Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Safe stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

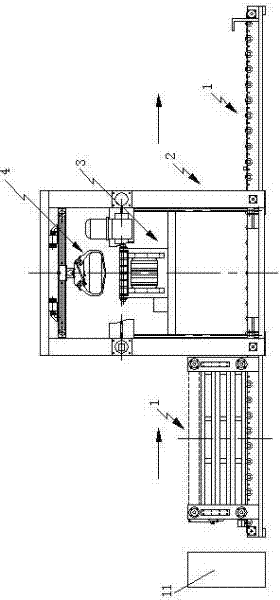

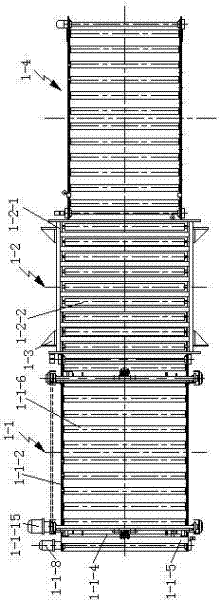

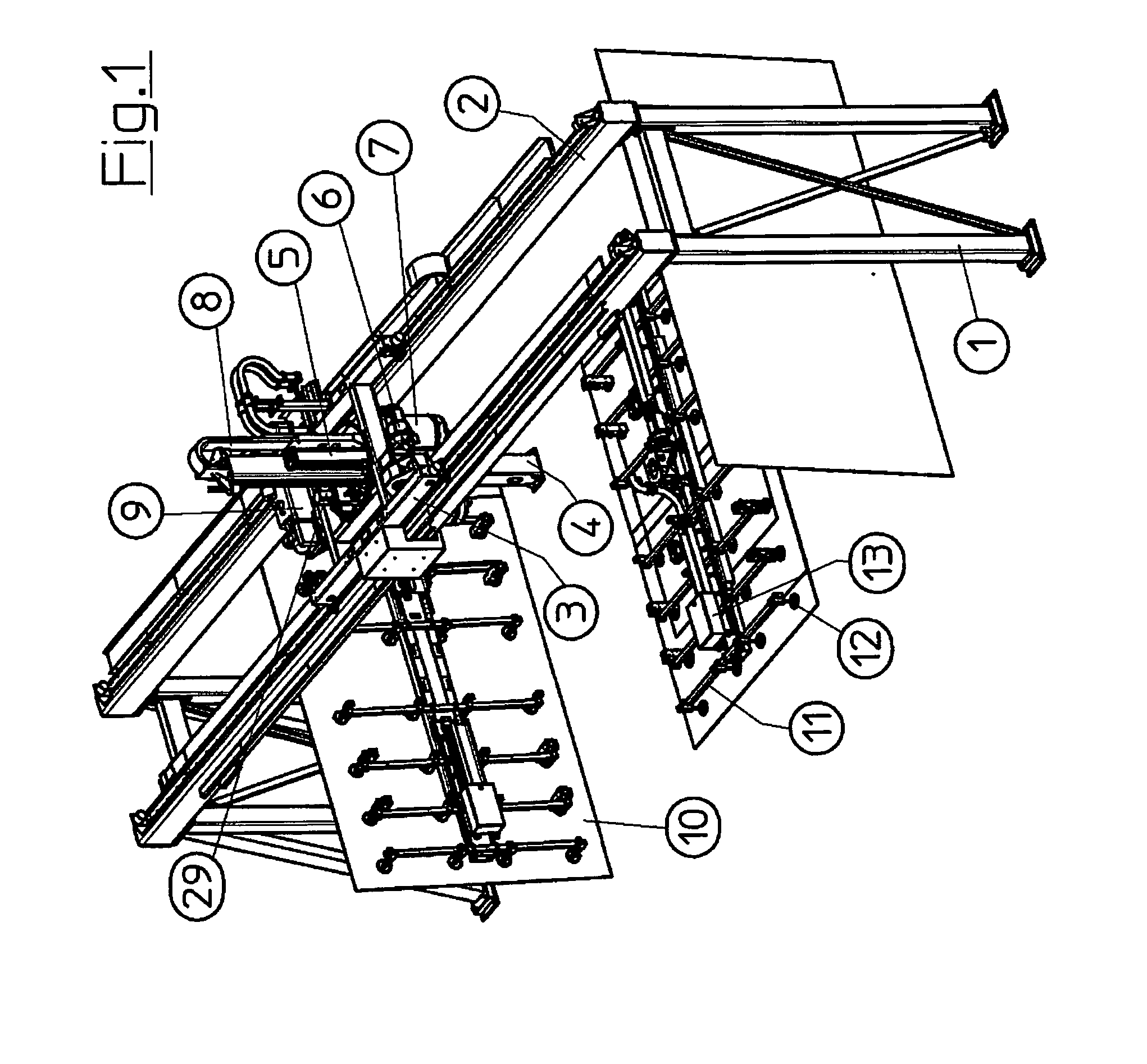

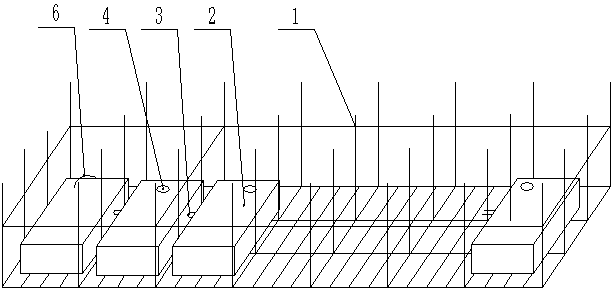

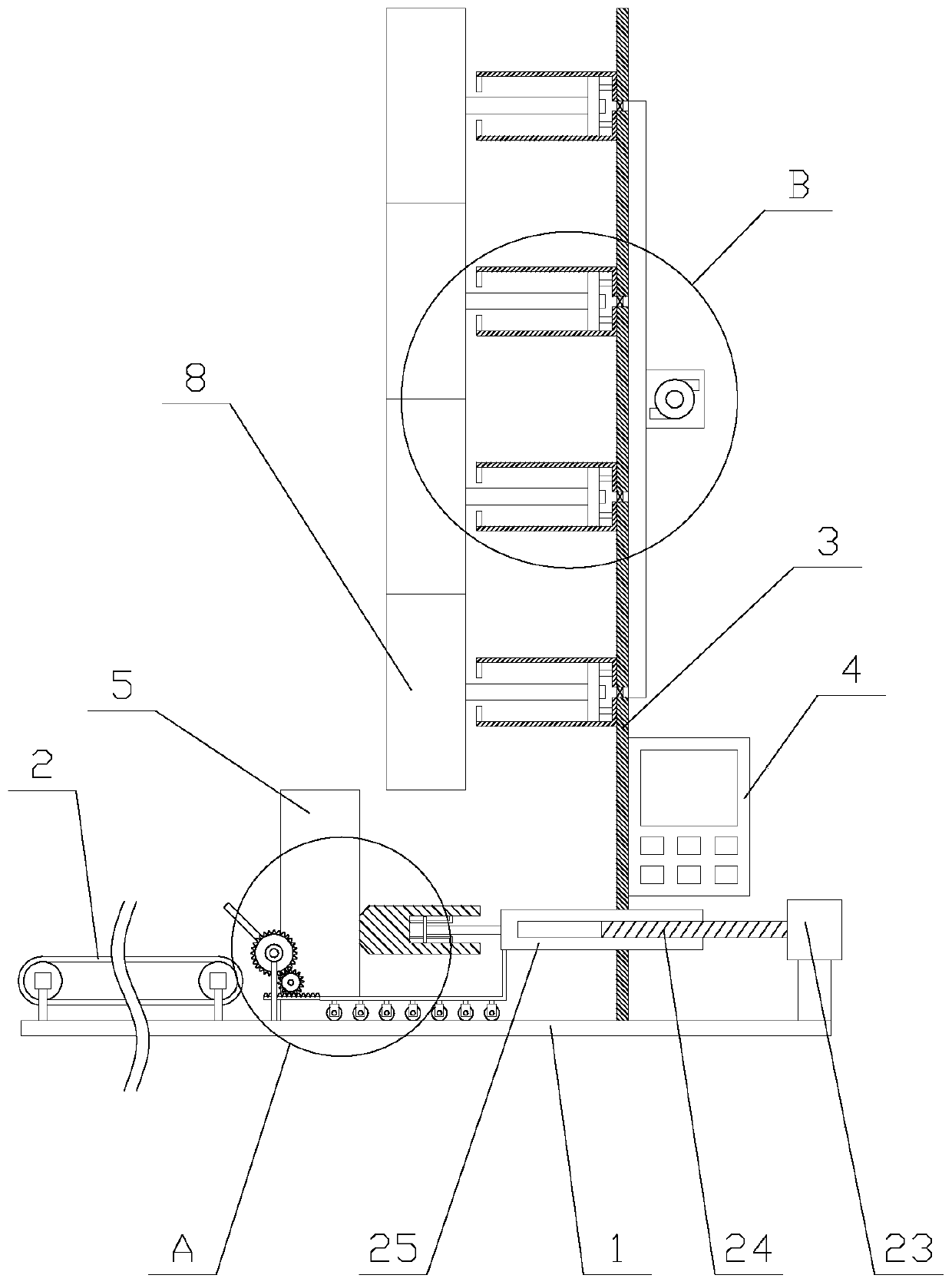

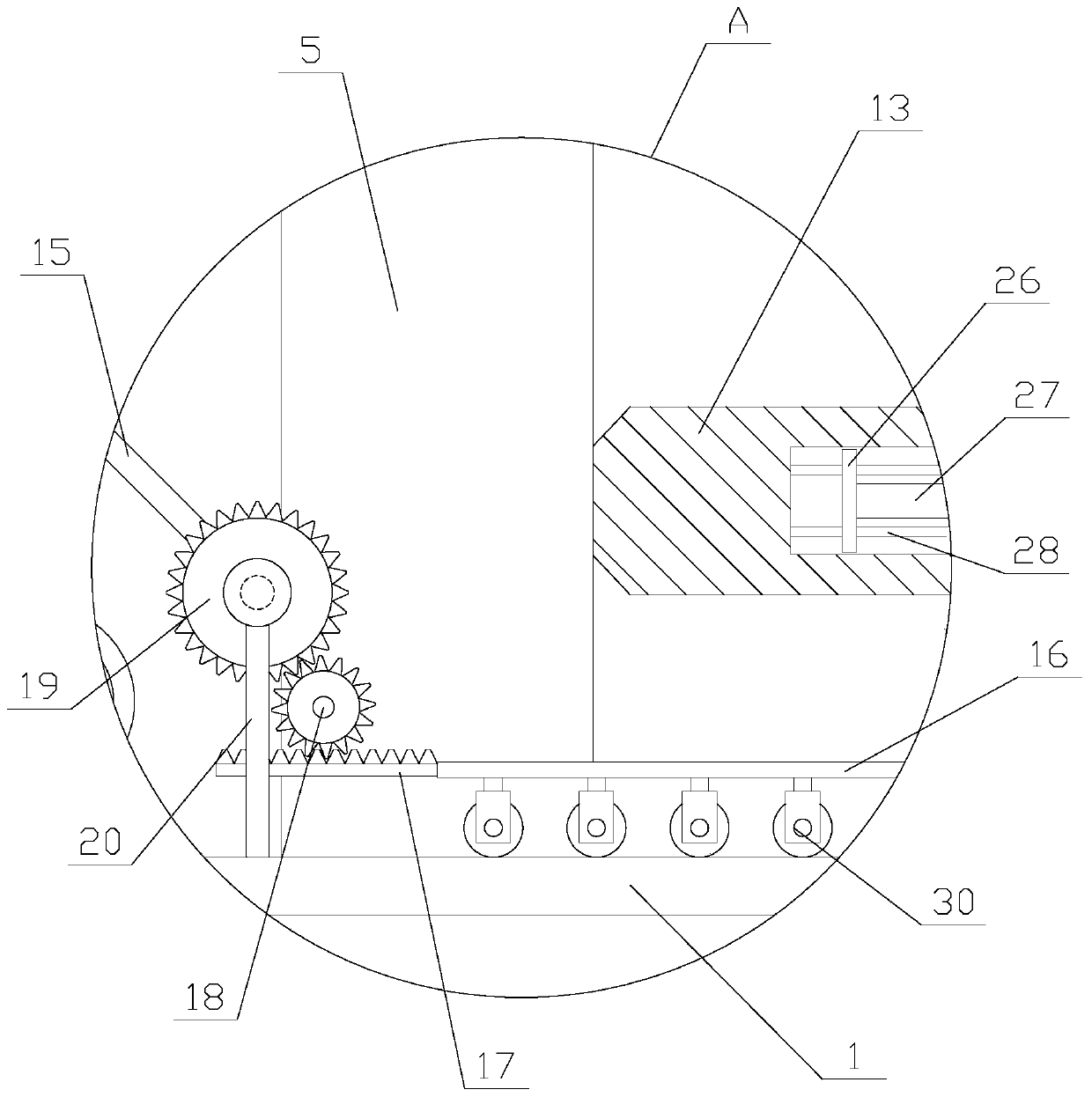

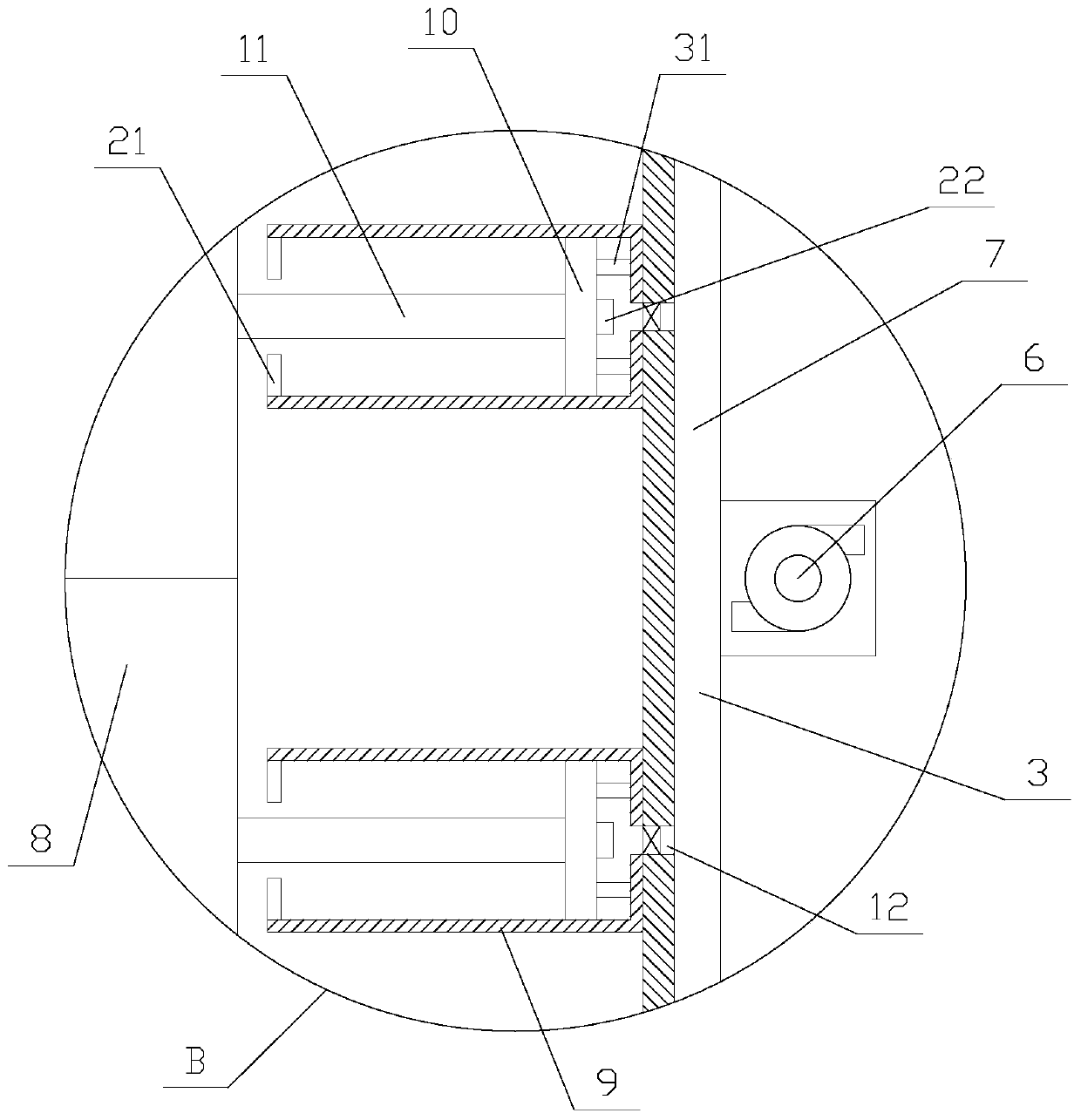

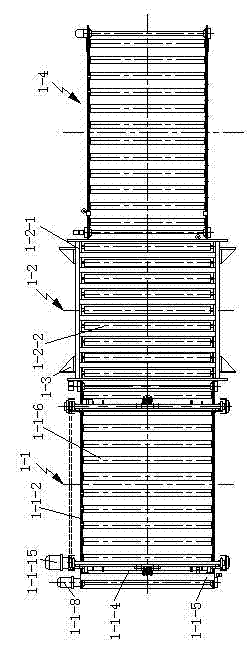

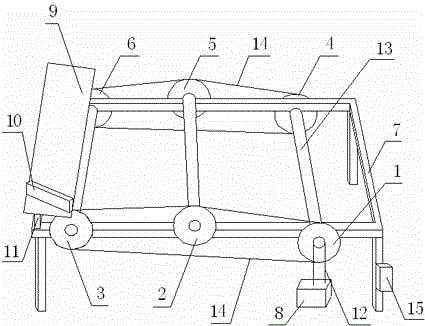

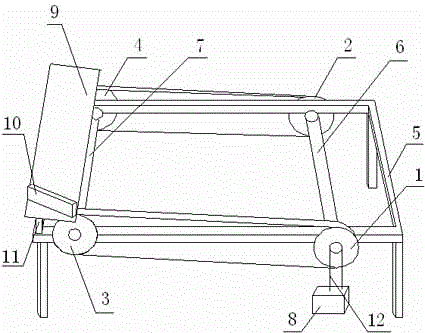

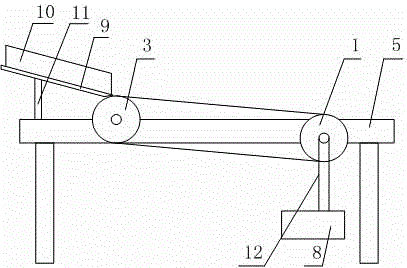

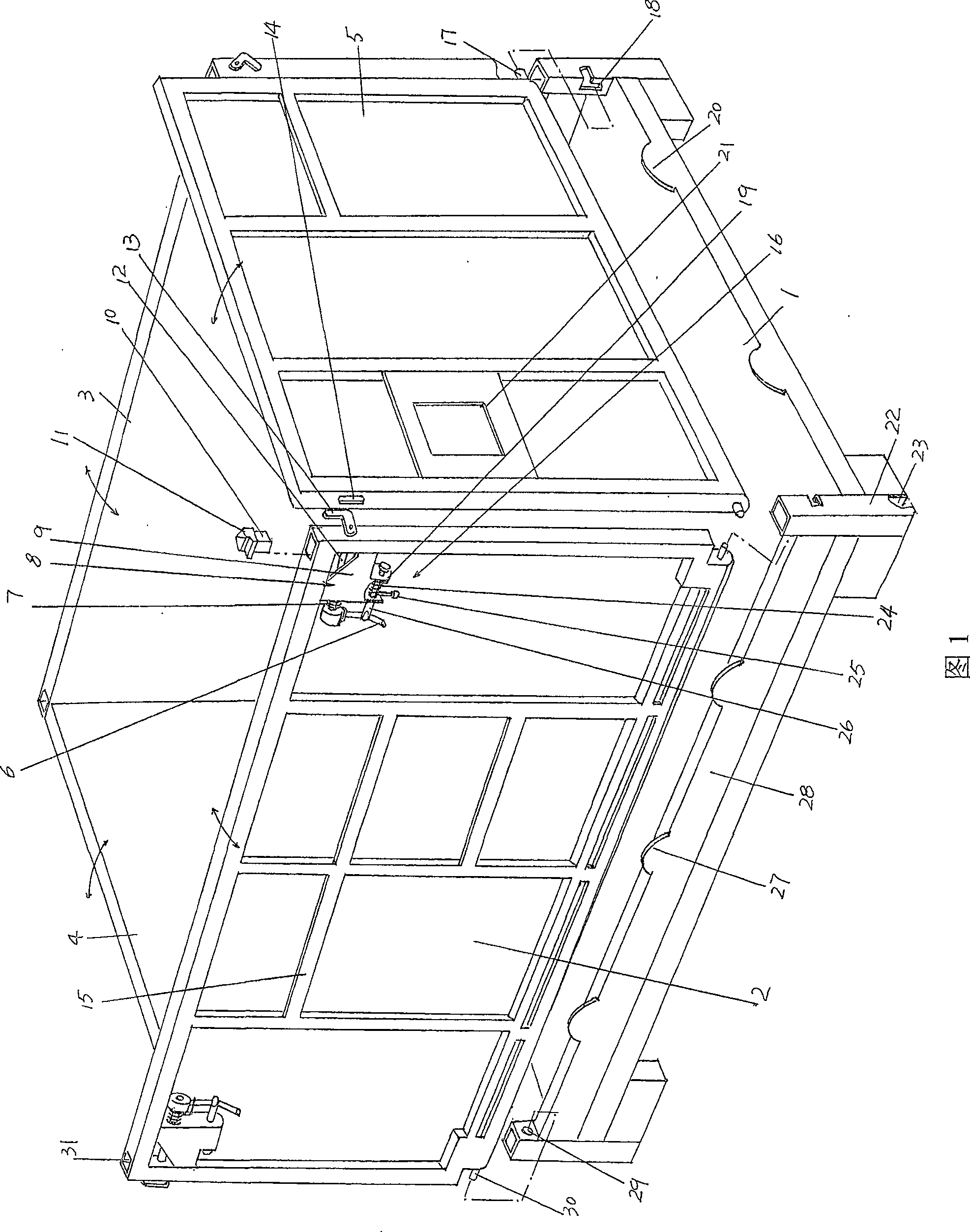

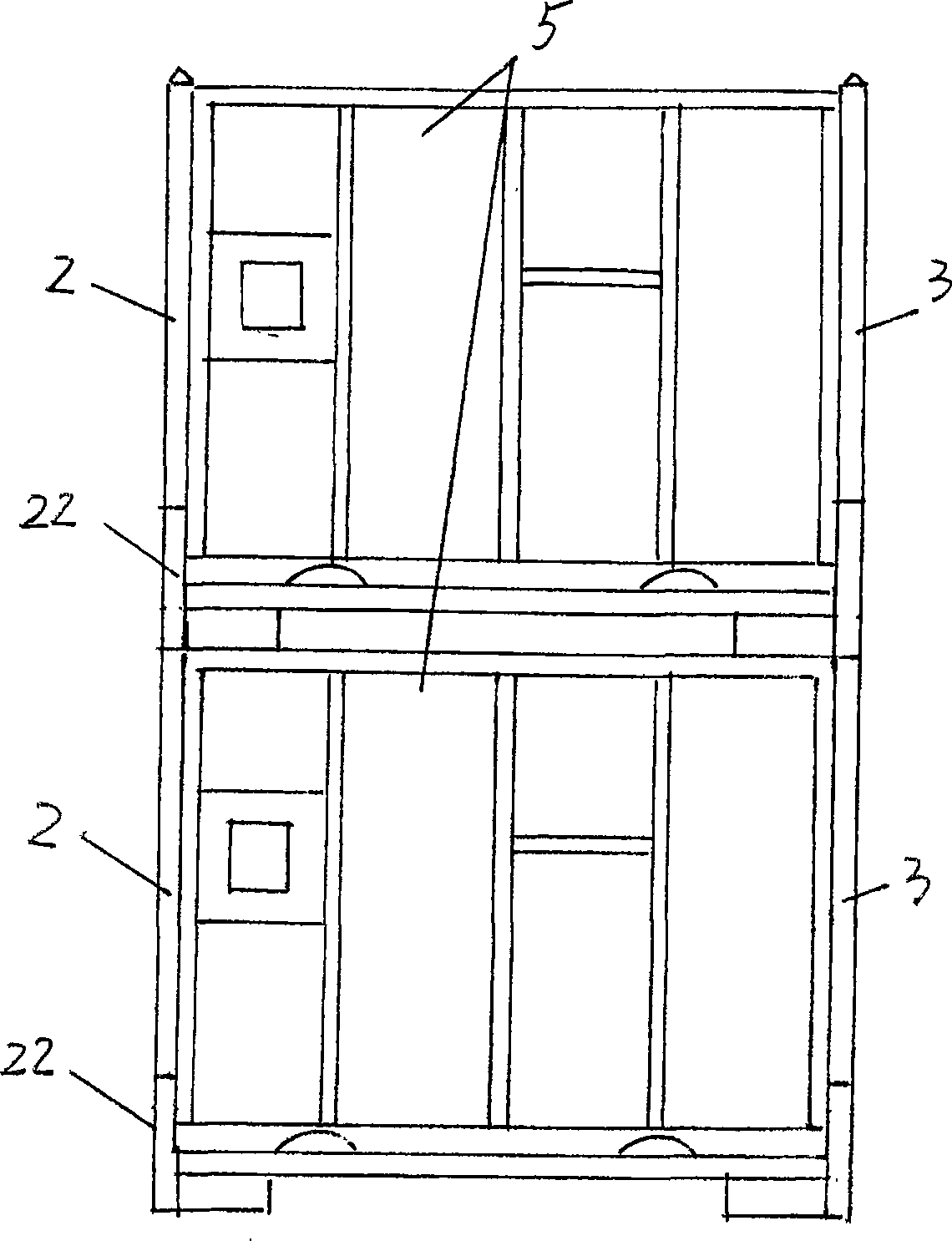

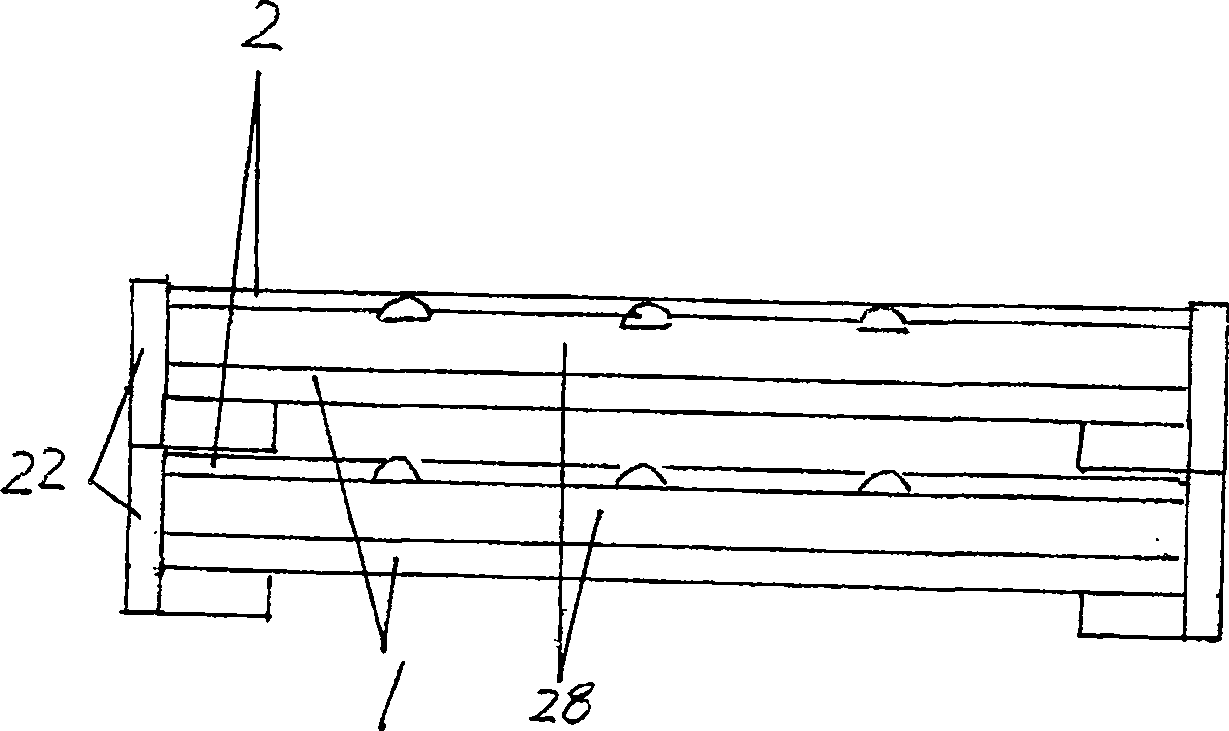

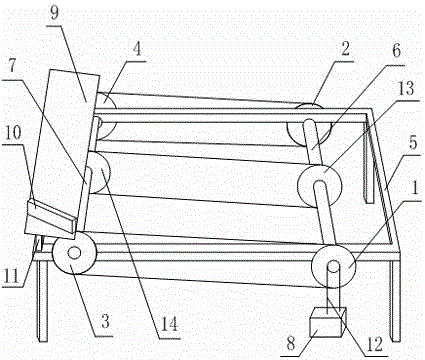

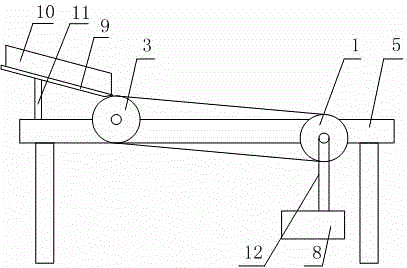

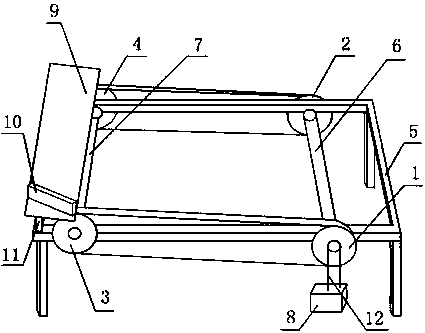

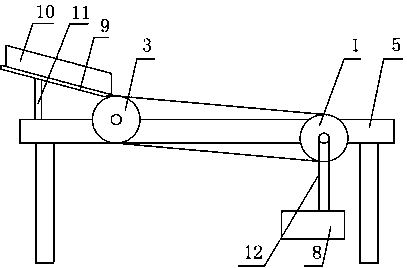

Stacking machine

InactiveCN102358519AStabilize the palletizing processReliable palletizing processStacking articlesStack machineMaterial resources

The invention relates to a stacking machine of bagged objects, comprising a stacking device, a tray lifting, propelling and conveying device, a mechanical arm and a bag supporting device, wherein the tray lifting, propelling and conveying device consists of a tray feeding device and an out-stacking conveying device; the stacking device is arranged between the tray feeding device and the out-stacking conveying device; the stacking device is in transmission connection with the mechanical arm; the bag supporting device is arranged at one side of the stacking device; the tray feeding device comprises a rack, a conveying frame, a lifting mechanism, a lifting beam and a pushing rod; the mechanical arm comprises a rotating motor, a plurality of grabbing fingers and a grabbing palm, the grabbing palm is fixedly provided with a driving cylinder which is provided with a piston rod in transmission connection with one rotating shaft on the grabbing palm through a rotating block, and each rotatingshaft is fixedly provided with a plurality of the grabbing fingers. The stacking machine provided by the invention is simple in structure, smooth in action, capable of continuously finishing stackingwork of the bagged objects in the automatic production process, saving in manpower and material resources and high in stacking efficiency.

Owner:溧阳市元创智能设备有限公司

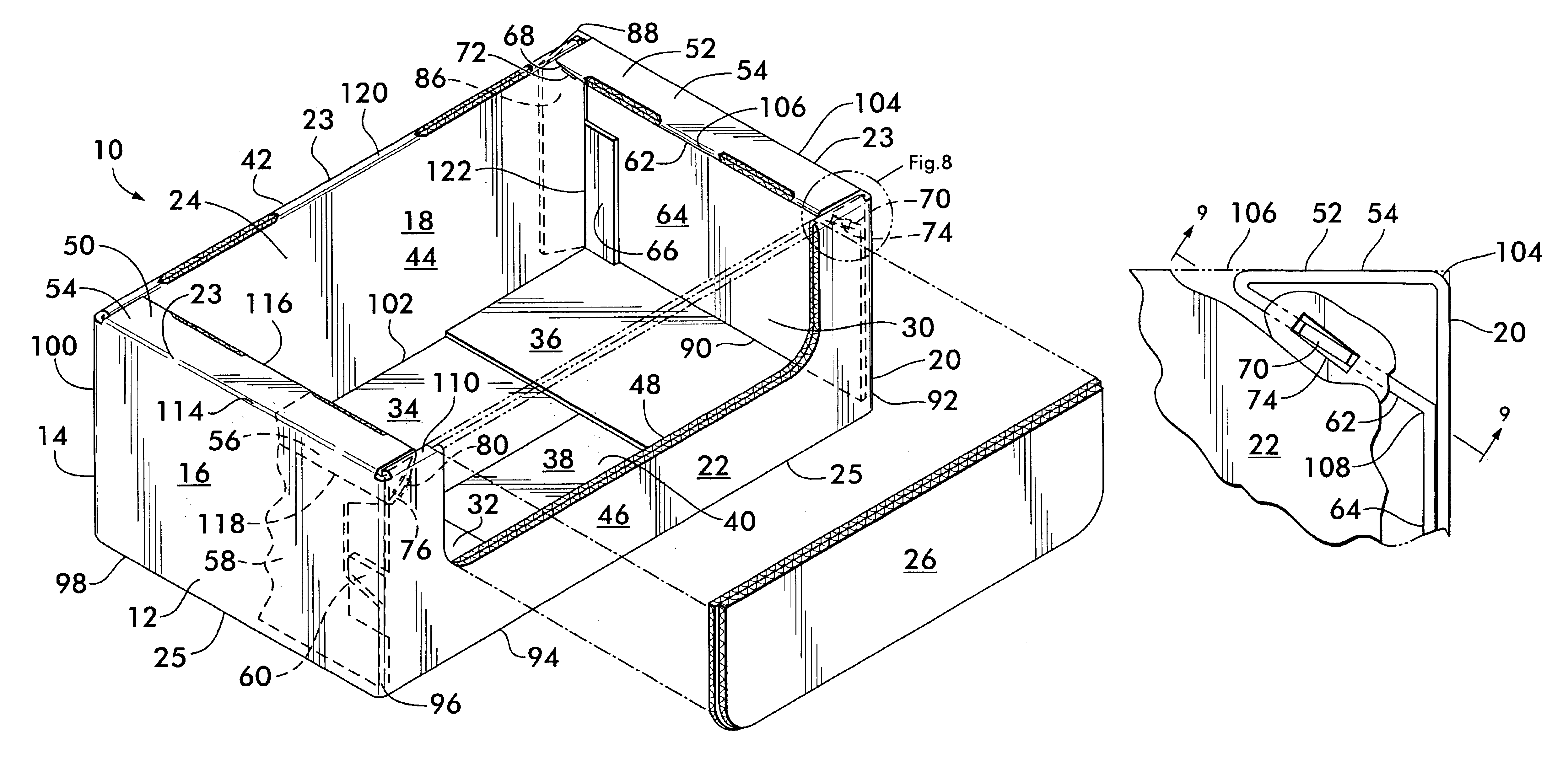

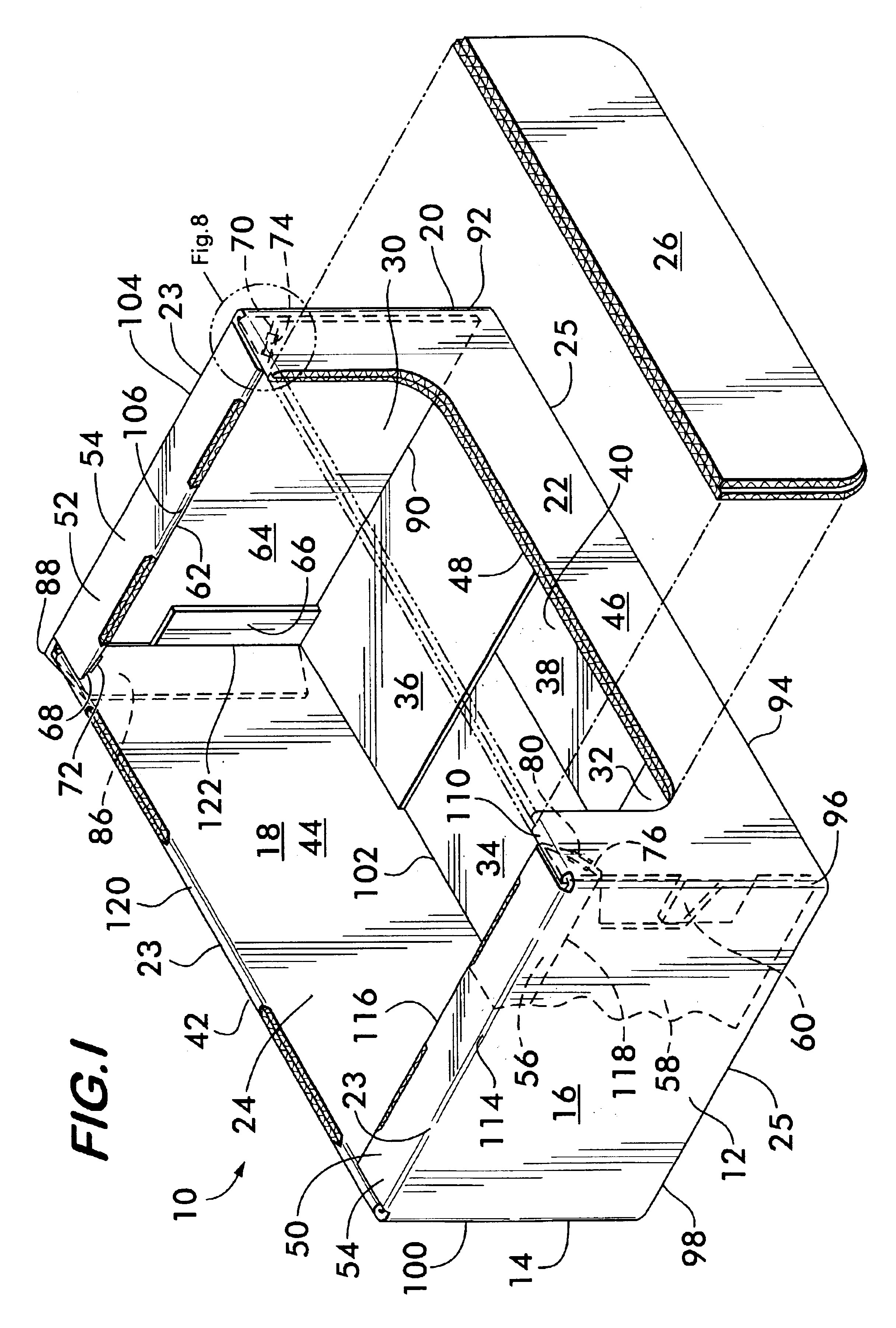

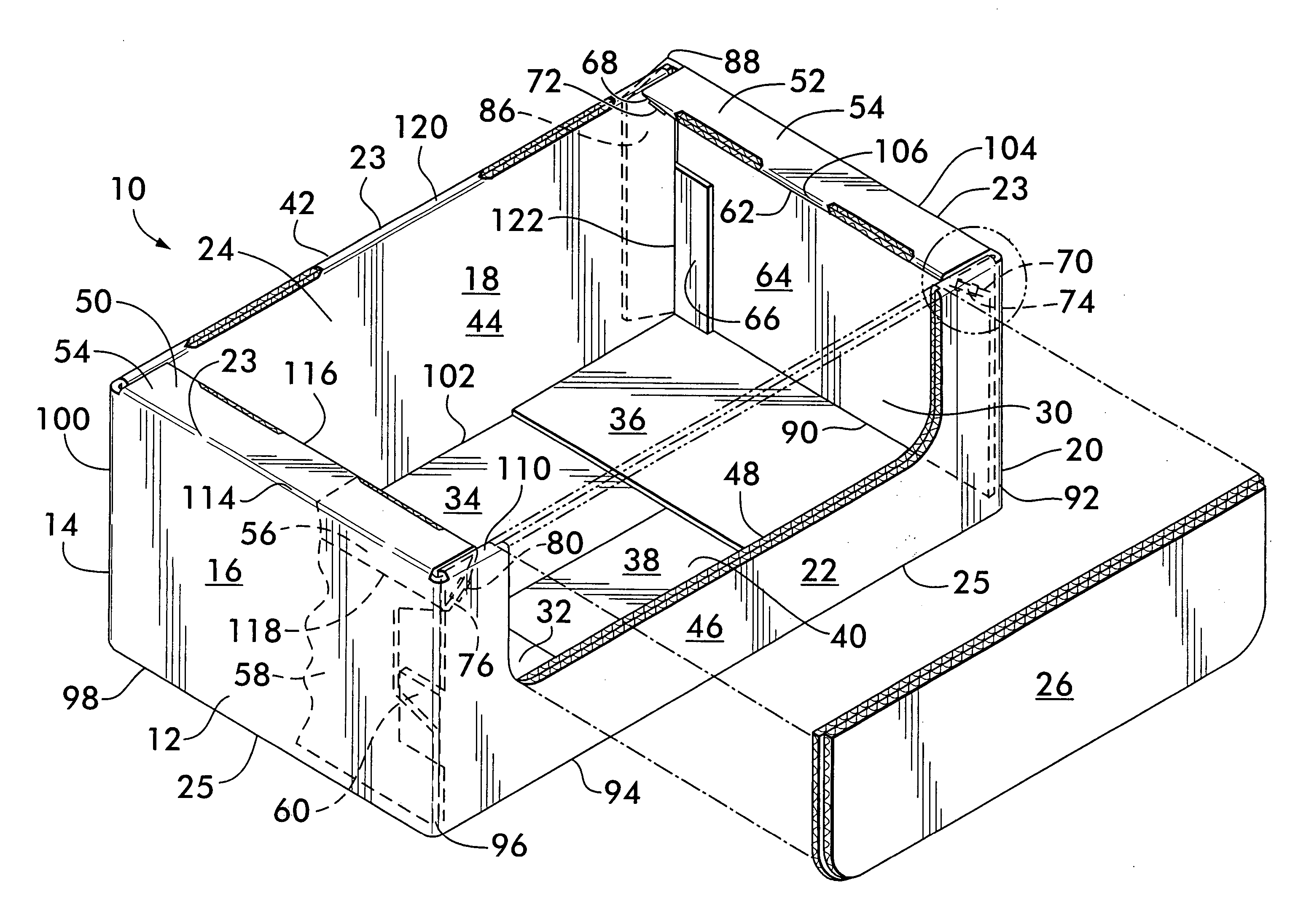

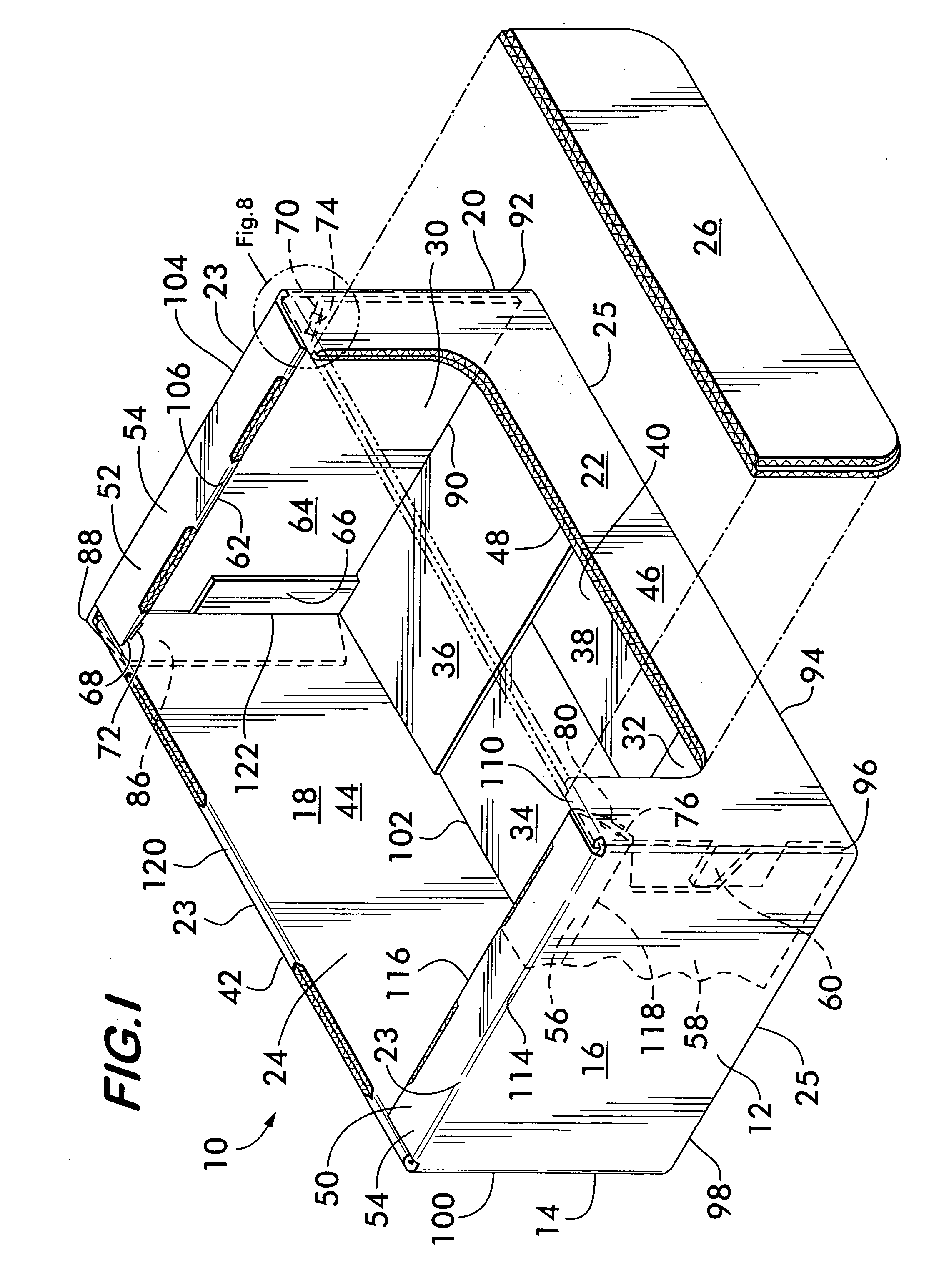

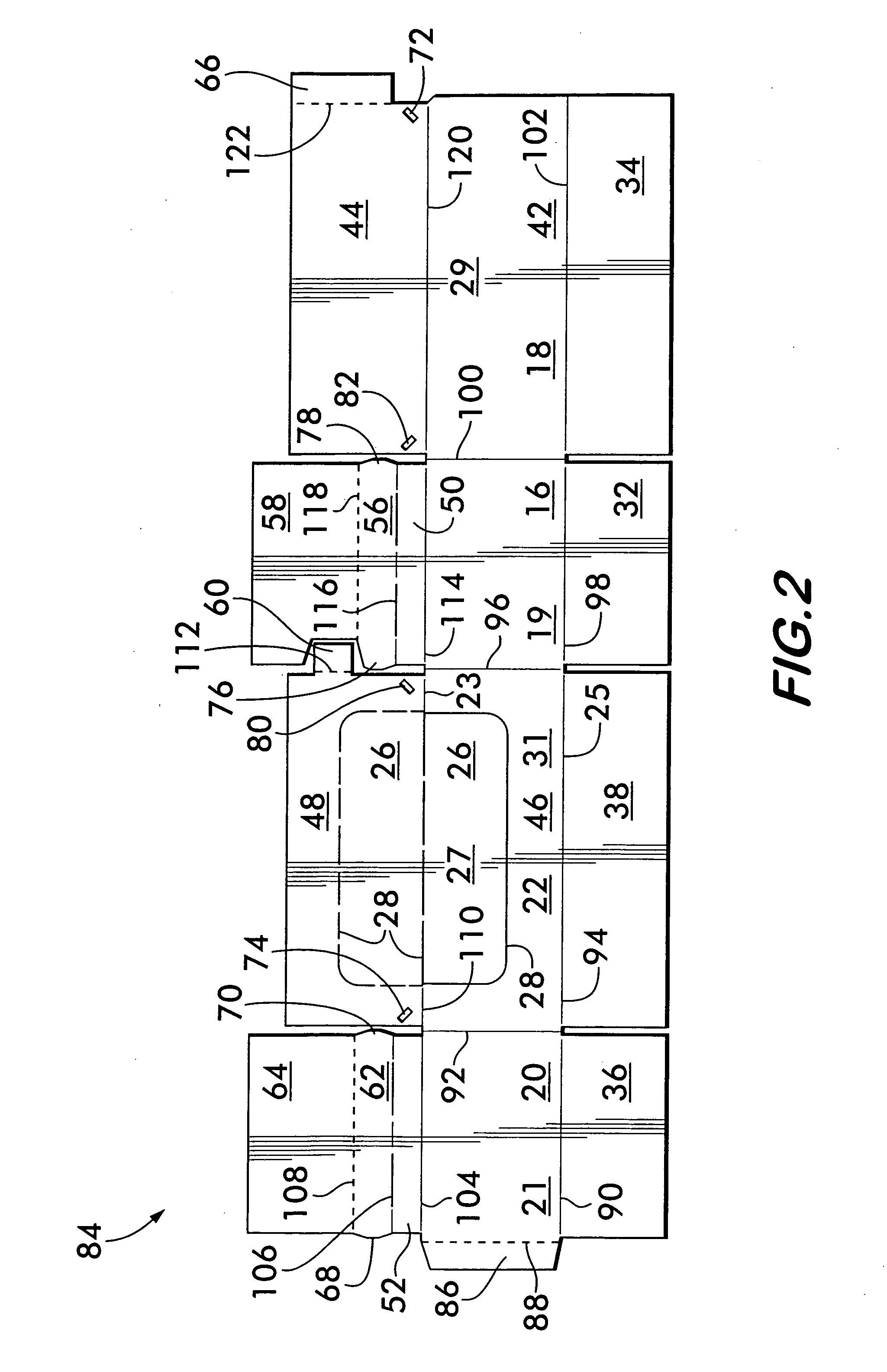

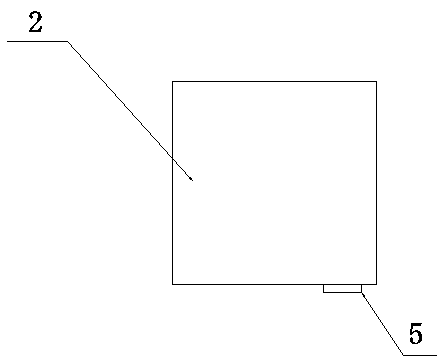

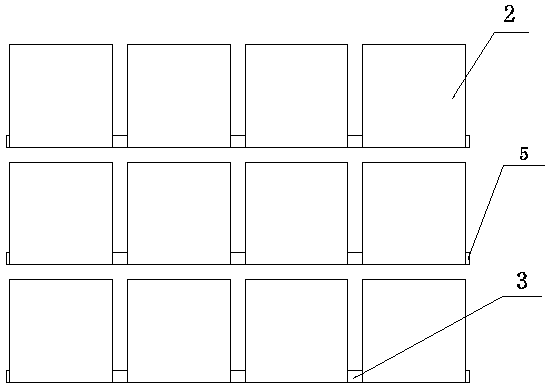

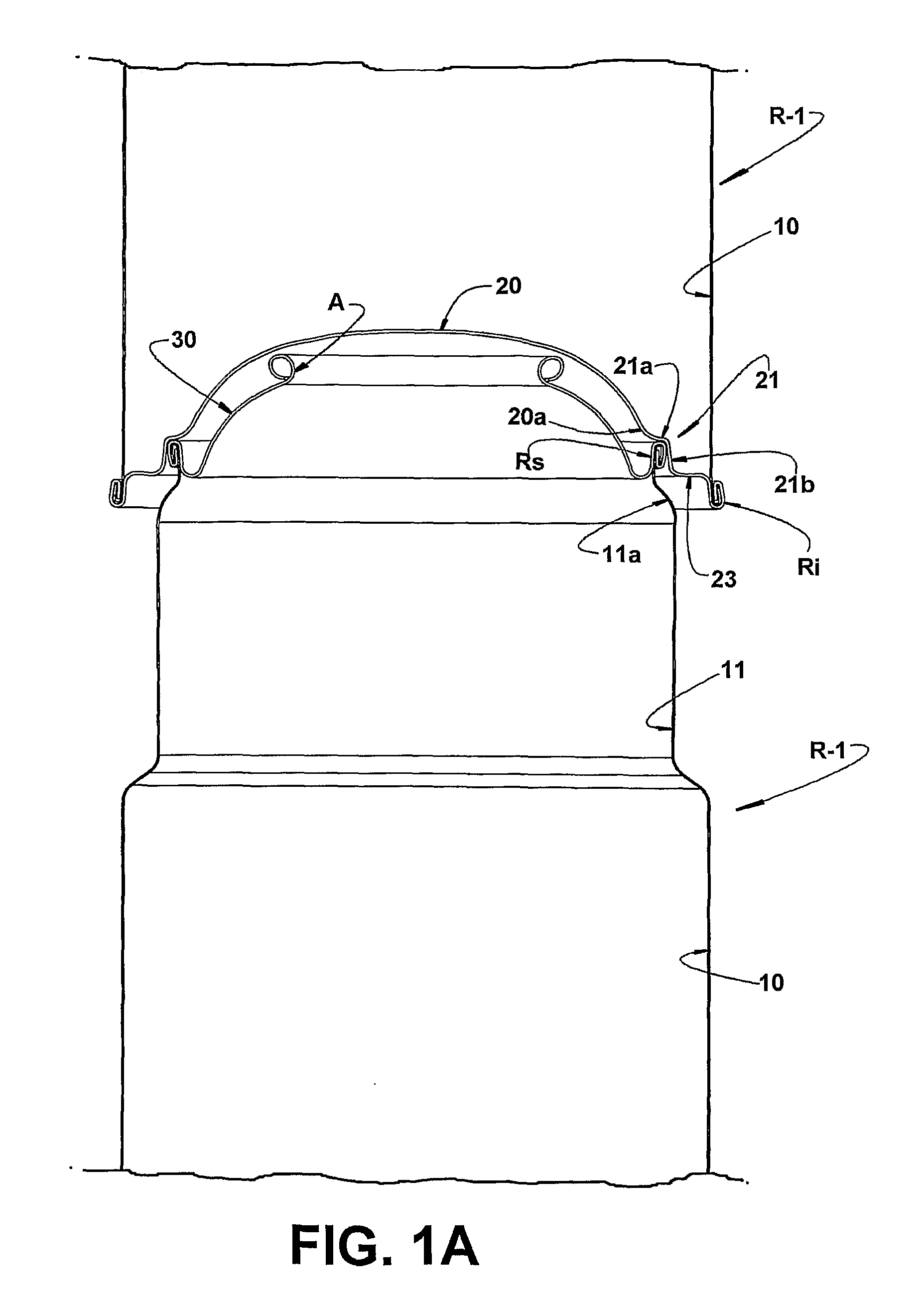

Stackable container with support flanges

InactiveUS6948617B2Easy to optimizeLow production costContainer/bottle contructionTray containersEngineeringTroffer

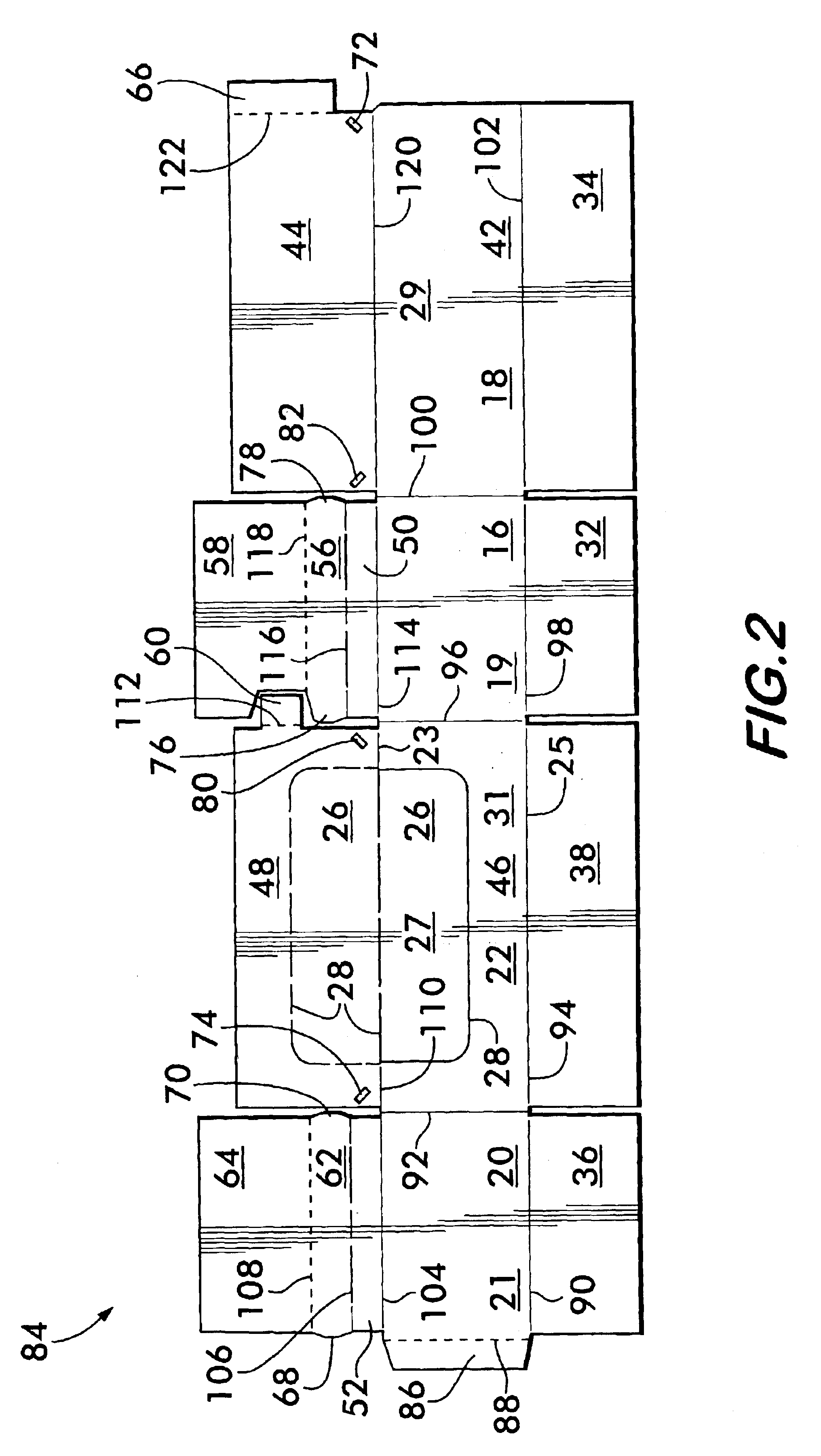

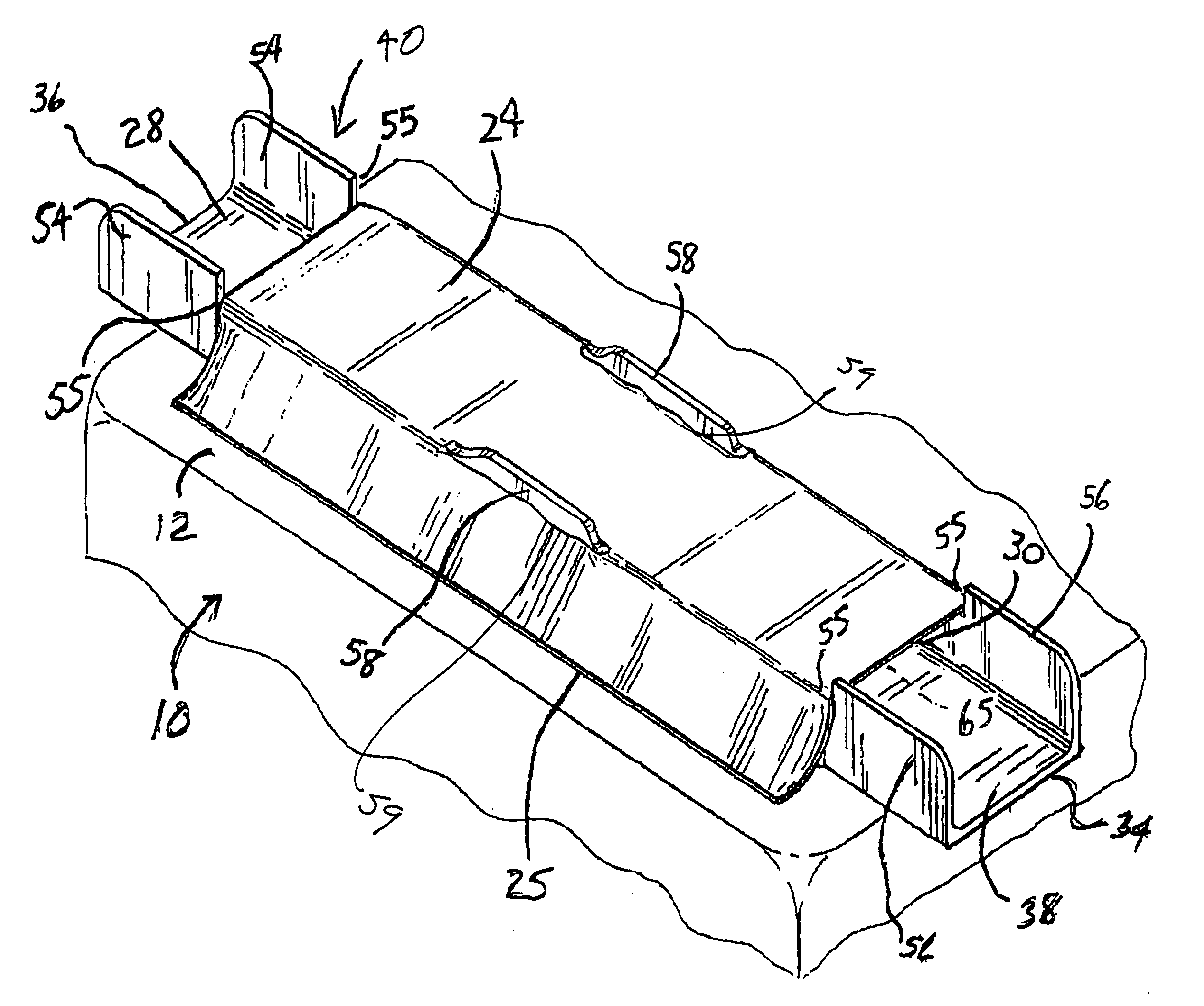

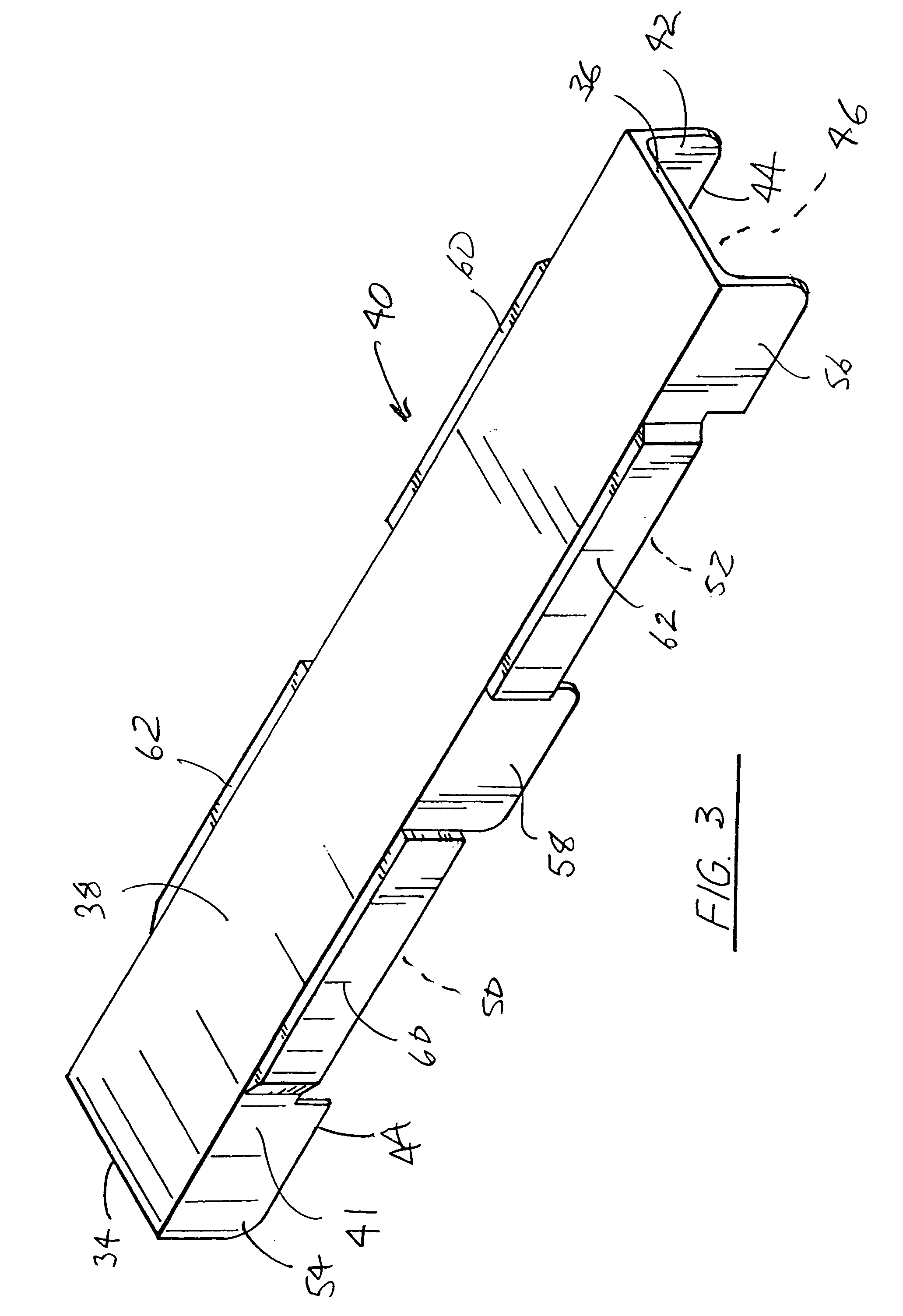

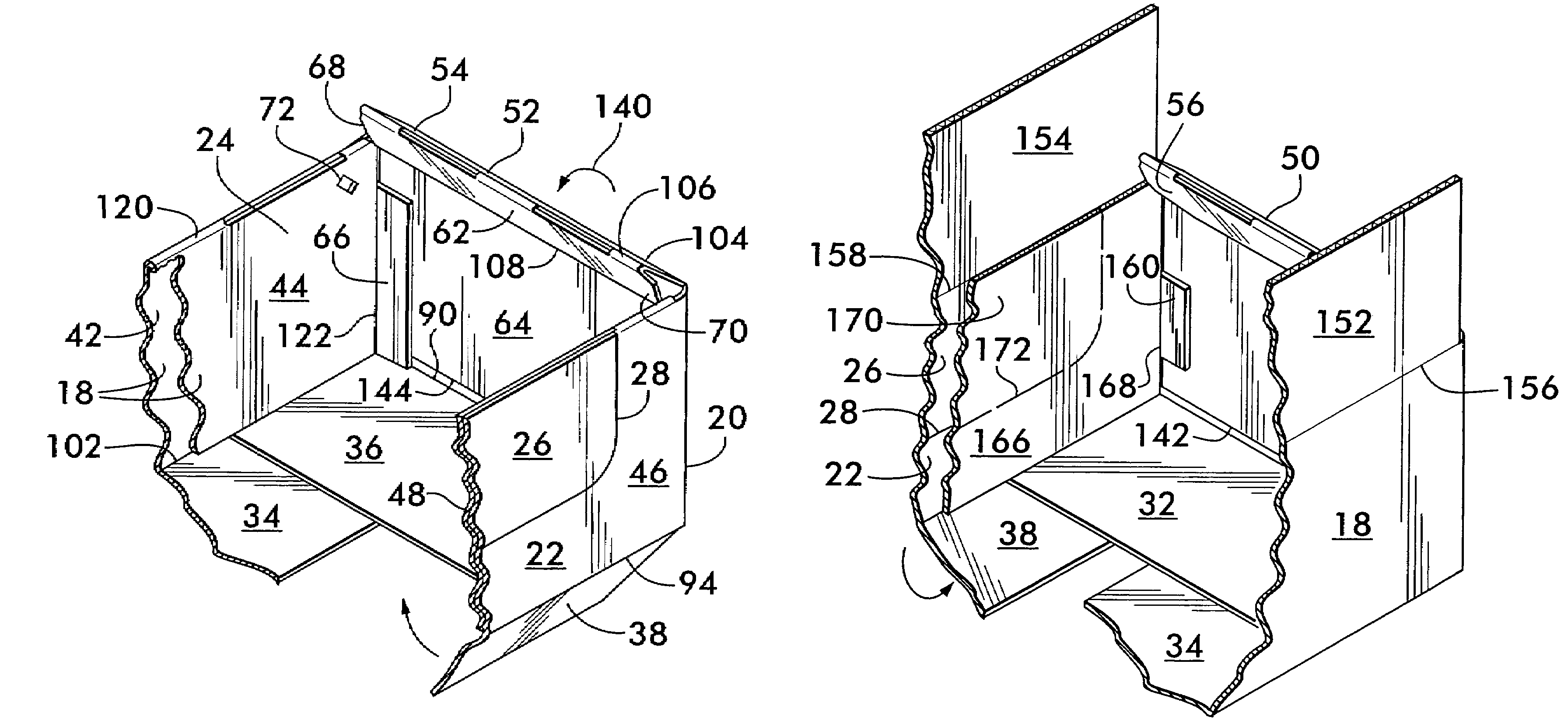

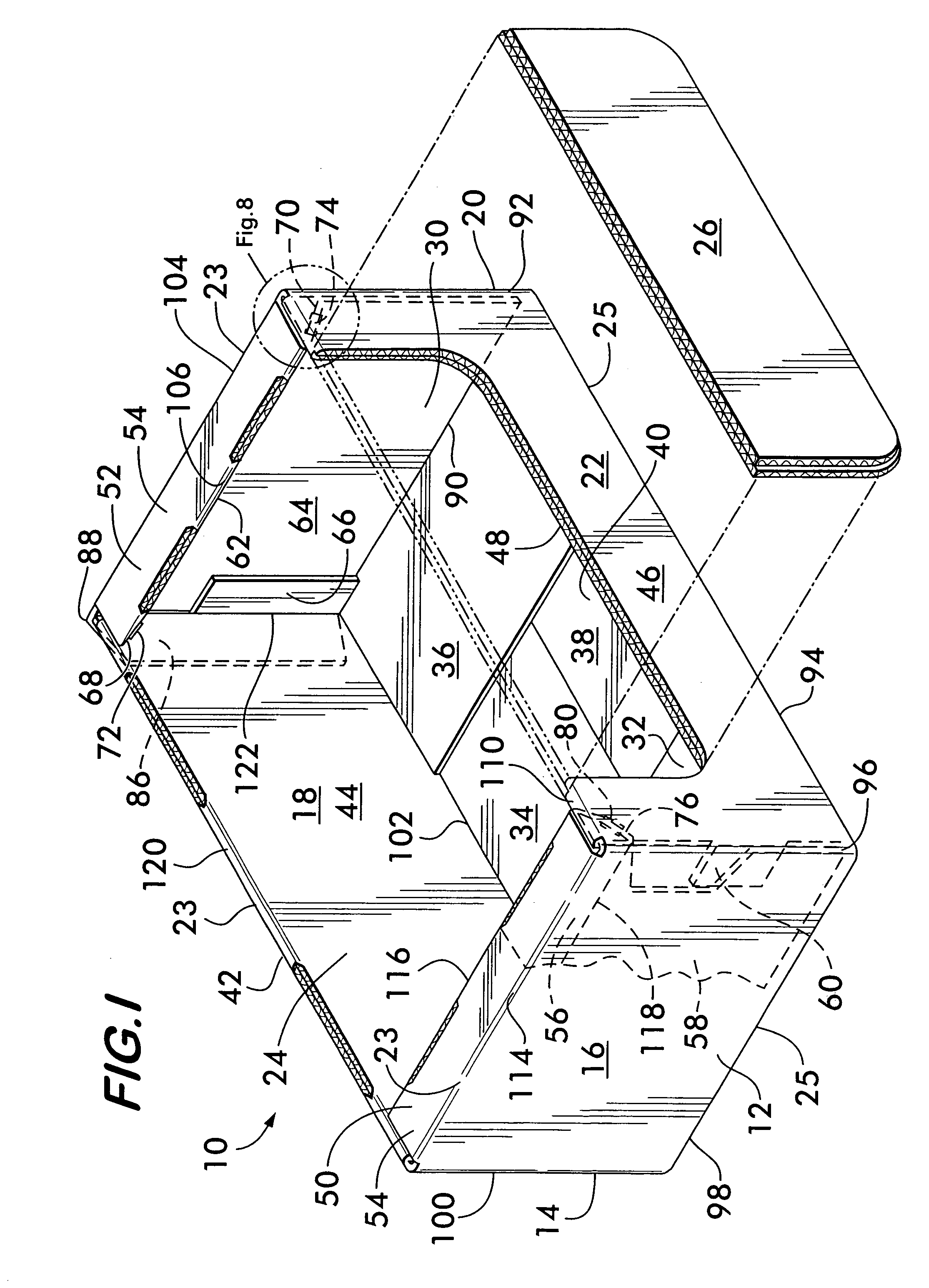

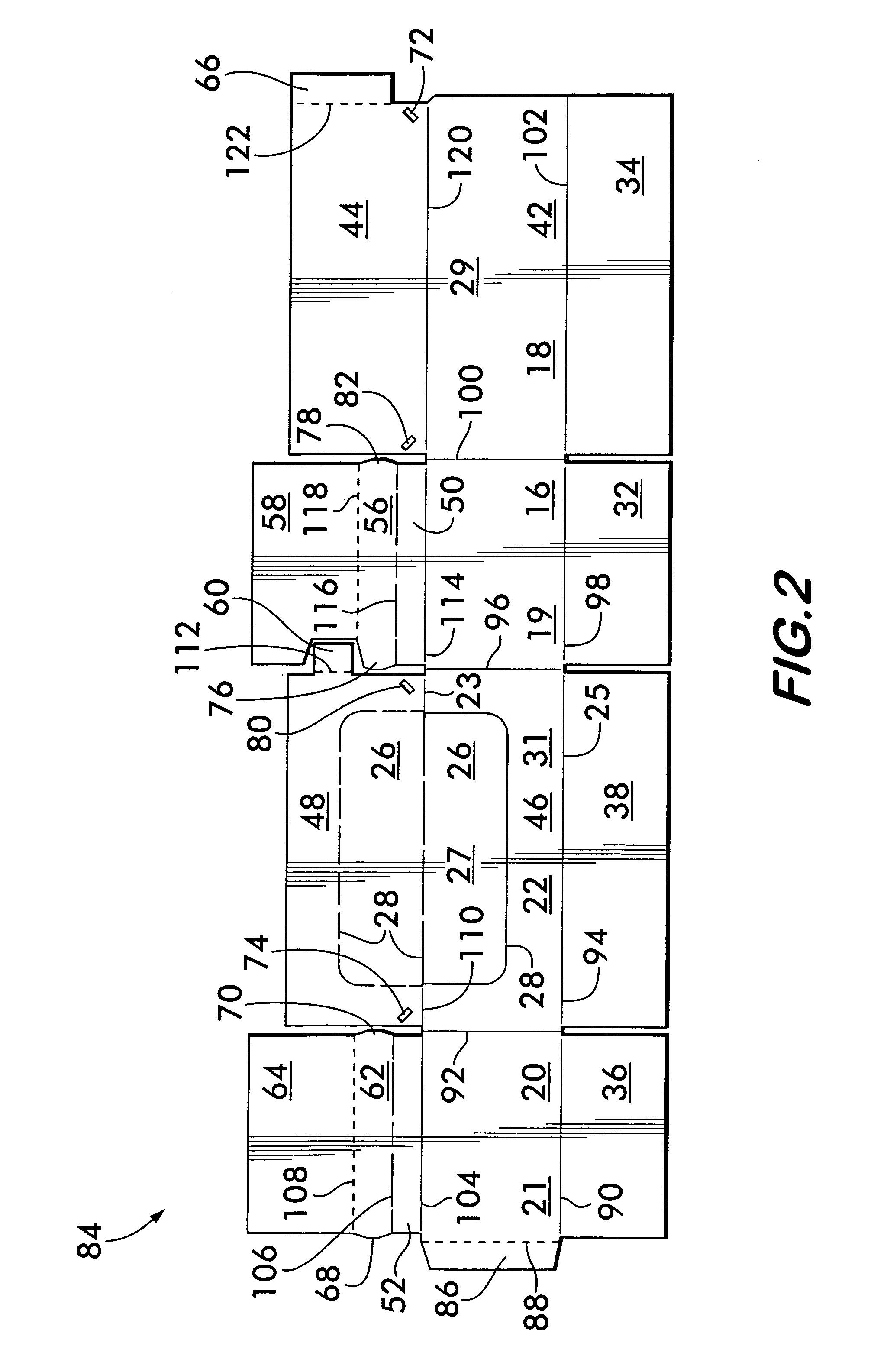

A container is disclosed having a plurality of interconnected panels forming sidewalls surrounding a central space. Flaps extend from lower sidewall edges and fold along fold lines to form a bottom. Support flanges are arranged along upper sidewall edges on oppositely facing sidewalls. The support flanges are oriented at right angles to the sidewalls and provide a support surface allowing the containers to be stacked one atop another without collapsing or nesting within each other. Each support flange is supported by a truss formed by a panel segment extending angularly from the support flange to a support panel biased against the sidewall to which the support flange is attached by a retaining flap extending from an inner sidewall layer. Locking tabs at the ends of each panel segment are received within recesses positioned in sidewall panels perpendicular to the support flanges. The container is transformed from a knockdown formed from a unitary blank.

Owner:ROYAL BOX GRP LLC

Bulk bag pallet tube apparatus

InactiveUS6926144B1Inexpensively moldEasily position into and removeLarge containersOther accessoriesEngineeringPallet

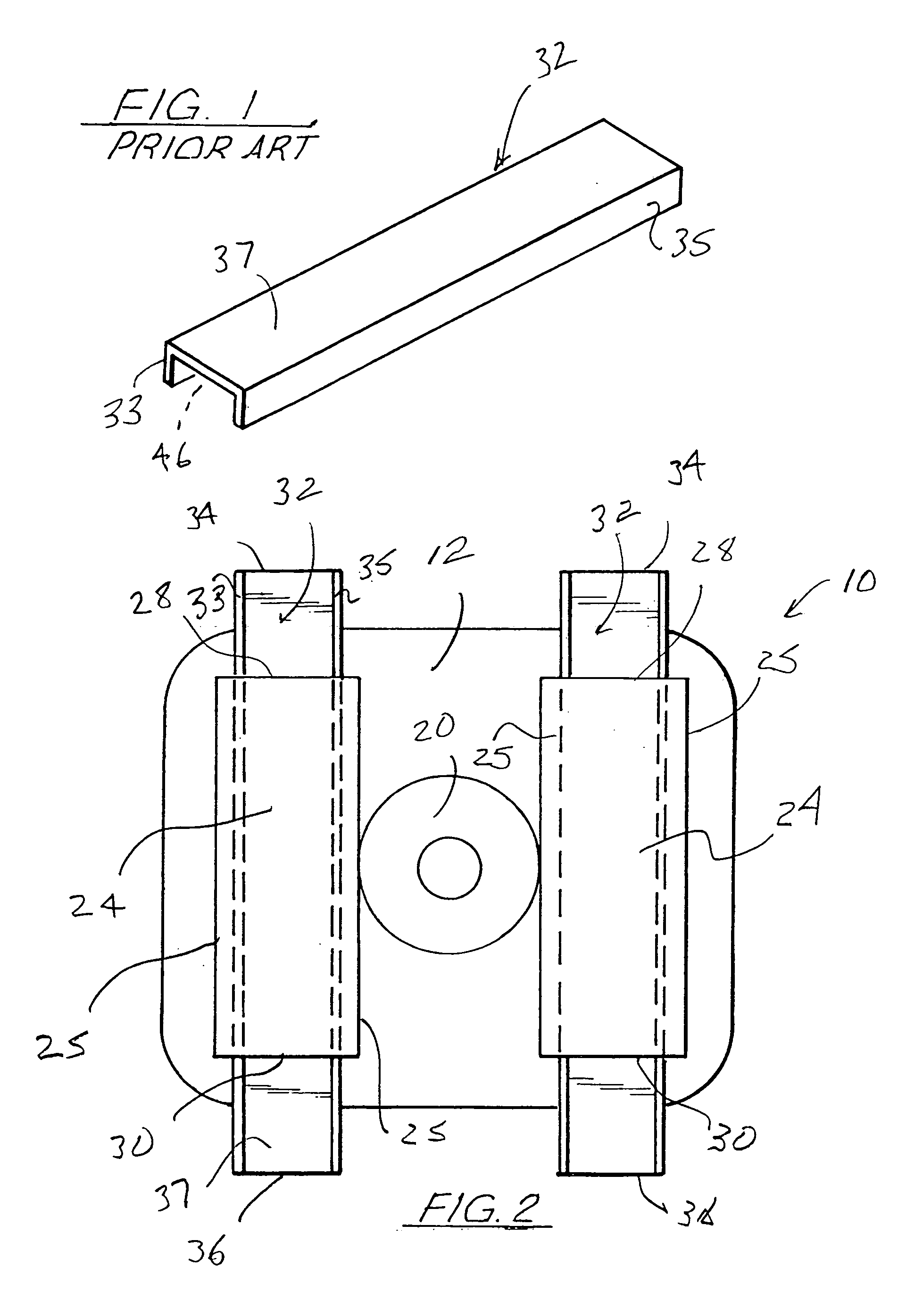

An improved fabric bulk bag, of the type having wall portions, a top portion, and a floor portion, all defining a space for storing bulk therein, and further providing a pair of channels, substantially parallel in relation, secured along the outer surface of the floor portion, each channel having two open ends; a substantially elongated rigid U-shaped support member insertable into each channel, the upper wall of the member contacting the outer surface of the bulk bag, and the two arms of the U-shaped member providing a travel space through the channel for receiving the tynes of a forklift, and allowing the tynes to contact the upper wall of the member when the bag is lifted; the two arms of the member also providing a stable pallet-like foundation for the bag when the bag is positioned atop another filled bag. There is further provided finger-like openings between the walls of the U-shaped member and the channels, to secure the edges of each channel to maintain the U-shaped member within each channel when the forklift tynes are engaging or disengaging from the channels. There is further provided blocks along the outer walls of the channel walls for filling any gaps between the fabric channels and the U-shaped members inserted therein.

Owner:SCHNAARS JR DANIEL R +1

Stackable container with support flanges

InactiveUS7331508B2Easy to optimizeLow production costContainer/bottle contructionRigid containersTrofferSupport surface

A container is disclosed having a plurality of interconnected panels forming sidewalls surrounding a central space. Flaps extend from lower sidewall edges and fold along fold lines to form a bottom. Support flanges are arranged along upper sidewall edges on oppositely facing sidewalls. The support flanges are oriented at right angles to the sidewalls and provide a support surface allowing the containers to be stacked one atop another without collapsing or nesting within each other. Each support flange is supported by a truss formed by a panel segment extending angularly from the support flange to a support panel biased against the sidewall to which the support flange is attached by a retaining flap extending from an inner sidewall layer. Locking tabs at the ends of each panel segment are received within recesses positioned in sidewall panels perpendicular to the support flanges. The container is transformed from a knockdown formed from a unitary blank.

Owner:ROYAL BOX GRP LLC

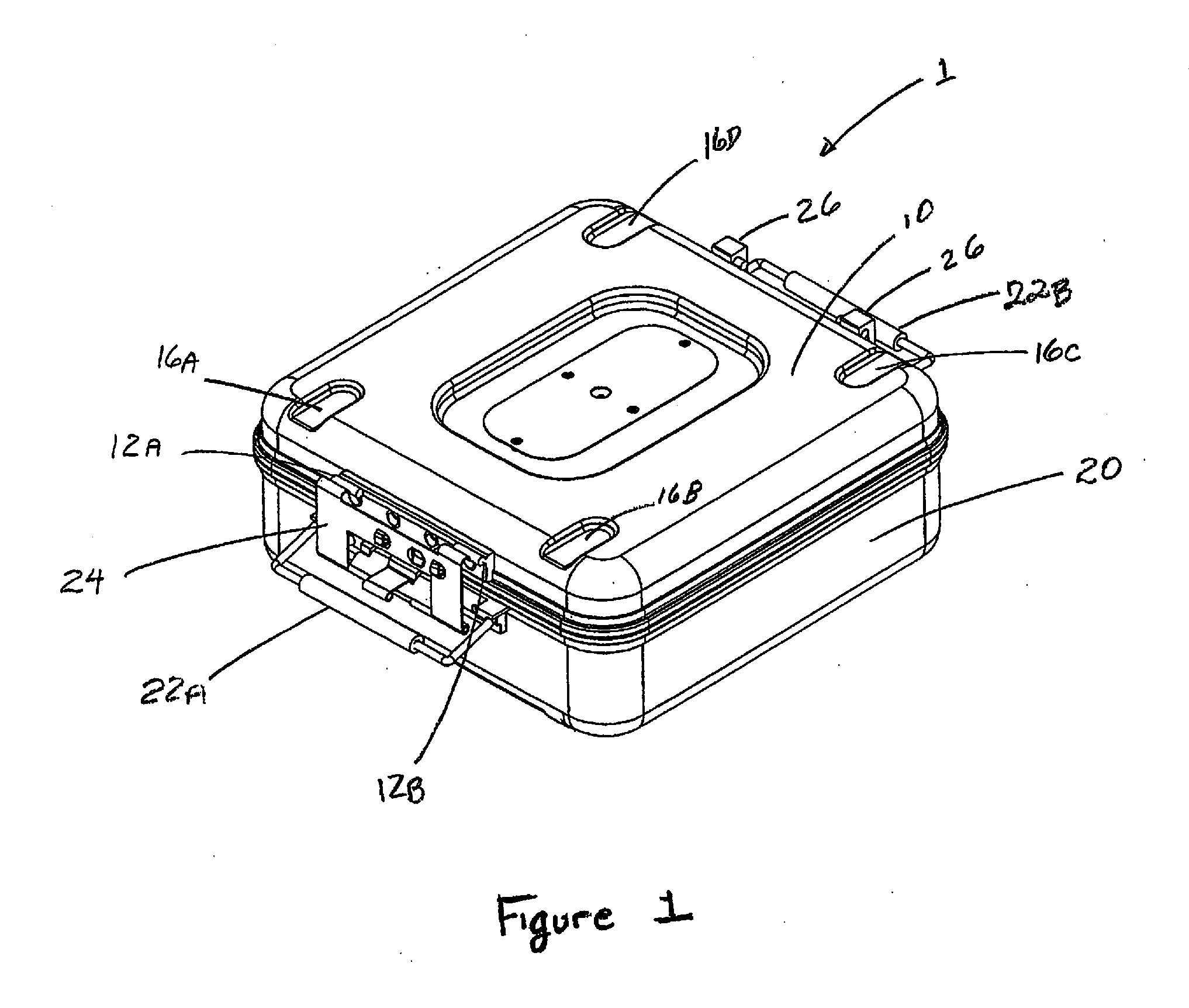

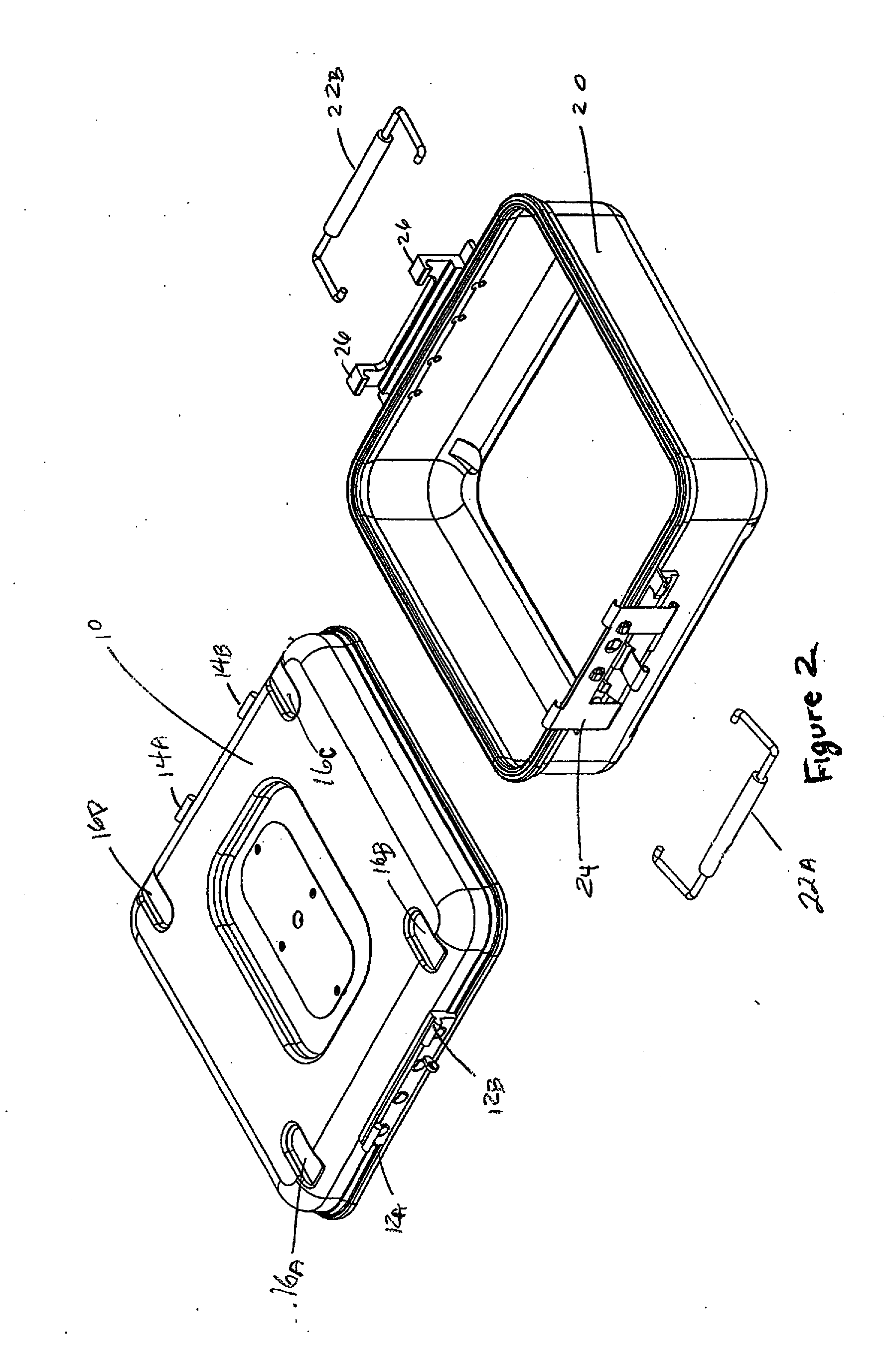

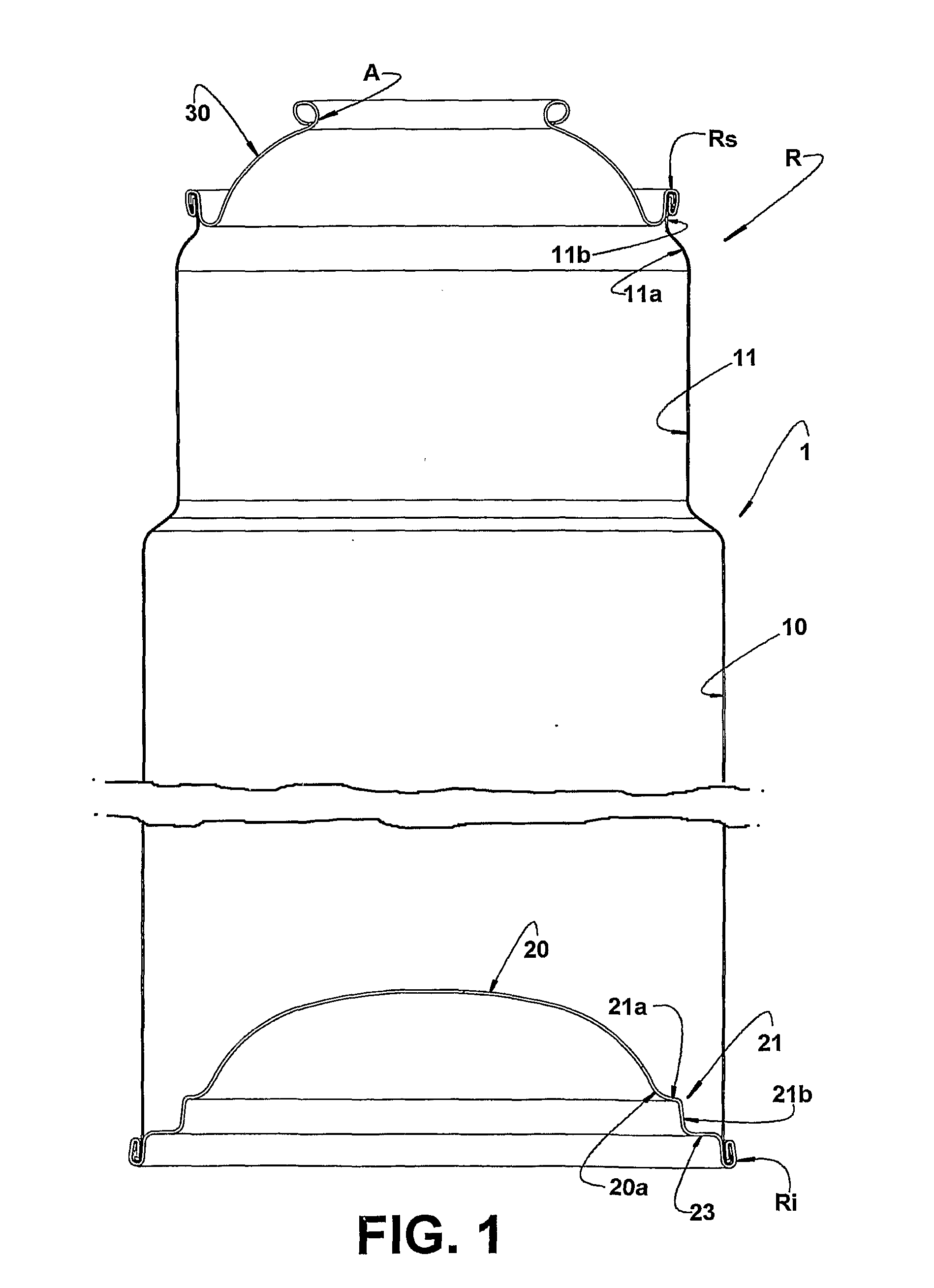

Sterilization container

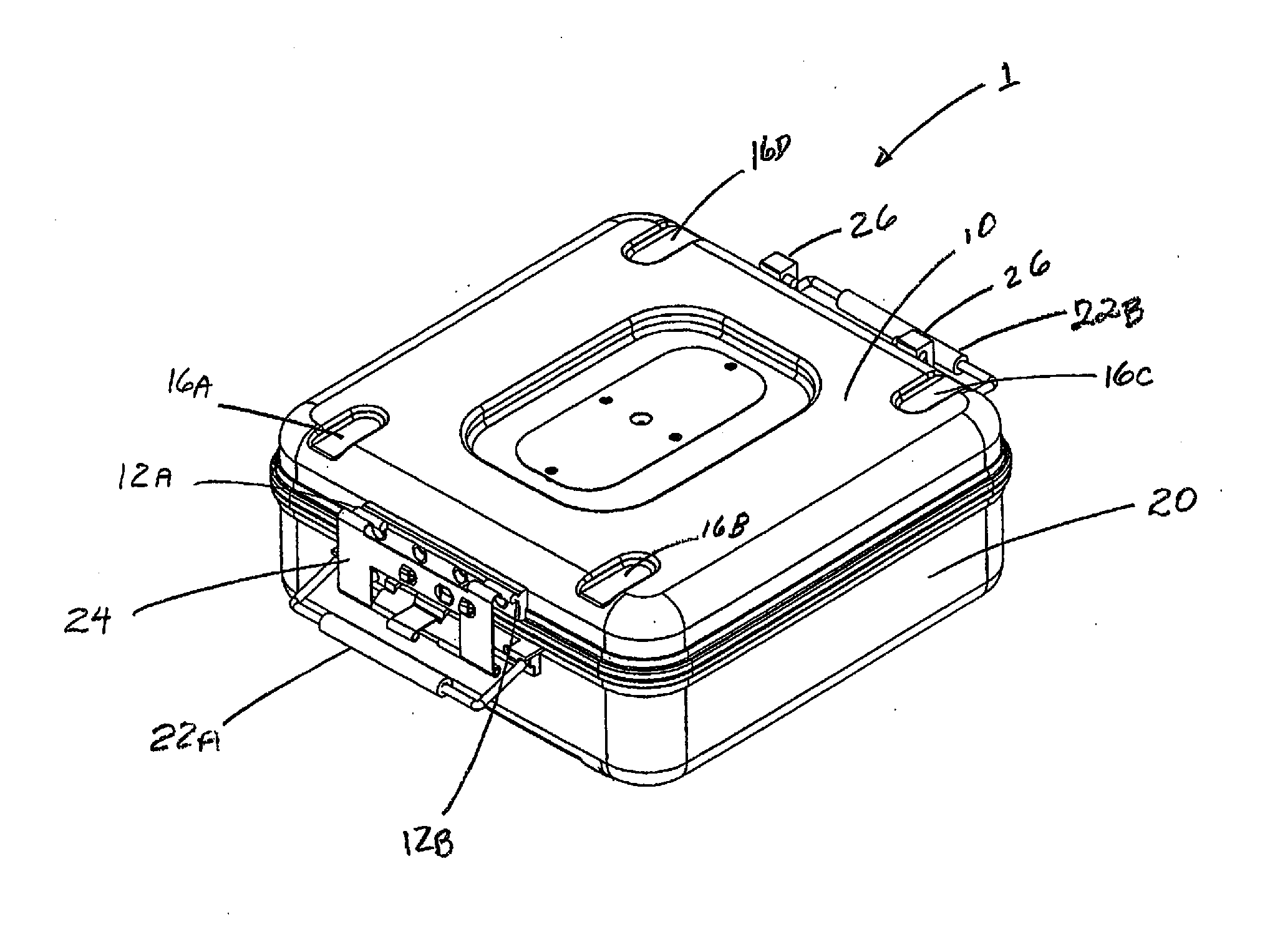

InactiveUS20130280134A1Limited in potentialLight weightOperating means/releasing devices for valvesLavatory sanitoryEngineeringEqualization

A sterilization container having a lid and a bottom. The lid is provided with a plurality if bimetal valves that will fully open and fully close at a preset temperature. The lid also includes a pressure equalization valve to relieve pressure from the container that will occur during the heating and cooling process. The bottom and the lid are formed from light weight and highly durable material so provide an easily handled and long lasting apparatus. Each lid includes a plurality of recesses and each bottom includes a plurality of complimentary projections such that multiple containers can be safely stacked upon one another.

Owner:HOFFMAN MICHAEL D +1

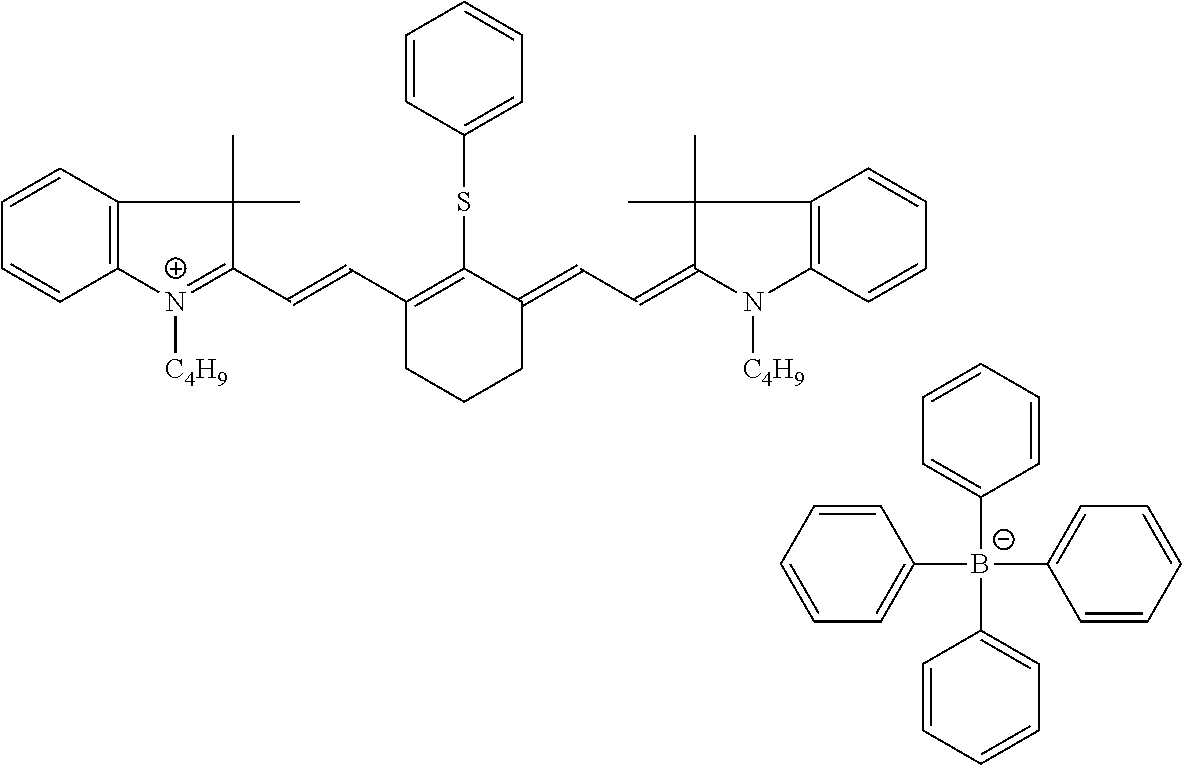

Lithographic printing plate precursors

InactiveUS20110287365A1Safe stackingPhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringPlanographic printing

A backside coating is applied to lithographic printing plate precursors and this coating provides sufficient protection so that adjacent precursors are not scratched or otherwise damaged when stacked. The backside coating is readily dissolved during processing or development at a pH of at least 6.5 after the precursors are imaged.

Owner:EASTMAN KODAK CO

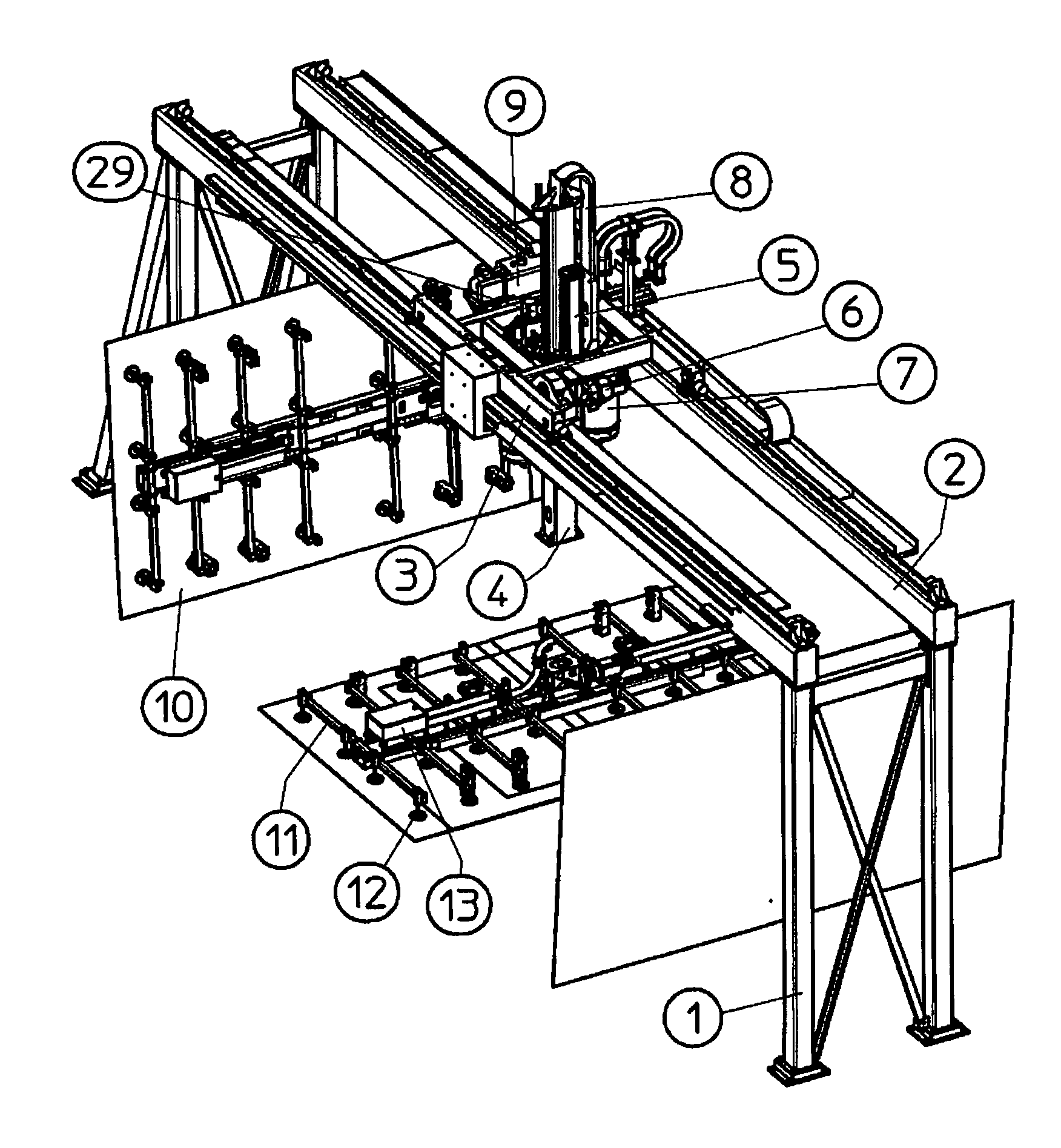

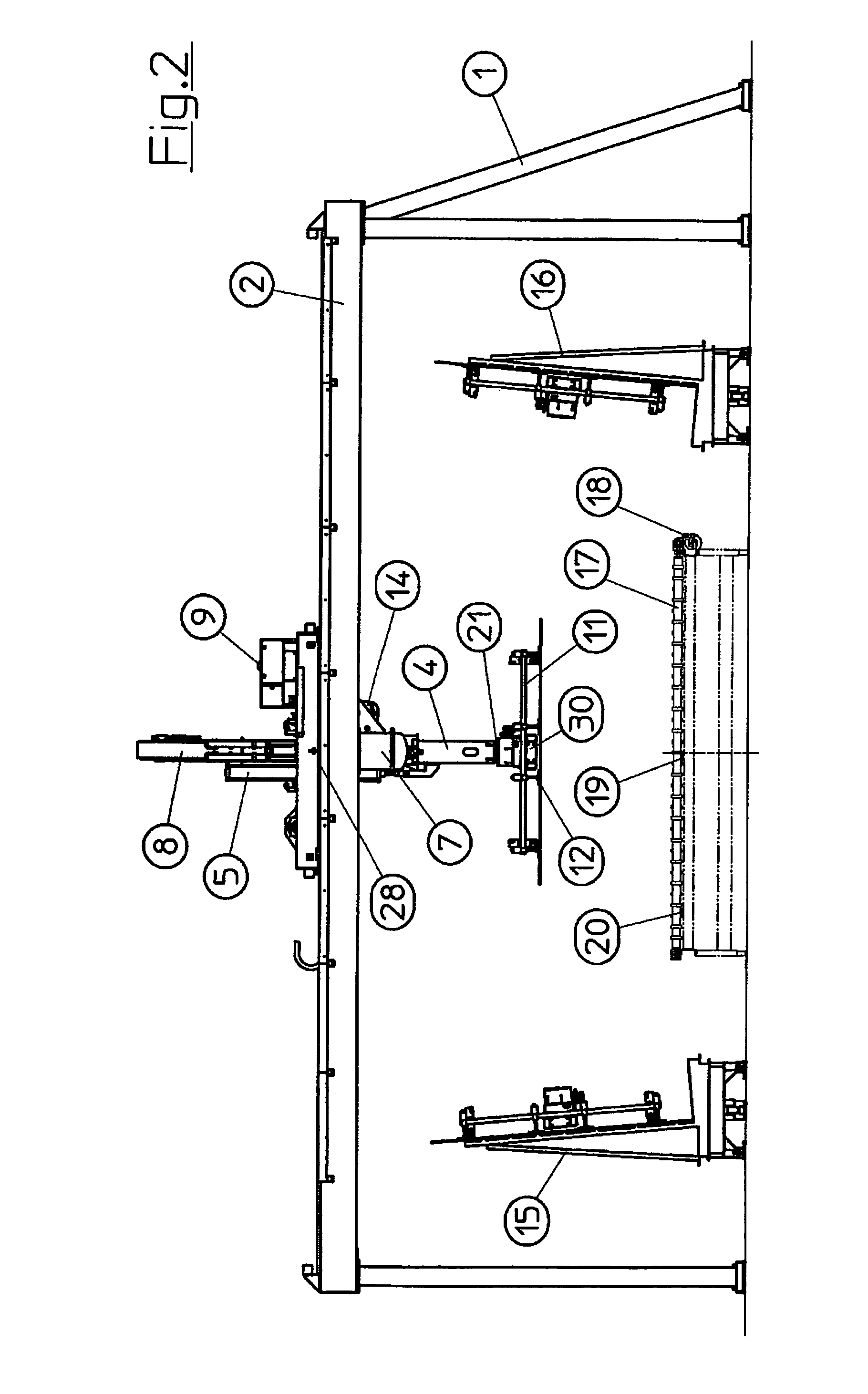

Portal re-positioning device for large-area glass plates

The invention relates to a method and device for changing the position of large-area glass plates which are stationary or moving, having the following features: one or more devices located on a level plane, each having a plurality of suction devices (12), are connected to the glass plates (10) to be re-positioned by means of a vacuum, b) the devices are connected to a lifting column (4) in a rotatable and pivotable manner, c) the devices can travel horizontally in the gripping area of the glass plates (10), d) the lifting column (4) has a counterweight (5) supplied with compressed air to compensate for the moving weight of the devices, e) the suction device (12) disk caps are spring-loaded in their holders, can be tilted in every direction, and are provided with a filter element (27), f) a controllable vacuum can be applied to each of the suction devices (12) individually, with a computer program as the controller.

Owner:GRENZEBACH MASCHINENBAU GMBH

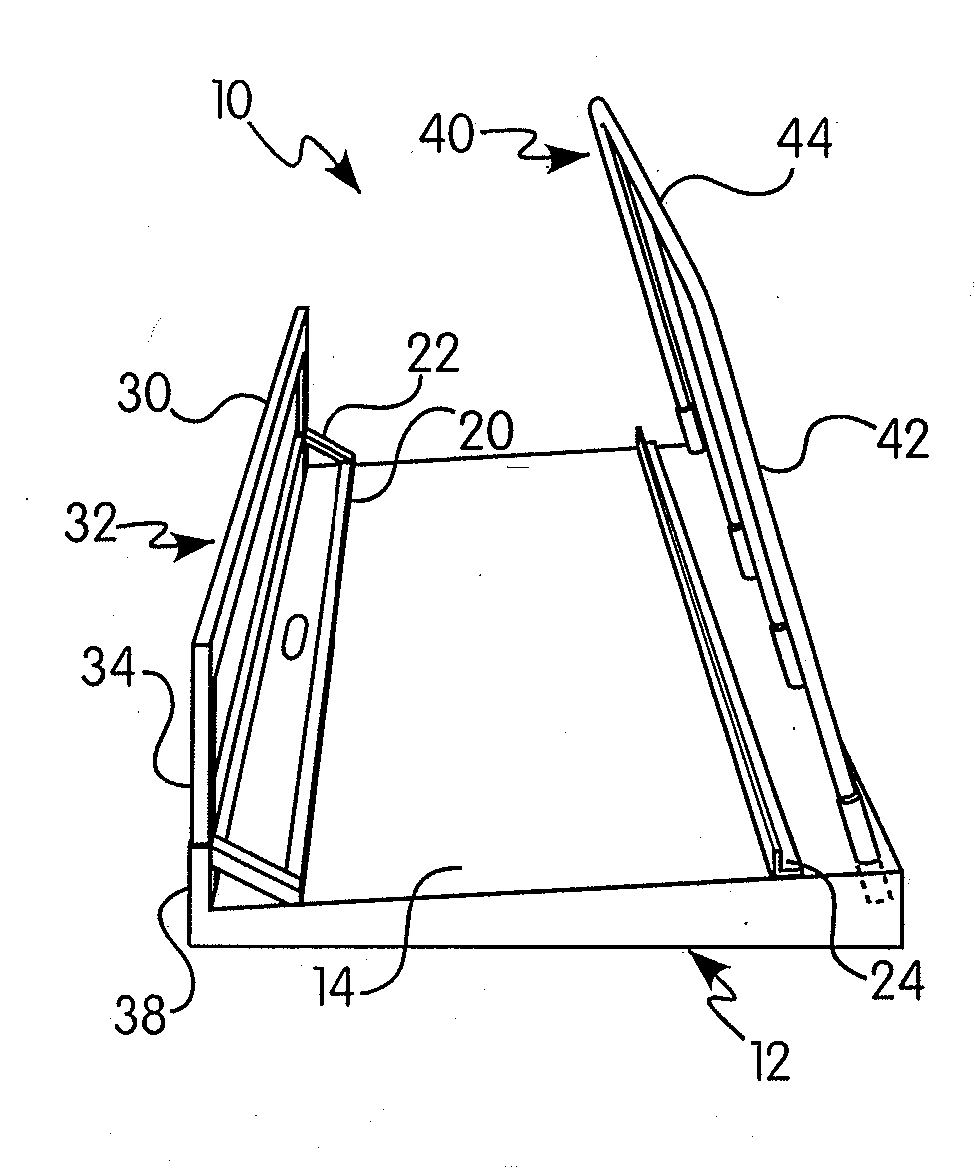

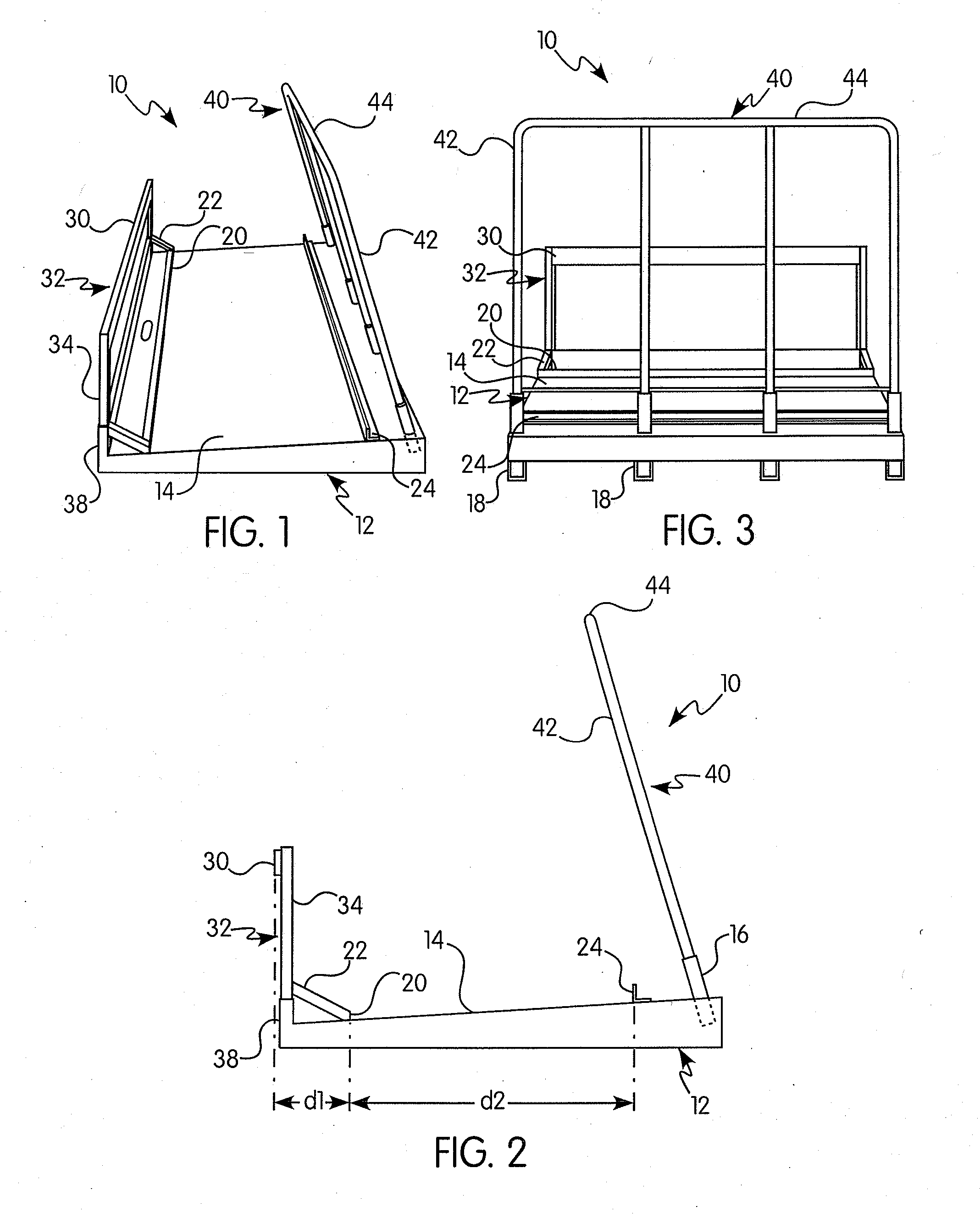

Panel Stack Safety Holder

InactiveUS20090314729A1Stop movingSafe stackingShow shelvesShow hangersBuilding under constructionEngineering

A holder apparatus (10,10′,110,210) for safely holding one or more construction material panels (52) at a work site within a building under construction. The holder rests on flooring (100) and is locatable adjacent a selected wall structure (102) and includes a base (12,12′,112,212) having a top load-bearing surface (14,114,214) canted at a small angle upwardly extending away from the adjacent wall. First and second stop rails (20,24) parallel to the wall define inner and outer stops for bottom edges (54) of a panel stack placeable onto the holder to be leaned against the wall (102), to assure that their bottom edges seated on the top surface (14,114,214) are at least a safe distance from the wall to prevent toppling, and a maximum distance to assure against sliding of the bottom panel edges away from the wall. An anti-tilt frame (40,40′,140,240) extends upwardly from the base beyond the second stop rail (24) and angled toward the wall to prevent toppling of the panels (52).

Owner:MCCARTHY LEO R +1

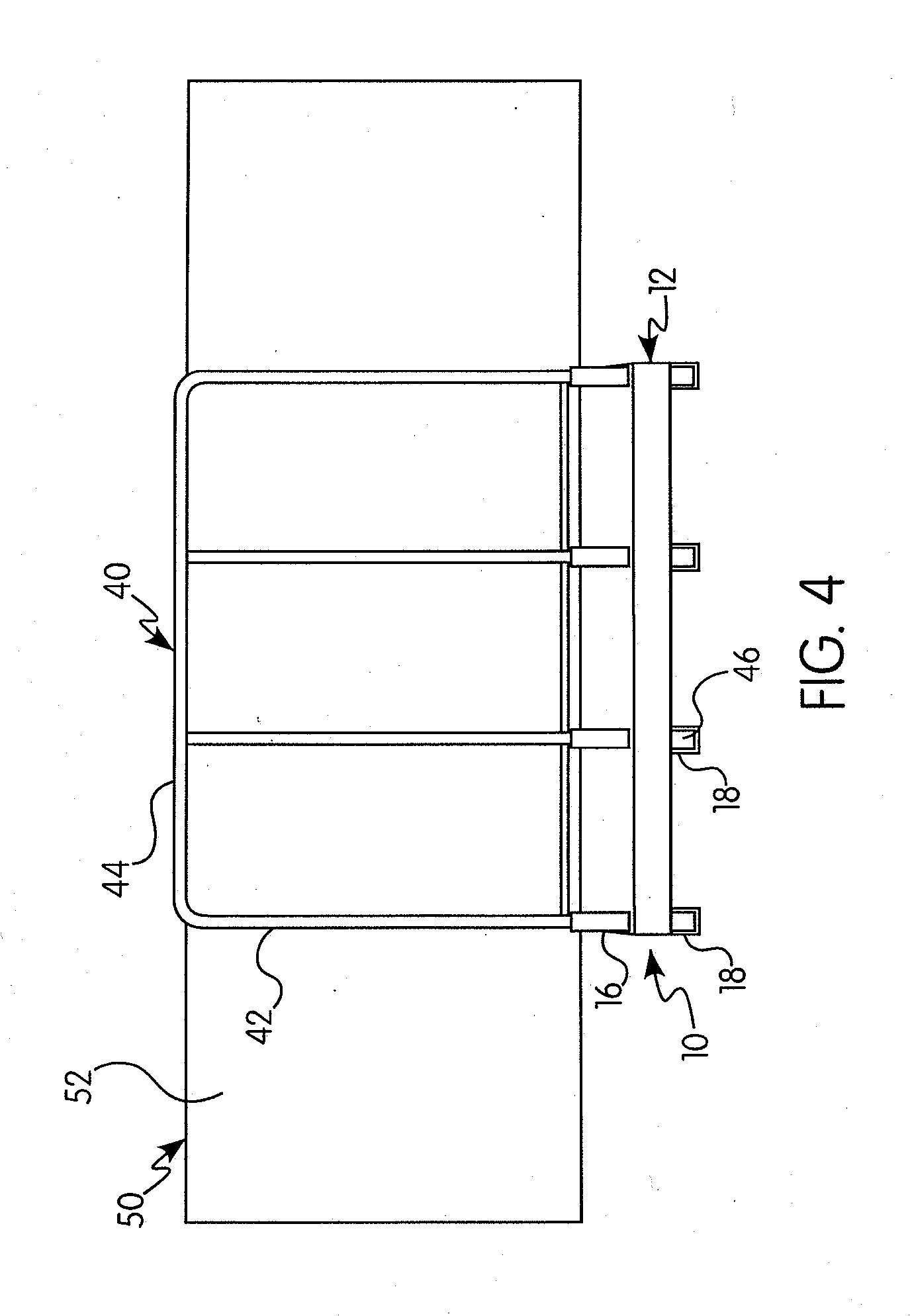

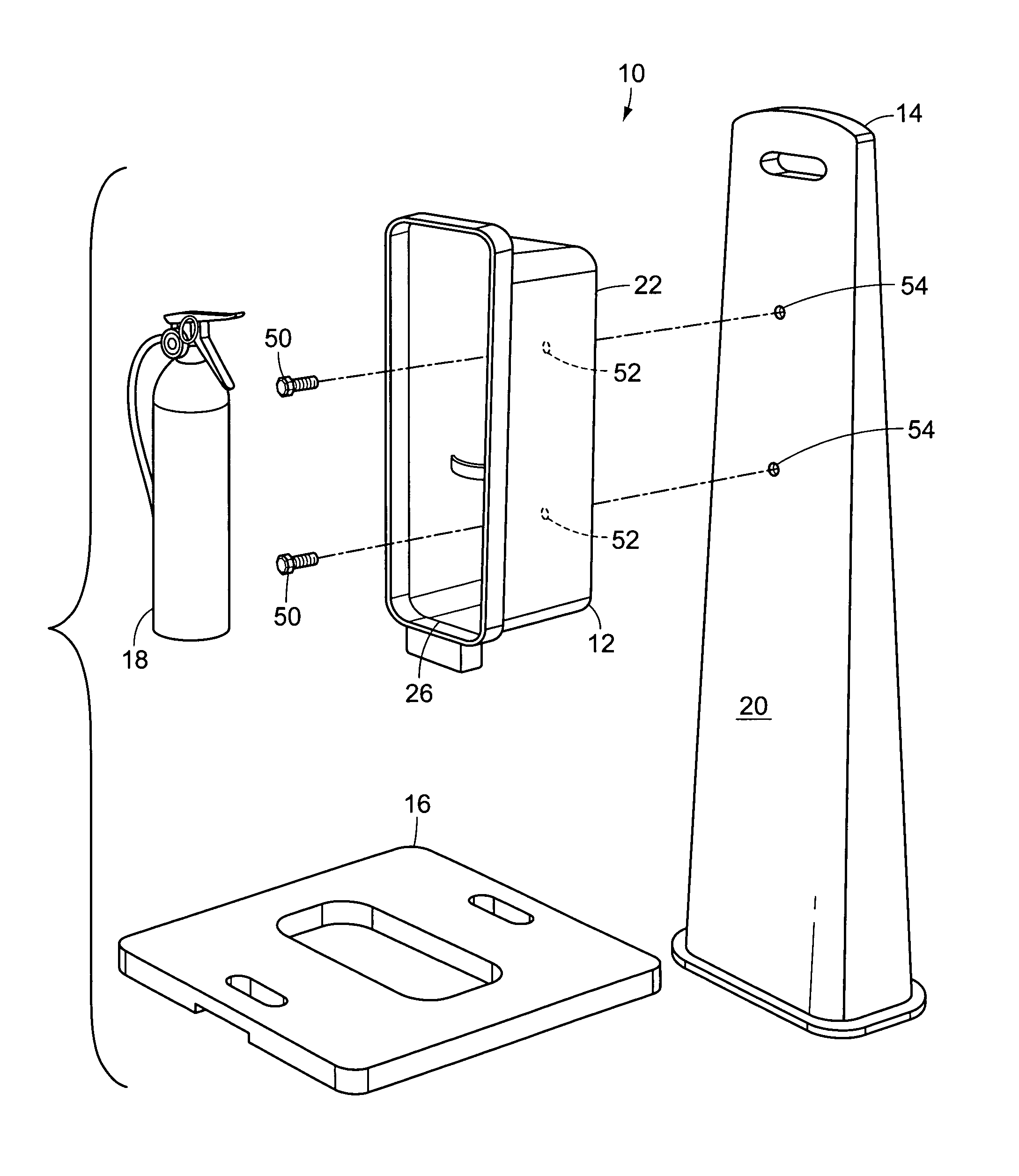

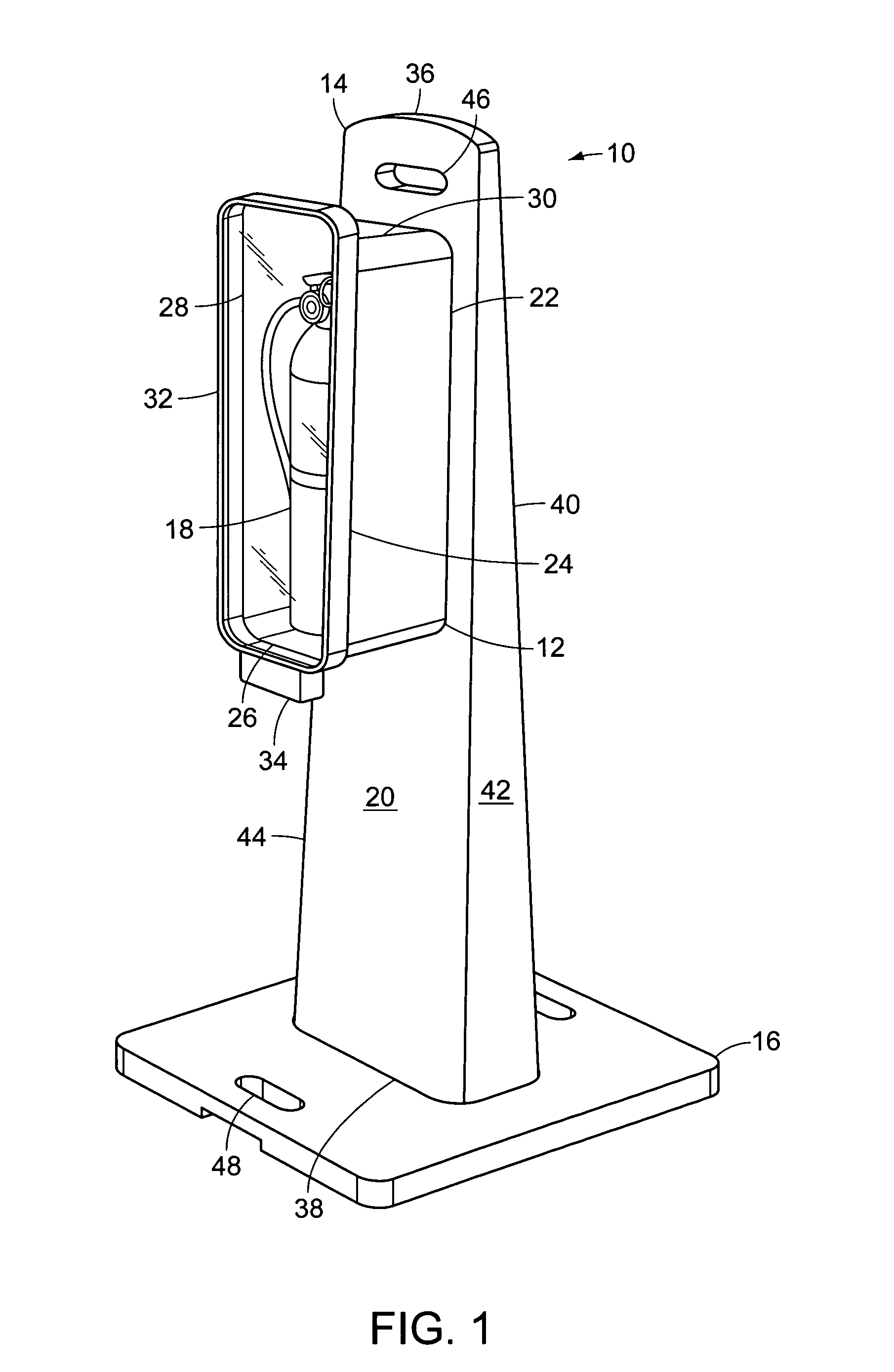

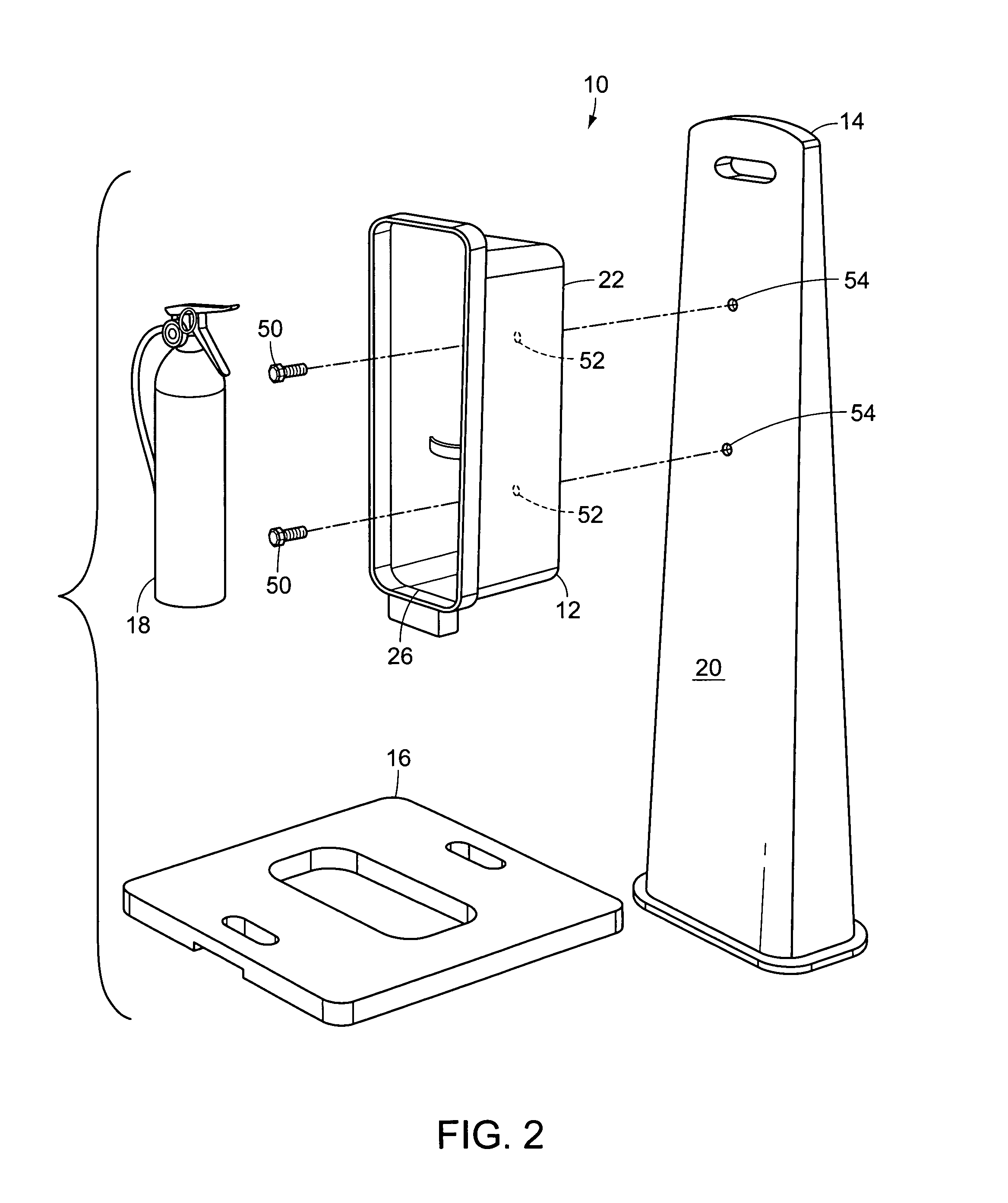

Portable fire extinguisher stand system

InactiveUS7171736B1Easy to transportEfficient use ofFire rescueMetal working apparatusEngineeringFire extinguisher

A method of assembling and storing a portable stand for a fire extinguisher having a case, a pylon and a base. The case has a rear wall and a bottom wall. The pylon has a front surface, an open bottom with an outer flange and a top that is narrower than the outer flange. In addition, the base is generally rectangular and has a central opening in its upper and lower surfaces. The assembly method involves inserting the top of the pylon upwardly through the central opening until the outer flange engages the base, mounting the case onto the front surface of the pylon and positioning the fire extinguisher inside the case such that it rests on the bottom wall. The storage method comprises detaching the case from the pylon of each stand, separating the pylon and the base of each stand, stacking the pylons and stacking the bases.

Owner:KENNON ADD

Stackable container with support flanges

InactiveUS20060124507A1Easy to optimizeLow production costContainer/bottle contructionRigid containersEngineeringTroffer

A container is disclosed having a plurality of interconnected panels forming sidewalls surrounding a central space. Flaps extend from lower sidewall edges and fold along fold lines to form a bottom. Support flanges are arranged along upper sidewall edges on oppositely facing sidewalls. The support flanges are oriented at right angles to the sidewalls and provide a support surface allowing the containers to be stacked one atop another without collapsing or nesting within each other. Each support flange is supported by a truss formed by a panel segment extending angularly from the support flange to a support panel biased against the sidewall to which the support flange is attached by a retaining flap extending from an inner sidewall layer. Locking tabs at the ends of each panel segment are received within recesses positioned in sidewall panels perpendicular to the support flanges. The container is transformed from a knockdown formed from a unitary blank.

Owner:ROYAL BOX GRP LLC

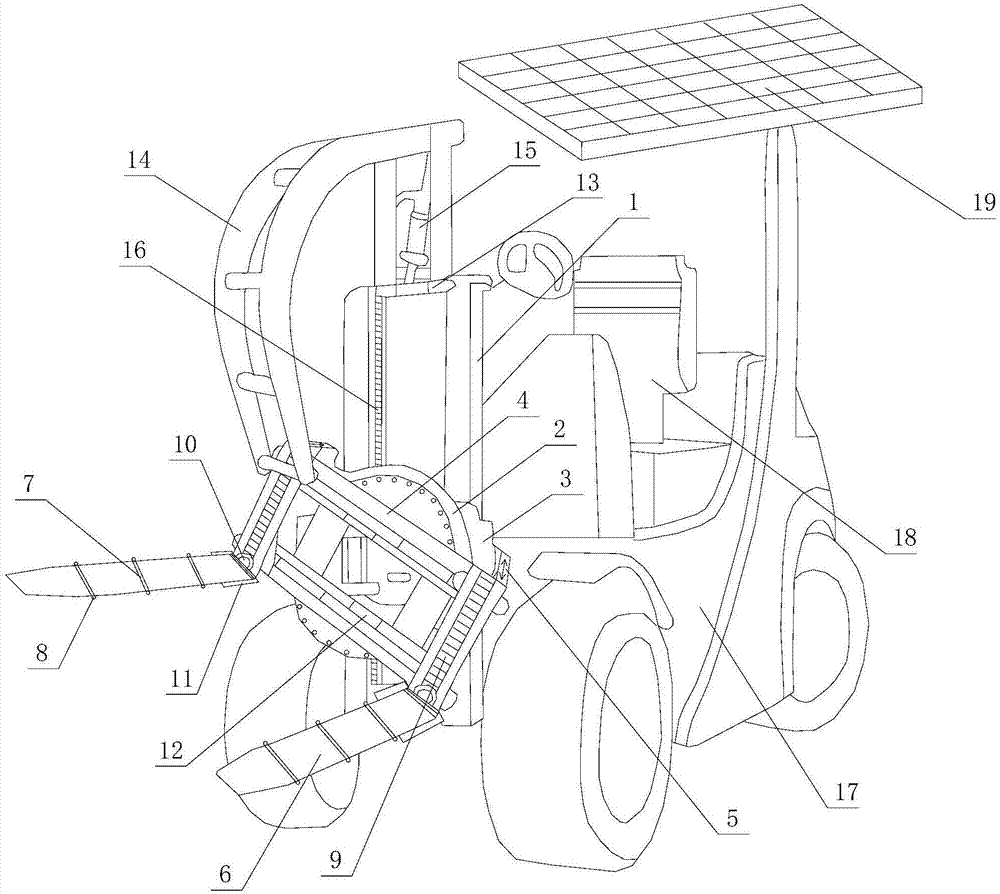

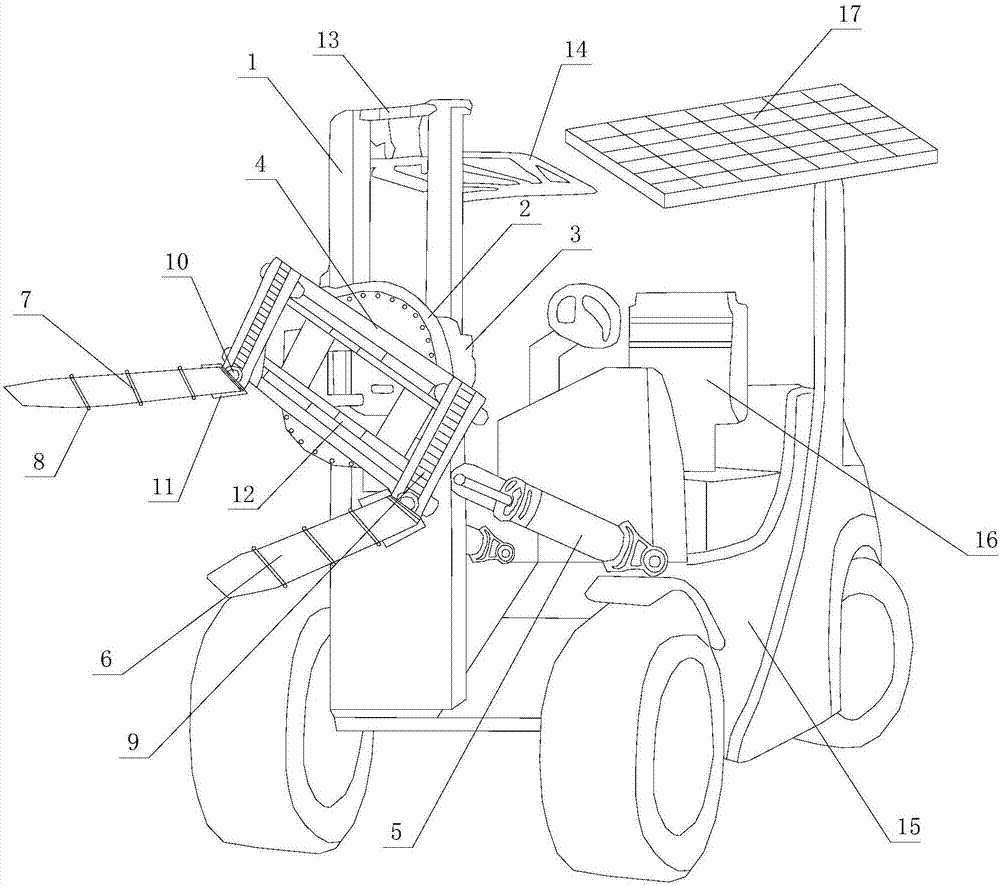

Forklift with steel pipe clamp

The invention proposes a forklift with steel pipe clamps, which includes a car body with a driver's cab, a solar panel installed on the roof of the driver's cab, a door frame at the front end of the car body, and a rotating door frame on the door frame. The rotator slides up and down on the door frame through the sliding parts on both sides, the rotator is provided with a fork frame, the fork frame is rotated and set on the door frame through the rotator, the lower end of the fork frame is connected with the rotator, and the upper end of the fork frame is connected with the door frame. There is a push-pull cylinder between the rotators, two sliding guides are provided on the fork frame, and a distance adjustment device is provided between the two sliding guides. Each sliding guide is connected to a fork, and the fork is provided with A plurality of bent joints for adjusting the shape of the cargo fork, fastening bolts are provided at both ends of the bent joints, slide rails are provided on both inner sides of the mast, a rotating shaft is provided between the two slide rails, and a control cylinder is provided on the steel pipe clamp. The forklift with steel pipe clamp is easy to operate and maintain, has comprehensive functions, safe and reliable operation, reduces the accident rate, and can be used for multiple purposes.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

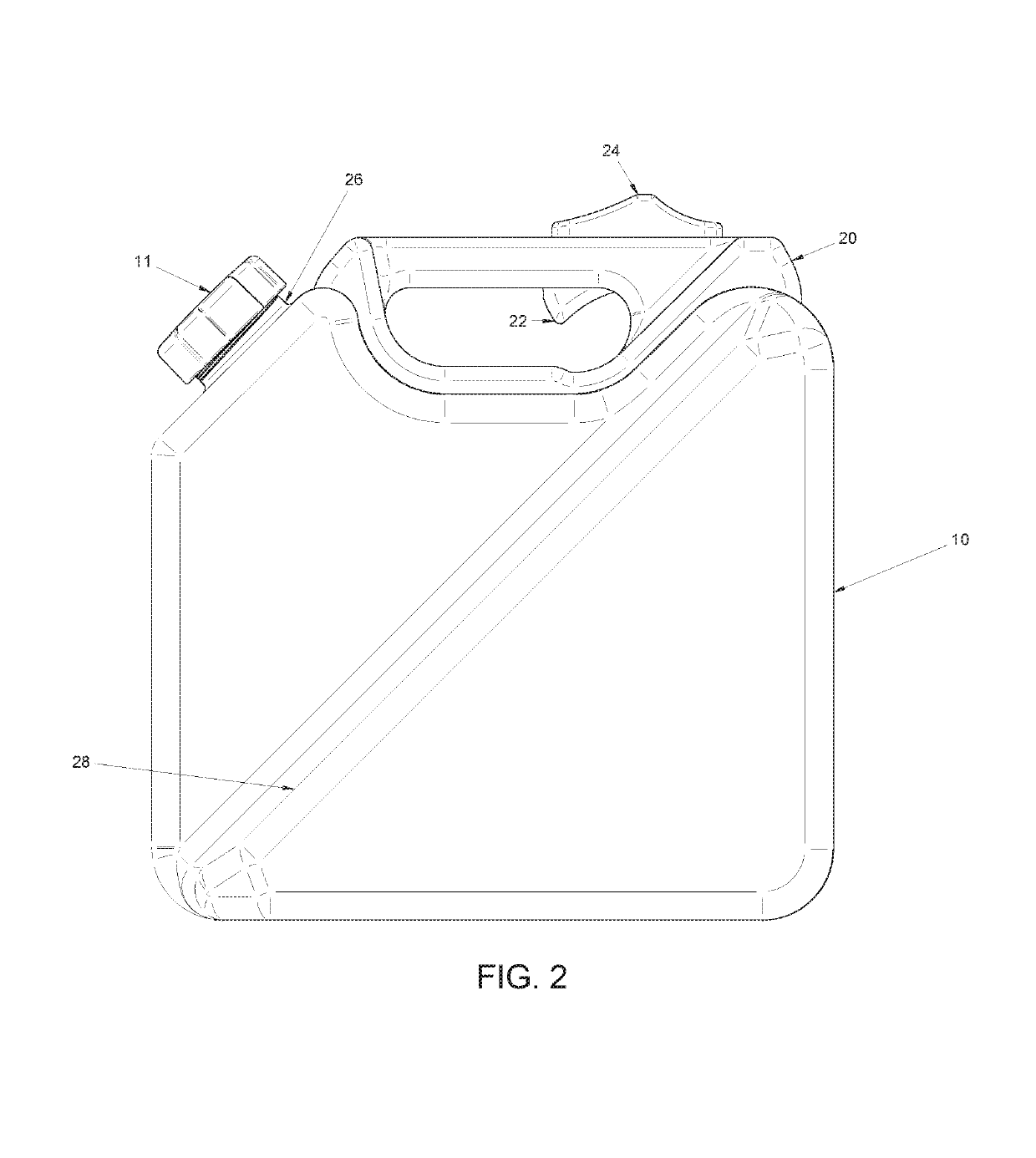

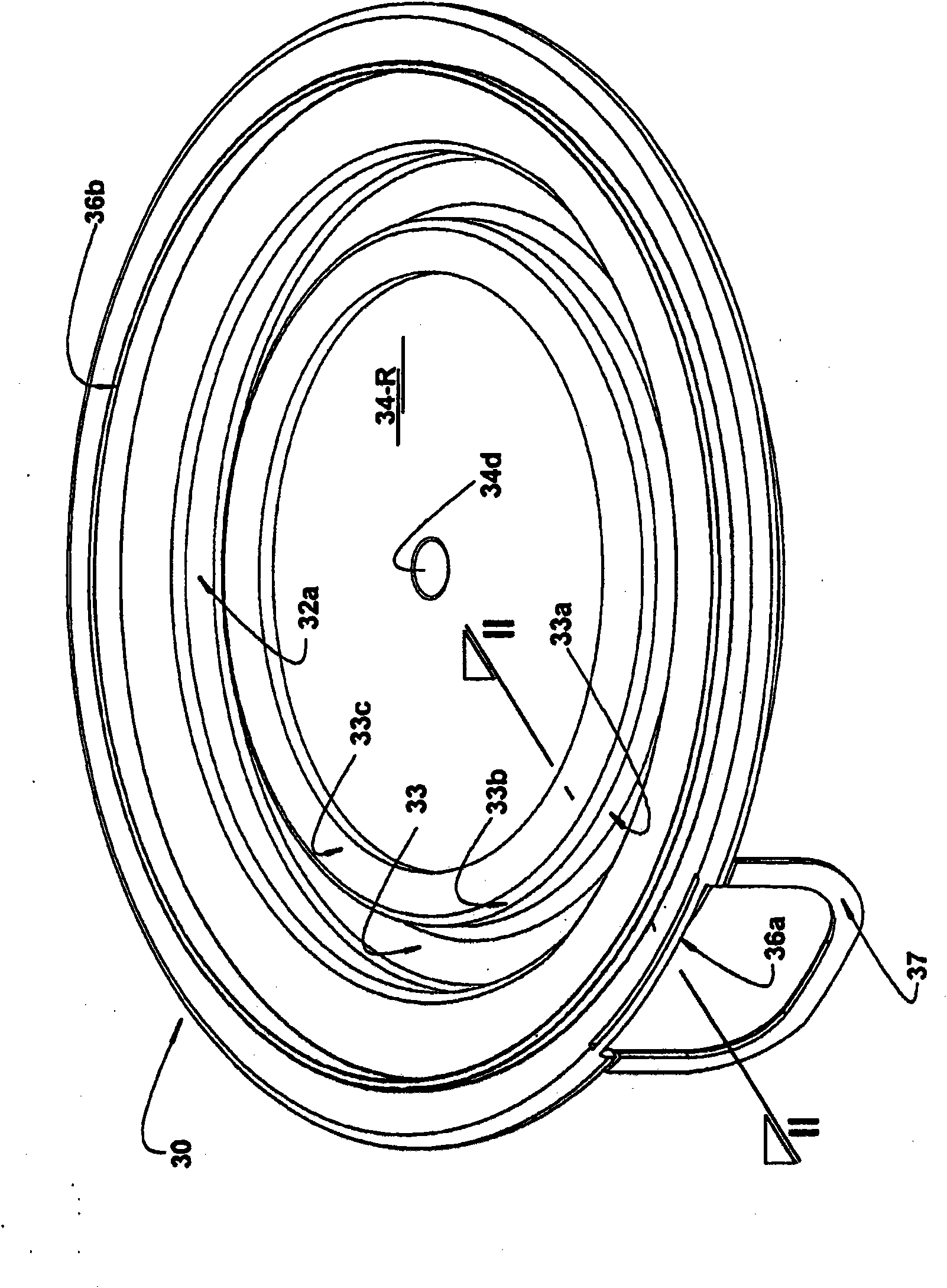

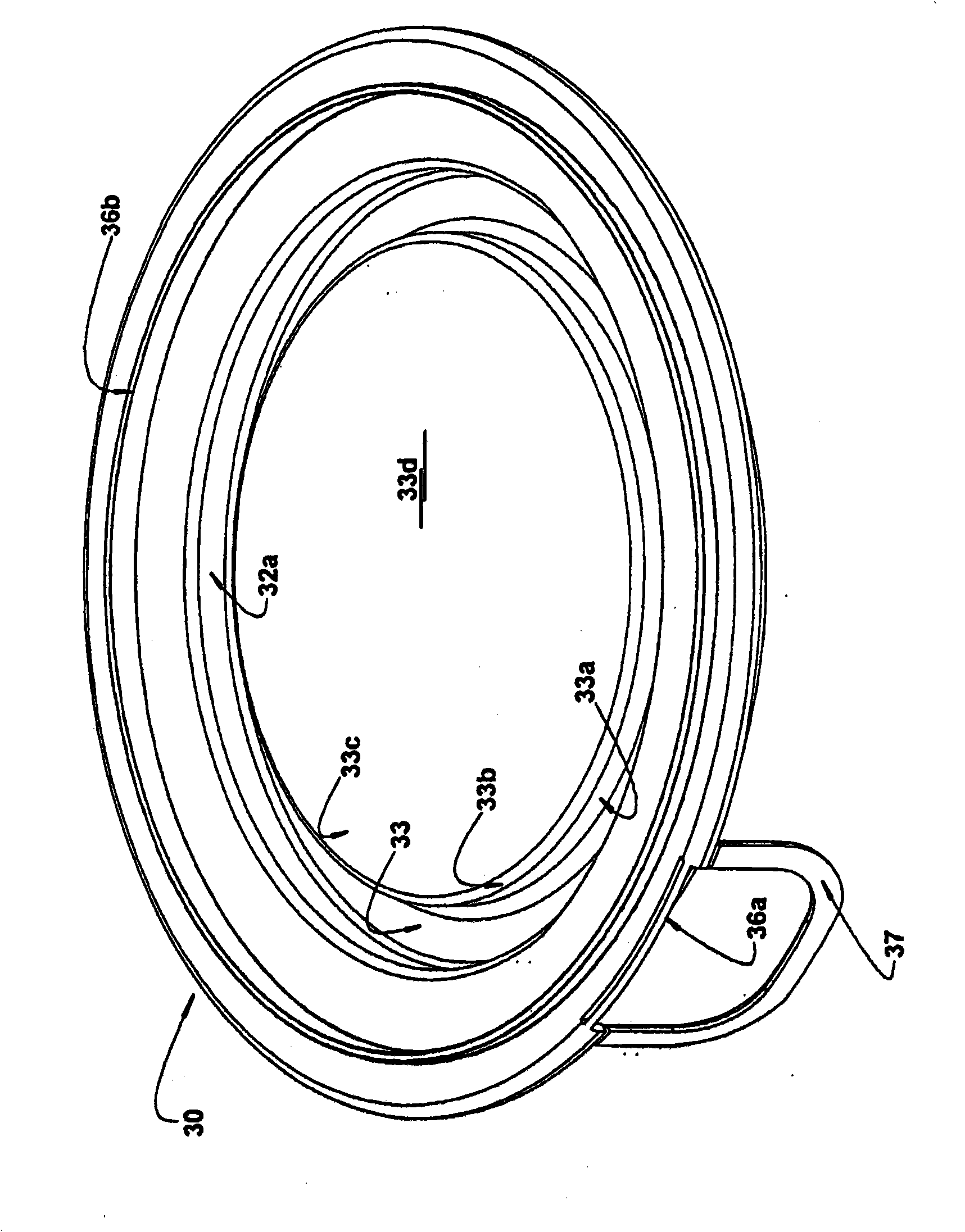

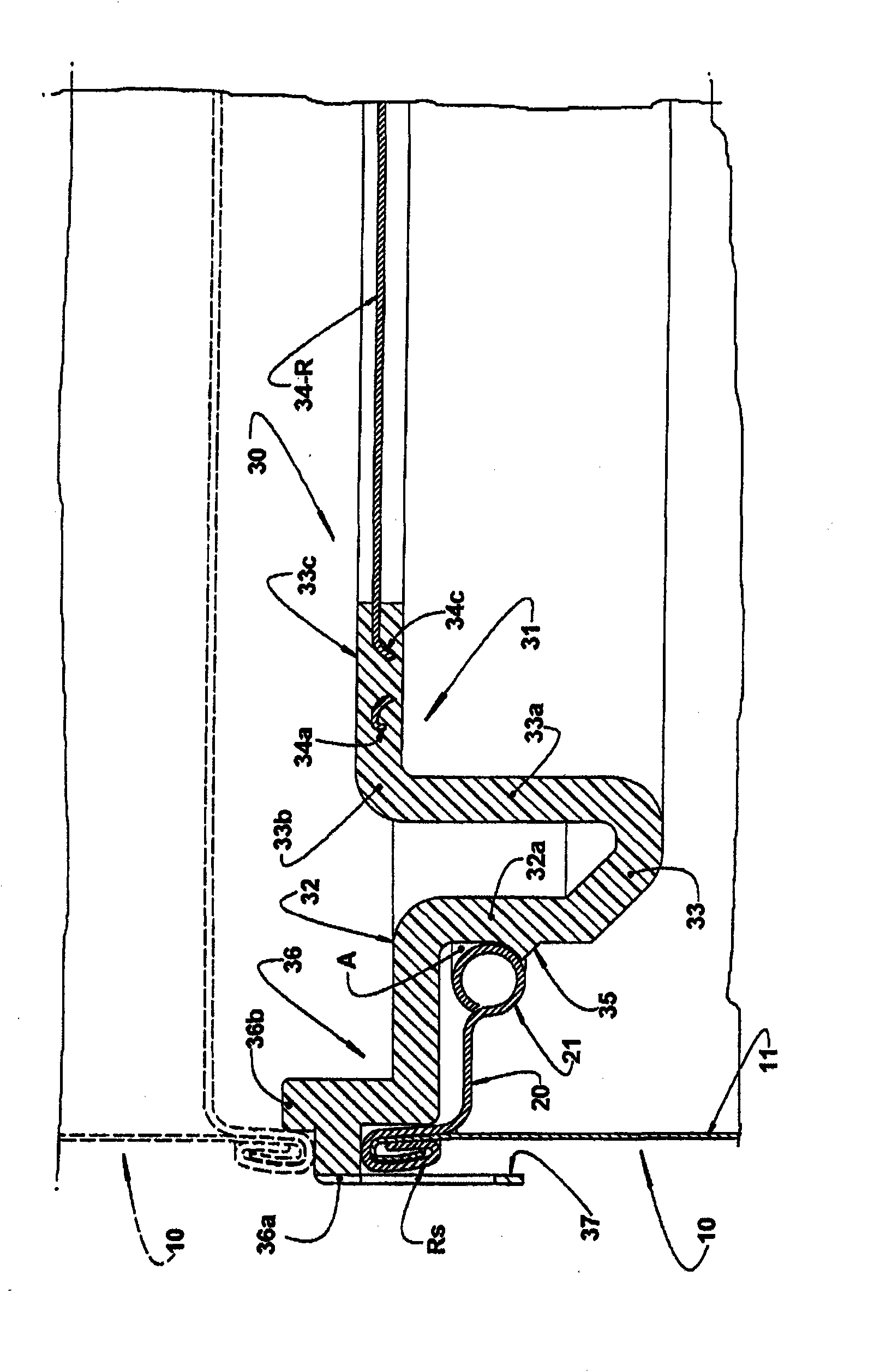

Composite lid for containers

InactiveUS20110121009A1Improve impermeabilityEasy constructionCapsClosure capsPlastic materialsEngineering

A composite lid for a container that includes a tubular body carrying an annular upper wall made of sheet metal, in which is defined an opening surrounded by a seat, which is configured to receive and retain the lid. The lid includes a base portion peripherally incorporating a retention portion to be seated and retained on the seat when the lid is closed. The base portion includes a peripheral annular element molded in a plastic material as a single piece with the retention portion, and a central element in the form of a sheet metal plate that has an outer peripheral edge attached to the peripheral annular element. The peripheral annular element includes, internally and in a single piece, a central panel disposed on the central element, which is incorporated to the lid during its injection or attached thereto afterwards.

Owner:BRASILATA S A EMBALAGENS METALICAS

Forklift with inclined cylinders

The invention provides a forklift with inclined cylinders. The forklift comprises a gantry; two sides of the lower part of the gantry are respectively connected with the inclined cylinders; the gantry is provided with a rotating machine; the rotating machine is arranged on the gantry in a manner of sliding up and down through slide parts on two sides; a fork frame is arranged on the rotating machine, and is rotationally arranged on the gantry through the rotating machine; two slide guide devices are arranged on the fork frame; a distance adjusting device is arranged between the two slide guide devices; each slide guide device is connected with a goods fork; the goods fork is provided with multiple bent joints for adjusting the shape of the goods fork; and fastening bolts are arranged at two ends of the bent joints. The forklift with the inclined cylinders is convenient in operation and maintenance, high in production efficiency, low in operating cost and safe and reliable in operation, reduces the accident rate, can achieve multiple purposes on one machine, reduces repeated purchase by user equipment, and effectively saves funds.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

Water tank structure for load test, test device and test method

PendingCN111350212ASafe stackingFill water quicklyFoundation testingStructural engineeringEnvironmental engineering

The invention provides a water tank structure for a load test, a test device and a test method. The water tank structure comprises a plurality of water tanks which are uniformly distributed layer by layer and stacked on a support, adjacent water tanks of each layer are communicated through a connecting water pipe, a top surface of each water tank is provided with a water inlet, the bottom surfaceof each water tank is provided with a water outlet, the water inlet is connected with a water pump through a detachable water inlet pipe, and a detachable sealing cover is installed at a water outletend. According to the wate tank structure for the load test and the load test method provided by the invention, the water tank is used as a loading device for the load test, a corresponding number ofwater tanks are assembled according to the load requirement, water is injected into the water tank during loading, and water in the water tank is discharged during unloading, so that one-time water filling and one-time water discharging are realized; the problems that time and labor are wasted and transportation is inconvenient due to transportation and stacking of concrete blocks or sand bags aresolved, meanwhile, the water tanks are safe to stack, water filling and water discharging are rapid, repeated utilization can be achieved, and transportation, loading and unloading are more convenient and faster.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

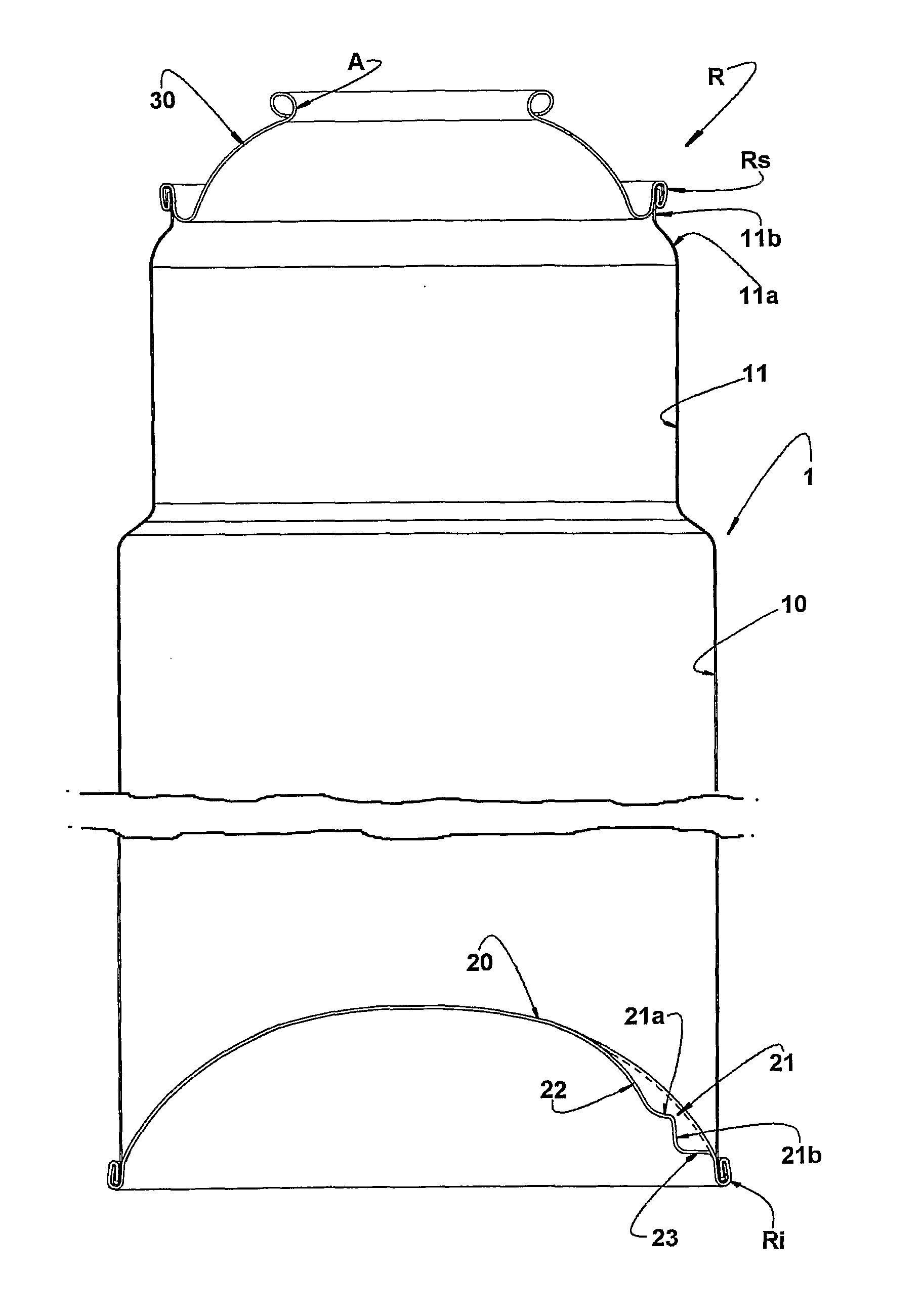

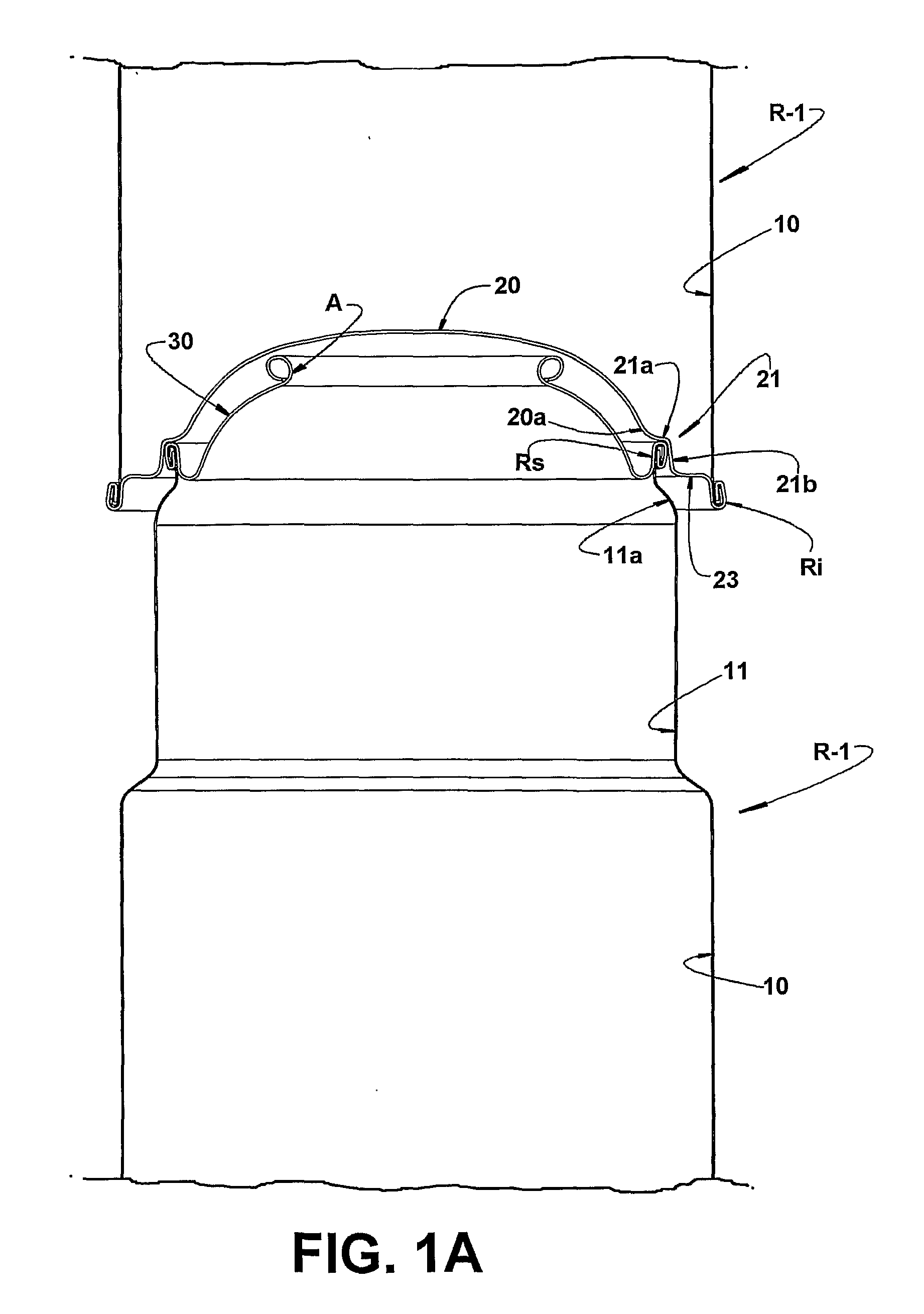

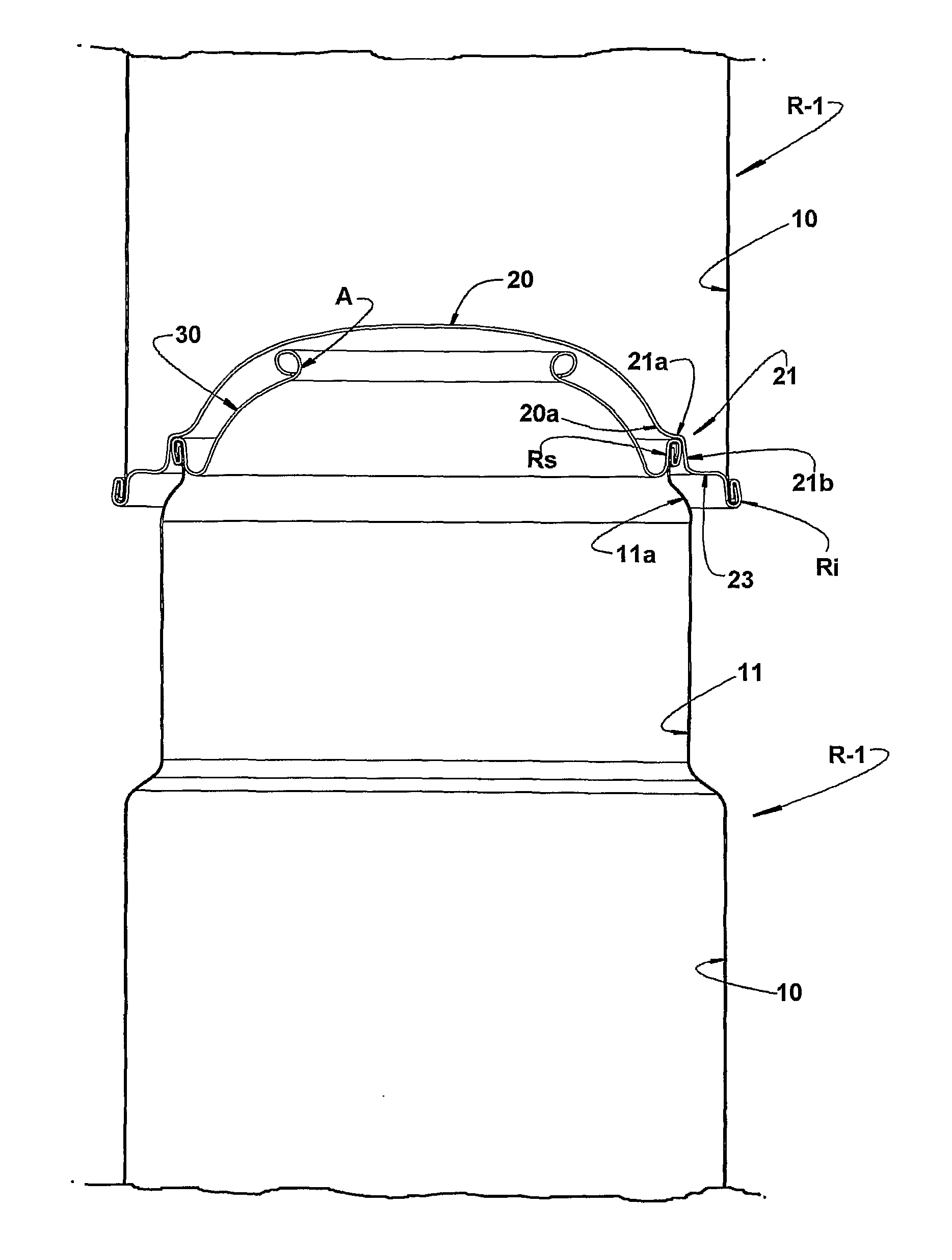

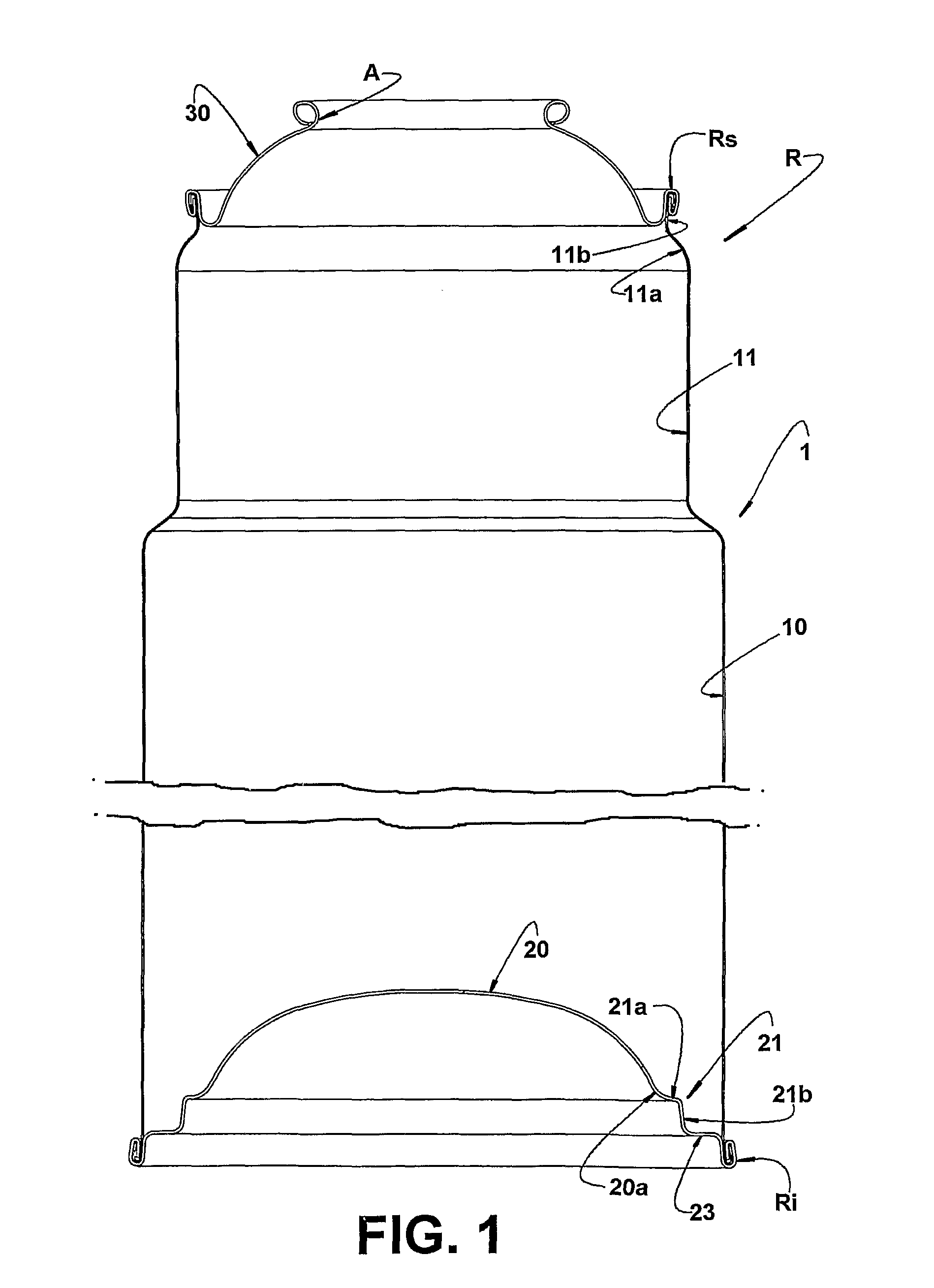

Container for pressurized fluids

InactiveUS20100300916A1Preventing relative transversal displacementSafe stackingLiquid dispensingTray containersEngineeringDouble seam

A container having a tubular body including a side wall, a bottom wall in the form of a spherical dome projecting to the interior of the container, and an upper wall in the form of an annular spherical dome, inferiorly attached to the side wall by an upper double seam. The bottom wall includes at least one seating region having a predetermined circumferential extension along a plane extending transversely with respect to an axis of the container and being axially spaced inwardly within the side wall of the container, the seating region being configured to be fitted around a respective circumferential extension a upper double seam of an identical and adjacent container inferiorly disposed in a vertical stack, and axially seated on said upper double seam, so as to define a single contact region between two vertically stacked containers.

Owner:BRASILATA S A EMBALAGENS METALICAS

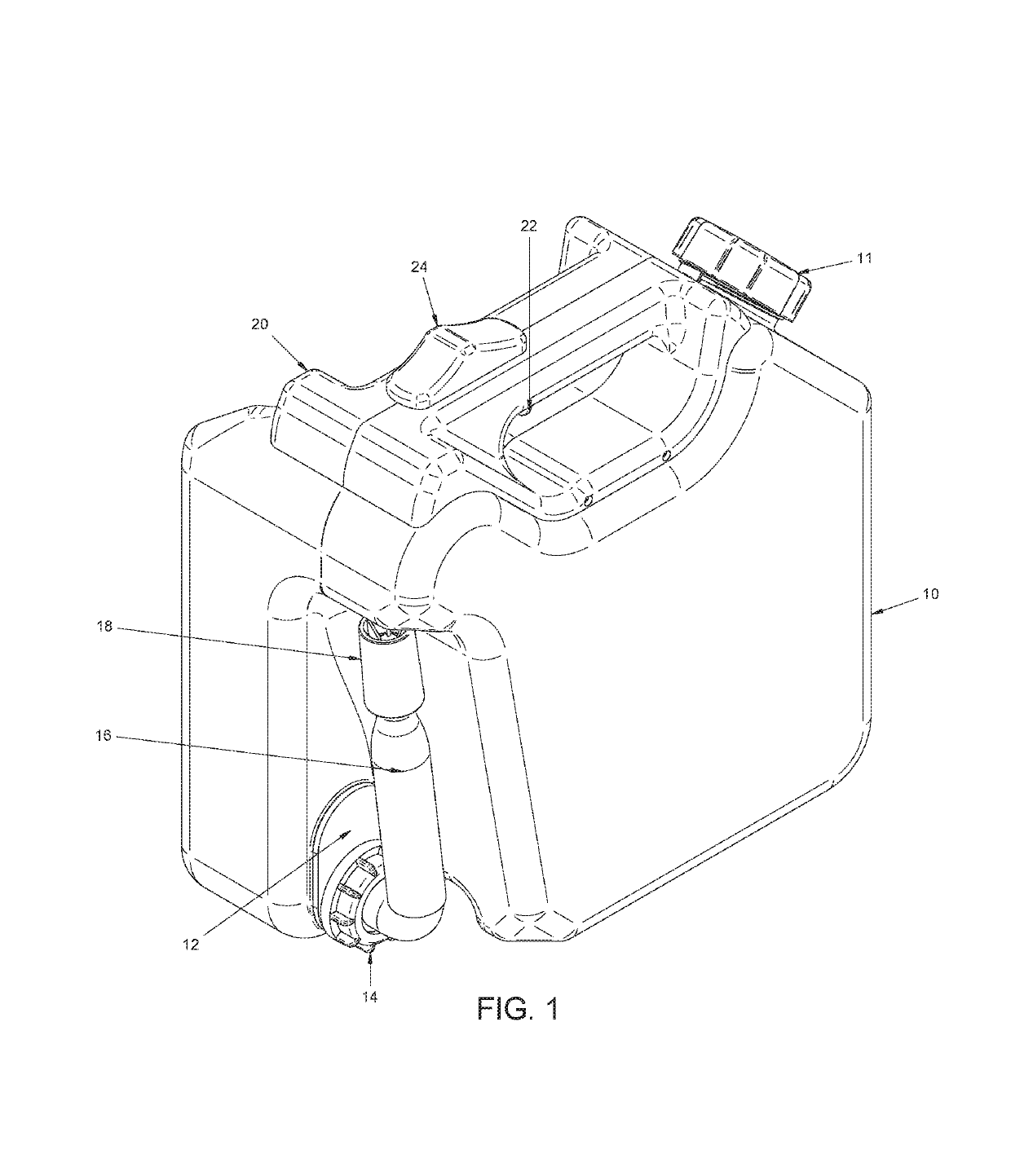

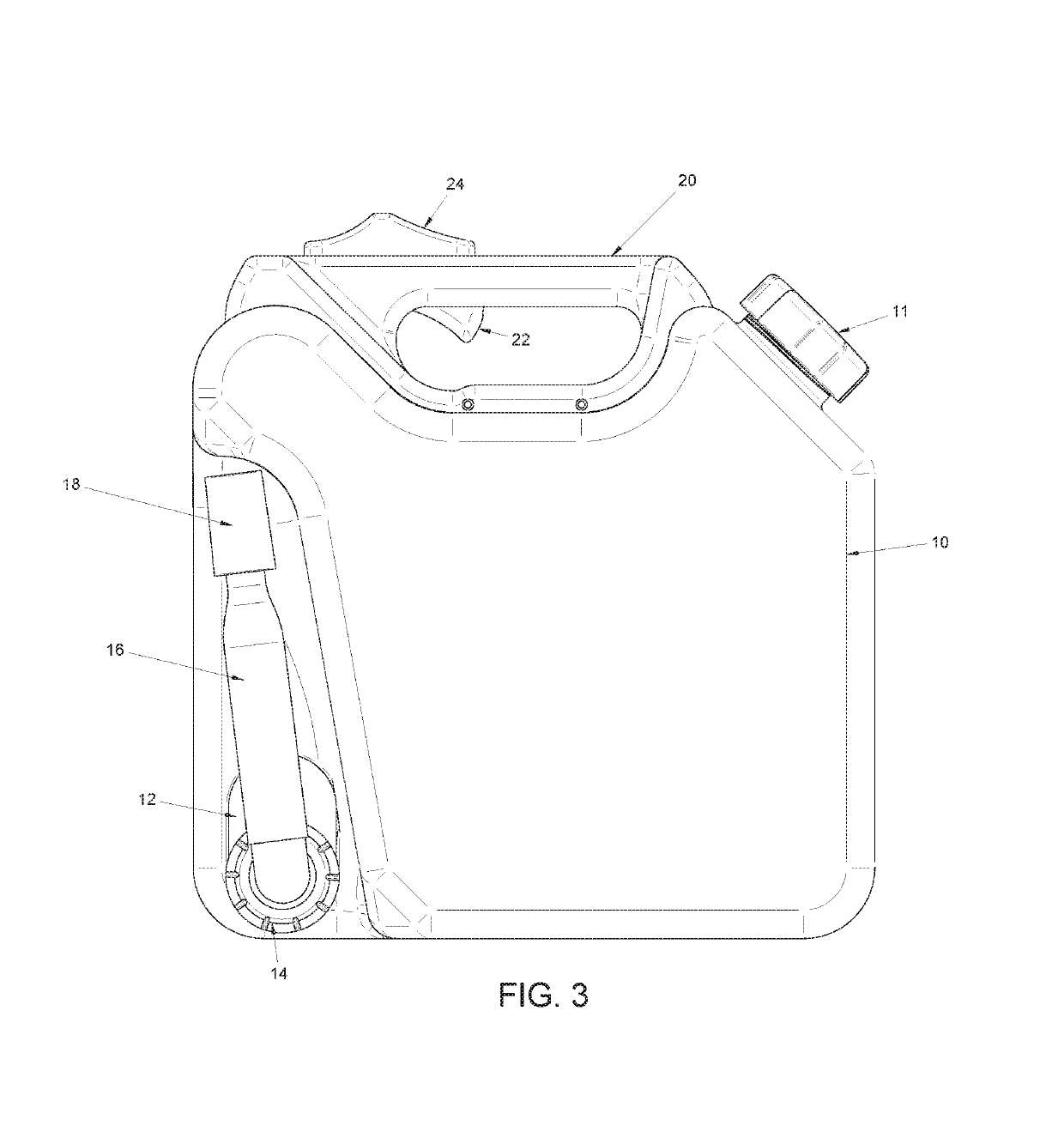

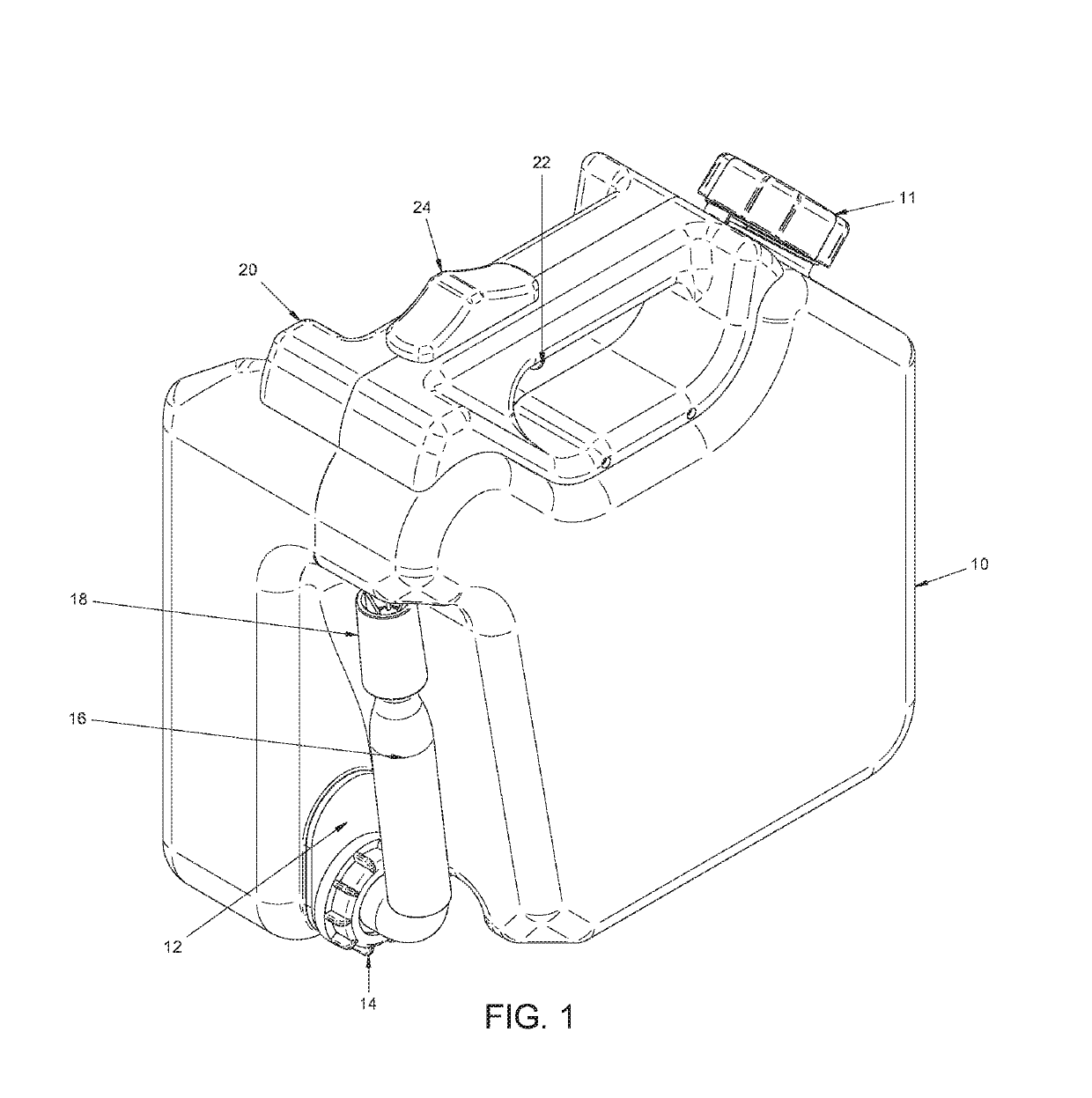

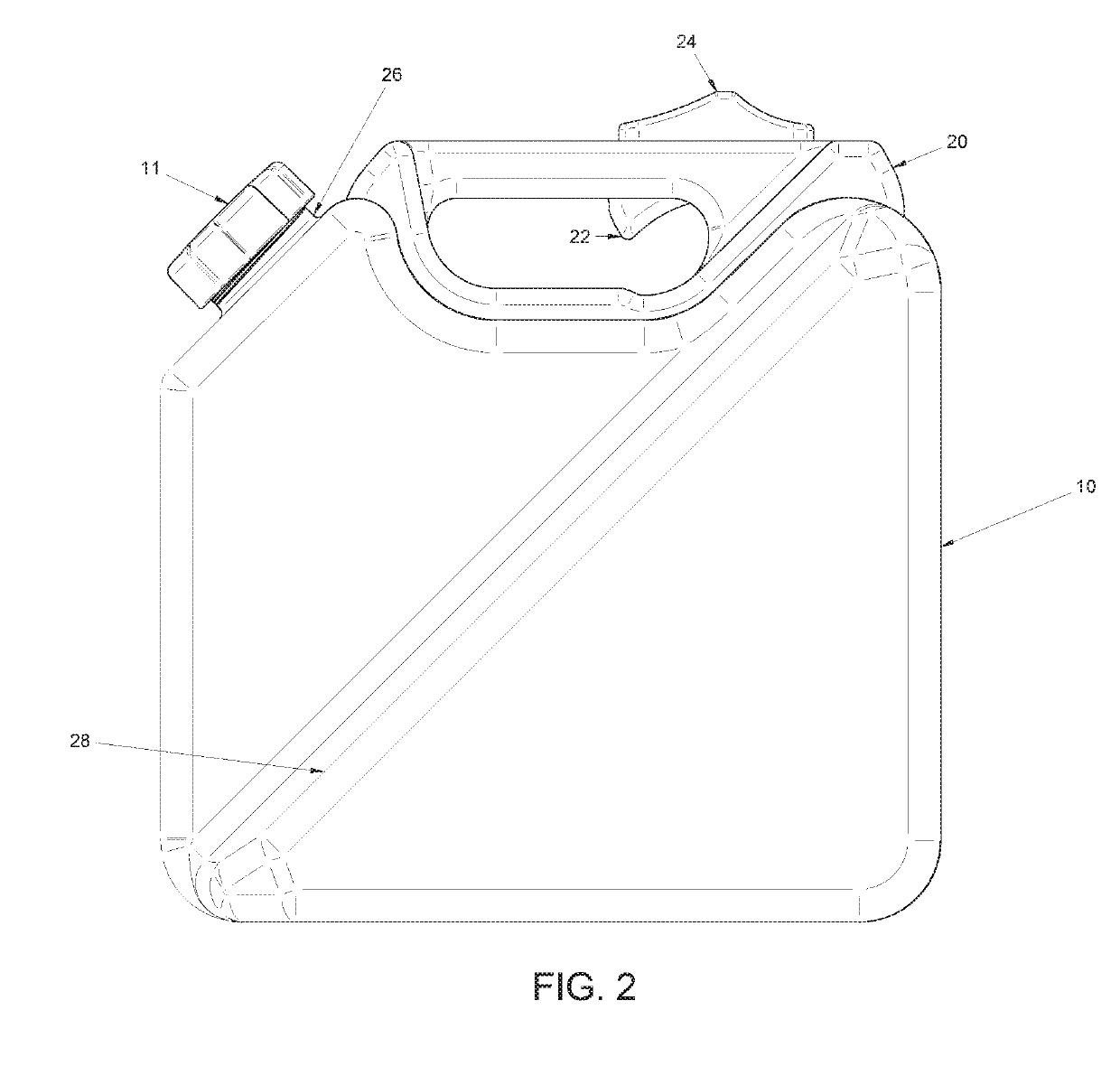

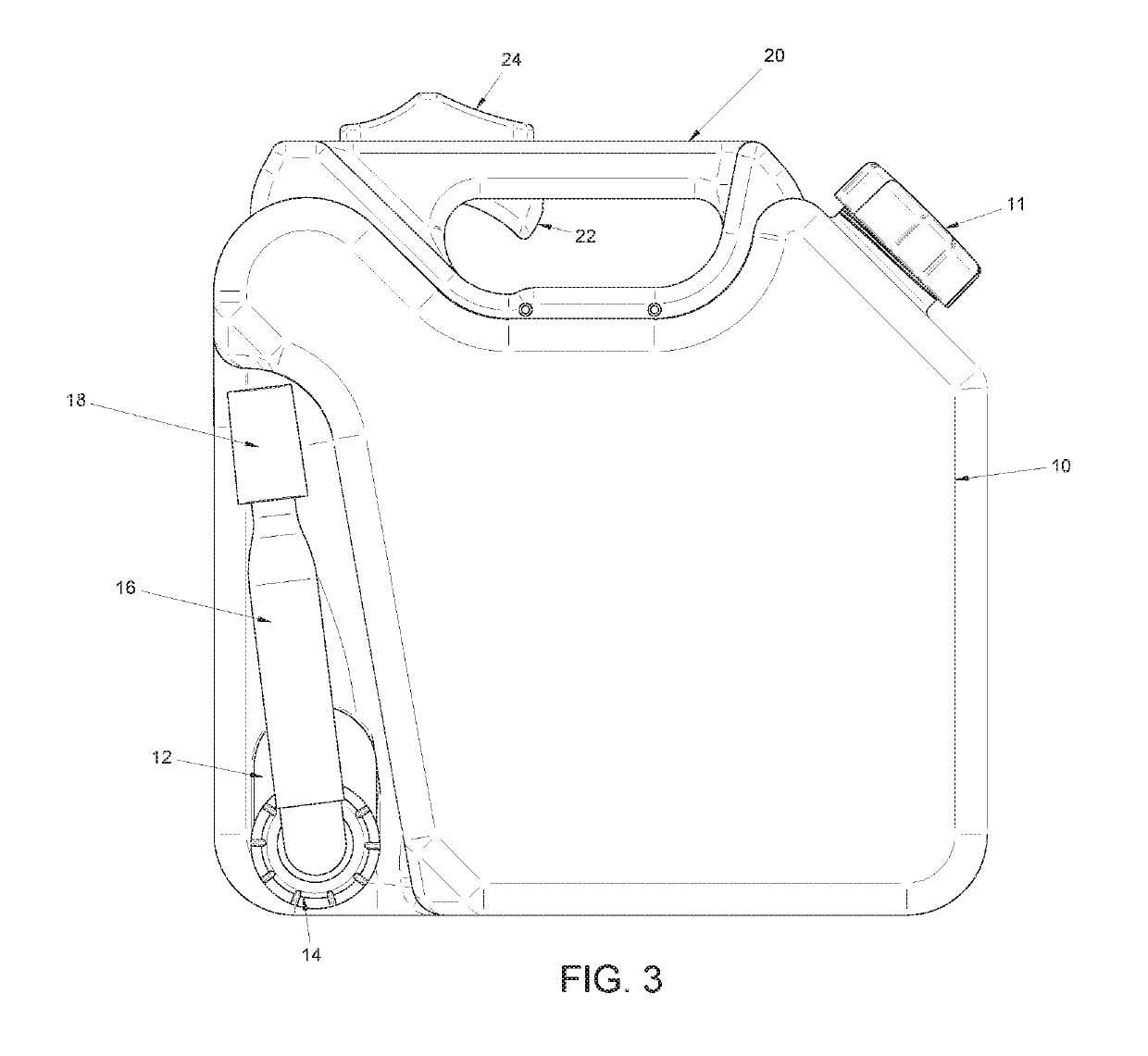

Fuel container

ActiveUS10280065B2Prevent accidental ventingSafely relieve excess internal pressureVenting meansPackaging corrosive chemicalsEngineeringBiological activation

Owner:FUELHOSS LLC

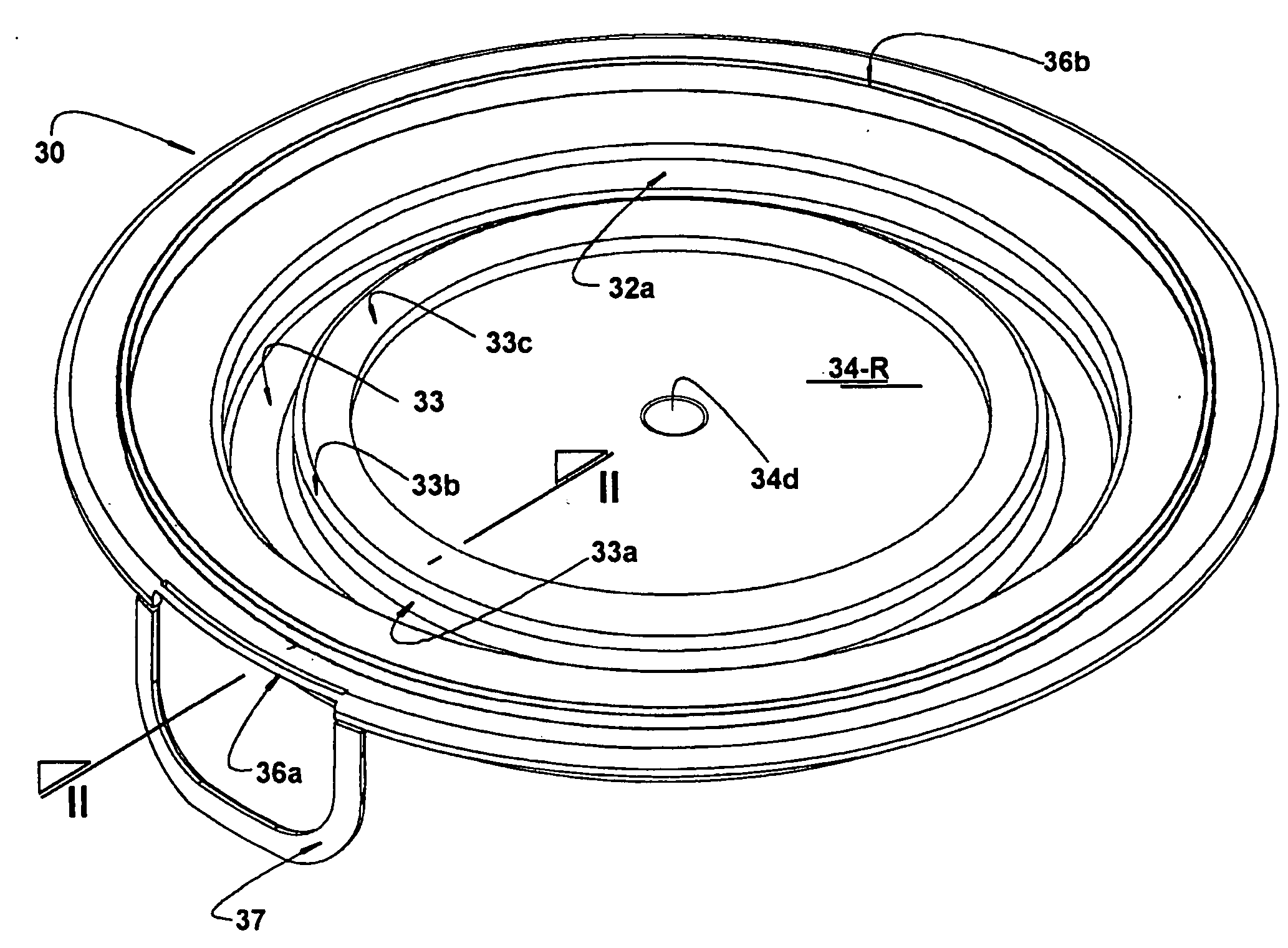

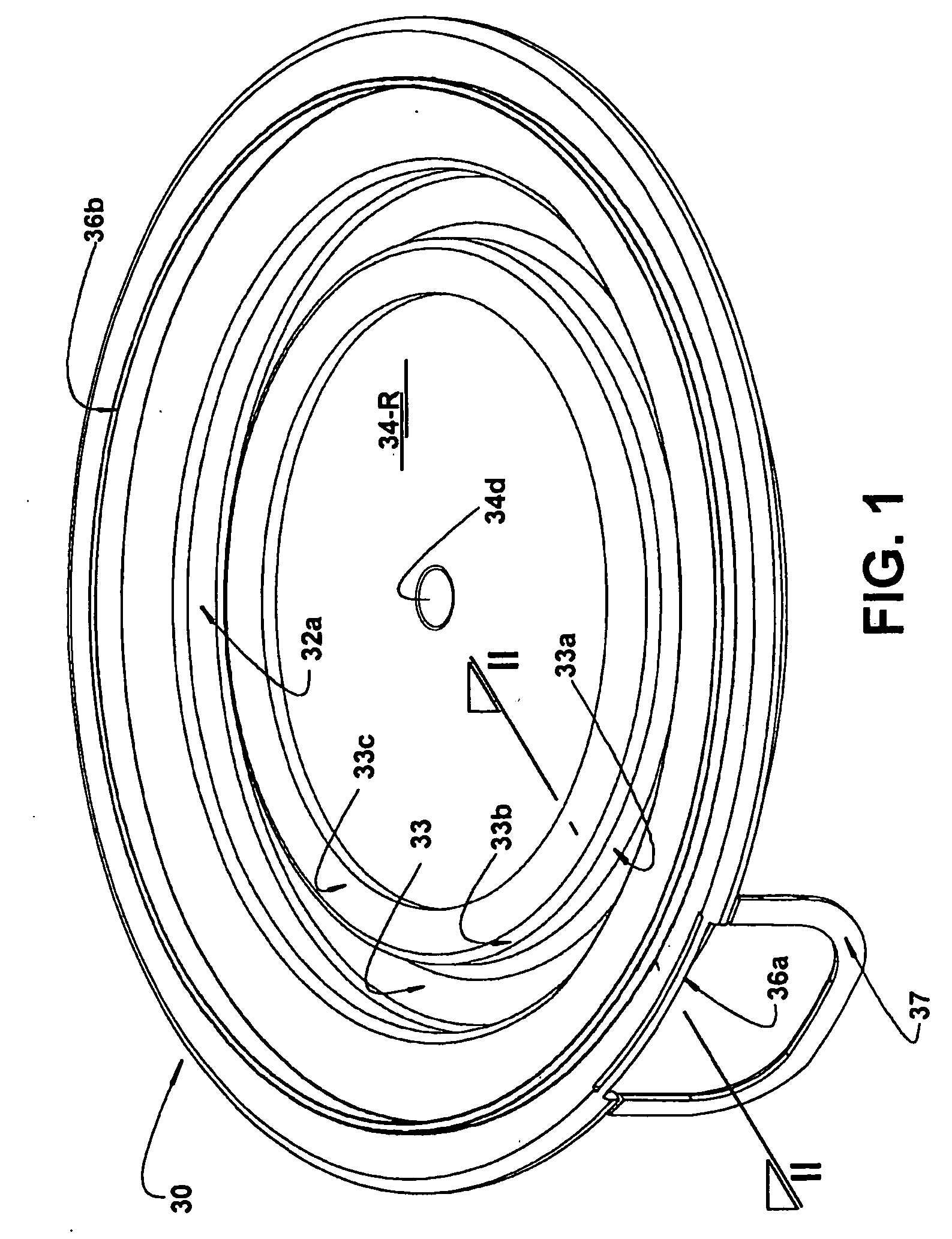

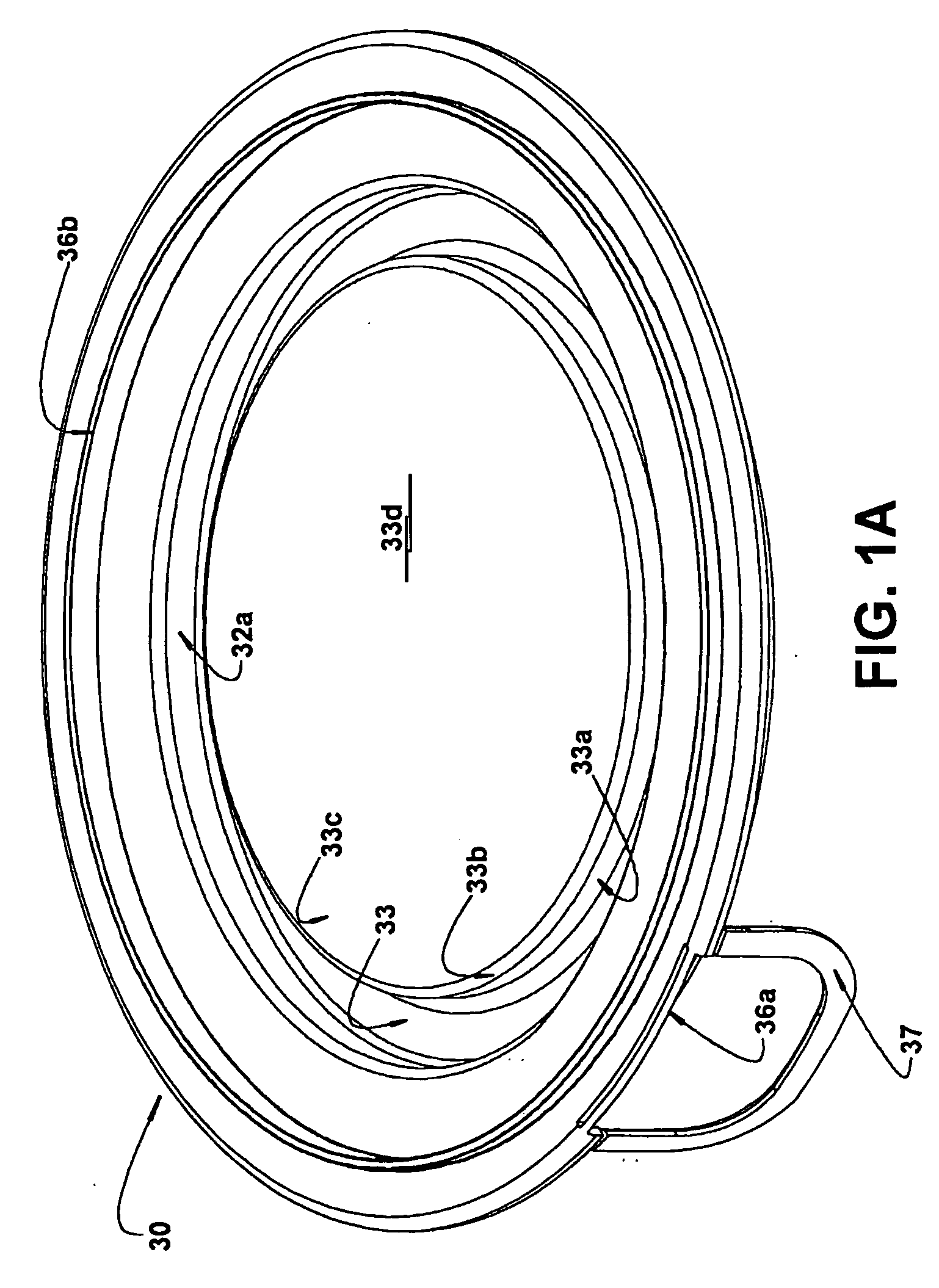

Packaging system with an overcap

A composite lid for containers which comprise a tubular body (10) carrying an annular upper wall (20) made of sheet metal, in which is defined an opening (A) surrounded by a seat (21), which is configured to receive and retain a lid (30), which comprises a base portion (31) peripherally incorporating a retention portion (32) to be seated and retained on the seat (21), when the lid (30) is closed. The base portion (31) of the lid (30) comprises: a peripheral annular element (33) molded in plastic material, in a single piece with the retention portion (32); and a central element (34) in the form of a sheet metal plate and having an outer peripheral edge (34a) attached to the peripheral annular element (33). The peripheral annular element (33) may incorporate, internally and in a single piece, a central panel (33d), disposed on the central element (34), which may be incorporated to the lid during its injection or attached thereto afterwards.

Owner:BRASILATA S A EMBALAGENS METALICAS

Fuel Container

ActiveUS20190106314A1Economies of scale in productionAvoid enteringVenting meansPackaging corrosive chemicalsEngineeringMechanical engineering

A fluid container having a body, a handle arranged in a top section of the body, a flow trigger in the handle, and a safety trigger that interacts with the flow trigger and prevents activation of the flow trigger. A vent assembly is arranged in the body and is configured to b activated by the safety trigger to vent the body. A spout assembly is movably coupled to the body and rotates between a use position and a storage position. A first valve opens as the spout assembly is moved from the storage position to the use position and a second valve is arranged upstream of the first valve to control fluid flow into the spout assembly. A linkage mechanism is arranged between the flow trigger and the second valve and configured to open the second valve when the flow trigger is activated and the safety trigger is released.

Owner:FUELHOSS LLC

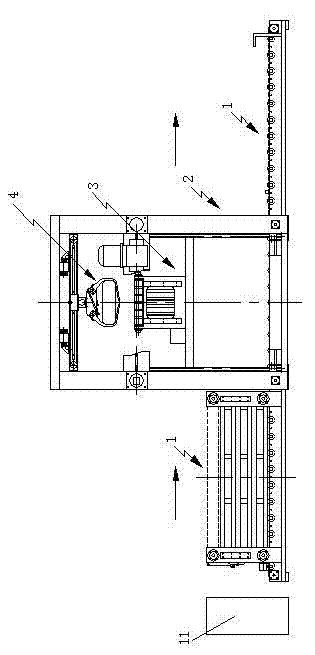

Material supply device with separation function for production line

The invention relates to a material supply device with a separation function for a production line. The material supply device comprises a base, a conveyor belt, a vertical plate, a transmission mechanism, a controller and a storage mechanism, wherein the storage mechanism comprises a fixing pipe, an air pump, an air pipe and a plurality of storage components and also comprises a storage pipe, aircylinders, pistons, movement rods and connecting pipes; and the transmission mechanism comprises a translation block, a translation component, a supporting block, a baffle and two connection components, wherein each connection component comprises a connection frame, a rack, a first gear, a second gear and a bracket. The material supply device with the separation function for the production line is convenient in safely stacking production raw materials through the storage mechanism, and can convey the stacked raw materials to the conveyor belt one by one from the bottom end through the transmission mechanism, the conveyor belt rotates to continuously convey each raw material to a production line at equal intervals to be processed, and therefore, the practicality of the material supply device is improved.

Owner:陆秀权

Novel comfortable chair

The invention discloses a novel comfortable chair comprising a chair back, a chair seat and chair legs and comprising an upper part and a lower part, wherein the upper part comprises a bottom surface and a U-shaped surrounding surface, the lower part comprises two pairs of chair legs and is fixedly connected with the bottom surface, the chair legs adopt U-shaped aluminum tube structures, bulges consistent with the chair legs in shape are arranged on outer surfaces of the chair legs, slots matched with the bulges are formed in inner surfaces of the chair legs, and the bulges of the chair legs are embedded in the slots for connection of the upper part and the lower part; the chair legs mounted on two sides of the chair seat adopt a mutually buckled structure; the gravity center of the upper part is located in the middle of the bottom surface, a first plane is parallel with the gravity center direction, and the included angle formed by a second plane and the gravity center direction ranges from 15 degrees to 18 degrees; a gas spring is arranged at a backrest of the chair seat; the chair further comprises a controller which is used for controlling the travel of the gas spring and linked with a control valve of the gas spring. The chair is simple in structure, comfortable and convenient to use and assemble.

Owner:于荣雪

Stacking machine

InactiveCN102358519BStabilize the palletizing processReliable palletizing processStacking articlesStack machineEngineering

The invention relates to a stacking machine of bagged objects, comprising a stacking device, a tray lifting, propelling and conveying device, a mechanical arm and a bag supporting device, wherein the tray lifting, propelling and conveying device consists of a tray feeding device and an out-stacking conveying device; the stacking device is arranged between the tray feeding device and the out-stacking conveying device; the stacking device is in transmission connection with the mechanical arm; the bag supporting device is arranged at one side of the stacking device; the tray feeding device comprises a rack, a conveying frame, a lifting mechanism, a lifting beam and a pushing rod; the mechanical arm comprises a rotating motor, a plurality of grabbing fingers and a grabbing palm, the grabbing palm is fixedly provided with a driving cylinder which is provided with a piston rod in transmission connection with one rotating shaft on the grabbing palm through a rotating block, and each rotatingshaft is fixedly provided with a plurality of the grabbing fingers. The stacking machine provided by the invention is simple in structure, smooth in action, capable of continuously finishing stackingwork of the bagged objects in the automatic production process, saving in manpower and material resources and high in stacking efficiency.

Owner:溧阳市元创智能设备有限公司

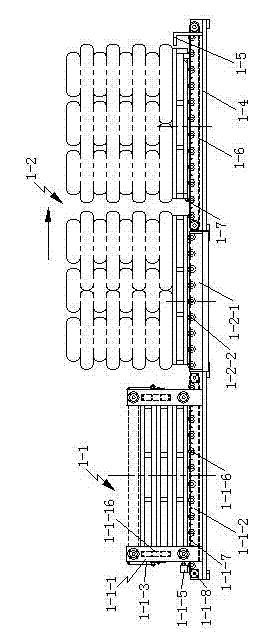

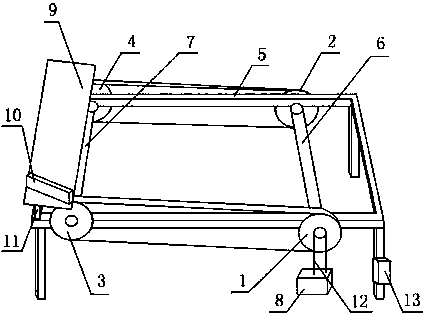

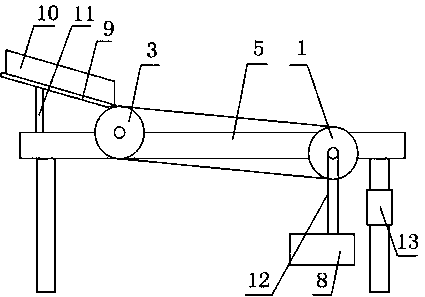

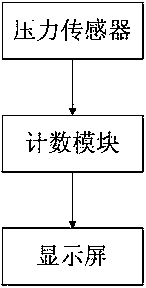

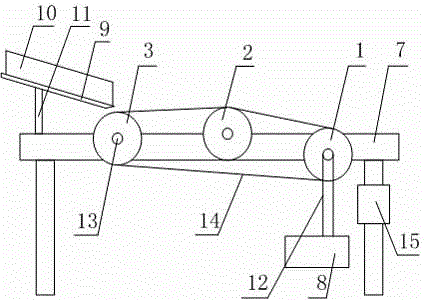

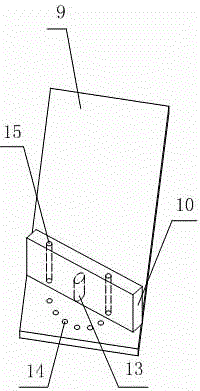

Counting, steering and decelerating device for strip-shaped material production line terminal

InactiveCN107758279ASafe stackingAutomatic stackingConveyorsCounting mechanisms/objectsProduction lineElectric machine

The invention discloses a counting and steering deceleration device for the terminal of a bar-shaped material production line, which comprises a frame-shaped frame body, and four rollers are arranged on the side of the frame body, wherein the first roller and the third roller are located on the same side of the frame body The second roller and the fourth roller are respectively arranged on the other side of the frame opposite to the first roller and the third roller, and the first roller is driven by a motor; one side of the frame is also provided with a slide plate inclined towards the belt, One end of the slide plate is provided with a baffle inclined towards the inside of the frame body; a pressure sensor and a counting module are arranged in the baffle, and a display screen is provided on the frame body, and the counting module is respectively connected with the pressure sensor and the display screen. The present invention solves the problem of inconvenient stacking and handling at the conveying terminal in the prior art in the production process of strips, and at the same time easily causes harm to workers, and achieves safe and automatic stacking of strips produced on the production line, and at the same time The purpose of counting products.

Owner:刘万洪

Bounce steering type strip conveying terminal apparatus with counting function

InactiveCN105731048ASafe stackingAutomatic stackingStacking articlesConveyor partsProduction lineSlide plate

The invention discloses a rebound-steering bar conveying terminal device with a counting function, which includes a frame-shaped frame body, and one side of the frame body is provided with a first roller, a second roller, and a third roller linked by a belt. The three rollers are respectively connected with the three connecting rods that run through to the other side of the frame, and the other sides of the three connecting rods are respectively connected with the fourth roller, the fifth roller and the sixth roller linked by belts; the second roller, The fifth rollers are higher than the other rollers on the same side; the frame body is provided with a support rod, the top of the support rod is connected with a slide plate inclined downward to the belt surface, and one end of the slide plate is provided with a baffle plate inclined toward the inside of the frame body . The present invention solves the problem of inconvenient stacking and handling at the conveying terminal in the prior art in the production process of strips, and at the same time easily causes injury to workers, and achieves the purpose of safely and automatically stacking the strips produced on the production line.

Owner:SICHUAN XINGAOLI DECORATION MATERIAL CO LTD

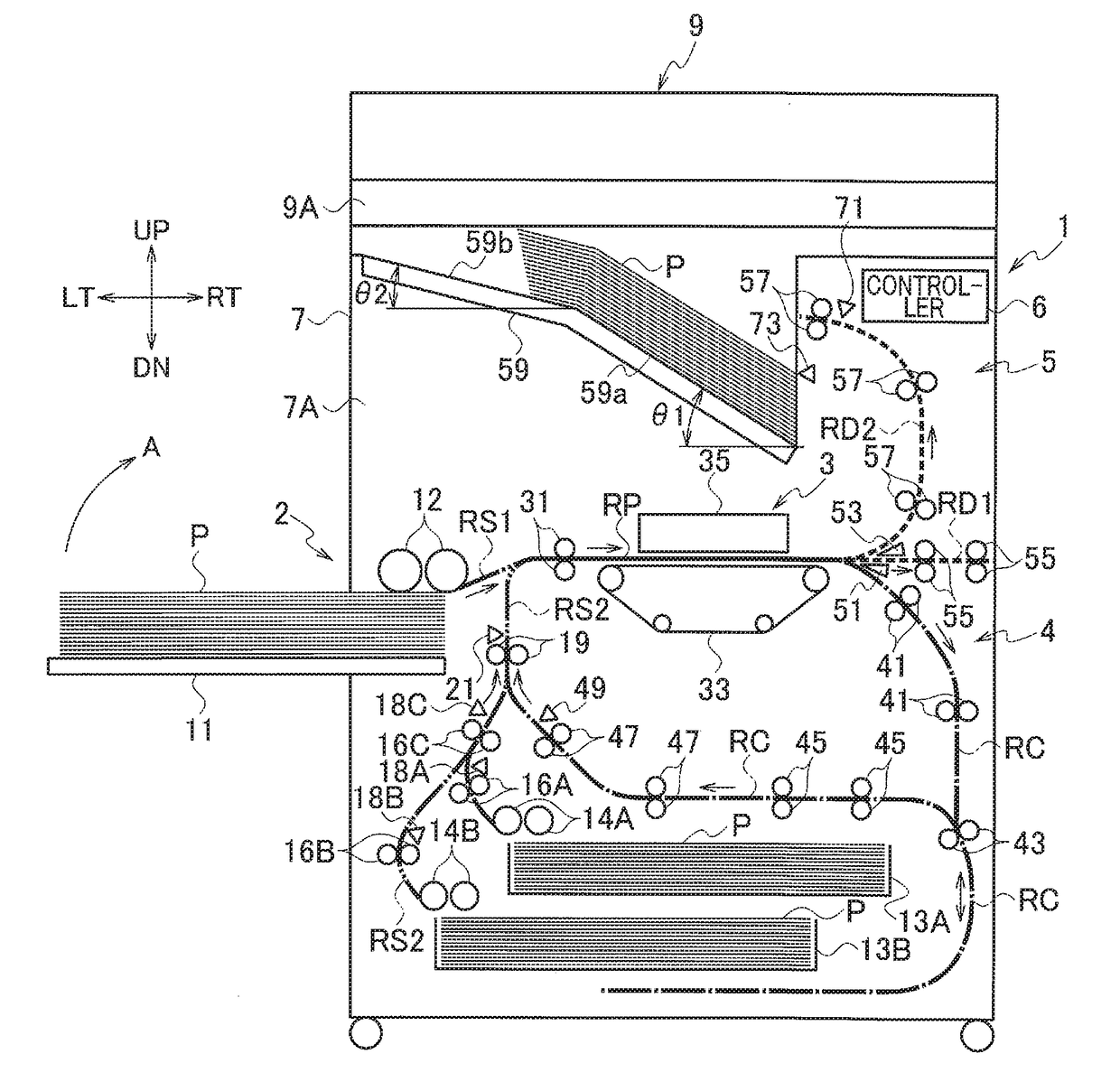

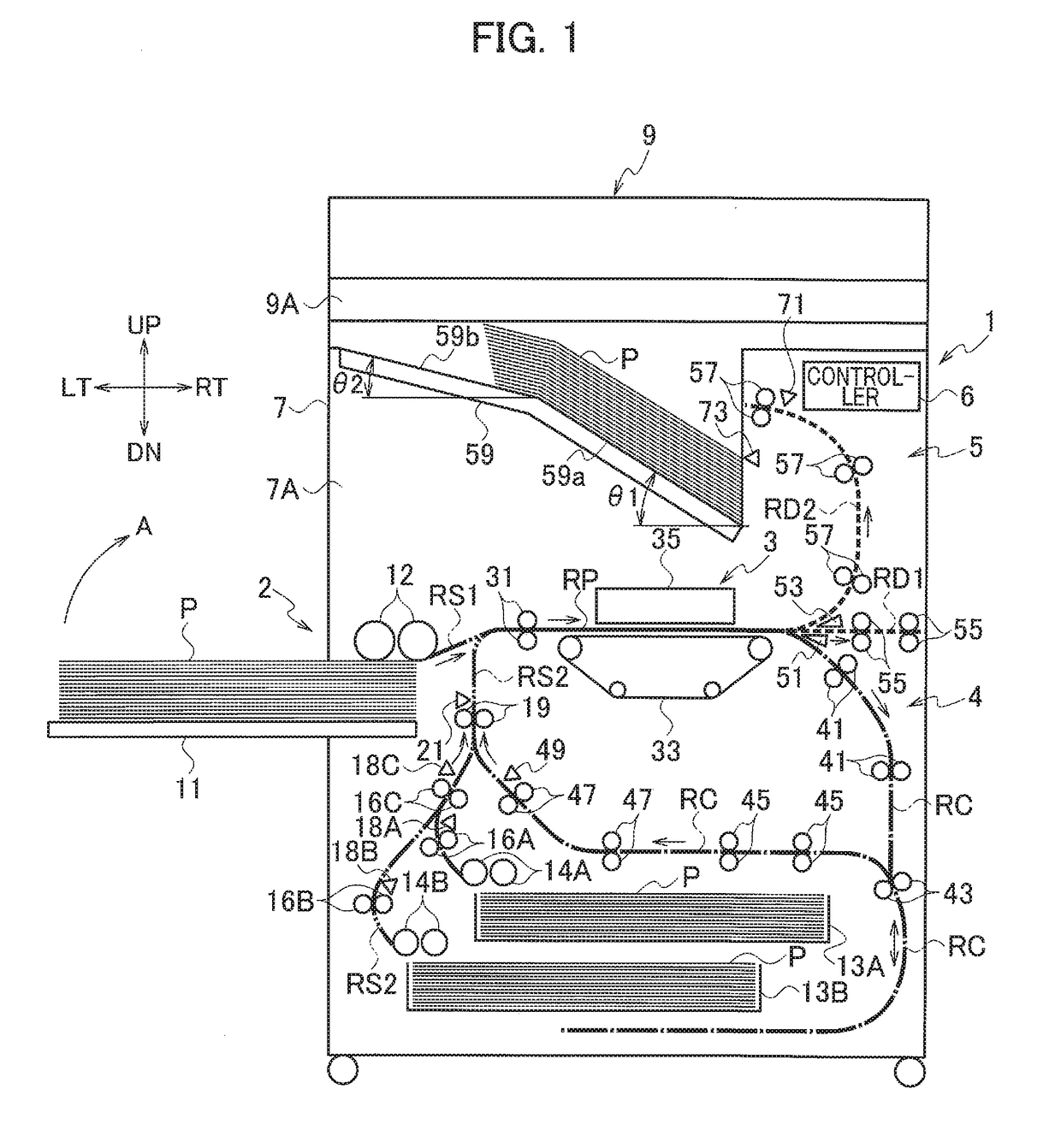

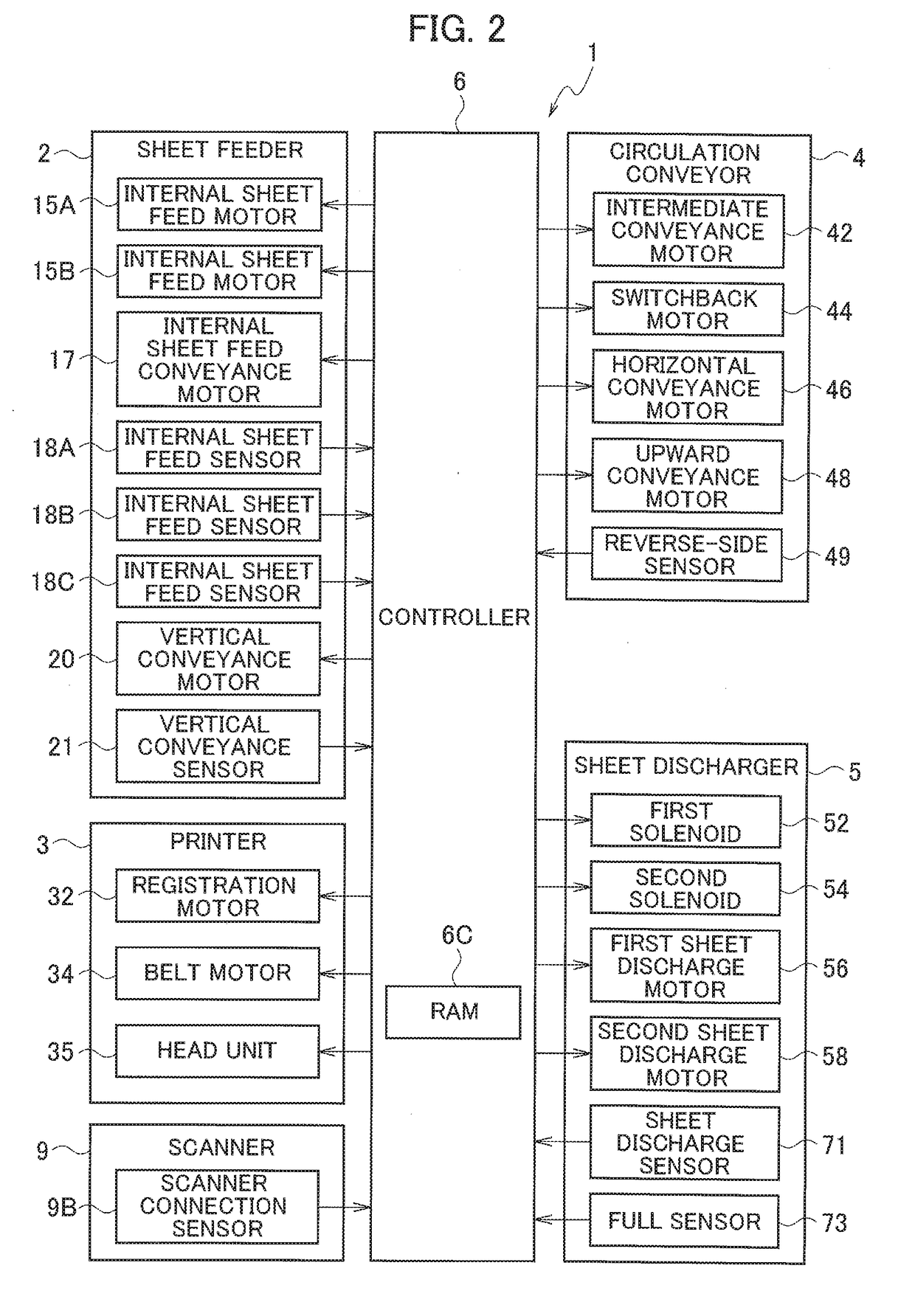

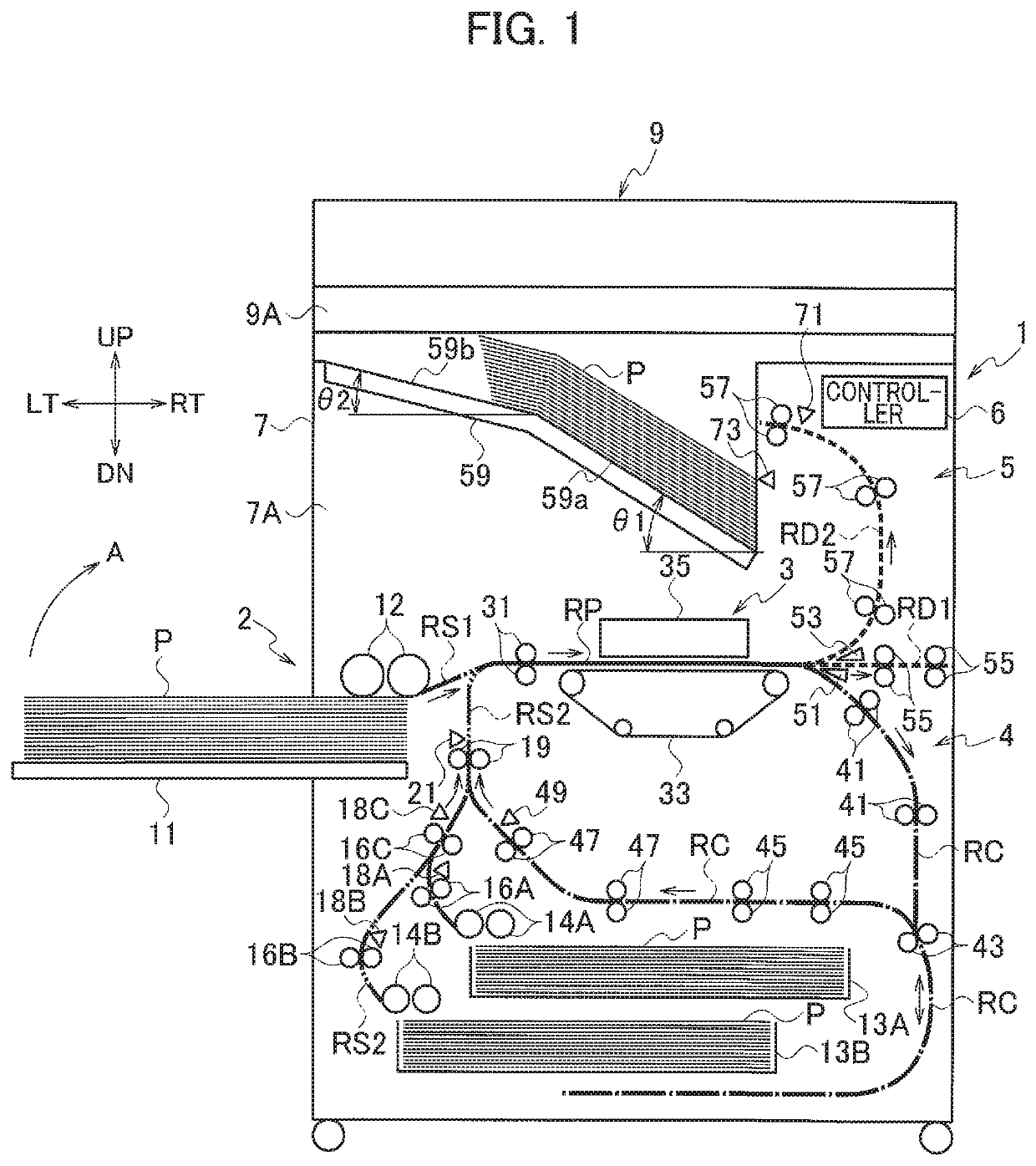

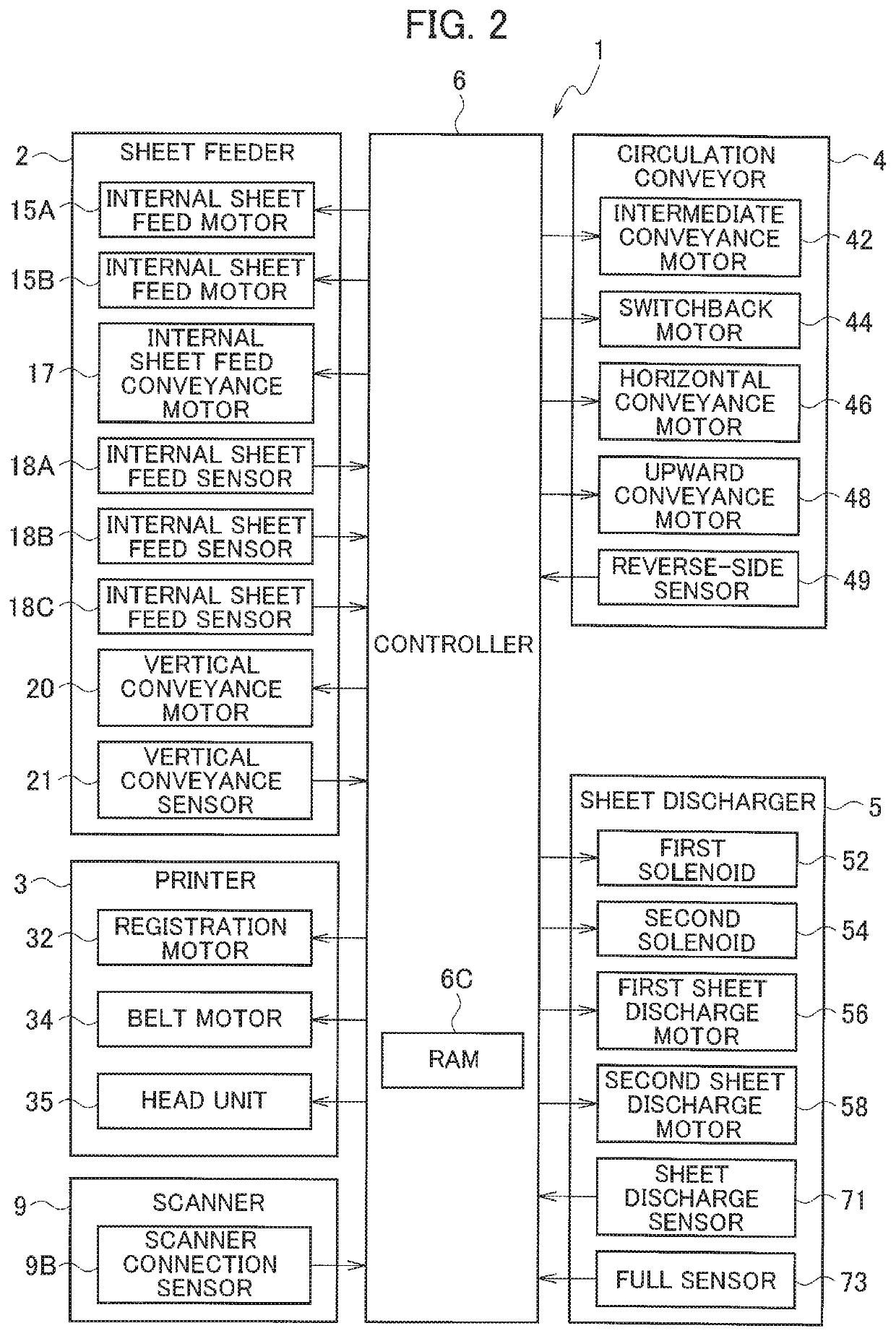

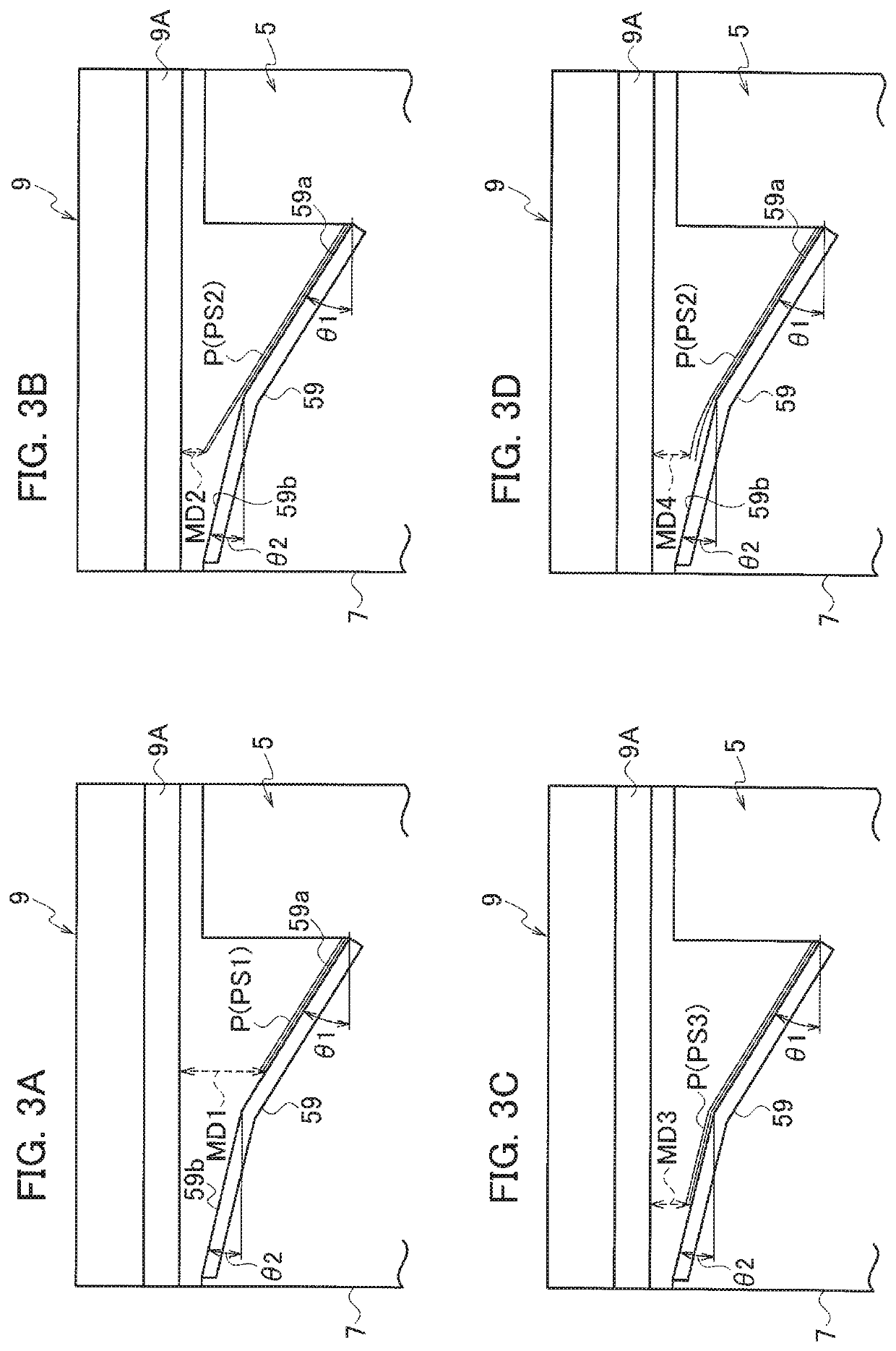

Printing apparatus capable of performing printing on partially-thick sheets

ActiveUS20180141354A1Avoid dischargeShorten the timeFunction indicatorsElectrographic process apparatusElectrical and Electronics engineering

A printing apparatus includes: a sheet discharge tray having an upstream portion tilted to extend downward in a direction of gravity; an upper member limiting a height of a space above the sheet discharge tray; a full sensor configured to detect an upstream end of a top sheet of sheets stacked on the sheet discharge tray; a counter configured to count a number of the sheets discharged onto the sheet discharge tray; and a controller. The controller determines whether to stop discharging of the sheets to the sheet discharge tray, based on a detection result of the full sensor upon the sheets to be stacked on the sheet discharge tray including only sheets each with uniform thickness and based on a count value of the counter upon the sheets to be stacked on the sheet discharge tray including a sheet with thickness varying partly.

Owner:RISO KAGAKU CORP

Container for pressurized fluids

InactiveUS8800771B2Safe stackingAvoid displacementLiquid dispensingTray containersEngineeringContact region

A container having a tubular body including a side wall, a bottom wall in the form of a spherical dome projecting to the interior of the container, and an upper wall in the form of an annular spherical dome, inferiorly attached to the side wall by an upper double seam. The bottom wall includes at least one seating region having a predetermined circumferential extension along a plane extending transversely with respect to an axis of the container and being axially spaced inwardly within the side wall of the container, the seating region being configured to be fitted around a respective circumferential extension a upper double seam of an identical and adjacent container inferiorly disposed in a vertical stack, and axially seated on said upper double seam, so as to define a single contact region between two vertically stacked containers.

Owner:BRASILATA S A EMBALAGENS METALICAS

Rebound steering type strip material conveying terminal equipment

The invention discloses rebound steering type strip material conveying terminal equipment. The rebound steering type strip material conveying terminal equipment comprises a frame-shaped stand and four rollers on the side faces of the stand, and the four rollers are linked through connection rods and belts. One side of the stand is further provided with a sliding plate tilting towards the belts. One end of the sliding plate is provided with a baffle titling towards the inner side of the stand. The baffle rotates on the surface of the sliding plate through a rotary shaft inside the baffle. The sliding plate is provided with a plurality of open holes which are distributed evenly and annularly around the rotary shaft. The two sides of the top of the baffle are provided with through holes matched with the open holes and plug pins matched with the through holes. By means of the rebound steering type strip material conveying terminal equipment provided in the invention, the problems that in the prior art, strip materials are inconvenient to stack and convey at the conveying terminal in the production process, and workers are likely to be injured are solved, and the purpose that strip materials produced on a production line are stacked in a steering mode safely and automatically is achieved.

Owner:SICHUAN XINGAOLI DECORATION MATERIAL CO LTD

Storage cage in improved structure

InactiveCN100482543CEasy to foldEasy and reliable stackingRigid containersLocking mechanismEngineering

Owner:SUZHOU PINGFANG IND CO LTD

Printing apparatus capable of performing printing on partially-thick sheets

ActiveUS10576761B2Avoid dischargeShorten the timeFunction indicatorsElectrographic process apparatusPaper sheetElectrical and Electronics engineering

A printing apparatus includes: a sheet discharge tray having an upstream portion tilted to extend downward in a direction of gravity; an upper member limiting a height of a space above the sheet discharge tray; a full sensor configured to detect an upstream end of a top sheet of sheets stacked on the sheet discharge tray; a counter configured to count a number of the sheets discharged onto the sheet discharge tray; and a controller. The controller determines whether to stop discharging of the sheets to the sheet discharge tray, based on a detection result of the full sensor upon the sheets to be stacked on the sheet discharge tray including only sheets each with uniform thickness and based on a count value of the counter upon the sheets to be stacked on the sheet discharge tray including a sheet with thickness varying partly.

Owner:RISO KAGAKU CORP

Steering conveying device for strip plates

Owner:SICHUAN XINGAOLI DECORATION MATERIAL CO LTD

Height-adjustable strip-shaped material steering device

The invention discloses a height-adjustable bar-shaped material steering device, which comprises a frame-shaped frame body, and four rollers whose highest points are higher than the surface of the frame body are arranged on the side of the frame body, wherein the first roller, the third roller Located on the same side of the frame body, the second roller and the fourth roller are set on the other side of the frame body opposite to the first roller and the third roller respectively, and the first roller is driven by a motor; the frame body is close to the third roller and the fourth roller One side of the slide plate is also provided with a slide plate inclined towards the belt, and one end of the slide plate is provided with a baffle plate inclined towards the inside of the frame body, and the slide plate is fixed on the surface of the frame body through N linked electric push rods, wherein N is a positive value greater than 1 integer. The present invention proposes a height-adjustable bar steering device to solve the problem of inconvenient stacking and handling at the conveying terminal in the production process of the bar in the prior art, and at the same time, it is easy to cause injury to workers, so as to achieve a safe and automatic The purpose of stacking strips produced on the production line.

Owner:刘万洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com