Manual combined clamping device

A clamping device and a technology of one center, applied in the field of manual combined clamping devices, can solve the problems of limiting the application range of manual clamping devices, low clamping force, etc., to reduce design and manufacturing costs and production preparation period, large clamping The effect of high clamping force and clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

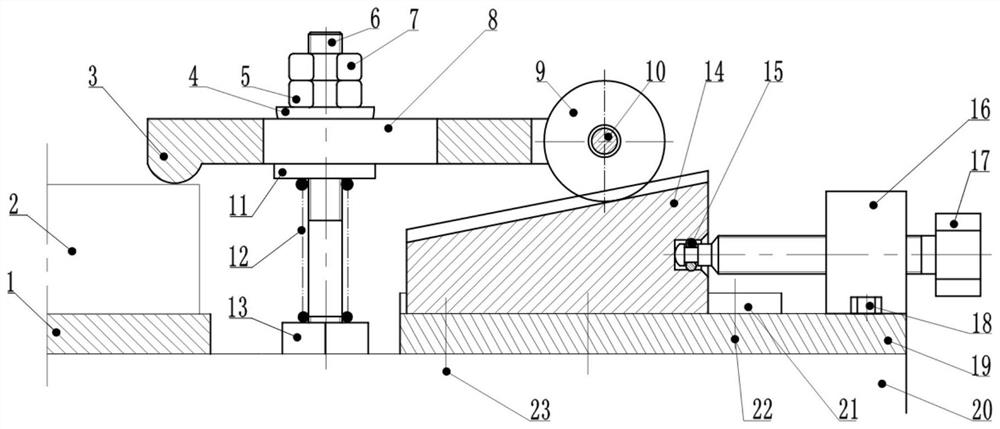

[0013] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the accompanying drawings. The invention can be implemented in different forms and is not limited to the embodiments described in the text. On the contrary, the embodiments are provided so that the disclosure of the present invention will be thorough and comprehensive.

[0014] As shown in the accompanying drawings, as shown in the accompanying drawings, a manual combined clamping device includes a pressing plate 3, a spherical washer 4, an adjusting nut 5, a screw rod 6, a lock nut 7, a runner 9, Pin 10, gasket 11, compression spring 12, screw lock nut 13, wedge 14, standard traveler 15, support 16, force screw 17, fastening screw 18, backing plate 19, guide rail 21, the first sink Head screw 22, second countersunk screw 23.

[0015] The backing plate is connected and arranged on the clamp body 20 through the second countersunk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com