Height-adjustable strip-shaped material steering device

A steering device and bar-shaped material technology, which is applied in the field of furniture, can solve the problems of inconvenient stacking and handling at the conveying terminal, and worker injuries, and achieve the effect of convenient stacking and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

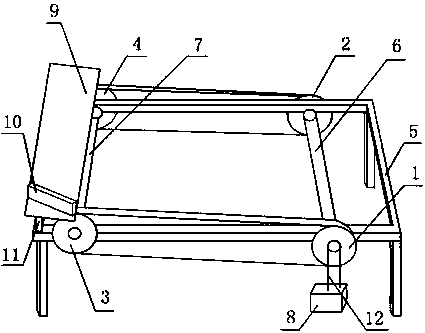

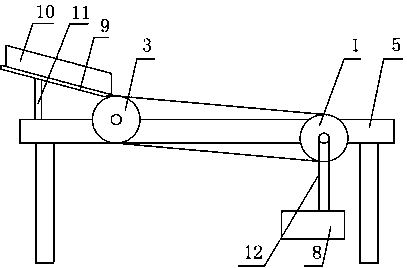

[0016] Such as figure 1 and figure 2 The height-adjustable strip turning device shown includes a frame-shaped frame body 5, and the side of the frame body 5 is provided with a first roller 1, a second roller 2, and a roller whose highest point exceeds the surface of the frame body 5. The third roller 3 and the fourth roller 4, wherein the first roller 1 and the third roller 3 are located on the same side of the frame body 1, the second roller 2 and the fourth roller 4 are set opposite to the first roller 1 and the third roller 3 respectively On the other side of the frame body 1, the first roller 1 and the second roller 2 are connected through the first connecting rod 6, the third roller 3 and the fourth roller 4 are connected through the second connecting rod 7, the first roller 1 and the third roller The rollers 3 are linked by a belt, the second roller 2 and the fourth roller 4 are linked by a belt, and the first roller 1 is driven by a motor 8; There is a slide plate 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com