Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Light display" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

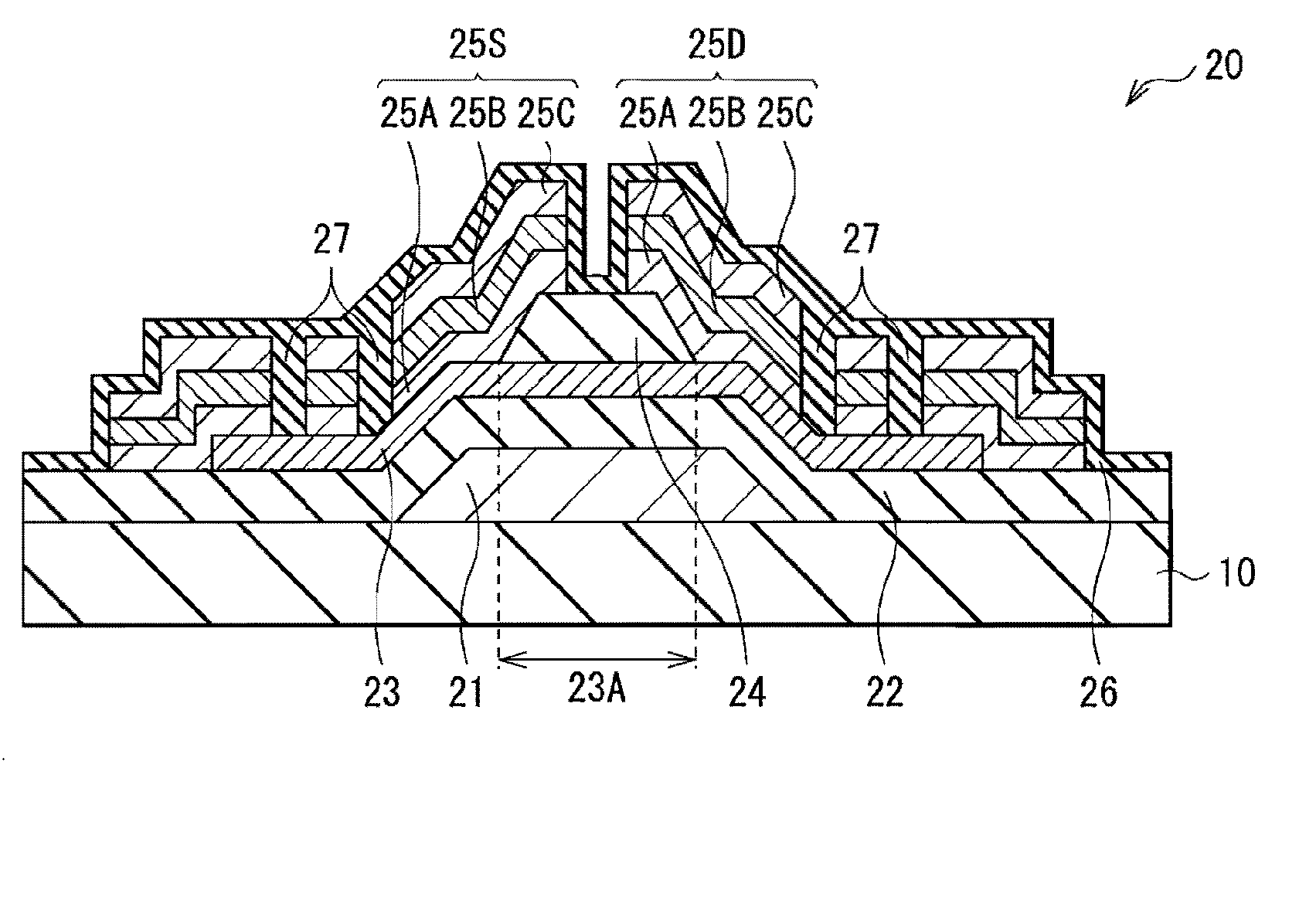

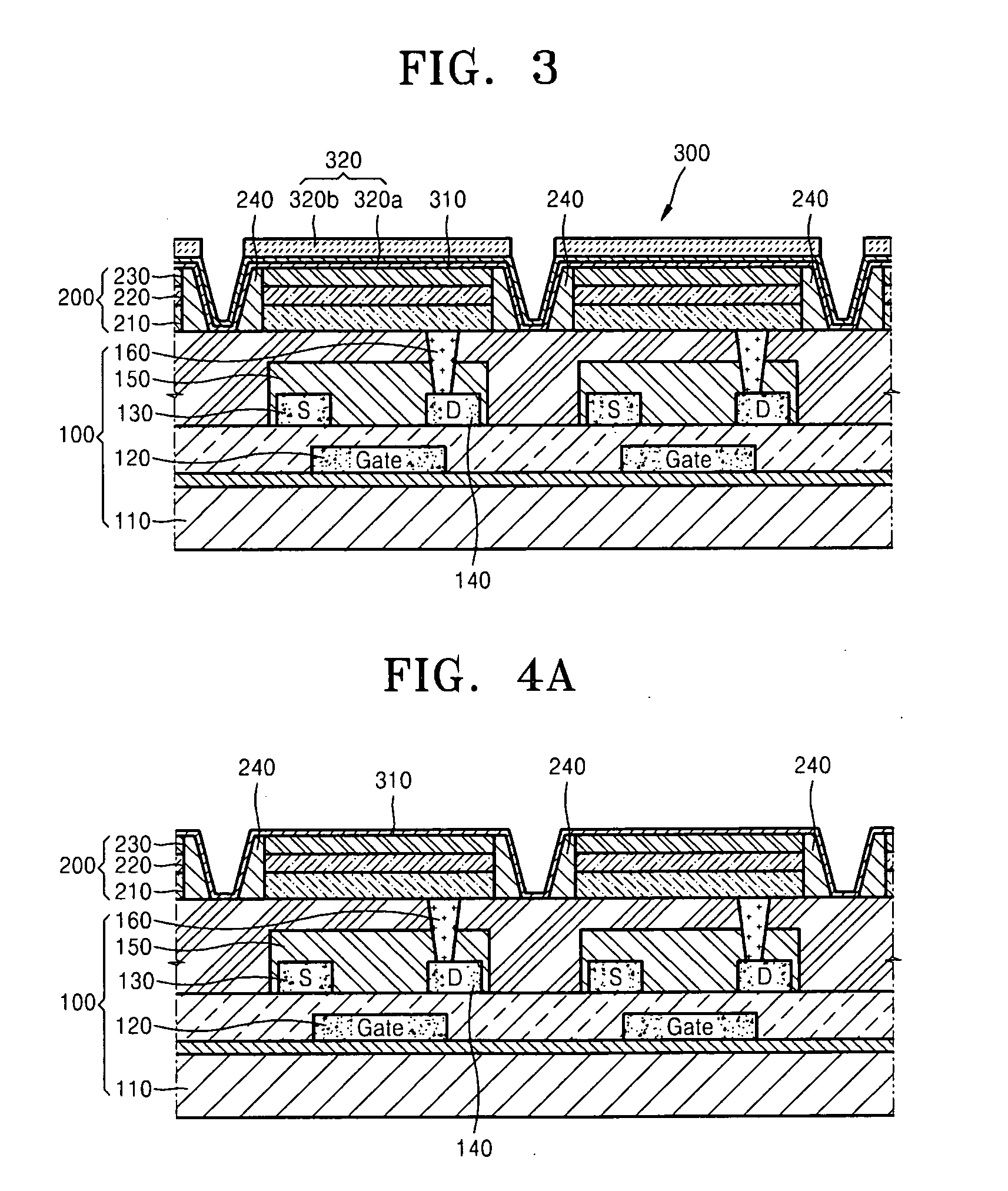

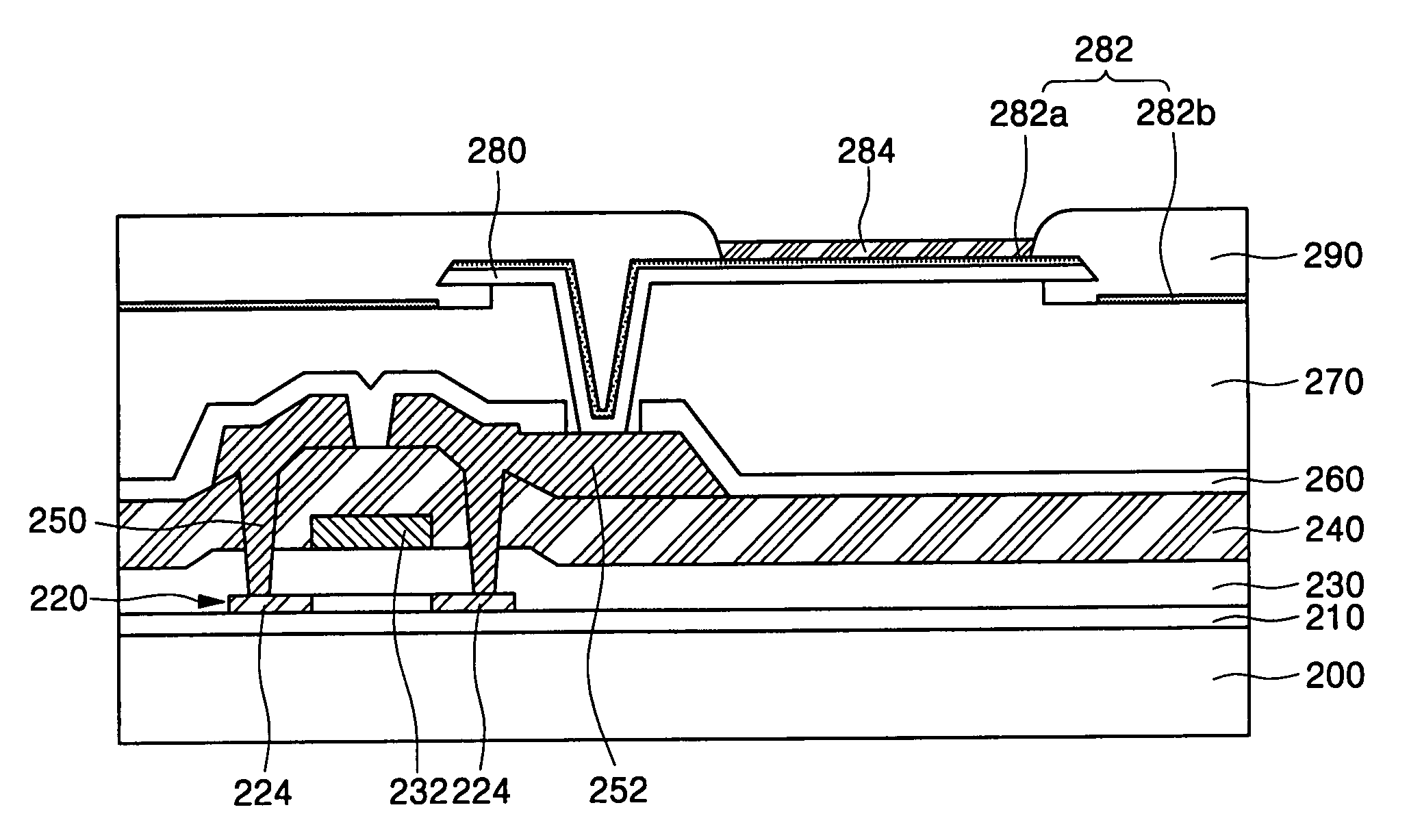

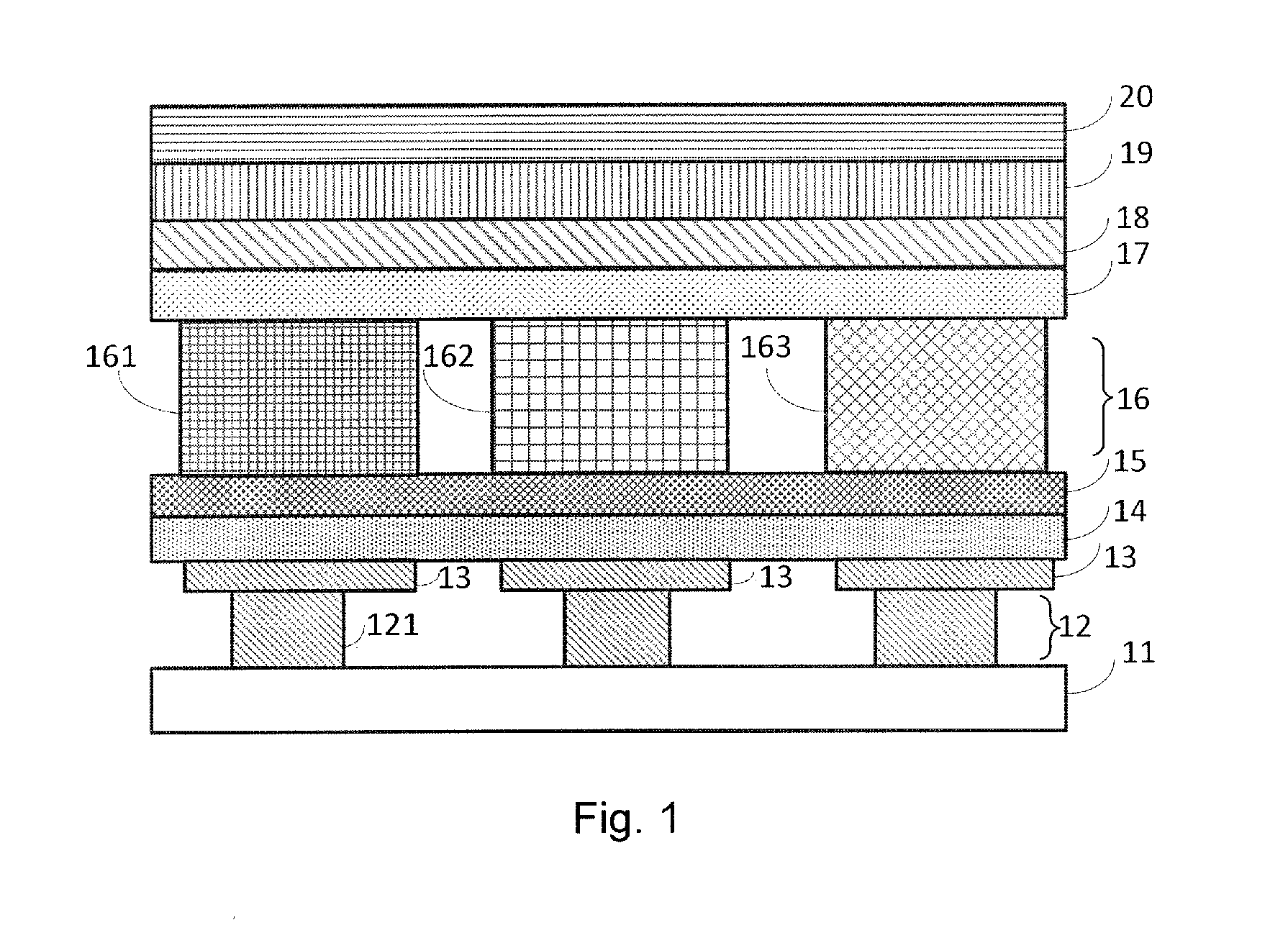

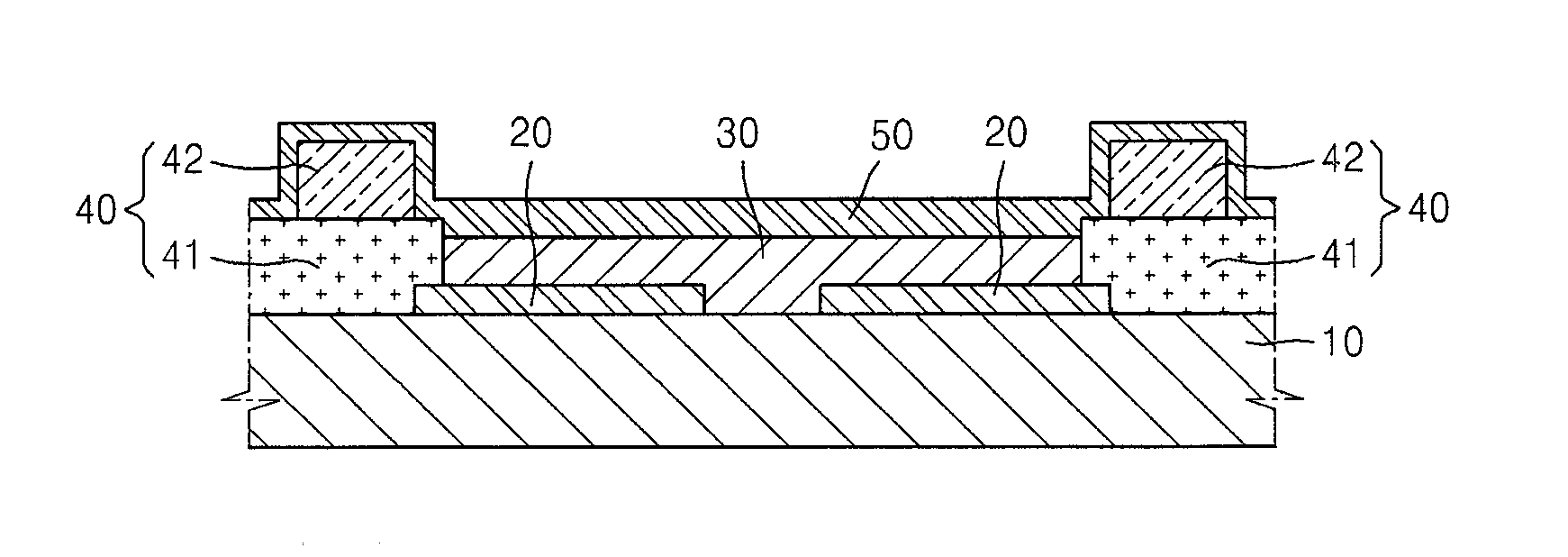

Thin film transistor and display unit

A thin film transistor with which oxygen is easily supplied to an oxide semiconductor layer and favorable transistor characteristics are able to be restored and a display unit including the same are provided. The thin film transistor includes sequentially over a substrate a gate electrode, a gate insulting film, an oxide semiconductor layer including a channel region, and a channel protective layer covering the channel region A source electrode and a drain electrode are formed on the oxide semiconductor layer located on both sides of the channel protective layer, and at least one of the source electrode and the drain electrode has an aperture to expose the oxide semiconductor layer.

Owner:JOLED INC

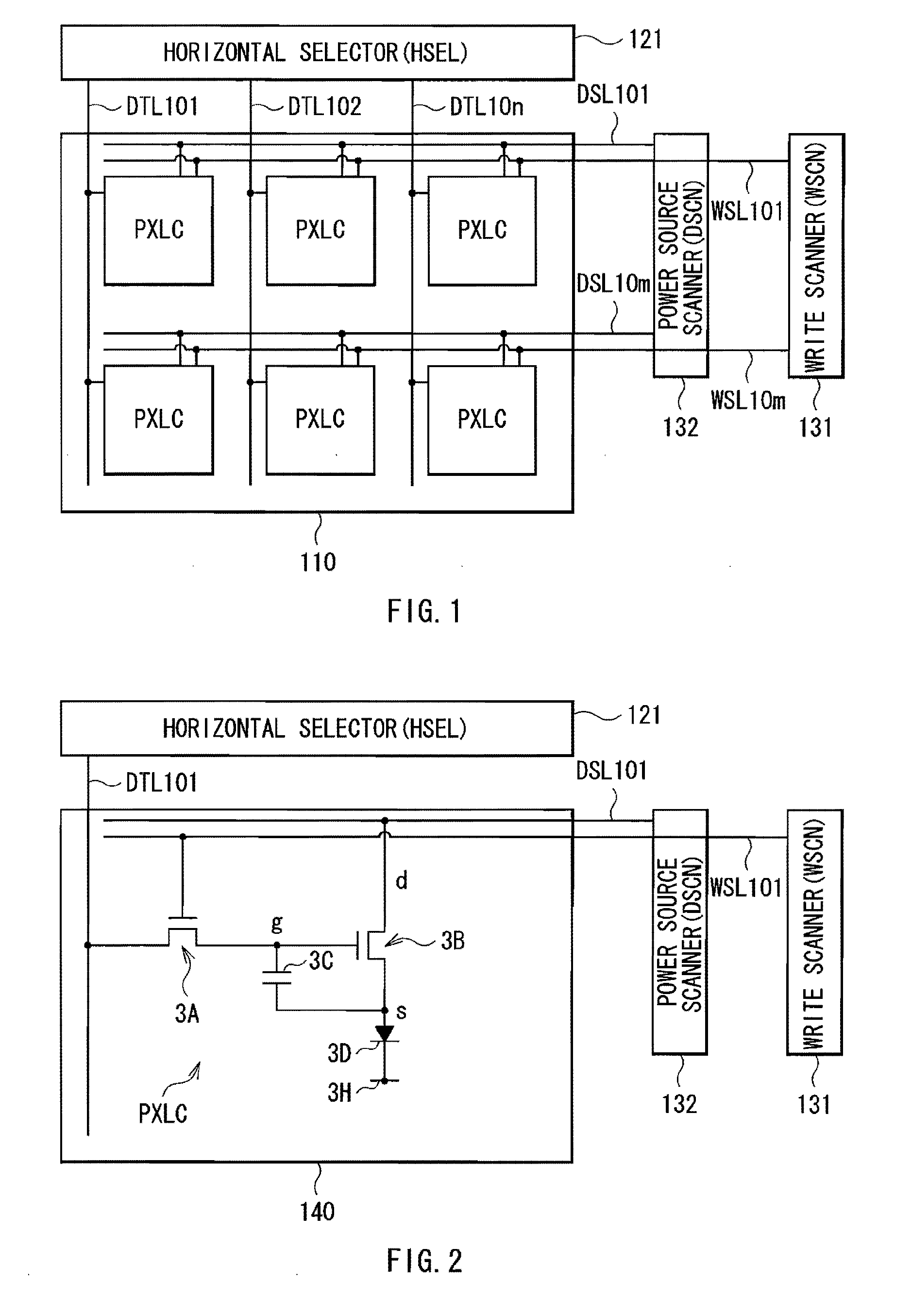

Data driving circuit and organic light emitting display comprising the same

InactiveUS20080122819A1Improve display qualityPrevent display quality degradationCathode-ray tube indicatorsDigital-analogue convertorsDigital analog converterReference current

Provided are a data driving circuit of an organic light emitting display and an organic light emitting display comprising the same. The organic light emitting display comprises a reference pixel controller, a data driver, and a display panel. The reference pixel controller comprises a light detector for detecting an amount of light emission of a reference pixel and outputting a first control signal thereof and a reference current controller for outputting a second control signal controlling an amount of a reference current according to the first control signal. The data driver comprises a current source for outputting a current having the same amount as the reference current according to the second control signal and a digital-analog converter for outputting a data current by scaling the current having the same amount as the reference signal to be proportioned to a data signal. The display panel formed of pixels, each of which comprises an organic light emitting device that emits light in accordance with the data current.

Owner:IKAIST CO LTD

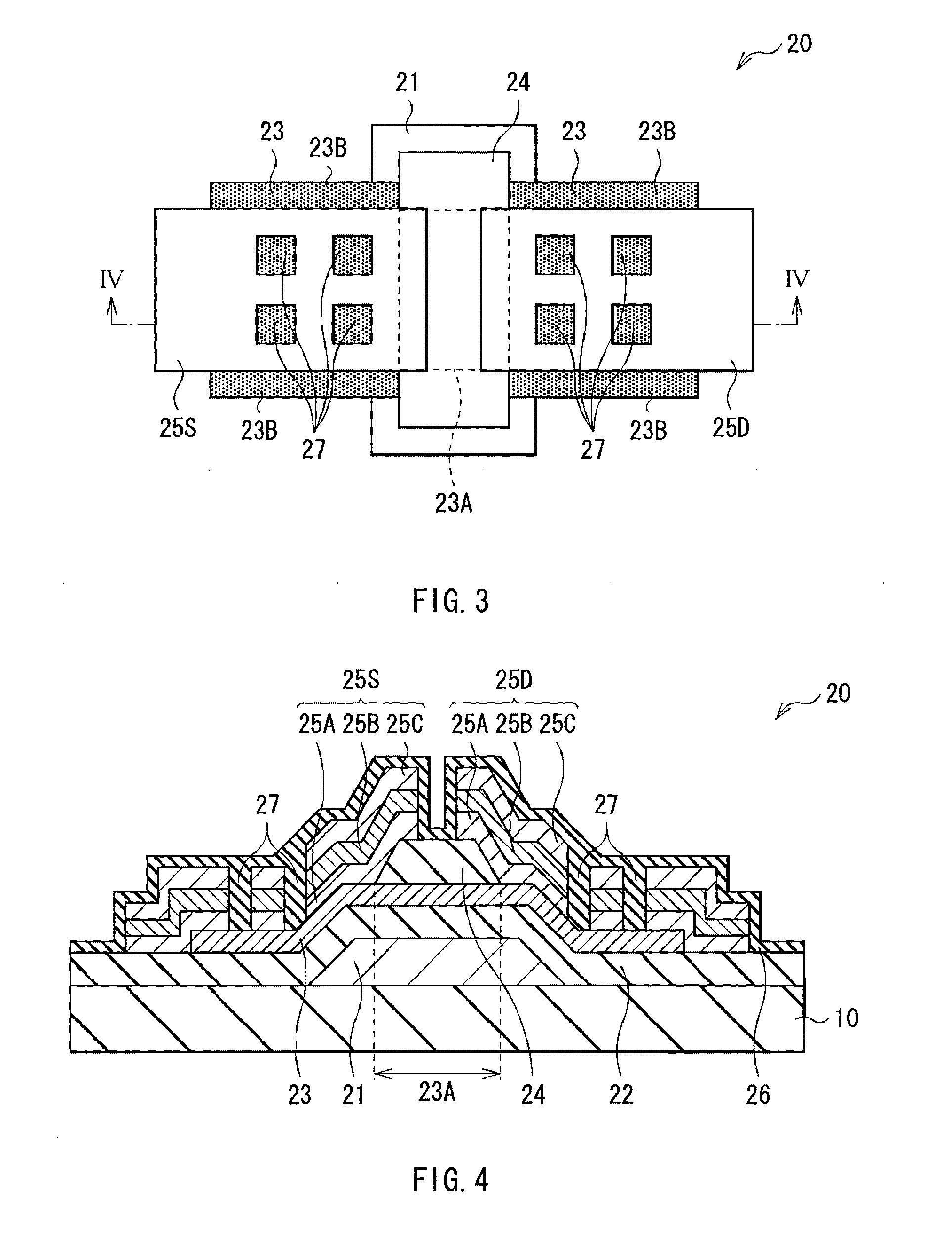

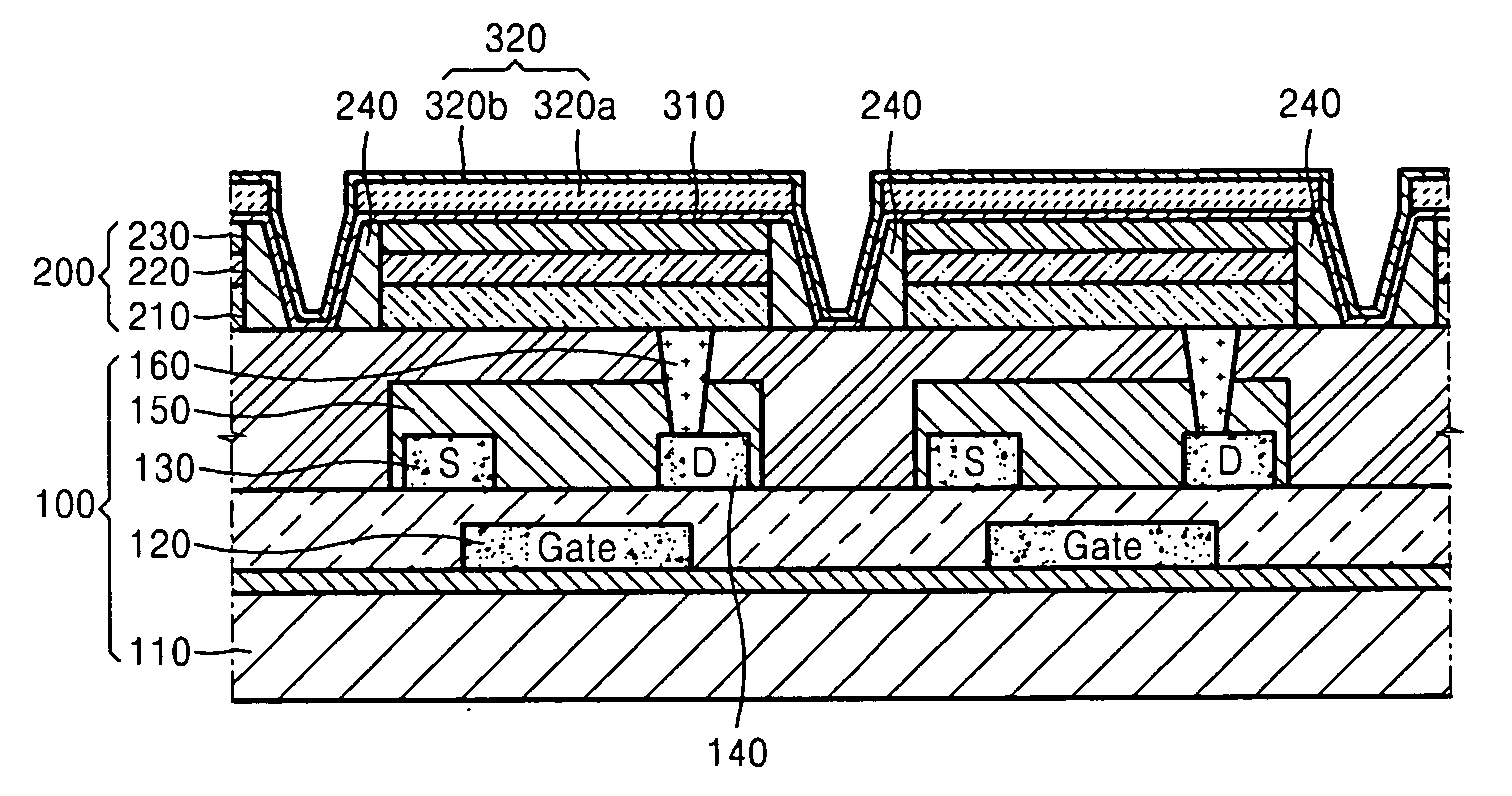

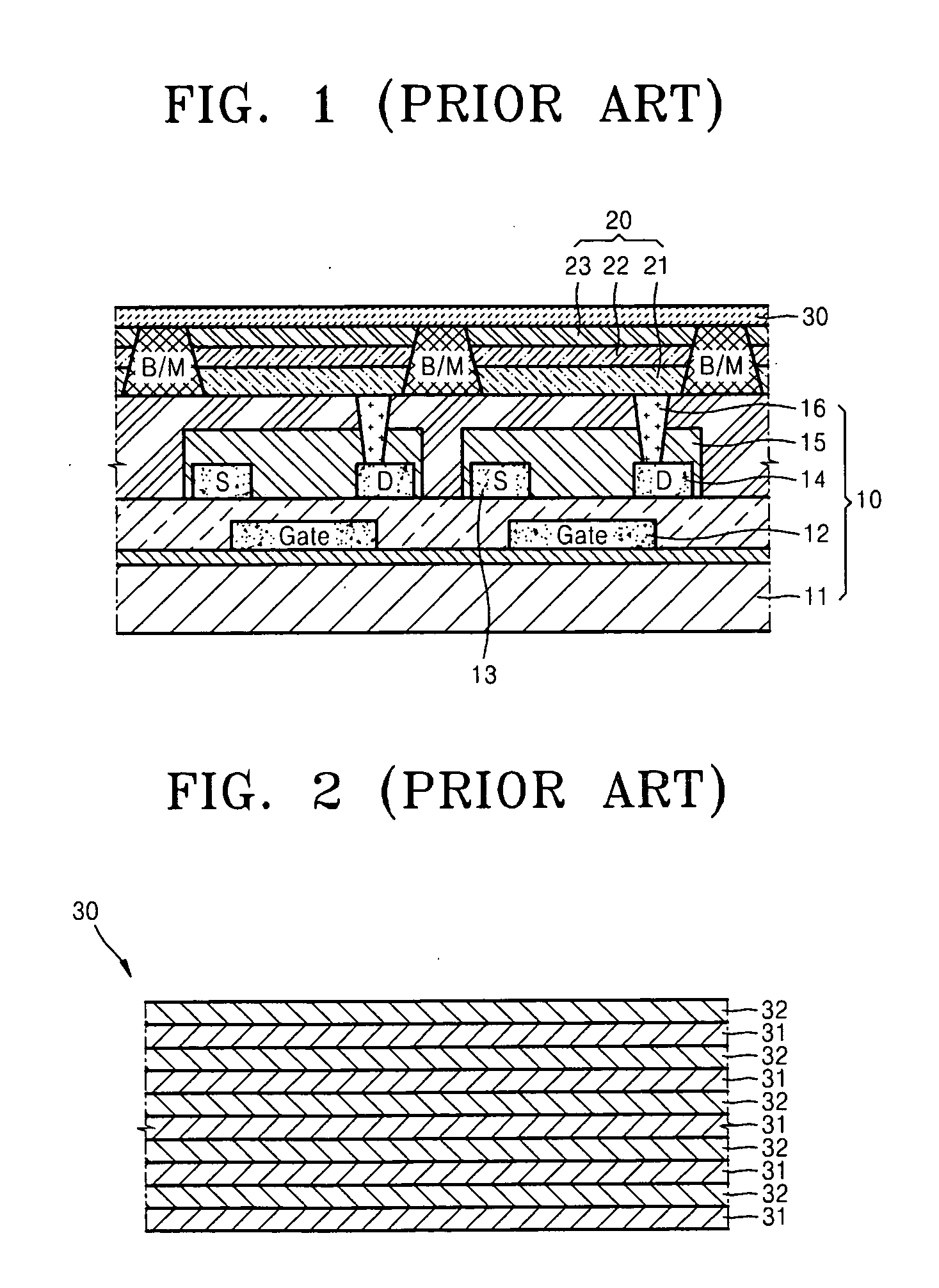

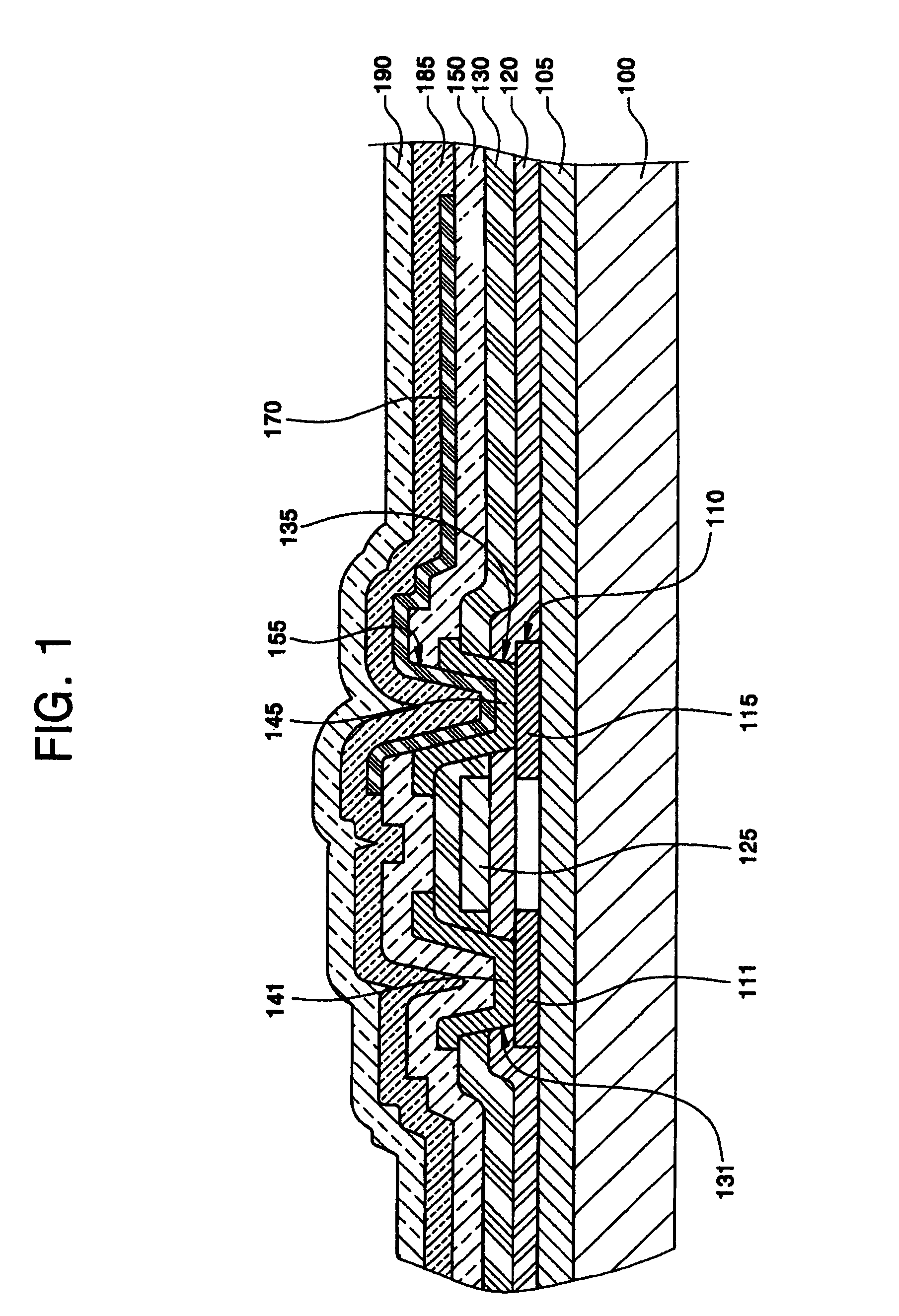

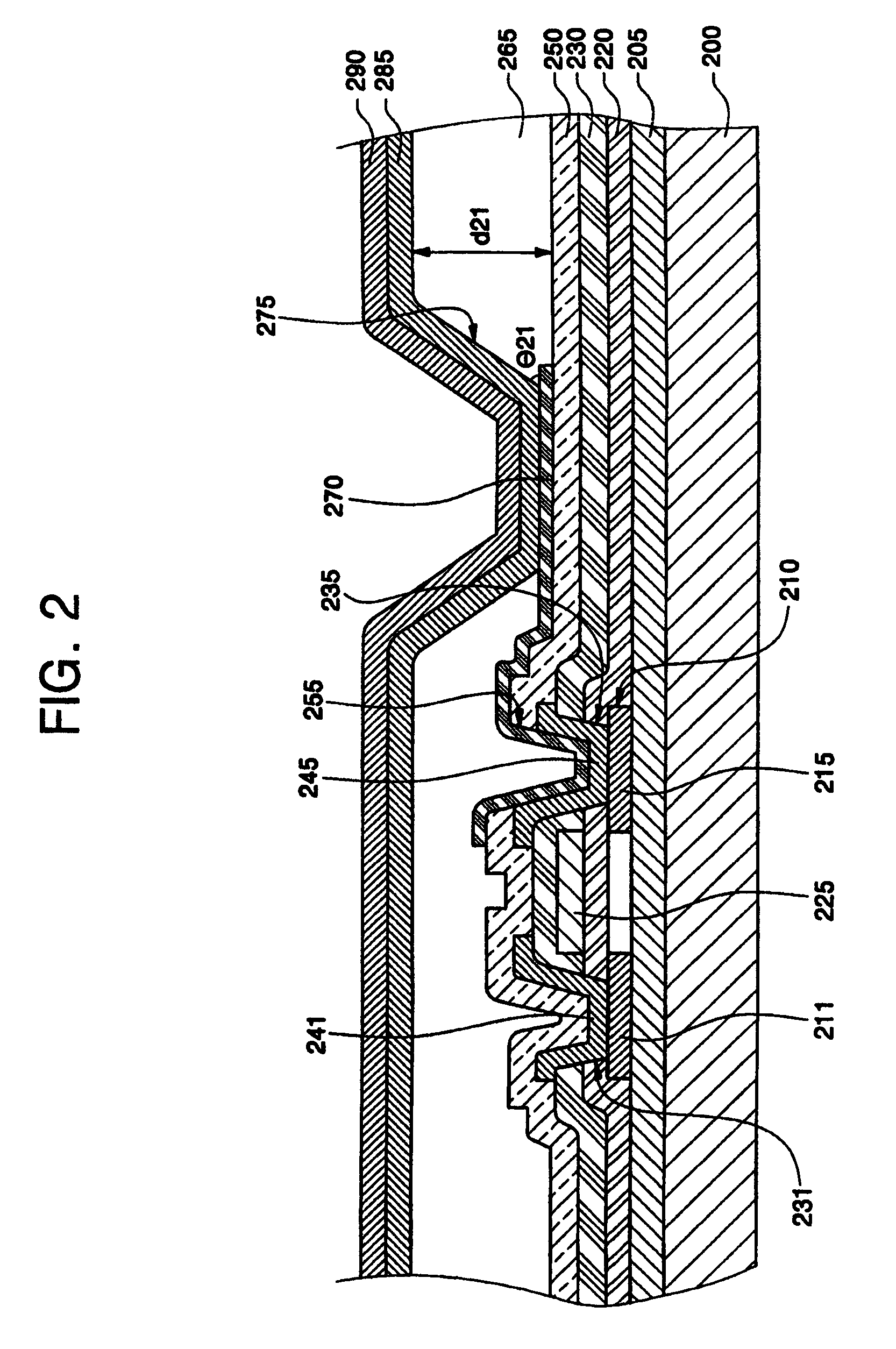

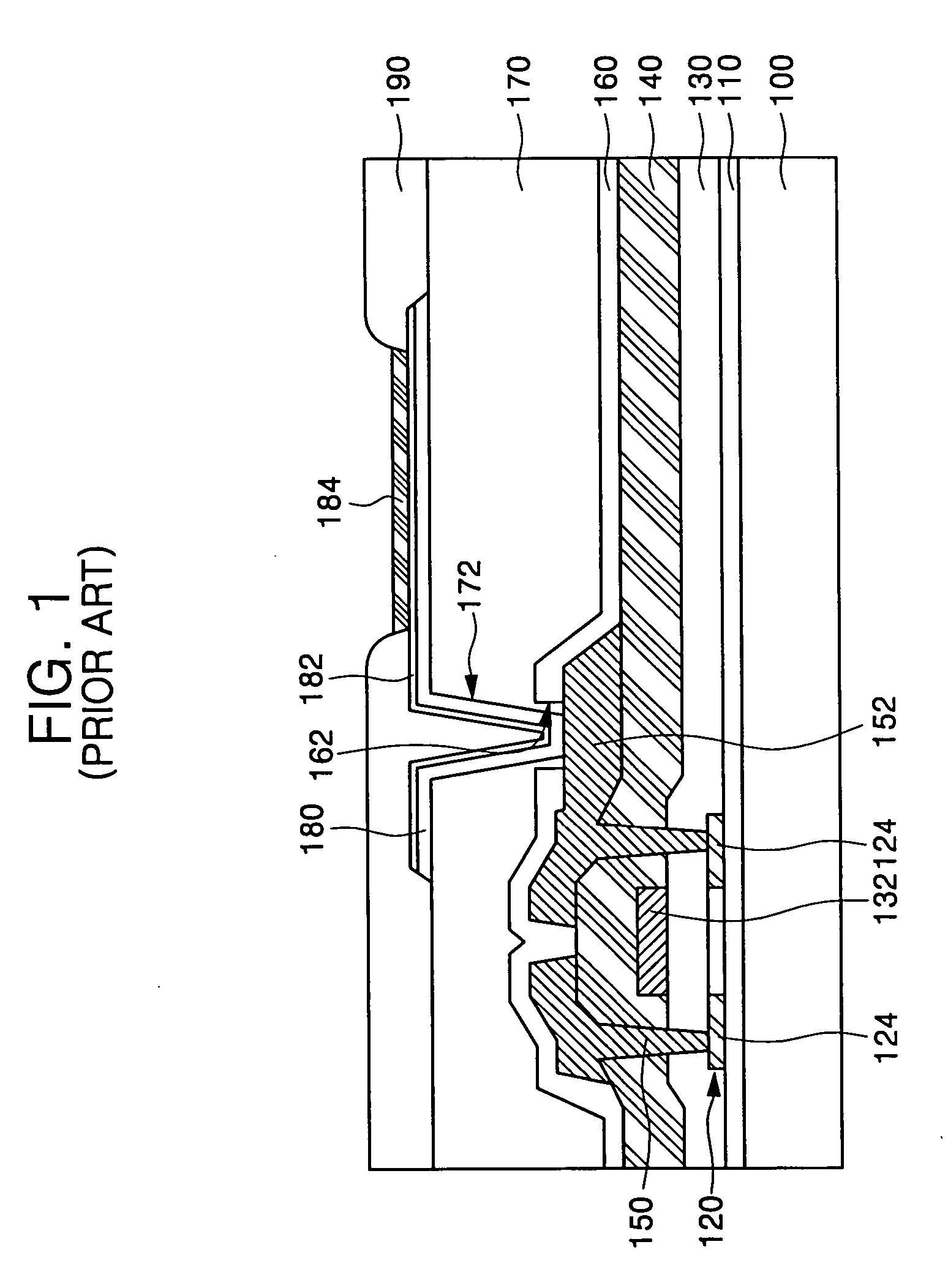

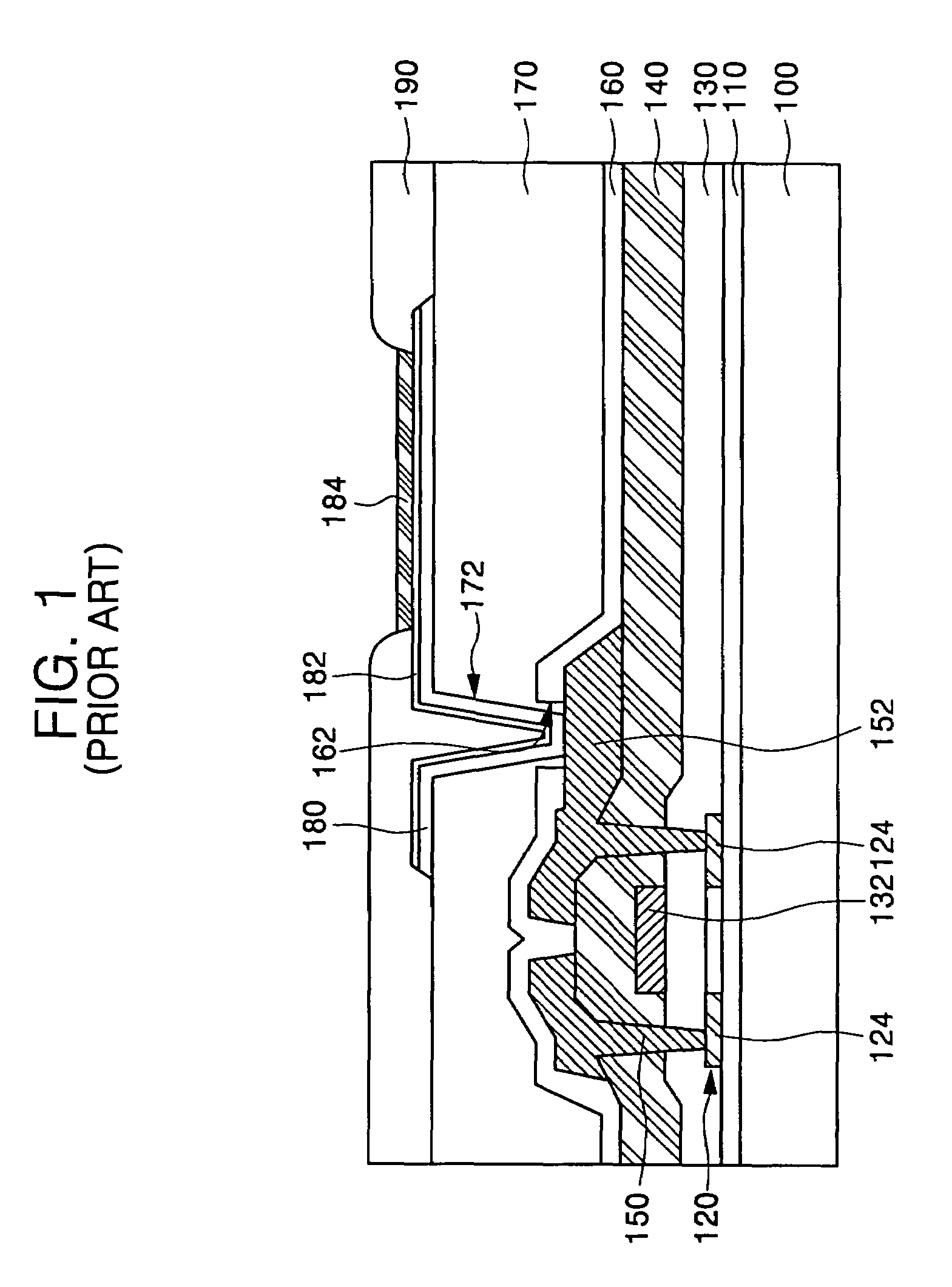

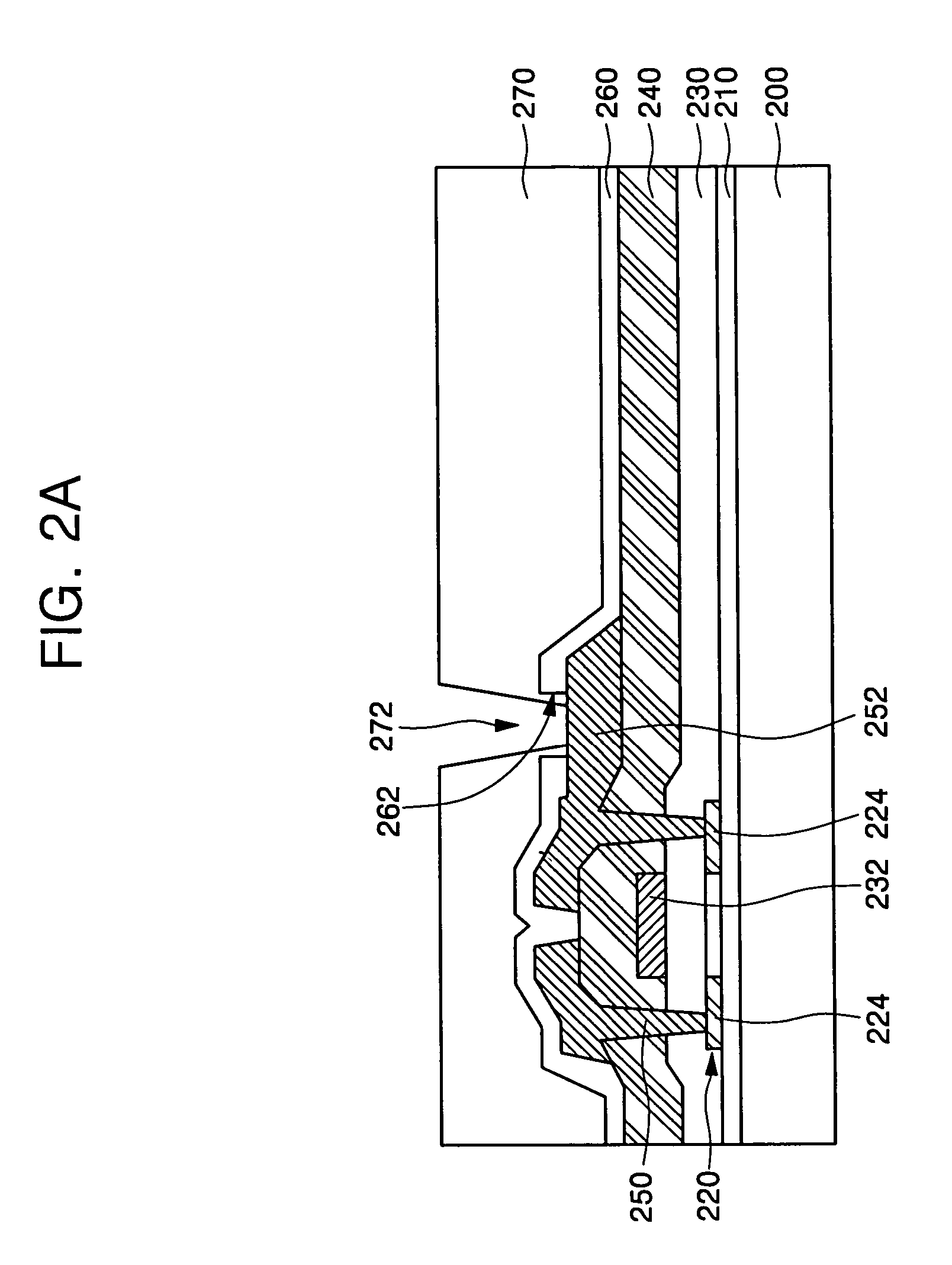

Organic light emitting display

ActiveUS20050116631A1Easy to optimizeLight displayDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsDevice failure

An organic light emitting display which is constructed with a TFT substrate having an insulating substrate and a TFT that has at least a source electrode and a drain electrode, a lower electrode formed on the TFT substrate and connected to one of source / drain electrodes, an insulating layer having an opening that exposes a portion of the lower electrode, an organic thin film layer formed on the exposed portion of the lower electrode and the insulating layer, and an upper electrode formed on the organic thin film layer, wherein the insulating layer has a taper angle less than 40° at an edge of the opening, and a step less than or equal to 3,000 Å is formed between the lower electrode and the organic thin film layer. The organic light emitting display can prevent device failure.

Owner:SAMSUNG DISPLAY CO LTD

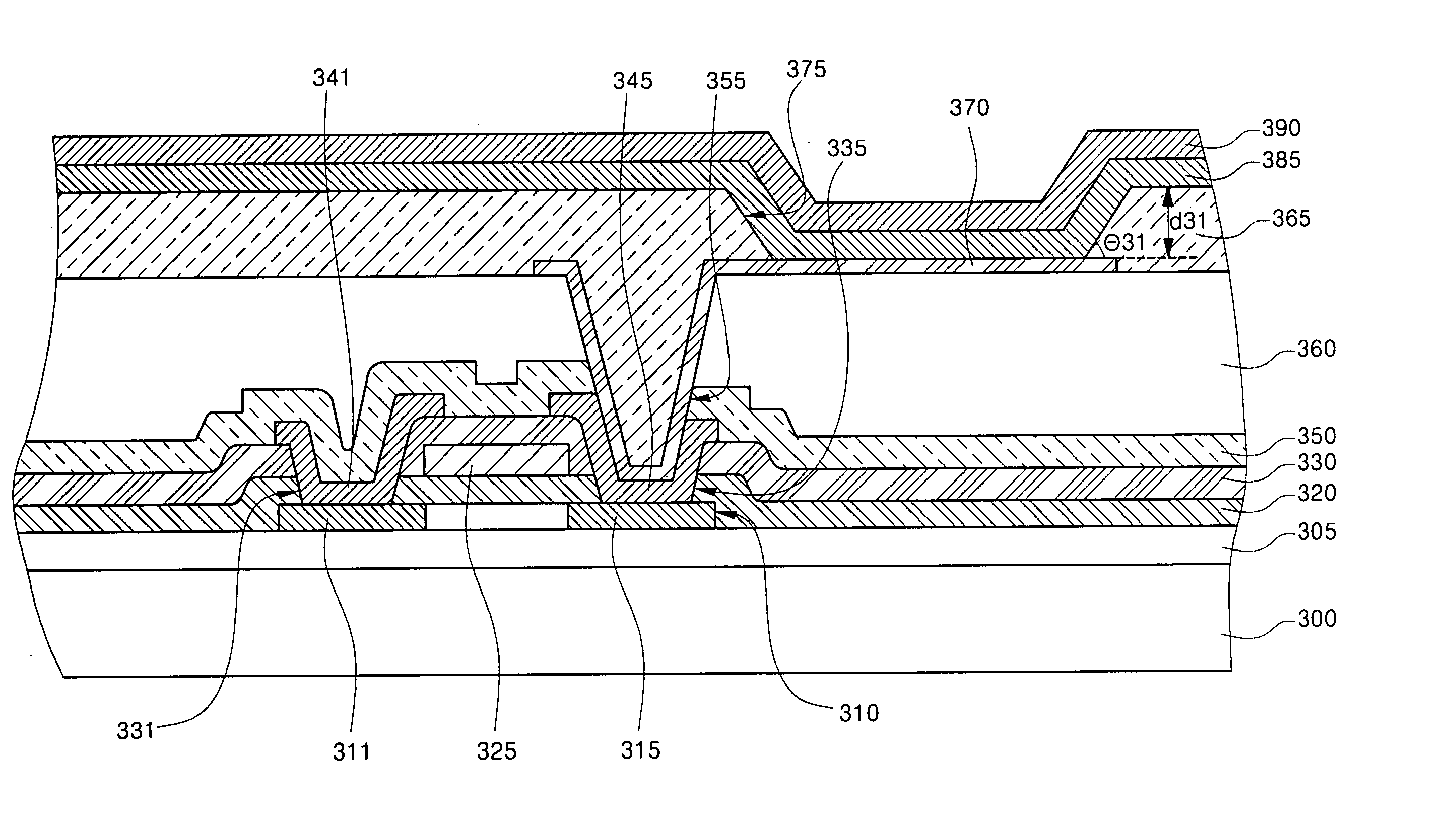

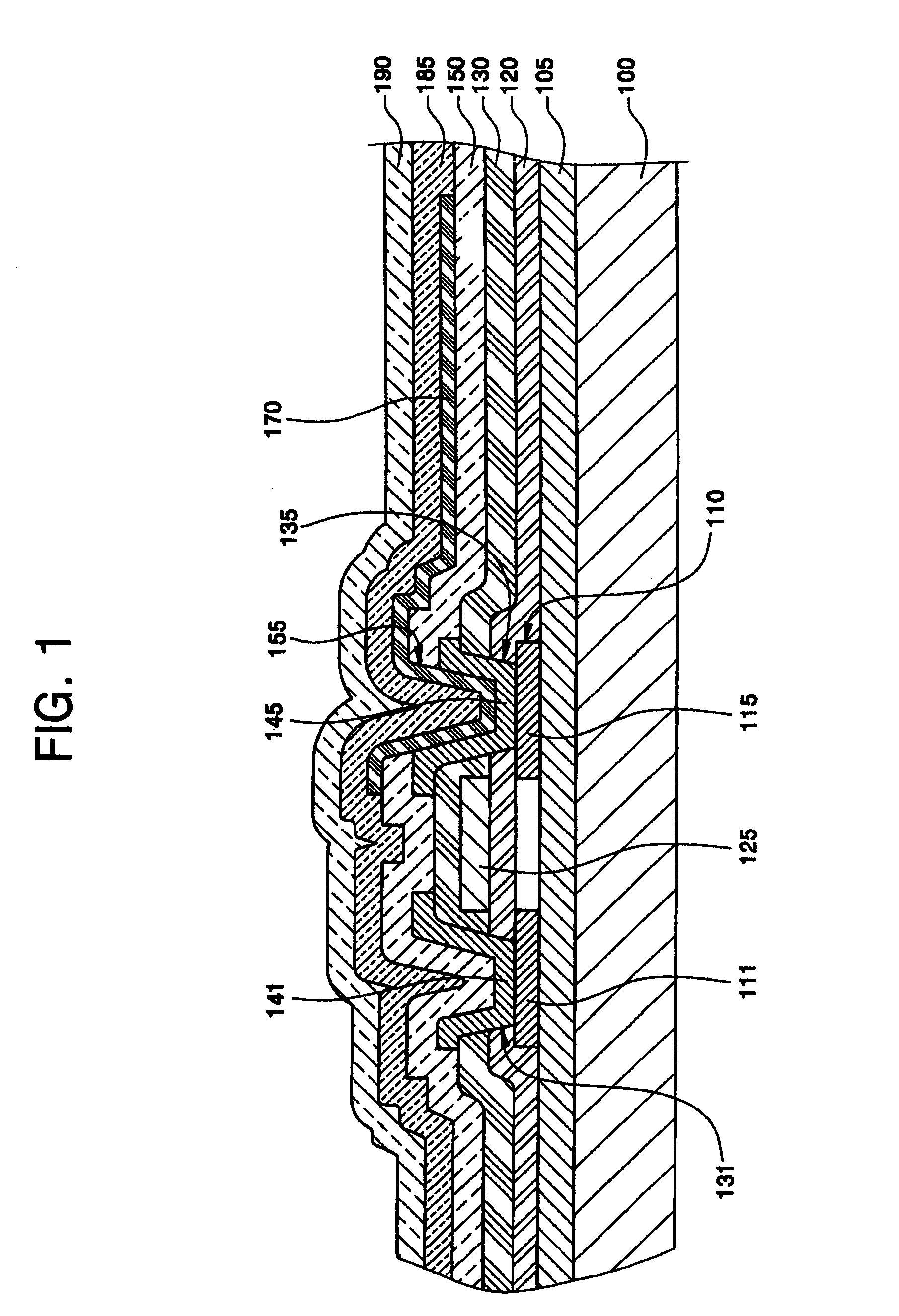

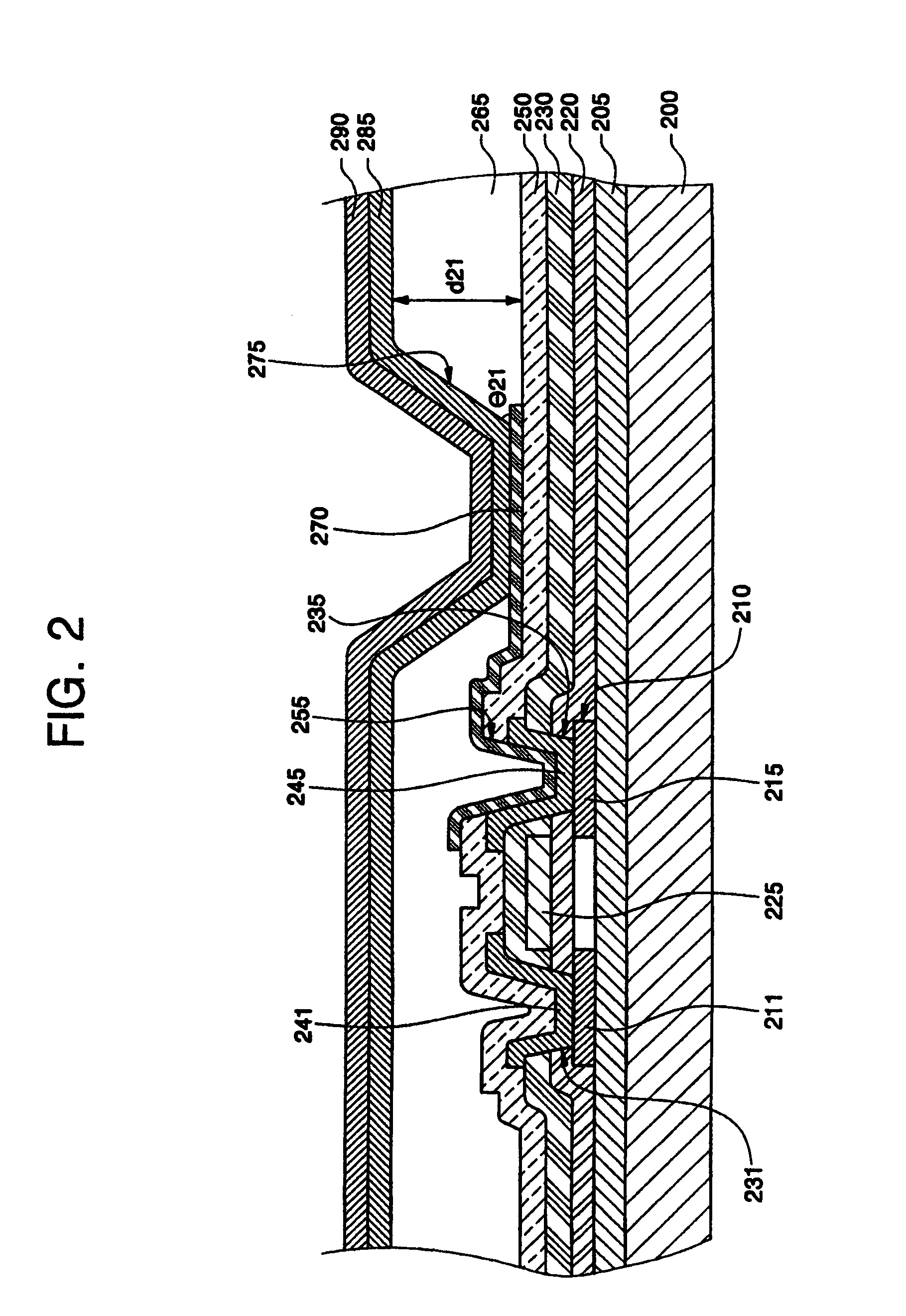

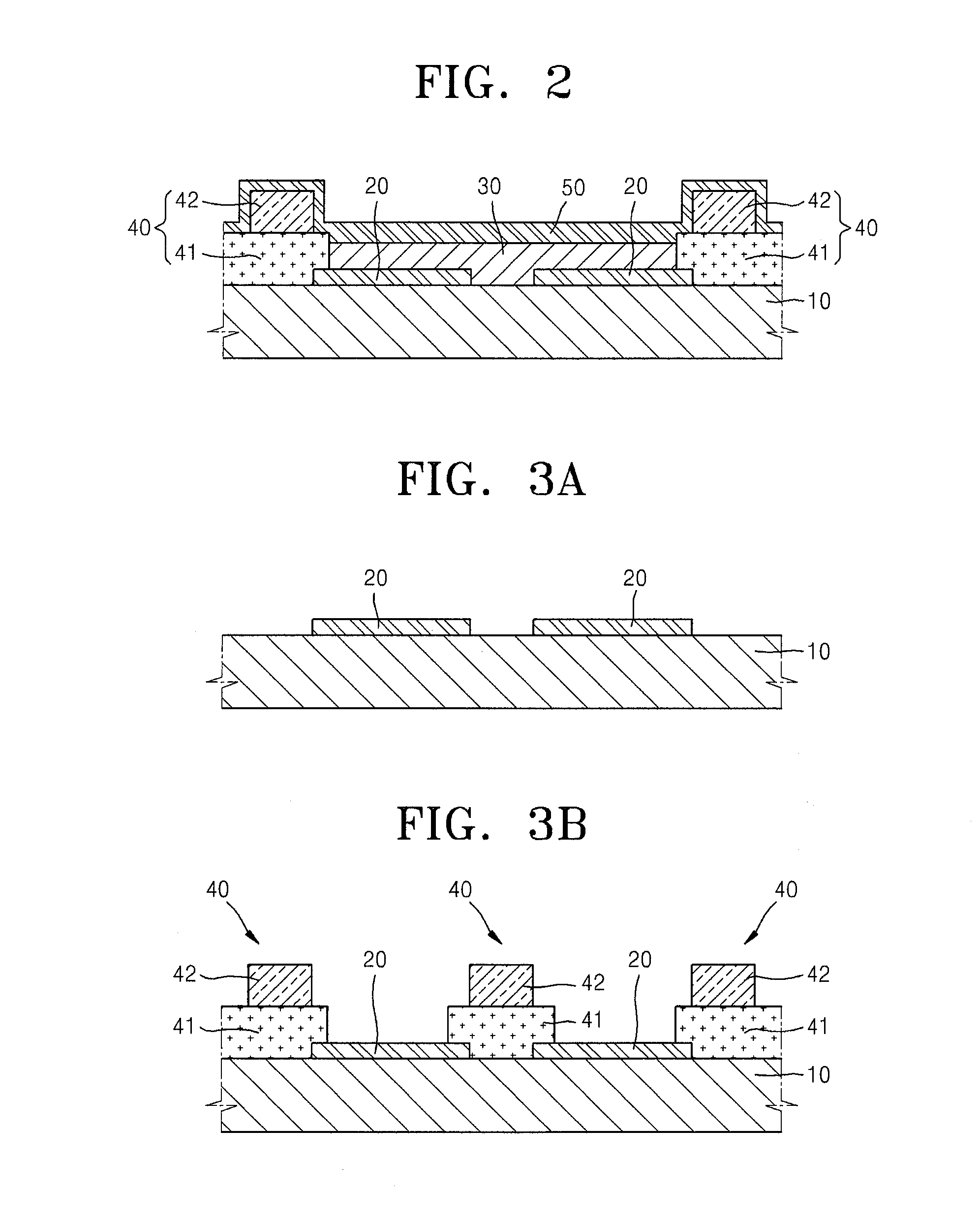

Organic light emitting display and manufacturing method thereof

ActiveUS20070181872A1Light displaySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light emitting display and a manufacturing method thereof include an improved encapsulation layer. The encapsulation layer of the organic light emitting display includes an organic layer uniformly covering bank portions and light emitting areas on a substrate; and an inorganic layer formed thicker on the light emitting areas than on the bank portions. In the organic light emitting display, the inorganic layer is thick on the light emitting area in which a sealing ability is required and the bank portion is thin in order to provide flexibility. Therefore, the encapsulation layer can be formed more easily compared to an encapsulation layer on a device in which the organic layer and inorganic layer are alternately formed at least 10 times.

Owner:SAMSUNG DISPLAY CO LTD

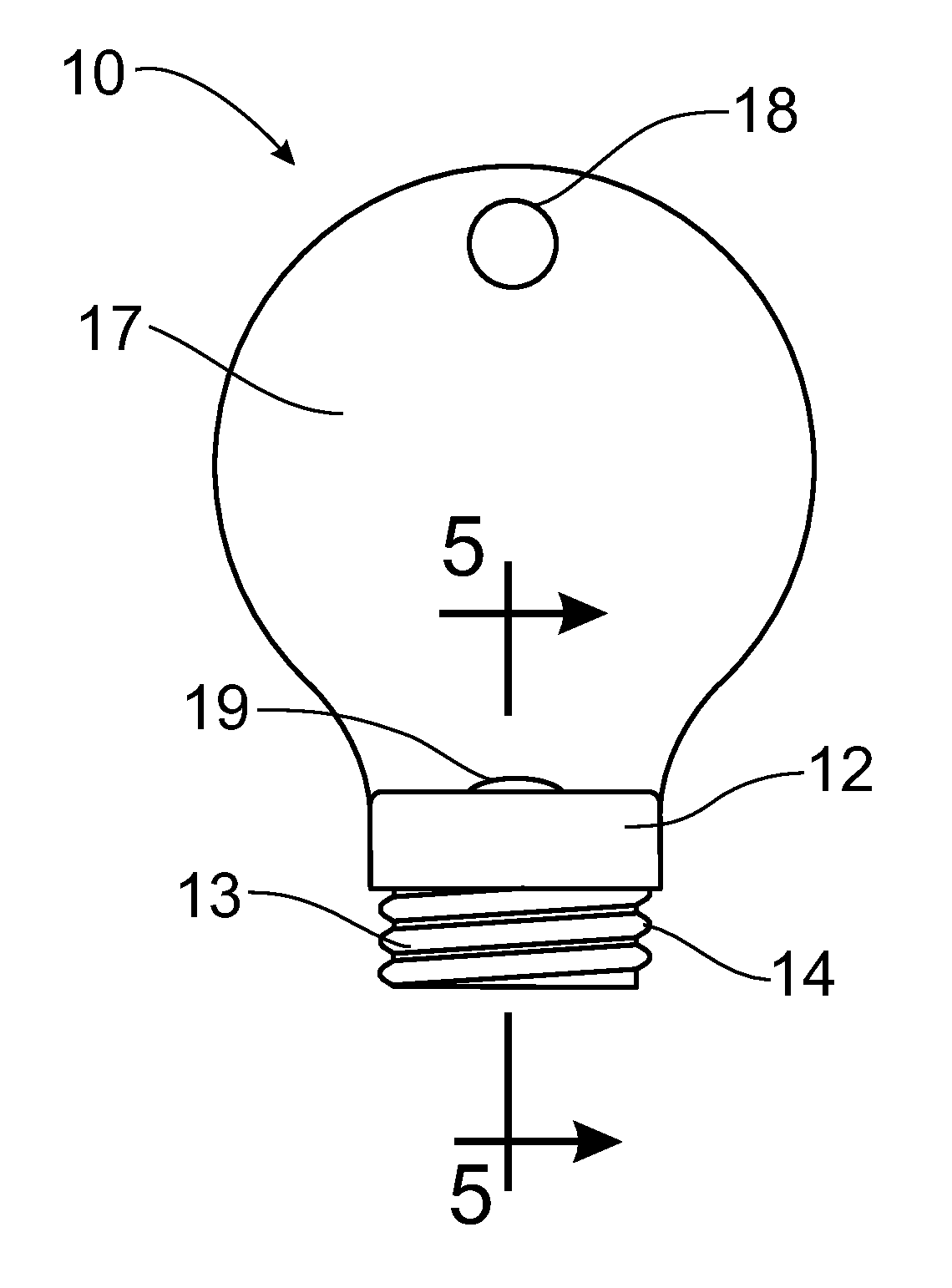

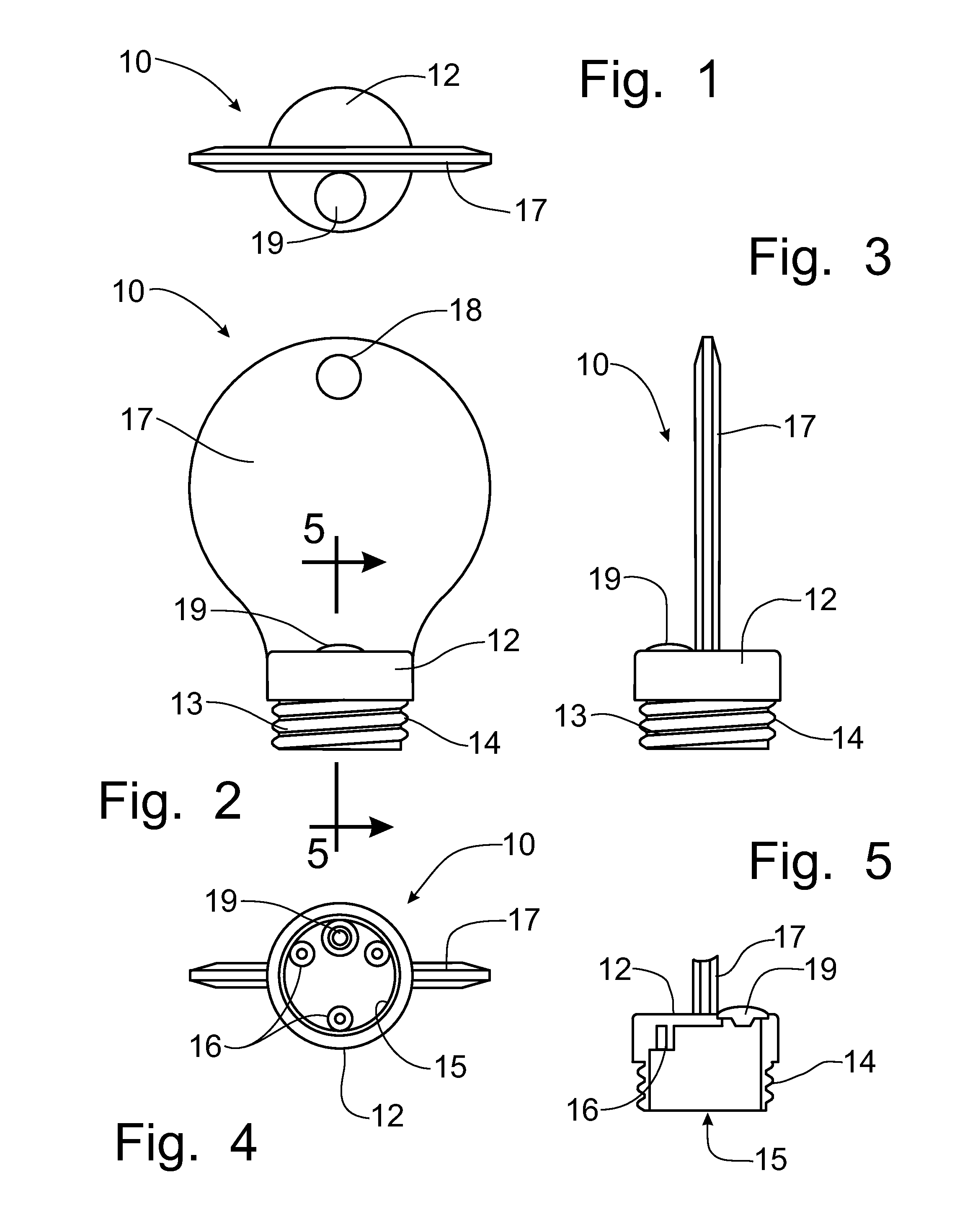

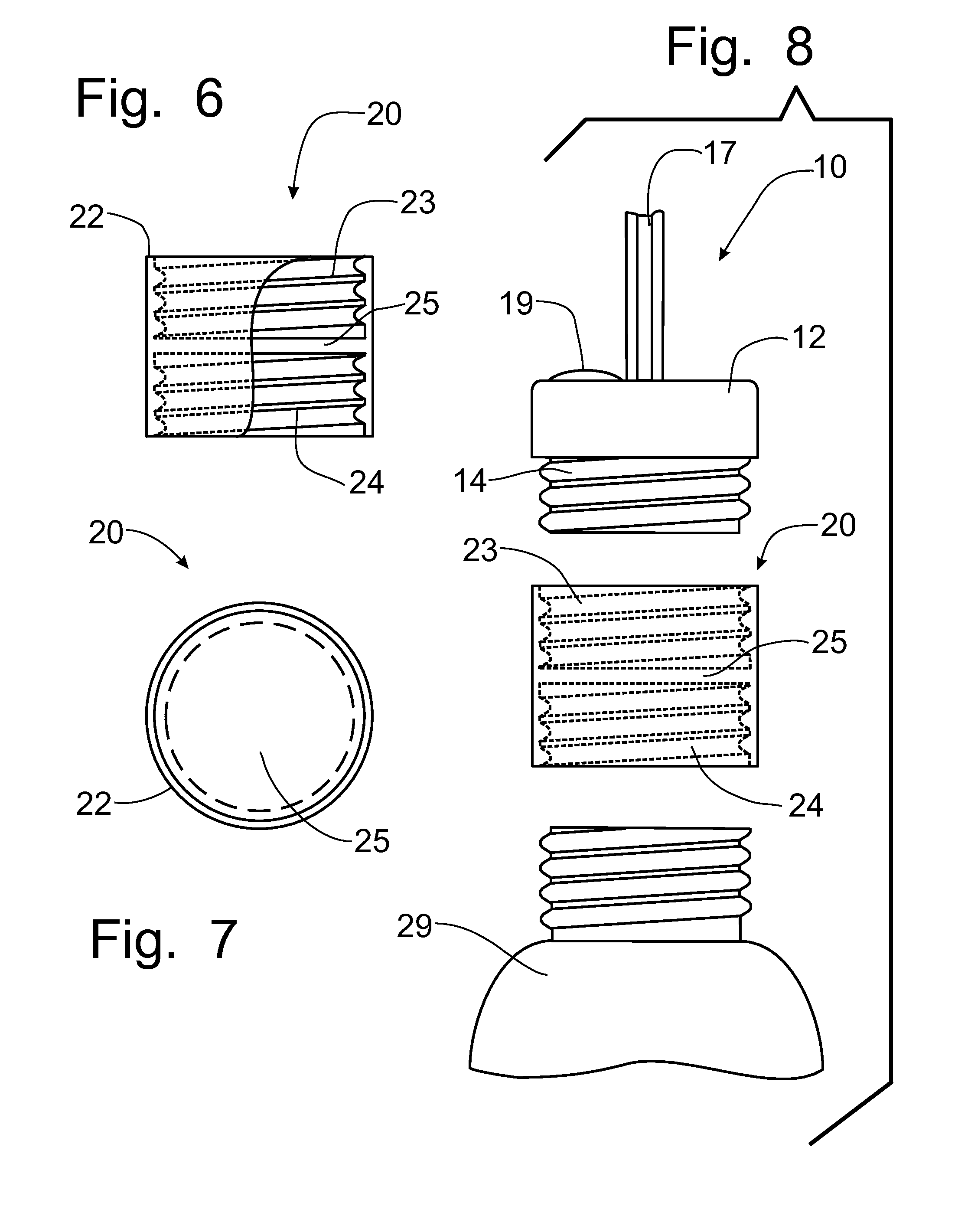

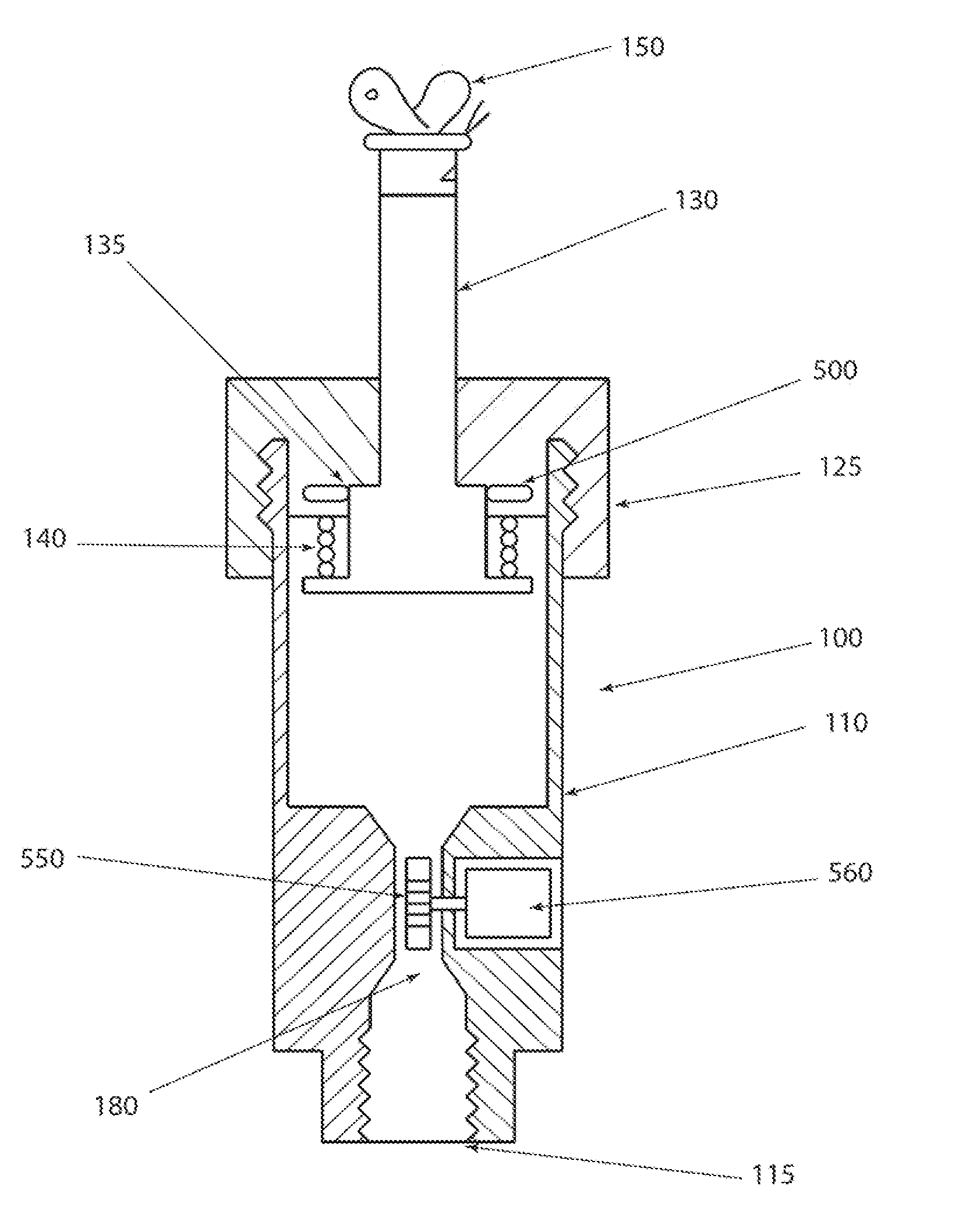

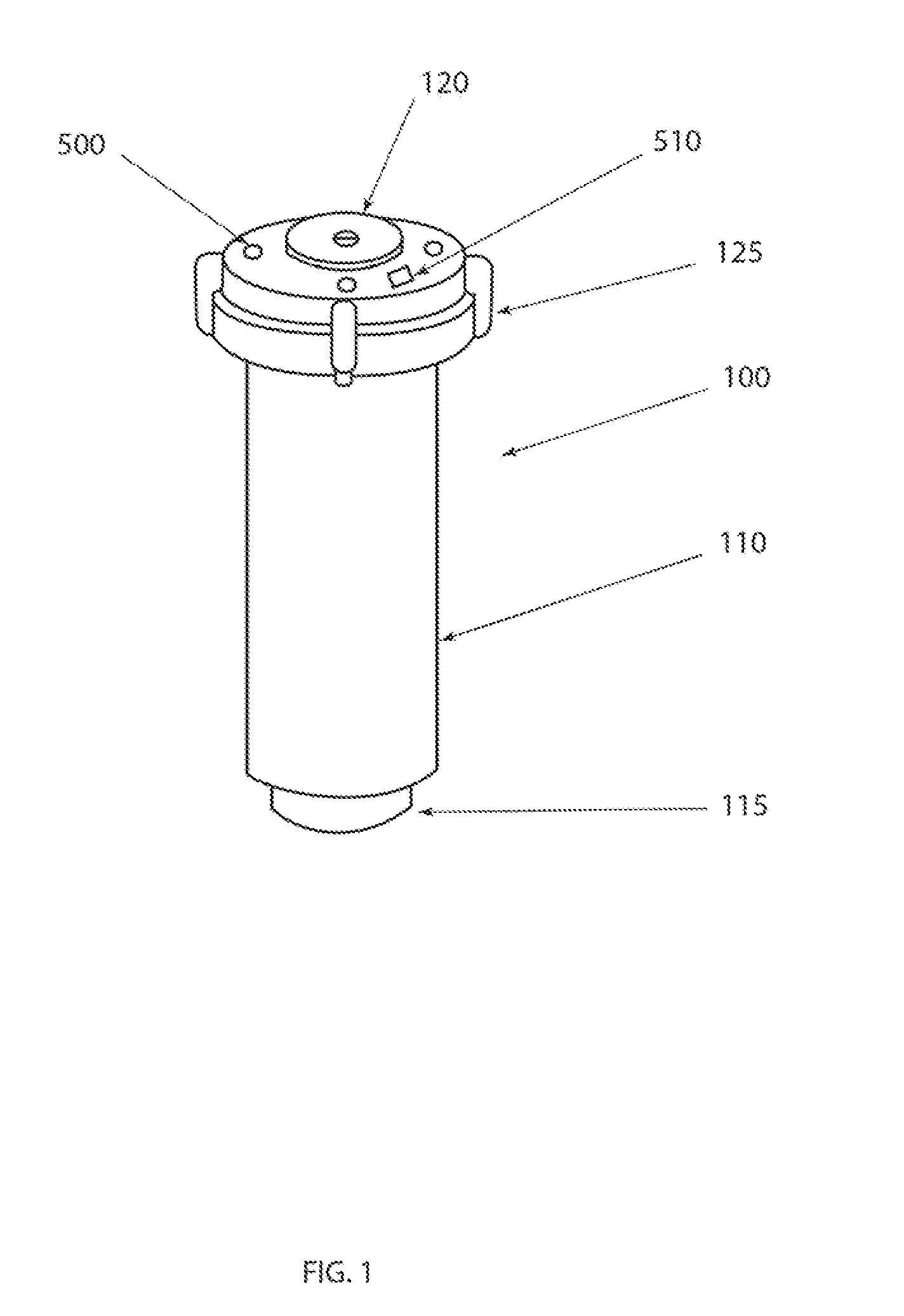

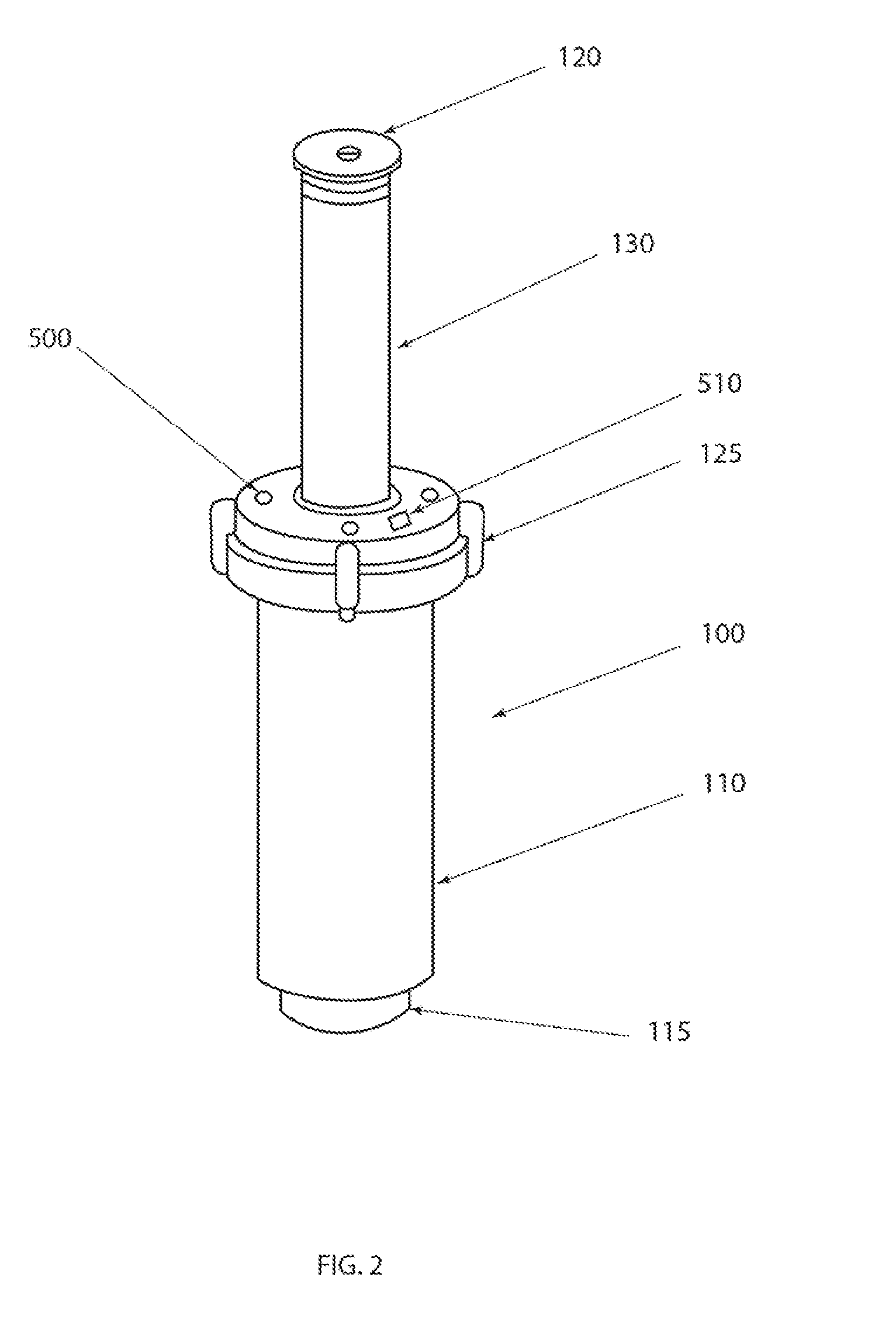

Lighted bottle cap apparatus

ActiveUS8011816B1Light displayPoint-like light sourceClosures with lifting/suspending meansLight energyDisplay device

A lighted bottle cap apparatus replaces a conventional threaded bottle cap to provide an entertaining light display externally of the bottle and also through the liquid contained within the bottle. The cap apparatus incorporates a battery powered lighting device that utilizes LED's to direct light energy into and away from the bottle. An optional advertising display can be formed as part of the cap apparatus to be illuminated from the lighting device. An alternative embodiment provides a central opening through the cap apparatus to allow the liquid within the bottle to be dispensed therethrough. The lighting device is oriented to direct light energy into the discharged liquid. An adaptor incorporating a translucent panel allows the standard cap apparatus to be connected to multiple bottle configurations. The adaptor has first and second sets of threads separated by the translucent panel to seal the lighting device from the liquid in the bottle.

Owner:JANDA WILLIAM P

Energy efficient decorative lighting

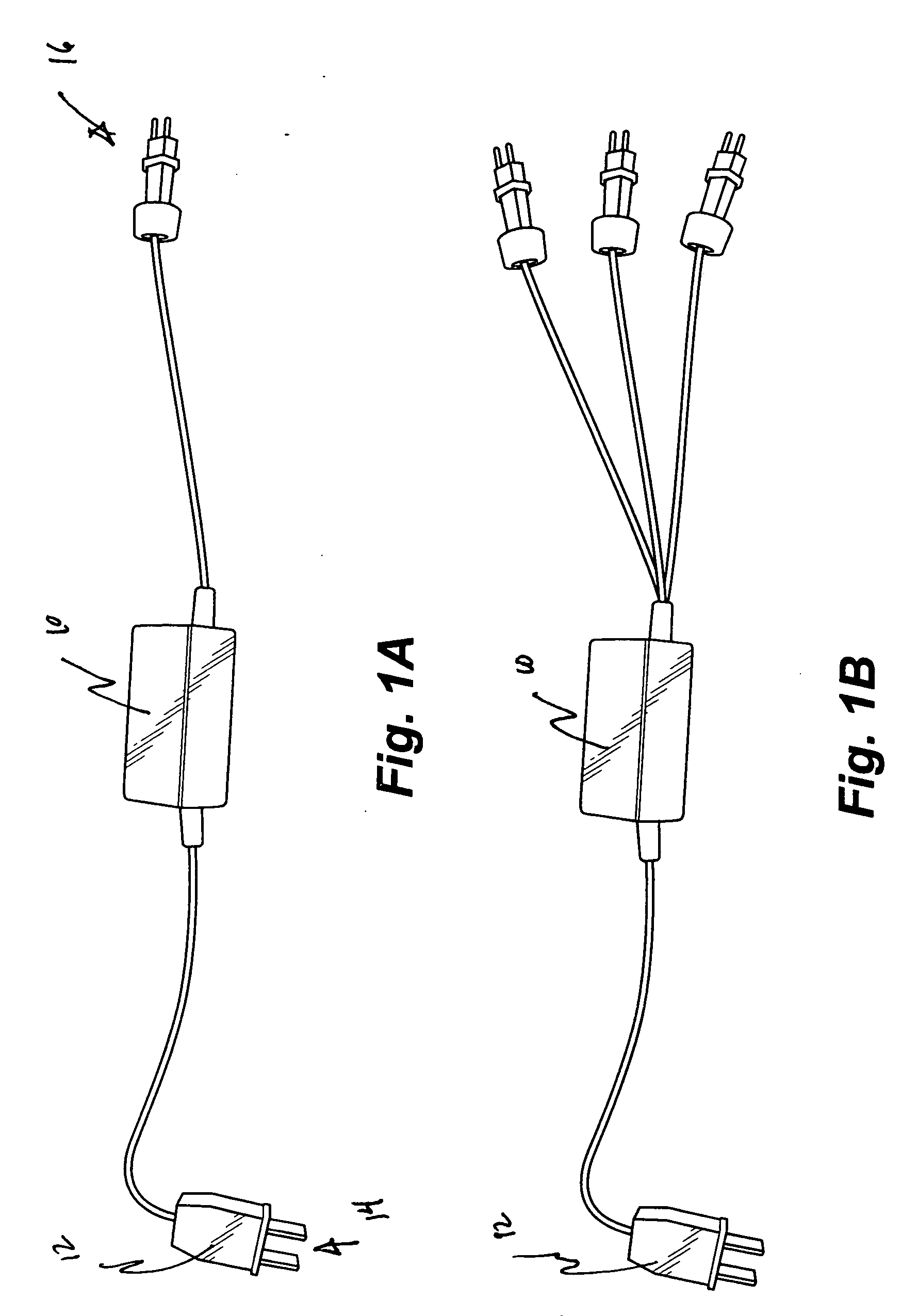

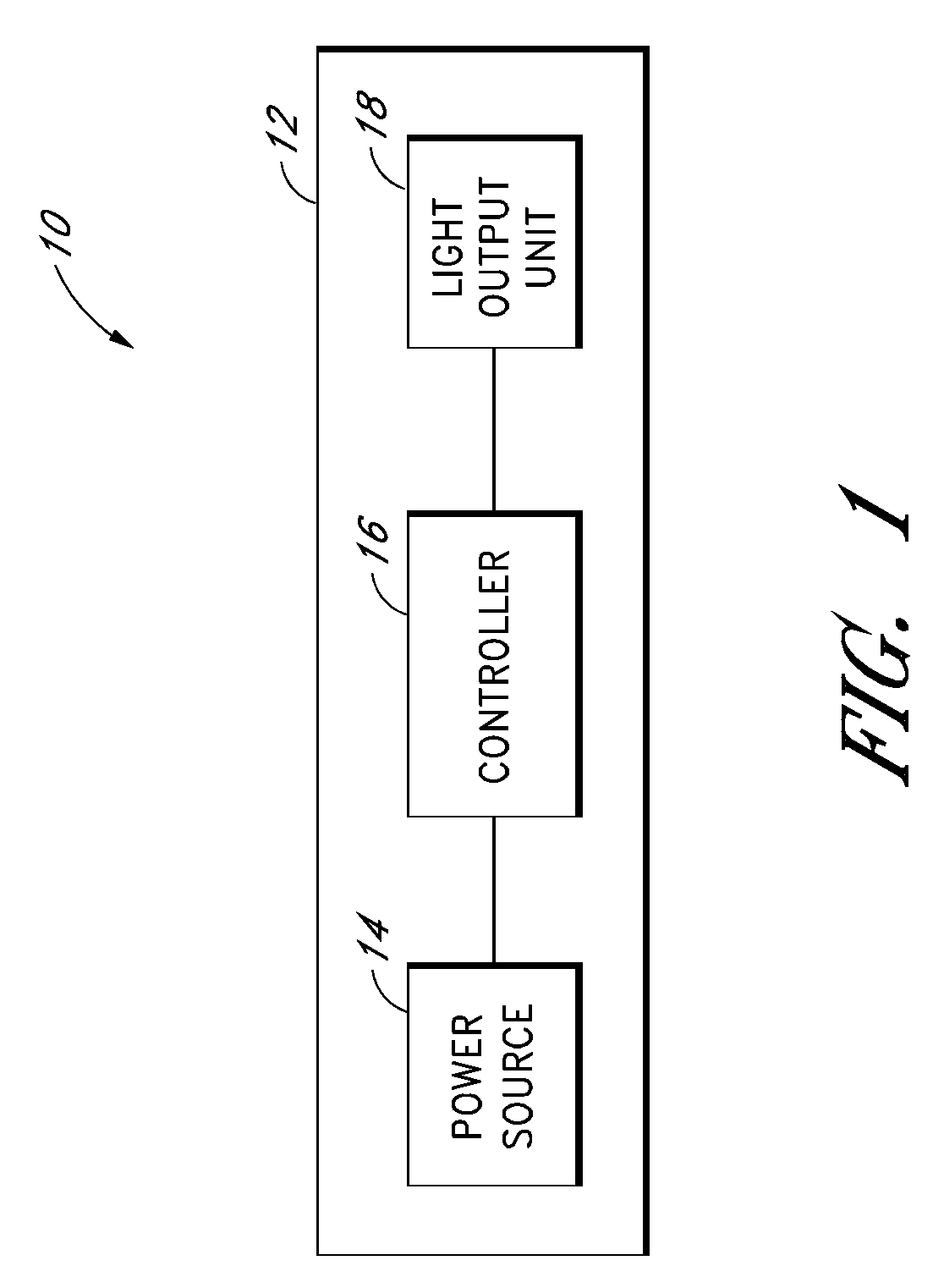

InactiveUS20100289415A1Low cost manufacturingEnergy efficiencyElectrical apparatusElectric circuit arrangementsLow voltageTransformer

Energy efficient system for lighting is provided that allows variation of length, density of illumination and positioning. The inventive system is particularly suitable for decorative lighting and seasonal display. The lighting system comprises at least one light string having a plurality of light emitting diodes (LEDS) interconnected to a parallel set of power wires maintaining output voltage within a prescribed range. A direct current (DC) transformer is connected to the parallel set of power wires to convert alternating current (AC) input to DC output to control power to the lighting system at relatively low voltage level and less than about fifteen watts. Multiple LED light strings may be connected to the parallel set of power wires to provide decorative lighting displays of desired length, configuration and density of illumination. Accordingly, the unique system provides decorative lighting that is energy efficient and suitable for low cost manufacture compared with conventional incandescent light strings.

Owner:WILLIS ELECTRIC

Systems and methods for ornamental variable intensity lighting displays

InactiveUS20080238345A1Light displayCost-effectivelyLighting support devicesPoint-like light sourceLighting systemBand shape

A device and method for illuminating an electrically powered decorative lighting system with a plurality of individual light elements that can be positioned in or on surrounding plants, windows, or other display areas to simulate fireflies. The plurality of light emitting elements, such as LEDs or fiber optic cables, are arrangable with mounting devices or can be suspended or attached to any surrounding structure to provide an ornamental lighting effects. Electrical power is provided with rechargeable batteries charged with a solar panel. One preferred embodiment uses insulation-displacement connectors and an insulation-displacement connector ribbon cable to attach the light emitters to a microprocessor control which creates unique and varied timing patterns for the various light emitters to simulate fireflies.

Owner:RSR SALES

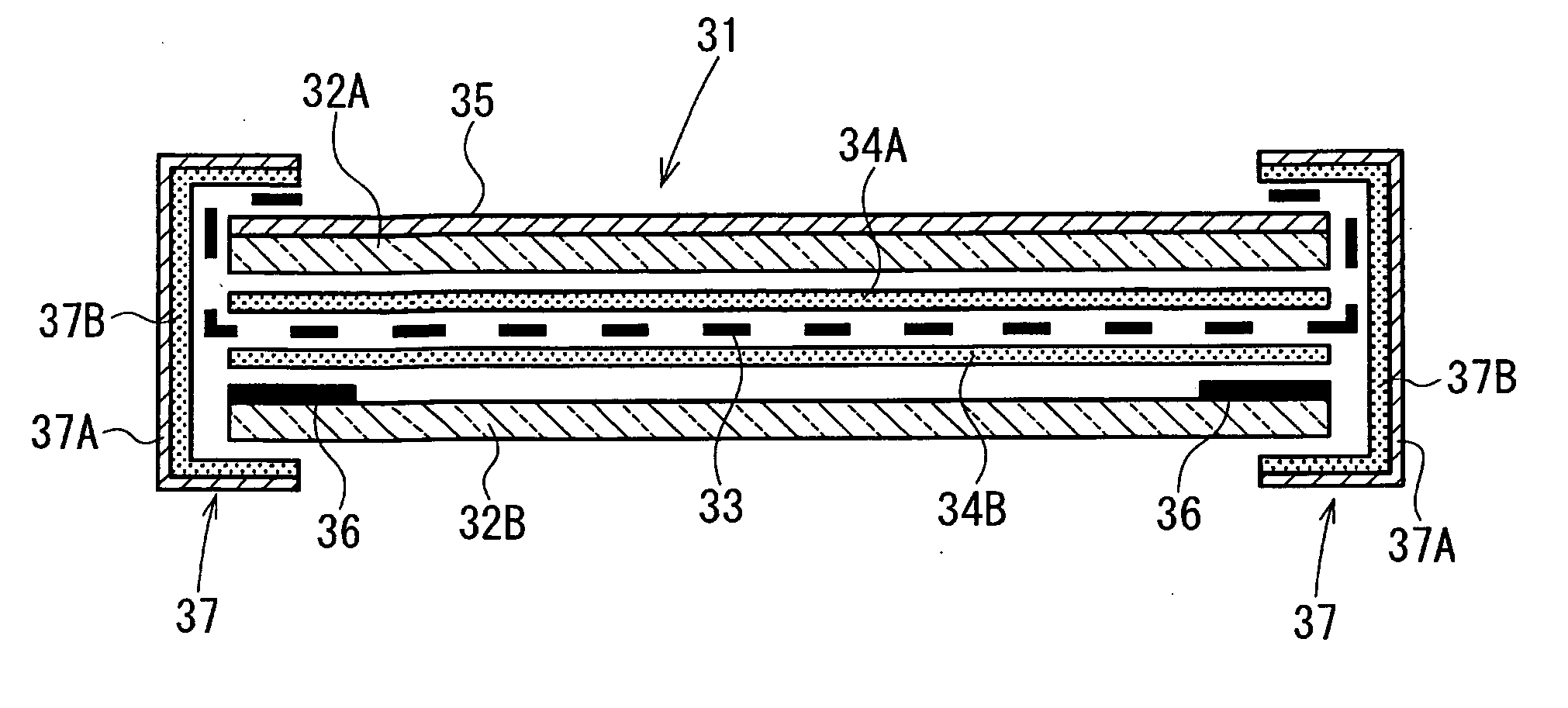

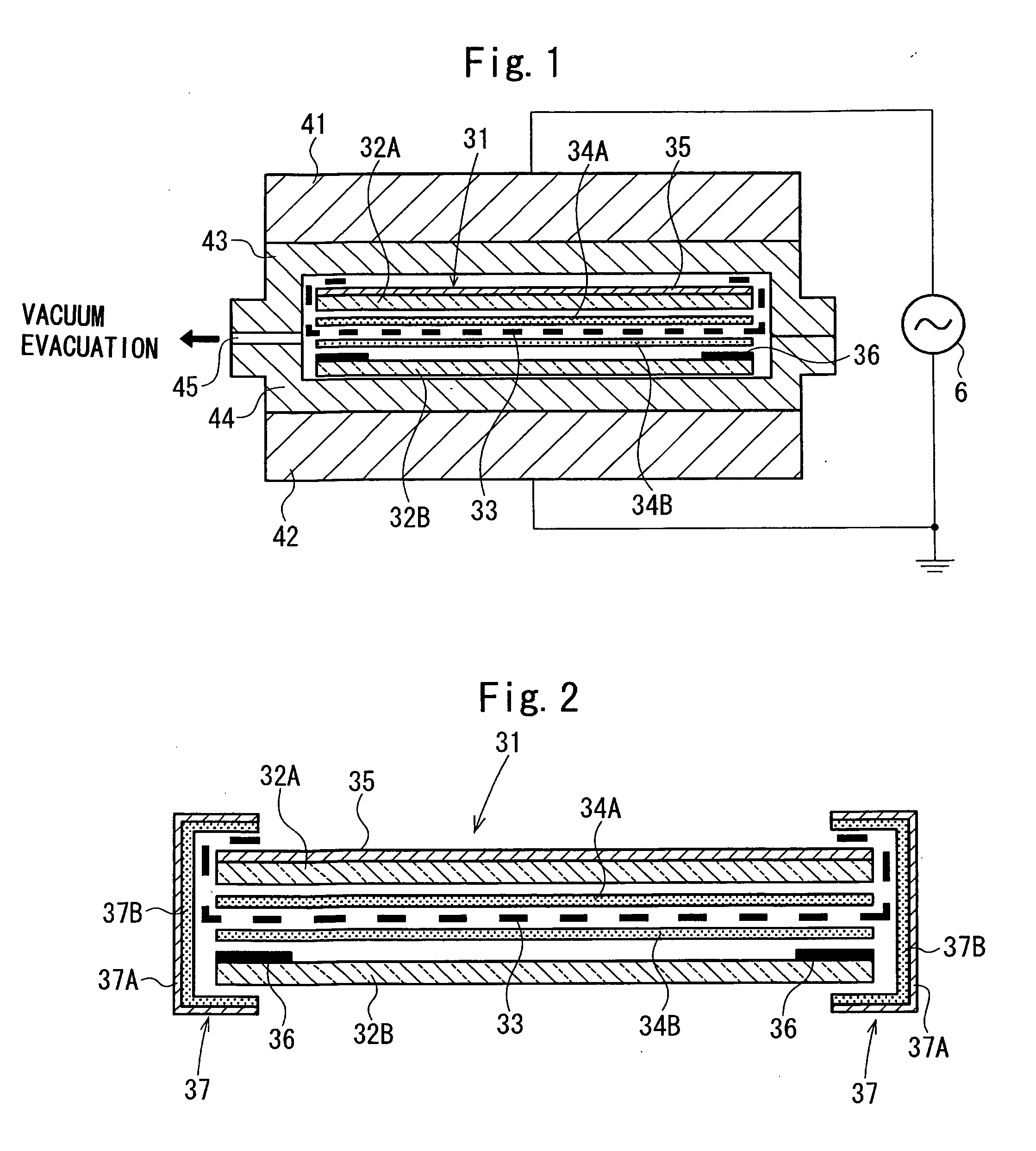

Manufacturing methods of electromagnetic-wave shielding and light transmitting window material, display panel, and solar battery module

InactiveUS20070011863A1Improve production efficiencyAddressing slow performanceGas-filled discharge tubesWave amplification devicesHigh frequency powerEngineering

In order to decrease the time (adhesion time in an adhesion step) for manufacturing an electromagnetic-wave shielding and light transmitting window material and a display panel, a top mold 43 and a bottom mold 44, which are made of a synthetic resin having high heat resistance, are disposed between a top and a bottom pressing plate 41 and 42, and a laminate is disposed between the molds 43 and 44. This laminate is formed of a transparent substrate 32A provided with an anti-reflection film 35, an adhesive interlayer film 34A used as an adhesive resin, an electrical conductive mesh 33, an adhesive interlayer film 34B, and a transparent substrate 32B provided with a black frame paint 36. While air in a molding space between the molds 43 and 44 is vacuum-evacuated via an exhaust port 45, a high-frequency voltage is simultaneously applied to the pressing plates 41 and 42 from a high-frequency power source 46, and in addition, the above laminate is pressed by the pressing plats 41 and 42 for a predetermined time. Accordingly, the interlayer films 34A and 34B is heated by induction heating and is cured, and as a result, the laminate is integrated.

Owner:BRIDGESTONE CORP

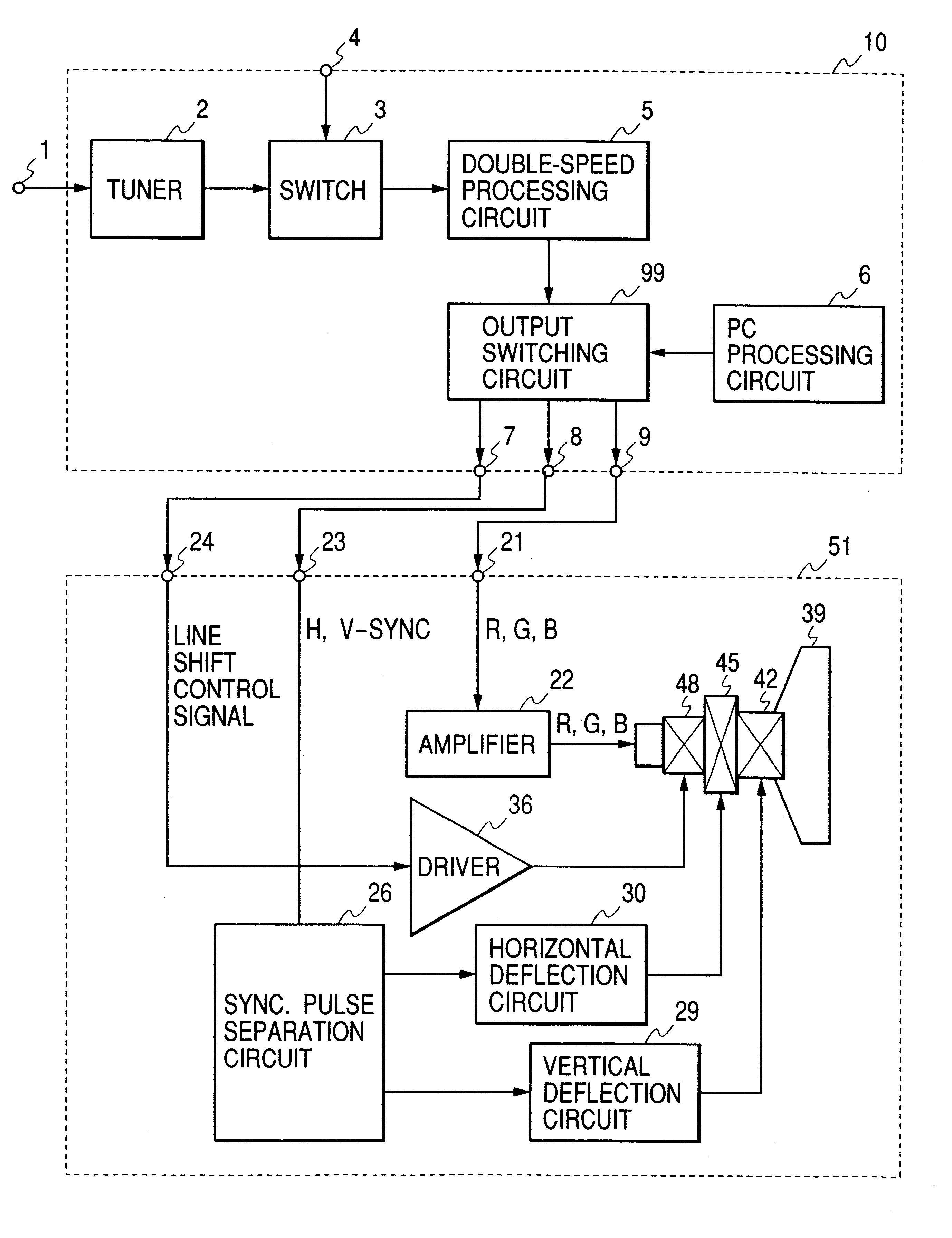

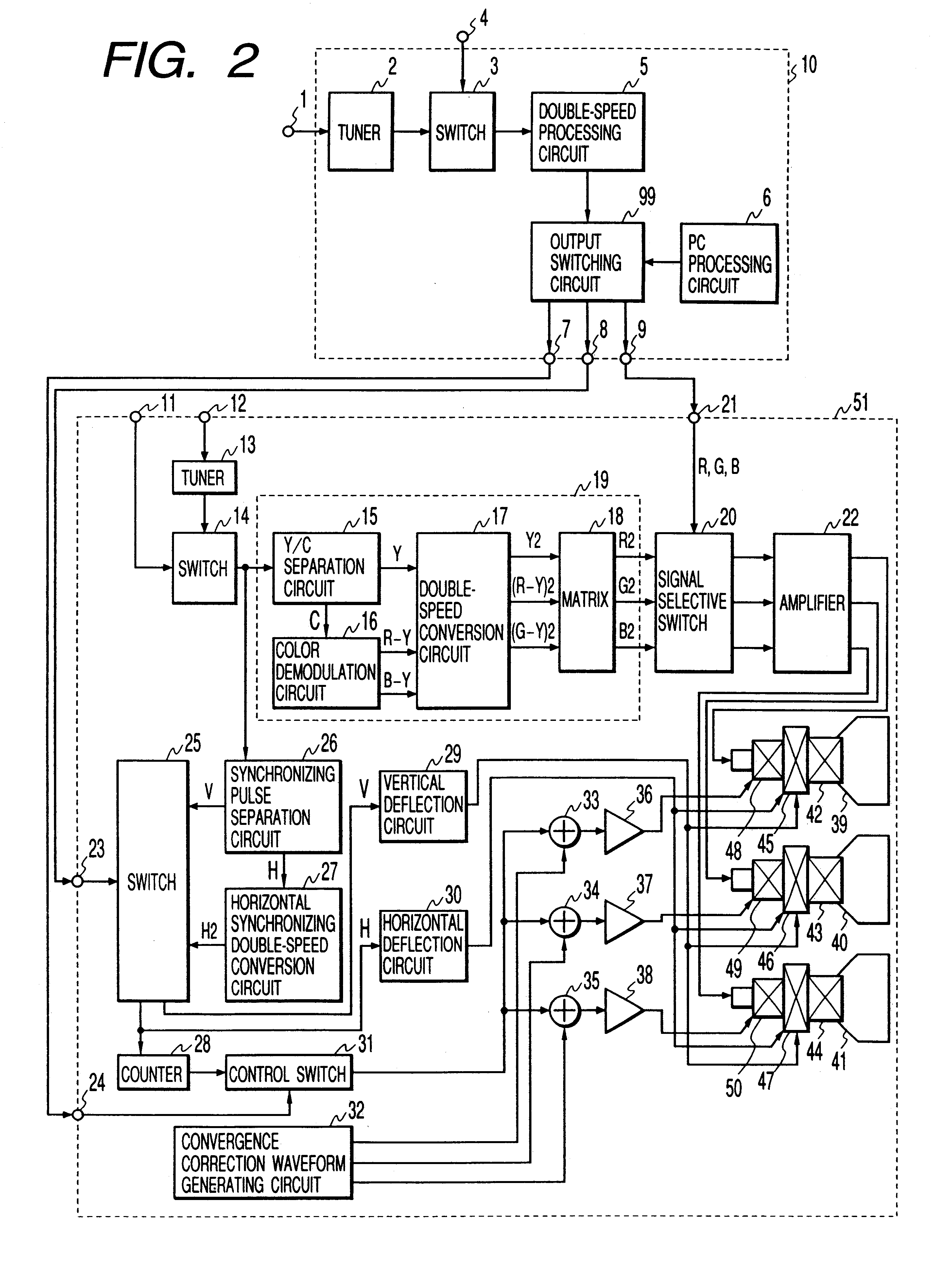

Image display apparatus and personal computer for displaying personal computer signals and broadcast signals

InactiveUS6268887B1High resolutionLow costTelevision system detailsColor signal processing circuitsVertical deflectionInterlaced video

When a video signal is double-speed processed by the first device, a slight vertical deflection process is performed for redundant similar scan lines by the second device, and any slight deflection in the second device is controlled by the first device to thereby enable setting so as to always display images with excellent resolution. More particularly, a discrimination signal is generated by the first device to designate interlaced scanning and flag a need for vertical scan-line deflection, and such discrimination signal is provided to the second device such that the second device can always appropriately determine the need for vertical scan-line deflection. Through monitoring for the discrimination signal, an image display apparatus is capable of preventing vertical resolution from being deteriorated when video signals possibly requiring vertical line-shifting are inputted from an external source. Further, an image display apparatus is capable of preventing the vertical resolution from being deteriorated when images of video signals having different systems are displayed within different areas on a same screen.

Owner:HITACHI LTD

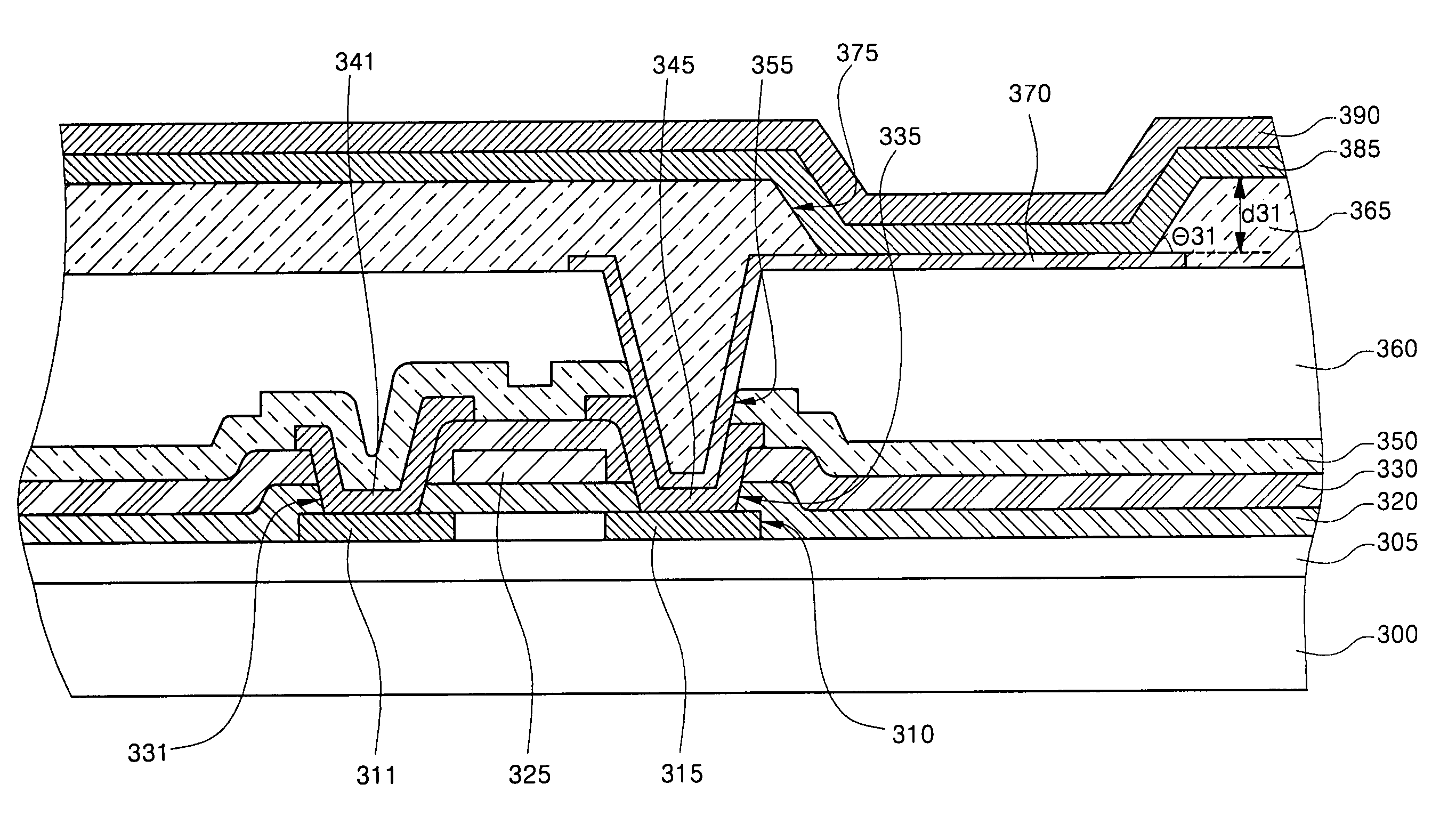

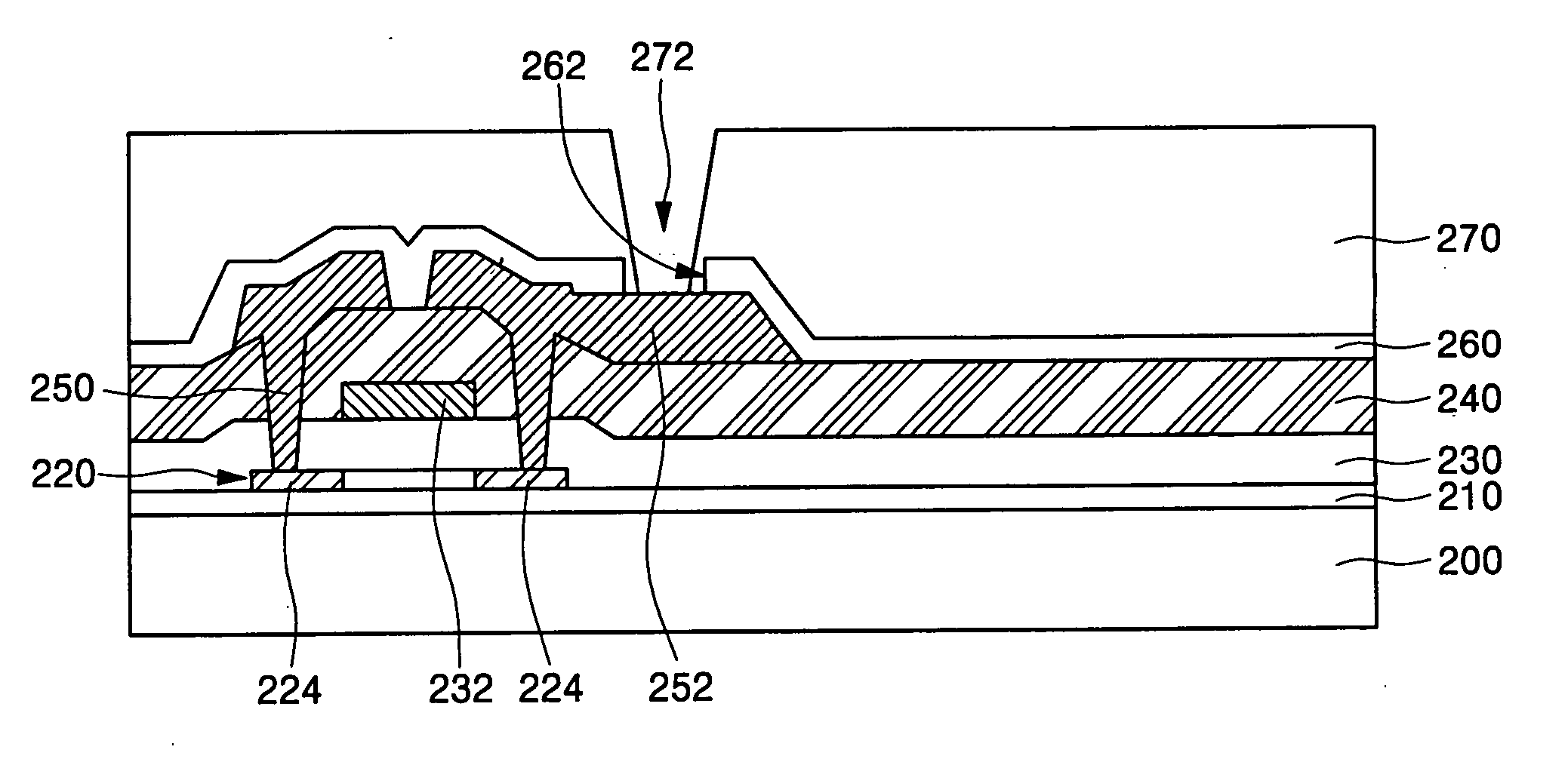

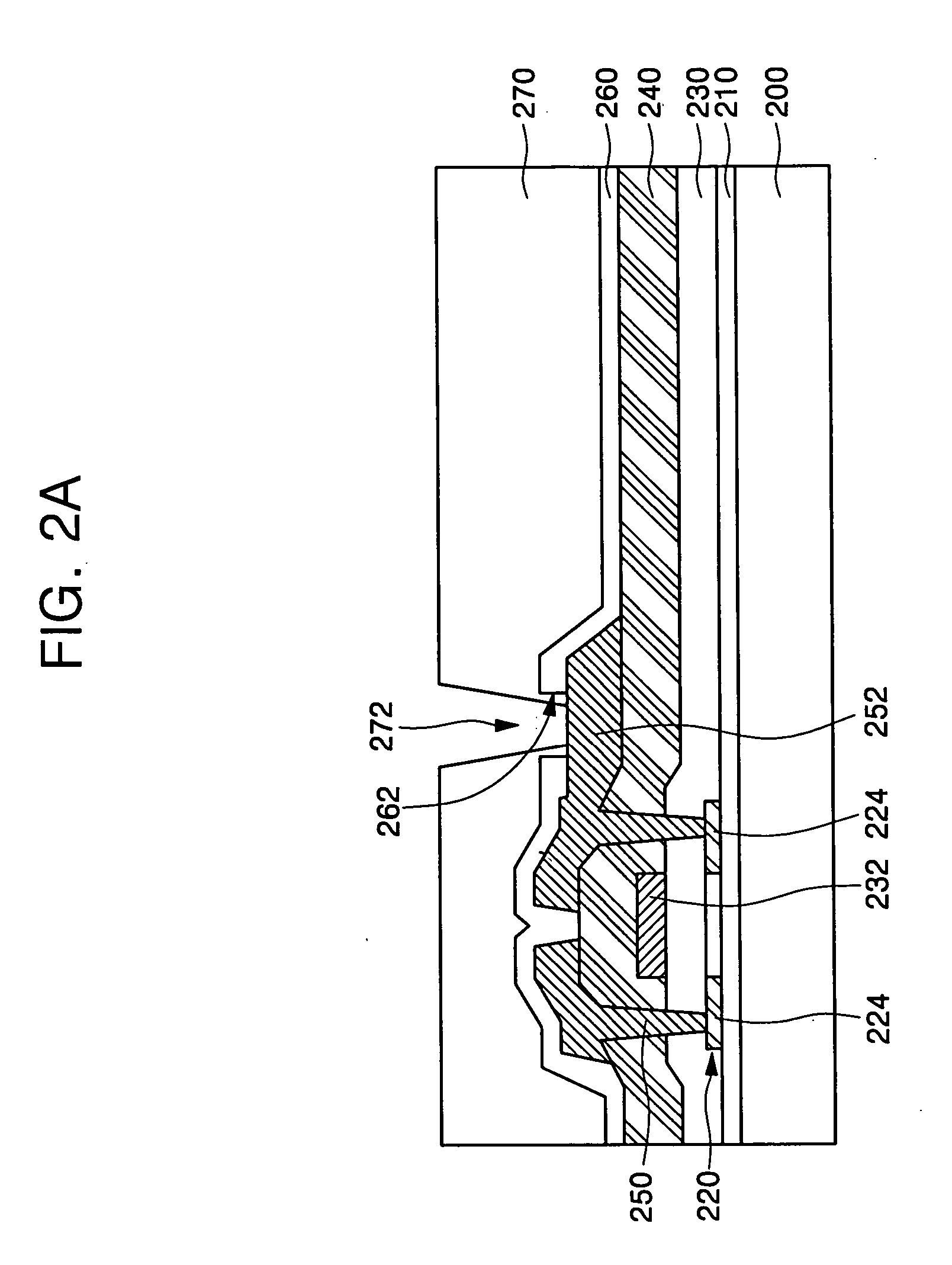

Organic light emitting display

ActiveUS7501756B2Light displayReduce step heightDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsDevice failure

An organic light emitting display which is constructed with a TFT substrate having an insulating substrate and a TFT that has at least a source electrode and a drain electrode, a lower electrode formed on the TFT substrate and connected to one of source / drain electrodes, an insulating layer having an opening that exposes a portion of the lower electrode, an organic thin film layer formed on the exposed portion of the lower electrode and the insulating layer, and an upper electrode formed on the organic thin film layer, wherein the insulating layer has a taper angle less than 40° at an edge of the opening, and a step less than or equal to 3,000 Å is formed between the lower electrode and the organic thin film layer. The organic light emitting display can prevent device failure.

Owner:SAMSUNG DISPLAY CO LTD

Organic light emitting display and method of fabricating the same

InactiveUS20060049753A1Easy to optimizeLight displayDischarge tube luminescnet screensElectroluminescent light sourcesThin layerReflective layer

An OLED and a method of fabricating the same are provided, in which, when a reflective layer pattern is formed, a thin layer for a pixel electrode is opened at an edge of an emission region to form the pixel electrode without additional photolithography and etching processes by forming an undercut under the edge of the reflective layer pattern, i.e., under the edge of the emission region by over-etching, thereby simplifying the process and increasing the yield.

Owner:SAMSUNG DISPLAY CO LTD

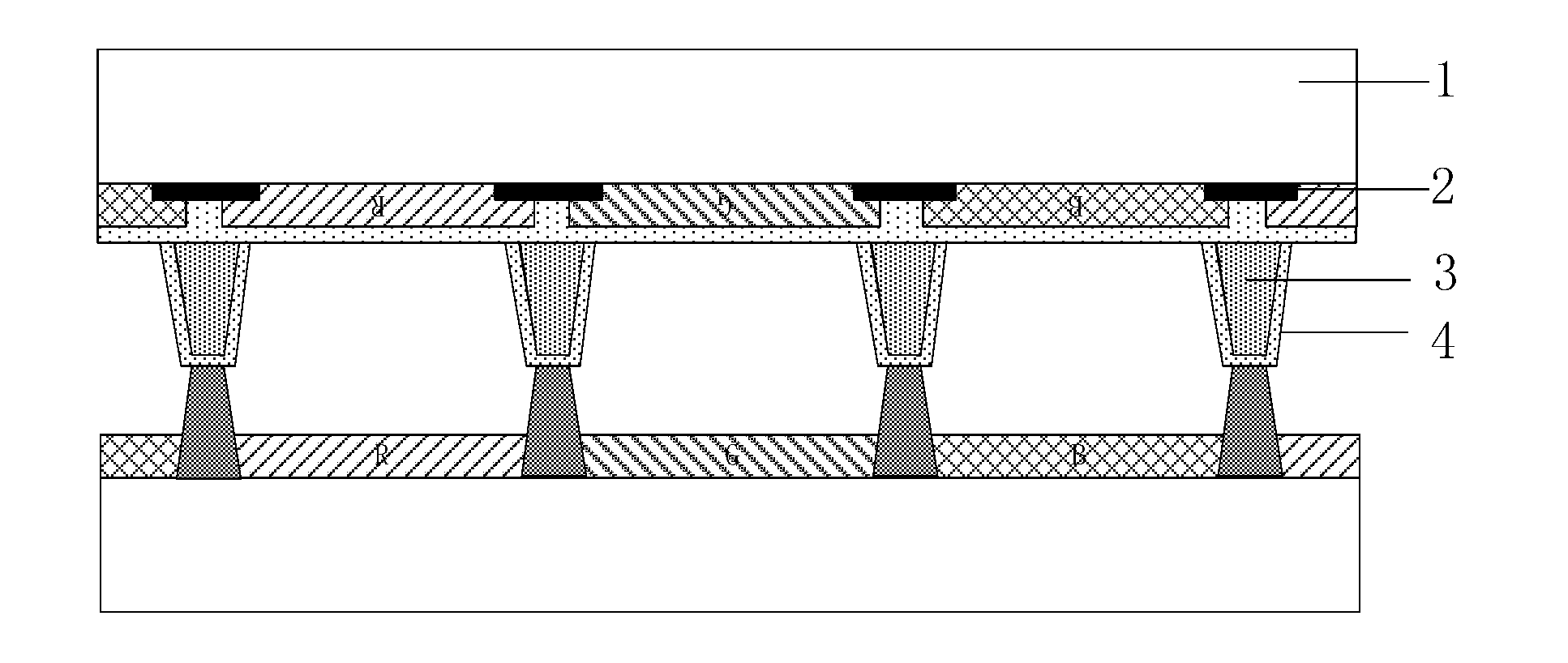

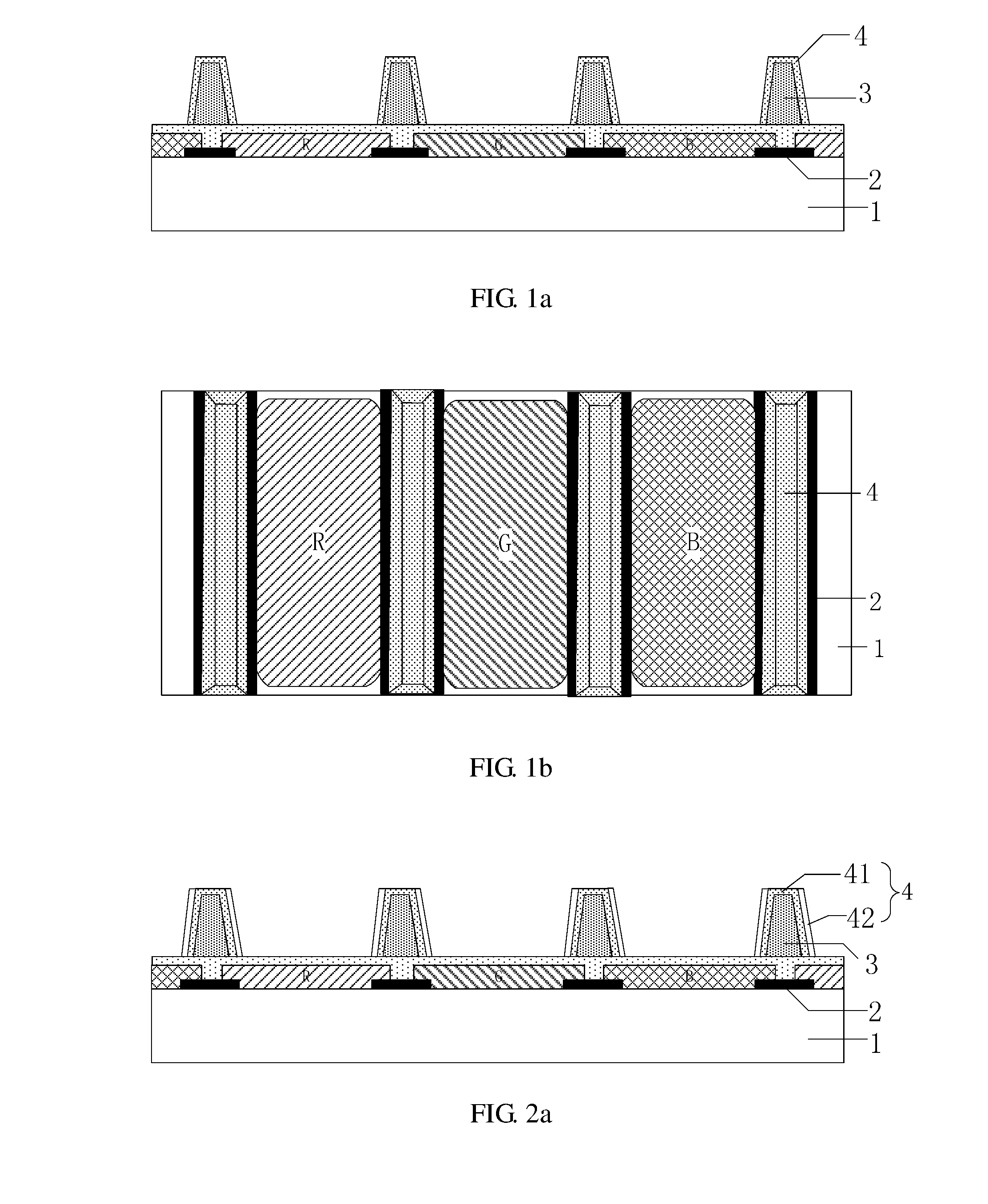

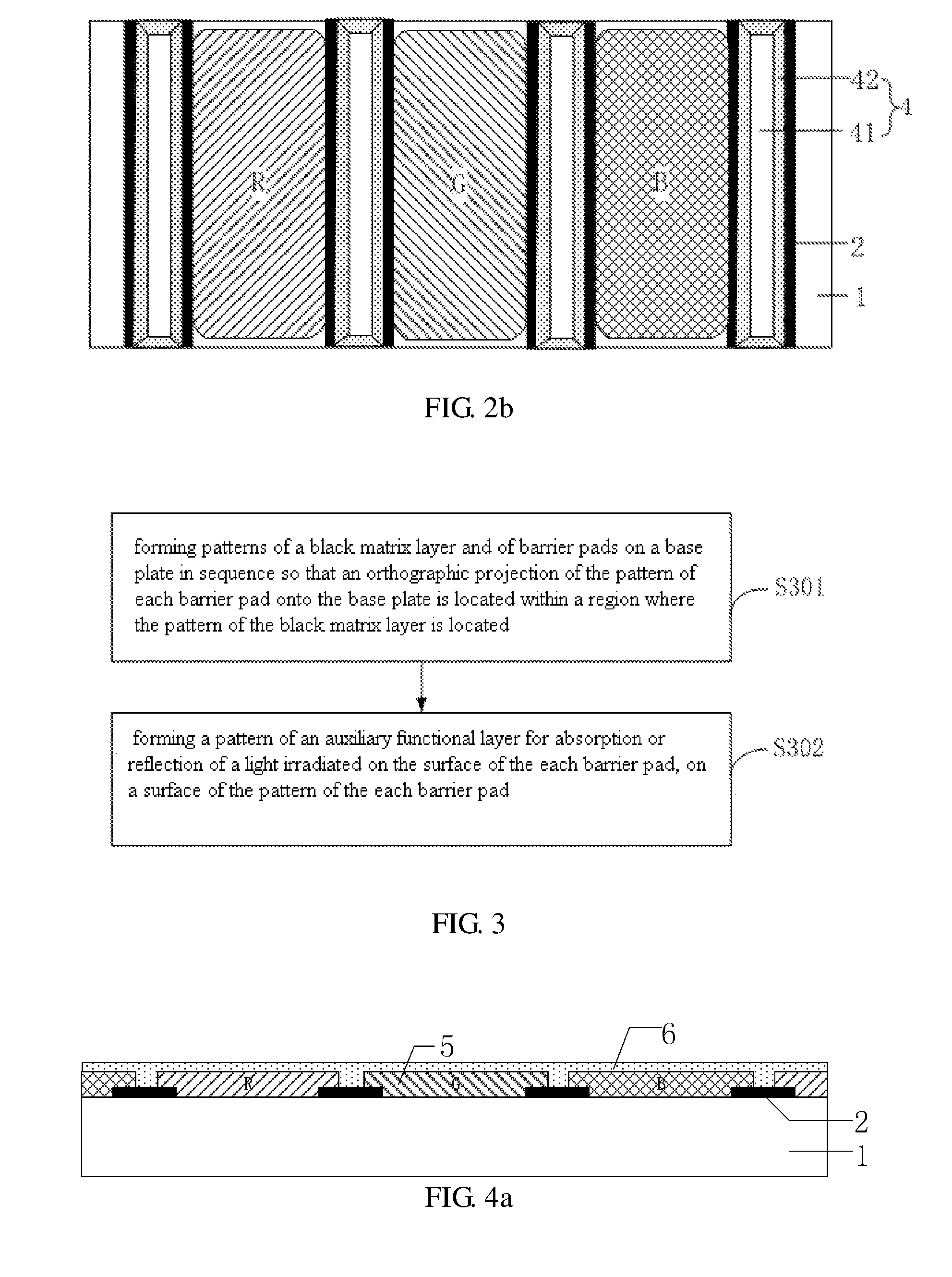

Color film substrate and method for manufacturing the same, OLED display panel and display apparatus

Embodiments of the present invention disclose a color filter substrate including: a base plate, and a black matrix layer and a barrier pad layer disposed stackedly in sequence on the base plate, the barrier pad layer including a plurality of barrier pads disposed on the same layer; wherein, an orthographic projection of a pattern of each barrier pad onto the base plate is located within a region where a pattern of the black matrix layer is located; and, a surface of each barrier pad is provided with an auxiliary functional layer for absorption or reflection of a light irradiated on the surface of each barrier pad. Correspondingly, embodiments of the present invention disclose a method for manufacturing a color filter substrate, an OLED display panel and a display apparatus.

Owner:BOE TECH GRP CO LTD

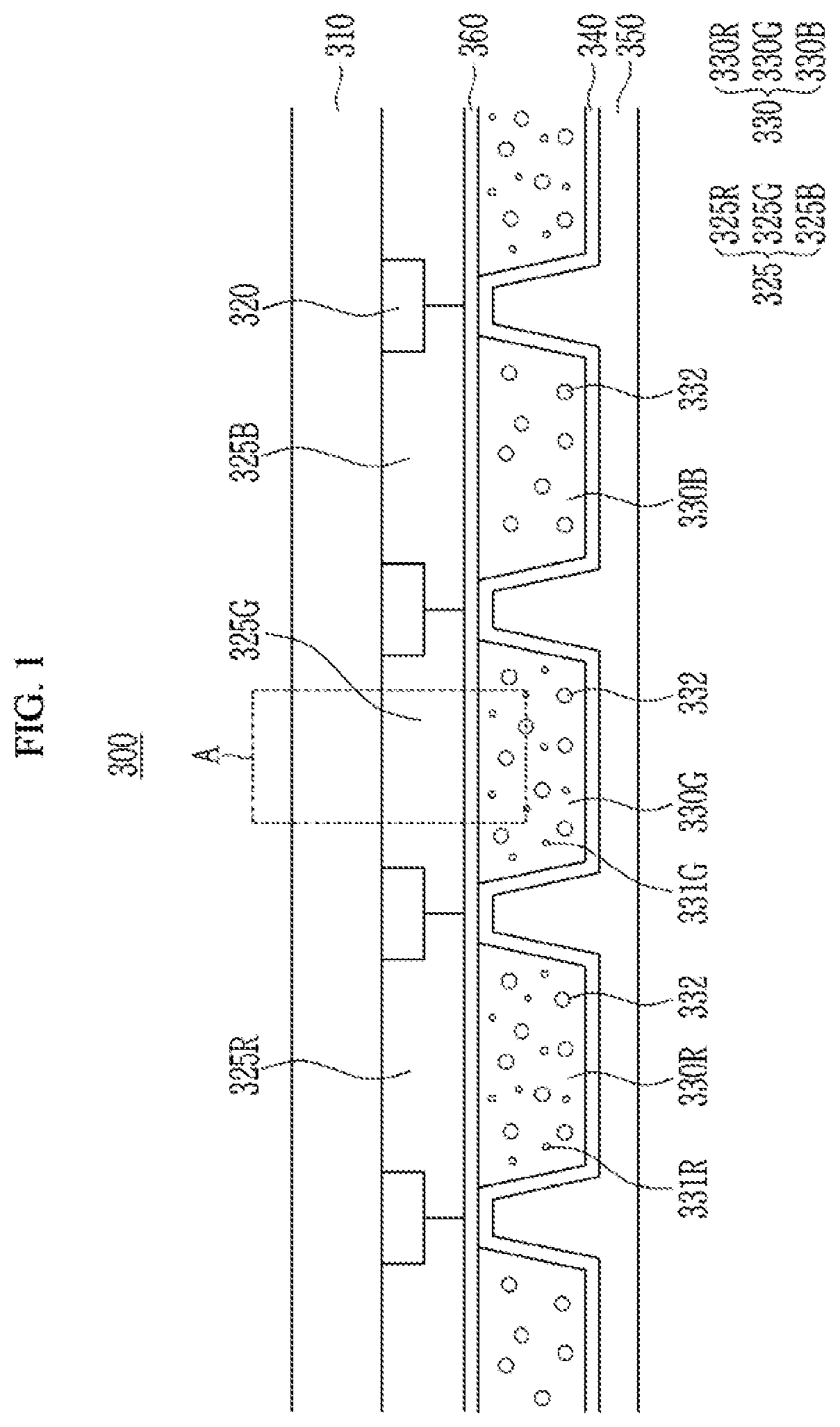

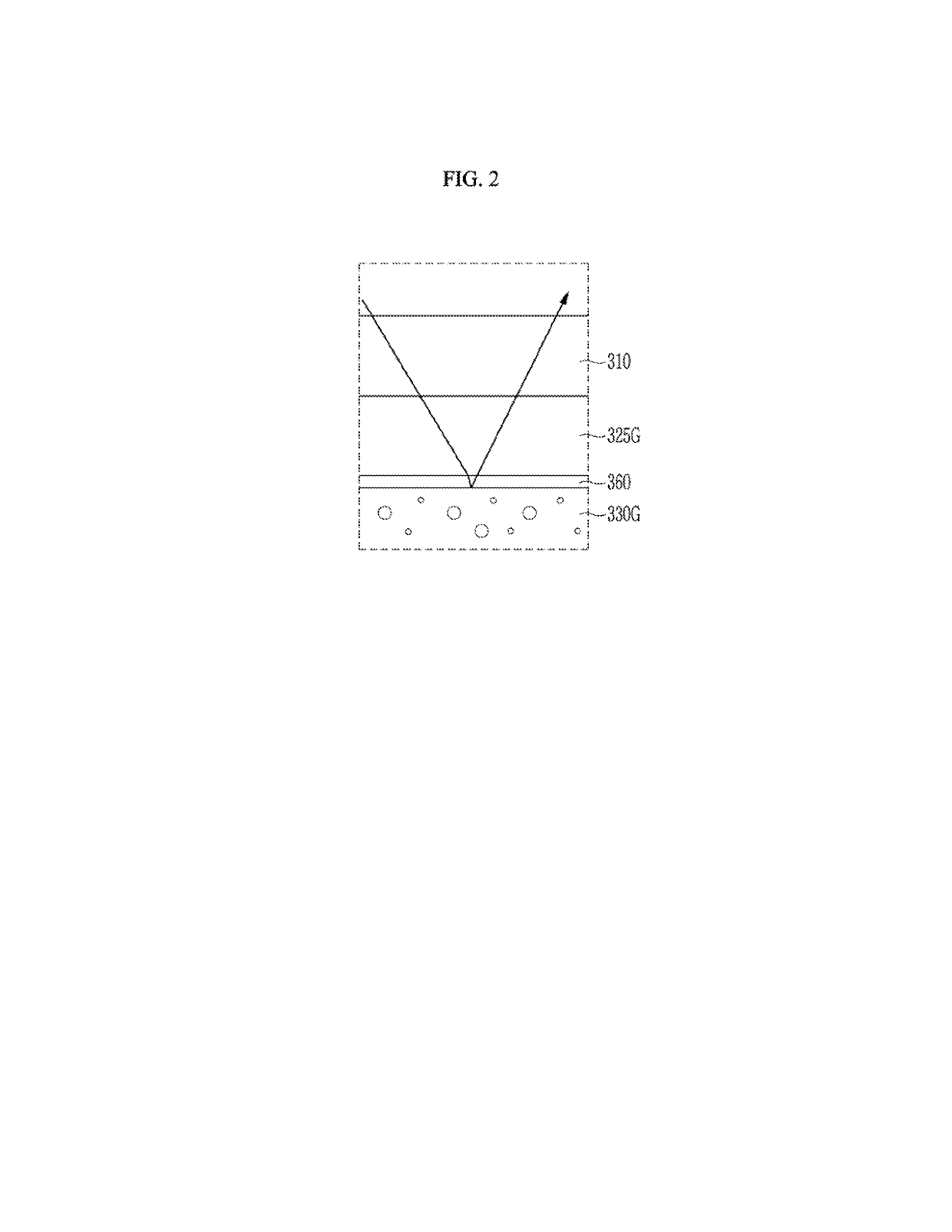

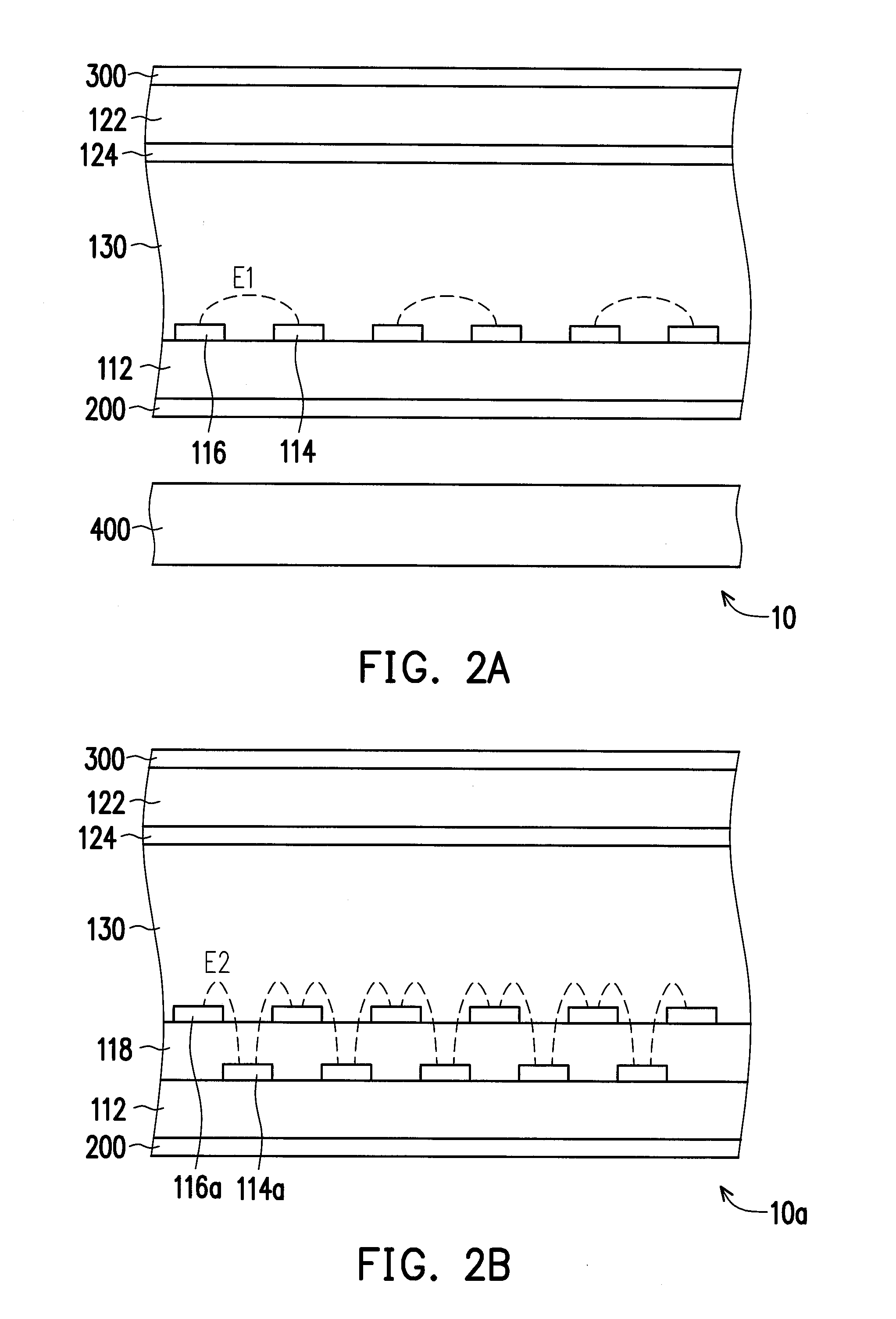

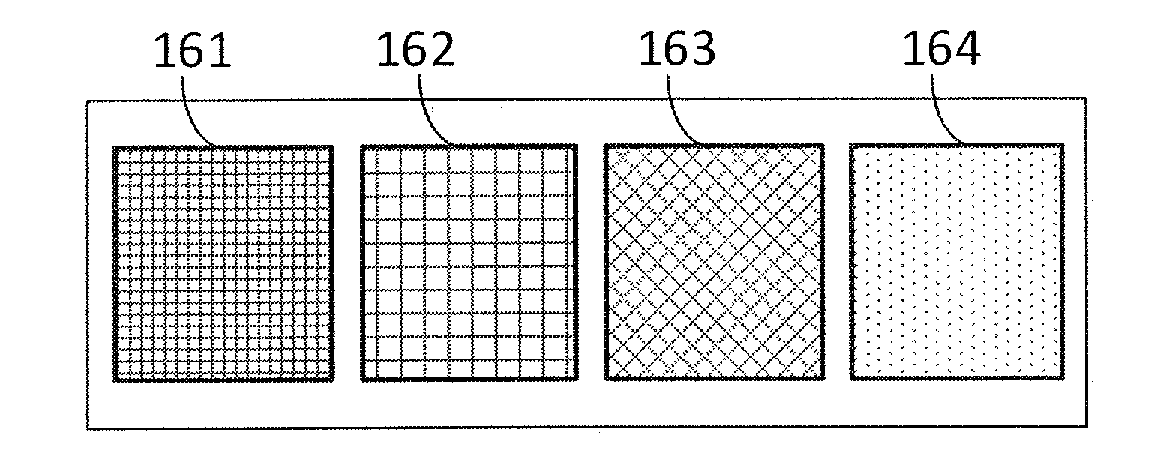

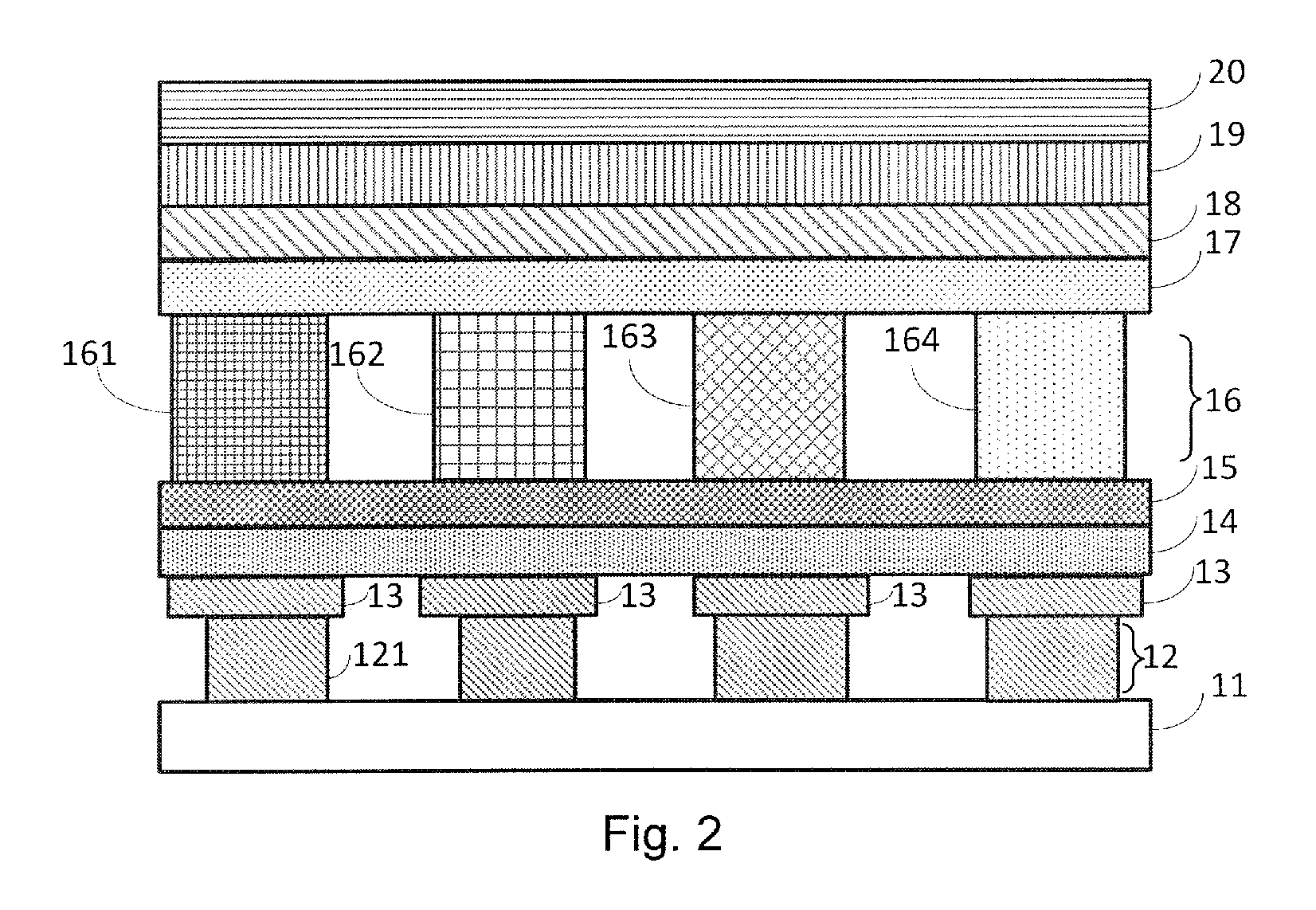

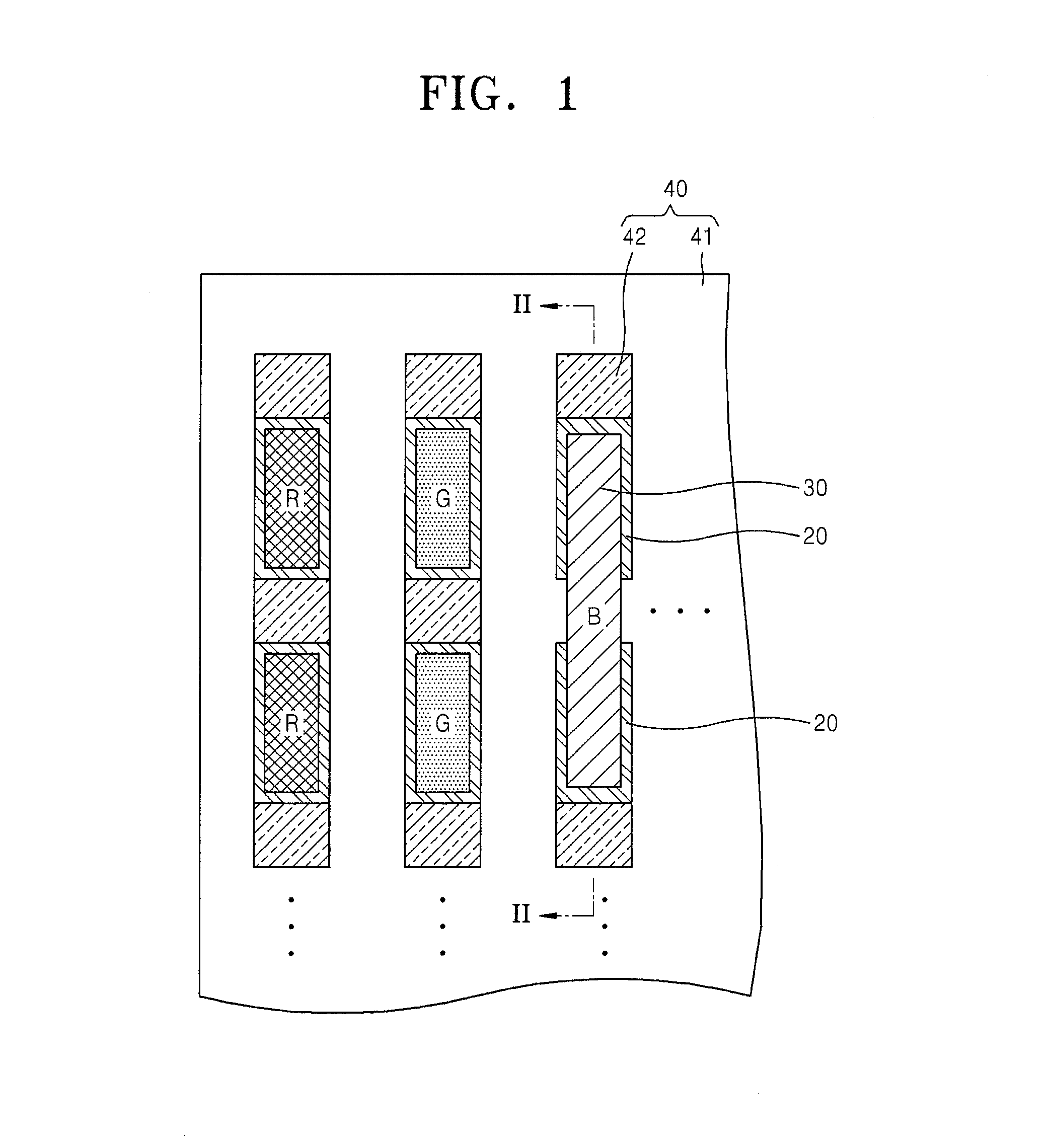

Organic light emitting diode display including color conversion panel

ActiveUS20190348470A1Improve efficiencyQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light emitting diode display includes: a display panel; and a color conversion panel positioned on the display panel. The color conversion panel includes: a substrate; a color filter layer disposed under the substrate; a first light blocking layer disposed under the color filter layer; and a first color conversion layer, a second color conversion layer, and a third color conversion layer positioned under the first light blocking layer. The color filter layer includes a first color filter, a second color filter, and a third color filter, the first light blocking layer includes a first portion that overlaps the first color filter, a second portion that overlaps the second color filter, and a third portion that overlaps the third color filter, and the first portion, the second portion, and the third portion are connected.

Owner:SAMSUNG DISPLAY CO LTD

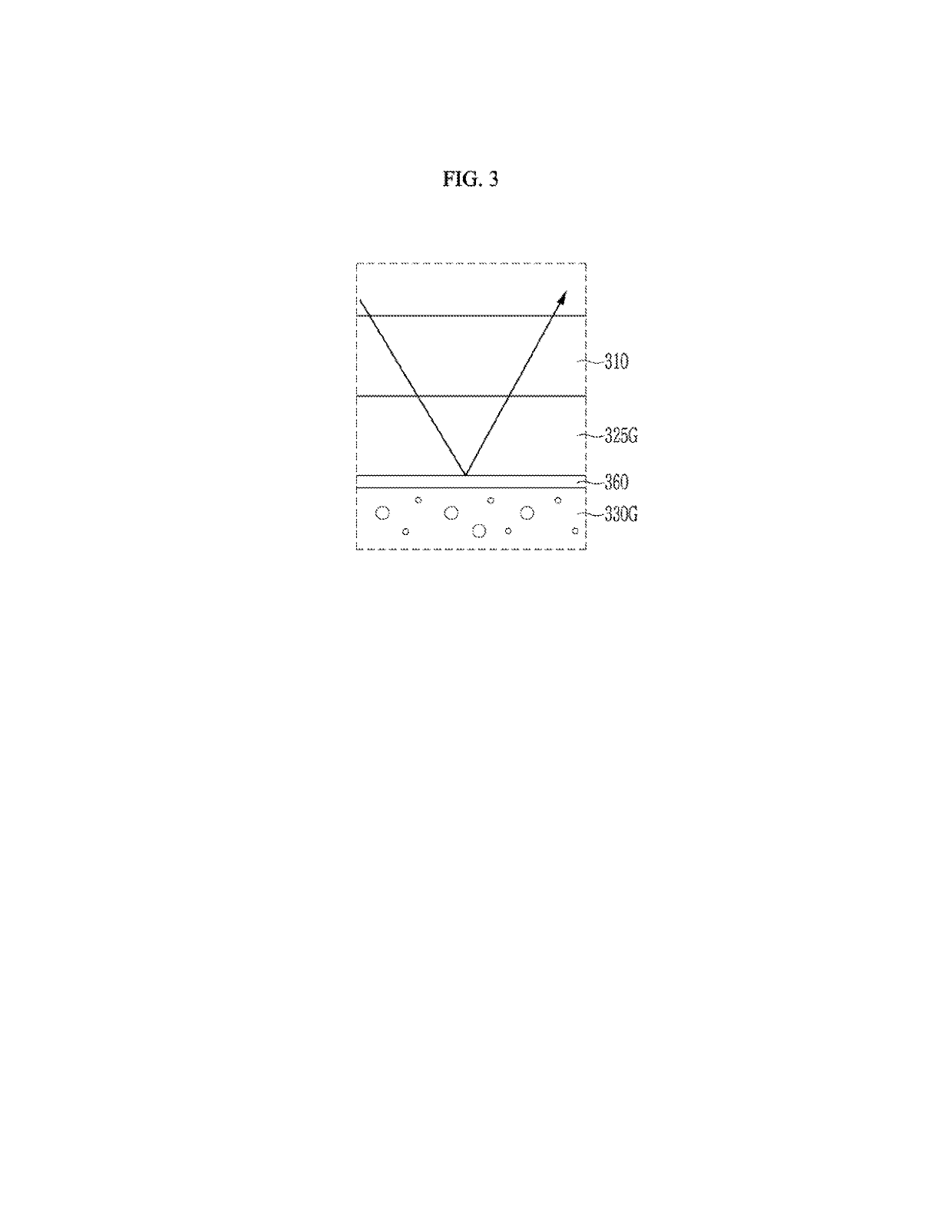

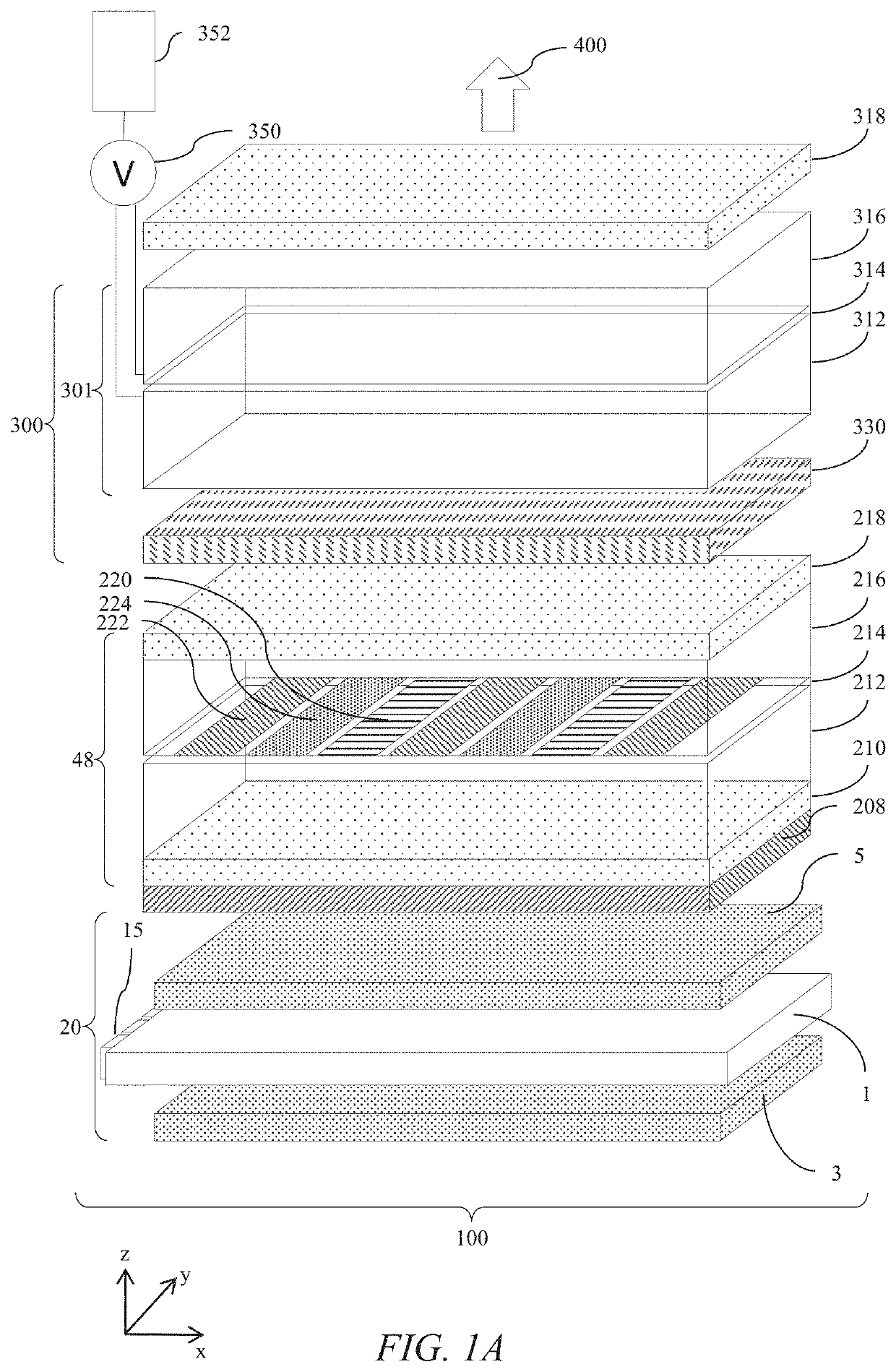

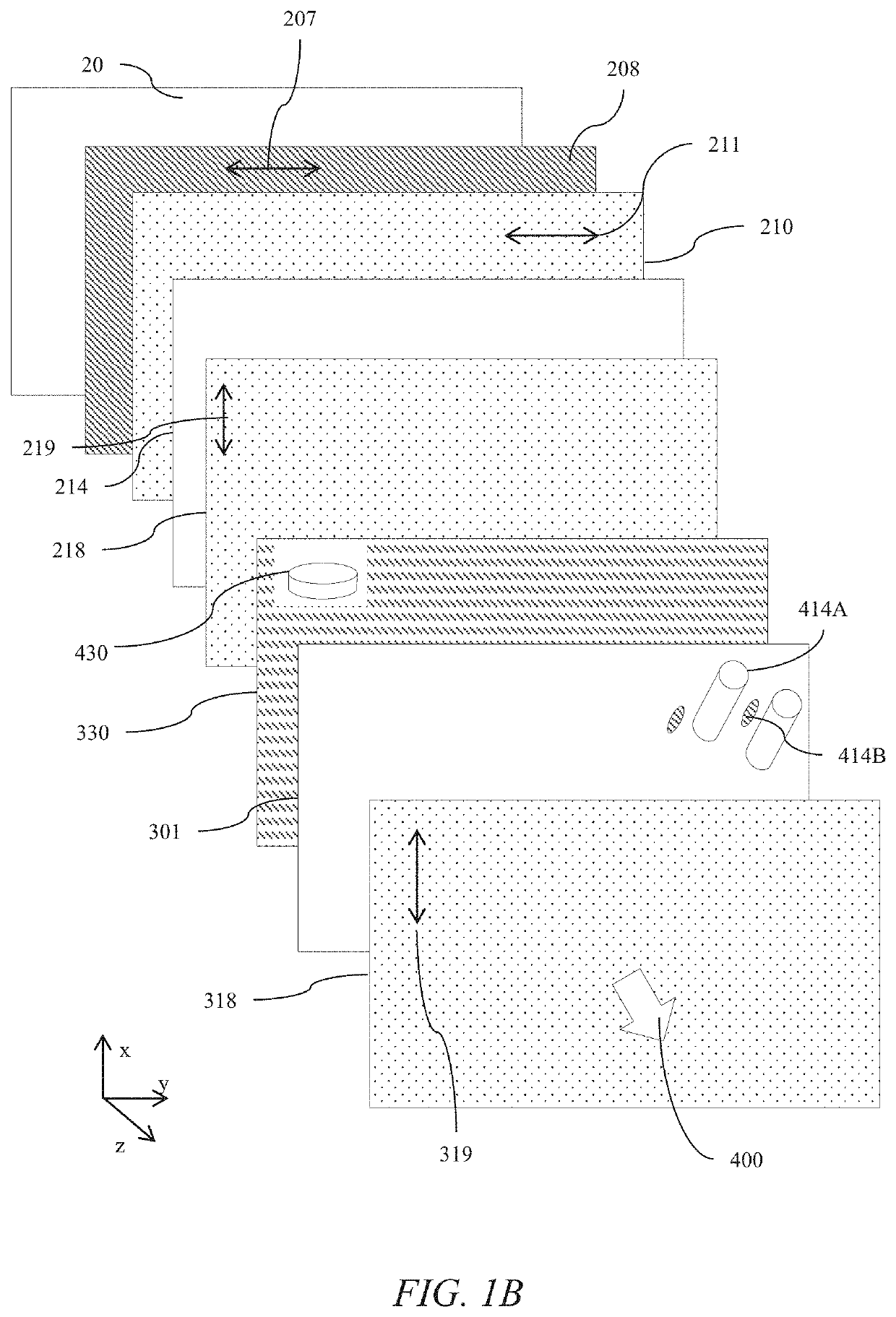

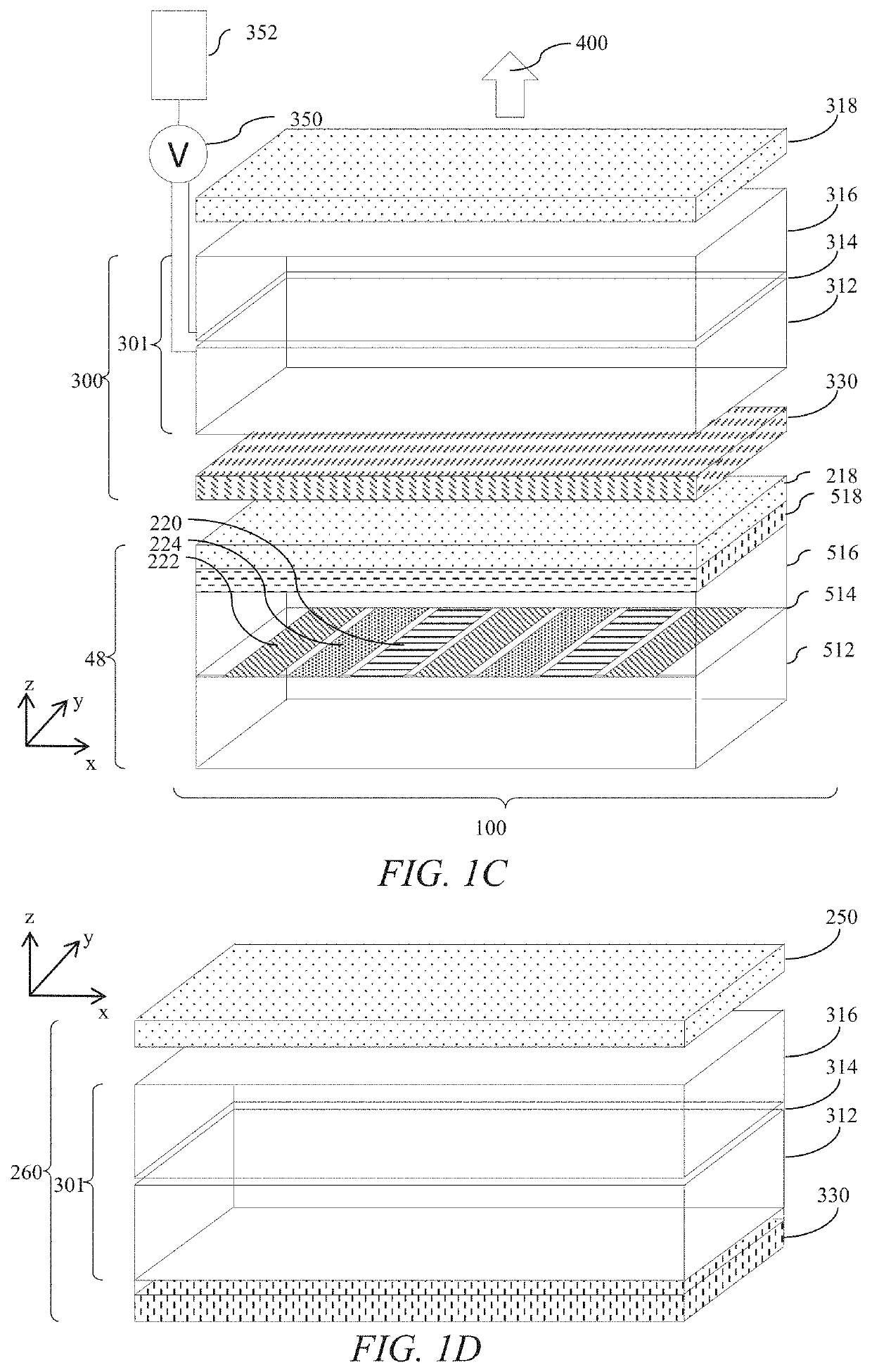

Optical stack for switchable directional display

ActiveUS20200026114A1Light displayDecrease in luminanceNon-linear opticsSpatial light modulatorDisplay device

A privacy display comprises a spatial light modulator and a compensated switchable guest-host liquid crystal retarder arranged between first and second polarisers arranged in series with the spatial light modulator. In a privacy mode of operation, on-axis light from the spatial light modulator is directed without loss, whereas off-axis light has reduced luminance. The visibility of the display to off-axis snoopers is reduced by means of luminance reduction over a wide polar field. In a wide angle mode of operation, the switchable liquid crystal retardance is adjusted so that off-axis luminance is substantially unmodified.

Owner:REALD SPARK LLC

Photoluminescent floor tile

InactiveUS6875989B2No additional labor costLight displayCovering/liningsSynthetic resin layered productsCeramic tilesEngineering

Owner:ND HLDG

Organic light emitting display and method of fabricating the same

InactiveUS7453198B2Light displayDischarge tube luminescnet screensElectroluminescent light sourcesThin layerReflective layer

Owner:SAMSUNG DISPLAY CO LTD

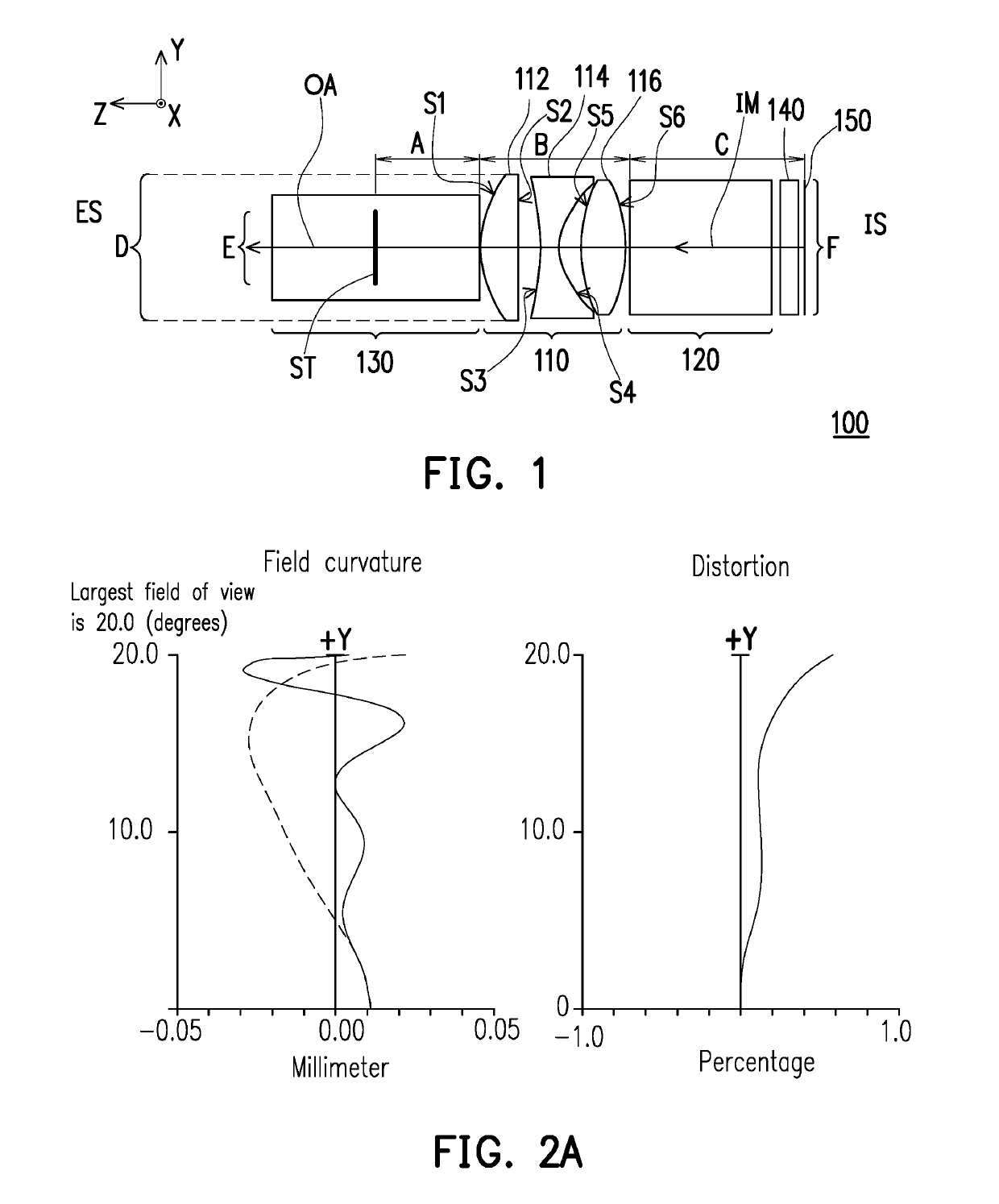

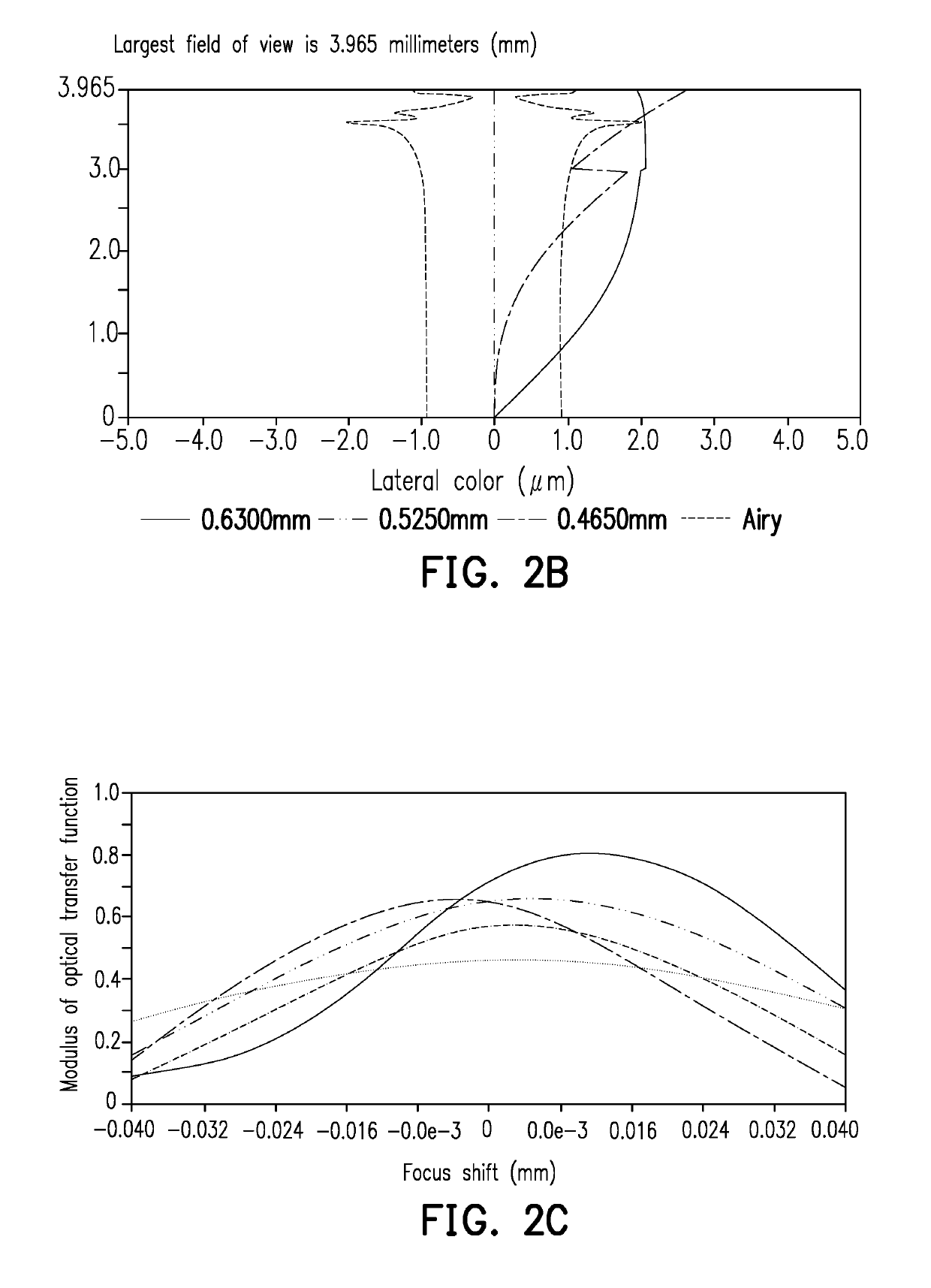

Display

InactiveUS20190187353A1Small sizeLight weightMechanical apparatusPlanar/plate-like light guidesDisplay deviceLight beam

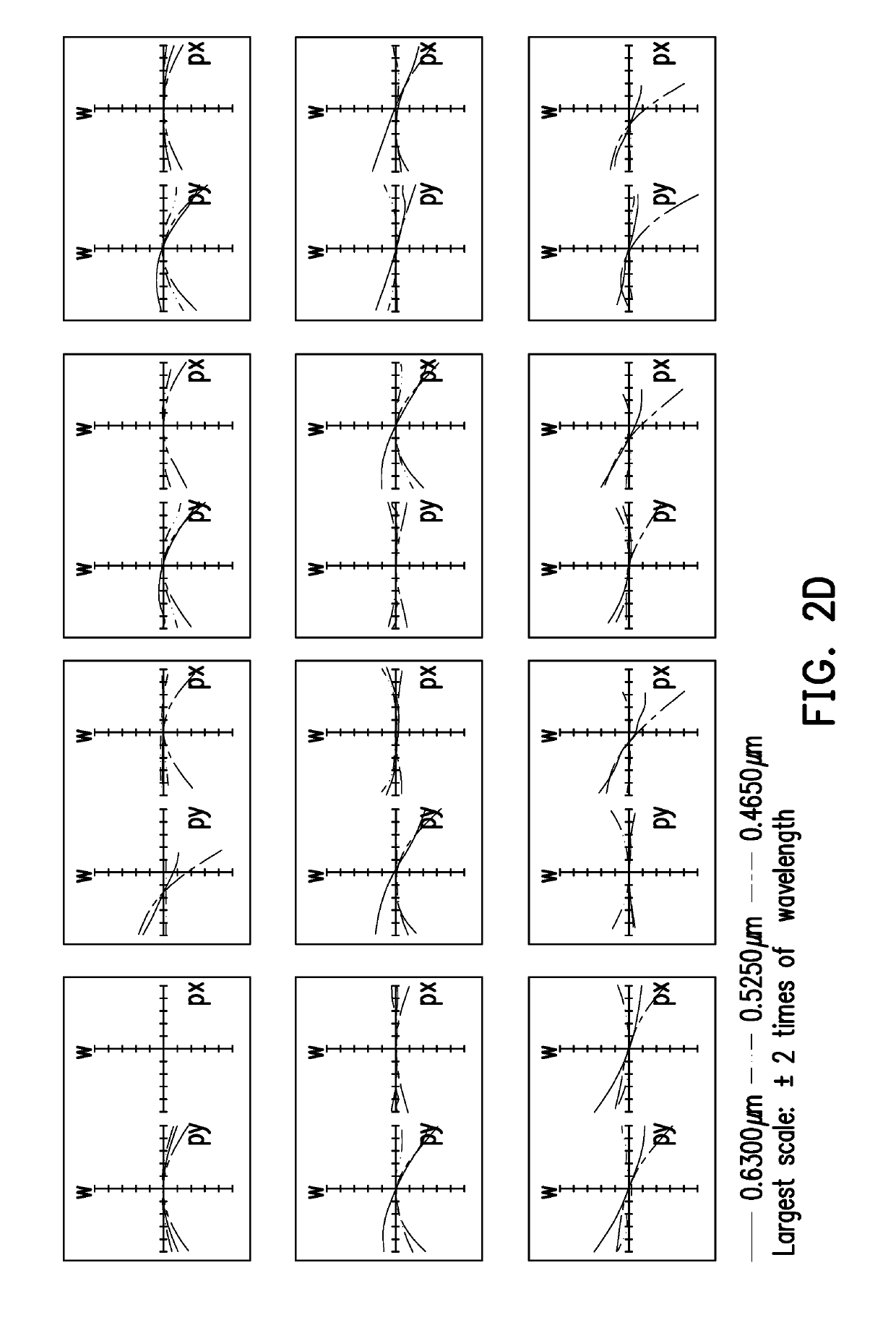

A display including an optical lens and a light valve is provided. The optical lens includes a first lens, a second lens, and a third lens arranged in sequence from a light emitting side to a light incident side. The light valve is disposed at the light incident side. The light valve provides an image beam. The optical lens is configured to receive the image beam. The image beam forms a stop at the light emitting side. The stop has the smallest cross-sectional area of a beam shrinkage of the image beam. A range of an OPD of the image beam on an active surface of the light valve is −2.0λ<OPD<2.0λ, wherein the OPD is an optical path difference at each field of view, and λ is a wavelength of each color light. The display of the invention has the advantages of small size, light weight, large viewing angle, and high resolution.

Owner:CORETRONIC

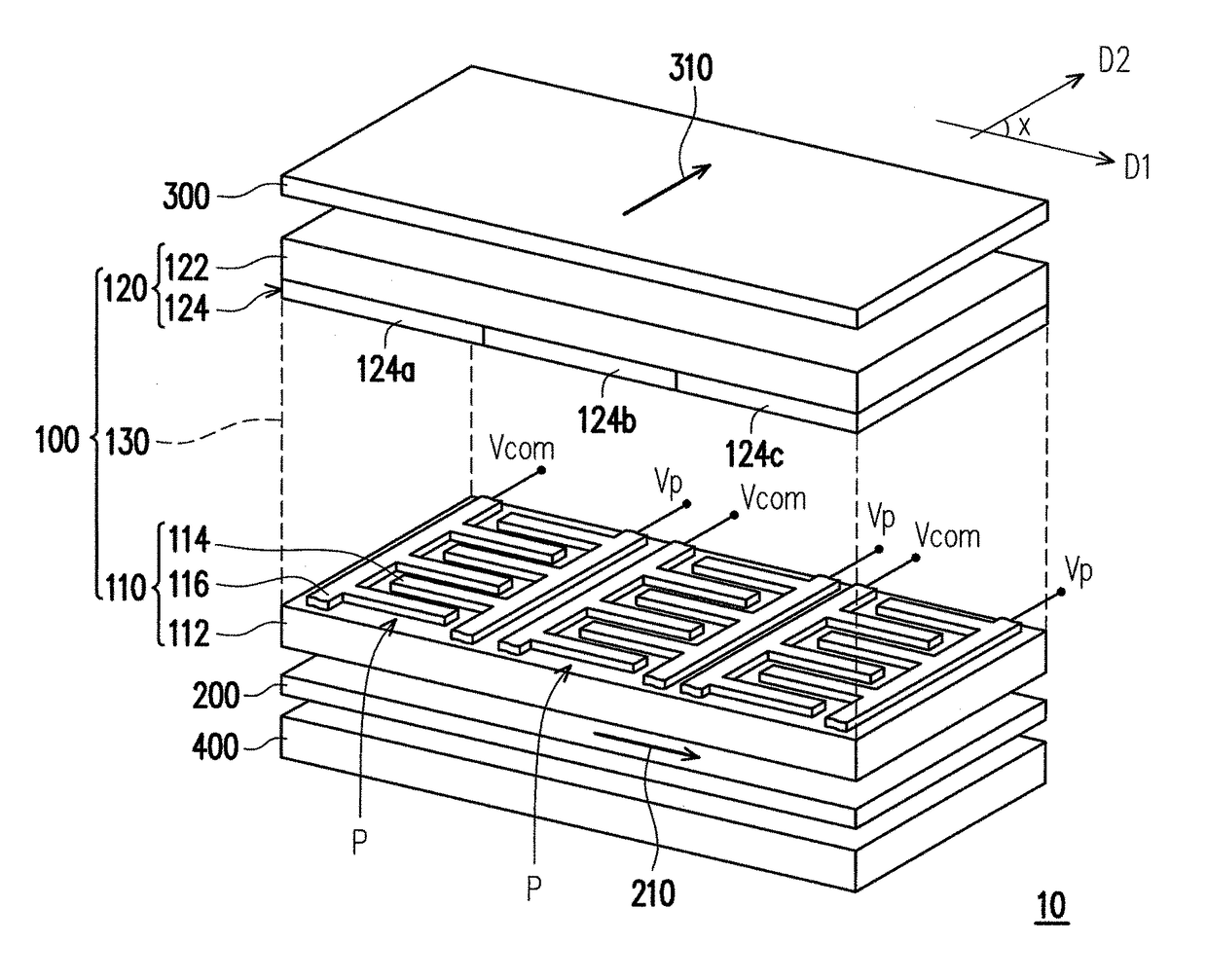

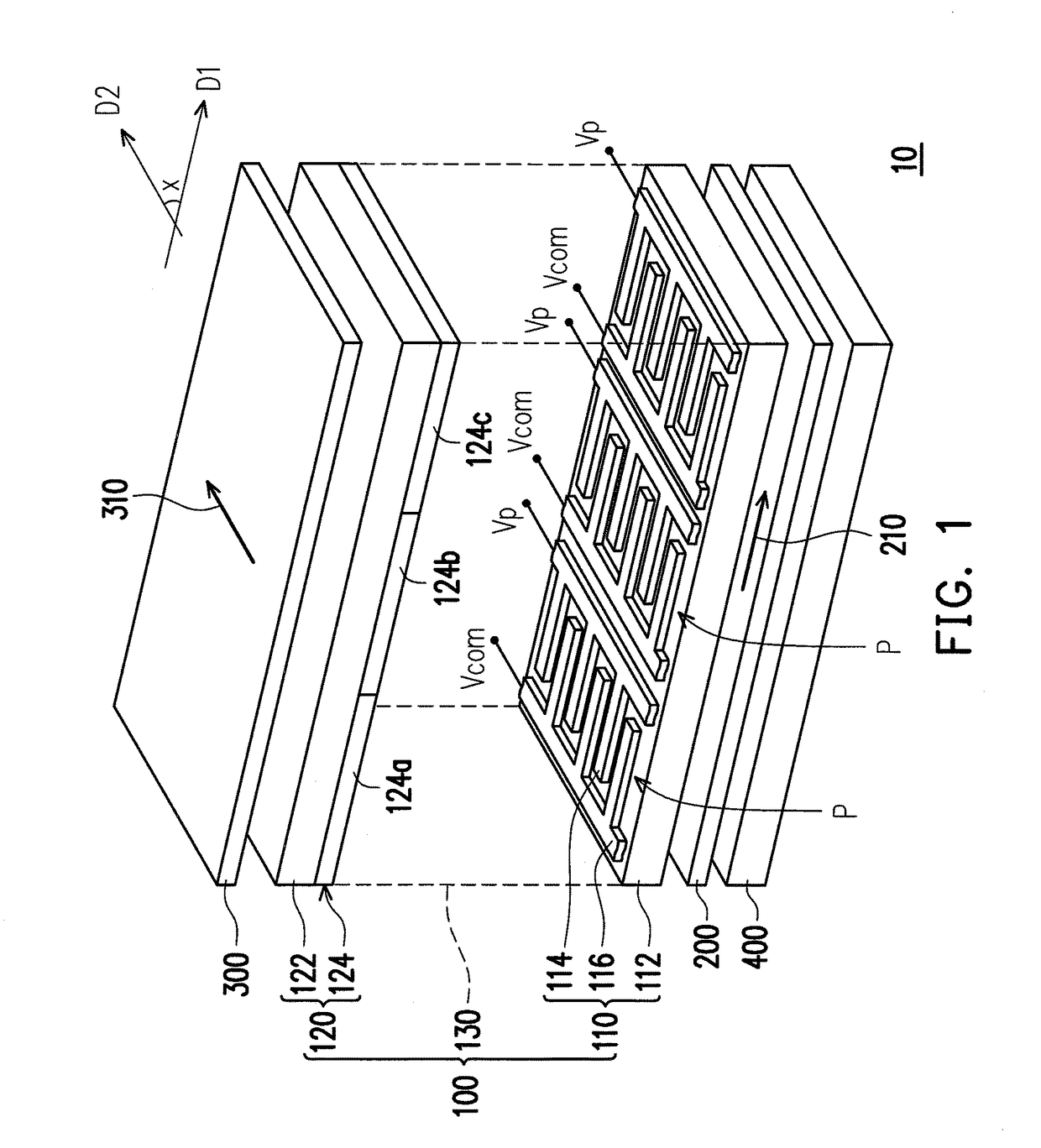

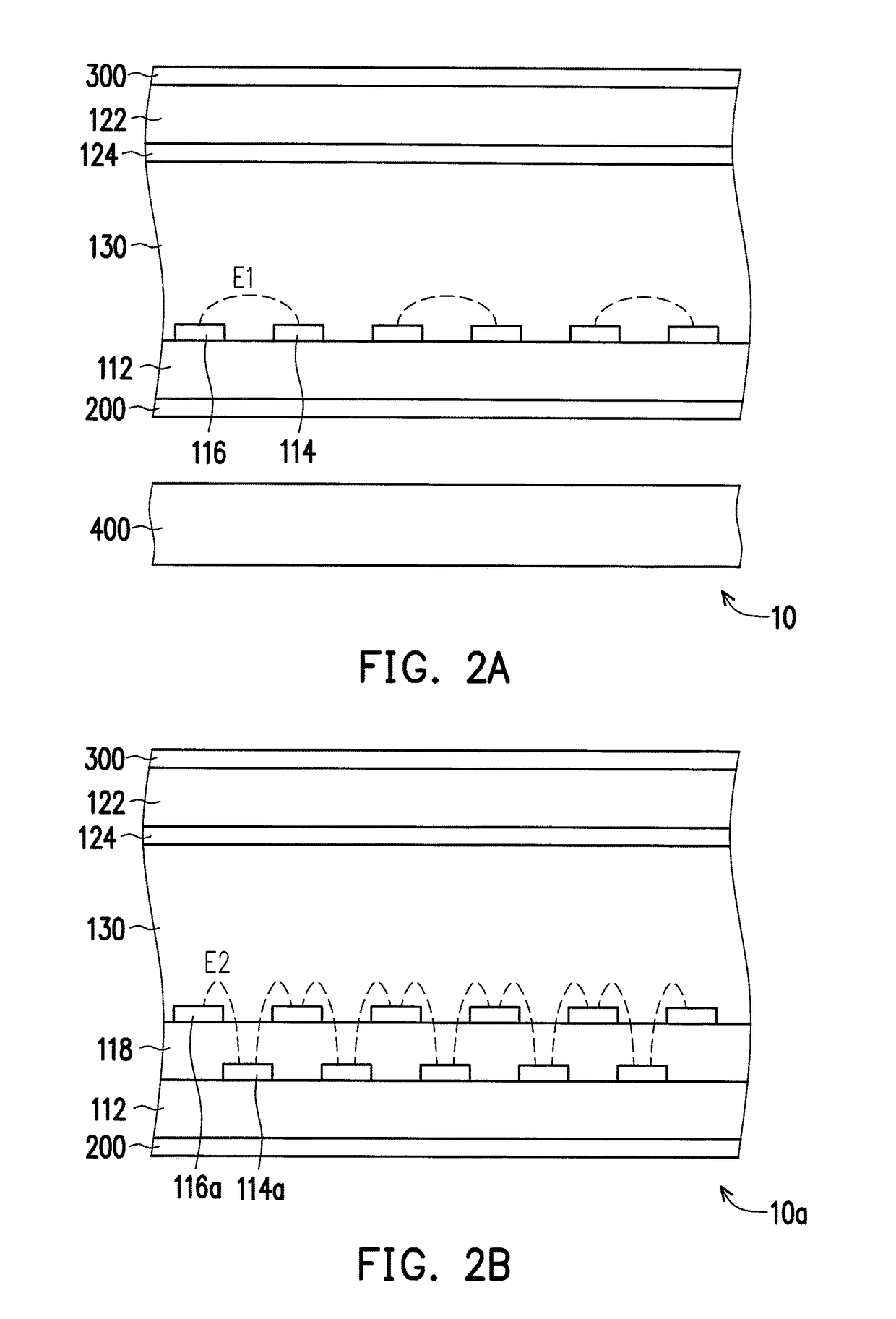

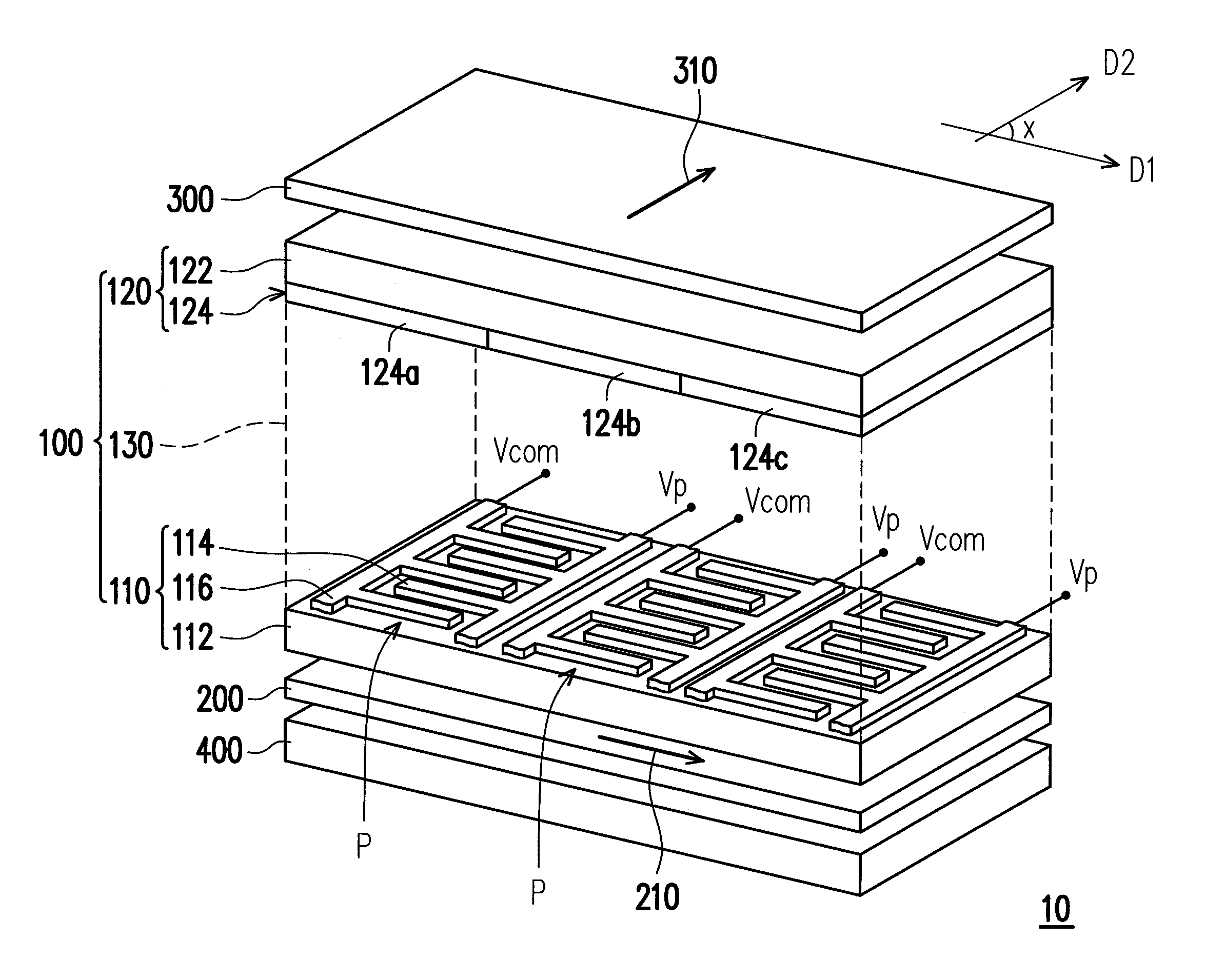

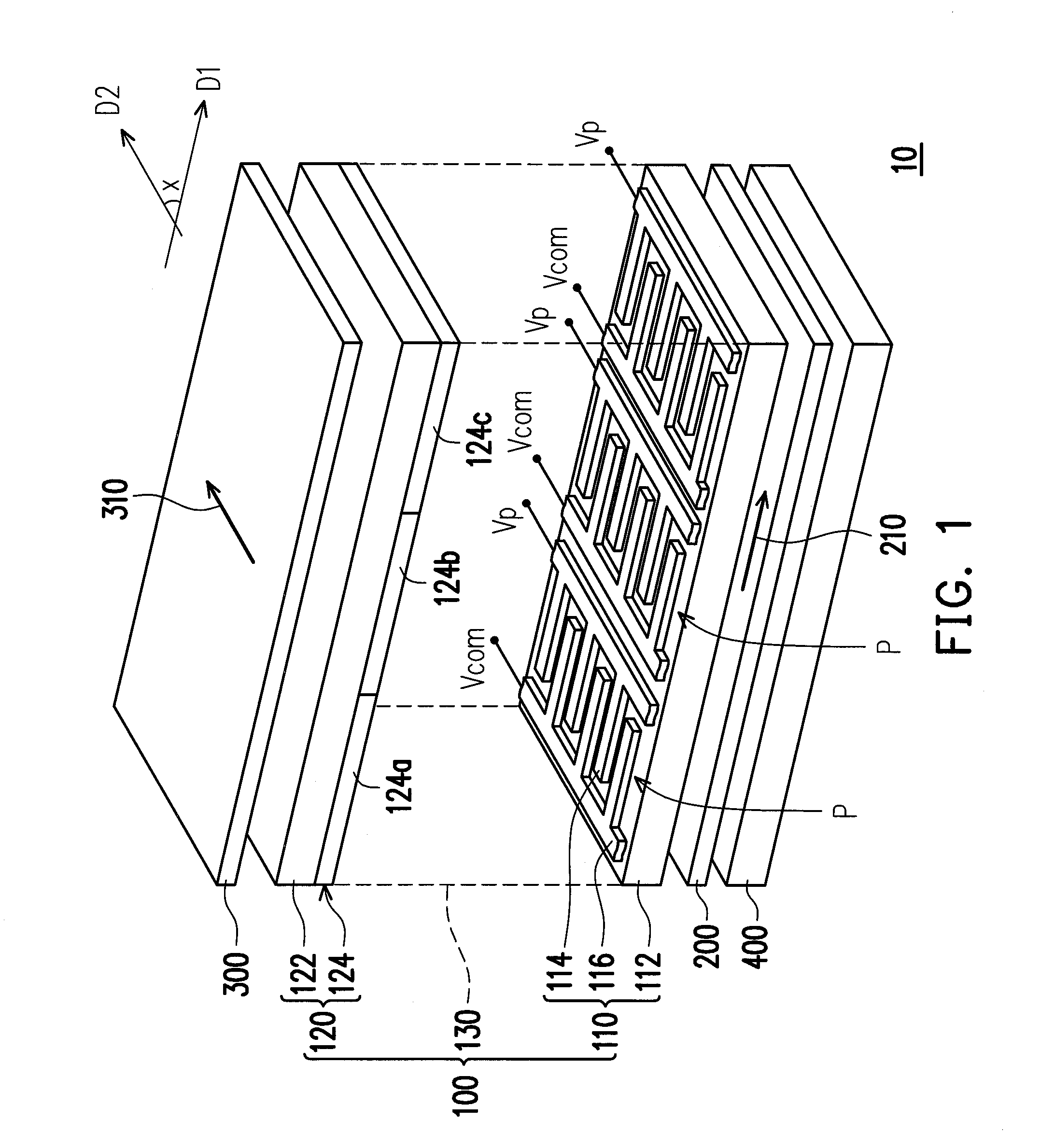

Display apparatus

InactiveUS9664945B2Reduce light leakageImprove display qualityNon-linear opticsOptical axisPolarizer

A display apparatus including a display panel, a first polarizer and a second polarizer is provided. The display panel includes a pixel array substrate, an opposite substrate and a display medium. The pixel array substrate includes a plurality of pixel units. Each pixel unit includes a first electrode and a second electrode. The first electrode and the second electrode are alternately arranged and a lateral electric field is existed between the first electrode and the second electrode. The opposite substrate is disposed opposite to the pixel array substrate. The display medium is disposed between the pixel array substrate and the opposite substrate. The first polarizer is disposed on the pixel array substrate. The second polarizer is disposed on the opposite substrate. An included angle between an optical axis of the first polarizer and an optical axis of the second polarizer is 90°±θ, and θ is 1° to 9°.

Owner:AU OPTRONICS CORP +1

Display apparatus

InactiveUS20140300847A1Reduce light leakageImprove display qualityNon-linear opticsOptical axisPolarizer

A display apparatus including a display panel, a first polarizer and a second polarizer is provided. The display panel includes a pixel array substrate, an opposite substrate and a display medium. The pixel array substrate includes a plurality of pixel units. Each pixel unit includes a first electrode and a second electrode. The first electrode and the second electrode are alternately arranged and a lateral electric field is existed between the first electrode and the second electrode. The opposite substrate is disposed opposite to the pixel array substrate. The display medium is disposed between the pixel array substrate and the opposite substrate. The first polarizer is disposed on the pixel array substrate. The second polarizer is disposed on the opposite substrate. An included angle between an optical axis of the first polarizer and an optical axis of the second polarizer is 90°±θ, and θ is 1° to 9°.

Owner:AU OPTRONICS CORP +1

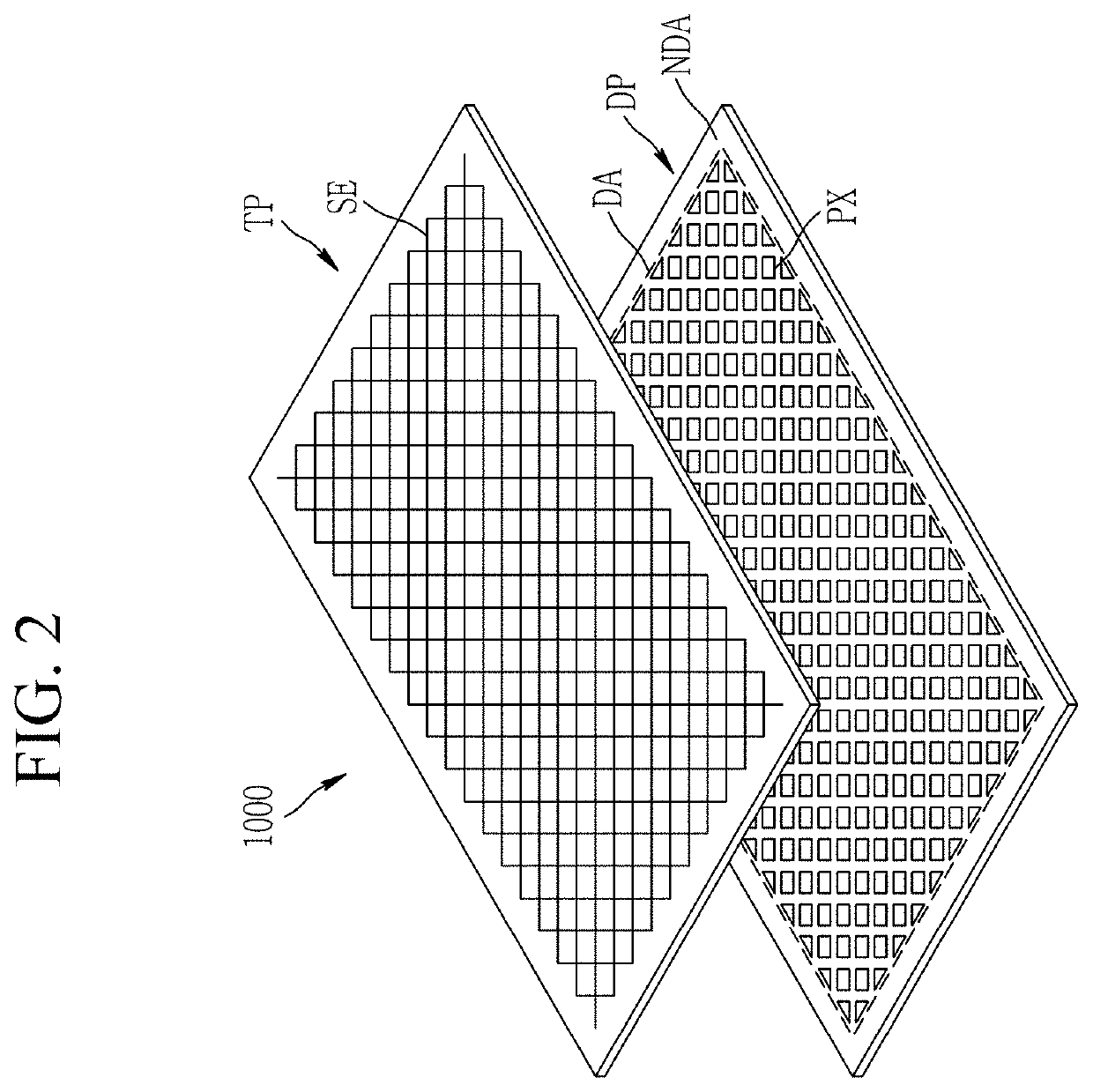

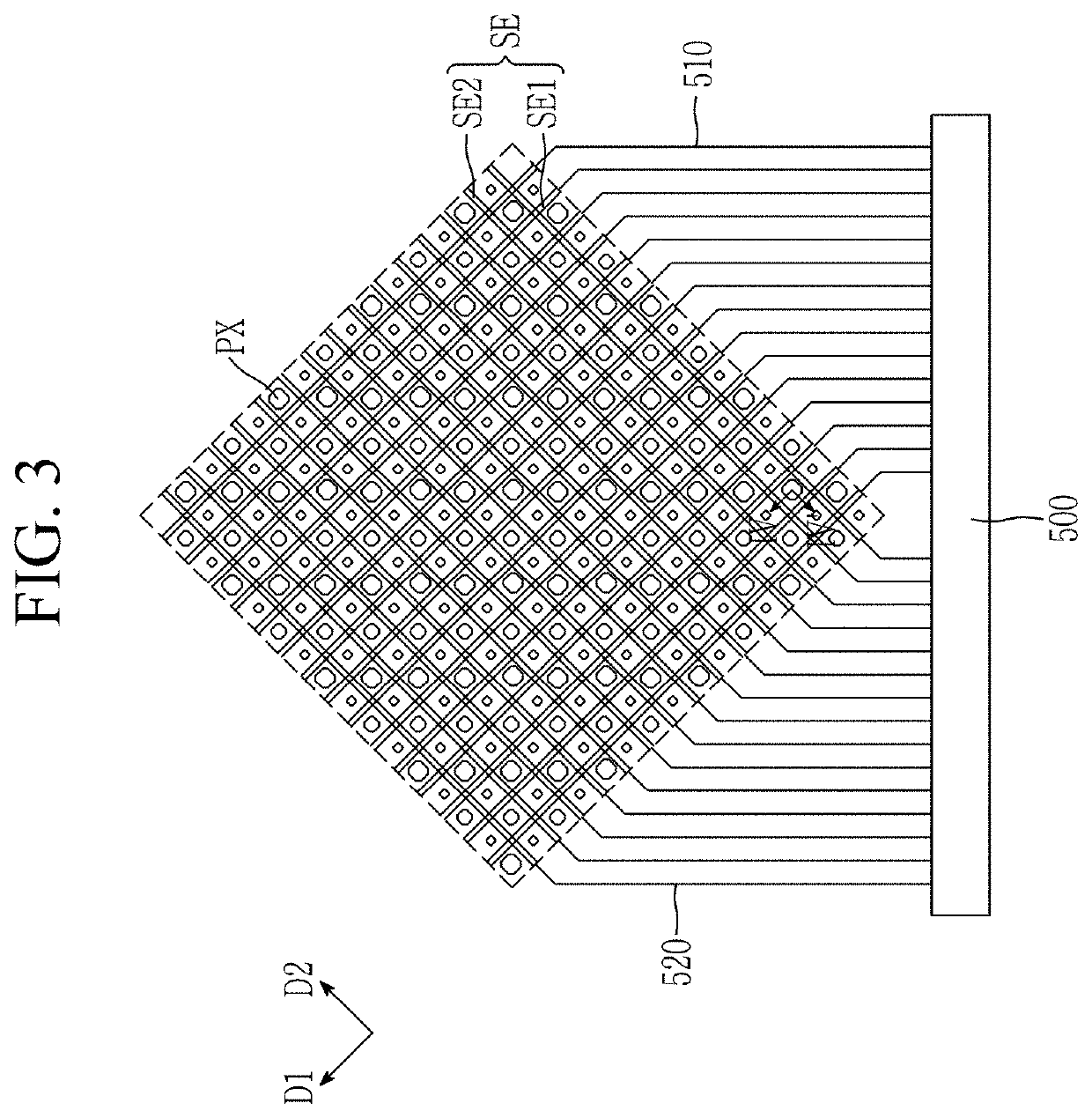

Display device

ActiveUS20210264823A1Light emission efficiency can be preventedLight displayStatic indicating devicesSolid-state devicesDisplay deviceEngineering

A display device including a substrate; a first electrode on the substrate; a partitioning wall on the first electrode that includes a first opening that overlaps the first electrode; a touch detection electrode on the partitioning wall; a low refractive layer on the partitioning wall and the touch detection electrode, the low refractive layer including a second opening that overlaps the first opening; and a high refractive layer on the low refractive layer. Planar shapes of the first opening and the second opening are polygons, each including a series of sides, and a distance between one side of the first opening and the second opening is different than another side of the first opening and the second opening in a plan view.

Owner:SAMSUNG DISPLAY CO LTD

Quantum dot light emitting diodes display

InactiveUS20160351843A1Tired easilyLight displaySolid-state devicesSemiconductor/solid-state device manufacturingLED displayHole injection layer

A quantum dot light emitting diodes display is provided. The quantum dot light emitting diodes display comprises a first electrode, a hole injection layer, a hole transmission layer, a quantum dot light emitting layer, an electron transporting layer, and a second electrode. The quantum dot light emitting layer comprises a plurality of pixel units including red sub-pixels, green sub-pixels, and blue sub-pixels. At least one color of the sub-pixels of the pixel units is formed by mixing at least two quantum dots with different peak emission wavelengths corresponding to different colors.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

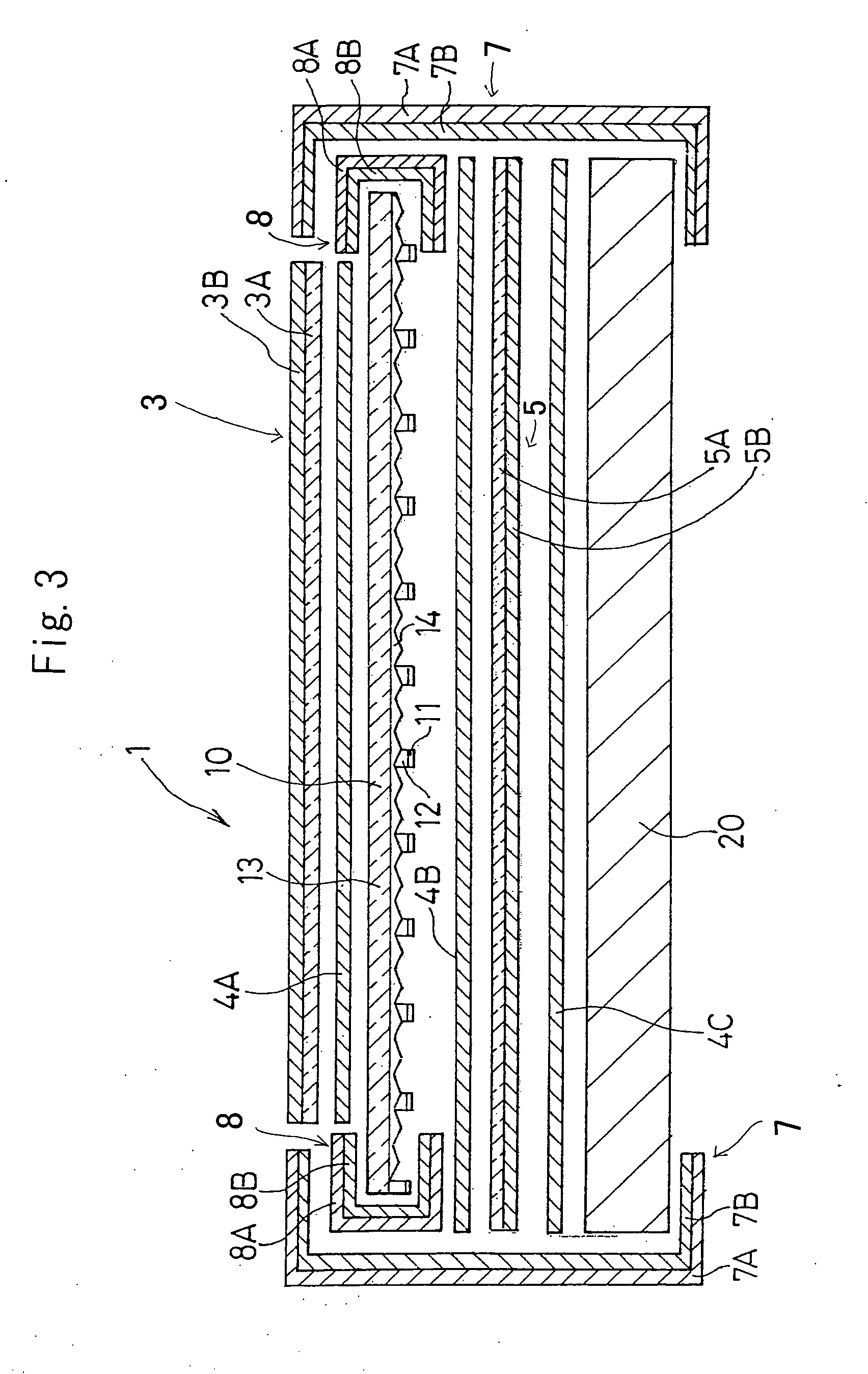

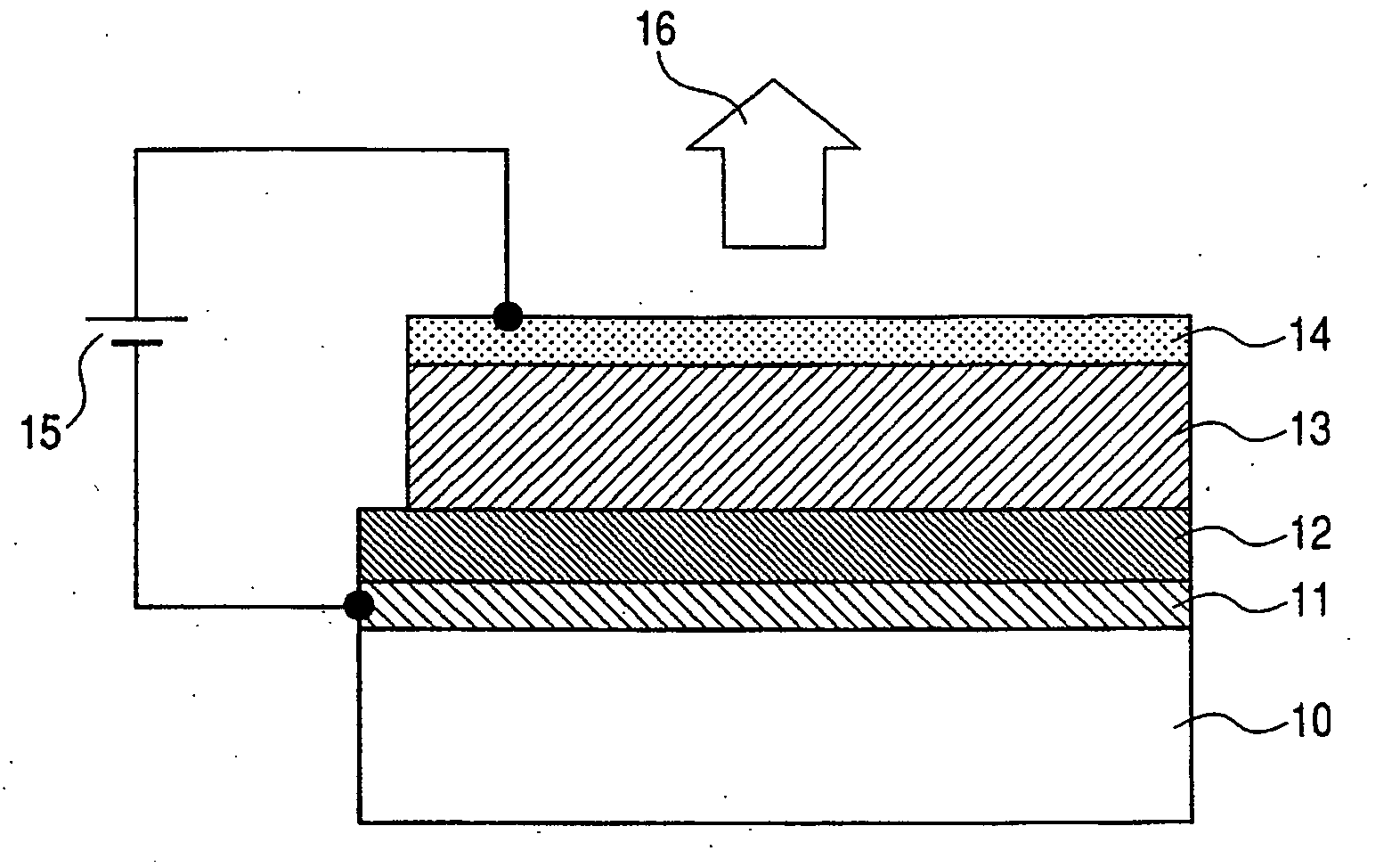

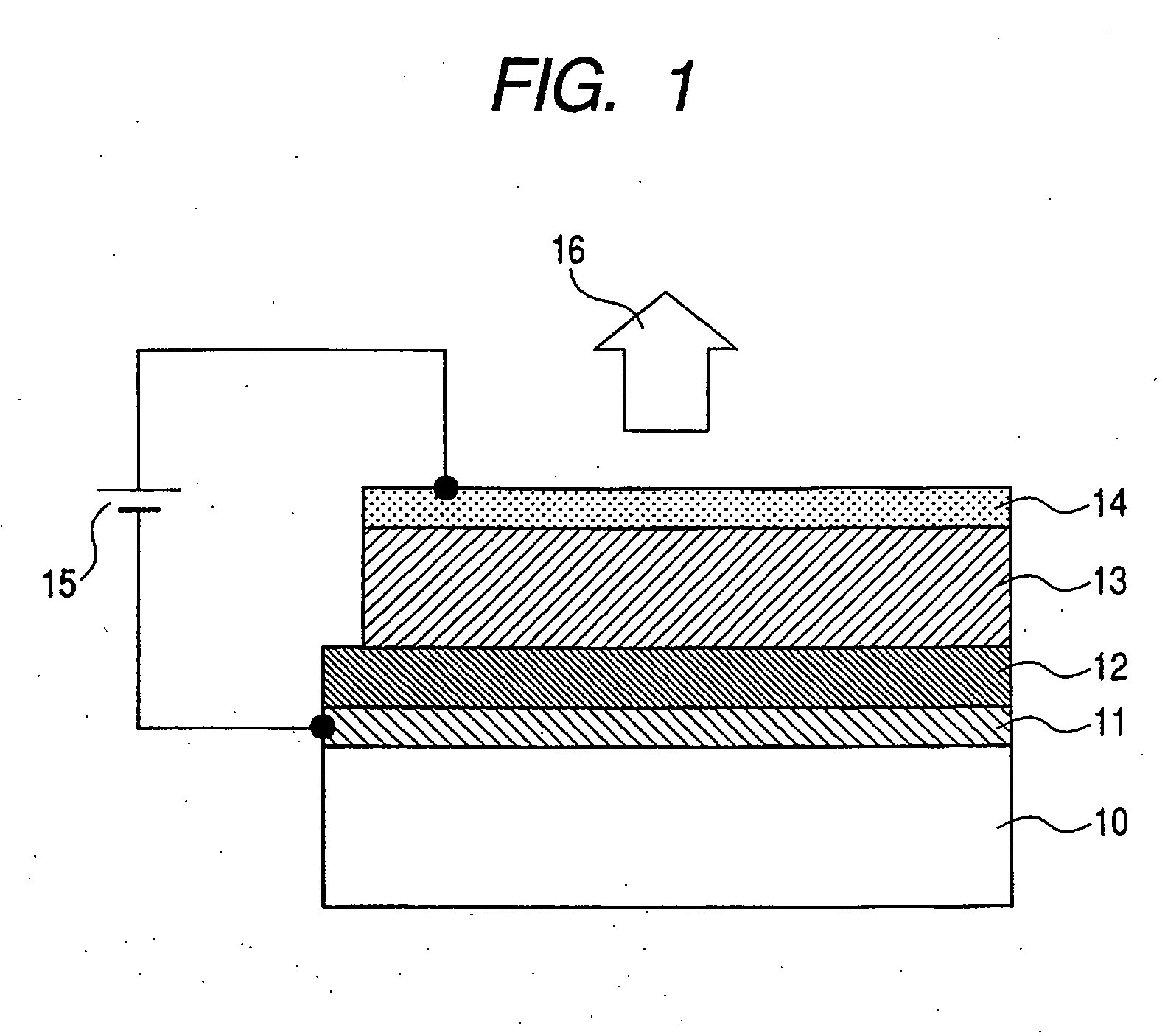

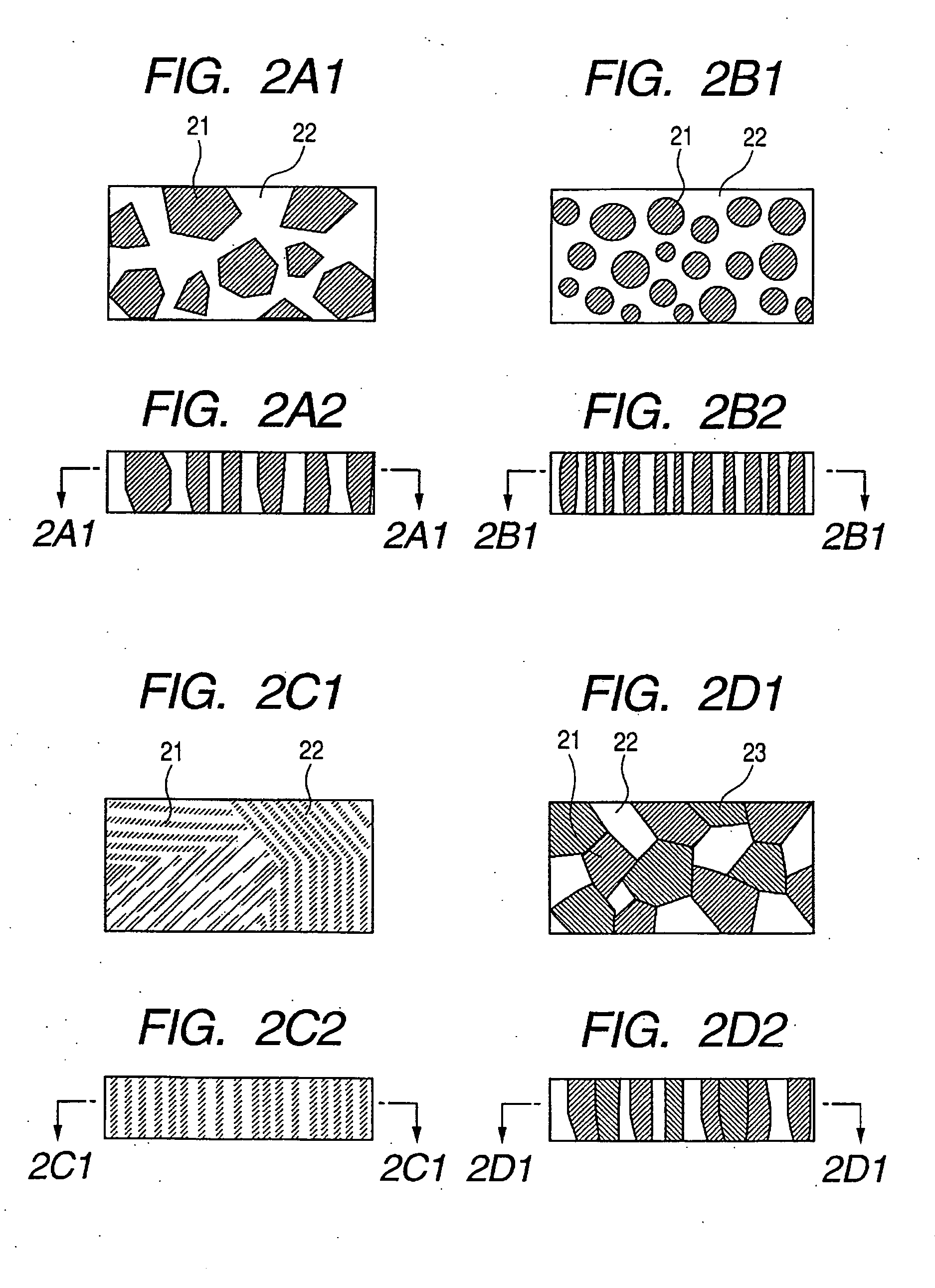

Light emitting device and its manufacturing method

InactiveUS20060220035A1Improve brightness uniformityDrive stabilityElectroluminescent light sourcesSolid-state devicesLow voltageLight emitting device

The present invention is intended to provide a light emitting device which can be operated at a low voltage, has excellent luminous efficiency, stability, production cost, and the like. A light emitting device which has at least electrode layers 11, 14, a light emitting layer 13, a structure layer 12 between the electrode layer 11 and light emitting layer 13, wherein structure layer 12 has domains composed of a first material, and domains composed of a second material. It is preferable for the structure layer to have a plurality of columnar domains composed of the first material, and the domains composed of the second material around the domains composed of the first material, and for the domains composed of the first material are arranged regularly. It is preferable that the first material and the second material are composed of different oxides.

Owner:CANON KK

Organic light emitting diode display

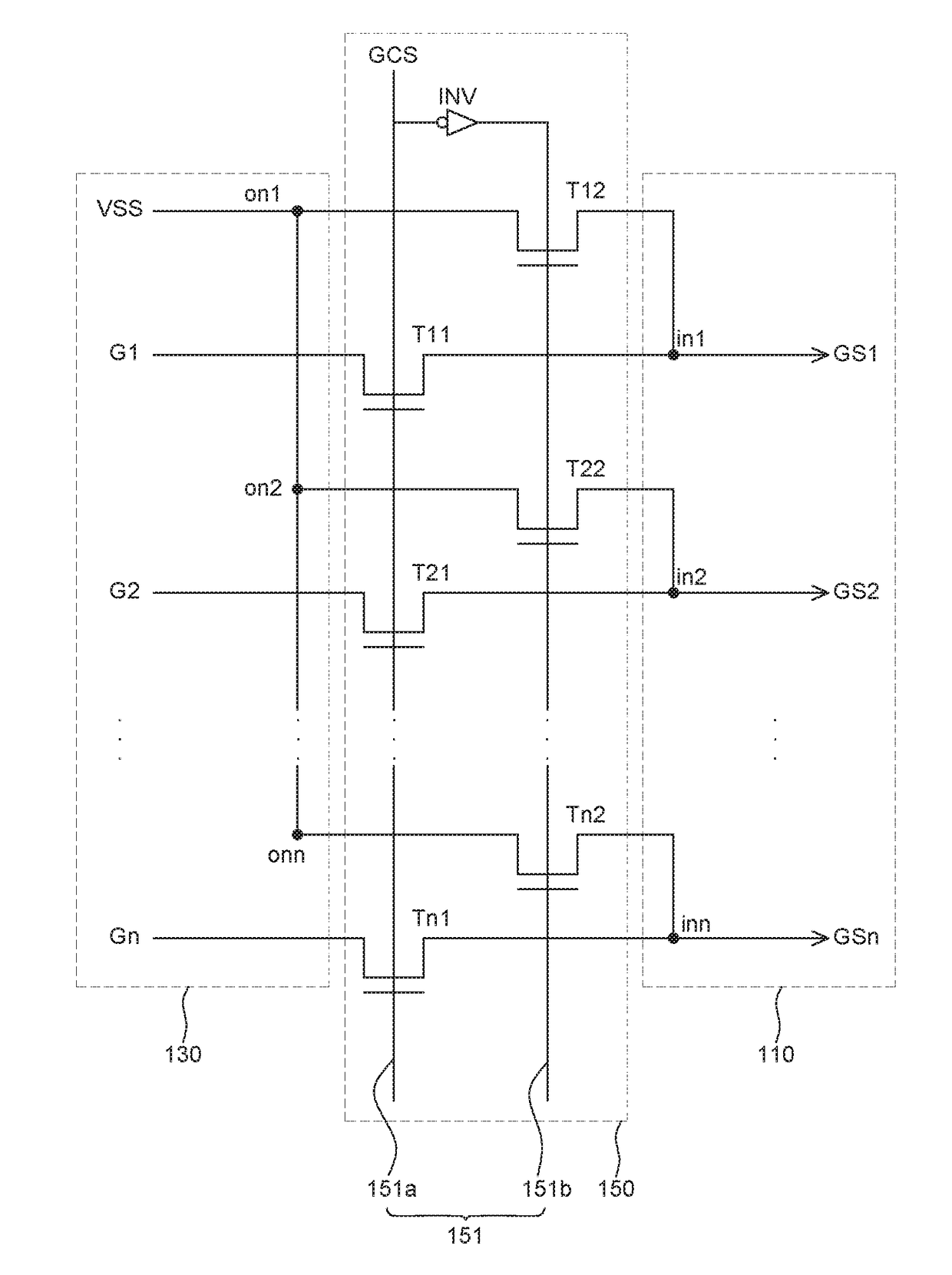

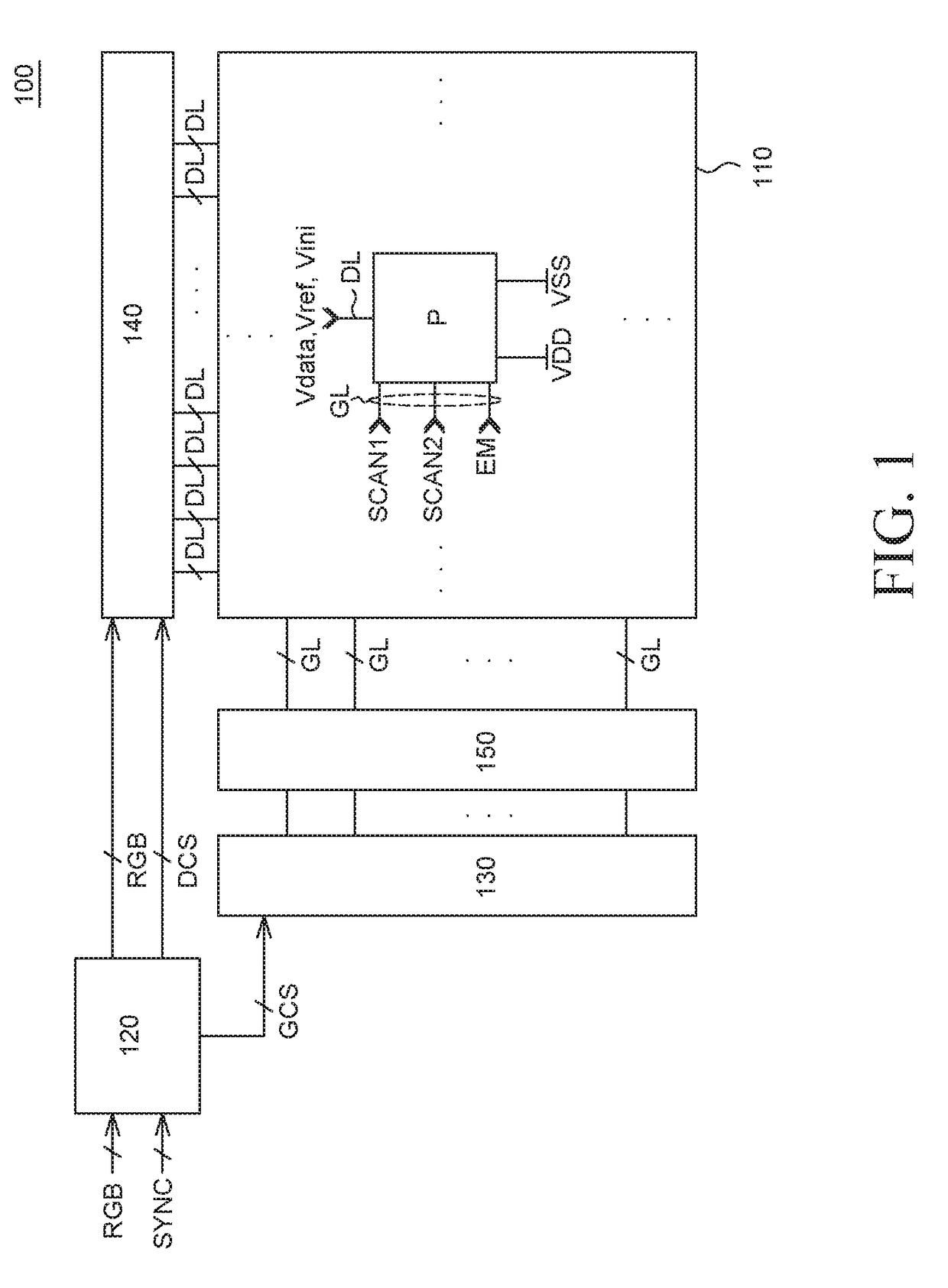

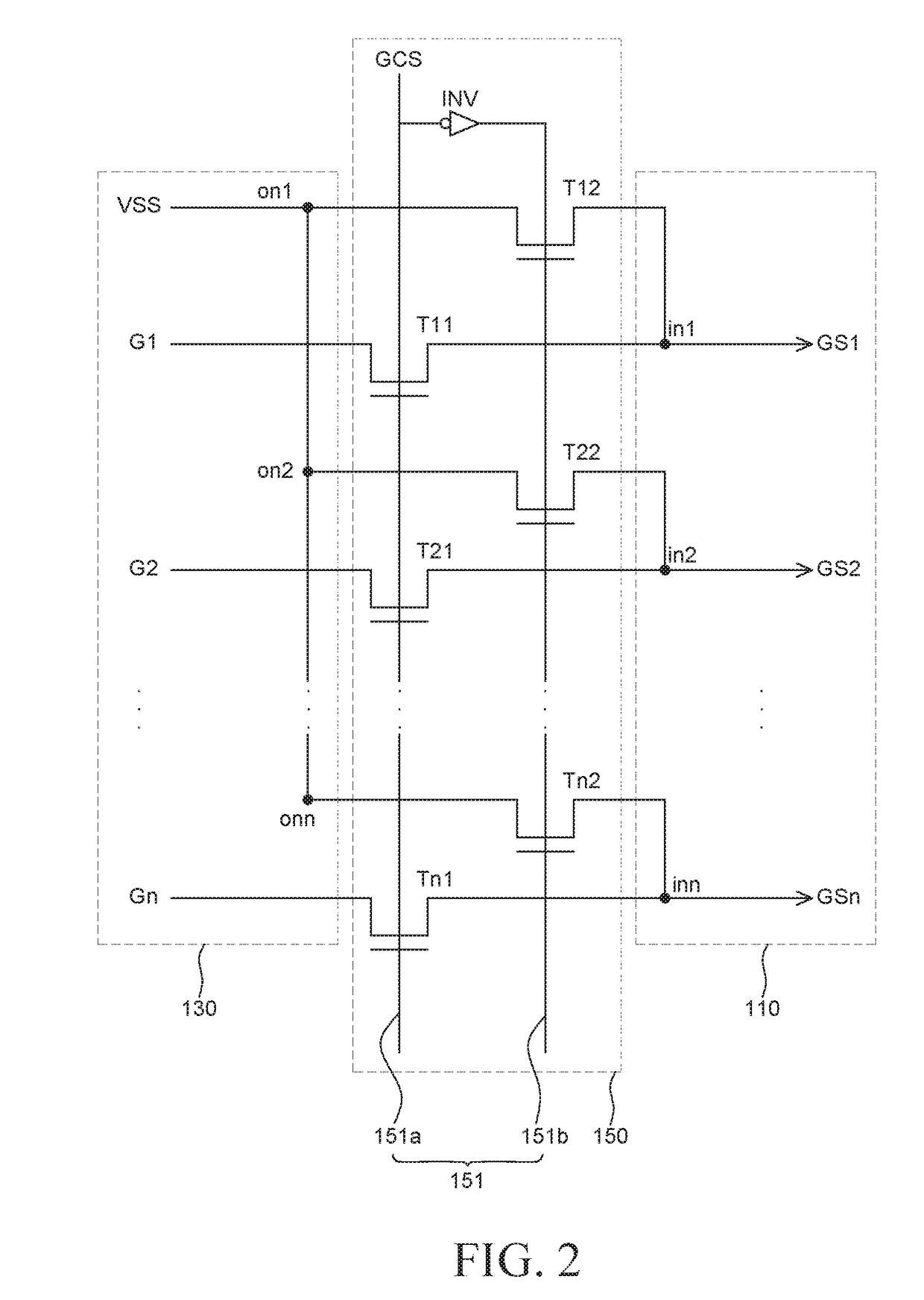

ActiveUS20180005601A1Suppress luminance decreaseReduce power consumptionCathode-ray tube indicatorsElectricityDisplay device

Provided is an organic light emitting display. The organic light emitting display can include a gate driving circuit configured to supply a gate signal through each of a plurality of gate lines connected to a display panel, and a luminance control unit between the gate driving circuit and the display panel and electrically connected to the plurality of gate lines and a power supply line. A gate signal is supplied to the pixels in a distributed manner during a plurality of refresh periods. Therefore, it is possible to reduce a luminance decrease in the pixels during the entire refresh period.

Owner:LG DISPLAY CO LTD

Organic light emitting display device and method of manufacturing the same

ActiveUS20130320367A1Reduce riskLight displaySolid-state devicesSemiconductor/solid-state device manufacturingComputer science

An organic light emitting display device including a plurality of sub pixels, each of the sub pixels including an emissive layer between a pixel electrode and a counter electrode; and a partition wall defining regions of the plurality of sub pixels, wherein the partition wall is not located between at least one pair of adjacent sub pixels of the plurality of sub pixels.

Owner:SAMSUNG DISPLAY CO LTD

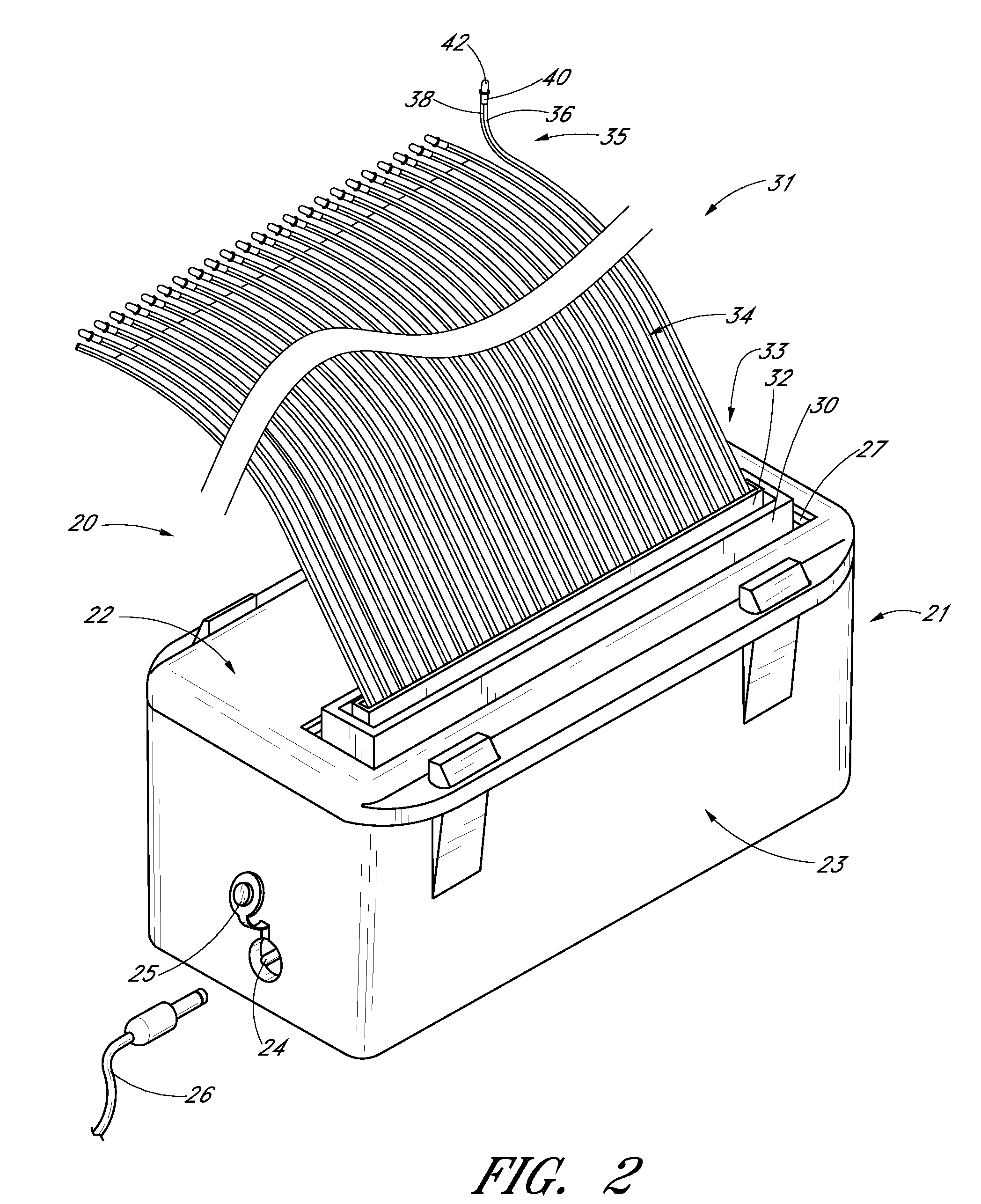

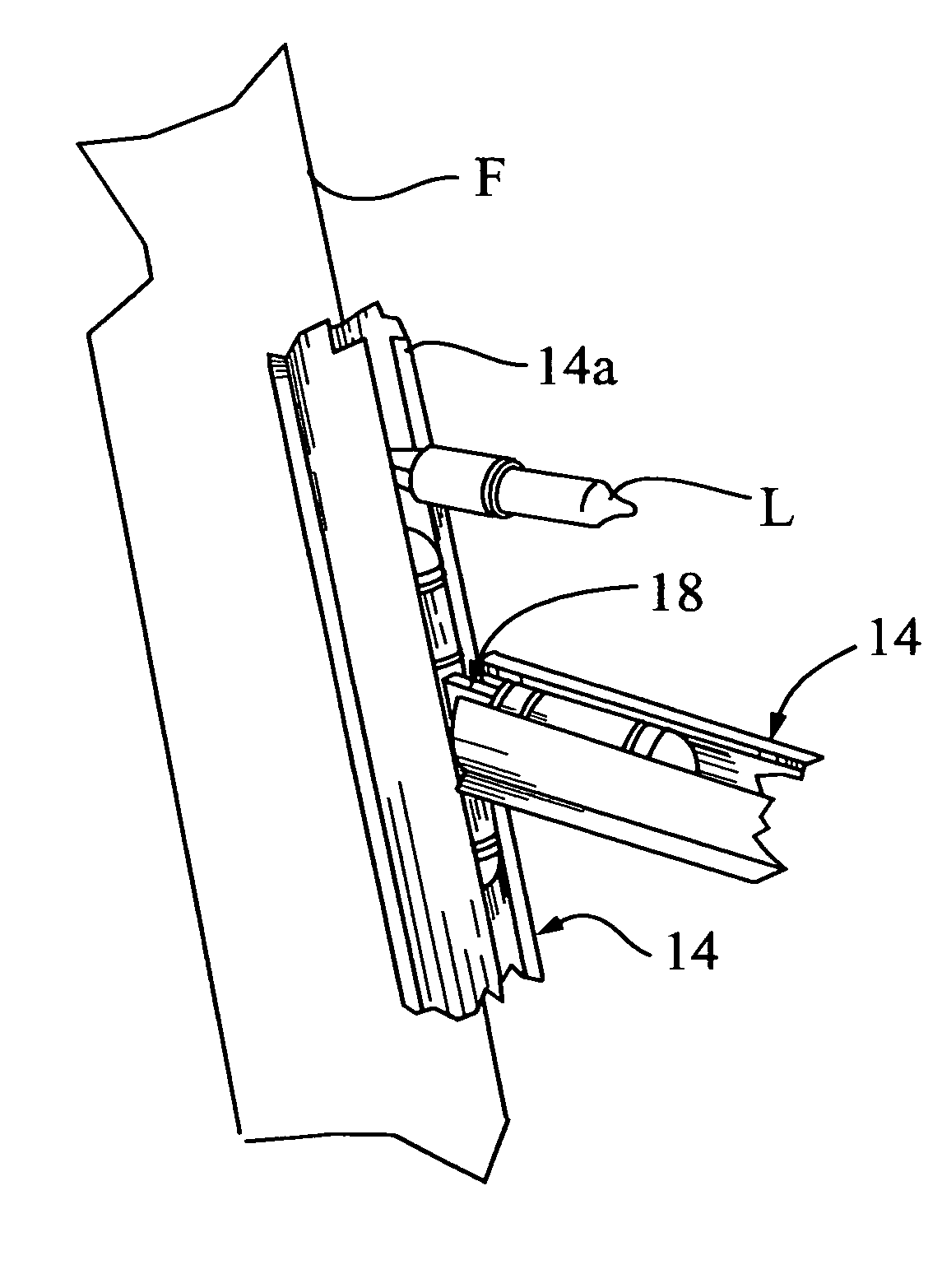

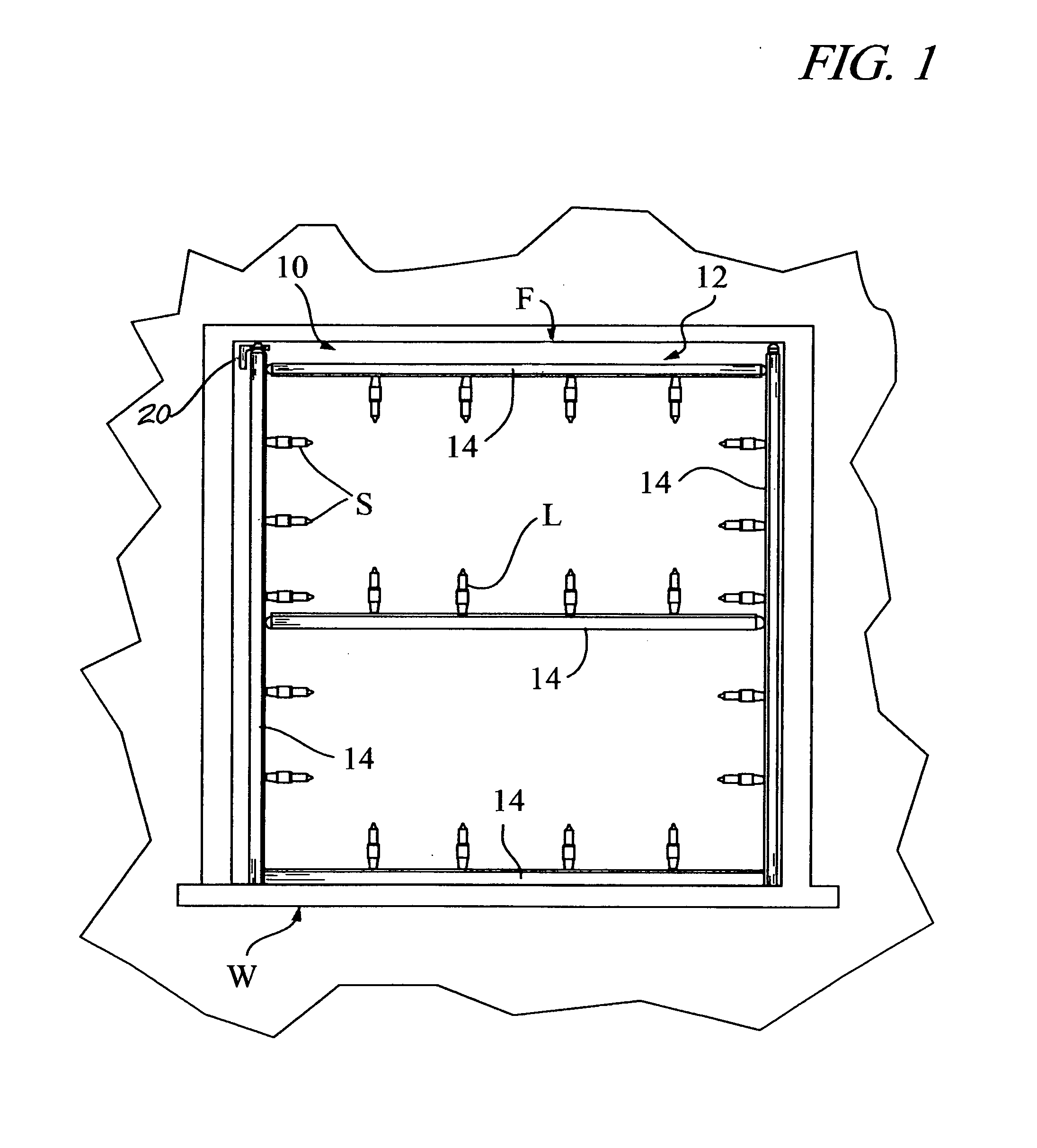

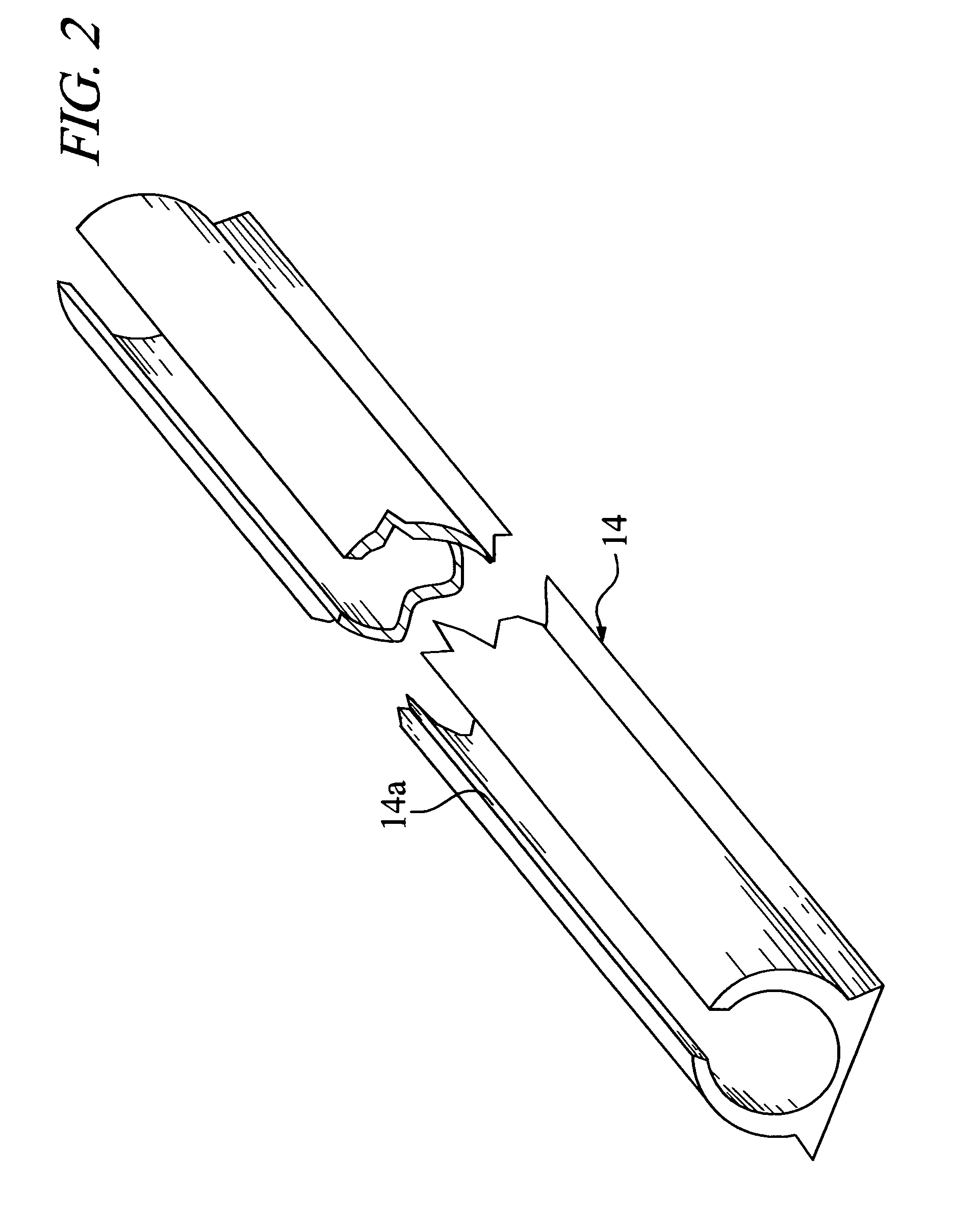

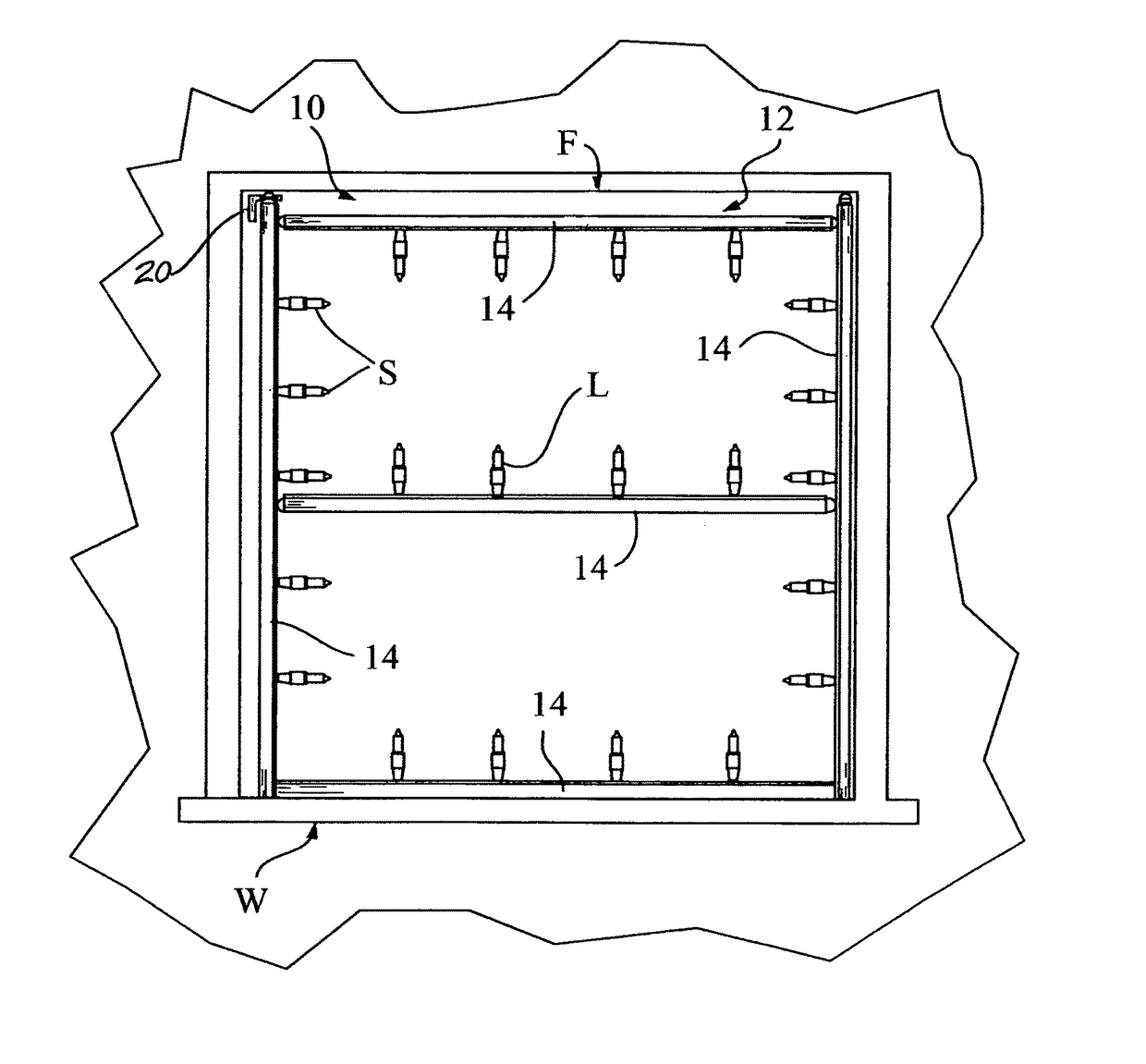

Mounting system and associated kit for installing decorative lights

ActiveUS20160153644A1Maximum aesthetic appealEasy to assembleLighting support devicesLight effect designsBraced frameEngineering

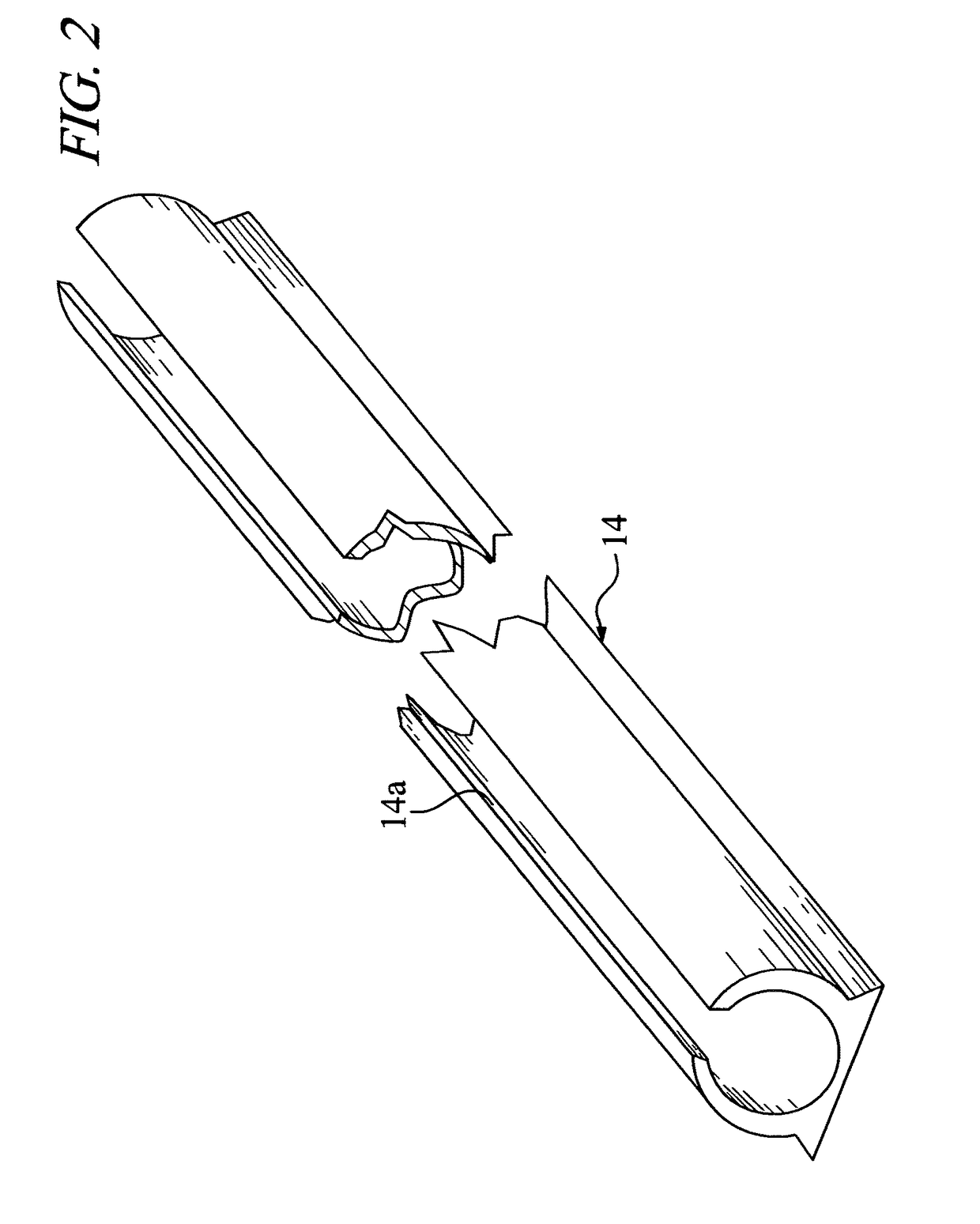

An improved mounting system and associated kit is disclosed for installing decorative lights within a window frame. The present system comprises a support framework assembly of separate tubular track members, each having a slotted opening running along its length and together joined in a substantially rectangular configuration or in an alternative form intended to conform to the shape of the window frame. Separate L-shaped and T-shaped connectors constructed having movable projecting sections are sized and fitted with O-ring members to provide a press-fit engagement with the tubular chambers of the track members at their respective ends and thereby join the tubular track members together in their assembly and secure the assembly in mounted position within the window with the respective slotted openings inwardly facing. A light insertion tool specially formed and used in association with the present system allows the user to complete installation of a string of decorative lights within the slotted openings of the tubular track members with the individual lights set apart equidistantly for optimal aesthetic effect.

Owner:RODAN ENTERPRISES LLC

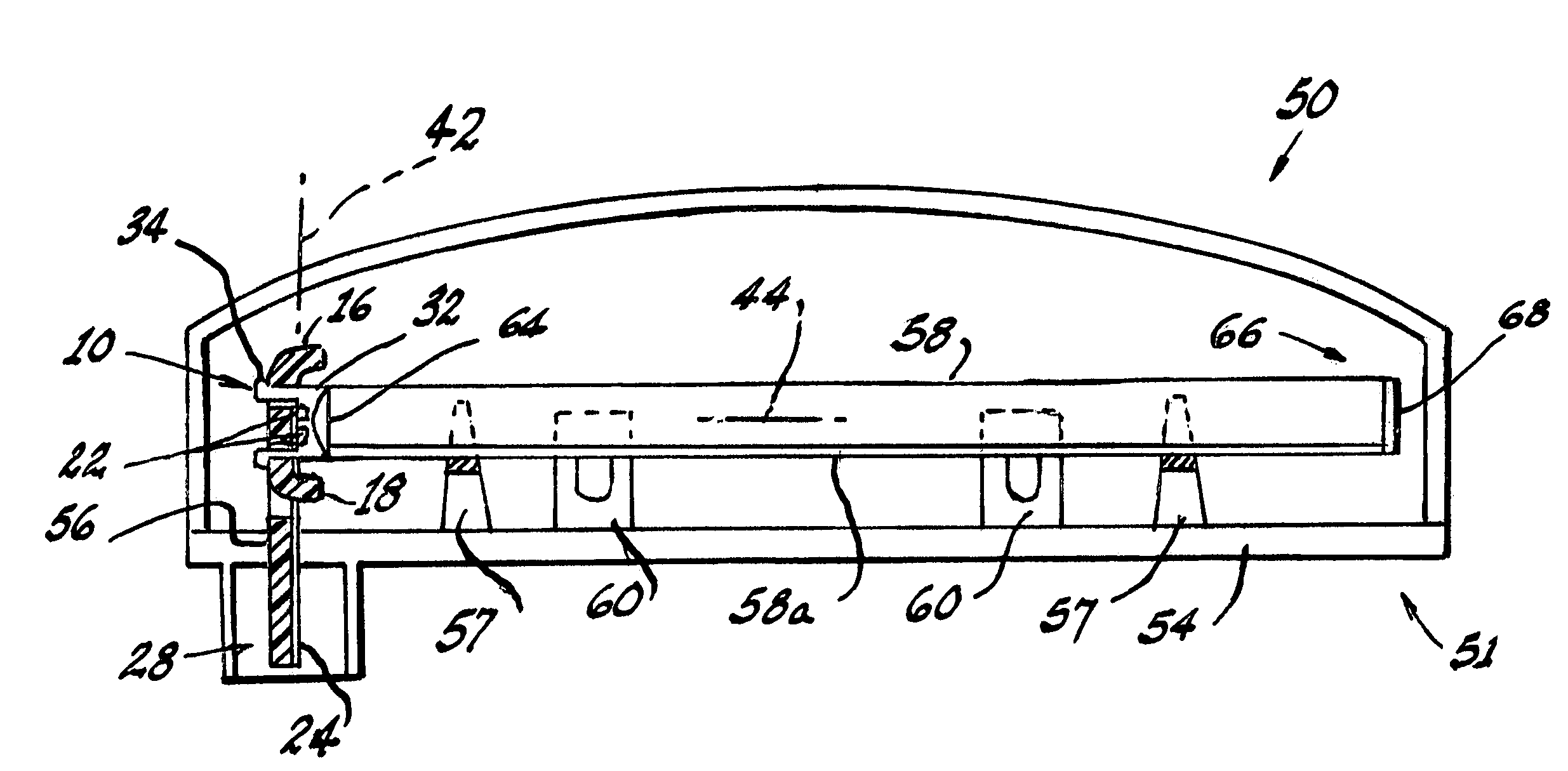

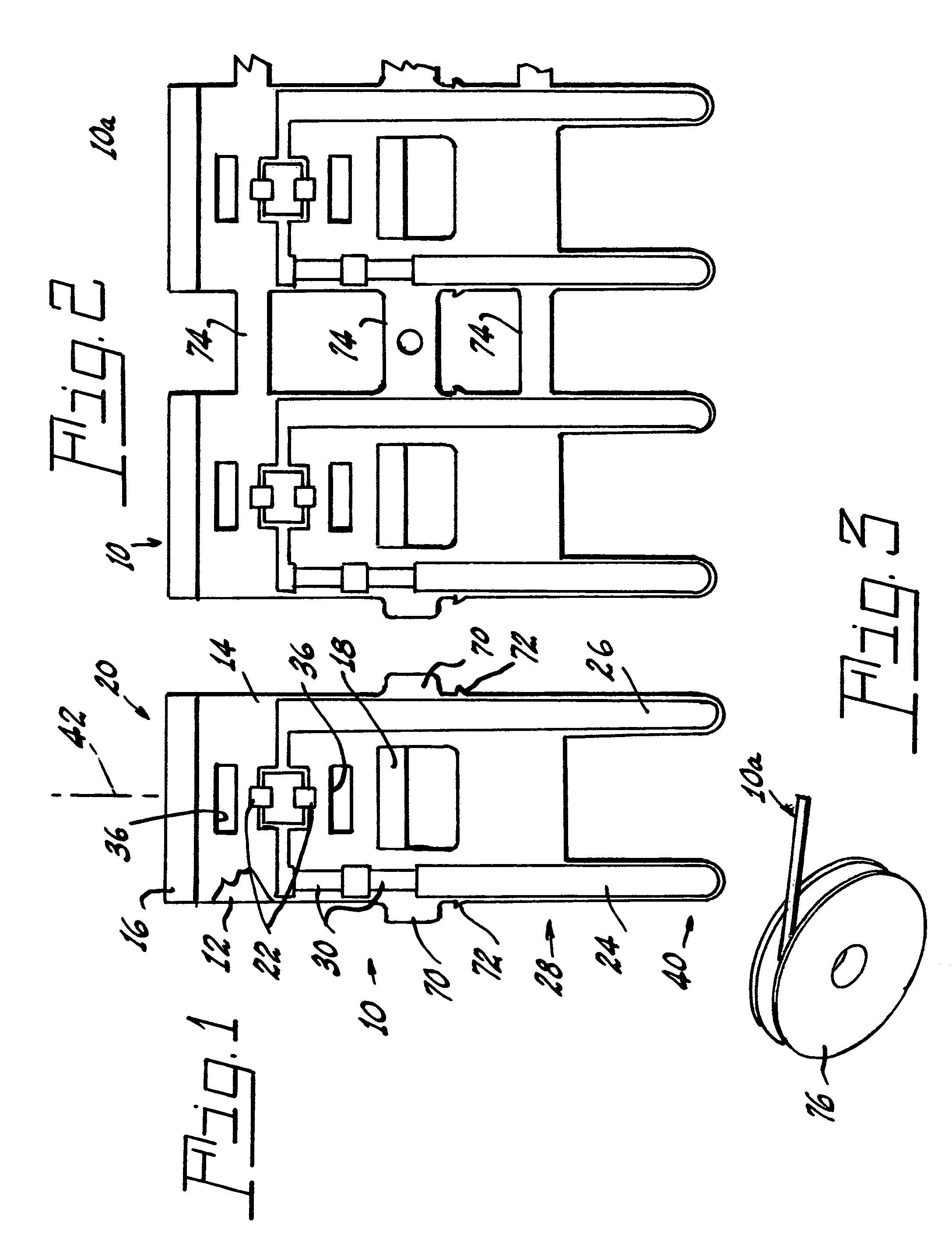

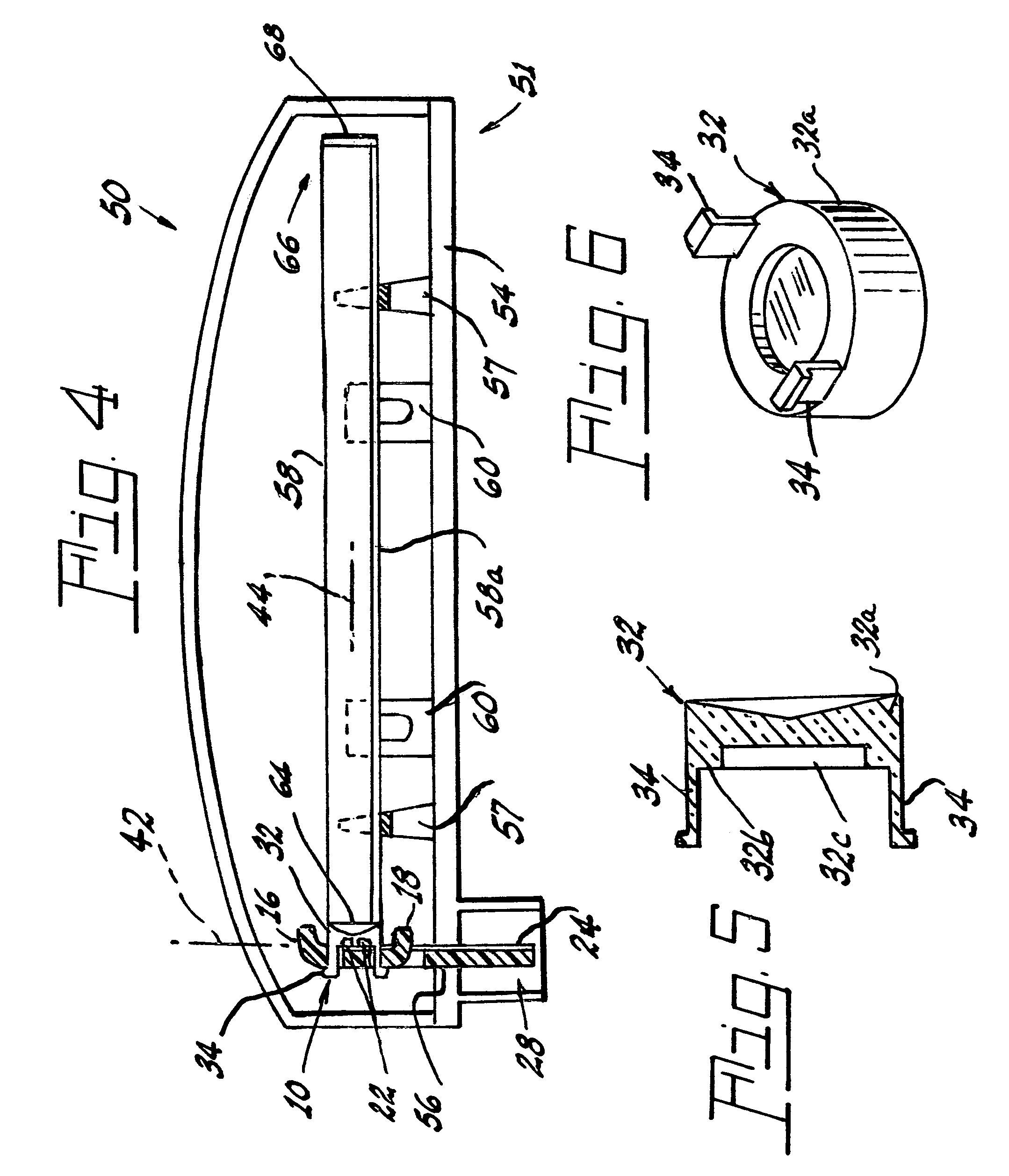

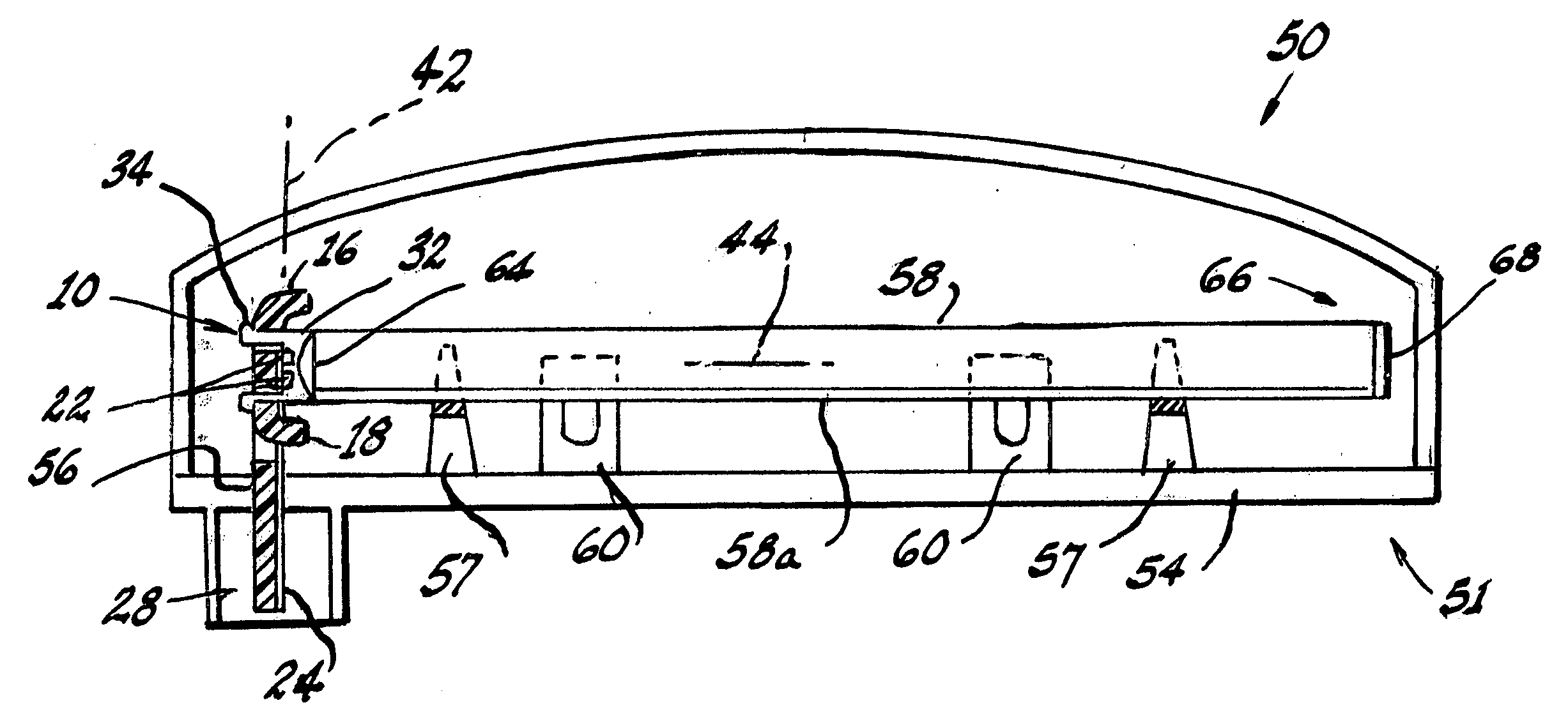

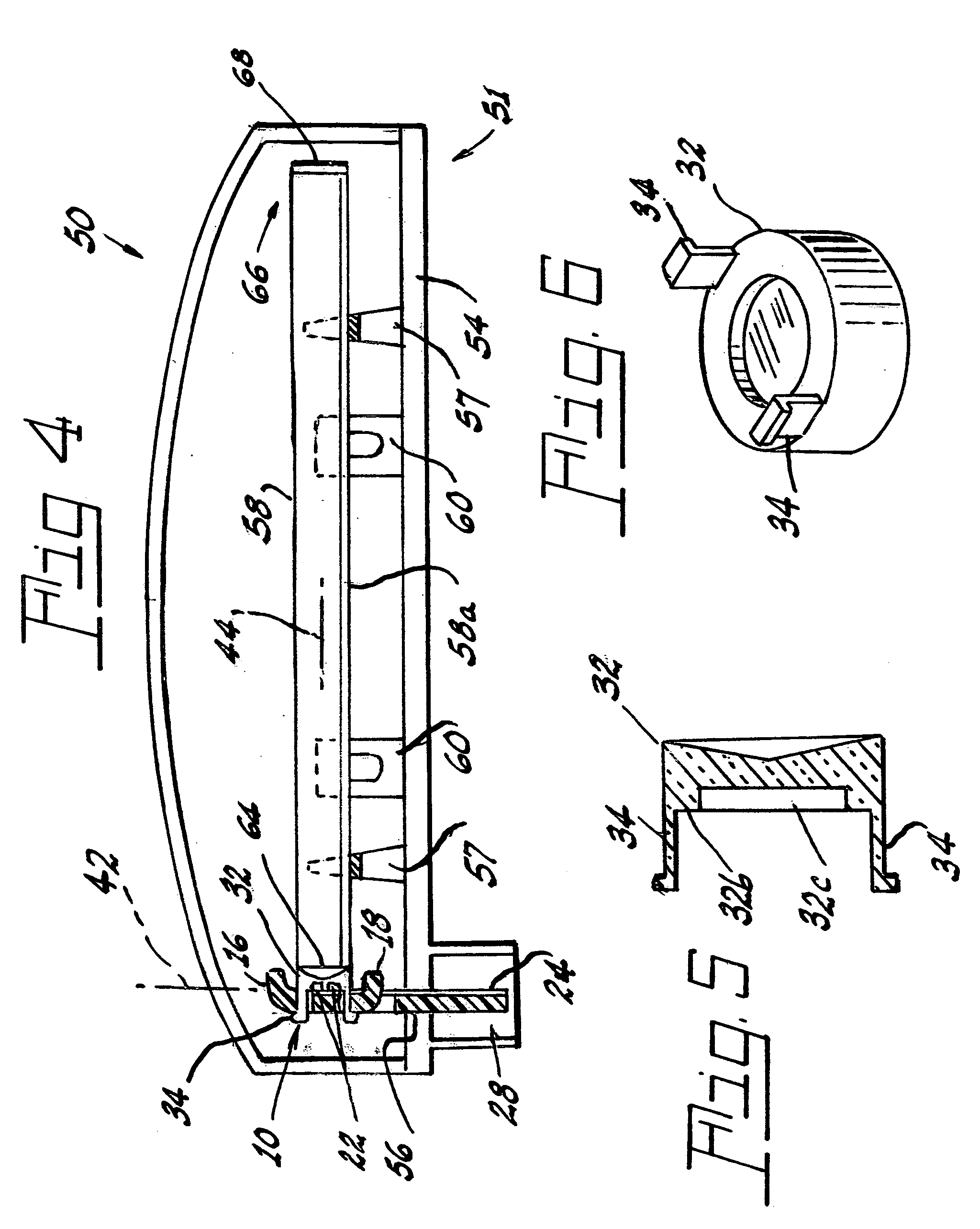

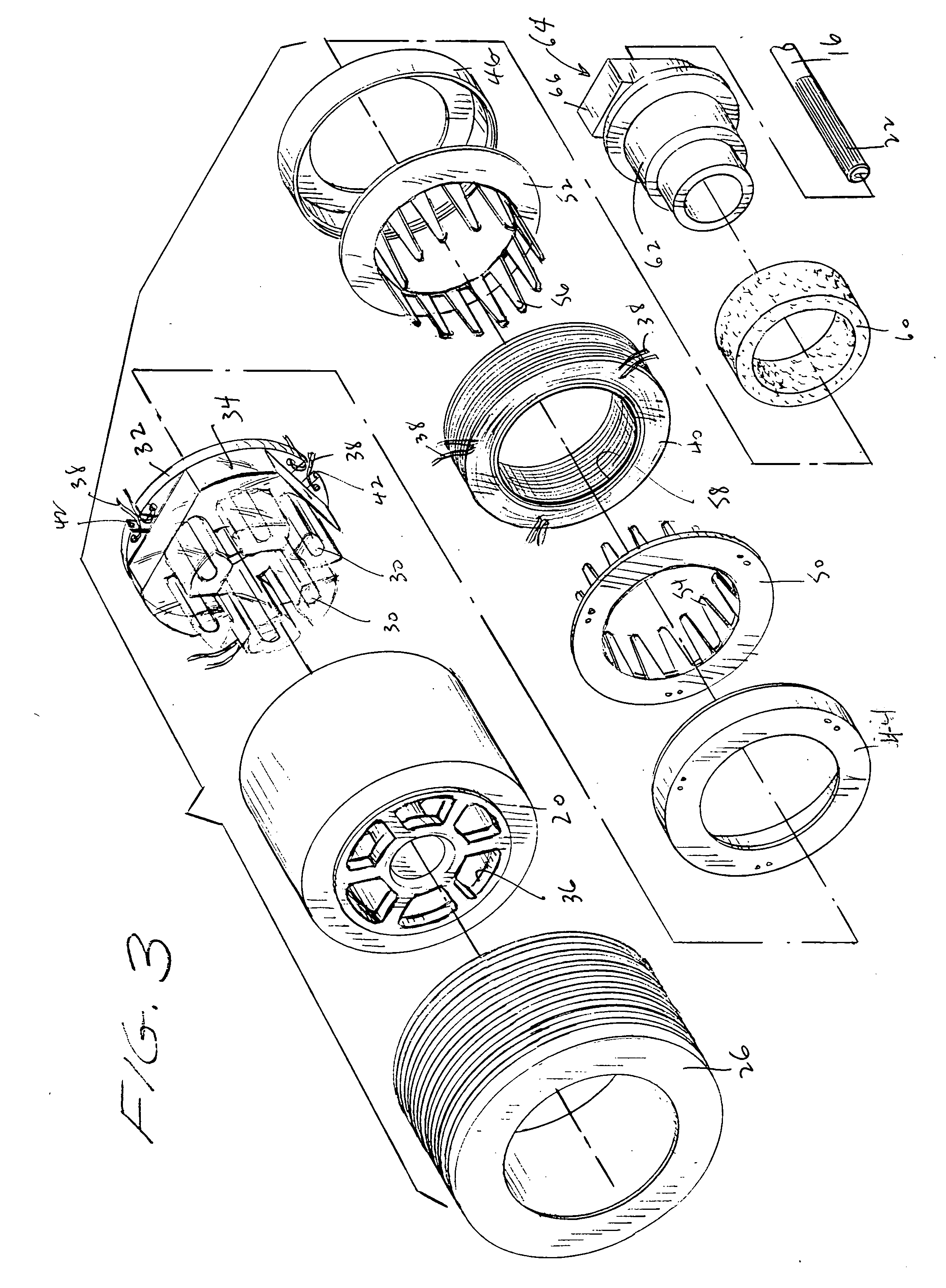

LED light source with integrated circuit and light guide

InactiveUS7598534B2Simple circuitLow costSemiconductor/solid-state device detailsSolid-state devicesDielectricElectrical conductor

An elongated light source (50) comprises a subassembly (51) including a base (54), a light engine (10) positioned in mounting means (56) formed with the base; a light guide (58) positioned in spaced apart supports (57), and a cover (62) fixed to the base (54). The light engine (10) comprises a thermally conductive substrate (12) having a dielectric (14) on one side thereof; upper and lower lens guards, (16, 18), respectively, positioned near one end (20) of the substrate (12); at least one LED (22) mounted on the substrate between the lens guards (16, 18); and electrical conductors (24, 26) mounted upon the substrate at another end (28) thereof for supplying power to the LED (22).

Owner:OSRAM SYLVANIA INC

Illuminated sprinkler with micro-generator

InactiveUS20120228399A1Prolong lifeDelay water lossLighting elementsMovable spraying apparatusLandscapingEngineering

The present invention relates generally to an illuminated lawn and garden sprinkler. More specifically, this disclosure relates to an, electrically independent, illuminated lawn and garden sprinkler, using a micro-generator for power and advanced circuitry, including a photoelectric sensor, for display control. Illuminated sprinklers are an aesthetic enhancement using light to interplay with the discharging water and highlighting landscaping. Illuminated sprinklers encourage nighttime watering, increasing watering efficiency and water conservation.

Owner:FORHAN RON

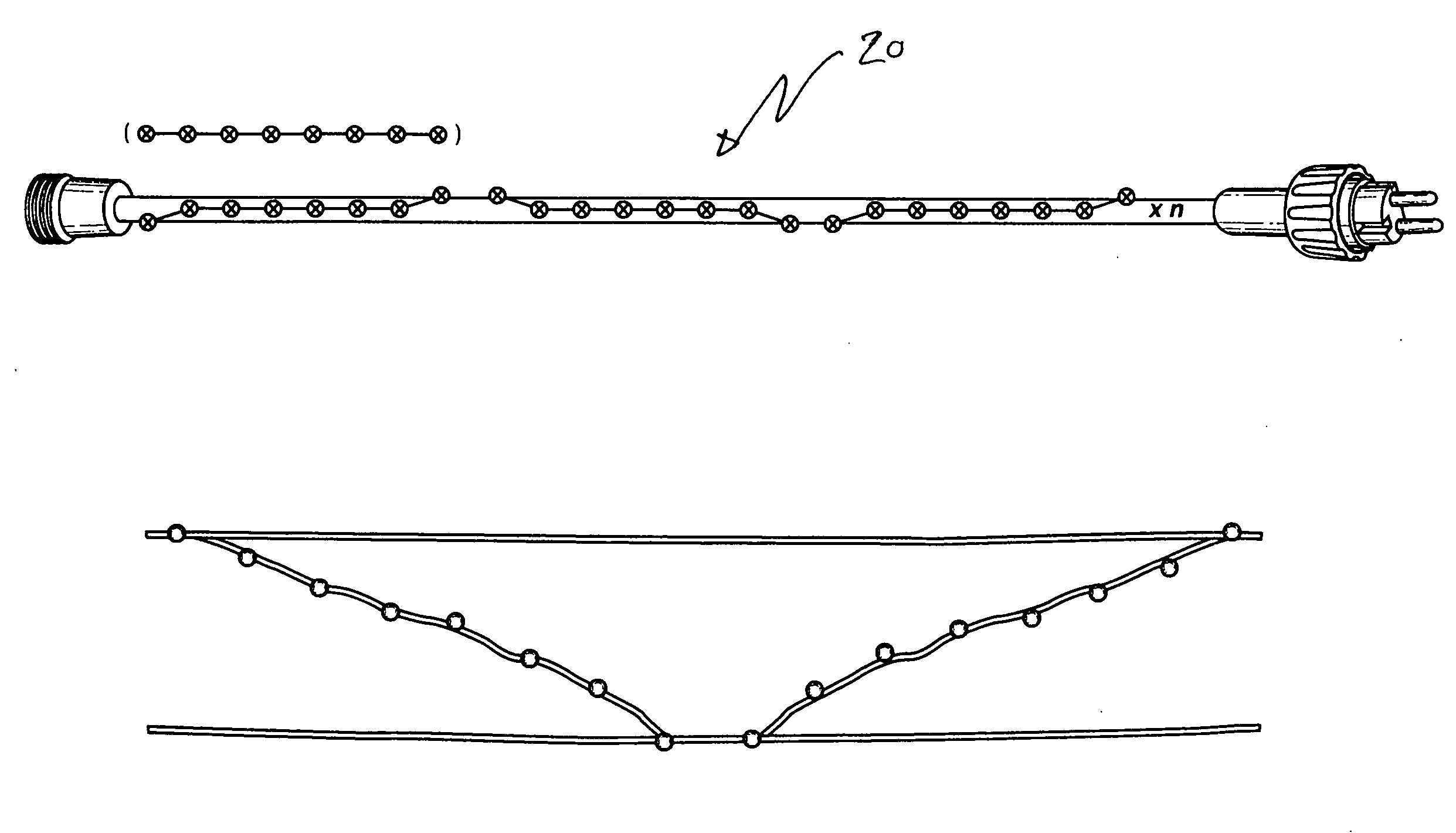

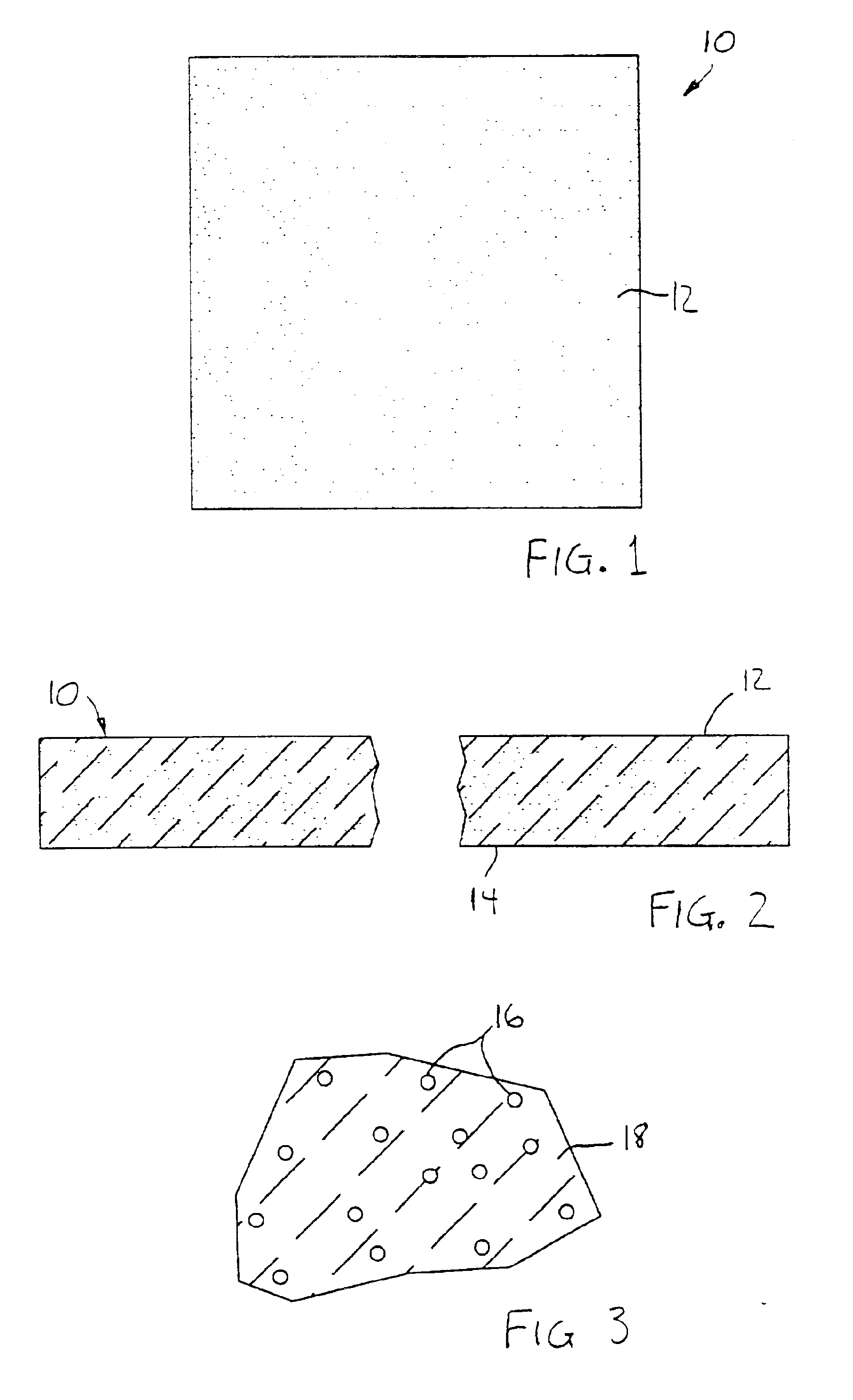

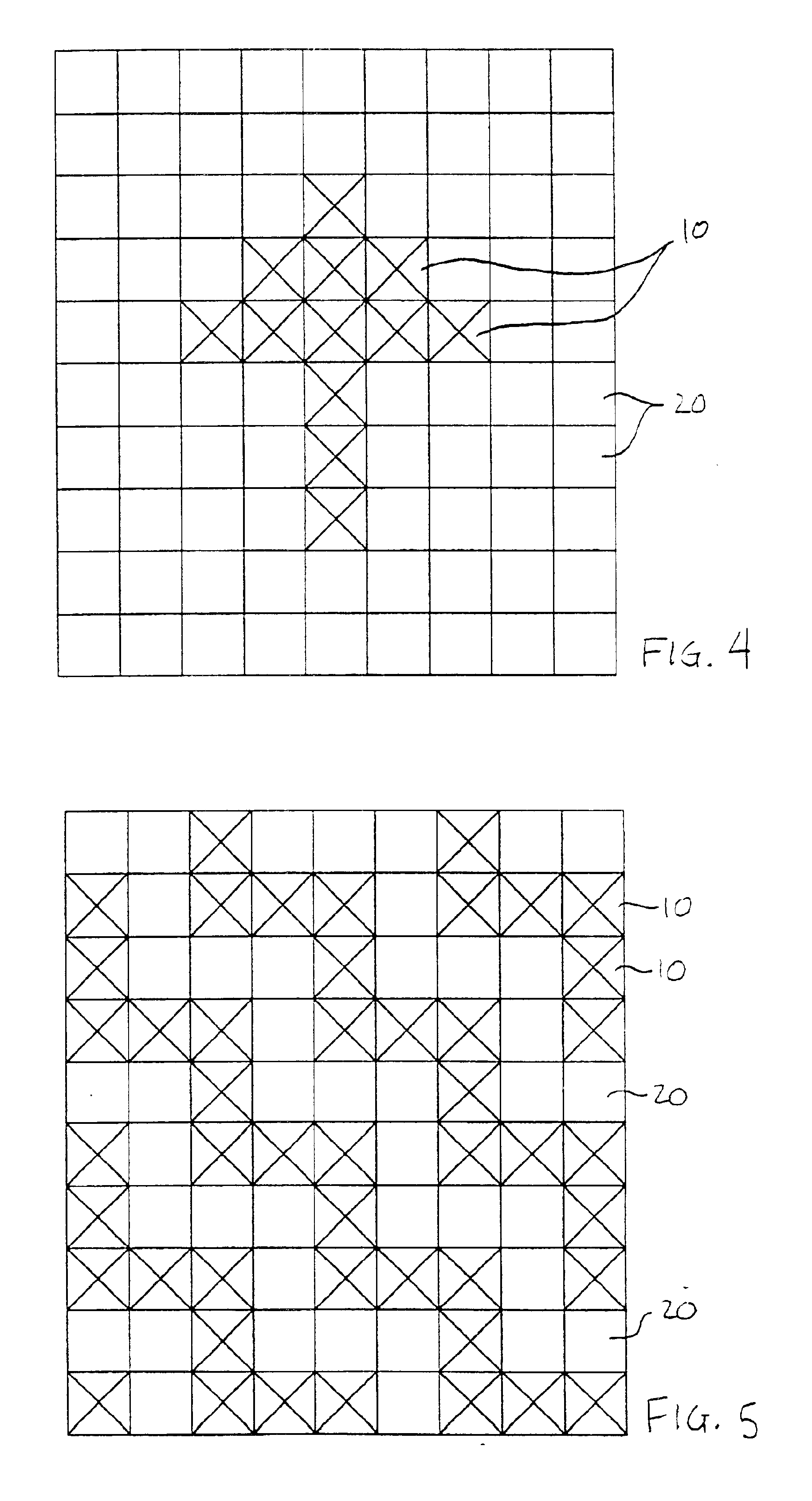

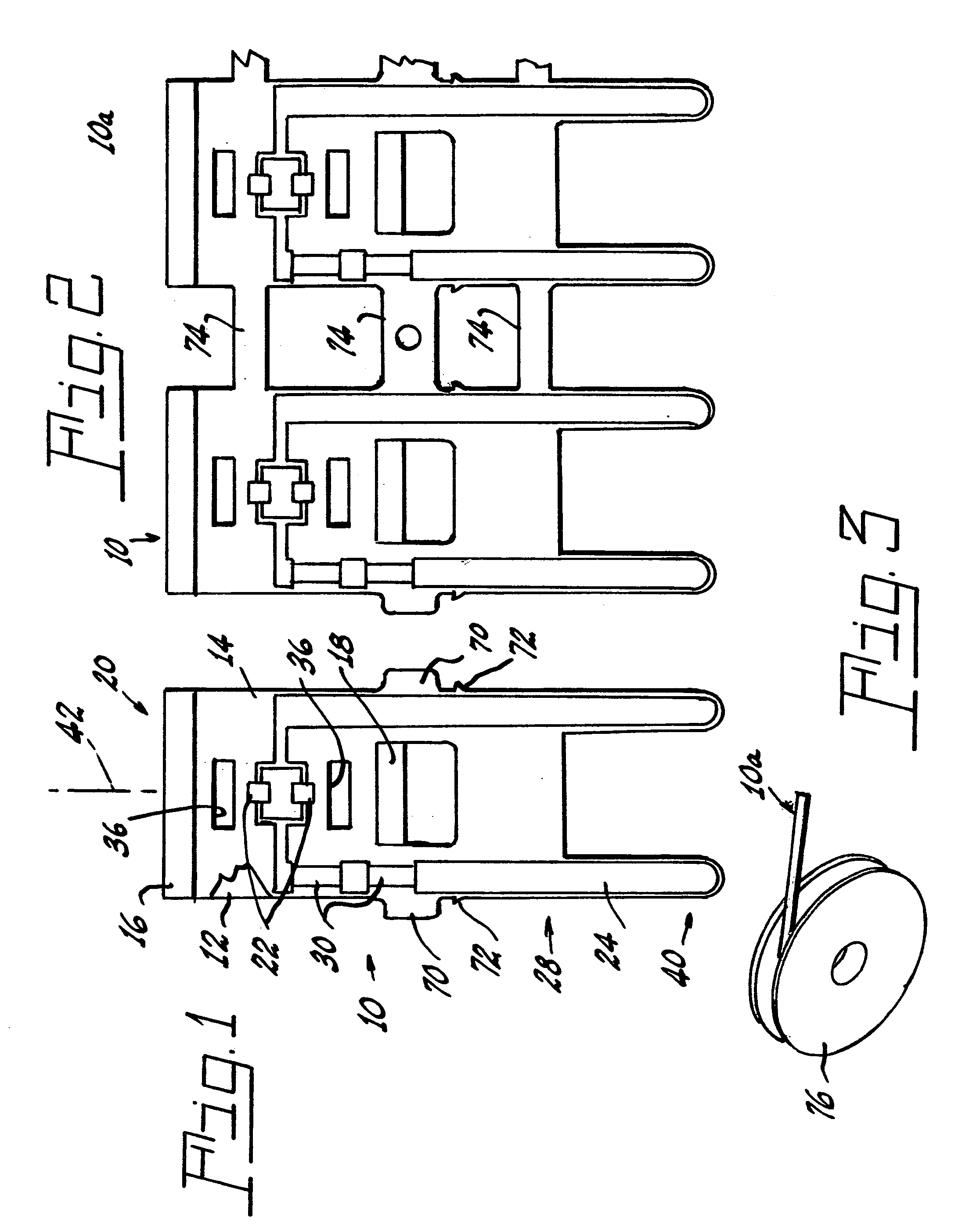

LED light source with integrated circuit and light guide

InactiveUS20080042147A1Increase heightSimple circuitSemiconductor/solid-state device detailsSolid-state devicesDielectricElectrical conductor

An elongated light source (50) comprises a subassembly (51) including a base (54), a light engine (10) positioned in mounting means (56) formed with the base; a light guide (58) positioned in spaced apart supports (57), and a cover (62) fixed to the base (54). The light engine (10) comprises a thermally conductive substrate (12) having a dielectric (14) on one side thereof; upper and lower lens guards, (16, 18), respectively, positioned near one end (20) of the substrate (12); at least one LED (22) mounted on the substrate between the lens guards (16, 18); and electrical conductors (24, 26) mounted upon the substrate at another end (28) thereof for supplying power to the LED (22).

Owner:OSRAM SYLVANIA INC

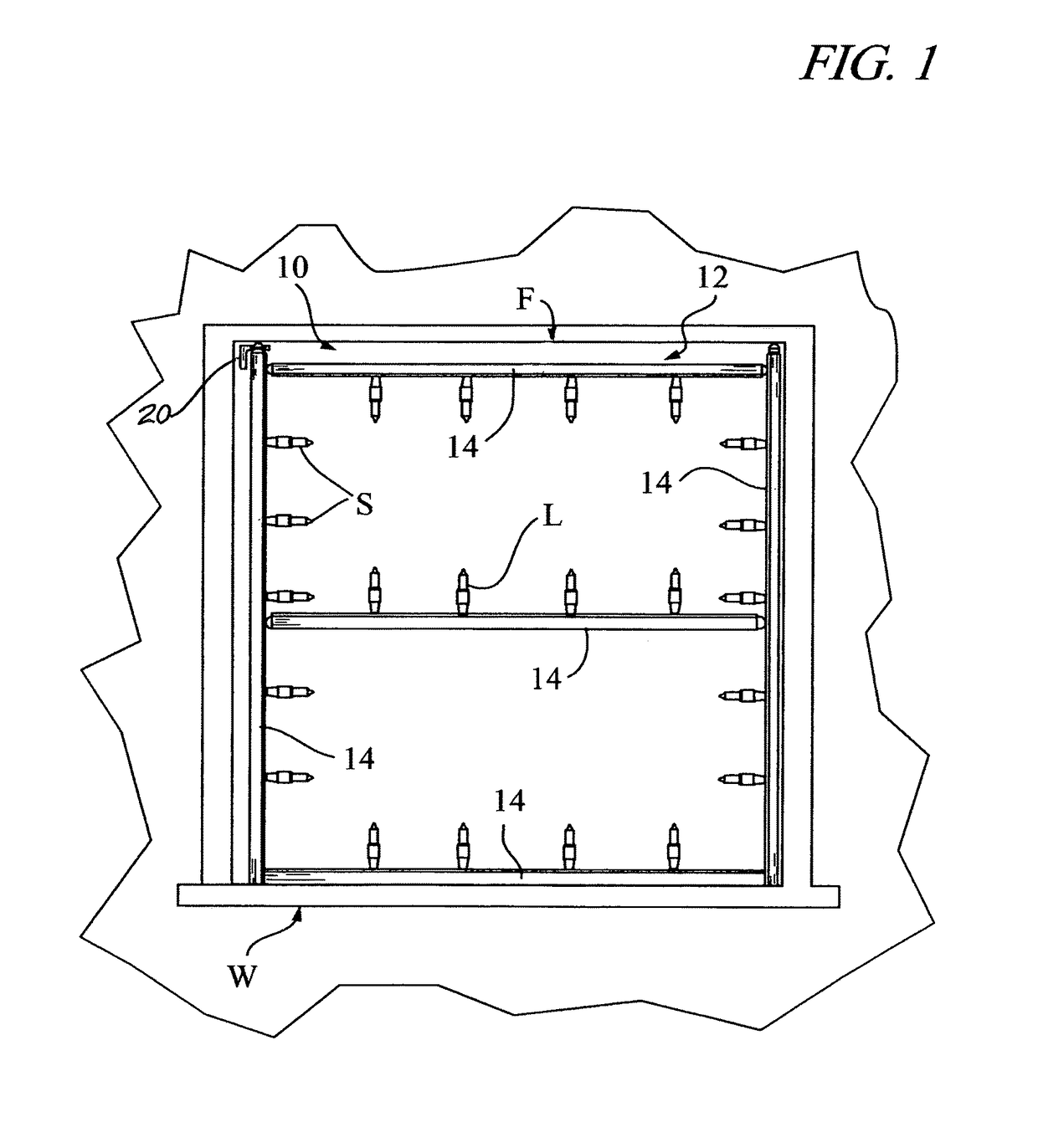

Mounting system and associated kit for installing decorative lights

ActiveUS9915401B2Maximum aesthetic appealEasy to assembleLighting support devicesElectric lightingMechanical engineeringEngineering

An improved mounting system and associated kit is disclosed for installing decorative lights within a window frame. The present system comprises a support framework assembly of separate tubular track members, each having a slotted opening running along its length and together joined in a substantially rectangular configuration or in an alternative form intended to conform to the shape of the window frame. Separate L-shaped and T-shaped connectors constructed having movable projecting sections are sized and fitted with O-ring members to provide a press-fit engagement with the tubular chambers of the track members at their respective ends and thereby join the tubular track members together in their assembly and secure the assembly in mounted position within the window with the respective slotted openings inwardly facing. A light insertion tool specially formed and used in association with the present system allows the user to complete installation of a string of decorative lights within the slotted openings of the tubular track members with the individual lights set apart equidistantly for optimal aesthetic effect.

Owner:RODAN ENTERPRISES LLC

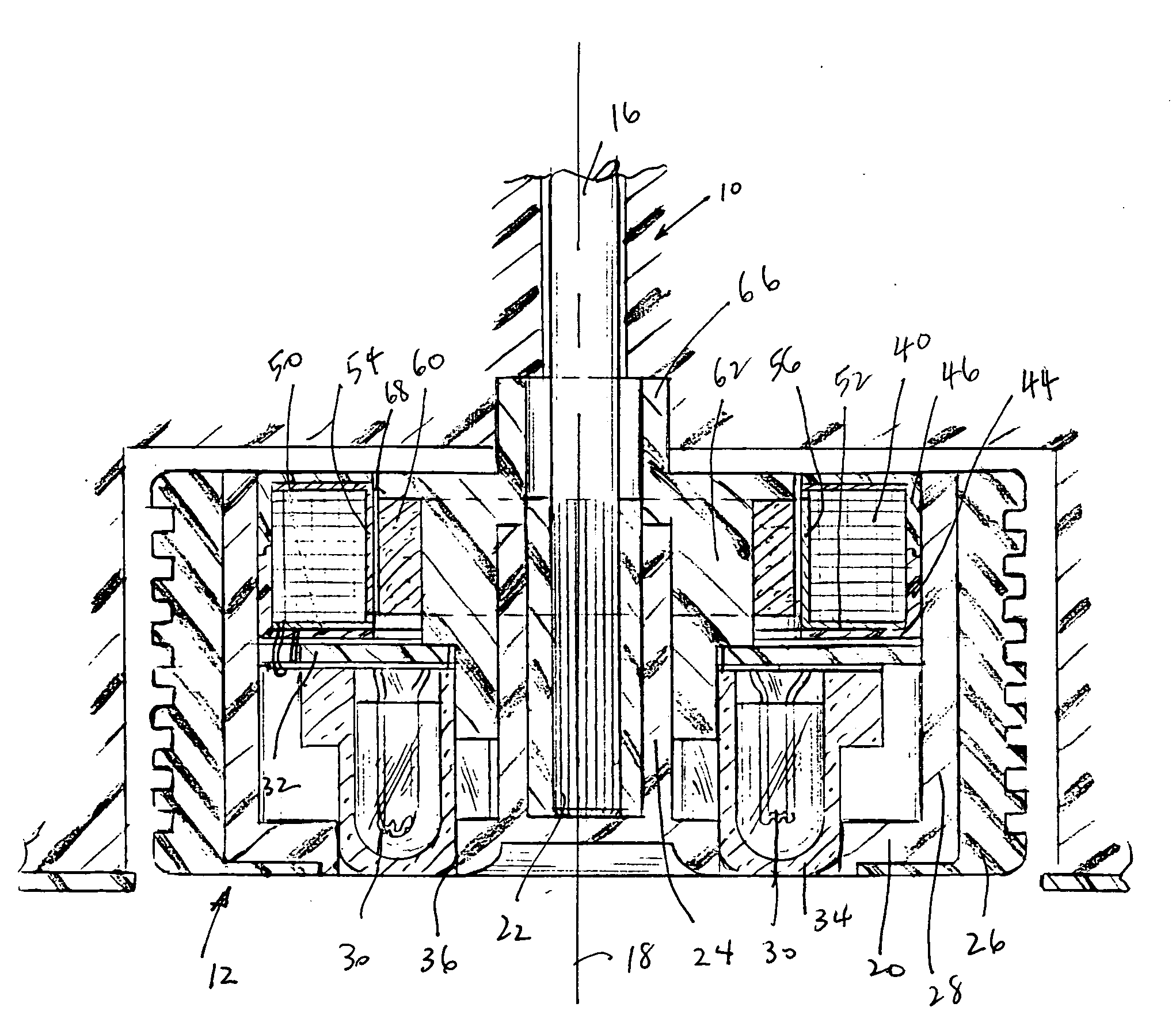

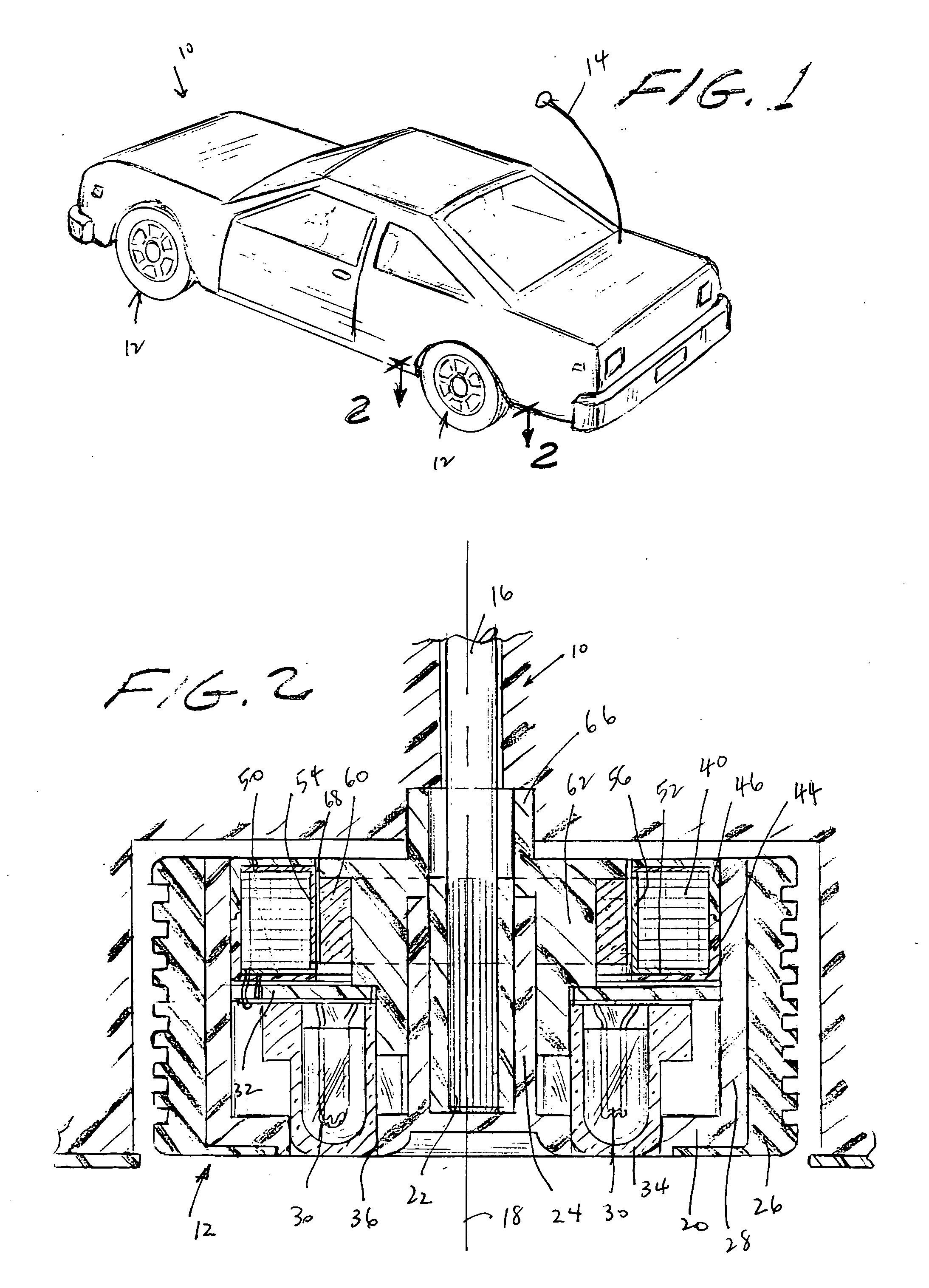

Self-powered lighting for wheeled arrangements

InactiveUS20060163960A1Light displayLighting support devicesOptical signalEffect lightElectrical impulse

A rotating wheel causes lights on and off the wheel to flash to create a light display. Moving pole teeth between a permanent magnet and an electromagnetic coil induce in the coil electrical pulses for flashing the lights.

Owner:K & B INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com