Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid error-prone situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

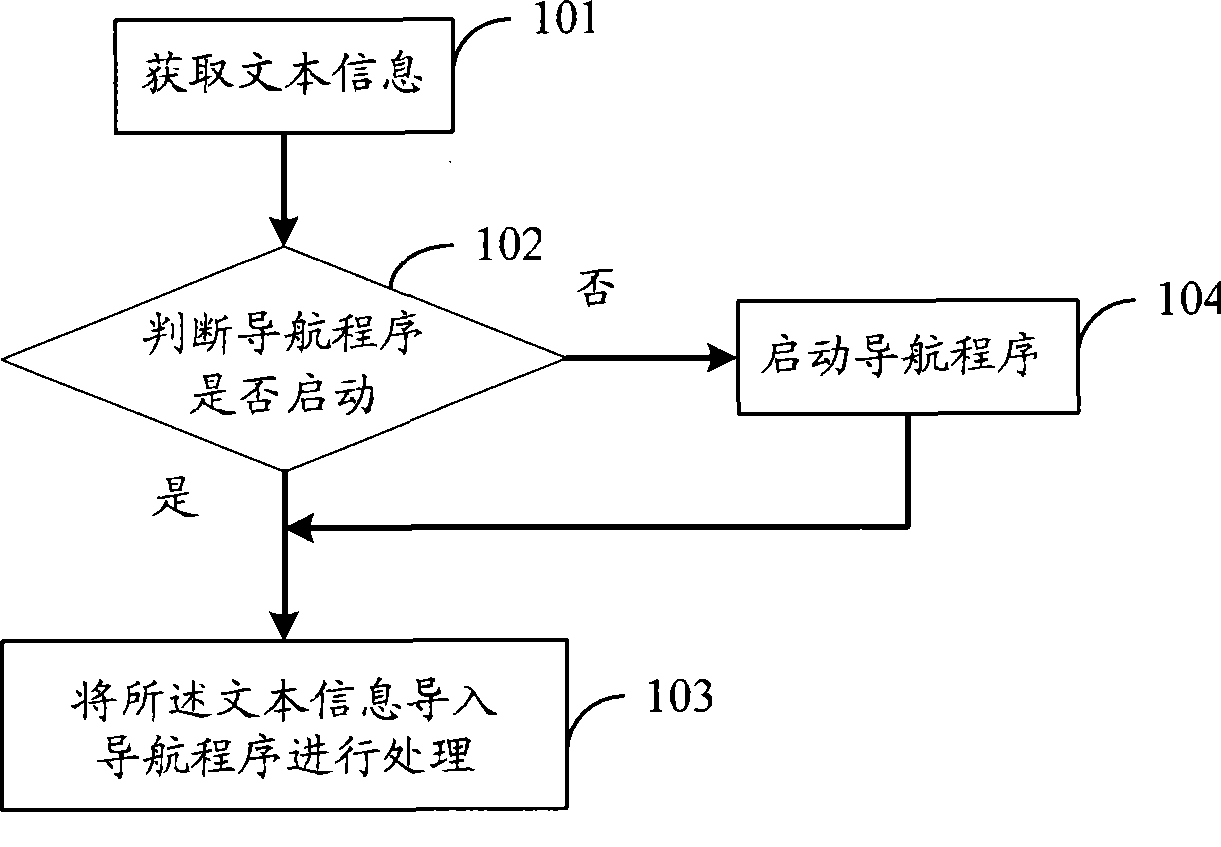

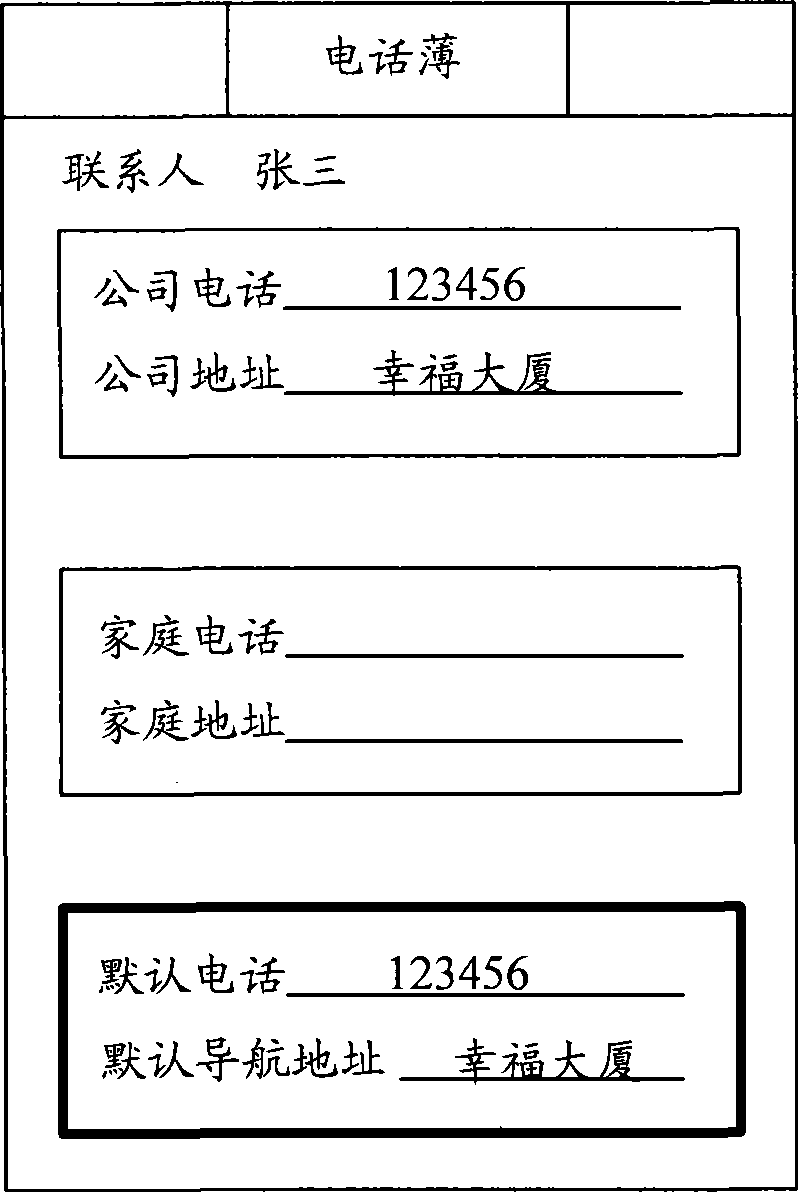

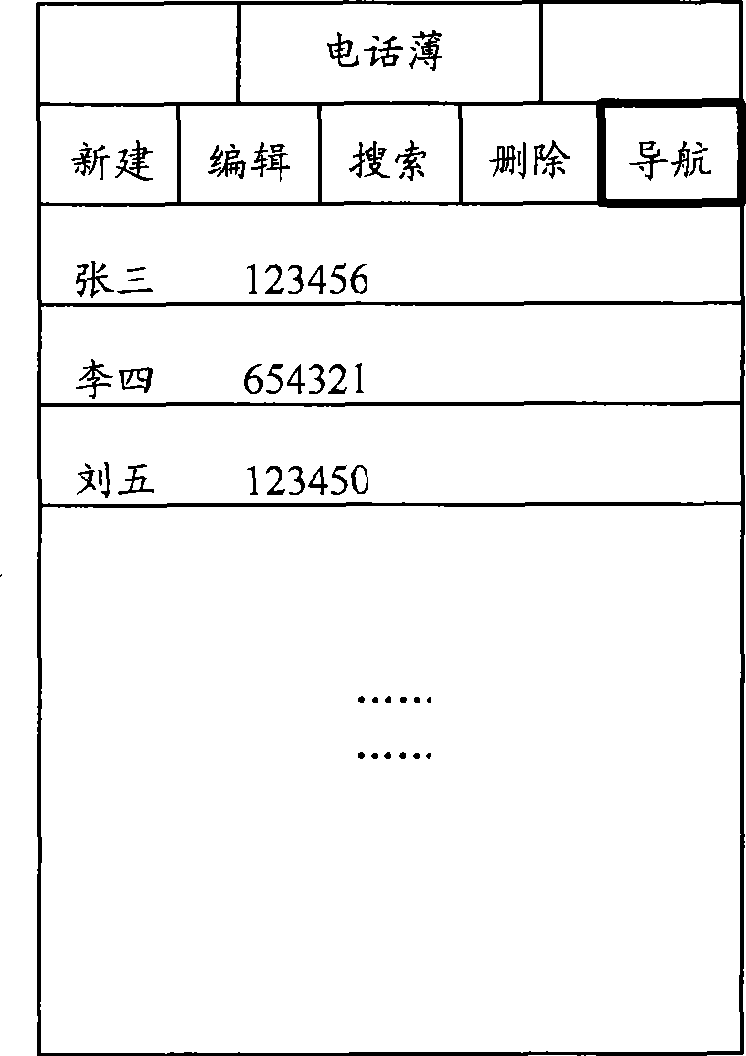

Intelligent navigation apparatus, navigation terminal and its information navigation method

InactiveCN101482420AImprove navigation efficiencyUser-friendlyInstruments for road network navigationSpecial data processing applicationsApplication softwareReal-time computing

The invention discloses an intelligent navigation device, a navigation terminal and an information navigation method in the terminal. The invention embodiment comprises: obtaining the text information in the terminal; judging whether the navigation program has started; if not, starting the navigation program and introducing the text information into the navigation program to process; if yes, introducing the text information into the navigation program directly to process; therefore, user can call the navigation program from other application programs in the terminal rapidly and conveniently; the system can induced the text information needing navigation automatically for navigation, avoids the errors caused by the user artificial input information, while increasing the navigation efficiency and facilitating users.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

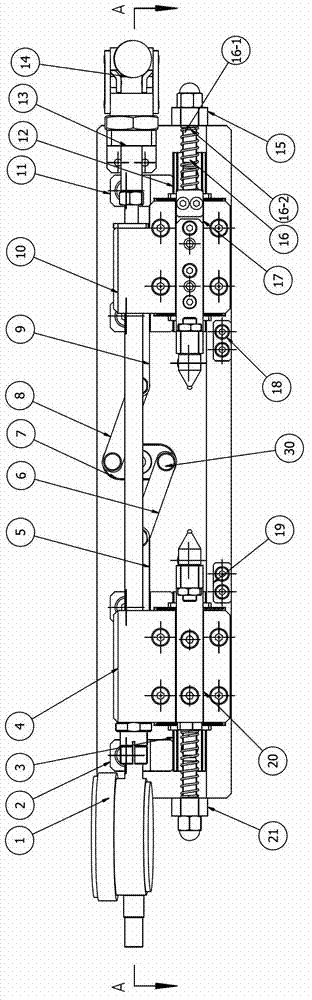

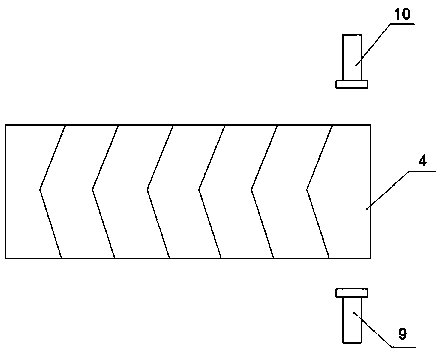

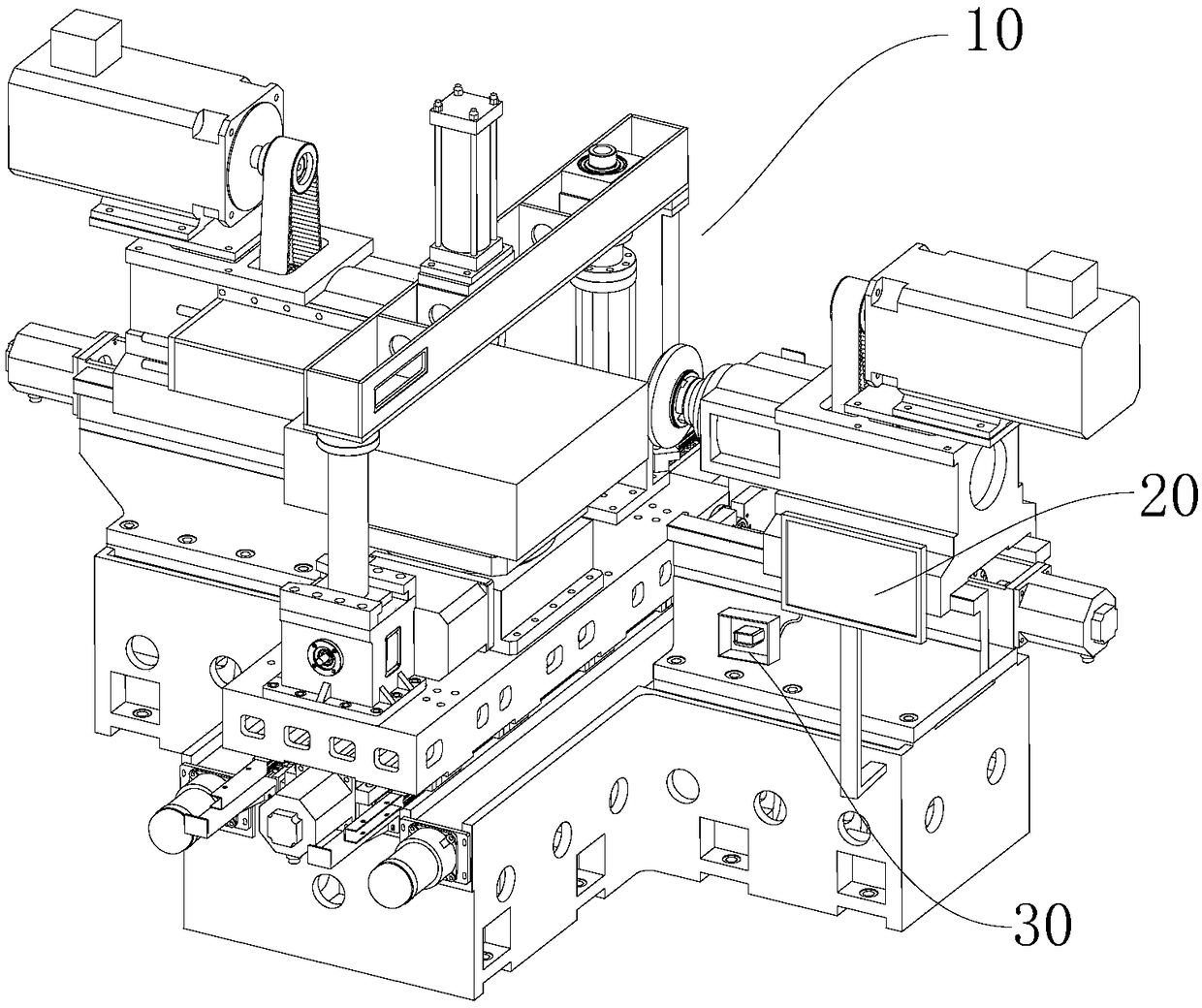

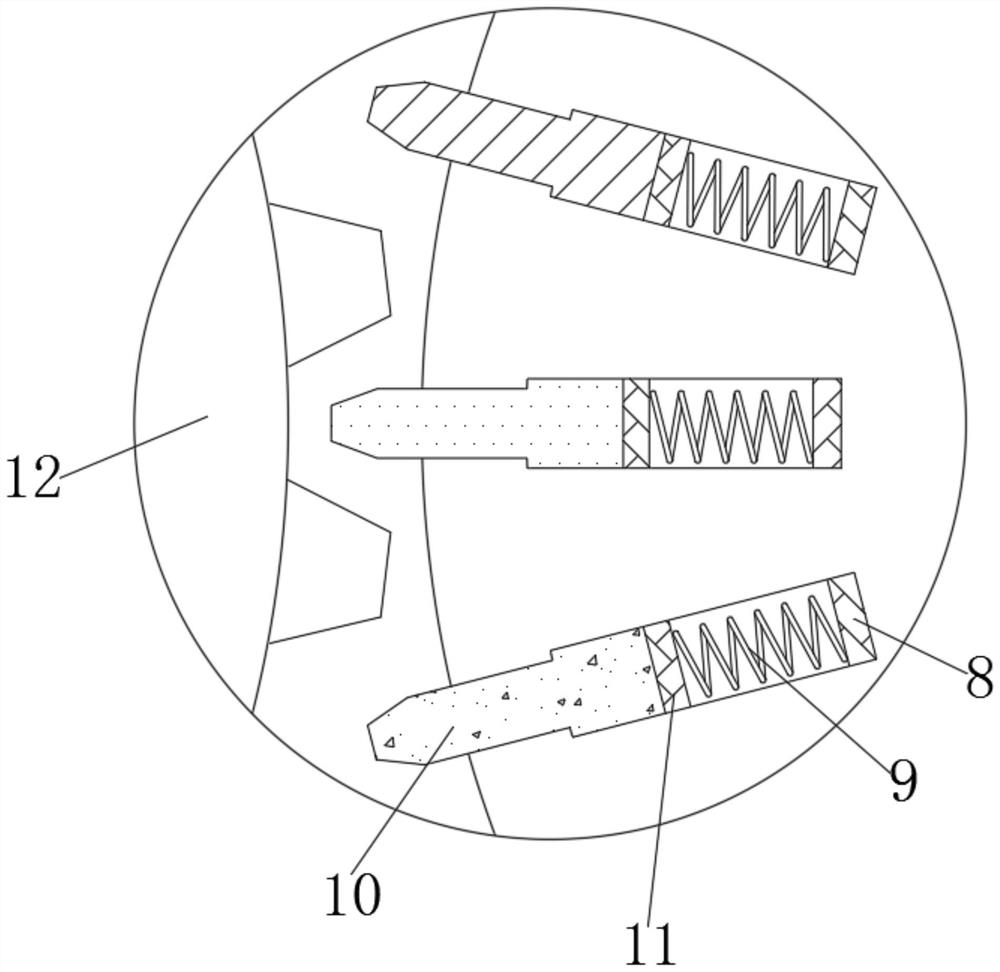

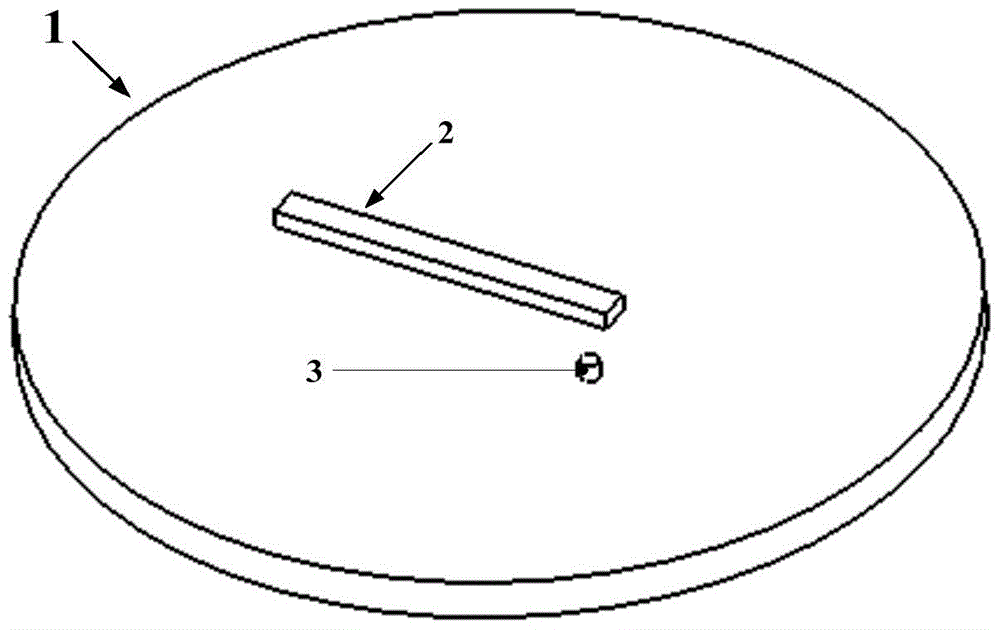

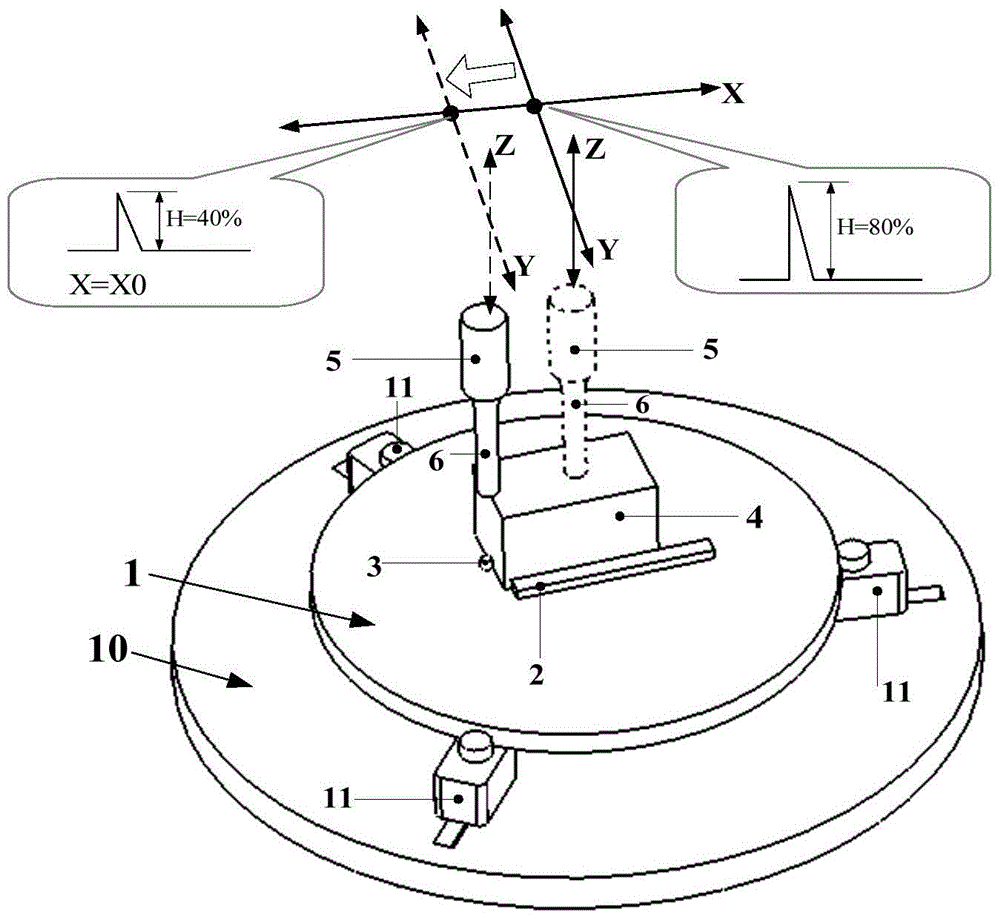

Gear M-value rapid diameter measuring jaw linkage mechanism

ActiveCN102889841AAvoid error-prone situationsReduce production and operating costsMechanical diameter measurementsEngineeringLinkage concept

The invention relates to a gear M-value rapid diameter measuring jaw linkage mechanism which is characterized by comprising a base plate, wherein a clamp support is installed at one end of the base plate and is provided with a clamp; a first hole of a first sliding block is internally provided with a summation and difference rod; the first sliding block is provided with a first sliding groove installation moving measuring rod device; a first pressing spring fixed seat is provided with a first spring device; a second guide rail is slidingly connected with a second sliding block; the second sliding block is provided with a second sliding groove installation fixed measuring rod device; second pressing spring fixed seats are installed on the base plate; a second spring device is arranged between the second pressing spring fixed seats; the second sliding block is threadedly connected with a clipping body; the clipping body is provided with a measuring device; and a connecting rod device is installed at the middle of the base plate. The gear M-value rapid diameter measuring jaw linkage mechanism provided by the invention is simple to operate, and is intuitive in reading, data is accurate, and the situation that the matched measurement of a clipping ruler and a measuring ball causes error easily is prevented; and the manufacturing cost is low, and the enterprise production operation cost can be lowered.

Owner:WUXI MEASURE MACHINE MFR

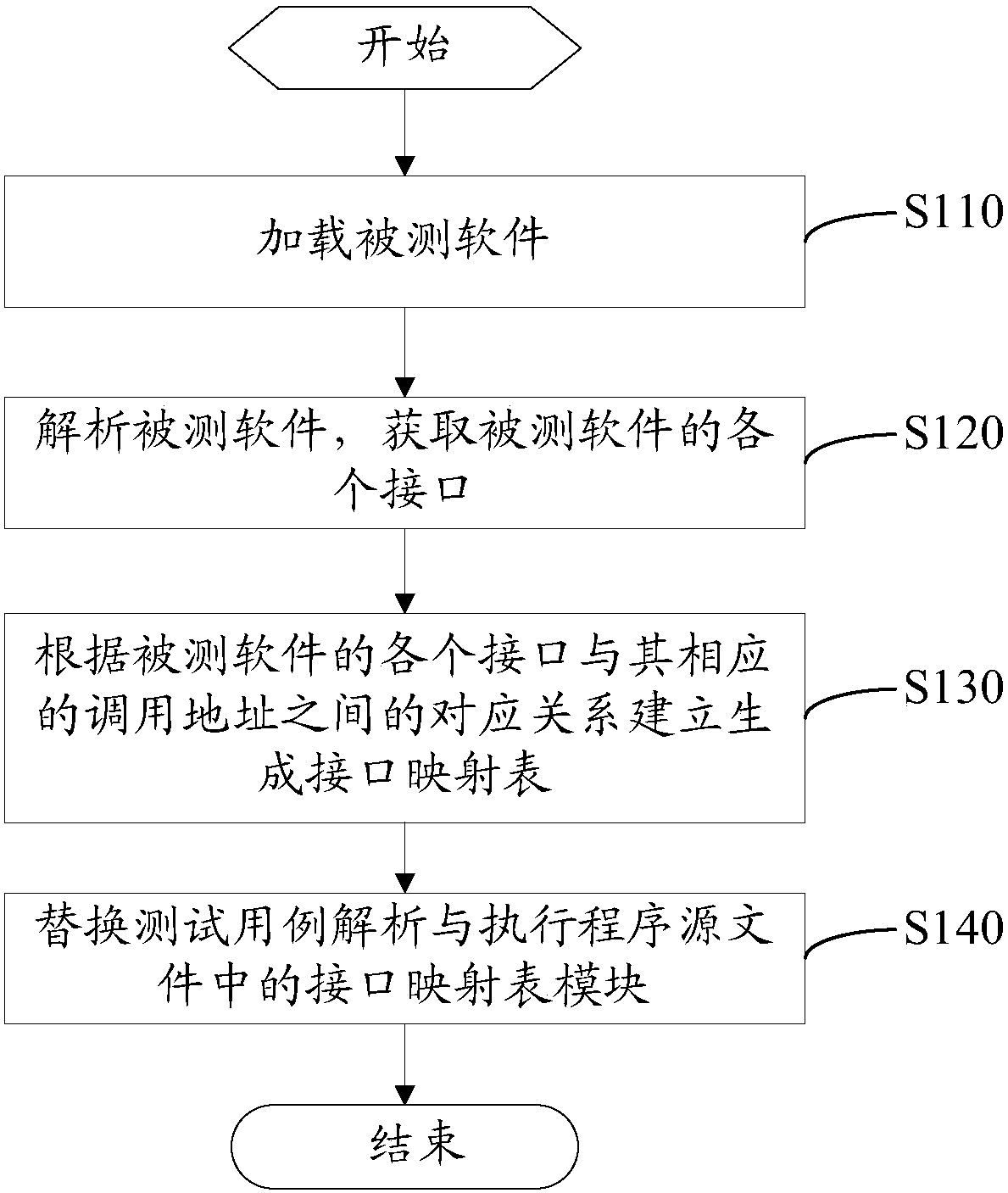

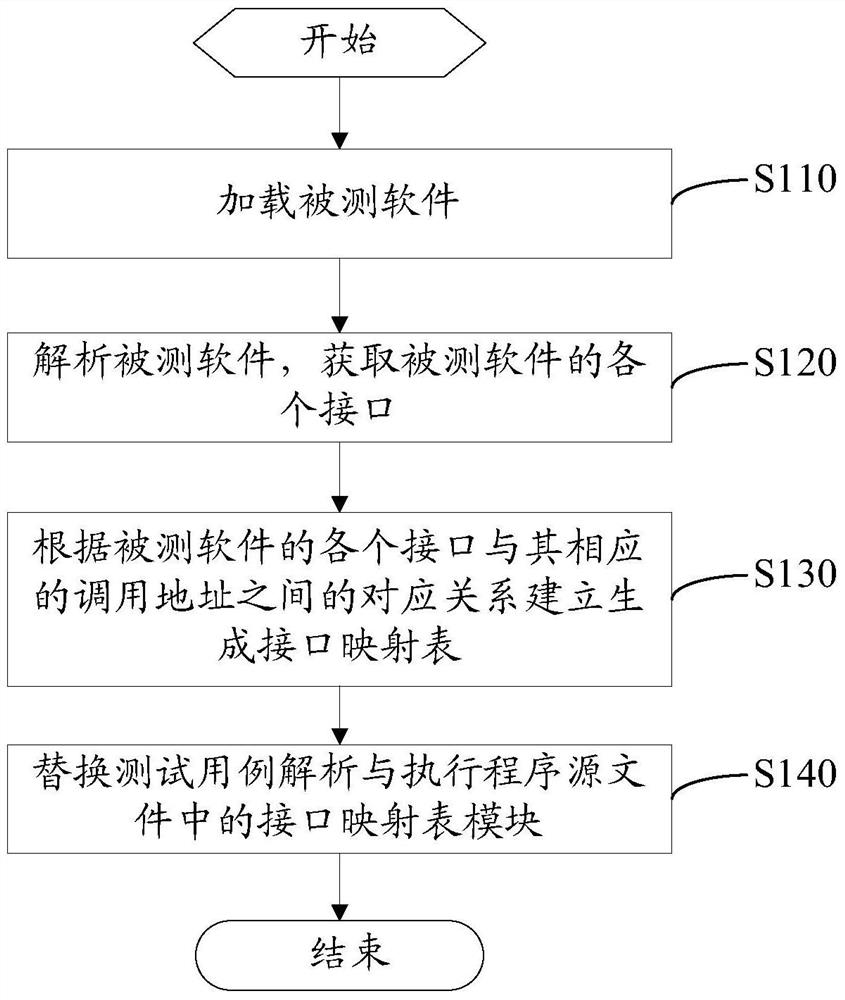

Software test method and system, and test platform

ActiveCN107608873AImprove accuracyLower performance requirementsSoftware testing/debuggingTest platformWorkload

The present invention discloses a software test method and system, and a test platform. The method comprises the following steps: according to the tested software, automatically generating a test caseparsed and executed program source file, and compiling the test case parsed and executed program source file to generate an executable file; writing the executable file into an running platform of the tested software; sending a preset test case corresponding to the tested software to the executable file, executing the test case through the executable file and testing the tested software; and receiving and saving the execution results of the test case executed by the executable file. According to the technical scheme of the present invention, by automatically generating the test case parsed and executed program source file according to the tested software, without manual edition of the source files by testers, the testing workload is effectively reduced, the testing difficulty is reduced,and the problem that the traditional software module interface test method has certain limitations and inefficiencies is finally effectively solved.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

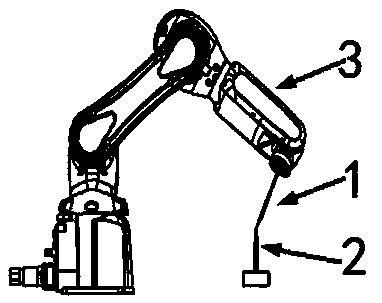

Robot calibration method, robot calibration system and readable storage medium

InactiveCN111216138AImprove trajectory accuracyHigh precisionProgramme-controlled manipulatorSimulationControl theory

The invention discloses a robot calibration method, a robot calibration system and a readable storage medium. The robot calibration method comprises the following steps: recording the joint data of each joint of a robot; obtaining the tail end simulation position of the robot through establishing a robot connecting rod structure D-H model; constructing a tail end simulation position error model according to the joint data and the tail end simulation model of the robot; constructing a zero error model according to the joint data and the robot connecting rod structure D-H model; and compensatingthe tail end simulation position error model into the zero error model to obtain the joint zero error. According to the robot calibration method, the track precision of the robot can be improved on the premise of simple operation.

Owner:JIHUA LAB

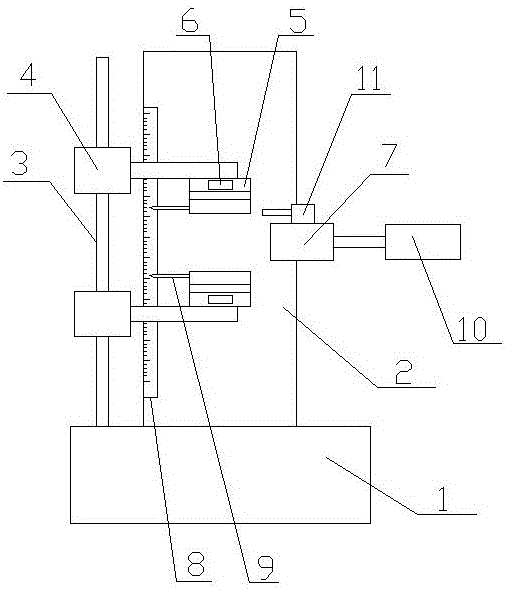

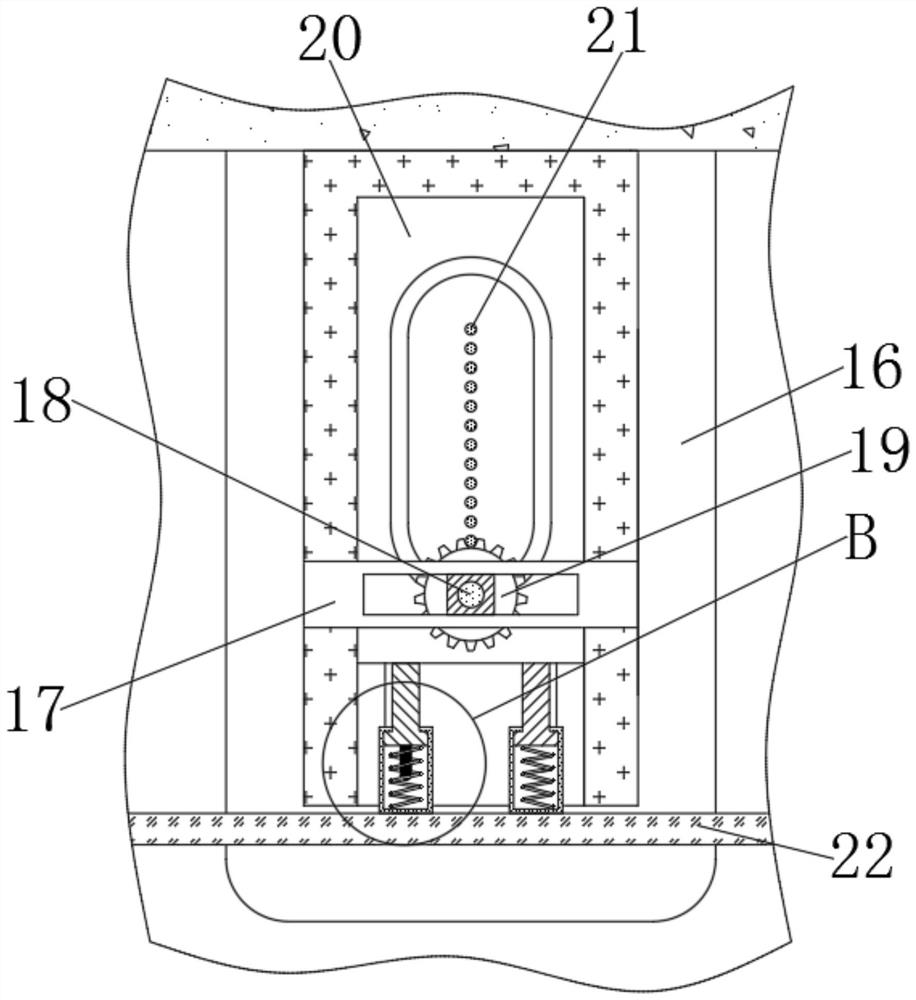

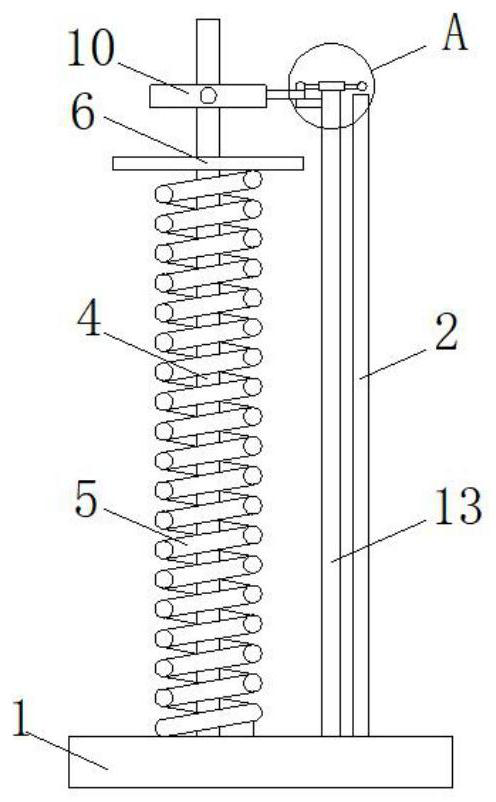

Wire insulation pulling force detection apparatus

InactiveCN106092741AAvoid error-prone situationsImprove detection accuracyMaterial strength using tensile/compressive forcesPull forceSkin surface

The invention provides a wire insulation pulling force detection apparatus. The apparatus comprises a pedestal, the pedestal is provided with a detection plate, the left side of the detection plate is provided with an elevating guide rod, the elevating guide rod is provided with two mobile blocks, every mobile block is provided with a clamping clamp, the mobile blocks drive the clamping clamps to move up and down, every clamping clamp is provided with a conducting device, a wire clamped by the clamping clamps is conducted by the conducting devices, and the right side of the clamping clamps is provided with an electric leakage detection device. The wire is clamped and fixed by the arranged clamping clamps, the mobile blocks drive the clamping clamps to move in order to pull the wire, the wire is conducted by the conducting devices, and electric leakage detection of the wire is carried out through the electric leakage detection device, so the detection precision is improved, and the easy get-wrong case of observation of the insulation skin surface of the wire is avoided; and a scale and a gauge rod are arranged to detect the extension amount of the wire, so the detection precision is improved, and detection data is increased.

Owner:WUHU SHUNCHENG ELECTRONICS

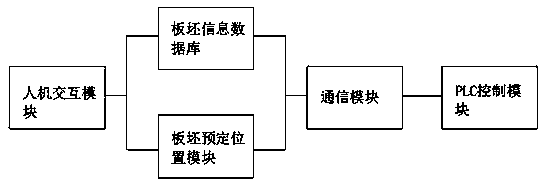

Automatic steel feeding system and method for slab heating furnaces

InactiveCN109916182ARealize real-time trackingReduce labor intensityCharge manipulationEngineeringEnergy consumption

The invention discloses an automatic steel feeding system for slab heating furnaces, and relates to the technical field of automation control. The automatic steel feeding system comprises the heatingfurnaces, a plurality of steel feeding roller beds and a feeding roller bed, and further includes a slab information database, a slab predetermined position module, a human-computer interaction module, a communication module and a PLC control module. The feeding roller bed and the multiple steel feeding roller beds are connected in sequence, and the steel feeding roller beds are located at different positions of the heating furnaces. A photoelectric detecting sensor is arranged at the front end of each of the steel feeding roller beds. The slab information database and the slab predetermined position module are both connected to the PLC control module through the communication module, and the human-computer interaction module is connected with the slab information database and the slab predetermined position module. The steel feeding roller beds, the feeding roller bed and the photoelectric detecting sensor are all connected with the PLC control module. The invention further disclosesan automatic steel feeding method for the slab heating furnaces. The automatic steel feeding system and method improve the efficiency of steel feeding of slabs, reduce the energy consumption and reduce the labor intensity of operators.

Owner:NANJING IRON & STEEL CO LTD

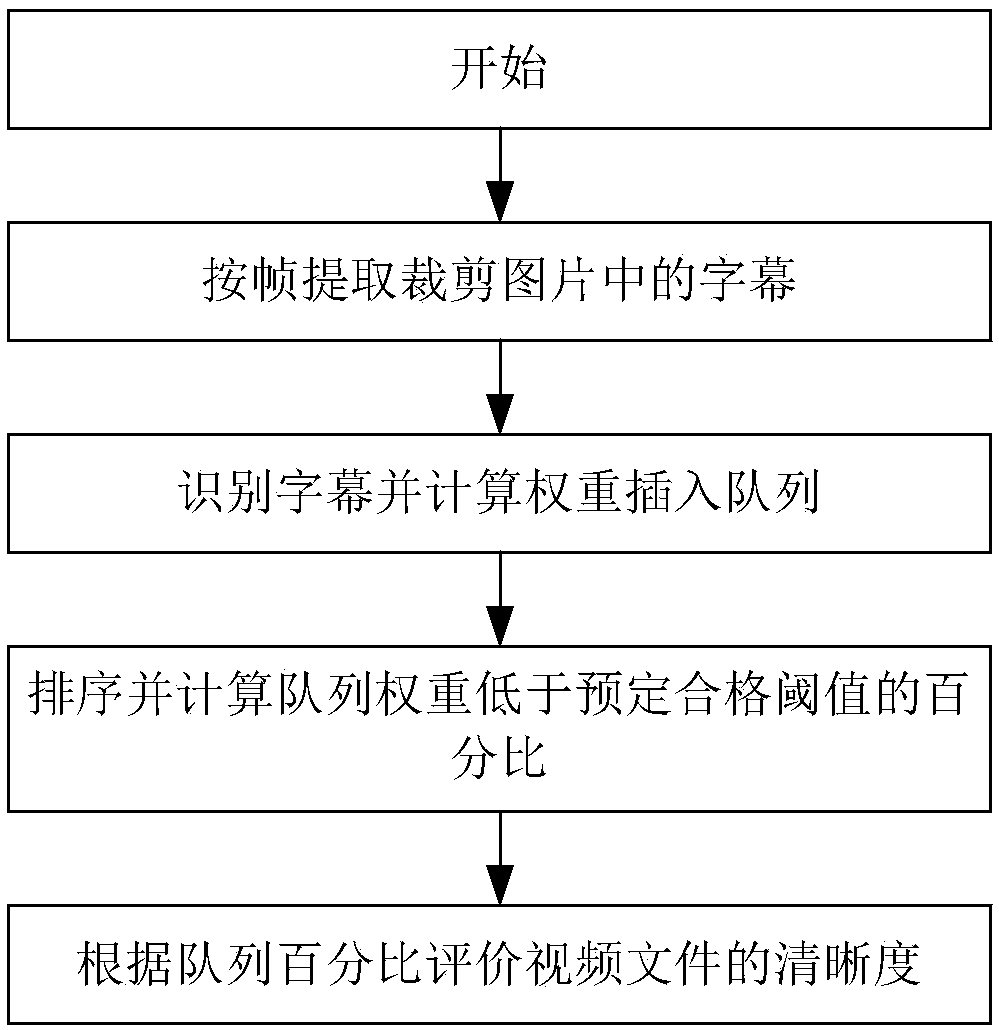

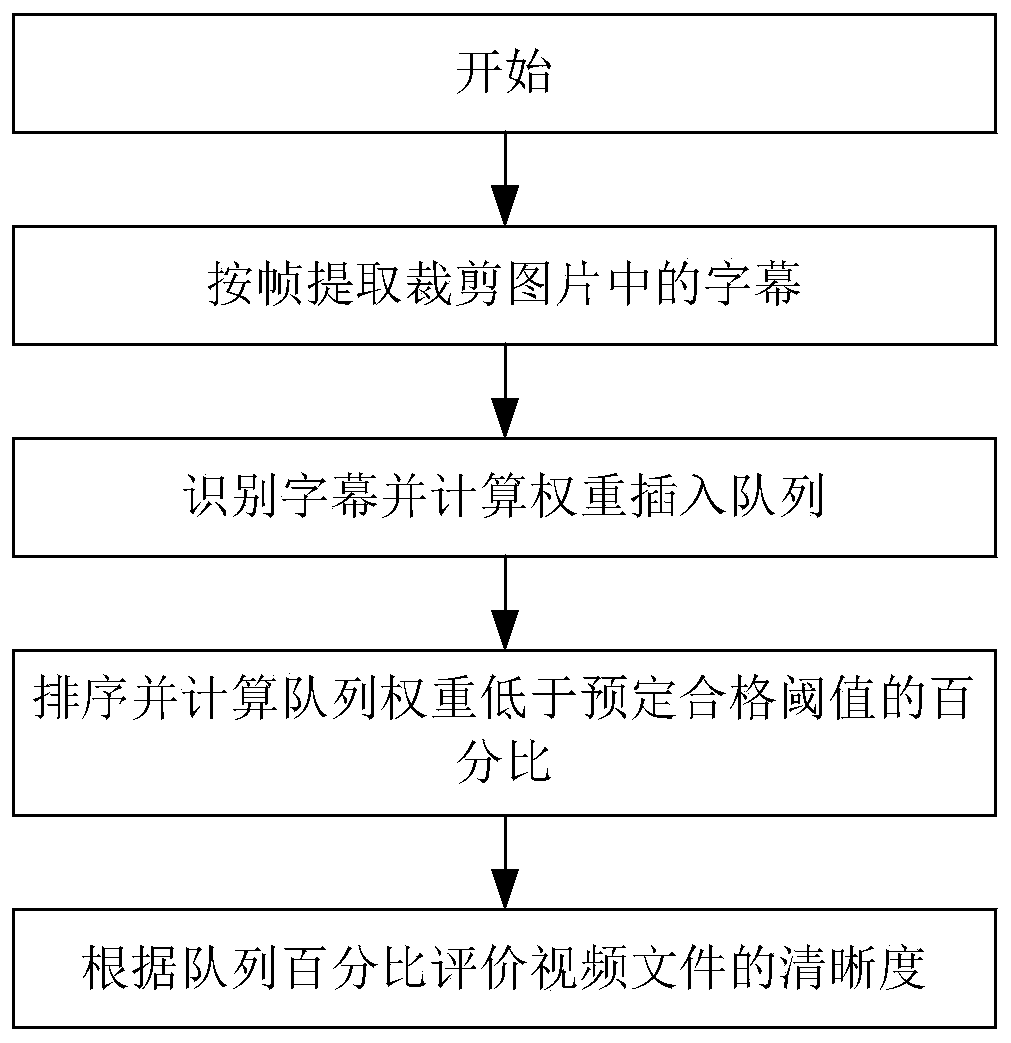

Method and device for detecting subtitle definition

ActiveCN107846622AClarity detectionImprove user experienceTelevision system detailsColor television detailsAlgorithmTheoretical computer science

The embodiment of the invention provides a method and device for detecting subtitle definition. The method comprises the steps of obtaining a video file of to-be-identified subtitles, carrying out analysis to obtain a picture of each frame in the video file, and storing the picture of each frame to a queue corresponding to the video file; identifying the total character string length and the totalcharacter number in each picture through an OCR algorithm and calculating a first ratio of the total character string length and the total character number in each picture; comparing each first ratiowith a preset ratio threshold and determining a weight value of each first ratio; and determining the number of the weight values smaller than the preset ratio threshold in the weight values of the first ratios, calculating a second ratio of the number and the total number of the second ratios, and judging whether a subtitle display effect of the video file is qualified or not according to the calculated second ratio. Through application of the method and the device, the definition degree of the subtitles in the video file can be detected rapidly and conveniently.

Owner:BEIJING THUNDERSTONE TECH CO LTD

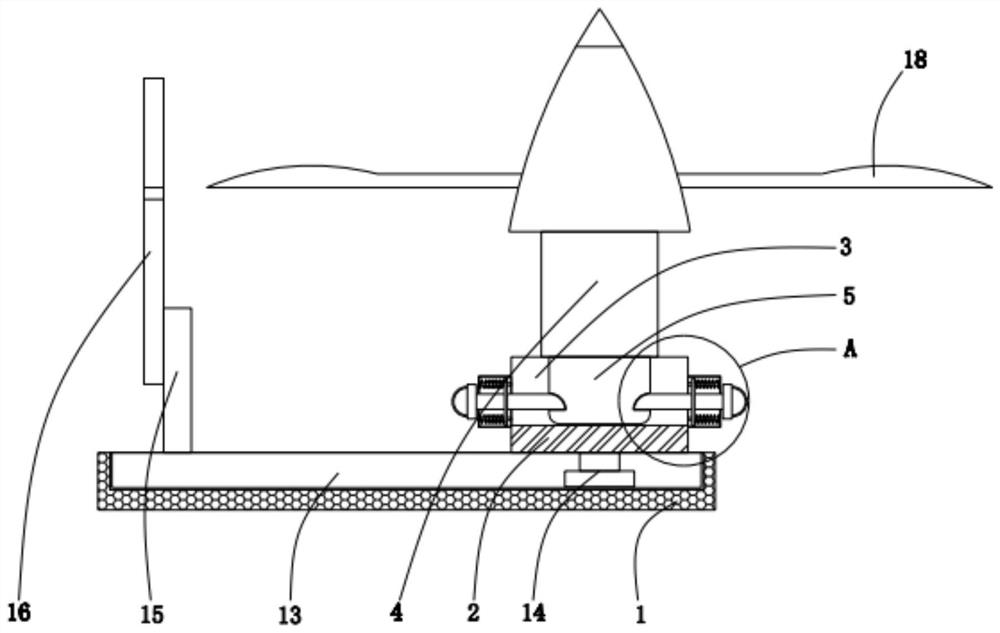

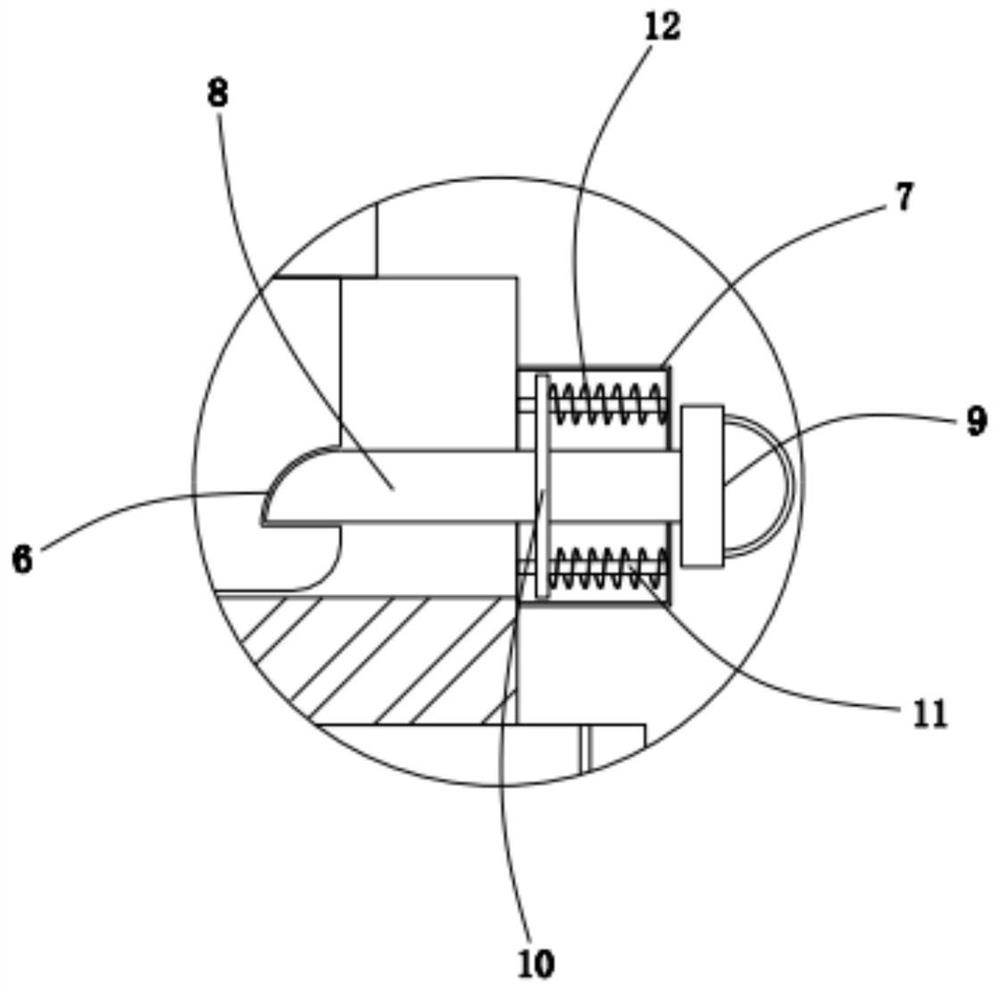

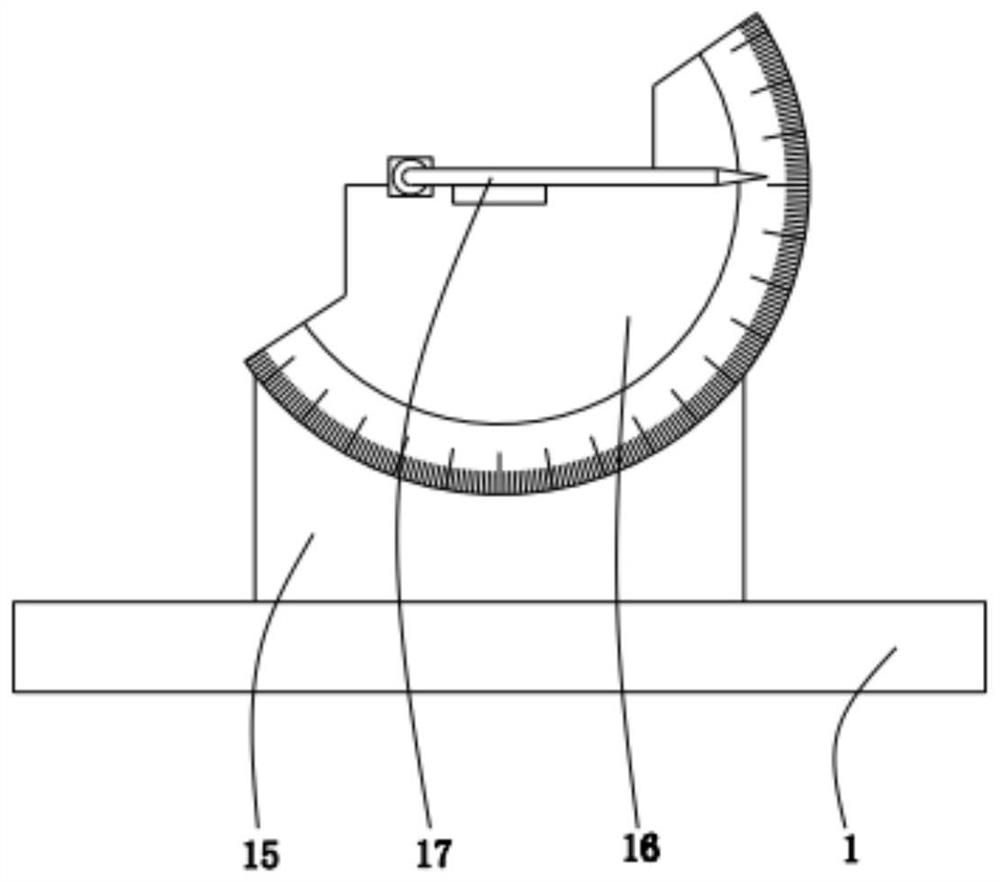

Real-time measuring device for propeller blade angles

The invention discloses a propeller blade angle real-time measuring device. The device comprises a base, a fixed plate is arranged at the top of the base, a clamping groove is formed in the fixed plate, and a propeller is clamped to the fixed plate through the clamping groove. Through the arrangement of the clamping block at the bottom of the propeller, the propeller can be placed in the clampinggroove, the clamping block extrudes the clamping head, and when the clamping head reaches the bottom of the clamping groove, the clamping head is tightly clamped in the clamping groove through the elastic force of the clamping spring, so that the propeller is fixed, and the situation of inaccurate measurement during measurement is avoided; according to the propeller angle measuring device, the angles of blades of a propeller can be accurately measured, a worker can conveniently use the corresponding propeller at the accurate angle, a sliding rod is arranged at the bottom of the fixed plate, the sliding rod can slide in a sliding groove, and therefore the blades are driven to move to a detected place to measure the angles of the blades; and the condition that errors are easy to occur in manual measurement is avoided.

Owner:安徽劲旋风航空科技有限公司

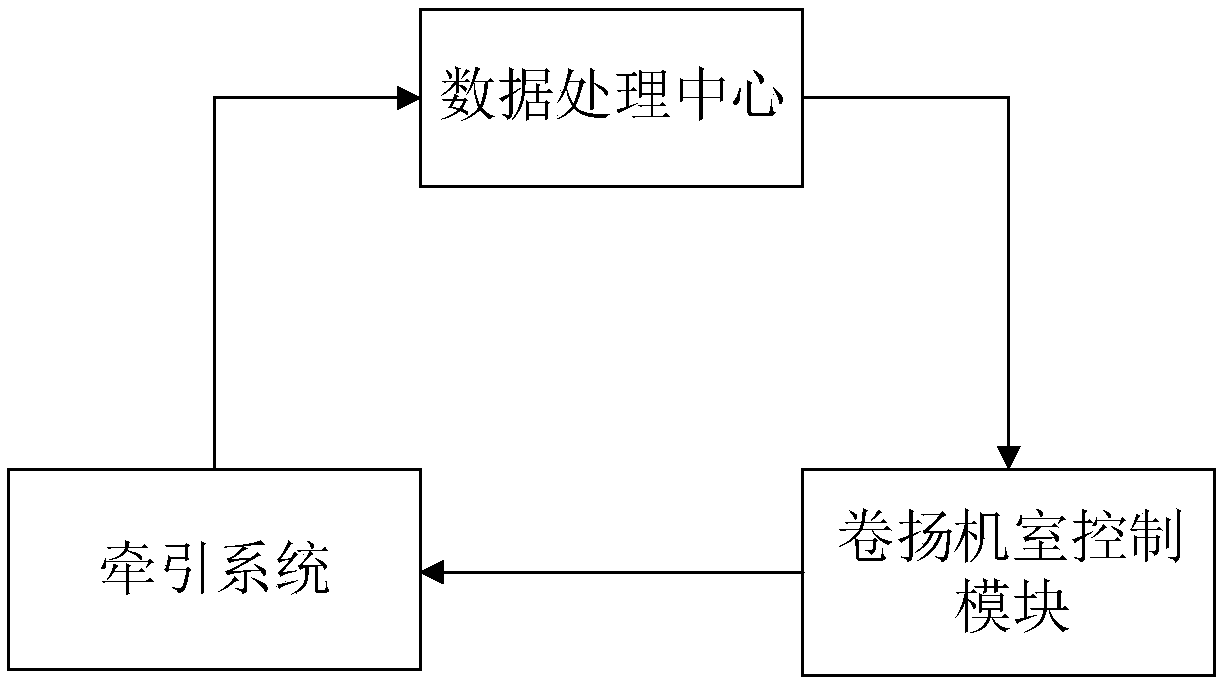

Automatic control system for a cable strand traction system of a suspension bridge, and monitoring platform

PendingCN109137741ARealize automatic controlHigh degree of automationBridge erection/assemblyTraction systemAutomatic train control

The invention discloses an automatic control system for a cable strand traction system of a suspension bridge, which comprises a traction system, a data processing center and a winch chamber control module. The traction system comprises a main traction winch, an auxiliary traction winch, a first traction rope, a second traction rope, a third traction rope, a first puller, a second puller, an anchor gantry guide wheel set, a catwalk gantry guide wheel set, a tower top gantry guide wheel set, an anchor back gantry guide wheel set, a rotary wheel, an RFID electronic tag, an RFID card reader and afirst wireless communication terminal. The RFID card reader can send the encoded information of the read RFID electronic tag to the data processing center through the first wireless communication terminal, and the data processing center analyzes the encoded information and sends corresponding control instructions to the control module of the hoist room to control the hoist or the hoist to performcorresponding operation. The control system can realize the automatic monitoring of the puller and the automatic control of the puller without human manipulation and save the human cost.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

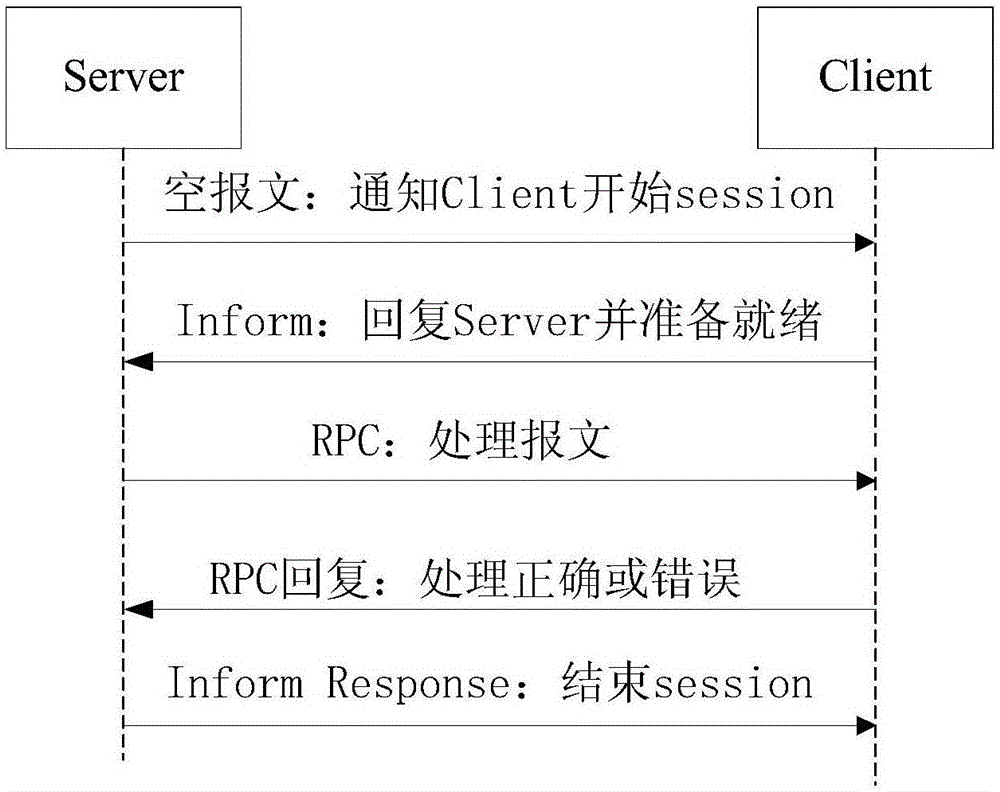

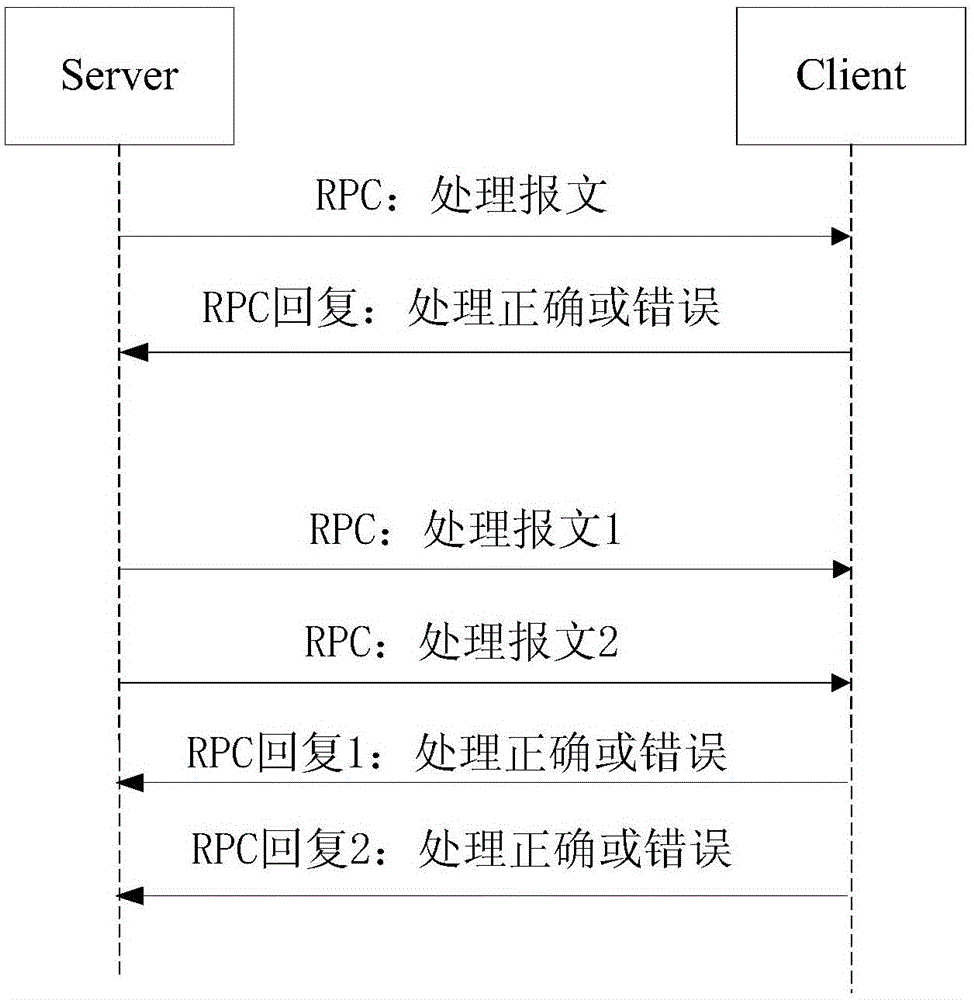

Method for processing messages

ActiveCN105119981AAvoid error proneImprove channel utilizationData switching networksClient-sideReal-time computing

The invention discloses a method for processing messages. The method for processing the messages is used for clients based on a Customer Premises Equipment (CPE) wide area network management protocol. The method includes the following steps that: S1, a long connection is established between the client and a server; S2, the client monitors whether data packets are transmitted in the long connection, if so, the step S3 is performed, otherwise the step S4 is performed; S3, the data packets are analyzed by the client, corresponding tasks are established according to analyzed results and are added to a pre-set queue, and then the step S2 is performed; and S4, the tasks in the queue are processed item by item according to the order of the queue by the client, processing results of the tasks are transmitted to the server, and then the step S2 is performed. The method for processing the messages avoids the case that a mistake is easily made in a message exchange process, and improves the utilization rate of channels.

Owner:湖州帷幄知识产权运营有限公司

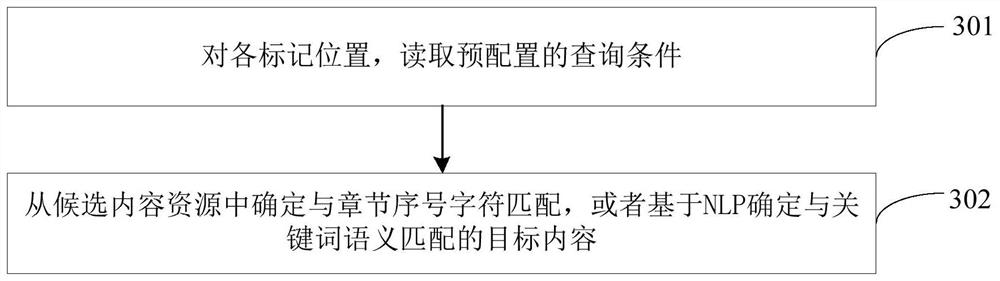

Document processing method and device combining RPA and AI, equipment and medium

PendingCN112560423AImprove processing efficiencyAvoid error-prone problemsDigital data information retrievalSemantic analysisEngineeringDocumentation

The invention provides a document processing method and device combining RPA and AI, equipment and a medium, and relates to the technical field of AI and RPA, and the method comprises the steps: querying target content meeting query conditions in candidate content resources by opening a template document and according to the query conditions configured by a plurality of mark positions contained inthe template document, so that the situation that errors are prone to occurring in the manual query process is avoided, further, the target content meeting the query condition is copied, the copied target content is pasted to the corresponding mark position in the template document to obtain the target document, the problem that errors are prone to occurring in the manual pasting process of a user is avoided, and the document processing efficiency is also improved.

Owner:BEIJING LAIYE NETWORK TECH CO LTD +1

Method for automatically executing tests and generating test reports on WEB page

The invention discloses a method for automatically executing tests and generating test reports on a WEB page. The method comprises the steps that (1) all elements needing to be tested on the WEB page are made into corresponding execution through redwood software; (2) a script is written through python software; (3) new items are constructed on jenkins software; and (4) the jenkins software is started and kept running. Through the method for automatically executing the tests and generating the test reports on the WEB page, computer resources can be reasonably utilized, sort-out of test results can be automatically completed, the sort-out difficulty of the test reports is lowered, and the accuracy, completeness and attractiveness of the test reports are improved.

Owner:丹露成都网络技术有限公司

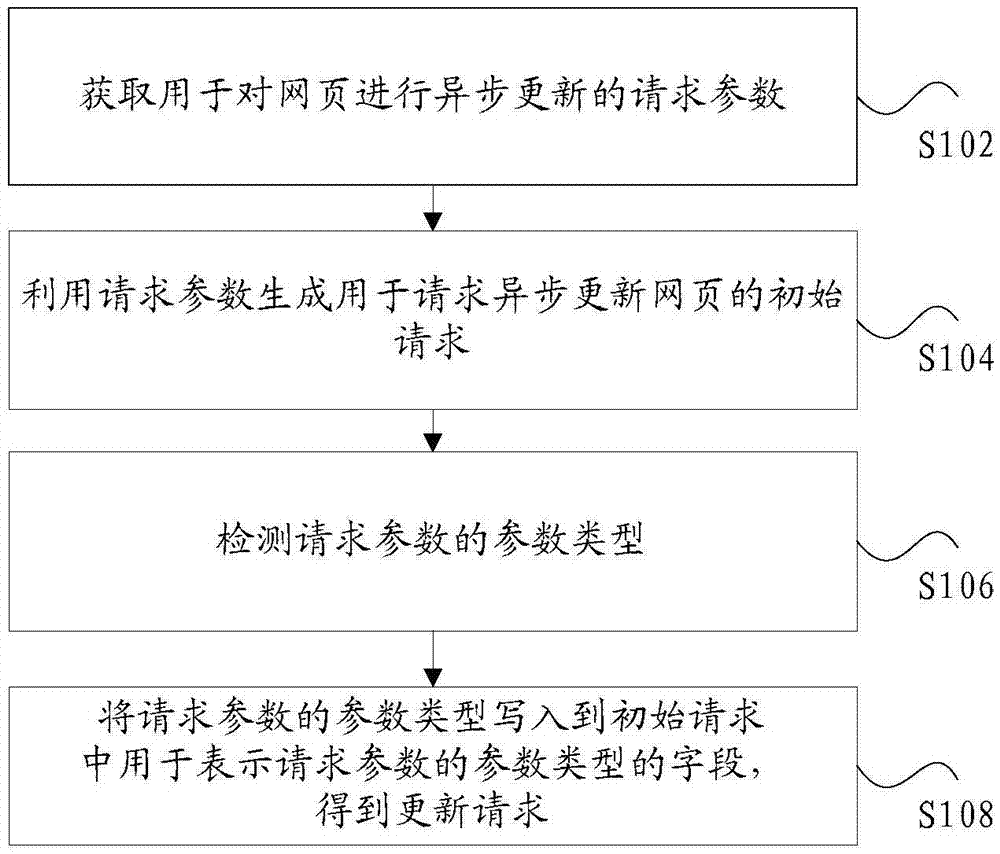

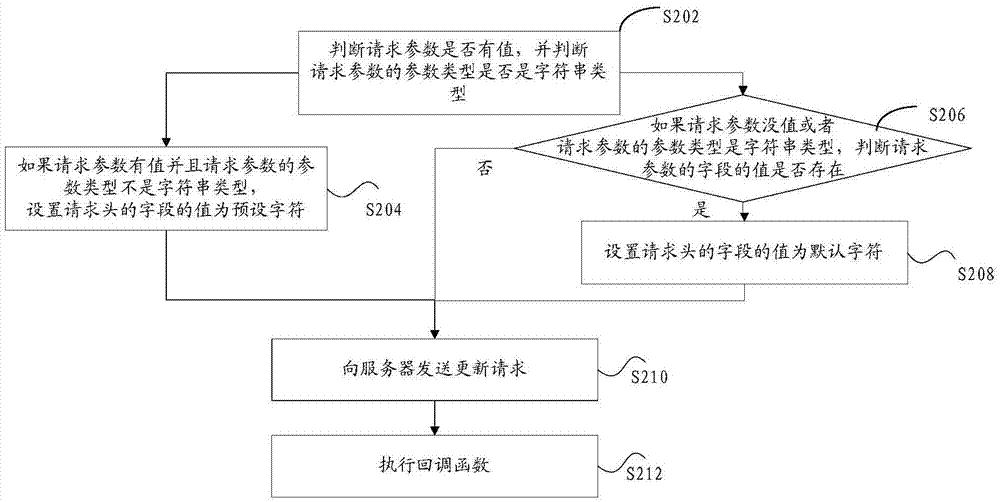

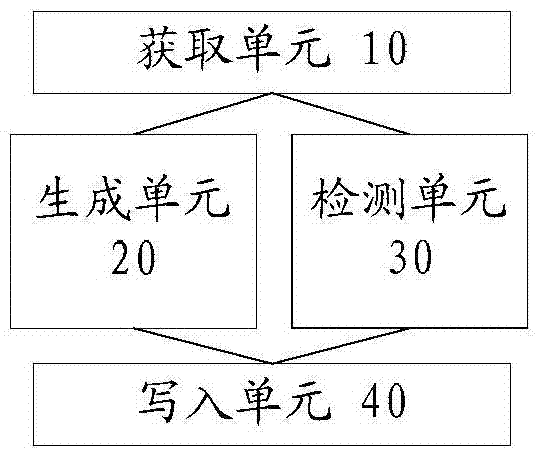

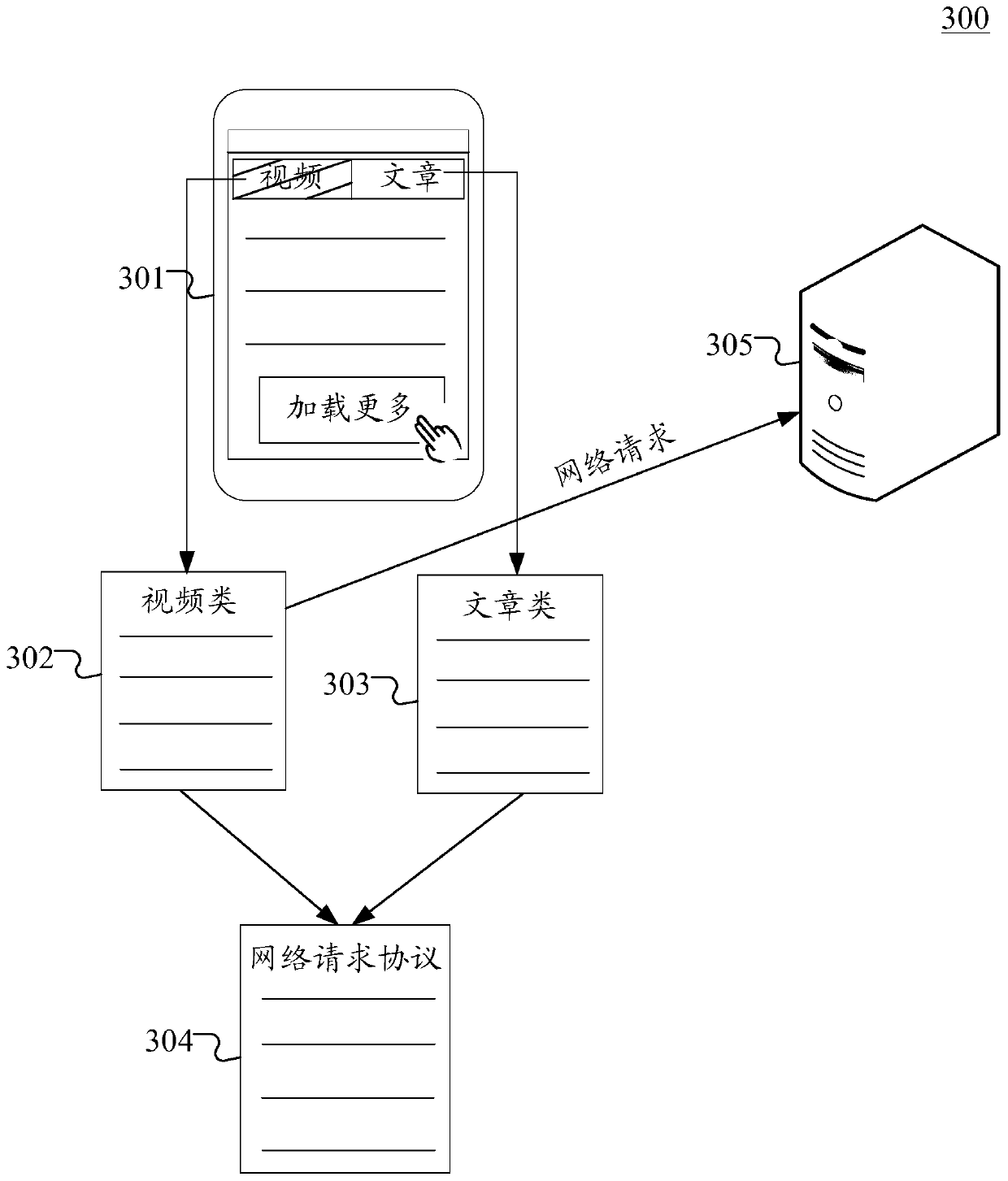

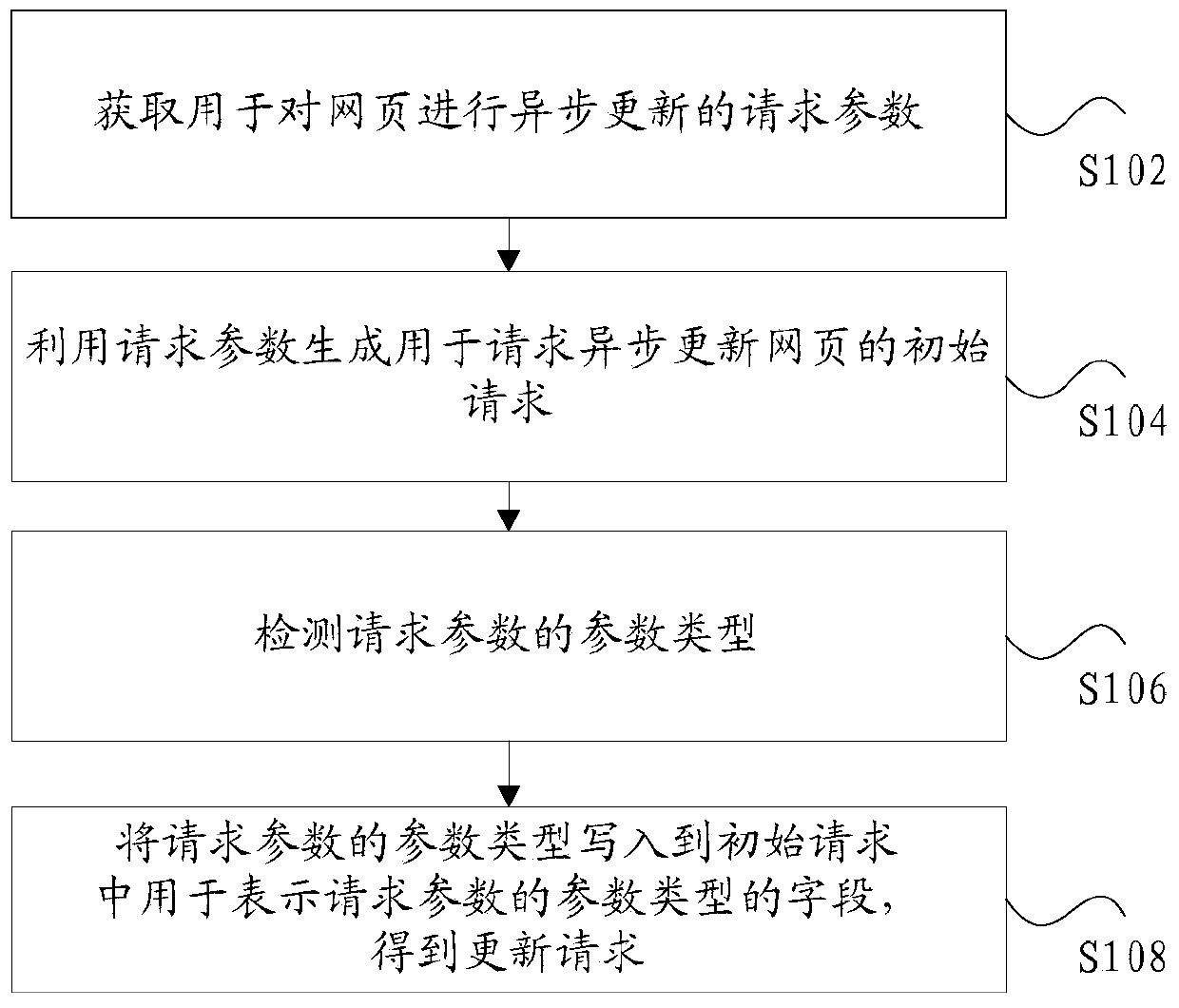

Webpage updating request generation method and apparatus

ActiveCN106933856ATroubleshoot error-prone technical issuesAvoid error-prone situationsWebsite content managementSpecial data processing applicationsData miningWeb page

Owner:BEIJING GRIDSUM TECH CO LTD

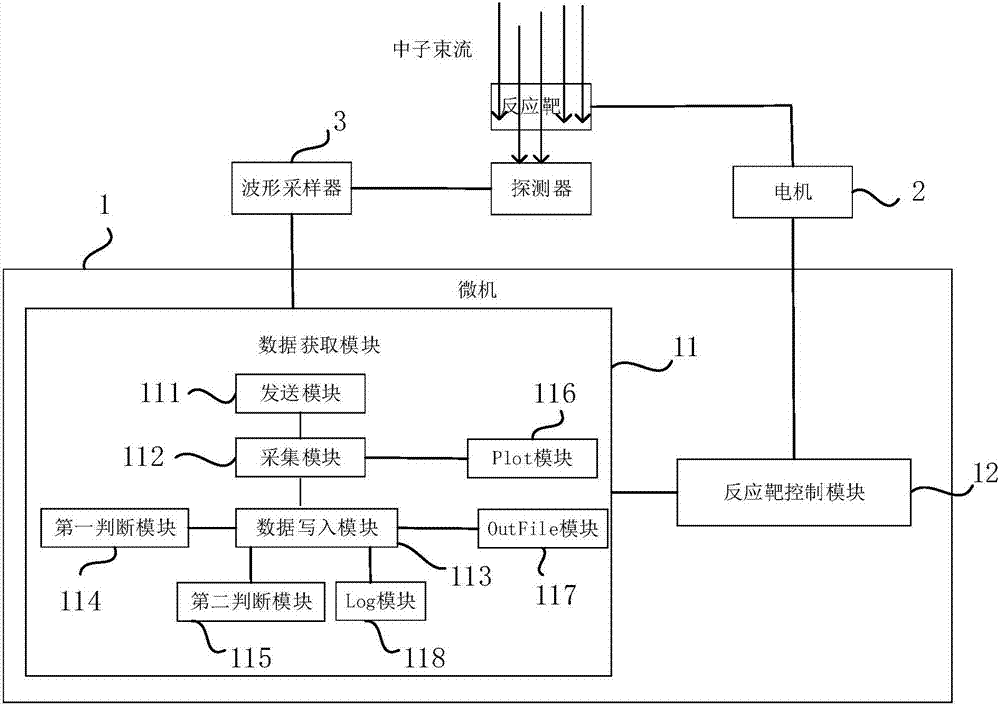

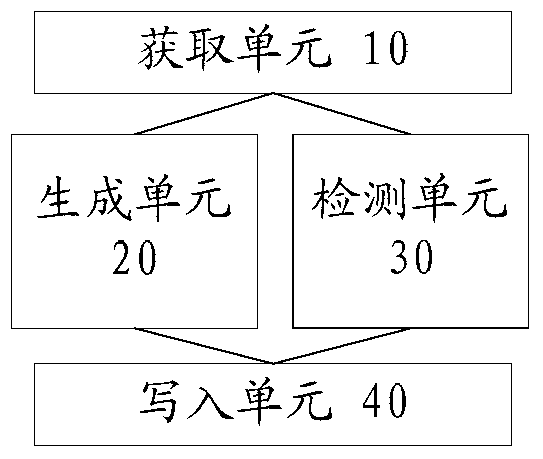

System for automatically obtaining data

ActiveCN107092200AAvoid error-prone situationsImprove data acquisition efficiencyProgramme control in sequence/logic controllersElectricityTarget control

The invention discloses a system for automatically obtaining data, and the system comprises a drive module, a data obtaining module, and an reaction target control module. The data obtaining module is in communication connection with the reaction target control module, and the reaction target control module is electrically connected with the drive module. The data obtaining module comprises a transmitting module, a collection module and a data writing-in module. The transmitting module is used for transmitting a target change signal to the reaction target control module. The reaction target control module is used for the all of the drive module after the target change signal, and transmits a feedback signal to the collection module after the drive module completes the target change. The collection module is used for collecting a waveform signal of particles, and the data writing-in module is used for writing the energy representation data of particles into a file, and carries out the call of the transmitting module. The system can automatically change the reaction target according to a preset sequence, automatically records a file formed by the data that the particles bombards the reaction target, avoids a problem that a mode of manually recording the cross-section data of particles is liable to cause an error, and improves the efficiency of data obtaining.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Numerical control machine tool capable of identifying workpieces and automatically inputting process parameters

PendingCN108663992AAutomate inputAvoid error-prone situationsNumerical controlMachine tool controlControl system

The invention provides a numerical control machine tool capable of identifying workpieces and automatically inputting process parameters, and belongs to the field of machine tools. The numerical control machine tool comprises a machine tool body, a machine tool control system, an OPS and a control panel, wherein the machine tool control system, the control panel and the OPS are arranged on the machine tool body, and plurality sets of workpiece identification codes and process parameters corresponding to each set of workpiece identification codes are stored in the machine tool control system. The numerical control machine tool further comprises a scanning device used for scanning the workpiece identification codes and transmitting the workpiece identification codes to the machine tool control system, wherein the scanning device is arranged on the machine tool body, the machine tool control system is electrically connected with the control panel and the OPS, and the OPS is electrically connected with the scanning device. According to the numerical control machine tool, process parameter input errors can be avoided, and the working efficiency is high.

Owner:DONGGUAN GOODA MASCH MFG CO LTD

Hot work ticket management system

ActiveCN109858819AAchieve productionAvoid error-prone situationsOffice automationResourcesHot workAlarm trigger

The invention aims to provide a management system of a hot work ticket, which gets rid of the use of a paper hot work ticket and can realize the management of equipment and personnel in the hot work ticket, and comprises an operation system used for creating the hot work ticket according to a hot work plan and performing SHE auditing on the hot work ticket; a mobile terminal which searches for thehot work content matched with the hot work plan, selects the relevant information of the matched hot work content and inputs the relevant information into the hot work ticket, inputs the hot work information in the hot work process into the hot work ticket in real time, uploads the work ticket with the input hot work information to the management and control platform; and positioning cards whichare respectively used for positioning personnel and equipment in the hot work process, and communicate with the management and control platform to report positioning information of the personnel andthe equipment, and when the personnel or the equipment carrying the positioning card meets an alarm triggering condition, the management and control platform gives an alarm.

Owner:重庆真趣信息科技有限公司

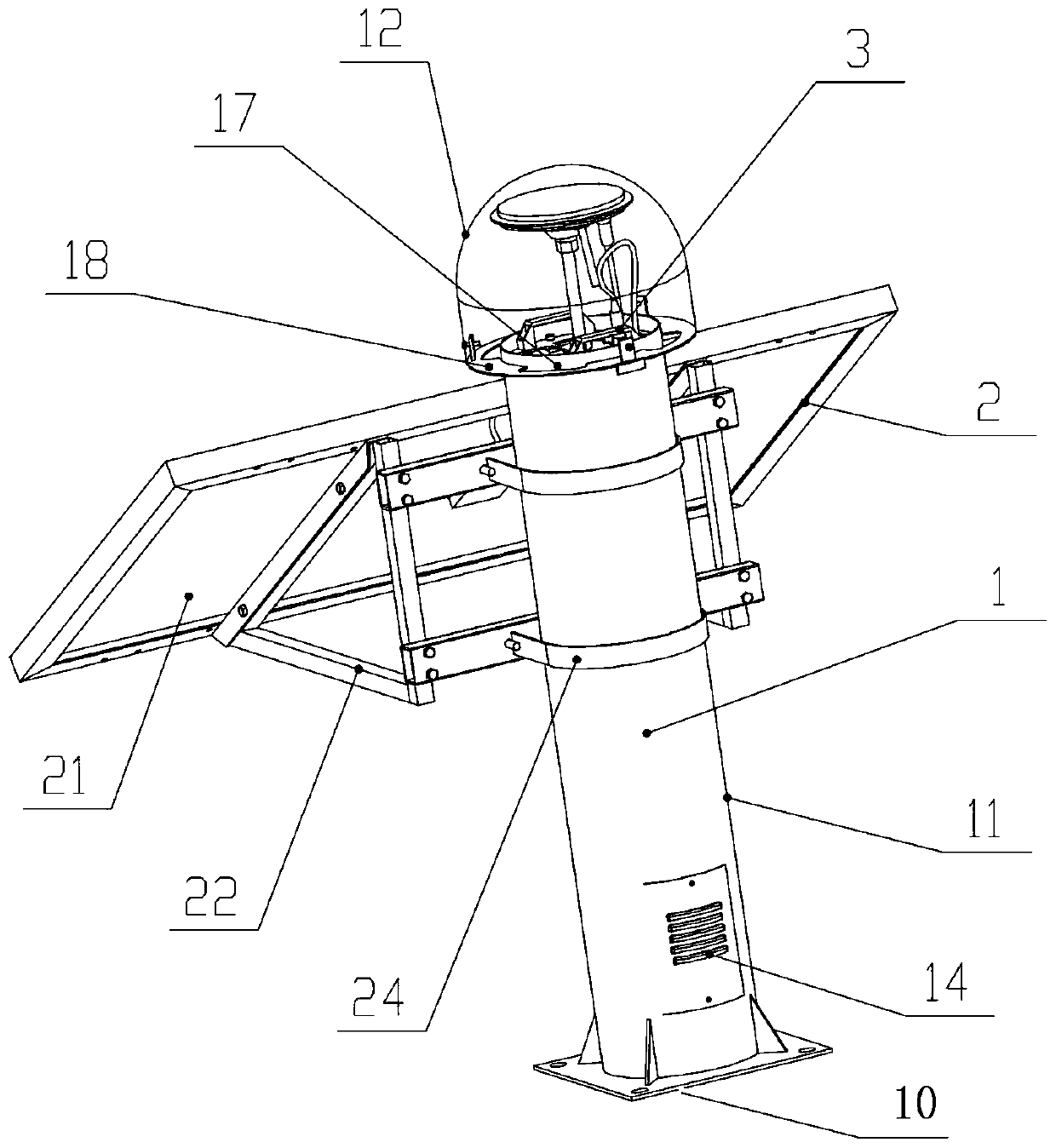

Mounting device of side slope deformation monitoring device

PendingCN109751951AImprove space utilization efficiencyEquipment security is guaranteedBatteries circuit arrangementsAntenna supports/mountingsEngineeringMoisture

The invention discloses a mounting device of a side slope deformation monitoring device. The mounting device of the side slope deformation monitoring device comprises three parts: a shell part, a detachable core component and a photovoltaic power generation component, wherein each part is independent of each other and can form an entirety by itself, and can be transported independently and installed conveniently; the mounting device of the side slope deformation monitoring device can be assembled quickly through bolts during on-site construction, therefore, the problems of difficult transportation and difficult installation are effectively solved; wherein the detachable core component is designed as a mode that an upper pulling plate and a lower pulling plate clamp a mounting plate; a wiring duct and a line bank are arranged on one side of the mounting plate, and monitoring components are centralizedly arranged on the other side of the mounting plate, so that the monitoring componentscan be arranged on the mounting plate in a standardized and unified manner, which facilitates the early installation and debugging of the monitoring components, and greatly improves the work efficiency; meanwhile, the detachable core component has normative wiring and neat appearance, which is easy for later inspection and maintenance; in addition, the outer shell cylinder is provided with a special heat-dissipating and moisture-proof design, which effectively ensures the working proper humidity and heat dissipation effect of the monitoring components.

Owner:HUNAN LIANZHI MONITORING TECH CO LTD

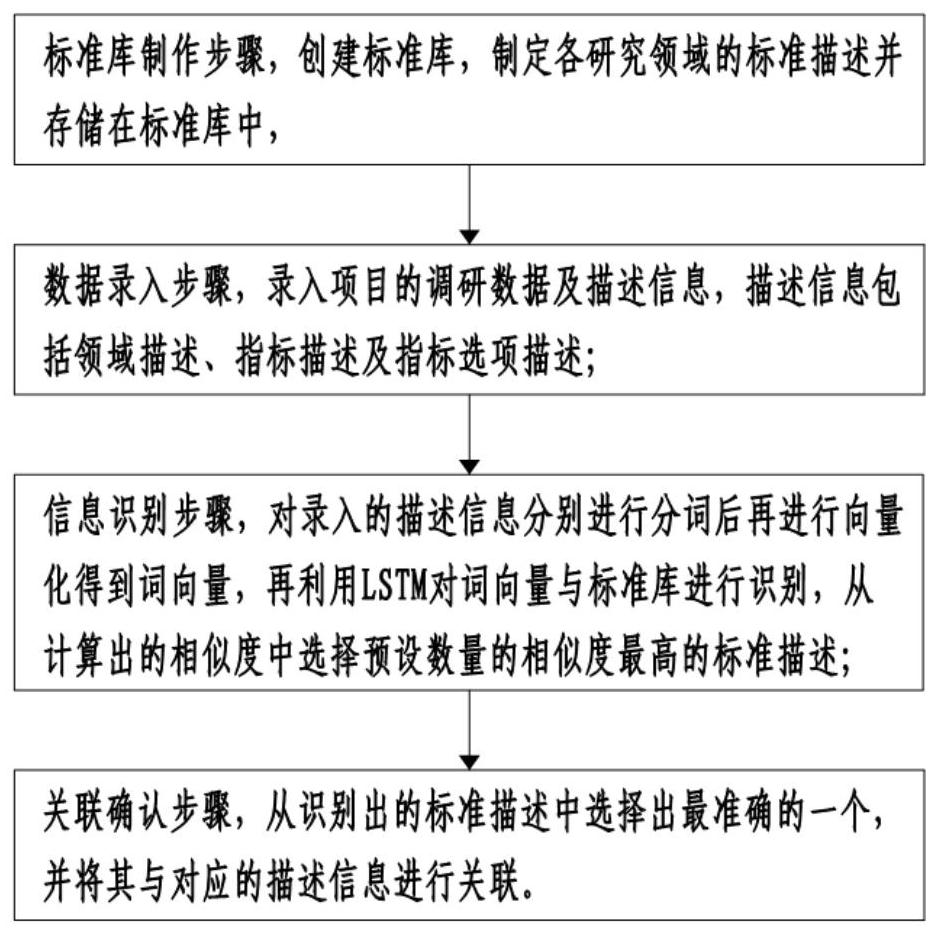

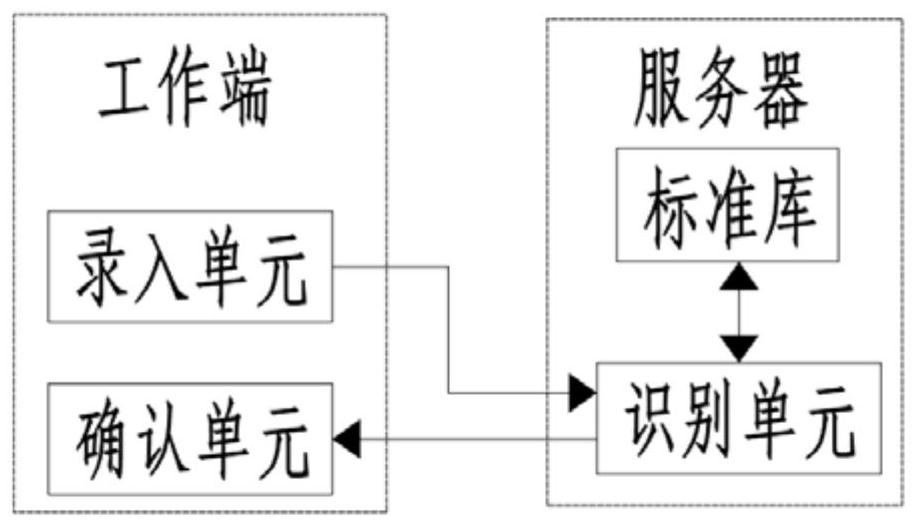

NLP-based research data standardization method and system

ActiveCN113326310ALower requirementImprove efficiencyDatabase management systemsSemantic analysisResearch dataEngineering

The invention belongs to the field of data processing, and particularly relates to an NLP-based research data standardization method and system. The method comprises the following steps: a standard library manufacturing step: creating a standard library, formulating standard descriptions of various research fields and storing the standard descriptions in the standard library, the standard descriptions comprising research field standard descriptions, index standard descriptions and index option standard descriptions; a data input step: inputting survey data and description information of the project, the description information including field description, index description and index option description; an information identification step: carrying out word segmentation on the input description information, then carrying out vectorization to obtain word vectors, carrying out identification on the word vectors and a standard library by utilizing LSTM, and selecting a preset number of standard descriptions with the highest similarity from the calculated similarities; and an association confirmation step: selecting the most accurate one from the identified standard descriptions, and associating the most accurate one with the corresponding description information. According to the method, the processing accuracy can be ensured while the processing efficiency is ensured.

Owner:立信(重庆)数据科技股份有限公司

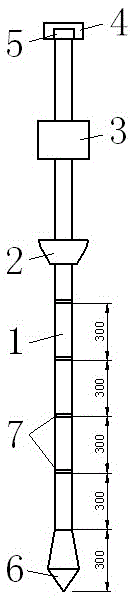

A method for recording drilling depth and hammering times and drilling device

ActiveCN103835276BAvoid error-prone situationsEasy to masterIn situ soil foundationEngineeringHammer drill

The invention discloses a method for recording drilling depth and hammering times and a drilling device. The method is to install a hammering sensor on a drilling rod, and a heavy hammer Each When the hammer sensor is hit once, the counter set on the top of the drill rod will record once; a group of infrared emitters are installed at intervals on the drill rod, and when the probe at the bottom of the drill rod enters the ground and reaches an interval depth under the hammer, the set The infrared alarm on the top of the drill rod immediately alarms because it cannot receive the signal from the infrared emitter, and reminds the operator to record the number of hammer strikes at the penetration depth in time through the alarm sound; it avoids manually looking at the scale and counting the number of strikes Insufficient errors are prone to occur. The present invention is novel in concept, small in size, light in weight, compact in structure, convenient in transportation, fast in machine transfer, safe and reliable, convenient in maintenance, simple in operation and easy to master.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method and device for sending network request

Embodiments of the present disclosure disclose methods and apparatuses for sending network requests. A specific implementation manner of the method includes: determining whether a user request indicating to send a target network request is detected, wherein the target network request belongs to a preset network request set; in response to determining that the user request is detected, determining the target network request to be sent The class to which the requested object belongs, wherein the determined class follows the network request protocol or the network request interface, wherein the network request protocol or the network request interface is used to encapsulate the method for sending the network request in the network request set; through the determined The class calls its corresponding method for sending a target network request to send a target network request. This implementation mode helps to improve the convenience of sending network requests.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

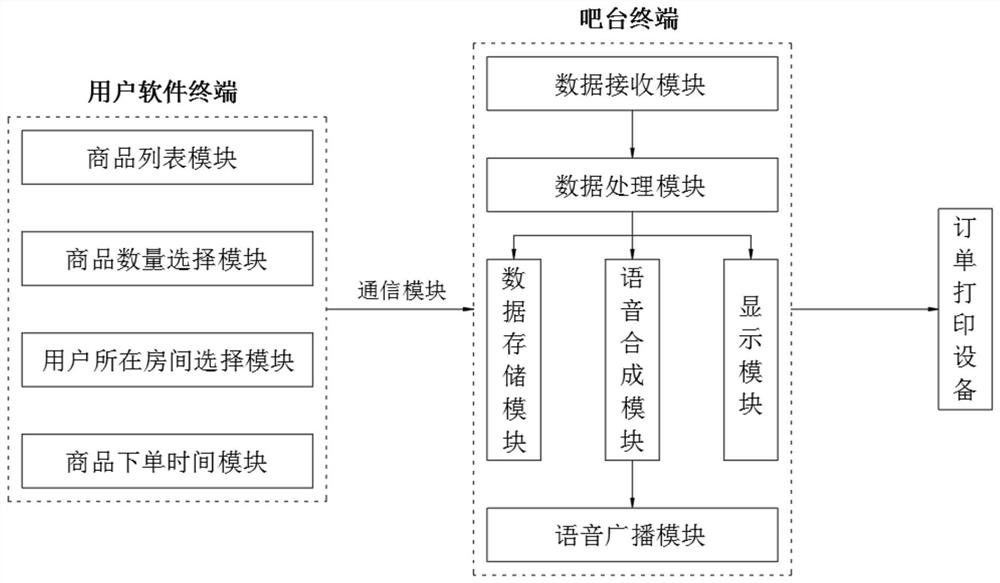

Commodity order printing and calling system

PendingCN114119134AEasy to checkRapid responseParticular environment based servicesBuying/selling/leasing transactionsTime informationTerminal equipment

The invention relates to the technical field of online consumption, and discloses a commodity order printing and calling system which comprises a user software terminal and a bar counter terminal. The user software terminal comprises a commodity list module used for commodity selection, a commodity quantity selection module used for commodity quantity selection, a user room selection module used for selecting a room number of a user, and a commodity ordering time module used for recording commodity ordering time. According to the invention, through the user software terminal, the user can directly select and place an order on the terminal device for the required commodities, the number of the commodities and the room where the user is located, and then the terminal device records the order placing time of the user and sends the demand of the user and the order placing time information to the bar counter terminal together. And after receiving the information, the bar counter terminal displays the information and broadcasts the requirements of the user, so that bar counter personnel can quickly respond.

Owner:长沙时代跳动科技有限公司

Cloth cutting device for garment production

InactiveCN112095331AMeet the needs of actual productionAvoid error-prone situationsSevering textilesEngineeringMechanical engineering

The invention relates to the technical field of clothing, and discloses a cloth cutting device for garment production. The cloth cutting device comprises a workbench, wherein a supporting rod is fixedly connected to the outer part of the workbench, lead screws I are movably connected to the outer part of the supporting rod, moving blocks I are movably connected to the outer parts of the lead screws I, and a cutting assembly is movably connected to the outer parts of moving blocks I. A rotating shaft is movably connected to the inner part of the workbench, a rotating disc is fixedly connected to the outer part of the rotating shaft in a sleeving mode, electromagnets are fixedly connected to the inner part of the rotating disc, and springs I are movably connected to the inner part of the rotating disc in a sleeving mode. Through interaction of the lead screws I, the moving blocks I, the rotating shaft, the rotating disc, a clamping rod, the springs I, the electromagnets, an iron block, afirst gear, a contact rod I and a stop rod, the cutting position of cloth can be adjusted during cloth cutting, fixed-distance cutting can be performed on the cloth according to the size requirement,the actual production requirement is met, and the condition that errors are easy to occur during manual measurement is also avoided.

Owner:广州麦火文化传媒有限公司

A method and device for detecting subtitle clarity

ActiveCN107846622BClarity detectionImprove user experienceTelevision system detailsColor television detailsComputer graphics (images)Algorithm

The embodiment of the invention provides a method and device for detecting subtitle definition. The method comprises the steps of obtaining a video file of to-be-identified subtitles, carrying out analysis to obtain a picture of each frame in the video file, and storing the picture of each frame to a queue corresponding to the video file; identifying the total character string length and the totalcharacter number in each picture through an OCR algorithm and calculating a first ratio of the total character string length and the total character number in each picture; comparing each first ratiowith a preset ratio threshold and determining a weight value of each first ratio; and determining the number of the weight values smaller than the preset ratio threshold in the weight values of the first ratios, calculating a second ratio of the number and the total number of the second ratios, and judging whether a subtitle display effect of the video file is qualified or not according to the calculated second ratio. Through application of the method and the device, the definition degree of the subtitles in the video file can be detected rapidly and conveniently.

Owner:BEIJING THUNDERSTONE TECH CO LTD

Gear M-value rapid diameter measuring jaw linkage mechanism

ActiveCN102889841BAvoid error-prone situationsReduce production and operating costsMechanical diameter measurementsEngineeringLinkage concept

The invention relates to a gear M-value rapid diameter measuring jaw linkage mechanism which is characterized by comprising a base plate, wherein a clamp support is installed at one end of the base plate and is provided with a clamp; a first hole of a first sliding block is internally provided with a summation and difference rod; the first sliding block is provided with a first sliding groove installation moving measuring rod device; a first pressing spring fixed seat is provided with a first spring device; a second guide rail is slidingly connected with a second sliding block; the second sliding block is provided with a second sliding groove installation fixed measuring rod device; second pressing spring fixed seats are installed on the base plate; a second spring device is arranged between the second pressing spring fixed seats; the second sliding block is threadedly connected with a clipping body; the clipping body is provided with a measuring device; and a connecting rod device is installed at the middle of the base plate. The gear M-value rapid diameter measuring jaw linkage mechanism provided by the invention is simple to operate, and is intuitive in reading, data is accurate, and the situation that the matched measurement of a clipping ruler and a measuring ball causes error easily is prevented; and the manufacturing cost is low, and the enterprise production operation cost can be lowered.

Owner:WUXI MEASURE MACHINE MFR

A management system for hot work tickets

ActiveCN109858819BAchieve productionAvoid error-prone situationsOffice automationResourcesHot workManagement system

The present invention aims to provide a management system for hot work tickets, which can get rid of the use of paper hot work tickets, and at the same time realize the management of equipment and personnel in hot work tickets, including: an operation system for The hot work plan creates a hot work ticket, and conducts SHE audit on the hot work ticket; the mobile terminal searches for the hot work content that matches the hot work plan, and selects the relevant information of the matching hot work content to enter into the hot work Work ticket, the mobile terminal enters the hot work information in the hot work process into the hot work ticket in real time; the mobile terminal uploads the work ticket entered with the hot work information to the management and control platform; the positioning card is used for the dynamic For the positioning of personnel and equipment during fire operations, the positioning card communicates with the management and control platform to report the positioning information of personnel and equipment. When the personnel or equipment carrying the positioning card meets the alarm trigger conditions, the management and control platform sends out an alarm.

Owner:重庆真趣信息科技有限公司

A Method for Precisely Locating Defects on Materials in Ultrasonic Testing

ActiveCN104730145BAchieve precise associationReduce positioning errorsAnalysing solids using sonic/ultrasonic/infrasonic wavesWater immersionBeam scanning

The invention relates to a method for accurately positioning the defects of a material during ultrasonic detection. The method comprises the following steps: firstly, establishing a reference position on a water-immersion based ultrasonic C scanning detection system, and calibrating the coordinate of the reference position in an ultrasonic probe acoustic-beam scanning position coordinate system; then putting the material to be detected in the reference position of the detection system through a positioning reference plane processed on the material to be detected, and carrying out ultrasonic C scanning detection, determining the accurate coordinates of all the defects in the ultrasonic probe acoustic-beam scanning position coordinate system on an ultrasonic C scanned image by using the defect searching function of the water-immersion based ultrasonic C scanning detection system, and deducting the coordinates of the detects on the ultrasonic C scanned image from the coordinate of the reference position on the water-immersion based ultrasonic C scanning detection system to obtain the accurate coordinates of the defects on the positioning reference plane processed on the material to be detected; and finally combining the coordinates of the defects on the positioning reference plane processed on the material to be detected with the depths of the defects read by an ultrasonic defect detection unit on the ultrasonic detection surface of the material to be detected to form the three-dimensional spacial position coordinates of the defects in the material to be detected.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Quartz ring product thickness measuring device

PendingCN112013745AMaintain accuracy and stabilityImprove convenienceMechanical thickness measurementsMechanical engineeringQuartz

The invention discloses a quartz ring product thickness measuring device. The device comprises a bottom plate, a main rod, a placing plate, a measuring plate, a pressing plate and a limiting plate, wherein the top of the bottom plate is connected with the main rod in a welding manner, the top of the bottom plate is connected with the measuring plate in an embedding manner, the outer part of the main rod is connected with the placing plate in a sleeving manner, the bottom of the placing plate is fixedly connected with a spring, and the outer part of the main rod is provided with a spring. According to the quartz ring product thickness measuring device, the main rod, the placing plate and the measuring plate are combined together, so that the problem that data errors are easy to occur due topoor stability during measurement of traditional quartz ring products is well solved, the stability and accuracy during measurement can be kept, the convenience during measurement is greatly improved, the overall structure is simple, the situation that errors are prone to occurring is avoided, measurement work can be completed only by placing quartz ring products on the placing plate and then pressing the pressing plate downwards, and the flexibility is high.

Owner:江苏富乐德石英科技有限公司

Method and device for generating web page update request

ActiveCN106933856BTroubleshoot error-prone technical issuesAvoid error-prone situationsWebsite content managementSpecial data processing applicationsTheoretical computer scienceEngineering

Owner:BEIJING GRIDSUM TECH CO LTD

Software testing method and system and testing platform

ActiveCN107608873BImprove accuracyLower performance requirementsSoftware testing/debuggingTest platformWorkload

The invention discloses a software testing method, system and testing platform, wherein the method includes the following steps: automatically generating a test case analysis and execution program source file according to the software to be tested, and compiling the test case analysis and execution program source file to generate an executable file; burn the executable file into the operating platform of the software under test; send the preset test case corresponding to the software under test to the executable file, and execute the test case by the executable file to test the software under test; Receive and save the execution result after the executable file executes the test case. By automatically generating test case analysis and execution program source files according to the software under test, it is no longer necessary for testers to manually write source files, which effectively reduces the workload of testing and reduces the difficulty of testing. Ultimately, the traditional software module interface testing method has certain limitations and low efficiency.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

A system that automatically captures data

ActiveCN107092200BAvoid error-prone situationsImprove data acquisition efficiencyProgramme control in sequence/logic controllersComputer hardwareTarget control

The invention discloses a system for automatically obtaining data, and the system comprises a drive module, a data obtaining module, and an reaction target control module. The data obtaining module is in communication connection with the reaction target control module, and the reaction target control module is electrically connected with the drive module. The data obtaining module comprises a transmitting module, a collection module and a data writing-in module. The transmitting module is used for transmitting a target change signal to the reaction target control module. The reaction target control module is used for the all of the drive module after the target change signal, and transmits a feedback signal to the collection module after the drive module completes the target change. The collection module is used for collecting a waveform signal of particles, and the data writing-in module is used for writing the energy representation data of particles into a file, and carries out the call of the transmitting module. The system can automatically change the reaction target according to a preset sequence, automatically records a file formed by the data that the particles bombards the reaction target, avoids a problem that a mode of manually recording the cross-section data of particles is liable to cause an error, and improves the efficiency of data obtaining.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com