Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

707results about "Mixing liquids with solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

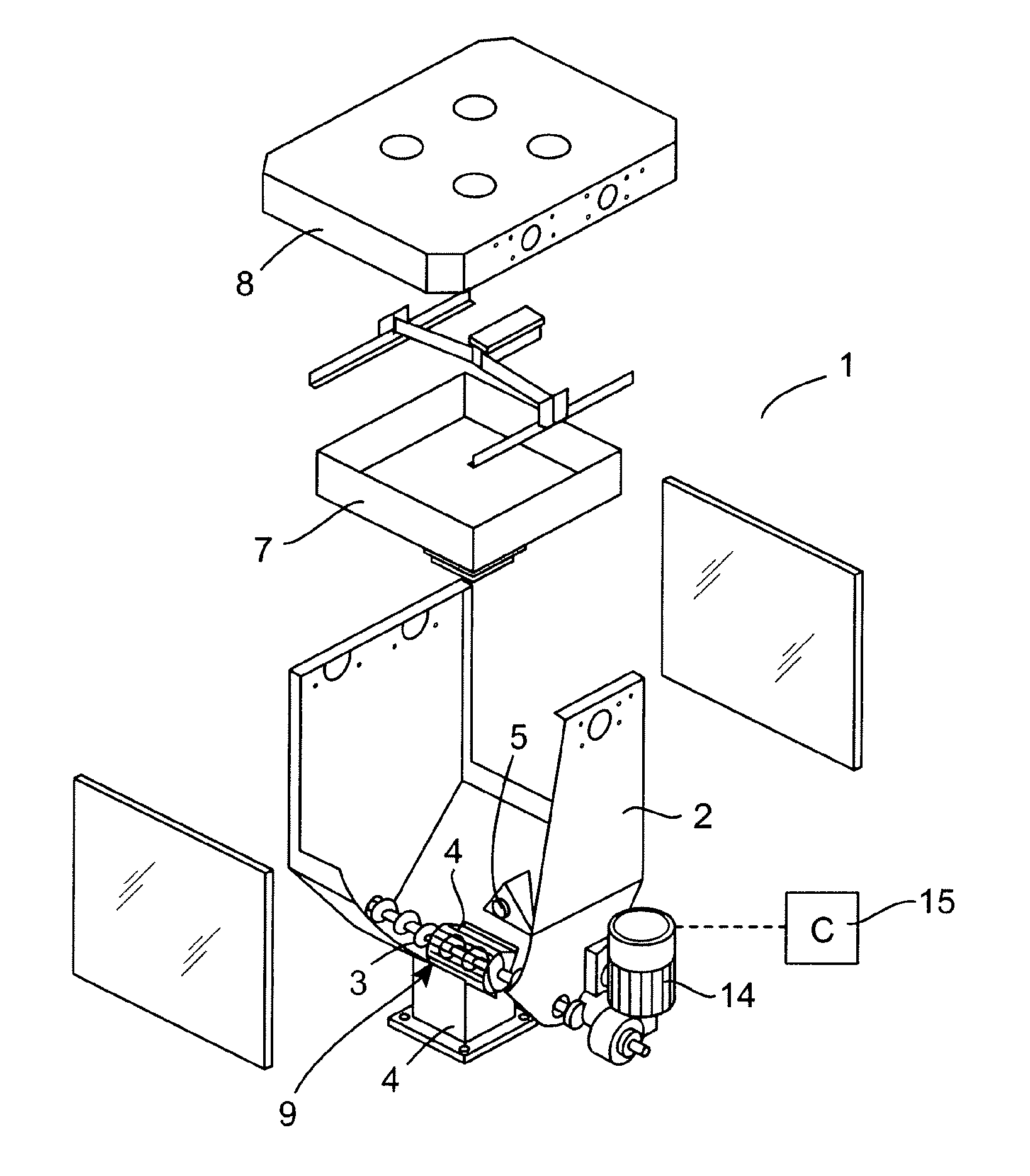

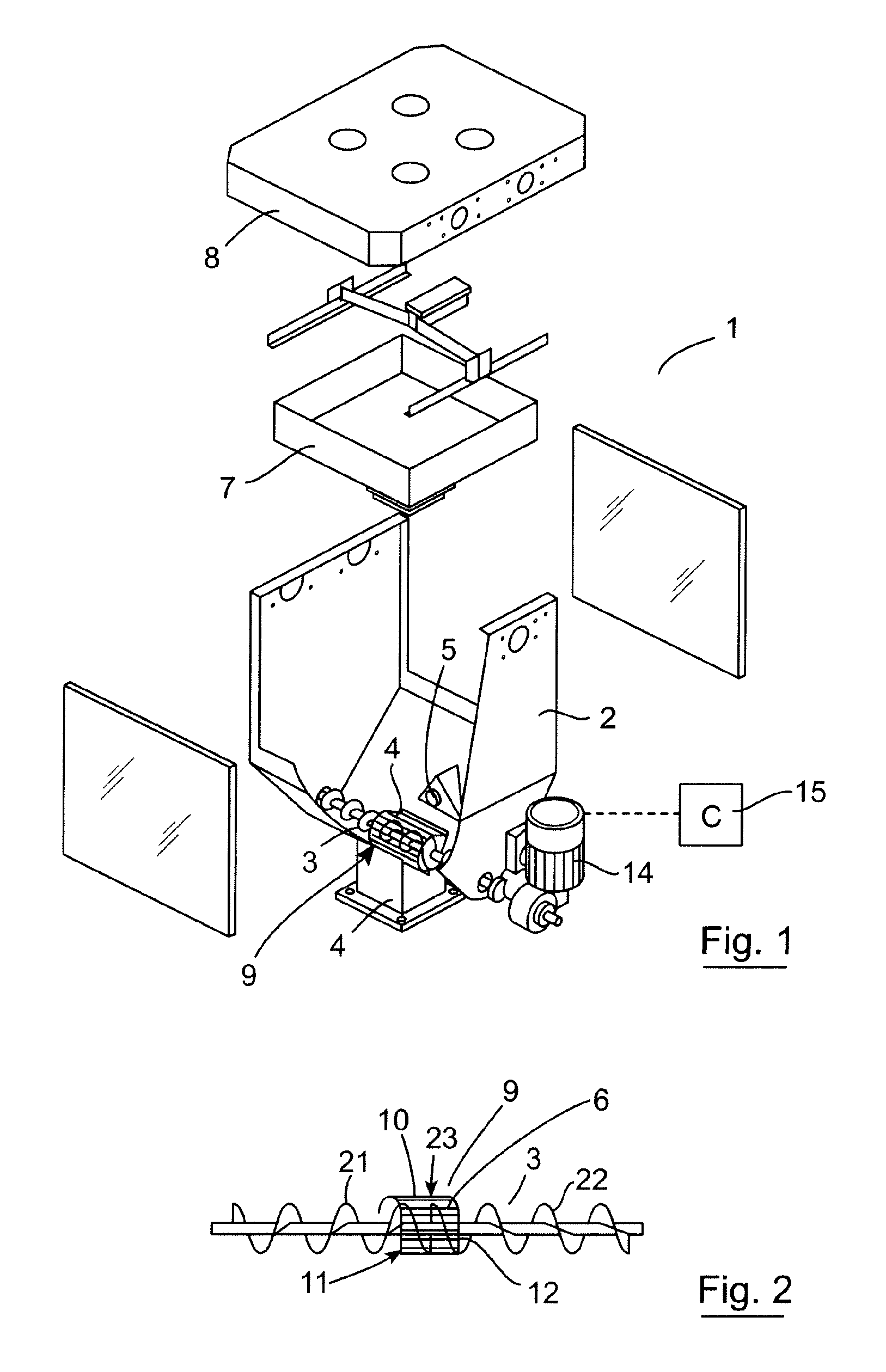

Dry additive and fluid mixing system, assembly and method

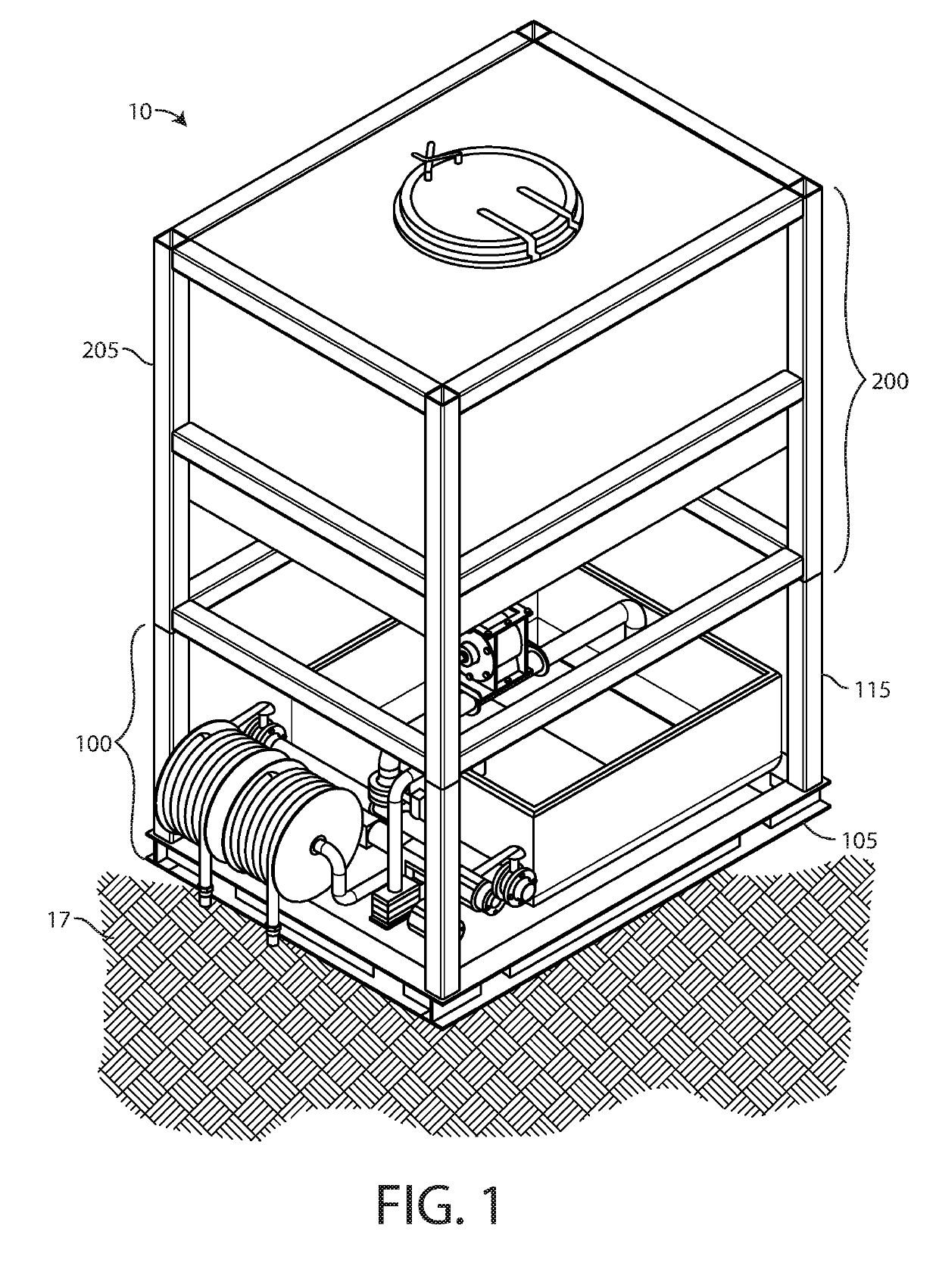

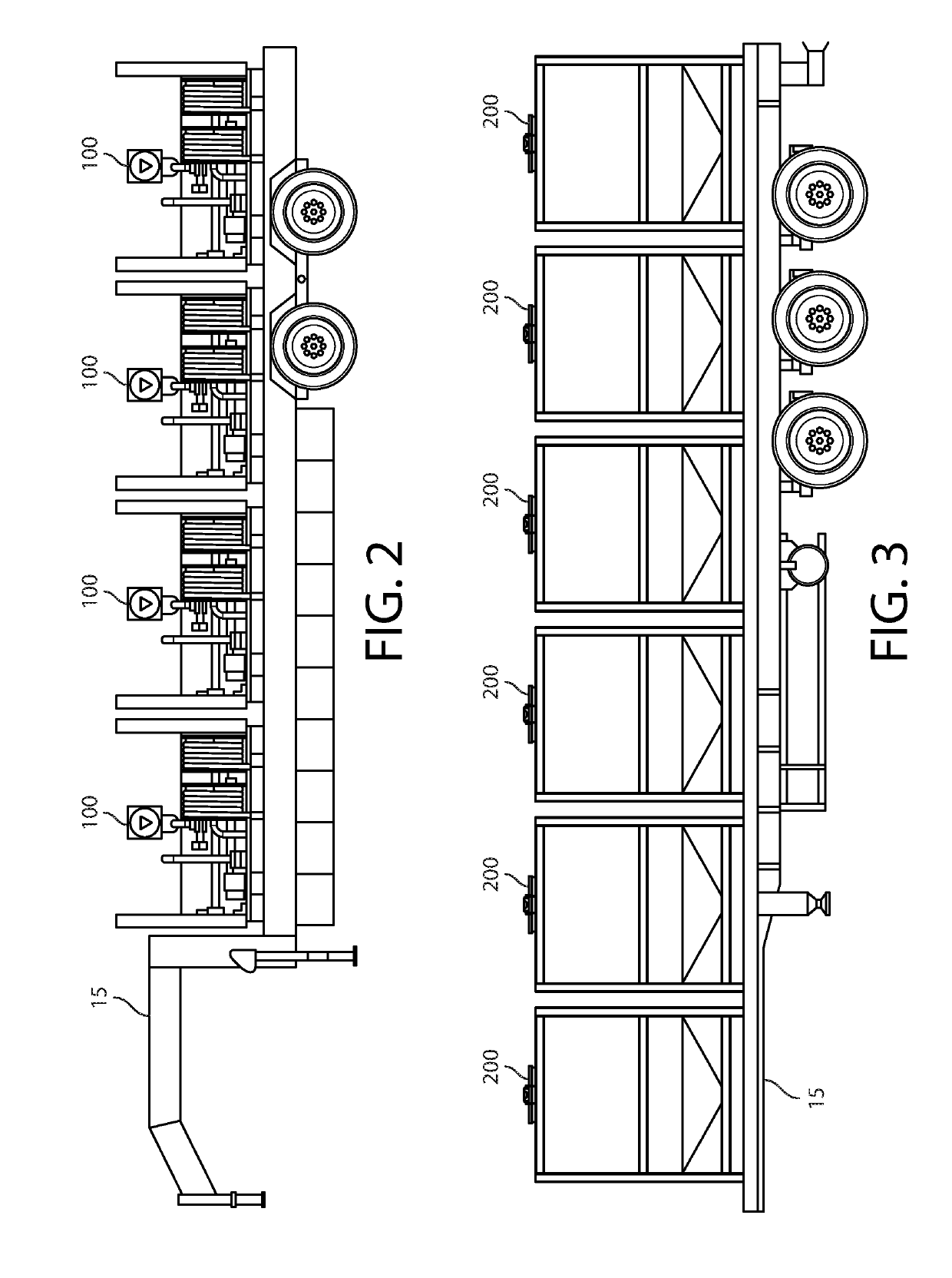

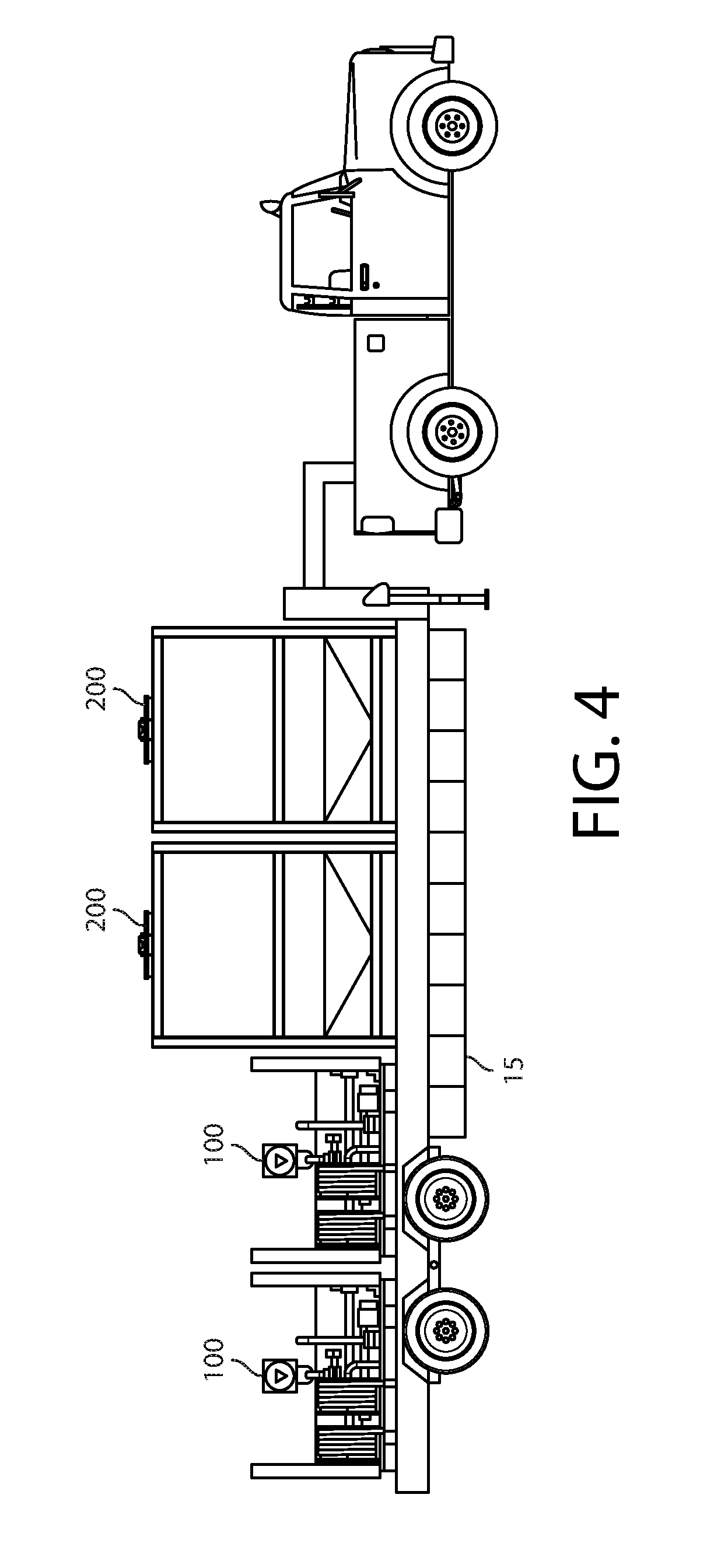

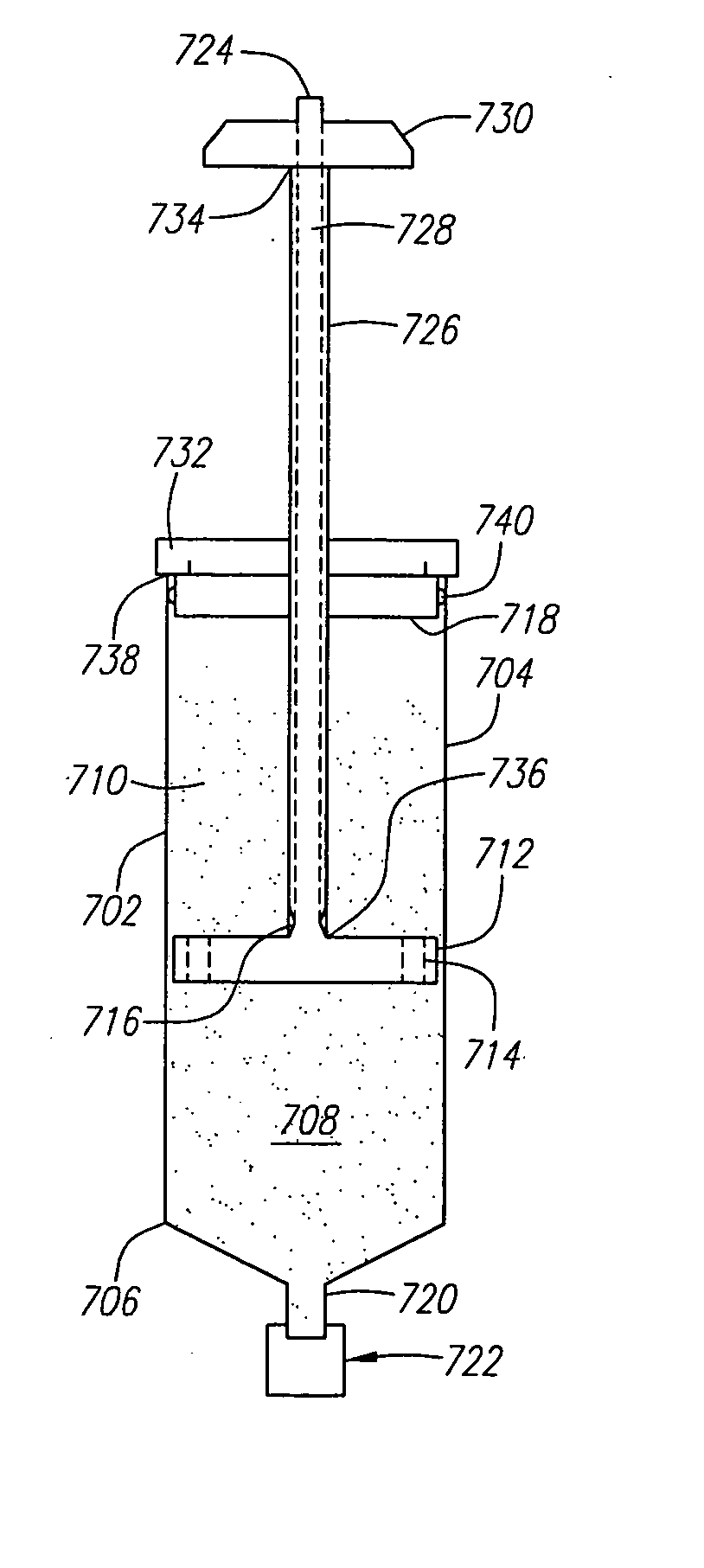

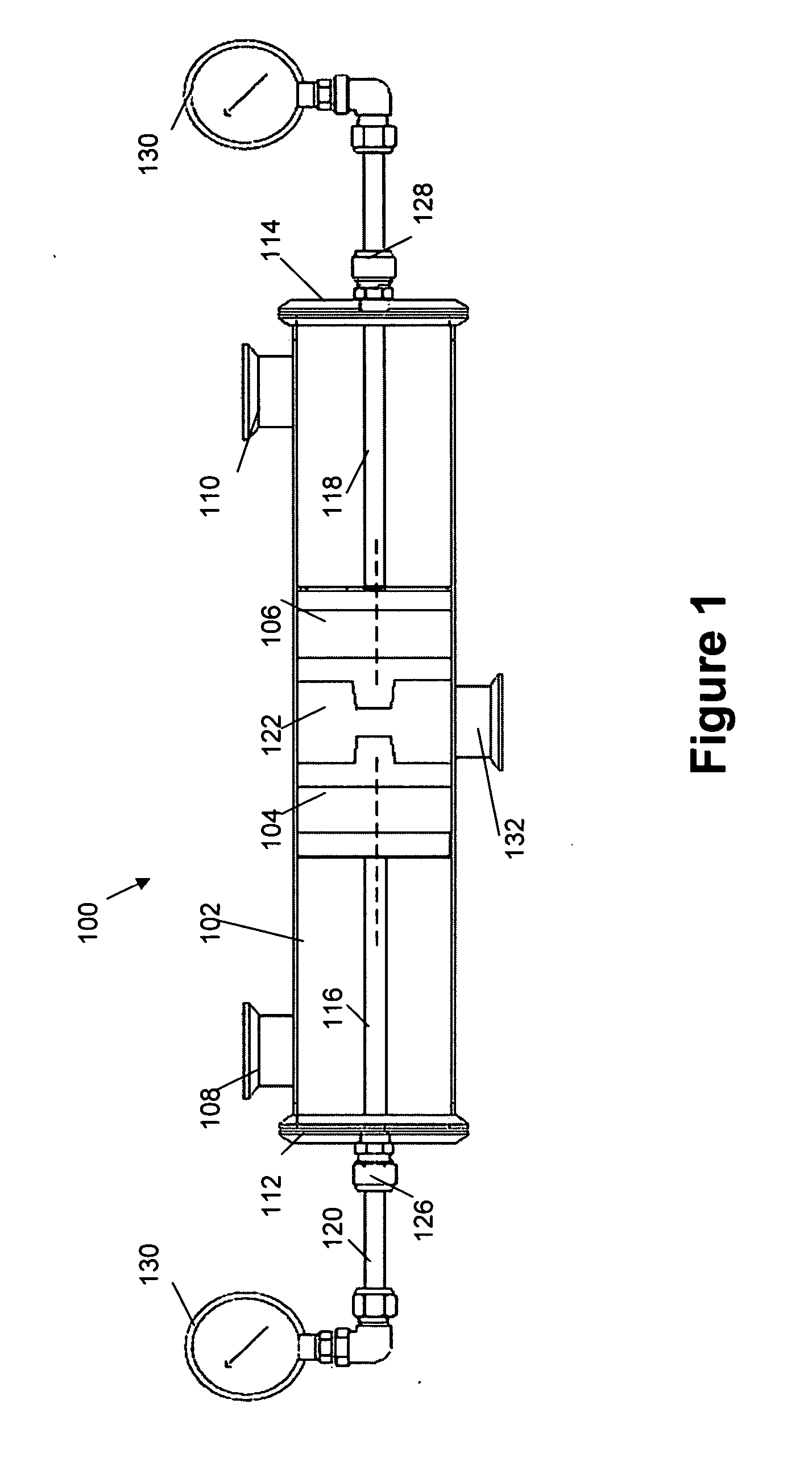

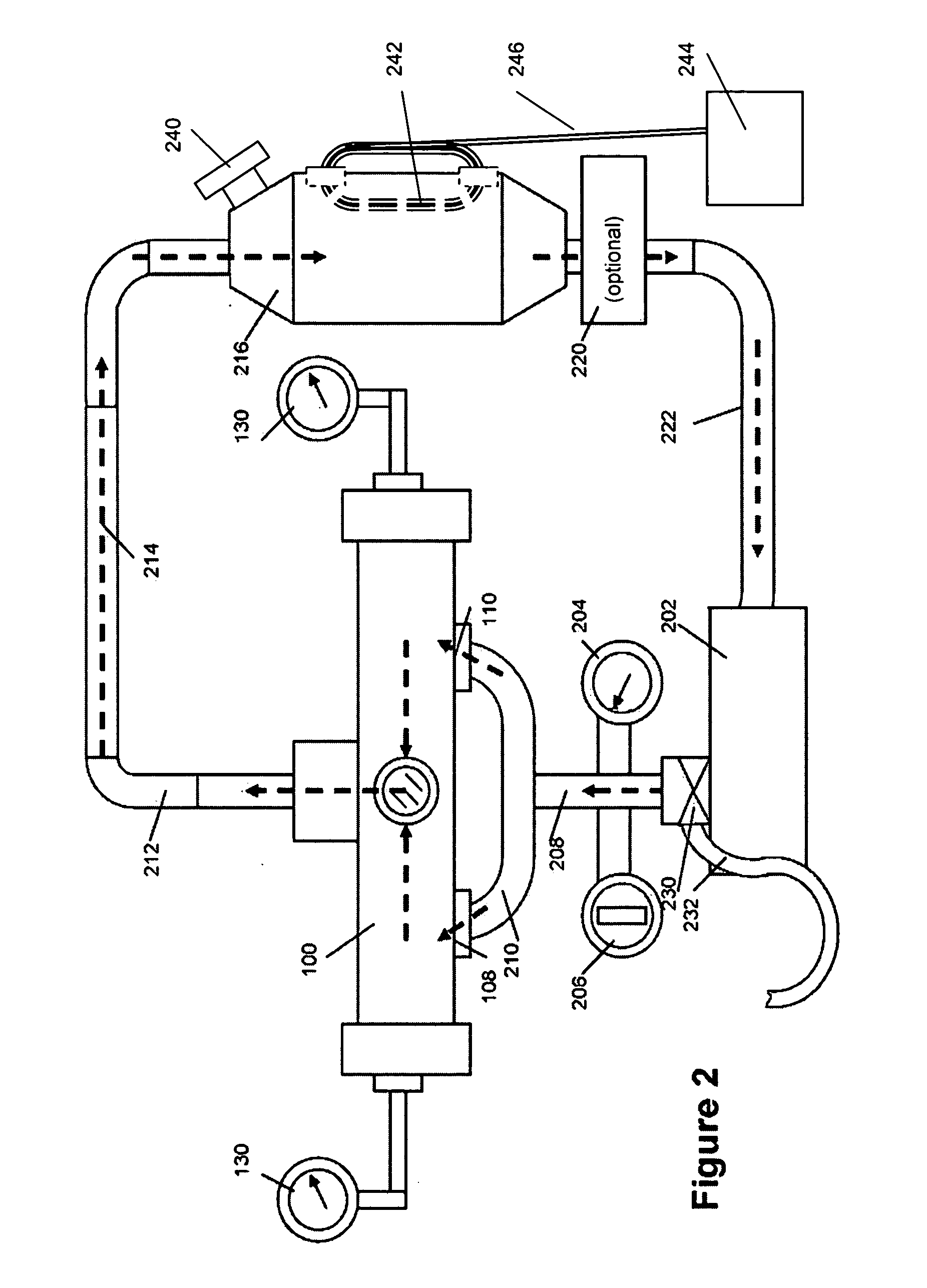

The application is directed to a system and method for mixing fluid and dry material to produce fluid mixture compositions. The system may be provided on a portable platform for transport of the system for use at different locations or the system may be provided as a permanent installation. The system includes a first module for receiving fluid into the system and an optional second module attachable to the first module for providing dry material to be mixed with the fluid received into the system. The fluid mixture compositions produced by the system can be conveyed out from the system to one or more target locations.

Owner:MGB OILFIELD SOLUTIONS LLC

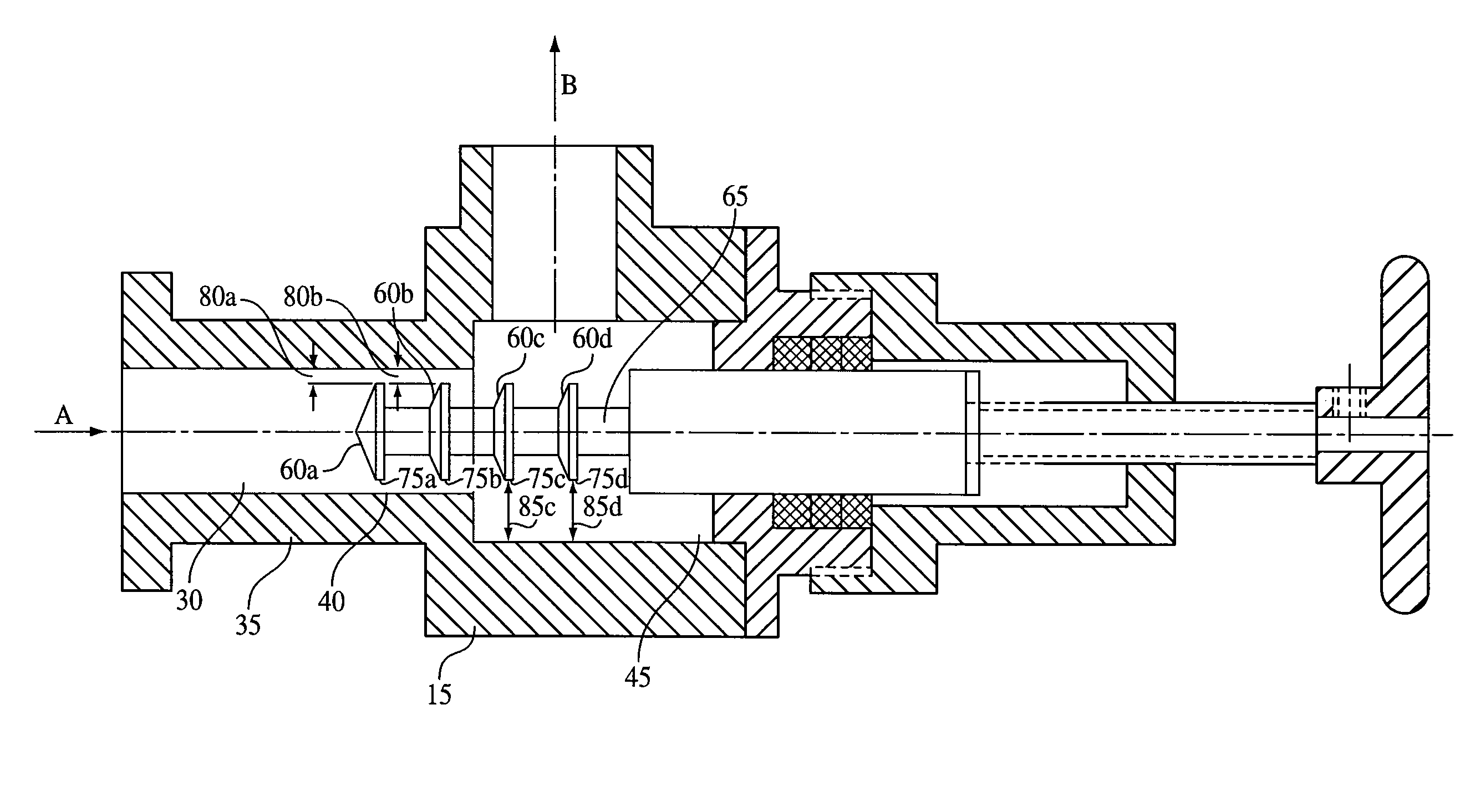

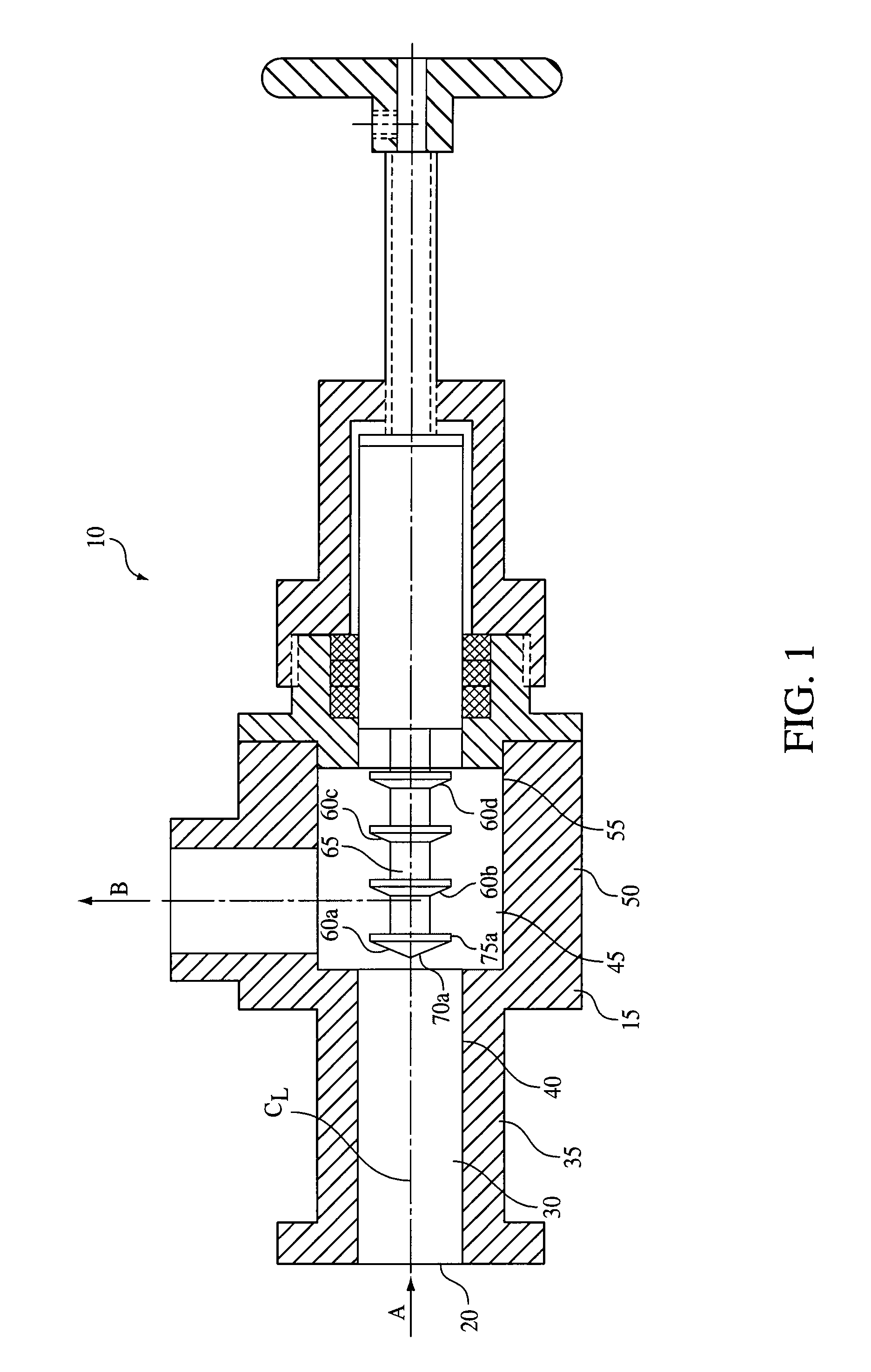

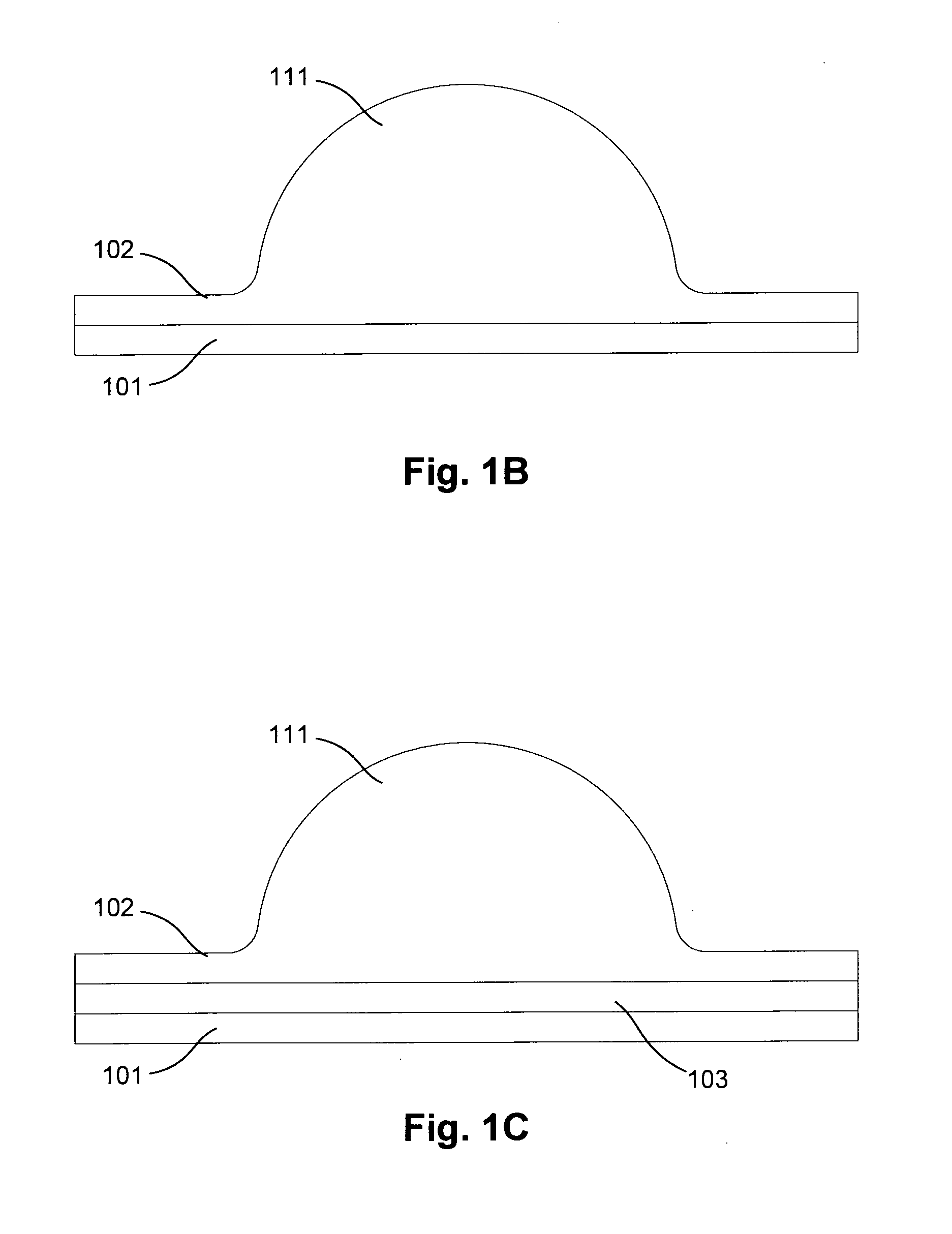

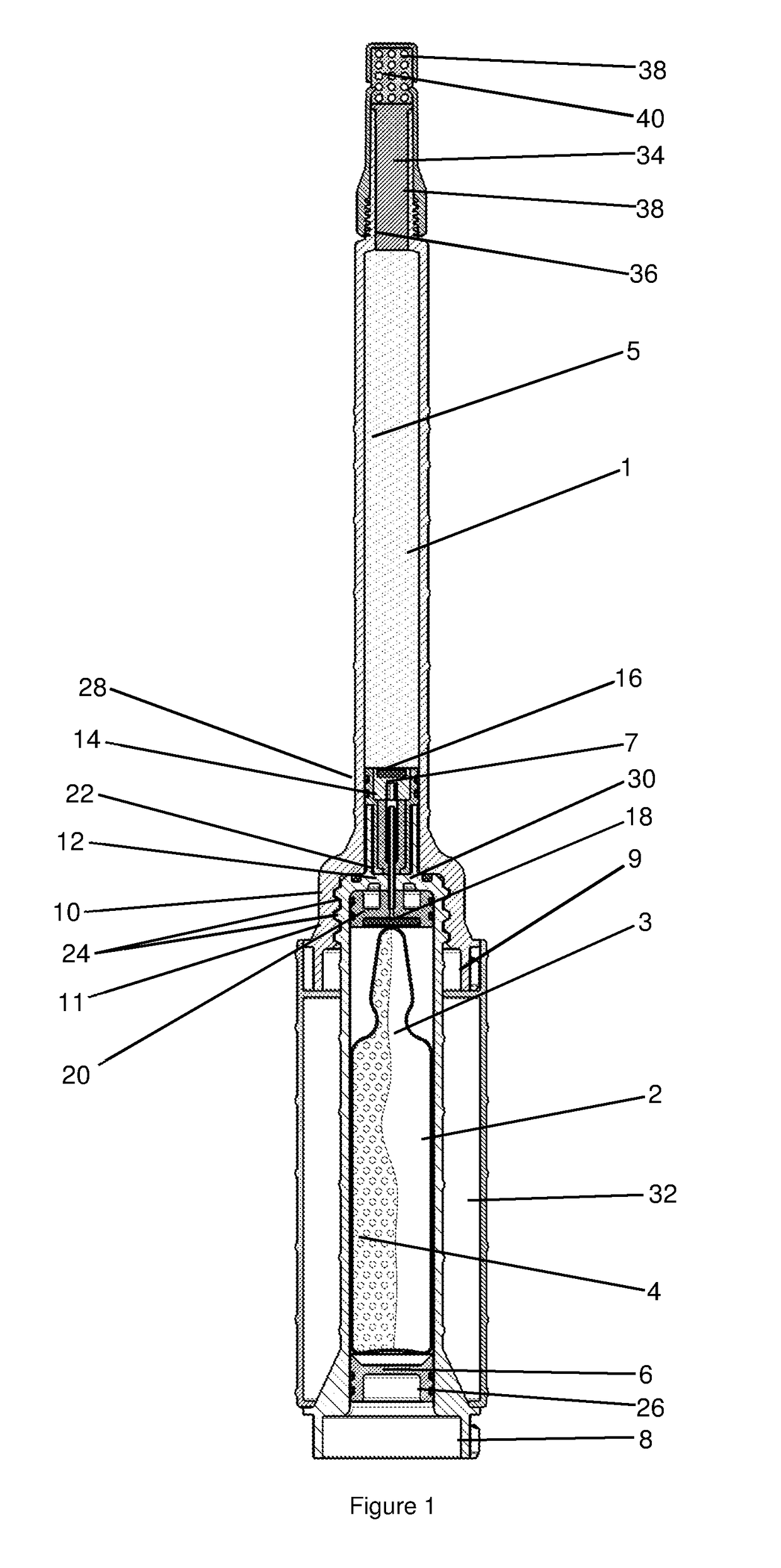

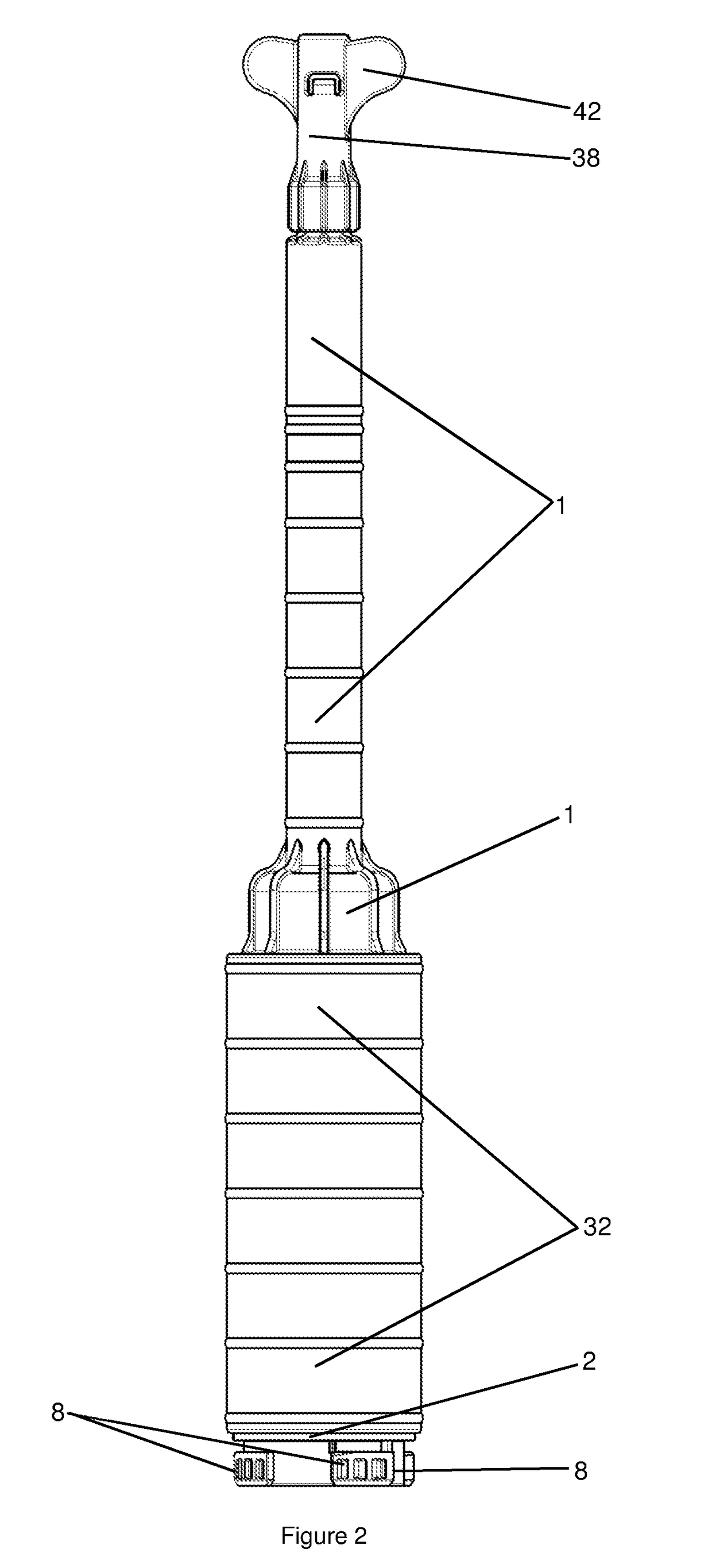

Apparatus for mixing and dispensing a multi-component bone cement

InactiveUS20050105385A1Shaking/oscillating/vibrating mixersRotary stirring mixersEngineeringBone cement

An apparatus for mixing and dispensing a multi-component compound. The device includes a tubular body with an internal chamber for mixing the multi-component compound. Disposed within and extending beyond the tubular body is a rod having a mixing disc located near a distal end. Also disposed within the tubular body is a moveable piston with a central opening through which the rod may pass.

Owner:BOSTON SCI SCIMED INC

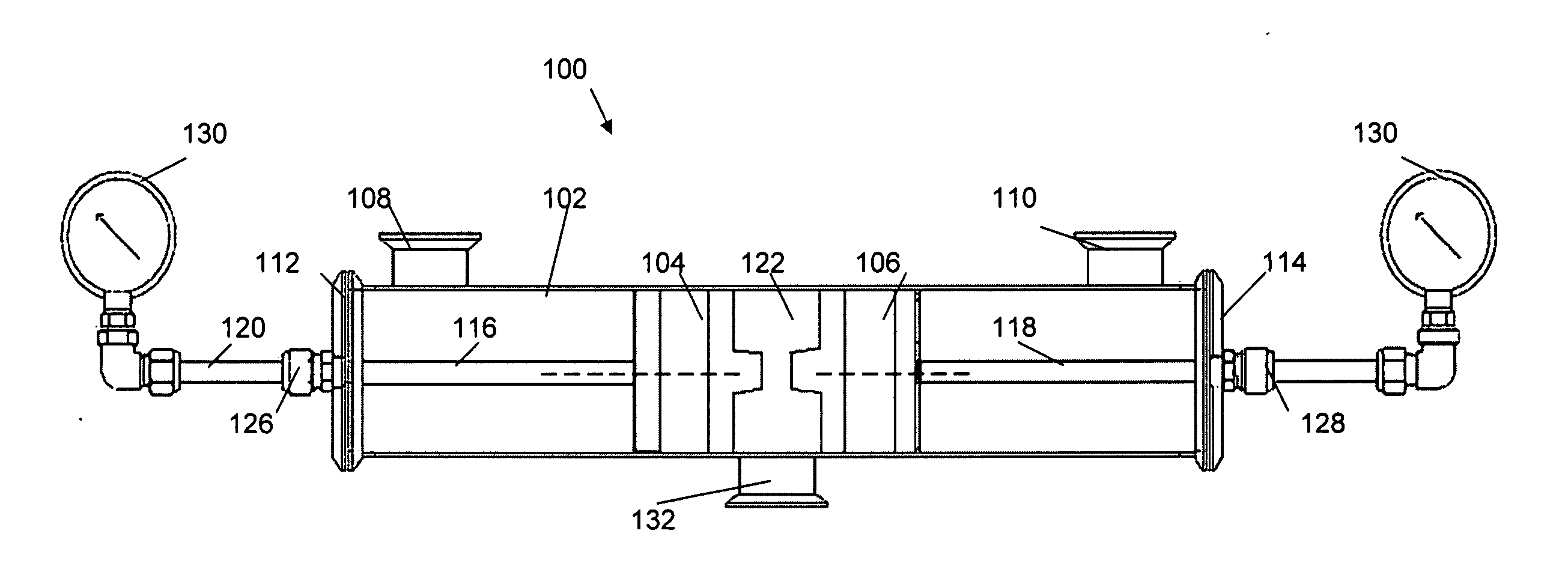

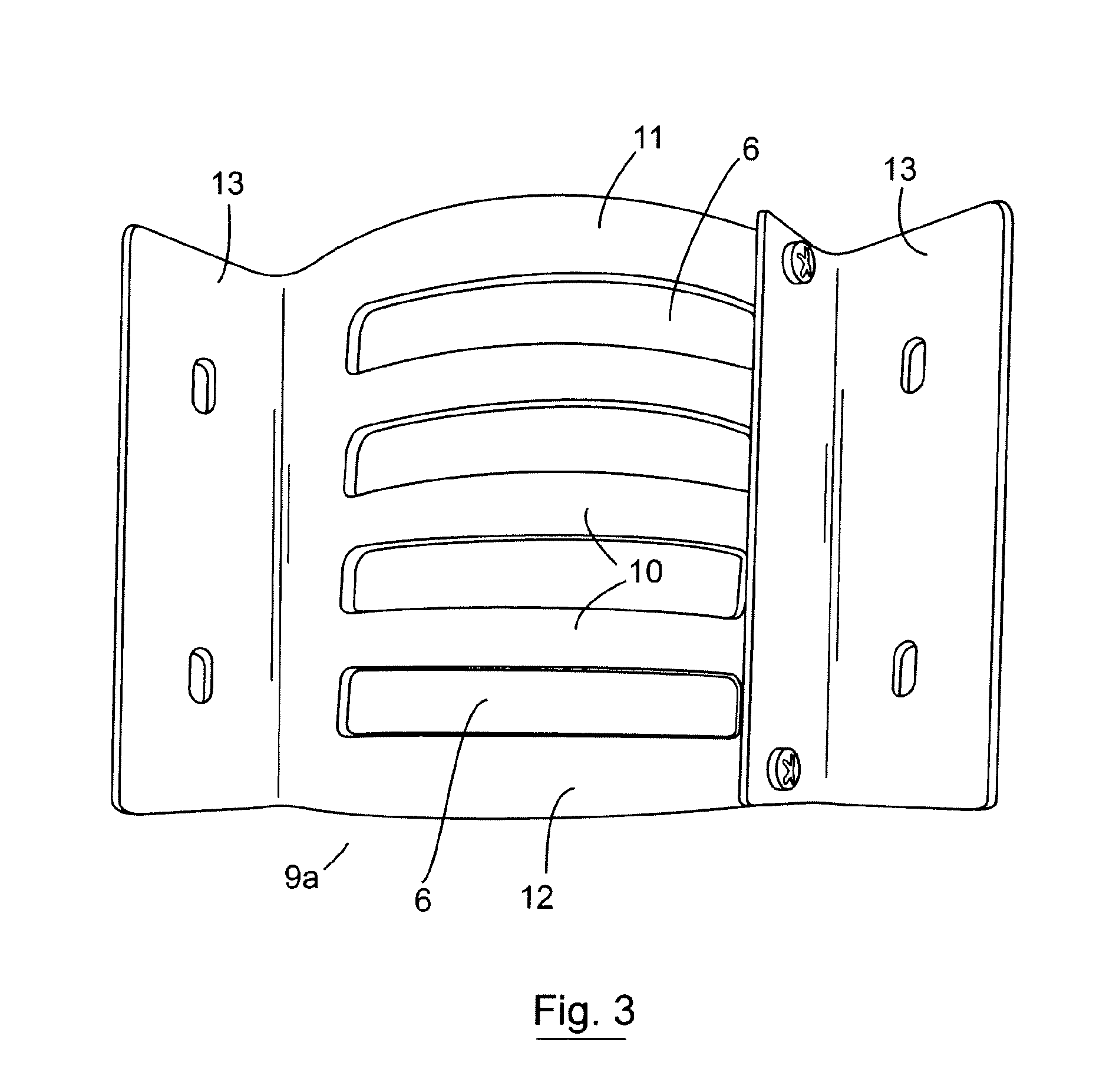

Device and method for creating hydrodynamic cavitation in fluids

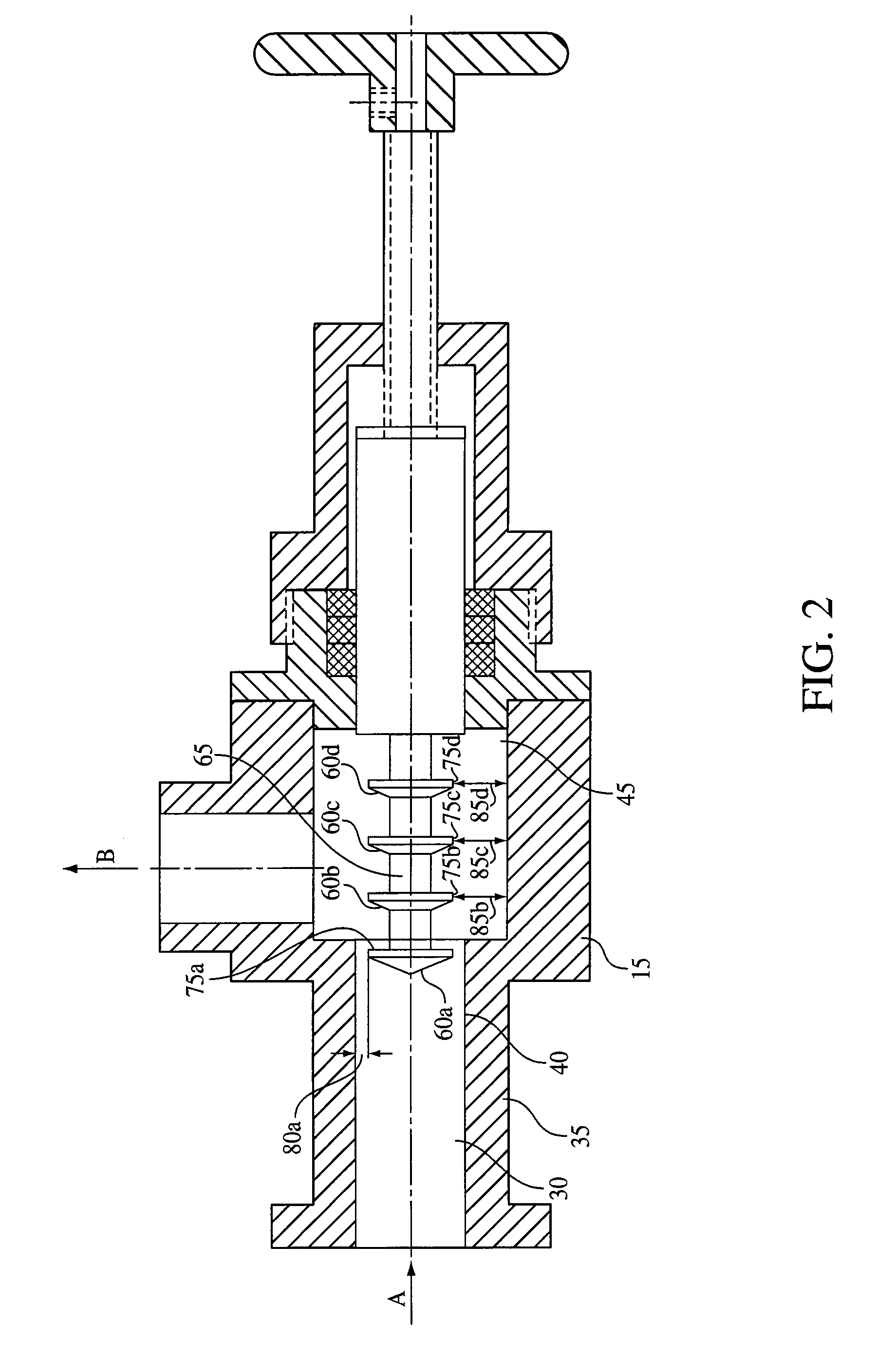

A device and method for creating hydrodynamic cavitation in fluid is provided. The device can include a flow-through chamber having a first portion and a second portion, and a plurality of baffles provided within the second portion of the flow-through chamber. One or more of the plurality of baffles can be configured to be selectively movable into the first portion of the flow-through chamber to generate a hydrodynamic cavitation field downstream from each baffle moved into the first portion of the flow-through chamber.

Owner:ARISDYNE STSTEMS INC

Surfactant Thickened Systems Comprising Microfibrous Cellulose and Methods of Making Same

ActiveUS20080108541A1Increase shear rateCosmetic preparationsSurface-active detergent compositionsCelluloseParticulates

Surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

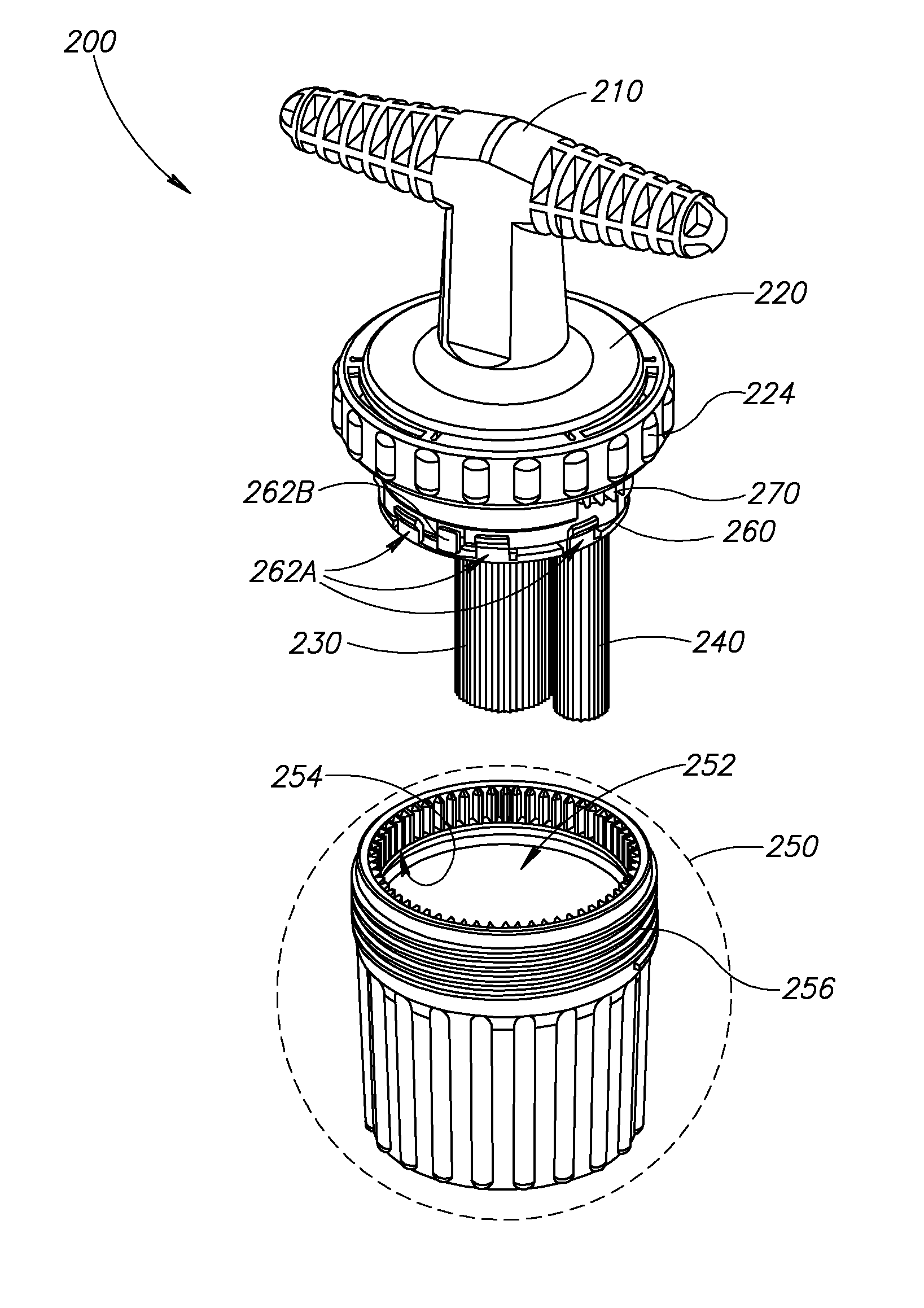

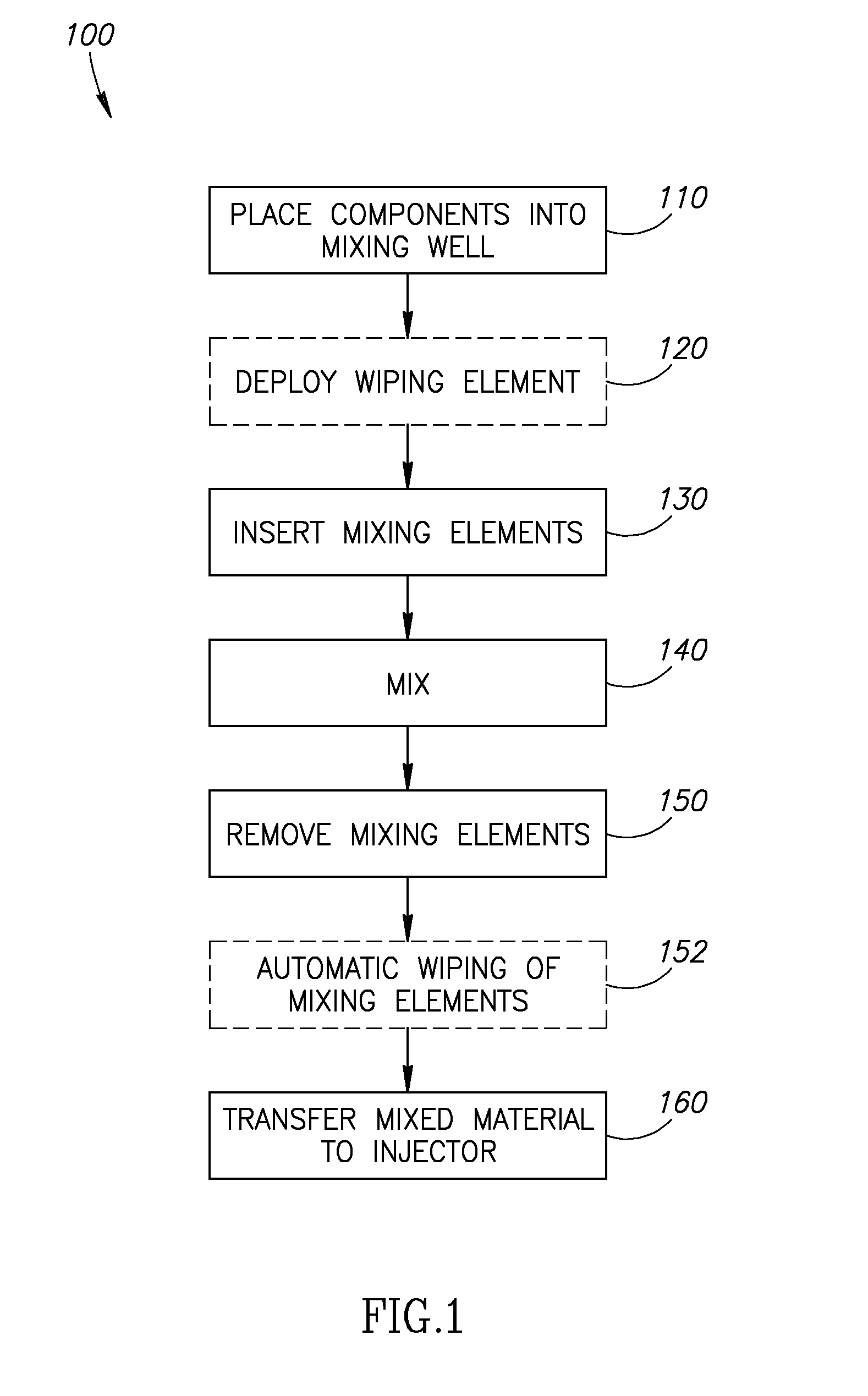

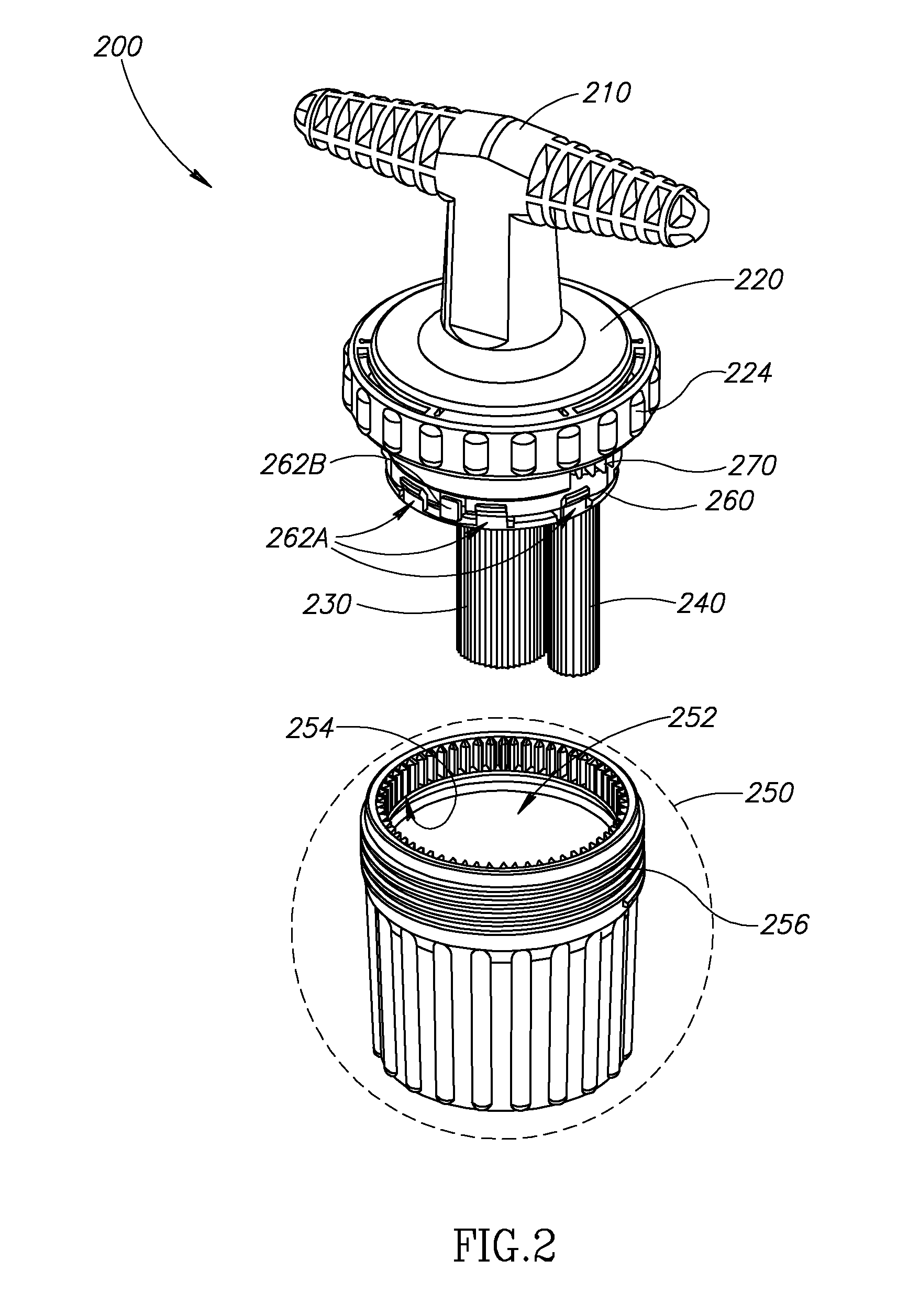

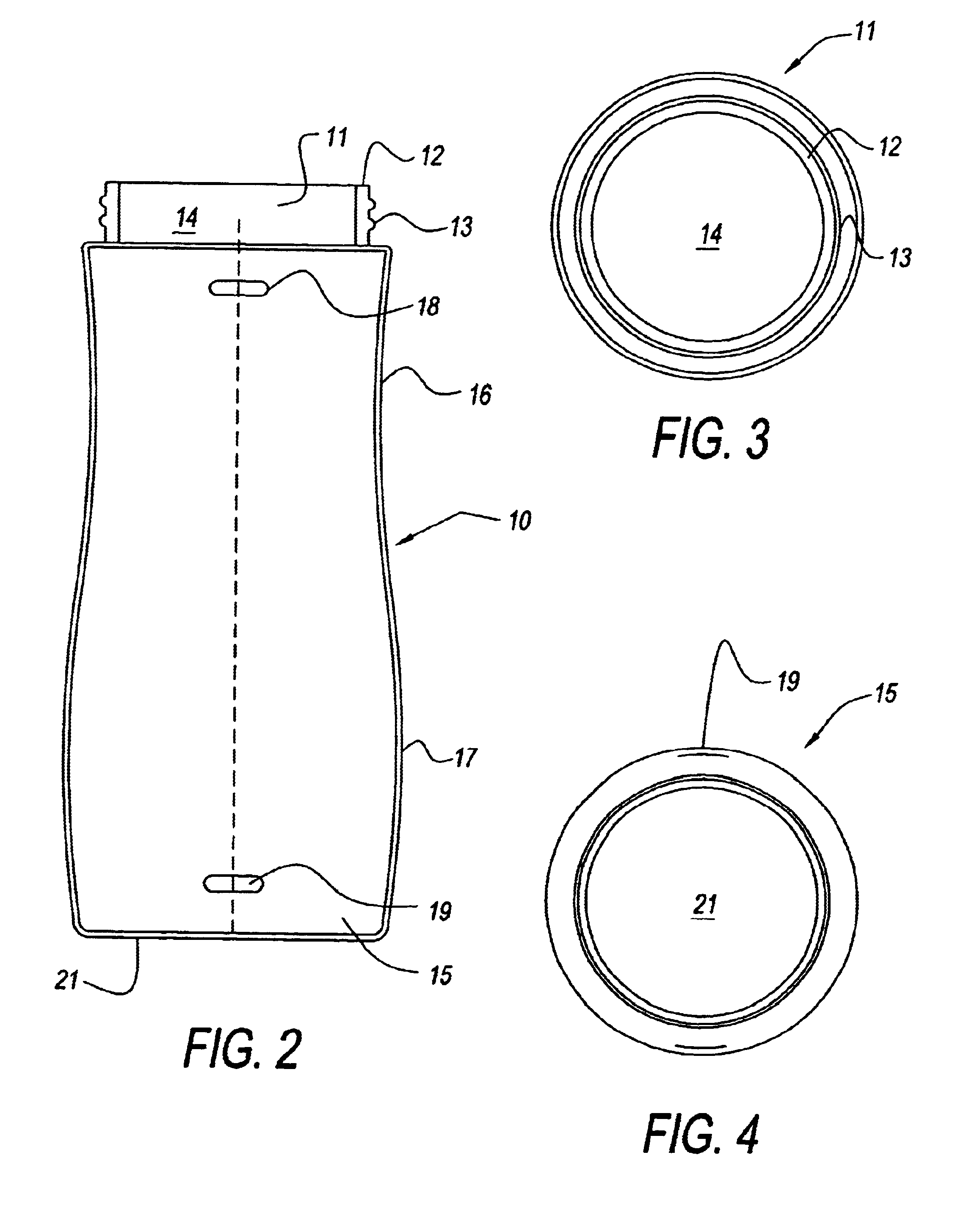

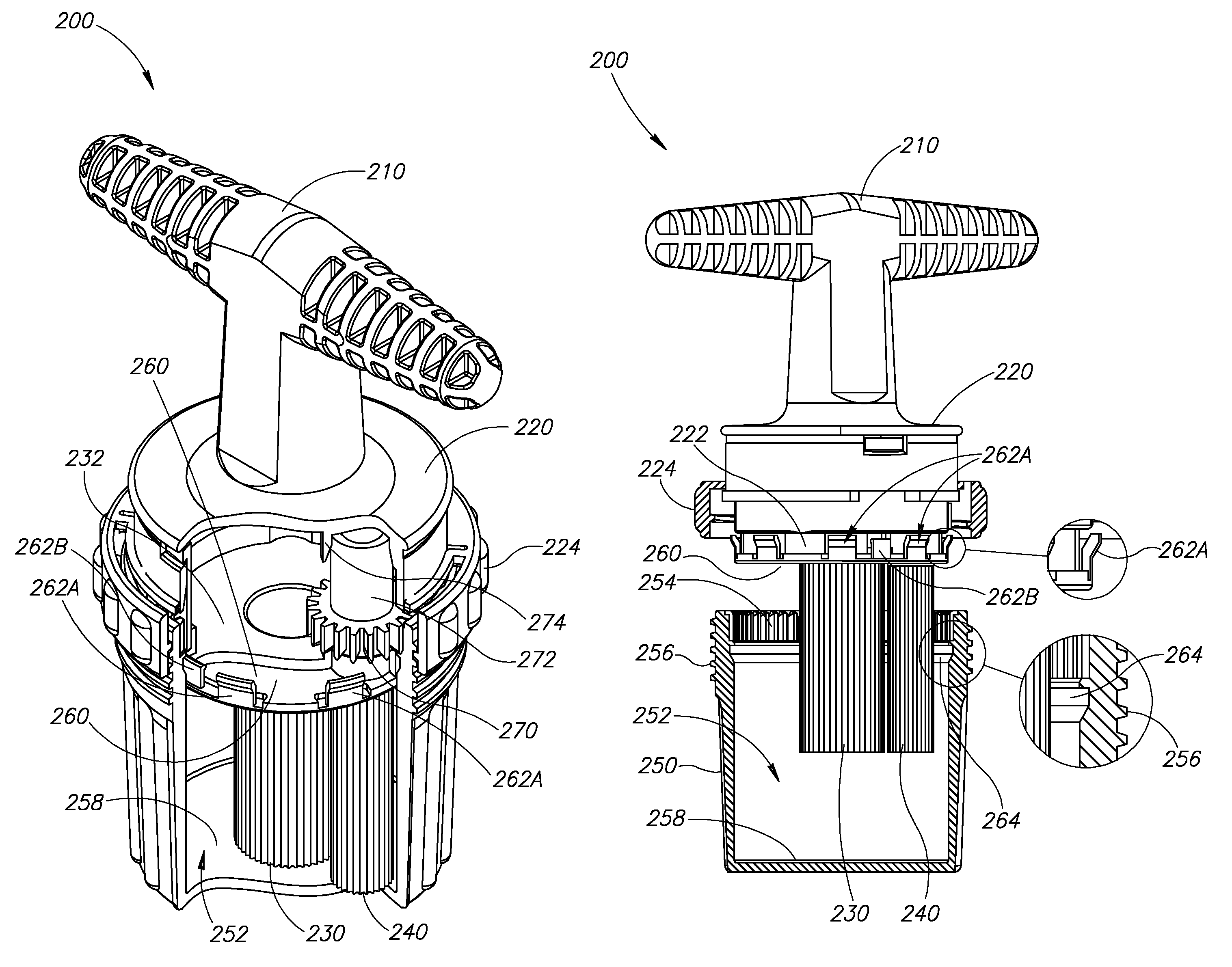

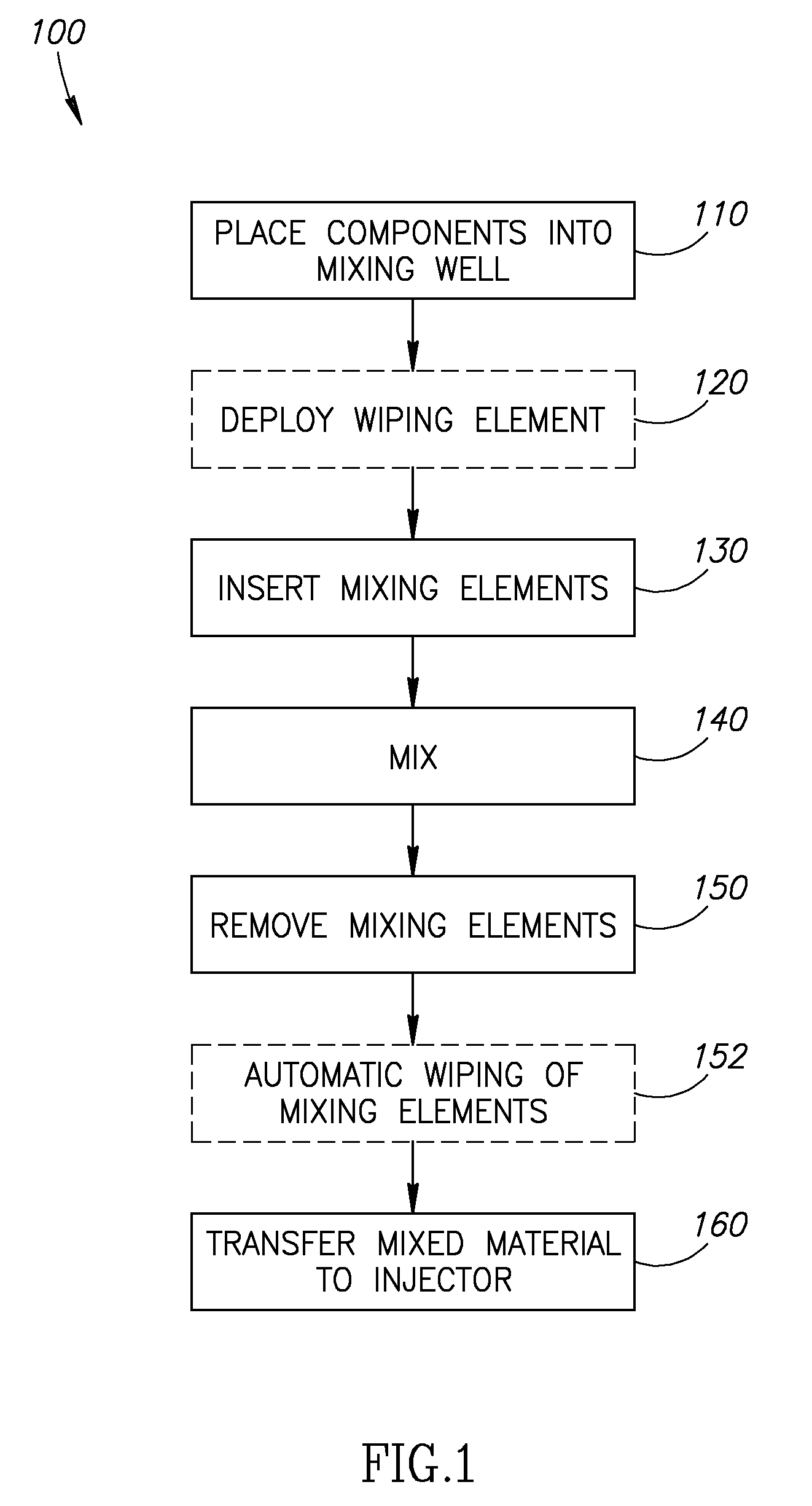

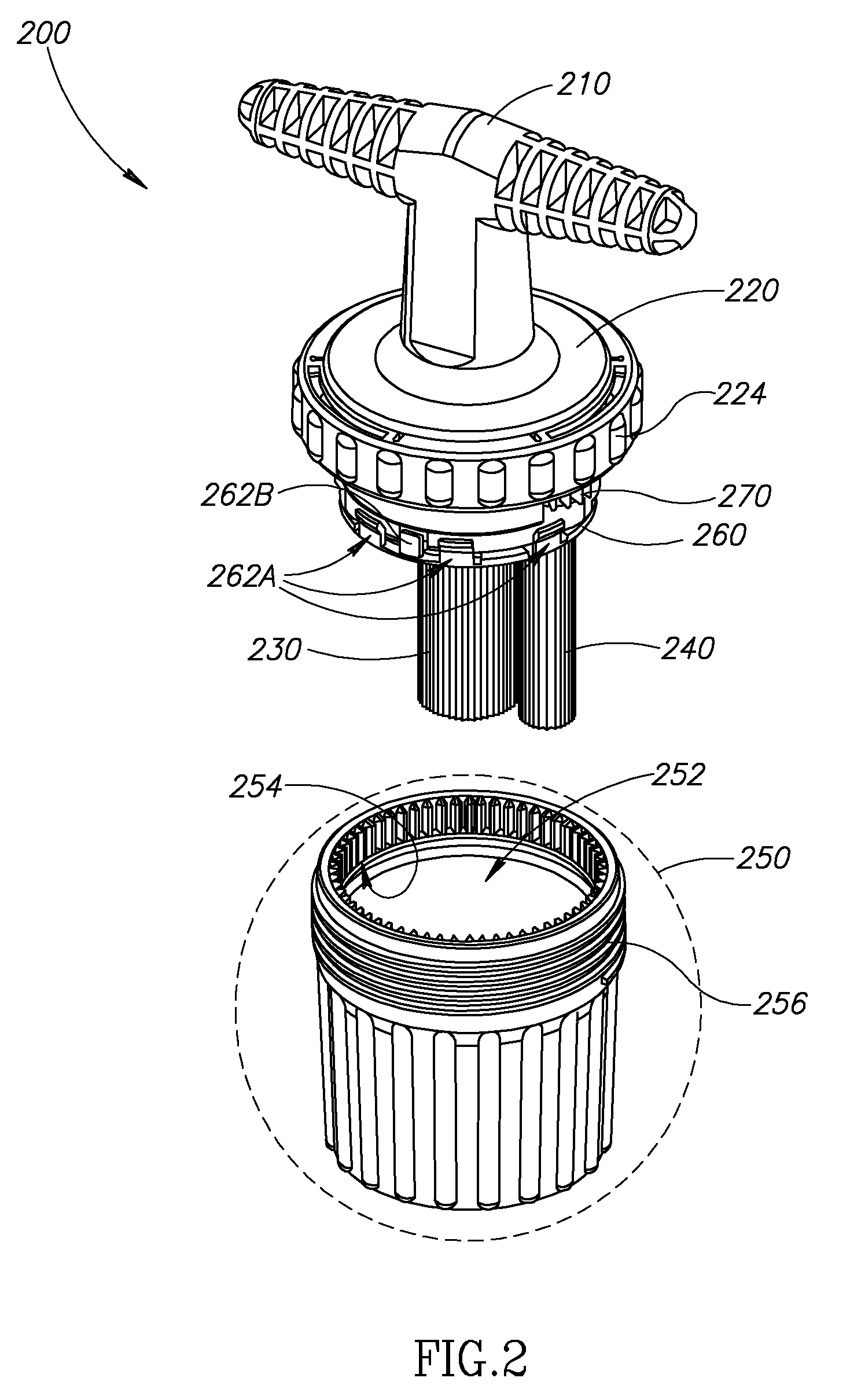

Mixing Apparatus

ActiveUS20080212405A1Sufficient forceFlow mixersRotary stirring mixersEngineeringMechanical engineering

Owner:DEPUY SYNTHES PROD INC

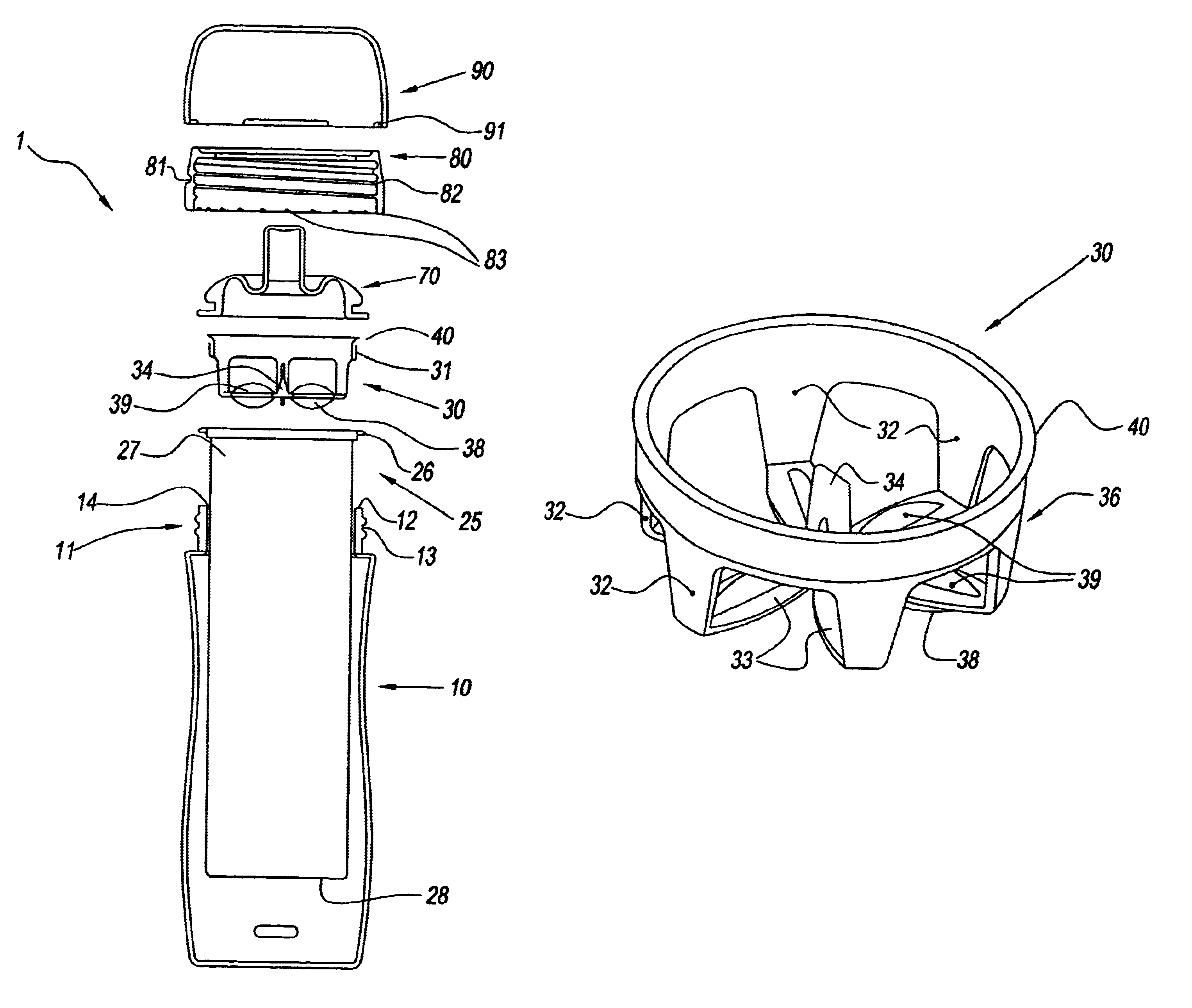

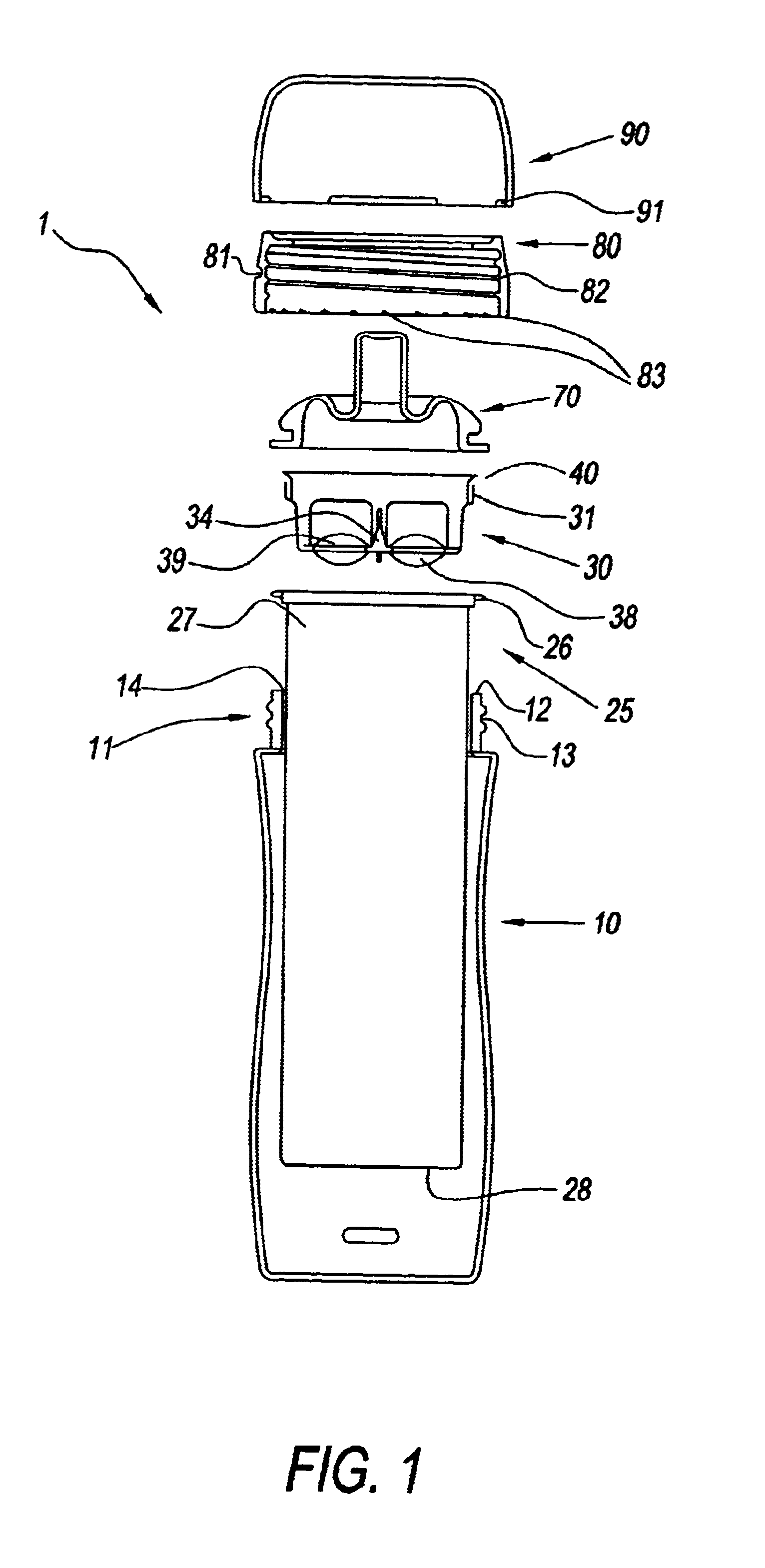

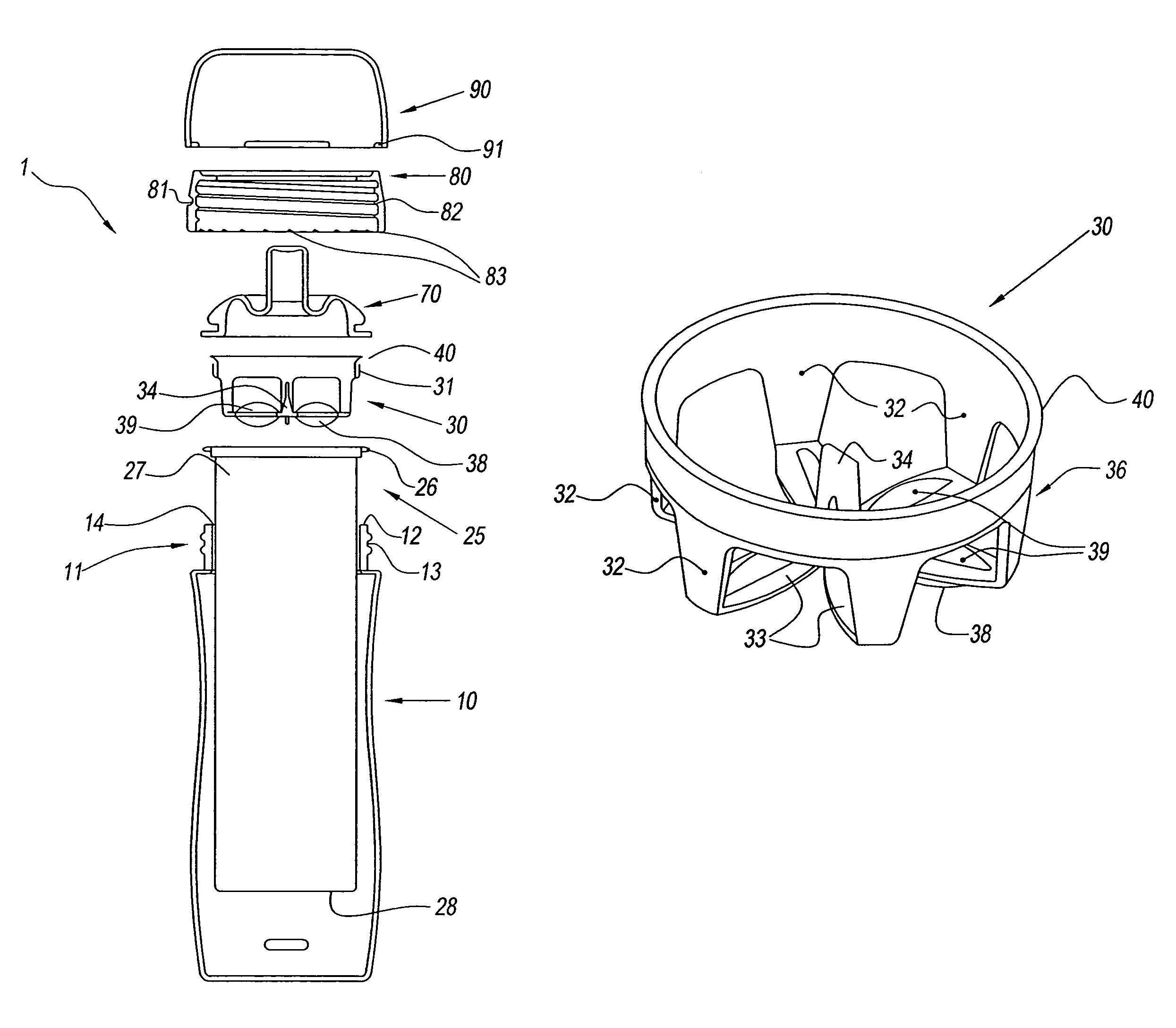

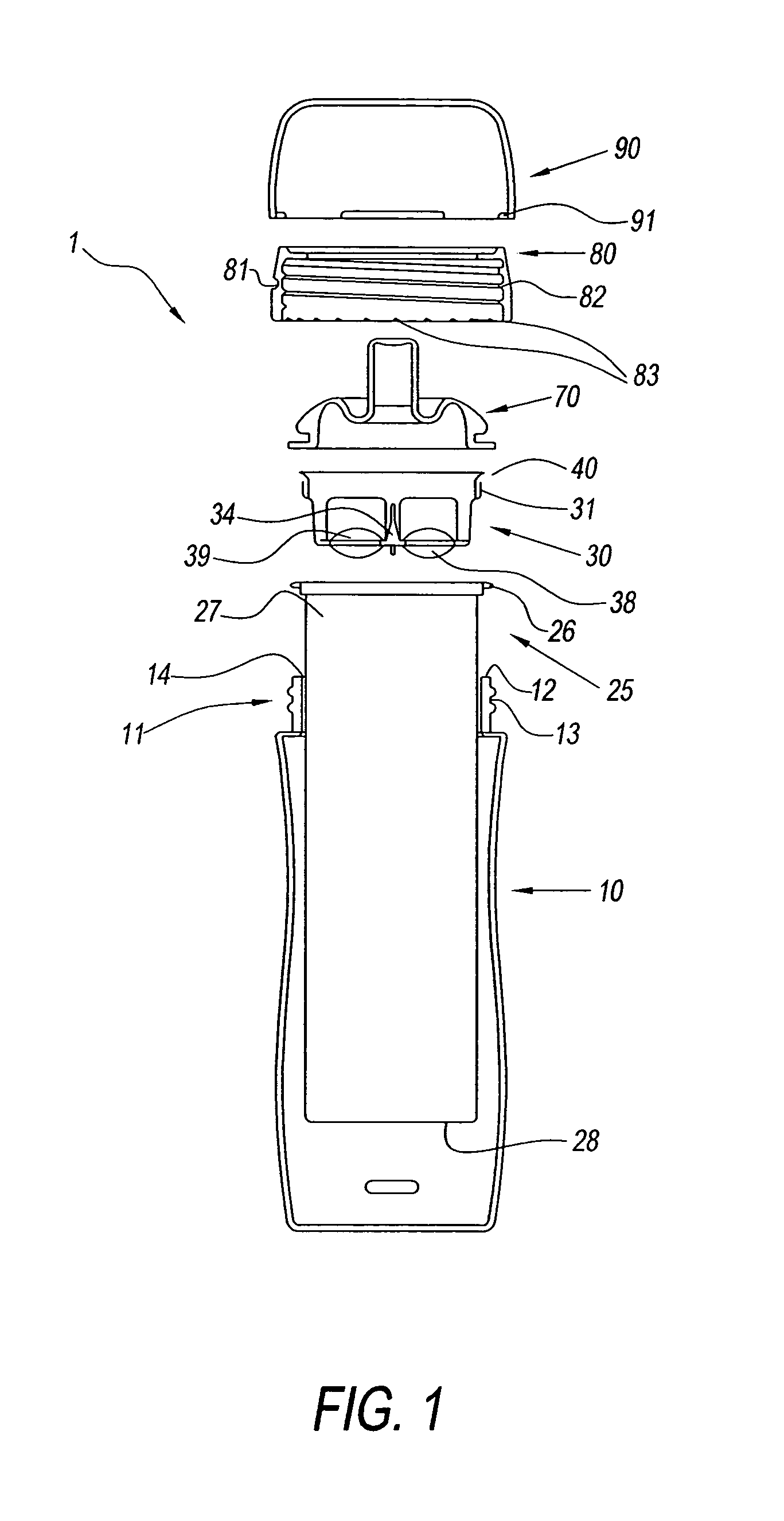

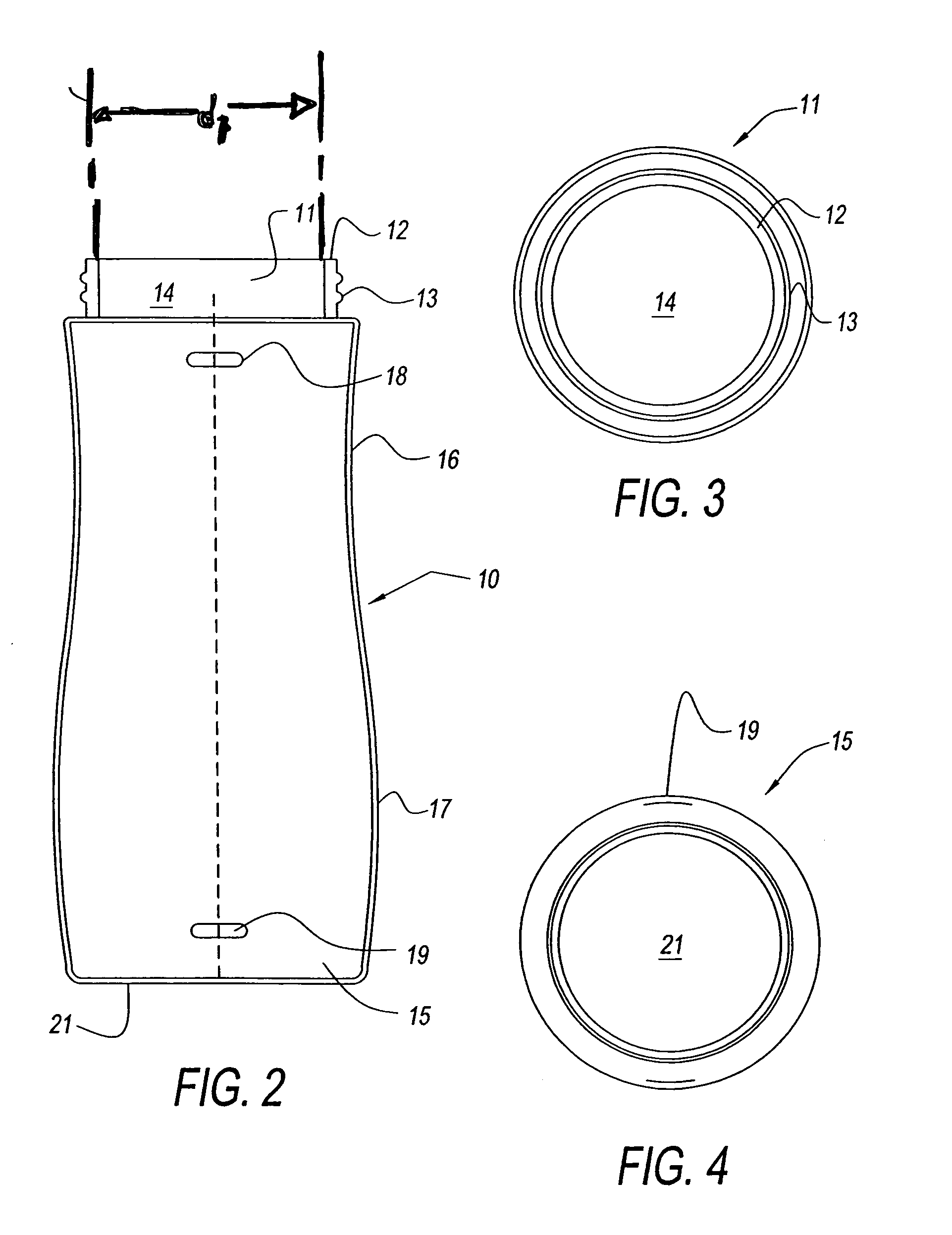

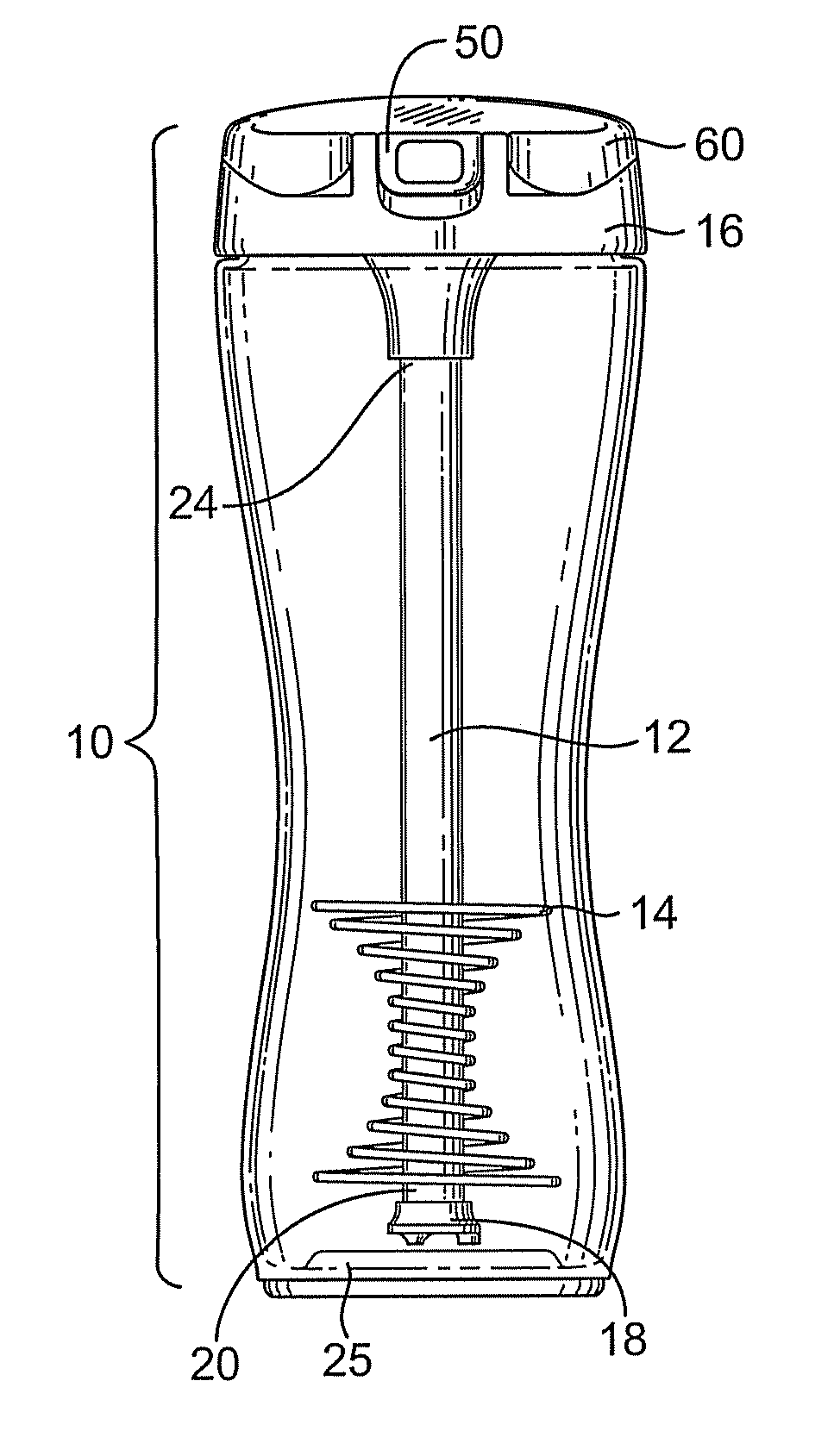

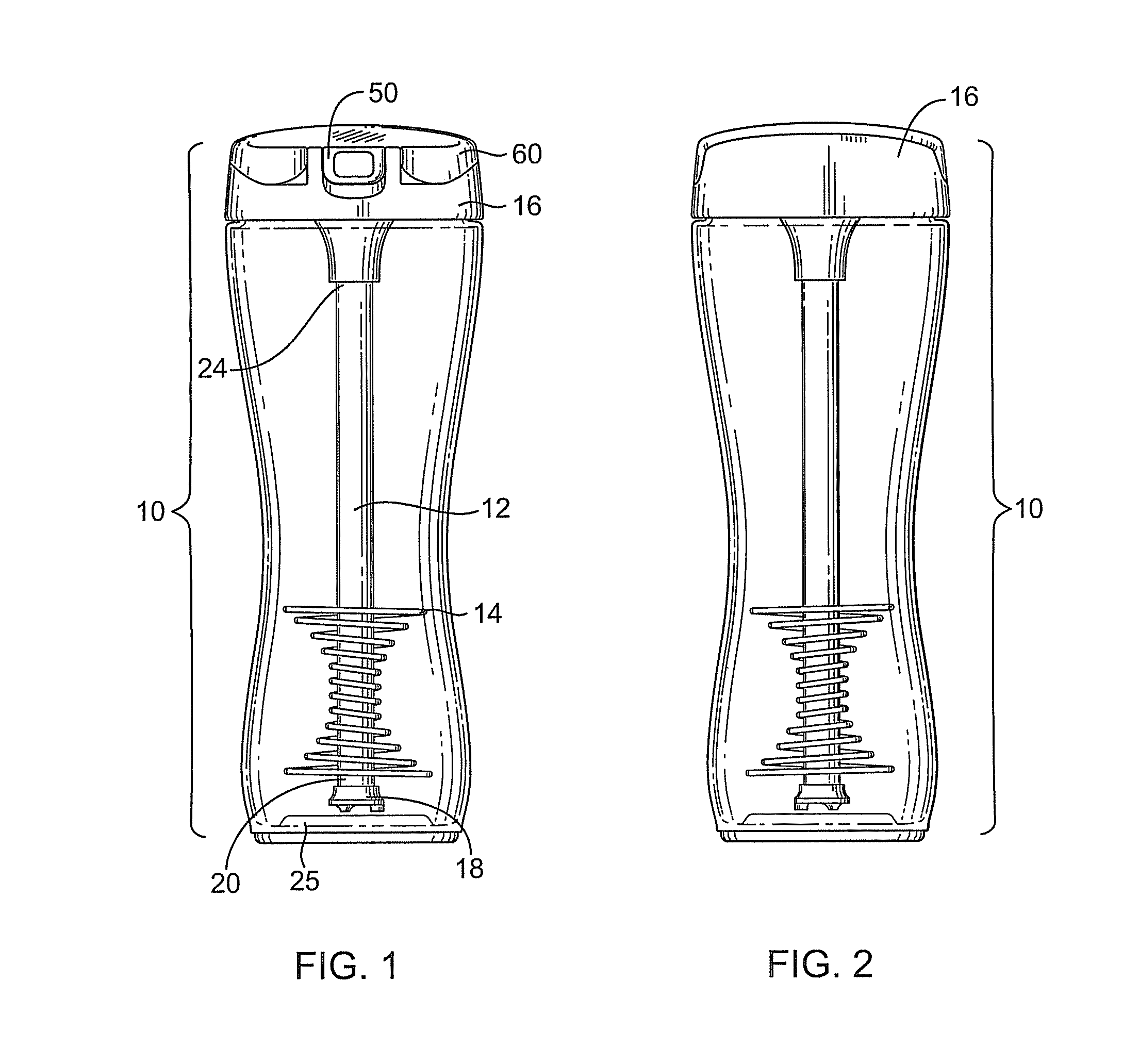

Bottle with mixing system

InactiveUS6616319B2Efficient mixingShaking/oscillating/vibrating mixersFlow mixersEngineeringMixing effect

There is provided an infant feeding bottle system having an agitator for mixing a powder substance with a liquid in a non-rigid disposable liner. The bottle system permits a user to mix powdered formula directly inside a non-rigid liner. The bottle system enhances the mixing effect, resulting in improved solubility, and provides for a self-contained uninterrupted mixing and feeding process.

Owner:JMBH HLDG LLC

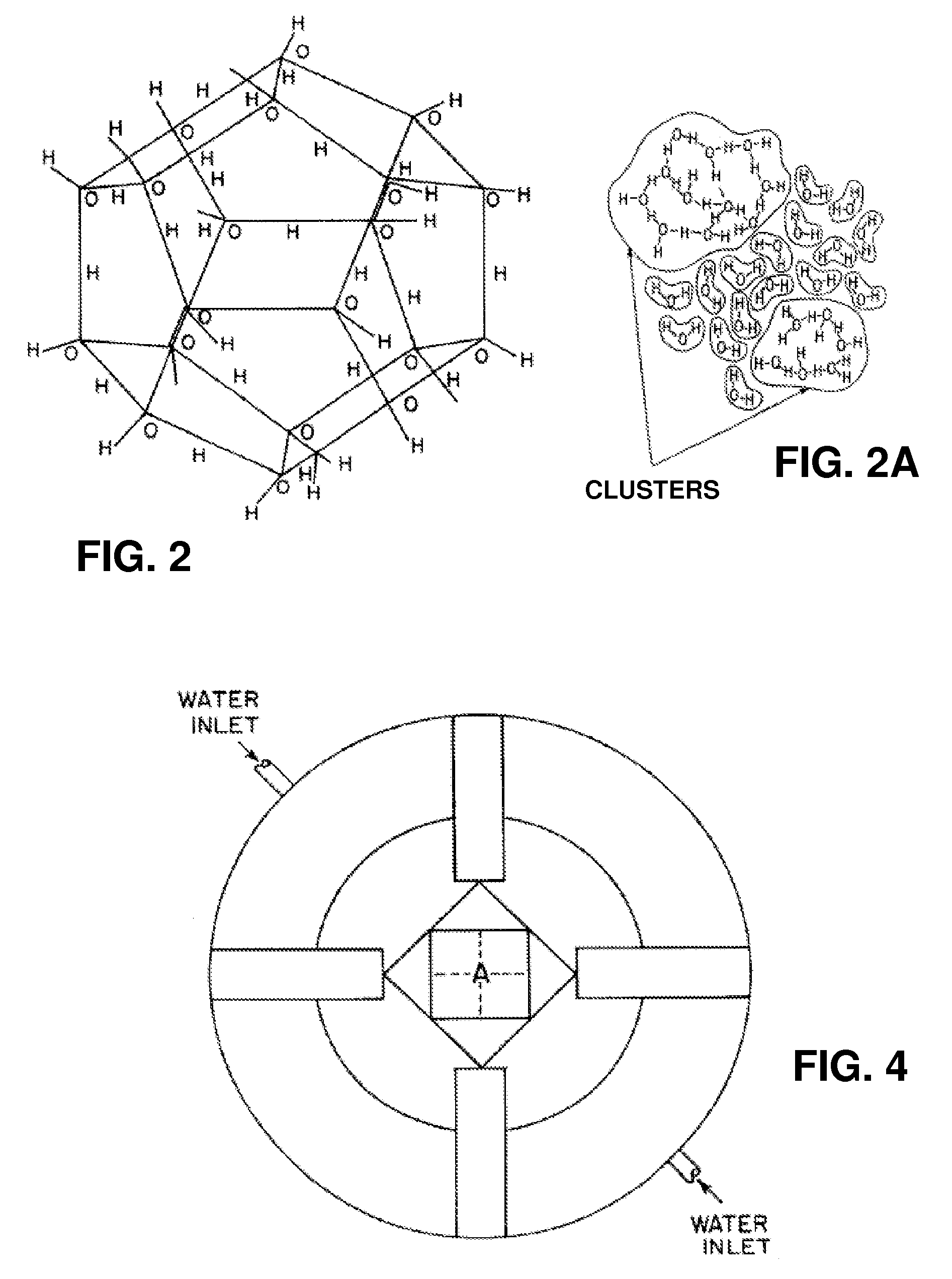

Device and method for mixing liquids and oils or particulate solids and mixtures generated therefrom

InactiveUS20070003497A1Increase heatSufficient acoustic energyCosmetic preparationsFlow mixersParticulatesCavitation

A cavitation device includes a pair of axially aligned opposing nozzles within a housing. Liquid is introduced into the nozzles at a pressure to create rotational vortices within the nozzles, causing cavitation. The thermo-physical reactions resulting from cavitation produce an increase in heat and breaking of the bonds holding large fluid arrays together. Additional cavitation is induced by a collision between the liquid outputs of the opposing nozzles to enhance mixing. By subjecting a mixture of material(s) to be dissolved in water to a cavitation device, a true solution of a lipophilic and water or stable suspension of particulate solids in water can be formed.

Owner:AQUAPHOTONICS INC

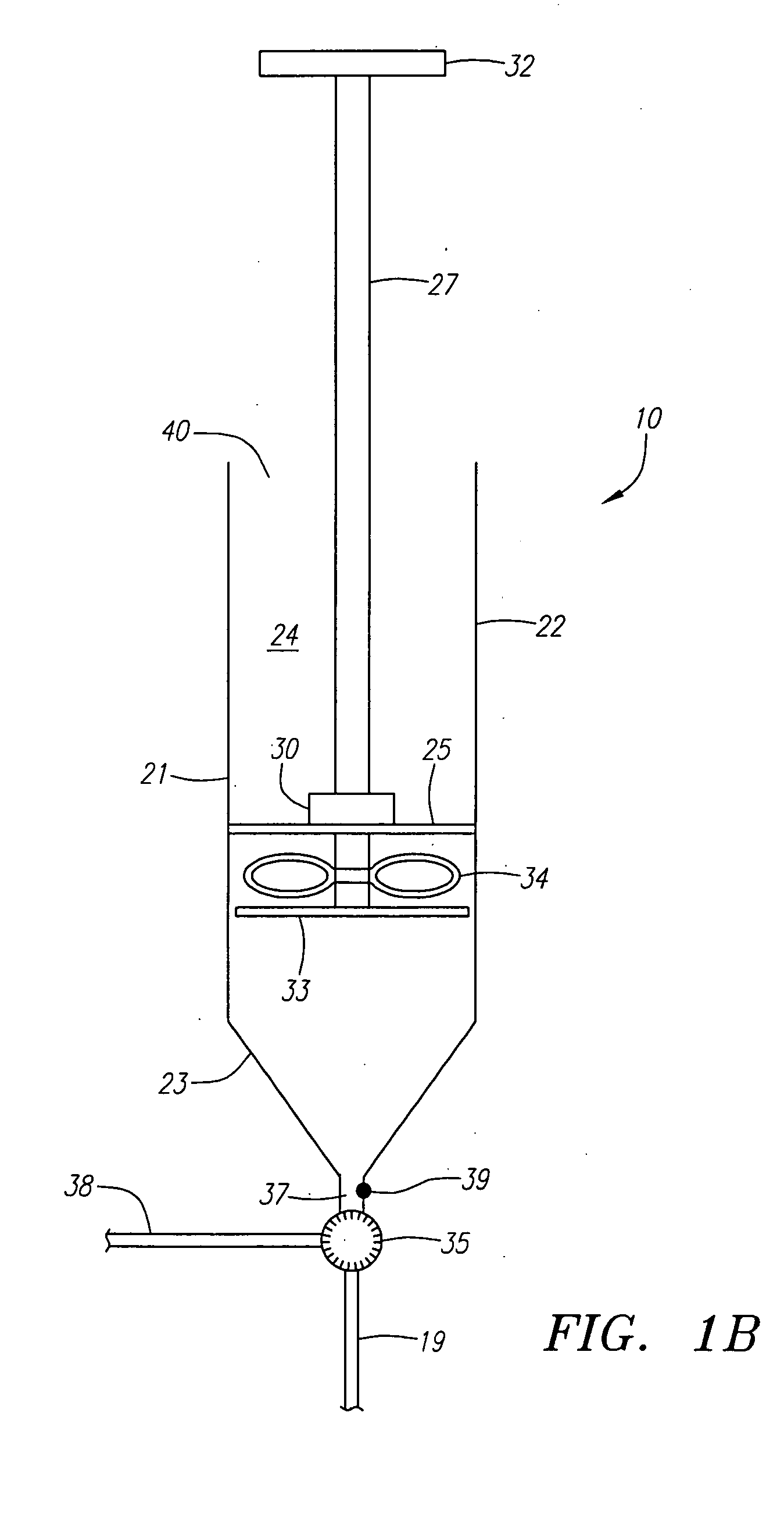

Homogenization device and method of using same

InactiveUS6802639B2Inexpensive and readily adjustable mannerMaintain qualityFlow mixersTransportation and packagingEngineeringConstriction

A homogenization device comprising a flow-through channel having at least two local constrictions of flow wherein the size of a first local constrictions is adjustable thereby permitting variable flow rate through one portion of the device and the size of a second local constriction is fixed thereby permitting constant flow rate through another portion of the device.

Owner:ARISDYNE STSTEMS INC

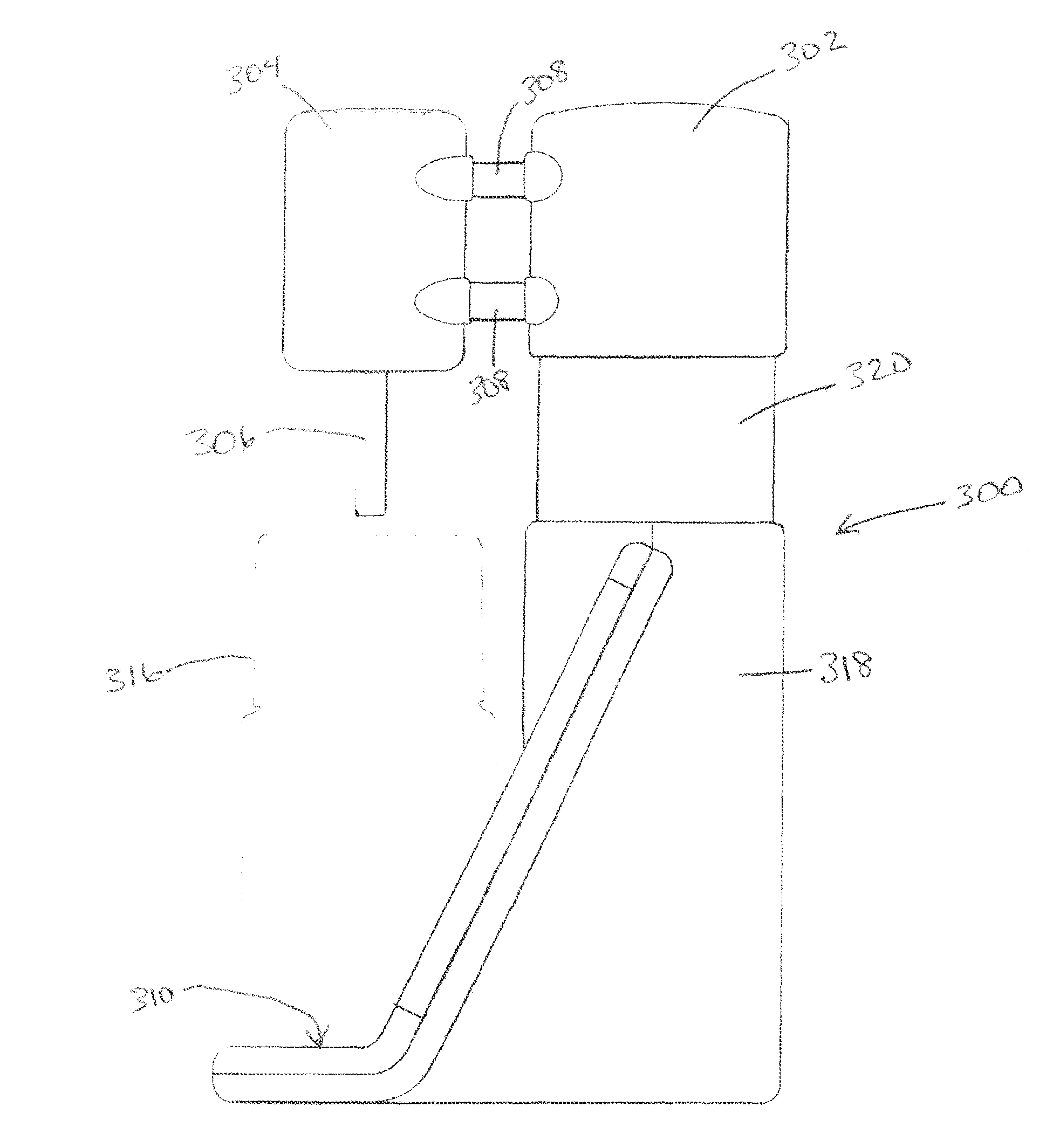

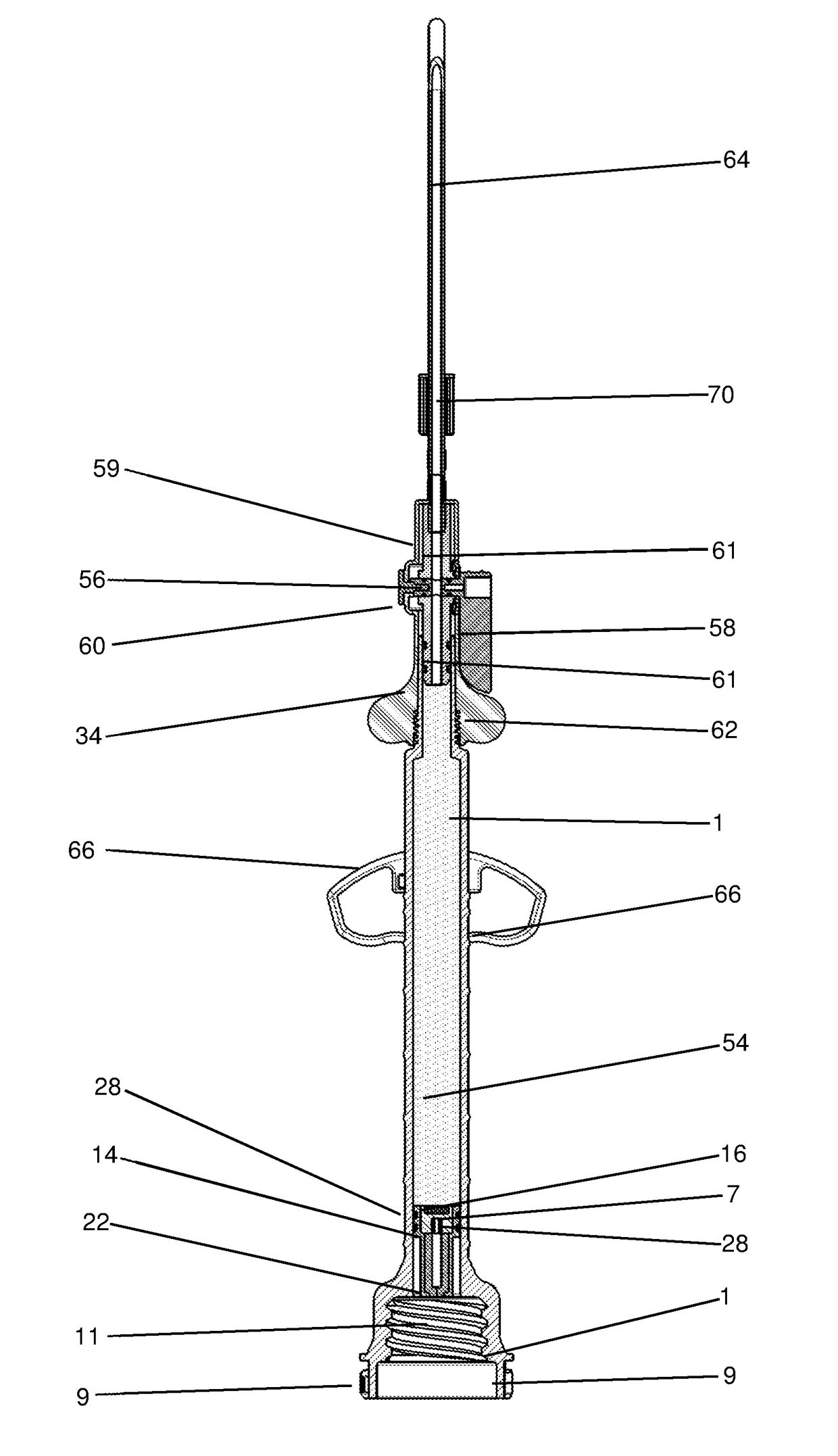

Apparatus for mixing and dispensing a multi-component bone cement

InactiveUS7524103B2Shaking/oscillating/vibrating mixersTransportation and packagingBone cementBiomedical engineering

An apparatus for mixing and dispensing a multi-component compound. The device includes a tubular body with an internal chamber for mixing the multi-component compound. Disposed within and extending beyond the tubular body is a rod having a mixing disc located near a distal end. Also disposed within the tubular body is a moveable piston with a central opening through which the rod may pass.

Owner:BOSTON SCI SCIMED INC

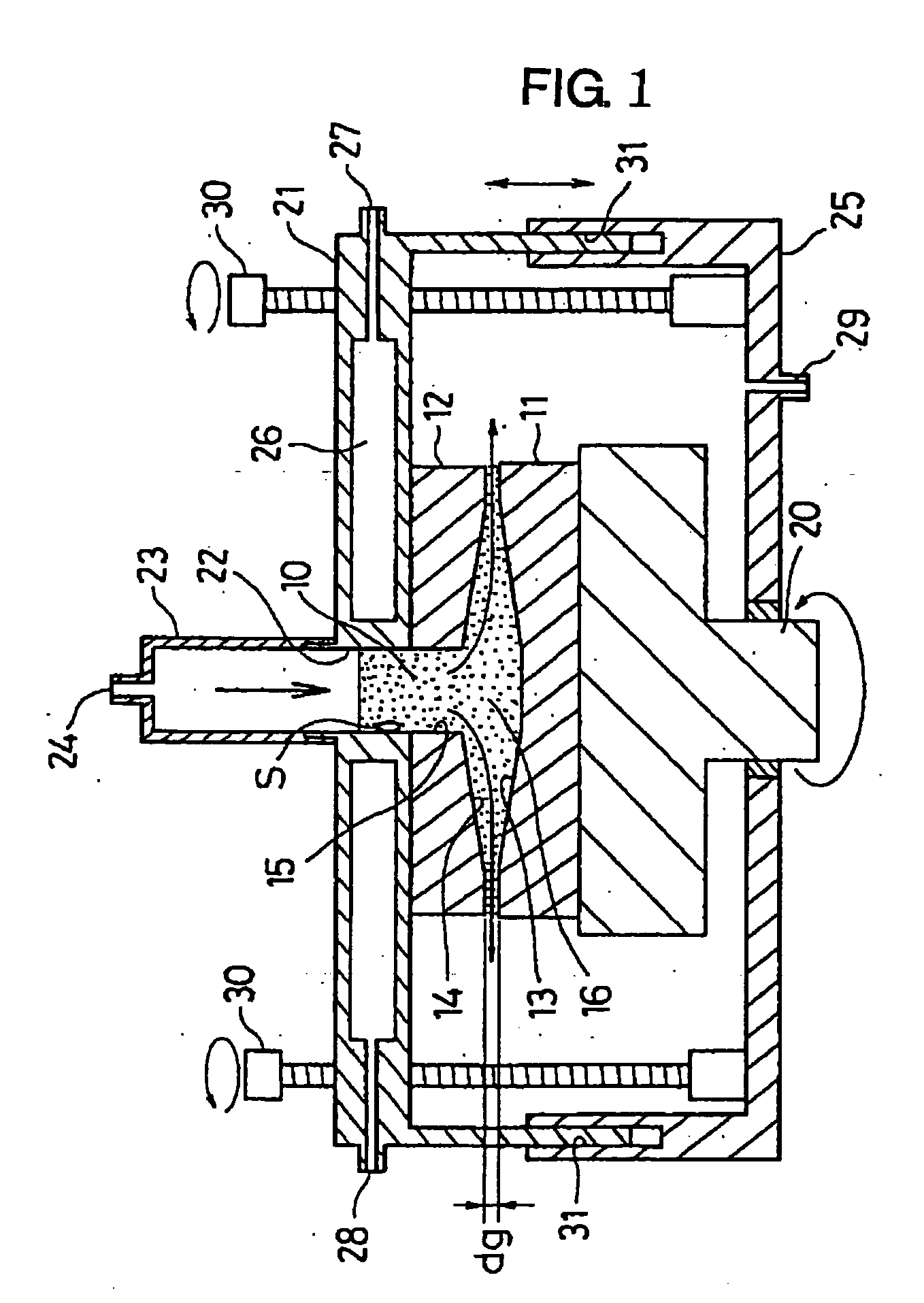

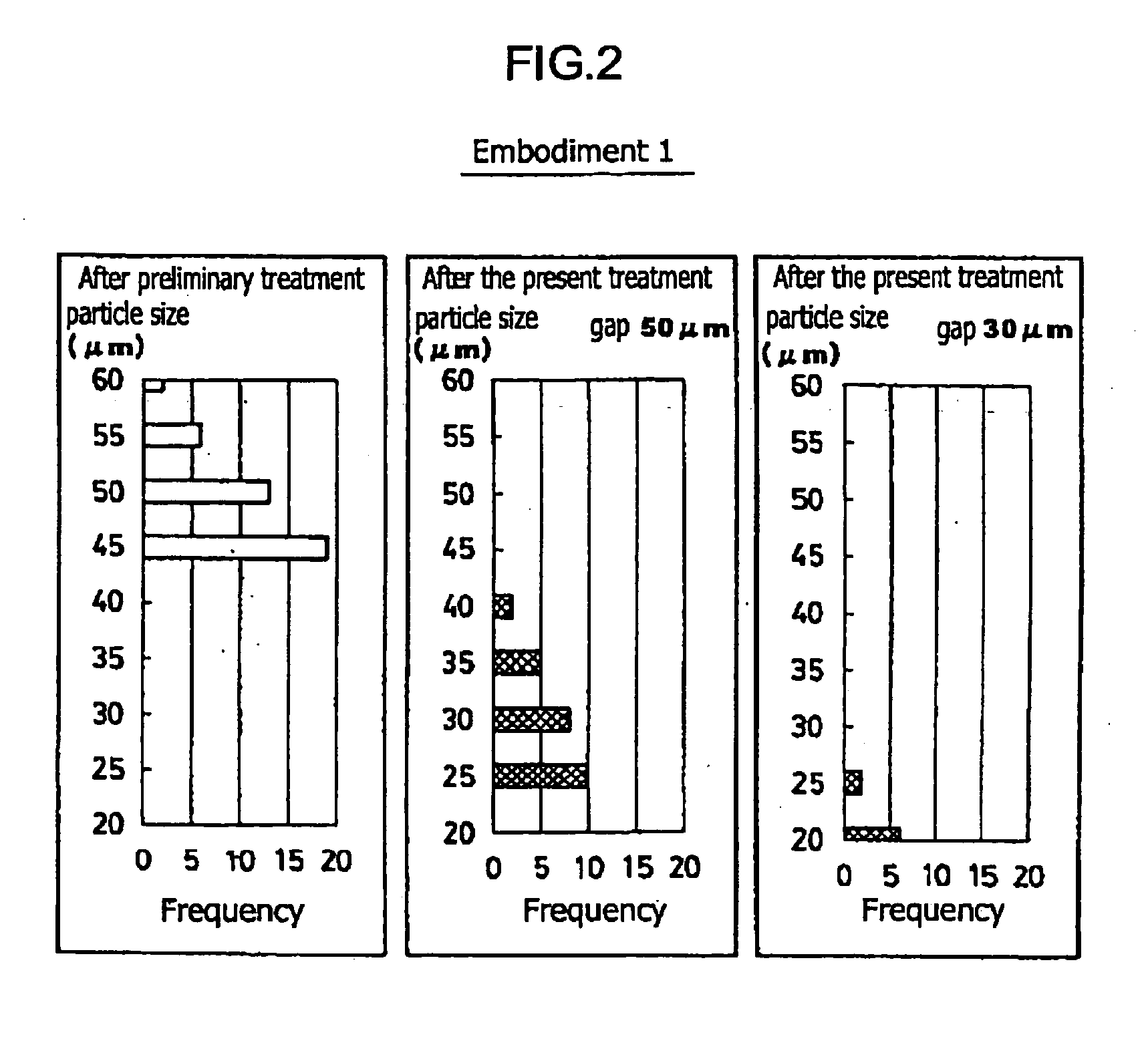

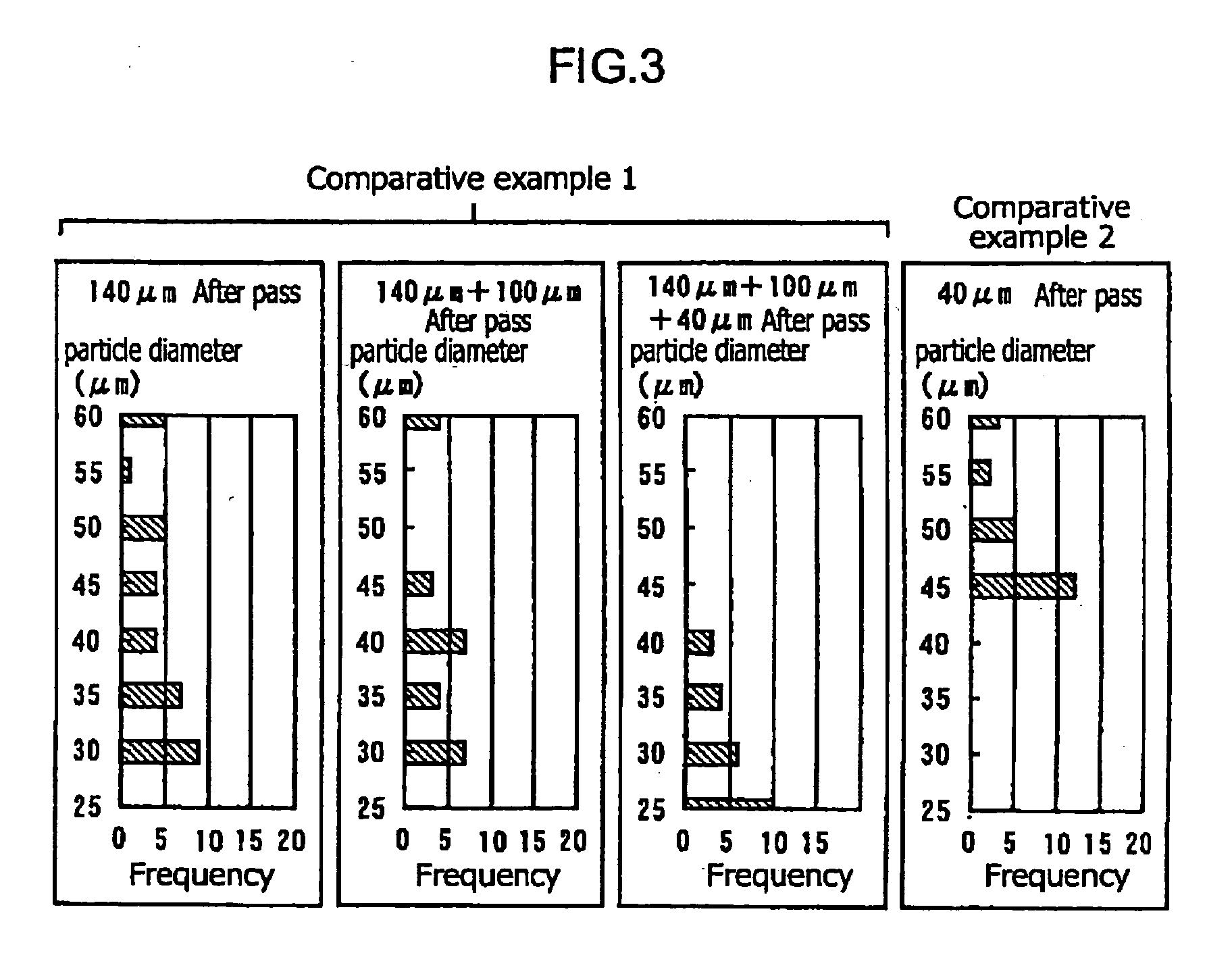

Manufacturing method of metal paste

InactiveUS20050267243A1Good dispersionIncrease production capacityPigmenting treatmentRotary stirring mixersProduction ratePositive pressure

A metal paste, in which a filler mainly composed of metal is mixed with good dispersibility, is manufactured with good productivity at a low cost without generating a foil of the metal. A paste-like material (referred to as a paste material hereafter) containing a metal filler is fed into a gap between a pair of rotating whetstones 11 and 12 which are relatively rotated while facing with each other having a specified gap therebetween, to pass and discharge therein. The paste material is thus kneaded and dispersed. In addition, the paste material is kneaded and dispersed by suppressing the generation of a metal foil, adjusting the gap to a specified interval dg and feeding the paste material into the interval while applying thereon a predetermined positive pressure and / or negative pressure.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

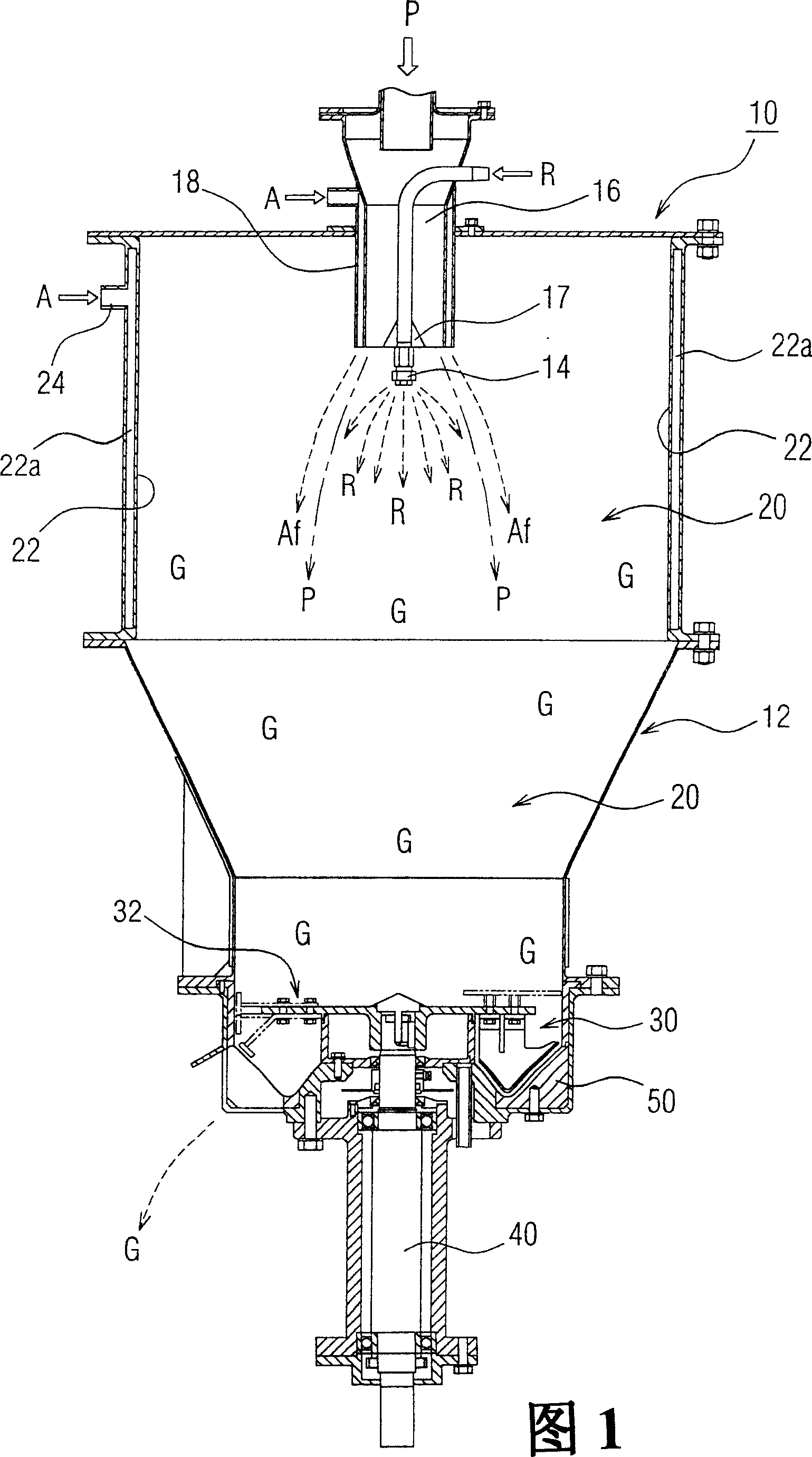

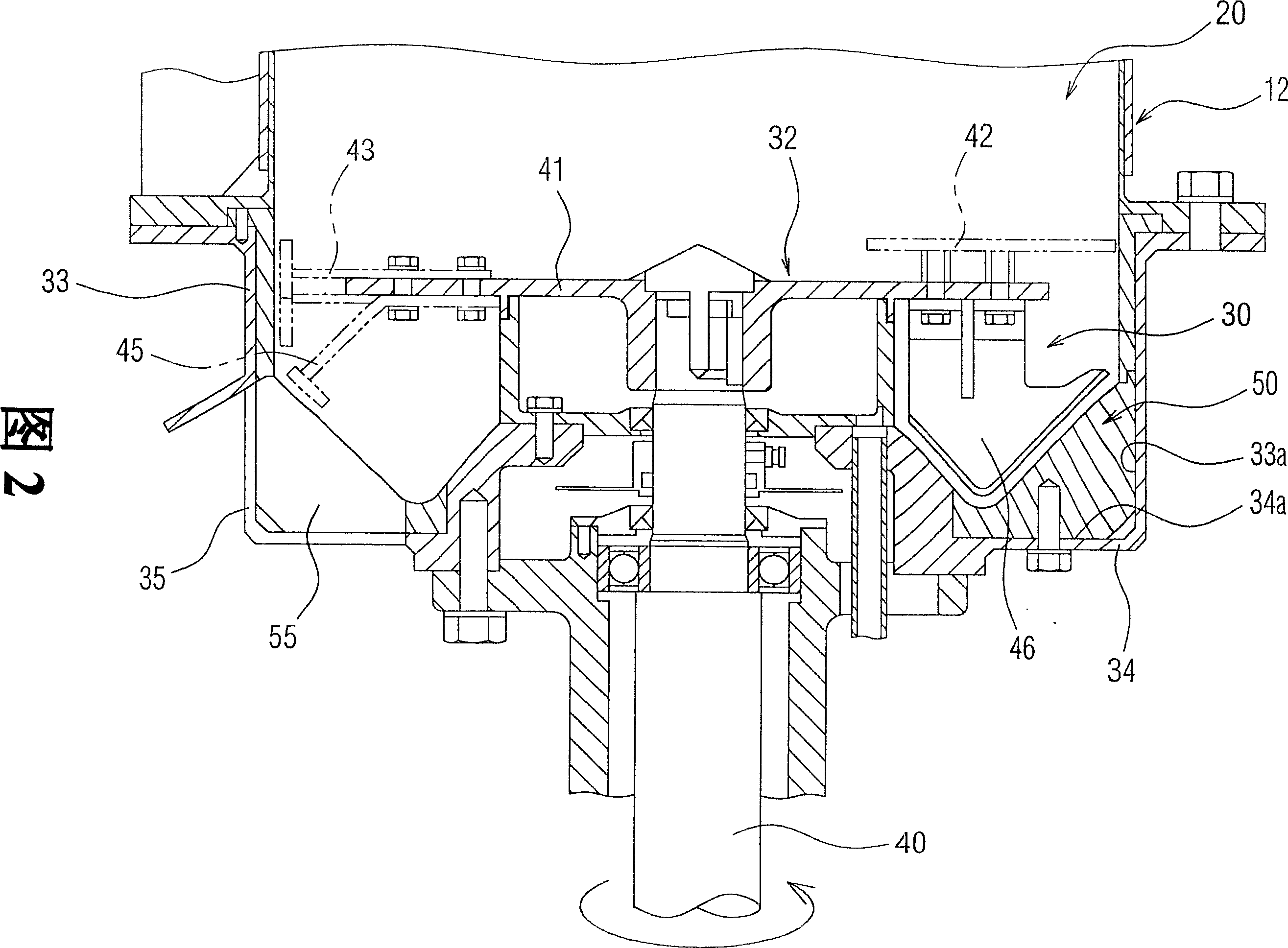

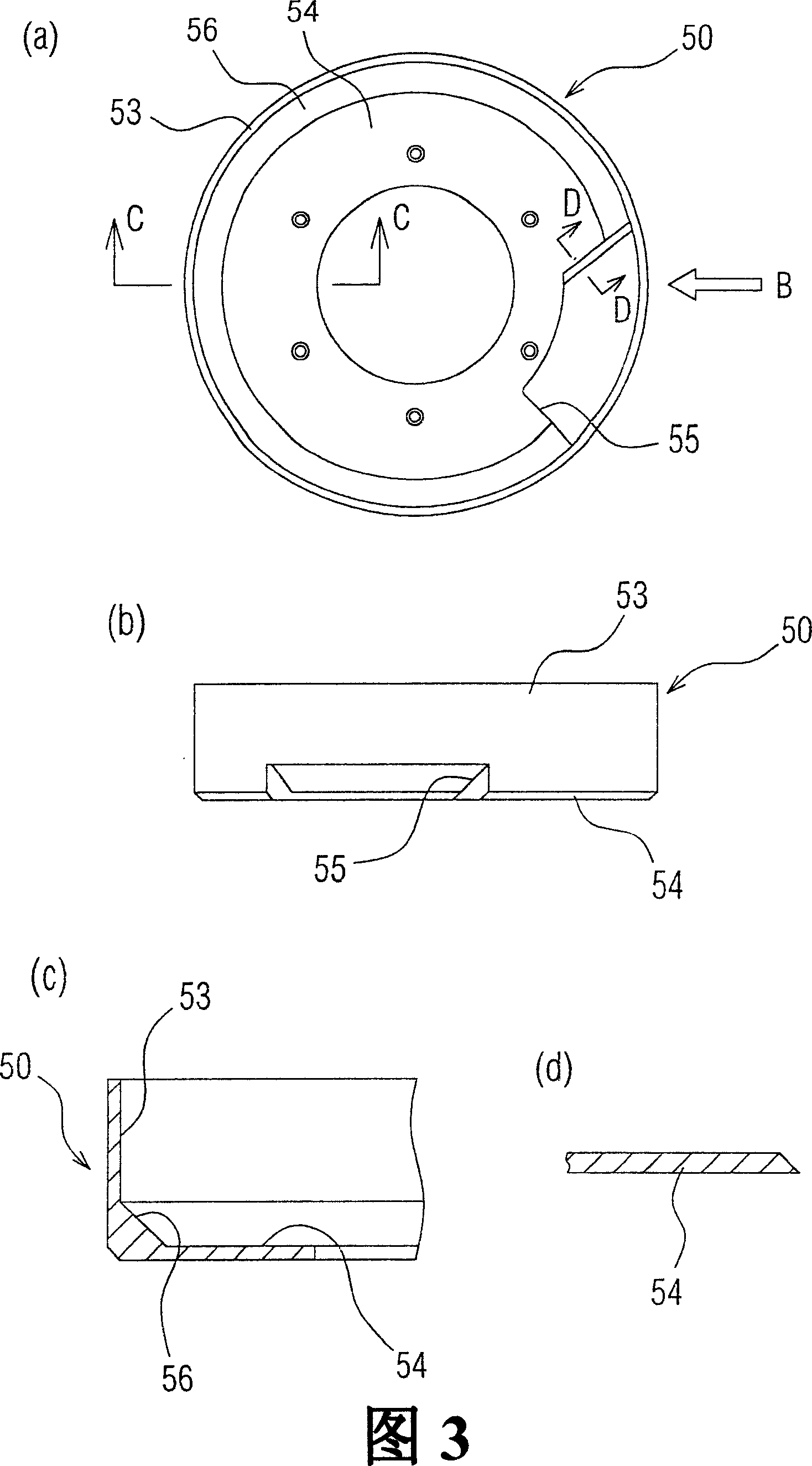

Method and apparatus for granulating by mixing powder and liquid continuously

ActiveCN1927437AImprove yieldWide applicabilityFlow mixersGranulation in rotating dishes/pansManufacturing cost reductionEngineering

The invention relates to a method of powder / liquid continuous mixing particle production. Wherein, said method comprises that sealing the top of hopper mixed particle producing room (12); the center at the top uses ejector (14) to continuously eject liquid downwards; the powder outlet (16) at the circumference of ejector disperses the atomized liquid to the powder; and the gas ejector (18) at the circumference of powder outlet feeds gas as the protective air film (Af) that avoiding dispersing the fed powder; therefore, the powder and liquid can continuously contact to form mixed particle (G); and the bottom of room (12) via the rotation of mixing disc (32) can make the air passive pressure, to generate eddy flow, to accelerate the particle (G) generation, and shear or mix the particle (G), to form and discharge uniform particles (G).

Owner:FUNKEN POWTECHS

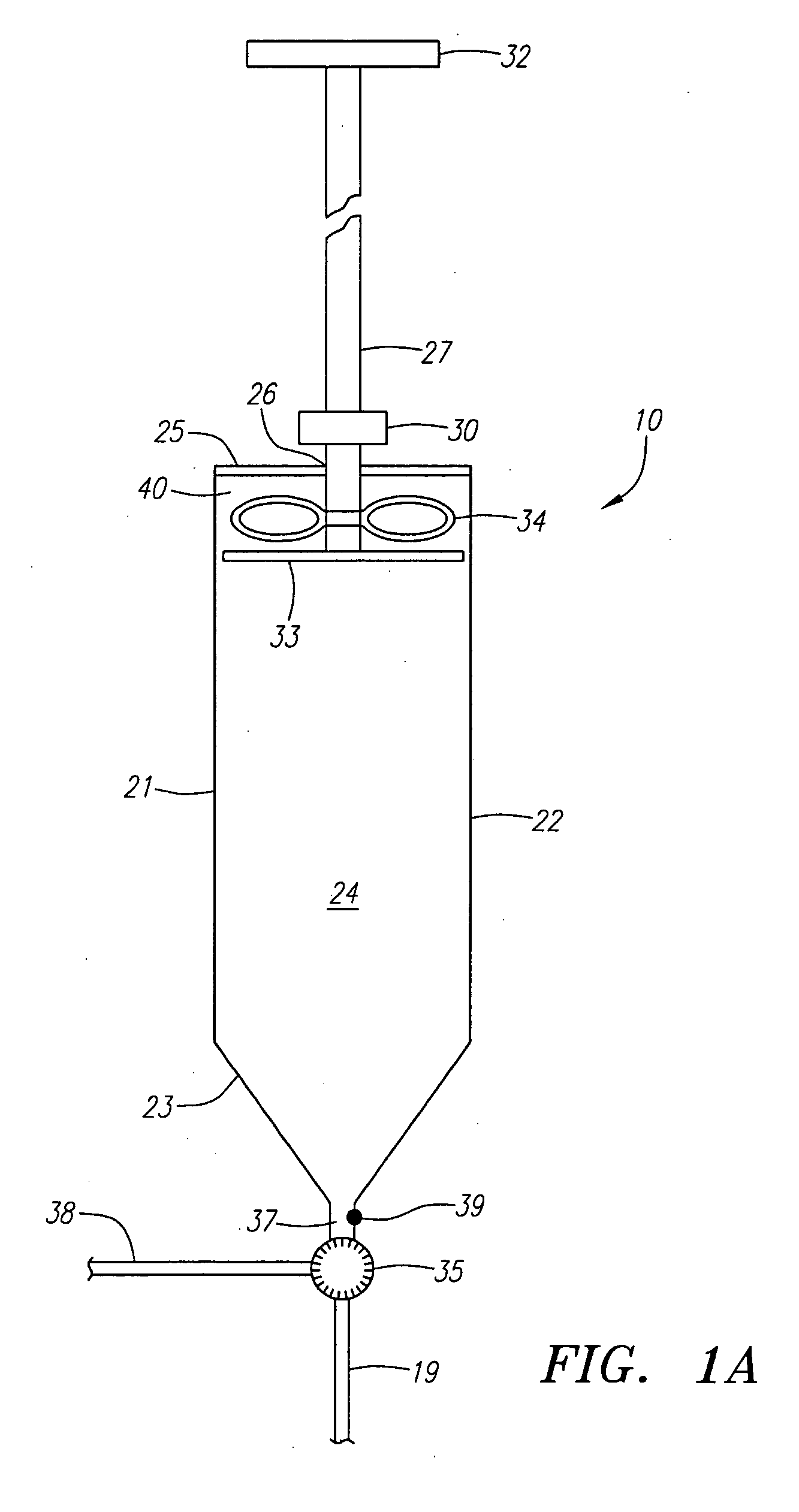

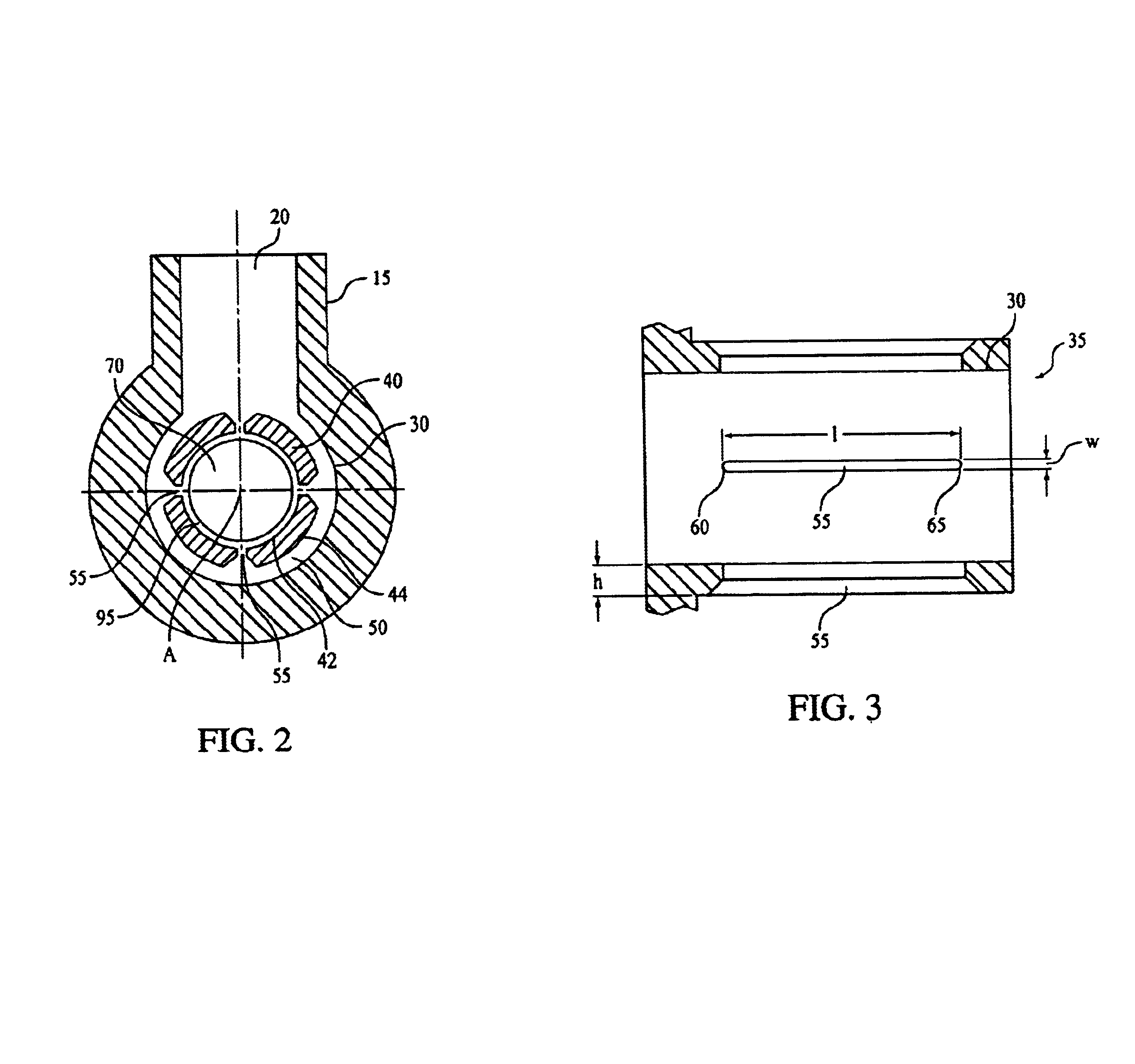

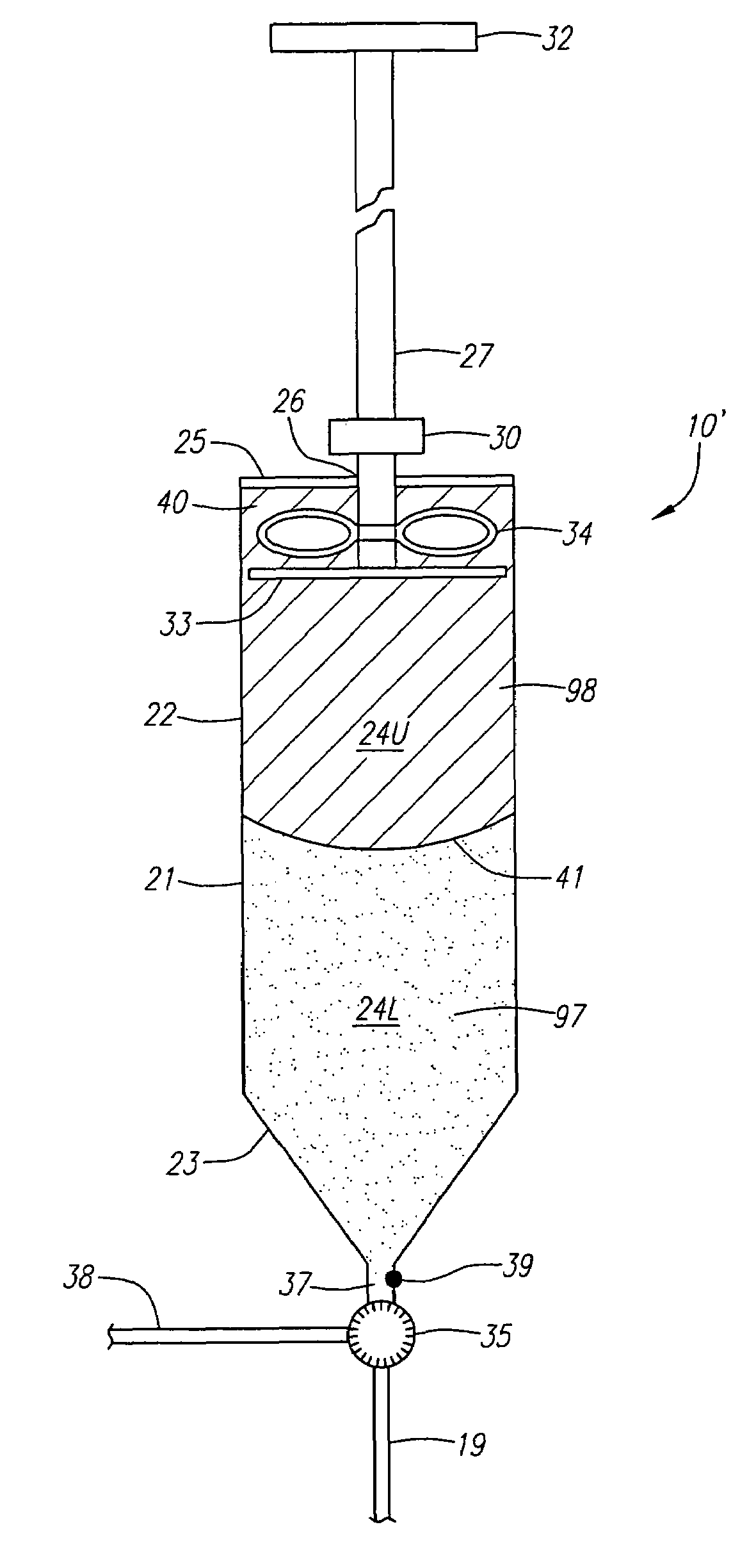

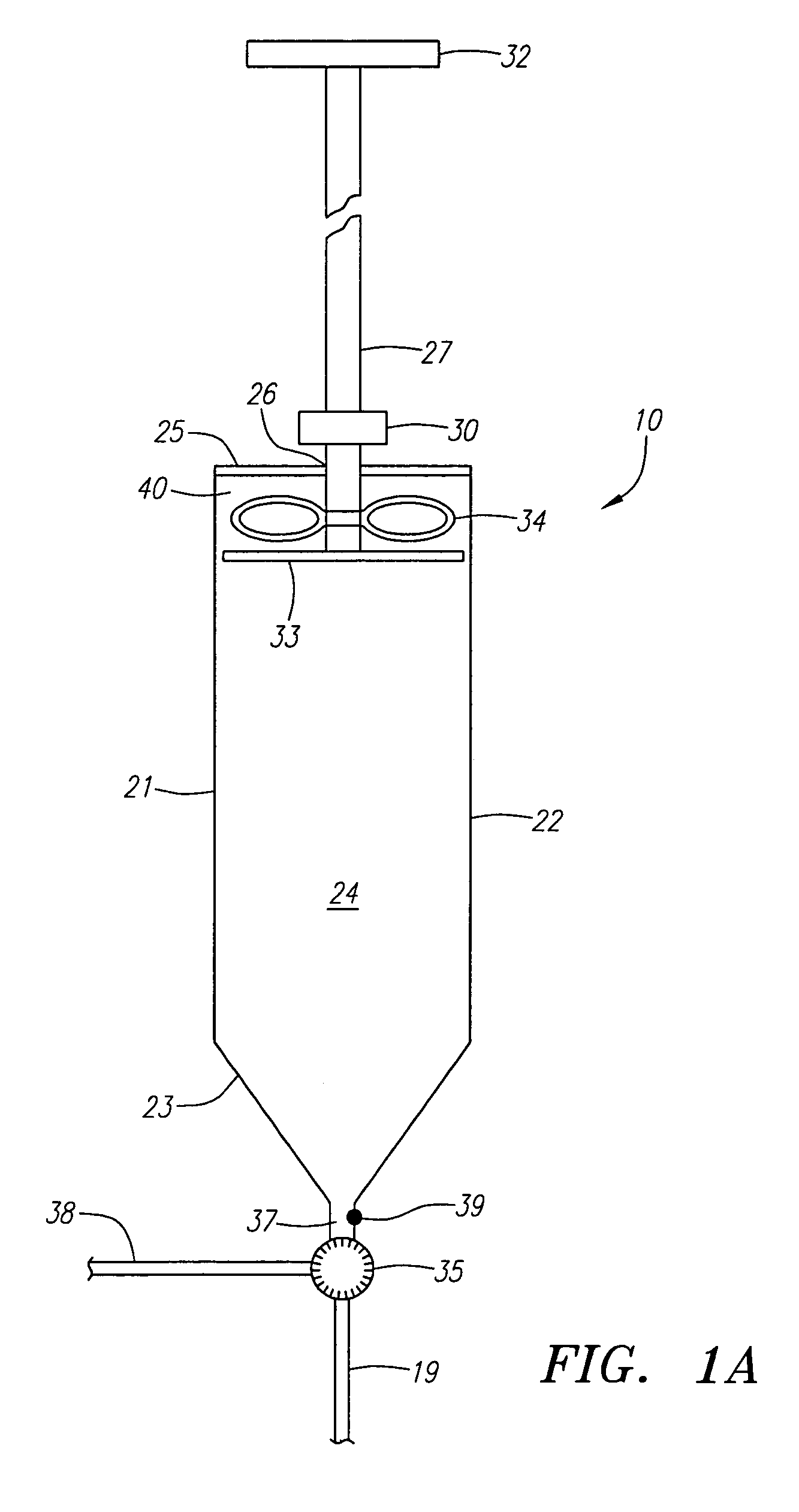

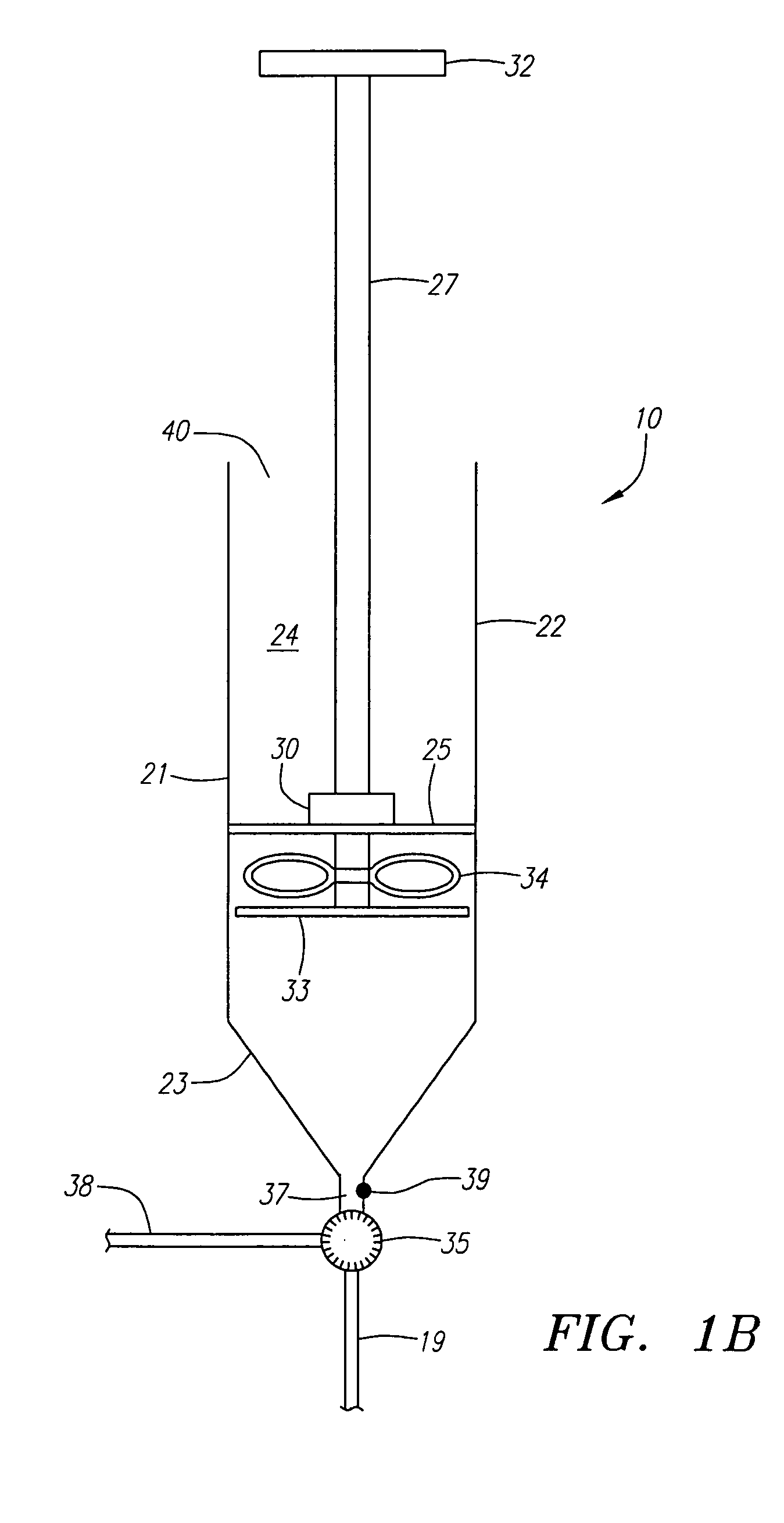

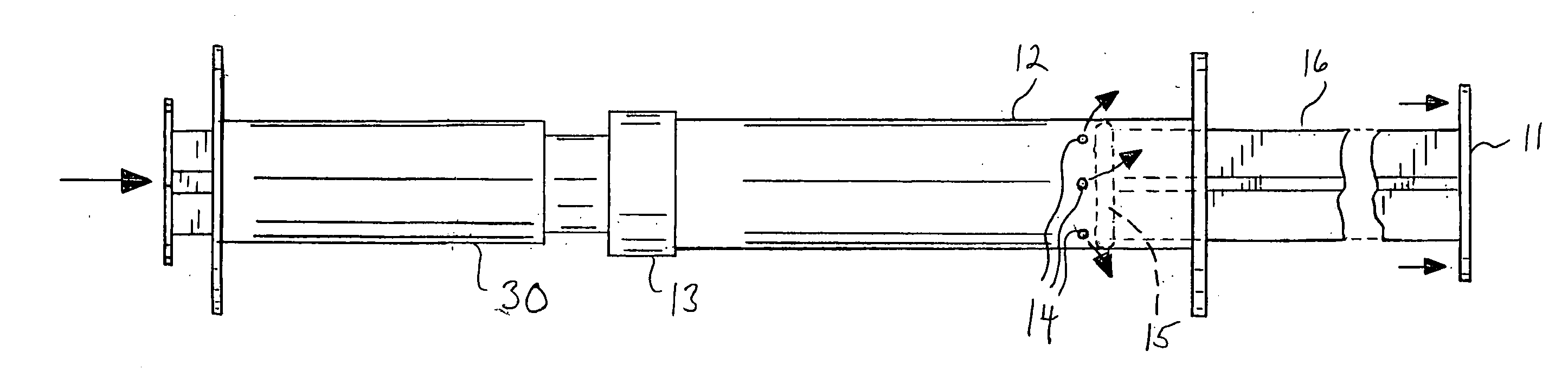

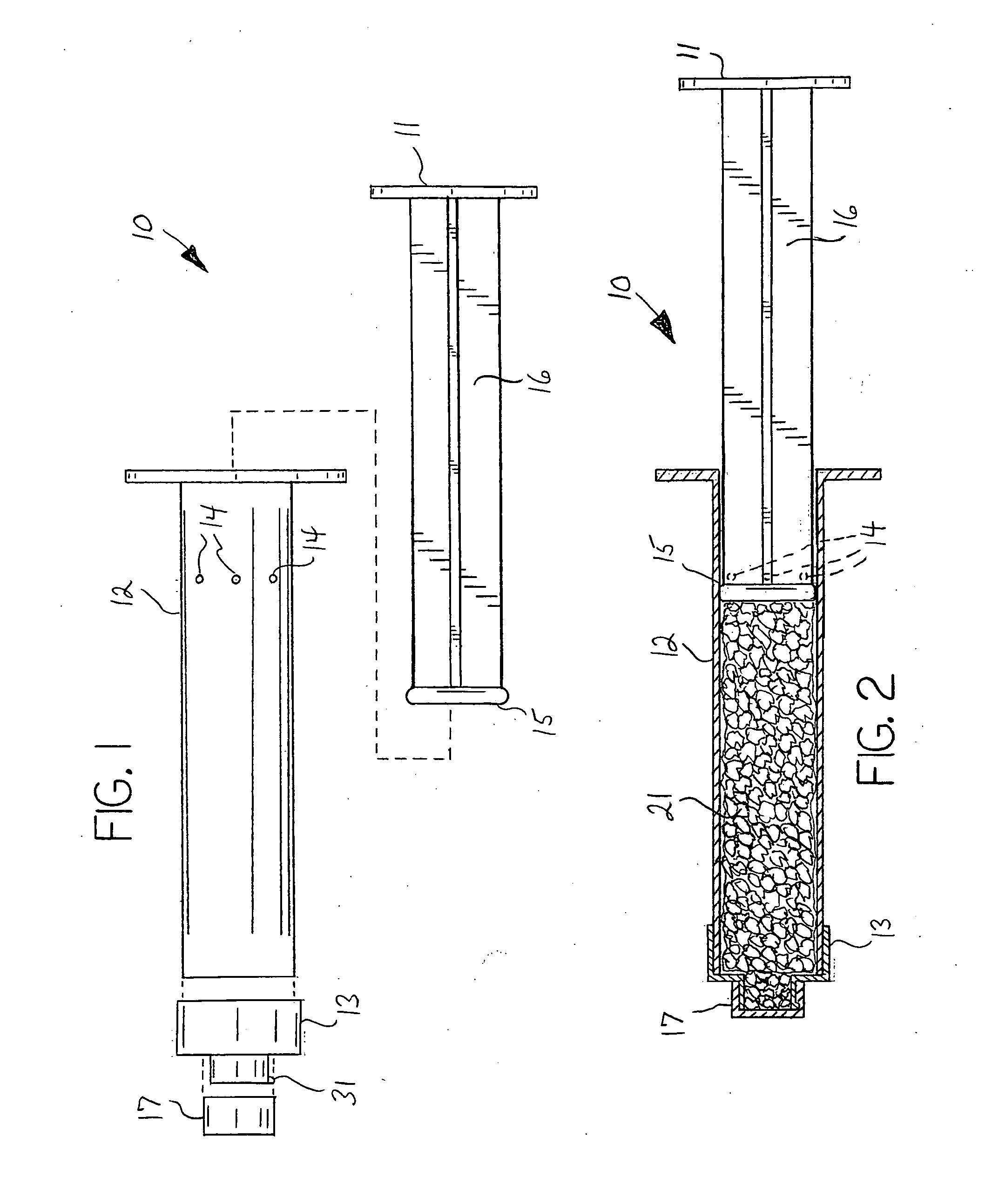

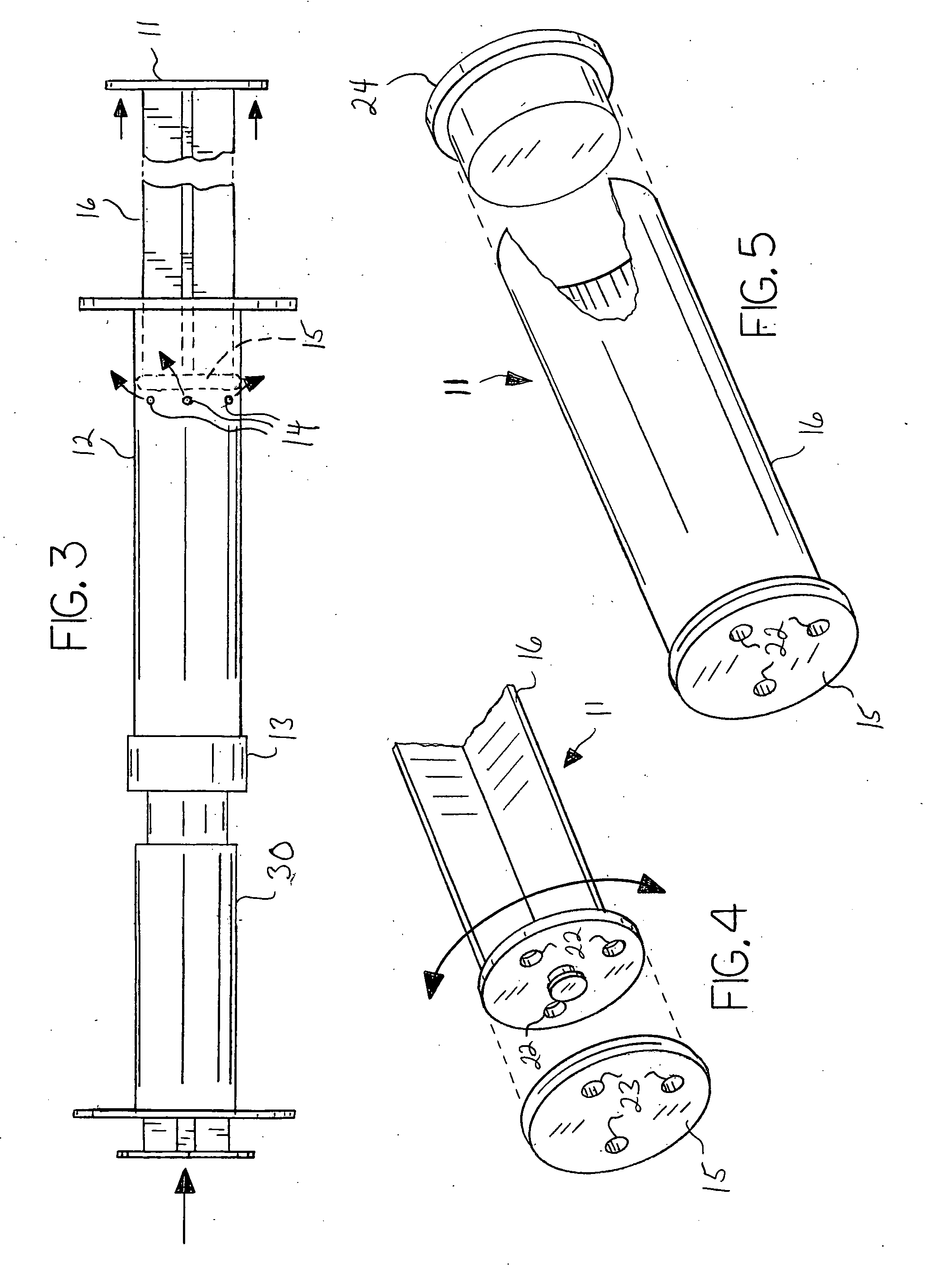

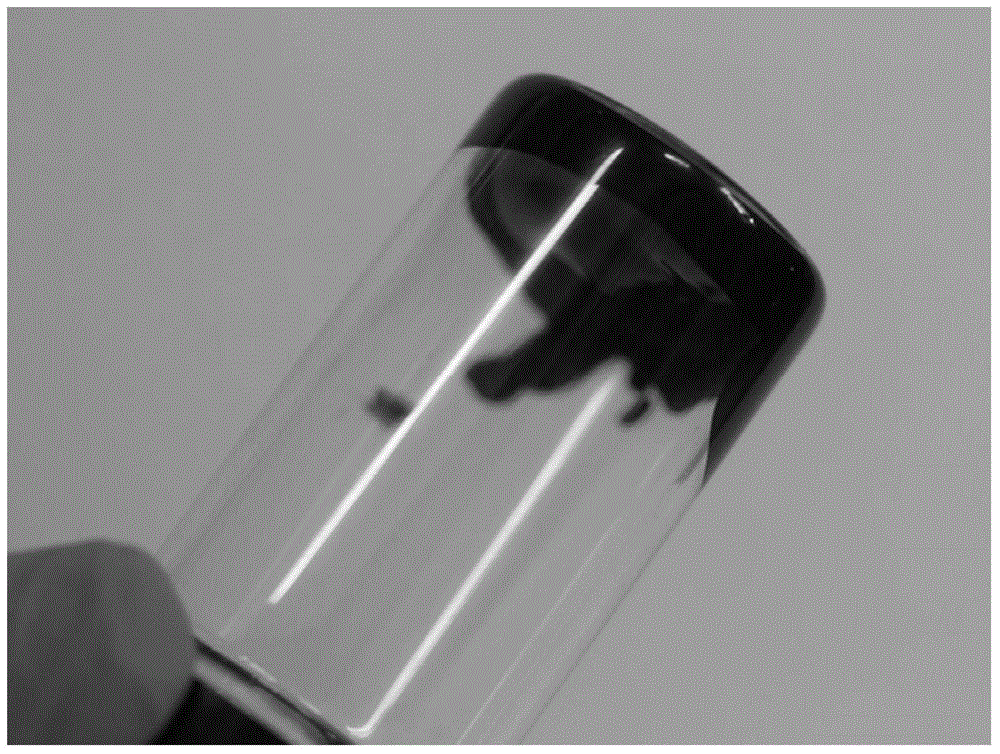

Vented syringe system and method for the containment, mixing and ejection of wetted particulate material

InactiveUS20100249753A1Efficient use ofImprove handlingTransportation and packagingMedical devicesEnvironmental engineeringParticulate material

A vented syringe system and method for particulate containment, mixing and delivery, the system having a vented syringe containing particulate material structured to enable entrapped gases to escape during the injection of liquid into the particulate material, such that gas is removed from the vented syringe prior to ejection of the wetted particulate material.

Owner:GAISSER DAVID M +1

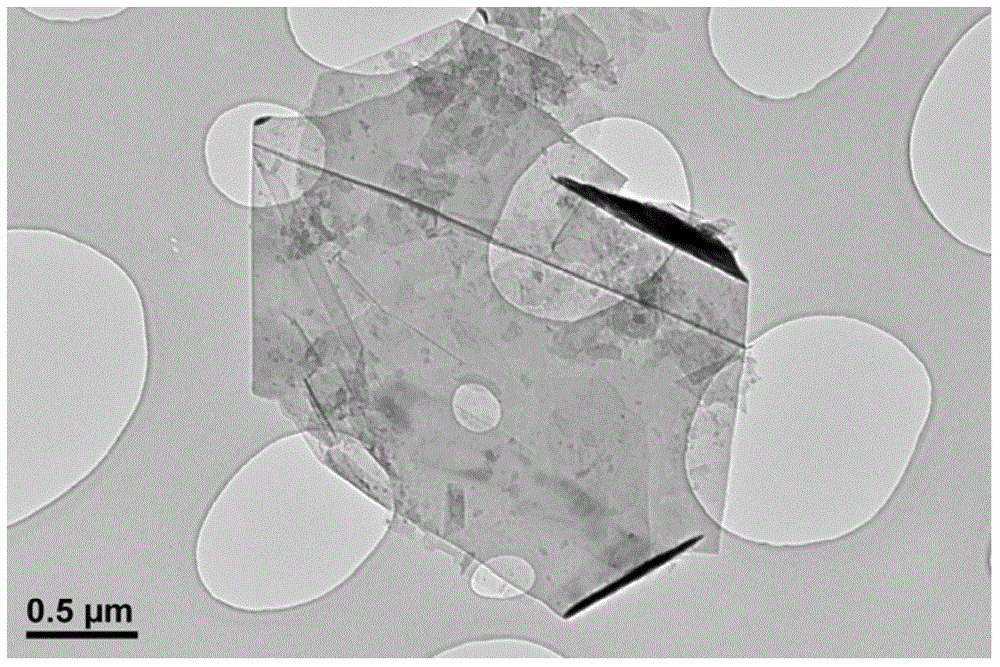

Highly dispersed highly stable high concentration and high yield graphene dispersion liquid and preparation method thereof

InactiveCN104959050AIncrease concentrationImprove stabilityCarbon compoundsTransportation and packagingHigh concentrationOrganic solvent

The present invention provides a highly dispersed highly stable high concentration and high yield graphene dispersion liquid and a preparation method thereof, and relates to the preparation method of the graphene dispersion liquid. The graphene dispersion liquid concentration is 1mg / mL-60mg / mL, and the graphene dispersion liquid comprises 0 to 6% (by weight) of a dispersant; the graphene diameter is 100-6000nm; the graphene yield is 40 %-99%; and the preparation method is a mechanical grinding technique based on a ball or a rod or a segment as a media. The graphene dispersion liquid solves the poor dispersibility, low stability, low concentration, low yield and other problems of the graphene in water and other various organic solvents, and the graphene dispersion liquid is a black viscous slurry, good in dispersion, has good stability, high dispersion concentration, and high production yield.

Owner:BEIJING NATURE STONE SCI TECH DEVP

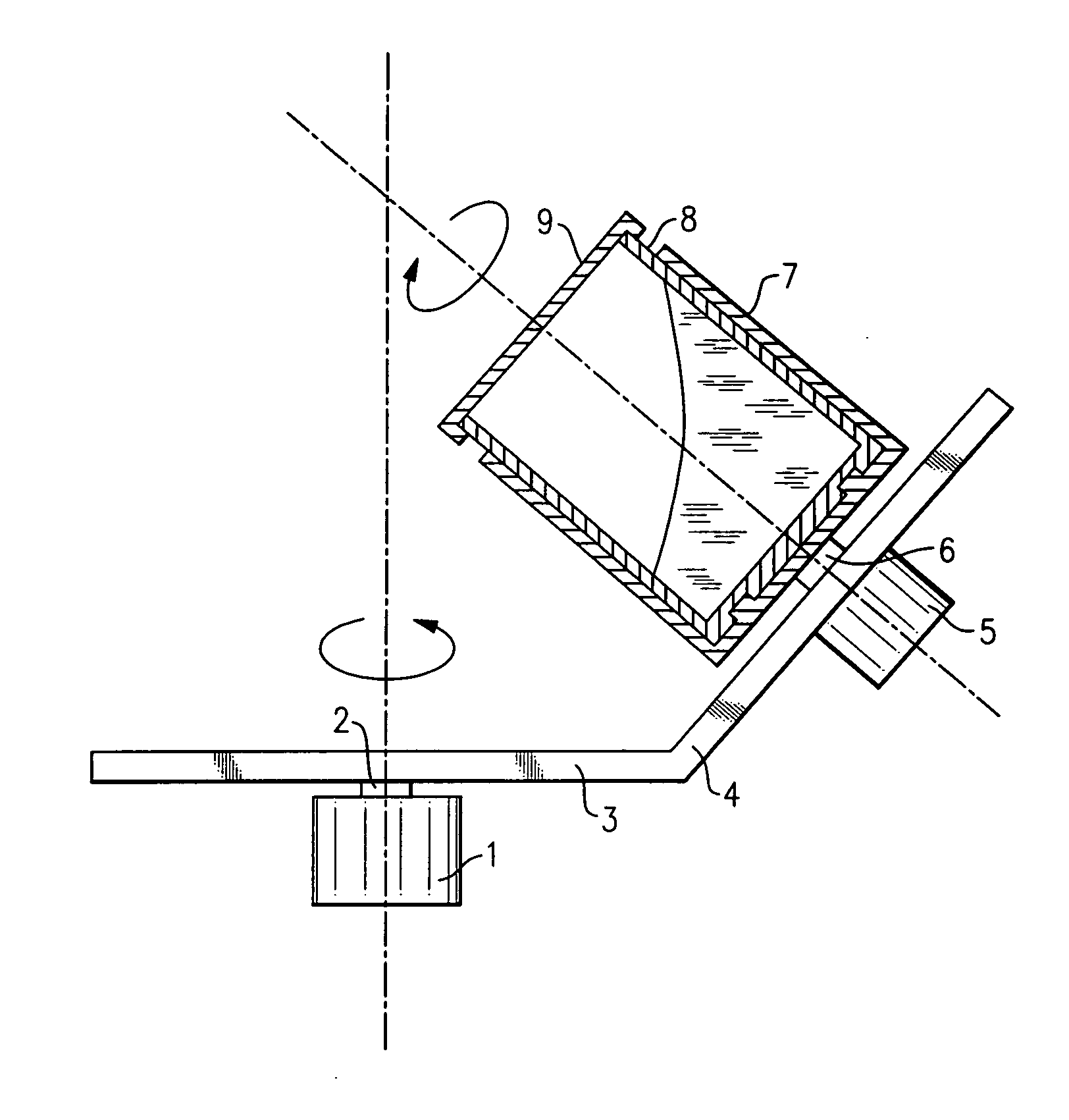

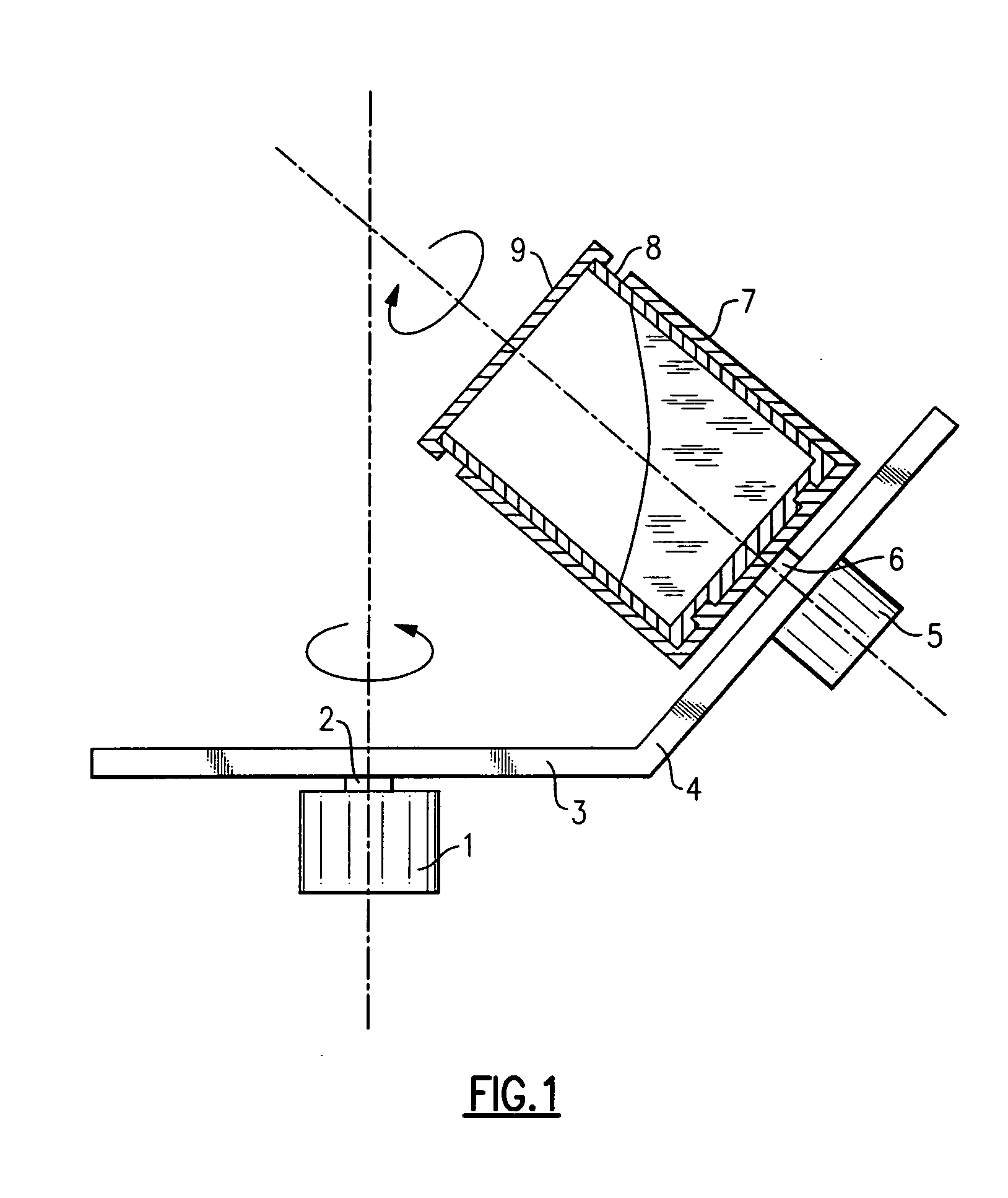

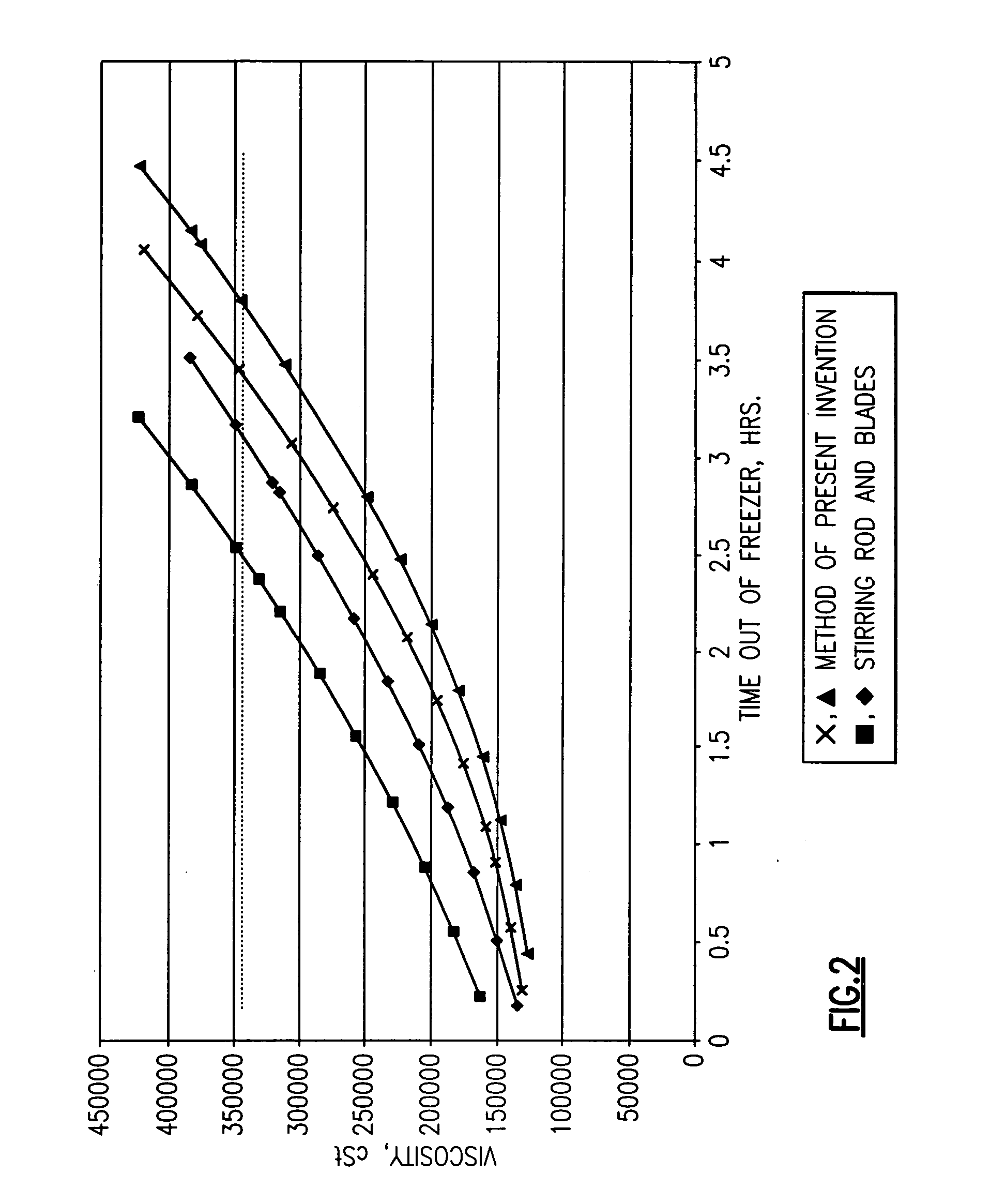

Method of producing liquid solutions comprising fusible solid materials

InactiveUS20070002682A1Short timeExtend working lifeRotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringDissolution

A method of producing a mixture or solution of a liquid and a fusible solid comprises providing, in a container, the liquid and the fusible solid; and subjecting the container to a rotational motion about a first axis in a first direction while rotating the container about a second axis in a second direction to effect a dissolution of the fusible solid and a mixing of the components of the mixture or solution.

Owner:BAUSCH & LOMB INC

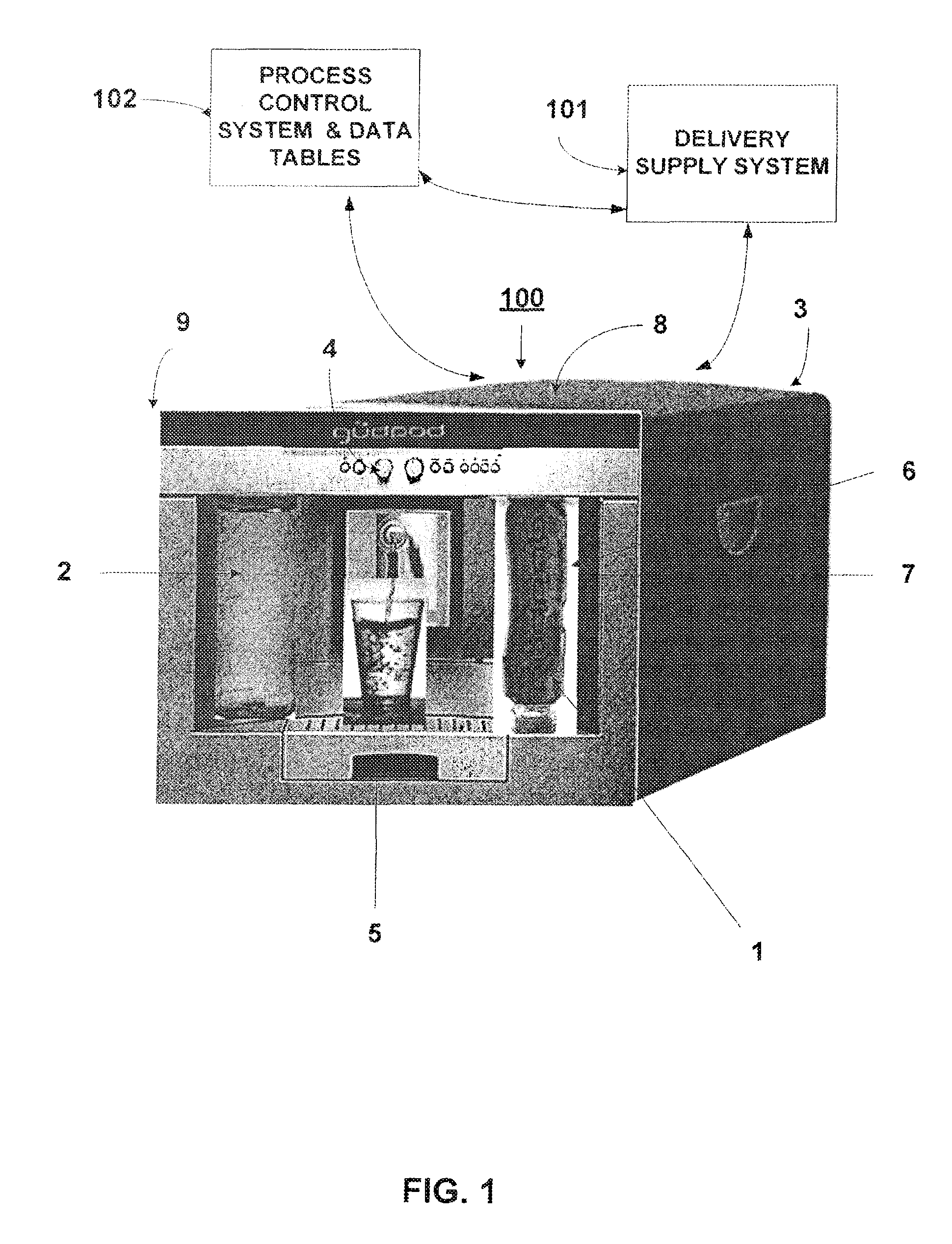

Beverage mixing system and process

ActiveUS8844426B2Simplifies waste streamEliminate separationRotary stirring mixersMixer accessoriesHybrid systemEngineering

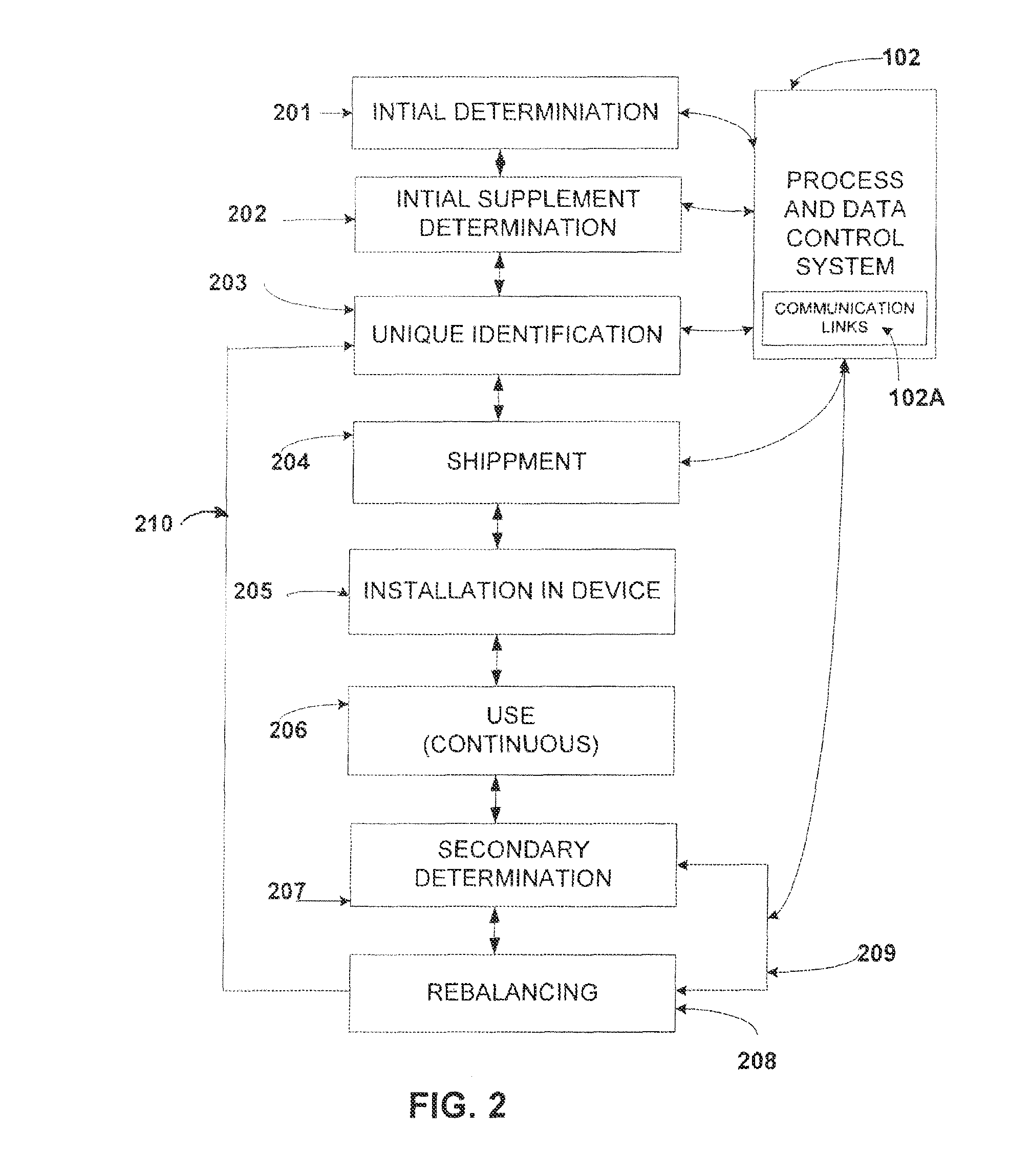

The present invention relates to a system and process for a nutraceutical beverage mixing system. Provided is a customizable supplement beverage system and method for personalizing and operating the same to a particular user and optionally for operative tracking. Proposed additionally is an operative system for receiving and individually identifying a concentrate or supplement combinations, for mixing the same prior to a use, and for dispensing the same for use, and for tracking control factors relating to the same.

Owner:GUDPOD CORP

Device and method for creating hydrodynamic cavitation in fluids

A device and method for creating hydrodynamic cavitation in fluid is provided. The device can include a flow-through chamber having a first portion and a second portion, and a plurality of baffles provided within the second portion of the flow-through chamber. One or more of the plurality of baffles can be configured to be selectively movable into the first portion of the flow-through chamber to generate a hydrodynamic cavitation field downstream from each baffle moved into the first portion of the flow-through chamber.

Owner:ARISDYNE STSTEMS INC

Bottle with mixing system

InactiveUS7036975B2Efficient mixingPlace safeShaking/oscillating/vibrating mixersFlow mixersEngineeringMixing effect

There is provided an infant feeding bottle system having an agitator for mixing a powder substance with a liquid in a non-rigid disposable liner. The bottle system permits a user to mix powdered formula directly inside a non-rigid liner. The bottle system enhances the mixing effect, resulting in improved solubility, and provides for a self-contained uninterrupted mixing and feeding process.

Owner:JMBH HLDG LLC

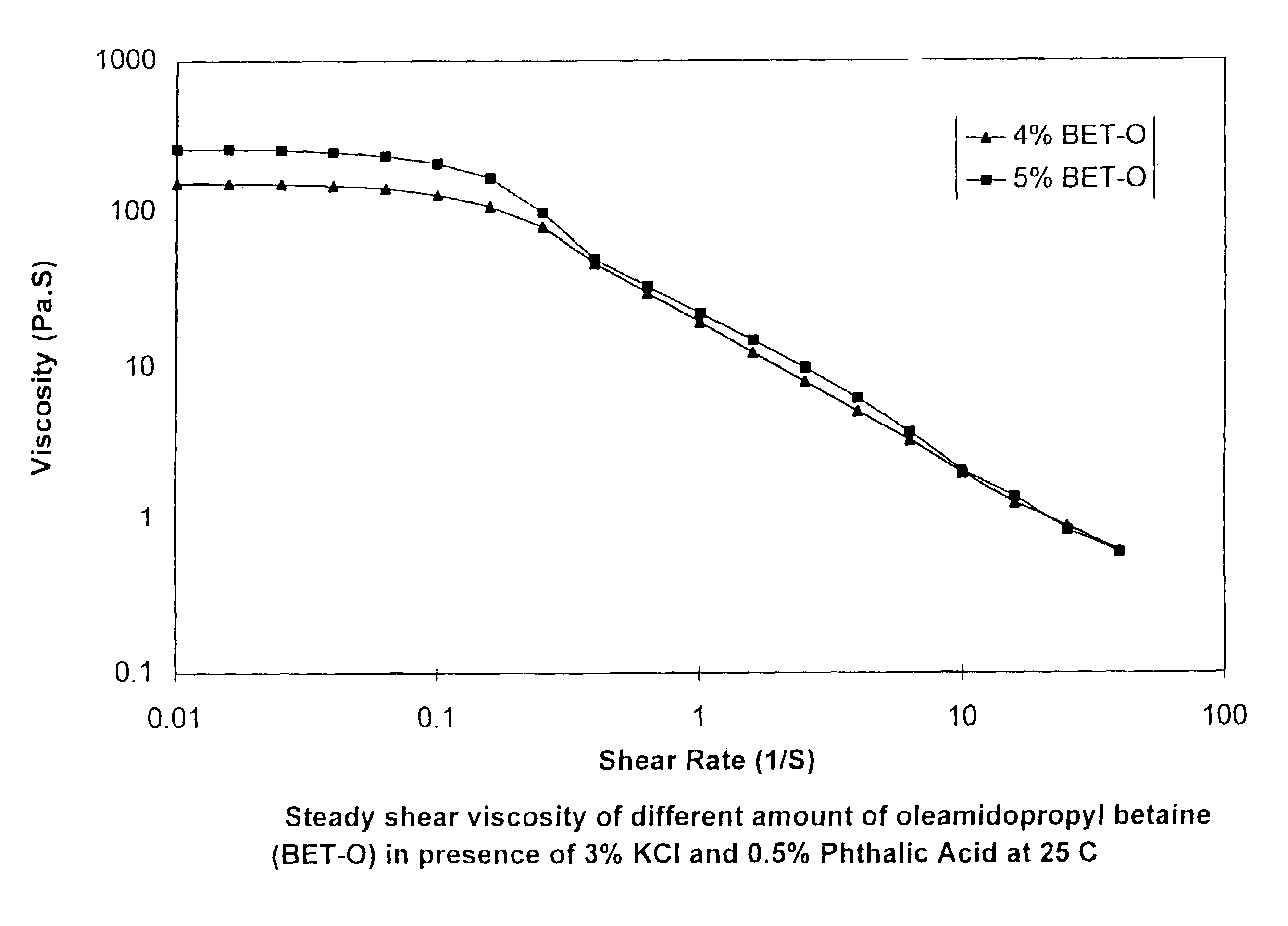

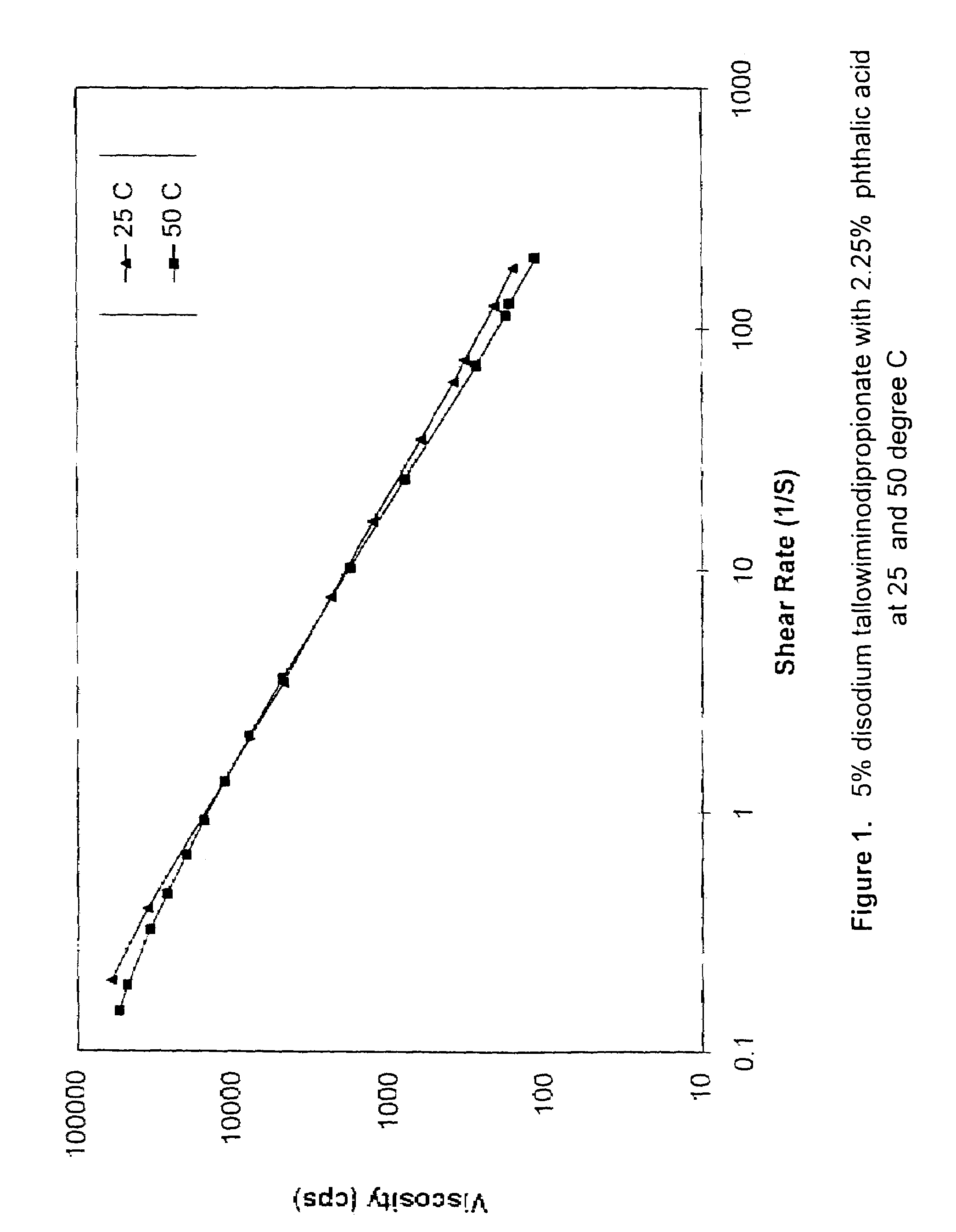

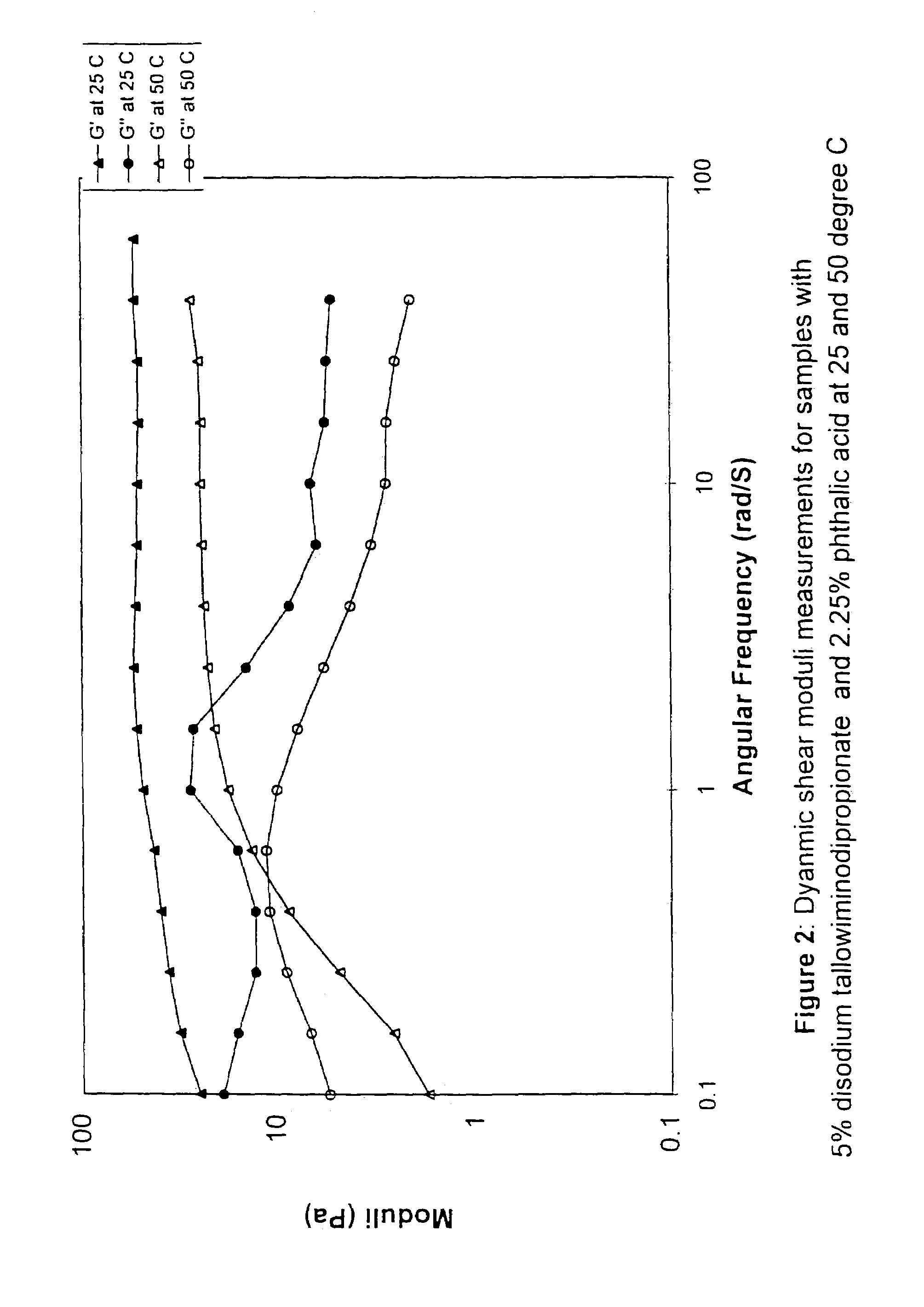

Viscoelastic surfactant fluids and related methods of use

InactiveUS7238648B2Increase droplet sizeIncrease in sizeInorganic/elemental detergent compounding agentsCosmetic preparationsSuspended particlesBetaine

Viscoelastic surfactant based aqueous fluid systems useful as thickening agents in various applications, e.g. to suspend particles produced during the excavation of geologic formations. The surfactants are zwitterionic / amphoteric surfactants such as dihydroxyl alkyl glycinate, alkyl ampho acetate or propionate, alkyl betaine, alkyl amidopropyl betaine and alkylimino mono- or di-propionates derived from certain waxes, fats and oils. The thickening agent is used in conjunction with an inorganic water-soluble salt or organic additive such as phthalic acid, salicylic acid or their salts.

Owner:SCHLUMBERGER TECH CORP

Device and method for combining oils with other fluids and mixtures generated therefrom

InactiveUS20090188157A1Amount of catalyst can be reducedHigh chemical activityCosmetic preparationsFlow mixersAlcoholBiodiesel

A device and method a provided for mixing and enhancing reaction between oil and a non-oil liquid by exploiting the formation, implosion and explosion of numerous cavitation bubbles within a cavitation device. Intense localized energy from the collapse of the cavitation bubbles subjects the mixture to intense heat and pressure, thereby accelerating reaction between the oil and non-oil liquid. In one embodiment, the non-oil liquid is an alcohol, and the cavitation device is used to enhance a transesterification reaction to convert the oil and alcohol into biodiesel in the presence of a catalyst.

Owner:AQUAPHOTONICS INC

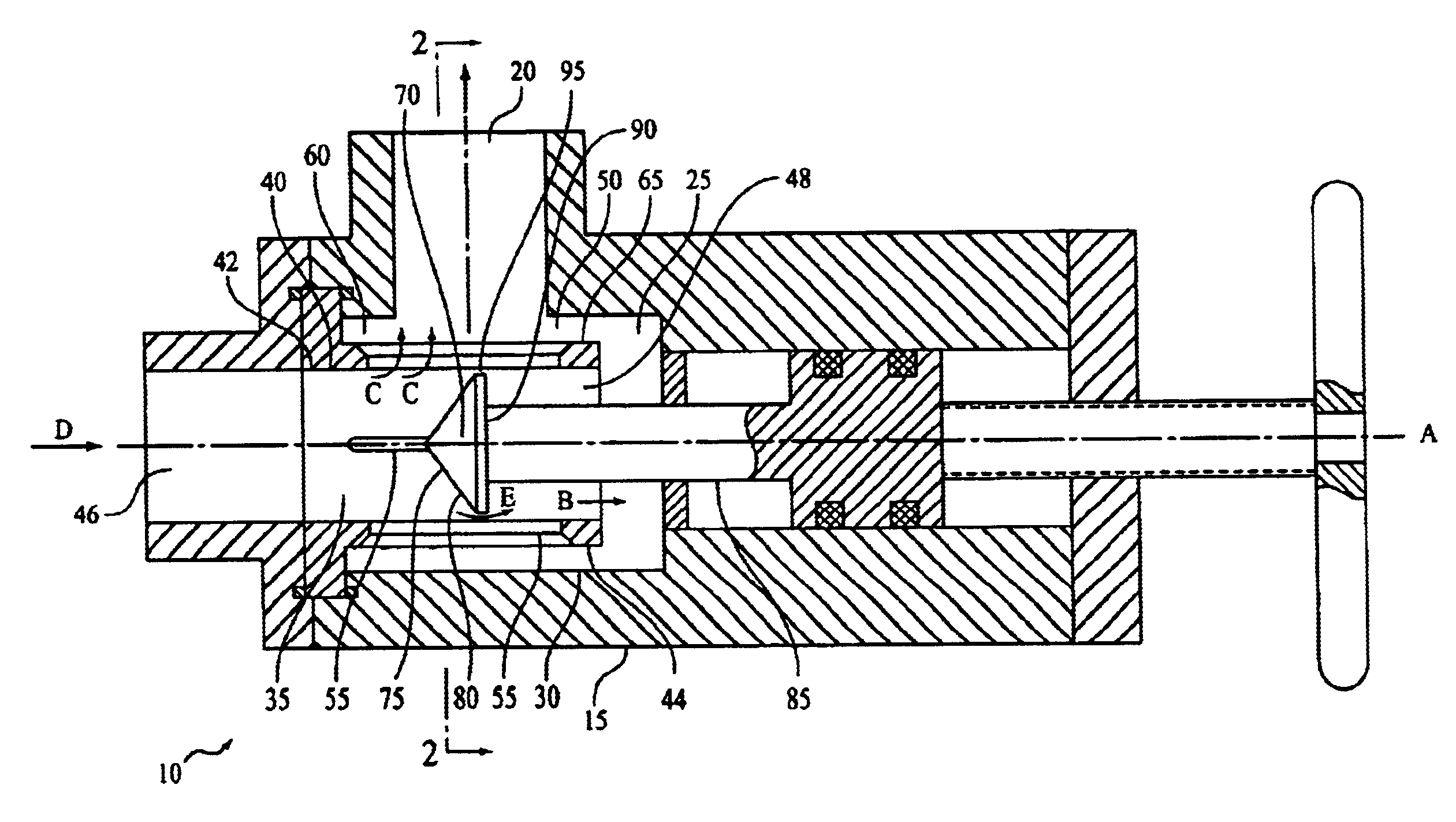

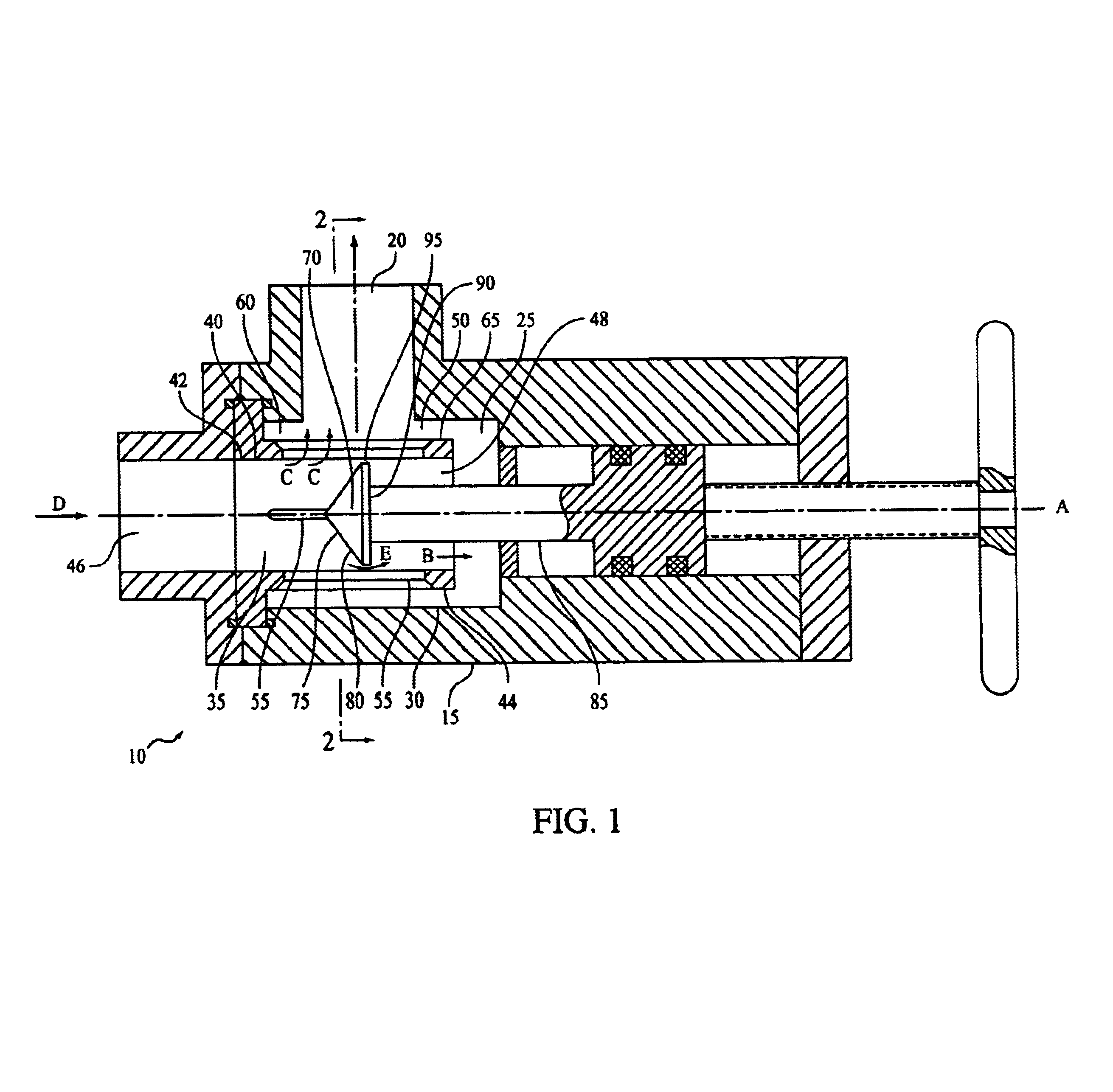

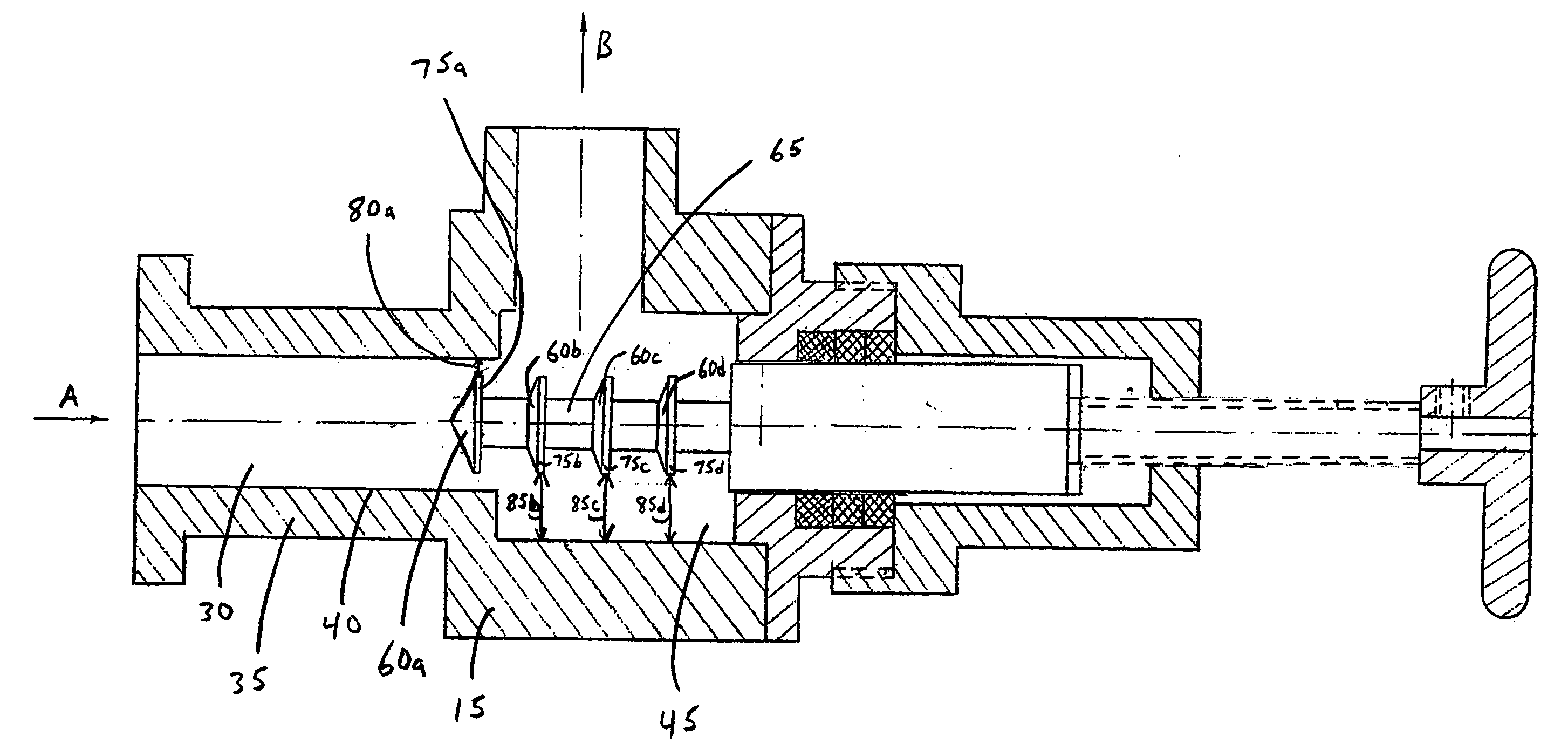

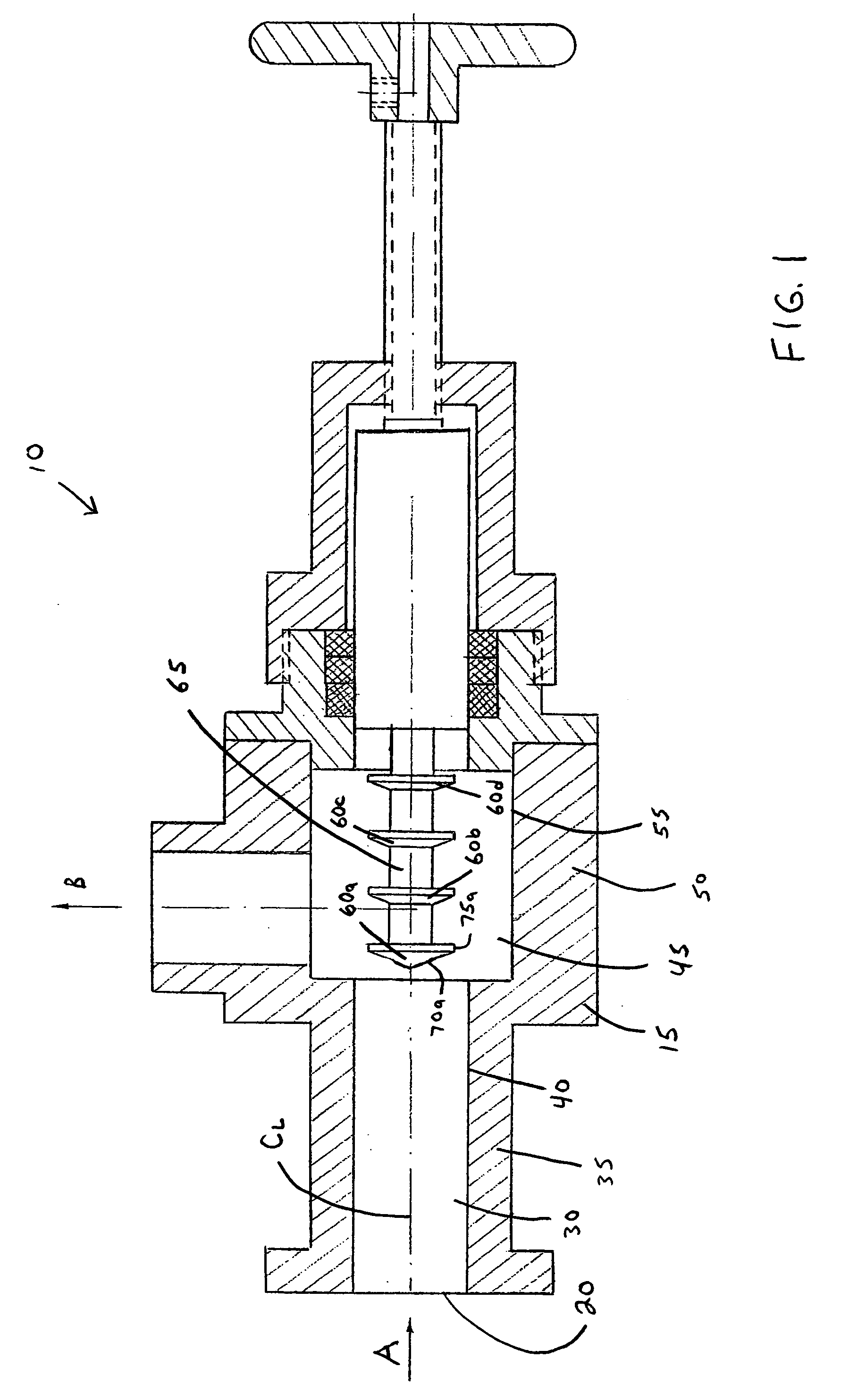

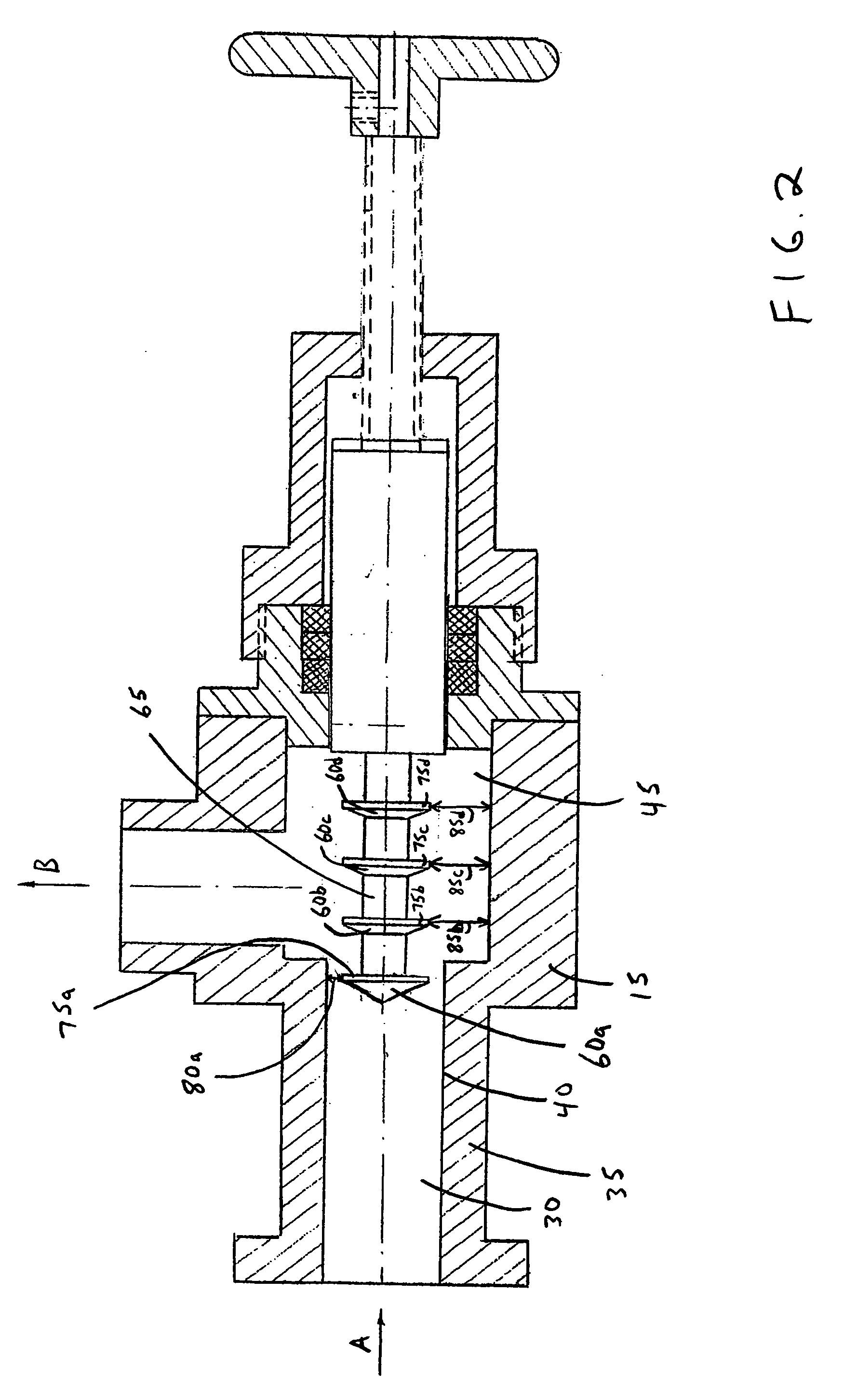

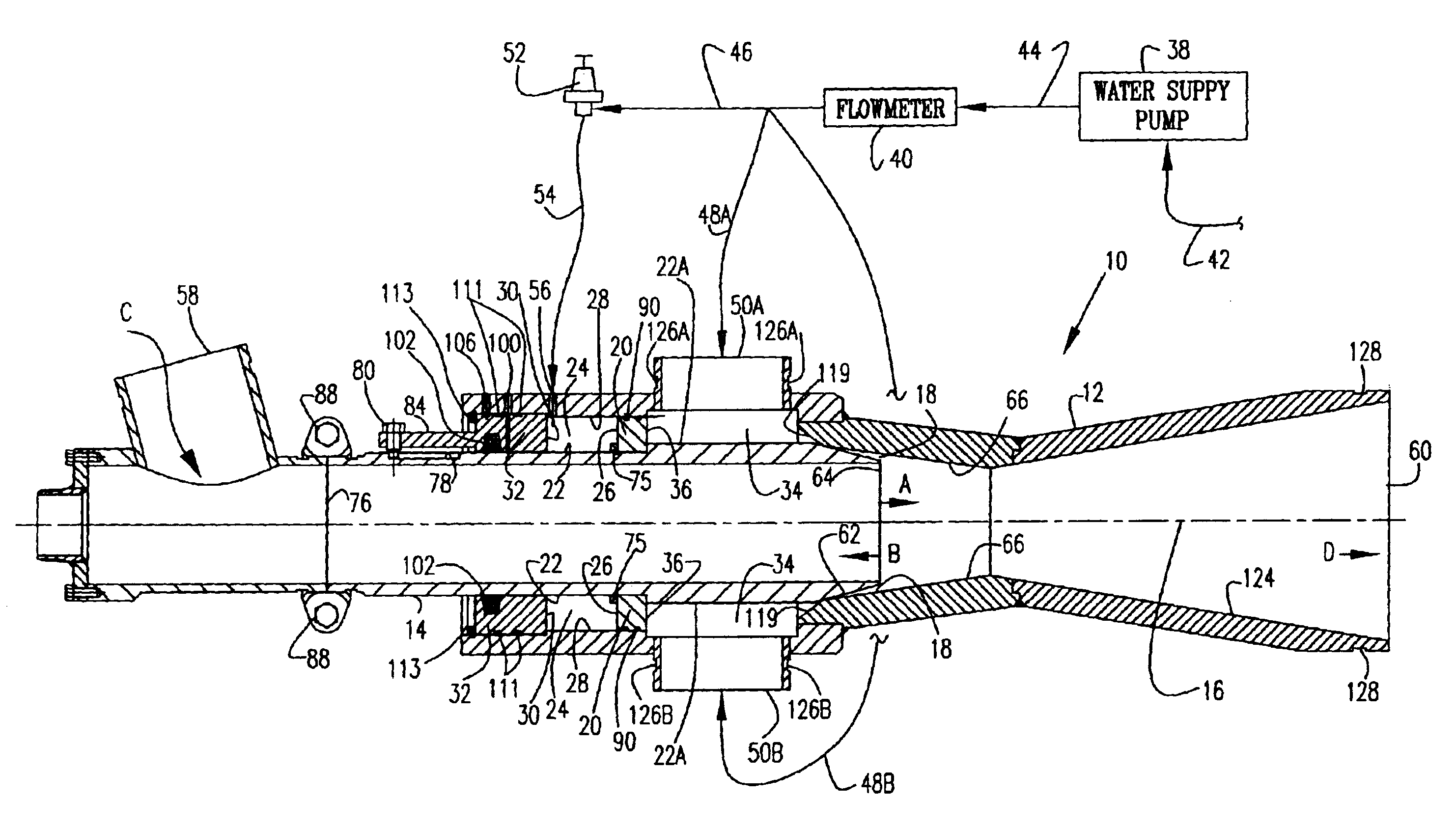

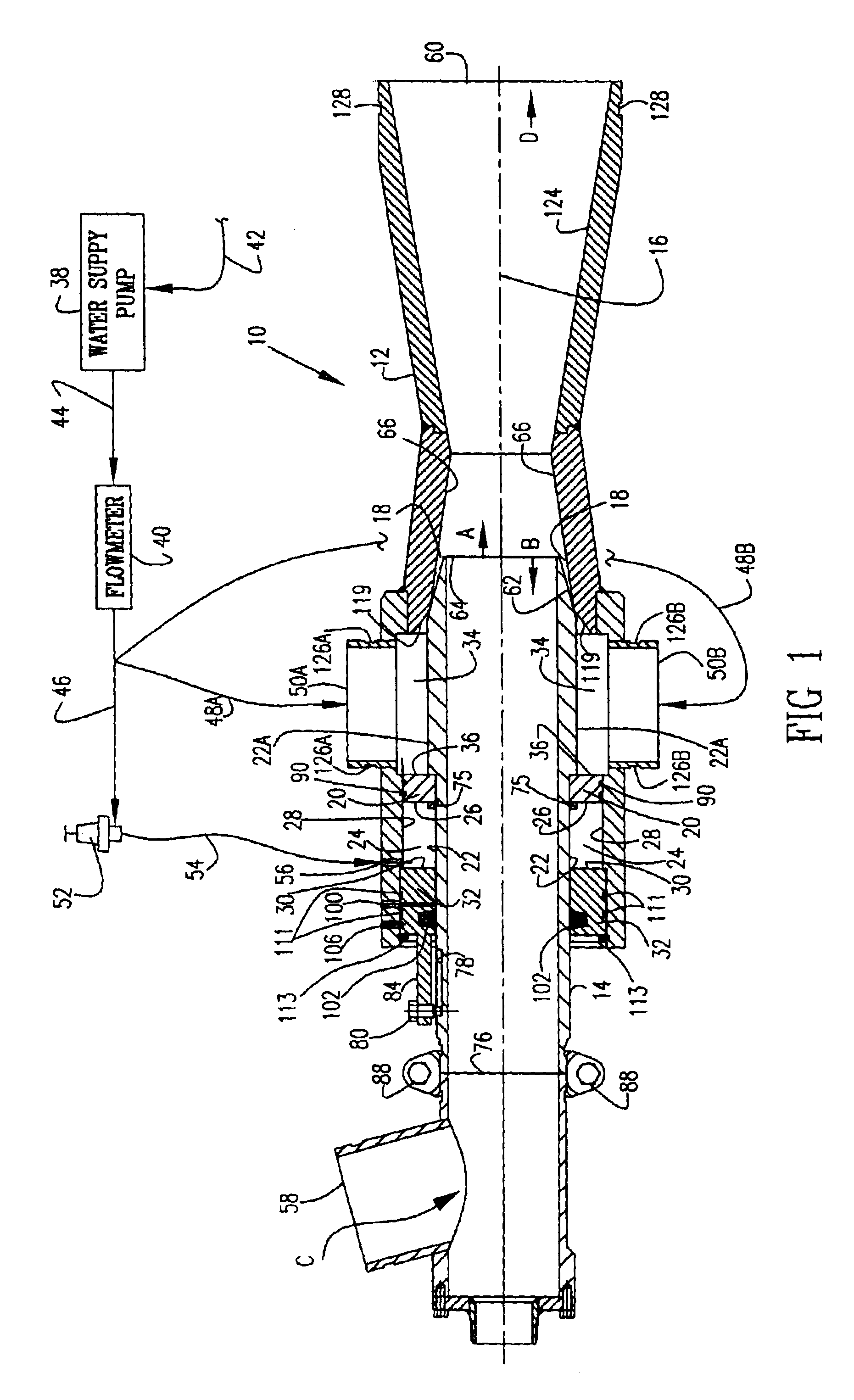

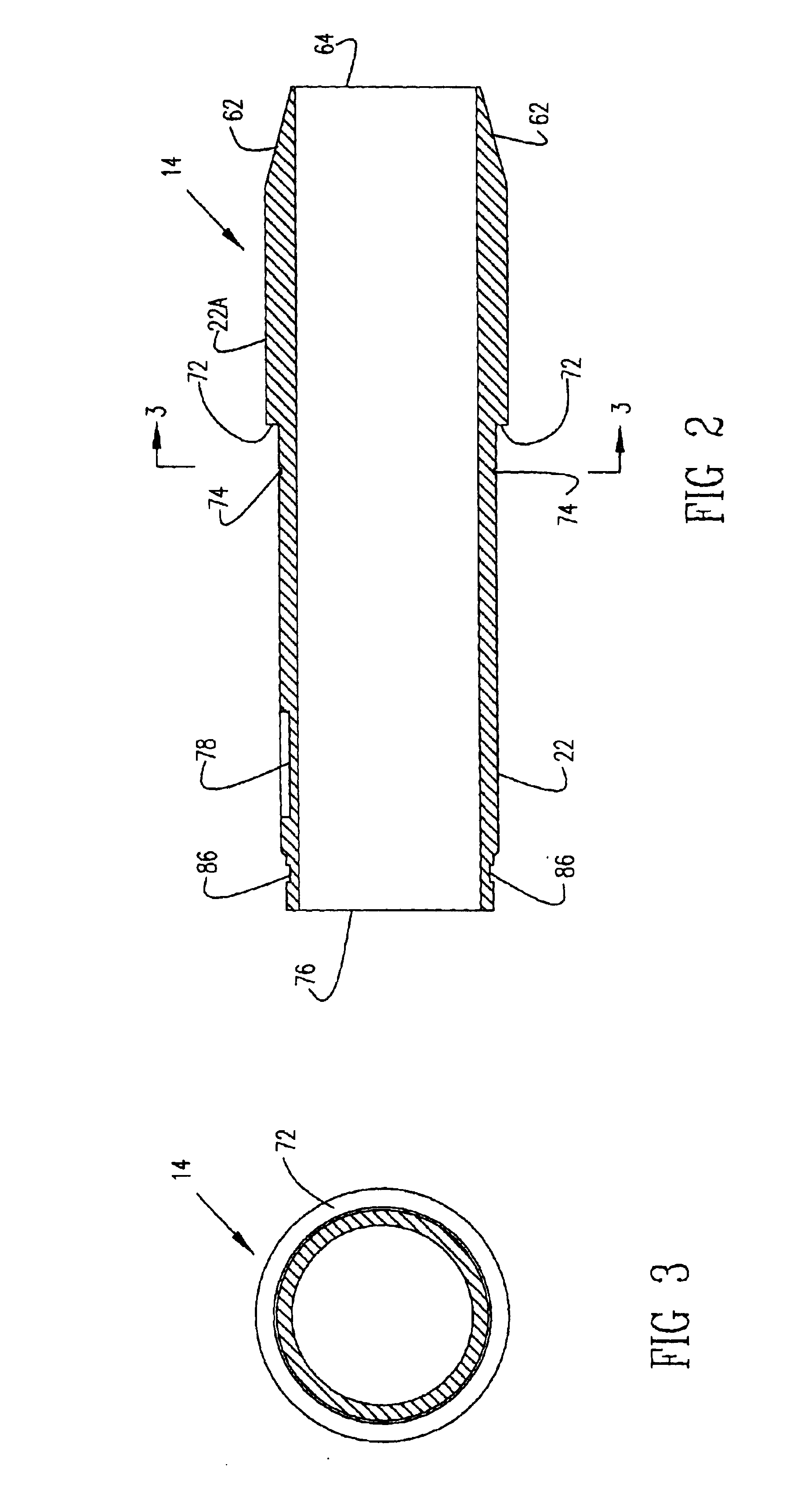

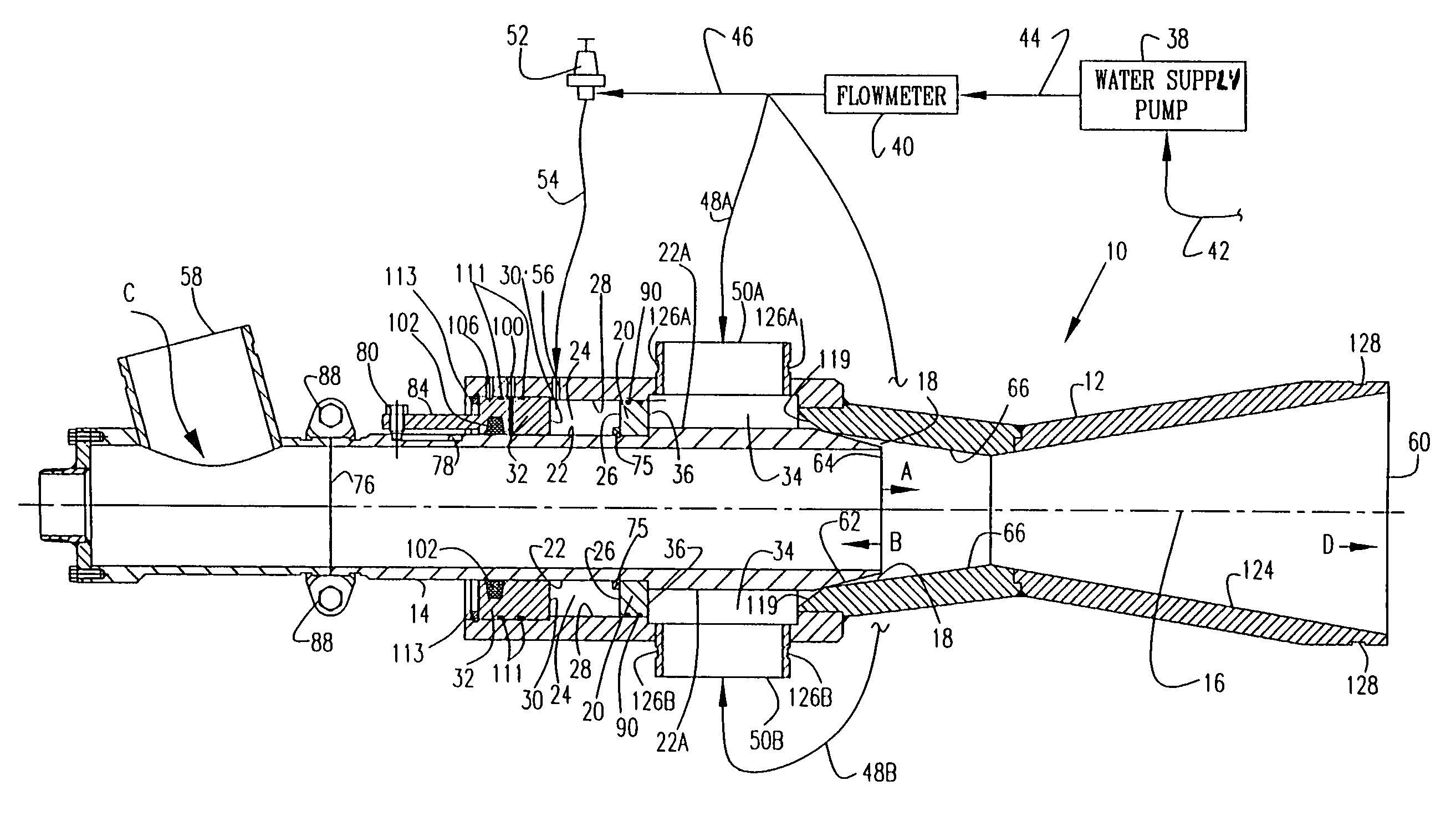

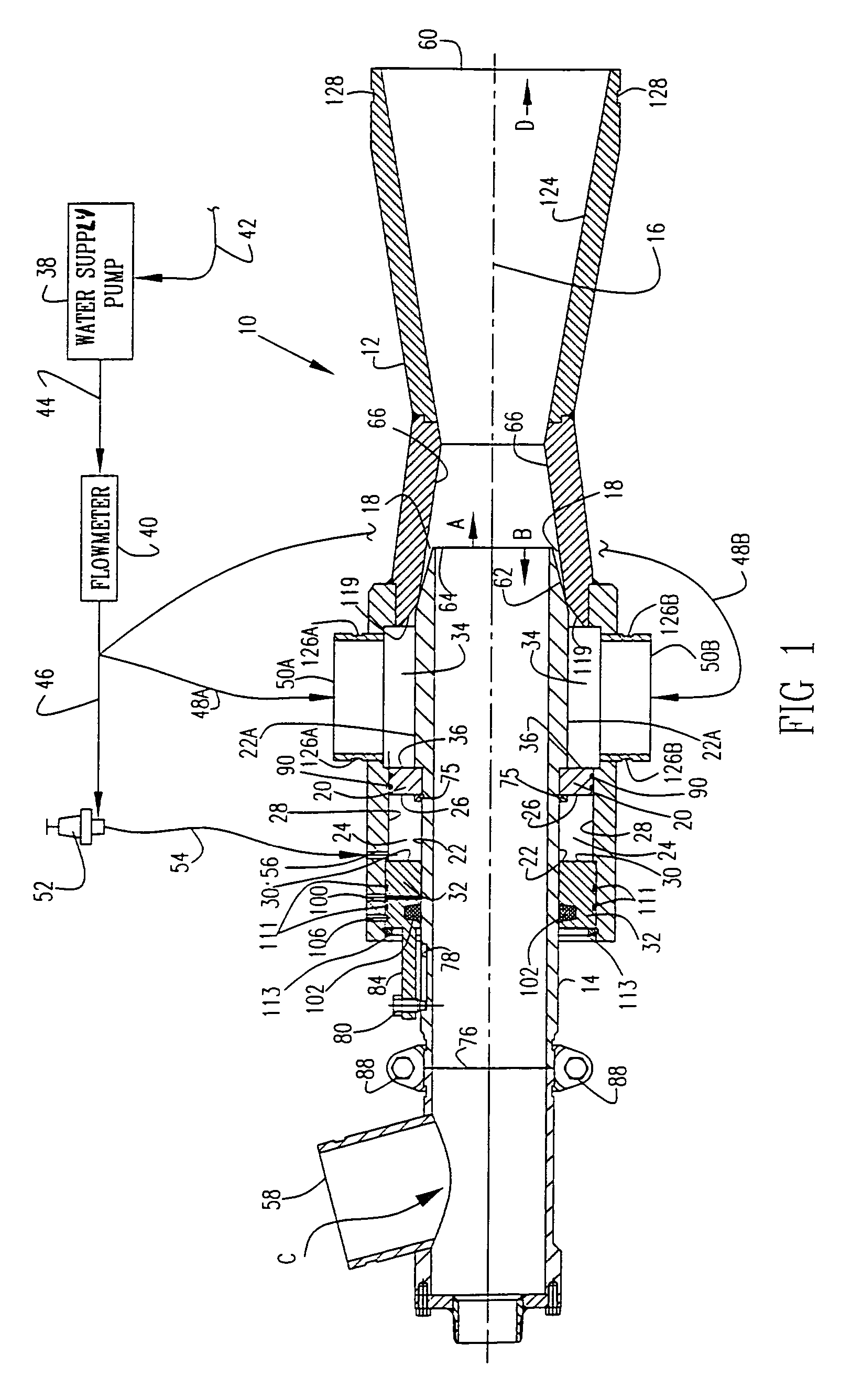

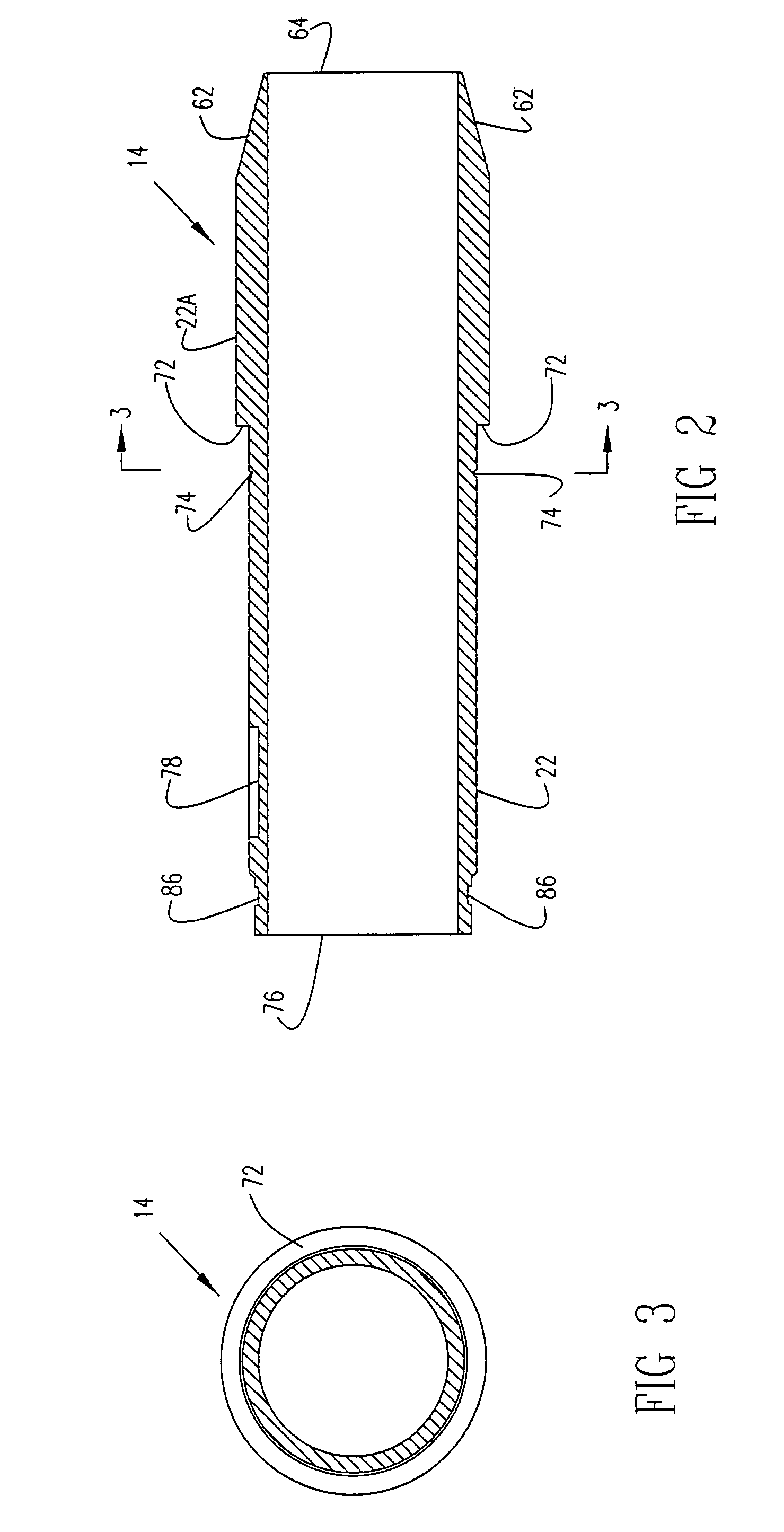

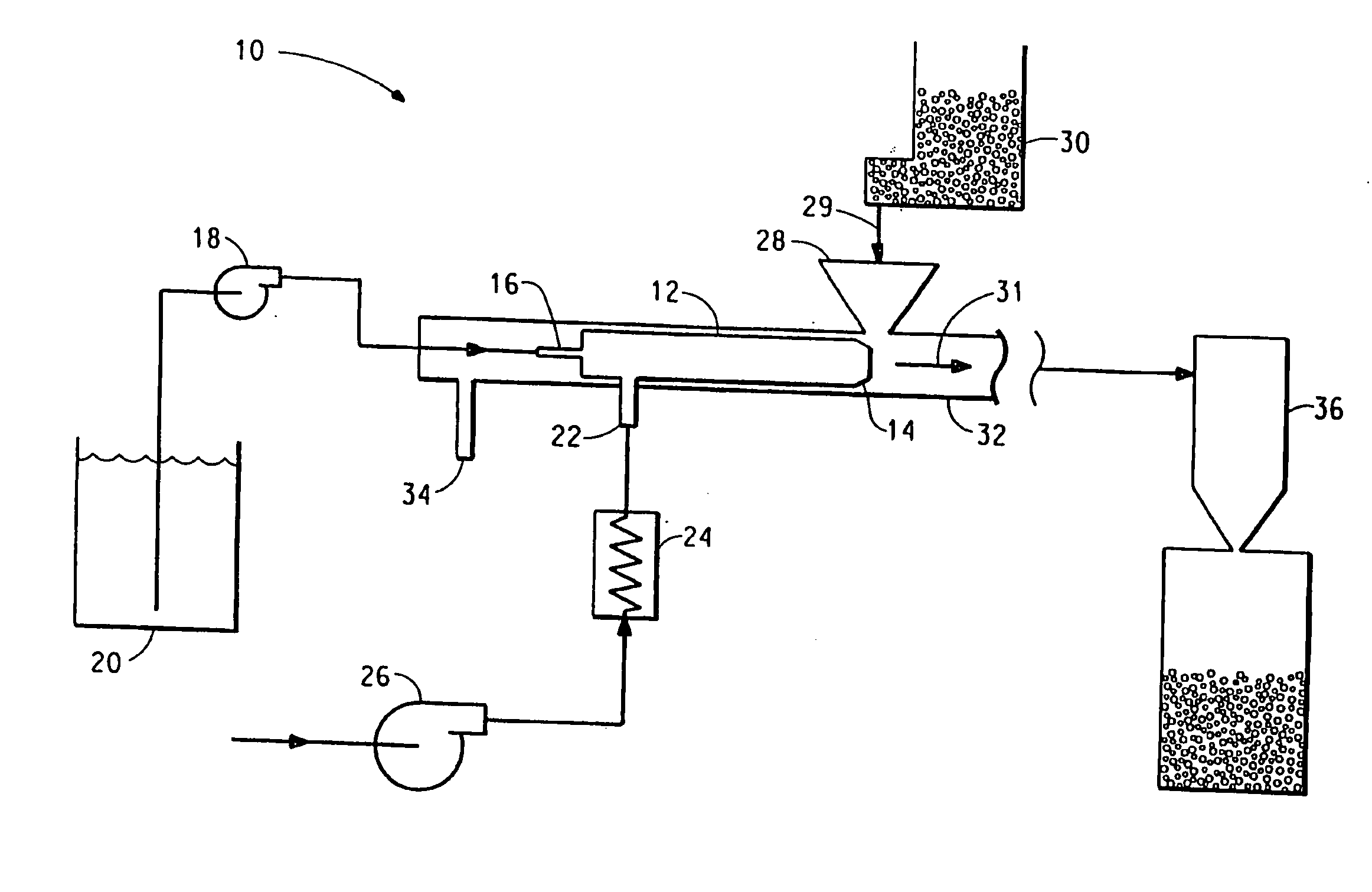

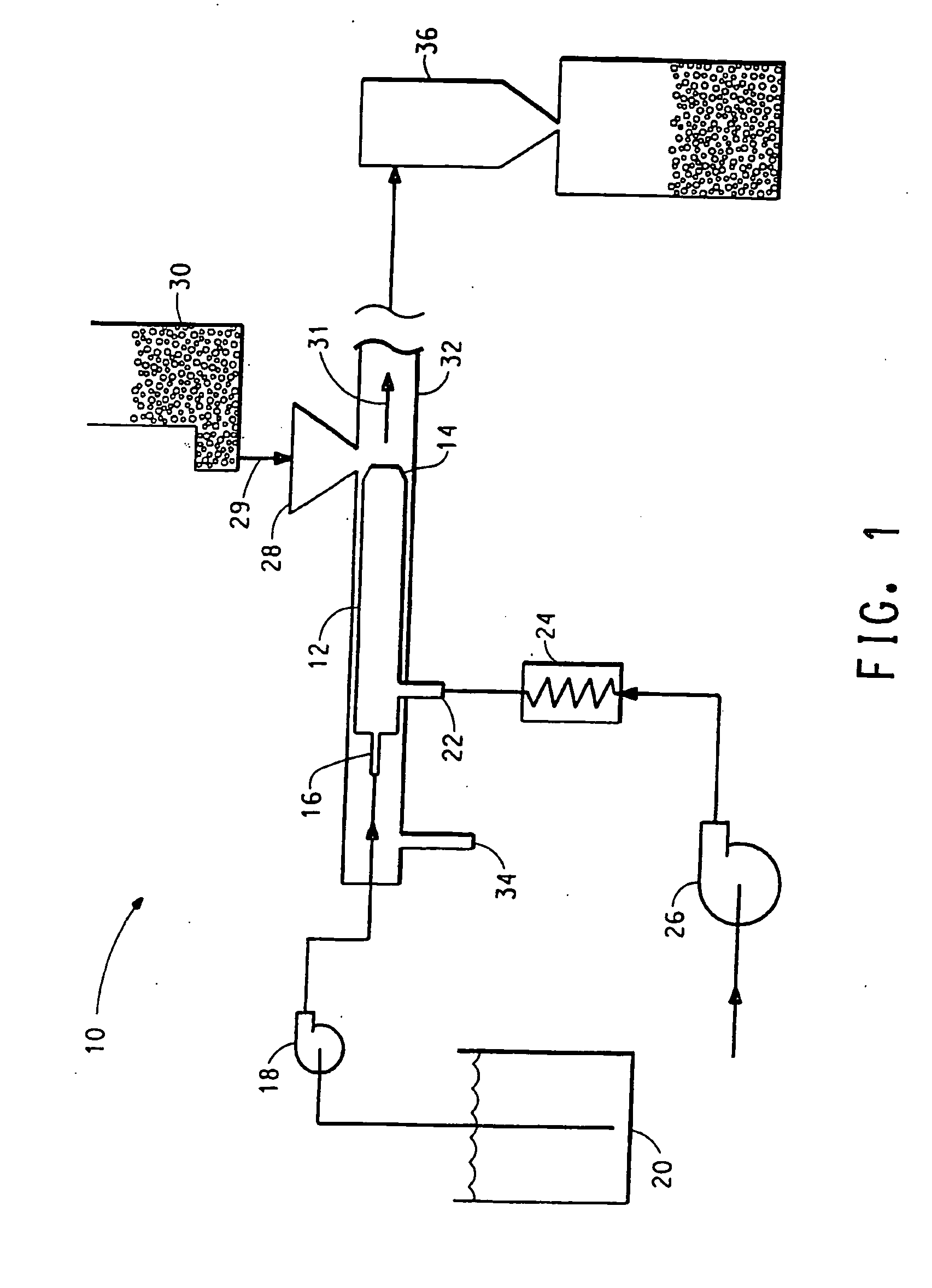

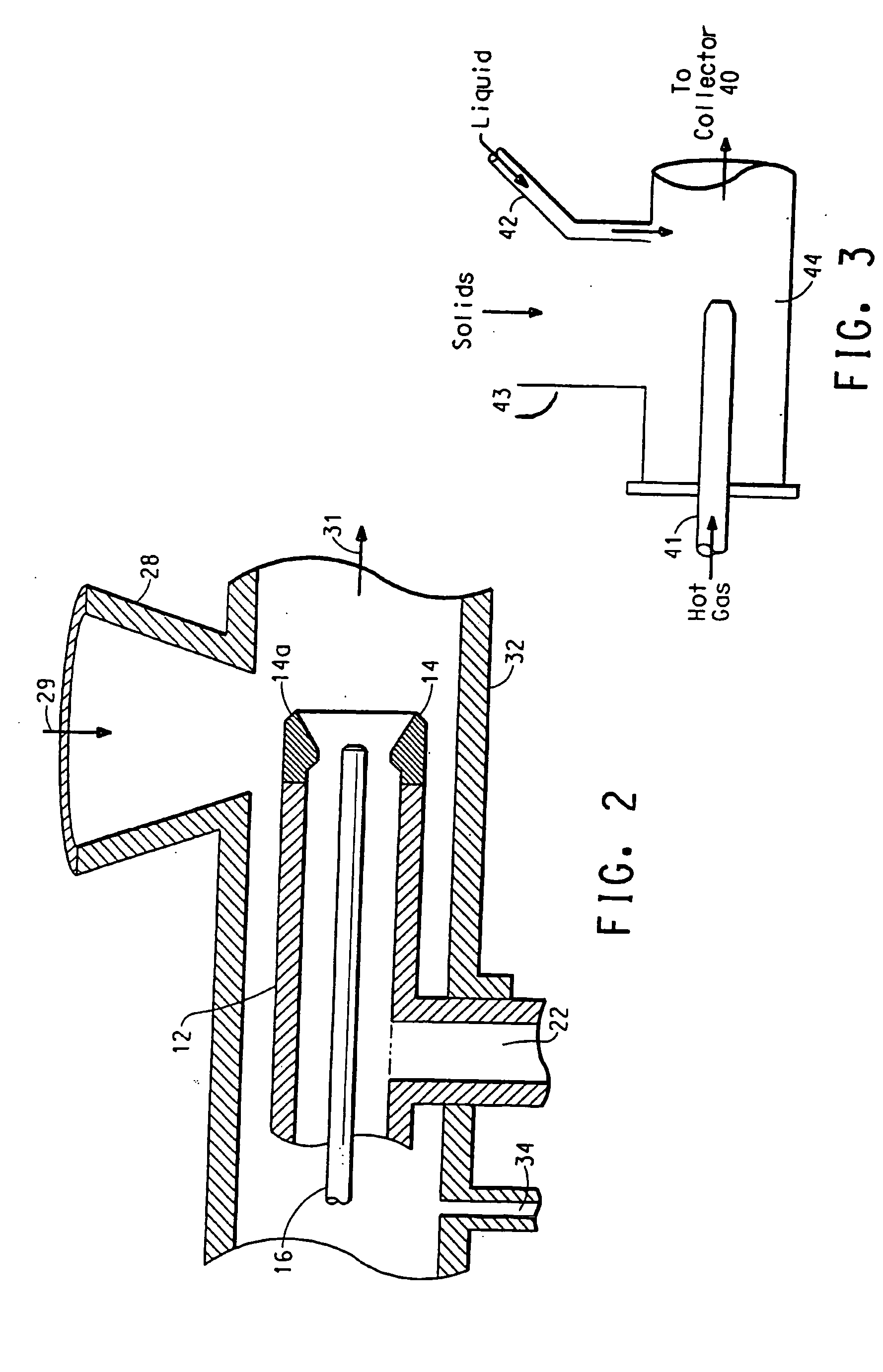

Automatically adjusting annular jet mixer

InactiveUS6802638B2Small sizeReduce pressureControlling ratio of multiple fluid flowsFlow mixersUnit massFracturing fluid

An automatically adjusting jet mixer used in mixing fracturing fluid gel for gas and oil wells. The mixer has an inner nozzle and an attached piston that move axially within the mixer's housing to change the size of the nozzle opening thorough which mix water enters the mixer. One side of the piston has an upstream area and an opposite side has a downstream area. The downstream area is connected to the mix water supply pump and the upstream area is connected to the outlet of a pressure regulator that maintains a constant pressure in the upstream area. The piston and the nozzle move via hydraulic pressure exerted on the piston in proportion to the change in pressure in the downstream area to a position that will maintain a constant mixing jet pressure, thus providing constant specific mixing energy, i.e. constant energy per unit mass of fluid.

Owner:SERVA CORP

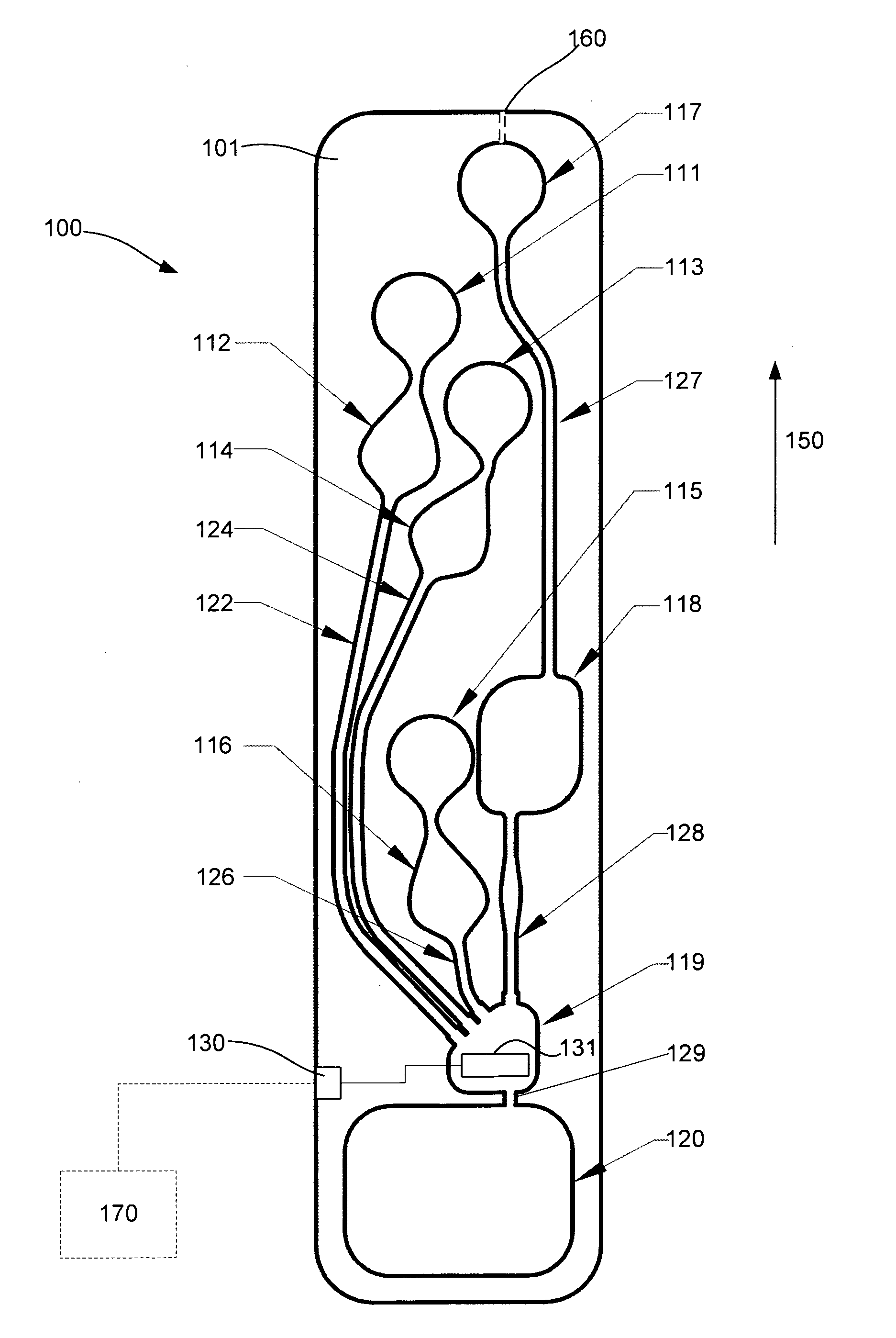

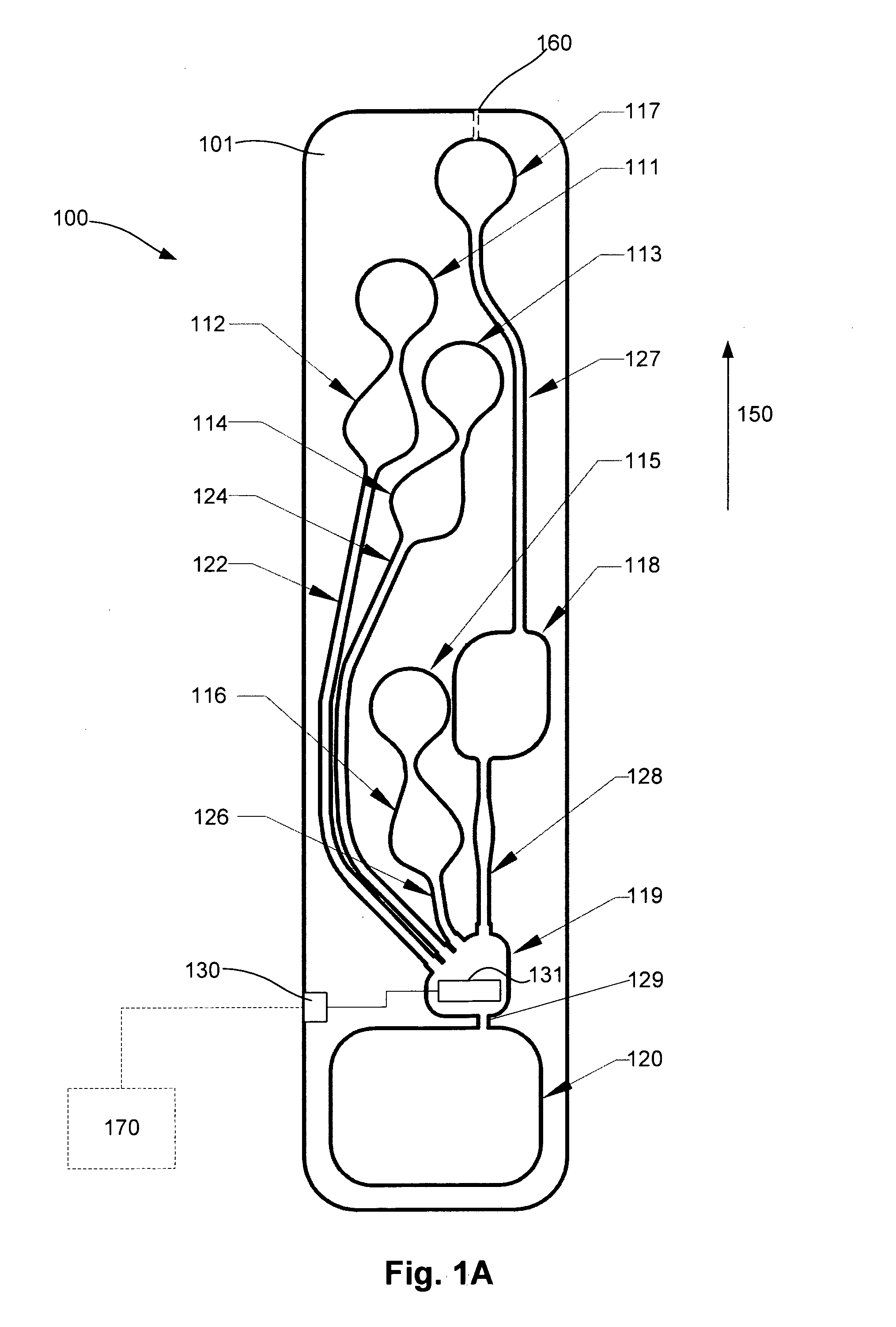

Sample handling device

Owner:ENVIRONMENTAL BIOTECH CRC

Mixing apparatus having central and planetary mixing elements

ActiveUS8360629B2Sufficient forceFlow mixersRotary stirring mixersMechanical engineeringHybrid device

Owner:DEPUY SYNTHES PROD INC

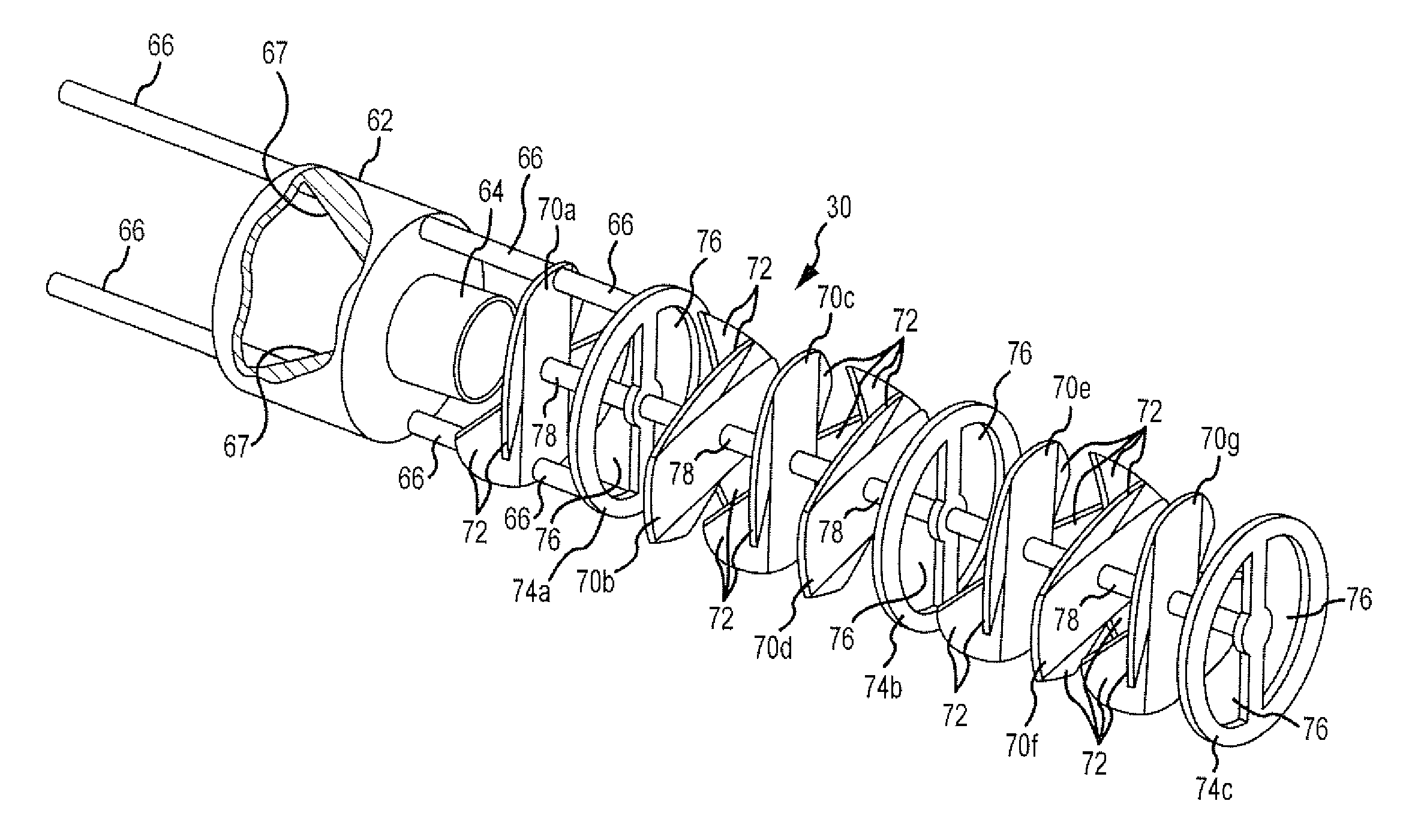

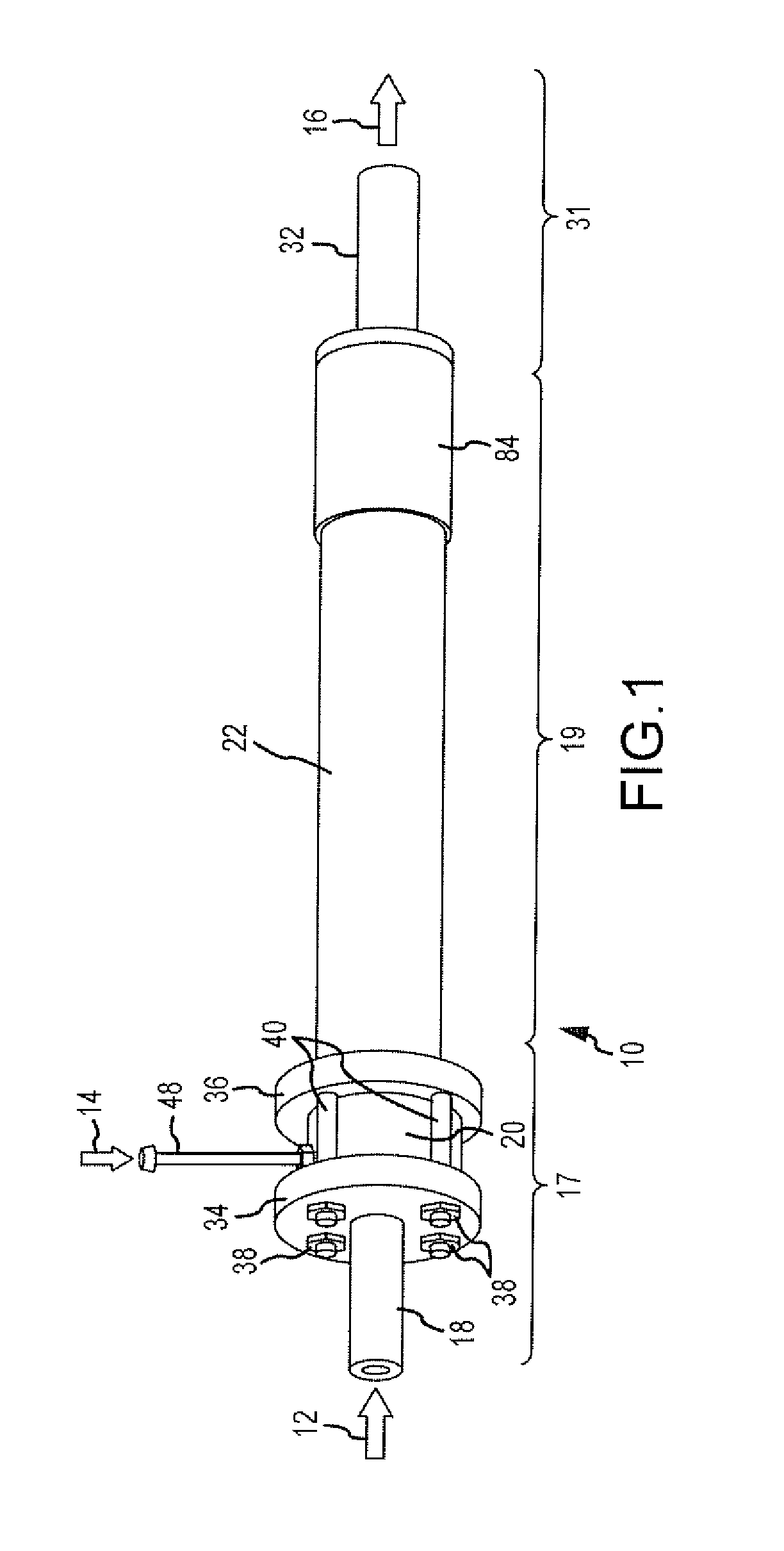

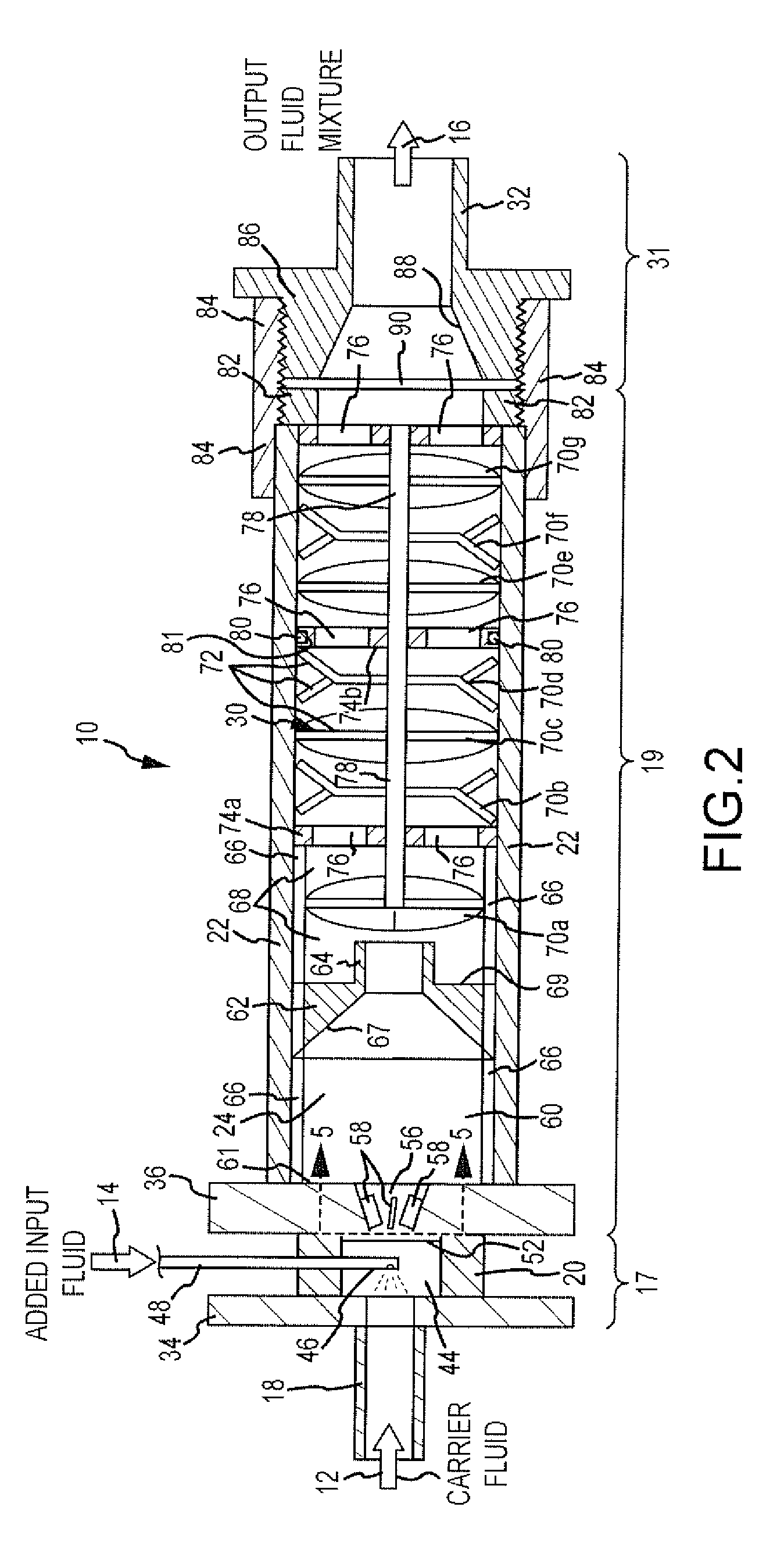

Static Fluid Mixer and Method

InactiveUS20130021868A1Weaken energyLower overall pressure dropFlow mixersTransportation and packagingEngineeringCarrier fluid

A carrier fluid and an added input fluid are mixed together in a static mixer to create an emulsified output fluid mixture. The static mixer comprises a plurality of mixing chambers whose cross-sectional size expand considerably relative to an inlet, a series of bent and curved baffle plates which divert, rotate, divide, reverse and otherwise create turbulence in the combined flow, and inlet chamber in which the added input fluid is dispensed upstream into the carrier fluid, and a number of other structural mixing elements which, through turbulence, abrupt pressure drops and velocity changes, subdivide the added input mixture into very small volumetric quantities evenly dispersed within the carrier fluid to create a homogeneous output fluid mixture.

Owner:DOOLIN MICHAEL B +1

Automatically adjusting annular jet mixer

InactiveUS7029165B2Small sizeReduce pressureControlling ratio of multiple fluid flowsFlow mixersUnit massFracturing fluid

An automatically adjusting jet mixer used in mixing fracturing fluid gel for gas and oil wells. The mixer has an inner nozzle and an attached piston that move axially within the mixer's housing to change the size of the nozzle opening thorough which mix water enters the mixer. One side of the piston has a pressure regulated area and an opposite side has an upstream area. The upstream area is connected to the mix water supply pump and the pressure regulated area is connected to the outlet of a pressure regulator that maintains a constant pressure in the pressure regulated area. The piston and the nozzle move via hydraulic pressure exerted on the piston in proportion to the change in pressure in the upstream area to a position that will maintain a constant mixing jet pressure, thus providing constant specific mixing energy, i.e. constant energy per unit mass of fluid.

Owner:SERVA CORP

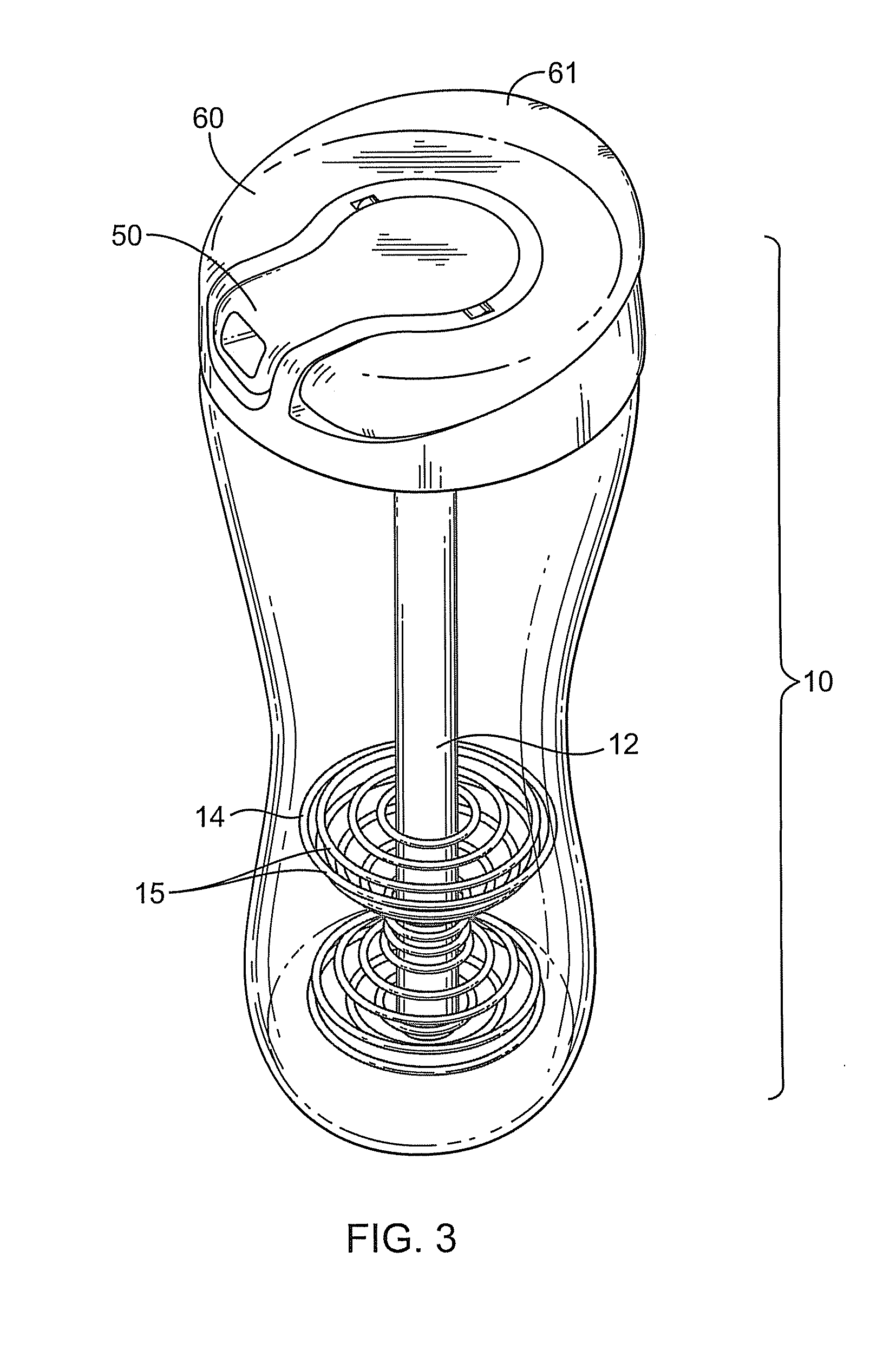

Shakeable container with agitator

ActiveUS20140119154A1Less effortIncrease inertiaShaking/oscillating/vibrating mixersClosuresProcess engineeringViscosity

Owner:ESUPPLEMENTS LLC

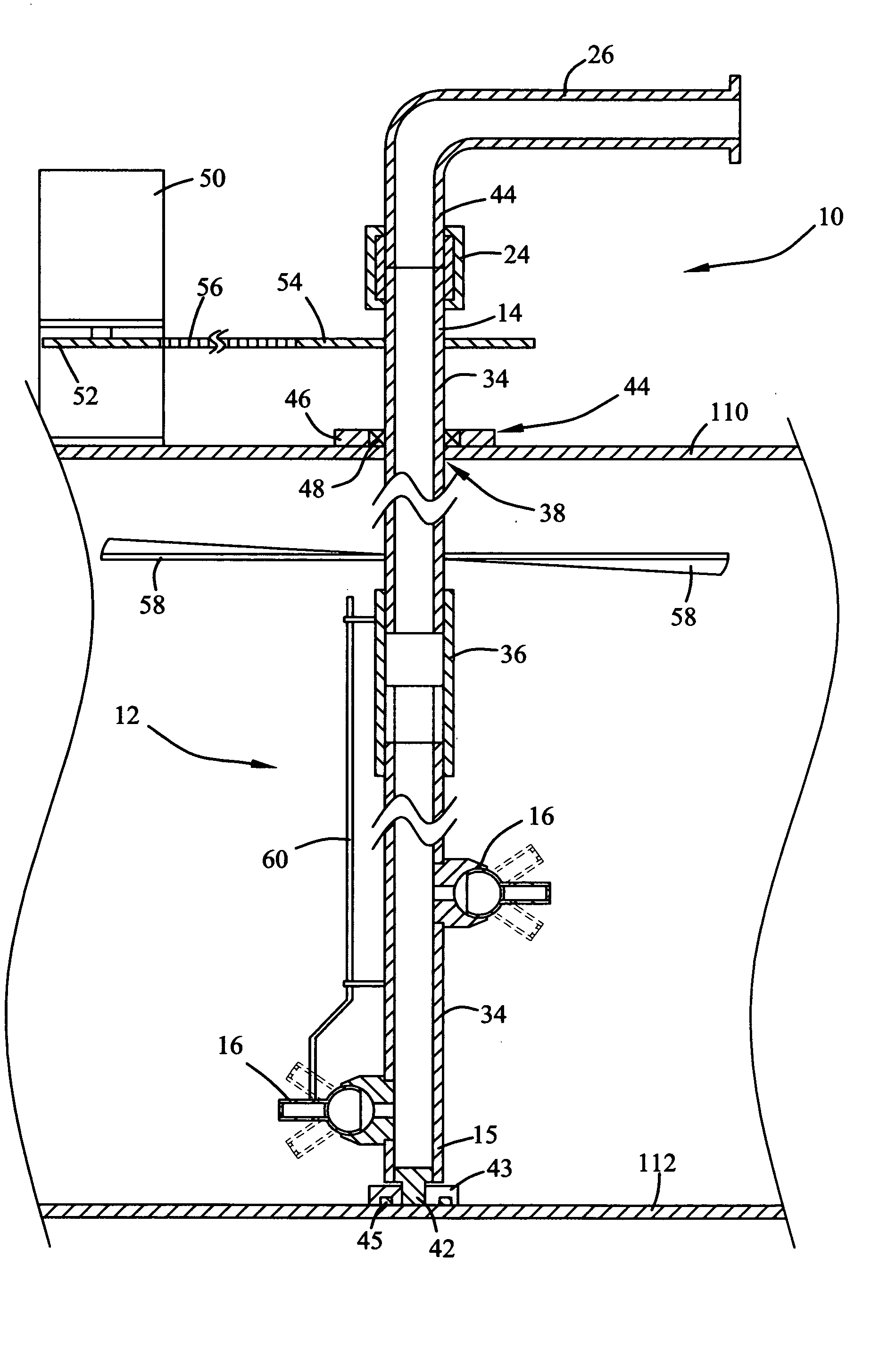

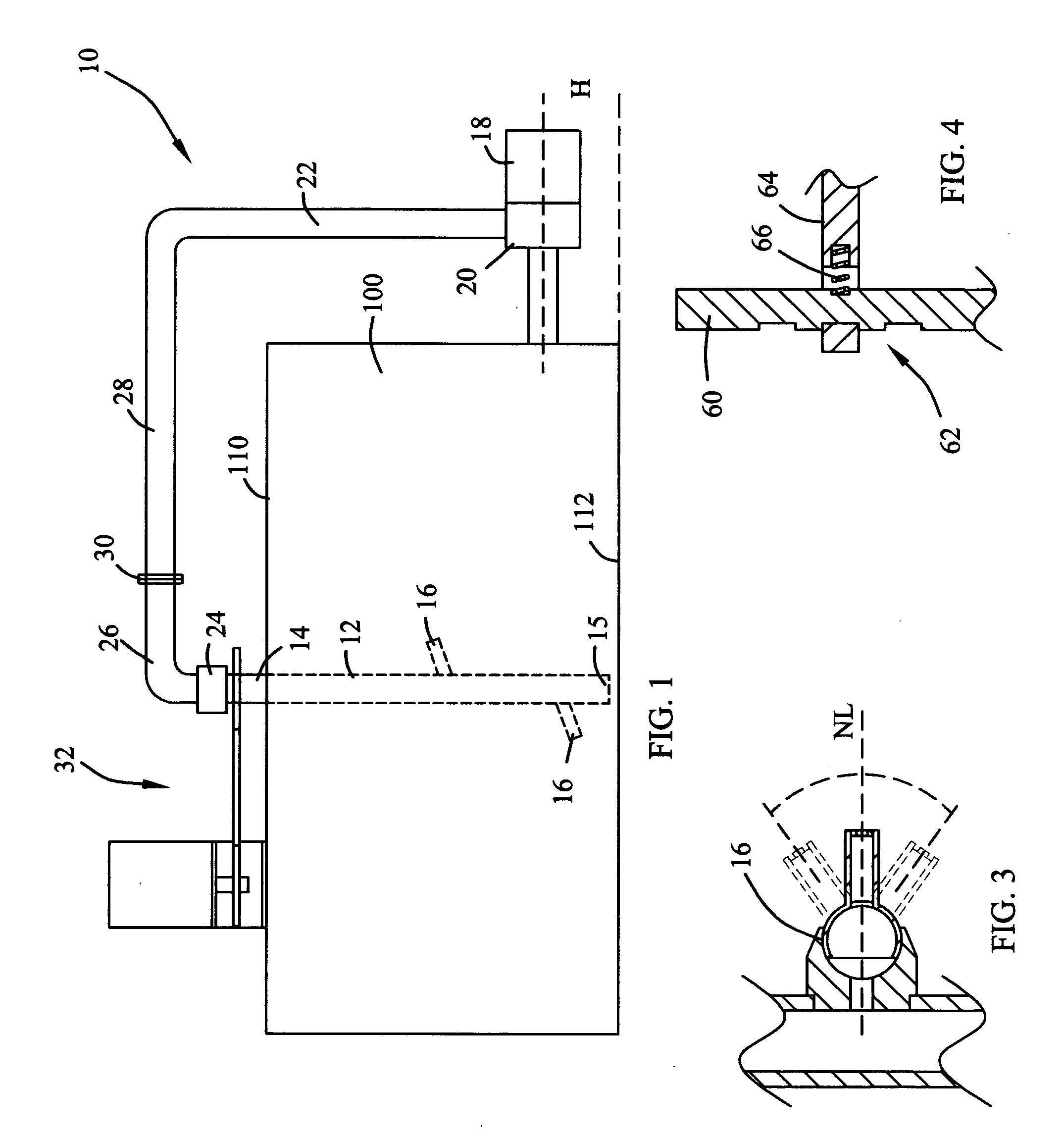

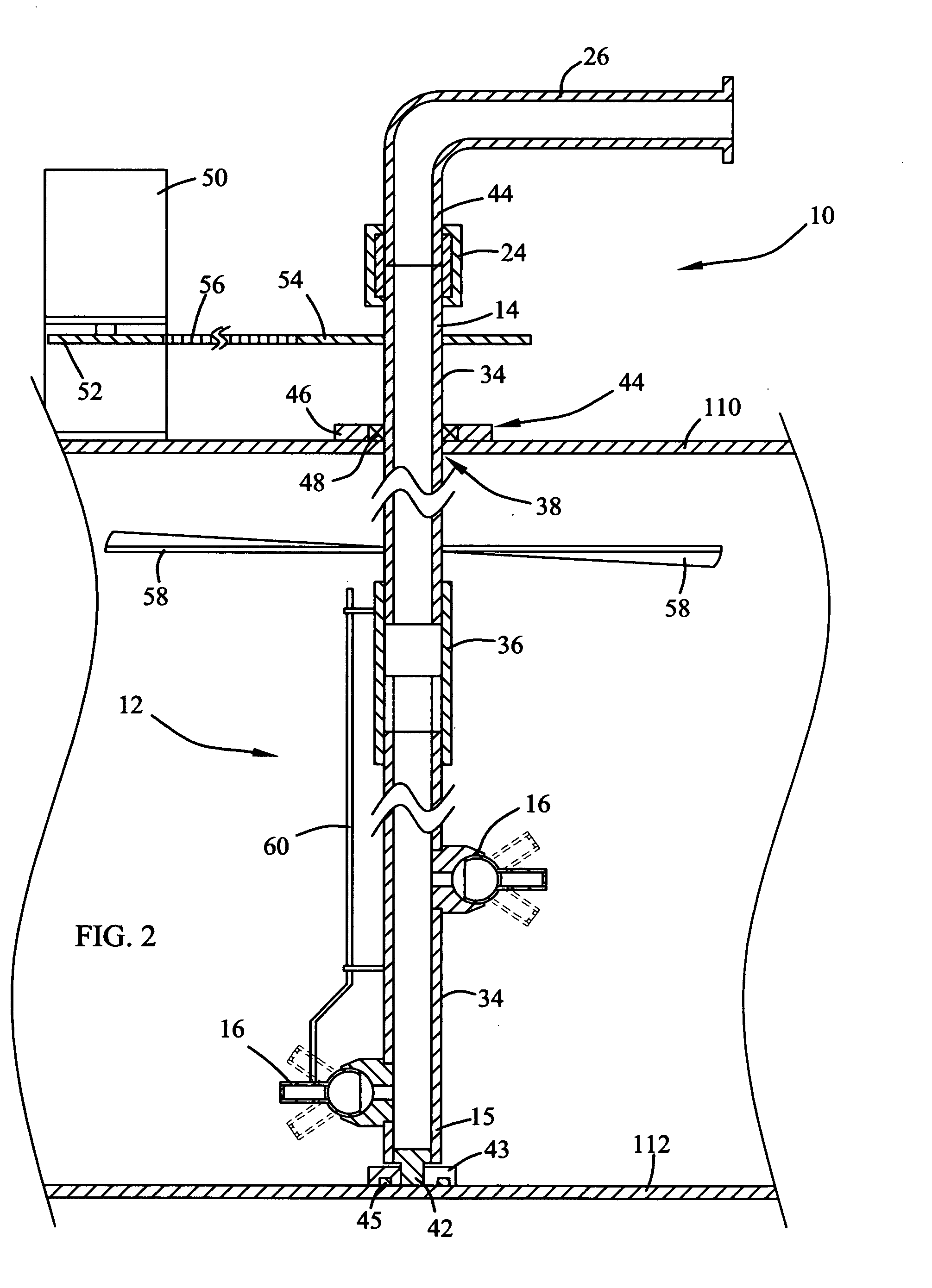

Rotary fluid agitator

InactiveUS20050281131A1Improve actionFlow mixersTransportation and packagingParticulatesSolid particle

A rotary fluid agitator is provided. The rotary fluid agitator essentially comprises a fluid conduit that is positioned vertically within a storage tank holding a quantity of fluid, such as a drilling fluid. At least one nozzle is attached to the fluid conduit for jetting a stream of fluid into to the fluid contained within the tank. A drive means is connected to the fluid conduit and rotates the conduit to sweep the nozzle through a 360-degree arcuate path at a predetermined rotational frequency. A fluid pump is attached in fluid communication with the interior volume of the tank and pumps a quantity of drilling fluid through a fluid circulation line and through the fluid conduit to be jetted out of the nozzle. As the nozzle is swept through the arcuate path a conically shaped fluid flow path is created in the fluid contained within the tank causing the jetted fluid to tangentially act upon the fluid thereby keeping all solid particulates mixed with the fluid in suspension.

Owner:YUNGBLUT JOHN DAVID

Solid flowable powder with high liquid loading

InactiveUS20050233074A1Cost efficientMore energyMaterial nanotechnologyPowder deliveryMaterials scienceCoating

A process of manufacturing compositions comprised of carrier particles under 100 nm that have been loaded to a level of greater than 60% by weight with a liquid. The highly-liquid-loaded particles can be further coated or encapsulated with functional coating or encapsulating materials.

Owner:SOLAE LLC

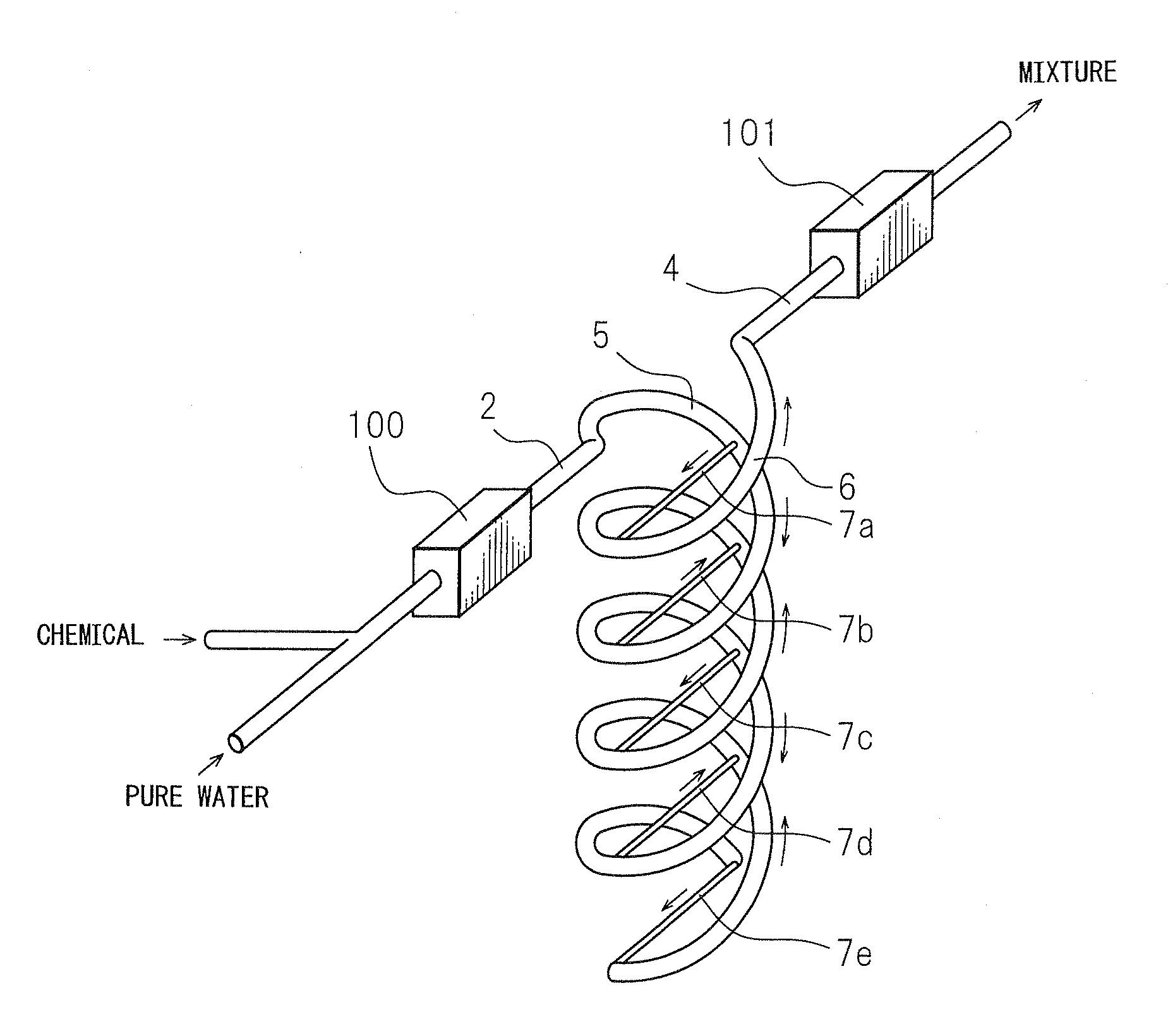

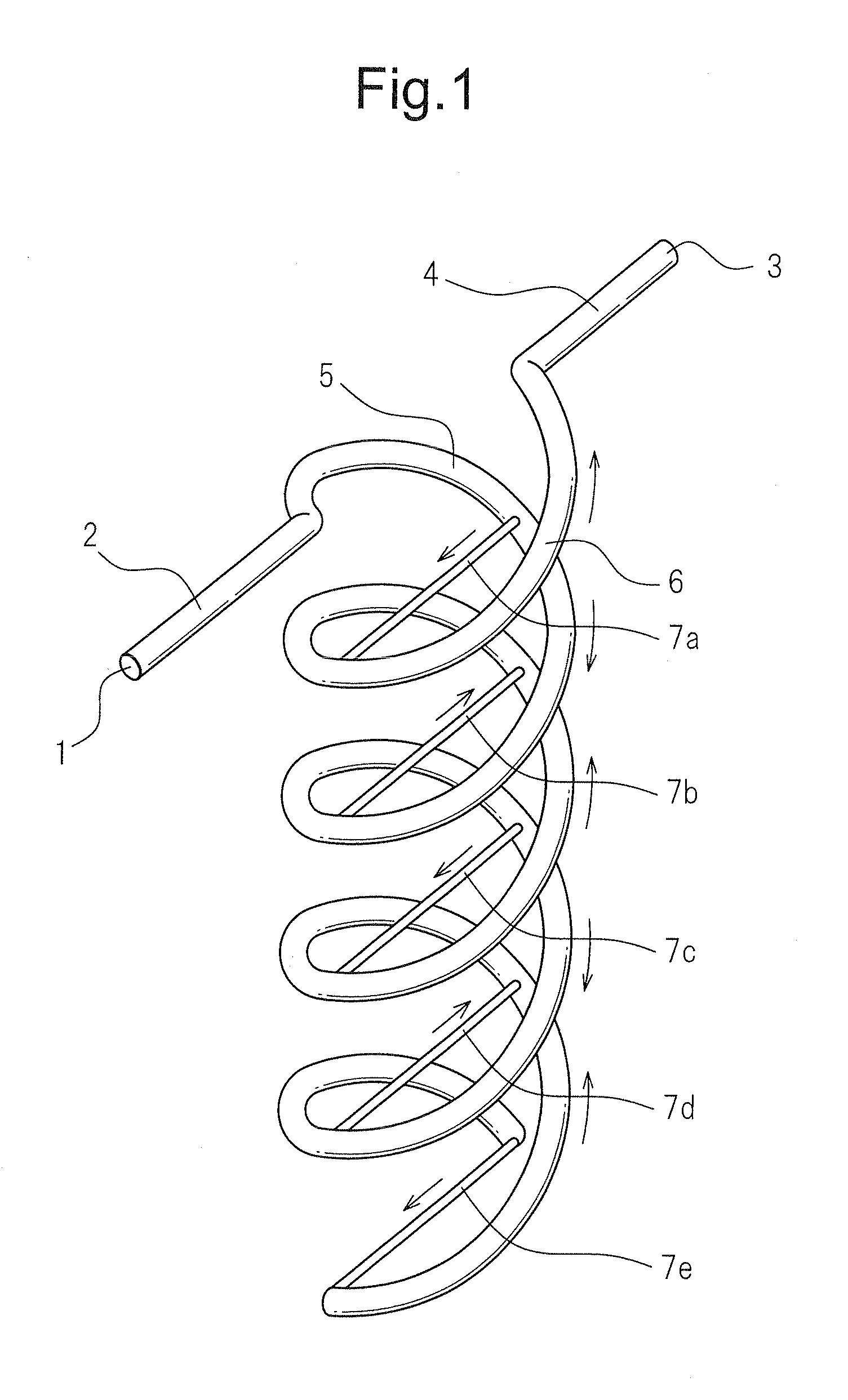

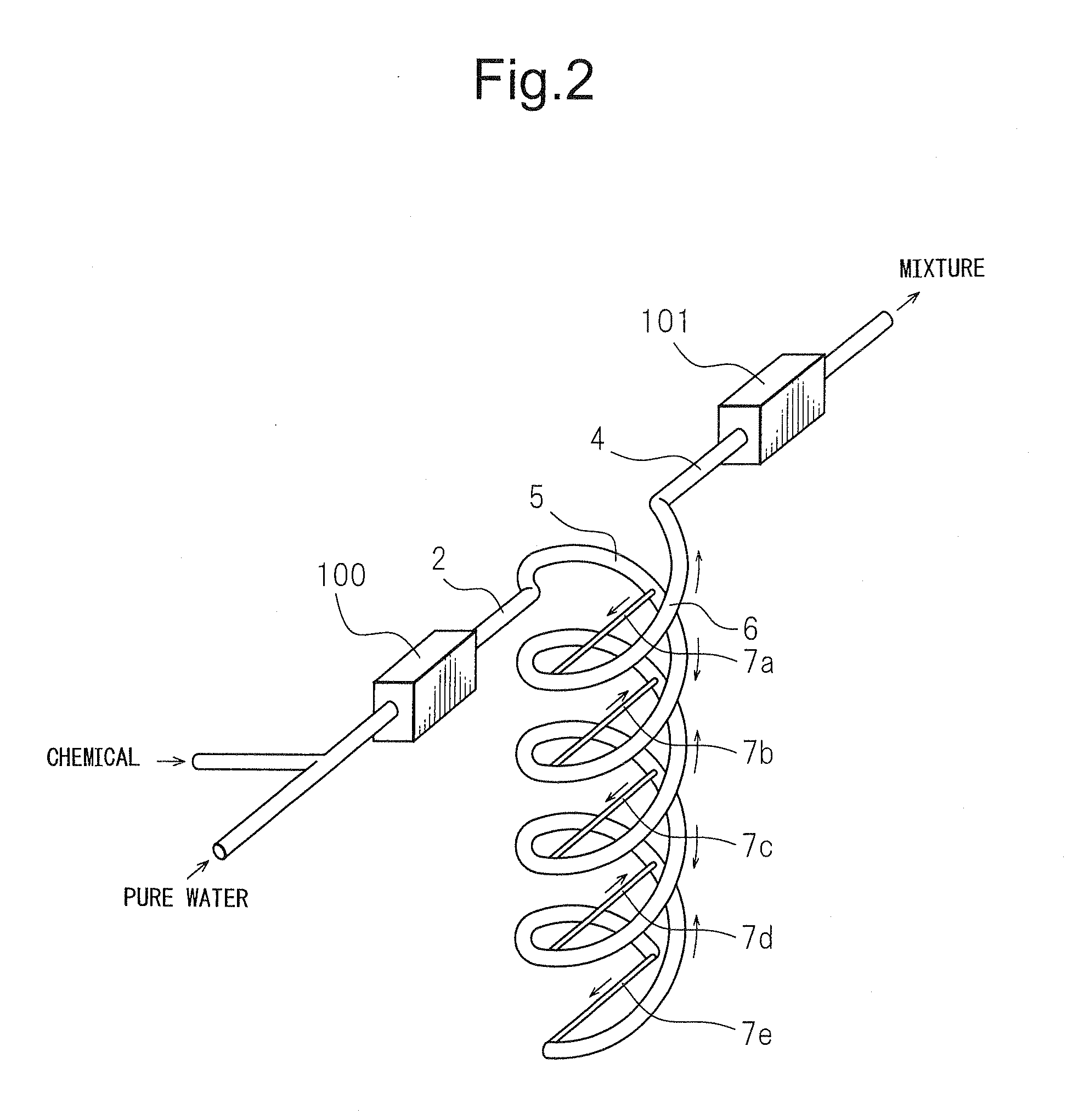

Spiral type fluid mixer and apparatus using spiral type fluid mixer

InactiveUS20110199855A1Avoid defectsStable temperatureFlow mixersTransportation and packagingEngineeringSpiral flow

A spiral type fluid mixer which enables mixing by a distribution of concentration or distribution of temperature in a flow direction of the fluid made uniform without unevenness and which is compact and enables easy piping work is provided. This spiral type fluid mixer is provided with a fluid inlet, a first flow path which is connected to the fluid inlet, a first spiral flow path which is connected to the first flow path, a plurality of branch flow paths which are branched from the first spiral flow path, a second spiral flow path to which the plurality of branch flow paths are connected, a second flow path which is connected to the second spiral flow path, and a fluid outlet which is connected to the second flow path, the plurality of branch flow path being branched from different positions of the first spiral flow path and being connected with the second spiral flow path at different positions of the second spiral flow path.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Blenders

ActiveUS20130135958A1Clean thoroughlySand dryingDrying solid materials with heatMixed materialsEngineering

A blender has a mixing chamber for reception of materials to be blended. A mixing screw is mounted at a bottom of the mixing chamber for mixing materials within the mixing chamber and delivering mixed materials to an outlet feeding a processing line. A baffle is mounted at the outlet extending about the mixing screw. The baffle inhibits upward movement of material at the outlet tending to cram material into the outlet.

Owner:VERVANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com