Blasting structure and blasting method

A technology of cutting holes at the bottom, which is applied in the field of coal mine blasting, can solve the problem that the blasting footage cannot meet the construction requirements, and achieve the effect of good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

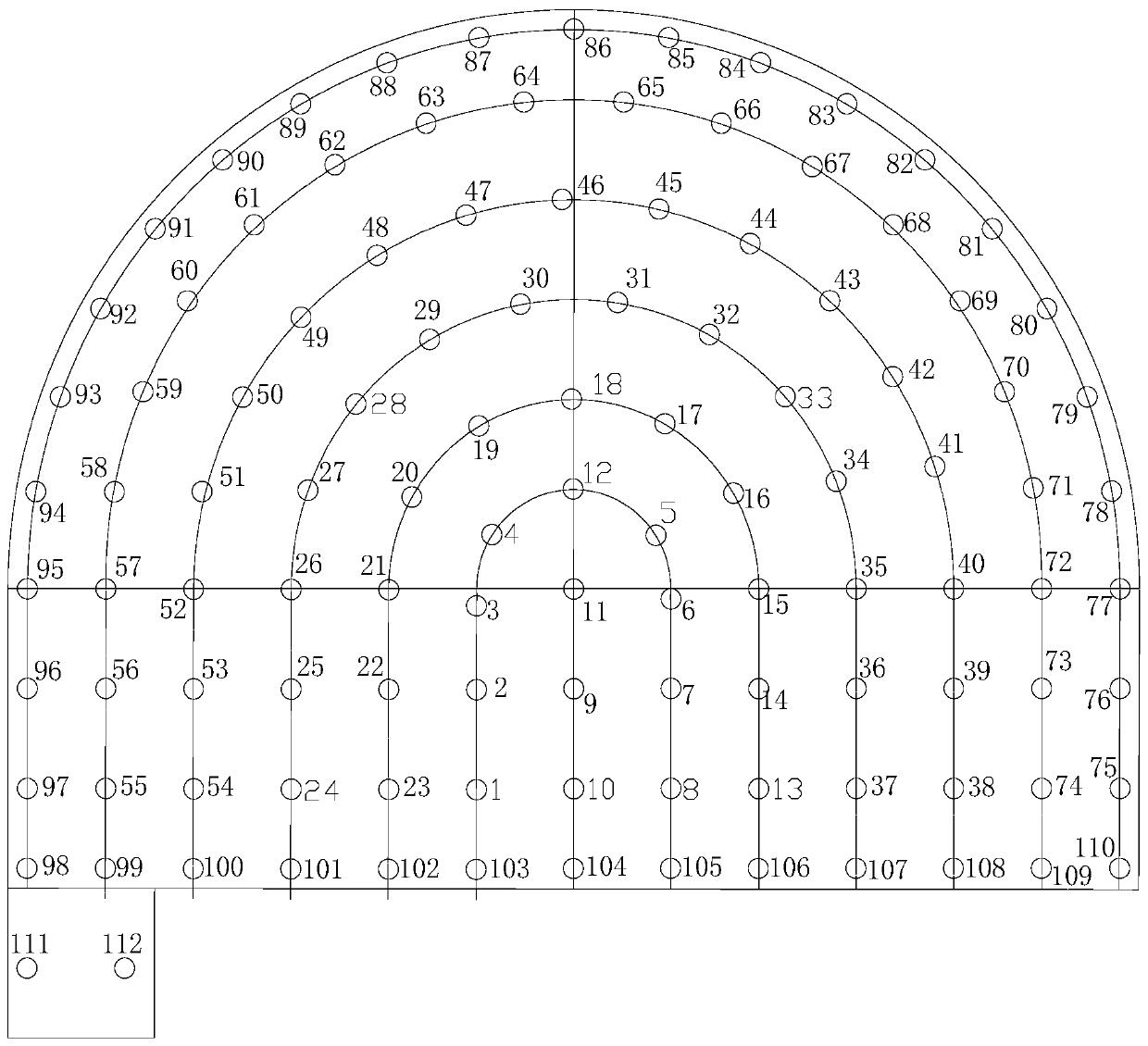

[0046] like figure 1 As shown, a blasting structure includes an auxiliary cut hole, a cut hole, a second ring hole, a third ring hole, a fourth ring hole, a fifth ring hole, a peripheral hole, a bottom hole, and a gutter hole.

[0047] like figure 1 As shown, the auxiliary cutouts are set in the middle of the blasting section, and the auxiliary cutouts are distributed at intervals up and down, and the distance between adjacent auxiliary cutouts is 480-520mm; in this embodiment, four auxiliary cutouts are set, namely figure 1 For blastholes marked as 9, 10, 11, and 12, the distance between adjacent auxiliary cutting holes is 500mm.

[0048] like figure 1 As shown, the cut eye ( figure 1 The blastholes marked as 1-8), the second ring holes ( figure 1 The blast hole marked as 13-23), the peripheral eye ( figure 1 The blastholes with the marks 75-97) are opened in the periphery of the auxiliary cutout hole in turn, and the cutout hole, the second ring hole, and the peripheral...

Embodiment 2

[0069] A blasting method based on the aforementioned blasting structure, comprising the steps of:

[0070] S1. Select blasting section;

[0071] S2. Drilling: Drilling holes on the blasting section according to the size in Embodiment 1;

[0072] S3, charging:

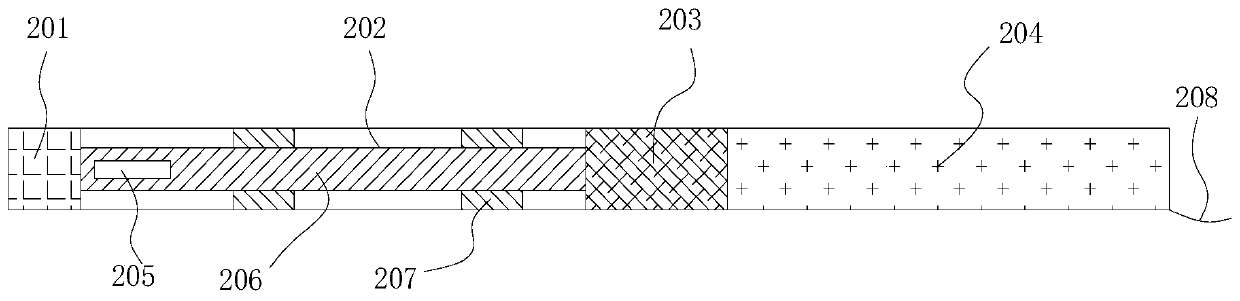

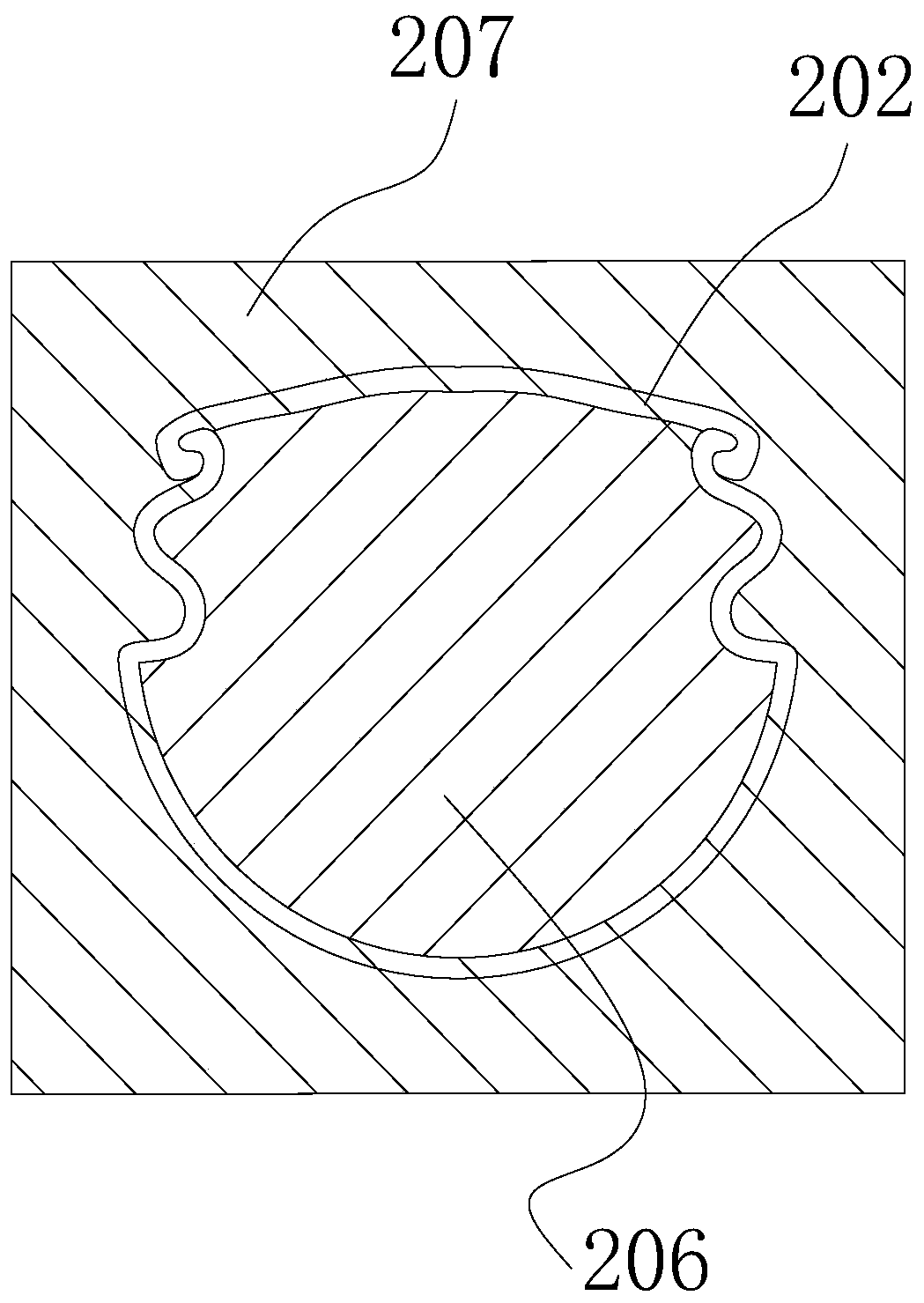

[0073]Peripheral eye charging: put the detonator roll containing the detonator 205 and the explosive 206 into the energy-concentrating tube 202, specifically place the detonator roll containing the detonator 205 and the explosive 206 in the energy-concentrating tube 202, and cover the cover sheet, then Bind the two ends of the energy-gathering tube 202 firmly with adhesive tape to ensure that the medicine rolls are tightly connected, put the seat mud 201 into the fundus of the peripheral eye, and then install the energy-gathering tube 202 in the peripheral eye through the positioning block 207, except for the most The detonators 205 in the peripheral eyes of the lower two rows of eyes are located at the end close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com