Angle-adjusting numerical control machine tool combined clamp

A technology of CNC machine tools and combined fixtures, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems that the precision of combined fixtures is difficult to reach a higher level, shorten the production preparation cycle, and have positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

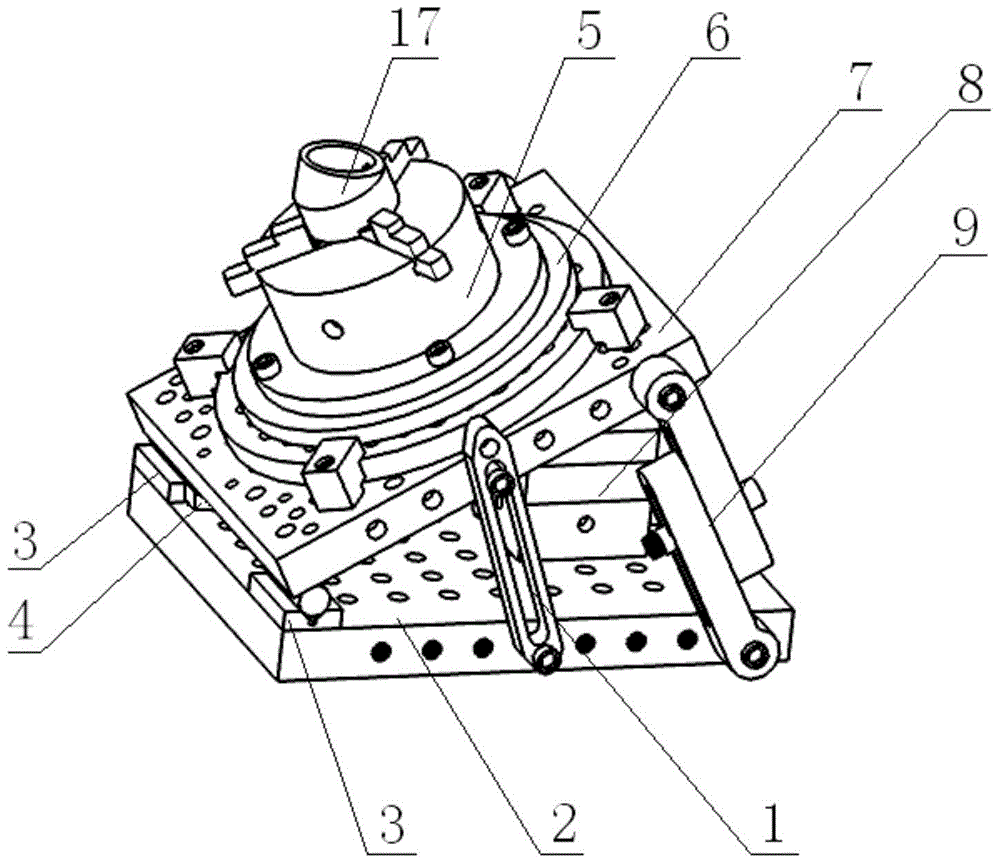

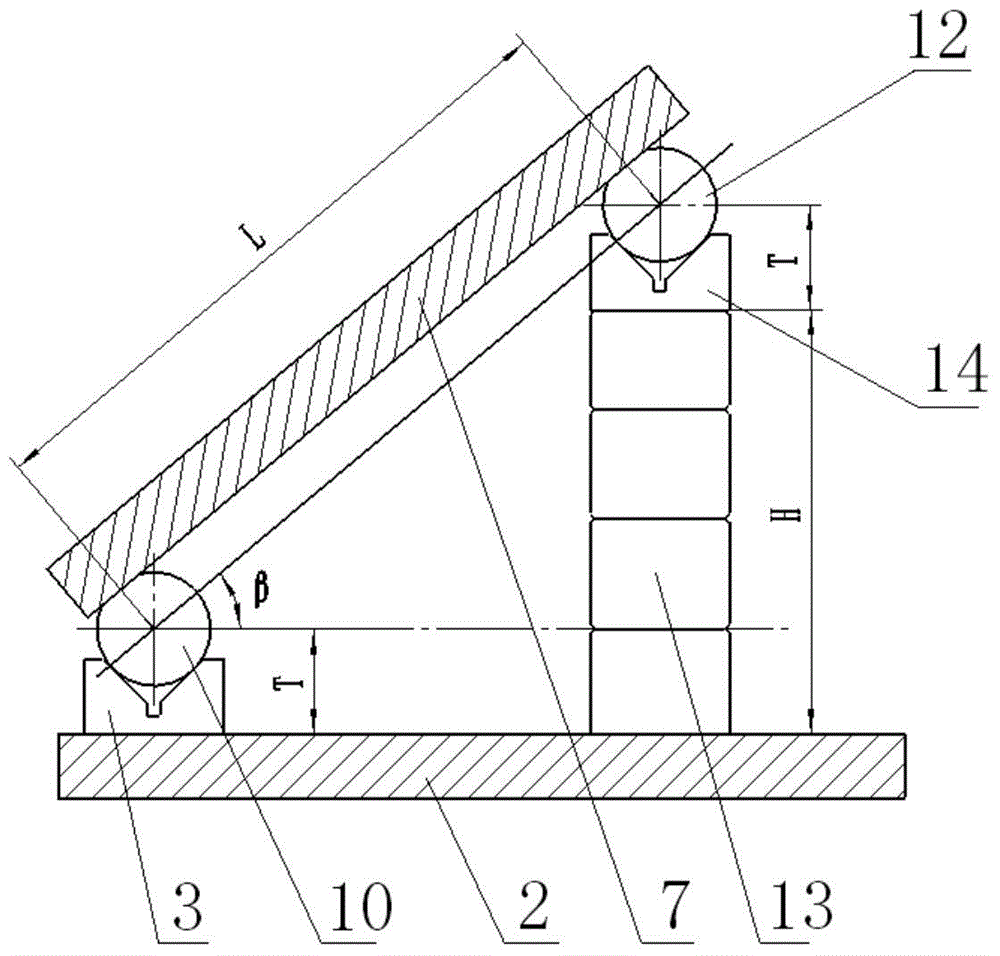

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, an angle-adjustable CNC machine tool combination fixture of the present invention includes a lower base plate 2, an upper base plate 7, a first connecting plate 1, a second connecting plate 9, a support member 8, an indexing plate 6 and a three-jaw chuck 5. The three-jaw chuck 5 is located above the upper base plate 7, and the workpiece 17 is clamped by the three-jaw chuck 5. There is an indexing plate 6 between the three-jaw chuck 5 and the upper base plate 7, and the holes on the upper base plate 7 The system consists of pin holes and bolt connection holes evenly distributed on the circumference of three different diameters, which is convenient for indexing and positioning. The support is vertically fixed on the lower base plate 2, and the lower base plate 2 is arranged near one side with two identical low V-shaped support blocks 3 whose centerlines coincide. The support 8 is composed of a rectangular suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com