Recyclable dacron gas blaster and manufacturing method thereof

A blaster and polyester technology, which is used in earth-moving drilling, discharging machinery, etc., can solve the problems of high density, heavy gas blaster, and time-consuming inflating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

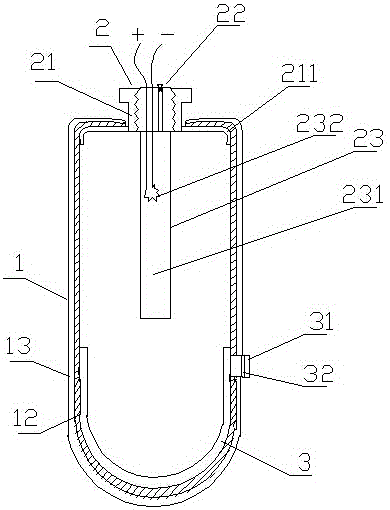

[0098] Such as figure 1As shown, a reusable polyester gas blaster includes an energy storage device 1 and an inflatable detonator 2, the energy storage device 1 is equipped with an inflatable detonator 2 at one end, and the other end is sealed or integrally formed; the energy storage device 1 It is made of solidified polyester material; the bottom inner layer of the energy storage device 1 is provided with an energy-discharging inner cover 3, and the energy-discharging inner cover 3 is provided with an energy-discharging window 31, and the energy-discharging window 31 is sealed and installed with a constant pressure rupture disc 32 , the energy dissipation inner cover 3 is made of metal.

[0099] As a further specific description of the above implementation, the energy storage device 1 has a two-layer structure, and the energy storage device 1 includes a mesh layer 12 and a hardened layer 13 distributed from the inside to the outside.

[0100] As a further specific descriptio...

Embodiment 2

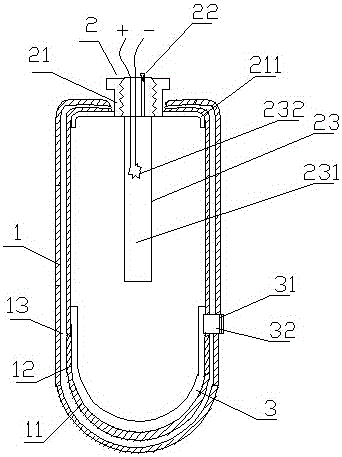

[0114] Embodiment two: the difference with embodiment one is: (such as figure 2 As shown) the energy storage device (1) has a three-layer structure, which consists of a base layer (11), a mesh layer (12) and a hardened layer (13) from the inside to the outside; the mesh layer (12) is made of polyester material, the hardened layer (13) is made of epoxy resin glue material, and the base layer (11) is made of polyethylene material.

Embodiment 3

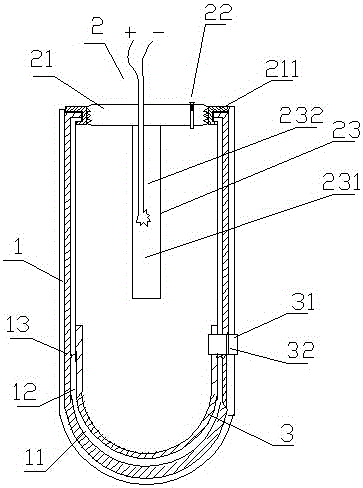

[0115] Embodiment three: the difference with embodiment two is: (such as image 3 As shown), the threaded structure in the middle of the sealing base 21 is inwardly recessed; this structure is convenient for transportation and saves the overall volume, and at the same time, it is convenient for protecting the inflatable detonator 2 from being hit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com