Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase the touch area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic device with dynamically adjusted touch area

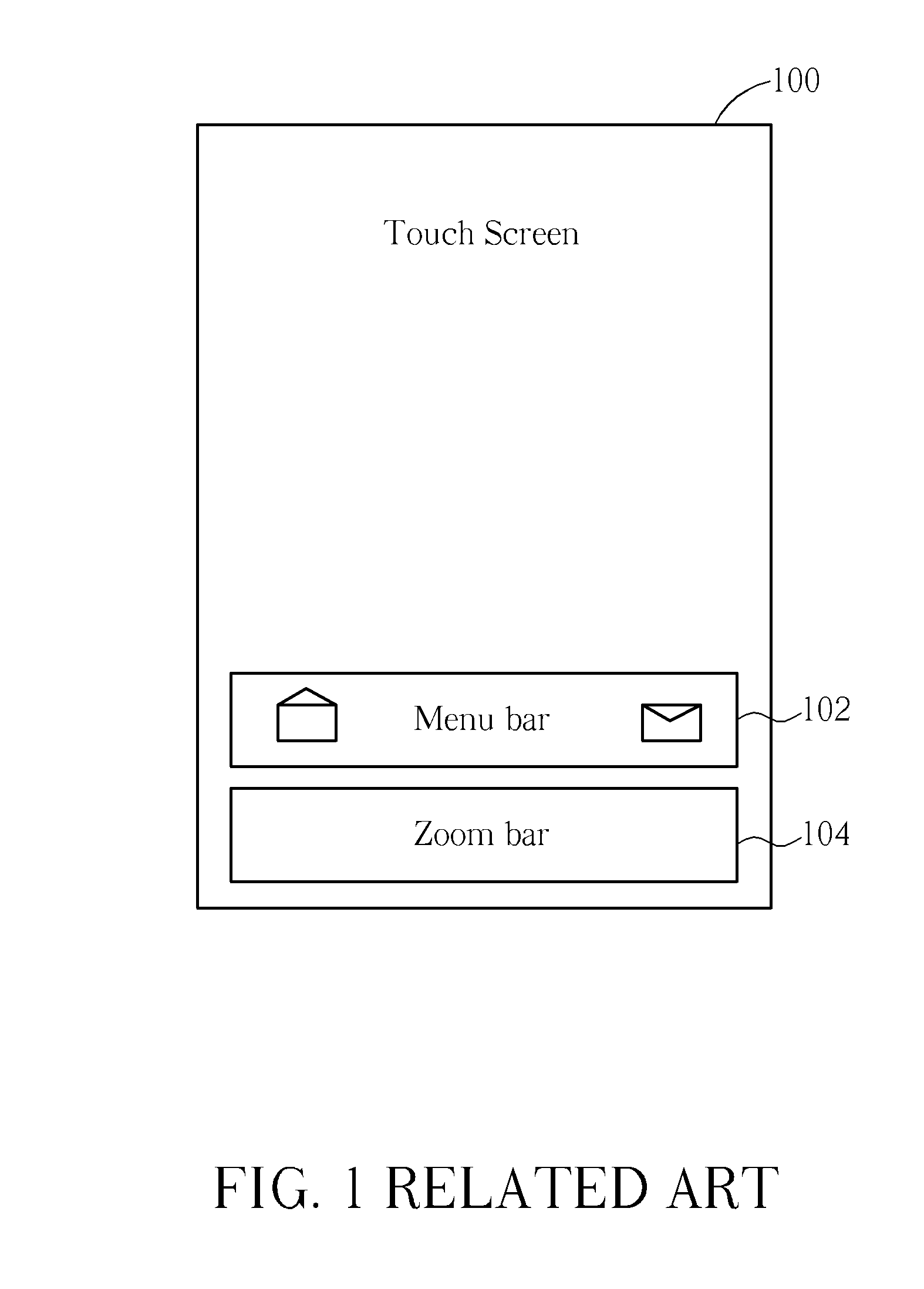

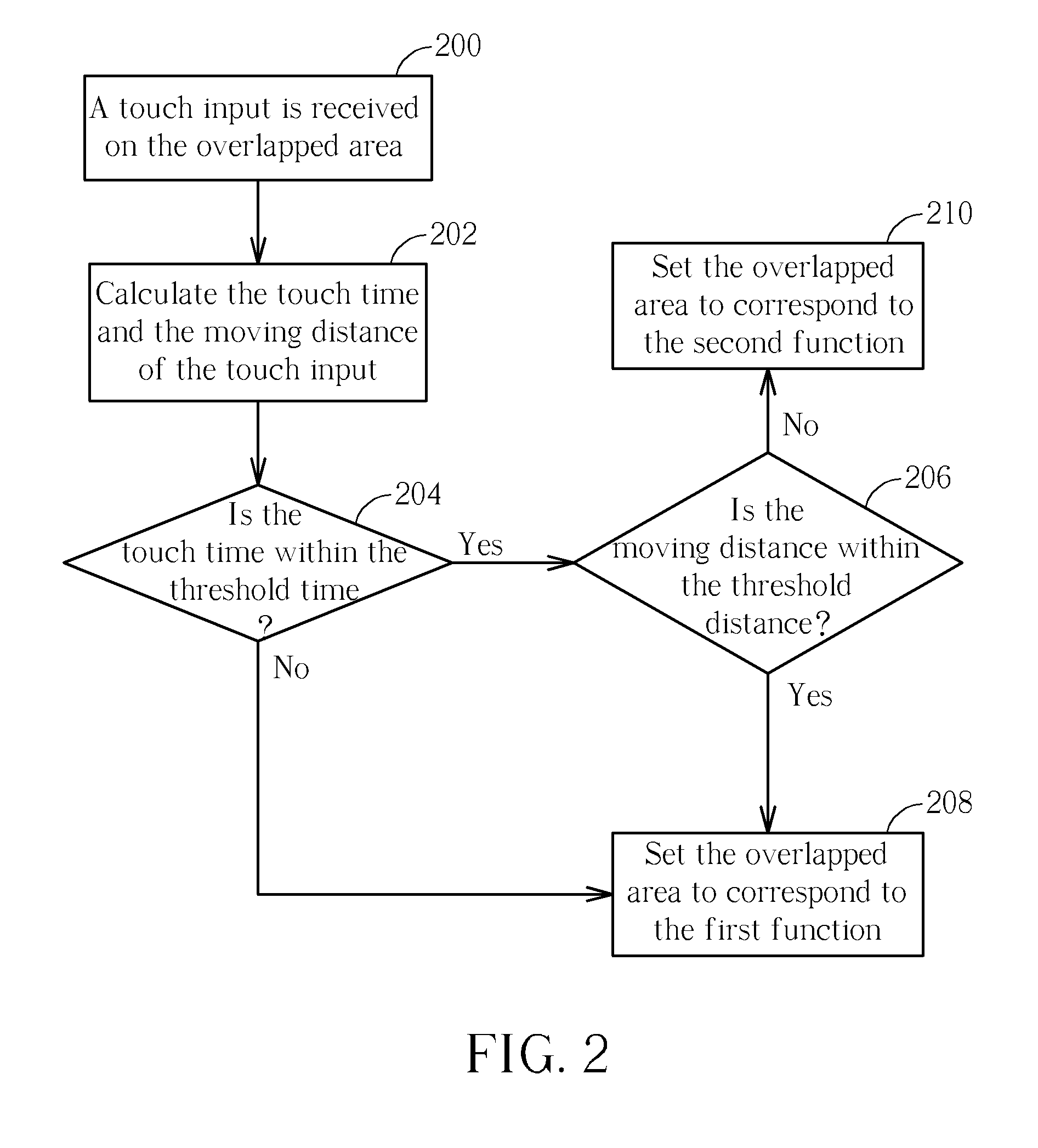

ActiveUS20110109563A1Increase the touch areaUndesired functions are not erroneously performedInput/output processes for data processingTouchscreenTouch panel

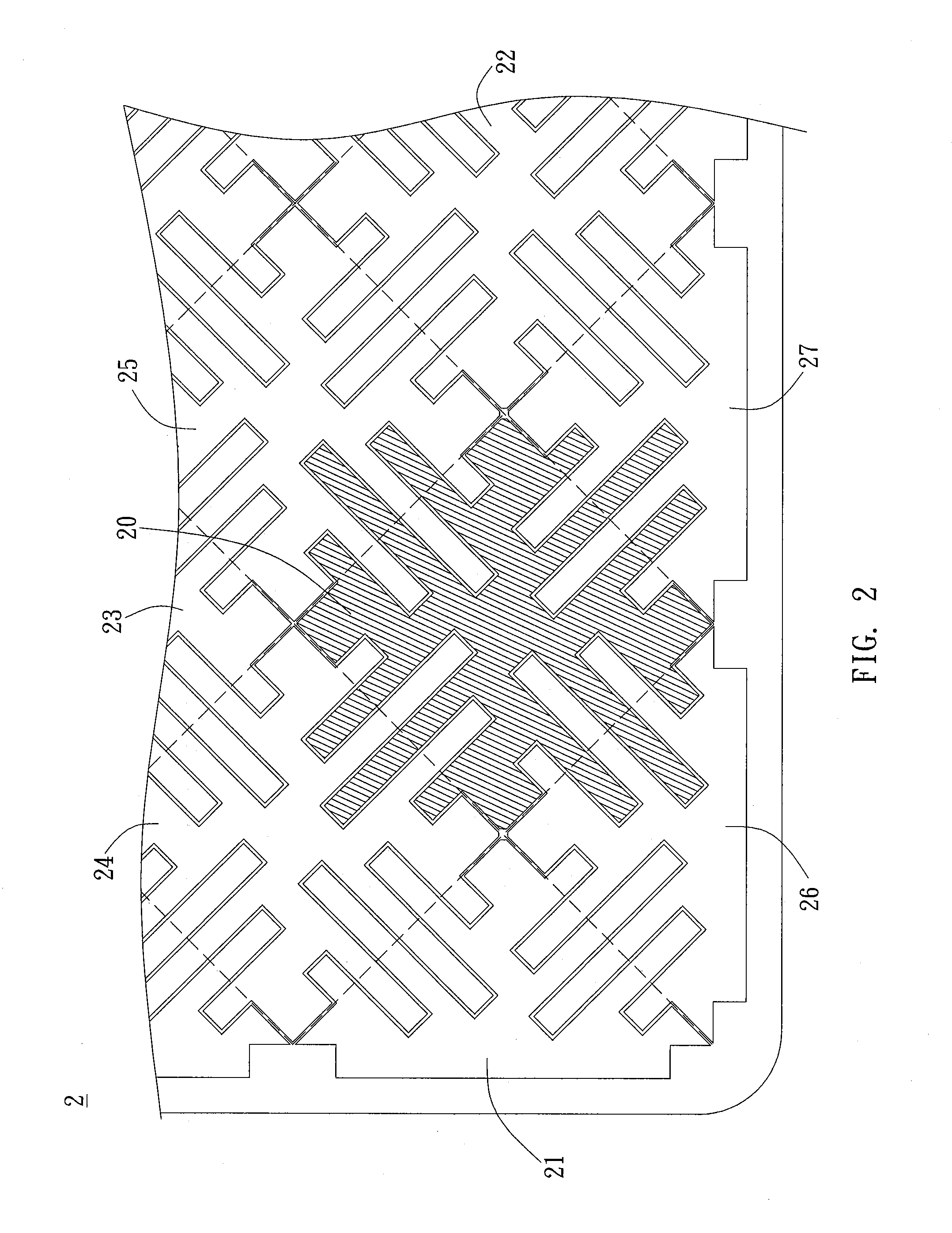

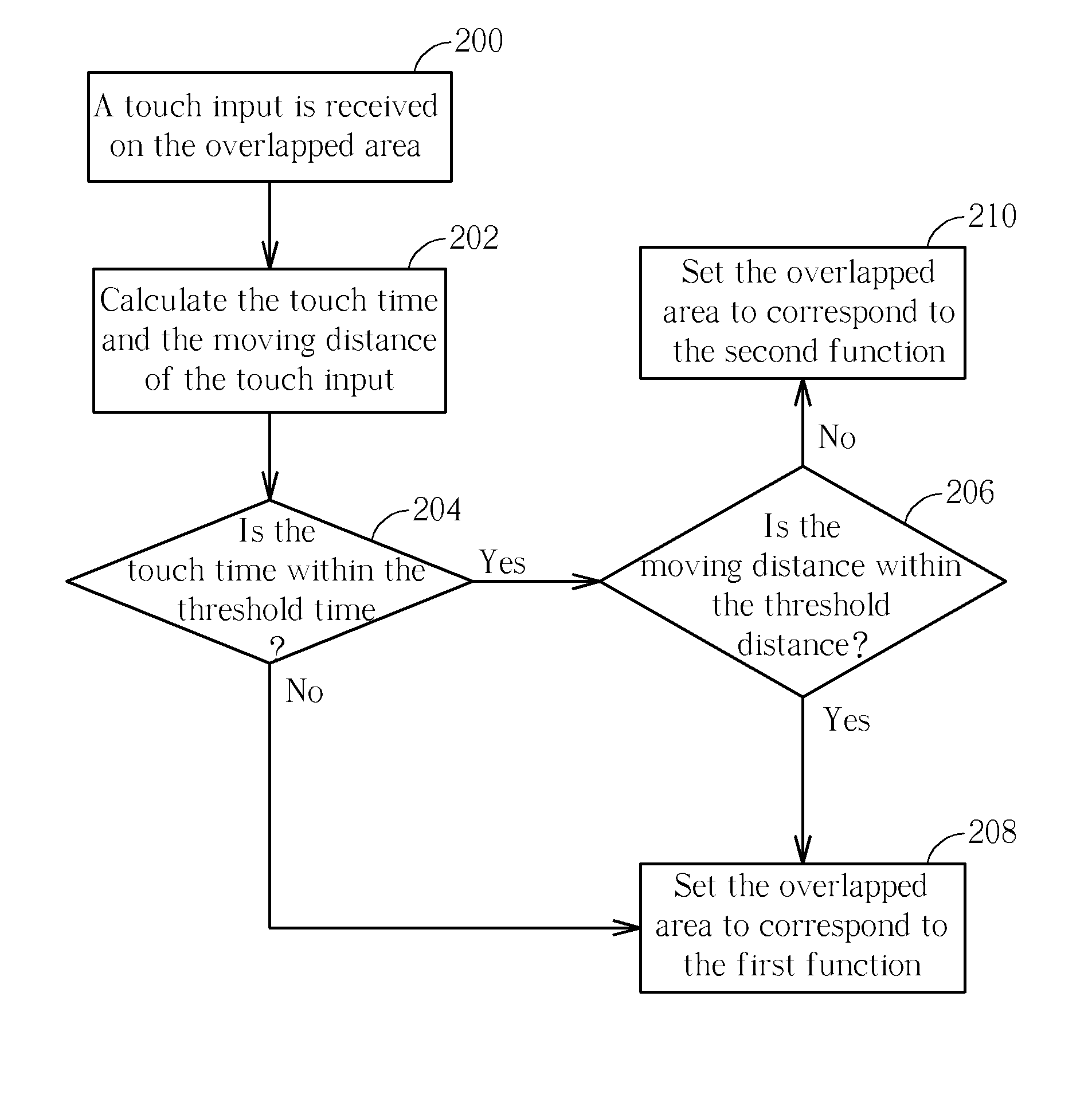

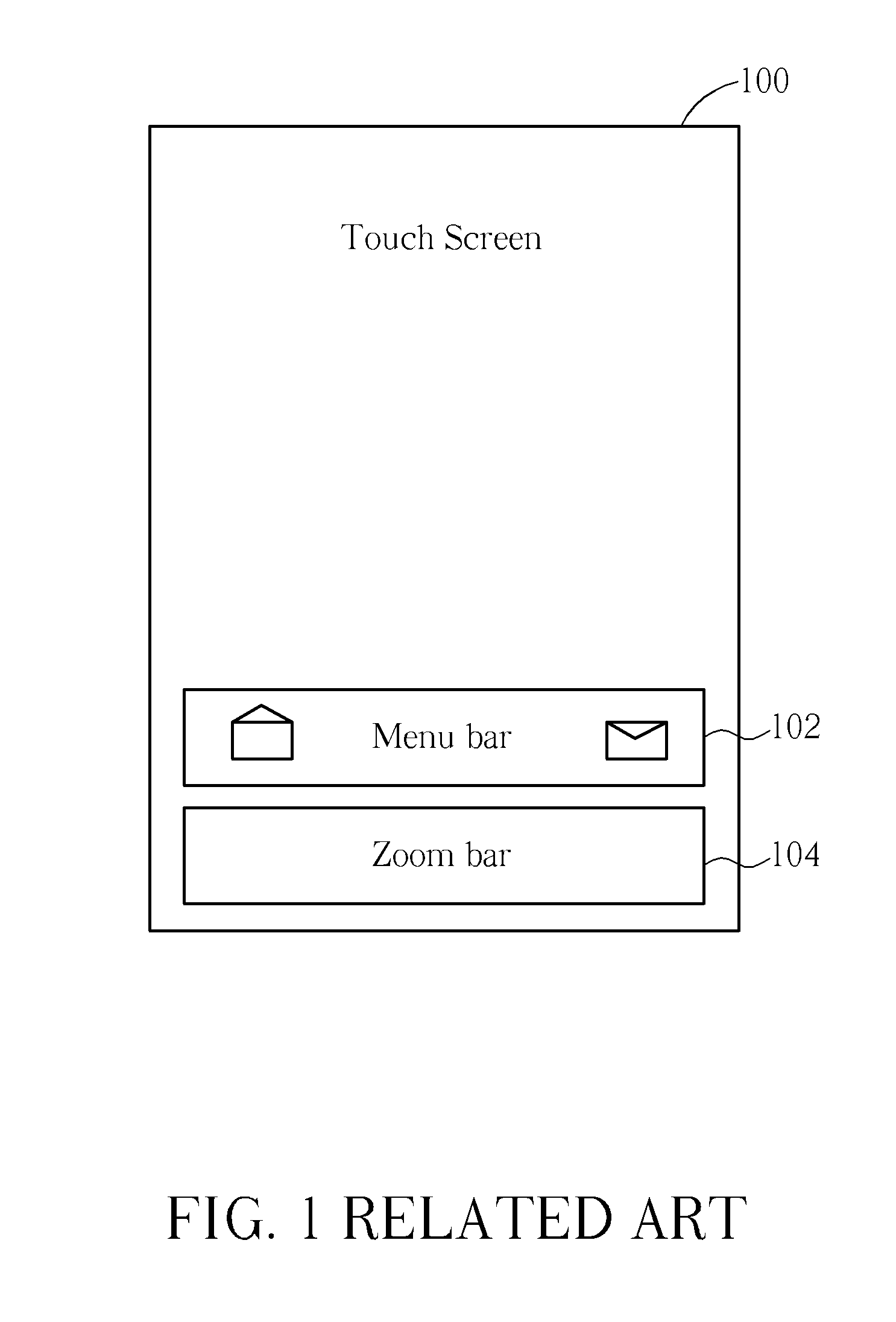

A method for adjusting at least a area of a touch screen is provided. The touch panel includes a first touch area and a second touch area, the first touch area is responsive to a stationary touch and corresponds to a first function, and the second touch area is responsive to a sliding touch and corresponds to a second function. The method includes: defining an overlapped touch area including at least part of the first touch area and at least part of the second touch area; receiving a touch input on the touch panel; when the touch input is started from the overlapped touch area, calculating a moving distance of the touch input and a touch time of the touch input; and when the touch time is within a threshold time, and the moving distance exceeds a threshold distance, setting the overlapped touch area to correspond to the second function.

Owner:HTC CORP

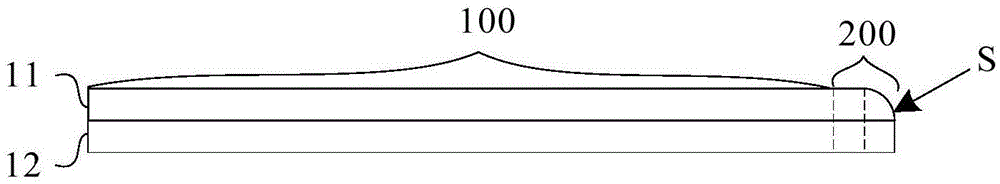

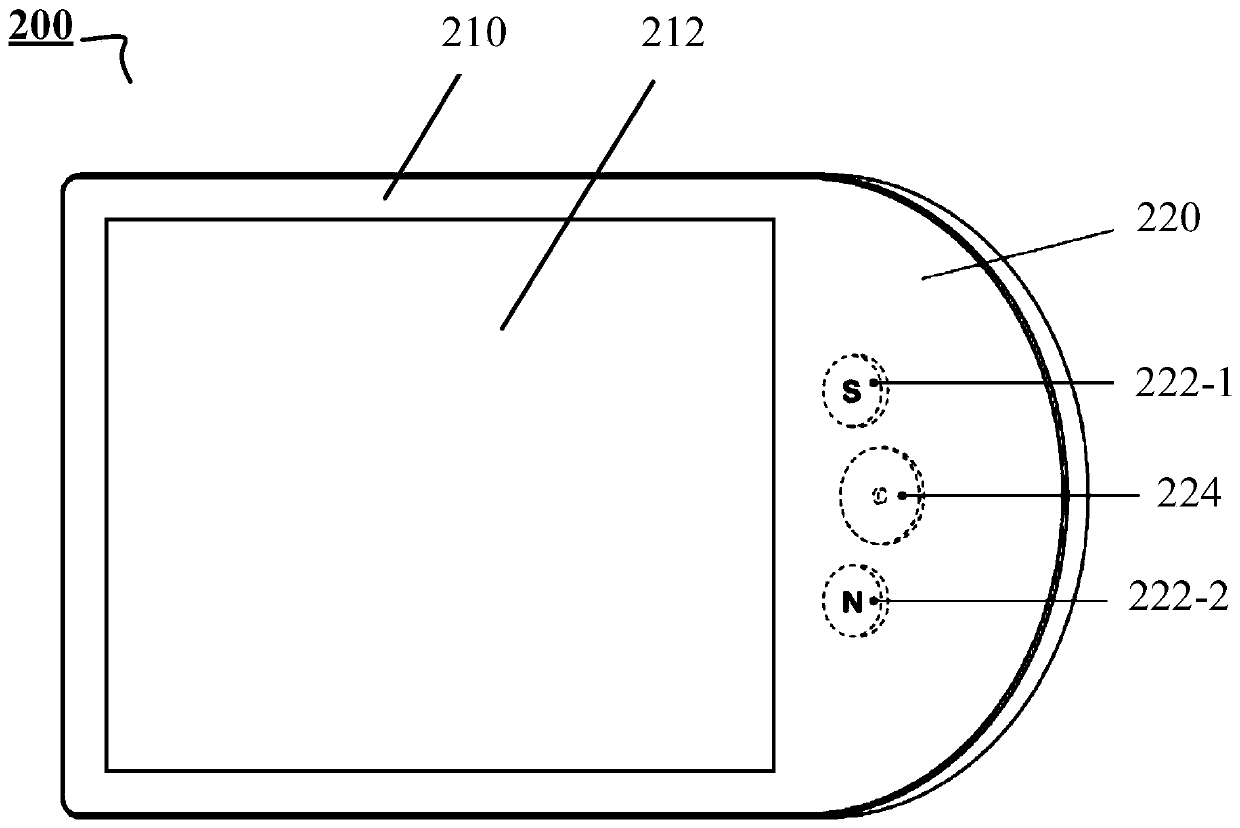

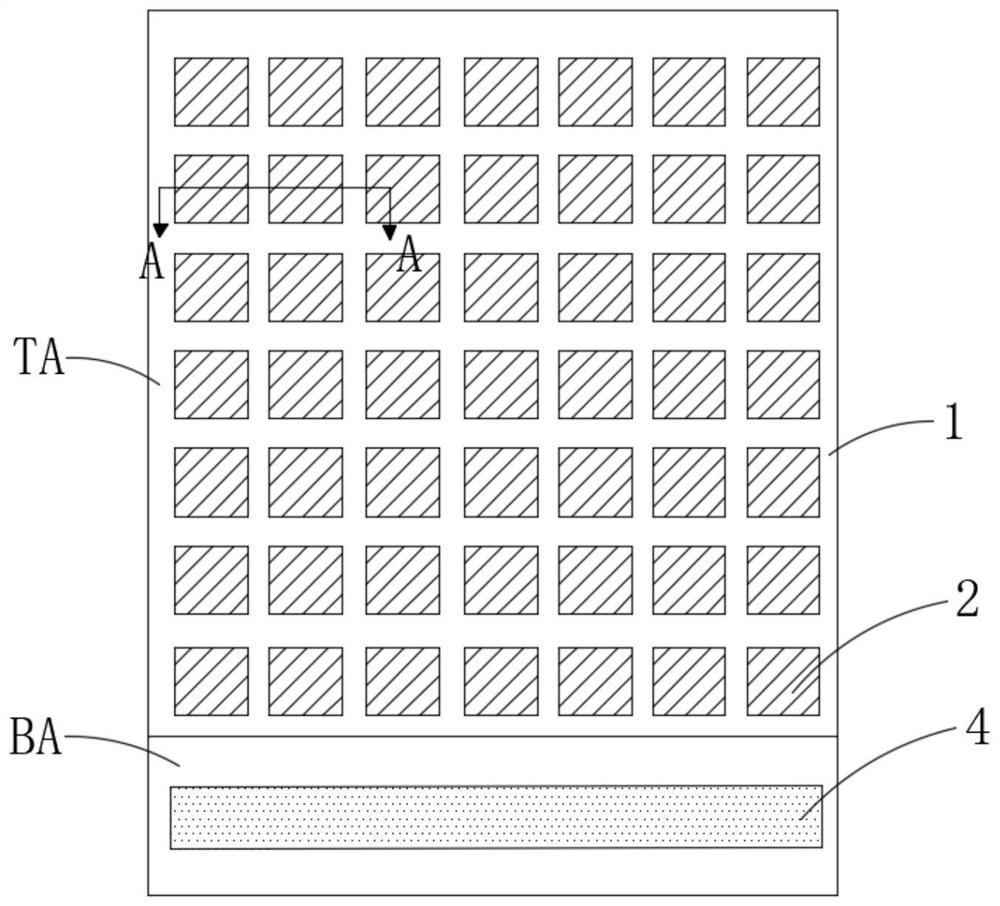

Wearable device and touch event response method of wearable device

ActiveCN105528109AEasy to operateImprove experienceInput/output processes for data processingResponse methodEngineering

The present invention provides a wearable device. An interaction panel comprises a display area and a non-display area. The non-display area comprises a wiring area and a touch area, and the wiring area is disposed at one side, close to the display area, of the non-display area. The non-display area can be used as the black edge (the area shielding wiring) of the interaction panel of the wearable device, and the touch area is disposed in the black edge. Users can operate the wearable device by operating the touch area to operate program loaded in the wearable device. The black edge is disposed outside the display area, so browsing obstacle can be prevented due to the fact that a screen cannot be covered when operating the wearable device, probability of mistouch and misoperation is also largely reduced, and operation convenience and user experience are improved. The present invention also provides a touch event response method of the wearable device.

Owner:BEIJING QIHOO TECH CO LTD

Interactive terminal and smart home system

ActiveCN109946989ARich interactionEasy for users to realize touch operationComputer controlTotal factory controlVirtual screenEmbedded system

The invention discloses an interactive terminal applicable to control of equipment in a room. The interactive terminal comprises a control panel and a moving knob which are detachably connected, the control panel comprises a first screen, and the moving knob comprises a second screen; when the control panel and the moving knob are fixedly connected and are in communication connection, the first screen and the second screen are combined to form a virtual screen; an equipment control interface is displayed on the virtual screen, so that a control instruction of a user is conveniently received. The invention also discloses a corresponding smart home system.

Owner:北京远鼎科技有限公司

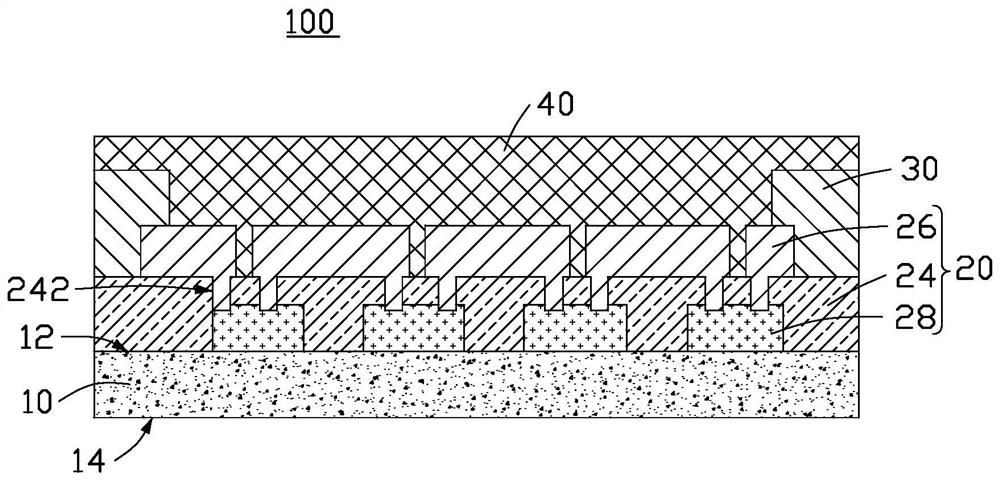

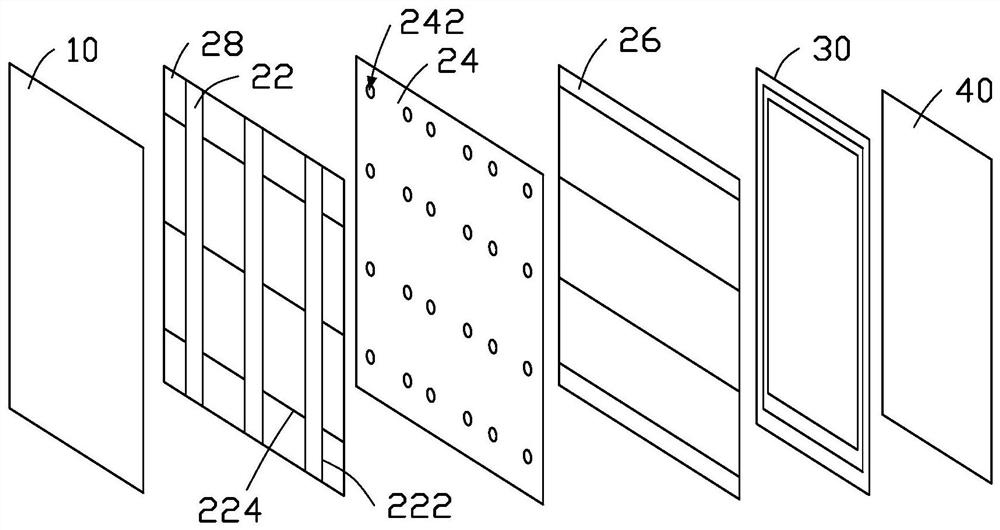

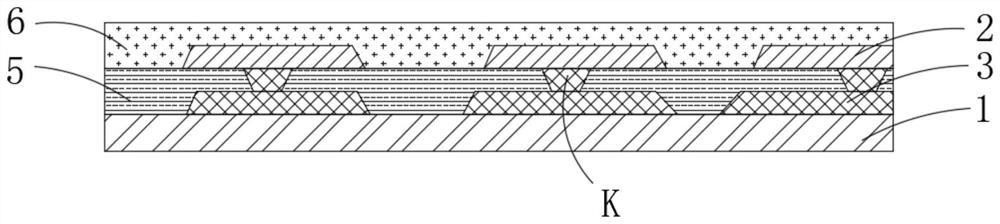

Touch panel and display device

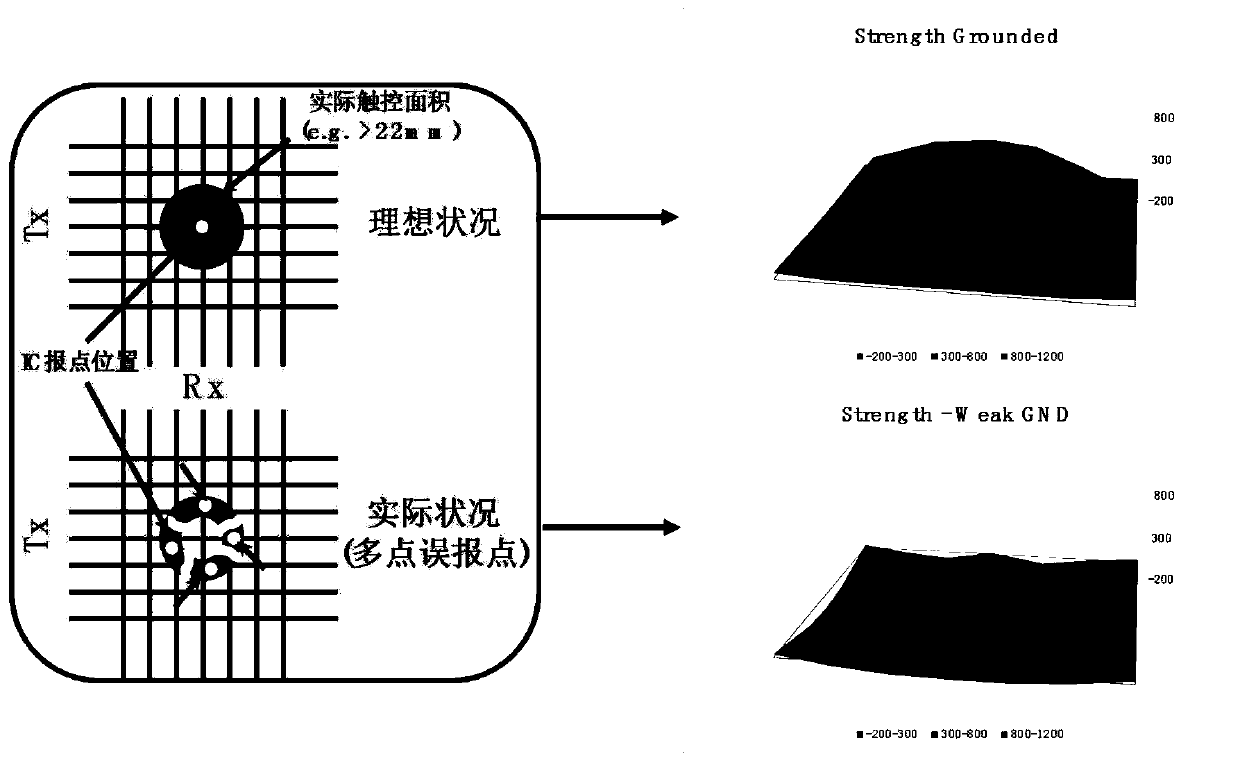

PendingCN111258462AIncrease the touch areaHigh sensitivityInput/output processes for data processingTouch panelEngineering

The invention discloses a touch panel and a display device. According to the touch display product, the virtual electrodes insulated from the touch electrodes are arranged on the electrode layer, whenthe touch display product is used under the normal grounding condition, the touch area can be enlarged through the arrangement of the virtual electrodes, more sensing areas can sensitively sense thetouch behavior of a user, and therefore the touch sensitivity is improved; when the touch display product is used under the weak grounding condition (for example, a mobile phone is placed on a desktopor a user lies on a bed and the like); a virtual electrode is manufactured on an electrode layer; the virtual electrode is grounded through a virtual electrode lead; when the touch display product isused under the weak grounding condition, the touch display product is lightly grounded; according to the touch panel, the virtual electrodes are arranged between the touch electrodes, electric charges between the touch electrodes can be transmitted to the virtual electrodes through fingers, due to the fact that the virtual electrodes are grounded, the electric charges between the touch electrodescan be well transmitted to the ground, strong semaphore can also be detected for the touch electrodes, the situation of multi-point false alarm of an IC is avoided, and the use experience of a user is improved.

Owner:BOE TECH GRP CO LTD +1

Touch screen and touch-control display device

ActiveCN104199588AReduce border widthIncrease the touch areaInput/output processes for data processingPower flowDisplay device

The invention discloses a touch screen and a touch-control display device. The touch screen and the touch-control display device comprises a plurality of first conducting wires and a plurality of second conducting wires, that are parallel to a first direction, and a plurality of third conducting wires parallel to a second direction, wherein each first conducting wire is correspondingly connected with a first leading wire; each second conducting wire is correspondingly connected with a second leading wire; each third conducting wire is correspondingly connected with a third leading wire; when electromagnetic touch happens, two optional first conducting wires are connected with each other; the current directions of two first leading wires that are correspondingly connected to the two optional first conducting wires are opposite to each other, so as to form a first coil; two optional second conducting wire are connected with each other; the current directions of two second leading wires that are correspondingly connected to the two optional second conducting wires are opposite, so as to form a second coil; two optional third conducting wires are connected with each other; the current directions of two third leading wires that are connected to the two optional third conducting wires are opposite, so as to form a third coil; the first coil and the second coil are used for detecting the coordinate of a touch position in the second direction; the third coil is used for detecting the coordinate of the touch position in the first direction.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

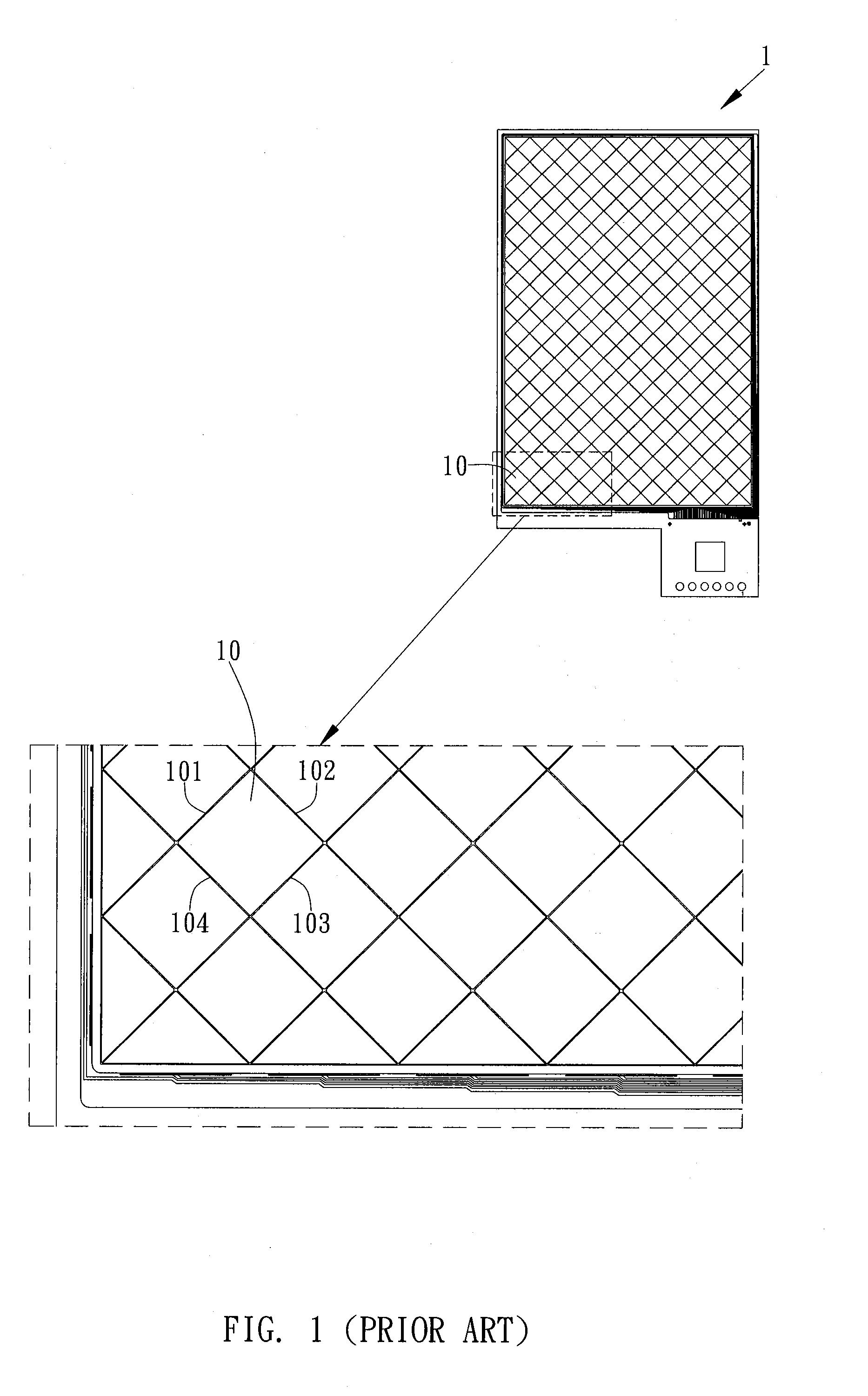

Inputting apparatus

InactiveUS20100164991A1Easy to operateReduce areaCathode-ray tube indicatorsInput/output processes for data processingComputer graphics (images)Region detection

Owner:BROTHER KOGYO KK

Mutual capacitance type touch screen

InactiveCN103530010AGuaranteed light transmittanceLower the resistance valueInput/output processes for data processingTouchscreenElectrically conductive

The invention provides a mutual capacitance type touch screen which comprises a touch substrate, a metal support layer, an insulating layer and at least two transparent conductive film layers, wherein the metal support layer is arranged on the lower portion of the touch substrate and comprises a transverse support and a longitudinal support; the insulating layer is arranged between the transverse support and the longitudinal support; the transparent conductive film layers comprise a transverse transparent conductive film layer and a longitudinal transparent conductive film layer, the transverse support is electrically connected with the transverse transparent conductive film layer to form a transverse electrode, and the longitudinal support is electrically connected with the longitudinal transparent conductive film layer to form a longitudinal electrode; a transverse transparent conductive film is arranged along the transverse support, and the width of the transverse transparent conductive film in the direction vertical to the transverse support is larger than the width of the transverse support. According to the mutual capacitance type touch screen, signal transmission is achieved through the metal support layer, RC loading is reduced, and the transverse transparent conductive film layer and the longitudinal transparent conductive film layer can be manufactured to be larger and can be suitable for a mutual capacitance type touch screen of a large dimension.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

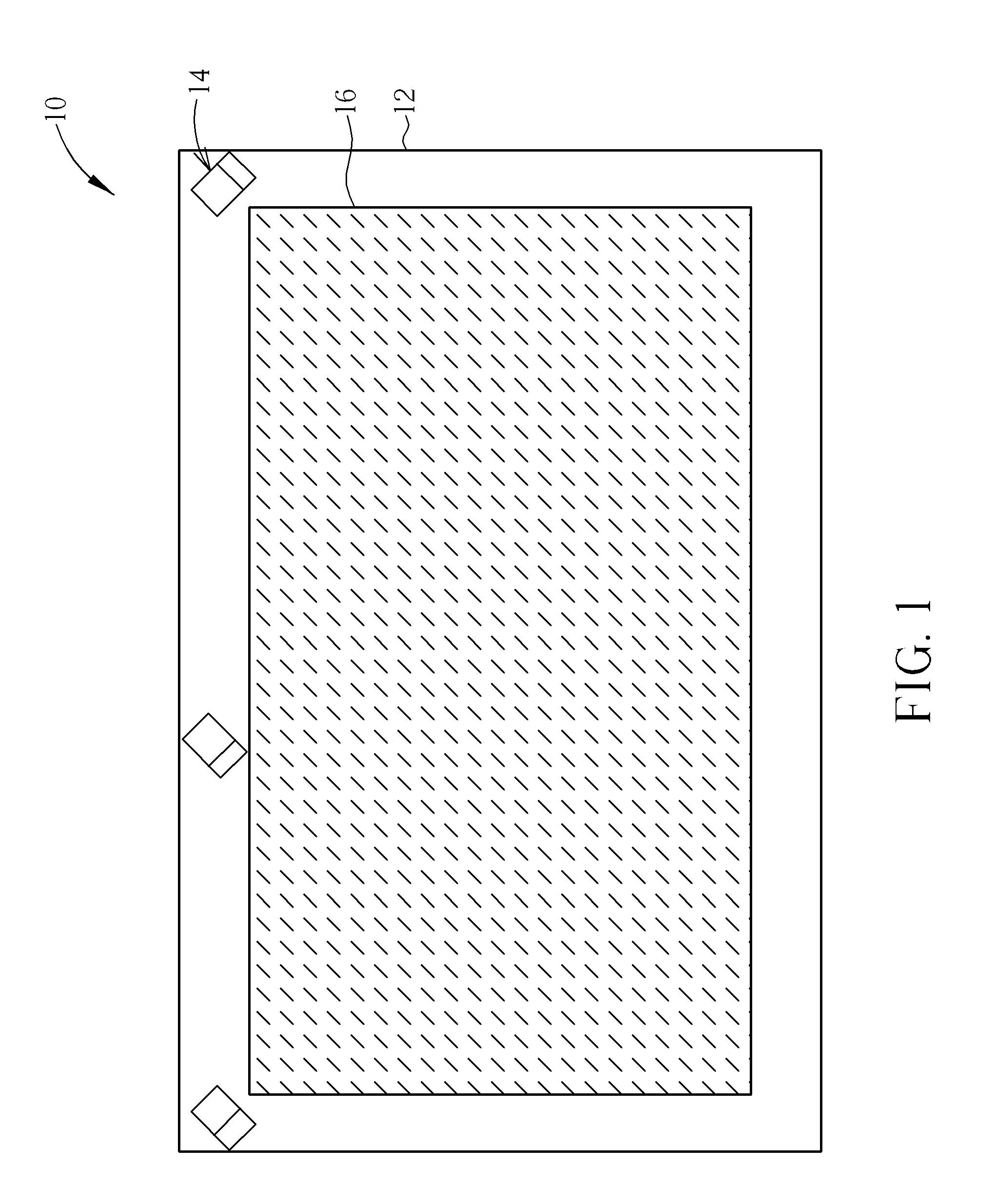

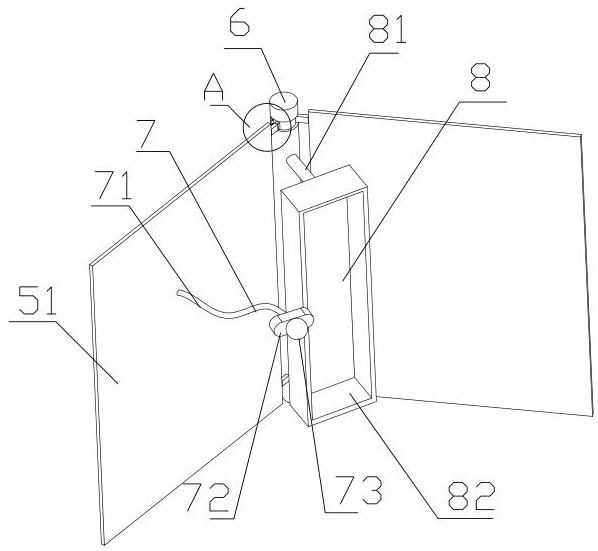

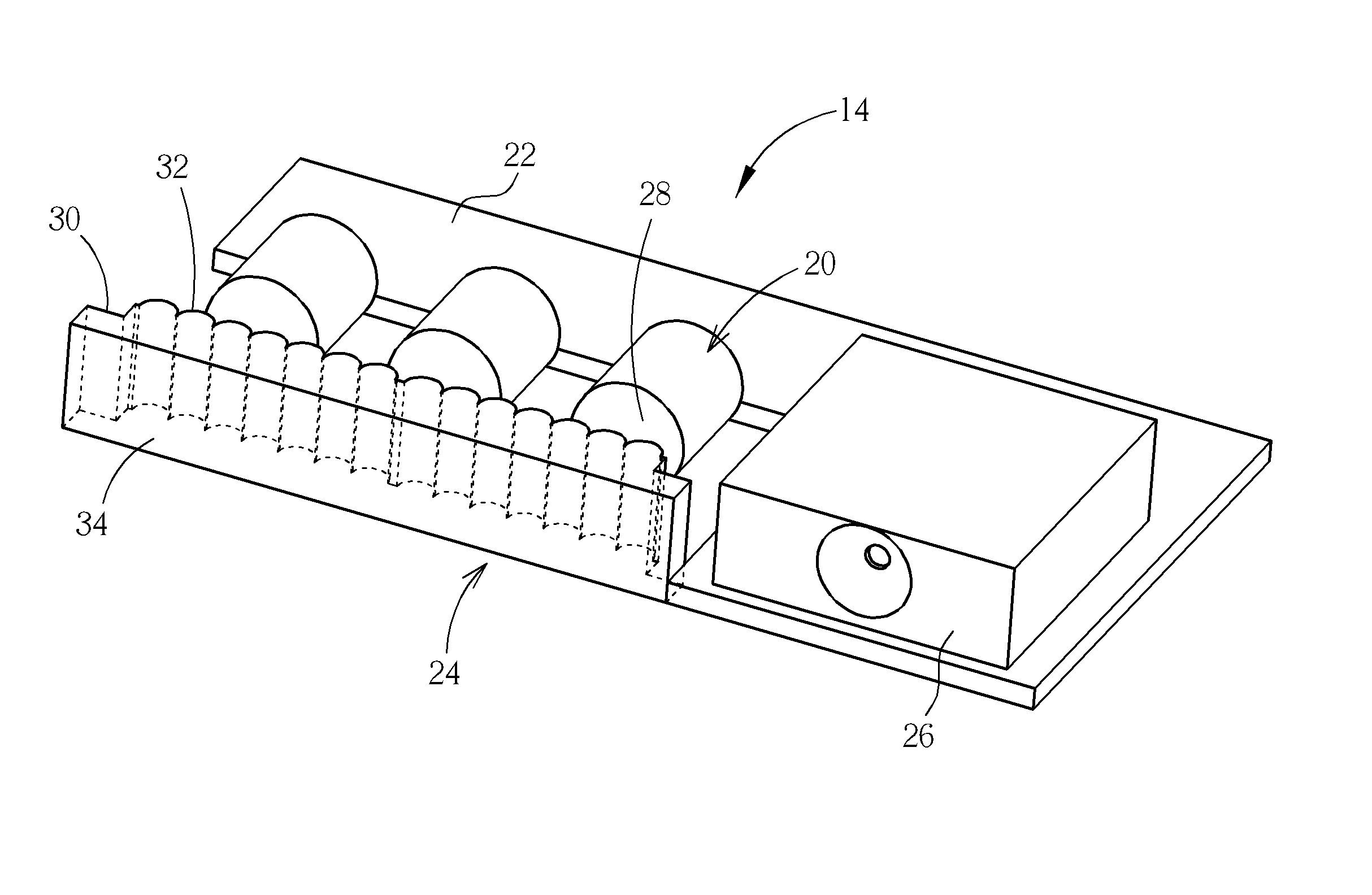

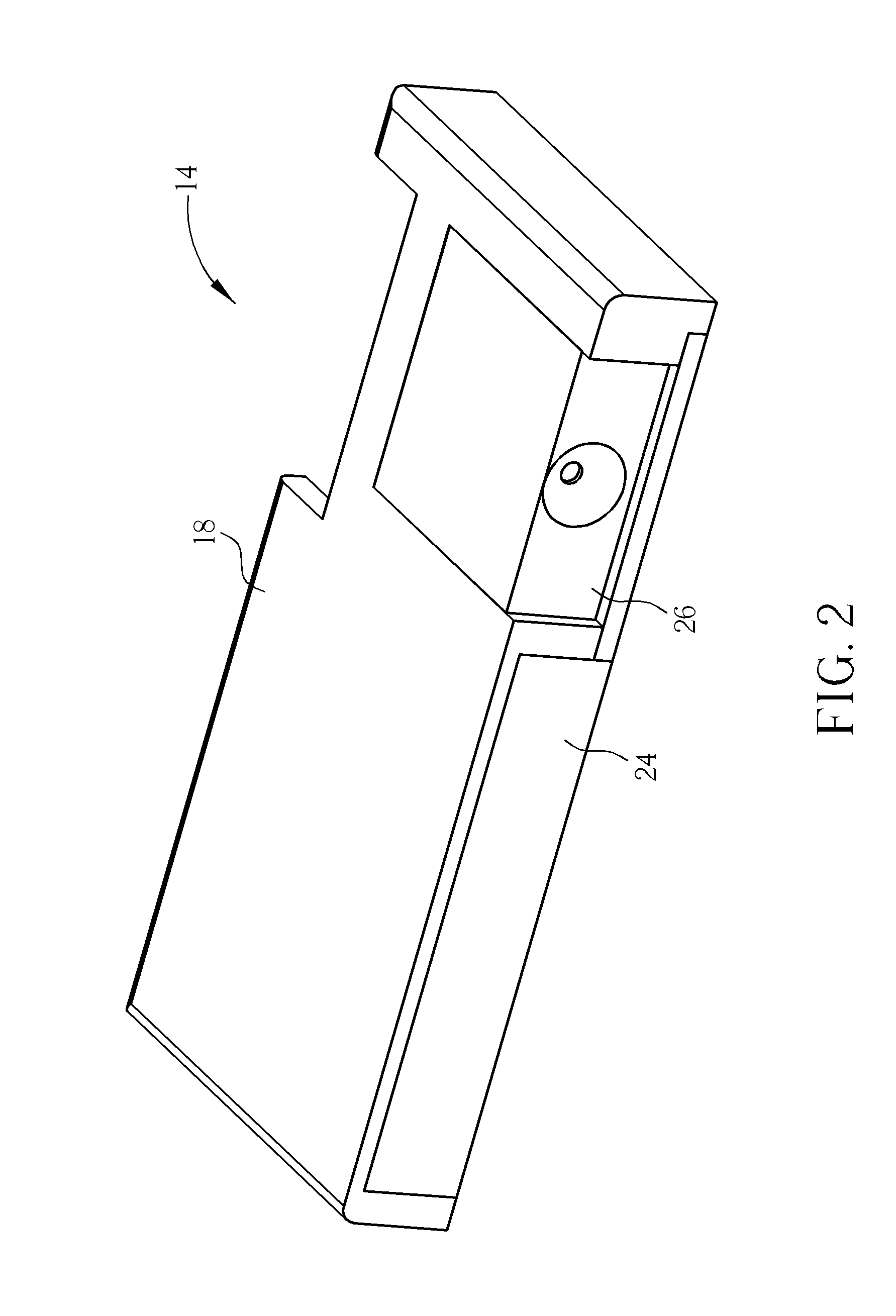

Optical touch module capable of increasing light emitting angle of light emitting unit

ActiveUS20120139875A1Improved light emissionInfluence accuracyInput/output processes for data processingLight-emitting diodeVisible light irradiation

An optical touch module includes a screen and at least one optical positioning device disposed on the screen. The optical positioning device includes a case, at least one light emitting unit, a circuit board, a transparent diffusing part and an image capturing unit. The light emitting unit is disposed on case for emitting invisible light. The circuit board is electrically connected to the light emitting unit for controlling the light emitting unit. The transparent diffusing part is disposed at a light emitting side of the light emitting unit. A bar structure is formed on a light entrance surface of the transparent diffusing part for scattering the invisible light to be distributed over a touch surface of the screen. The image capturing unit is disposed on the case to capture an optical image for a touch object on the touch surface when the touch object is illuminated by the invisible light.

Owner:WISTRON CORP

High-power lithium-cathode-intercalated hybrid asymmetric super-capacitor pole piece and manufacturing method thereof

InactiveCN102610397AImprove high-power charging and discharging performanceIncrease energy densityHybrid capacitor electrodesDouble layer capacitorsLithiumNew energy

The invention discloses a high-power lithium-cathode-intercalated hybrid asymmetric super-capacitor pole piece and a manufacturing method of the high-power lithium-cathode-intercalated hybrid asymmetric super-capacitor pole piece, which belongs to new energy material technology and relative field; high-power charging / discharging capacity of a hybrid asymmetric super-capacitor is enhanced effectively; after lithium is led to cathode, a potential window of the hybrid asymmetric super-capacitor is widened; energy density of the super-capacitor is increased effectively; finally, the super-capacitor is encapsulated by soft package; production efficiency of the super-capacitor is also increased greatly; and production cost is reduced.

Owner:长沙亚科新能源科技有限公司

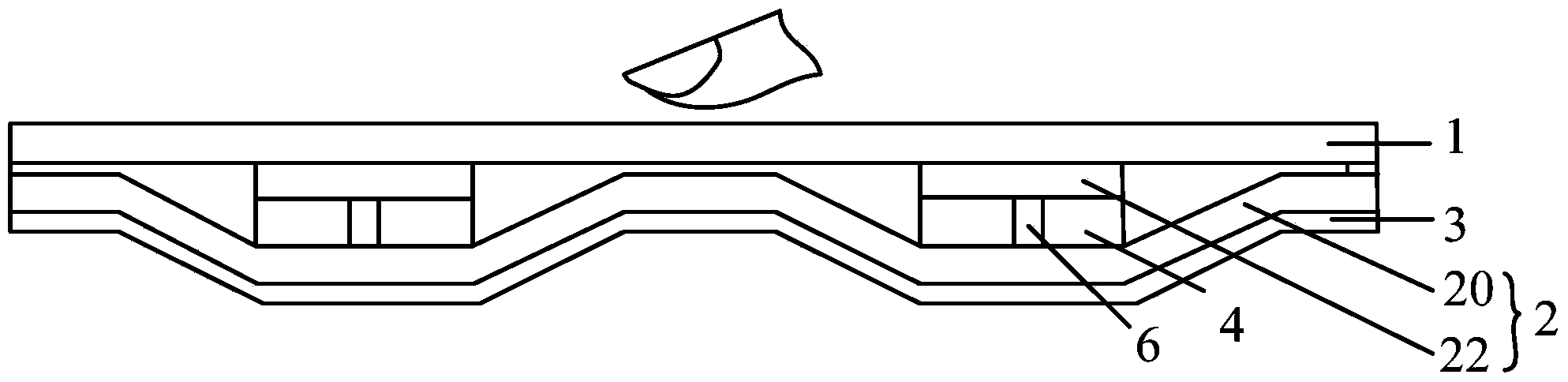

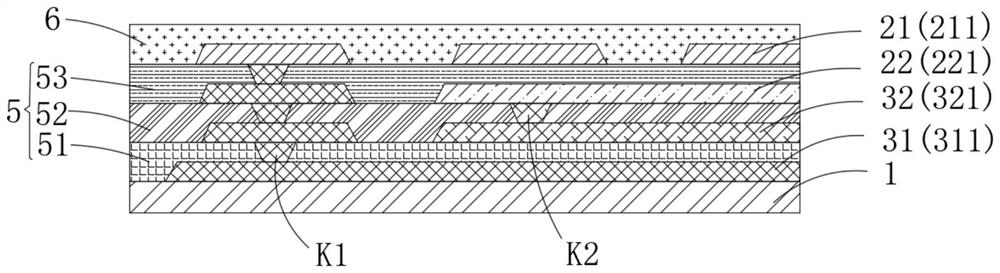

Touch projection screen and touch projection system

InactiveUS20160266705A1Reduce areaNarrow frameElectronic switchingInput/output processes for data processingProjection screenLight beam

A touch projection screen includes a substrate, a first touch layer, a second touch layer, a reflective projection film and a circuit board. The substrate has a first surface and a second surface. The first touch layer is disposed on the first surface and extends around an edge of the substrate to cover a part of the second surface of the substrate. The second touch layer is disposed on the first touch layer and extends around an edge of the substrate to cover a part of the second surface of the substrate. The reflective projection film is disposed on the second touch layer. The circuit board is disposed on the second surface of the substrate and electrically connects the first and second touch layers. A touch projection system includes the touch projection screen and a projection device. The projection device projects an image beam onto the touch projection screen.

Owner:CORETRONIC

A texture haptic reproducing apparatus, a display apparatus, and a radian reproducing apparatus

InactiveCN109240485AIncrease the touch areaPracticalInput/output for user-computer interactionGraph readingElectricityComputer graphics (images)

The invention relates to a texture haptic reproducing device. The display device and the radian reproducing device are respectively provided with two rows of piezoelectric ceramics at two ends of a conductive surface of a touch panel. Based on the squeeze film effect, the finger can touch the interface surface dynamically by changing the friction force between the finger and the contact surface and reproducing the surface texture information of the virtual object in the form of variable friction force, which is the closest natural detection method. The invention improves the piezoelectric ceramic matrix of the prior art, realizes texture reproduction by using two rows of piezoelectric ceramics, makes the device lighter and thinner, increases effective touch area greatly, can be integratedwith common electronic products on the market, and has strong practicability. The texture tactile reproducing device can be integrated on the display screen of the electronic product, and the tactilefeedback function of the electronic product is added. The operator can perceive the surface texture information of the virtual object in the form of variable friction force, thereby enhancing the sense of reality and immersion of the virtual environment.

Owner:XIAMEN UNIV +1

Touch panel and touch pad

InactiveUS20120223893A1Increase the touch areaImprove touch sensitivityInput/output processes for data processingTouchpadEngineering

A touch panel and a plurality of touch pads thereof are disclosed. Each touch pad includes a plurality of the same edges. Each edge includes two edge ends, an edge center, at least one convex, and at least one concave. A line between the two edge ends is defined as a reference line. The edge center is located at the center of the reference line. A first region is surrounded by the at least one convex and the reference line. A second region is surrounded by the at least one concave and the reference line. The at least one convex and the at least one concave are symmetrical to the edge center.

Owner:RAYDIUM SEMICON

Electronic device with dynamically adjusted touch area

ActiveUS8373670B2Increase the touch areaUndesired functions are not erroneously performedInput/output processes for data processingTouchscreenTouch panel

A method for adjusting at least a area of a touch screen is provided. The touch panel includes a first touch area and a second touch area, the first touch area is responsive to a stationary touch and corresponds to a first function, and the second touch area is responsive to a sliding touch and corresponds to a second function. The method includes: defining an overlapped touch area including at least part of the first touch area and at least part of the second touch area; receiving a touch input on the touch panel; when the touch input is started from the overlapped touch area, calculating a moving distance of the touch input and a touch time of the touch input; and when the touch time is within a threshold time, and the moving distance exceeds a threshold distance, setting the overlapped touch area to correspond to the second function.

Owner:HTC CORP

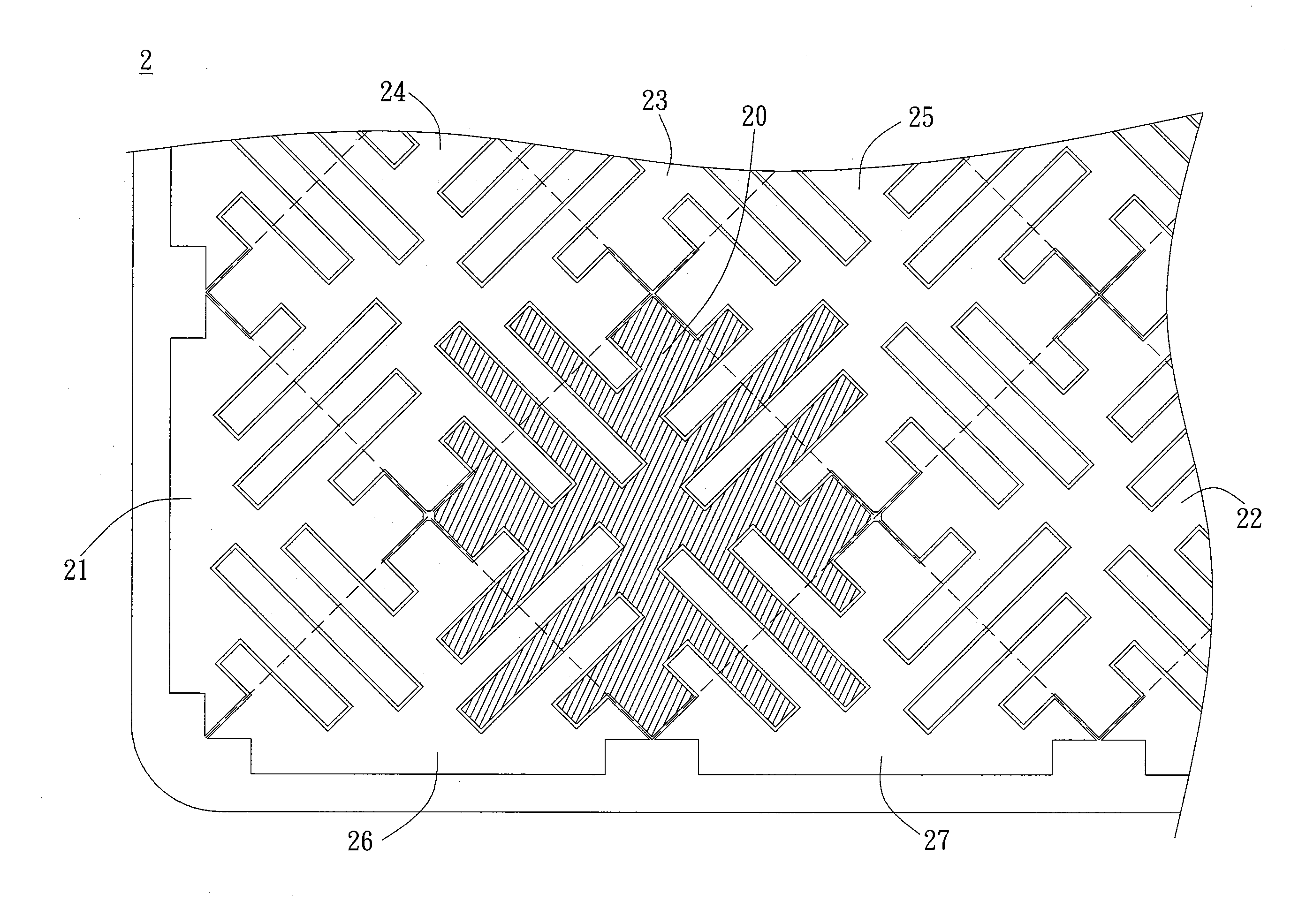

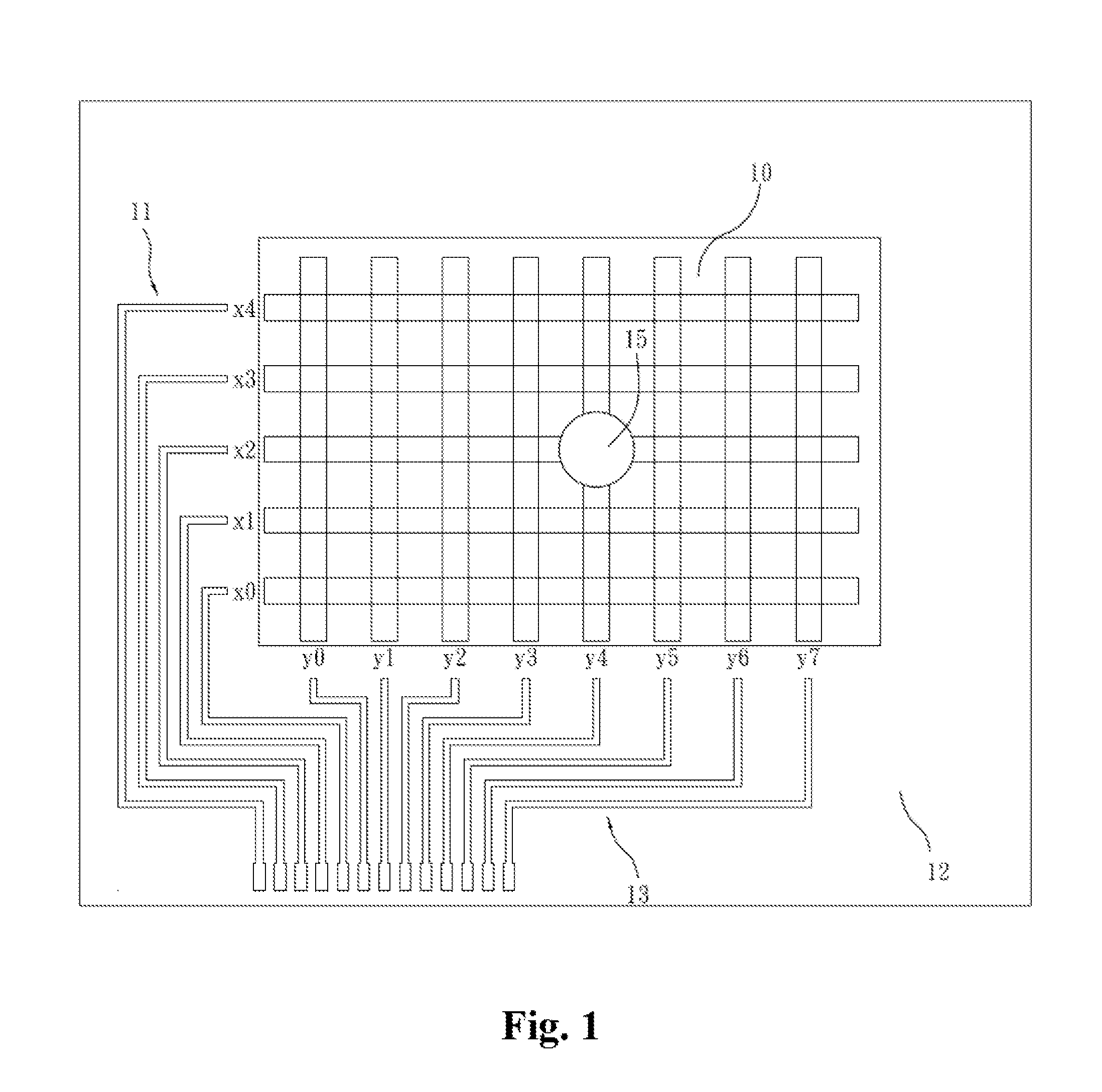

Touch panel and a manufacturing method thereof

ActiveUS20130176234A1Increase the touch areaReduce areaLine/current collector detailsInput/output processes for data processingEngineeringTouch panel

The present disclosure relates to a touch technology and more particularly, to a touch panel and a manufacturing method thereof. The touch panel comprises a plurality of first sensing electrode axes, a plurality of second sensing electrode axes, and a plurality of conductive wire axes. The first sensing electrode axes are disposed along a first axis. The second sensing electrode axes are disposed along a second axis and electrically insulated from the first sensing electrode axes. The plurality of conductive wire axes are disposed along the second axis and extended to the first peripheral area. Any two of the conductive wire axes are electrically connected to different first sensing electrode axes. According to the touch panel and the manufacturing method provided in the present disclosure, areas of the available touch area and a visible area on the touch panel can be effectively increased.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

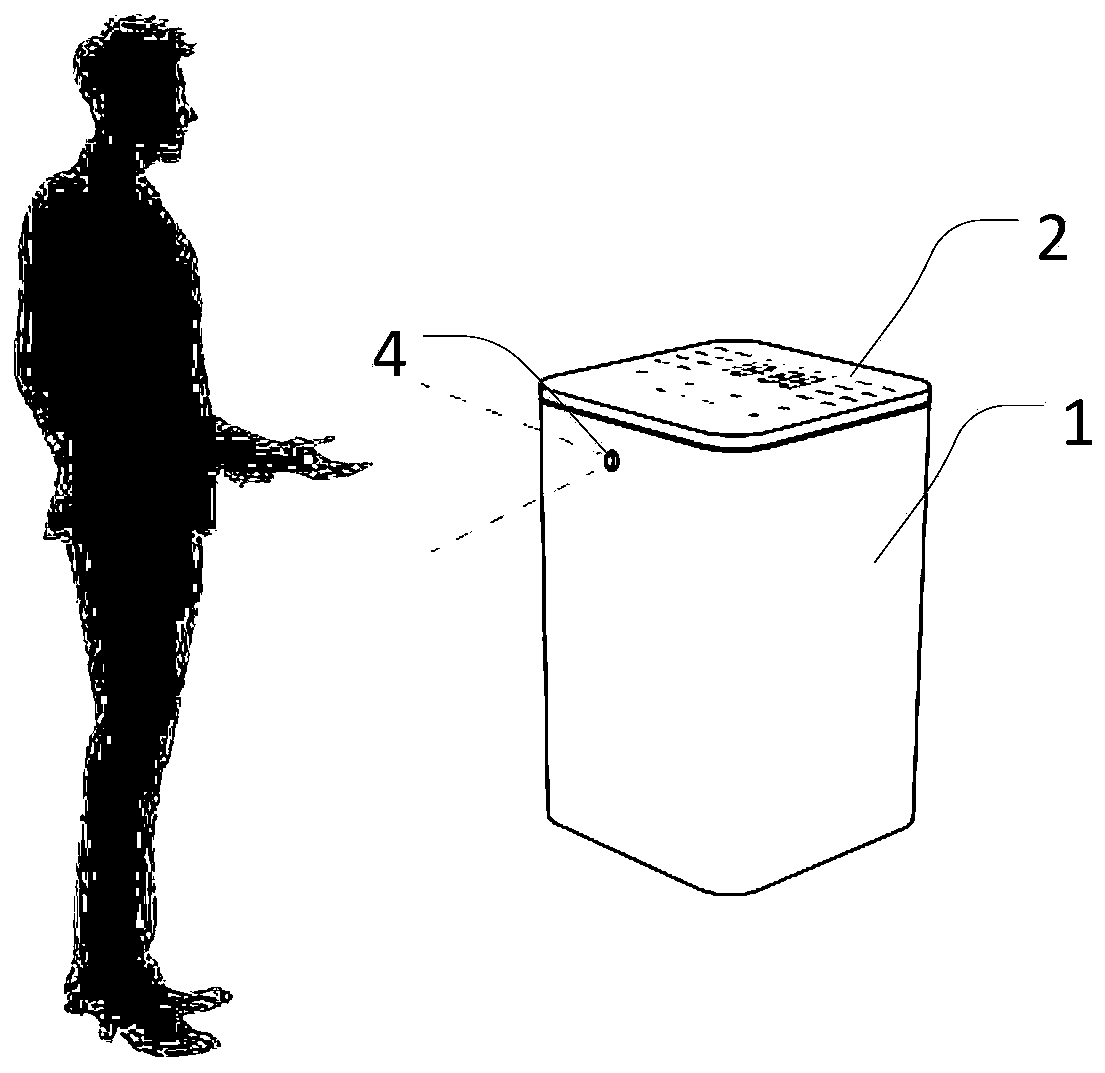

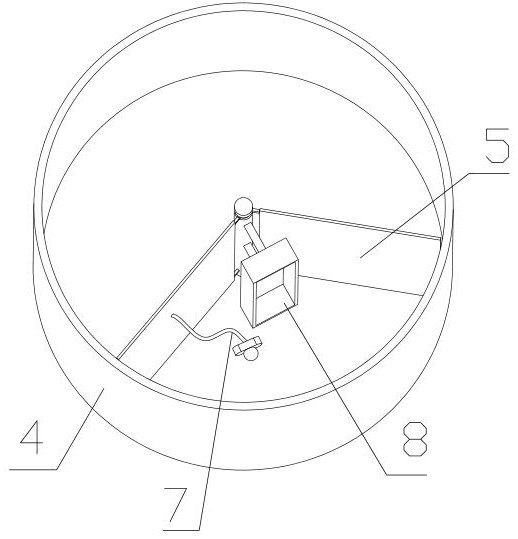

Control method for washing machine, device and equipment for washing and storage medium

PendingCN111411480AIncrease the display areaIncrease the touch areaControl devices for washing apparatusTextiles and paperEmbedded systemComputer hardware

The invention discloses a control method for a washing machine, a device and equipment for washing and a storage medium. The control method is applied to the washing machine with a door cover with a touch control display screen, and the washing machine is in communication connection with terminal equipment. The control method includes the steps of receiving a function call instruction sent by theterminal equipment; displaying a target function interface corresponding to the function call instruction; obtaining a touch control instruction acting on the target function interface; and controlling the washing machine to execute target functions according to the touch control instruction. The door cover of the washing machine has the touch control display screen which can display the content of a display screen of the terminal equipment, the display interface of the terminal equipment is amplified and displayed on the door cover of the washing machine, and the washing machine can be controlled to perform the corresponding target functions by directly touching the door cover. As the size of the door cover of the washing machine is much larger than the size of a display screen of a mobile terminal, the touch control display screen is arranged on the door cover, the display area and the touch control area are increased, and user operation is facilitated.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

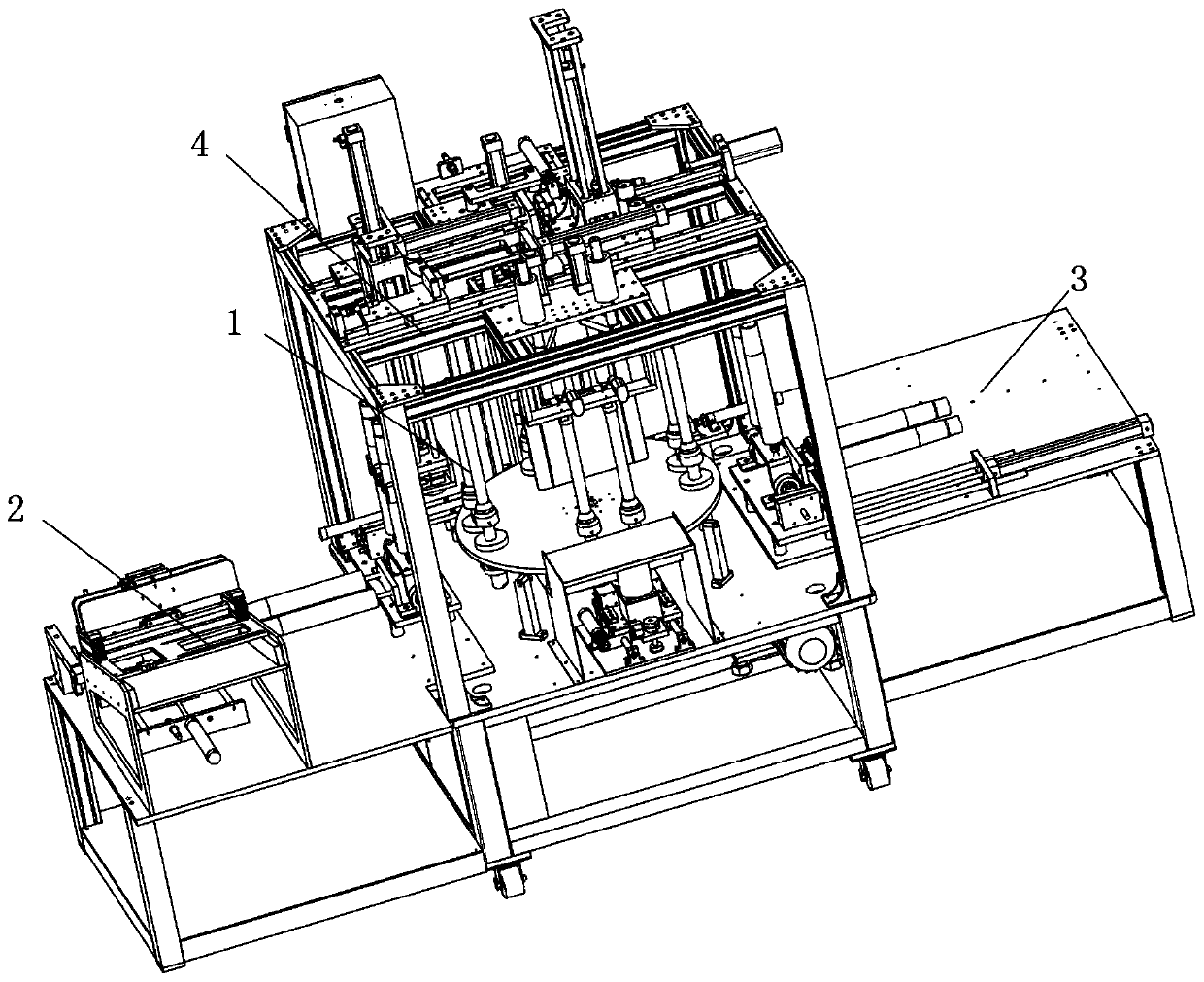

Circular grinding device for removing burrs of parting face of casting

InactiveCN109822416ARound grinding and polishing positions are comprehensiveImprove efficiencyEdge grinding machinesGrinding carriagesEngineeringHydraulic pump

The invention discloses a circular grinding device for removing burrs of a parting face of a casting. The circular grinding device comprises a circular grinding table, a first pushing disc, a second pushing disc and a mounting base. The circular grinding table is longitudinally arranged. One end of the circular grinding table is provided with the first pushing disc, and the other end of the circular grinding table is provided with the second pushing disc. The upper end of the circular grinding table is fixedly connected with the mounting base through a bolt. The circular grinding device has the beneficial effects that a movable push piece on the second pushing disc pushes the casting to move left and right at the other end of a placing plate in front-and-back directions, the touch probability of the parting face on the casting and a grinding sheet is increased, the touch area of a film and the grinding sheet is expanded, and the efficiency of circularly grinding the parting face of thecasting and removing the burrs by the circular grinding device is improved; moreover, sixth hydraulic pumps arranged on the two sides of the placing plate drive a pushing column to push a third pushing plate to move forwards and backwards so as to push the placing plate to move forwards and backwards, a plurality of grinding frames can be used for grinding and deburring the parting face of the casting more comprehensively and thoroughly; and the circular grinding device is high in working automation degree, time-saving and labor-saving.

Owner:绍兴柯桥亮剑机械有限公司

Toothbrush head

The invention is related to a toothbrush head which comprises a head base, a head frame, and bristles. The head base comprises a front end, a back end, multiple strip-substrates, and multiple junctions. The multiple strip-substrates are aligned between the front end and the back end and each two adjacent strip-substrates link with each other with each of the multiple junctions, and each of the multiple strip-substrates comprises multiple sockets for inserting the bristles. The head frame comprises a bottom surface and multiple accommodating spaces for accommodating the head base. The toothbrush head allows the bristles to be bent into the arc shape when touching the teeth, so as to increase touching areas between the brushes and the teeth for enhancing cleaning effect and decreasing risks of causing caries.

Owner:ACUMEN

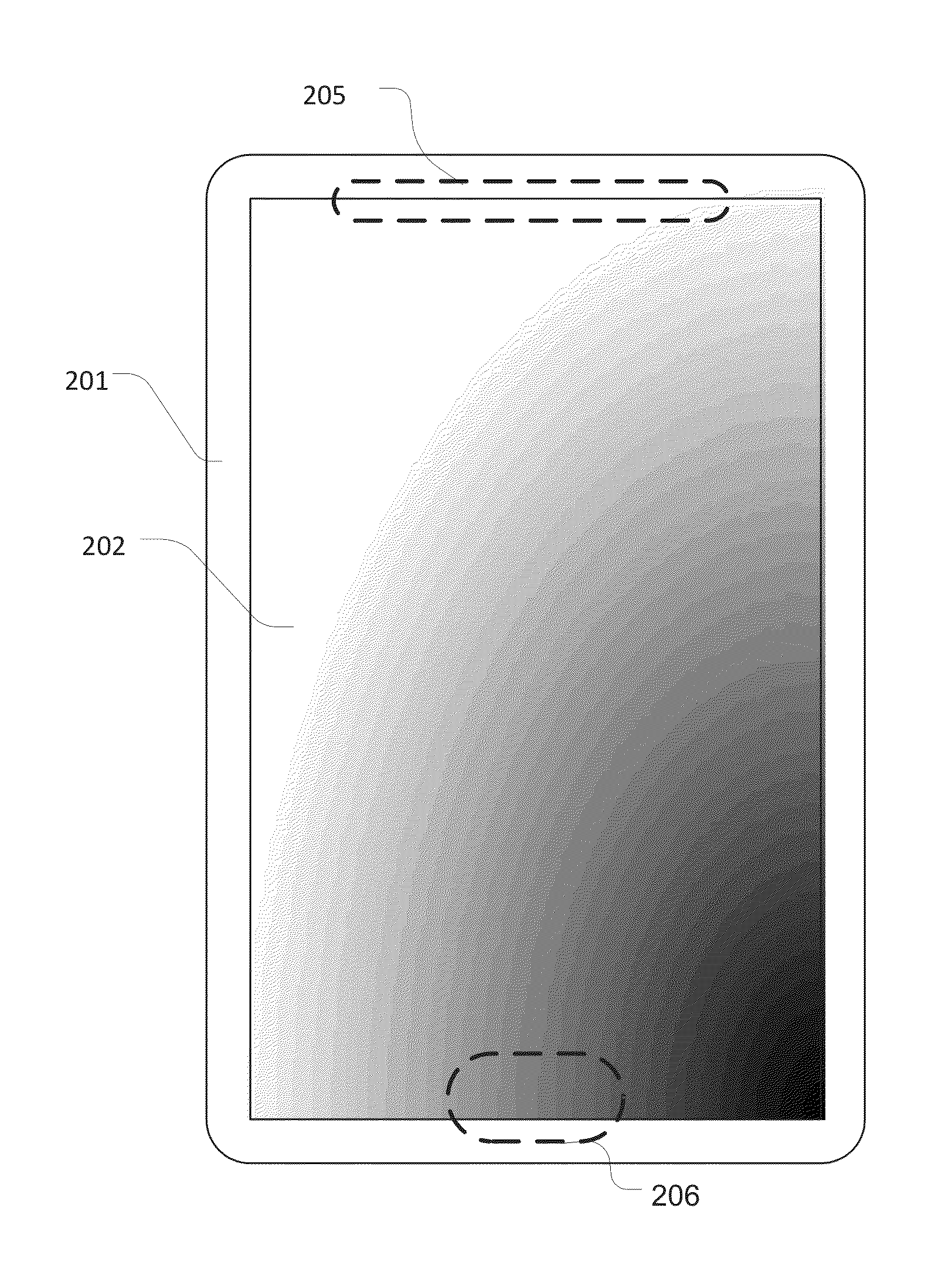

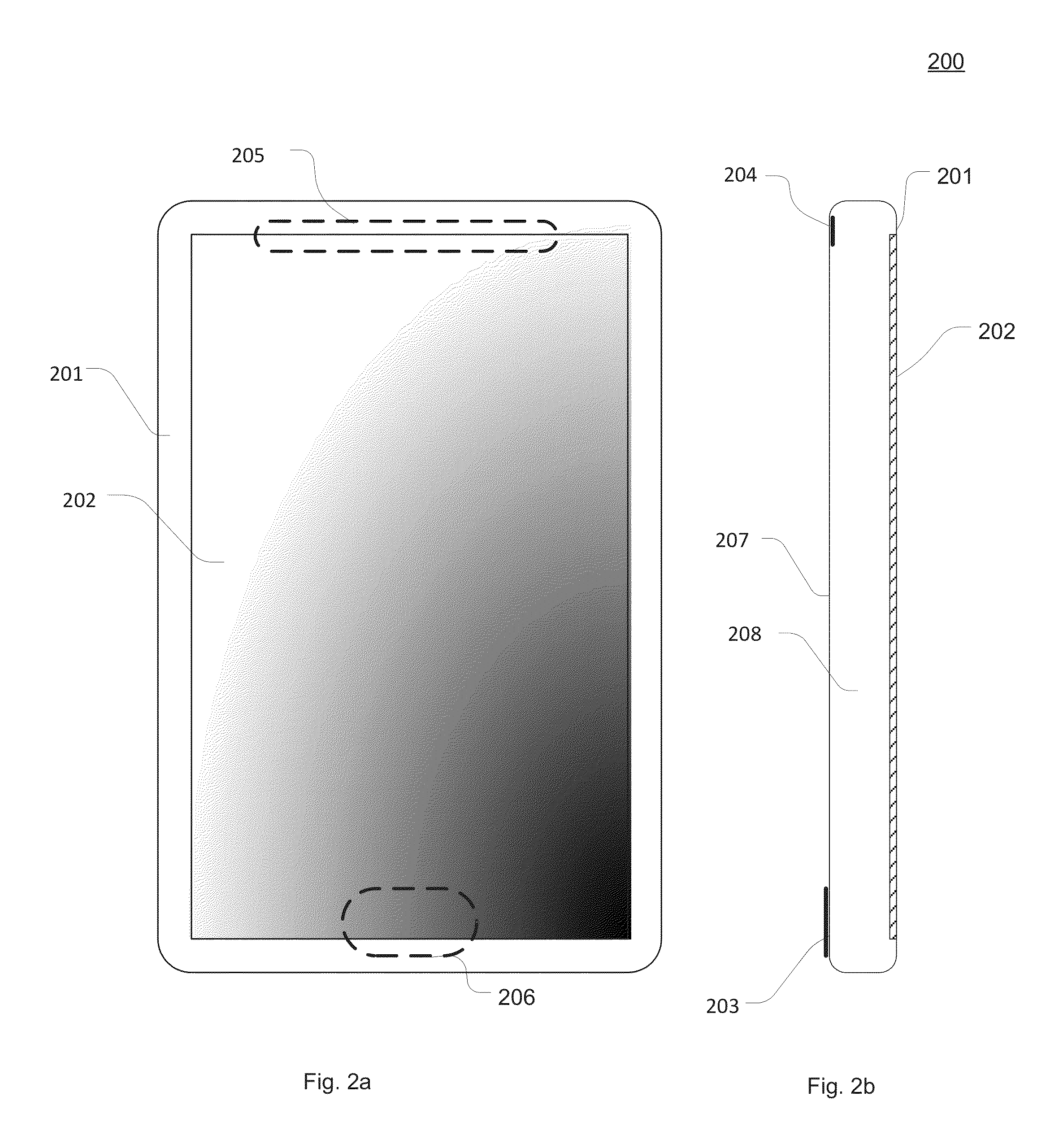

Mobile computing device with expanded display size

ActiveUS9423825B2Increase the touch areaBulky designEnergy efficient ICTUnauthorised/fraudulent call preventionAccelerometerUser input

A mobile computing device comprising a display panel and a home button, the display panel being disposed on the exterior front surface and the home button being disposed on the exterior back surface of the mobile computing device. The front surface may be free of any additional user Input / Output devices apart from the display panel. The mobile computing device may further comprise an accelerometer and a phone circuit. Upon detection that the display panel faces away from a user during a phone call, displayed information on the display panel may be concealed automatically. The accelerometer may be also operable to detect shaking motions on the mobile computing device as a user command to turn on or turn off the display panel.

Owner:NVIDIA CORP

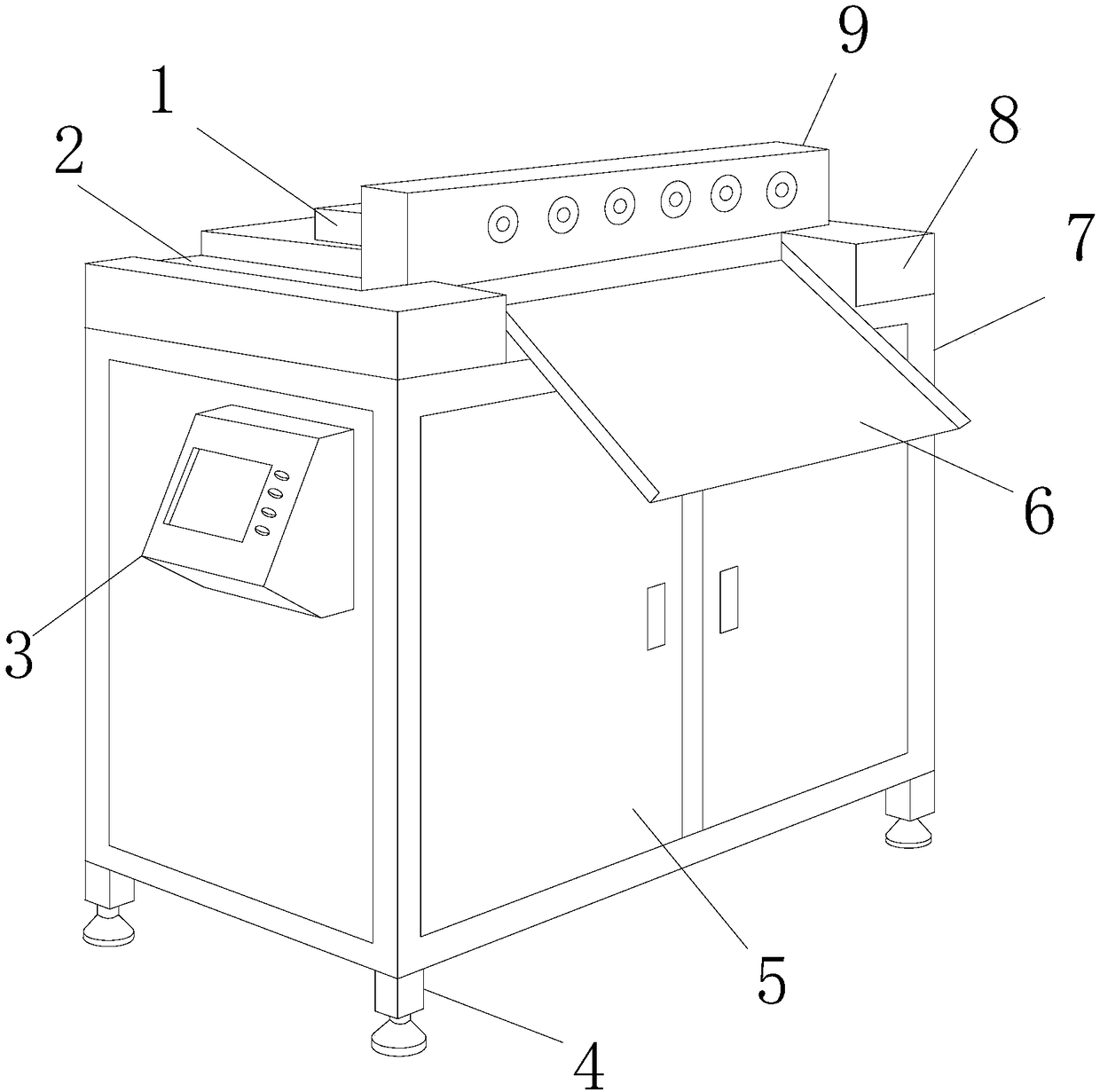

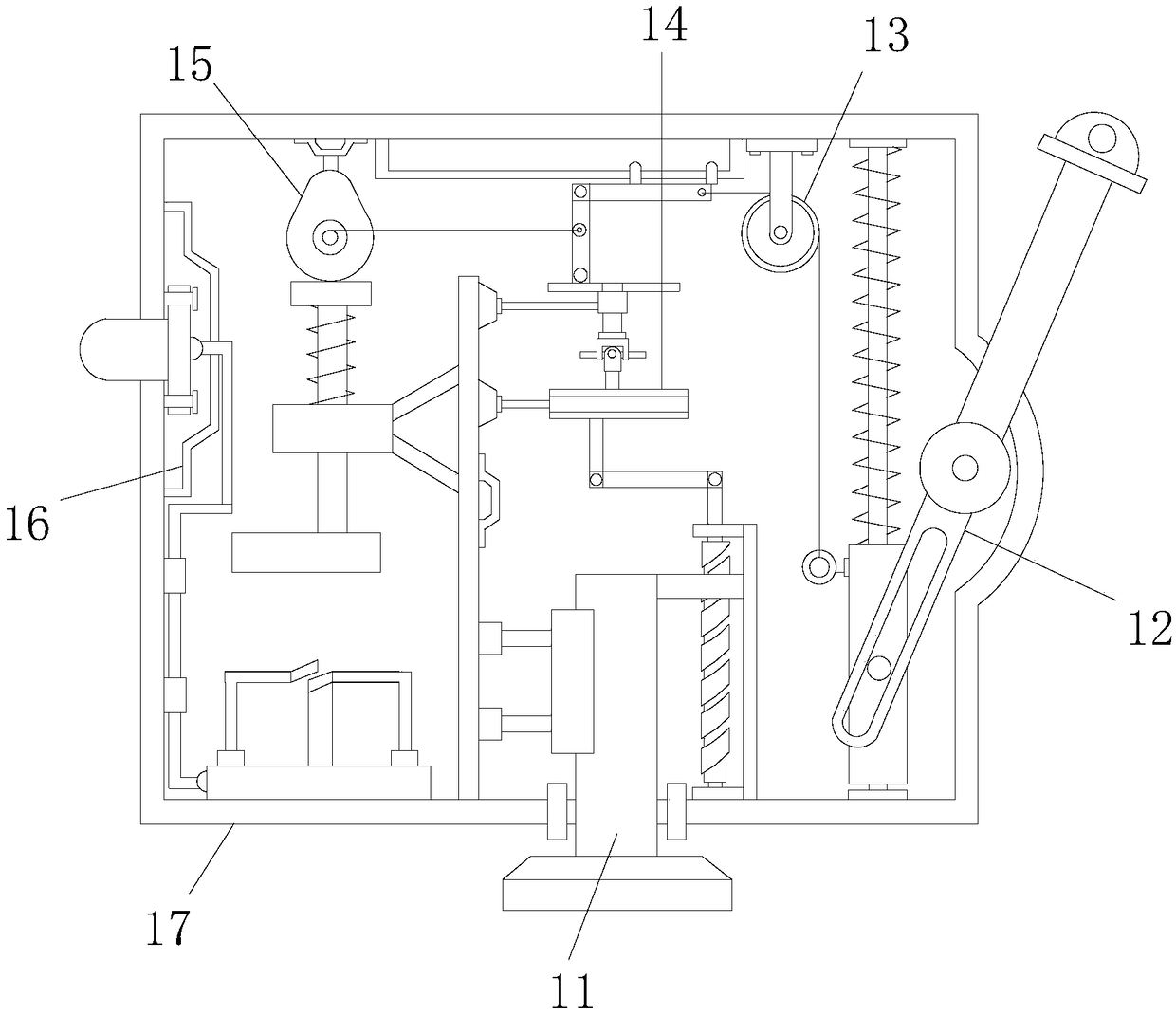

Automatic cloth cutter for garment machine

InactiveCN109132681APrevents fabric damage and wasted timeImprove cloth cutting efficiencyArticle deliveryPull forceEngineering

The invention discloses an automatic cloth cutter for a garment machine. The automatic cloth cutter for the garment machine comprises a cutting traction structure, an operation panel, a controller, supporting columns, cabinet doors, an oblique plate, a cloth cutter body, a fixer and a cutting tool. The cutting traction structure is provided with a stress descending structure, an up-down adjustmentstructure, a steel rope driving structure, a fixed transmission mechanism, an arc-shaped pressing structure, a trigger starting structure and a metal frame. The automatic cloth cutter for the garmentmachine has the beneficial effects that when the automatic cloth cutter is used for cutting cloth, the cutting traction structure can be started to separate to-be-cut part of cloth from to-be-left part of the cloth, the cutting tool in the automatic cloth cutter cuts the cloth along the edge of a magnetic plate in the cutting traction structure, the problem that the cloth is torn due to large pulling force is solved, cloth damage and time waste are prevented, and the cloth cutting efficiency of the cloth cutter is improved.

Owner:HUZHOU NANXUN ZHONGLI TEXTILE CO LTD

Microswitch

InactiveCN102044366AIncrease the touch areaSwitch button fastElectric switchesEngineeringPush-button

Owner:姜菊利

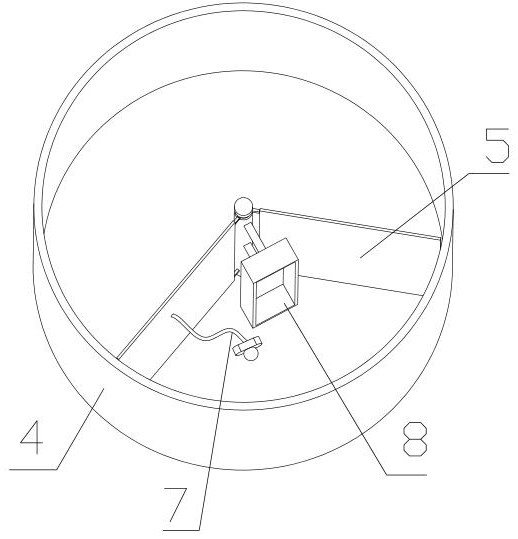

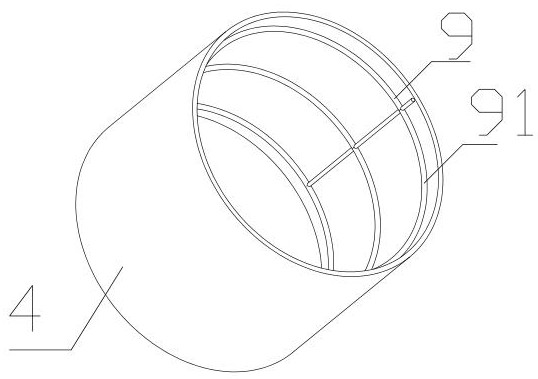

Collecting device suitable for melt-blown cloth production

ActiveCN112011897ASufficient air suction effectEasy to operatePlastic recyclingCleaning using toolsProcess engineeringAir blower

The invention relates to the field of automatic equipment, in particular to design of melt-blown fabric production equipment. The invention is realized through the following technical scheme: a collecting device suitable for melt-blown cloth production comprises a blower device, the collecting device comprises a middle fixing shaft and a collecting cylinder which is located on the outer ring of the middle fixing shaft and rotates relative to the middle fixing shaft, a separating device is further included, the separating device comprises a separating plate for separating the inner cavity of the collecting cylinder into an air blowing area, the air blowing device is located in the air blowing area, the air blowing device comprises a telescopic column which is connected to the middle fixingshaft and can stretch out and draw back and an air blower installed on the telescopic column, and the collecting device suitable for melt-blown cloth production further comprises a temperature adjusting device used for adjusting the temperature of the collecting cylinder. The invention aims to provide the collecting device suitable for the production of melt-blown cloth, the collecting position isnewly designed, the collecting effect is improved, and the product quality of polymers at the collecting position is improved.

Owner:福州法莫优科机械科技有限公司

Touch screen and electronic equipment

InactiveCN112799549AIncrease the touch areaImprove accuracyInput/output processes for data processingElectrical connectionEngineering

The invention provides a touch screen and electronic equipment. The touch screen comprises a base material and a first touch unit, and the base material is provided with a first face and a second face which are opposite; the first touch unit comprises a plurality of first conductive electrodes, a first insulating layer and a plurality of second conductive electrodes; the plurality of first conductive electrodes are arranged on the first surface and are arranged at intervals in a first direction; a plurality of first bridging electrodes are arranged between every two adjacent first conductive electrodes at intervals; the first bridging electrodes are arranged at intervals in the first direction; the first insulating layer covers the first conductive electrodes and is provided with a plurality of first via holes; the second conductive electrodes are arranged on the side, away from the base material, of the first insulating layer; the second conductive electrodes are arranged at intervals in a second direction; and each second conductive electrode is electrically connected with the plurality of first bridging electrodes through the first conducting holes, the second conductive electrodes are electrically connected with the bridging electrodes through the conducting holes of the first insulating layer, so that the effective area of the touch screen is increased, and a touch position can be accurately obtained.

Owner:NANCHANG O FILM DISPLAY TECH CO LTD

Touch substrate, touch substrate preparation method and display device

PendingCN114371792AIncrease the setting rangeIncrease the touch areaInput/output processes for data processingEngineeringElectrical connection

The invention discloses a touch substrate, a preparation method of the touch substrate and a display device. The touch substrate comprises a substrate body, a first electrode and a second electrode, the touch electrode layer is arranged on one side of the substrate, and the touch electrode layer comprises touch electrode blocks; the wiring layer is arranged between the substrate and the touch electrode layer, the wiring layer comprises touch wires, and each touch wire is electrically connected with at least one touch electrode block; the orthographic projection of at least part of the touch wires on the substrate and the orthographic projection of the touch electrode blocks on the substrate are partially overlapped. According to the embodiment of the invention, the touch wire does not need to be routed from the peripheral frame part of the touch electrode layer, but is routed between the substrate and the touch electrode layer, so that the setting range of the touch electrode layer is effectively enlarged, the touch area of the touch substrate is further improved, and the use experience of a user is also improved.

Owner:YUNGU GUAN TECH CO LTD

Optical touch module capable of increasing light emitting angle of light emitting unit

ActiveUS8462138B2Influence accuracyIncrease the touch areaInput/output processes for data processingVisible light irradiationOptical image

An optical touch module includes a screen and at least one optical positioning device disposed on the screen. The optical positioning device includes a case, at least one light emitting unit, a circuit board, a transparent diffusing part and an image capturing unit. The light emitting unit is disposed on case for emitting invisible light. The circuit board is electrically connected to the light emitting unit for controlling the light emitting unit. The transparent diffusing part is disposed at a light emitting side of the light emitting unit. A bar structure is formed on a light entrance surface of the transparent diffusing part for scattering the invisible light to be distributed over a touch surface of the screen. The image capturing unit is disposed on the case to capture an optical image for a touch object on the touch surface when the touch object is illuminated by the invisible light.

Owner:WISTRON CORP

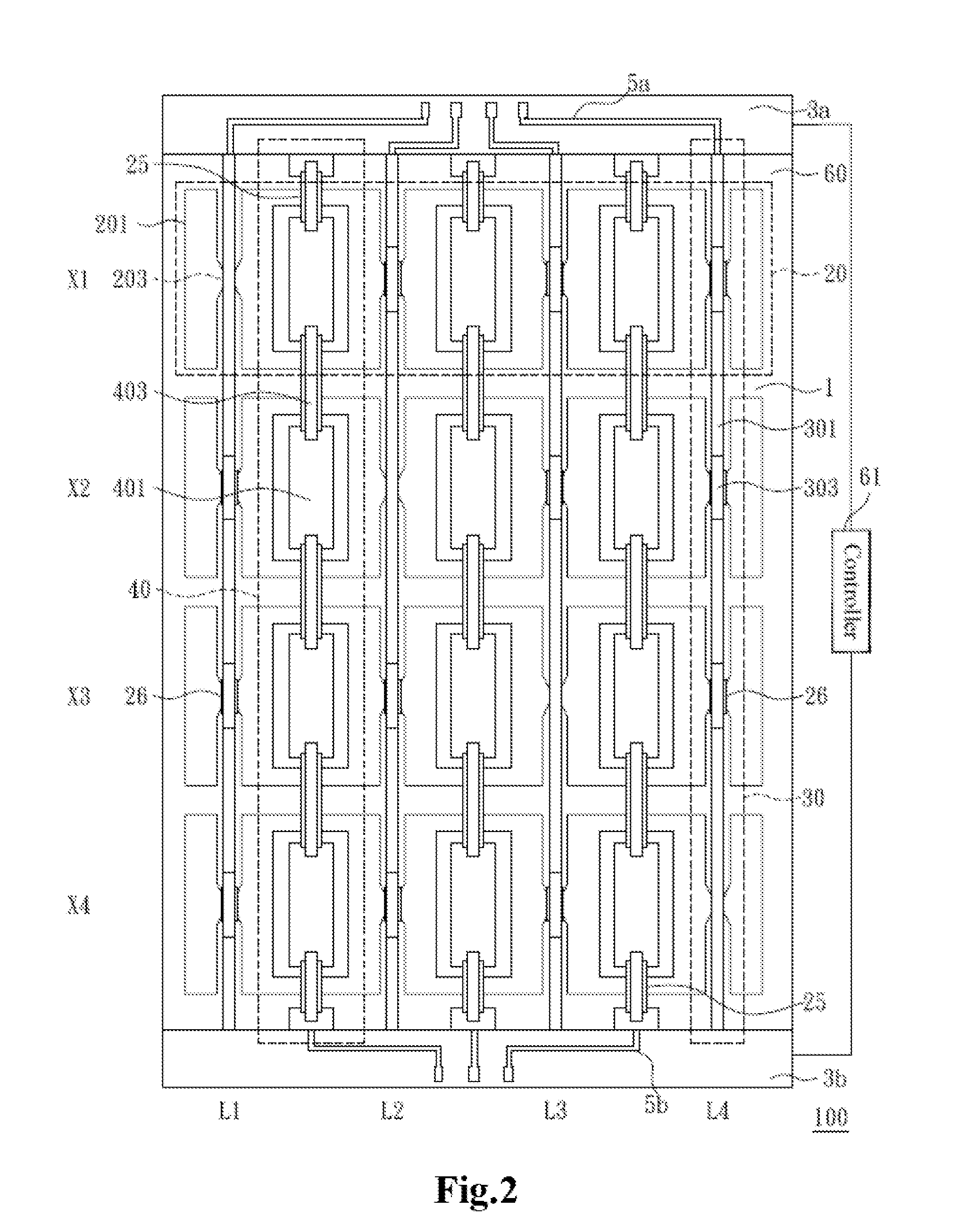

Touch panel and a manufacturing method thereof

ActiveUS9483145B2Increase the touch areaReduce areaLine/current collector detailsInput/output processes for data processingTouch panelElectrical and Electronics engineering

The present disclosure relates to a touch technology and more particularly, to a touch panel and a manufacturing method thereof. The touch panel comprises a plurality of first sensing electrode axes, a plurality of second sensing electrode axes, and a plurality of conductive wire axes. The first sensing electrode axes are disposed along a first axis. The second sensing electrode axes are disposed along a second axis and electrically insulated from the first sensing electrode axes. The plurality of conductive wire axes are disposed along the second axis and extended to the first peripheral area. Any two of the conductive wire axes are electrically connected to different first sensing electrode axes. According to the touch panel and the manufacturing method provided in the present disclosure, areas of the available touch area and a visible area on the touch panel can be effectively increased.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

A collection device suitable for the production of melt-blown cloth

ActiveCN112011897BSufficient air suction effectEasy to operatePlastic recyclingCleaning using toolsProcess engineeringMechanical engineering

Owner:福州法莫优科机械科技有限公司

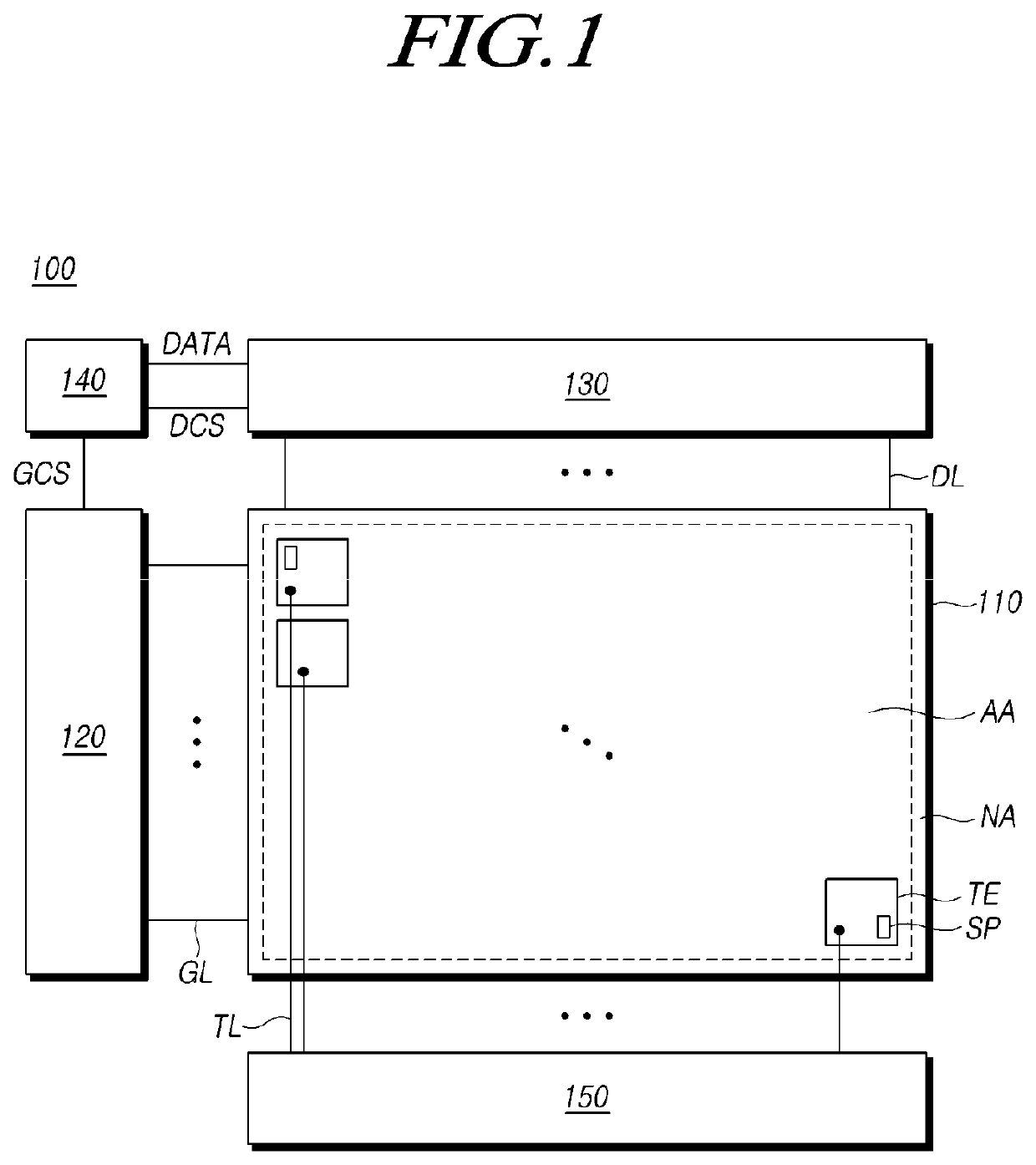

Touch display device

PendingUS20220206651A1Reduce aperture ratioReduce transmittanceInput/output processes for data processingDisplay deviceEngineering

Embodiments of the present disclosure are related to a touch display device, as a plurality of first line parts disposed on a first sensor layer and a plurality of second line parts disposed on a second sensor layer are alternated to make a touch line, at least a portion of different touch lines can be disposed to be overlapped each other, thus a plurality of touch lines can be disposed while reducing or minimizing a reduction of an aperture ratio or a transmittance of a subpixel due to an arrangement of the touch line. Accordingly, a touch sensitivity can be enhanced by further disposing touch electrodes, or the touch display device having a large area with many channels can be implemented easily by further disposing touch lines.

Owner:LG DISPLAY CO LTD

Button structure for touch screen and touch screen

ActiveCN105700746BIncrease the touch areaAvoid injuryInput/output processes for data processingKey pressingFlexible circuits

Owner:BIEL OPTIC HUIZHOU

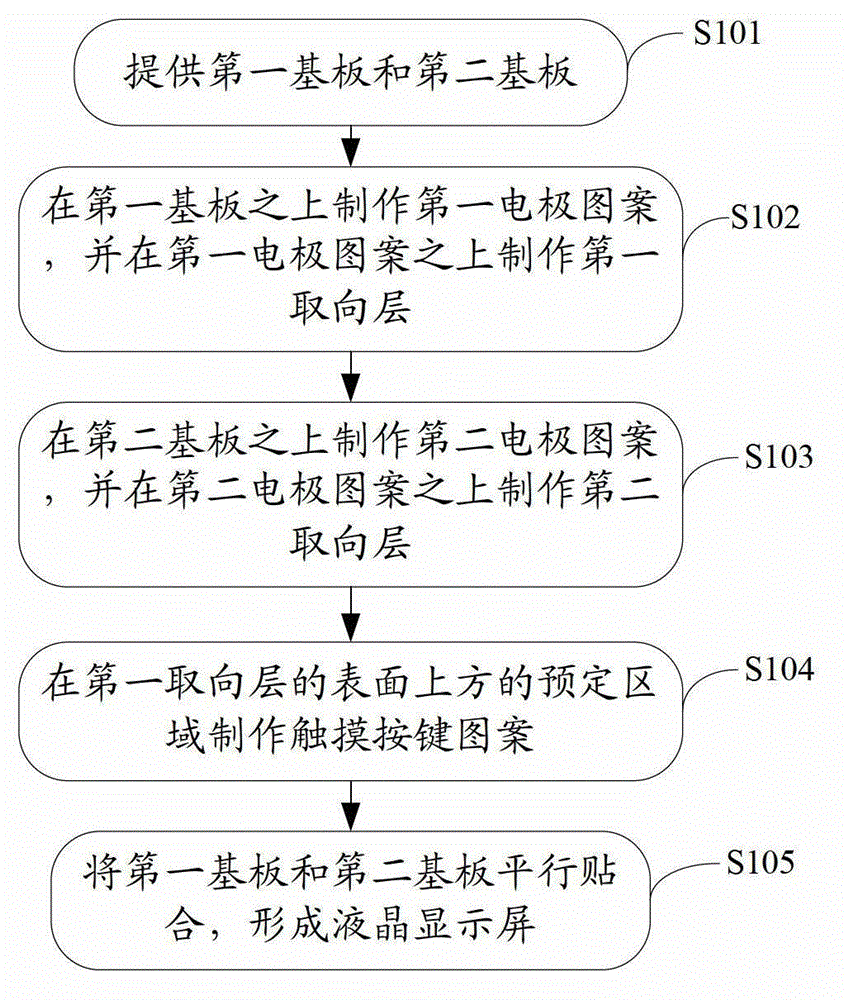

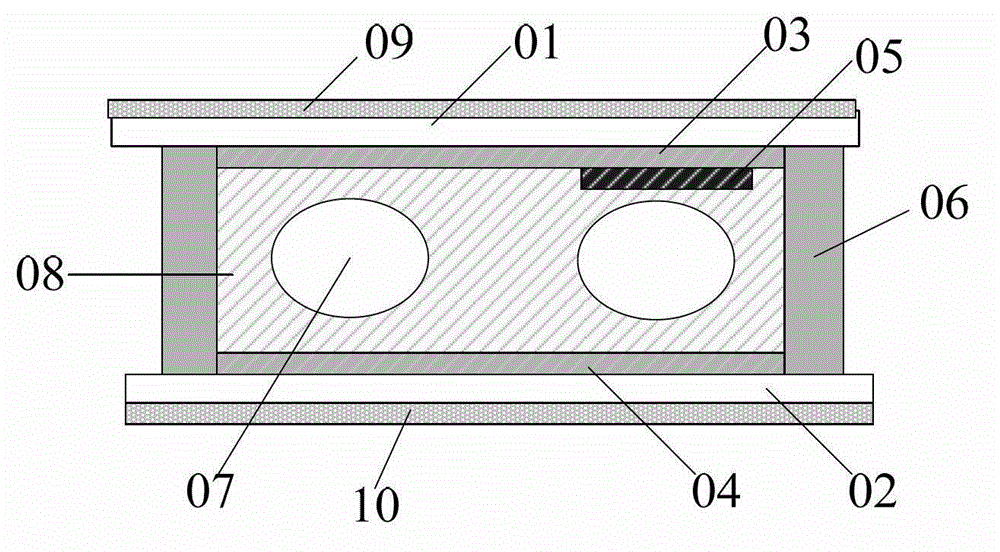

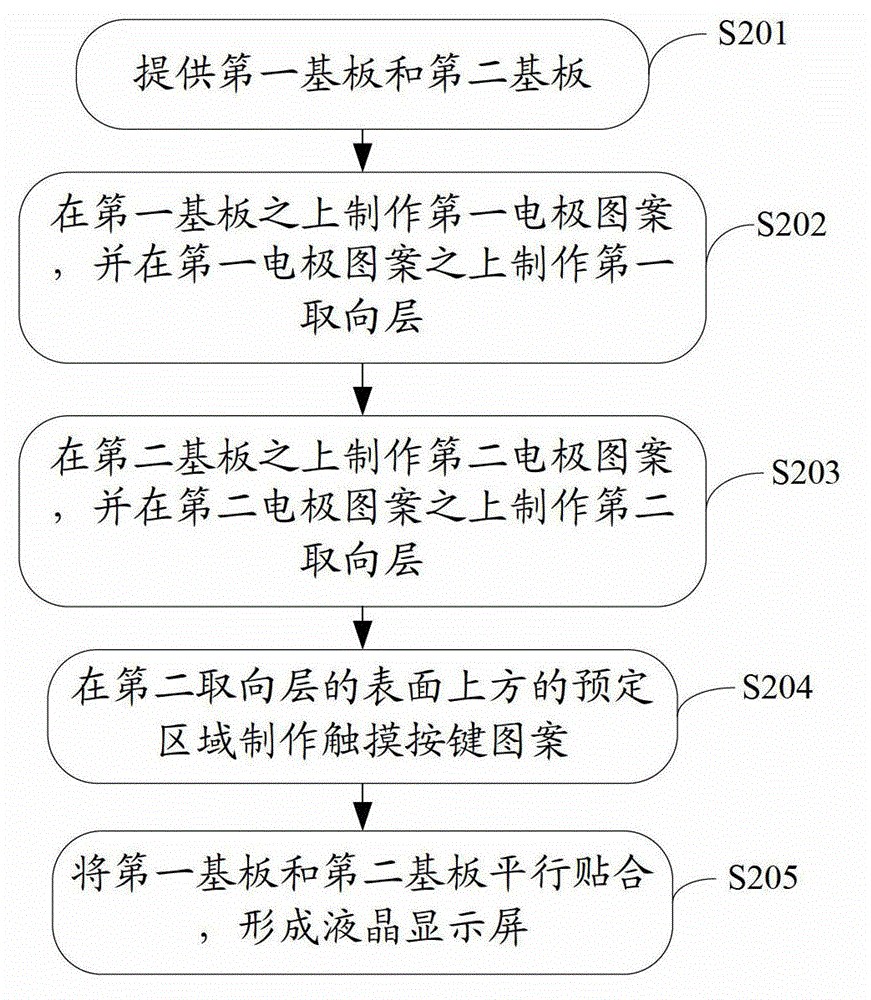

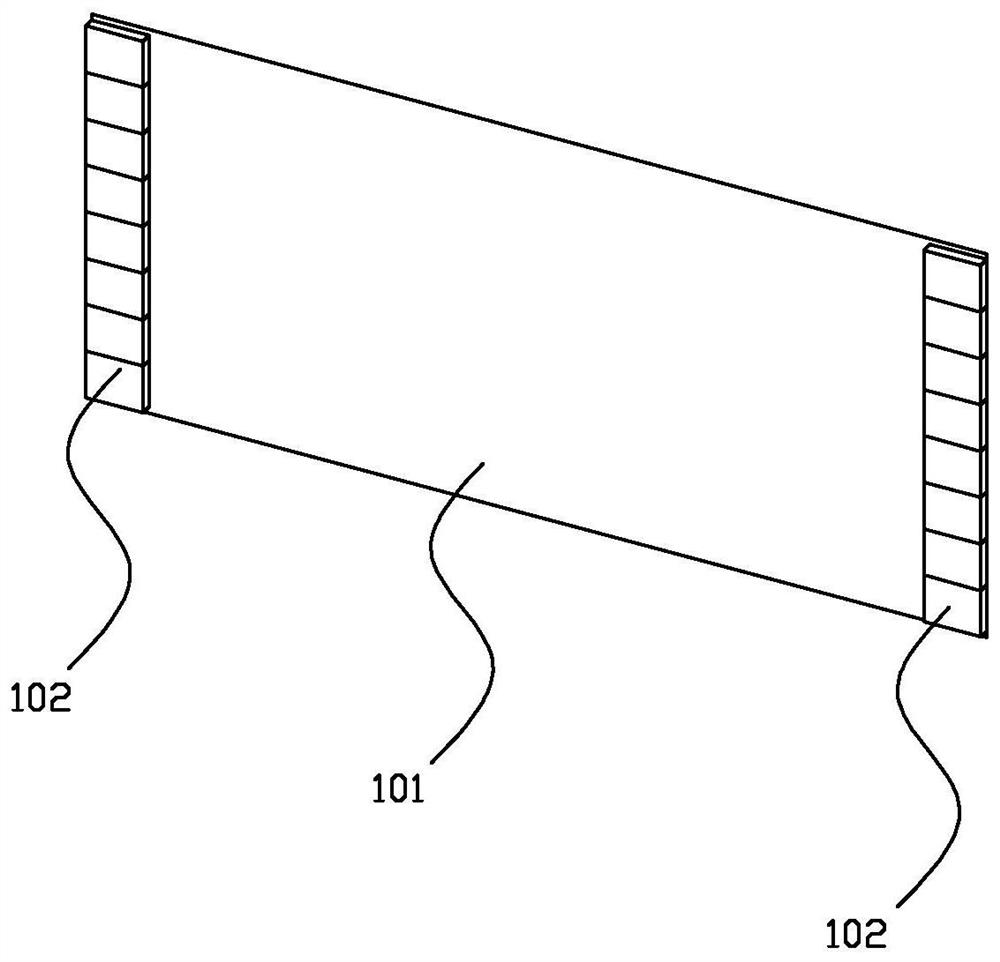

Method for manufacturing a liquid crystal display

ActiveCN103091890BExpand line spacingEliminate signal interferenceNon-linear opticsInput/output processes for data processingLiquid-crystal displayEngineering

The invention provides a liquid crystal display and a preparation method of the liquid crystal display. A touching button pattern is manufactured on a pre-arranged region of the interior of the liquid crystal display or on a pre-arranged region of the outer surface of the liquid crystal display and is visible when being observed outside. The liquid crystal display with a touch button function reduces the process that pattern wiring is conducted on the display touch button on a base plate of the liquid crystal display, ensures that the whole area of the base plate is occupied when electrodes with inducting-touching-controlling functions are wired, increases electrode-wiring wire distances and the wired area when the electrodes with the inducting-touching-controlling functions are wired is increased. The larger the wiring area of the electrodes with the inducting-touching-controlling functions is, the stronger the signal intensity is. Therefore, the liquid crystal display and the preparation method of the liquid crystal display weaken or eliminate signal interference between electrode wiring. Meanwhile, the liquid crystal display and the preparation method of the liquid crystal display reduce wiring on a printed circuit board (PCB), and ensure that wiring of the PCB is simplified.

Owner:TRULY OPTO ELECTRONICS

A texture tactile reproduction device, a display device and a radian reproduction device

InactiveCN109240485BIncrease the touch areaPracticalInput/output for user-computer interactionGraph readingTouch SensesDisplay device

The invention relates to a texture haptic reproducing device. The display device and the radian reproducing device are respectively provided with two rows of piezoelectric ceramics at two ends of a conductive surface of a touch panel. Based on the squeeze film effect, the finger can touch the interface surface dynamically by changing the friction force between the finger and the contact surface and reproducing the surface texture information of the virtual object in the form of variable friction force, which is the closest natural detection method. The invention improves the piezoelectric ceramic matrix of the prior art, realizes texture reproduction by using two rows of piezoelectric ceramics, makes the device lighter and thinner, increases effective touch area greatly, can be integratedwith common electronic products on the market, and has strong practicability. The texture tactile reproducing device can be integrated on the display screen of the electronic product, and the tactilefeedback function of the electronic product is added. The operator can perceive the surface texture information of the virtual object in the form of variable friction force, thereby enhancing the sense of reality and immersion of the virtual environment.

Owner:XIAMEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com