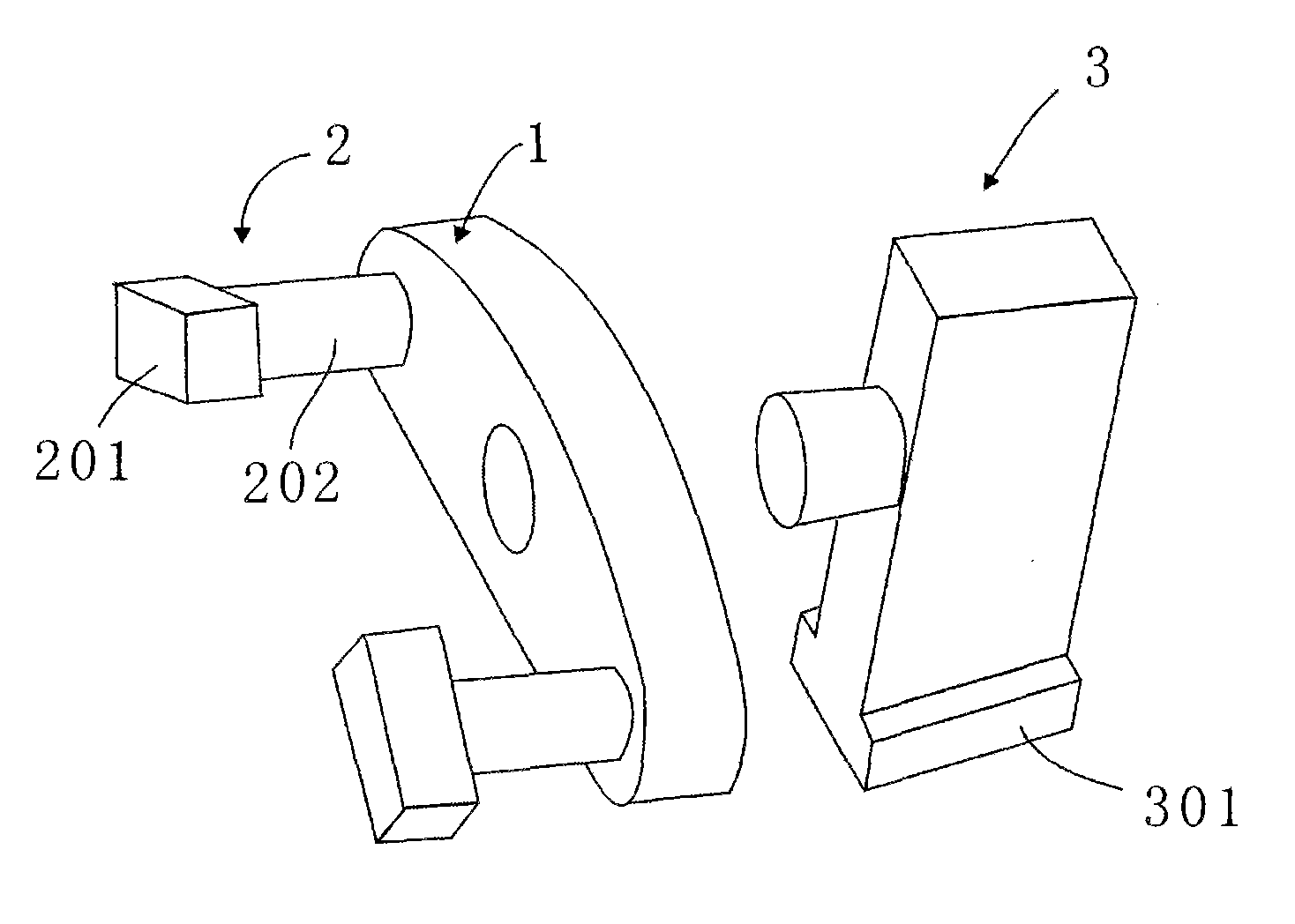

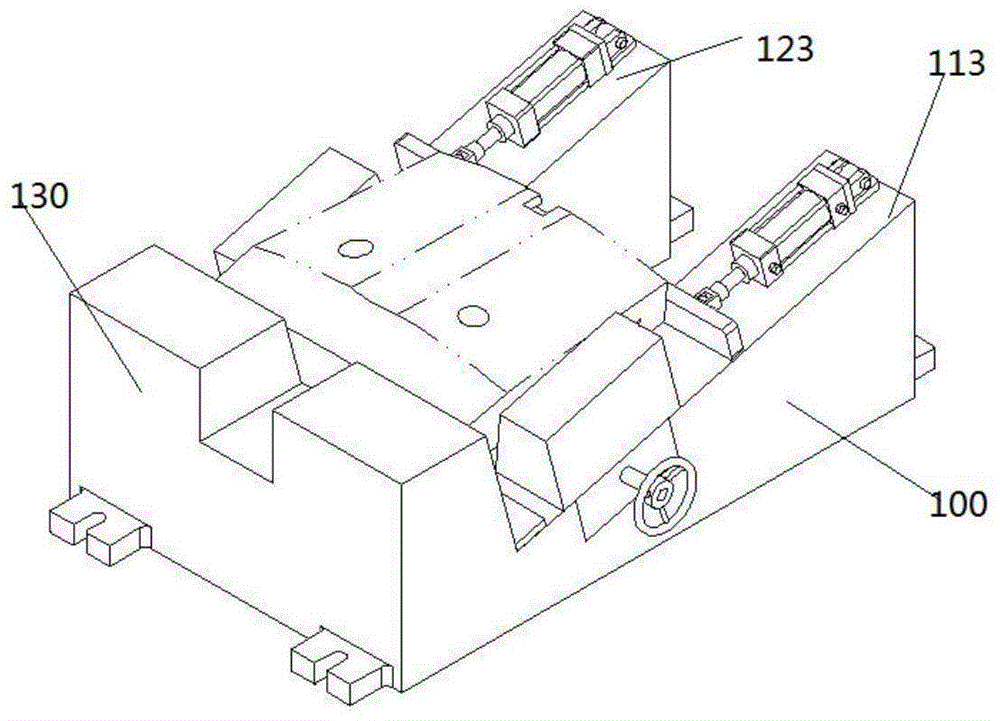

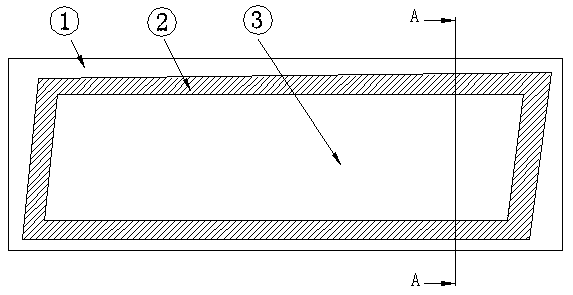

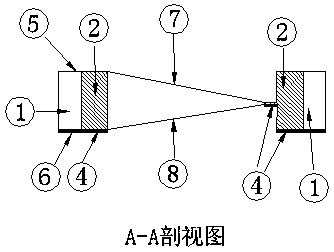

High-efficient modular fixture for processing part

InactiveCN101372083AReduce design man-hoursReduce production man-hoursPositioning apparatusMetal-working holdersModular fixtureEngineering

The invention relates to a group of clamps used for part processing, mainly consisting of a basic part and an adjustable part; wherein, the basic part comprises a clamping body (1) and transmission clamping parts (2, 3); the adjustable part consists of replaceable parts (4, 6) and an elastic expanding part (5); during the part processing, each dimension group of the part is provided with a group of corresponding replaceable parts. When parts of different dimension groups are processed, replaceable parts (4, 6) are all needed to be replaced; but in the same dimension group, only elastic expanding part (5) of corresponding dimension is needed to be replaced for the workpiece of difference positioning aperture; the clamp can shorten the design and manufacture time of normal clamp, saves the material and reduces the production cost.

Owner:BEIJING UNION UNIVERSITY

Digital manufacturing method for bucket tooth of excavator for mine

InactiveCN105436407AShorten production preparation cycleThe molding method is convenientFoundry mouldsFoundry coresWaxParaffin oils

The invention provides a digital manufacturing method for a bucket tooth of an excavator for a mine and belongs to the field of digital manufacturing of bucket teeth. The digital manufacturing method for the bucket tooth of the excavator for the mine includes the following steps that firstly, a bucket tooth part drawing is drawn, and a cad software model is used for establishing a three-dimensional bucket tooth solid model; secondly, casting analog simulation software is used for simulating casting technology analysis and optimization; thirdly, a model part of a bucket tooth casting mold is generated; fourthly, trial manufacture is conducted on a bucket tooth paraffin mold paraffin blank; fifthly, the paraffin blank obtained after trial manufacture is cast, and a cast iron bucket tooth blank is obtained; sixthly, mechanical testing and paraffin mold paraffin blank parameter modification are conducted on the cast iron bucket tooth blank; and seventhly, paraffin mold paraffin blanks are produced in a batched manner. A mold manufacturing method for the bucket tooth of the excavator based on digital design is adopted, more convenience is achieved, the production preparation period of castings is effectively shortened, the risk of developing new products is lowered, product precision is improved, labor intensity is lowered, cost is reduced, a production database is established, and a product family is formed.

Owner:TIANJIN CMC XIONGFENG CONSTR MACHINERY

Locating device for welding guide pipe connector at any angle

ActiveCN105345348APrecise positioningSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention belongs to the technical field of material engineering, and relates to a locating device for welding a guide pipe connector at any angle. The locating device comprises a base and a movable supporting arm, and an angle disc is fixed to a shaft. The part, below the angle disc, of the shaft is sleeved with a rotating block, and a rotating supporting arm is fixed to the rotating block. An angle indication block is fixed to the rotating block and provided with a first locking screw. A connector mounting block is fixed to the top of the angle disc. A connector mounting groove is formed in the top of the connector mounting block. A connector locating pin is arranged on one side of the connector mounting block, and a limiting plate is arranged on the other side of the connector mounting block. A locking screw of the guide pipe connector is arranged on the connector mounting block. The rotating supporting arm is sleeved with a sliding block, and an axial clamping block is arranged on the sliding block. The movable supporting arm is provided with a first guide groove, the axial clamping block is provided with a second guide groove, and the movable supporting arm and the axial clamping block are connected through pins arranged in the first guide groove and the second guide groove. An angular clamping block is hinged to the upper end of the movable supporting arm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Manual combined clamping device

PendingCN113001216AMeet the design requirementsReduce design requirementsPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a manual combined clamping device. The device is characterized by comprising a pressing plate, a spherical washer, an adjusting nut, a screw rod, a locking nut, a rotating wheel, a pin, a gasket, a pressure spring, a screw rod locking nut, a tapered wedge, a standard steel wire ring, a support, a force application screw, a fastening screw, a base plate, guide rails, first countersunk head screws and second countersunk head screws. The base plate is connected to a clamp body through the second countersunk head screws, and the two guide rails are connected to the two sides of the upper portion of the base plate through the first countersunk head screws; the support is arranged on the base plate; the force application screw vertically penetrates through the support; and the top of the force application screw is connected with the tapered wedge. According to the clamping device, three-stage reinforcement manual clamping of a spiral-tapered wedge-pressing plate combination is adopted, and larger clamping force can be obtained. When the height size of the clamping face of a workpiece is changed, the workpiece can be clamped only by replacing the base plate, the design requirement of a flexible clamp is met, and therefore the design and manufacturing cost of the clamping device is effectively reduced, and the production preparation period of the clamping device is effectively shortened.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

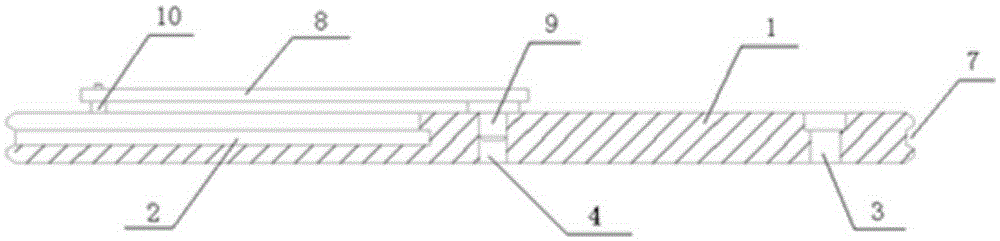

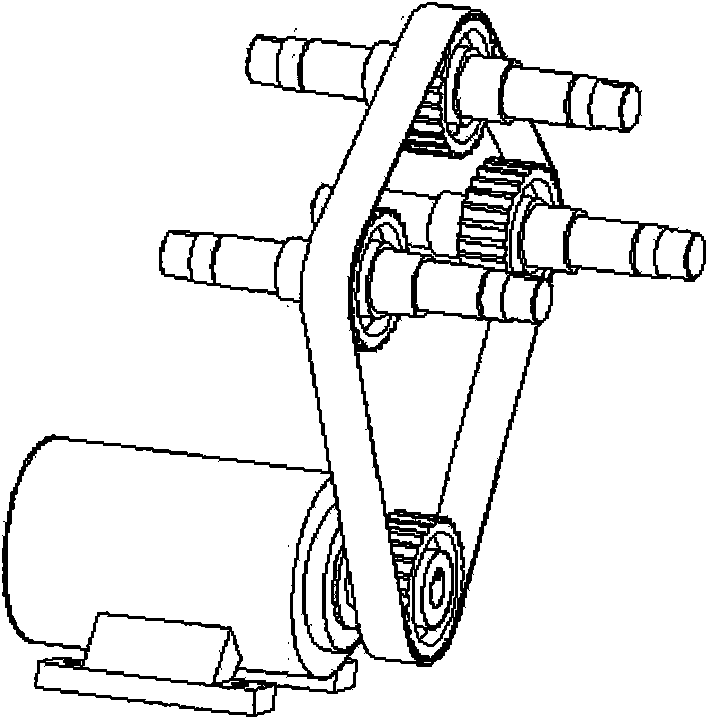

Helical six-point floating centering mechanism

ActiveCN102225473AGood centering clampingEasy to install the card at easeChucksEngineeringMechanical engineering

The invention discloses a helical six-point floating centering mechanism which is characterized in that a paired floating six-claw centering process can be realized by helical meshing transmission of three groups of transmission assemblies formed by virtue of mutual meshing of a second slider, a third slider and a fourth slider, thus achieving good six-point centering and clamping performances onrotating body parts, effectively reducing the deformation of parts with weak rigidity and thin wall due to clamping, and playing a positive role in promoting the process standardization.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Bi-directional pre-tensioned prestressed ballastless track slab mobile tensioning equipment

Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment comprises a side pre-locking beam, a side tensioning beam, an end pre-locking beam and an end tensioning beam; the side pre-locking beam and the side tensioning beam are assembled on two walking beams through a pair of side beam linear guide rails, and each walking beam is provided with wheels matched with a running rail, walking guide wheel sets, a wheel speed reduction motor and side beam advancing and retreating oil cylinders; portal frames are arranged at the two ends of the walking beams, and a lifting frame, a lifting frame lifting oil cylinder and a lifting frame lifting guide device are assembled on each portal frame; and the end pre-locking beam and the end tensioning beam are assembled on the lower faces of the lifting frames through a pair of end beam linear guide rails, and end beam advancing and retreating oil cylinders are arranged on the lifting frames. According to the equipment, the production preparation period can be effectively shortened, the engineering construction cost is reduced, industrial pollutions are avoided, and meanwhile a steel mold fixed mounting production manner facilitates simplifying of a mold structure, reduction of cost, improvement of precision and reduction of occupied areas and working energy consumption of production equipment.

Owner:秦皇岛老虎重工有限公司

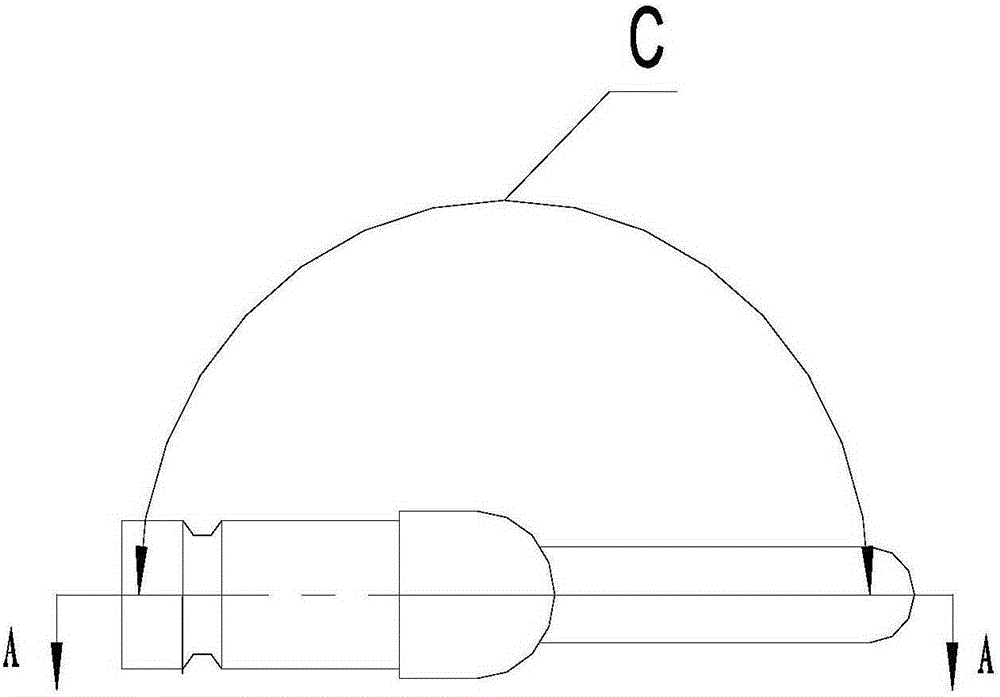

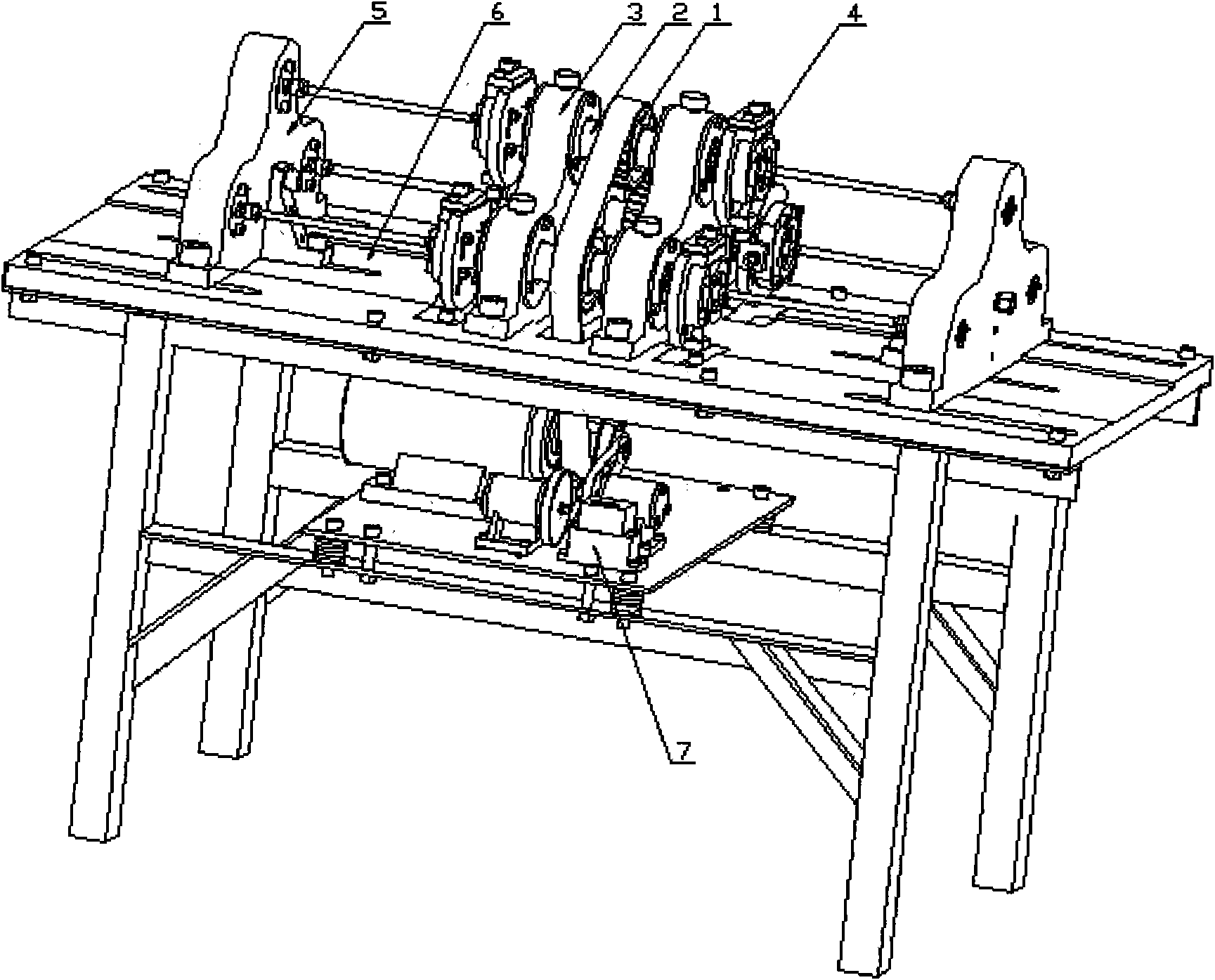

Rotary bending fatigue tester of aviation conduit assembly

InactiveCN101982755ACompact structureIncrease available swing angleMaterial strength using steady bending forcesAviationTest efficiency

A rotary bending fatigue tester of an aviation conduit assembly is designed for solving technical problems of prior equipment, such as low test precision, low test efficiency and the like. The tester comprises a synchronous belt transmission mechanism, a main shaft mechanism, a main support vertical plate, a deflection adjusting mechanism, a tailstock shaft / pipe installation mechanism, a worktable and a mounting mechanism. The tester distributes power by the synchronous belt transmission mechanism; the main support vertical plate and the tailstock shaft / pipe installation mechanism guarantee coaxial precision in an assembling and locating period via a U-shaped through channel formed on the worktable; the deflection adjusting mechanism uses a shaft inclined hole mounting mode; and the tailstock shaft / pipe installation mechanism uses a detachably changeable design. The rotary bending fatigue tester of the aviation conduit assembly has the following benefits: the transmission mechanism has compact structure, the shaft inclined hole mounting mode in the deflection adjusting mechanism effectively adjusts up a usable pivot angle of a self-aligning bearing; and mobility and detachable design of the tailstock shaft / pipe installation mechanism improve applicability and generality of the equipment. Tests for different strengths of different pipes / shafts can be performed simultaneously on same equipment, so that testing efficiency is improved, and cost and production cycle are both reduced.

Owner:SHENYANG AEROSPACE UNIVERSITY

Modularized intelligent reconstruction general work stair platform

The invention discloses a modularized intelligent reconstruction general work stair platform having a plurality of liftable work stairs. A work area for airplane assembling is enclosed by the plurality of work stairs. The modularized intelligent reconstruction general work stair platform is characterized in that each work stair is a shearing hydraulic elevating work stair; a buried-in groove is arranged on the ground; a pedestal of the work stairs is fixed in the buried-in groove; when expansion amount of the work stairs at a non-work state is zero, the stair platform surfaces of the work stairs are in a seamless connection to form a plane; and the plane is on the same level as the work area ground. Space can be fully utilized by the use of the work stair platform, so use area of a factory plant is increased and low cost and convenience can be achieved for airplane assembling; relative reconstructions can be achieved based on various products by the use of the modularized general work stair platform, so an assembling demand for various reconstructions via one work stair platform can be achieved; and numbers of specific work stairs can be reduced, so manufacturing cost can be lowered.

Owner:SHENYANG AIRCRAFT CORP

Casting mold structure and base plate applicable to medium and large-scale vertical centrifugal casting machines

The invention belongs to the technical field of centrifugal casting and particularly relates to a casting mold structure and a base plate applicable to medium and large-scale vertical centrifugal casting machines. The casting mold structure and the base plate comprise baseboards, cover plates and metal sleeves. The baseboards have N models, a baseboard of each model corresponds to one cover plate of one model and a metal sleeve of one model, and the outer diameters of the baseboards, the cover plates and the metal sleeves of the same models are the same. The outer diameters of the baseboards of different models are different. Pressing plates have P models, and a pressing plate of each model corresponds to 1-2 cover plates of adjacent models. When an annular pressing plate of one model corresponds to two cover plates of adjacent models, annular outer radius of the pressing plate>=outer radius as 30mm of the cover plate of a corresponding larger model, and the inner radius of the pressing plate>=a pouring port step position outer end size as 30mm of the cover plate of a corresponding smaller model. The casting mold structure and the base plate have the advantages of forming a series of baseboards, cover plates and metal sleeves, enabling repeat use rate of the baseboards and the cover plates to be high, enabling the comprehensive cost price of a casting mold to be reduced, and simultaneously reducing production preparation periods.

Owner:武汉武船金属制造有限责任公司

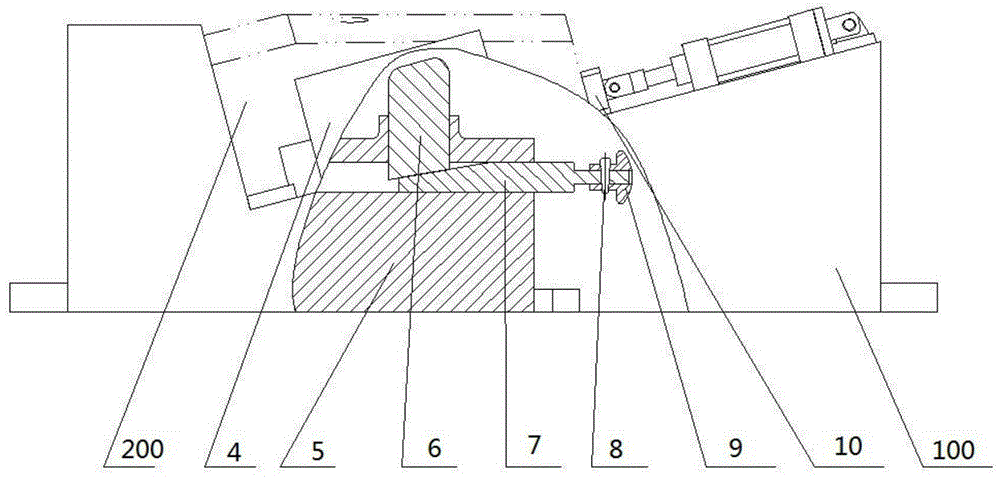

Special clamp for pneumatic type tire mold slideway

InactiveCN105234719AEasy to put into productionShorten production preparation cycleWork clamping meansPositioning apparatusEngineeringMachining process

The invention discloses a special clamp for a pneumatic type tire mold slideway. The research direction of the generalization design in a special range is determined according to the problem caused during clamping and processing of tire mold slideways. A slope type tire mold slideway clamp is disclosed and designed by taking an included angle between a T-shaped slideway and the horizontal plane as a fixed constant. The slope type tire mold slideway clamp comprises a hand wheel, a screw, a cylinder, a tire mold, a side barrier part, a thrust-assisted support, a baffle and a clamp body support seat and is characterized in that one end of the cylinder is rotationally connected with the clamp body support seat; the other end of the cylinder is connected with the baffle; the screw is arranged in a straight slot of the clamp body support seat; the thrust-assisted support is arranged at the interior of the clamp body support seat. The special clamp for the pneumatic type tire mold slideway is capable of locating and clamping the tire mold, avoiding deformation and compression in the processing process and implementing generalization of the special clamp in a certain range.

Owner:GUANGXI UNIV

Honeycomb core part machining method based on boss holding

ActiveCN110480076AReduce processing costsShorten production preparation cycleMilling equipment detailsAdhesiveHoneycomb

The invention discloses a honeycomb core part machining method based on boss holding. The honeycomb core part machining method based on boss holding comprises the steps of arranging a false boss alongthe contour of a part; connecting a false excess material with the part through the false boss; machining a first surface profile of the part; enabling the false boss to be aligned with the profile of the part; and then machining a second surface profile on a turned-over surface; and with the process boss as reference, arranging a press plate on the process boss to fix the part. According to thehoneycomb core part machining method based on boss holding, a standard honeycomb core part can be machined without customizing a special profile tool so that the part machining cost is reduced; without using a double-face adhesive tape to fixedly hold the part, the production preparation period of the part during machining is effectively shortened; without using ethyl alcohol to soak the part, thedeformation of the part after being machined is avoided, and the part machining quality is guaranteed; and the part tool assembling and disassembling process is eliminated, the part production efficiency is enhanced, and the labor intensity of operation personnel is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com