Storage cage in improved structure

A storage cage and locking mechanism technology, applied in the field of storage cages, can solve problems such as stuck, not suitable for stacking, large space occupation, etc., and achieve the effect of reliable locking, convenient and reliable stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

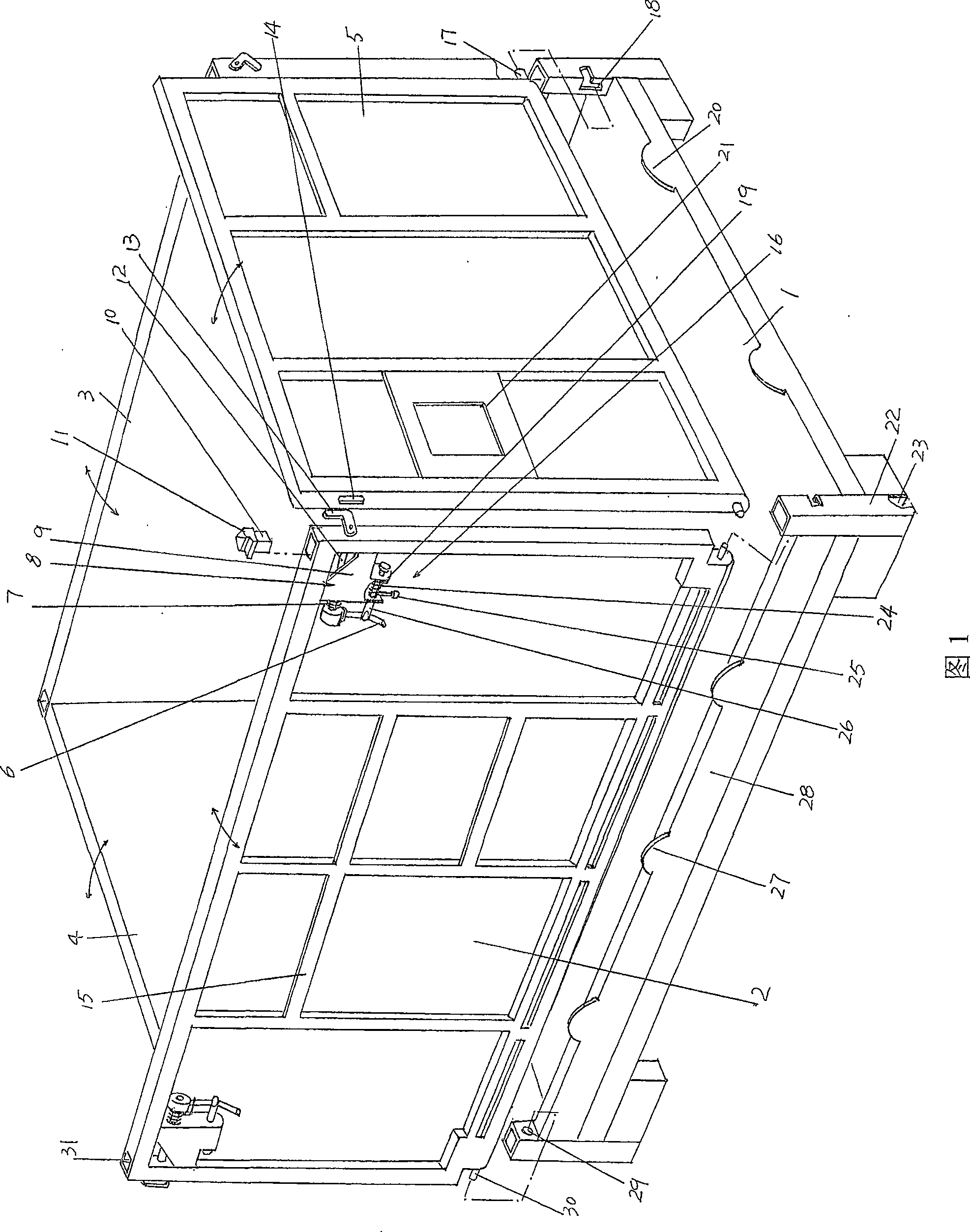

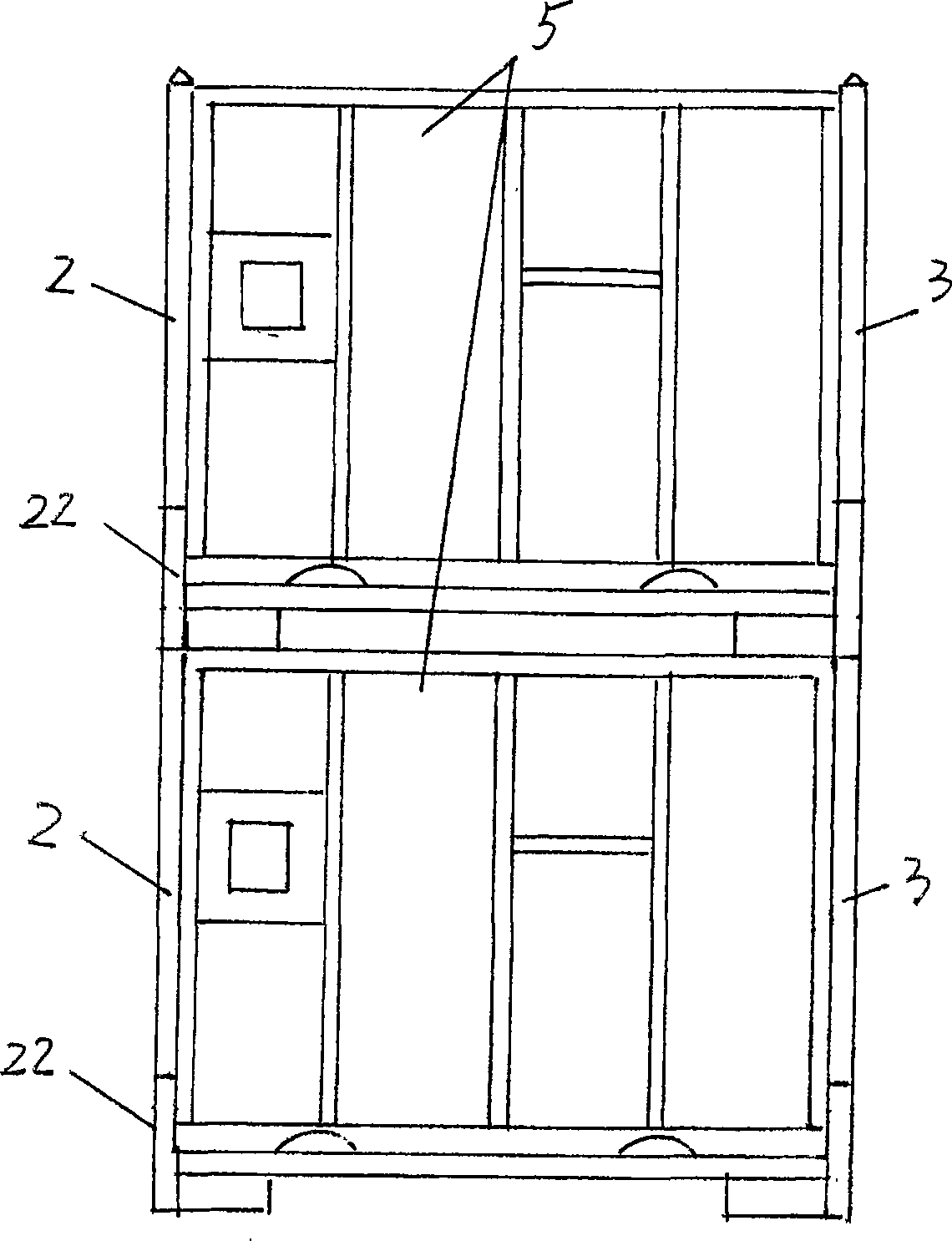

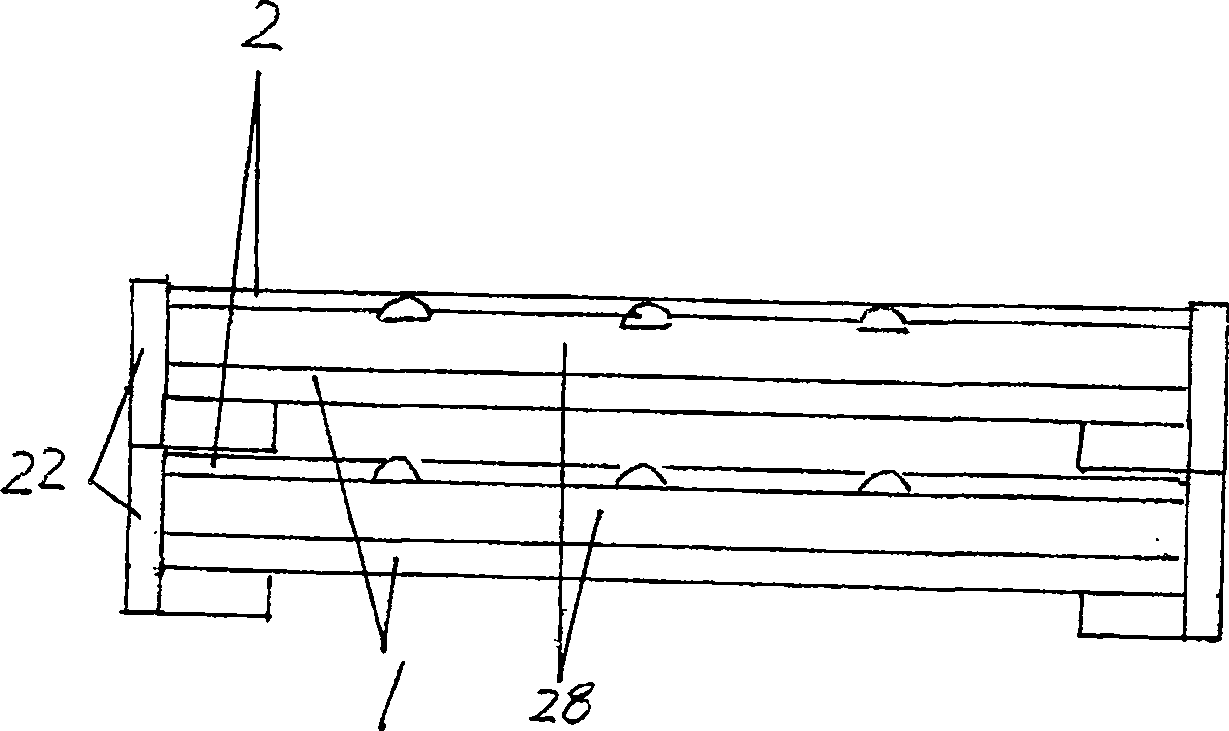

[0017] Please refer to Fig. 1, the shape of the chassis 1 provided is preferably rectangular, and preferably in the shape of a cuboid, each of the four corners of the chassis 1 is formed with a supporting foot 22, and the bottom of the supporting foot 22 is formed with a first tenon hole 23. The hole shape of the first tenon hole 23 does not need to be limited in the present invention, because as the shape of the tenon 11 mentioned below changes, the shape of the first tenon hole 23 also changes, so the figure The shape of the first tenon hole 23 and the tenon 11 shown in is just an example. The upper part of the supporting foot 22, that is, the upper part of the chassis 1, is provided with a small shaft groove 18 and a shaft hole 29 respectively. There is a chassis coaming plate 28, and on the chassis coaming plate 28, a group of first retaining protrusions 27 with no specific limit are extended, and at least one (shown in the figure) is extended on the upper edge of the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com