Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Fast and efficient solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

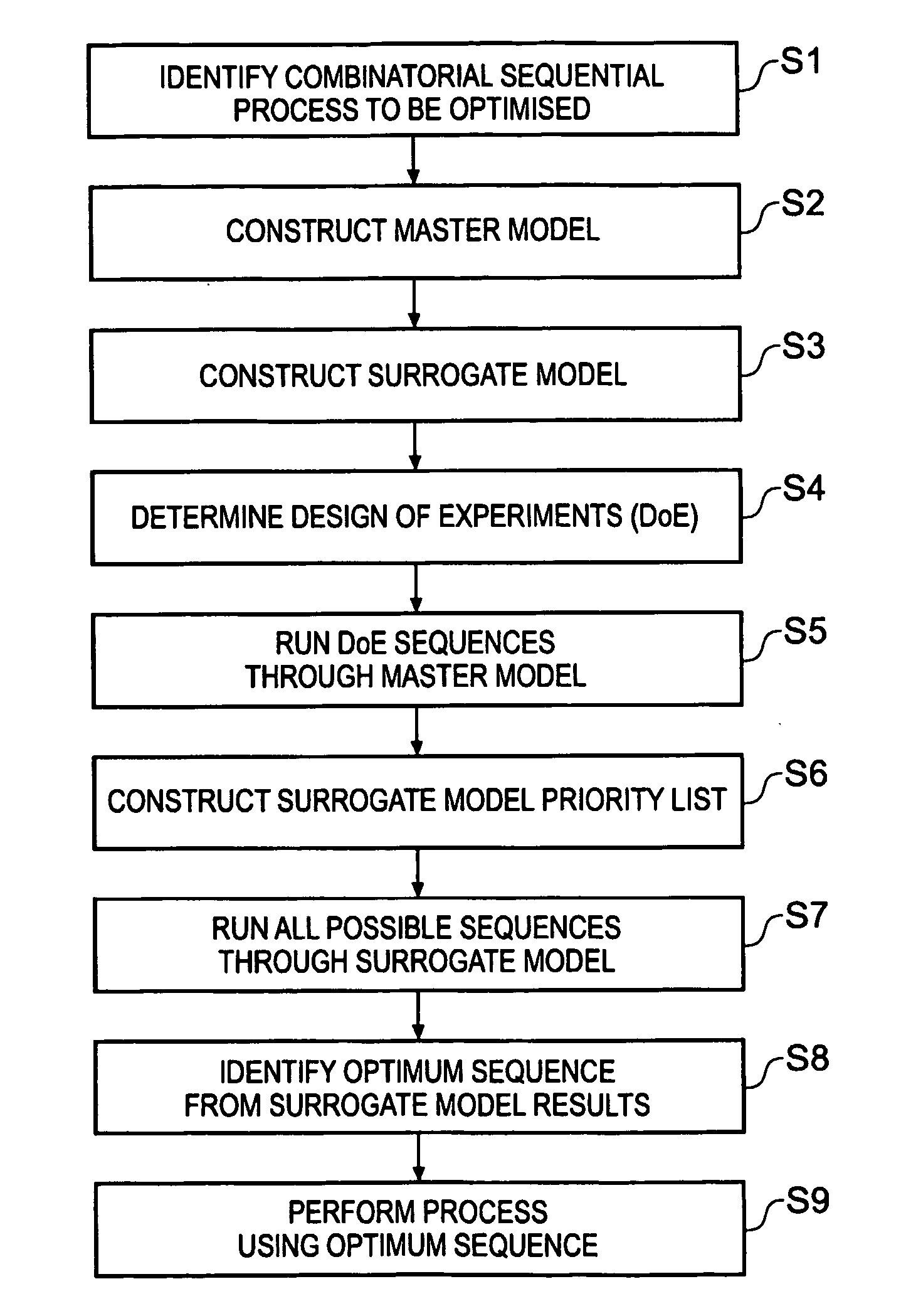

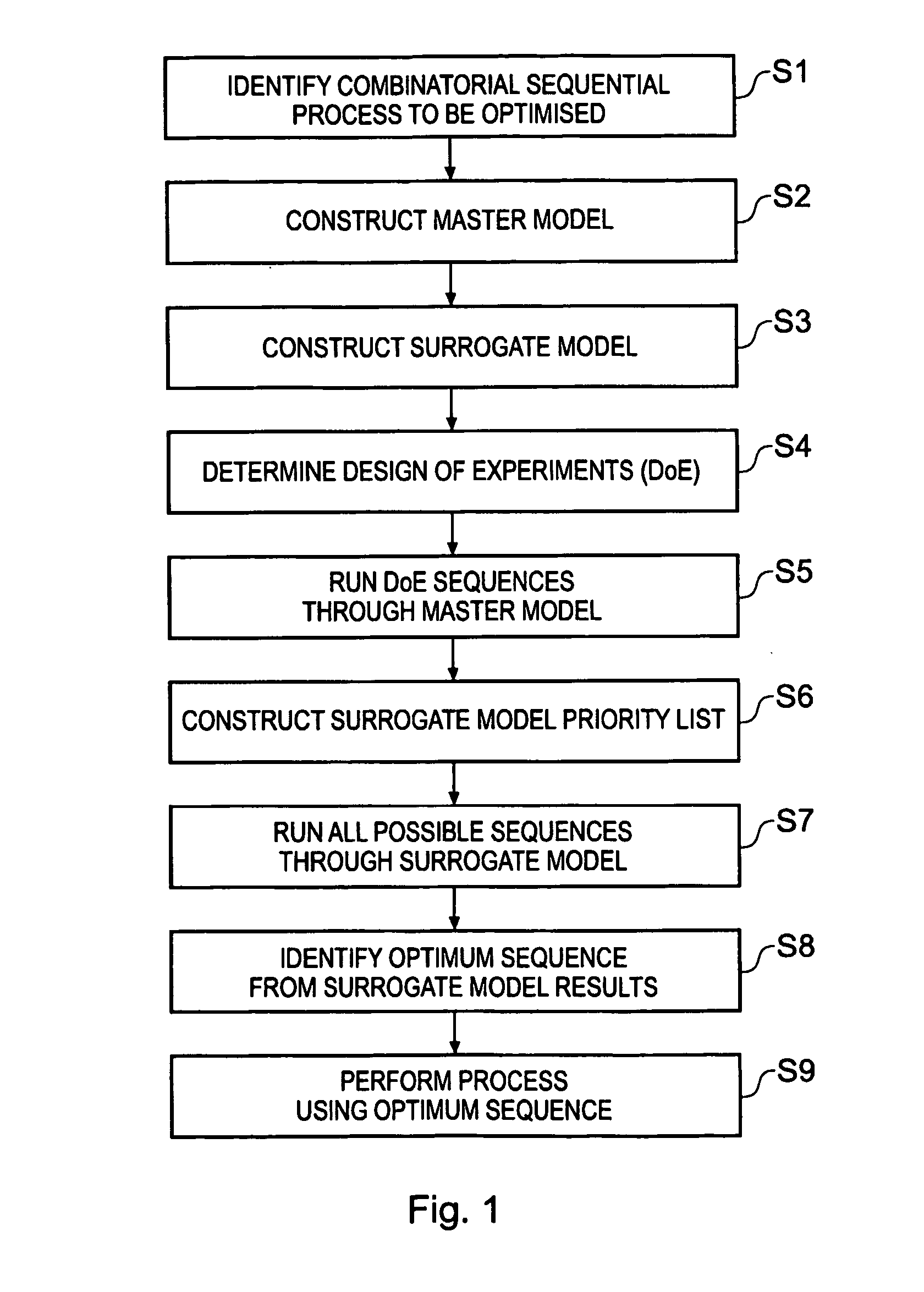

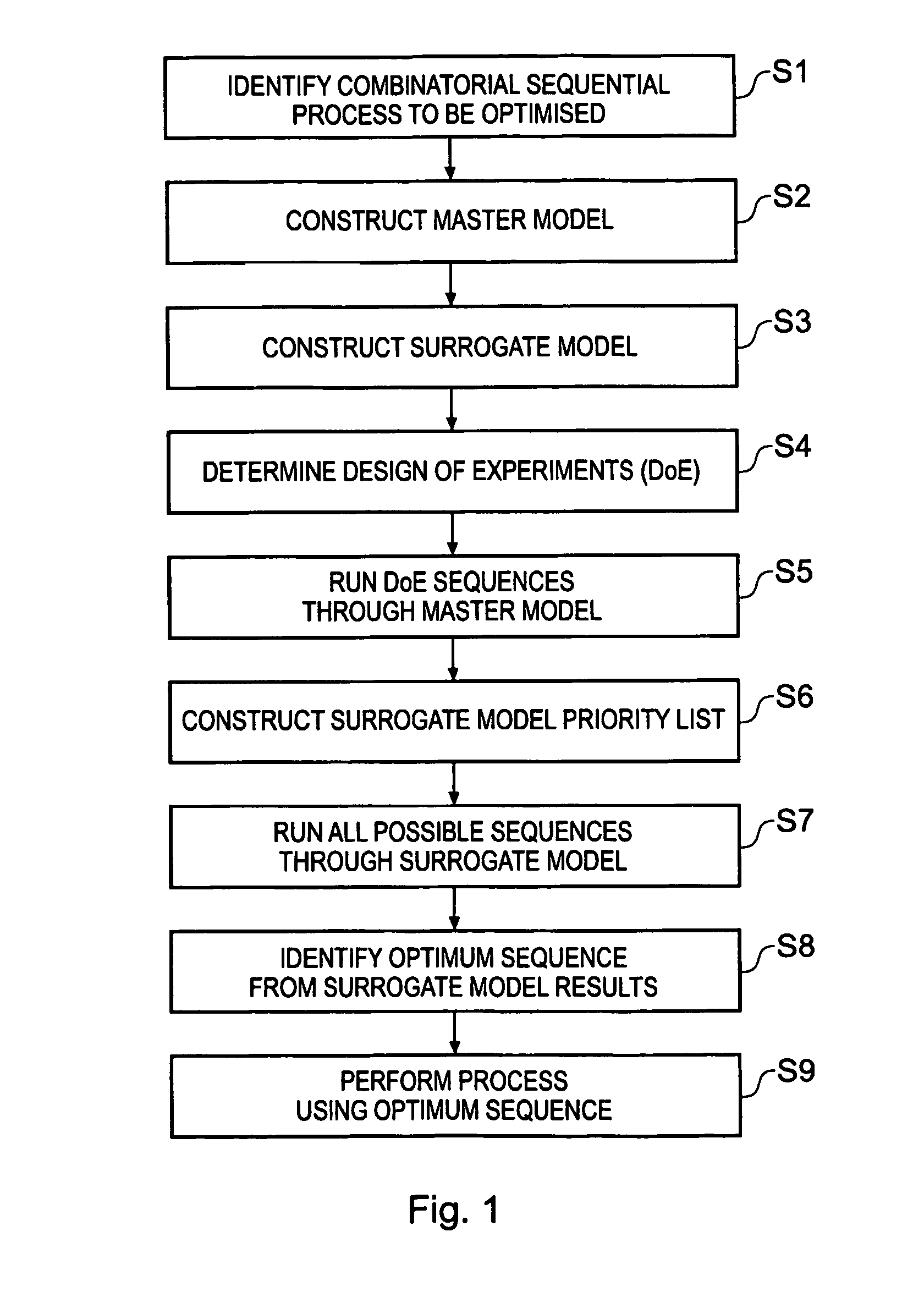

Optimisation of sequential combinatorial process

ActiveUS20070043622A1Small amount of informationSimplifying and speeding optimisationHand manipulated computer devicesForecastingFleet managementSurrogate model

A method of optimising a sequential combinatorial process comprising an interchangeable sequence of events comprises using a master model to model a selection of the possible sequences, and using information derived from the master model in a surrogate model that approximates the master model with a much shorter computation time. The surrogate model calculates all the possible sequences using an algorithm to select from the information calculated by the master model that which most closely matches the events of a present sequence, following a prioritised system so that the best match is used wherever possible. All results from the surrogate model are compared so that the modelled sequence that gives the result closest to a desired optimum result for the process can be identified, and potentially applied to the process. Accuracy can be enhanced y running the optimum sequence through the master model as a check, and further by adding the optimum sequence to the information used by the surrogate model in future calculations. Any sequential combinatorial process, in which the quality of the end result of the process depends on the order in which events in the process are performed, can be optimised in this way, including manufacturing process such as machining, cutting, shaping, forming and / or heat treating a workpiece, flow of material through a factory or oil or gas through a pipeline network, chemical and material science mixing processes, computational biology modelling, and fleet management.

Owner:GKN AEROSPACE SWEDEN AB +1

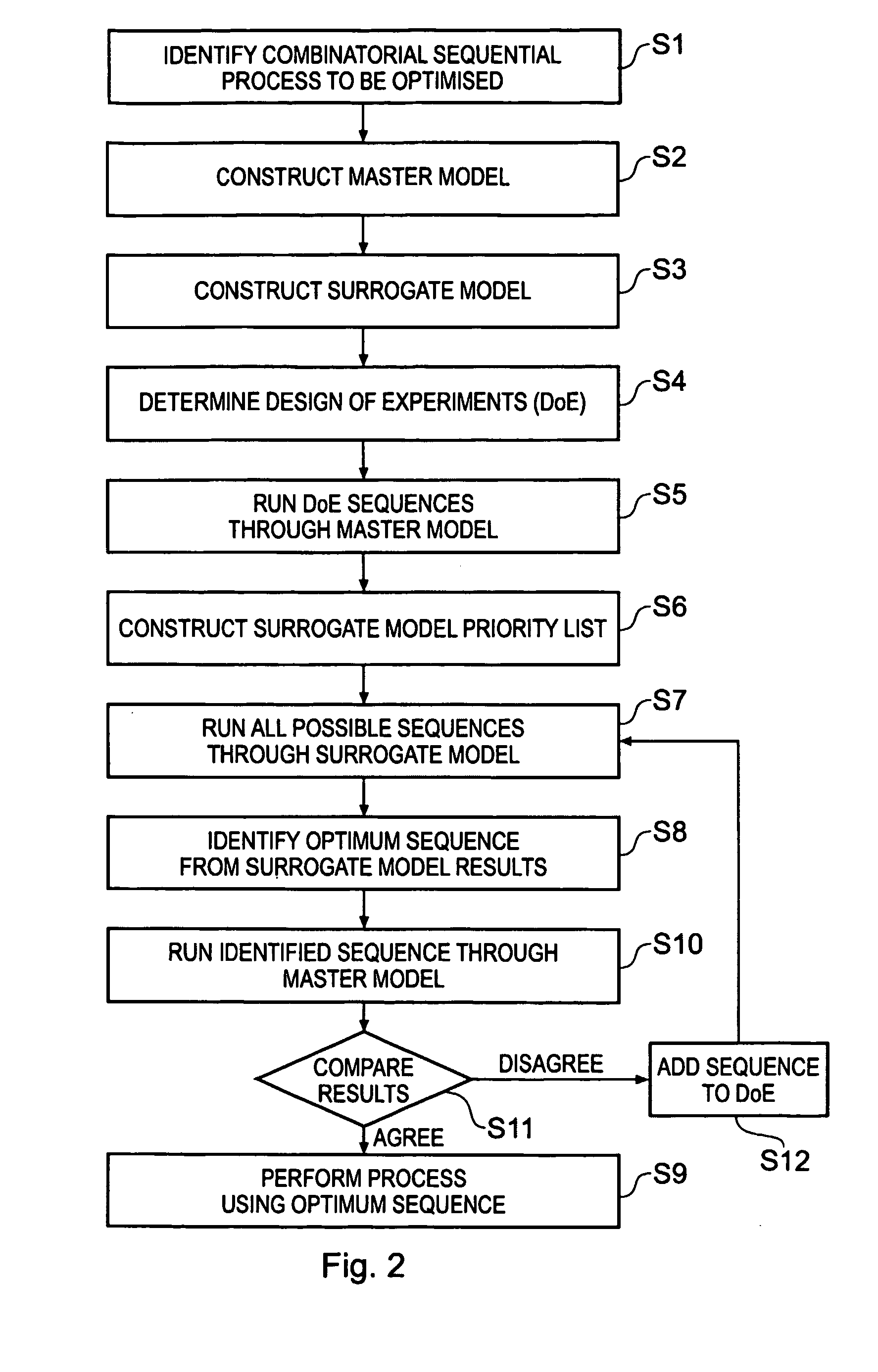

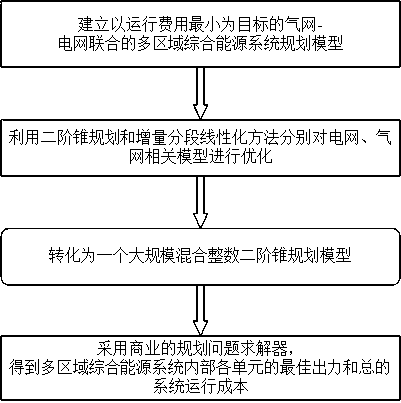

Modeling and system planning method for gas power grid combined multi-region comprehensive energy system

The invention particularly relates to a modeling and system planning method for a gas power grid combined multi-region comprehensive energy system. The method comprises the following steps: S1, establishing a coupling model of a power grid, a gas net, and a power grid-gas net and a multi-region comprehensive energy system model combined with constrained gas net-power grid; S2, establishing a planning model for optimal economic operation of a gas net-power grid combined multi-region comprehensive energy system, aiming at minimizing the total system operation cost; S3, converting the mixed integer nonlinear programming model in the model into a mixed integer second-order cone programming model by using a second-order cone programming method; performing nonlinear quantity linearization processing in the incremental piecewise linearization method model; and therefore, a large-scale mixed integer second-order cone programming model is established by taking the minimum total system operationcost as a target; and S4, a commercial planning problem solver is adopted to solve the large-scale mixed integer second-order cone programming model, and the optimal output and the total system operation cost of each unit in the multi-region comprehensive energy system are obtained.

Owner:NANJING INST OF TECH

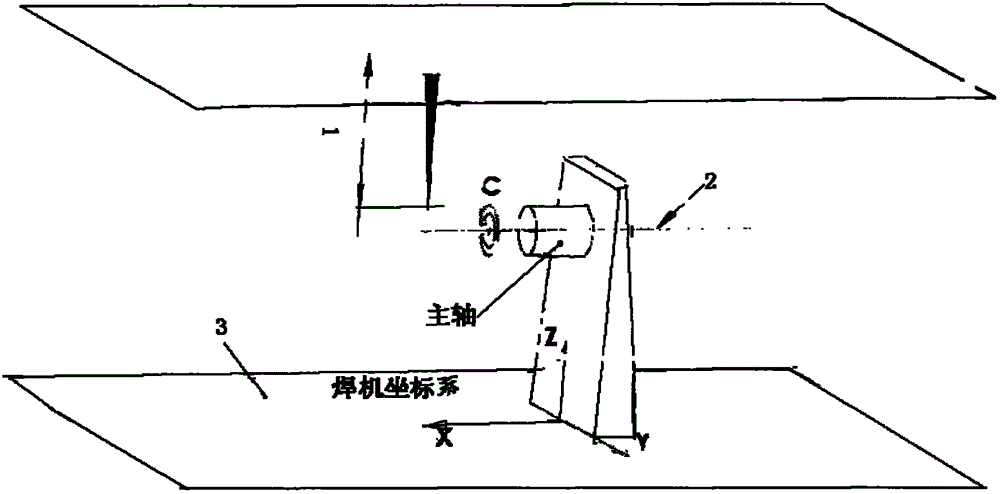

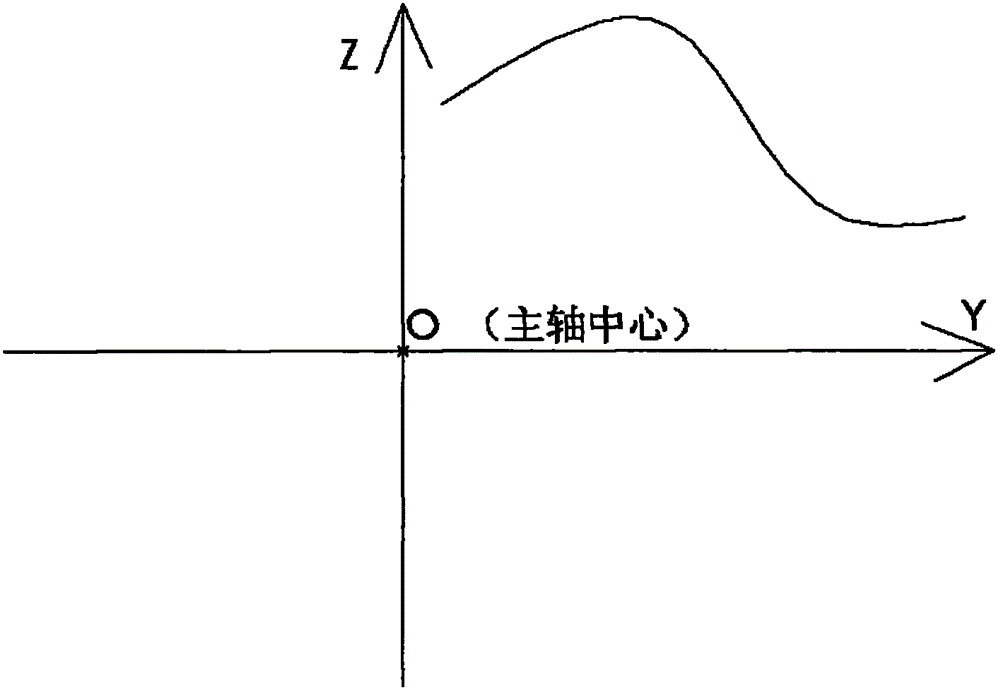

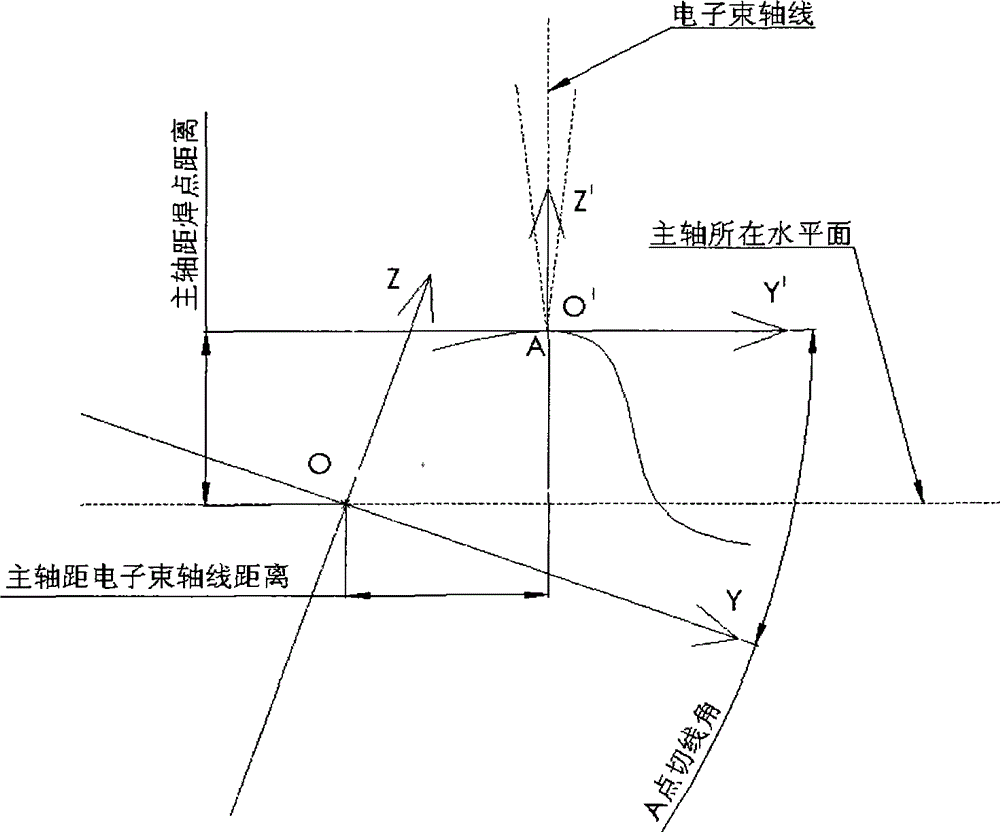

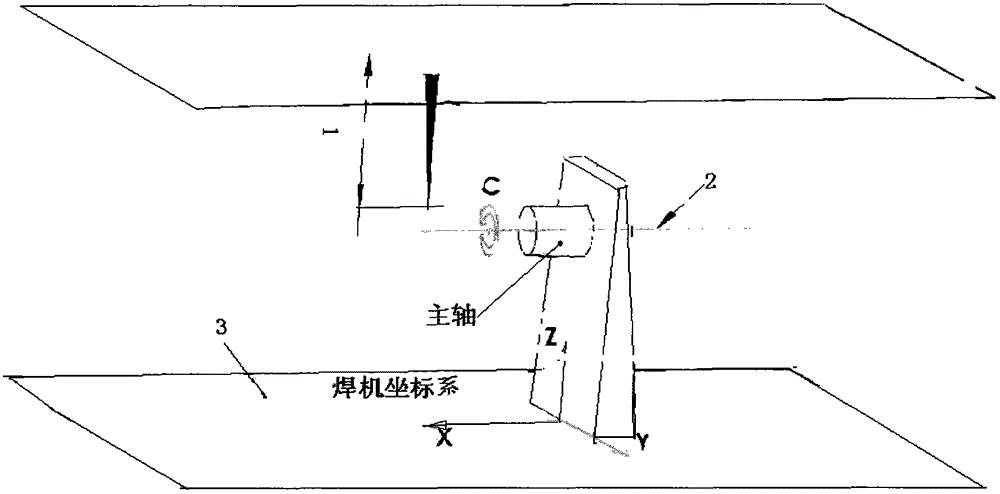

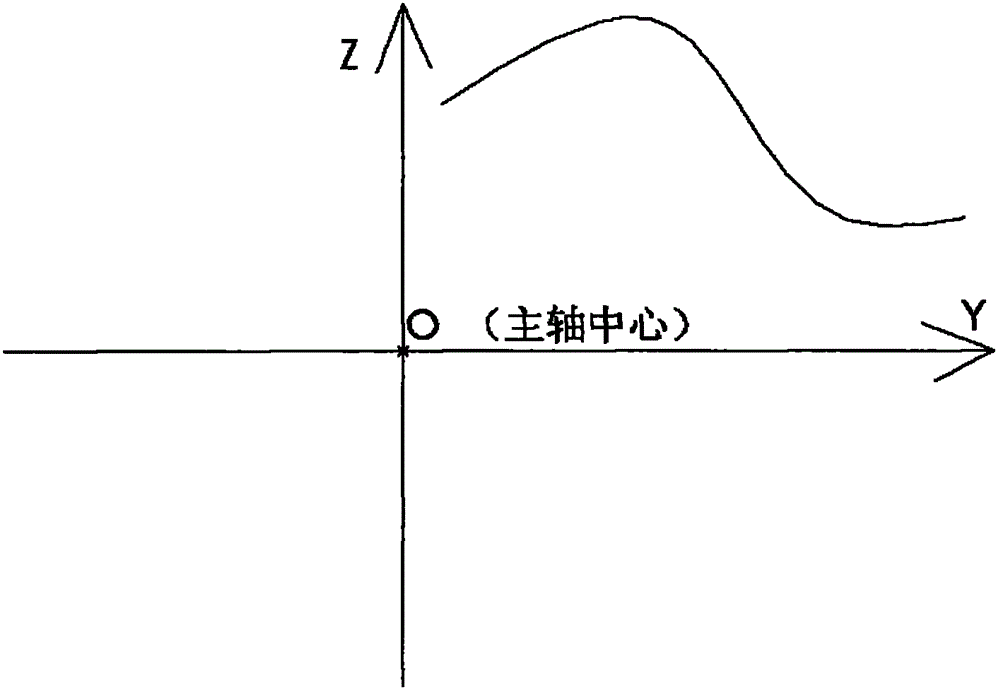

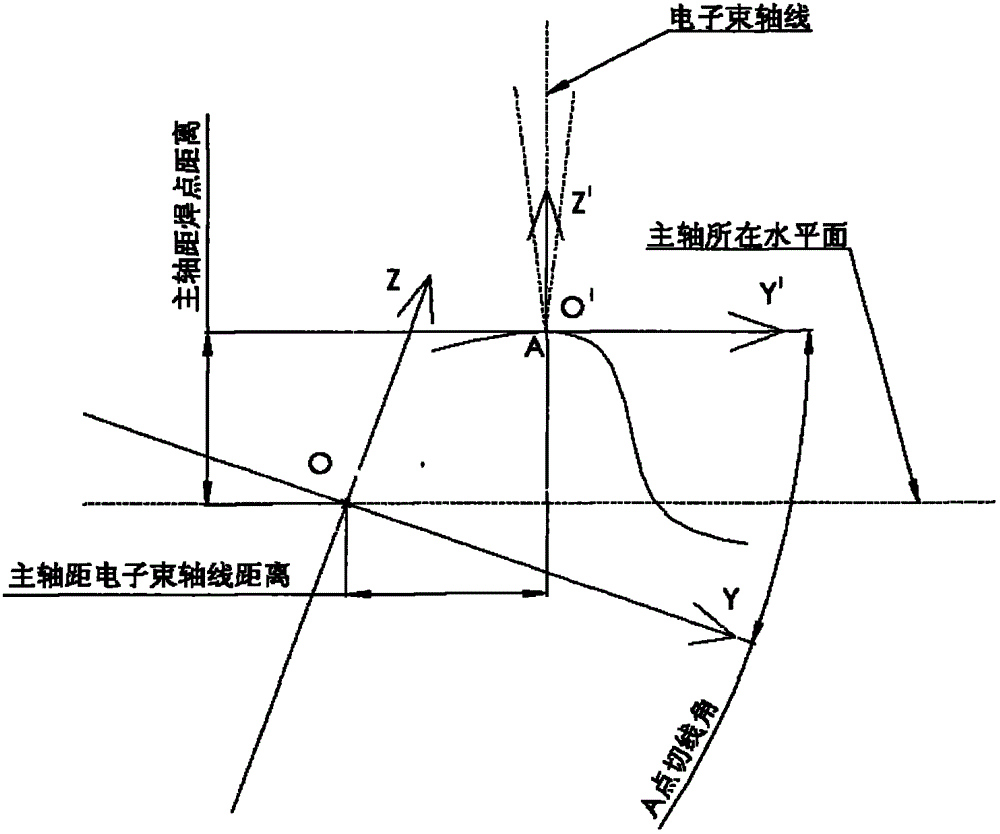

Electron beam welding method of special-shaped surface

ActiveCN103331512AFast and efficient solutionGuaranteed welding shapeElectron beam welding apparatusElectronLine segment

The invention belongs to the electron beam welding field, and particularly relates to an electron beam welding method of a special-shaped surface. The method comprises a first step of building a weld joint plane curve, wherein a trace curve of the weld joint to be welded is generated based on a three-dimensional model of a part to be welded; a second step of decomposing the curve, wherein the curve is decomposed according to the characteristics of the curve, and the decomposing principle is that the curve is decomposed to be straight-line segments and arc segments according to the weld joint curve; a third step of collecting and resolving spots, wherein an electron beam current focusing height, the translation of an electron beam welding machine main shaft on the Y direction, the rotating angle of the main shaft around a C axis and a rotary radius are resolved; and a fourth step of idling for commissioning, wherein a welding procedure is commissioned once in a manner of idling so as to verify the validity of the data in the third step; and if the data are correct, performing the welding with the parameters, otherwise returning to the second step to increase the number of the decomposed curves in curve decomposing. The electron beam welding method has the advantages that a weld joint trace equation is resolved fast and efficiently when the electron beam wielding is performed for a complicated special-shaped surface, and the welding is formed once.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

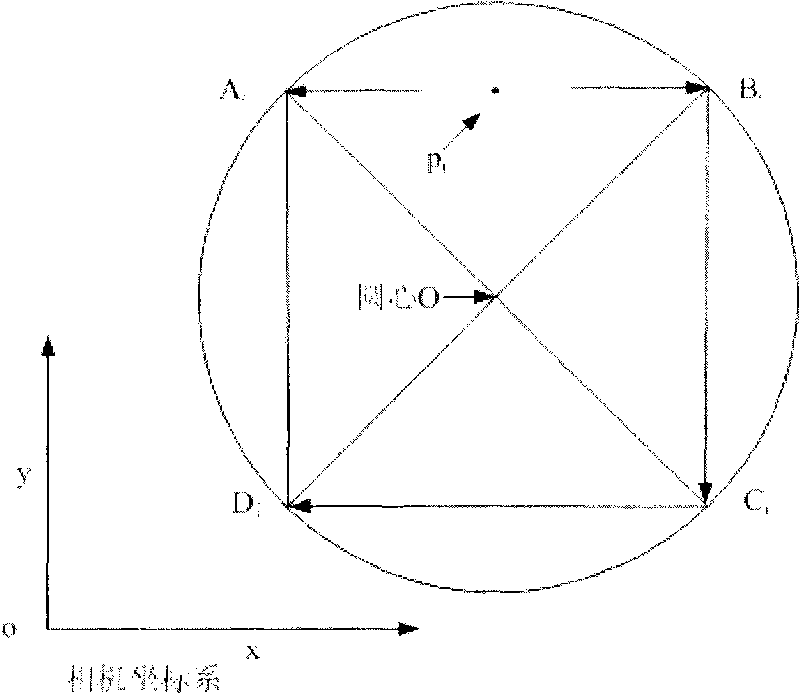

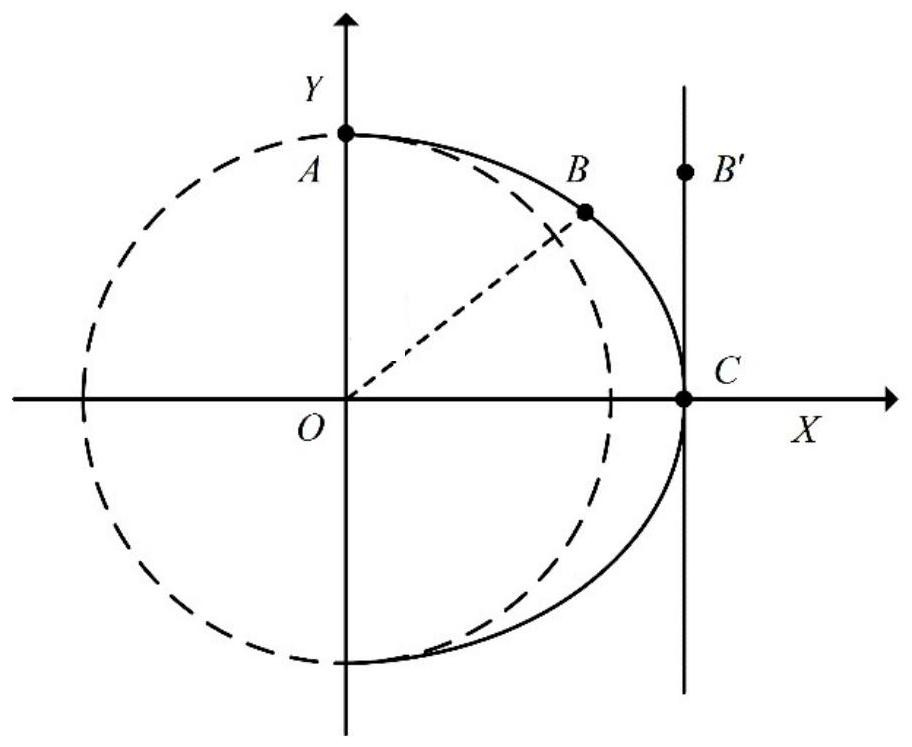

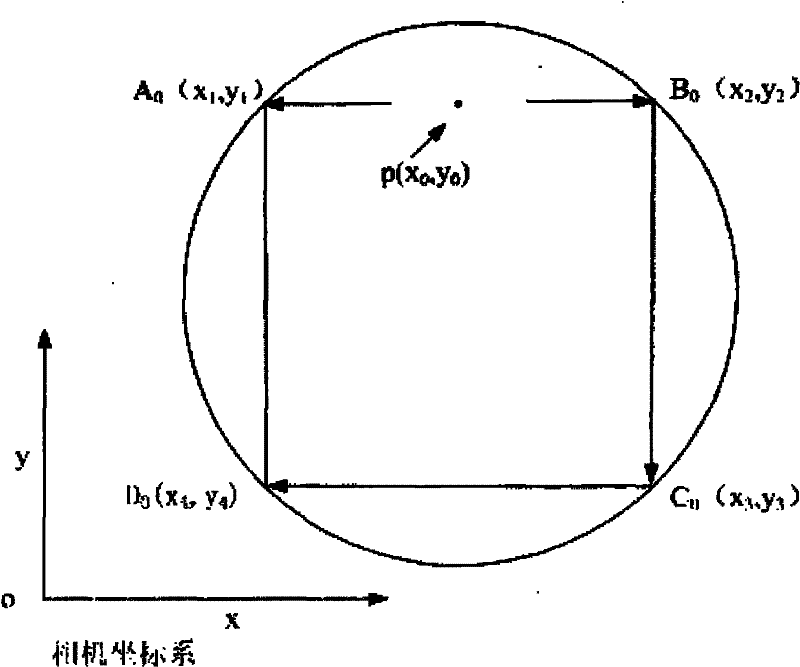

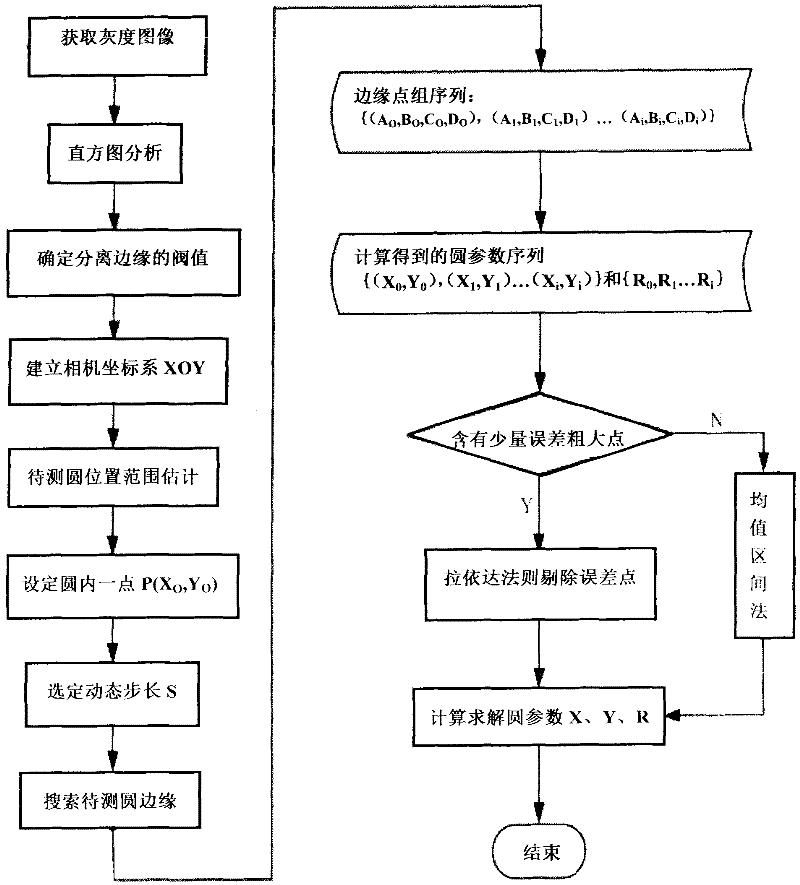

Digital image based rapid solving method of circle parameters

The invention relates to a digital image based rapid solving method of circle parameters, which comprises the steps of: 1, acquiring an image of a measured object by using a digital image sensor to establish a plane coordinate system; 2, carrying out Histogram analysis on the image to determine a threshold suitable for separating a boundary of a circle to be measured; and carrying out region segmentation on the acquired image to set a square region including the circle to be measured; 3, selecting an inner point of the circle according to the threshold determined in the step 2, and searching from the point to obtain a point at the edge of the circle to be measured in the image; 4, setting a dynamic step length S, obtaining a point set sequence at the edge of the circle to be measured according to an edge point searching rule in the step 3; and 5, solving coordinates of the center of the circle and diameter parameters of the circle. The invention can be applied to the geometric parameter measurement of a circular pat or instrument in the fields of industrial detection, medical biology and the like, better solves the contradiction between speed and effect during solving the circle parameters in the digital image, and has high practical application value.

Owner:UNIV OF SCI & TECH BEIJING

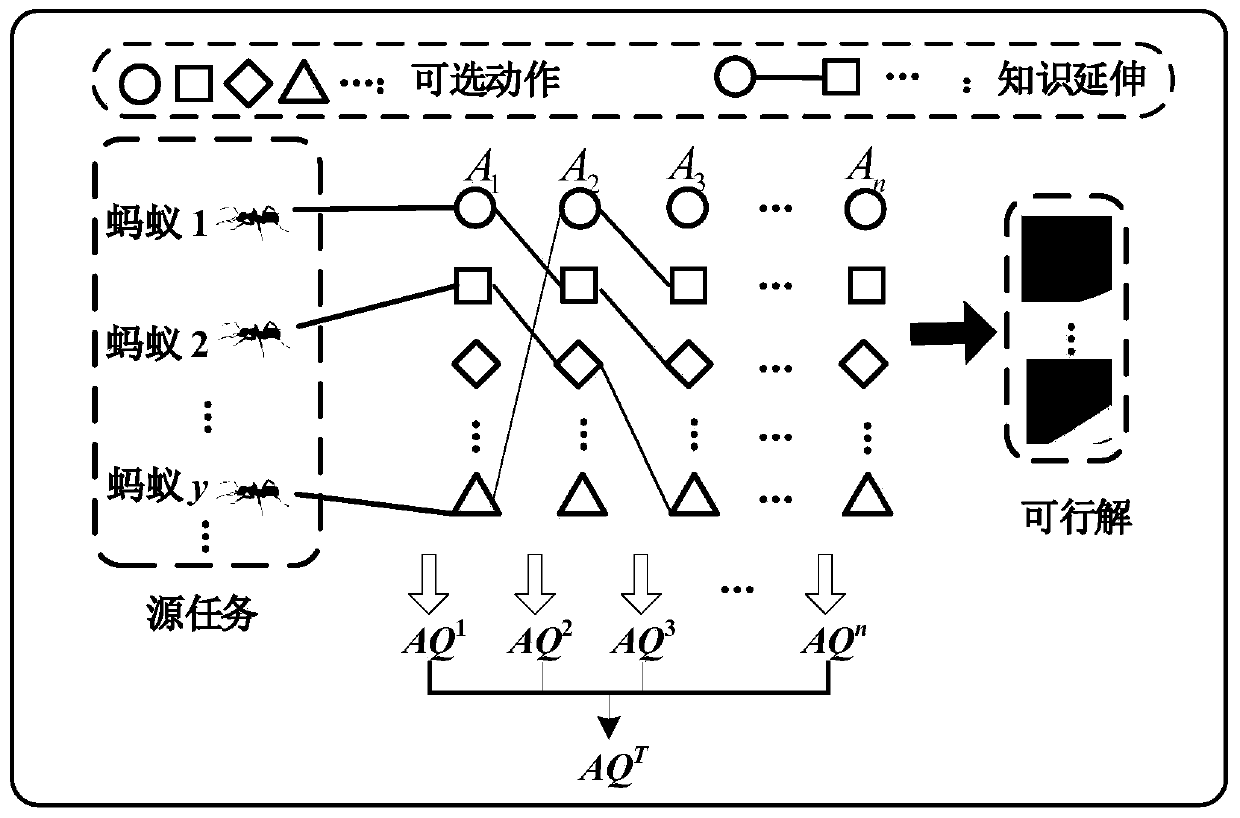

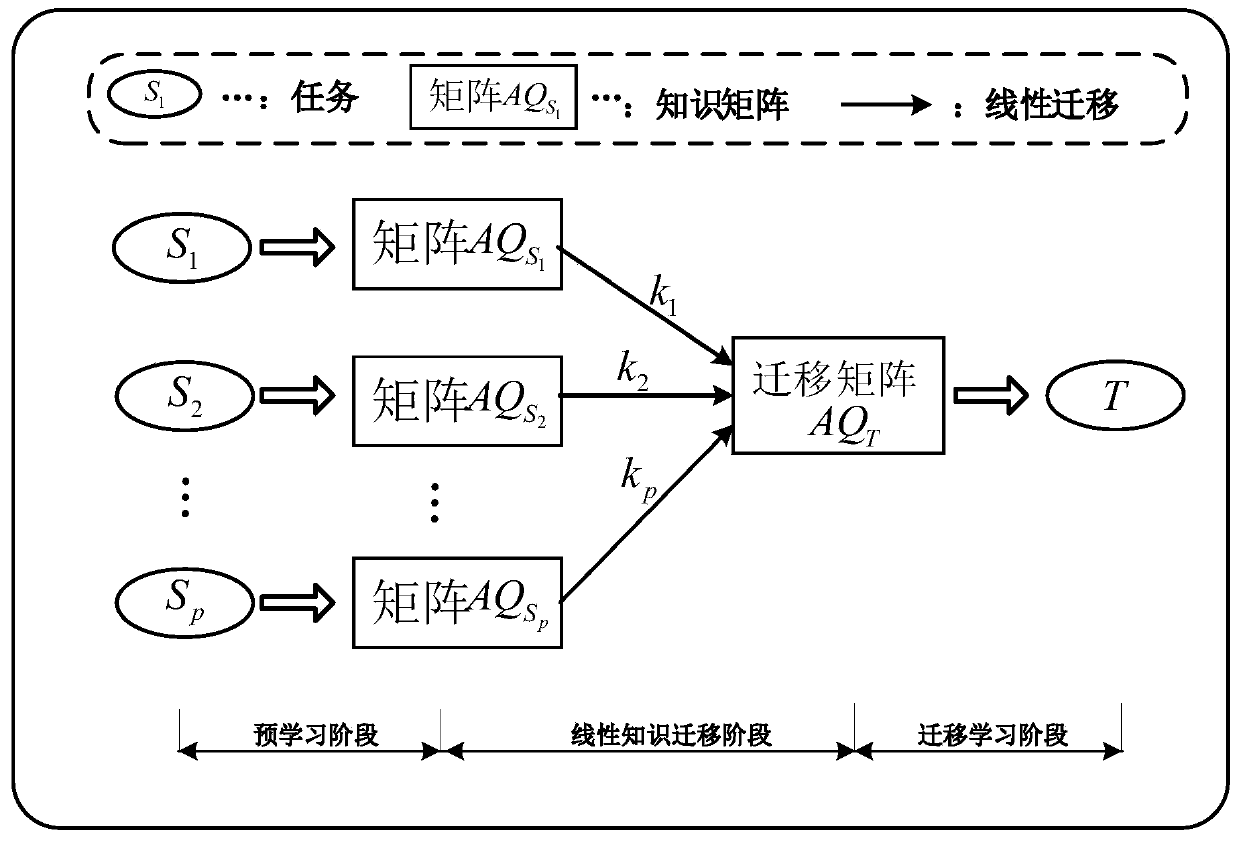

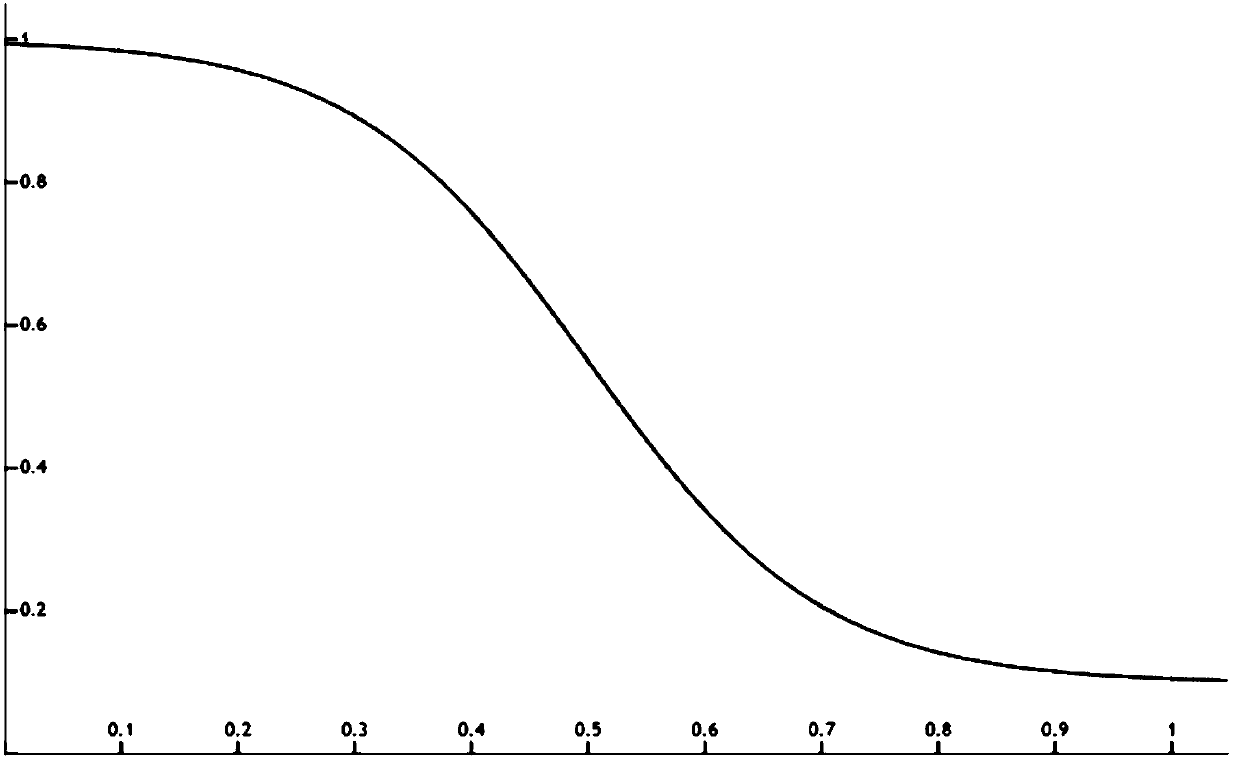

Rectangular intelligent layout method and system based on knowledge migration

ActiveCN110059864AQuick searchEfficient learning processForecastingArtificial lifeRelevant informationReinforcement learning algorithm

The invention discloses a rectangular intelligent layout method and system based on knowledge migration, and belongs to the field of optimized blanking of structural parts, and the method comprises the steps: (1) selecting a plurality of groups of parts to be subjected to layout as source tasks, and extracting the relevant information of the parts and plates; (2) solving the selected multiple groups of source tasks by using an ant colony reinforcement learning algorithm, and storing the learned optimal knowledge matrix into a knowledge base; (3) extracting two groups of source tasks most similar to the target task to be solved from the knowledge base, and linearly migrating the knowledge matrixes corresponding to the two groups of source tasks to the target task; (4) enabling the target task to calculate an optimal layout scheme by means of a migration knowledge matrix and an ant colony reinforcement learning algorithm; and (5) outputting an optimal layout scheme of the target task. According to the rectangular intelligent layout method based on knowledge migration, the plate utilization rate can be increased, the solving speed can be increased, and the rectangular intelligent layout method has good practicability in solving the large-scale and medium-scale rectangular layout problem.

Owner:HUAZHONG UNIV OF SCI & TECH

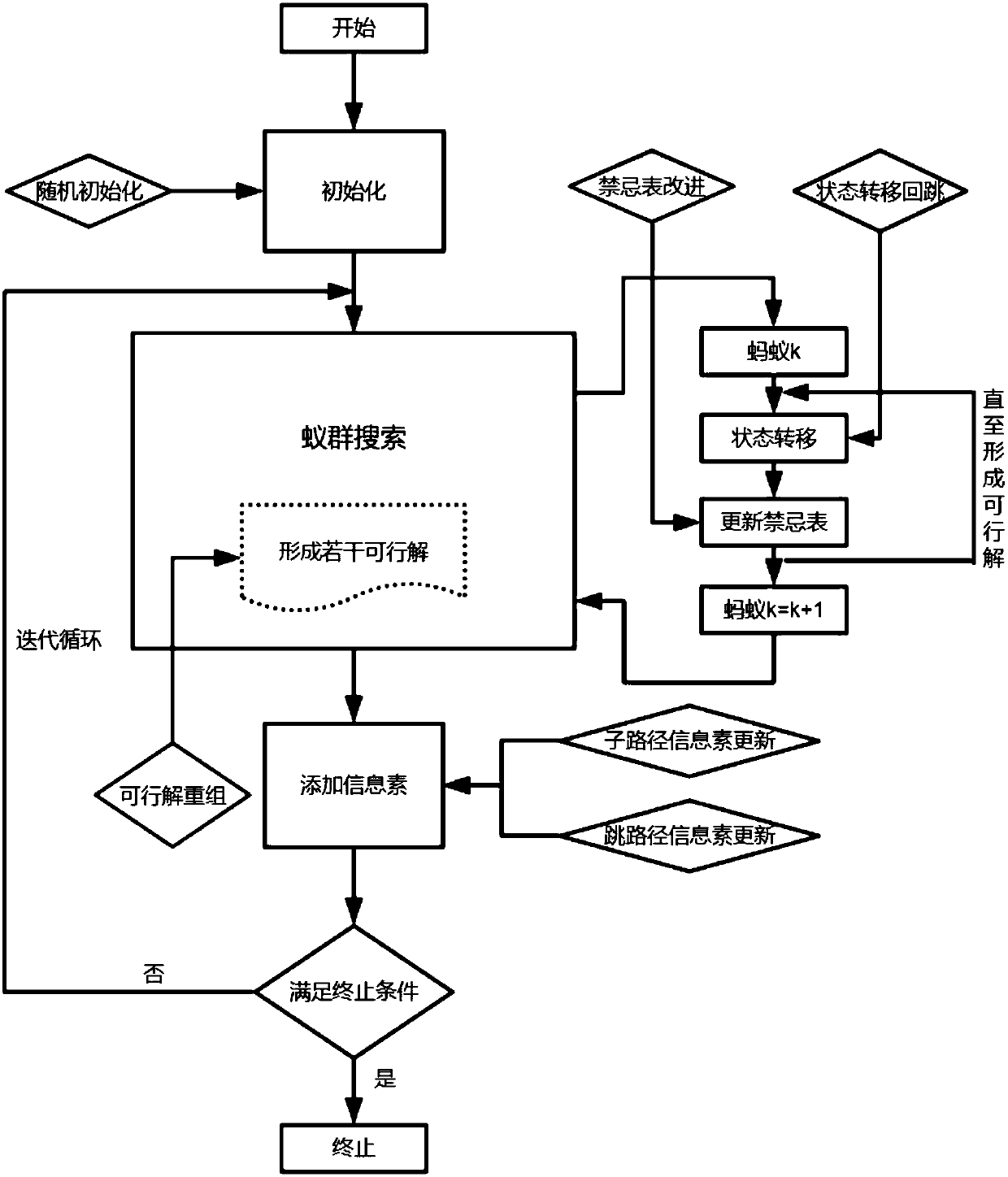

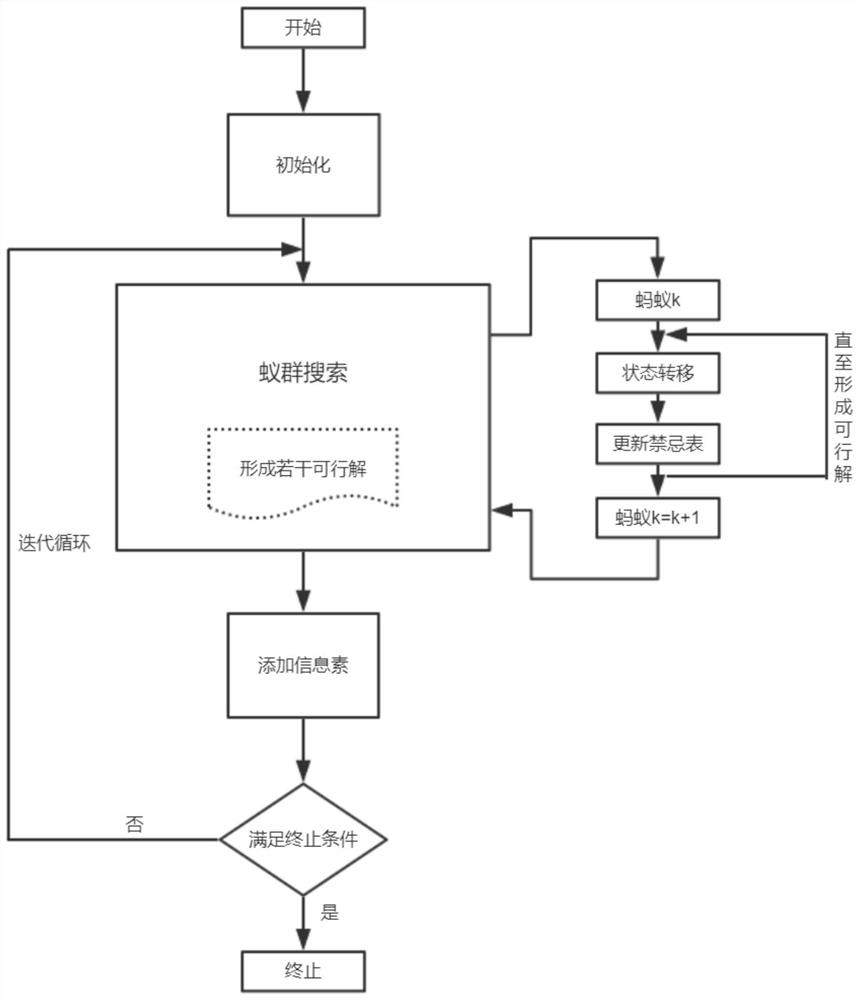

Improved ant colony algorithm for solving multi-objective multi-traveler problem

ActiveCN108564163AGood flexibility and expandabilityClear orientationArtificial lifeSelection algorithmCollaboration

The present invention discloses an improved ant colony algorithm for solving the multi-objective multi-traveler problem. By changing the taboo table, a feasible solution can be constructed separatelyfor each ant of the ant colony. Compared with the traditional method for randomly selecting an ant for movement each time and constructing a feasible solution through multi-ant collaboration, the improved ant colony algorithm disclosed by the present invention has superior efficiency and uniformity; and in addition, added strategies of the improved ant colony algorithm further comprise randomly initializing the pheromone matrix, modifying a state transition formula to make ants return to the warehouse center with a certain probability when the ants move between cities, extra adding rounds of pheromone updates with each target optimization as an orientation, and the like. The algorithm comprises the following steps that: after randomly initializing the pheromone matrix, the ant colony willuse the improved state transition formula combined with the rotation selection algorithm to successively select the next city until a feasible solution is constructed; and after weighted scoring the feasible solution, the score is taken as a reference for the pheromone addition amount, and in combination with multiple features of the sub-path, pheromone addition with multiple rounds and differentamounts is performed.

Owner:SOUTH CHINA UNIV OF TECH

Method for in-situ rapidly removing lake-flooding deposits

InactiveCN102408164APrevent resuspensionAvoid secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationClay mineralsEnvironmental engineering

The invention provides a method for in-situ rapidly removing lake-flooding deposits, which uses a three-step removal method and aims at the characteristic of lake-flooding deposits pollutant. In the first step, a natural polymeric flocculant is used for rapidly flocculating and depositing colloidal state and particulate form pollutant in a lake-flooding deposits water area; in the second step, a natural clay mineral is used for loading nano bubble, a dissolved pollutant in the lake-flooding deposits water area can be removed with high efficiency, and an anaerobic sludge state can be reversed; in the third step, natural sandstones are sprayed to the lake-flooding deposits water area for preventing secondary pollution caused by regeneration of pollutant and sediment. The method of the invention has the advantages of economy and safety, is capable of in-situ rapidly removing large area lake-flooding deposits with high efficiency, and can be used in emergent treatment for lakes, rivers or reservoirs.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Optimisation of sequential combinatorial process

InactiveUS7991593B2Fast and efficient solutionShorten the timeGenetic modelsDigital computer detailsAlgorithmEngineering

A method of optimising a sequential combinatorial process comprising an interchangeable sequence of events uses a master model to model a selection of the possible sequences. Information derived from the master model is used in a surrogate model that approximates the master model. The surrogate model calculates all possible sequences using an algorithm to select information calculated by the master model that most closely matches the events of a present sequence, following a prioritised system so that the best match is used wherever possible. All results from the surrogate model are compared to identify the modelled sequence that gives results closest to a desired optimum result.

Owner:GKN AEROSPACE SWEDEN AB +1

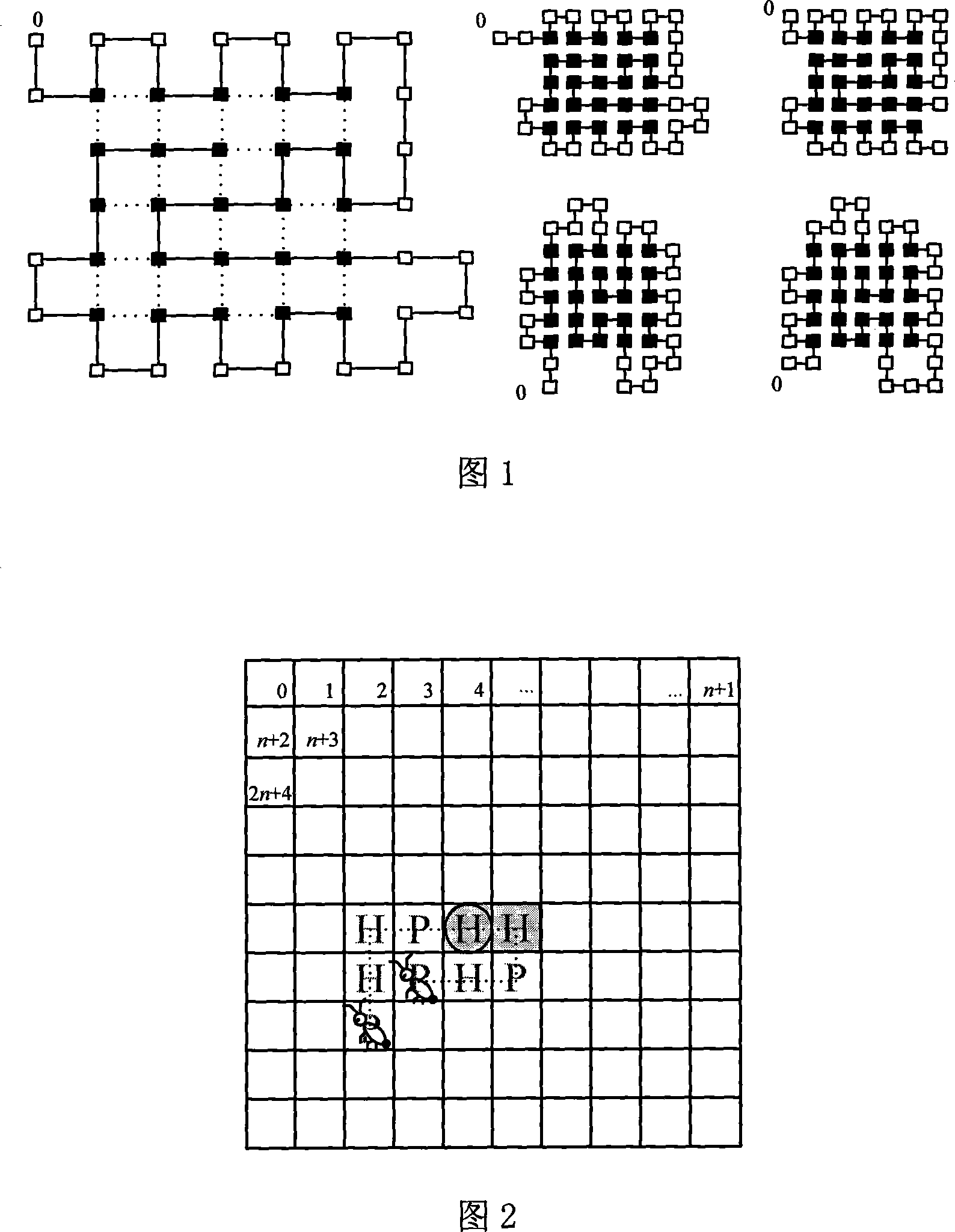

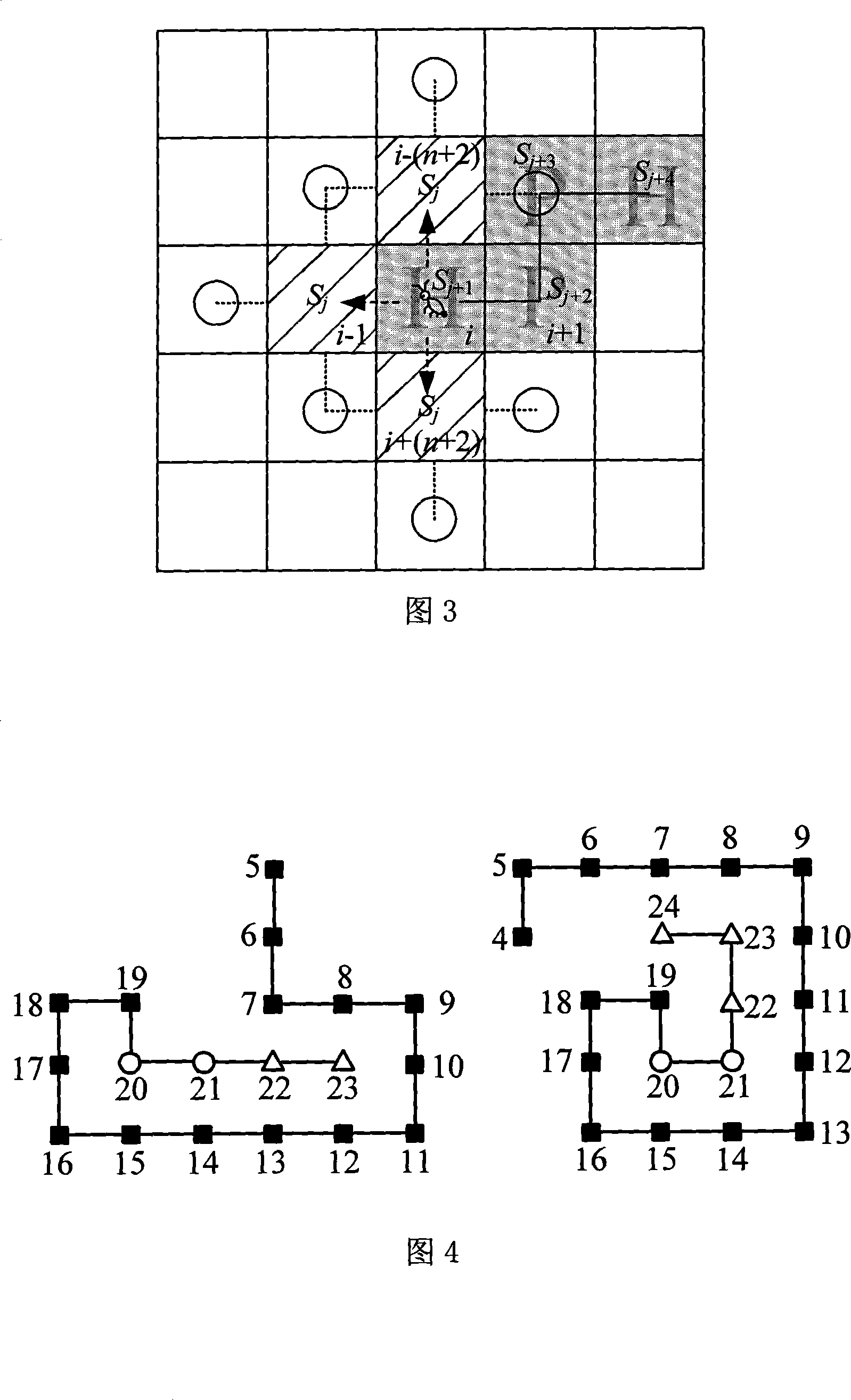

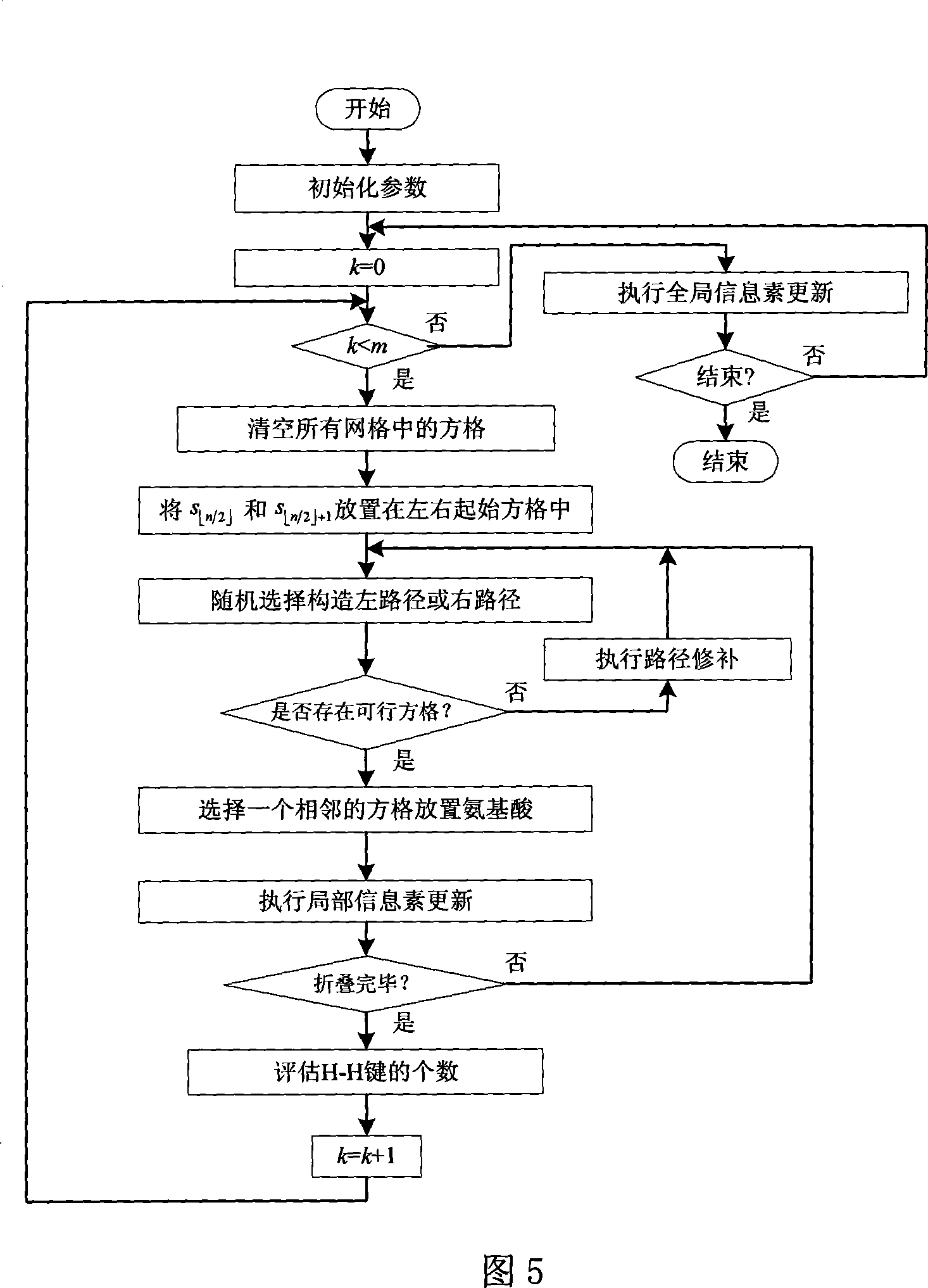

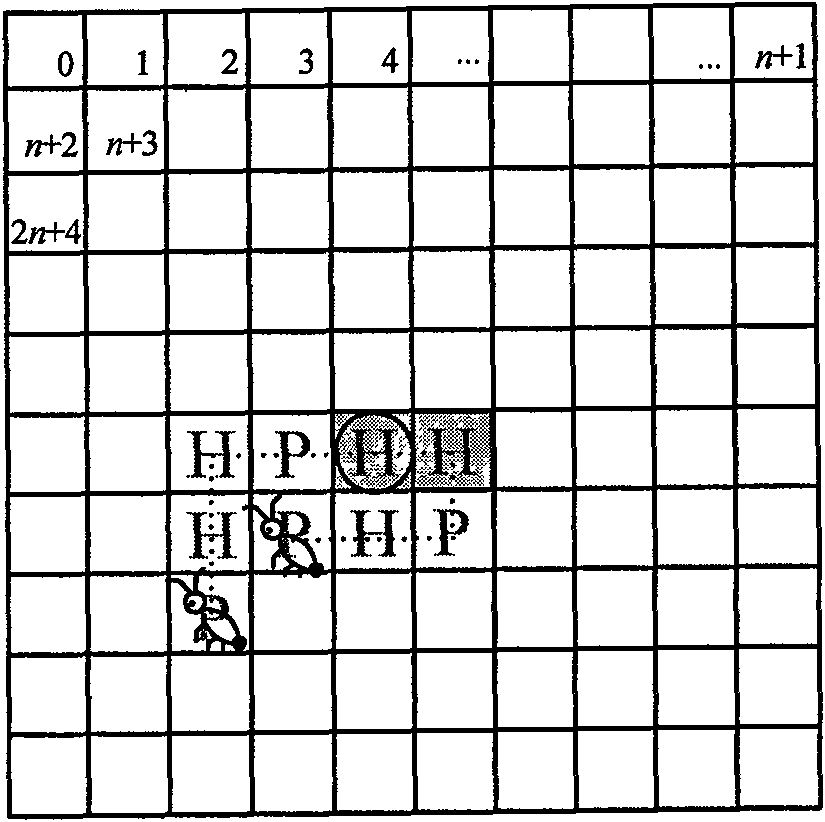

Protein folding optimizing method based on ant group algorithm

The invention discloses a protein folding optimizing method based on an ant colony algorithm. The method comprises the following steps that: firstly, ants are arranged in a left initial square grid and a right initial square grid by using a hydrophobic-polar model; then, amino acids in the protein are arranged into grids by the ants according to a pheromone and heuristic information, updating of the local pheromone is executed while the ants make a movement, if an occurrence of stasis occurs, a maintenance is performed to a corresponding pathway; finally, after all the ants complete a construction for protein folding pathways, updating for the global pheromone is executed. A protein structure with smallest free energy can be obtained by constantly repeating the steps. Compared with the prior algorithm for solving the problem of protein folding, the protein folding optimizing method provided by the invention has the advantages of high efficiency, quickness, etc.

Owner:SUN YAT SEN UNIV

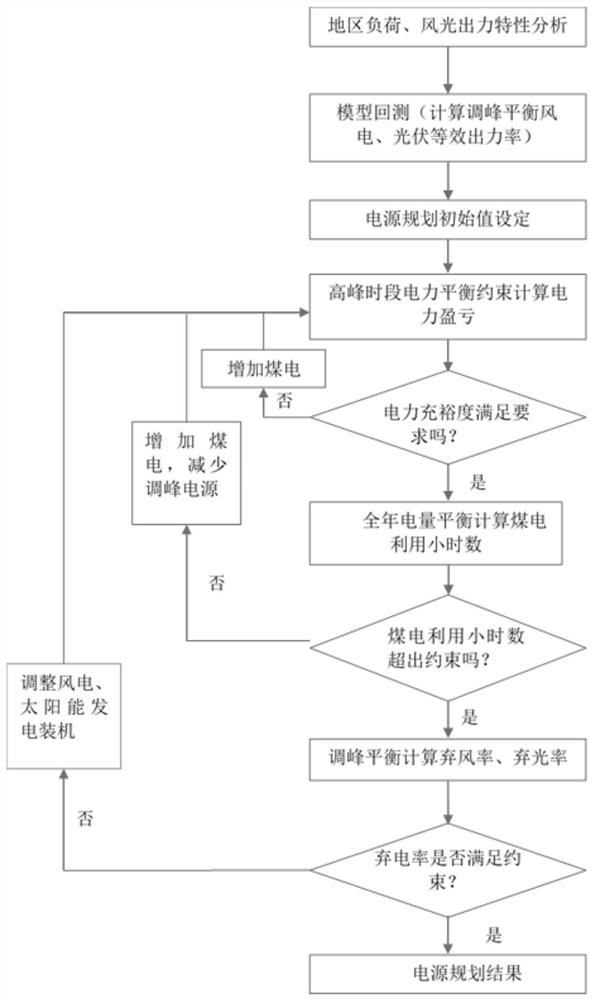

Wind-solar consumption planning method based on flexible resources

PendingCN112736961AFully consider the operating characteristicsImprove scienceSingle network parallel feeding arrangementsPhotovoltaic energy generationNew energyControl theory

The invention relates to a wind-solar consumption planning method based on flexible resources. The method is characterized in that under the limitation of power supply development capability, flexible resources such as a peak regulation power supply, energy storage, interruptible load and the like are preferentially developed in combination with expert experience, the adjustable capability of a system is increased to the maximum extent, reasonable power abandoning space is considered, and the new energy admitting capability is improved. According to the balance method, a balance verification time period is selected based on excavation of regional loads and wind-solar characteristics. The wind-solar output rates in the peak regulation balance period are judged through historical data back measurement, and the wind curtailment rate and the light curtailment rate are calculated respectively through integration of typical day wind-solar curtailment power. According to the method, the system capacity adequacy and the new energy consumption capacity are comprehensively considered, the wind-solar comprehensive consumption planning method based on the balance method is constructed, a certain electricity abandoning space is considered, and new energy development is promoted.

Owner:STATE GRID ENERGY CONSERVATION SERVICE

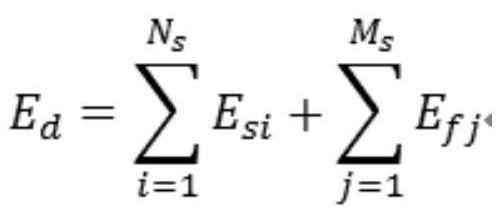

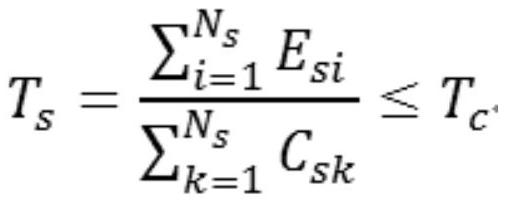

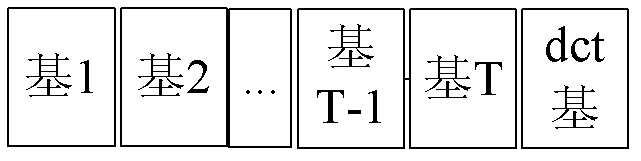

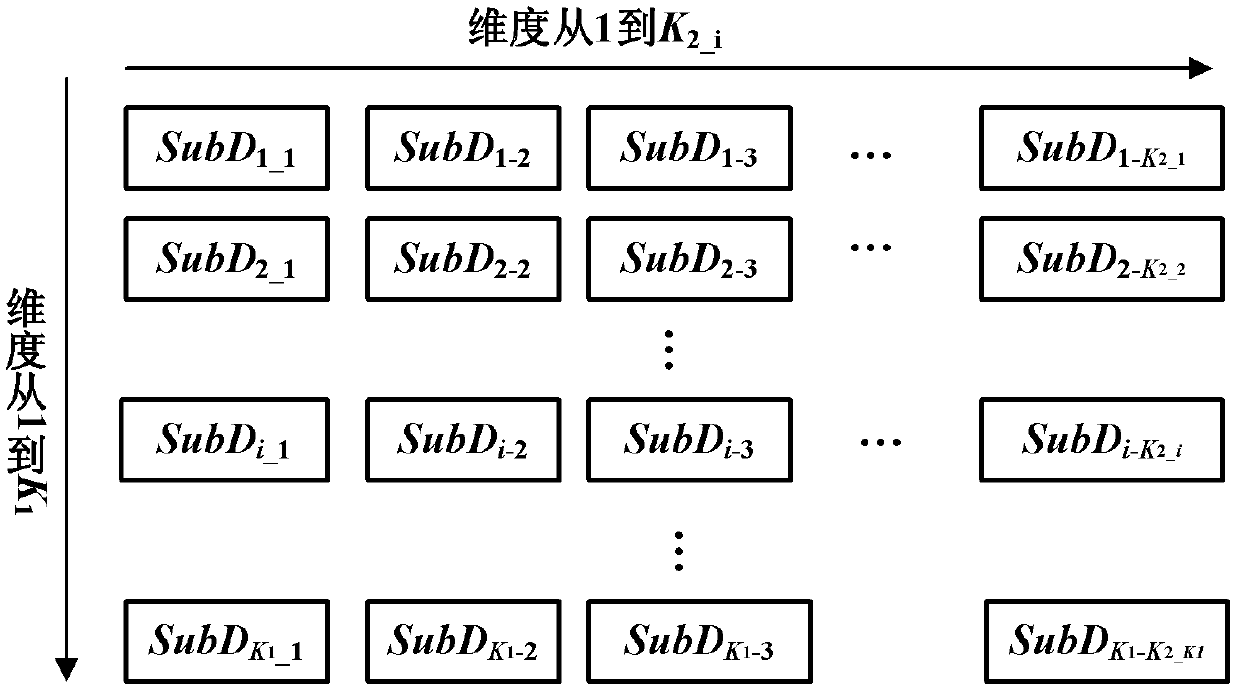

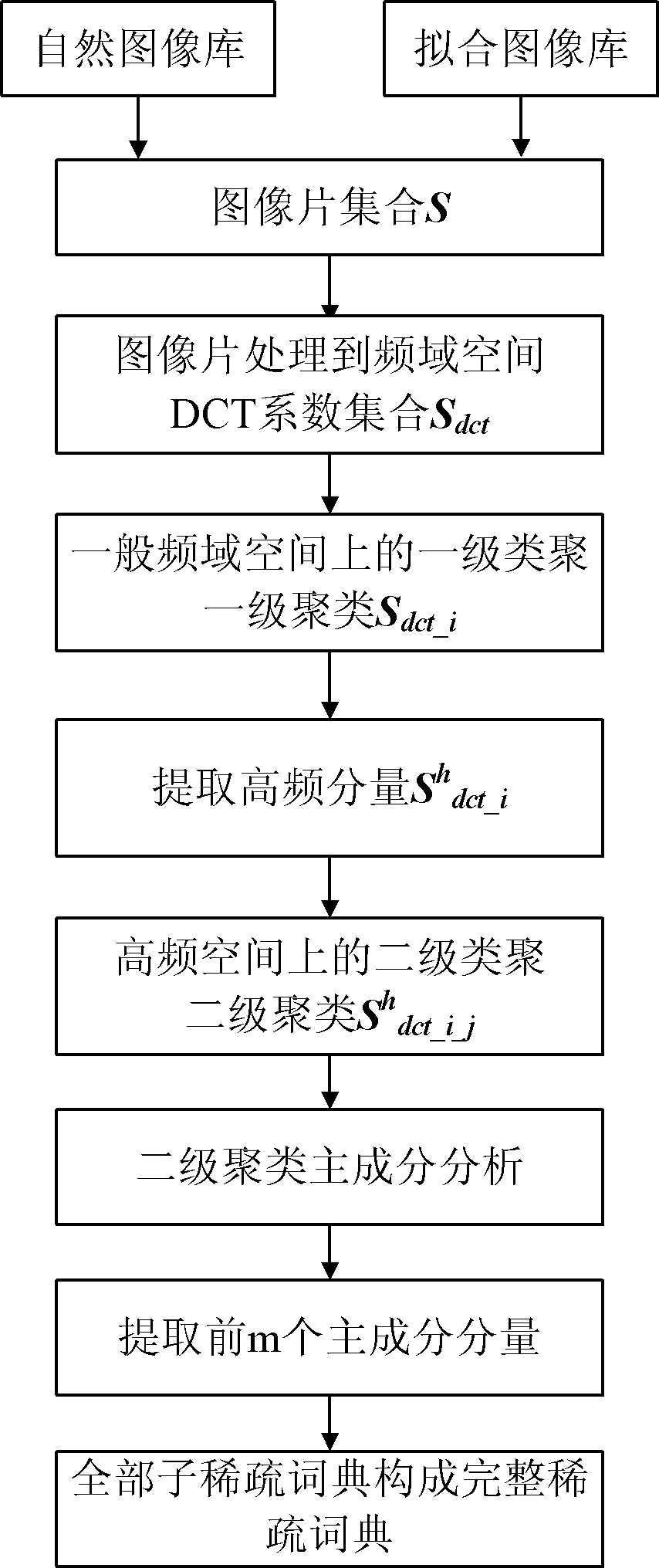

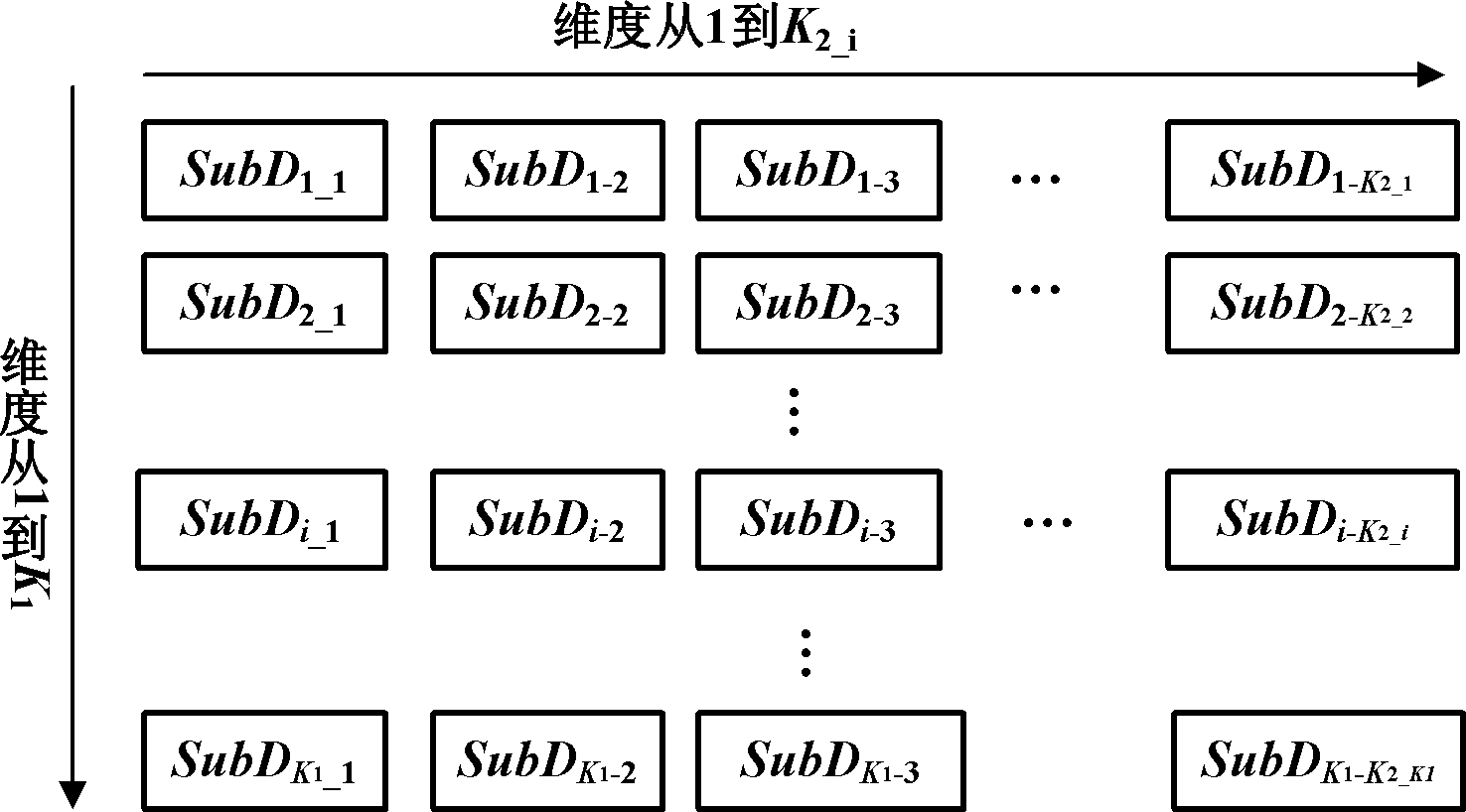

Acquisition method of sparse coefficient vector for recovering and enhancing video image

InactiveCN102510438AFast and efficient solutionAvoid lengthy calculationsImage enhancementTelevision system detailsCluster basedImage based

The invention discloses an acquisition method of a sparse coefficient vector for recovering and enhancing a video image; images are respectively selected from a natural image library and fitting images with distinctive edges for (discrete cosine transform) DCT conversion, mapped to a frequency domain space, and are initially clustered based on the general frequency domain characteristics of the images; then each cluster is further secondarily clustered based on the high-frequency information characteristics thereof; finally the first m main component variables of the obtained secondary cluster are extracted, and the sparse sub dictionary subDi_j of the cluster is obtained; all the sparse sub dictionary subDi_js form the final structural sparse dictionary; and consequently, an established two-stage structural sparse dictionary library is different from a traditional long and low-efficiency linear complete dictionary. The method can quickly and efficiently solve the sparse expression of an input image video signal, can acquire the accurate and effective sparse coefficient vector a~ by carrying out collaborate level sparse building to any image video signal, and has rather high anti-noise performance.

Owner:SICHUAN PANOVASIC TECH

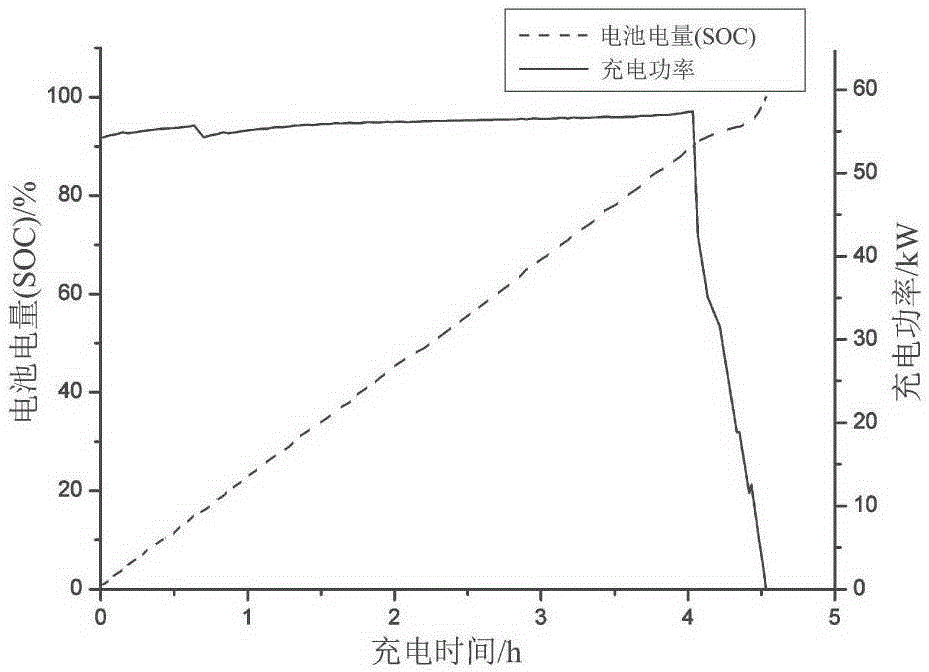

Ordered charging method based on linear power flow model solution for electric automobile battery charging and replacing station

InactiveCN105244941AIncrease load factorIncrease profitBatteries circuit arrangementsElectric powerPower flowBattery charge

The invention discloses an ordered charging method based on a linear power flow model solution for an electric automobile battery charging and replacing station. The method comprises the following steps: (1) establishing a replaceable battery ordered charging optimization model of the electric automobile battery charging and replacing station; (2) performing power flow computation; (3) solving the ordered charging optimization model; and (4) charging replaceable batteries according to a solution. A method combining linear power flow and a genetic algorithm is provided. Variations of a node voltage and branch power after variation of a charging load is rapidly computed through a linearization method, and errors in a linear power flow process are compensated through iteration of the genetic algorithm, thereby rapidly and effectively solving the replaceable battery ordered charging optimization model of the battery charging and replacing station being not supplied with power through a special line. Through adoption of the method, valley filling effects of the charging loads of the electric automobile replaceable batteries on a power grid load curve can be brought into play; the utilization ratio of power grid power equipment is increased; the power grid risk is lowered; the charging cost can be lowered remarkably; and the running economic benefit of an electric automobile is increased.

Owner:STATE GRID SHANDONG ELECTRIC POWER

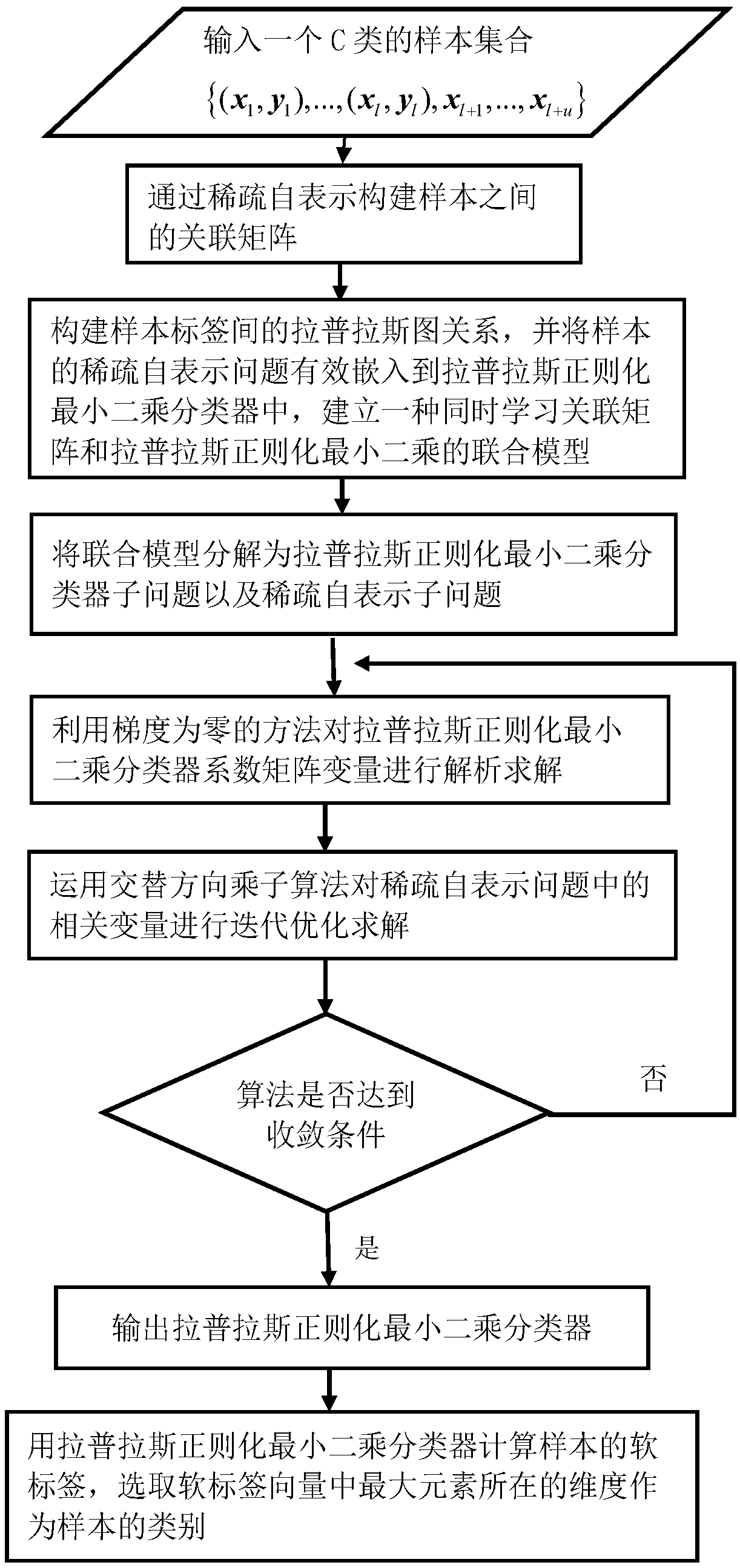

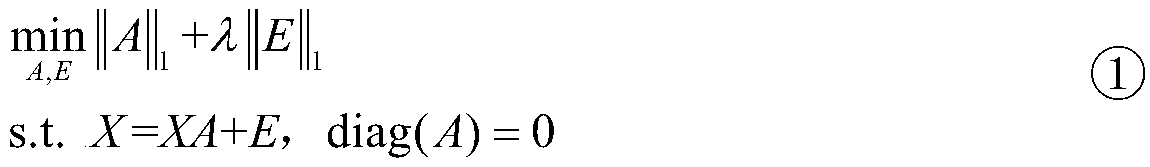

Semi-supervised classification method capable of simultaneously learning affinity matrix and Laplacian regularized least square

InactiveCN108805155AImprove performanceEasy to handleCharacter and pattern recognitionCoordinate descent methodClassification methods

The invention discloses a semi-supervised classification method capable of simultaneously learning an affinity matrix and a Laplacian regularized least square, which mainly comprises the following steps: firstly, a joint model capable of simultaneously learning the affinity matrix and the Laplacian regularized least square is established according to a training sample; secondly, the block coordinate descent method is used to optimize all kinds of variables in the model; and finally, the soft label of the sample is obtained by a Laplacian regularized least square classifier, and the dimension with the largest element in a label vector is selected as the category of the sample. The invention effectively fuses the sparse self-representation problem of samples and the Laplacian regularized least square classifier, and realizes the simultaneous optimization and mutual improvement of the sample affinity matrix and the Laplacian regularized least square classifier in the learning process. Theinvention has an explicit classifier function, so that the problem of an external sample can be effectively handled. Compared with other semi-supervised classification methods, the method has more accurate classification accuracy and good application prospects.

Owner:温州大学苍南研究院

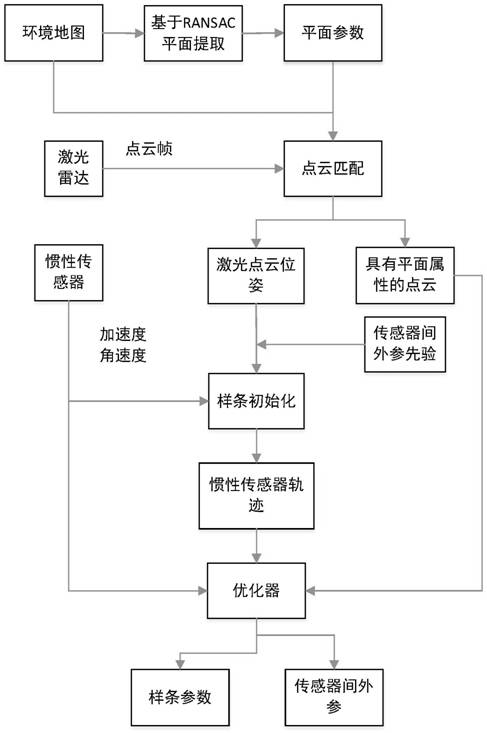

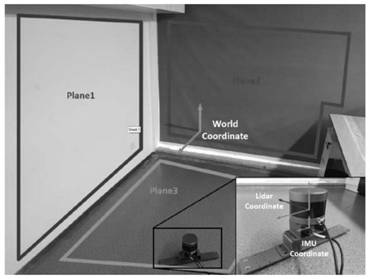

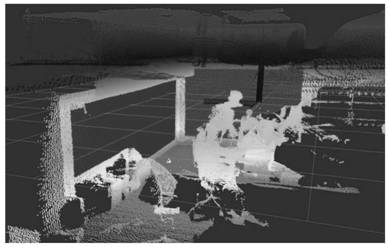

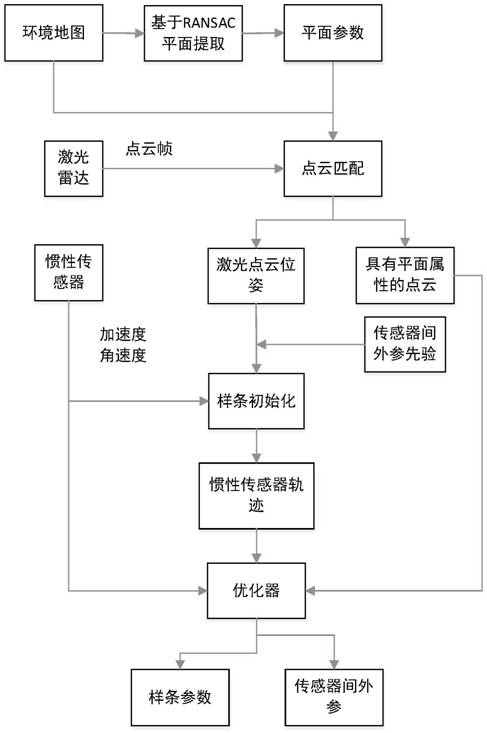

Spline function-based external parameter calibration method for 3D laser radar and inertial sensor at continuous time

ActiveCN112147599AFast and efficient solutionEfficient solutionWave based measurement systemsICT adaptationPoint cloudRadar

The invention provides a spline function-based external parameter calibration method for a 3D laser radar and an inertial sensor at continuous time. The method is divided into two stages, wherein thefirst stage is to preprocess 3D laser point cloud in calibration data based on a known environment map; and the second stage is to model a motion track of a high-frequency inertial sensor into a continuous track by using a spline function, obtain a pose of the inertial sensor at any moment based on the spline function, introduce an external parameter between the 3D laser radar and the inertial sensor, constrain a laser point, construct an optimization problem and solve the problem. According to the method, the track of the inertial sensor is serialized by utilizing the spline function, so thatthe difficulty of tight coupling caused by different measurement frequencies between the sensors is effectively solved. The method is relatively low in environmental requirement and only needs an open wall corner. A calibration result obtained by the method can be directly applied to tasks of robot navigation, unmanned driving and the like, so that basic conditions are provided for multi-sensor data fusion.

Owner:ZHEJIANG UNIV

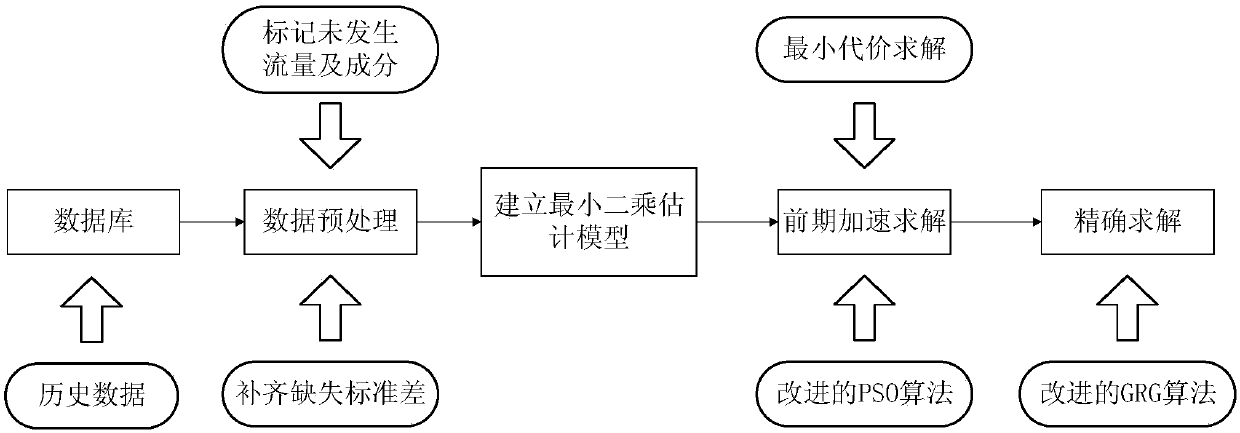

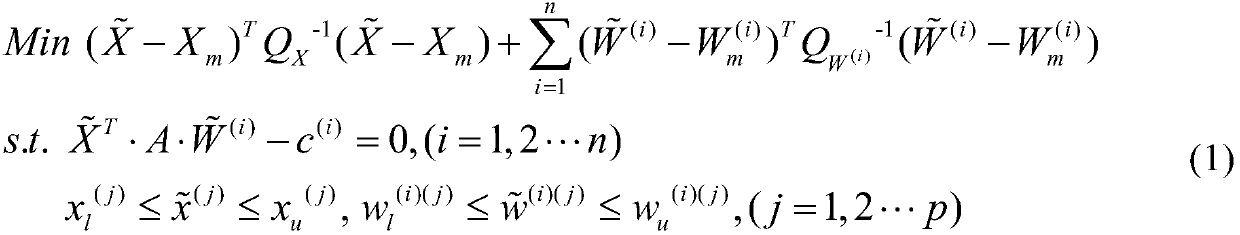

Data coordination method based on accelerated generalized reduced gradient

InactiveCN108519957AFast and efficient solutionGuaranteed accuracyForecastingArtificial lifeAlgorithmStatistician

The invention provides a data coordination method based on accelerated generalized reduced gradient, pertaining to the field of information technology. The method is used for coordinating bilinear metal balance data in a real industry and comprises the following steps: firstly, solving minimum cost according to a constraint equation or utilizing a penalty function method in conjunction with an improved particle swarm algorithm to solve such that early-period acceleration is performed and a initial feasible solution is acquired; on the former basis, applying an improved generalized reduced gradient algorithm in conjunction with optimal selection of basic variables, optimization of iteration step lengths and the like in order to perform accelerated solving operation, thereby acquiring a final data coordination result. While ensuring precision, a bilinear data coordination problem is effectively and rapidly solved, which better helps statisticians on spot balance and optimize work including material, resources and production processes.

Owner:大连智慧海洋软件有限公司

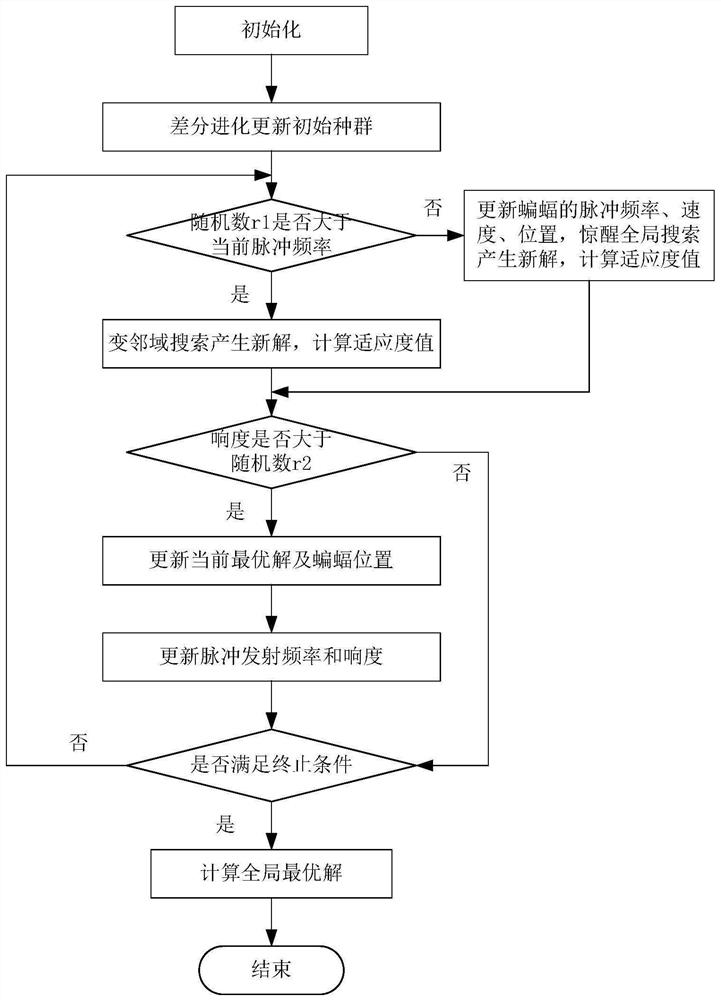

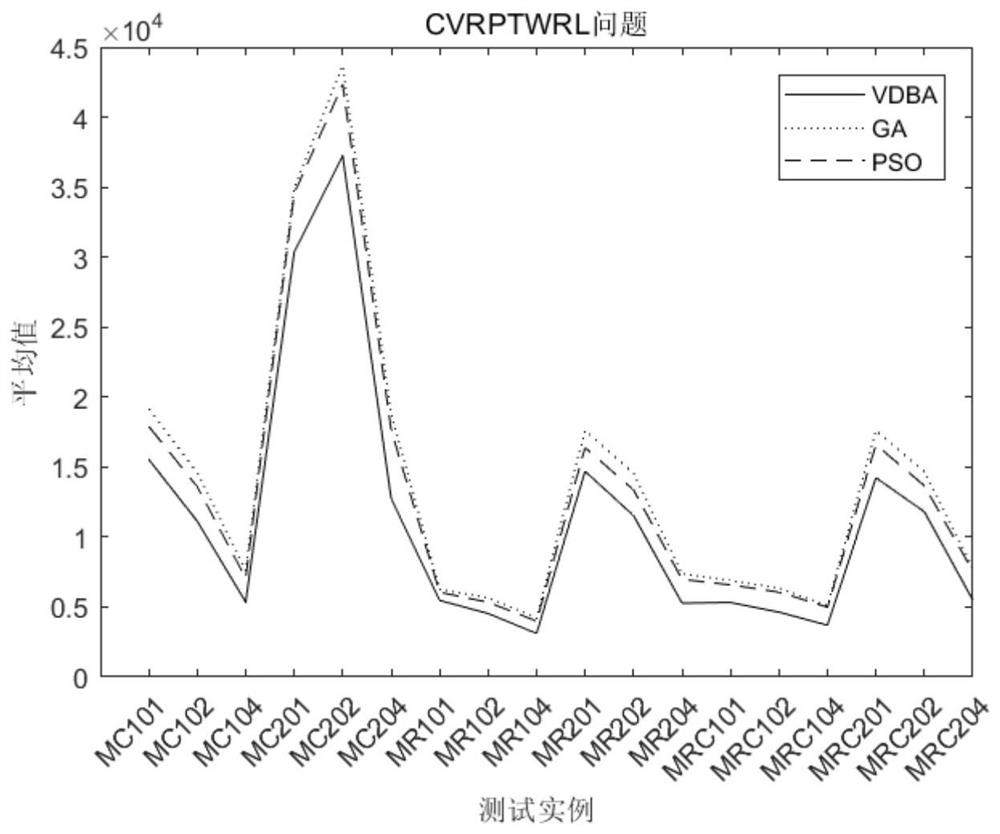

Logistics distribution vehicle path optimization method based on discrete bat algorithm

PendingCN112330001AIncrease the disturbance mechanismImprove search speedForecastingArtificial lifeBat algorithmLocal search (optimization)

The invention provides a logistics distribution vehicle path optimization method based on a discrete bat algorithm. The method is used for solving the technical problems that an existing vehicle pathoptimization method is low in convergence speed and low in solving precision. The method comprises the following steps: constructing a model of a logistics distribution vehicle path under traffic restriction constraints, and designing a decoding strategy and a speed coding strategy; initializing a bat algorithm as an initialized client point; optimizing the initial population by using a differential evolution algorithm; updating the optimized bat position by using a discrete bat algorithm; selecting a random number, selecting local search or global search according to the random number and thecurrent pulse frequency, and updating the bat position, the fitness value, the pulse emissivity and the loudness; judging whether a termination condition is met or not, and outputting a globally optimal solution. According to the method, the regional traffic restriction constrained vehicle path problem can be quickly and effectively solved, the solving speed can be greatly improved, the distribution cost is reduced, and the method has higher robustness and feasibility.

Owner:HENAN UNIVERSITY

Protein folding optimizing method based on ant group algorithm

The invention discloses a protein folding optimizing method based on an ant colony algorithm. The method comprises the following steps that: firstly, ants are arranged in a left initial square grid and a right initial square grid by using a hydrophobic-polar model; then, amino acids in the protein are arranged into grids by the ants according to a pheromone and heuristic information, updating of the local pheromone is executed while the ants make a movement, if an occurrence of stasis occurs, a maintenance is performed to a corresponding pathway; finally, after all the ants complete a construction for protein folding pathways, updating for the global pheromone is executed. A protein structure with smallest free energy can be obtained by constantly repeating the steps. Compared with the prior algorithm for solving the problem of protein folding, the protein folding optimizing method provided by the invention has the advantages of high efficiency, quickness, etc.

Owner:SUN YAT SEN UNIV

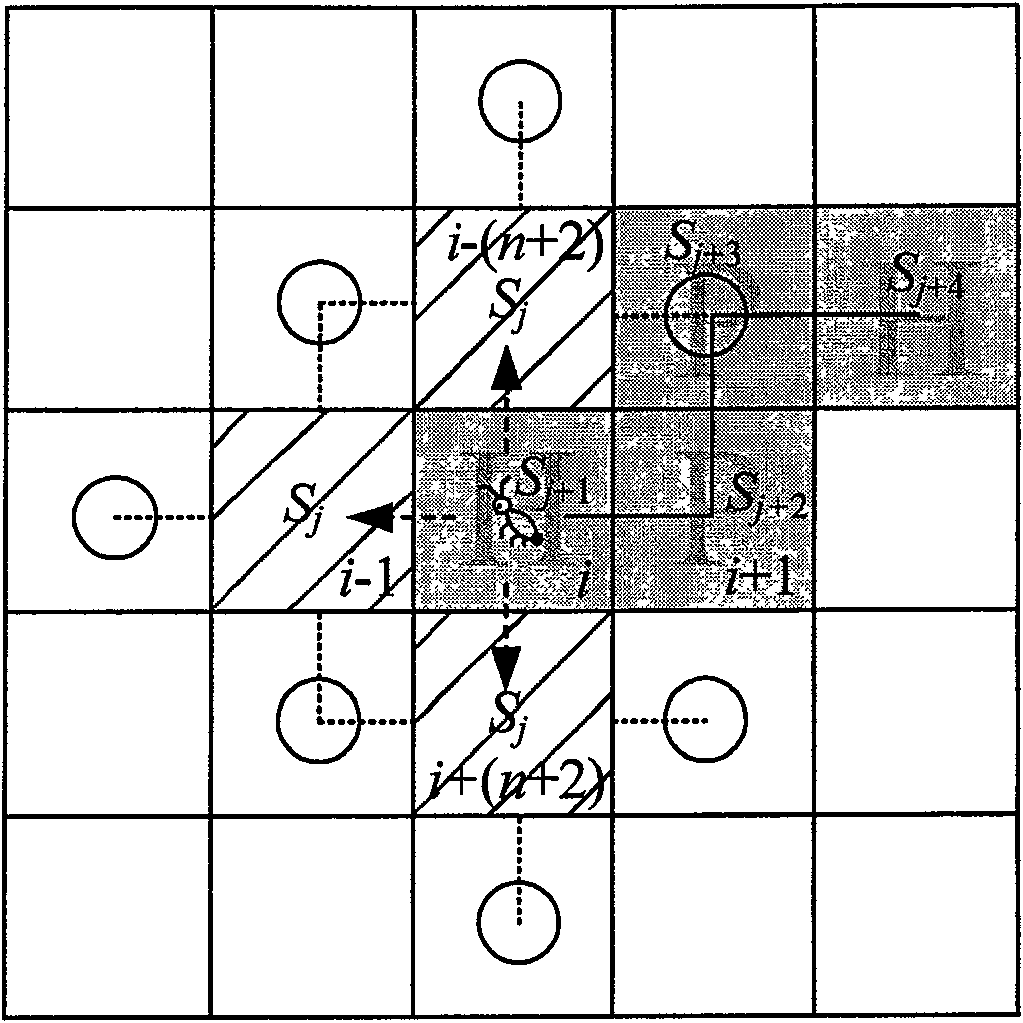

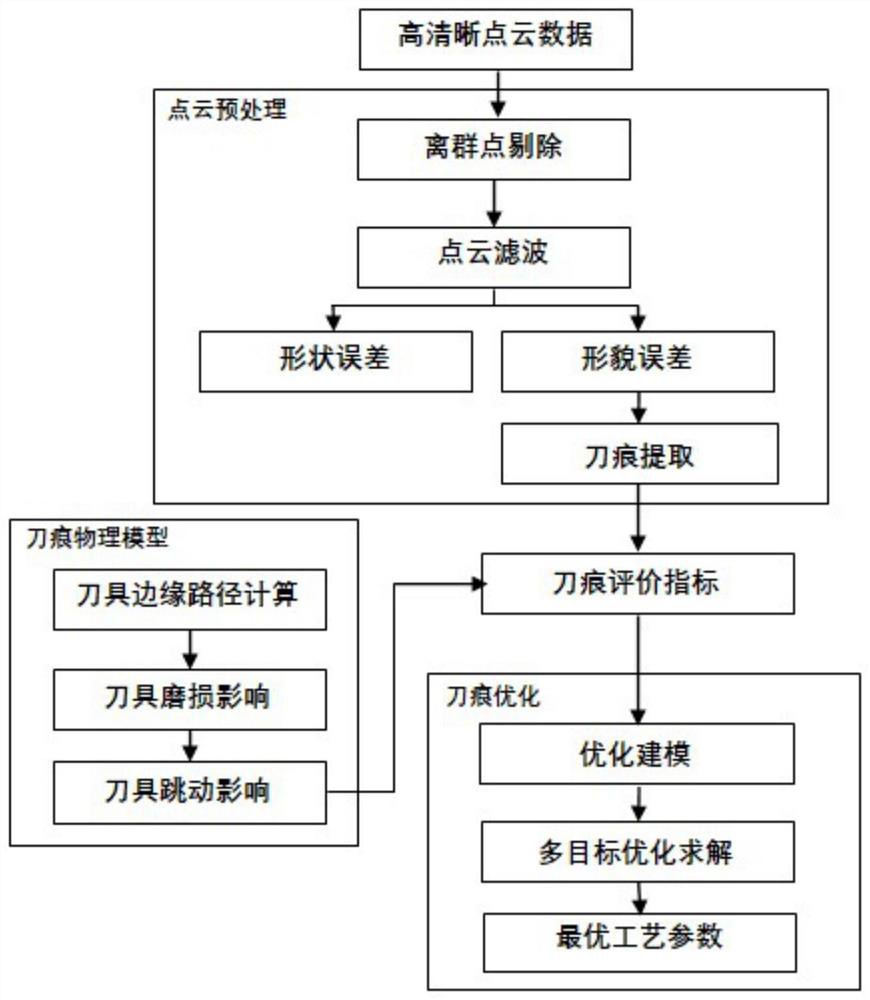

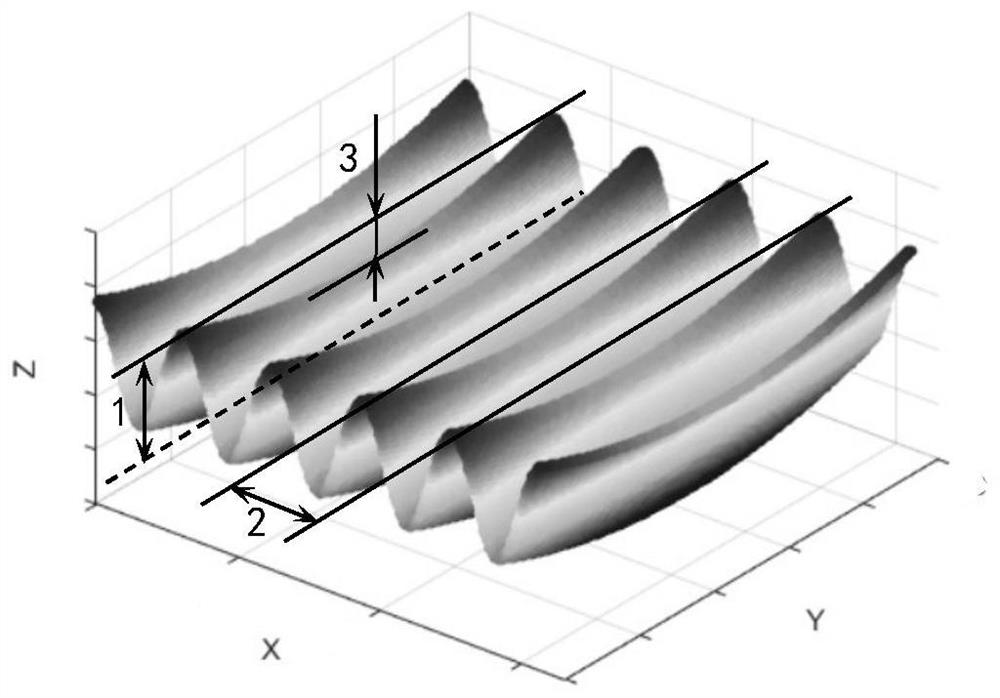

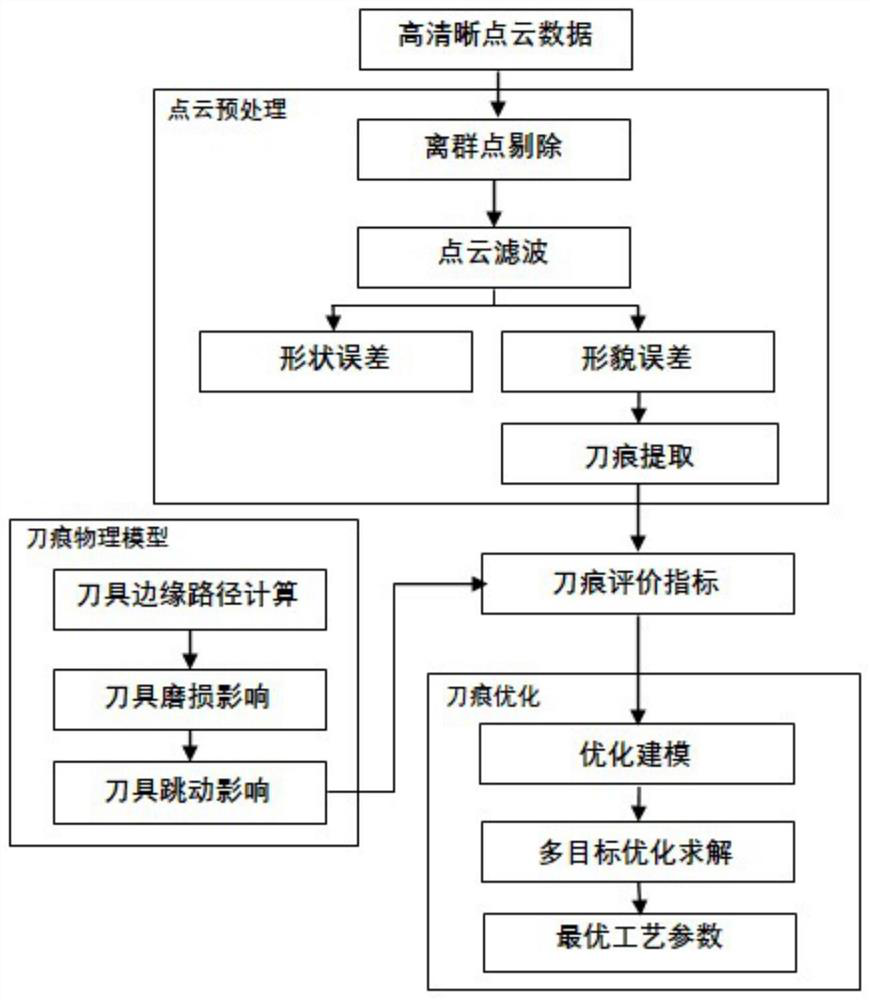

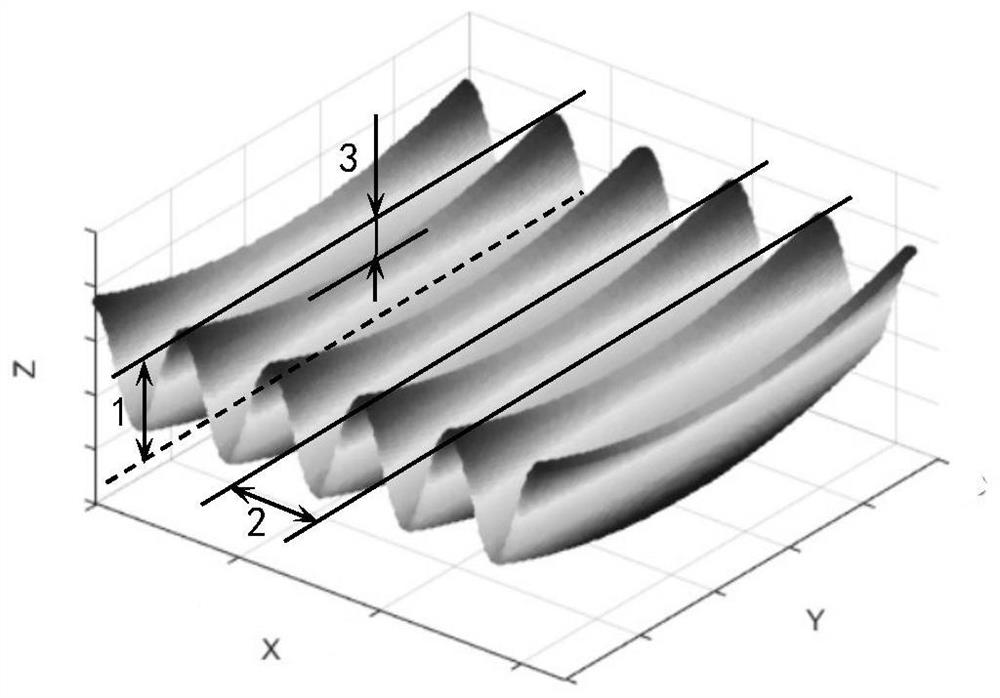

Method and device for measuring, predicting and optimizing milling tool marks on top surface of engine cylinder block

ActiveCN113145905AAvoid non-evenPrecise control of milling process parametersMeasurement/indication equipmentsMilling equipment detailsPoint cloudMachined surface

The invention discloses a method and device for measuring, predicting and optimizing milling tool marks on the top surface of an engine cylinder block. The method comprises the steps that preprocessing of cylinder block top surface point cloud data obtained through high-definition measurement is conducted, abnormal outliers are removed, filtering of the point cloud data is conducted, the tool mark features in a high-pass signal are extracted, and a three-dimensional evaluation index of the tool marks is defined; according to the milling machining characteristics of the top face of the engine cylinder block, influences caused by spindle inclination, tool abrasion and tool jumping are comprehensively considered, and physical modeling is conducted on the tool mark forming process; and the milling surface quality is predicated according to a tool mark physical model, a three-dimensional evaluation index numerical value of the tool marks generated under a specific process parameter condition is calculated, a process parameter multi-target optimization model is established on the basis, and an optimization model is solved to obtain an optimal process parameter scheme suitable for milling the top surface of the engine cylinder block. According to the method, milling surface tool mark feature indexes are defined and accurately predicted, so that the milling process parameters of the top surface of the engine cylinder block are effectively optimized, and the milling quality of the top surface of the engine cylinder block is improved.

Owner:力度工业智能科技(苏州)有限公司

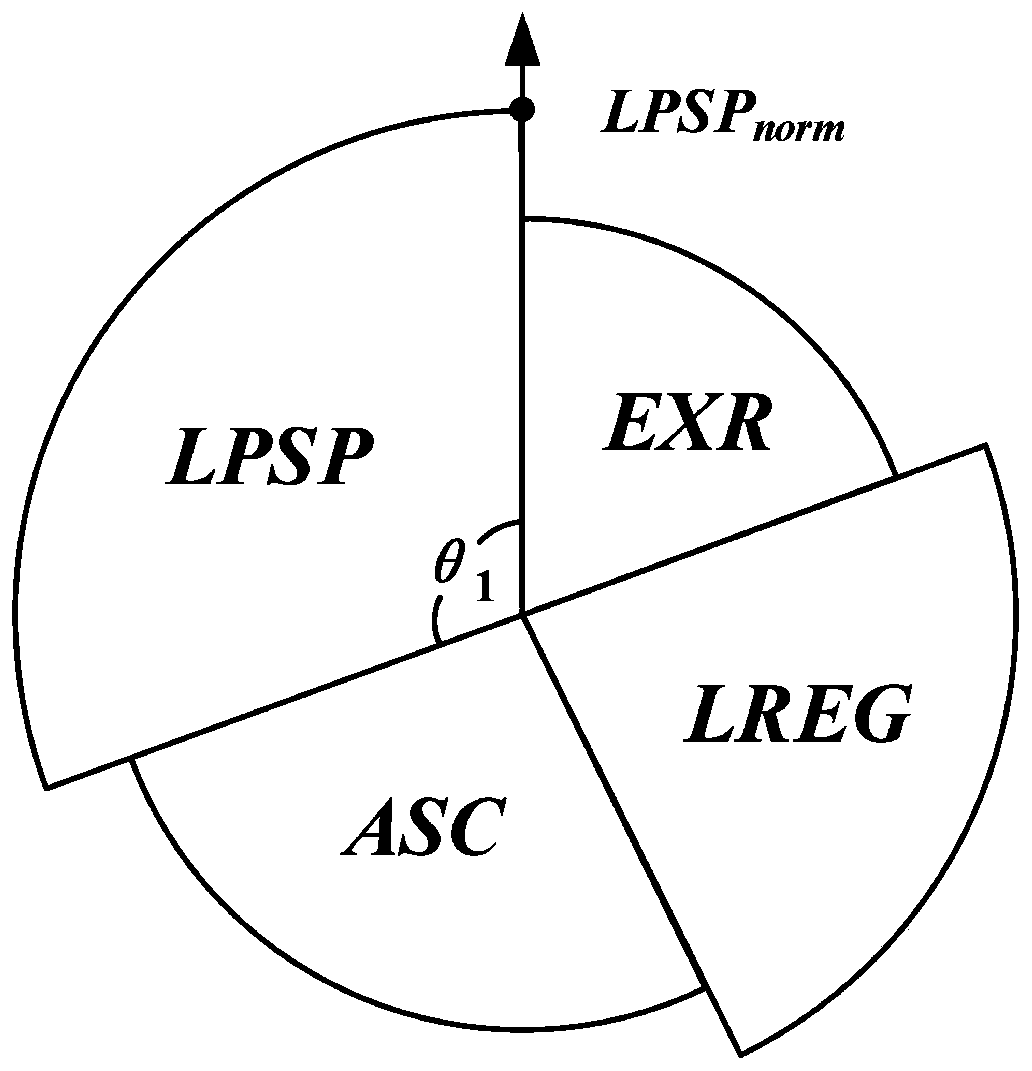

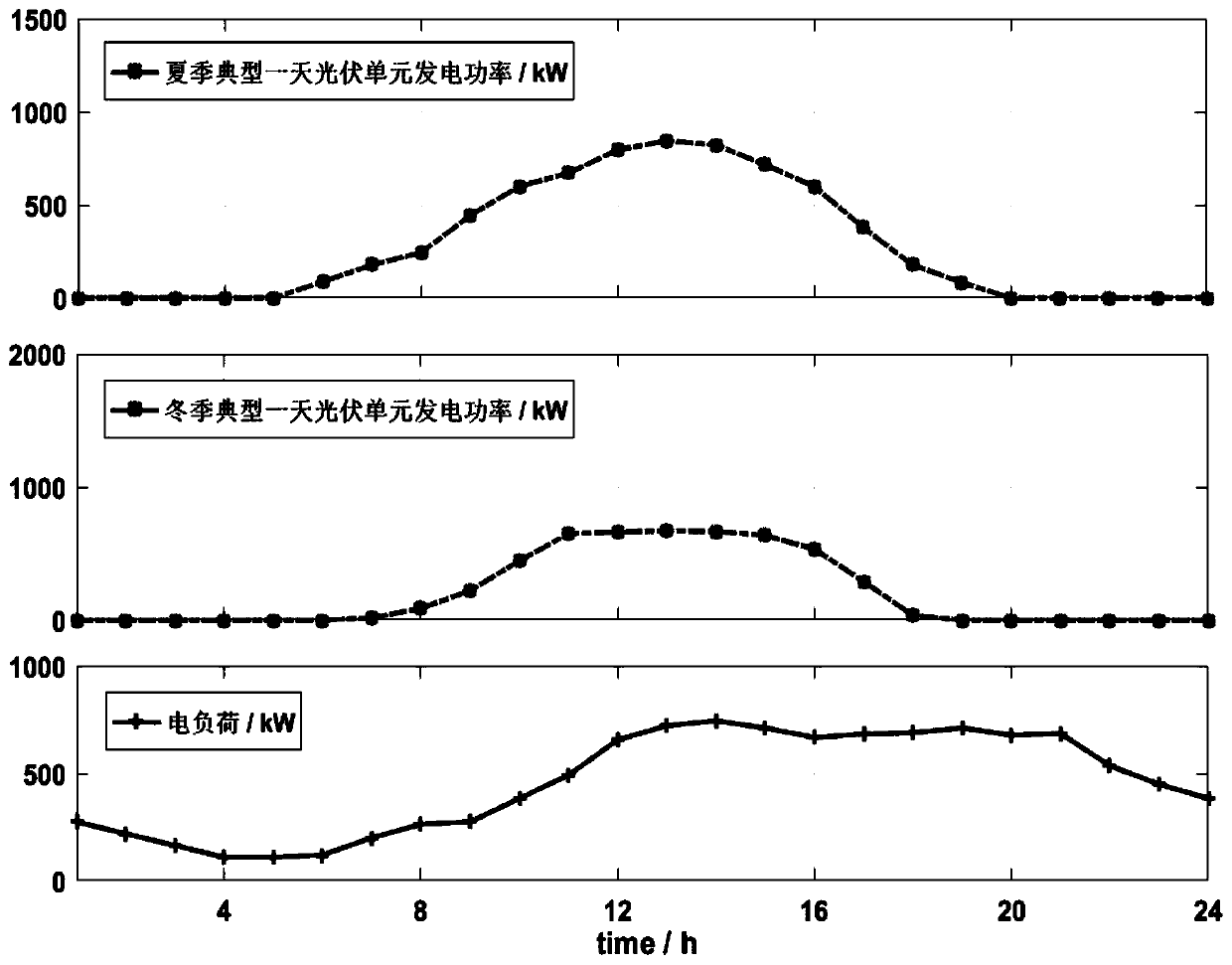

Micro-grid system capacity optimal configuration method based on fan-shaped radar map model

ActiveCN111311032AImprove power supply reliabilityComprehensive excellentSingle network parallel feeding arrangementsForecastingMicrogridNew energy

The invention discloses a micro-grid system capacity optimal configuration method based on a fan-shaped radar map model. The method comprises the following steps: firstly, selecting a load power lossrate, an annual cost, a renewable energy power generation loss rate and an energy excess rate as evaluation indexes in four aspects of microgrid system power supply stability, economy, a new energy consumption condition and an energy utilization rate, establishing a fan-shaped radar map model, and setting the area of a fan-shaped radar map as an objective function; taking the maximum area of the fan-shaped radar map as a target, obeying constraint conditions, and establishing an optimization mathematical model of micro-grid system capacity configuration; finally, a genetic algorithm based on aload tracking management strategy is adopted; solving an optimal configuration scheme of the micro-grid system capacity; the correctness and feasibility of the optimization method are verified through actual examples, the optimization configuration scheme can meet the stable operation target of the microgrid system composed of various new energy modules and energy storage devices, and economic operation of the microgrid system and efficient utilization of renewable energy sources are facilitated.

Owner:ZHEJIANG UNIV +1

An Improved Ant Colony Method for Solving Multi-objective Multi-Traveling Salesman Problem

ActiveCN108564163BIncrease flexibilityStrong expandabilityArtificial lifeTheoretical computer sciencePheromone matrix

The invention discloses an improved ant colony method for solving the multi-objective multi-traveling salesman problem. By changing the taboo table, each ant in the ant colony can independently construct a feasible solution. Compared with the traditional method of randomly selecting one ant to move each time, multi-ants cooperative construction of feasible solutions has advantages in efficiency and uniformity. In addition, the strategy added by the improved ant colony method also includes random initialization of the pheromone matrix, modification of the state transition formula so that the ants have a certain probability of returning to the warehouse center when moving between distribution points, and additional rounds of pheromone oriented by the optimization of each goal. update etc. The algorithm steps are as follows. After the pheromone matrix is randomly initialized, the ant colony will use the improved state transition formula combined with the round-robin selection algorithm to select the next delivery point successively until a feasible solution is constructed. After the feasible solutions are weighted and scored, this score is used as the benchmark for the amount of pheromone added, and multiple rounds of different amounts of pheromone are added in combination with multiple characteristics of the sub-path.

Owner:SOUTH CHINA UNIV OF TECH

Digital image based rapid solving method of circle parameters

InactiveCN101718528BFast and efficient solutionSolve the speed problemUsing optical meansDigital imageMedical biology

The invention relates to a digital image based rapid solving method of circle parameters, which comprises the steps of: 1, acquiring an image of a measured object by using a digital image sensor to establish a plane coordinate system; 2, carrying out Histogram analysis on the image to determine a threshold suitable for separating a boundary of a circle to be measured; and carrying out region segmentation on the acquired image to set a square region including the circle to be measured; 3, selecting an inner point of the circle according to the threshold determined in the step 2, and searching from the point to obtain a point at the edge of the circle to be measured in the image; 4, setting a dynamic step length S, obtaining a point set sequence at the edge of the circle to be measured according to an edge point searching rule in the step 3; and 5, solving coordinates of the center of the circle and diameter parameters of the circle. The invention can be applied to the geometric parameter measurement of a circular pat or instrument in the fields of industrial detection, medical biology and the like, better solves the contradiction between speed and effect during solving the circle parameters in the digital image, and has high practical application value.

Owner:UNIV OF SCI & TECH BEIJING

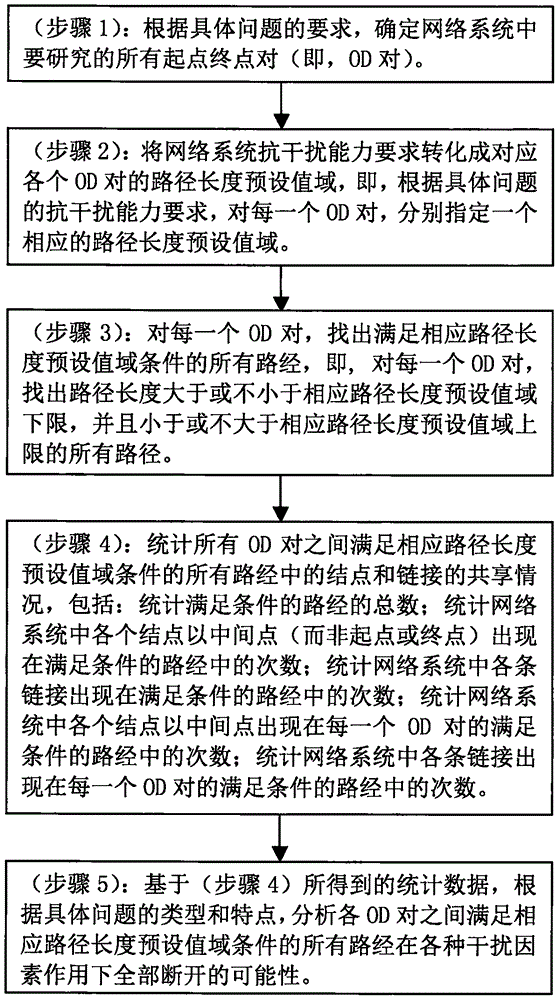

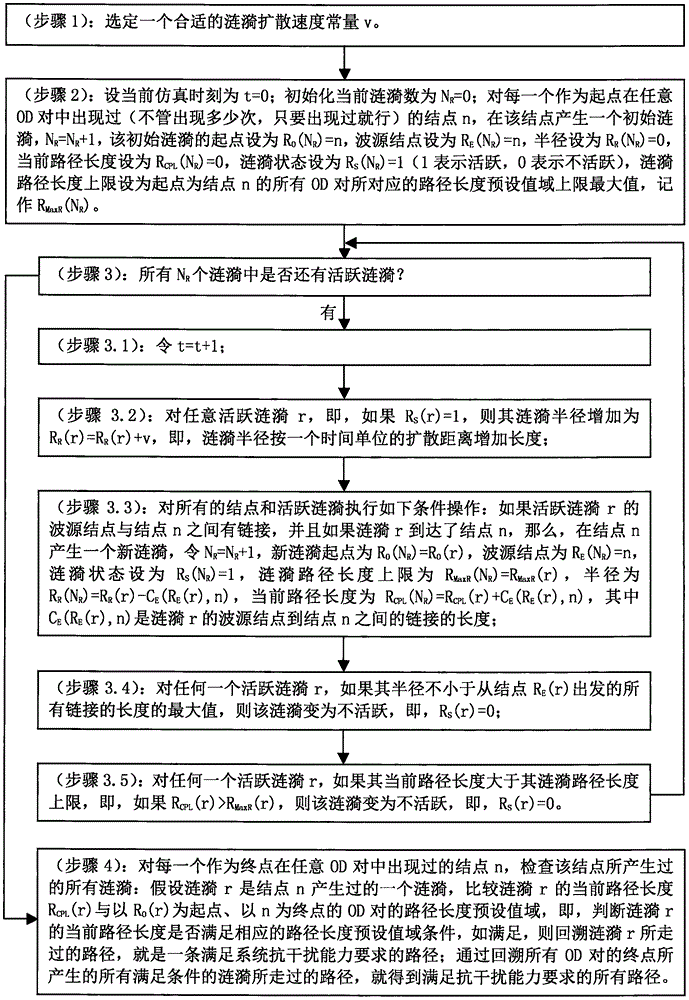

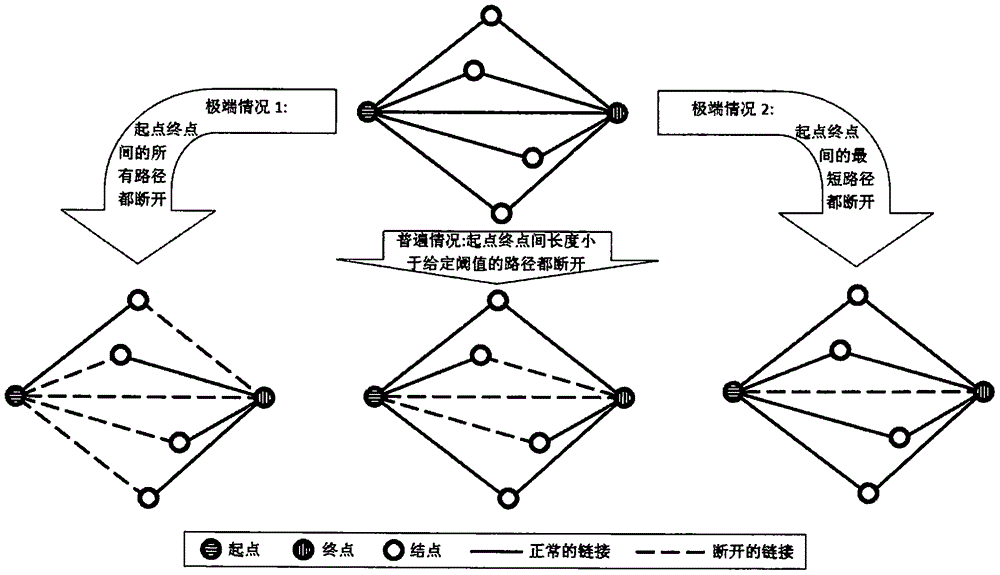

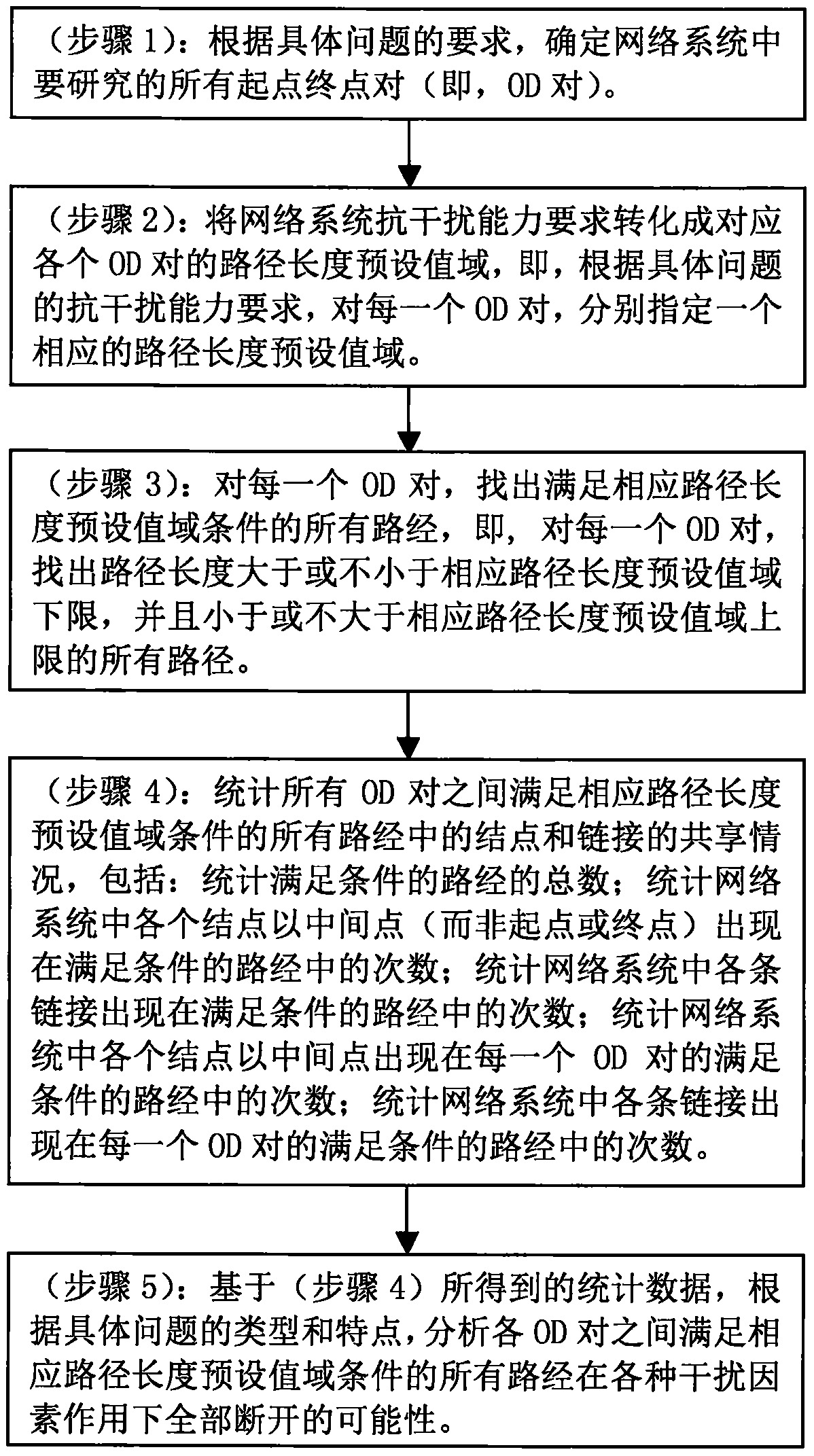

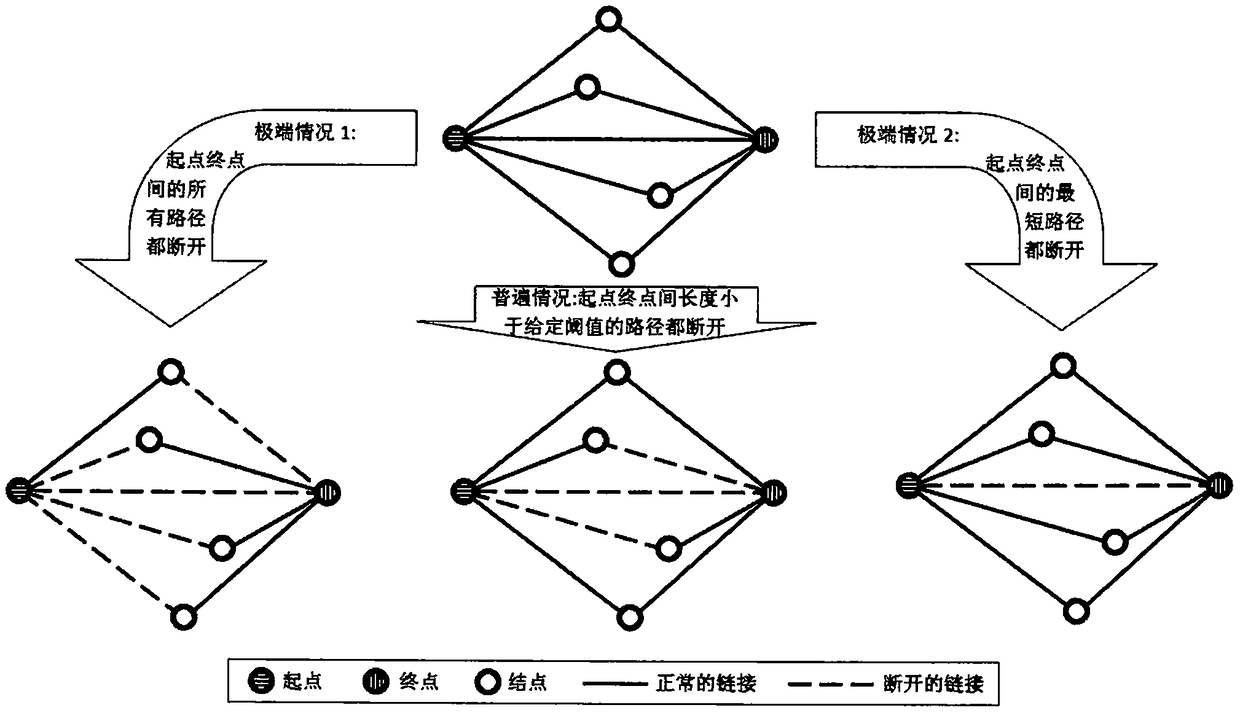

Method for evaluating anti-interference capability of network system

ActiveCN105956357AEvaluate anti-interference abilityOvercome limitationsSpecial data processing applicationsInformaticsPath lengthStatistical analysis

The invention discloses a method for evaluating the anti-interference capability of a network system. The invention aims at evaluating whether the network system still can guarantee that the capability of connecting Original and Destination pairs (OD pairs) according to a path length meeting a preset value condition under the action of various types of factors. The method comprises the steps: firstly enabling the anti-interference capability of the network system to be converted into path length preset value ranges corresponding to all OD pairs; secondly simulating a natural ripple spread phenomenon, and carrying out one-off ripple spread relay race in the network, so as to solve all paths, meeting the corresponding preset value condition, among all OD pairs in the network (not just solving the shortest path among the OD pairs and not all paths among the OD pairs); and finally carrying out the statistic analysis of the sharing condition of nodes and links in the paths with the lengths meeting the preset value range condition. The method can be used for solving a problem of anti-interference capability evaluation of a physical network and an extract virtual network.

Owner:BEIJING NORMAL UNIVERSITY +1

Calibration method of extrinsic parameters of 3D lidar and inertial sensor based on spline function

ActiveCN112147599BFast and efficient solutionEfficient solutionWave based measurement systemsICT adaptationPoint cloudEngineering

The invention provides a method for calibrating external parameters of 3D laser radar and inertial sensor in continuous time based on spline function, and provides a method for calibrating external parameters of 3D laser radar and inertial sensor based on continuous time. The method is divided into two stages. The first stage is to preprocess the 3D laser point cloud in the calibration data based on the known environmental map. The second stage is to model the trajectory of the high-frequency inertial sensor with a spline function as Continuous trajectory, the pose of the inertial sensor at any time is obtained based on the spline function, the external parameters between the 3D lidar and the inertial sensor are introduced, the laser points are constrained, and an optimization problem is constructed to solve it. The method uses the spline function to continue the trajectory of the inertial sensor, effectively solving the difficulty of tight coupling caused by the different measurement frequencies between the sensors. This method has lower requirements on the environment, and only needs to have an open corner. The calibration results obtained by the method of the invention can be directly applied to tasks such as robot navigation and unmanned driving, and provide basic conditions for multi-sensor data fusion.

Owner:ZHEJIANG UNIV

GNSS single-epoch double-difference integer ambiguity rapid determination method

ActiveCN111751855AFast and efficient solutionDoes not affect positioning accuracySatellite radio beaconingTelecommunicationsCarrier signal

The invention relates to a GNSS single-epoch double-difference integer ambiguity rapid determination method. The method comprises the following steps: screening and grading all single-epoch observation satellites into reference satellites, class I satellites and class II satellites; establishing a double-difference carrier phase observation equation of the class I satellite pair and the class II satellite pair; calculating and checking the double-difference integer ambiguity of the class I satellite pair to obtain the double-difference integer ambiguity of the class I satellite pair passing the check, and then calculating the local solution of the class I satellite pair for positioning; substituting the local solution for positioning of the class I satellite pair into a double-difference carrier phase observation equation of a class II satellite pair, and taking an integer to calculate double-difference integer ambiguity of the class II satellite pair; and determining GNSS single-epochdouble-difference integer ambiguity according to the double-difference integer ambiguity of the class I satellite pair and the class II satellite pair.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Method and device for measuring, predicting and optimizing tool marks in engine block top milling

ActiveCN113145905BAvoid non-evenPrecise control of milling process parametersMeasurement/indication equipmentsMilling equipment detailsMilling cutterMachined surface

The invention discloses a method and device for measuring, predicting and optimizing tool marks based on engine cylinder top surface milling, including: preprocessing the cylinder top surface point cloud data obtained by high-definition measurement, eliminating abnormal and outlier points, and point The cloud data is filtered to extract the tool mark features in the high-pass signal, and the three-dimensional evaluation index of the tool mark is defined accordingly; according to the milling characteristics of the top surface of the engine block, the influence of the spindle tilt, tool wear and tool jump is comprehensively considered , carry out physical modeling on the tool mark forming process; predict the milling surface quality according to the tool mark physical model, calculate the three-dimensional evaluation index value of the tool mark under specific process parameters, and establish a multi-objective optimization model of process parameters, by solving Optimize the model to obtain the optimal process parameter scheme suitable for the milling of the top surface of the engine block. The invention effectively optimizes the milling process parameters of the top surface of the engine cylinder by defining and accurately predicting the characteristic index of the tool mark on the milling surface, thereby improving the milling quality of the top surface of the engine cylinder.

Owner:力度工业智能科技(苏州)有限公司

Acquisition method of sparse coefficient vector for recovering and enhancing video image

InactiveCN102510438BFast and efficient solutionAvoid lengthy calculationsImage enhancementTelevision system detailsPattern recognitionDiscrete cosine transform

The invention discloses an acquisition method of a sparse coefficient vector for recovering and enhancing a video image; images are respectively selected from a natural image library and fitting images with distinctive edges for (discrete cosine transform) DCT conversion, mapped to a frequency domain space, and are initially clustered based on the general frequency domain characteristics of the images; then each cluster is further secondarily clustered based on the high-frequency information characteristics thereof; finally the first m main component variables of the obtained secondary cluster are extracted, and the sparse sub dictionary subDi_j of the cluster is obtained; all the sparse sub dictionary subDi_js form the final structural sparse dictionary; and consequently, an established two-stage structural sparse dictionary library is different from a traditional long and low-efficiency linear complete dictionary. The method can quickly and efficiently solve the sparse expression of an input image video signal, can acquire the accurate and effective sparse coefficient vector a~ by carrying out collaborate level sparse building to any image video signal, and has rather high anti-noise performance.

Owner:SICHUAN PANOVASIC TECH

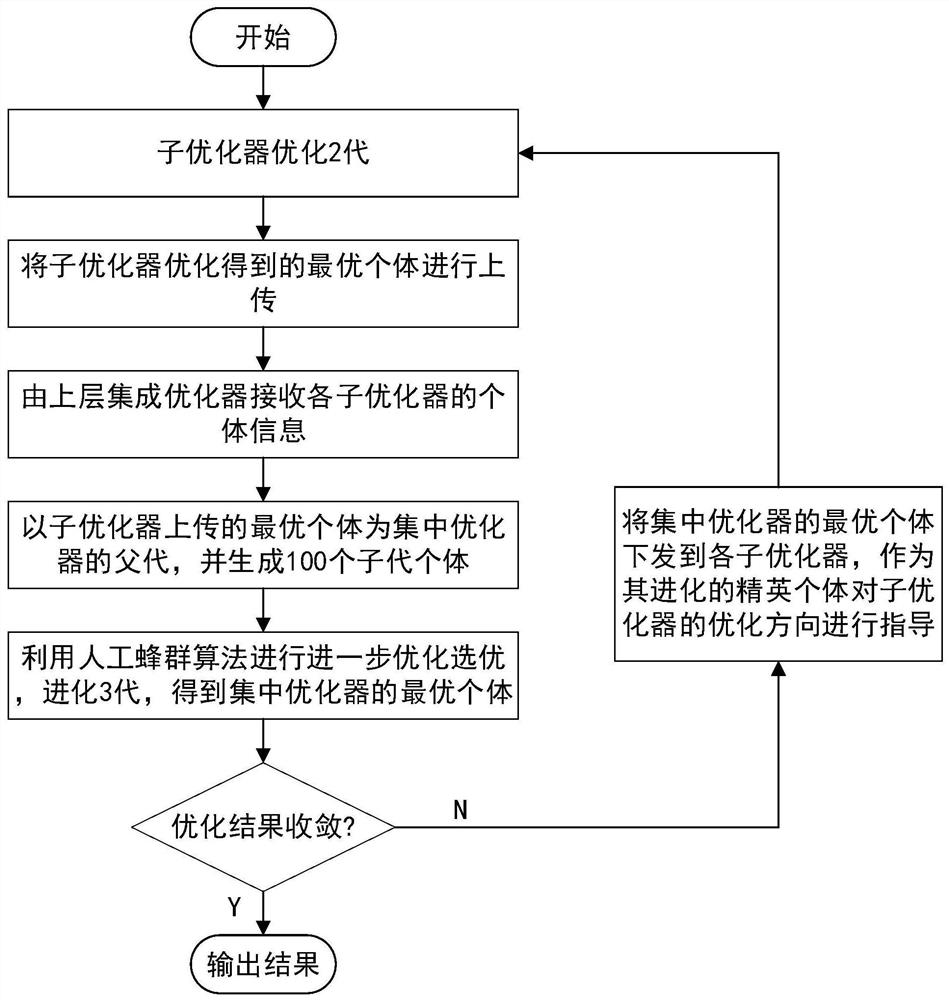

Reactive power optimization method based on integrated learning

ActiveCN110365020BAdaptableFast and efficient solutionReactive power adjustment/elimination/compensationAc networks with different sources same frequencyAlgorithmPower optimization

Owner:SOUTH CHINA UNIV OF TECH

A Method for Evaluating Anti-interference Capability of Network System

ActiveCN105956357BEvaluate anti-interference abilityOvercome limitationsInformaticsSpecial data processing applicationsPath lengthStatistical analysis

The invention discloses a method for evaluating the anti-interference capability of a network system. The invention aims at evaluating whether the network system still can guarantee that the capability of connecting Original and Destination pairs (OD pairs) according to a path length meeting a preset value condition under the action of various types of factors. The method comprises the steps: firstly enabling the anti-interference capability of the network system to be converted into path length preset value ranges corresponding to all OD pairs; secondly simulating a natural ripple spread phenomenon, and carrying out one-off ripple spread relay race in the network, so as to solve all paths, meeting the corresponding preset value condition, among all OD pairs in the network (not just solving the shortest path among the OD pairs and not all paths among the OD pairs); and finally carrying out the statistic analysis of the sharing condition of nodes and links in the paths with the lengths meeting the preset value range condition. The method can be used for solving a problem of anti-interference capability evaluation of a physical network and an extract virtual network.

Owner:BEIJING NORMAL UNIVERSITY +1

An Electron Beam Welding Method for Irregular Curved Surfaces

ActiveCN103331512BFast and efficient solutionGuaranteed welding shapeElectron beam welding apparatusEngineeringElectron

The invention belongs to the electron beam welding field, and particularly relates to an electron beam welding method of a special-shaped surface. The method comprises a first step of building a weld joint plane curve, wherein a trace curve of the weld joint to be welded is generated based on a three-dimensional model of a part to be welded; a second step of decomposing the curve, wherein the curve is decomposed according to the characteristics of the curve, and the decomposing principle is that the curve is decomposed to be straight-line segments and arc segments according to the weld joint curve; a third step of collecting and resolving spots, wherein an electron beam current focusing height, the translation of an electron beam welding machine main shaft on the Y direction, the rotating angle of the main shaft around a C axis and a rotary radius are resolved; and a fourth step of idling for commissioning, wherein a welding procedure is commissioned once in a manner of idling so as to verify the validity of the data in the third step; and if the data are correct, performing the welding with the parameters, otherwise returning to the second step to increase the number of the decomposed curves in curve decomposing. The electron beam welding method has the advantages that a weld joint trace equation is resolved fast and efficiently when the electron beam wielding is performed for a complicated special-shaped surface, and the welding is formed once.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

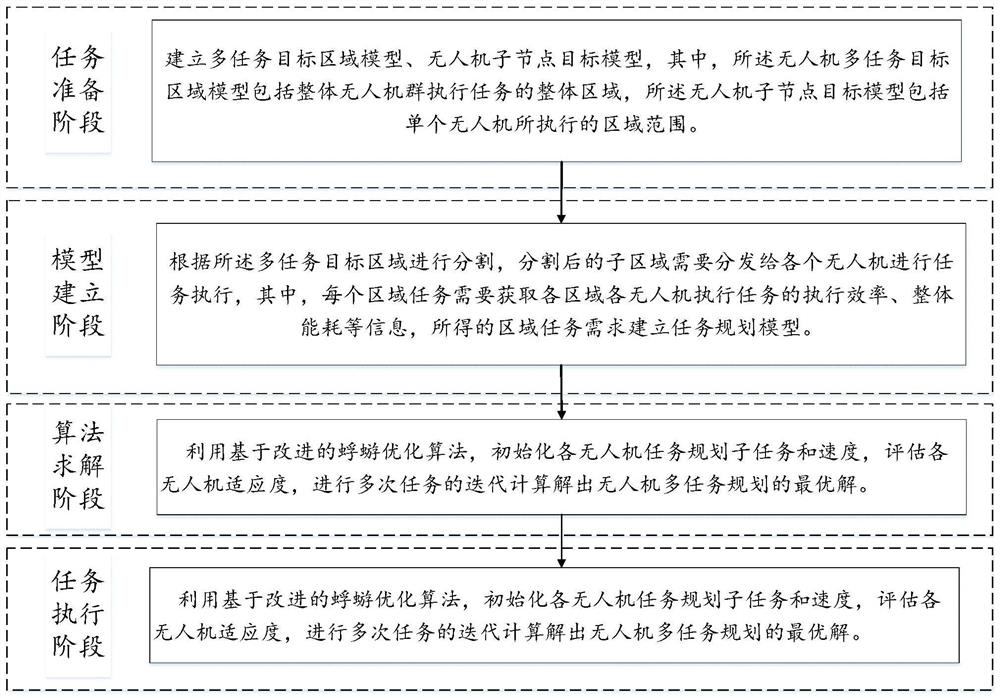

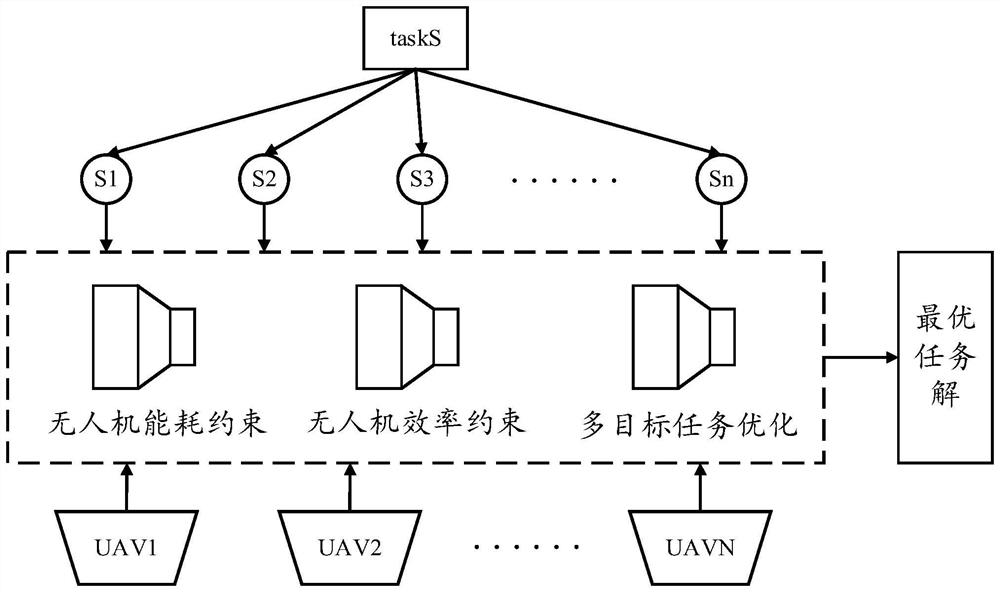

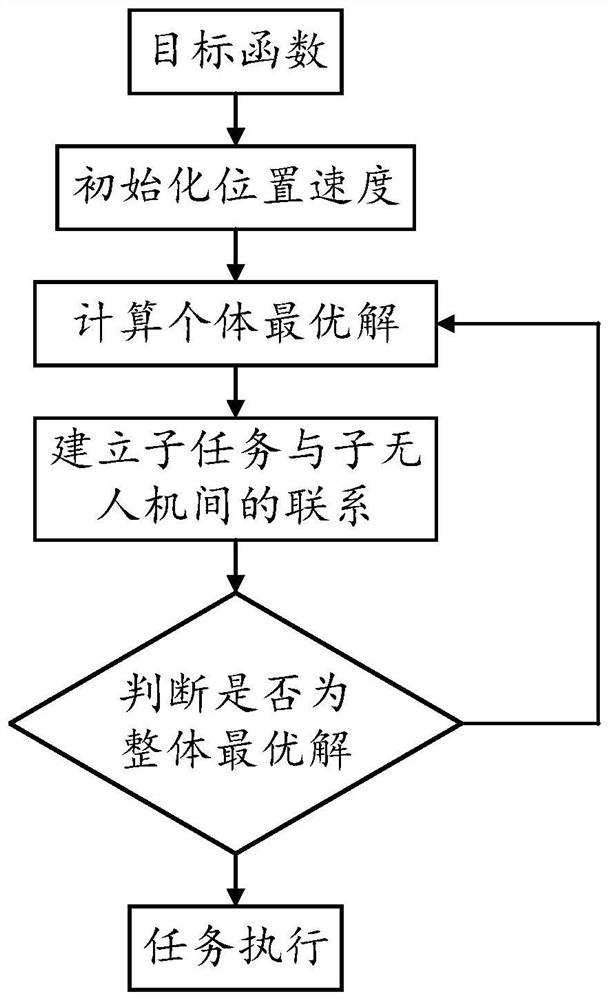

Unmanned aerial vehicle multi-task planning method based on improved mayfly naiad algorithm

PendingCN114237284AImprove performanceFast and efficient solutionArtificial lifePosition/course control in three dimensionsAlgorithmSimulation

The embodiment of the invention discloses an unmanned aerial vehicle multi-task planning method based on an improved mayfly naiad algorithm, relates to the technical field of unmanned aerial vehicle task planning, and aims at unmanned aerial vehicle multi-task planning based on the improved mayfly naiad algorithm for multi-target area planning to realize multi-unmanned aerial vehicle multi-target task planning. The method comprises the following steps: acquiring a multi-task target area and an unmanned aerial vehicle sub-node target according to task information; segmenting the multi-task target area to obtain sub-areas, and distributing the segmented sub-areas to each unmanned aerial vehicle; establishing a task planning model by using the task execution information of the regional task of each sub-region; through a mayfly naiad optimization algorithm, obtaining a solution for multi-task planning of the unmanned aerial vehicle; and evaluating multi-task data by using the solution of the unmanned aerial vehicle multi-task planning, and then distributing the multi-task data to the unmanned aerial vehicles in the unmanned aerial vehicle group.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com