Bounce steering type strip conveying terminal apparatus with counting function

A terminal device and bar-shaped material technology, which is applied to conveyor objects, transportation and packaging, and object stacking, etc., can solve the problems of worker injury, inconvenient stacking and handling at the conveying terminal, and achieve the effect of reducing damage and facilitating stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

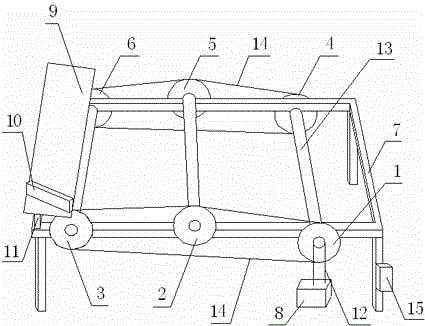

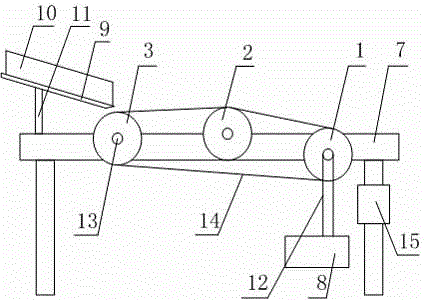

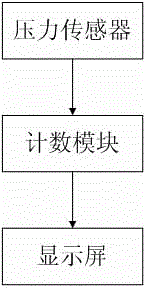

[0018] like Figure 1 to Figure 3 The shown rebound-steering bar conveying terminal device with a counting function includes a frame-shaped frame body 7, and one side of the frame body 7 is sequentially provided with a first roller 1 and a second roller 2 linked by a belt 14. , the third roller 3, the three rollers are respectively connected with the three connecting rods 13 penetrating to the other side of the frame body, and the other side of the three connecting rods are respectively connected with the fourth roller 4 and the fifth roller 5 which are also linked by the belt 14 , the sixth roller 6; the first roller 1 is driven by a motor 8; the second roller 2 is higher than the first roller 1 and the third roller 3, and the fifth roller 5 is higher than the fourth roller 4, the sixth roller Roller 6; described frame body 5 is provided with support rod 11 on the parallel side of connecting rod 13, and the top of support rod 11 is connected with the slide plate 9 that slopes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com