Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Big blasting power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

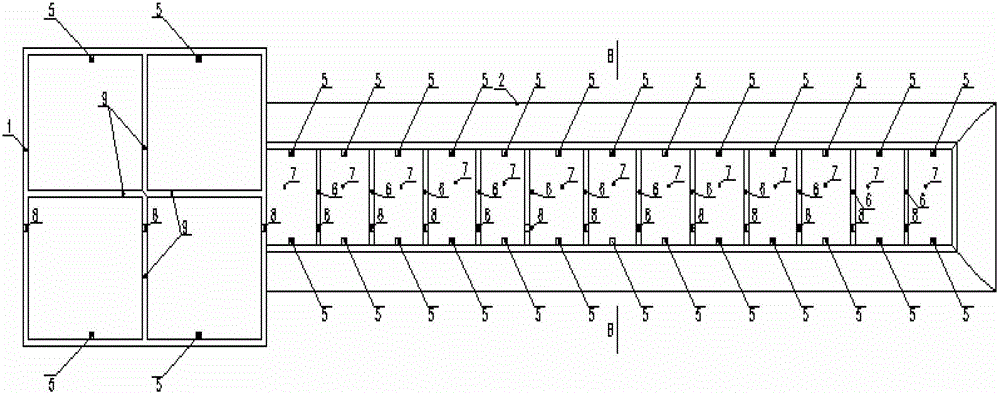

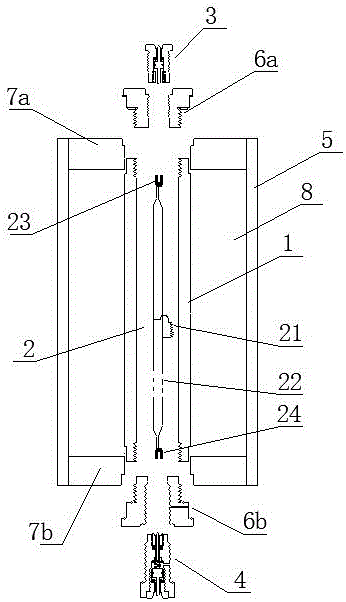

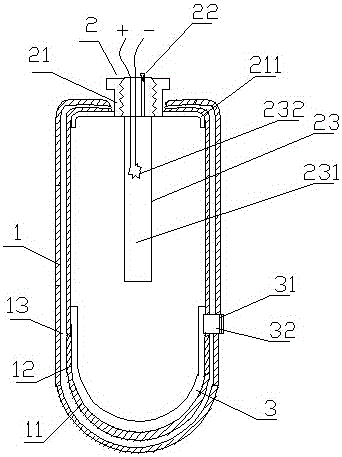

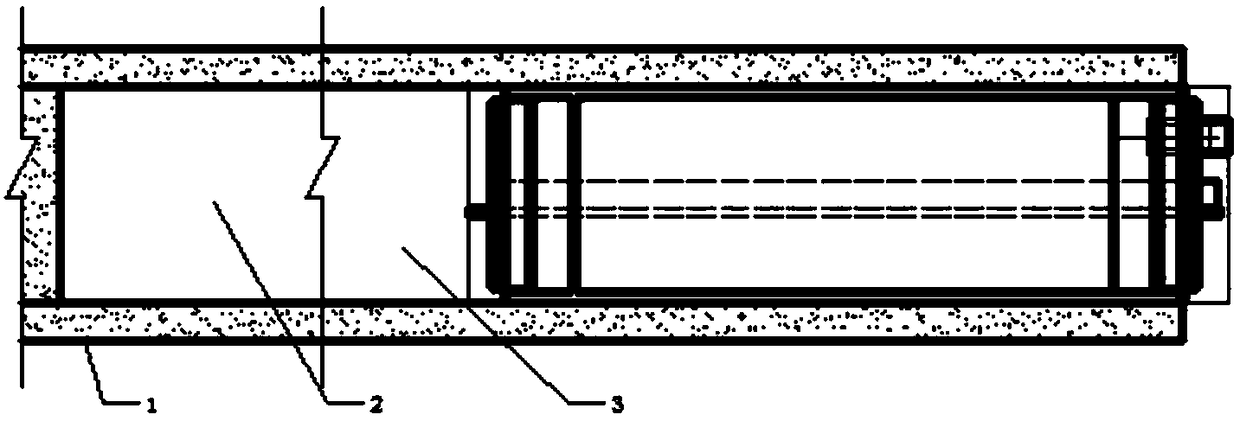

Gas-inflating-and-locking-integrated gas blaster

InactiveCN106643314AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesCheck valvesEngineeringLiquid carbon

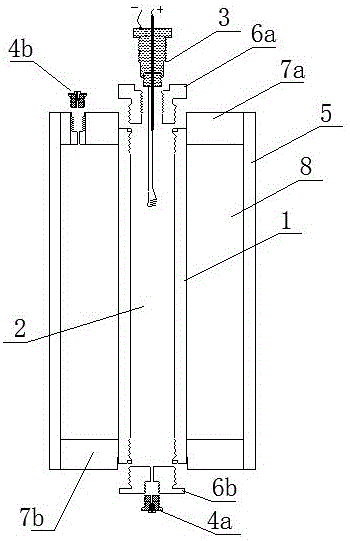

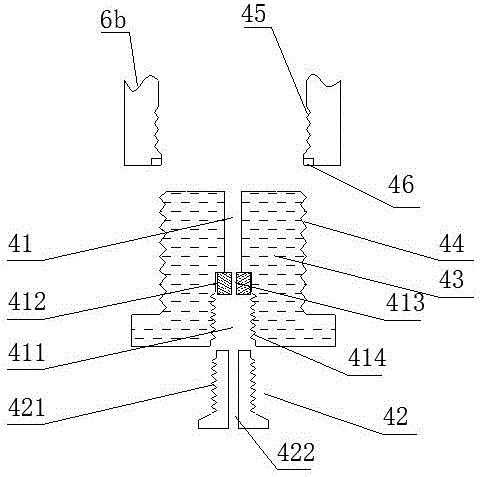

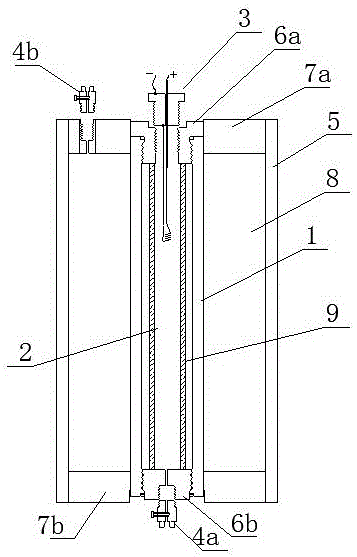

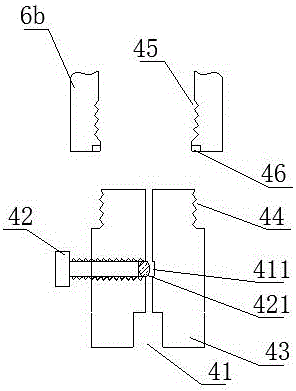

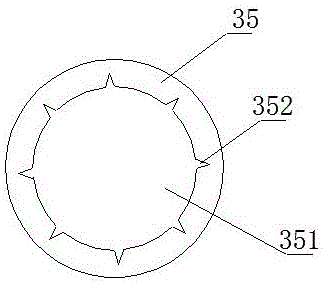

The invention discloses a gas-inflating-and-locking-integrated gas blaster. The gas-inflating-and-locking-integrated gas blaster comprises an inner tube, an inner-tube filling cavity, an ignition mechanism, an inner-tube gas inflating mechanism and an outer tube. The inner-tube filling cavity is formed in the inner tube, a first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner tube in a sealed mode respectively, the outer tube is arranged on the outer layer of the inner tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, the ignition mechanism and the inner-tube gas inflating mechanism are installed on the first sealing inner cover or the second sealing inner cover, and an outer-tube gas inflating mechanism is installed on the first sealing outer cover or the second sealing outer cover; a sealed cavity between the inner tube and the outer tube is an outer-tube filling cavity, the inner-tube filling cavity is filled with supercritical oxygen and carbonaceous organic materials, and the outer-tube filling cavity is filled with liquid easy-to-gasify materials such as liquid carbon dioxide or liquid nitrogen. The gas-inflating-and-locking-integrated gas blaster has the advantages that the manufacturing cost is low, the mixing uniformity of reaction materials is high, the heat releasing efficiency is high, the transportation safety is good, and the blasting power is large.

Owner:郭远军

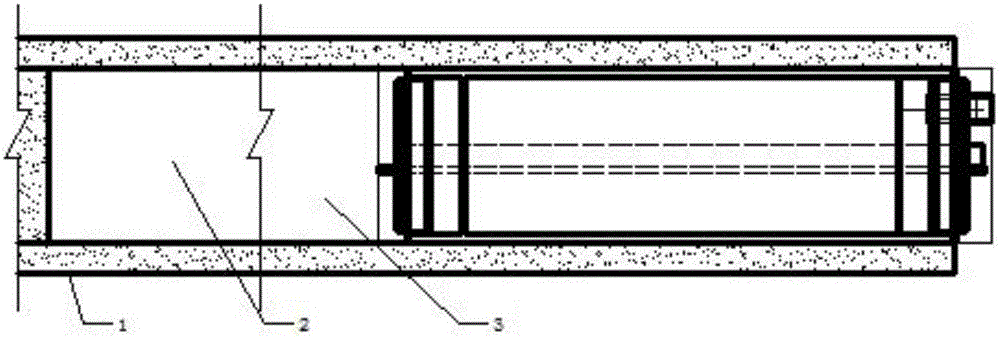

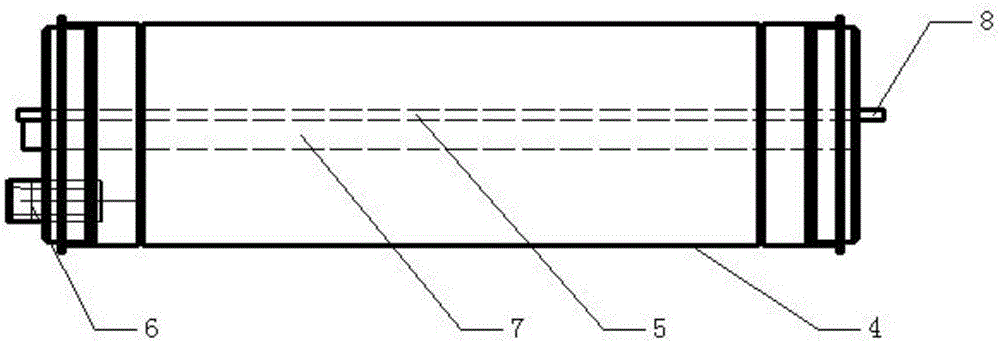

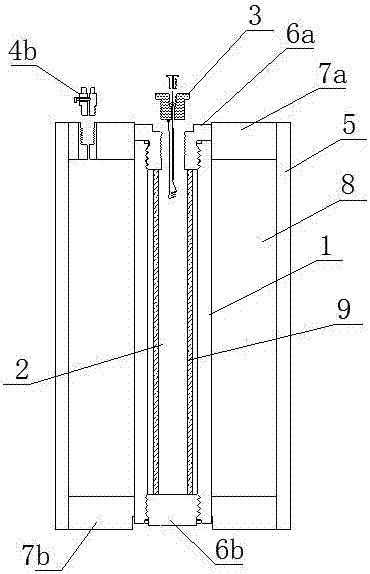

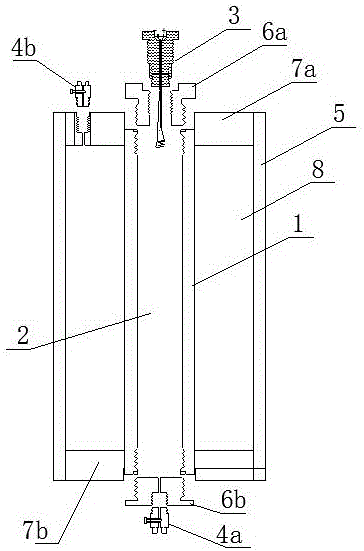

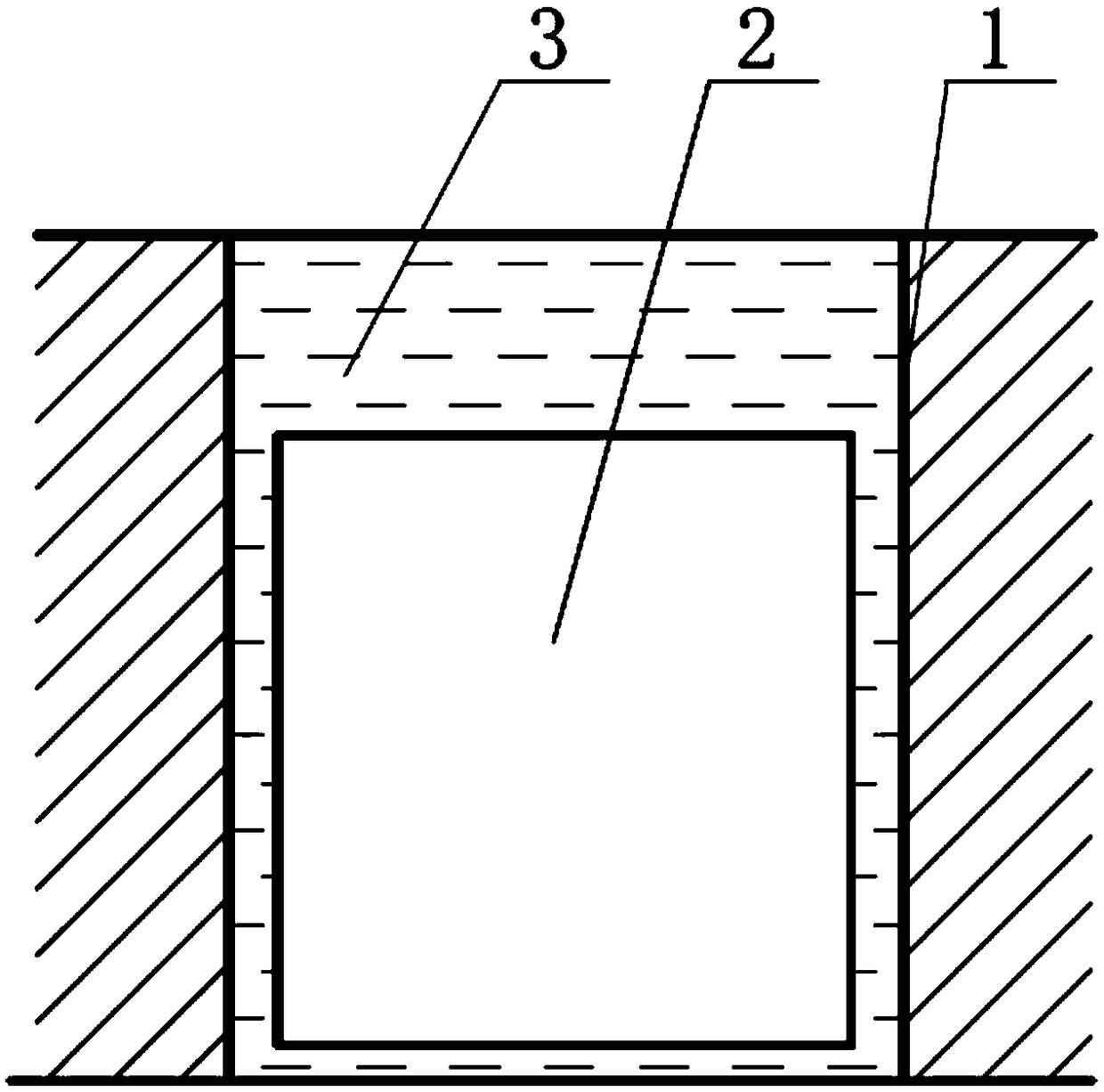

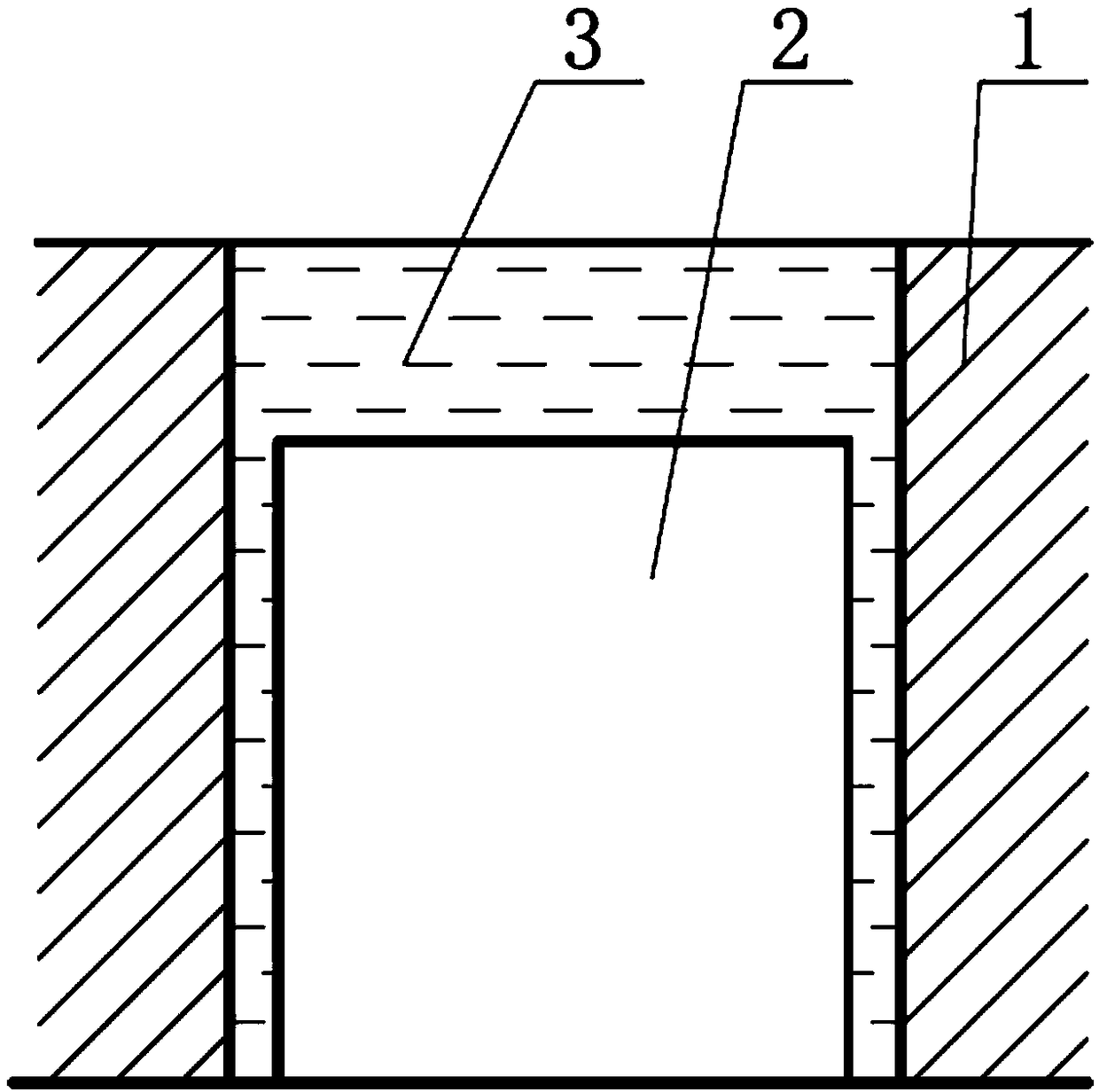

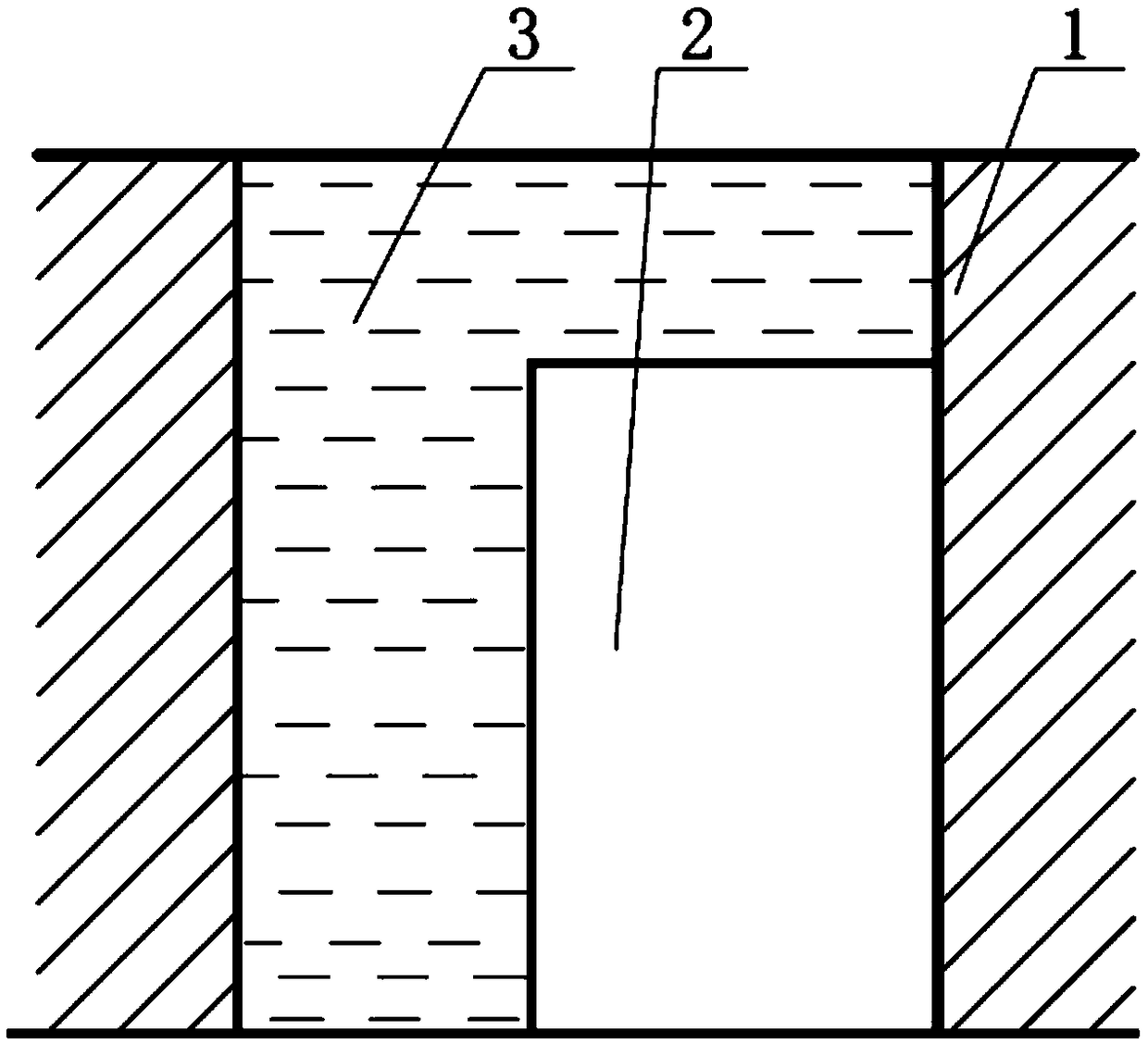

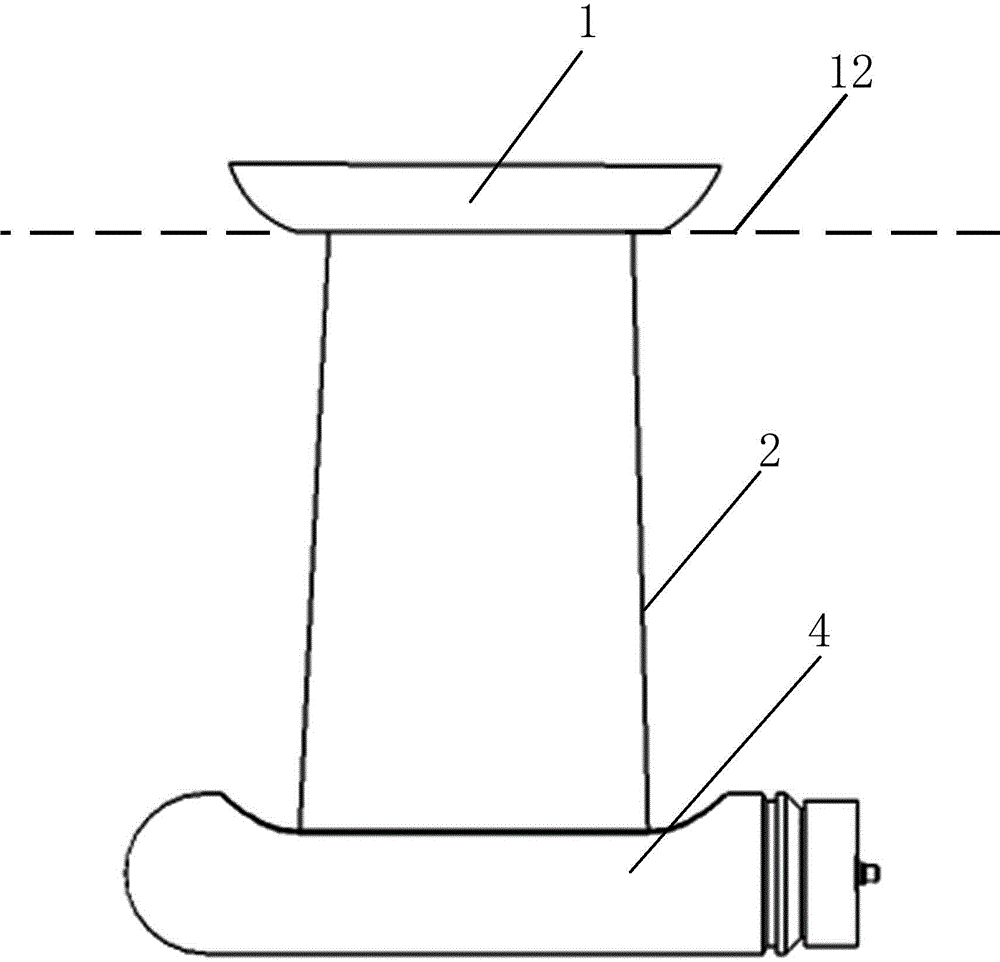

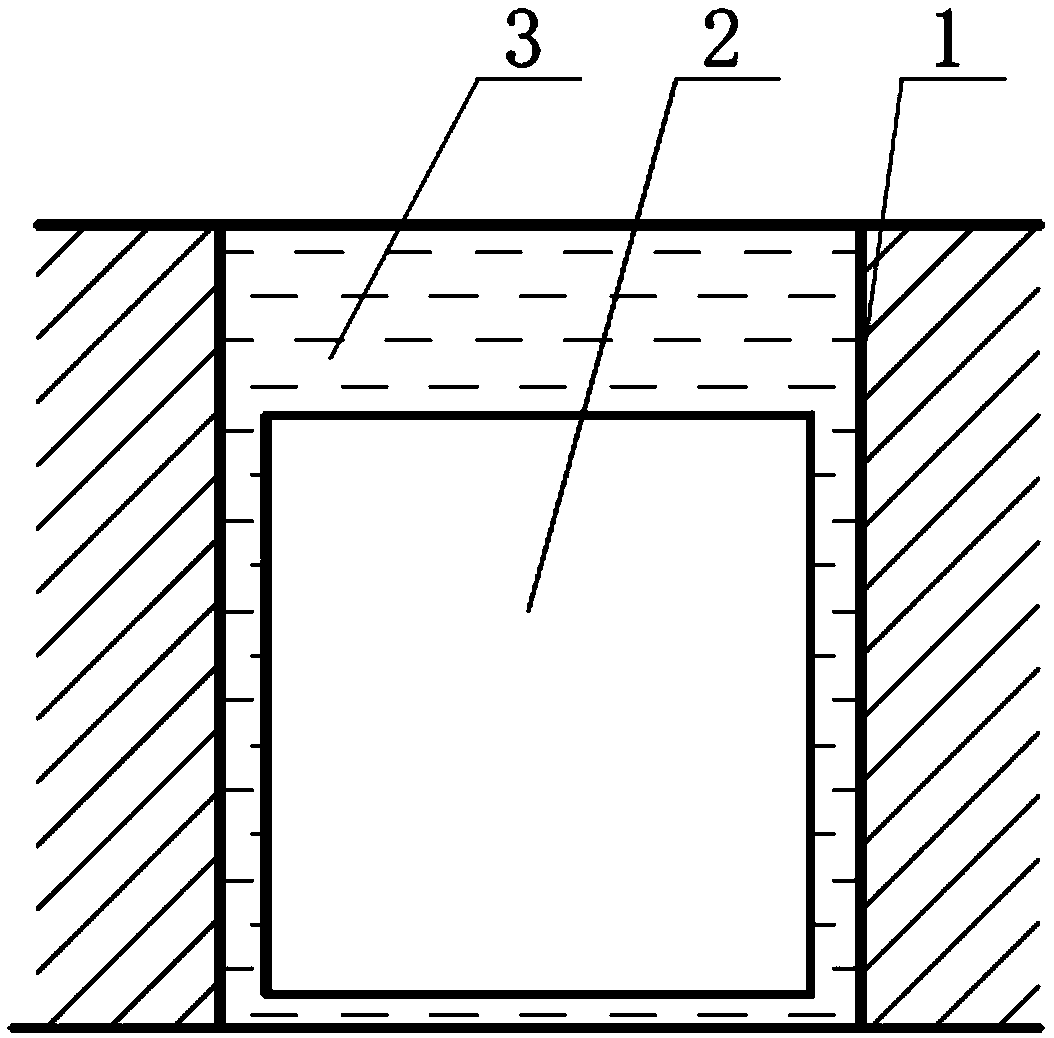

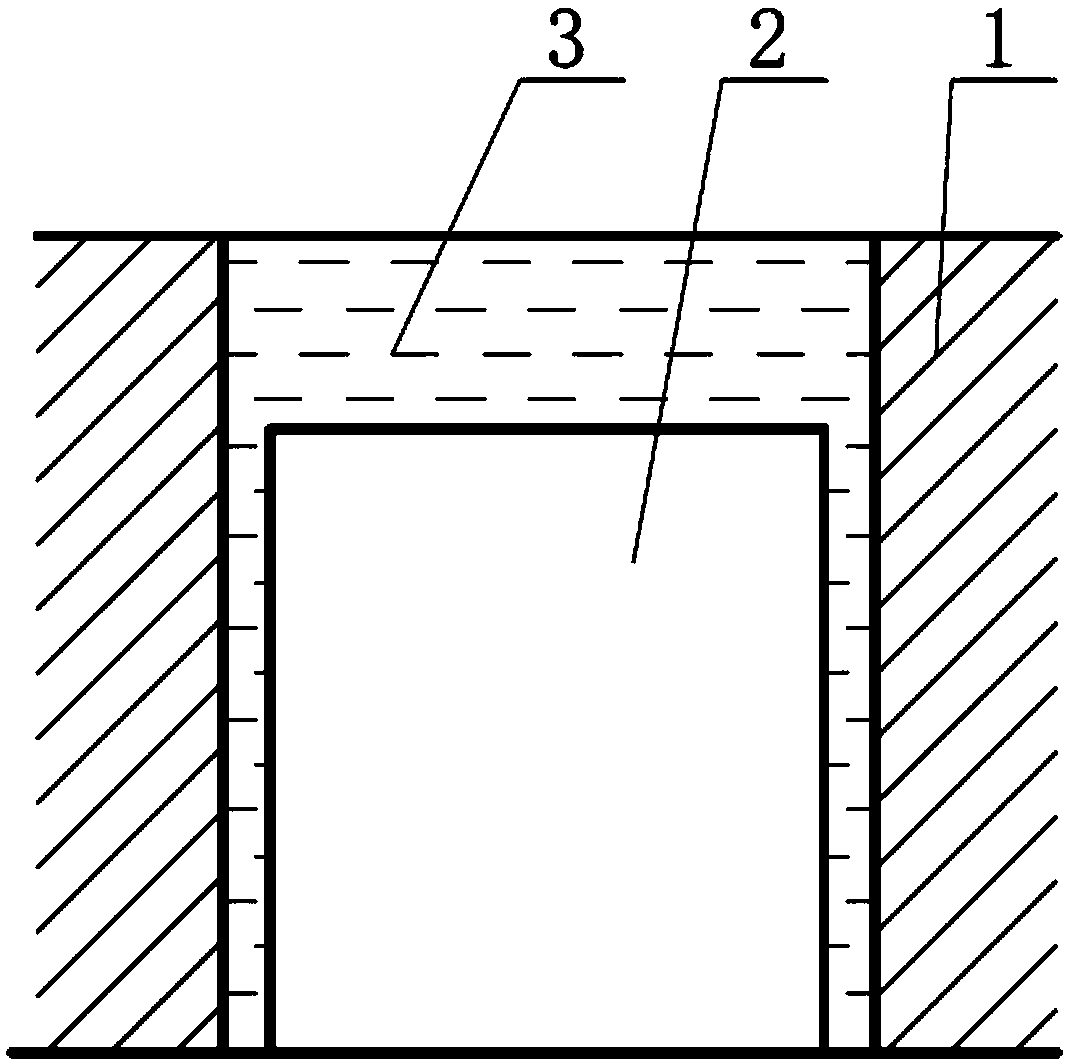

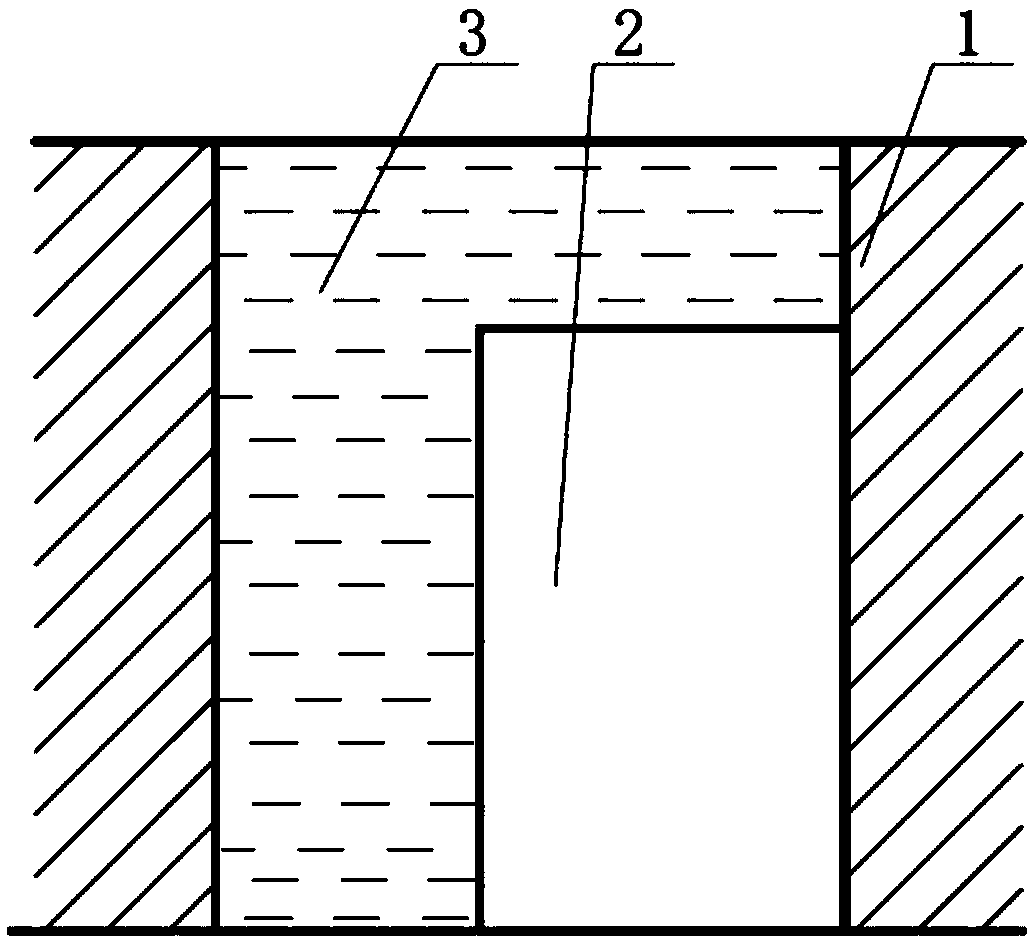

Cold blasting method using liquid carbon dioxide in enclosed blast holes

The invention provides a cold blasting method using liquid carbon dioxide in enclosed blast holes. The method comprises following steps: firstly, a blast hole is drilled in rocks to be blasted; then a hole sealing device is mounted, wherein one end, provided with an initiator, of the hole sealing device is placed into the hole and the hole sealing device is totally immerged in the hole; a high pressure liquid injection port, a carbon dioxide liquid injection port and a lead nozzle are kept outside the blasting hole in advance; the high pressure liquid injection port is connected with a high pressure liquid injection gun; the hole sealing device is injected with liquid and expands to block the blast hole; the carbon dioxide liquid injection port is connected with a liquid carbon dioxide injection pipe; quantified liquid carbon dioxide is injected to the blast hole according to blasting design requirement; initiator leads which are pre-kept at one side of the lead nozzle are connected in a parallel mode; the initiator is electrified for blasting the liquid carbon dioxide in the blasting hole to complete blasting. The blasting power of the invention is great and the initial investment and use cost for blasting are reduced; the construction is simple and convenient; the method is easy to promote.

Owner:DALIAN UNIV

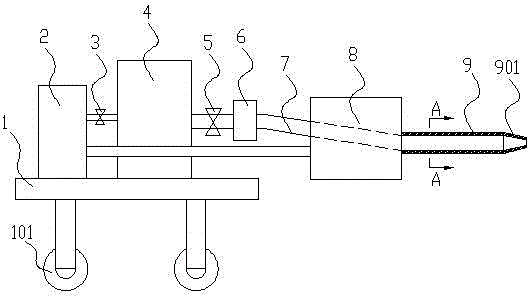

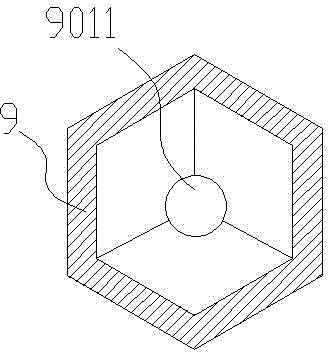

Safe, efficient and environment-friendly rock blasting device and blasting method

The invention relates to the field of rock blasting, and specifically relates to a safe, efficient and environment-friendly rock blasting device. The rock blasting device comprises a blasting device, and a perforating device. The perforating device comprises a bracket, and an air compressor as well as a water tank arranged on the bracket. The air compressor is communicated with the water tank through a high pressure pipe. The water tank is further communicated with a drilling steel through the high pressure pipe. The air compressor is further connected with an air impact wrench through the high pressure pipe. The drilling steel is arranged on the air impact wrench. The drilling steel is of a hollow body, and the tip at the drilling head thereof is provided with a water outlet. The invention further relates to a safe, efficient and environment-friendly rock blasting method comprising the steps of determining a position and an angle of a blasting hole, drilling the blasting hole, enlarging the blasting hole, and blasting. The purpose of the invention is to provide the safe, efficient and environment-friendly rock blasting device and the blasting method. By using the device and the method, the most amount of rocks can be blasted with the least amount of detonators and explosive materials, and the blasting workers are prevented from being contaminated by the dust, thereby avoiding the occurrence of accidents, and achieving the energy-saving and environment-friendly rock blasting.

Owner:唐立华 +2

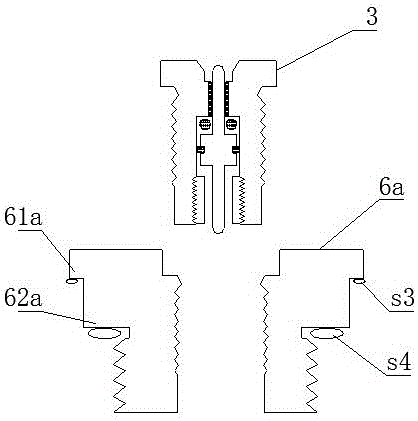

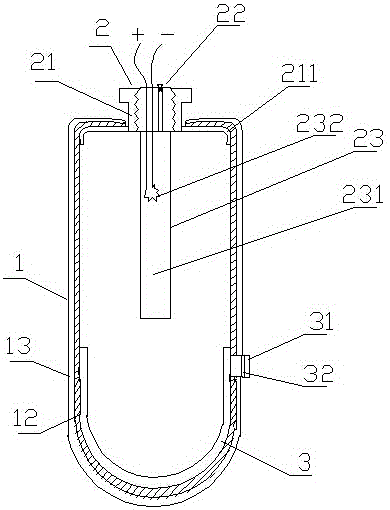

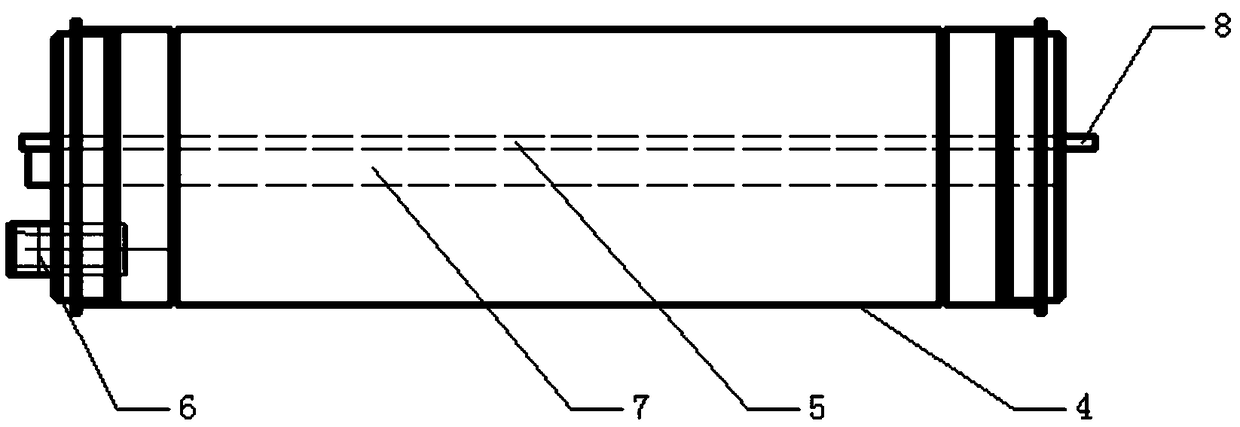

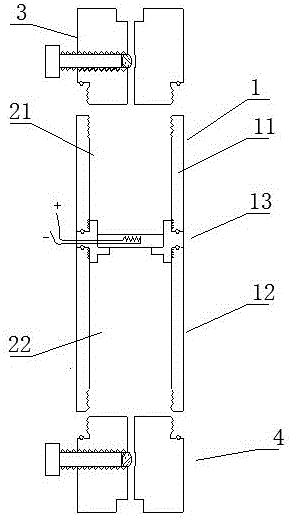

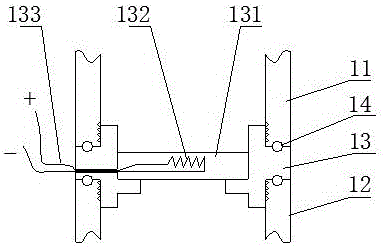

Inflation and ignition integrated gas blaster

PendingCN106931838AReduce mixReduce production processBlasting cartridgesCheck valvesHeating efficiencyNitrogen gas

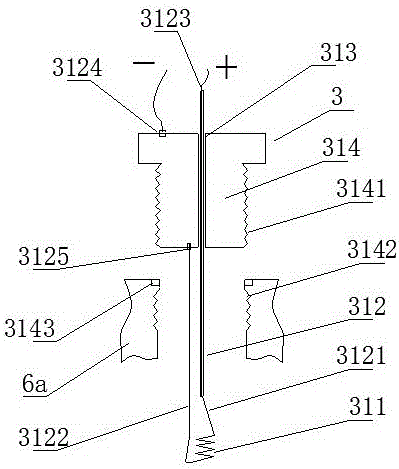

The invention discloses an inflation and ignition integrated gas blaster. The inflation and ignition integrated gas blaster comprises an inner pipe, an inner pipe filling cavity, an inflation and ignition mechanism, an inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; the two ends of the inner pipe are in sealed connection with a first inner sealing cap and a second inner sealing cap correspondingly; the first inner sealing cap and the second inner sealing cap are connected through a connecting piece; the outer pipe is arranged outside the inner pipe; a first outer sealing cap and a second outer sealing cap are connected between the inner pipe and the outer pipe in a sealed mode; the inflation and ignition mechanism is installed on the first inner sealing cap; the first outer sealing cap is provided with the inflation mechanism; a sealed cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer pipe filling cavity is filled with liquid carbon dioxide, liquid nitrogen or other liquid substances liable to gasify. The inflation and ignition integrated gas blaster has the advantages of being low in manufacturing cost, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

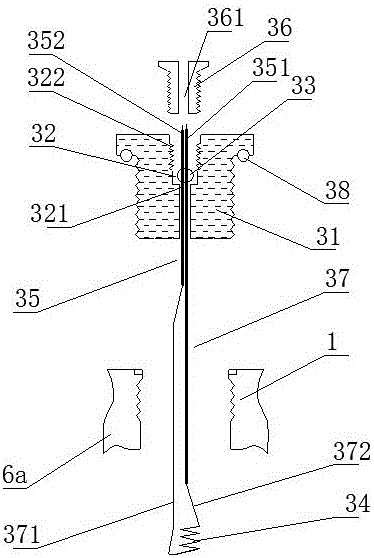

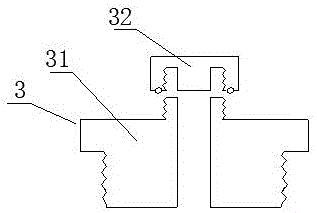

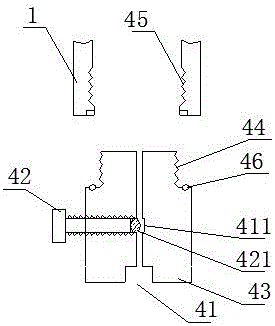

Plug-in type gas blaster

PendingCN106595397AUniform responseAdequate responseBlasting cartridgesCheck valvesLiquid carbonEngineering

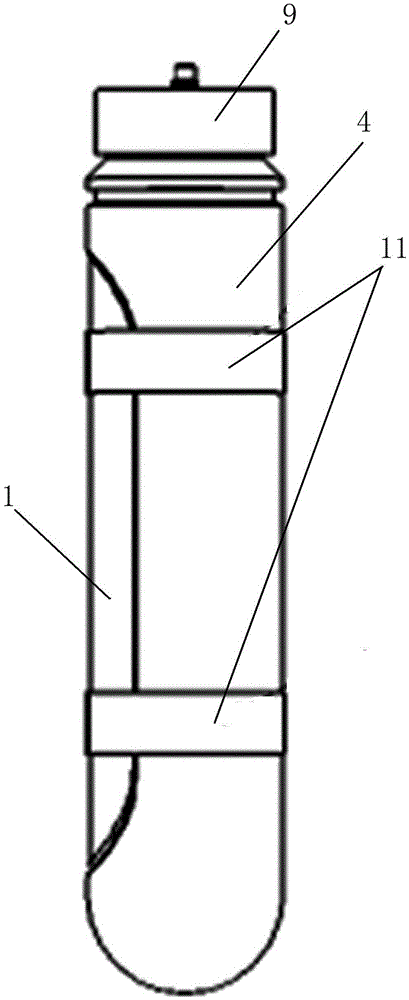

The invention discloses a plug-in type gas blaster. The plug-in type gas blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube gas inflation mechanism and an outer tube. The inner tube is internally provided with the inner tube filling cavity. A first sealed inner cover and a second sealed inner cover are connected to the two ends of the inner tube in a sealed manner correspondingly. The outer tube is arranged on the outer layer of the inner tube. A first sealed outer cover and a second sealed outer cover are connected between the inner tube and the outer tube in a sealed manner. The ignition mechanism and the inner tube gas inflation mechanism are mounted on the first sealed inner cover or the second sealed inner cover. The first sealed outer cover or the second sealed outer cover is provided with an outer tube gas inflation mechanism. A seal cavity formed between the inner tube and the outer tube is an outer tube filling cavity. The inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter. The outer tube filling cavity is filled with liquid matter easy to gasify such as liquid carbon dioxide or liquid nitrogen. The plug-in type gas blaster has the beneficial effects of being low in manufacturing cost, high in reaction material mixing uniformity, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Blasting method and application of using shear thickening liquid as blockage of blasting blast holes

The invention discloses a blasting method and application of using shear thickening liquid as blockage of blasting blast holes. The method comprises the steps of filling the blasting blast holes withthe shear thickening liquid, and using the shear thickening liquid to completely cover or partially cover gas blasters in the blasting blast holes; using the shear thickening liquid to completely cover the blasting blast holes to completely fill the gas blasters in the blasting blast holes; detonating the gas blasters. The blasting method applies the shear thickening liquid as a blast hole blockage material for blocking the blast holes, the blockage effect of the blast holes is good, flying stones and splashing are hardly generated during the blasting process, the blasting degree is deep, theblasting efficiency is high, the method is not limited to the arrangement of the blasting blast holes, the freedom of arrangement of the blasting blast holes is more flexible, the blasting process ismore moderate, strong air shock waves are nor generated, damage to the surrounding environment and workers is not caused, blasting noise is small, and the blasting process is safe.

Owner:远军热能动力科技有限公司

Inflation and ignition integrated air blaster

InactiveCN106643324AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses an inflation and ignition integrated air blaster. The inflation and ignition integrated air blaster comprises an inner tube, an inner tube filling cavity, an inner tube inflation and ignition head, an outer tube inflation head and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner correspondingly; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the inner tube inflation and ignition head is mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer tube filling cavity is filled with liquid easy-to-gasify matter such as liquid carbon dioxide and liquid nitrogen. The inflation and ignition integrated air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

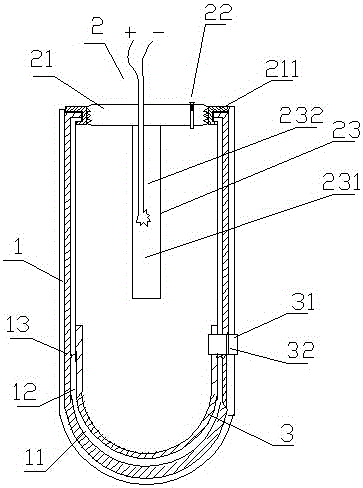

Air blaster

PendingCN106643327AReduce mixReduce production processBlasting cartridgesCheck valvesTransport securityNitrogen gas

The invention discloses an air blaster. The air blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube inflation mechanism and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner respectively; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the ignition mechanism and the inner tube inflation mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matters; and the outer tube filling cavity is filled with such liquid easy-to-gasify matters as liquid carbon dioxide and liquid nitrogen. The air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

Gas blasting device

InactiveCN106767183AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a gas blasting device which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, a first inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is arranged in the inner pipe; the two ends of the inner pipe are in sealing connection with a first inner sealing cover and a second inner sealing cover; the first inner sealing cover and the second inner sealing cover are connected through a connecting piece; the outer pipe is arranged on the outer layer of the inner pipe; a first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe in a sealing manner; the ignition mechanism and the first inflation mechanism are mounted on the first inner sealing cover; a second inflation mechanism is mounted on the first outer sealing cover; the sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matters; the outer pipe filling cavity is filled with liquid easy gasifying materials such as liquid carbon dioxide or liquid nitrogen. The gas blasting device has the advantages that the manufacture cost is low, the heat release efficiency is high, the transport security is good and the blast power is high.

Owner:郭远军

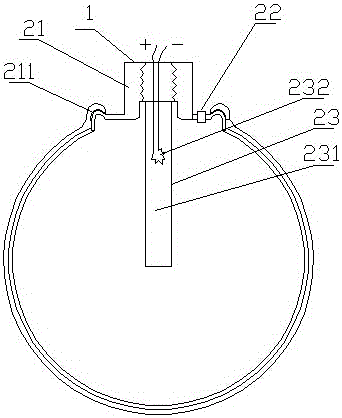

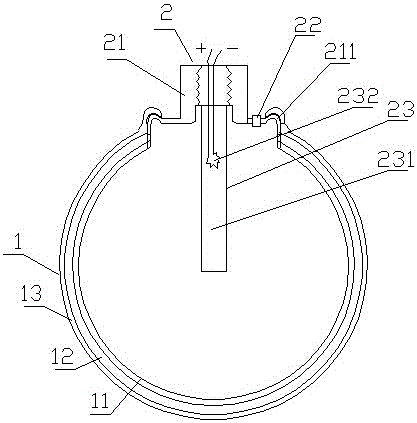

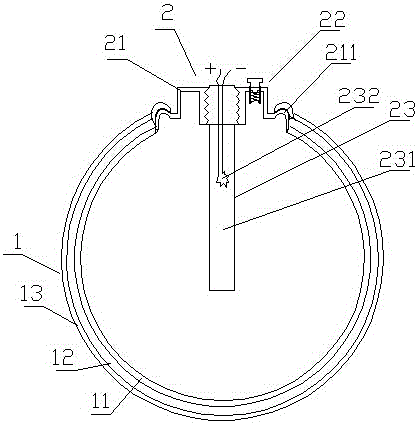

Disposable spherical dacron gas blaster and manufacturing method thereof

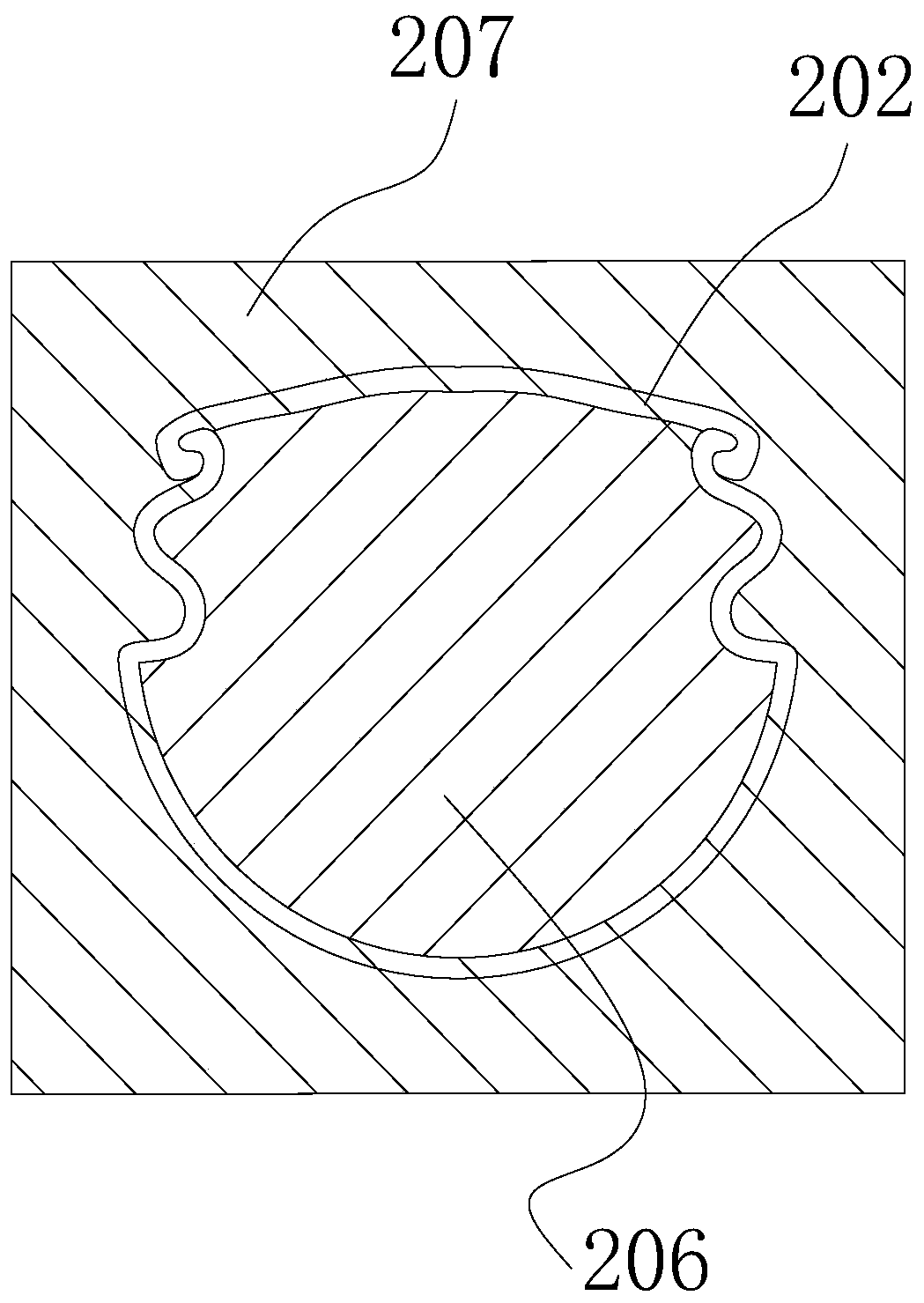

InactiveCN106440957AReduce weightPowerful explosionBlasting cartridgesAmmunitionEngineeringEnergy storage

The invention discloses a disposable spherical dacron gas blaster and a manufacturing method thereof. The disposable spherical dacron gas blaster comprises an energy storage device and an inflating and detonating device. The inflating and detonating device is installed at one end of the energy storage device, and the other end of the energy storage device is sealed or integrally formed. The disposable spherical dacron gas blaster is characterized in that the energy storage device is made of a dacron material in a curing mode and is spherical. The disposable spherical dacron gas blaster has the advantages of being small in thickness, light in weight, convenient to transport and install, easy to manufacture, low in consumable cost and production cost, rapid in inflating, good in sealing performance, long in service life and the like.

Owner:郭远军

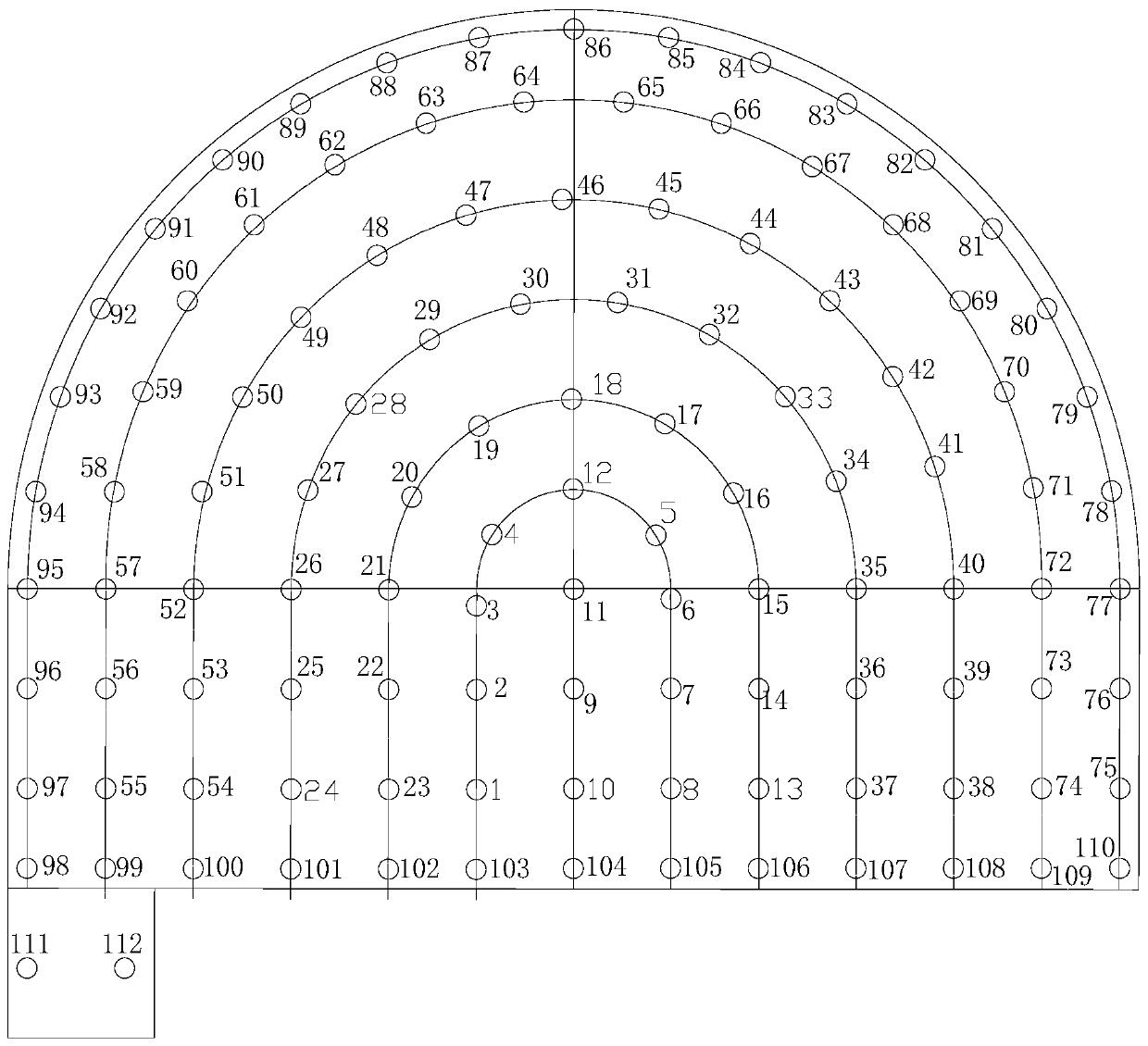

Blasting structure and blasting method

The invention discloses a blasting structure and a blasting method. The blasting structure comprises auxiliary cutholes, cutholes, two circles of holes and peripheral holes; the auxiliary cutholes areformed in the middle of the blasting section, the auxiliary cutholes are distributed up and down at intervals, and the distance between every two adjacent auxiliary cutholes is 480-520 mm; the cutholes, the two circles of holes and the peripheral holes are sequentially formed in the peripheries of the auxiliary cutholes and distributed in the corresponding virtual inverted U-shaped lines correspondingly, the distance between the straight line position of each U-shaped line of each cuthole and the vertical line where the corresponding auxiliary cuthole is located is 480-520 mm; the distance between the U-shaped line of the two circle of holes and the U-shaped line of the cuthole is 450-500 mm, and if no other holes are formed between the two circle of holes and the peripheral holes, the distance between the U-shaped line of the peripheral holes and the U-shaped line of the two circle of holes is 400-500 mm; and the method comprises the following steps of selecting a blasting section, drilling, charging and blasting. The method has the advantages that the requirement for footage during actual blasting can be met, and the requirement for rapid tunneling can be met.

Owner:HUAINAN MINING IND GRP

Gas blasting machine convenient to inflate

InactiveCN106643318AReduce wall thicknessReduce weightBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses a gas blasting machine convenient to inflate. The gas blasting machine comprises an inner pipe, an inner pipe filling cavity, a first inflating conductive head, a second inflating conductive head and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are connected to between the inner pipe and the outer pipe; the inner pipe is in clearance fit with the first sealing outer cap and the second sealing outer cap; the outer pipe is in sealing connection with the first sealing outer cap and the second sealing outer cap; the first sealing inner cap is in sealing connection with the first sealing outer cap, and the second sealing inner cap is in sealing connection with the second sealing outer cap; the first inflating conductive head is mounted in the first sealing inner cap, and the second inflating conductive head mounted in the second sealing inner cap; and an outer pipe filling cavity is formed between the inner pipe and the outer pipe. The gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in homogeneity degree of reacting materials, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Peripheral eye charge device for smooth blasting

Owner:中铁隧道局集团建设有限公司 +1

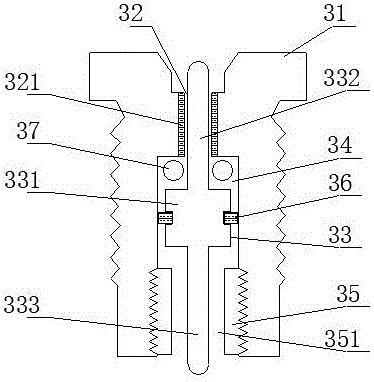

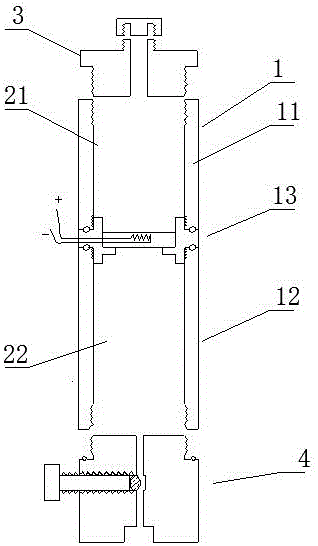

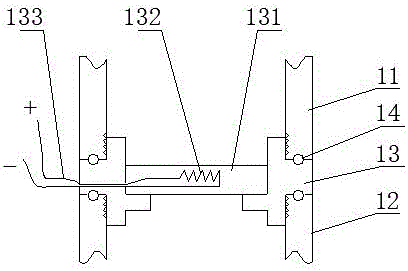

Ejector pin sealing type gas blasting machine

PendingCN106643321AReduce mixReduce production processBlasting cartridgesExplosivesNitrogen gasEngineering

The invention discloses an ejector pin sealing type gas blasting machine which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, an inner pipe inflating mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; two ends of the inner pipe are hermitically connected with a first sealing inner cover and a second sealing inner cover respectively; the outer pipe is arranged on the outer layer of the inner pipe; a first sealing outer cover and a second sealing outer cover are hermitically connected between the inner pipe and the outer pipe; the ignition mechanism and the inner pipe inflating mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer pipe inflating mechanism is mounted on the first sealing outer cover or the second sealing outer cover; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbonaceous organic materials; and the outer pipe filling cavity is filled with liquid gasification-liable substances such as liquid carbon dioxide or liquid nitrogen. The ejector pin sealing type gas blasting machine has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, high transportation safety and high blasting power.

Owner:郭远军

Inflating type gas blasting machine

PendingCN106643319AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesEngineeringMechanical engineering

The invention discloses an inflating type gas blasting machine. The inflating type gas blasting machine comprises an inner pipe, an inner pipe inflating conductive head, an outer pipe inflating head and an outer pipe, wherein a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are respectively connected between the inner pipe and the outer pipe; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe inflating conductive head is arranged at the shaft center part of the first sealing inner cap; a first radial air hole in the radial direction is formed in the second sealing inner cap; a second mounting cavity and an axial through hole which communicate with each other are formed in the shaft center part of the second sealing inner cap; the axial through hole penetrates through the first radial air hole; a conductive connection head is mounted in the second mounting cavity; a first radial air hole in the radial direction is formed in the second sealing outer cap; and the outer pipe inflating head is arranged on the inner side surface of the second sealing outer cap. The inflating type gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Dual supercritical state gas detonator

InactiveCN106871731AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesExplosivesDetonatorDetonation

The invention discloses a dual supercritical state gas detonator. The dual supercritical state gas detonator comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation ignition head, an outer pipe inflation head and an outer pipe. The inner pipe is internally provided with the inner pipe filling cavity. A first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner pipe in a sealing manner correspondingly. The outer layer of the inner pipe is provided with the outer pipe. A first sealing outer cover and a second sealing outer cover are connected between the inner pipe and the outer pipe in a sealing manner. A sealing cavity formed by the inner pipe, the outer pipe, the first sealing outer cover and the second sealing outer cover is an outer pipe filling cavity. The outer pipe filling cavity is filled with liquid carbon dioxide or liquid nitrogen. The inner pipe filling cavity comprises a first inner cavity and a second inner cavity which are sealed and isolated through a thermoplastic sheet. The first inner cavity and the second inner cavity are filled with supercritical oxygen and supercritical state alkane correspondingly. The dual supercritical state gas detonator has the beneficial effects that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high, the transporting safety is good, and the detonation power is high.

Owner:郭远军

Inflation lead integral gas blasting device

InactiveCN106643320AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesLiquid stateNitrogen

The invention discloses an inflation lead integral gas blasting device. The device comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation electric conducting head, an outer pipe inflation head and an outer pipe; the inner pipe filling cavity is in the inner pipe; two ends of the inner pipe are tightly connected with a first sealing inner cover and a second sealing inner cover; the outer layer of the inner pipe is the outer pipe; a first sealing outer cover and a second sealing outer cover are tightly connected between the inner pipe and the outer pipe; the inner pipe inflation electric conducting head is mounted on the first sealing inner cover or the second sealing inner cover; the outer pipe inflation head is mounted on the first sealing outer cover or the second sealing outer cover; an outer pipe filling cavity is a sealing cavity between the inner pipe and the outer pipe; an electric heating wire is mounted in the inner pipe filling cavity; supercritical oxygen and carbon-contained organic matters are filled in the inner pipe filling cavity; and such liquid-state gasified matters as liquid-state carbon dioxide or liquid-state nitrogen are filled in the outer pipe filling cavity. The inflation lead integral gas blasting device has the advantages of low production cost, high mixing uniformity of reaction materials, high heat releasing efficiency, good transportation safety and high blasting power.

Owner:郭远军

Gas detonation device convenient to inflate

PendingCN106595400AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesDetonationEngineering

The invention discloses a gas detonation device convenient to inflate. The gas detonation device comprises an inner pipe, an inner pipe filling cavity, a first inflation conductive head, a second inflation conductive head and an outer pipe. The inner pipe filling cavity is formed in the inner pipe, a first inner sealing cover and a second inner sealing cover are connected to the two ends of the inner pipe in a sealed mode correspondingly, and the outer pipe is arranged outside the inner pipe. A first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe. The inner pipe is in clearance fit with the first outer sealing cover and the second outer sealing cover, and the outer pipe is connected with the first outer sealing cover and the second outer sealing cover in a sealed mode. The first inner sealing cover and the second inner sealing cover are connected with the first outer sealing cover and the second outer sealing cover in a sealed mode correspondingly. The first inflation conductive head and the second inflation conductive head are mounted on the first inner sealing cover and the second inner sealing cover correspondingly, and an outer pipe filling cavity is located between the inner pipe and the outer pipe. The gas detonation device has the advantages of being low in manufacturing cost, high in reaction material mixing uniformity, high in heat releasing efficiency, good in transporting safety and high in detonation power.

Owner:郭远军

Depth-defining ice-breaking projectile under ice based on automatic delivery by UAV

InactiveCN103557751BReduce volumeReduce weightAmmunition projectilesProjectilesRubber ringWhole body

The invention discloses an under-ice fixed-depth ice breaking bullet capable of being thrown automatically and based on a drone. The bullet comprises a bullet body, a floater, an inner end cover, an outer end cover, an explosion timer arranged in the inner end cover and a water-proof plug arranged on the outer end cover. A floater chamber matched with the floater is arranged on a lateral wall of the bullet body, the floater is arranged in the floating chamber to form a cylindrical whole body with the bullet body and fixed by a water-soluble ribbon, and the floater is connected with the bullet body through two fixed-depth ropes. Outer threads are arranged on a port of the bullet body, a flange is arranged at the open end of the inner end cover, the inner end cover is arranged at the port position of the bullet body, the outer end cover is in threaded connection with the port of the bullet body, and a sealing rubber ring is arranged between the flange of the inner end cover and the outer end cover. The bullet has the advantages of being small in size, light in weight, novel in design, simple in throwing, adjustable in delay, safe, reliable, large in explosive force, good in ice breaking effect and capable of conducting continuous throwing operation.

Owner:中国人民解放军66267部队装备部 +1

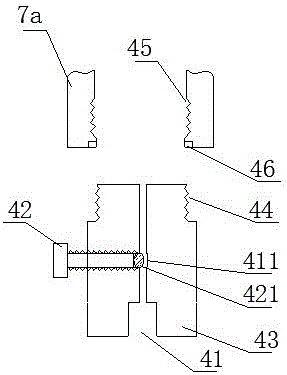

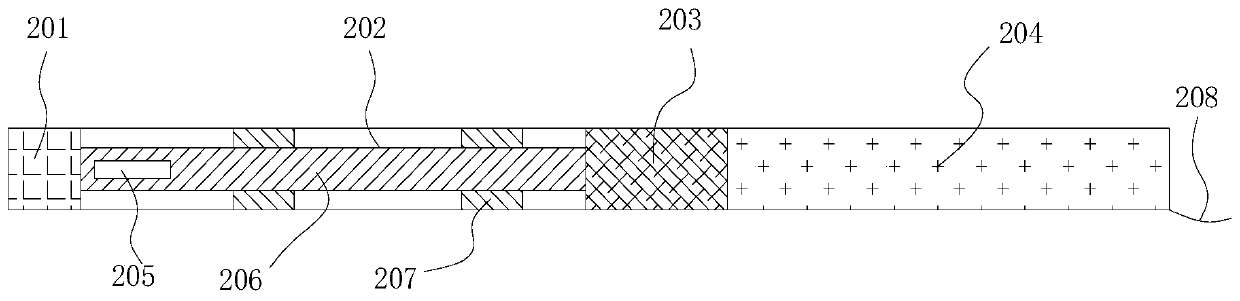

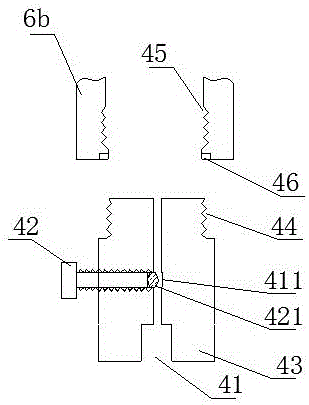

Fluid type igniter for gas blaster, and fracturing device

InactiveCN106595402AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesChemical industryElectricityCoupling

The invention discloses a fluid type igniter for a gas blaster, and a fracturing device. The igniter comprises a casing and a filling cavity located in the casing; the casing comprises a first sub-joint, a second sub-joint and a coupling head; the filling cavity comprises a reducing agent filling cavity and an oxidizing agent filling cavity; the reducing agent filling cavity is formed in the first sub-joint, and the oxidizing agent filling cavity is formed in the second sub-joint; two ends of the coupling head are in threaded and sealed connection with one end of the first sub-joint and one end of the second sub-joint or are seamlessly welded at one end of the first sub-joint and one end of the second sub-joint; the other end of the first sub-joint is connected with a liquid filling nozzle, and the other end of the second sub-joint is connected with an inflation mechanism; an isolation thermoplastic piece is mounted in the middle of the coupling head; and an electric heating wire is packaged in the isolation thermoplastic piece and is led out of the casing through a wire. The igniter has the advantages that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high and the transportation safety is good.

Owner:郭远军

Opposite-inflatable air blasting device

InactiveCN106643317AReduce mixReduce production processBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses an opposite-inflatable air blasting device. The device comprises an inner pipe, an inner pipe inflatable conductive head, an outer pipe inflatable head and an outer pipe, the two ends of the inner pipe are connected with a first seal inner cover and a second seal inner cover in a sealed mode respectively, the outer pipe is arranged on the outer layer of the inner pipe, the first seal outer cover and the second seal outer cover are connected between the inner pipe and the outer pipe, a seal cavity formed between the inner pipe and the outer pipe is an outer pipe filling cavity, the inner pipe inflatable conductive head is arranged at the axial core of the first seal inner cover, a first radial air hole is formed in the second seal inner cover in the radial direction, the axial core of the second seal inner cover is provided with a second installation cavity and an axial through hole which are communicated with each other, the axial through hole penetrates through the first radial air hole, a conductive connector is installed in the second installation cavity, the first radial air hole is formed in the second seal outer cover in the radial direction, and an outer pipe inflatable head is arranged on the inner side face of the second seal outer cover. The device has the advantages of being low in manufacturing cost, high in heat release efficiency, good in transport safety and large in blast power.

Owner:郭远军

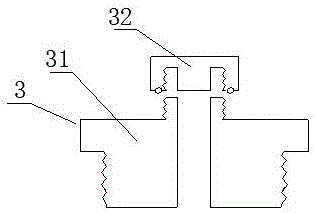

Thread twisting-joint type gas blasting machine

InactiveCN106643323AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a thread twisting-joint type gas blasting machine. The thread twisting-joint type gas blasting machine comprises an inner pipe, an inner pipe filling cavity, a firing mechanism, an inner pipe inflating mechanism and an outer pipe, wherein the inner pipe filling cavity is in the inner pipe; a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are connected between the inner pipe and the outer pipe; the firing mechanism and the inner pipe inflating mechanism are mounted on the first sealing inner cap or the second sealing inner cap; an outer pipe inflating mechanism is mounted on the first sealing outer cap or the second sealing outer cover; an outer pipe filling cavity is formed between the inner pipe and the outer pipe; supercritical oxygen and carbonaceous organic material are stuffed into the inner pipe filling cavity; and liquid materials easy to gasify including liquid carbon dioxide, liquid nitrogen and the like are stuffed into the outer pipe filling cavity. The thread twisting-joint type gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in homogeneity degree of reacting materials, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Fluid type gas blaster

PendingCN106643322AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesExplosivesEngineeringLiquid carbon

The invention discloses a fluid type gas blaster. The fluid type gas blaster comprises an inner tube, an inner tube filling cavity, an inner tube air inflation ignition head, an outer tube air inflation head, and an outer tube, wherein the inner tube filling cavity is formed in the inner tube, the two ends of the inner tube are connected to a first sealing inner cover and a second sealing inner cover respectively in a sealed mode, the outer layer of the inner tube is the outer tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, a sealing cavity formed by the inner tube, the outer tube, the first sealing outer cover, and the second sealing outer cover is an outer tube filling cavity, the outer tube filling cavity is filled with liquid carbon dioxide or liquid nitrogen, the inner tube filling cavity comprises a first inner cavity and a second inner cavity, the first inner cavity and the second inner cavity are separated through a thermoplastic sheet in a sealed mode, and the first inner cavity and the second inner cavity are filled with supercritical oxygen and liquid carbonaceous organic matter respectively. The fluid type gas blaster has the advantages of being low in manufacturing cost, high in reaction material mixing uniformity, high in heat releasing efficiency, good in transportation safety and large in blasting power.

Owner:郭远军

Assembly type gas blaster having sealed lead wire

InactiveCN106643309AReduce mixReduce production processBlasting cartridgesCheck valvesEngineeringLiquid carbon

The invention discloses an assembly type gas blaster having a sealed lead wire. The assembly type gas blaster comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, an inner pipe inflating mechanism and an outer pipe, wherein the inner pipe filling cavity is arranged in the inner pipe; a first sealing inner cap and a second sealing inner cap are respectively in sealed connection to two ends of the inner pipe; the outer pipe is the outer layer of the inner pipe; a first sealing outer cap and a second sealing outer cap are in sealed connection to a position between the inner pipe and the outer pipe; the ignition mechanism and the inner pipe inflating mechanism are mounted on the first sealing inner cap or the second sealing inner cap; an outer pipe inflating mechanism is mounted on the first sealing outer cap or the second sealing outer cover; an outer pipe filling cavity is a sealing cavity formed between the inner pipe and the outer pipe; the inner pipe filling cavity is filled with supercritical oxygen and carbonaceous organic materials; and the outer pipe filling cavity is filled with liquid materials easy to gasify including liquid carbon dioxide, or liquid nitrogen and the like. The assembly type gas blaster disclosed by the invention has the advantages of being low in manufacturing cost, high in homogeneity degree of reacting materials, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Inflation and lead integrated gas detonator

InactiveCN106871733AReduce mixReduce production processBlasting cartridgesExplosivesDetonatorDetonation

The invention discloses an inflation and lead integrated gas detonator. The inflation and lead integrated gas detonator comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation conductive head, an outer pipe inflation head and an outer pipe. The inner pipe is internally provided with the inner pipe filling cavity. A first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner pipe in a sealing manner correspondingly. The outer layer of the inner pipe is provided with the outer pipe. A first sealing outer cover and a second sealing outer cover are connected between the inner pipe and the outer pipe in a sealing manner. The inner pipe inflation conductive head is arranged on the first sealing inner cover or the second sealing inner cover, and the first sealing outer cover or the second sealing outer cover is provided with the outer pipe inflation head. A sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity. The inner pipe filling cavity is internally provided with an electric heating wire, the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matter, and the outer pipe filling cavity is filled with liquid carbon dioxide or liquid nitrogen or other liquid objects prone to gasification. The inflation and lead integrated gas detonator has the beneficial effects that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high, the transporting safety is good, and the detonation power is high.

Owner:郭远军

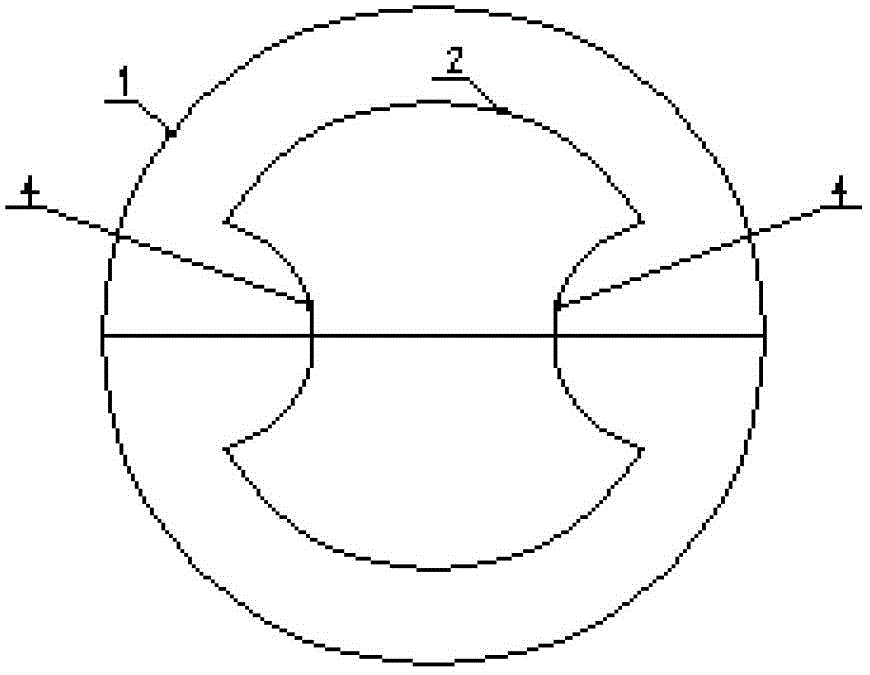

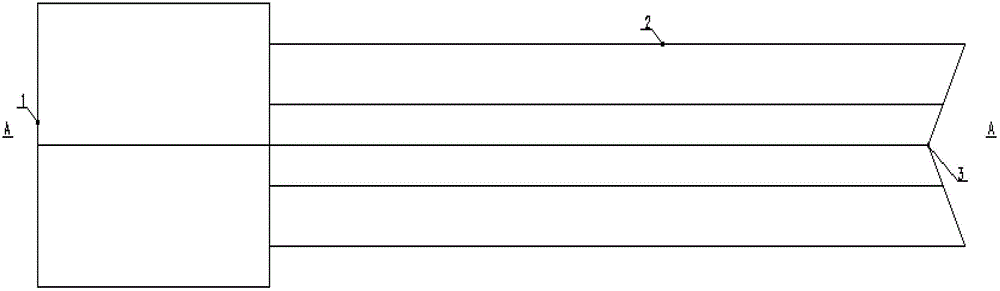

Recyclable dacron gas blaster and manufacturing method thereof

InactiveCN106223954AReduce weightPowerful explosionDisloding machinesProcess engineeringEnergy storage

The invention discloses a recyclable dacron gas blaster and a manufacturing method thereof. The recyclable dacron gas blaster comprises an energy storage device and a gas inflating igniter, the igniter is installed at one end of the energy storage device, and the other end of the igniter is sealed or integrally formed. The recyclable dacron gas blaster is characterized in that the energy storage device is prepared from dacron materials in a cured mode, an energy-releasing inner cover is arranged on the inner layer of the bottom of the energy storage device and provided with an energy releasing window, a pressure-fixed blasting sheet is installed on the energy releasing window in a sealed mode, and the energy-releasing inner cover is made of metal materials. The recyclable dacron gas blaster has the advantages of being small in thickness and weight, convenient to transport and install, easy to manufacture, low in material cost and production cost, high in inflating speed, good in sealing performance, long in service life and the like.

Owner:郭远军

Cold Blasting Method of Liquid Carbon Dioxide in Closed Blasting Hole

The invention provides a cold blasting method using liquid carbon dioxide in enclosed blast holes. The method comprises following steps: firstly, a blast hole is drilled in rocks to be blasted; then a hole sealing device is mounted, wherein one end, provided with an initiator, of the hole sealing device is placed into the hole and the hole sealing device is totally immerged in the hole; a high pressure liquid injection port, a carbon dioxide liquid injection port and a lead nozzle are kept outside the blasting hole in advance; the high pressure liquid injection port is connected with a high pressure liquid injection gun; the hole sealing device is injected with liquid and expands to block the blast hole; the carbon dioxide liquid injection port is connected with a liquid carbon dioxide injection pipe; quantified liquid carbon dioxide is injected to the blast hole according to blasting design requirement; initiator leads which are pre-kept at one side of the lead nozzle are connected in a parallel mode; the initiator is electrified for blasting the liquid carbon dioxide in the blasting hole to complete blasting. The blasting power of the invention is great and the initial investment and use cost for blasting are reduced; the construction is simple and convenient; the method is easy to promote.

Owner:DALIAN UNIV

Fluid type trigger and fracturing device

InactiveCN106643313AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesCheck valvesOxygenThermal efficiency

The invention discloses a fluid type trigger and fracturing device. A shell and a filling cavity located in the shell are involved. The shell comprises first segments, second segments and connecting joints. The filling cavity comprises a reductant filling cavity body and an oxidant filled cavity body, and the reductant filling cavity body and the oxidant filling cavity body are correspondingly filled with supercritical oxygen and liquid carbonaceous organic materials. The reductant filling cavity body and the oxidant filling cavity body are formed in the first segments and the second segments correspondingly. The two ends of each connecting joint are connected with one ends of the first segments and the second segments correspondingly in threaded and sealed modes or in a seamless welded mode. The other ends of the first segments and the second segments are connected with fluid-filling nozzles and air inflation mechanisms correspondingly. An isolation thermoplastic sheet is mounted in the middles of the connecting joints, a heating wire is mounted in the isolation thermoplastic sheet in a sealed mode, and the heating wire is guided out of the shell through guide lines. The fluid type trigger and fracturing device has the advantages that manufacture cost is low, mixing uniformity of reaction materials is high, heat releasing efficiency is high, and transport safety is good.

Owner:郭远军

Application of shearing thickening liquid as blasting hole blockages

The invention discloses the application of shearing thickening liquid as blasting hole blockages, and the shearing thickening liquid completely coats or partially coats the blasting energy accumulatorin the blasting hole; the blasting process comprises the following steps of: filling shearing thickening liquid in a blasting hole, wherein the shearing thickening liquid completely coats or partially coats the blasting energy accumulator in the blasting hole; the shearing thickening liquid completely closes the blasting hole so as to completely bury the blasting energy accumulator in the blasting hole; detonating the blasting energy accumulator. According to the invention, no flying stone splashing is generated during the blasting process,, the blasting degree is deep, the blasting efficiency is high, the blasting effect is not limited by the arrangement mode of the blasting hole, and the degree of freedom of the blasting hole arrangement is greater; the blasting process does not generate strong air shock waves, does not cause damage to the surrounding environment and the staff, has small blasting noise and blasting process is safe.

Owner:远军热能动力科技有限公司

Detonating device for double-supercritical-gas blaster and fracturing device

InactiveCN106643329AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesCheck valvesElectricityThermal efficiency

The invention discloses a detonating device for a double-supercritical-gas blaster and a fracturing device. The detonating device comprises a shell and a filling cavity located in the shell. The shell comprises a first segment, a second segment and a connector. The filling cavity comprises a reductant filling cavity body and an oxidant filling cavity body, and the reductant filling cavity body and the oxidant filling cavity body are located in the first segment and the second segment respectively. The two ends of the connector are connected with one end of the first segment and one end of the second segment respectively in a thread sealing mode or a seamless welding mode, the other end of the first segment and the other end of the second segment are connected with a first gas charging mechanism and a second gas charging mechanism respectively, an isolating thermoplastic sheet is installed in the middle of the connector, and an electric heating wire is packaged in the isolating thermoplastic sheet and is led out of the shell through a lead. The detonating device has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency and good transport safety.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com