Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment

A ballastless track and mobile technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of large floor area and operation energy consumption, uneven stress on prestressed steel bars, long production preparation period, etc., and achieve the goal of manufacturing and low operating costs, reducing floor space and energy consumption, and solving operational troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described with reference to the drawings and examples.

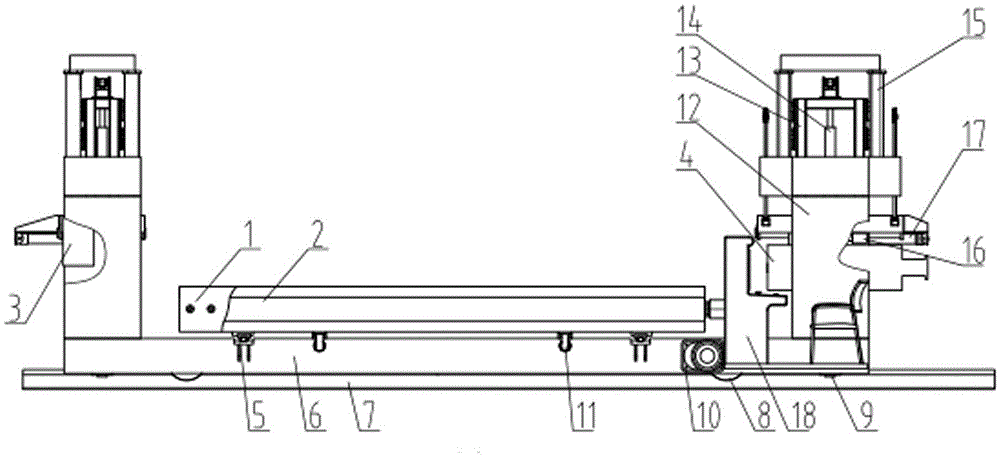

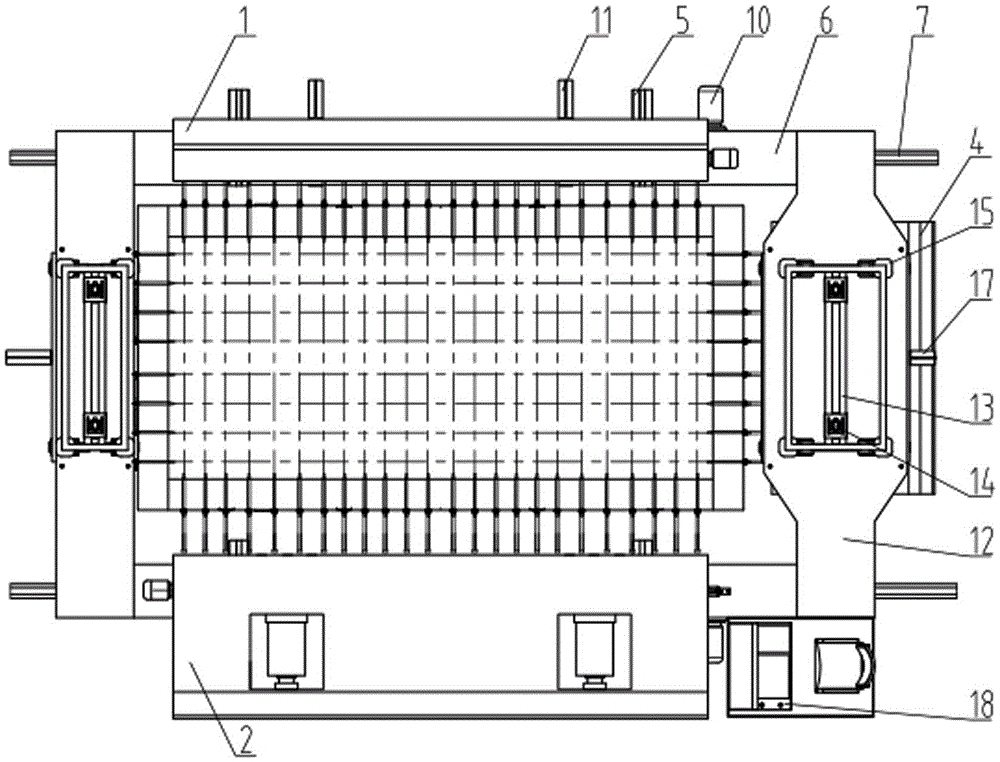

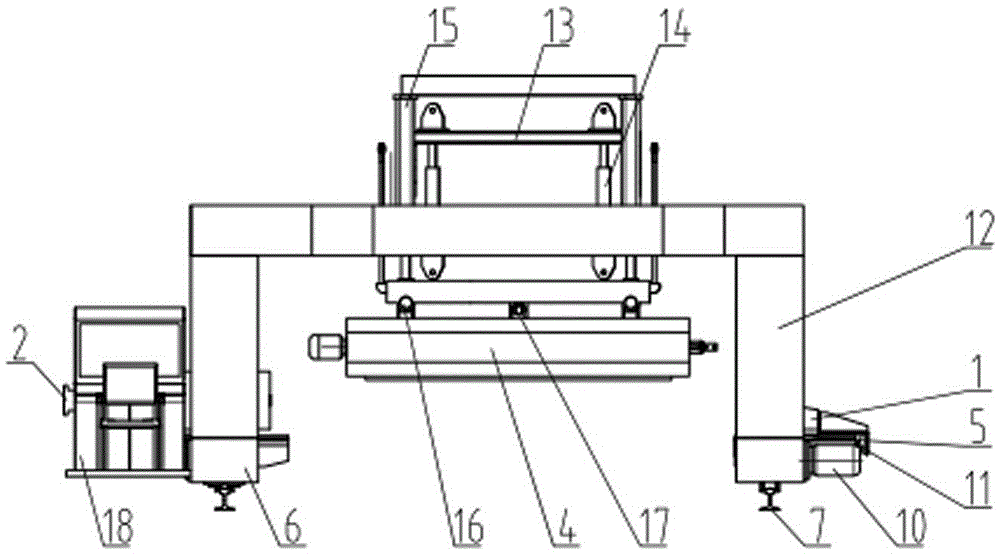

[0022] Such as figure 1 , figure 2 and image 3 , the bidirectional pre-tensioned prestressed ballastless track slab mobile tensioning equipment includes side pre-locking beam 1 and side tension beam used for stretching the vertical and horizontal bidirectional prestressed steel bars of CRTSⅢ bidirectional pretensioned prestressed ballastless track slab 2. End pre-lock beam 3 and end tension beam 4. The side pre-locking beam 1 and the side tensioning beam 2 are respectively assembled on the two walking beams 6 through a pair of side beam linear guide rails 5, and the side pre-locking beam 1 is relatively parallel to the side tensioning beam 2 and the two running beams 6. Setting, a pair of side beam linear guide rails 5 above each walking beam 6 are arranged in parallel, and the axis of the side beam linear guide rails 5 is perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com