Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Rigid in construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

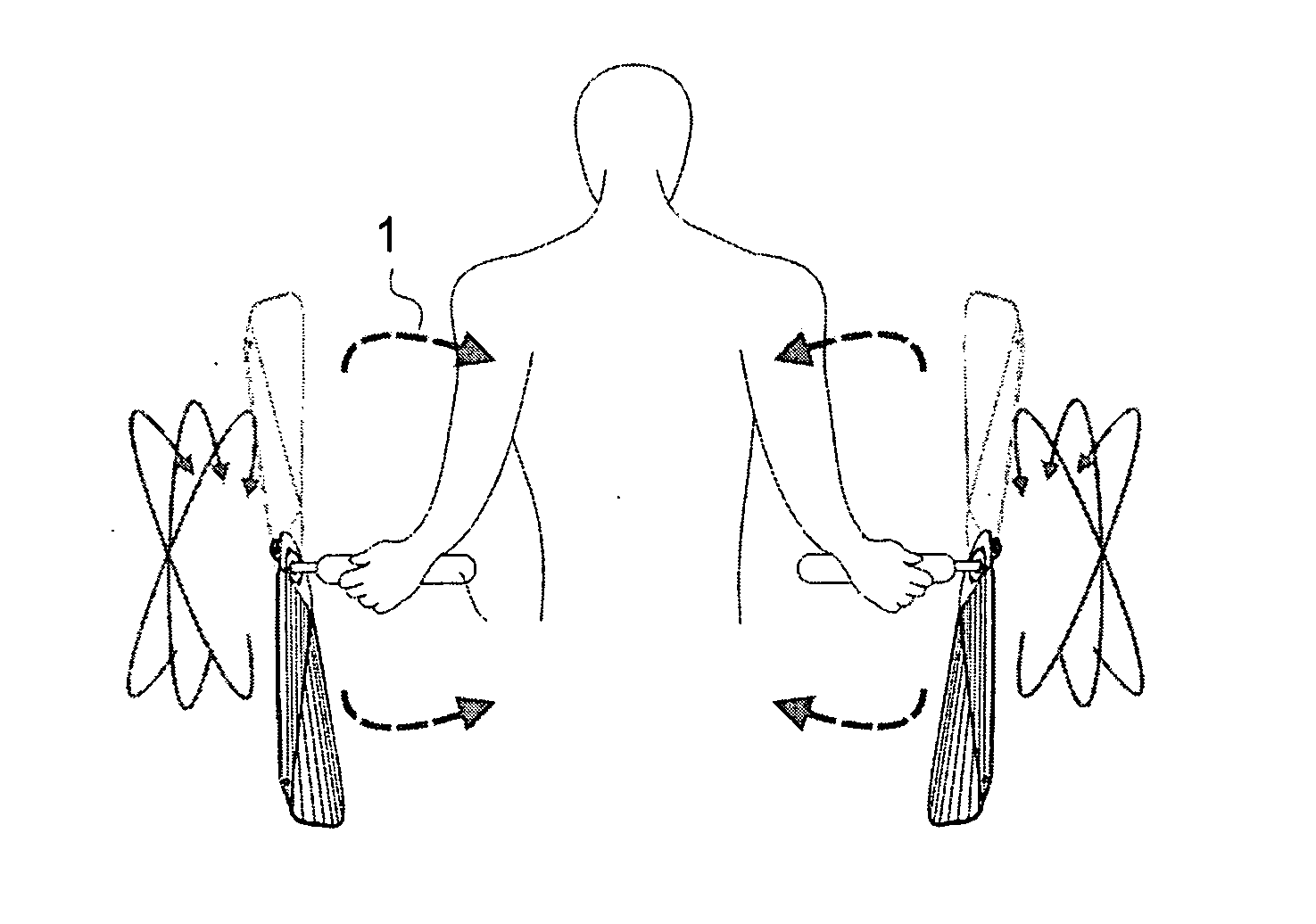

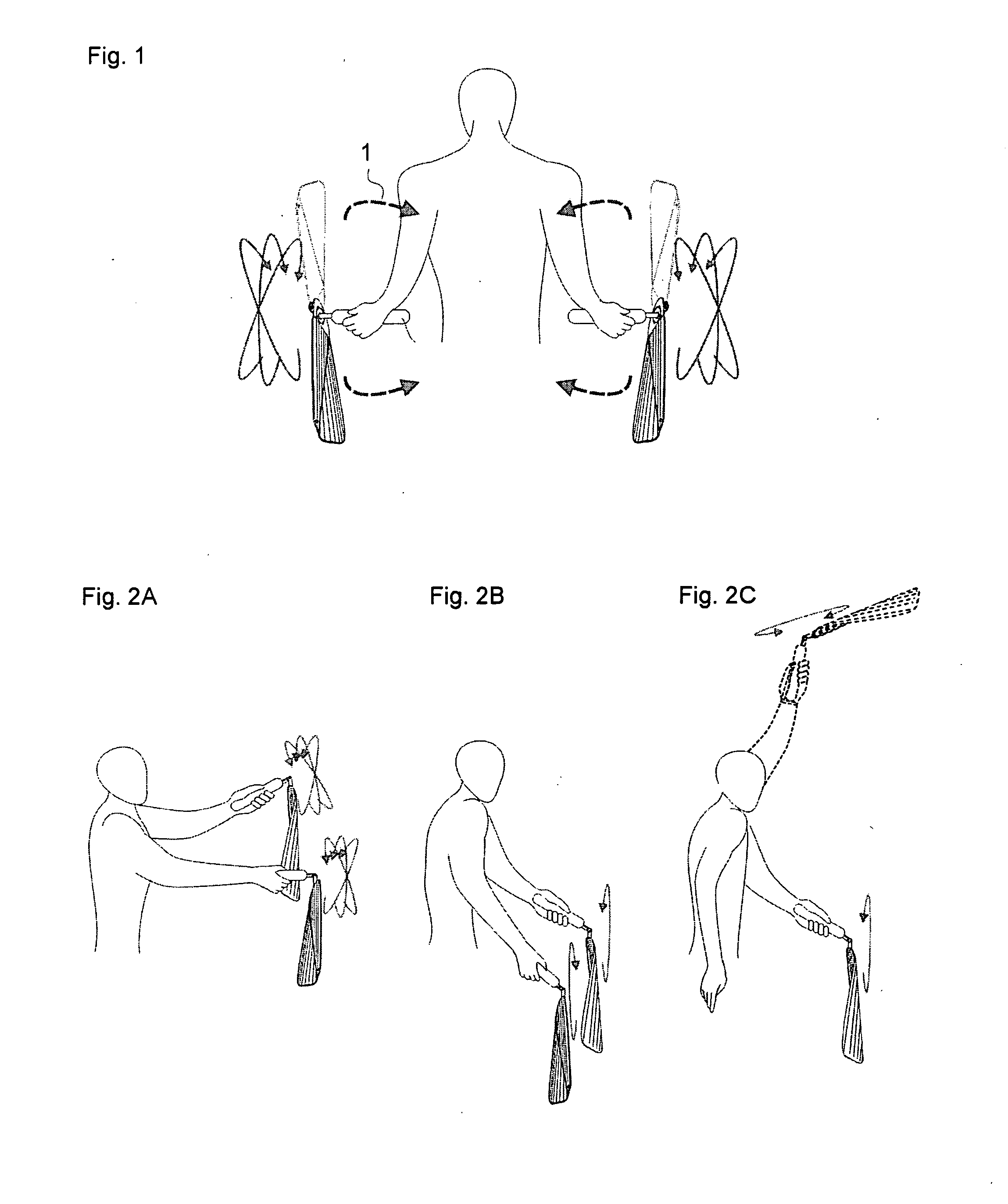

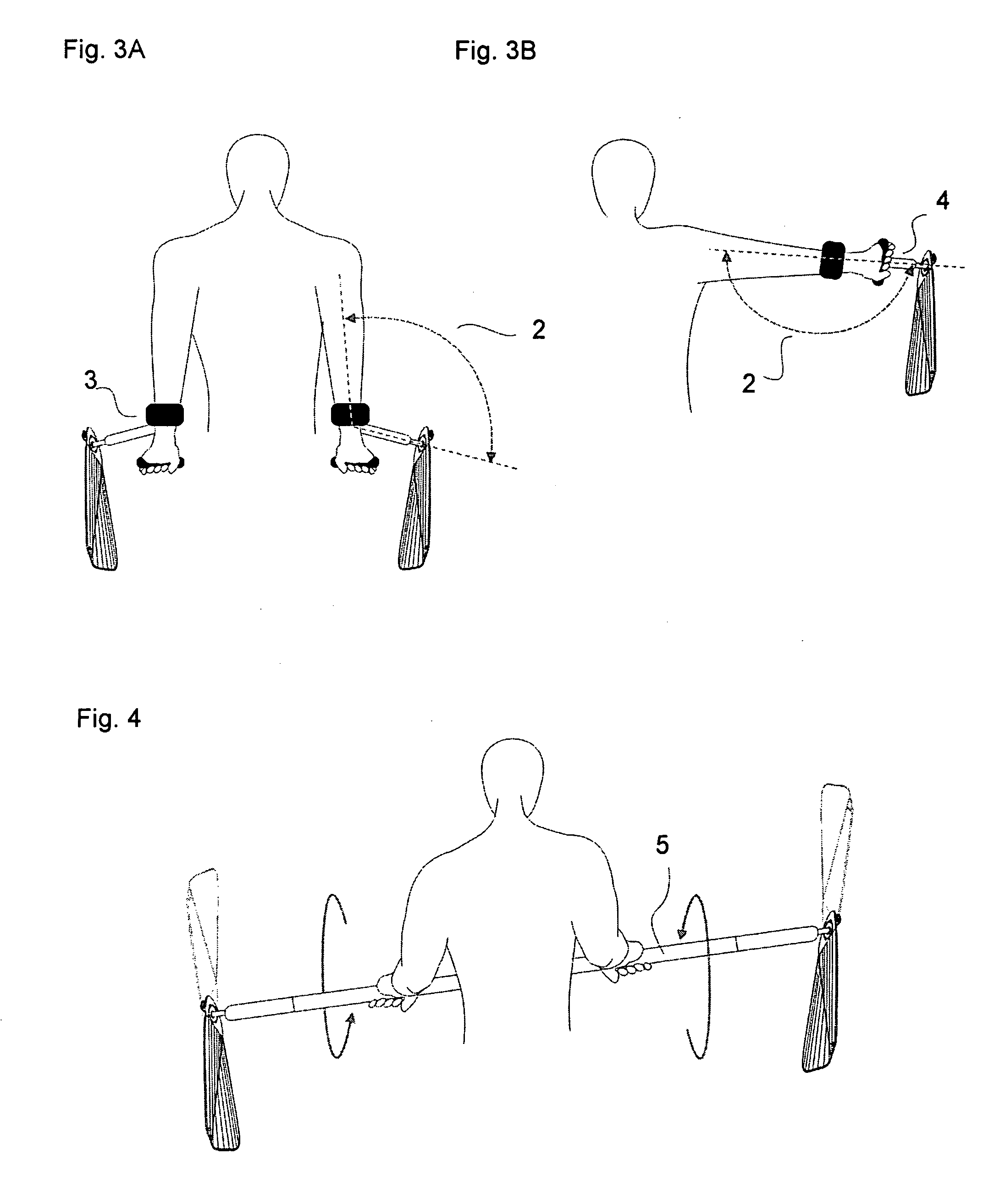

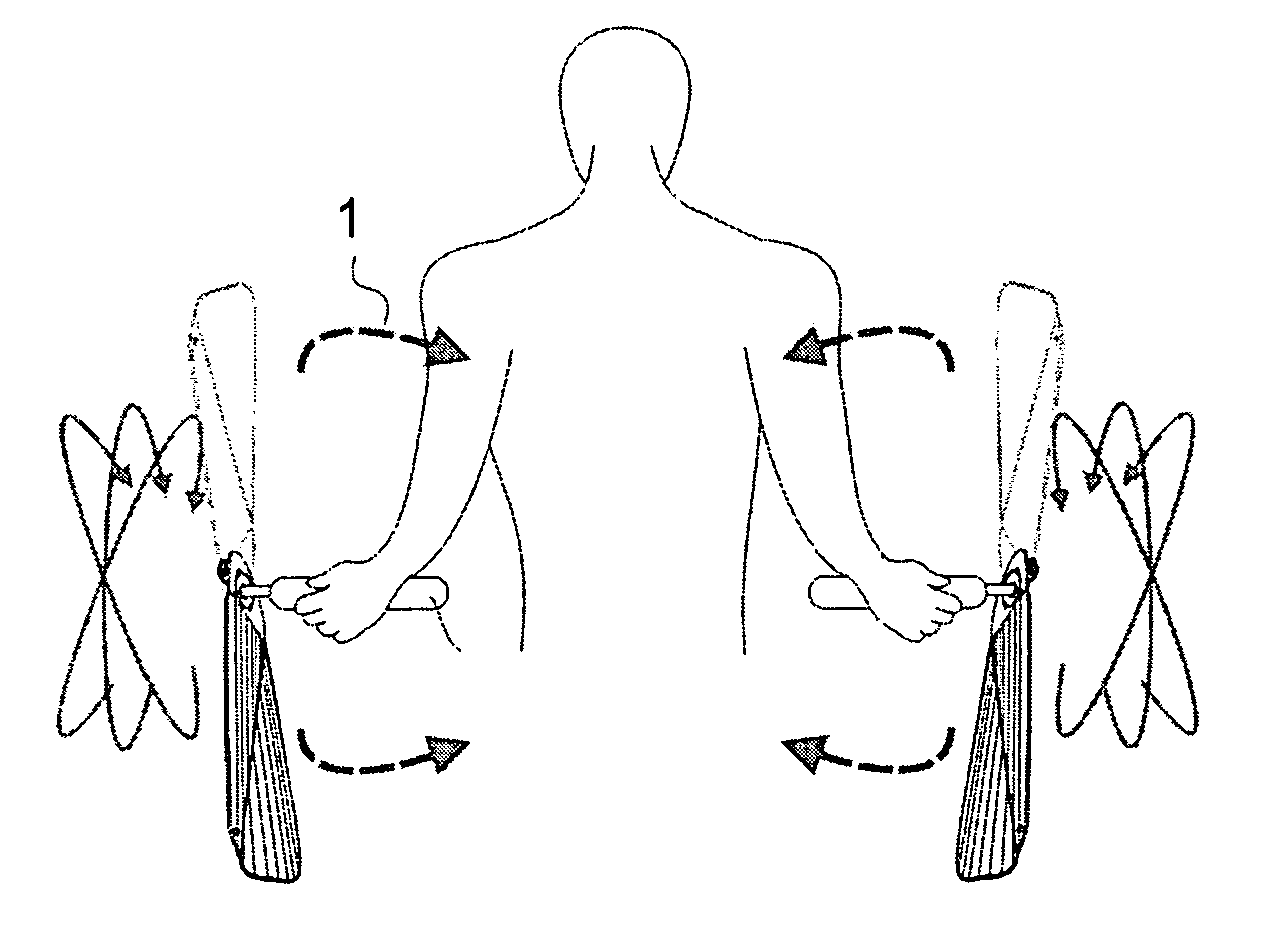

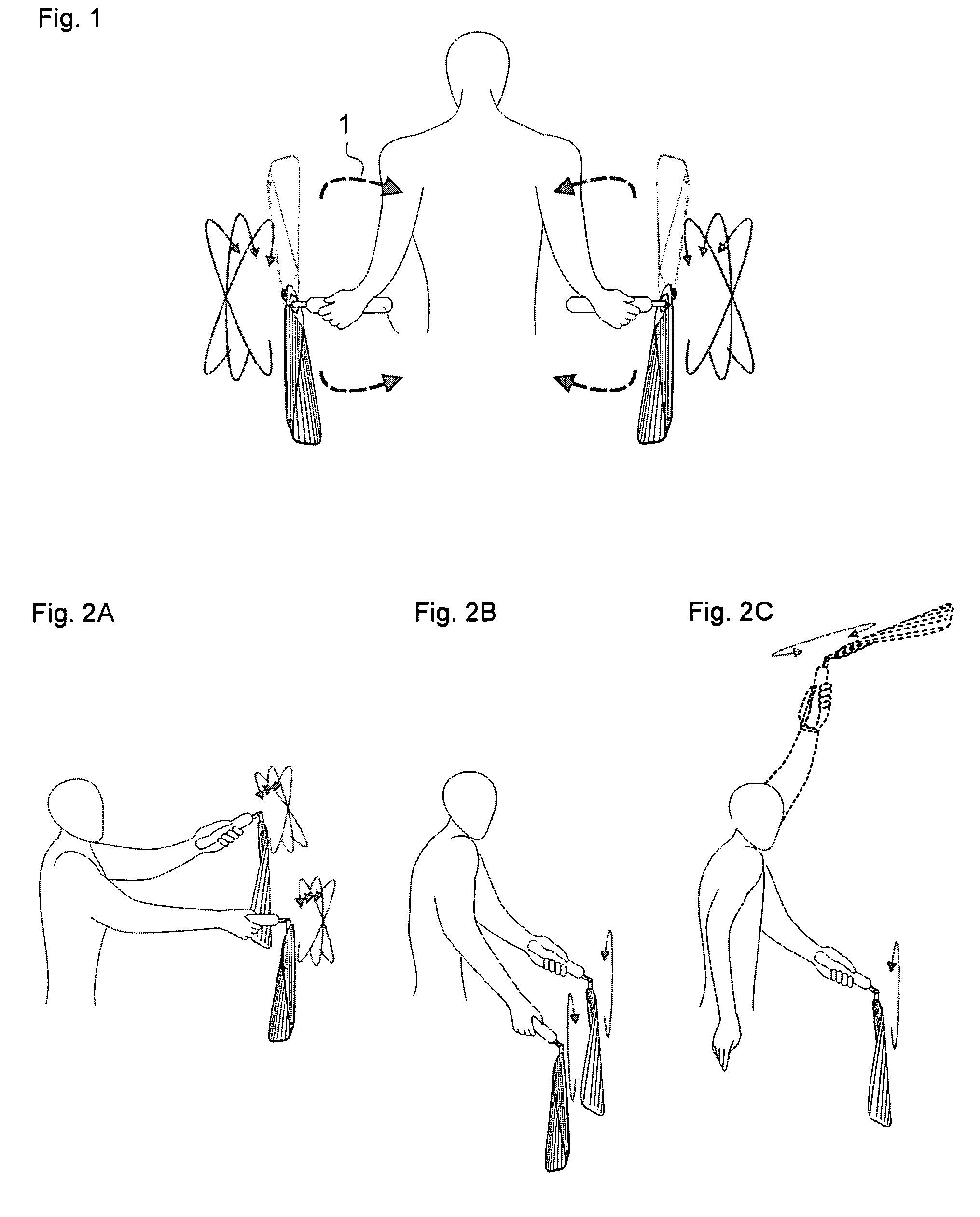

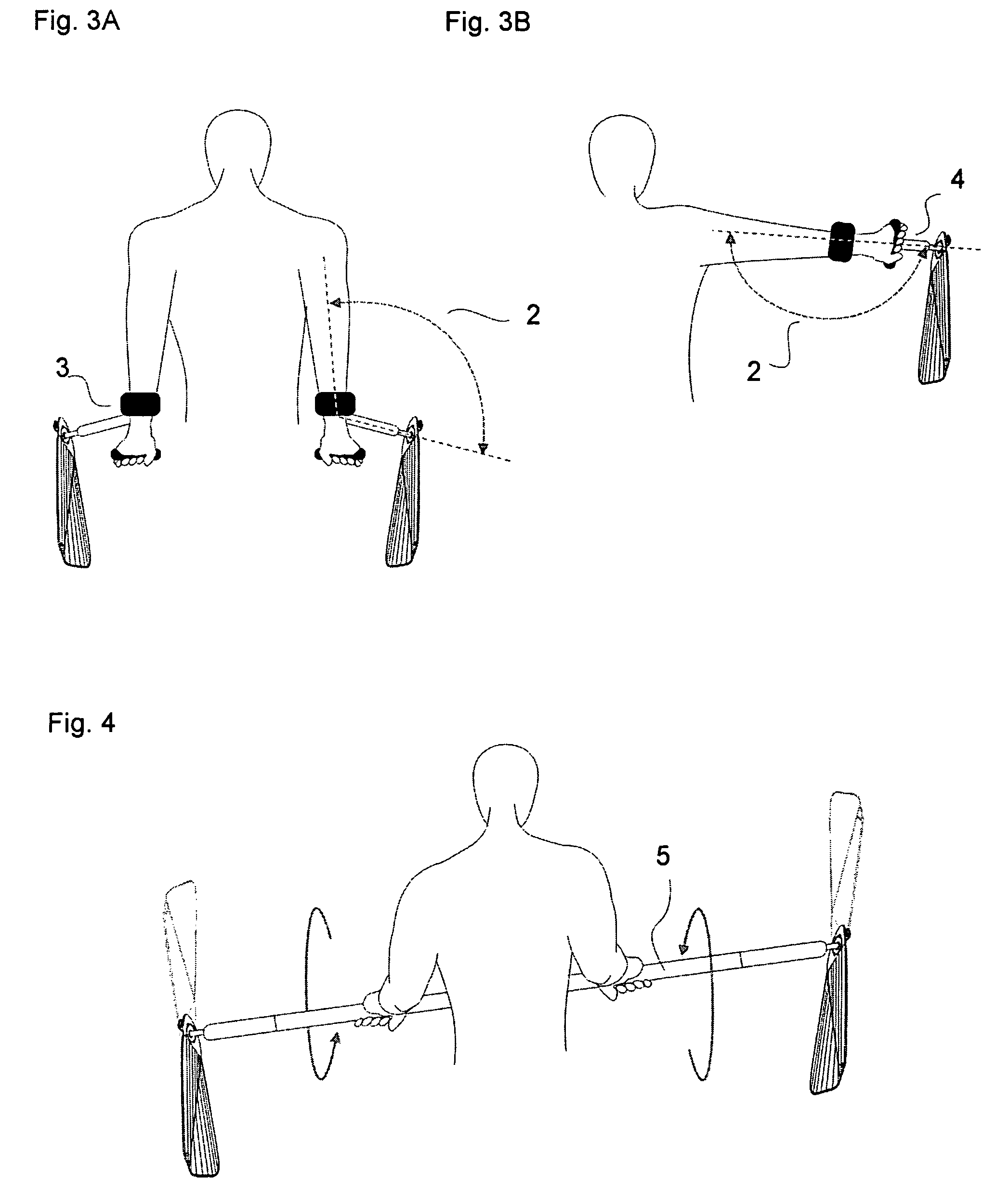

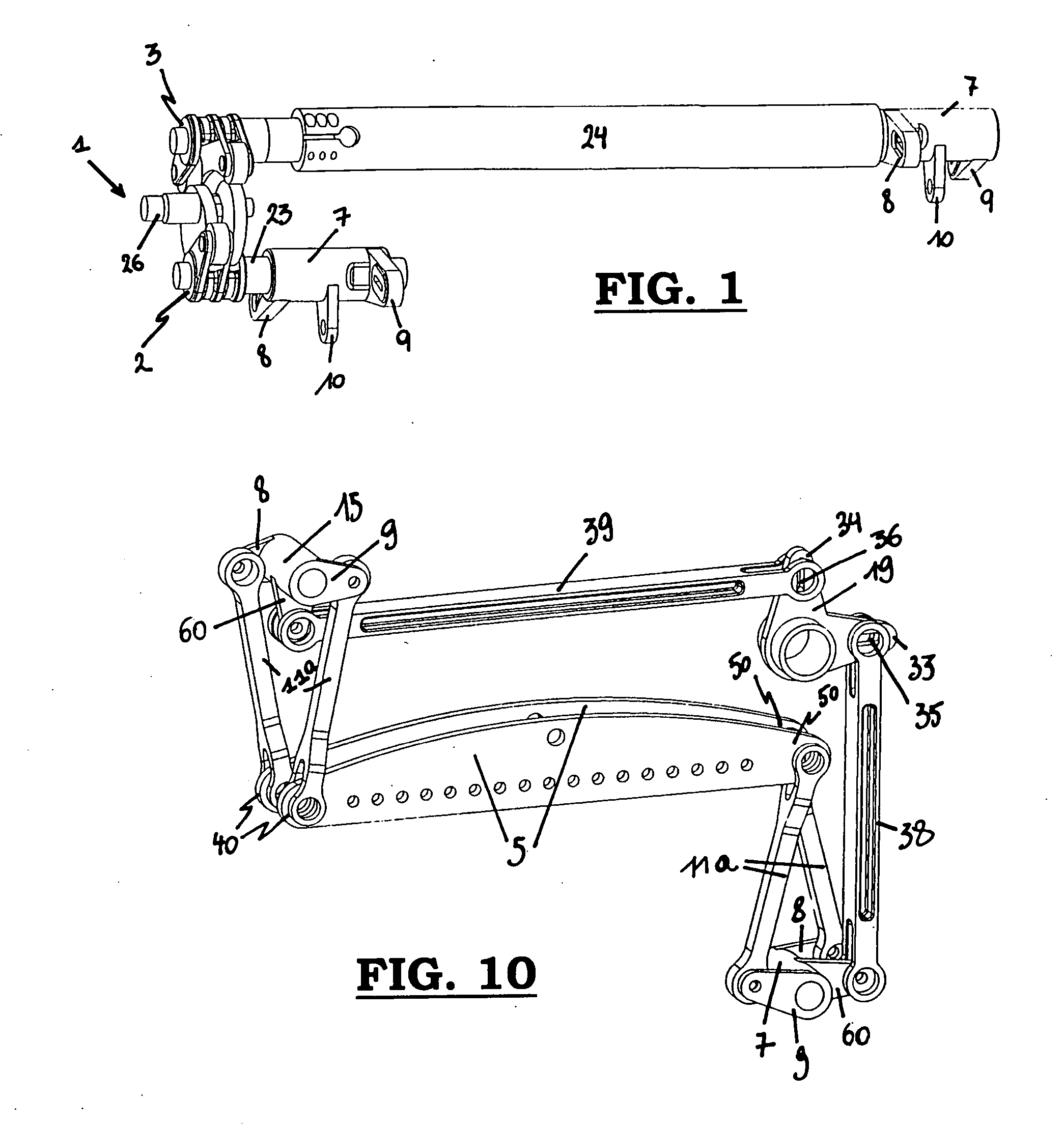

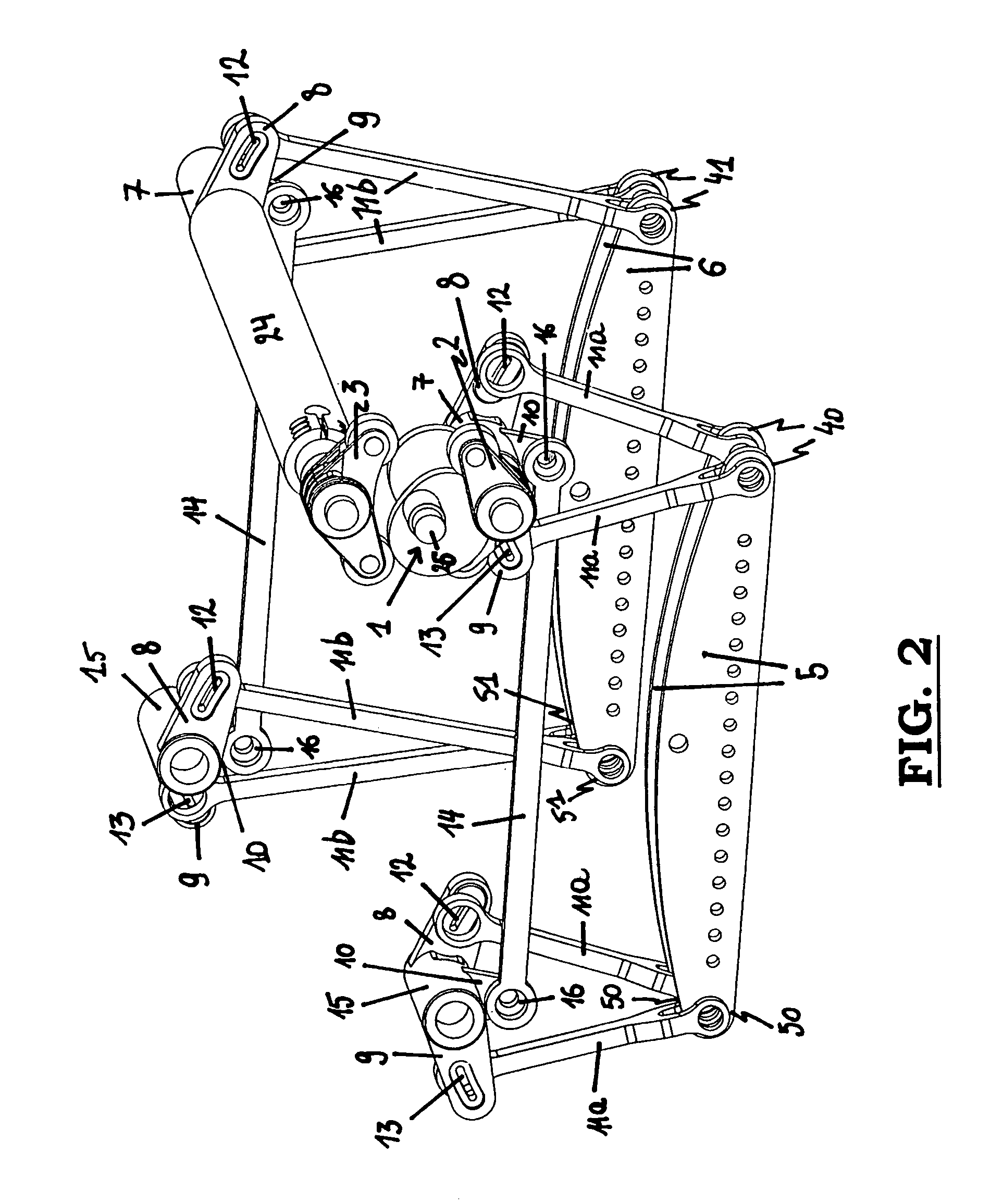

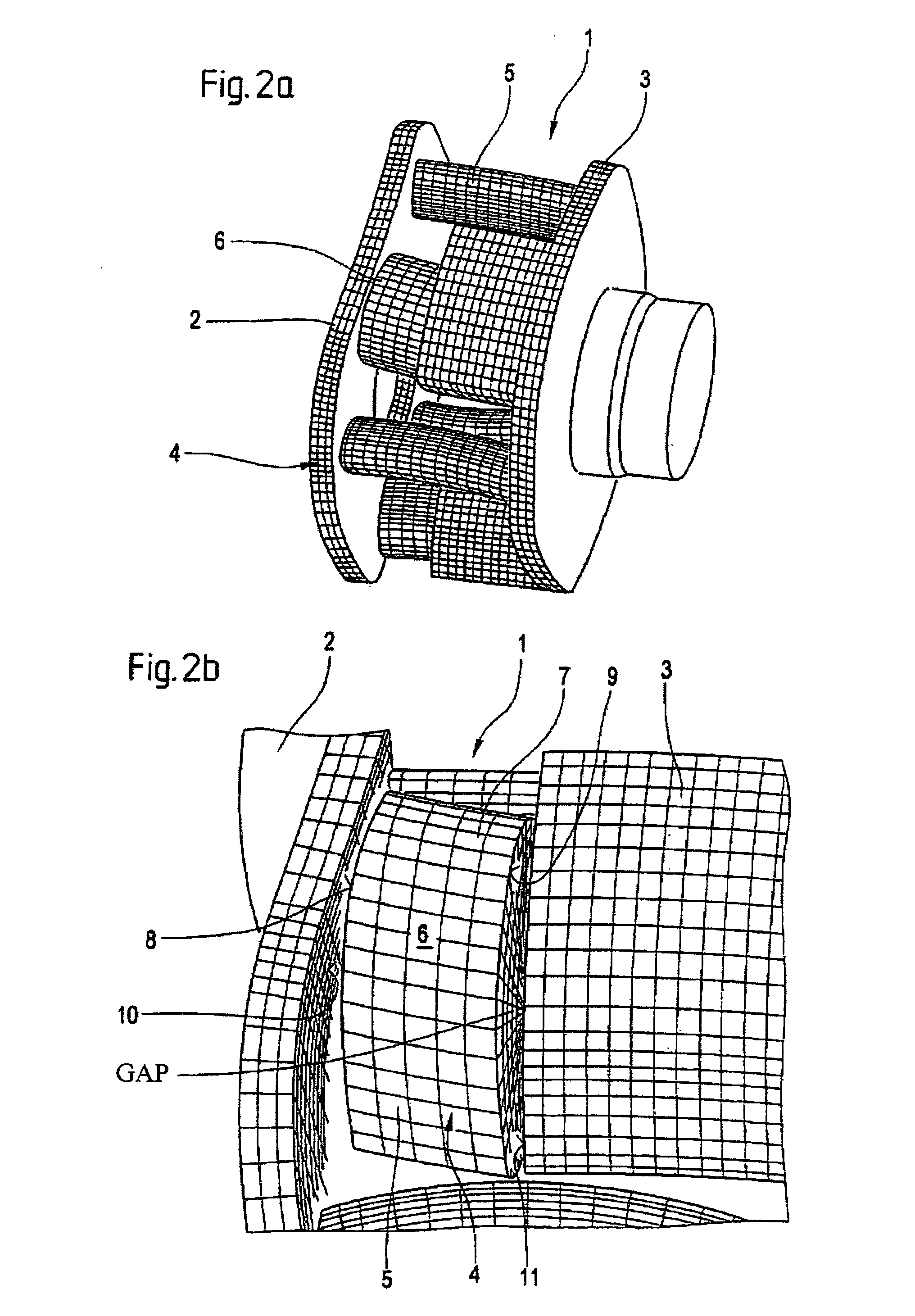

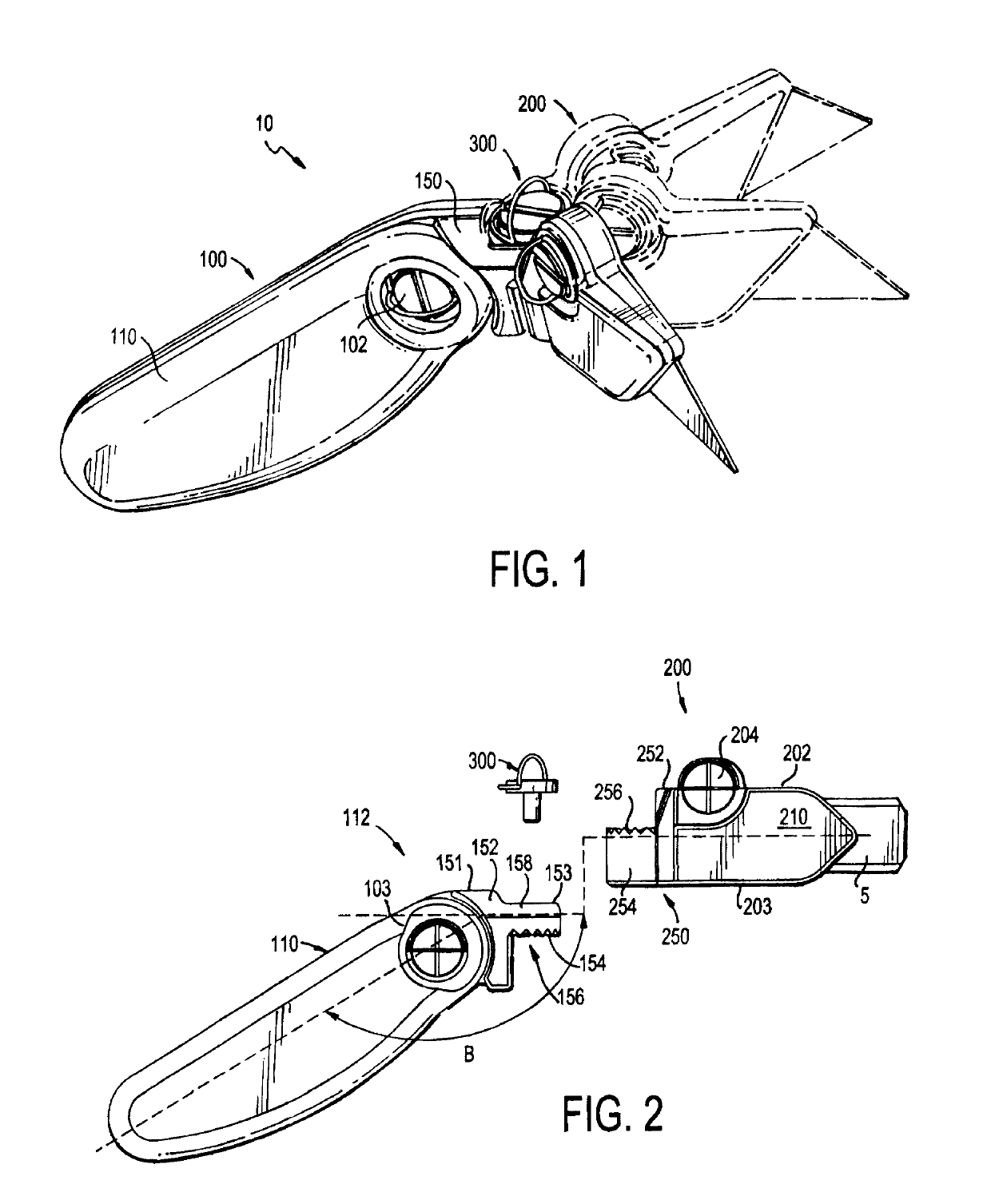

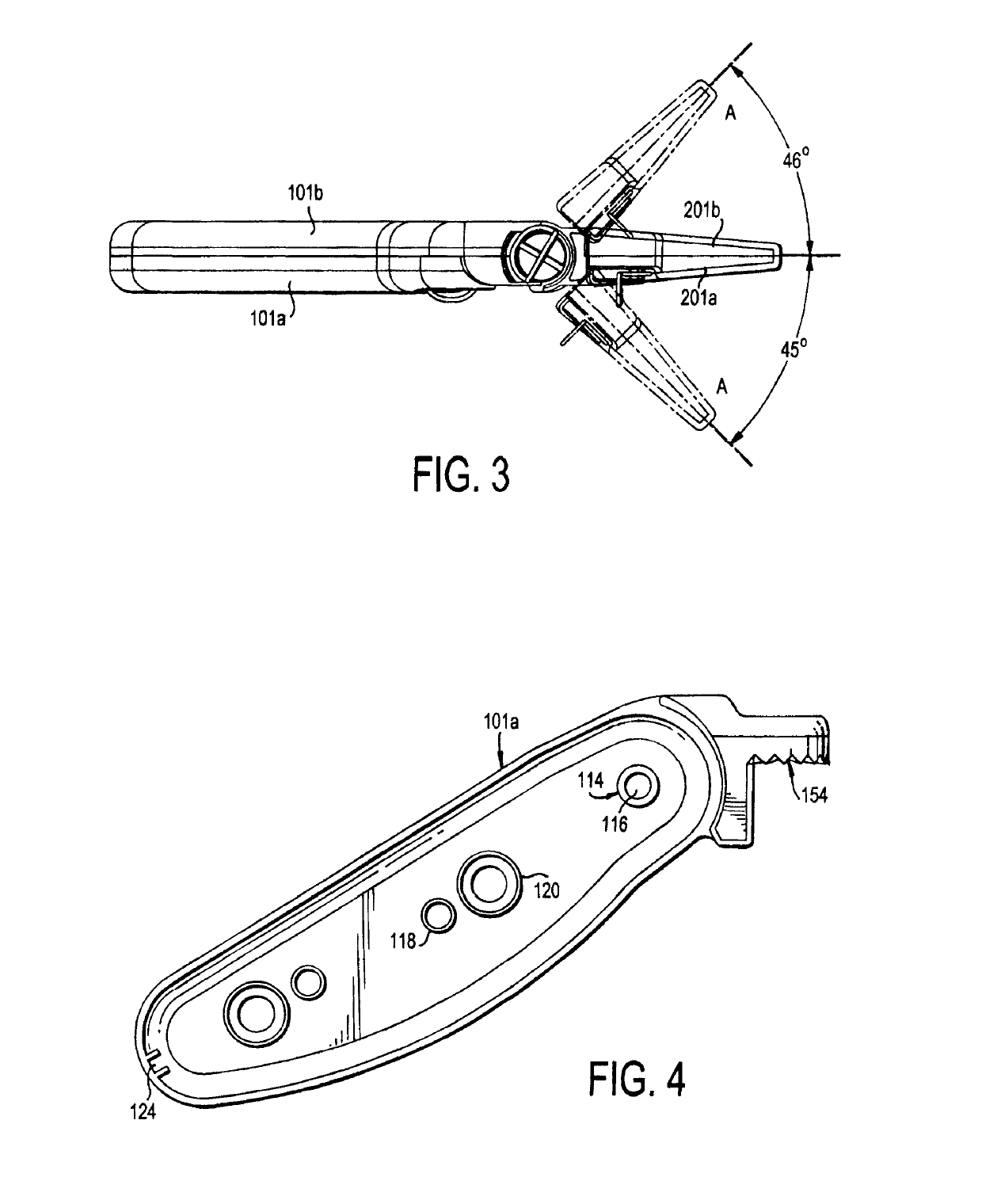

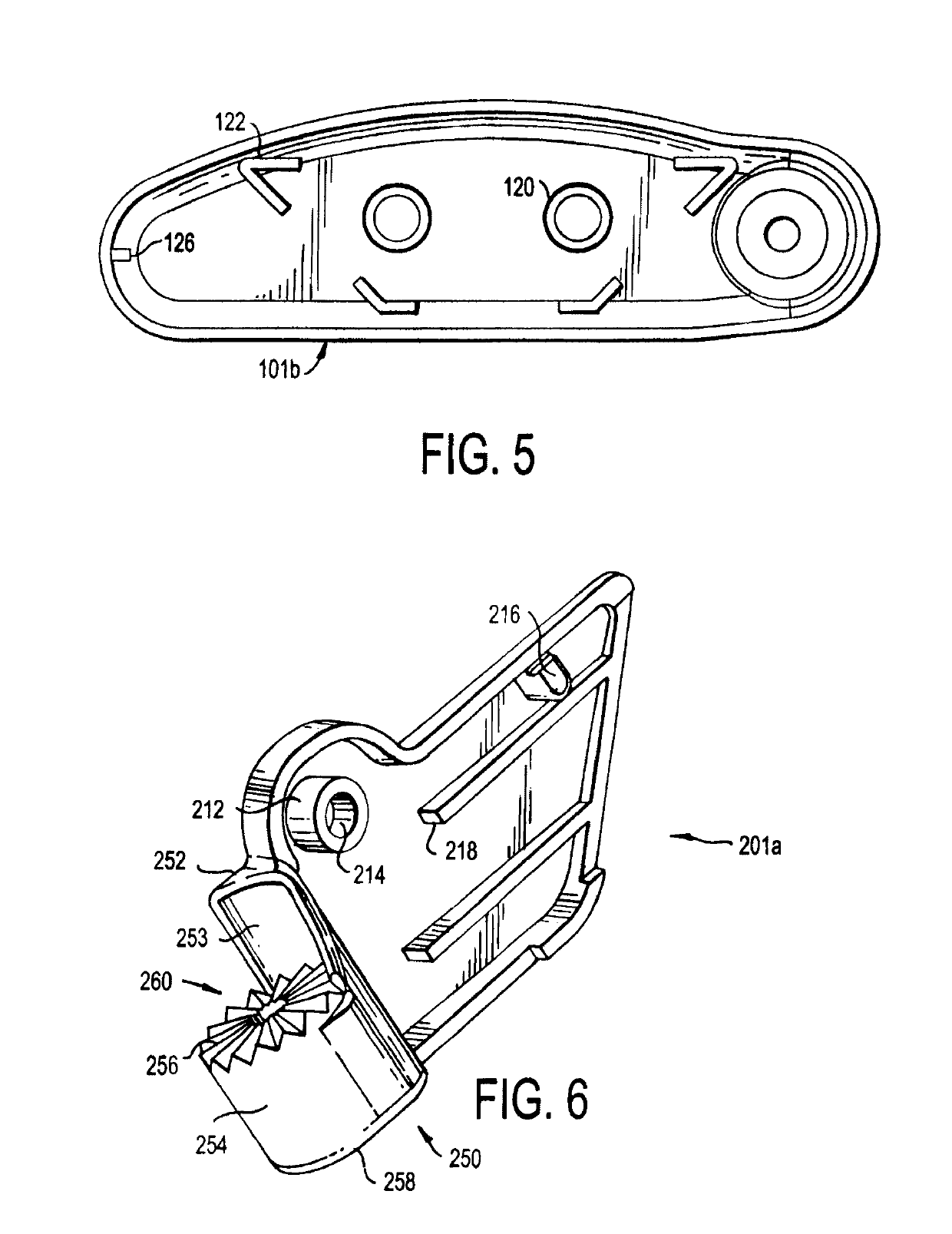

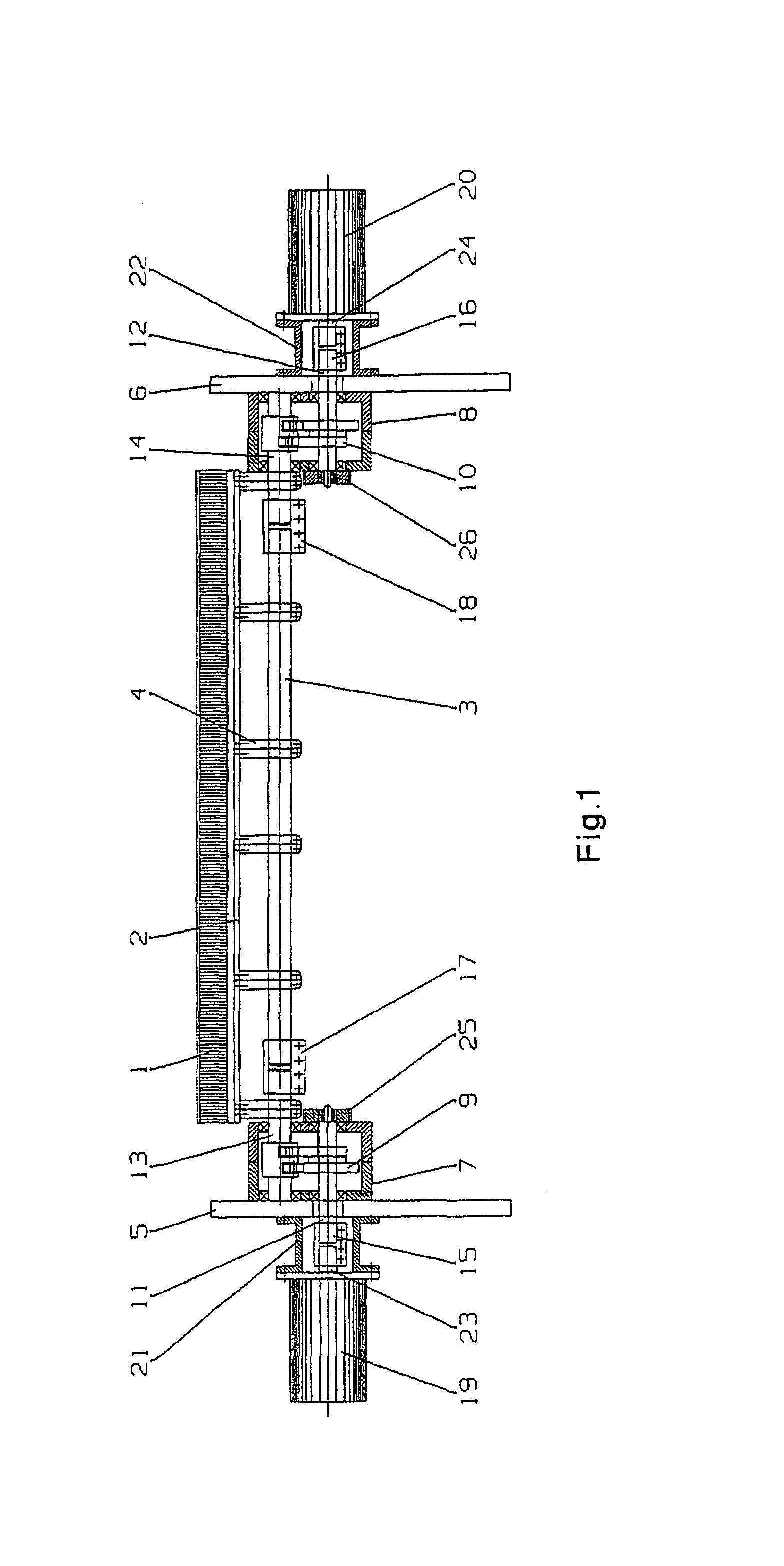

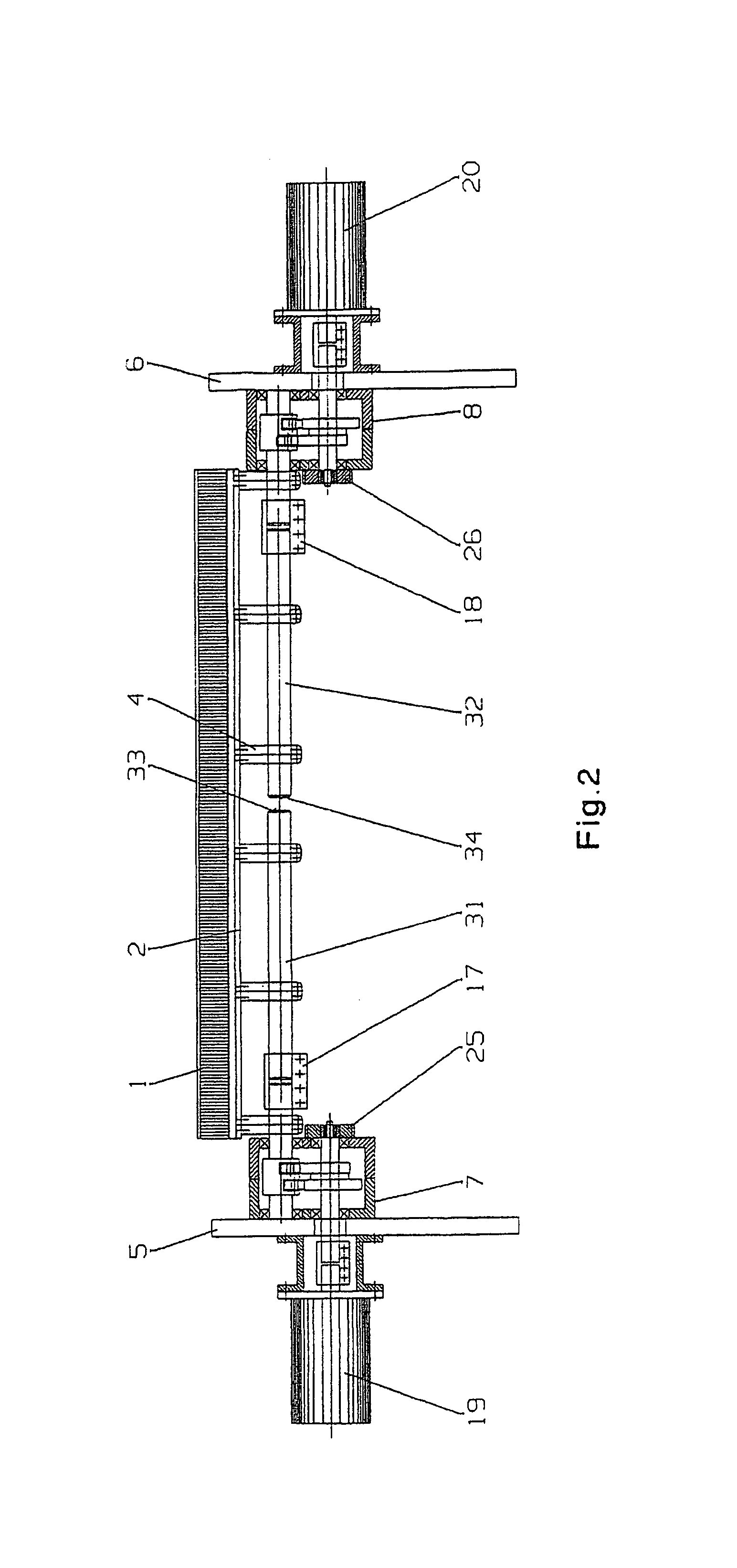

Multi-exercise rotary device

InactiveUS20060128534A1Safely simulateShorten the lengthClubsSkipping-ropesEngineeringMechanical engineering

A multi-exercise rotary device, comprising: at least one elongate body-supported member, the body-supported member having a first end adapted to be supported by the body of the user, and a second end opposite the first end, at least one rotating member having a longitudinal axis that is at least semi-rigid, and which axis has a weight-biased distribution toward a distal end thereof; and a rotary mechanism for coupling the rotating member to a point on the body-supported member which is near the second end thereof. The rotary mechanism allows rotational movement of the rotating member about the longitudinal axis of the body-supported member. The rotary mechanism includes a device for constraining the angular movement between the weight-biased longitudinal axis of the rotating member and the longitudinal axis of the body-supported unit to be substantially only in a predetermined plane axially aligned with the body-supported member, and for constraining said plane from twisting with respect to the longitudinal axis of said body-supported member.

Owner:ROQUE ALDRIN

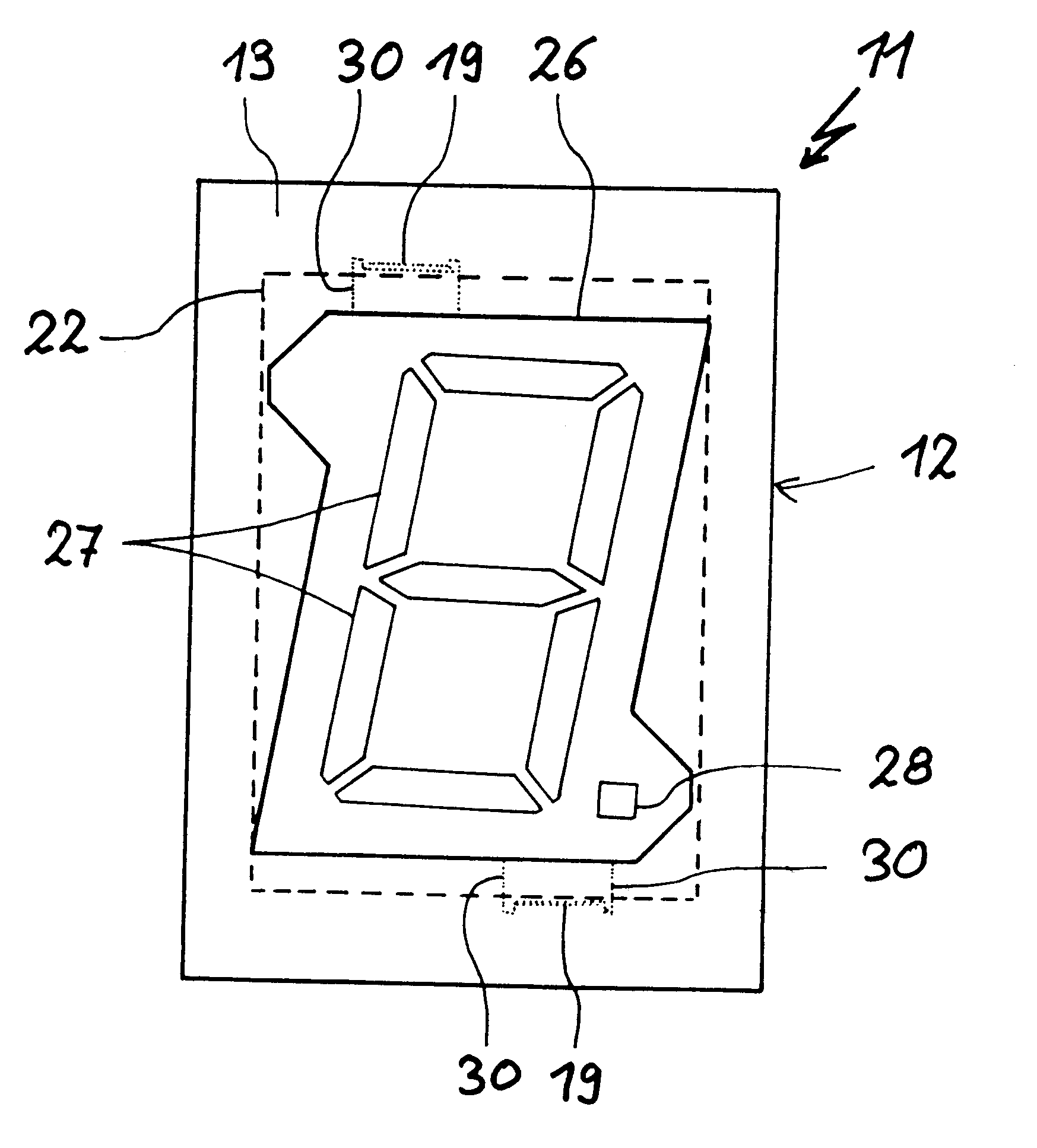

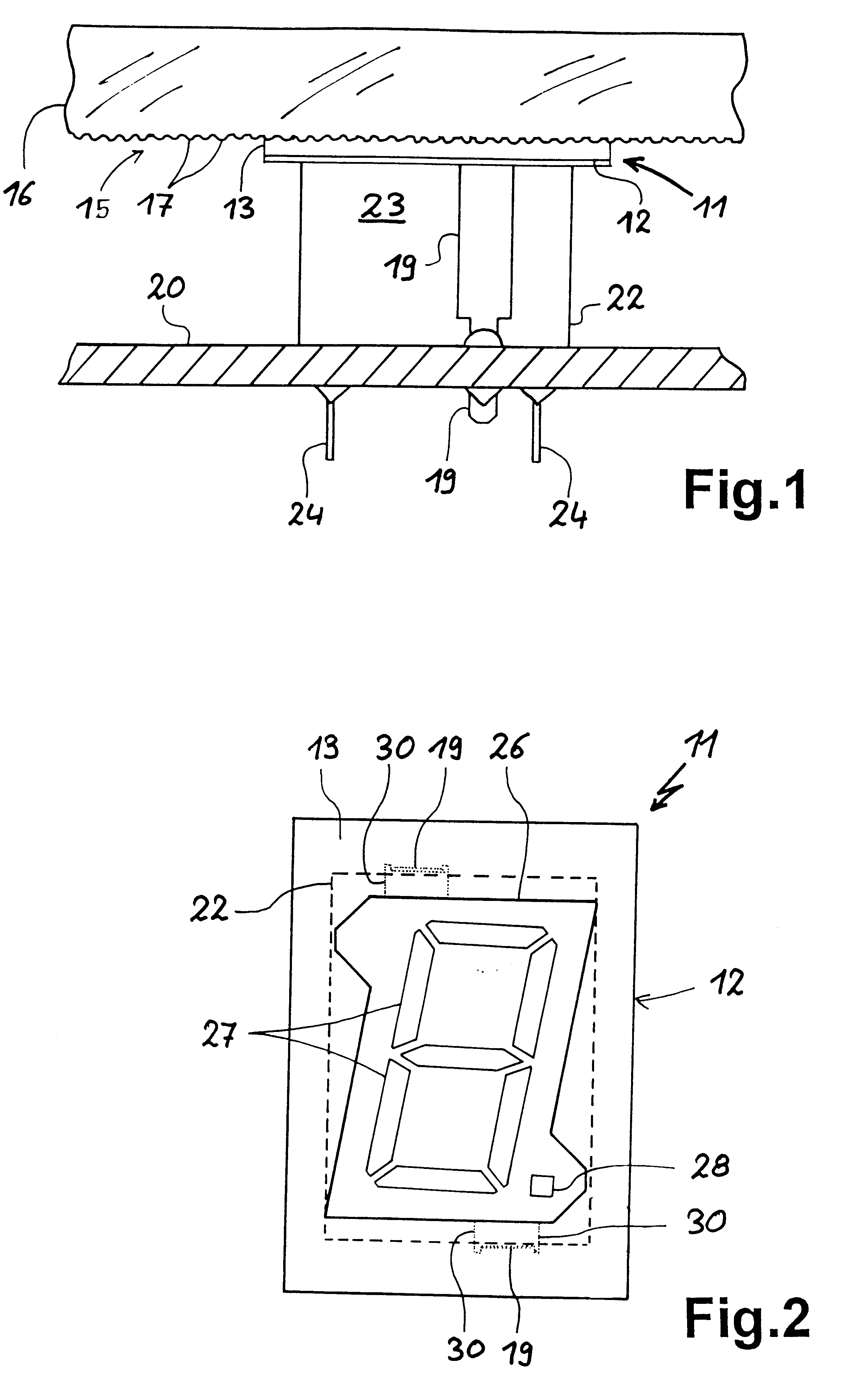

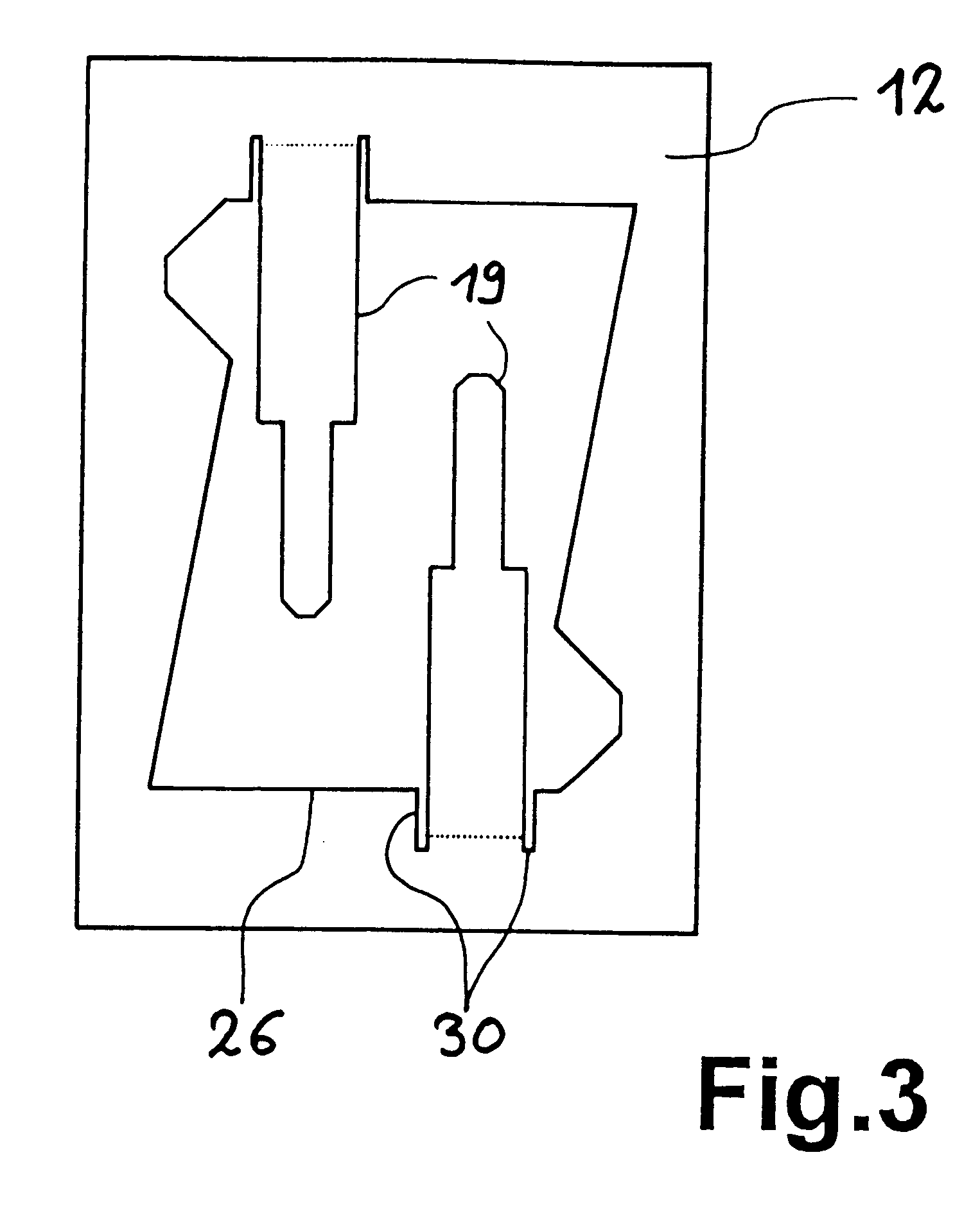

Contact switch for an electrical appliance

InactiveUS6403904B1Shine wellReducing light emissionElectronic switchingHot plates heating arrangementsDisplay deviceLight emitting device

A contact switch having a sensor element with a flat sensor surface, with which is associated an illuminated display in a housing. The sensor surface passes over the housing and has a cutout corresponding to the shape of the lighting means. The sensor surface surrounds the lighting means in a substantially non-overlapping manner and in particular additionally rests on the housing. The sensor surface can also be provided with an elastic, electrically conductive plate for improved adaptation to irregular covers.

Owner:E G O ELEKTRO GERAETEBAU GMBH

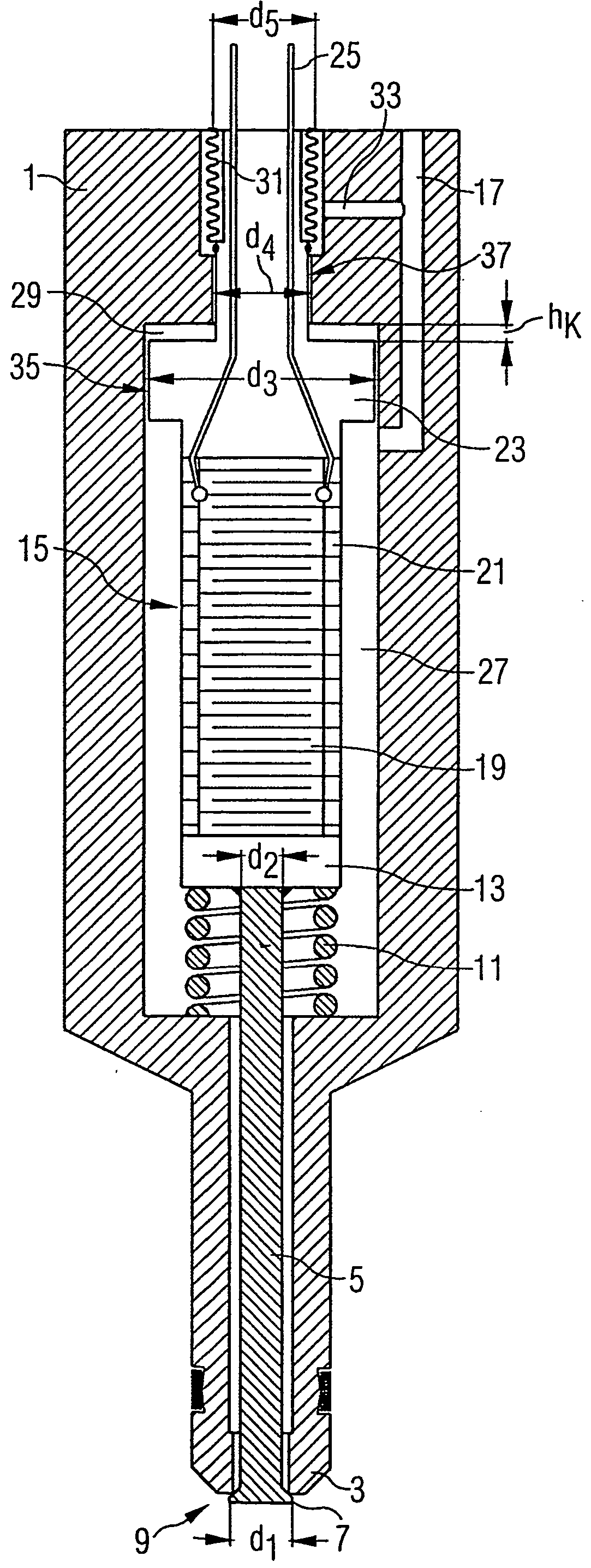

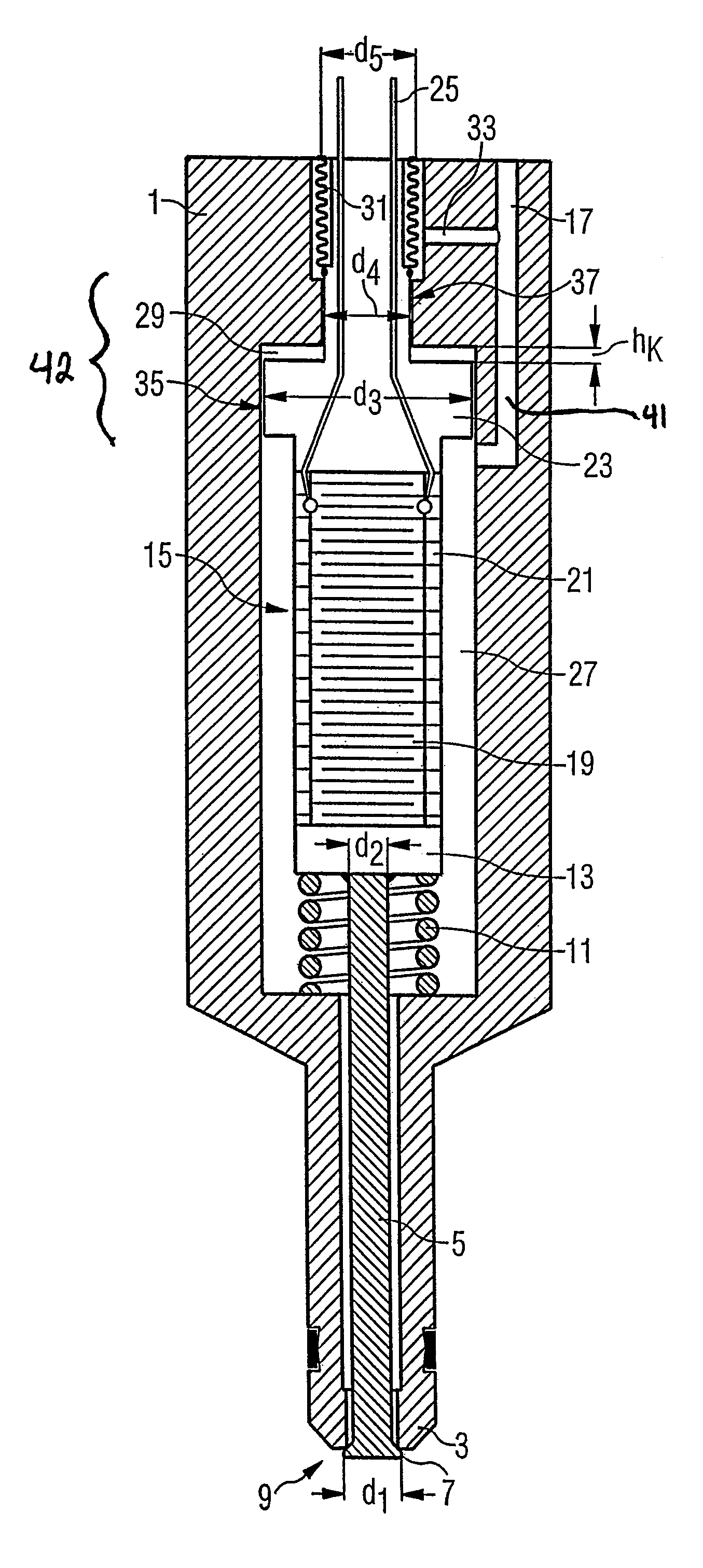

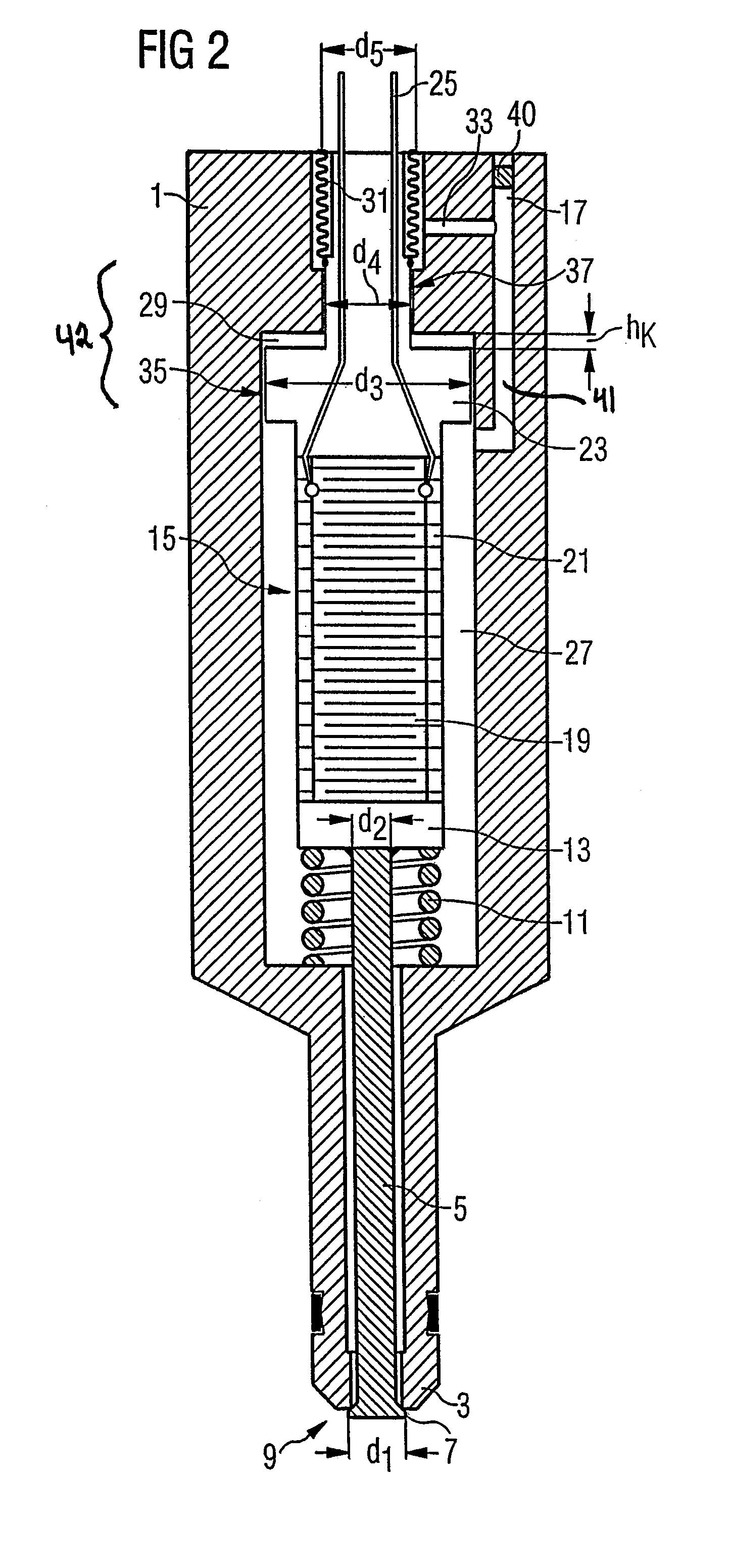

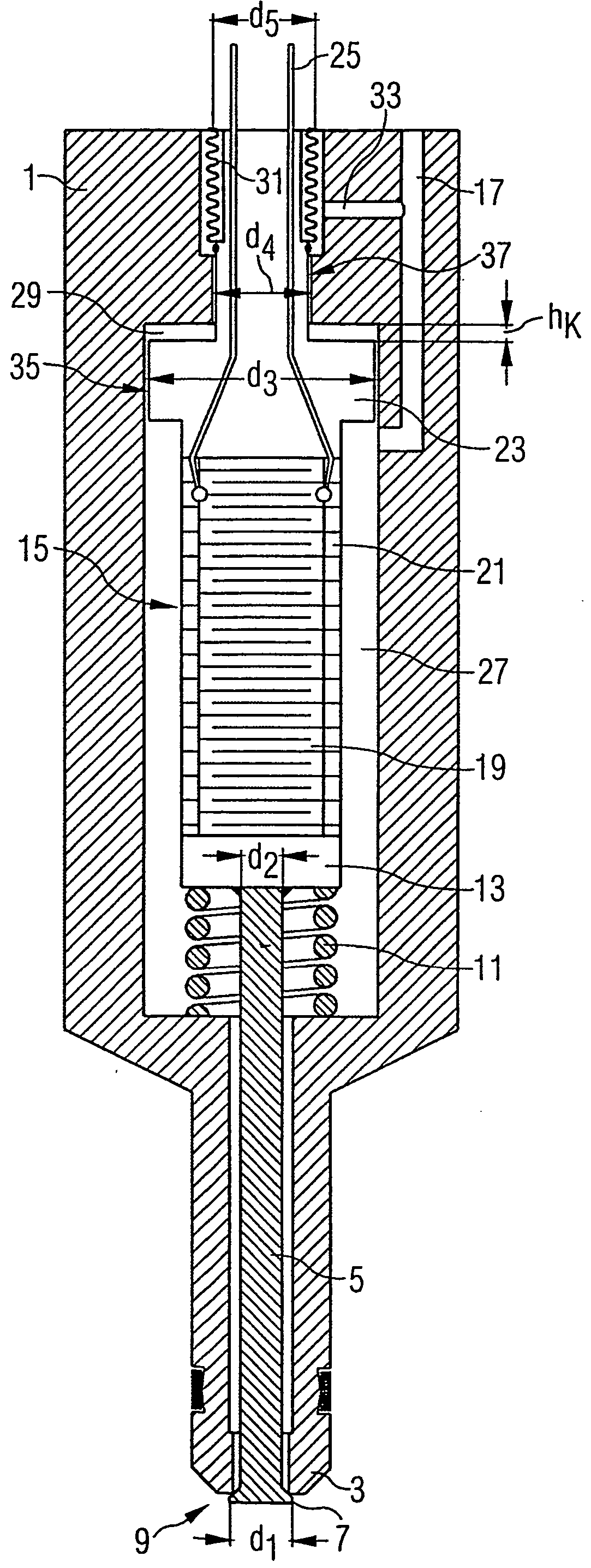

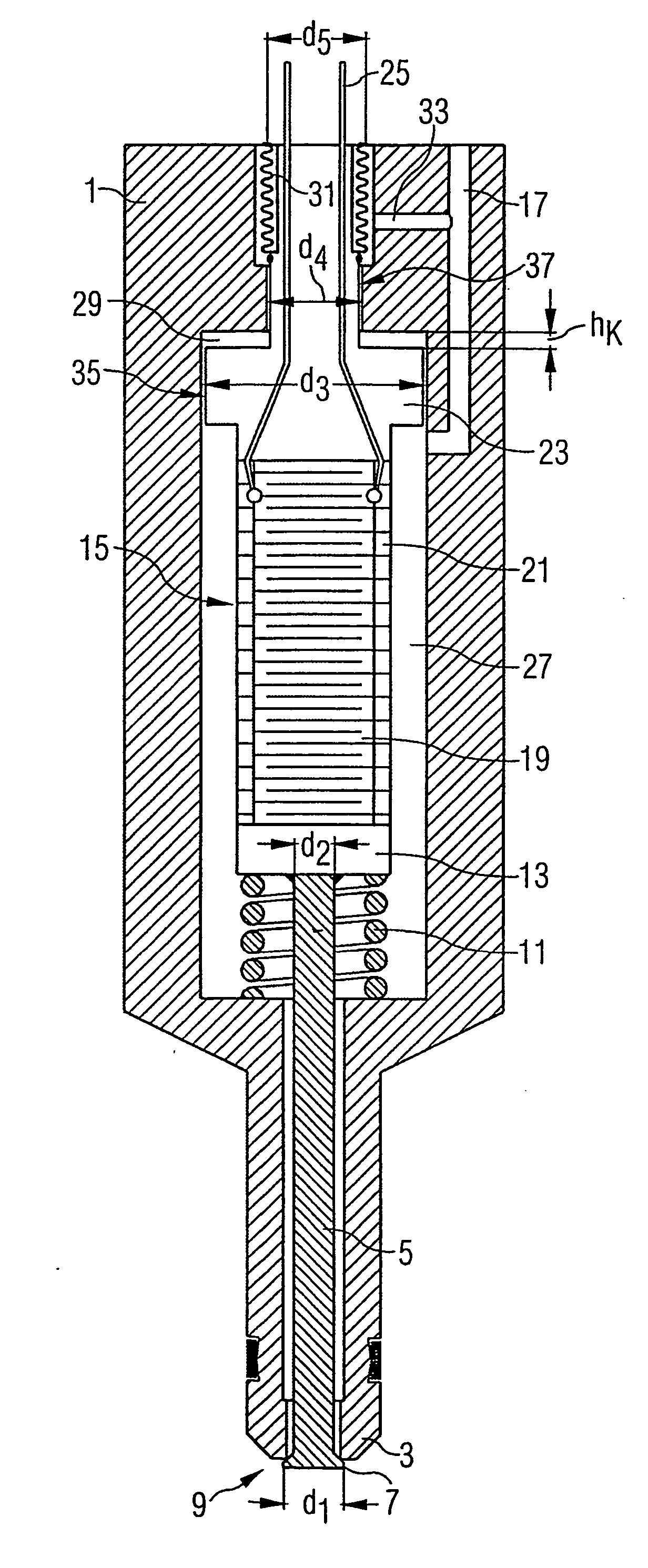

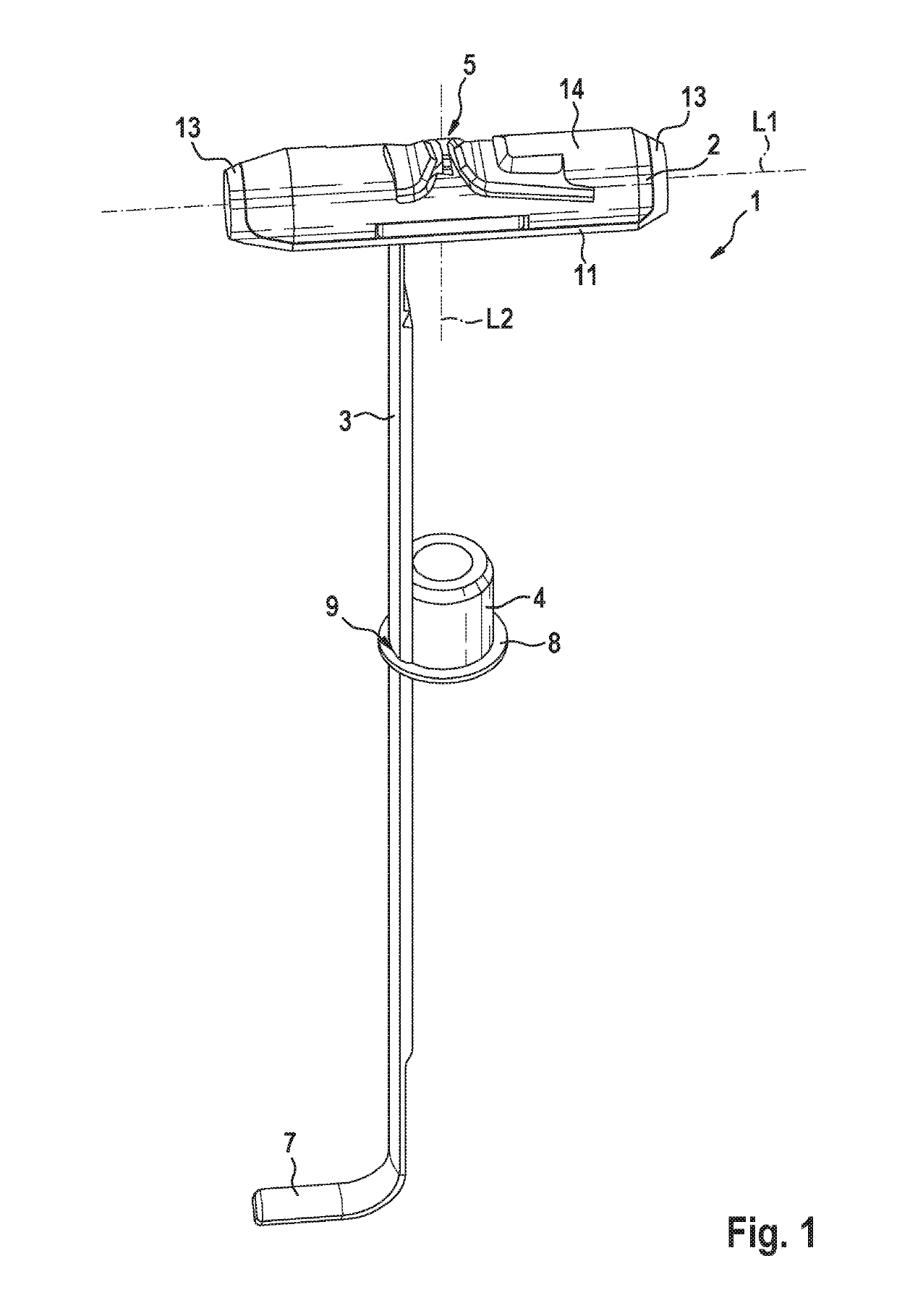

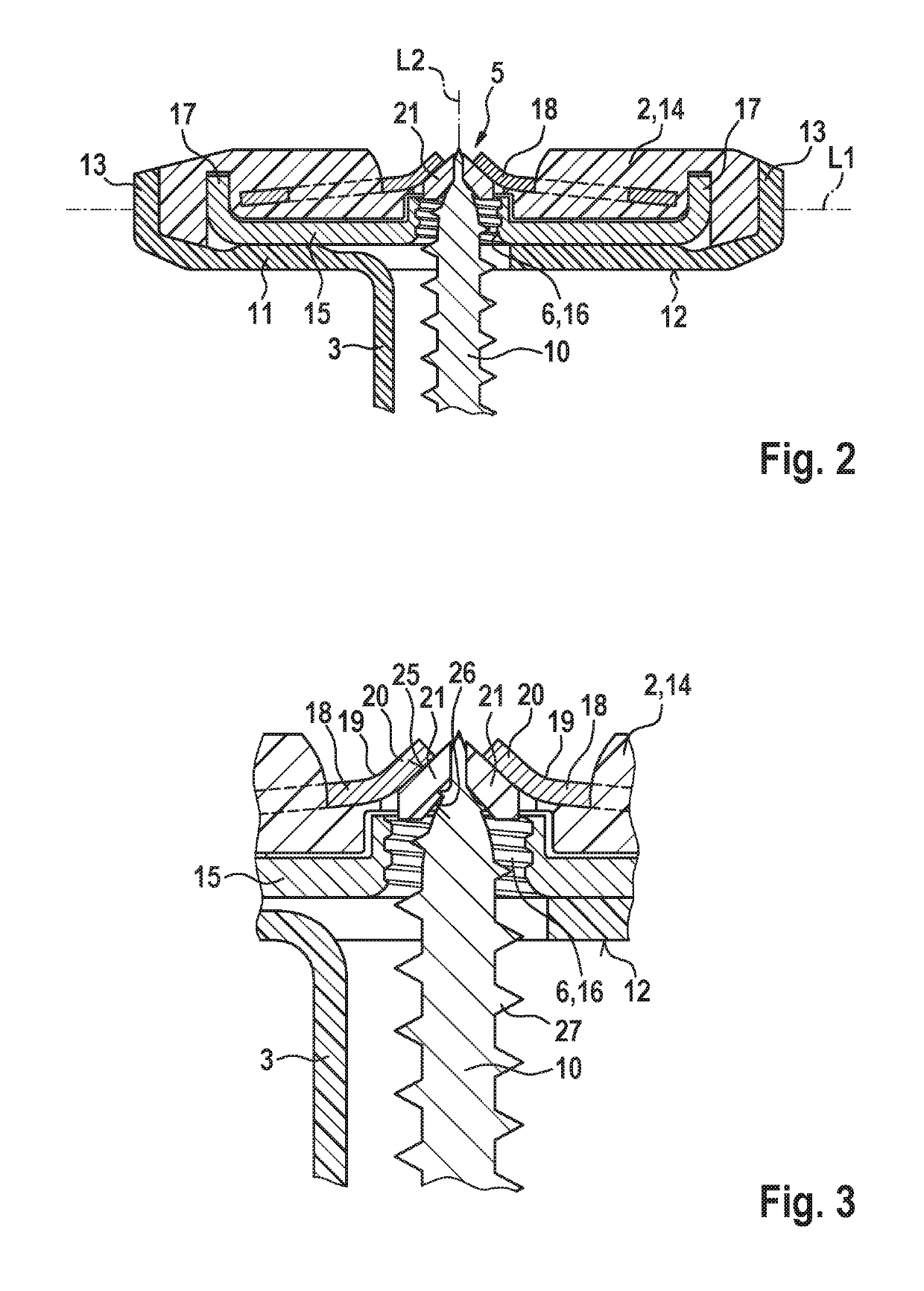

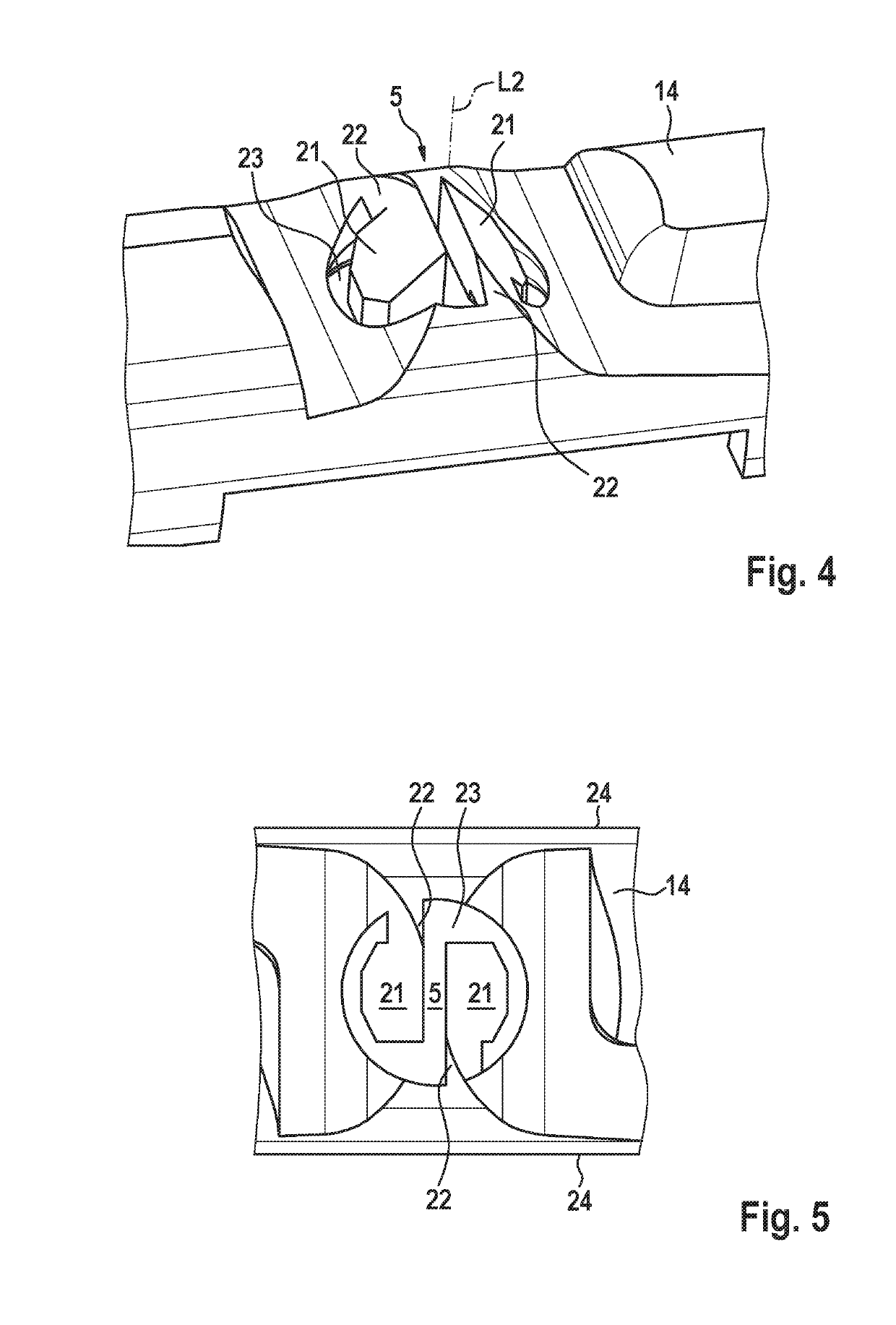

Injection valve

InactiveUS7886993B2Simple hydraulic bearingEliminate needMovable spraying apparatusSpray nozzlesEngineeringMechanical engineering

Owner:SIEMENS AG

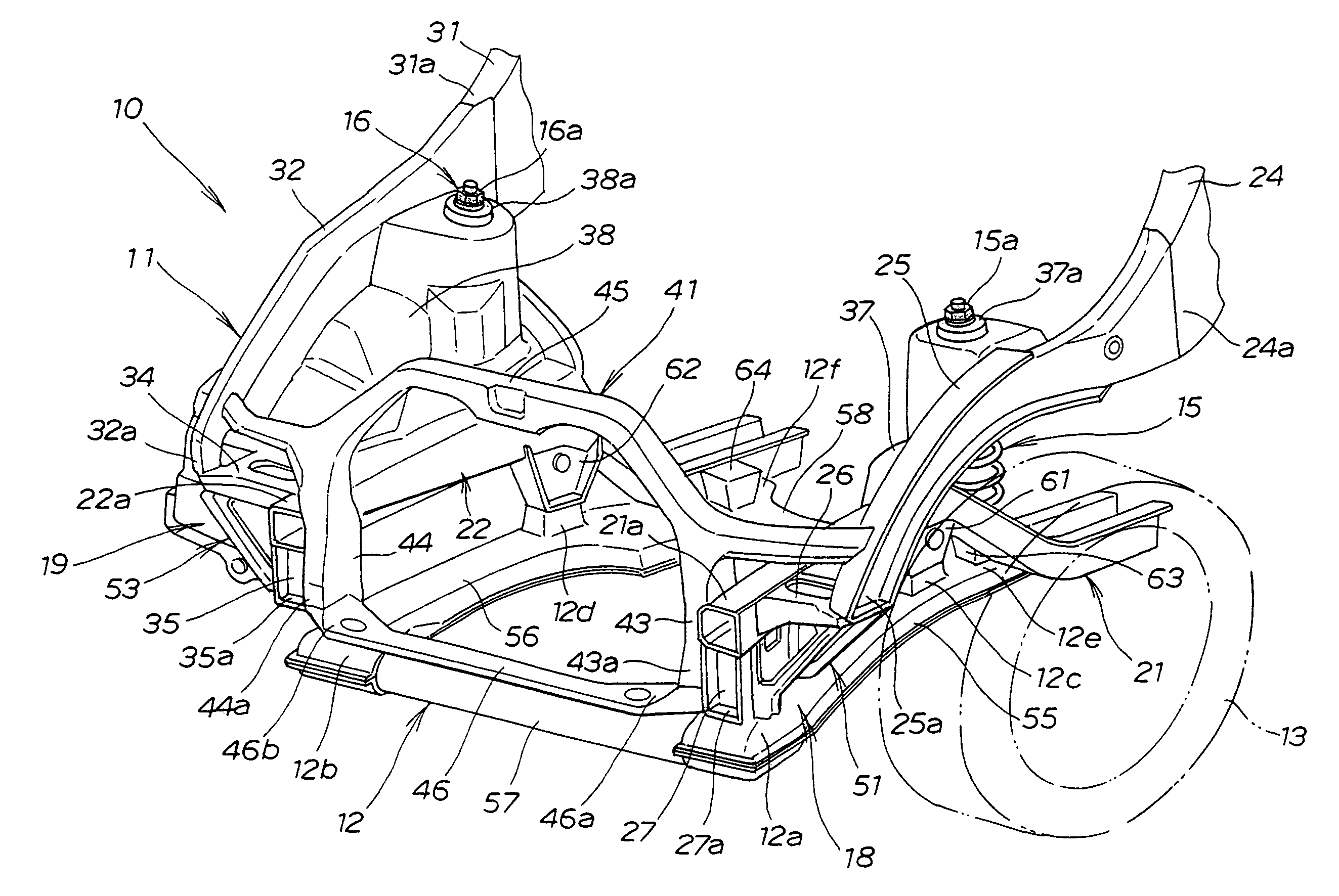

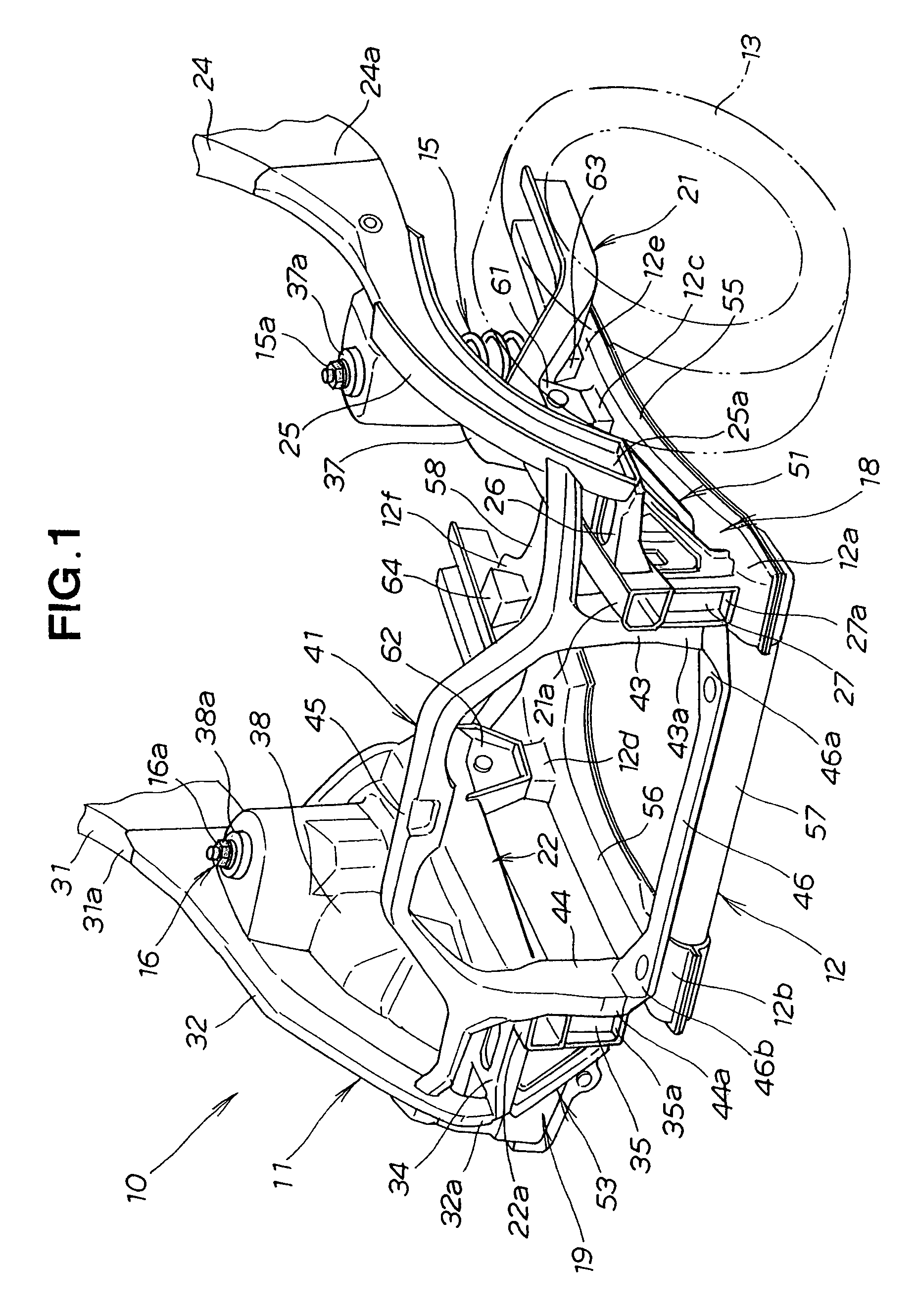

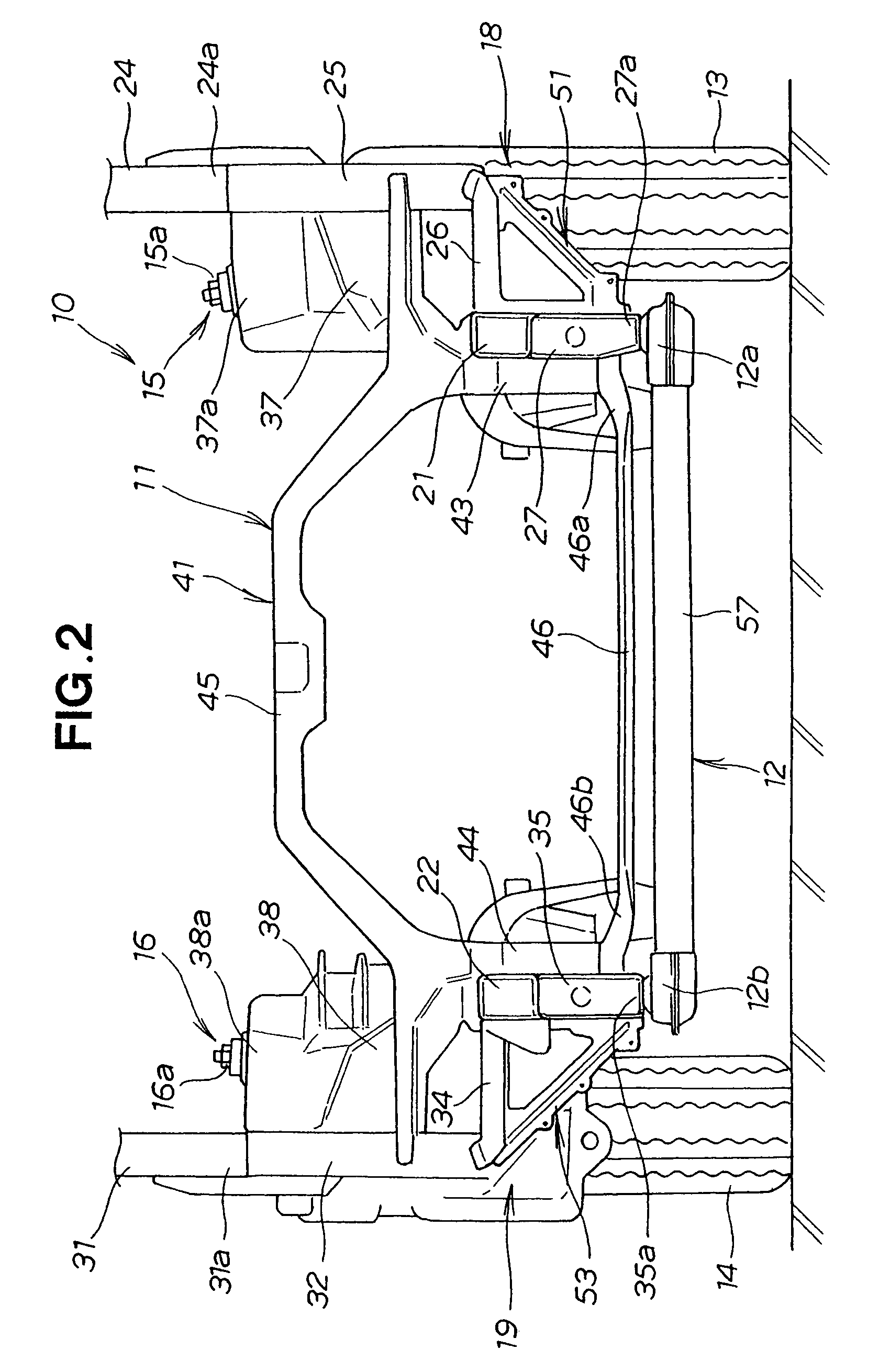

Vehicle front body structure

A vehicle front body structure includes left and right diagonal connecting members extending diagonally between and connecting together the lower end portions of left and right legs and the front end portions of left and right upper members. Left and right horizontal connecting members, the left and right legs and the left and right diagonal connecting members together form left and right frame sections of substantially triangular hollow prismoidal configuration having an axis extending in the longitudinal direction of the vehicle body.

Owner:HONDA MOTOR CO LTD

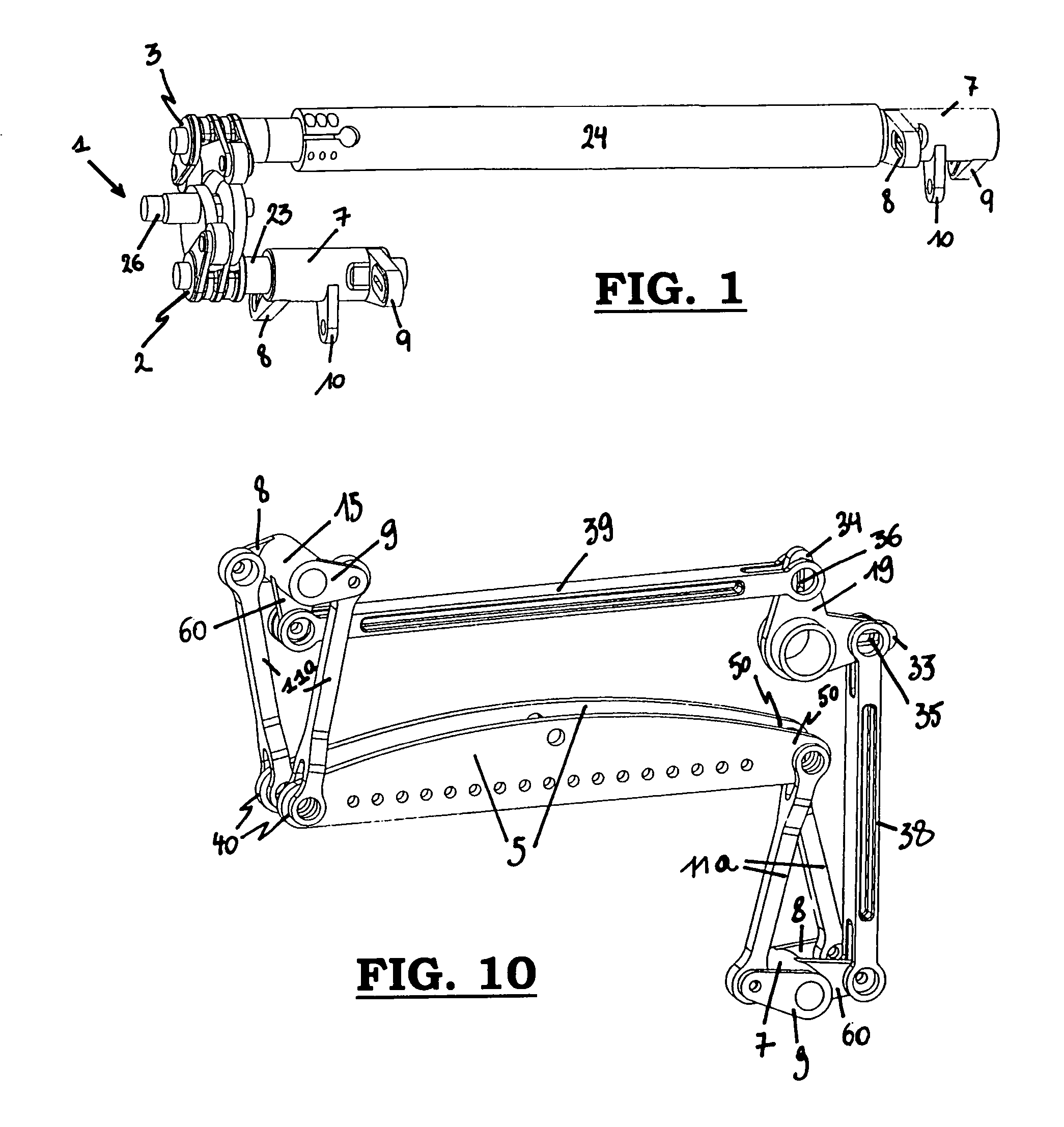

Multi-exercise rotary device

InactiveUS7329212B2Safely simulateShorten the lengthClubsSkipping-ropesEngineeringMechanical engineering

A multi-exercise rotary device, comprising: at least one elongate body-supported member, the body-supported member having a first end adapted to be supported by the body of the user, and a second end opposite the first end, at least one rotating member having a longitudinal axis that is at least semi-rigid, and which axis has a weight-biased distribution toward a distal end thereof; and a rotary mechanism for coupling the rotating member to a point on the body-supported member which is near the second end thereof. The rotary mechanism allows rotational movement of the rotating member about the longitudinal axis of the body-supported member. The rotary mechanism includes a device for constraining the angular movement between the weight-biased longitudinal axis of the rotating member and the longitudinal axis of the body-supported unit to be substantially only in a predetermined plane axially aligned with the body-supported member, and for constraining said plane from twisting with respect to the longitudinal axis of said body-supported member.

Owner:ROQUE ALDRIN

Injection valve

InactiveUS20050017096A1Simple processSimple hydraulic bearingMovable spraying apparatusSpray nozzlesEngineeringMechanical engineering

Owner:SIEMENS AG

Elevated toilet seat

InactiveUS20080235858A1Easier for a user sitting down and getting upHigh tensile strengthBathroom coversArchitectural engineeringEngineering

Owner:SCHANZ RICHARD W

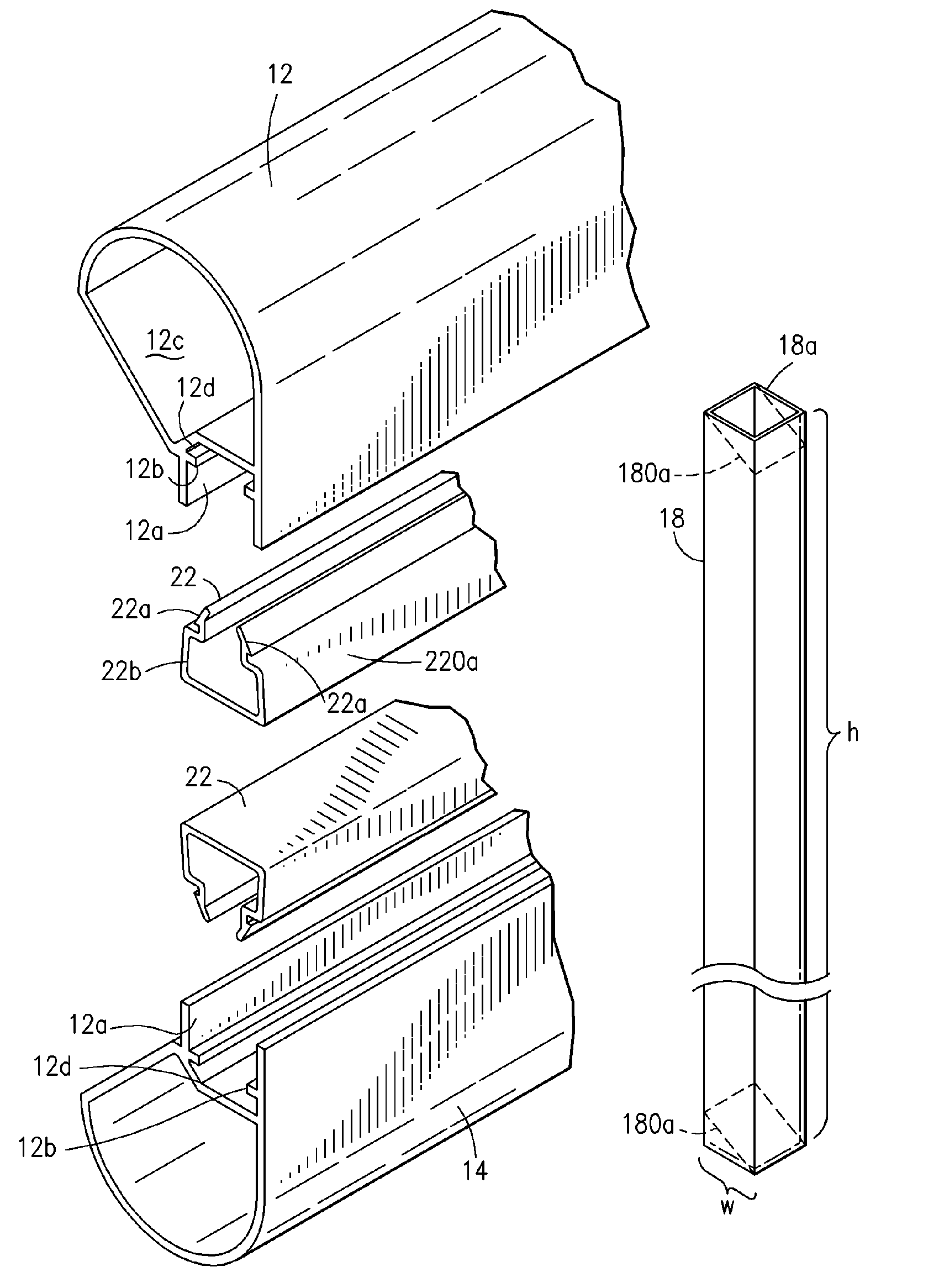

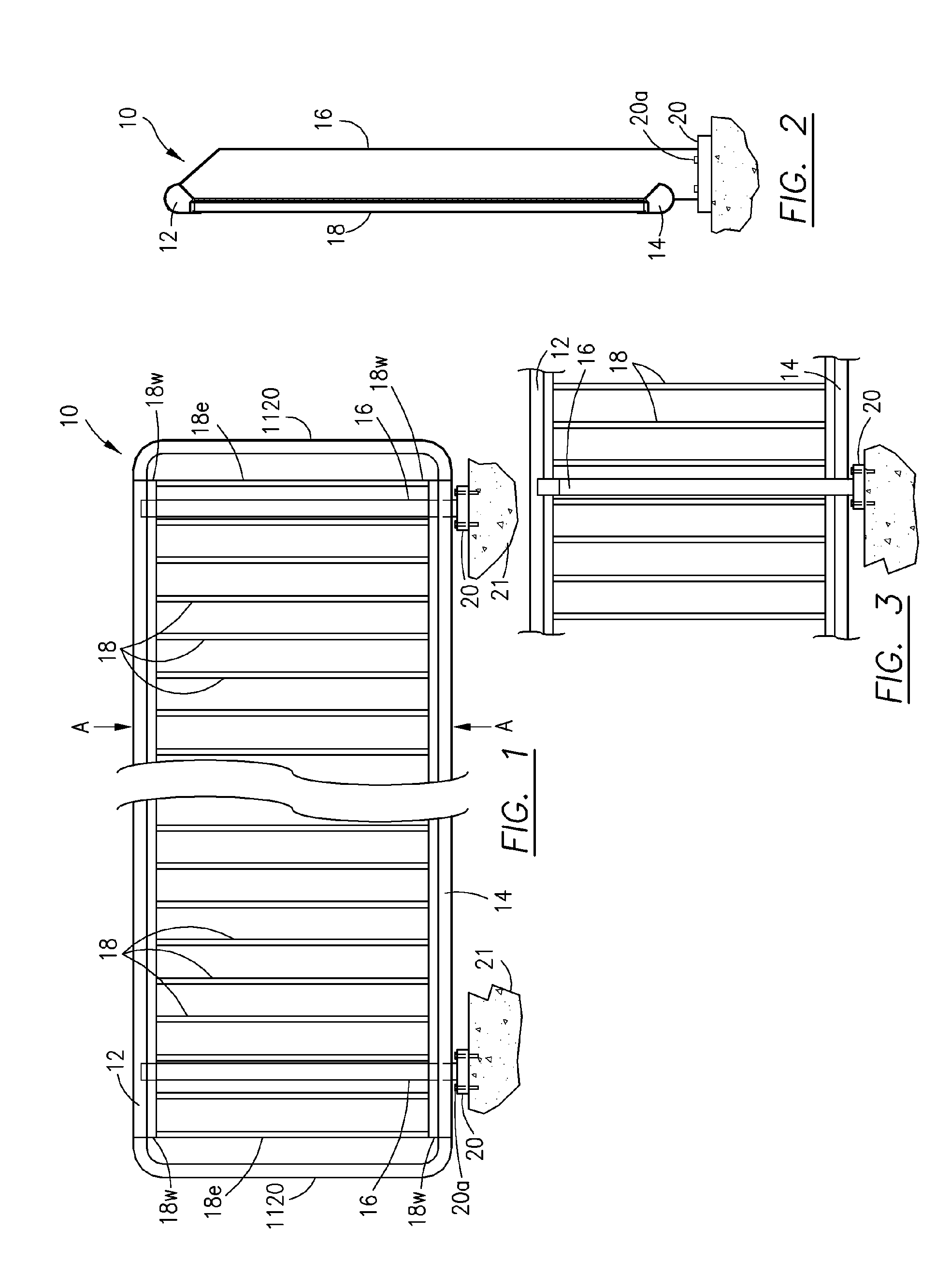

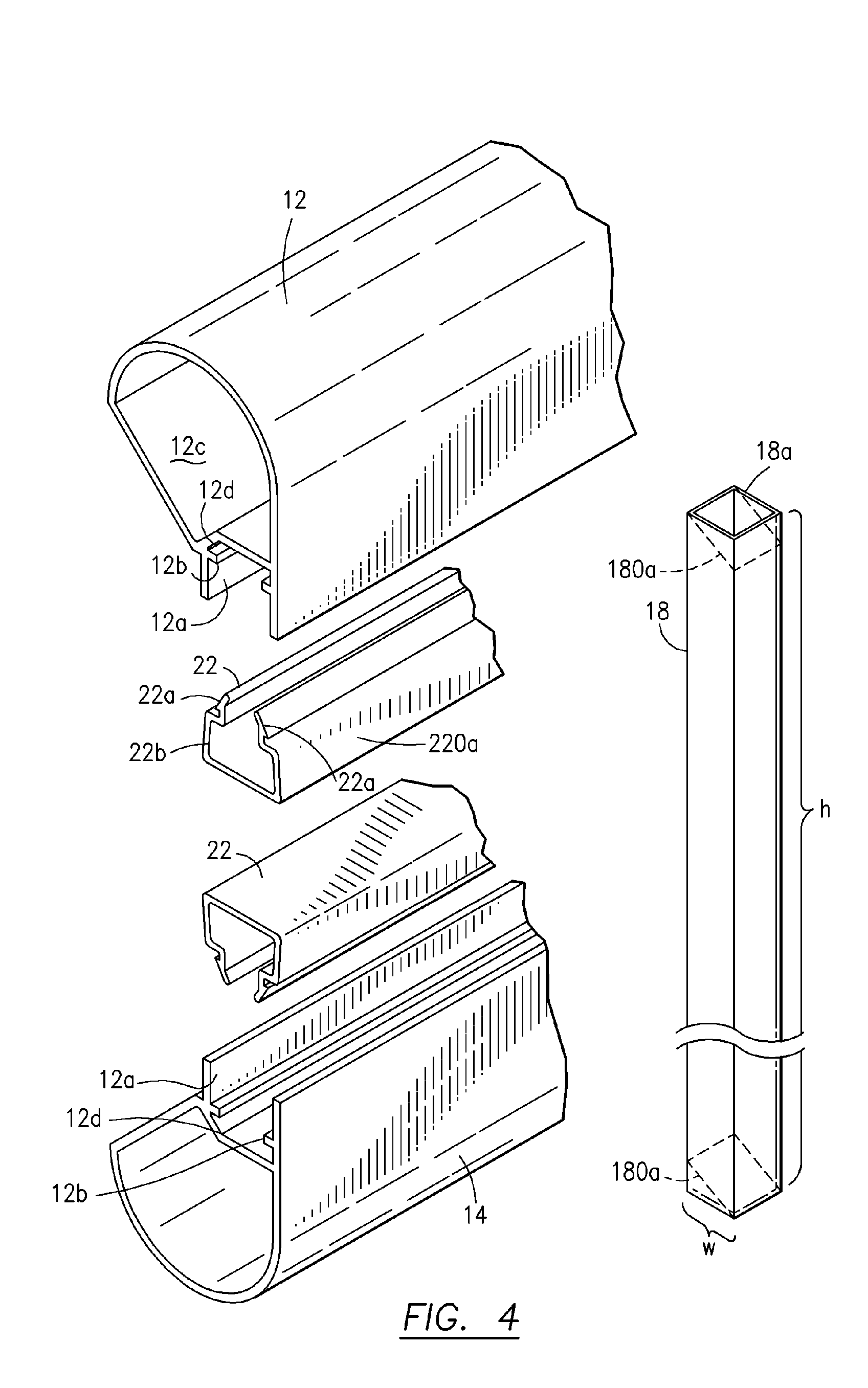

Apparatus for pedestrian railing with snap-in spacer and method of making

A sturdy aluminum pedestrian and bicyclist safety railing that reduces the amount of welding required during construction, comprising top and bottom rigid bars, each having a longitudinal, radially extending exterior passage and a plurality of aluminum pickets mounted within said bar top and bottom channels and held apart by a plurality of spacer plugs that interlock and snap snugly into each top and bottom bar channel and act as spacers to separate the pickets. The top and bottom bars may be welded together at each end of the railing to hold the entire unit together, retaining the plurality of rigid pickets that are substantially perpendicular (or inclined) to the top and bottom bars. The pickets are supported in the top and bottom bar channels without welding for increased strength and reduced cost of construction.

Owner:GIRALT PEDRO P

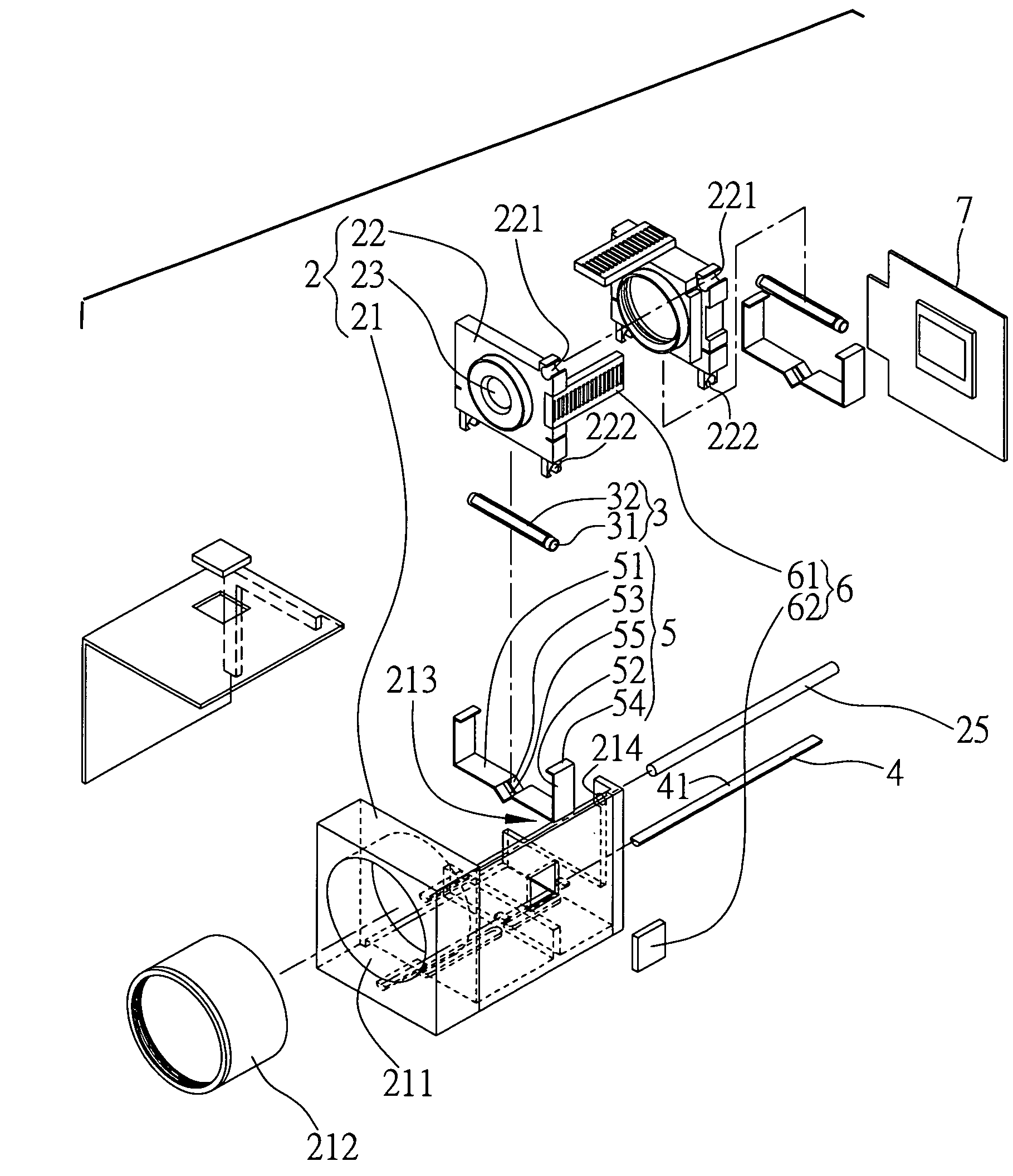

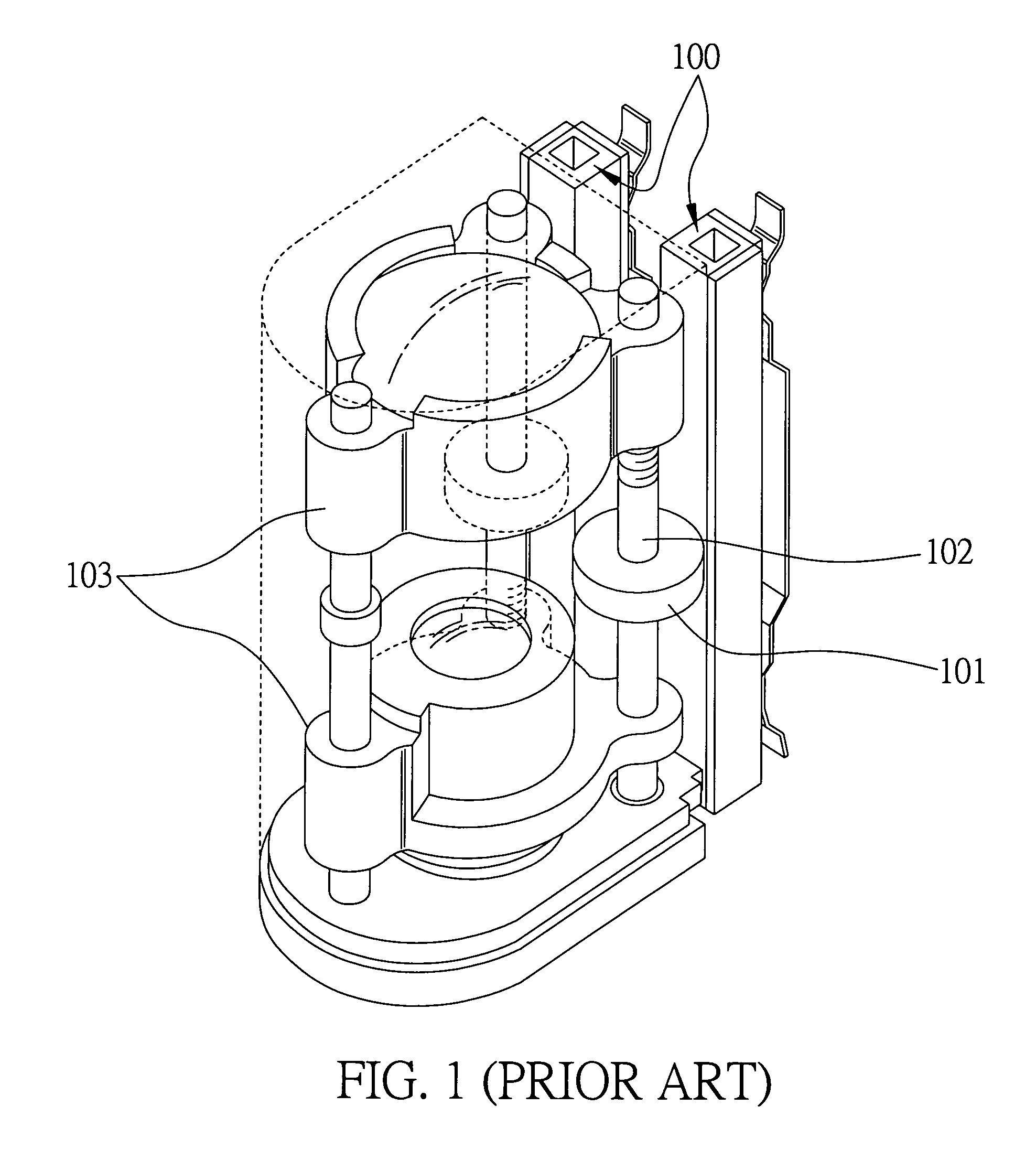

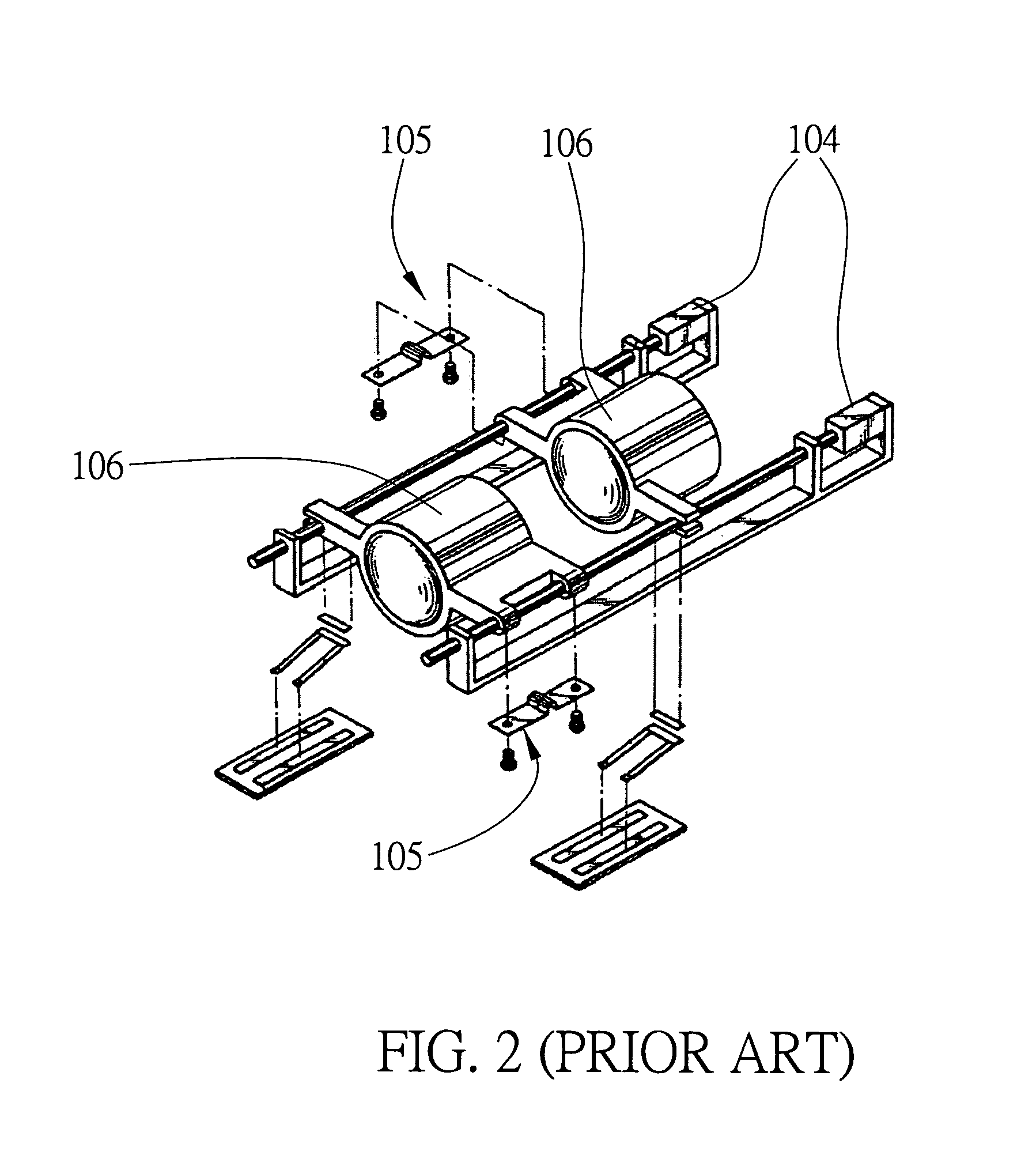

Piezoelectrically driven optical lens module

InactiveUS7480109B1High torqueSmall sizeTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCamera lensOptical Module

The present invention provides a piezoelectrically driven optical lens module. The piezoelectrically driven optical lens module includes at least a lens body, a guiding rod for providing an axial movement track, a piezoelectric element for providing driving force, and an elastic element for providing the piezoelectric element with pre-load, so as to allow the piezoelectric element to be in contact with the guiding rod. The lens body includes at least an enclosed hollow structure, a lens barrel axially moveable and fixed to the enclosed hollow structure, and a lens element fixed to the lens barrel. The piezoelectric element is in contact with the guiding rod via the elastic elements, and the piezoelectric element is used for driving the lens barrel to move linearly along the guiding rod. The present invention provides a piezoelectrically driven optical lens module with a simple structure, to overcome the drawbacks of the prior art.

Owner:IND TECH RES INST

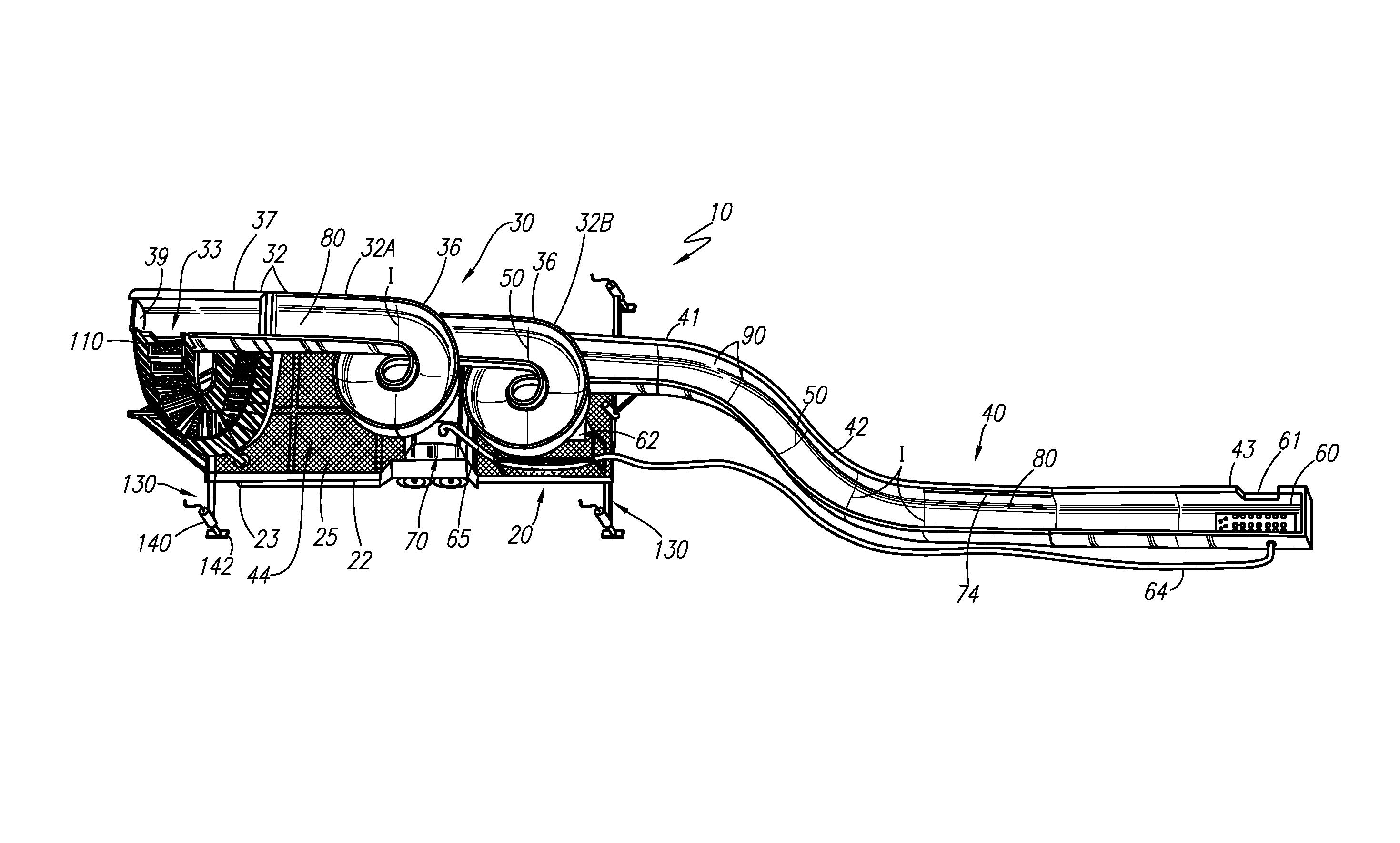

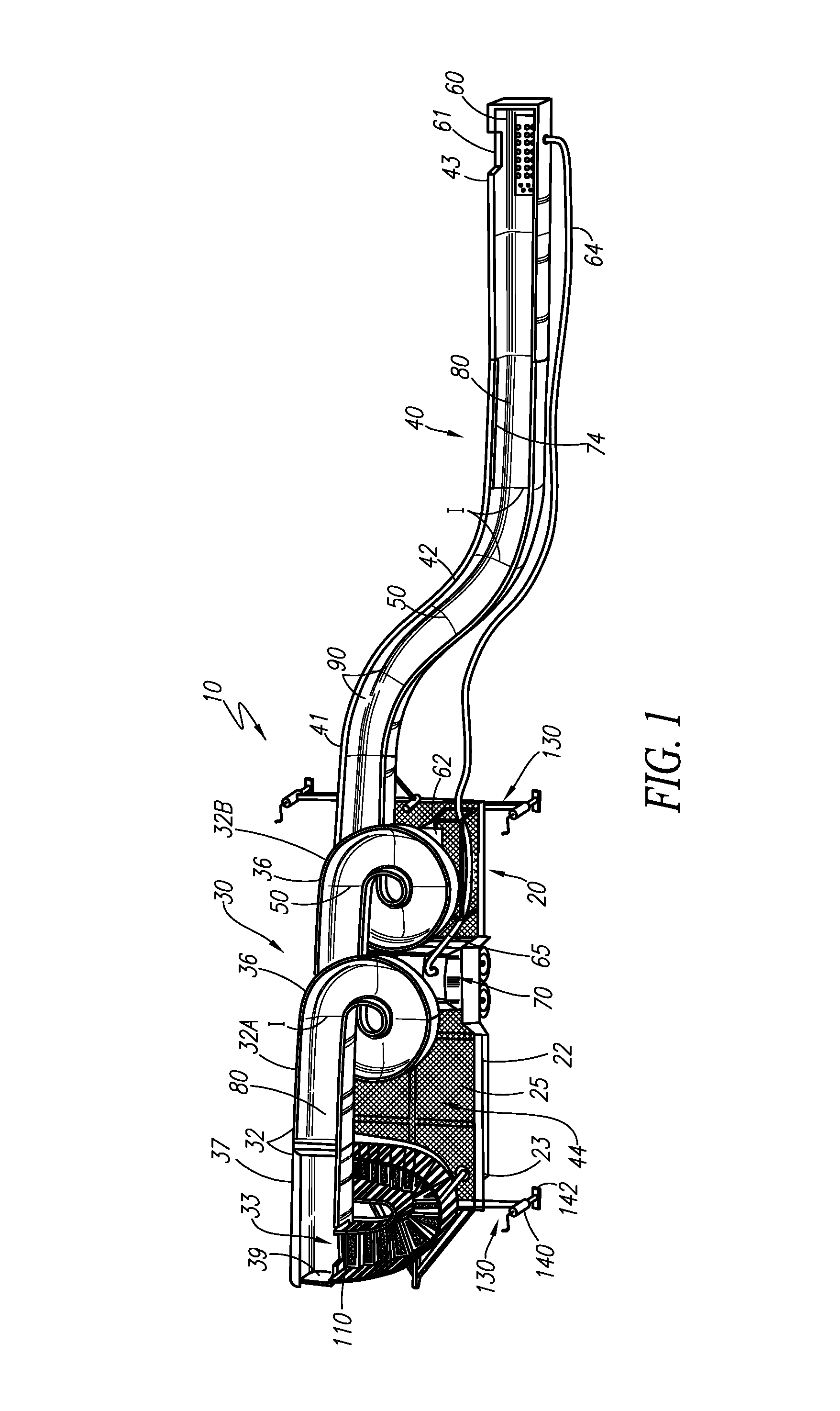

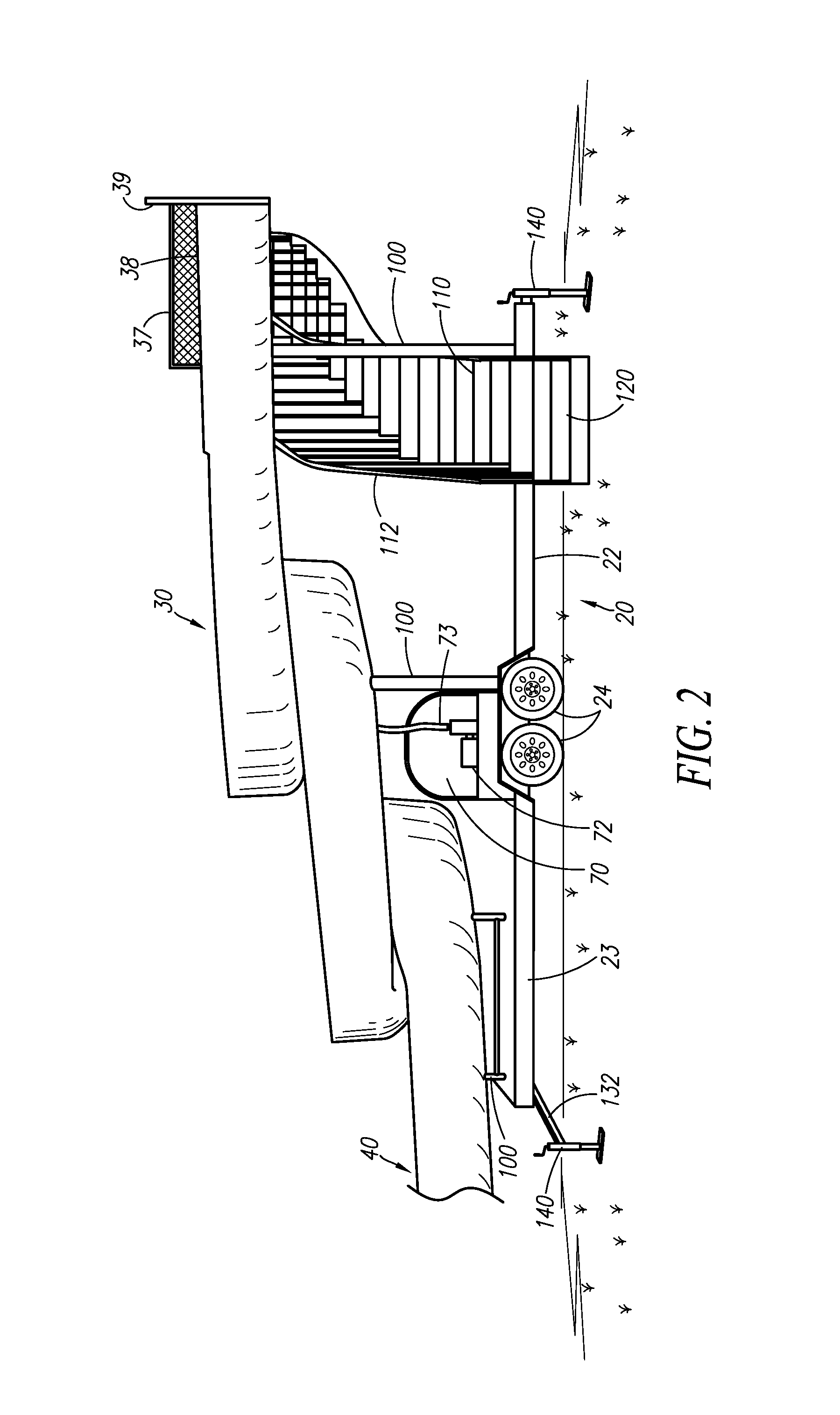

Mobile, modular water amusement ride

A modular water slide apparatus integrated with a transportable unit includes a major slide structure, a minor slide structure, a plurality of water jet nozzles, a trailer, a water supply and storage tank, a water catch basin, a plurality of anchor columns, and at least one circular, spiral, or winding staircase.

Owner:SCHAFER BRIAN E

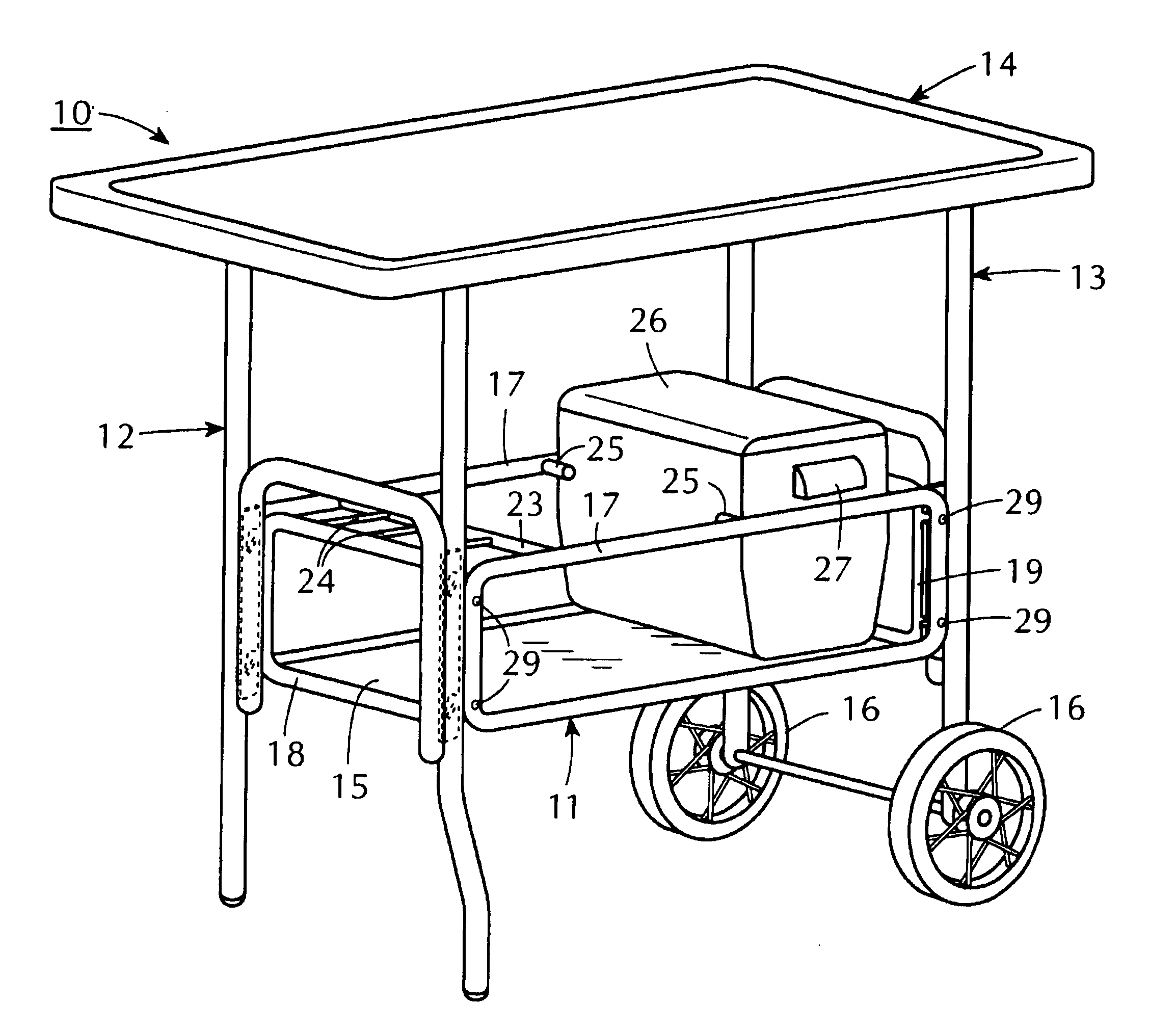

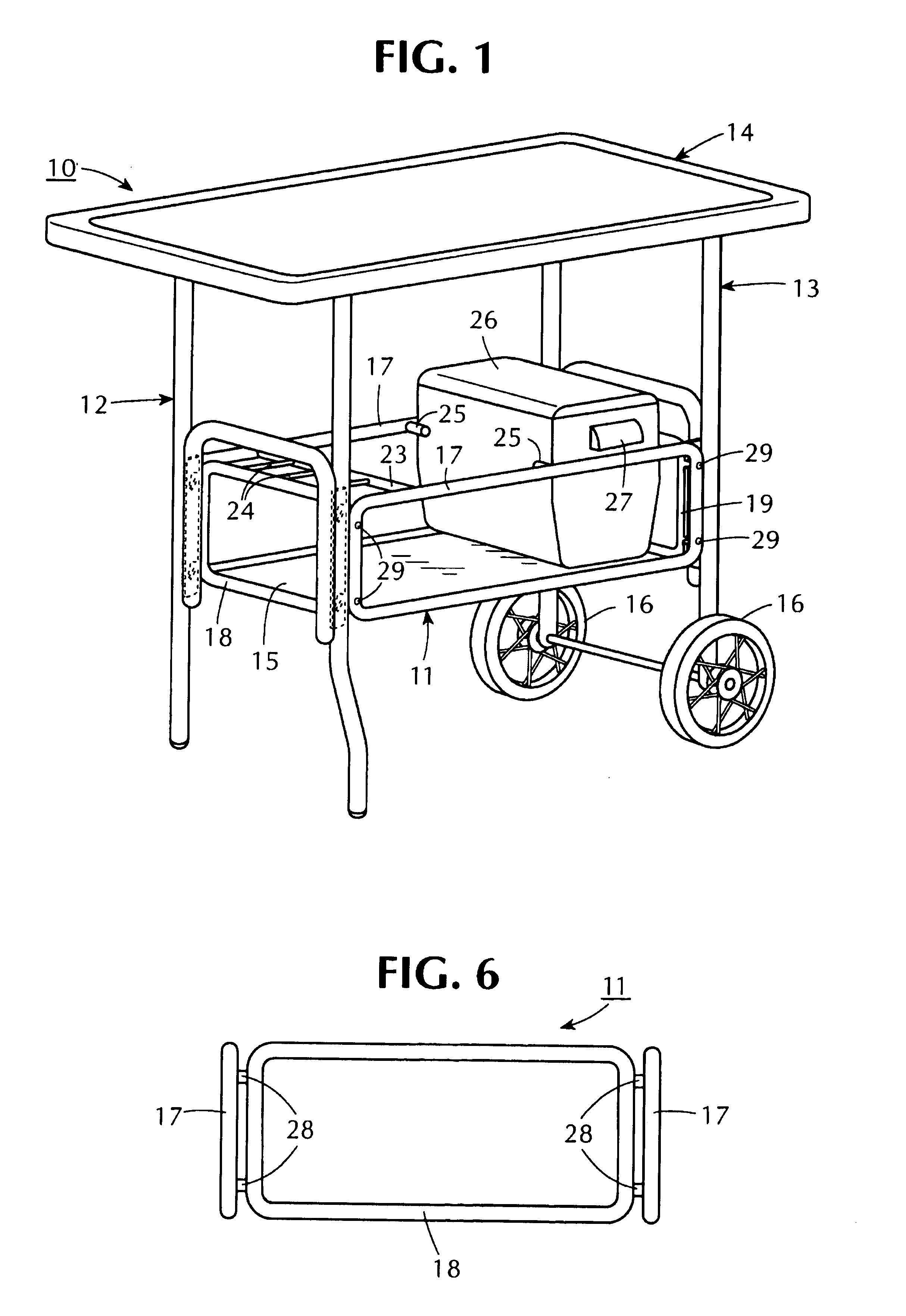

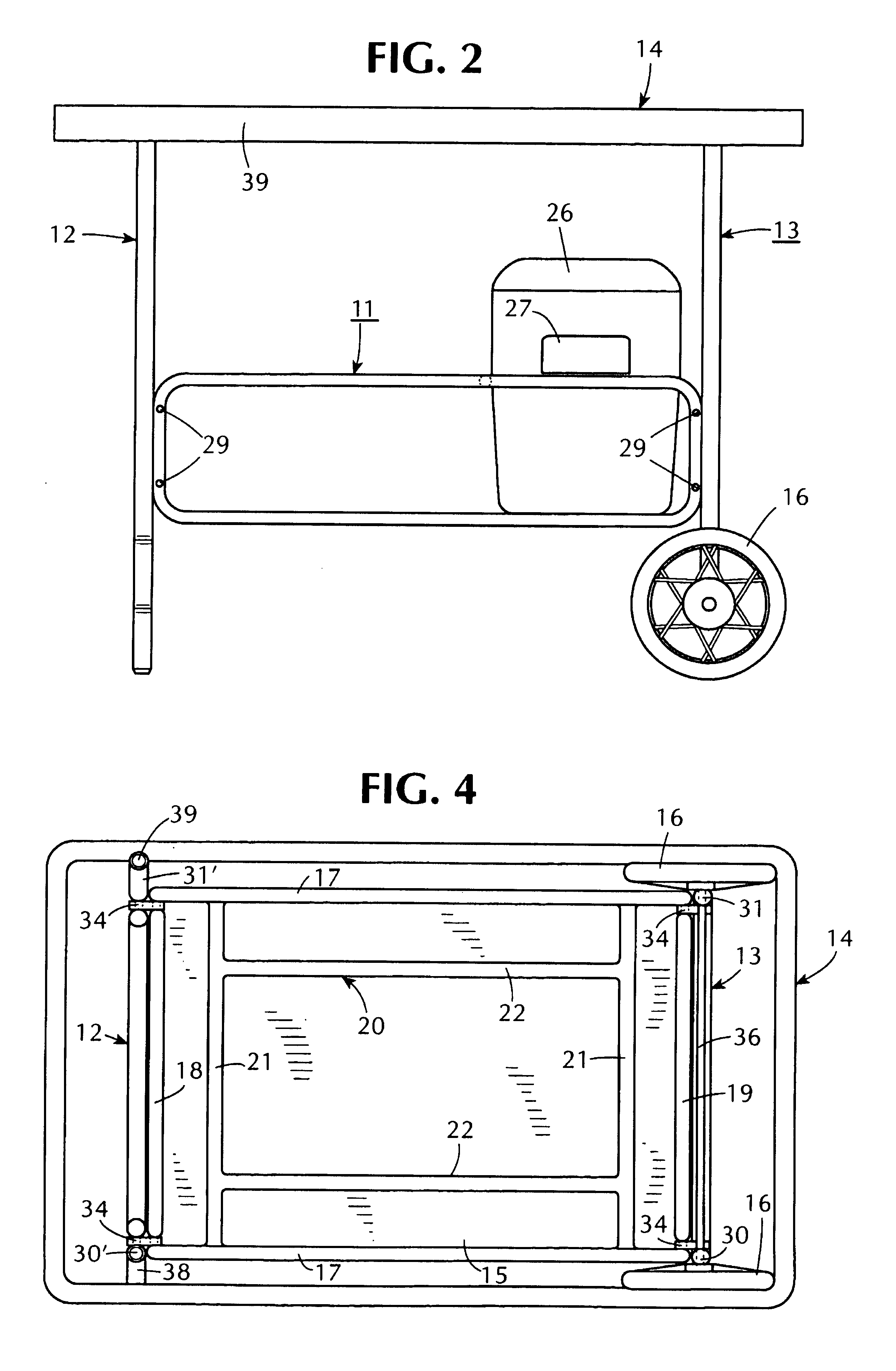

Bar cart

InactiveUS7204509B1Robust rigid constructionIncrease surface areaCarriage/perambulator accessoriesHand carts with one axisDesk mountEngineering

The bar cart is composed of individual components to be assembled and readily disassembled in a knock-down manner. A body frame is made of four individual skeletal rectangular frames which are interconnected in spaced apart relation. Spacers between the individual frames of the body frame fit into slots in vertical plates on the leg frames to provide for a rigid connection between the body frame and the two leg frames. A table top fits onto outstanding arms of the leg frames and interlocks with the arms to provide a rigid structure. Guides are provided in the body frame to define compartments for receiving bottles and containers as well as to define a recess for receiving a cooler. The bar cart is transportable via wheels and is disassembled without tools into a compact condition for storage in a minimum of space.

Owner:TELESCOPE CASUAL FURNITURE

Toggle fixing

A toggle fixing for fixing an article to a thin-walled component, having a crosspiece and a strip for holding the crosspiece during mounting, wherein the crosspiece has an opening for receiving a screw, with two counterbearing elements made of metal for better hold of the screw. In order to prevent certain screws from becoming jammed between the counterbearing elements, the a plastics body is arranged on each of the counterbearing elements on the side thereof facing towards the strip, which plastics body is movably joined to the crosspiece and narrows the opening.

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

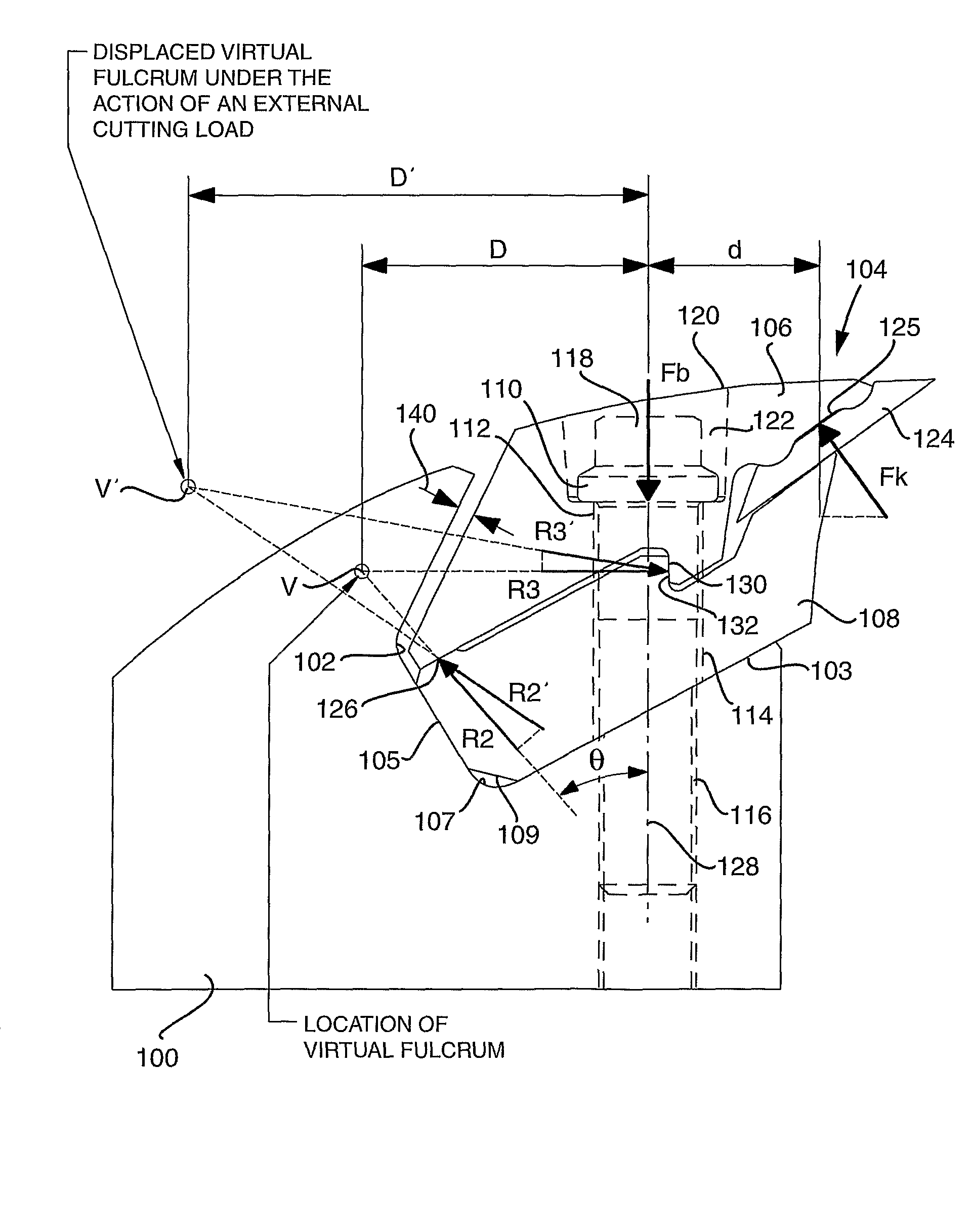

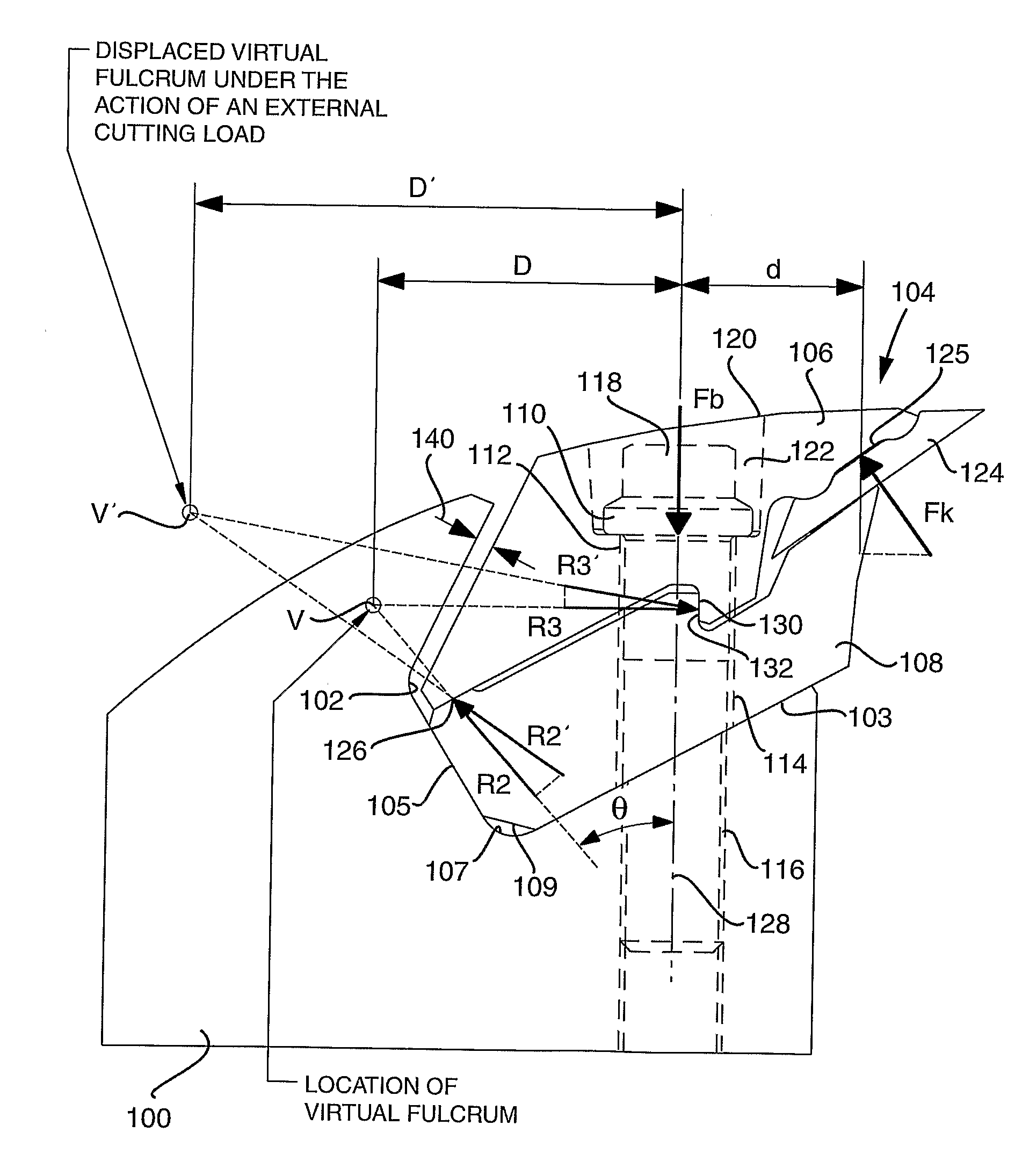

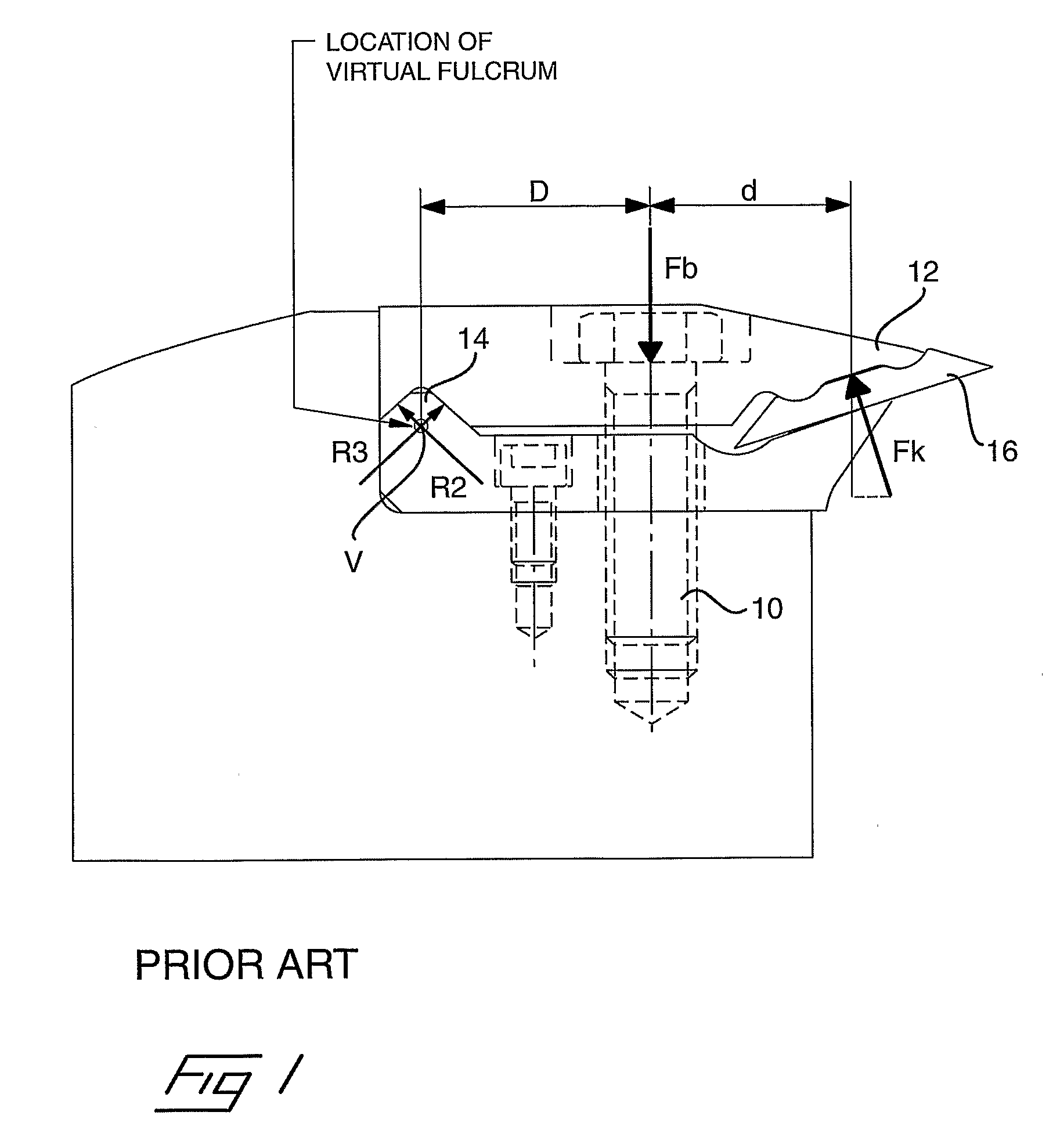

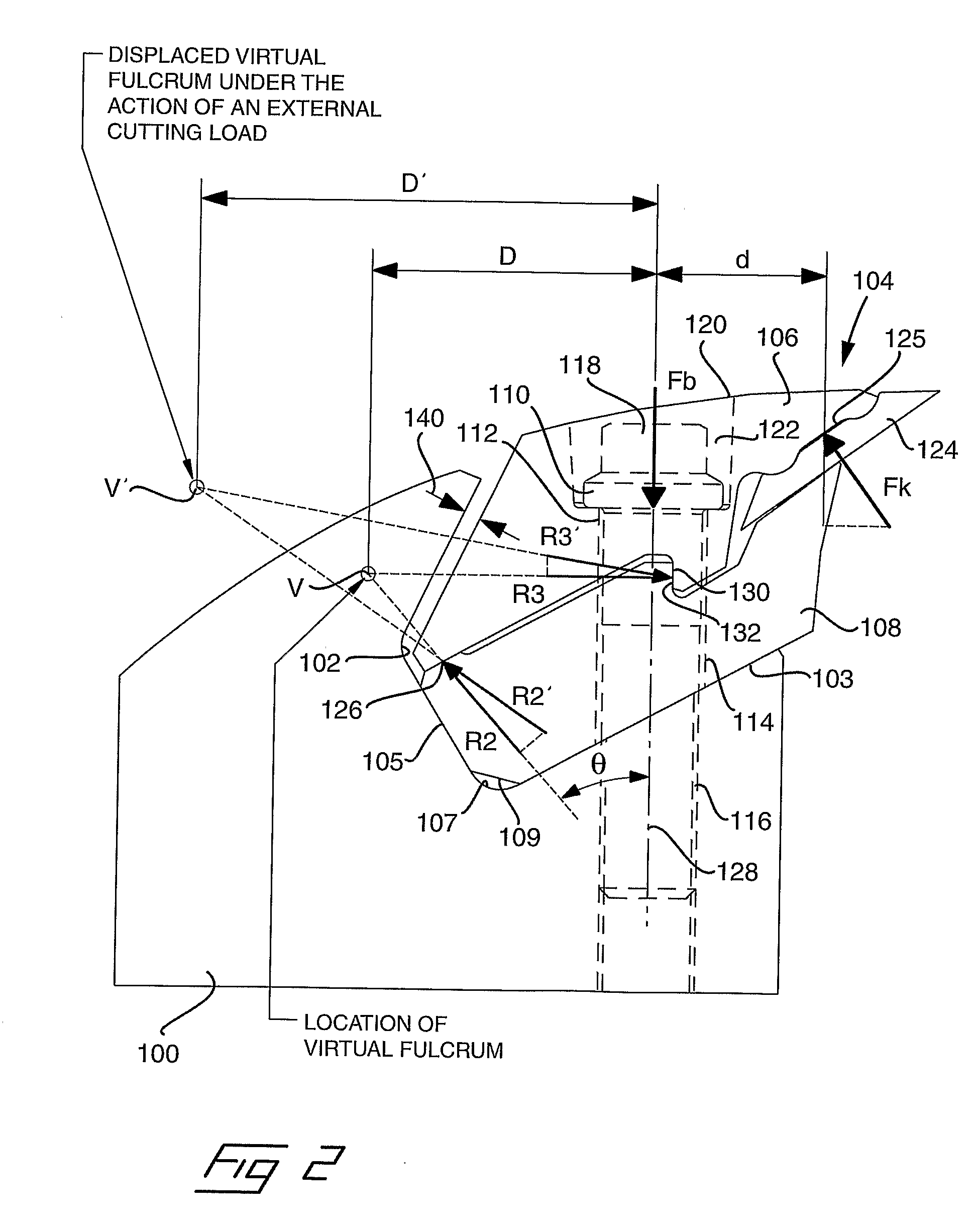

Clamping assembly for woodworking knife

ActiveUS8205650B2Easy to adaptDurable in constructionMulti-purpose machinesCocoaWoodworking machineContact position

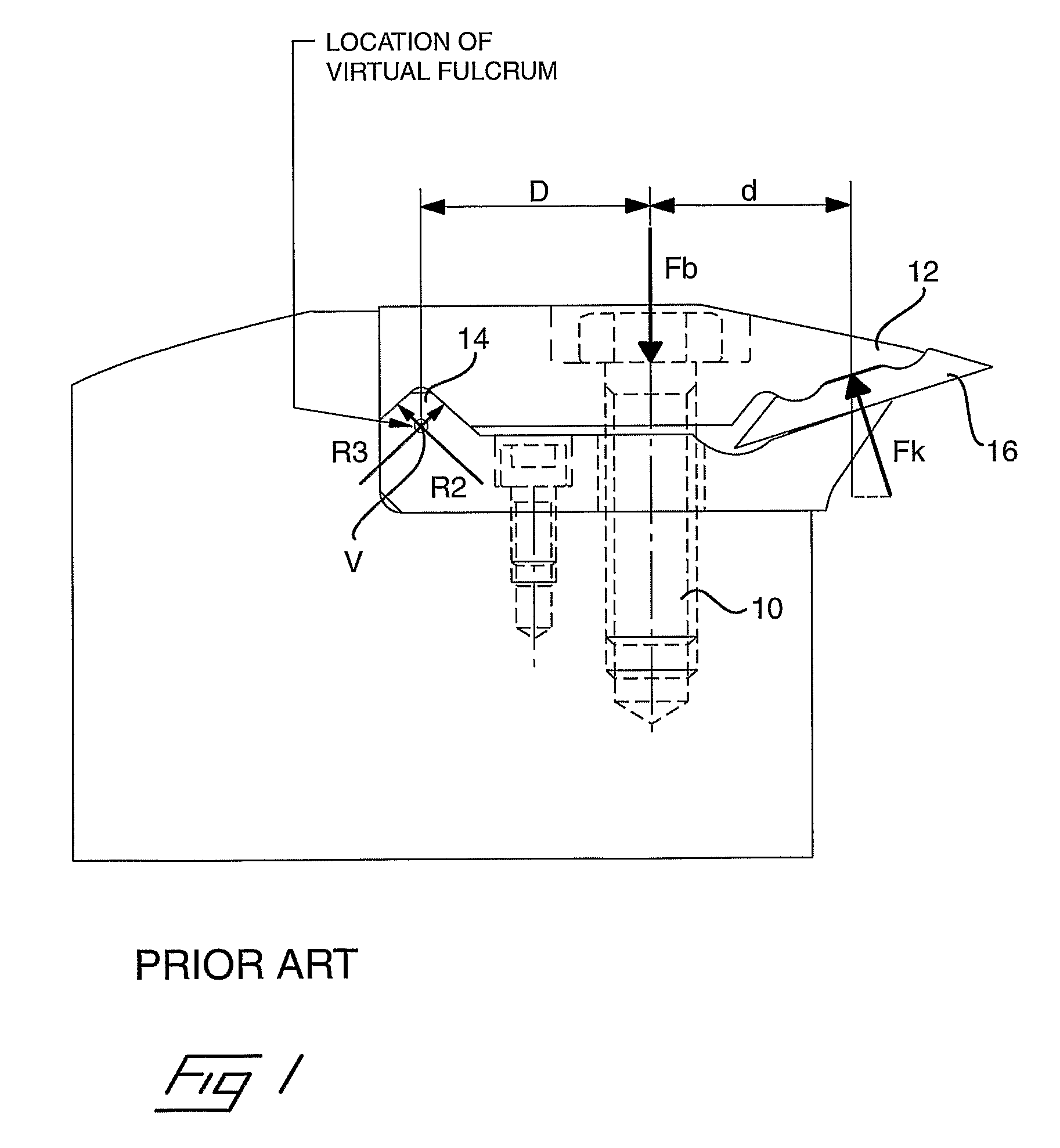

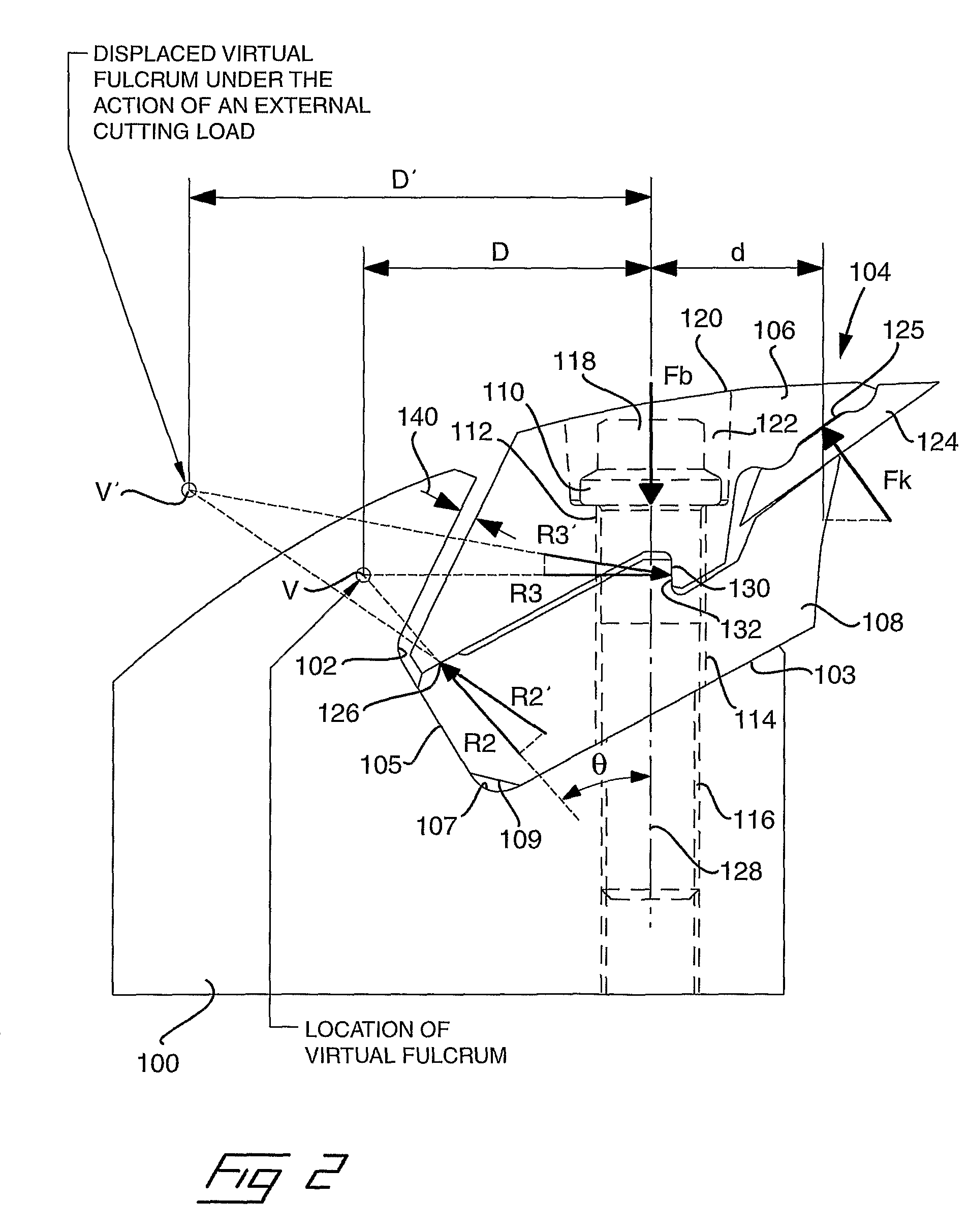

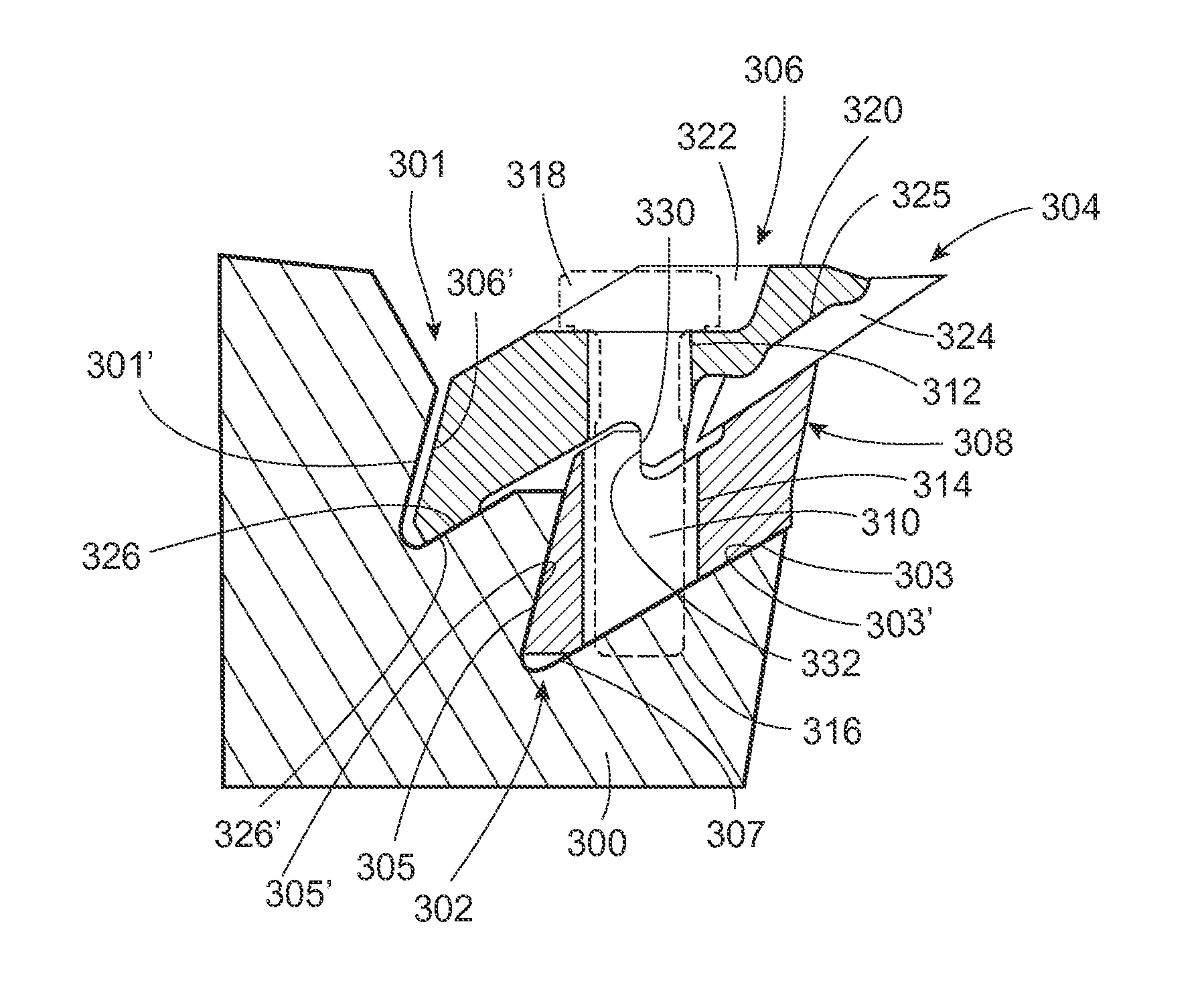

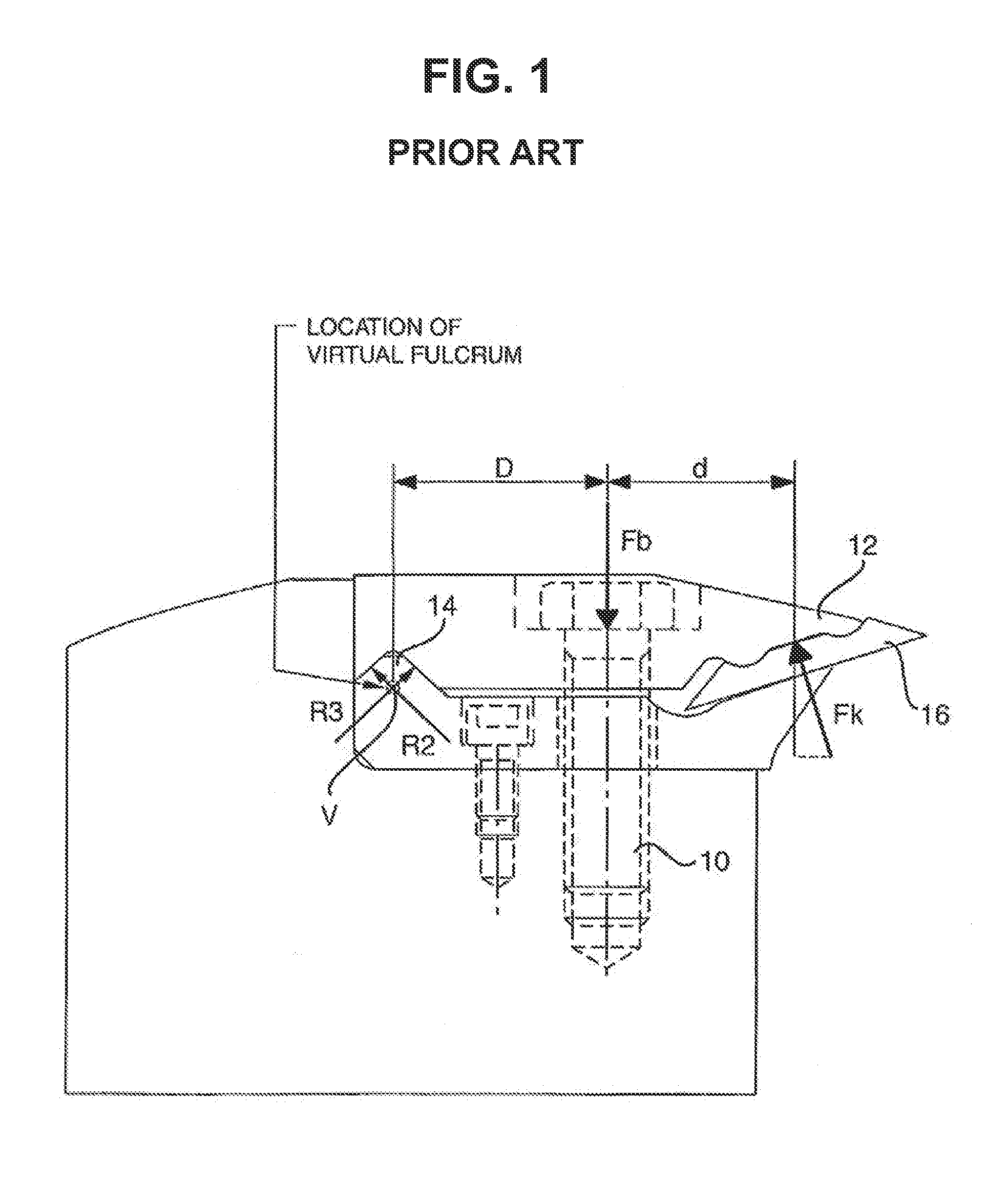

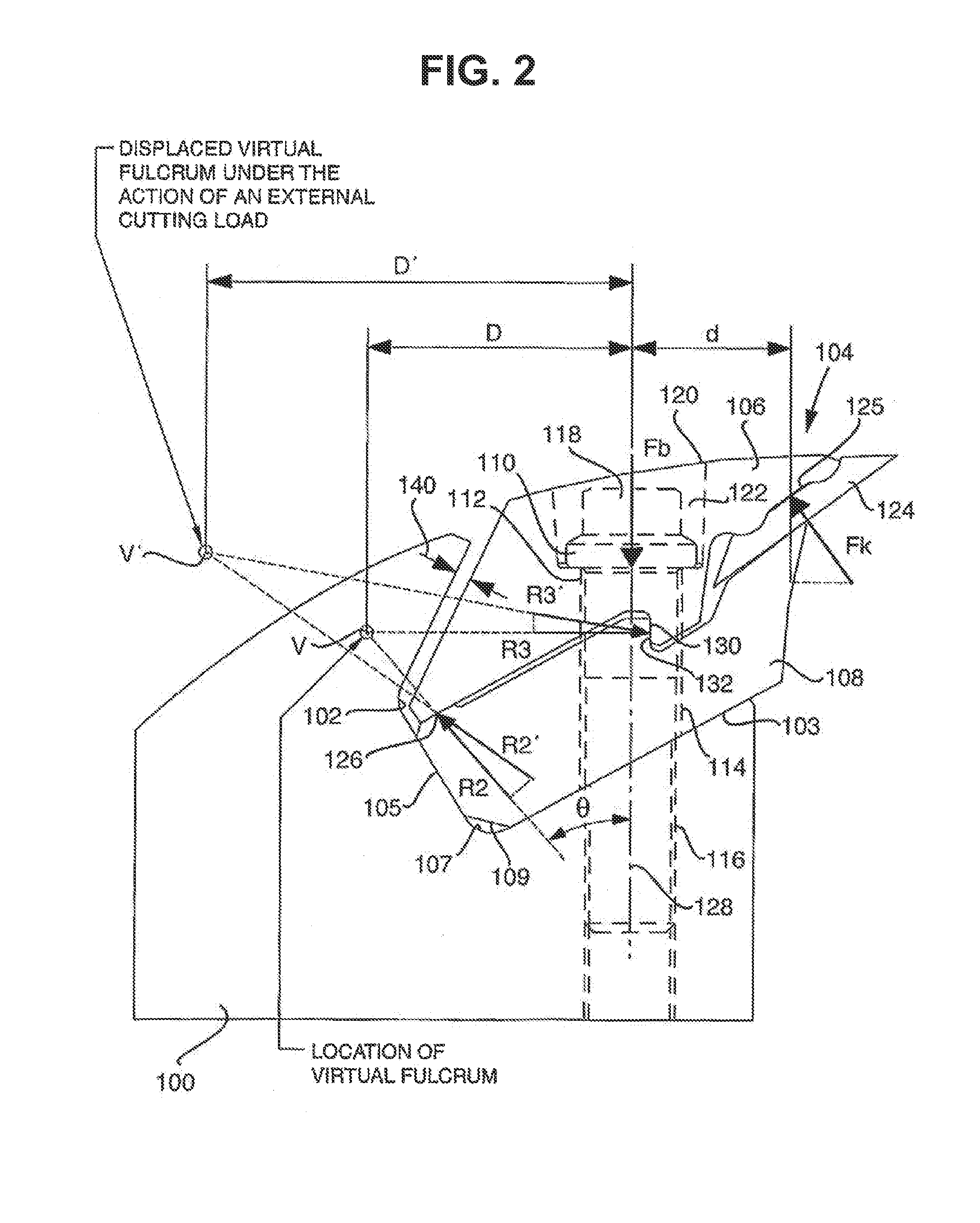

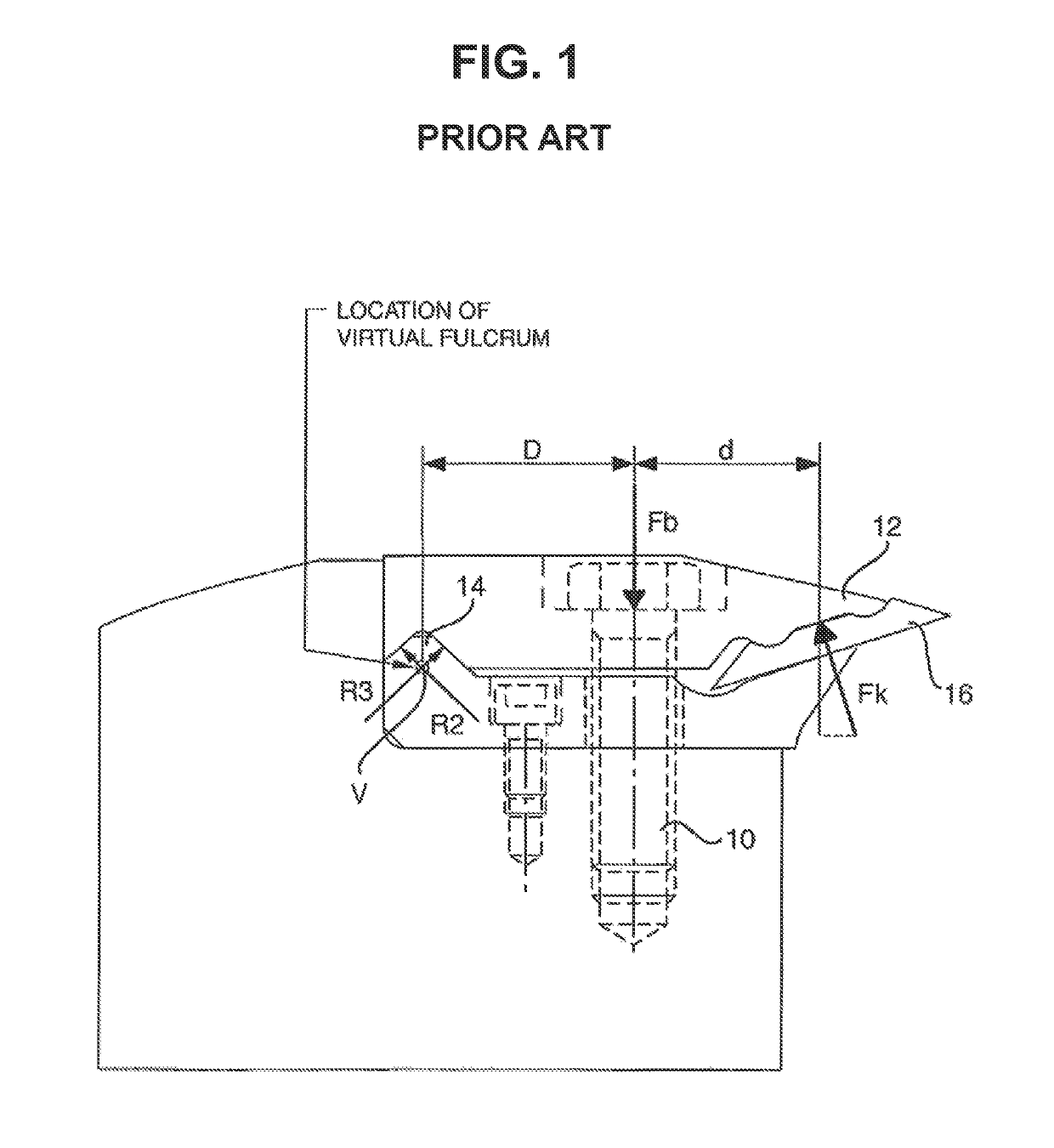

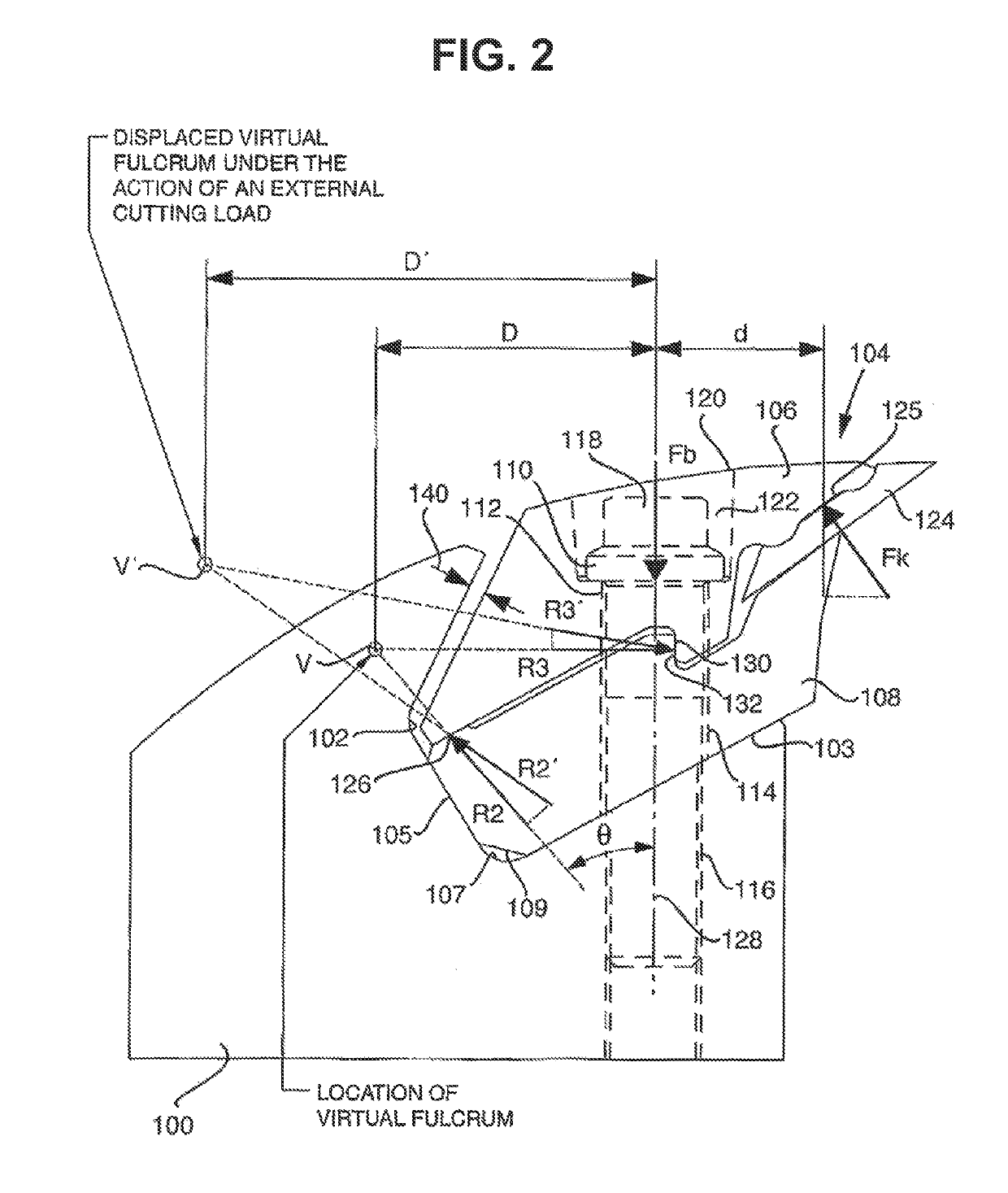

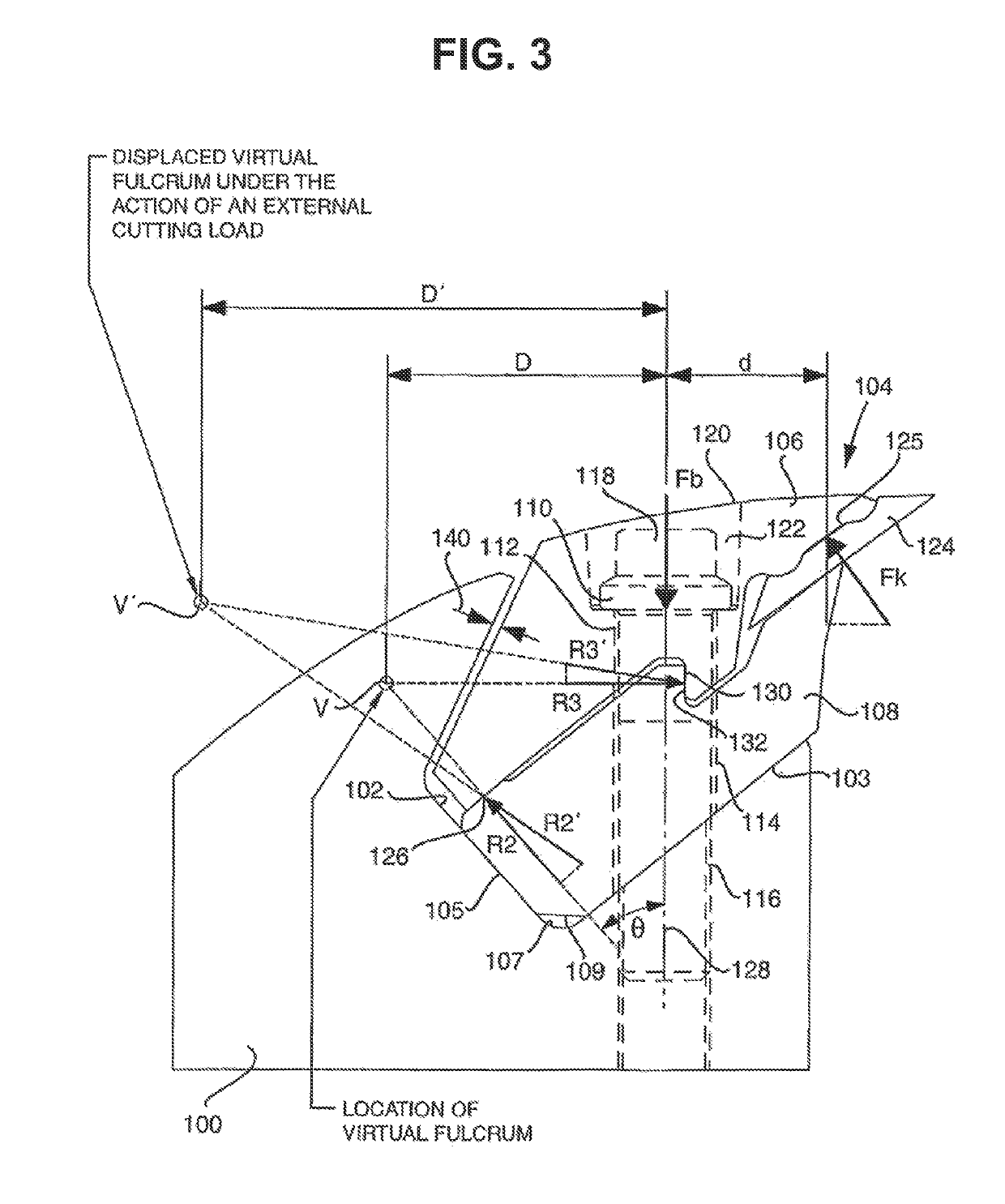

A clamping assembly to hold a woodworking knife in place in a woodworking machine. The clamping assembly comprises a clamping component comprising a body and an actuator. The body has three discrete contact positions distributed thereon: 1) a fulcrum located generally at one end, 2) a knife abutting portion located generally at the other end, and 3) a bearing surface located elsewhere. The actuator is for applying a clamping force to the body along a clamping axis located intermediate of the knife abutting portion and the fulcrum. The fulcrum is a surface having a normal that is at an angle to the clamping axis. The bearing surface is a surface wherein a line normal to the bearing surface intersects the line normal to the fulcrum at a position outside of the clamping component at a location farther askew of the clamping axis than the fulcrum.

Owner:IGGESUND TOOLS

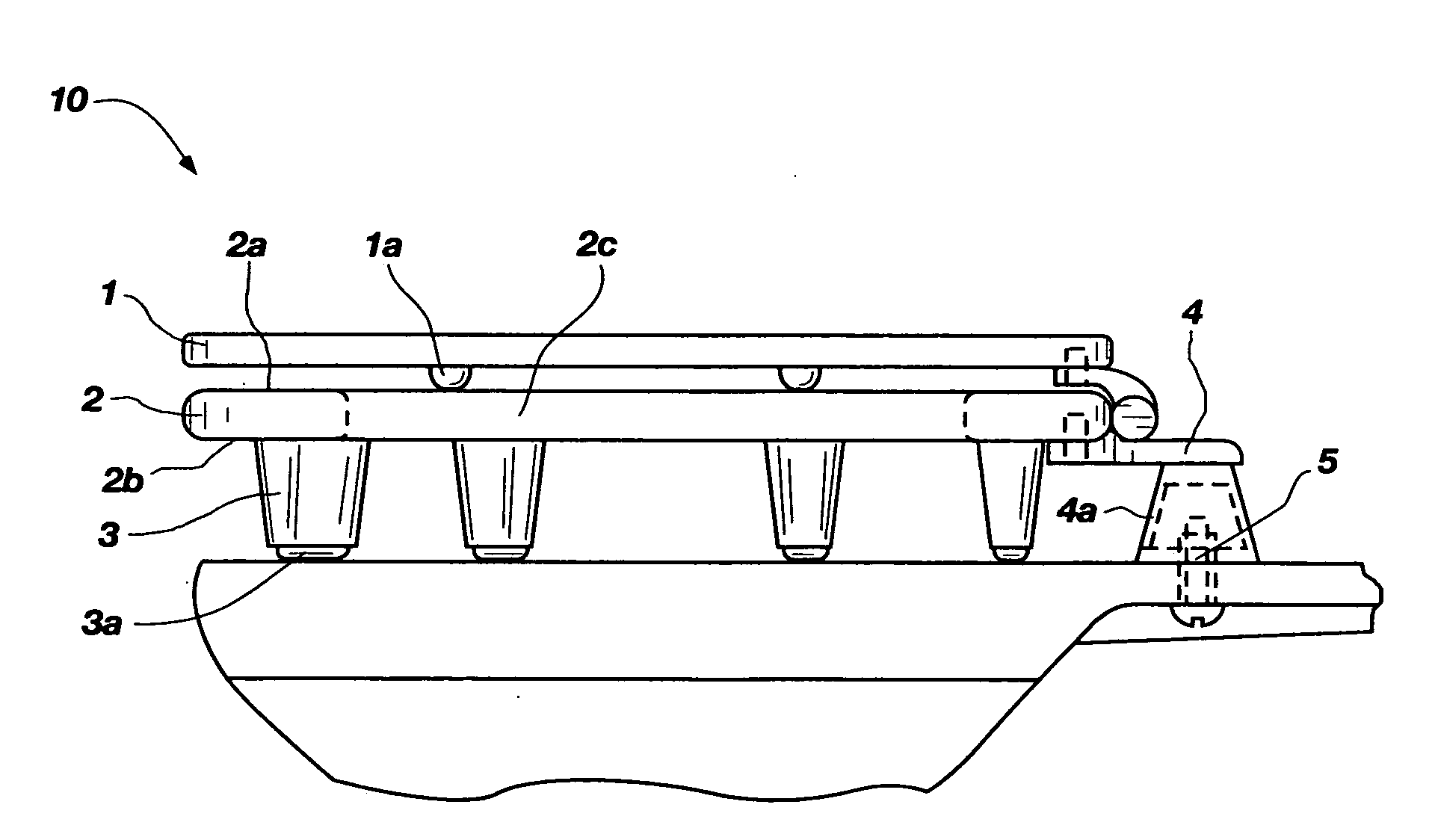

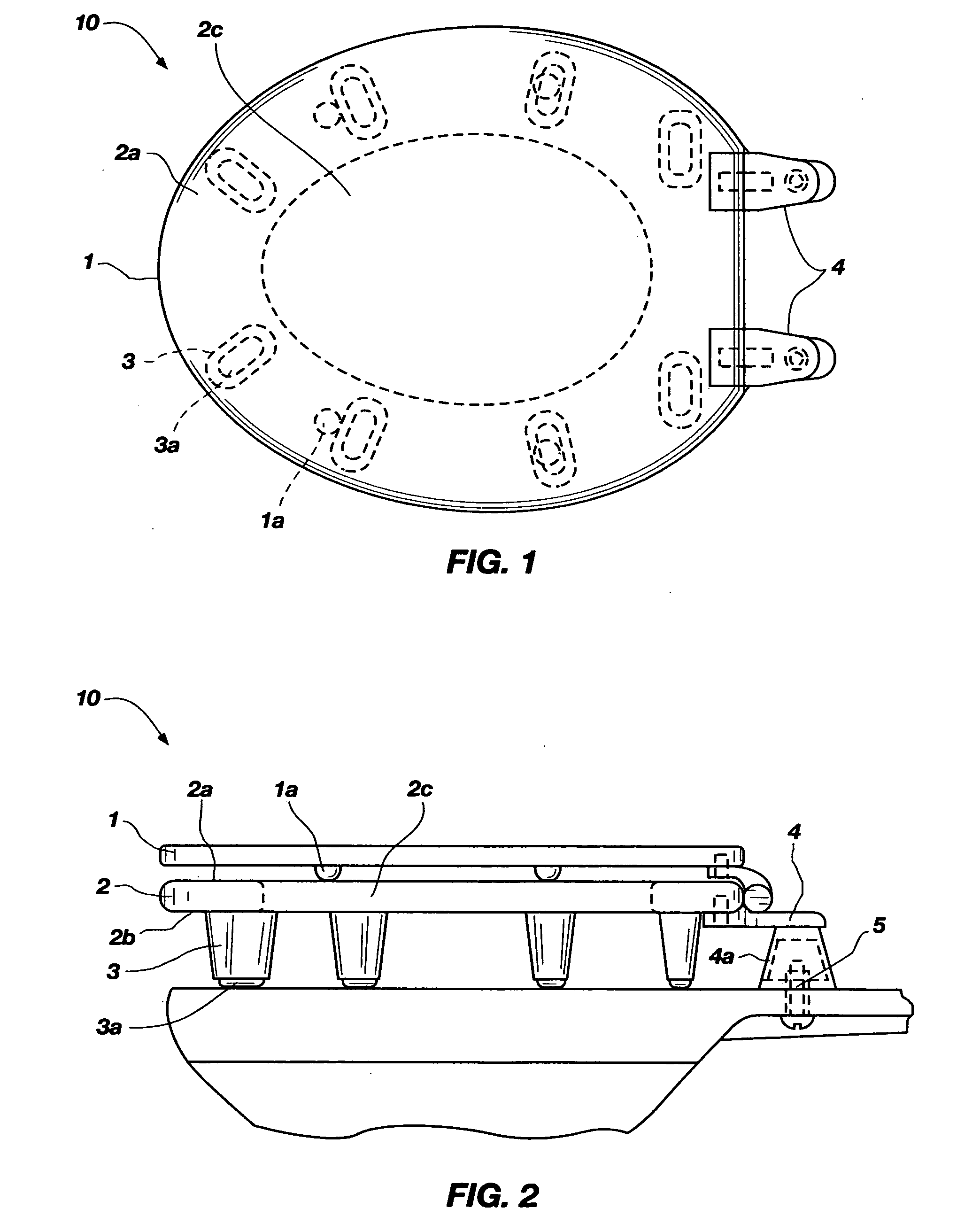

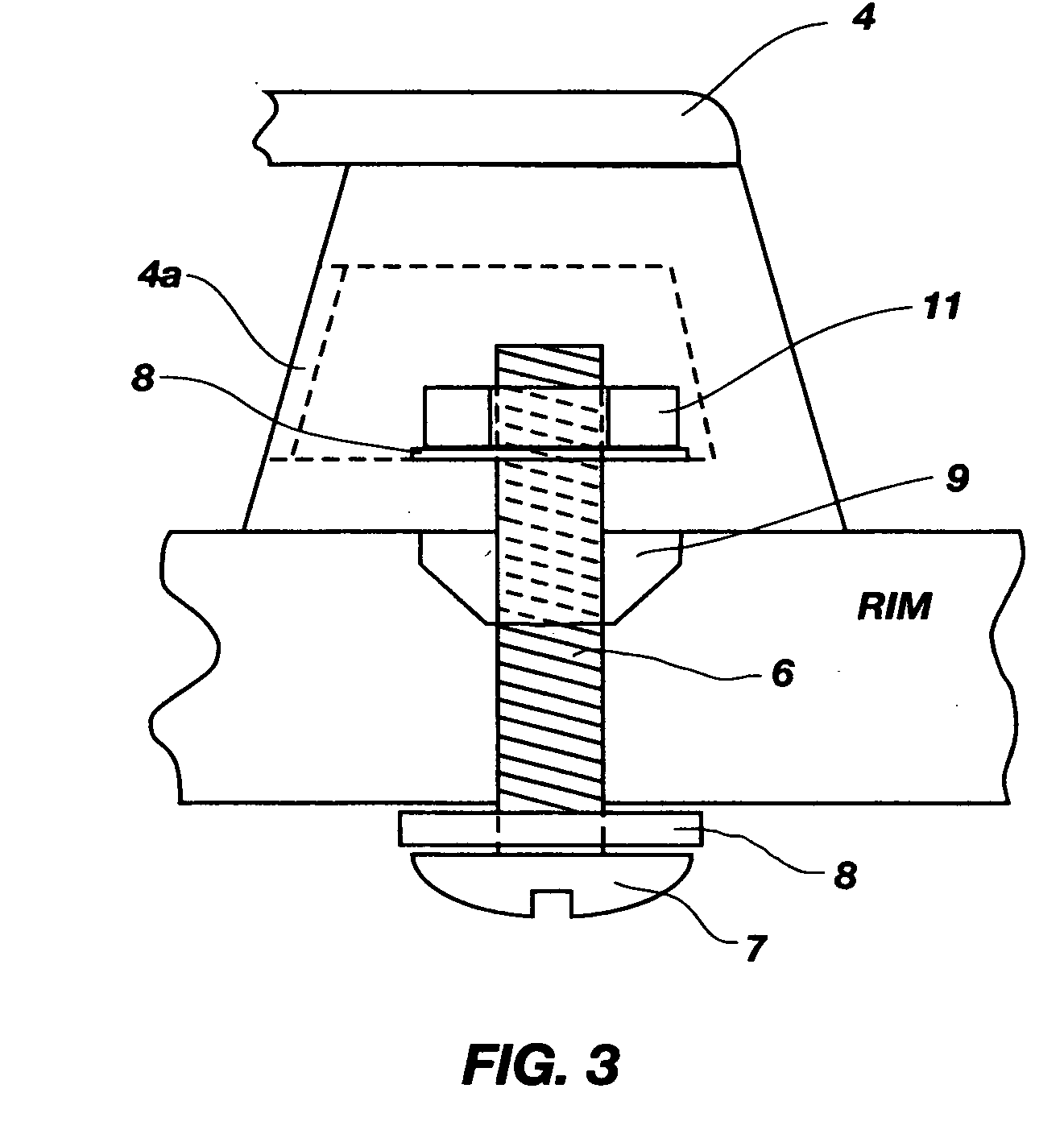

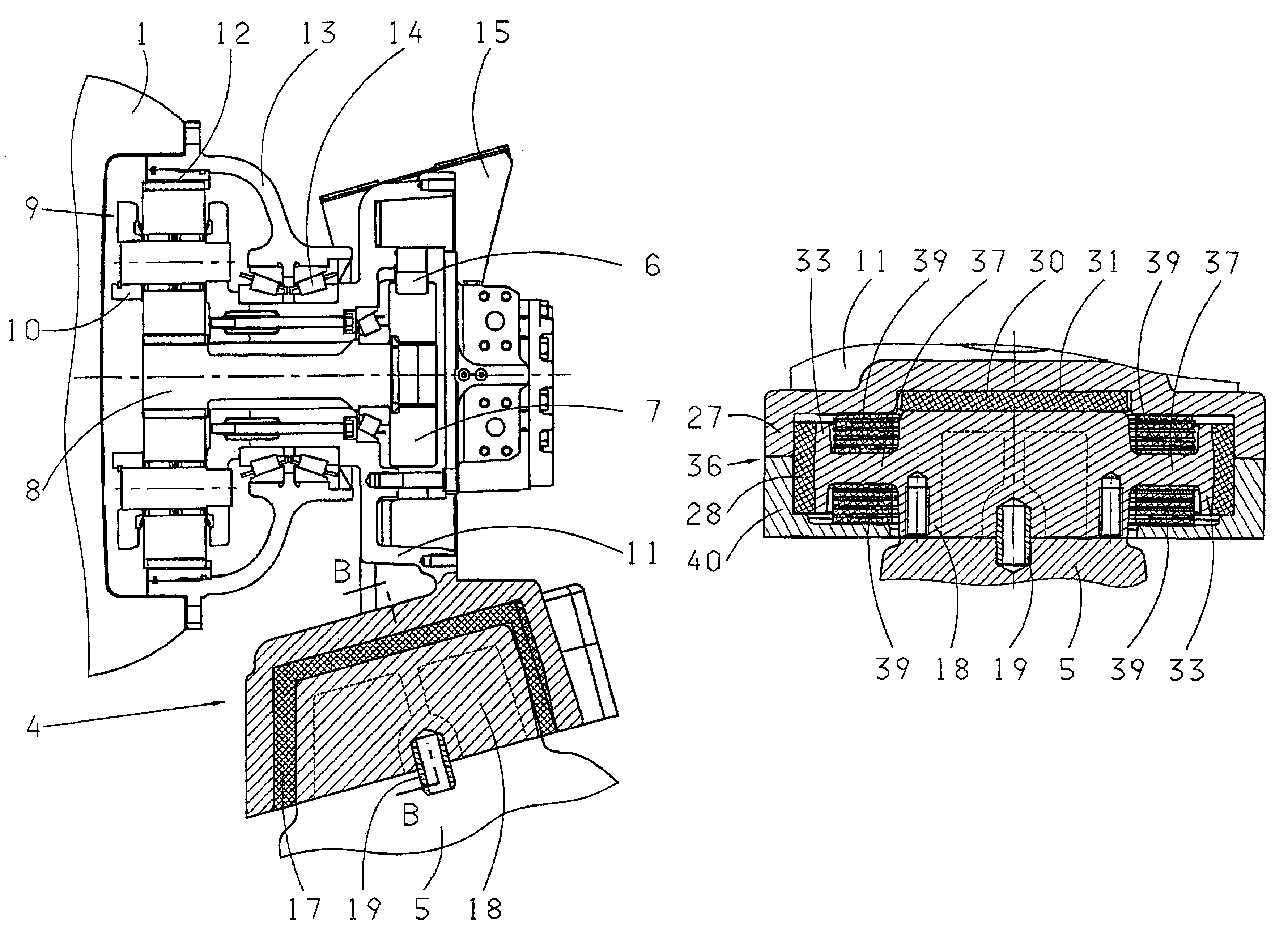

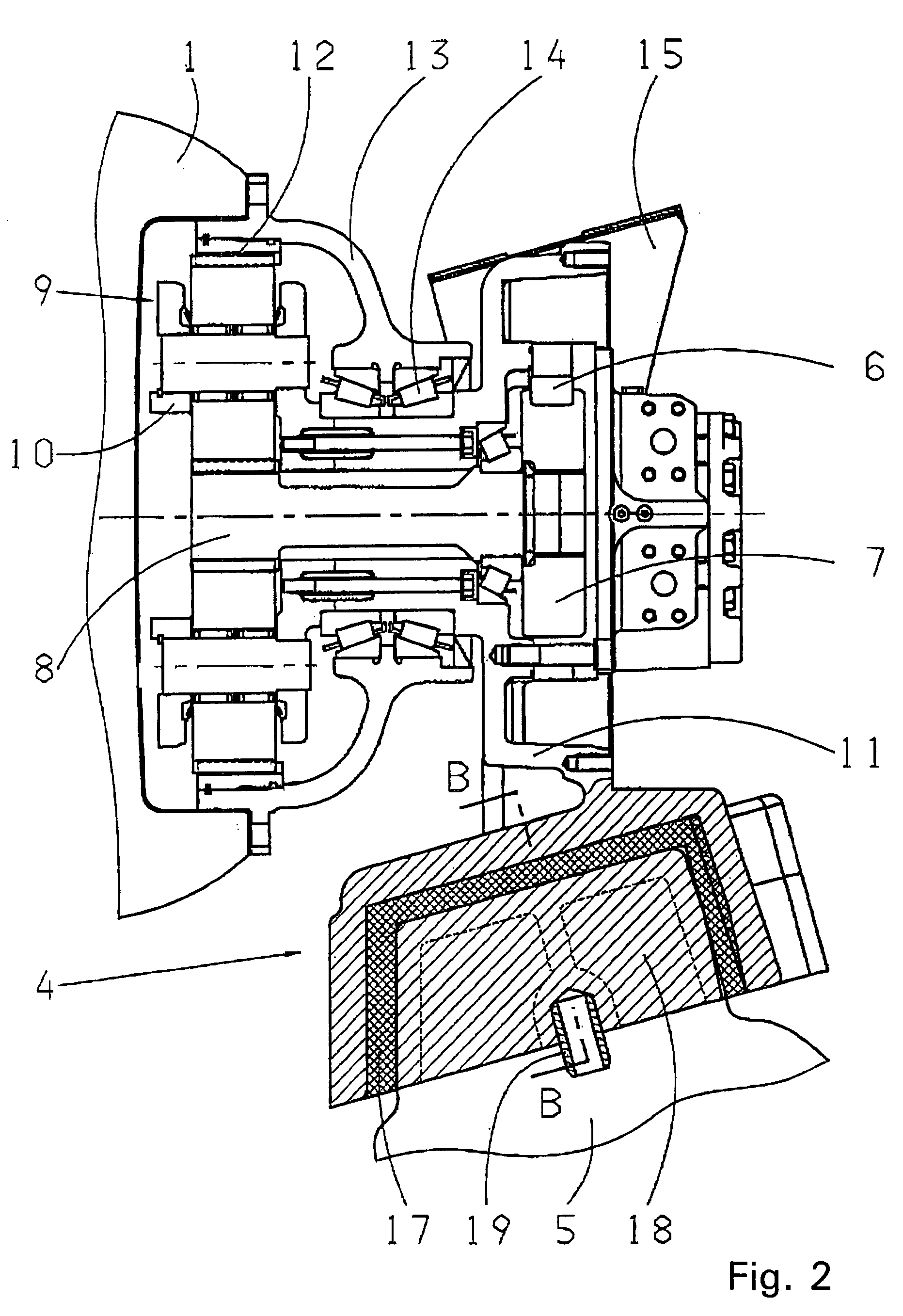

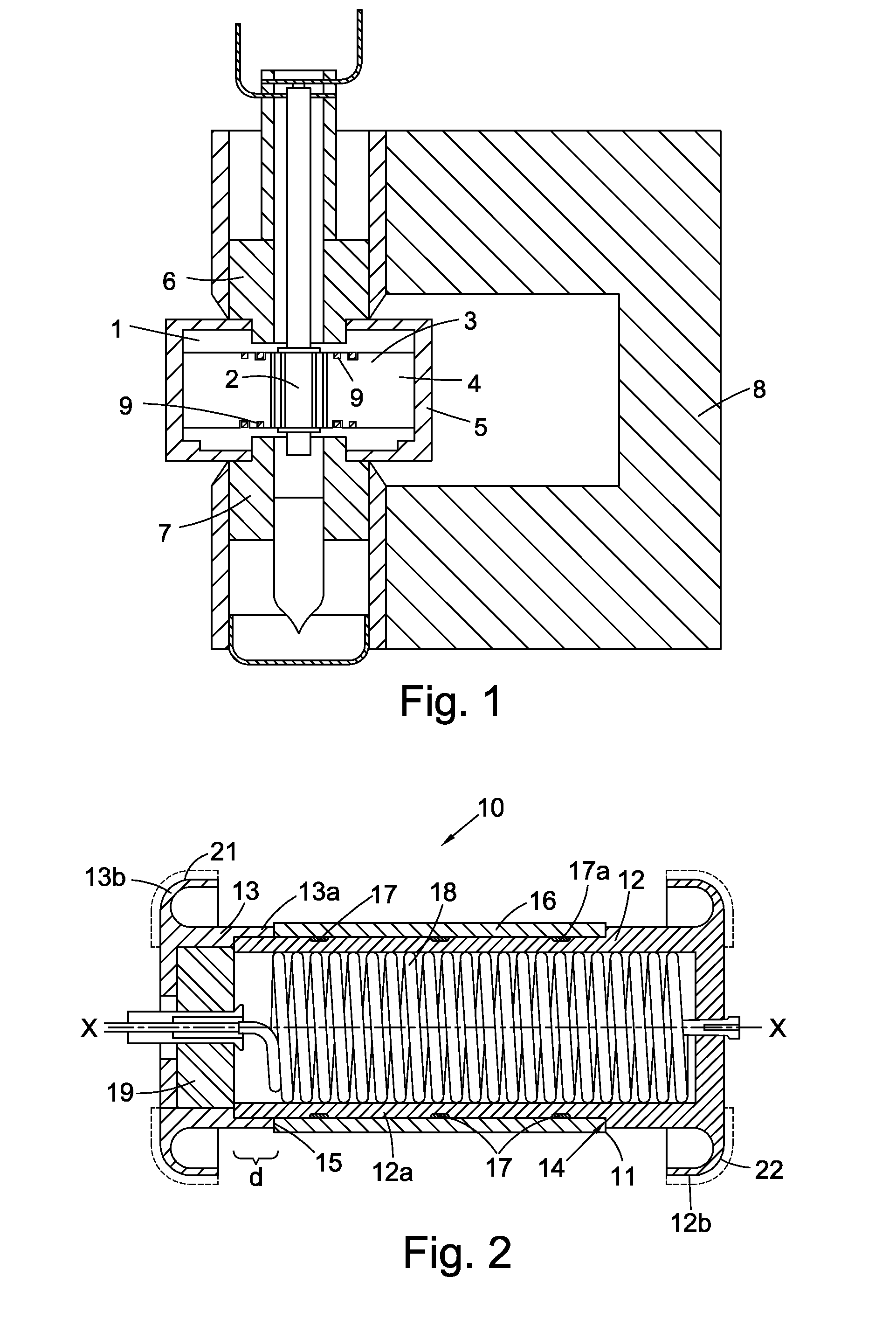

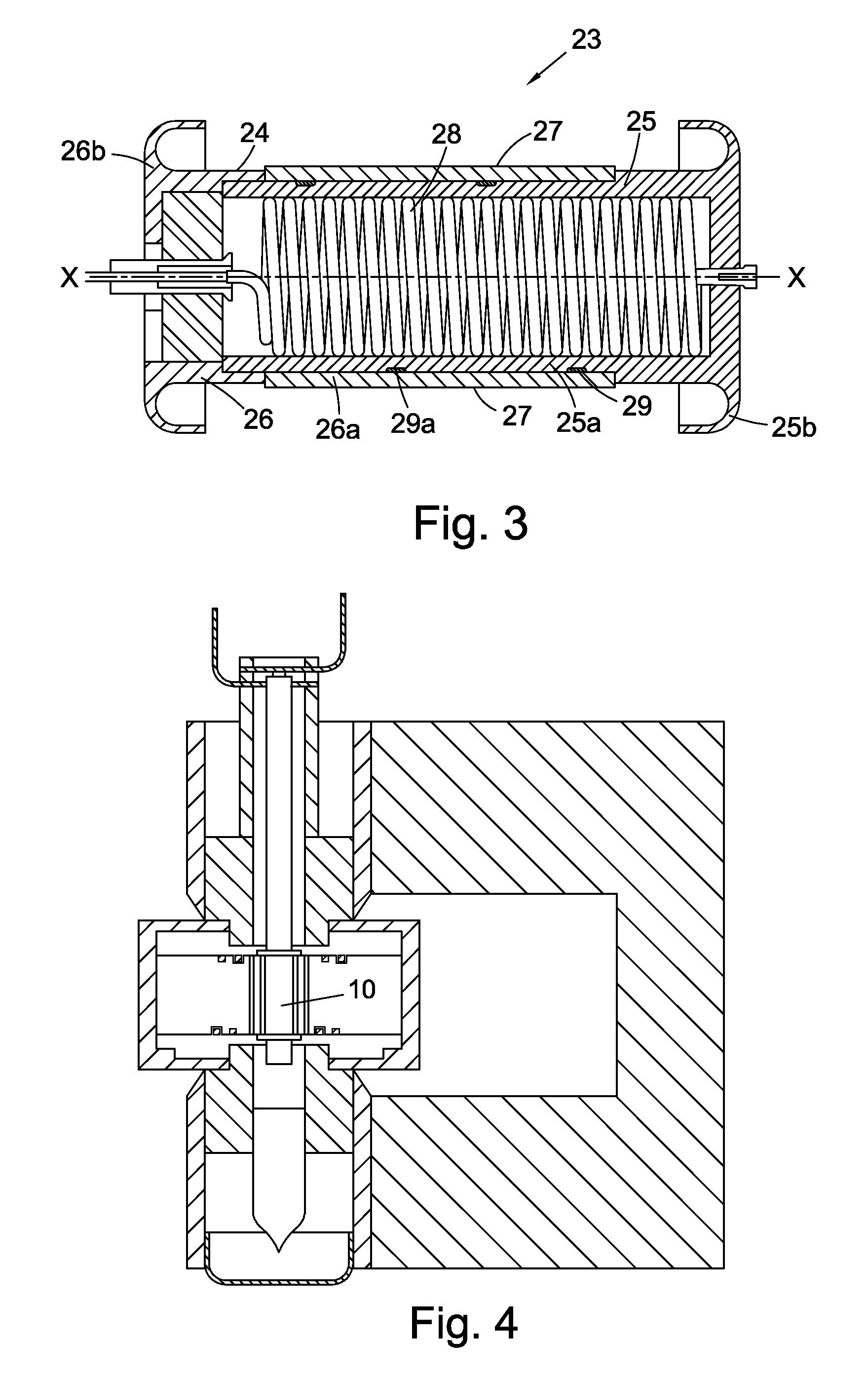

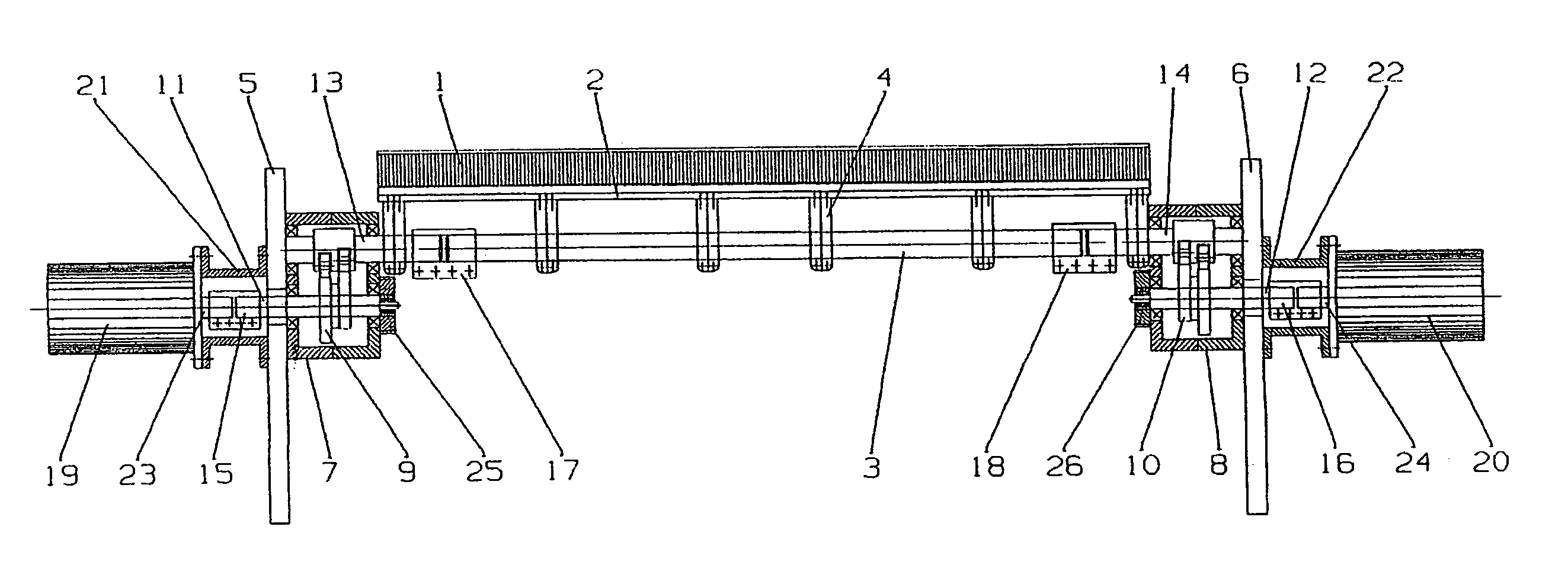

Drive for mixing drum with elastic element arranged between bearing incorporating drive system and base

ActiveUS7878699B2Torque is limitedHigh spring stiffnessRotating receptacle mixersRoller bearingsMechanical engineeringBarrel

A drive system for a mixer barrel for absorbing weight of the mixer barrel (1). The drive system communicates with a base (5) via a weight supporting element which supports the mixer barrel (1) and enables relative movement therebetween. The weight supporting element comprises at least one distortable elastic element (28, 29, 30, 39) enabling the movement between the drive system and the base (5). The at least one elastic element (28, 29, 30, 39) supports the weight of the mixer barrel (1) above the at least one elastic element (28, 29, 30, 39). The drive system (4) has at least one component (36) which limits movement of the drive system (4) and increases a distance between the drive system (4) and the base (5) such that a torque strain on the drive system (4) is braced by the base (5).

Owner:ZF FRIEDRICHSHAFEN AG

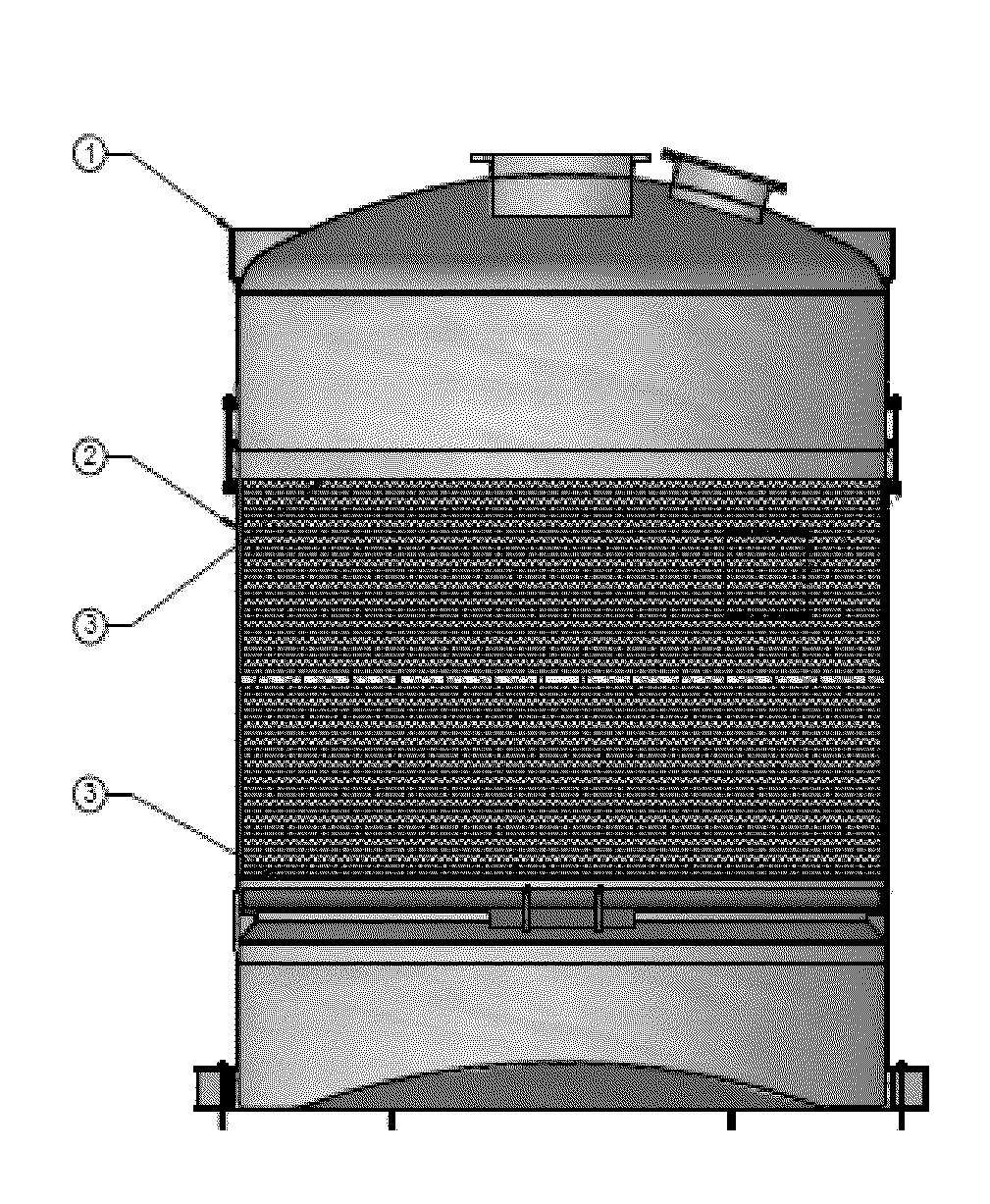

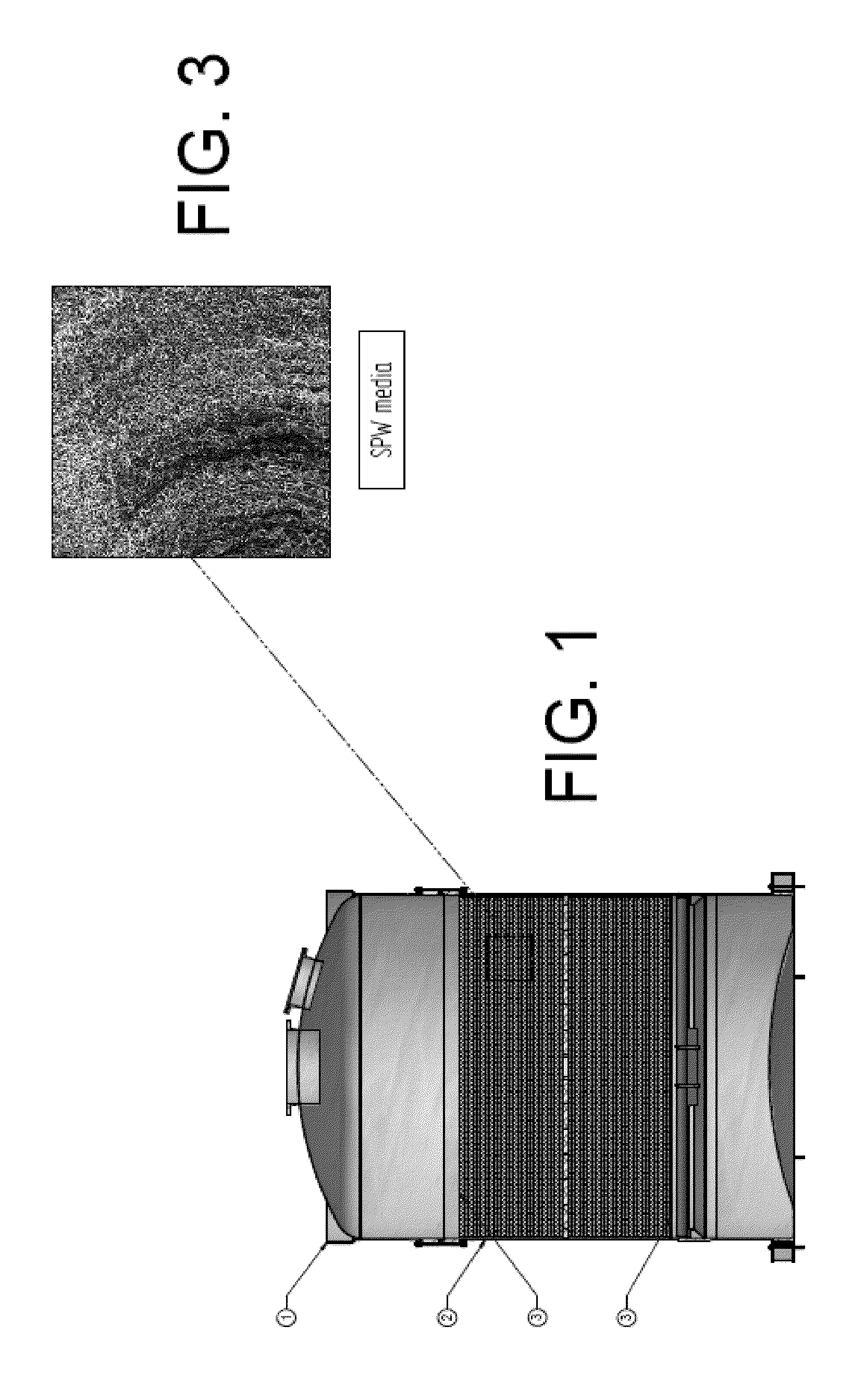

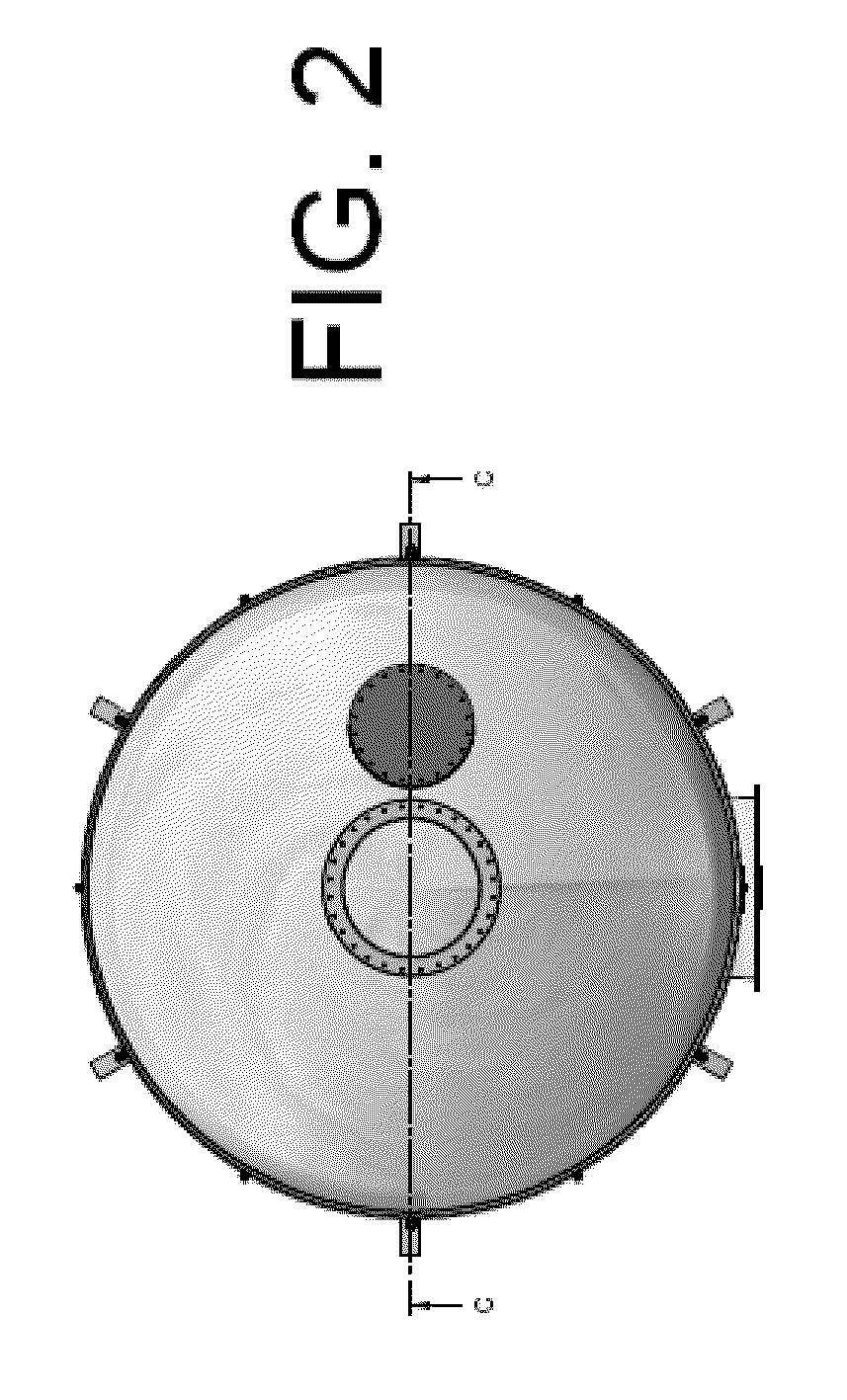

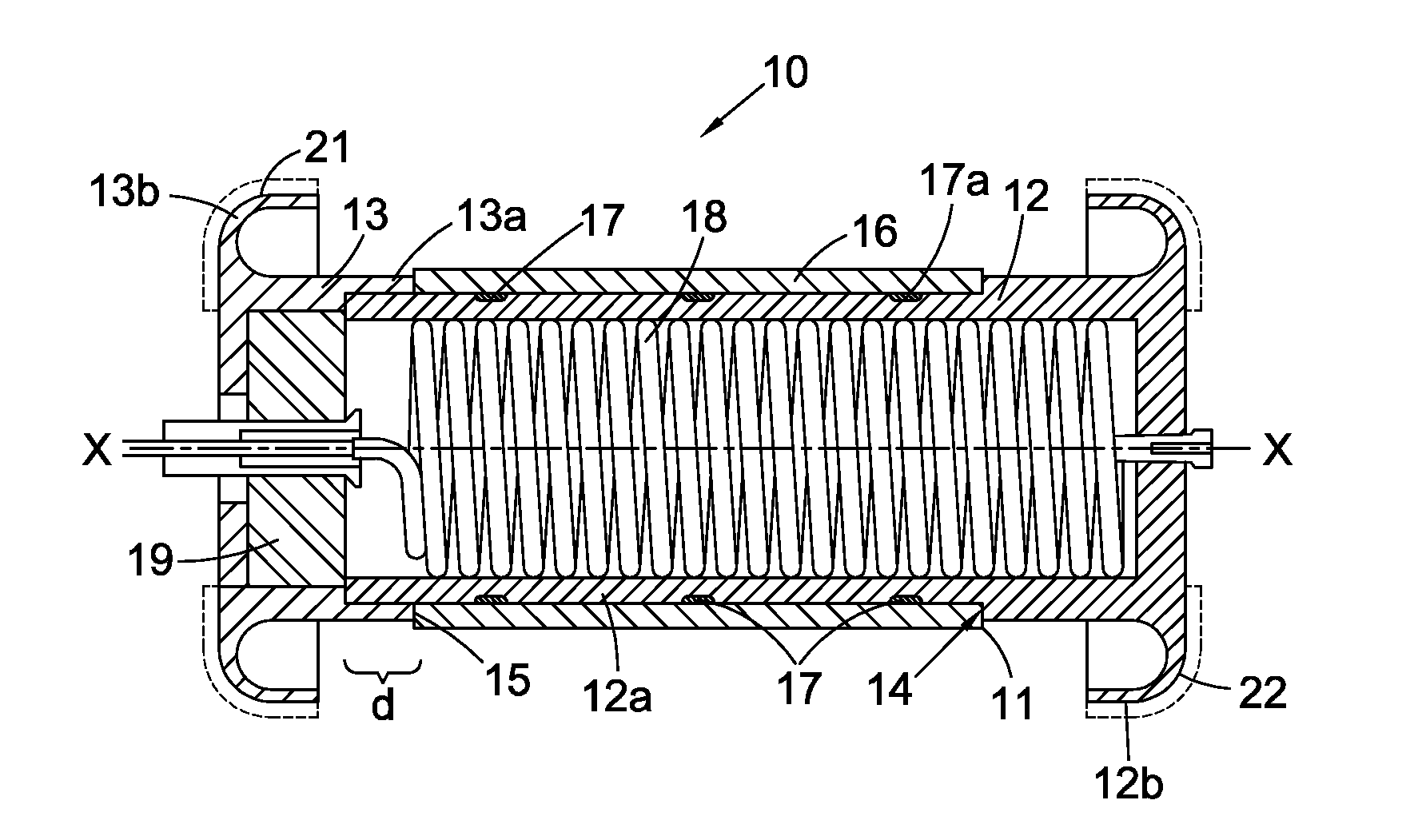

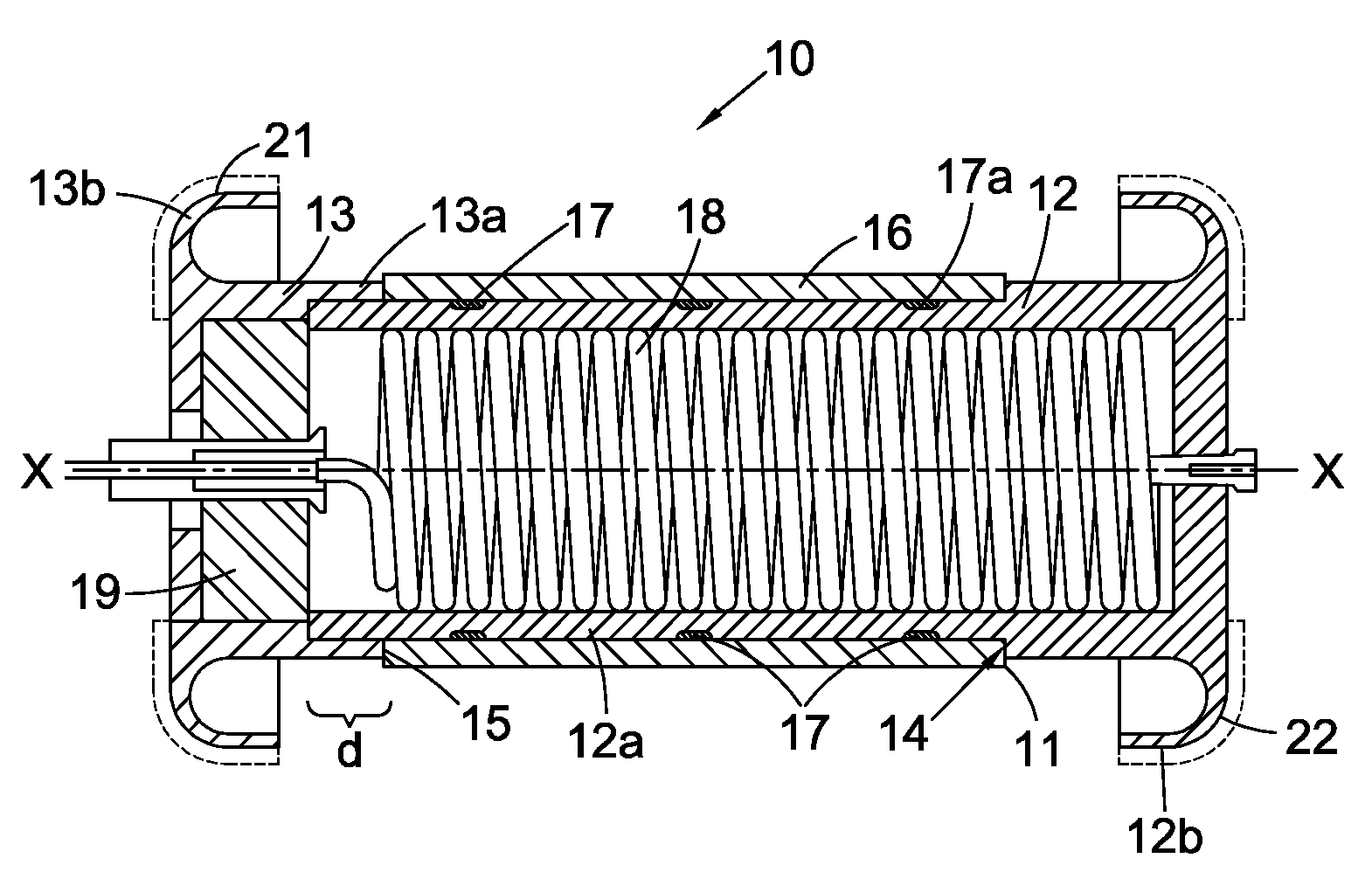

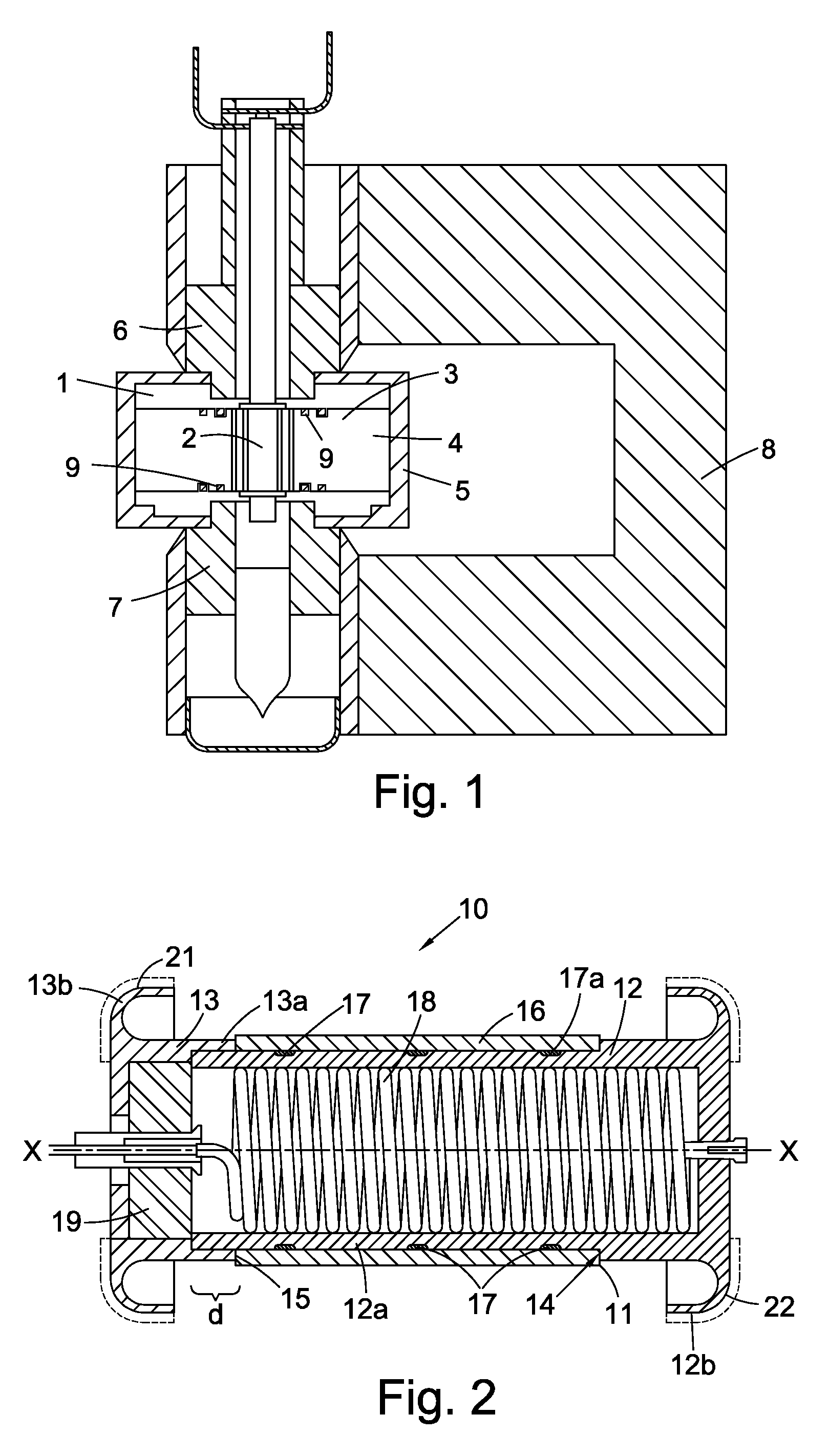

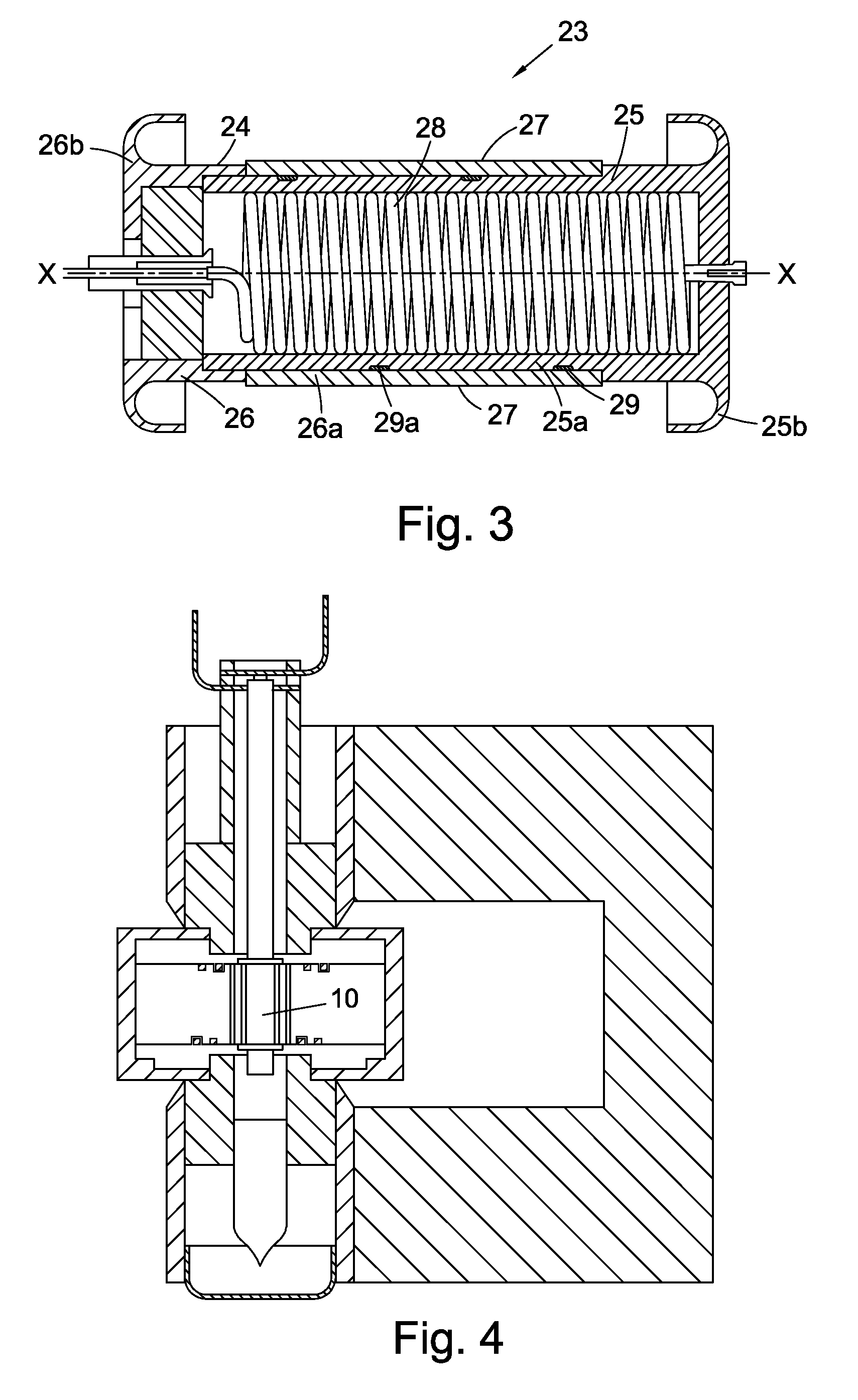

Device for purifying gases, such as air in particular, or liquids, such as water in particular

InactiveUS20100089818A1Small pressure dropLose weightDispersed particle separationLoose filtering material filtersEngineeringProduct gas

Device for purifying gases, such as air in particular, or liquids, such as water in particular, in which use is made of micro-organisms. The device comprises a chamber (1) containing at least one filter pattern (7) and having intakes and outlets (12, 13) for the medium that is to be purified. The filter pattern is obtained by making use of virtually two-dimensional geo-textile (8) made from sprayed plastic threads with a thickness of approximately 2 mm for retaining the micro-organisms, and a three-dimensional geo-textile (9) with a thickness of approximately 10 mm, allowing the medium that is to be treated to flow alongside the micro-organisms. The geotextile materials (8, 9) are placed on top of each other and jointly rolled up to form the filter pattern (7). The geo-textile material may for instance be made of HDPE or polypropylene.

Owner:KOERS BONNO

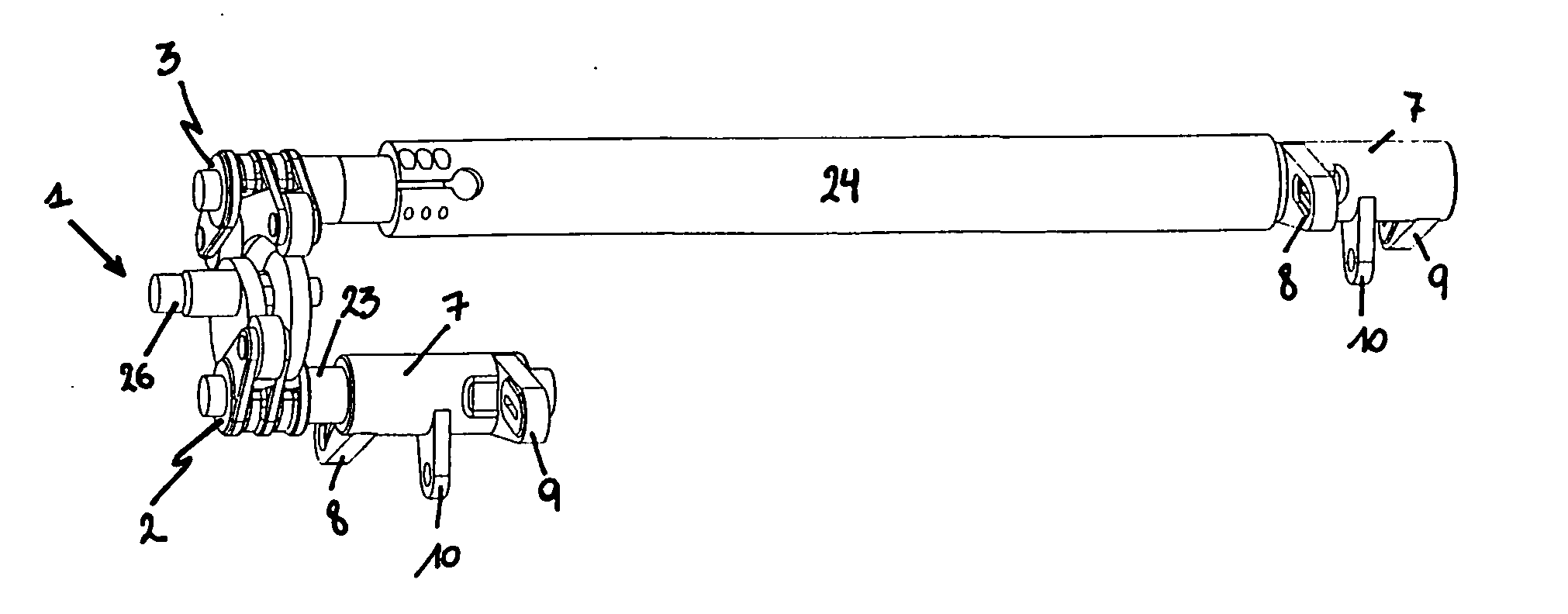

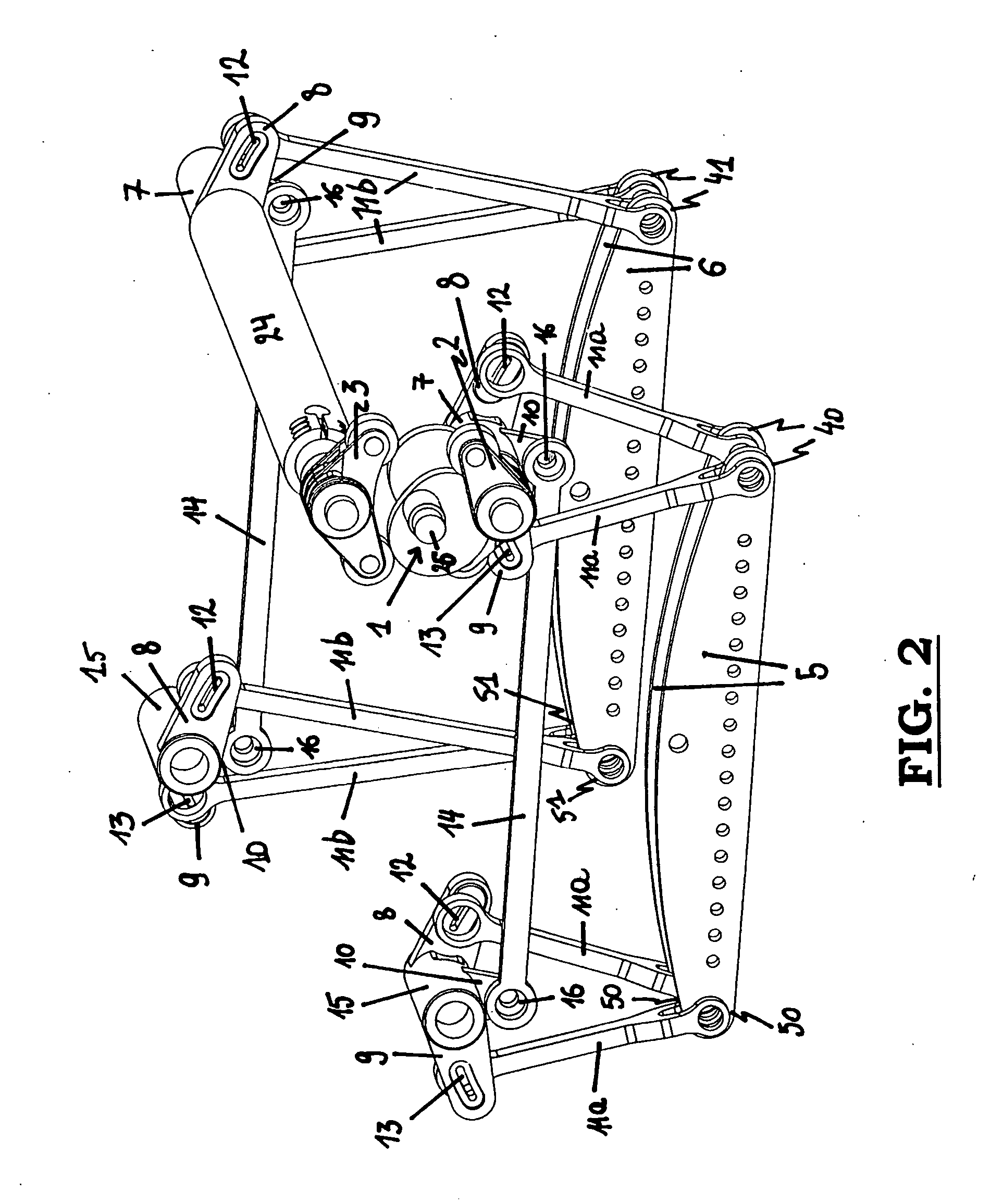

Jacquard machine

The invention relates to a Jacquard machine, comprising at least two knife grids (5, 6) moving up and down in opposition on either side of the Jacquard machine, the Jacquard machine comprising a single-sided drive (1) for driving at least one driving lever (2,3) which is provided for driving the motion of the knife grids (5, 6) on either side of the Jacquard machine, and one traversing rocking shaft (24) being provided to transmit the motion of the said driving lever (2 and 3 respectively) to the knife grids (5, 6) of one of the sides of the Jacquard machine.

Owner:VAN DE WIELE MICHEL

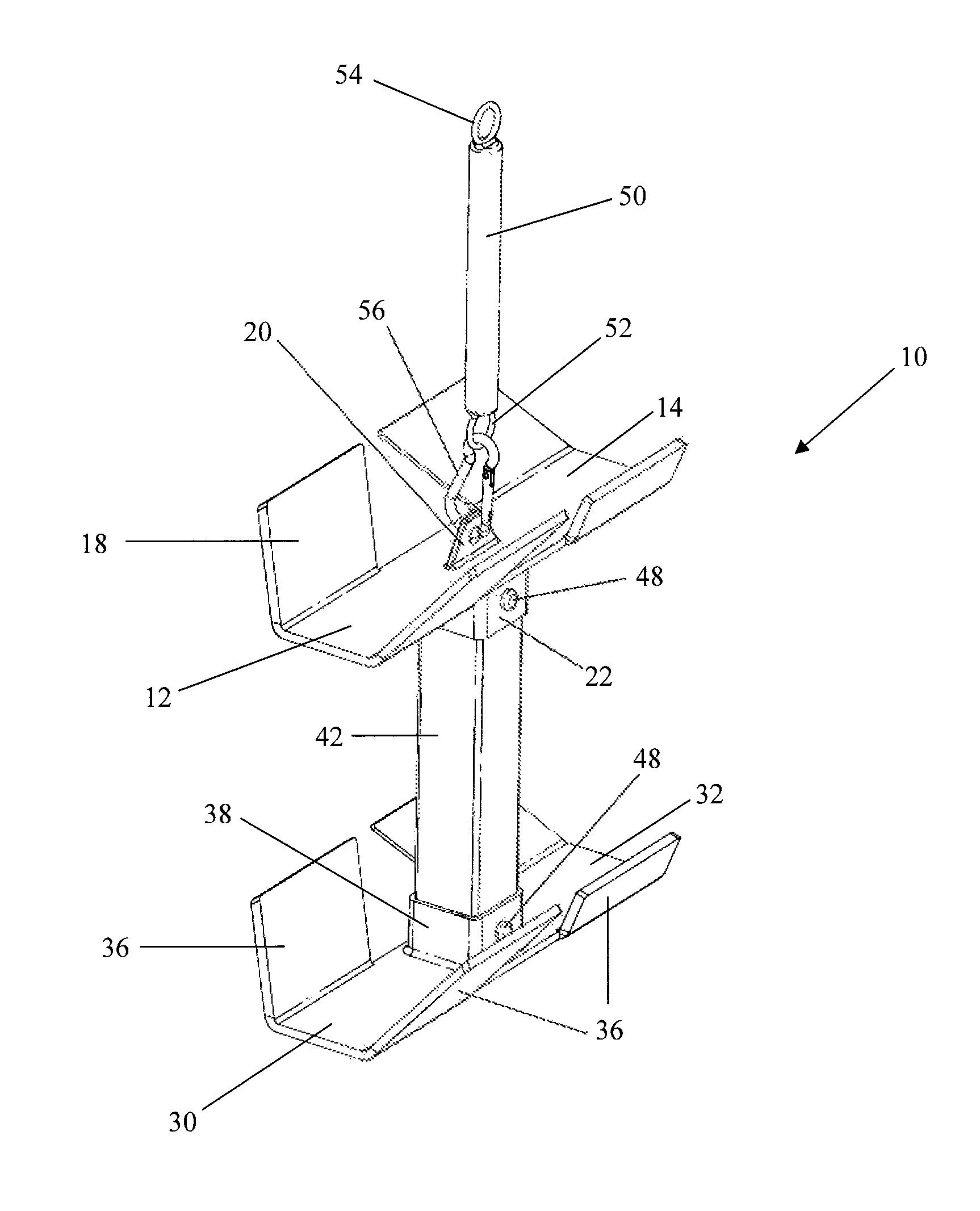

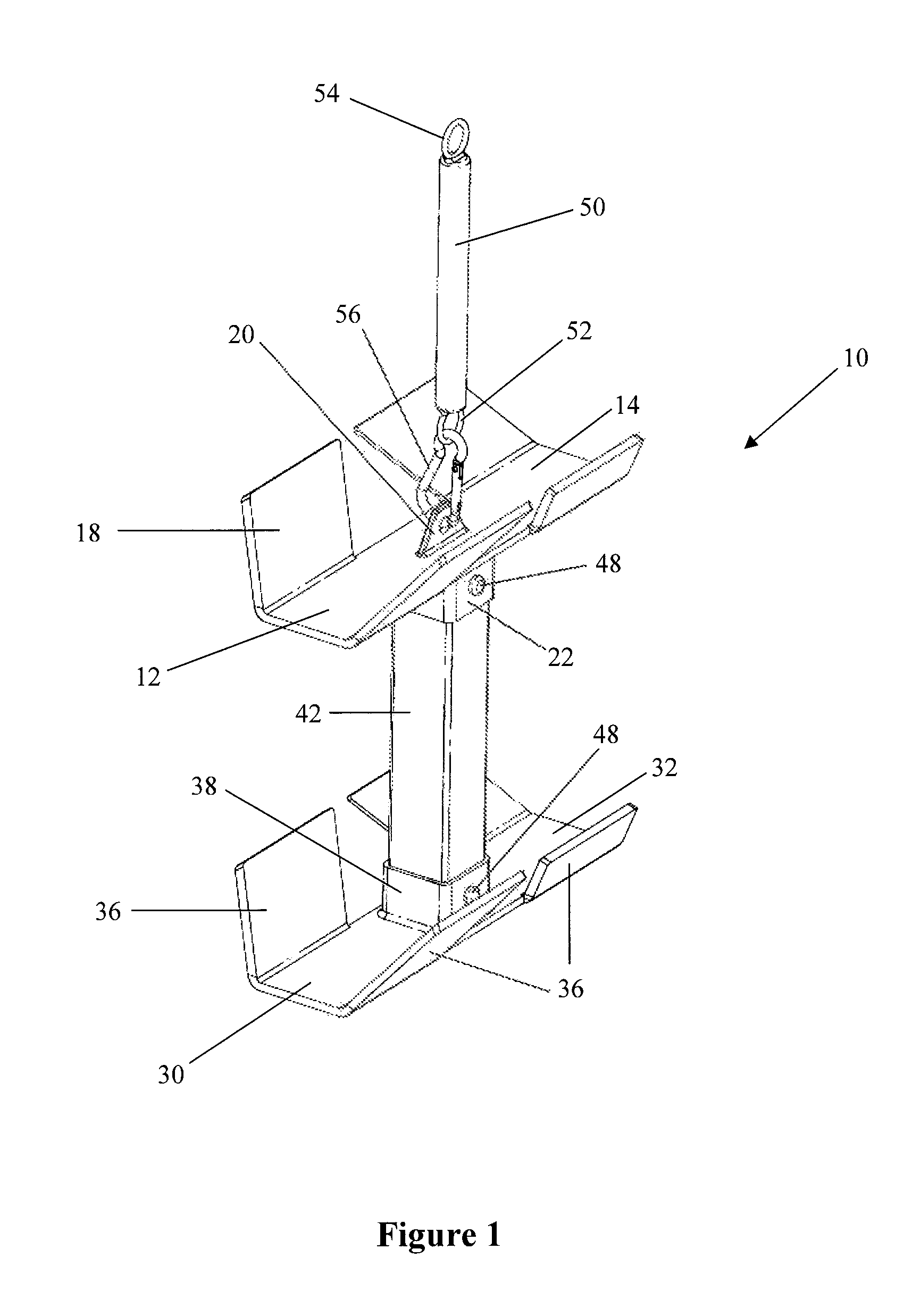

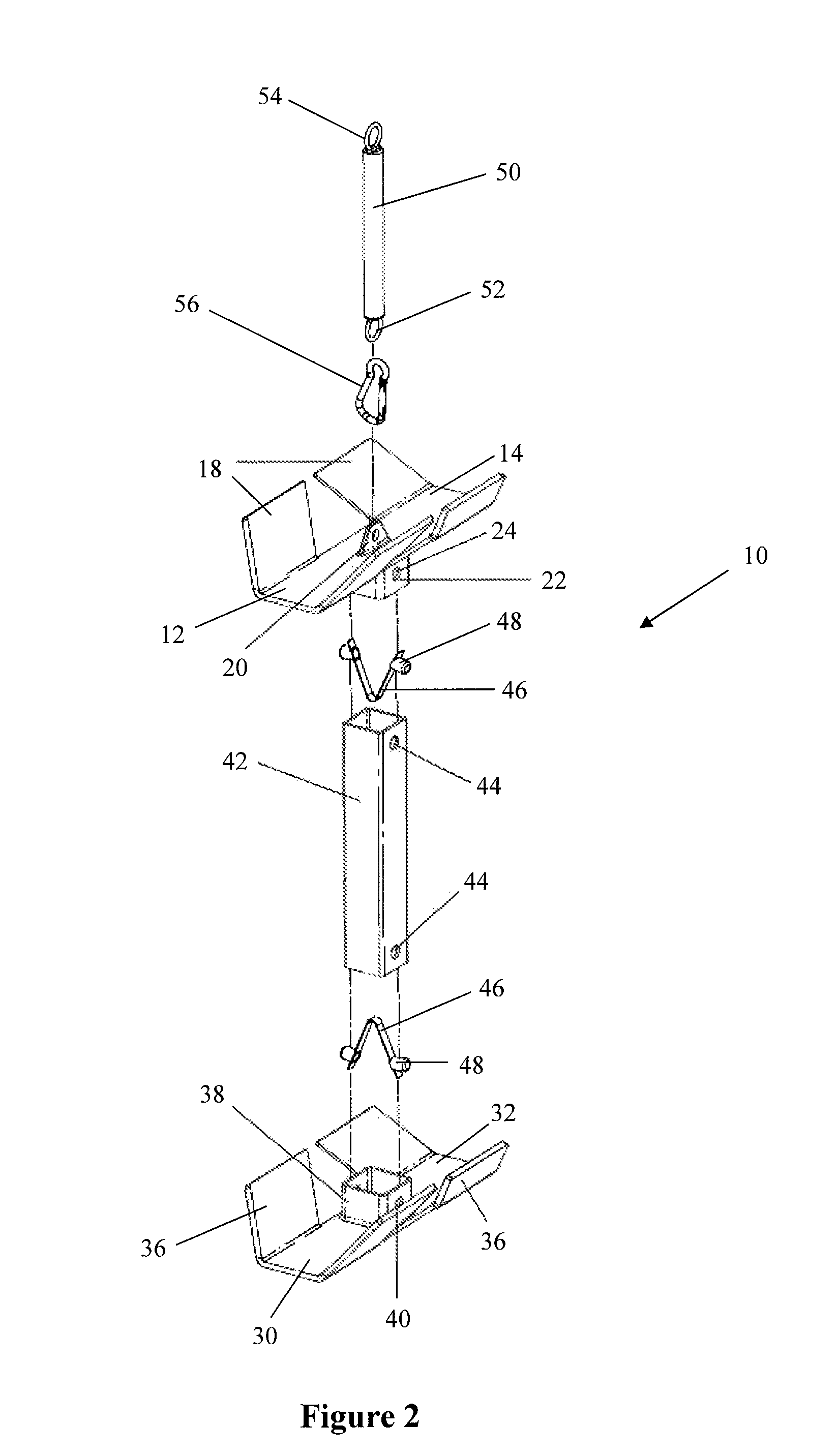

Boat anchor

InactiveUS8869728B1Easy connect and disconnectQuickly and easily set itselfAnchorsEngineeringLeaf spring

A detachable boat anchor comprises of a first plate having a housing on the bottom central surface and a second plate having a housing on the top central surface. The two plates are connected by a central shank by means of a leaf spring with engagement pin. The shank has two open ends with radial holes formed therethrough proximate to the open ends. The housing has an open end and radial holes formed therethrough and is shaped to receive the shank in a mating relationship to provide a snug fit such that when the radial holes of the shank and the radial holes of the housing are aligned, the engagement pin protrudes from the radial holes to prevent disengagement.

Owner:PAUGH JOSH

Magnetron cathodes

ActiveUS20140210340A1Reduce decreaseRobust constructionIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationEngineeringCathode

A magnetron cathode comprises electron emissive material included in a cathode body and a support structure for supporting the cathode body. The support structure has a longitudinal axis and includes a first part having a first cylinder integrally formed with a first end hat and a second part having a second cylinder integrally formed with a second end hat. The first cylinder and the second cylinder have an overlapping region in the longitudinal axial direction and are joined together. The cathode body is located around the first cylinder of the first part of the support structure and is joined to the first cylinder by a brazed joint. The outer surface of the first cylinder is grooved at the brazed joint.

Owner:E2V TECH (UK) LTD

Clamping assembly for woodworking knife

ActiveUS20130214076A1Increased mechanical advantageResist unclamping forceRotary cutting toolsCocoaEngineeringWoodworking machine

A clamping assembly to hold a woodworking knife in place in a woodworking machine. The clamping assembly comprises a clamping component comprising a body and an actuator. The body has three discrete contact positions distributed thereon: 1) a fulcrum located generally at one end, 2) a knife abutting portion located generally at the other end, and 3) a bearing surface located elsewhere. The actuator is for applying a clamping force to the body along a clamping axis located intermediate of the knife abutting portion and the fulcrum. The fulcrum is a surface having a normal that is at an angle to the clamping axis. The bearing surface is a surface wherein a line normal to the bearing surface intersects the line normal to the fulcrum at a position outside of the clamping component at a location farther askew of the clamping axis than the fulcrum.

Owner:ANDRITZ IGUND TOOLS

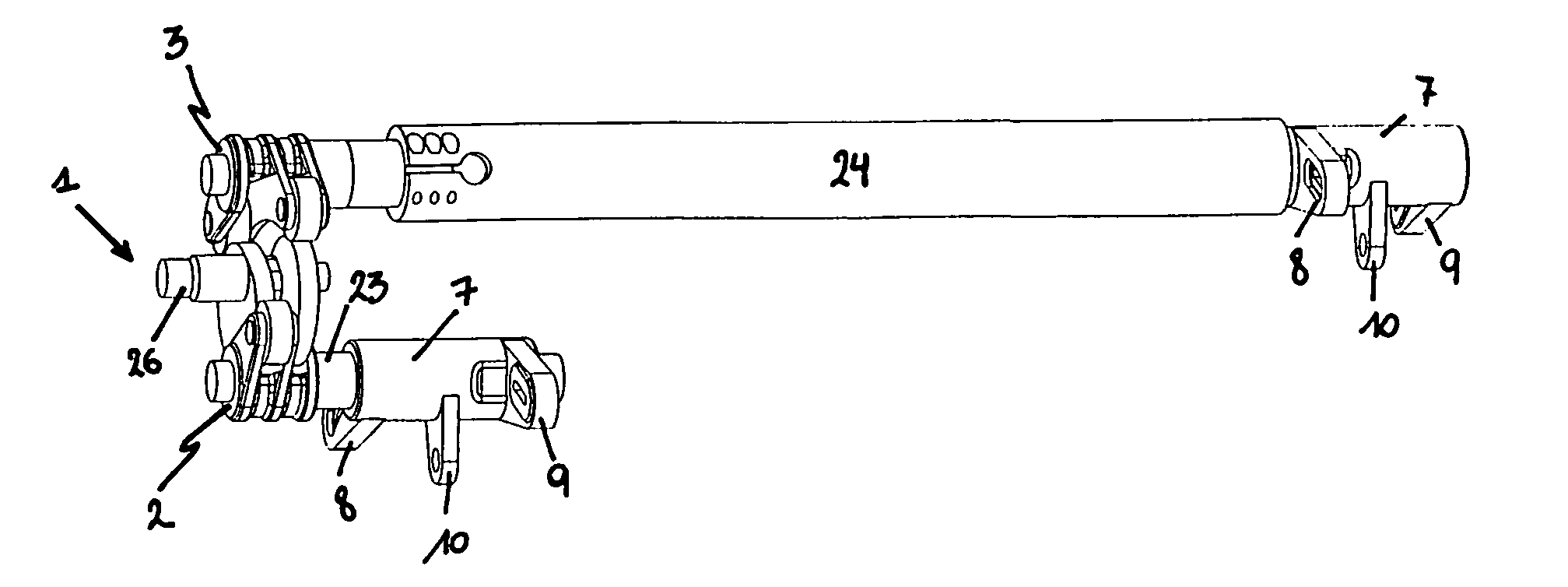

Jacquard machine

InactiveUS7464729B2Increase speedCost of construction remainsJacquardsDobbiesMechanical engineeringEngineering

Owner:VAN DE WIELE MICHEL

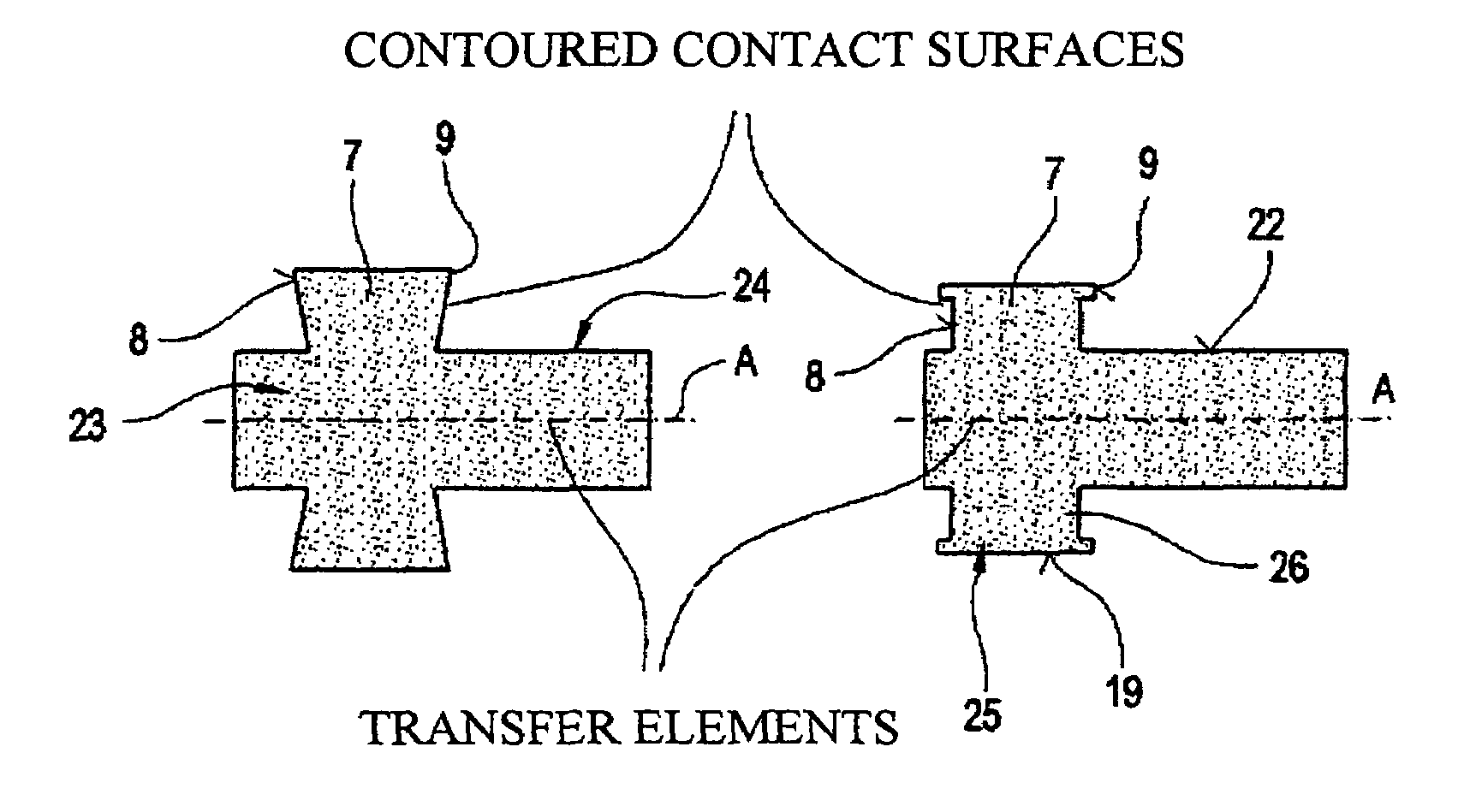

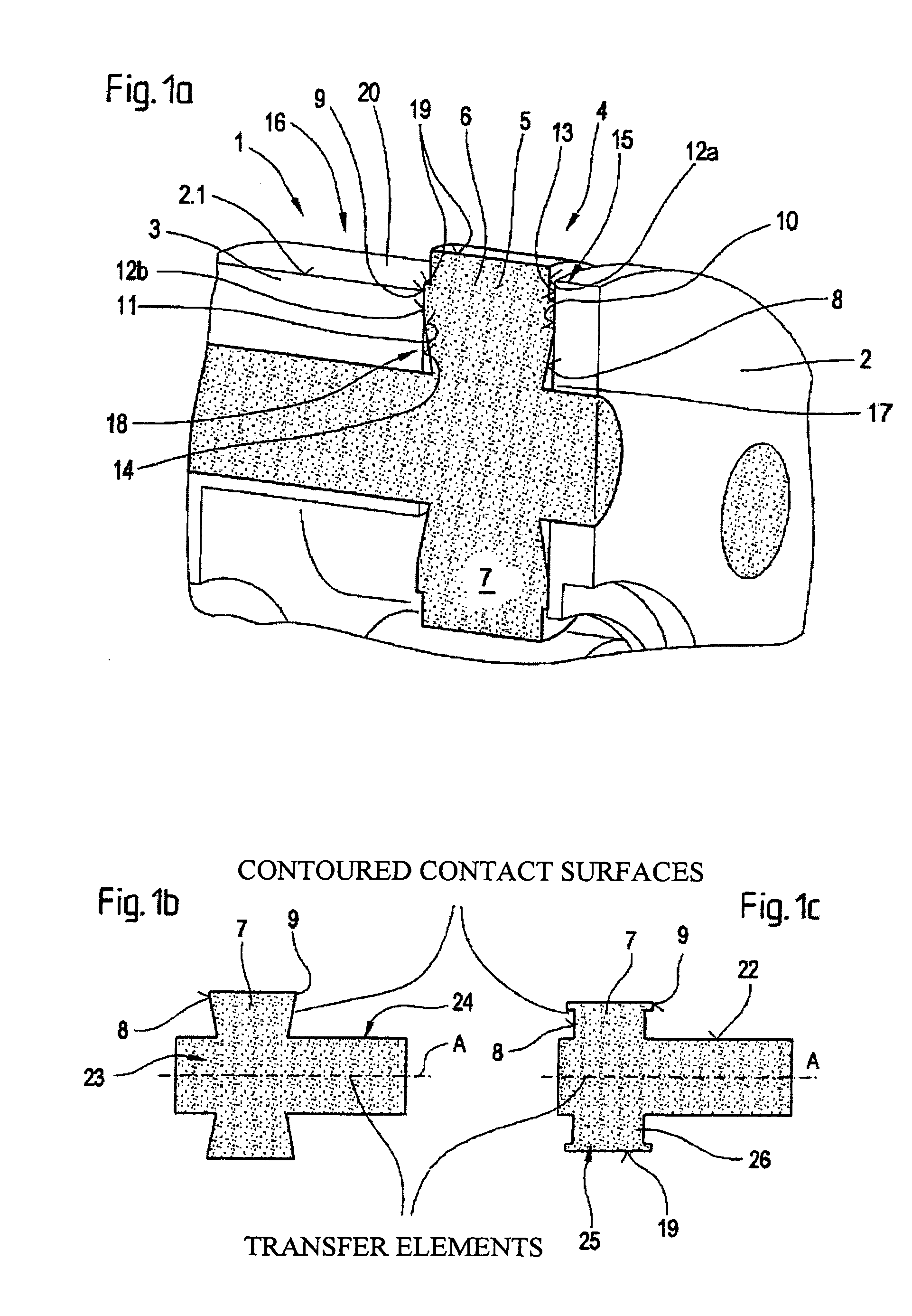

Web unit

InactiveUS7144348B2Compensation for deformationImprove load characteristicsToothed gearingsGearing detailsWeb siteGear wheel

A web unit for planet gear sets for the mounting of planet gears including a first web element and a second web element, which are tightly connected and can be tensioned in axial direction by transmission or connecting elements progressing in axial direction and describing a theoretical connecting axis. Each transmission or connecting element has regions of differing radial dimensions, the front faces of the regions, thus formed and facing the individual web elements, form a first and a second contact surface, resting either directly or through an intermediate element against the contact surfaces in contact regions, formed by the front faces of the web elements facing each other. At least one element forming a contact surface of a contact region includes a profile. The profile is characterized in the radially external region by at least one region of greater axial extension in the direction of the theoretical connecting axis.

Owner:VOITH PATENT GMBH

Clamping Assembly for Woodworking Knife

ActiveUS20090129875A1Increased mechanical advantageResist unclamping forceMulti-purpose machinesRotary cutting toolsEngineeringActuator

A clamping assembly to hold a woodworking knife in place in a woodworking machine. The clamping assembly comprises a clamping component comprising a body and an actuator. The body has three discrete contact positions distributed thereon: 1) a fulcrum located generally at one end, 2) a knife abutting portion located generally at the other end, and 3) a bearing surface located elsewhere. The actuator is for applying a clamping force to the body along a clamping axis located intermediate of the knife abutting portion and the fulcrum. The fulcrum is a surface having a normal that is at an angle to the clamping axis. The bearing surface is a surface wherein a line normal to the bearing surface intersects the line normal to the fulcrum at a position outside of the clamping component at a location farther askew of the clamping axis than the fulcrum.

Owner:IGGESUND TOOLS

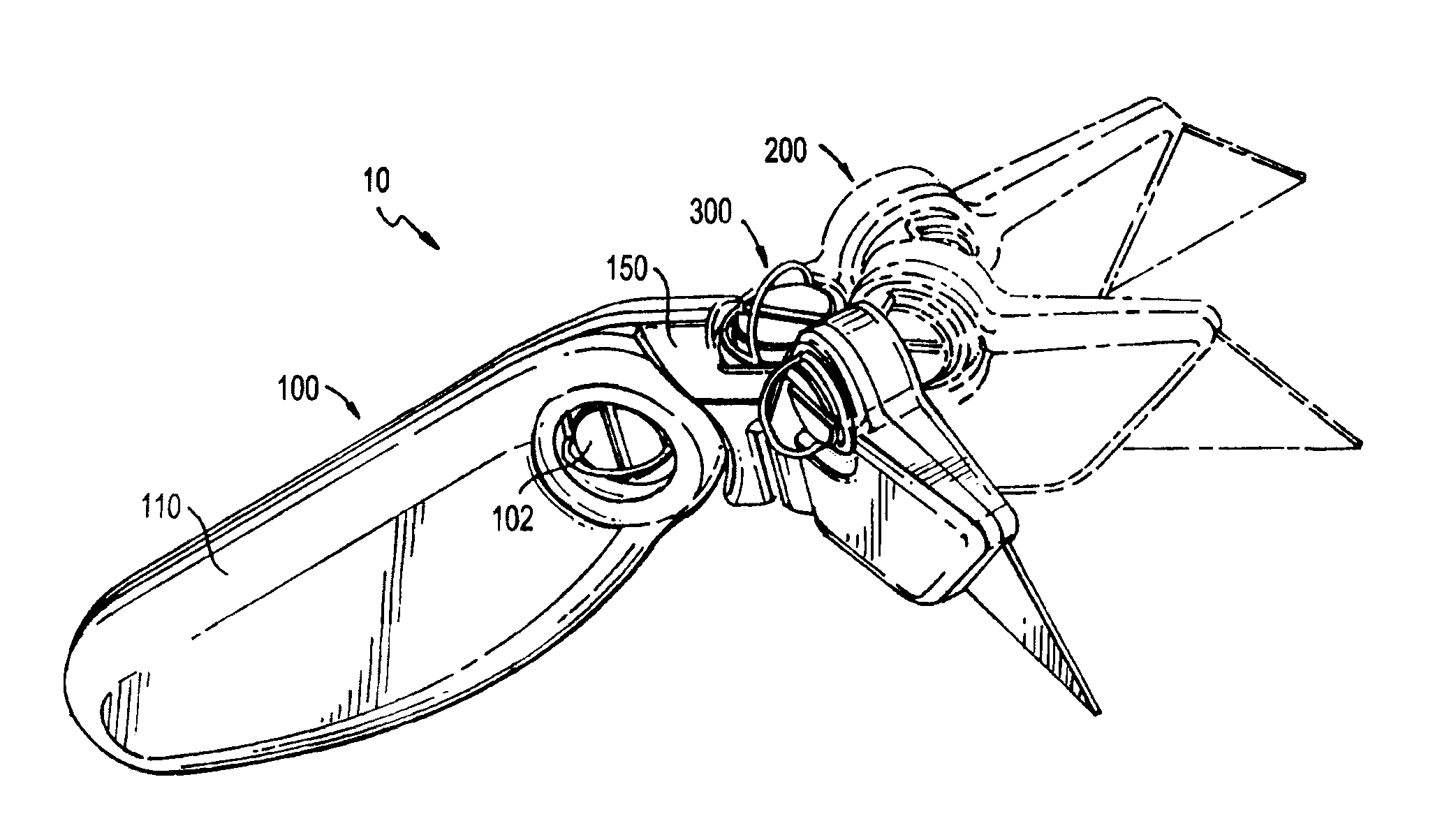

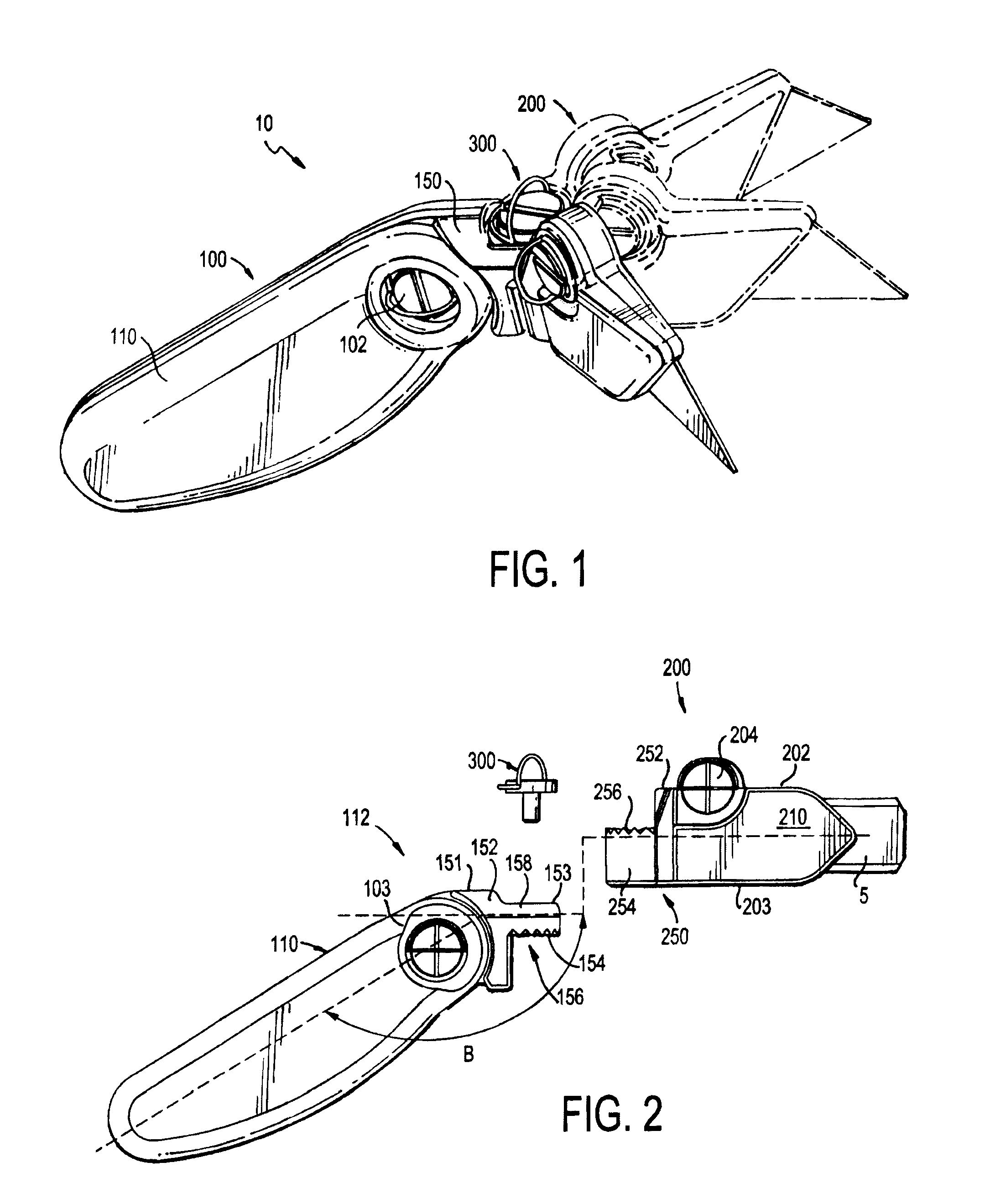

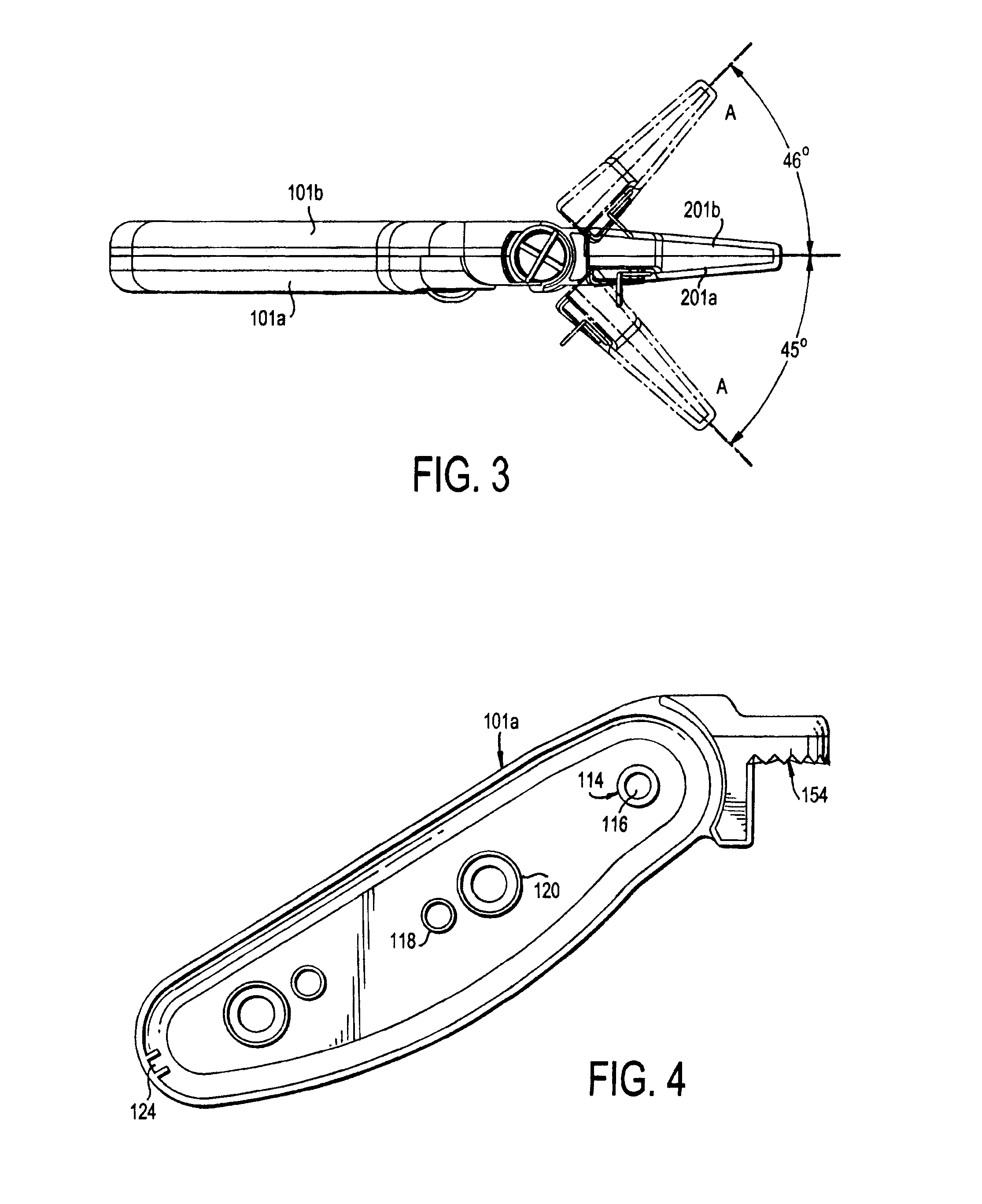

Utility knife with pivoting head assembly

InactiveUS10279490B2Rigid in constructionEasy to useMetal working apparatusEngineeringMechanical engineering

A utility knife is provided that has an elongated main body portion and a head assembly that is separate from the main body portion. The main body portion has a handle assembly. A main body fastening mechanism is provided at one distal end of the handle assembly, and a handle assembly fastening mechanism is provided at one end of the handle assembly. A threaded pin pivotally fastens the main body portion to the head assembly by connecting the main body fastening mechanism to the handle assembly fastening mechanism. Accordingly, the head assembly can pivot with respect to the main body portion and handle assembly, so that the utility knife can be configured to cut an object at different angles, which can be particularly useful for the knife to fit in a tight cutting space.

Owner:GILBERT JAMES +2

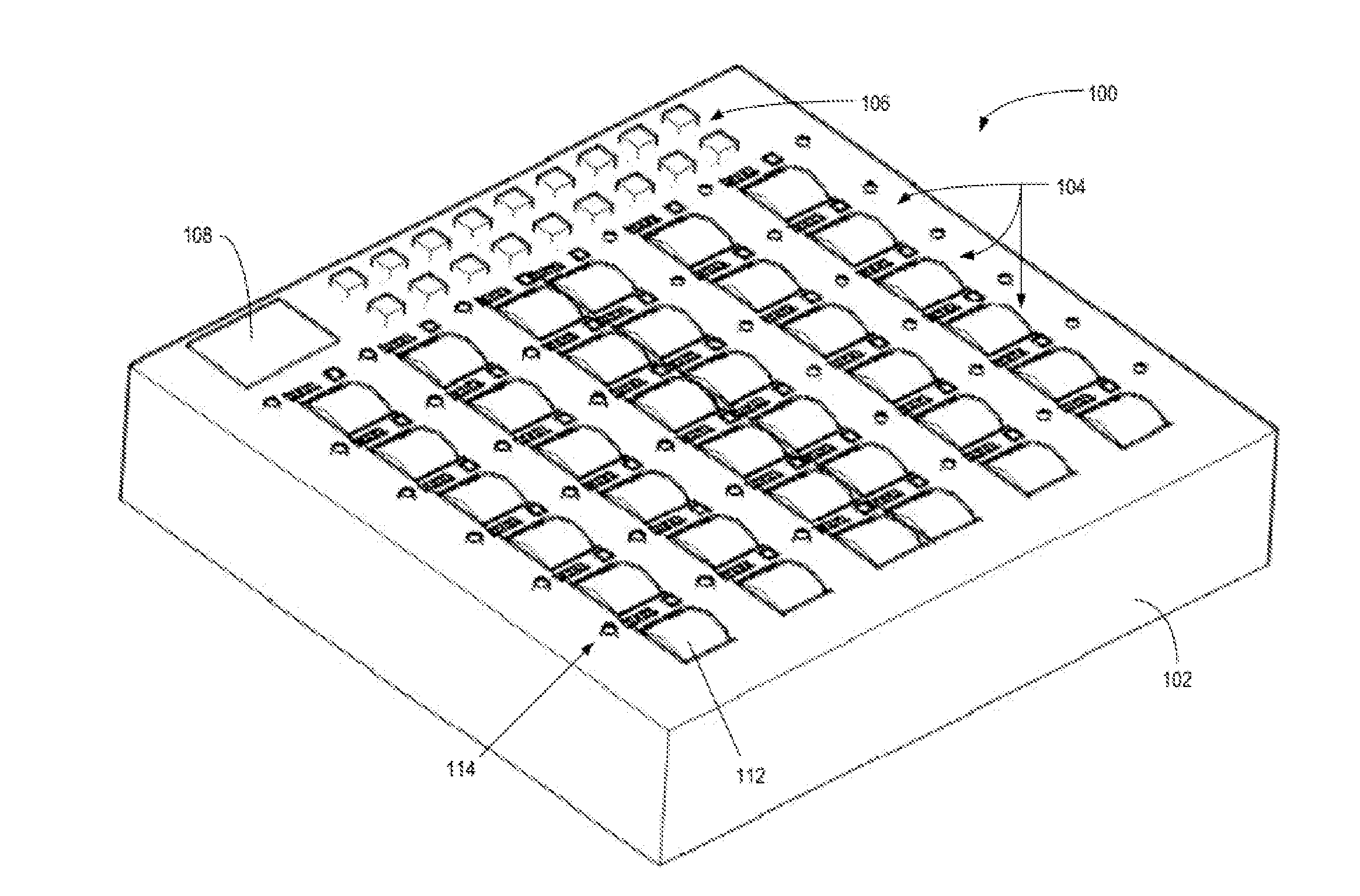

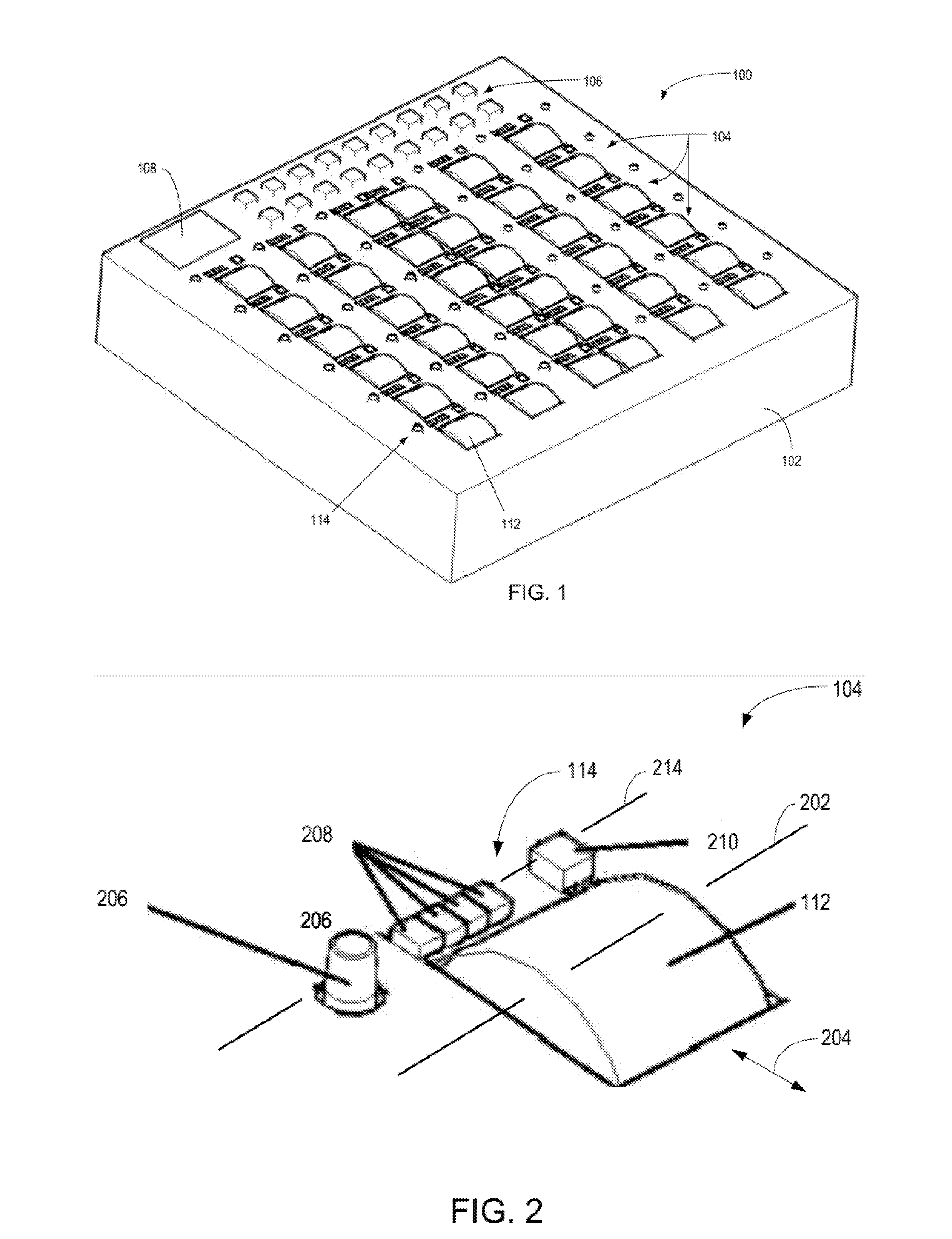

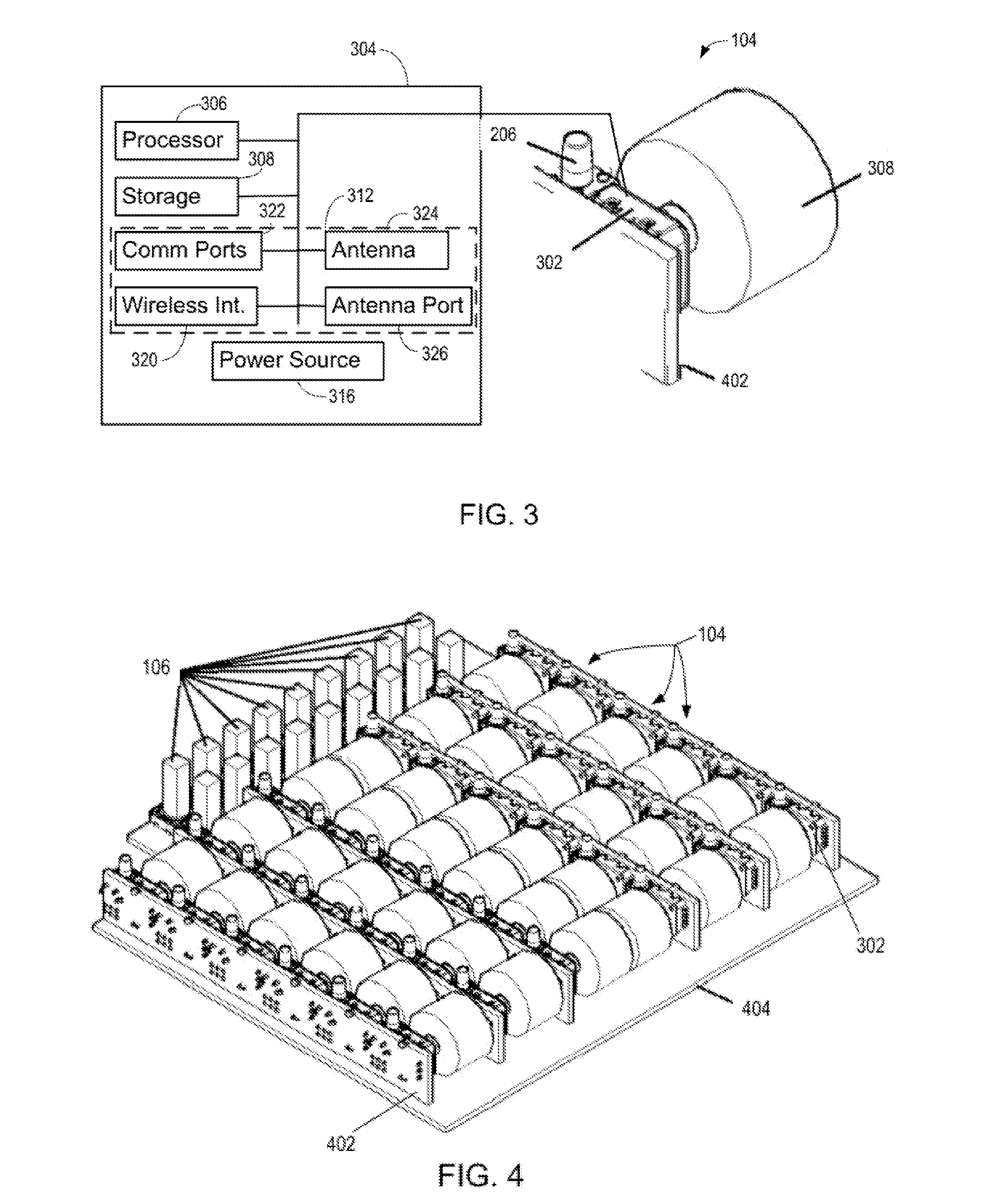

Wireless handheld controller

InactiveUS20150097816A1Reduce down timeMaximize communication rangeCathode-ray tube indicatorsBroadcast information generationElectricitySensing system

Owner:BEKLEMISEV JURIJ

Utility knife with pivoting head assembly

InactiveUS20160184999A1Rigid in constructionEasy to useThrusting weaponsWeapon componentsMechanical engineering

A utility knife is provided that has an elongated main body portion and a head assembly that is separate from the main body portion. The main body portion has a handle assembly. A main body fastening mechanism is provided at one distal end of the handle assembly, and a handle assembly fastening mechanism is provided at one end of the handle assembly. A threaded pin pivotally fastens the main body portion to the head assembly by connecting the main body fastening mechanism to the handle assembly fastening mechanism. Accordingly, the head assembly can pivot with respect to the main body portion and handle assembly, so that the utility knife can be configured to cut an object at different angles, which can be particularly useful for the knife to fit in a tight cutting space.

Owner:GILBERT JAMES +2

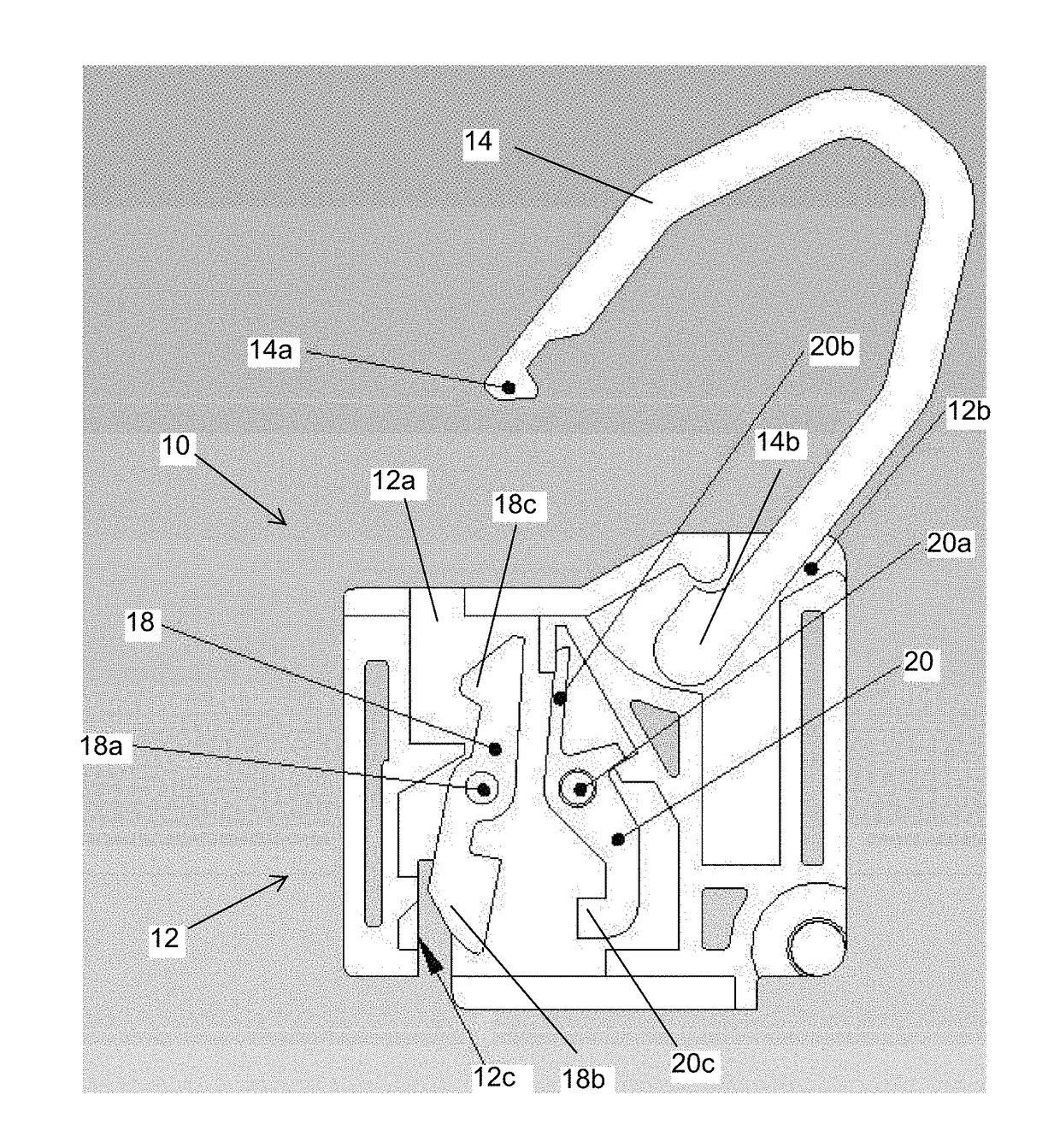

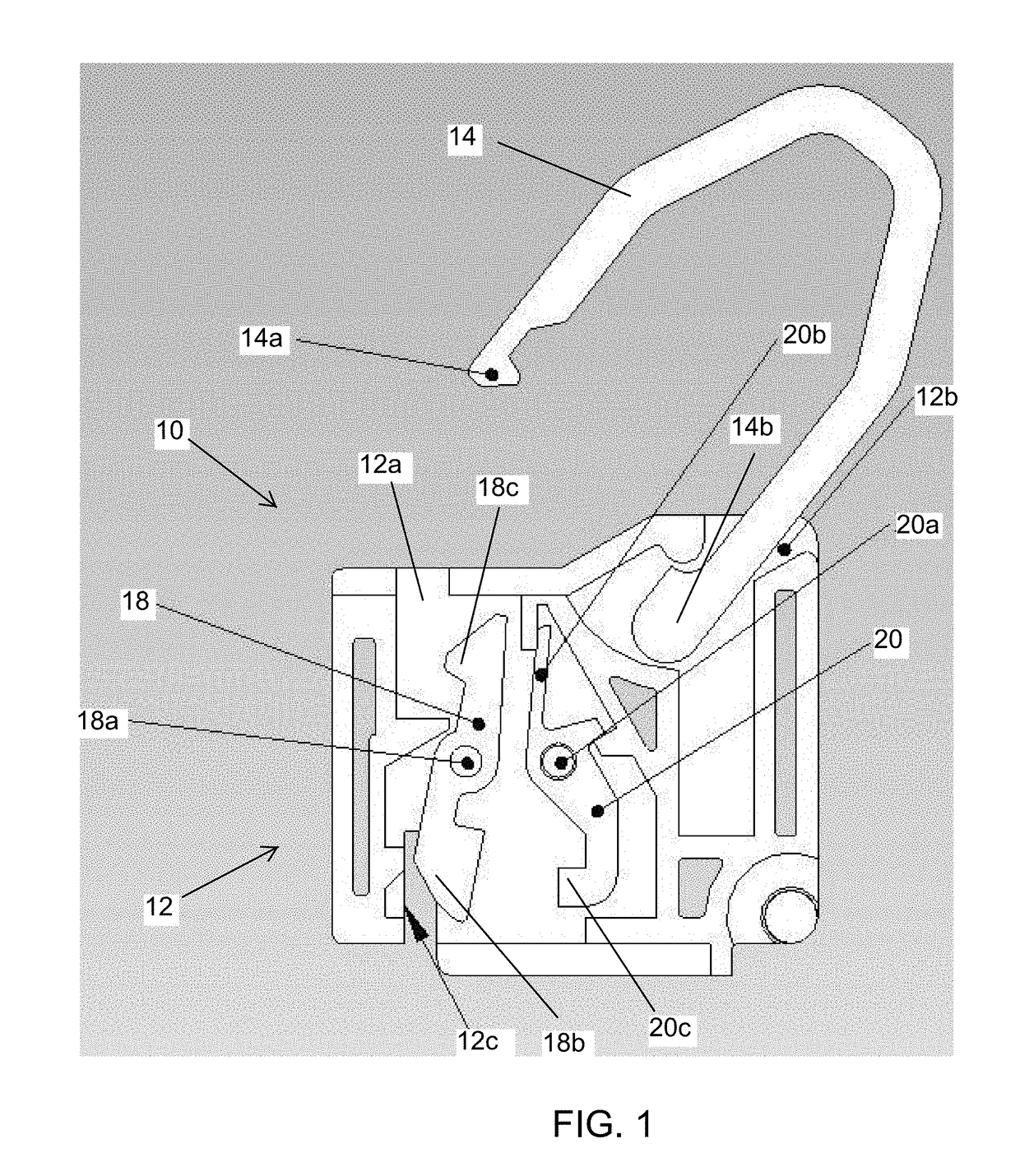

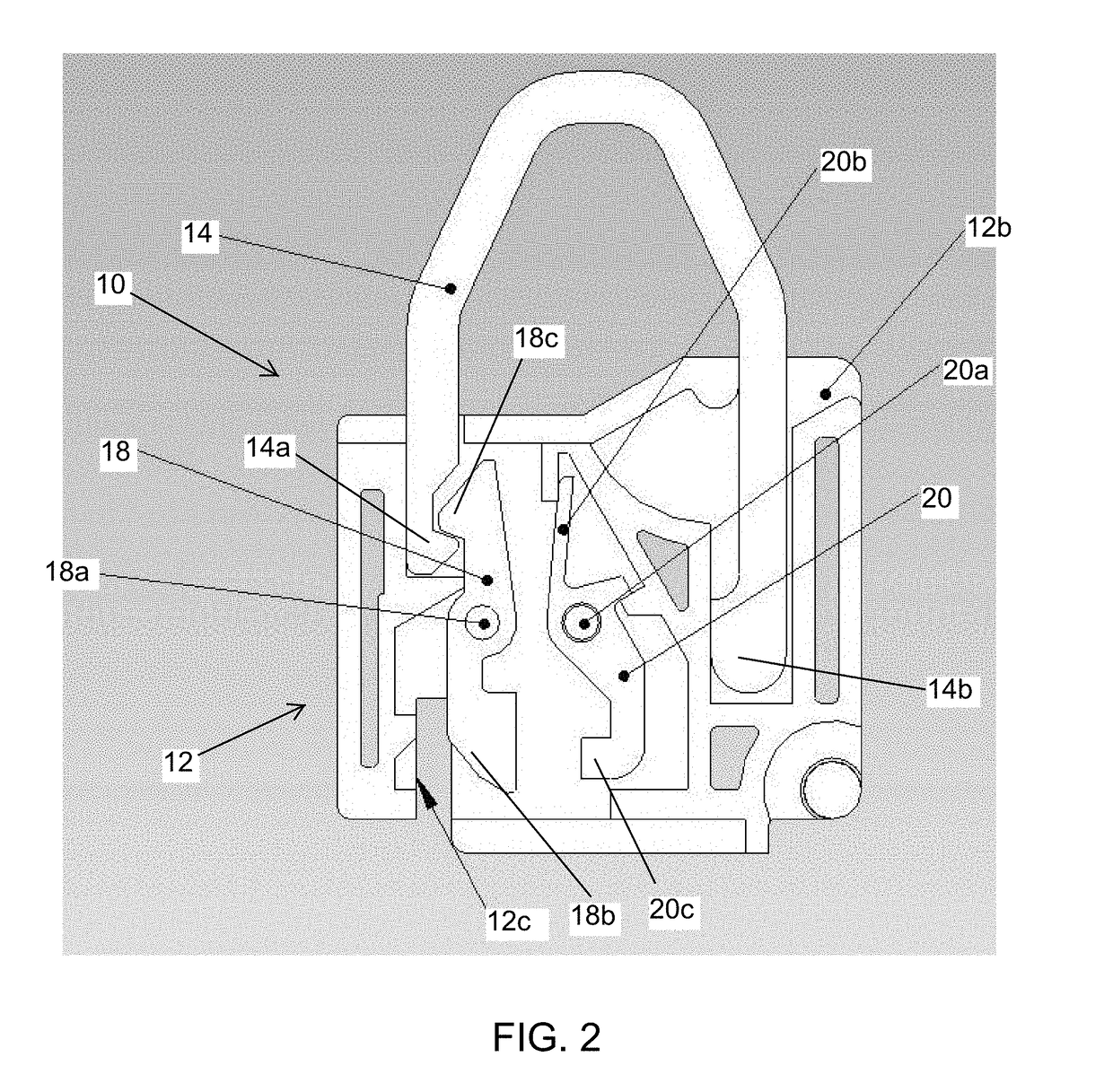

Tamper evident locking device

A locking device includes a lock body, a hasp and a seal. The lock body includes a hasp locking latch pivotally disposed therein and a seal locking latch pivotally disposed therein. The hasp is disposed at the lock body and movable between an open state, where a free end of the hasp is external the lock body, and a closed state, where the free end of the hasp is within the lock body. The seal, when inserted into the lock body when the hasp is in its closed state, engages the hasp locking latch to pivot the hasp locking latch to engage and lock the hasp in its closed state, and the seal, when inserted into the lock body, engages the seal locking latch to lock the seal within the lock body. The seal includes a frangible portion that is configured to break the seal into first and second portions.

Owner:E J BROOKS

Clamping assembly for woodworking knife

ActiveUS10245751B2Easy to adaptDurable in constructionCocoaRotary cutting toolsEngineeringWoodworking machine

A clamping assembly to hold a woodworking knife in place in a woodworking machine. The clamping assembly comprises a clamping component comprising a body and an actuator. The body has three discrete contact positions distributed thereon: 1) a fulcrum located generally at one end, 2) a knife abutting portion located generally at the other end, and 3) a bearing surface located elsewhere. The actuator is for applying a clamping force to the body along a clamping axis located intermediate of the knife abutting portion and the fulcrum. The fulcrum is a surface having a normal that is at an angle to the clamping axis. The bearing surface is a surface wherein a line normal to the bearing surface intersects the line normal to the fulcrum at a position outside of the clamping component at a location farther askew of the clamping axis than the fulcrum.

Owner:ANDRITZ IGUND TOOLS

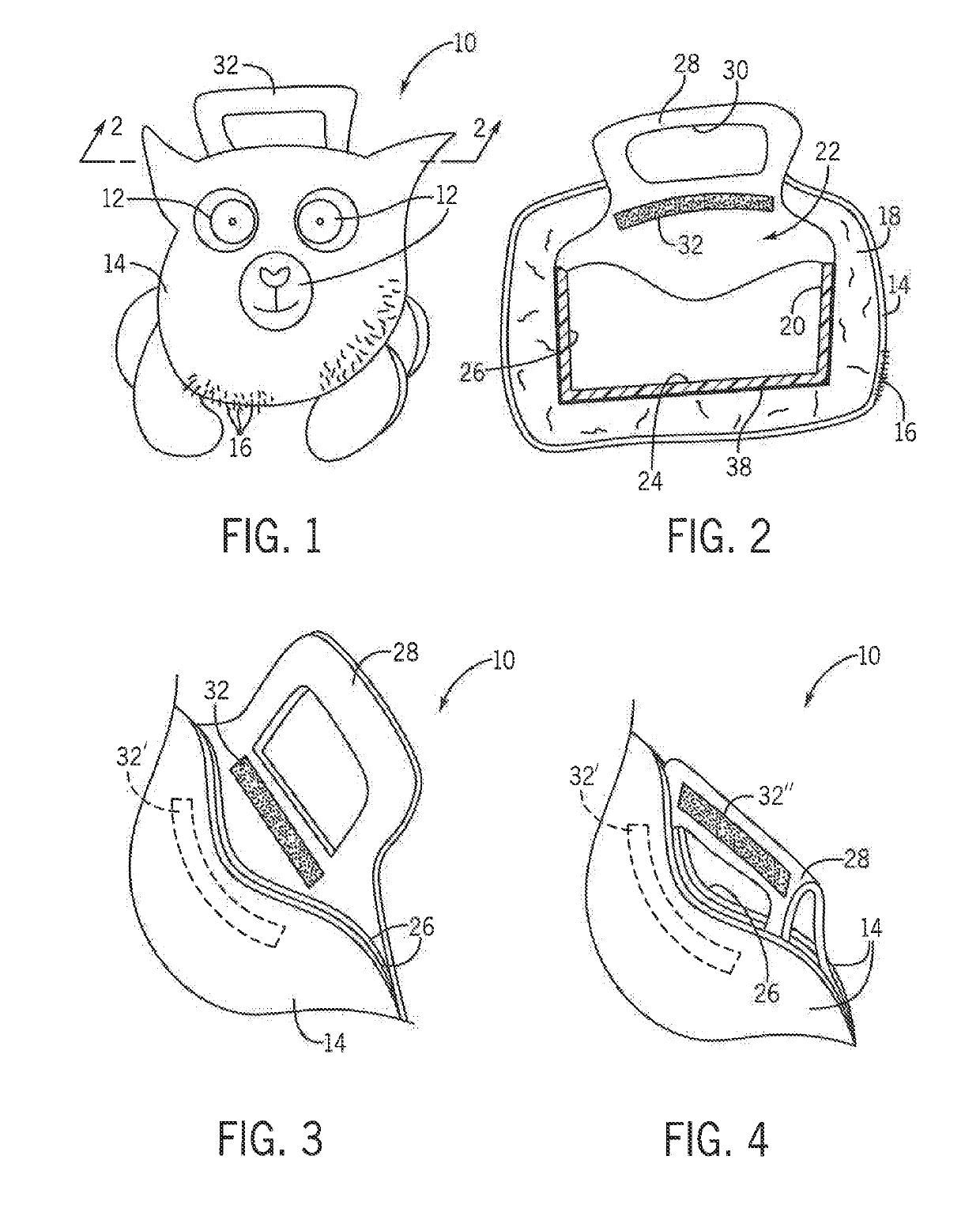

Stuffed Animal Lunch Box

InactiveUS20190208881A1Rigid in constructionDomestic cooling apparatusLighting and heating apparatusBiomedical engineeringIndividual animal

Owner:BROWN MARGARET A

Magnetron cathodes

ActiveUS9177749B2Reduce decreaseRobust constructionTransit-tube cathodesMulti-cavity magnetronsMicrowaveEngineering

Owner:E2V TECH (UK) LTD

Reed drive of a loom

InactiveUS7481249B2Lower energy requirementsRigid in constructionCam shedding mechanismLoomsDrive shaftRotation velocity

A reed drive of a loom includes a reed shaft connected to a reed. A conversion gearing having an input element and an output element is provided at each end of the reed shaft. The input elements are coupled to driven shafts of electromotive rotary drives to produce a common rotational motion with the same rotational speed as the driven shafts. The conversion gearings convert the rotating motion of their input elements into a reversible rotation of the output elements, and the output elements are coupled to the reed shaft in a rotationally fixed manner. Thus, the number of complete rotations of an input element is equal to the number of complete motion cycles of the reed shaft per unit of time.

Owner:LINDAUER DORNIER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com