Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Engine viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

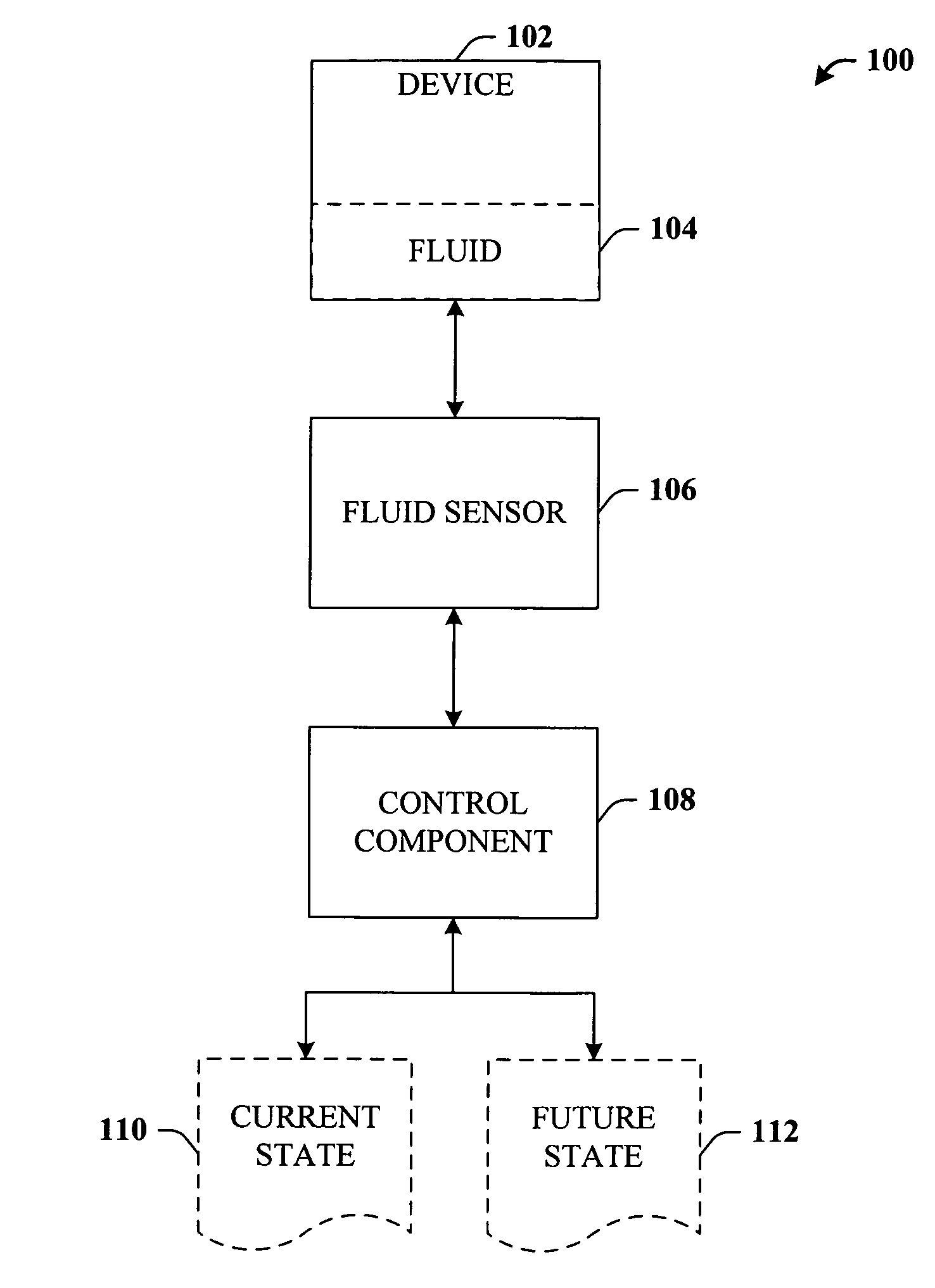

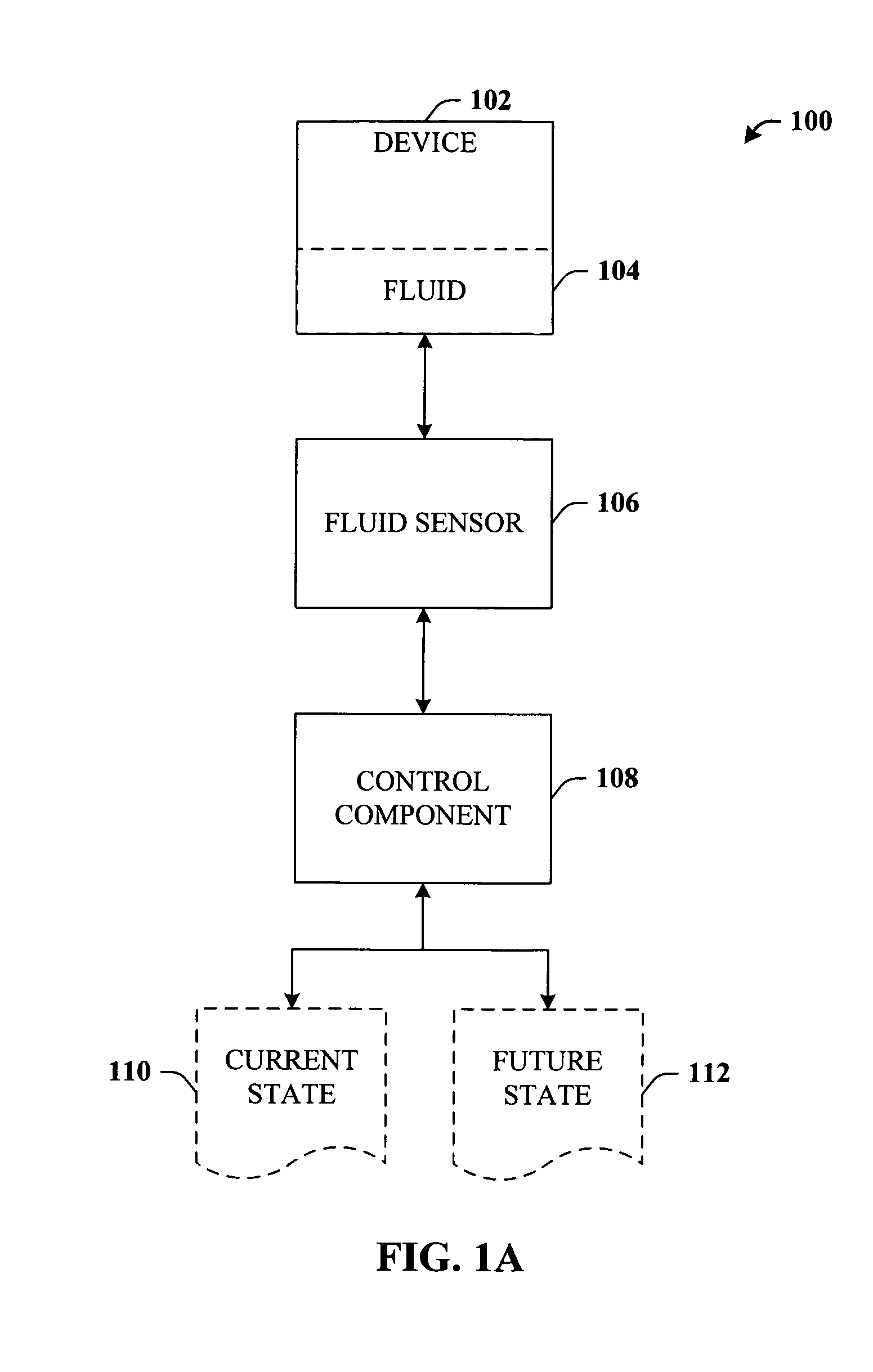

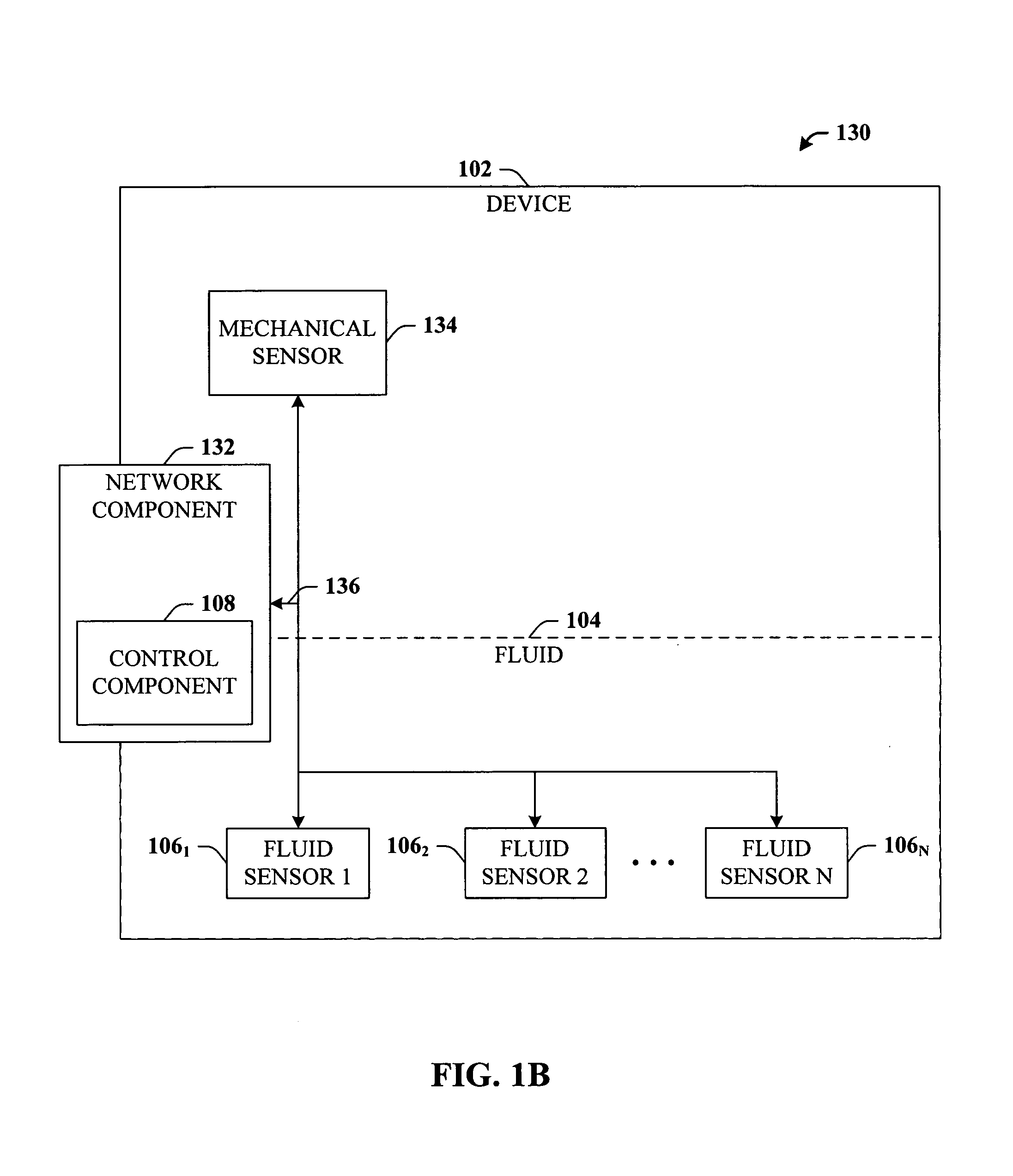

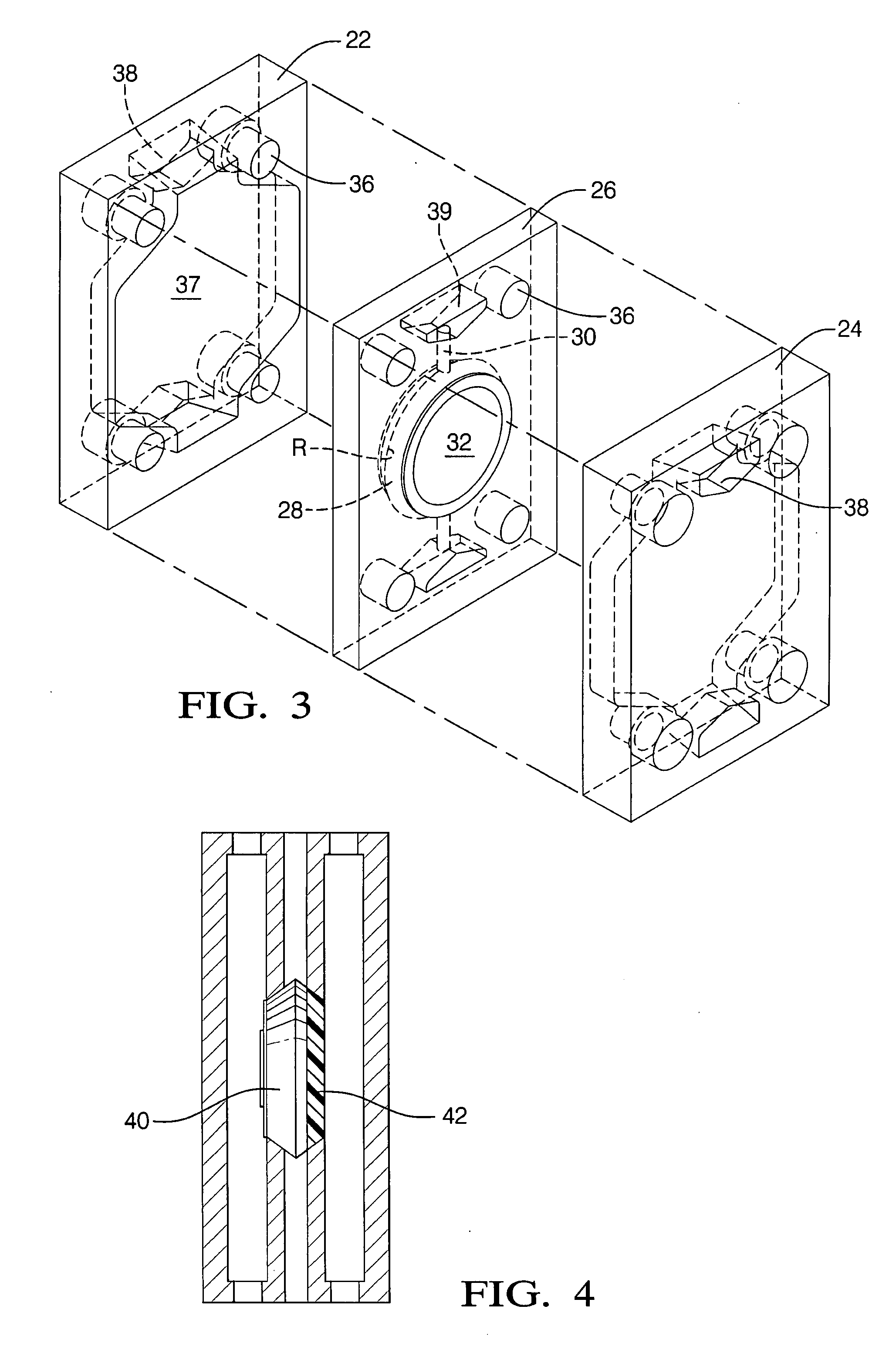

Intelligent fluid sensor for machinery diagnostics, prognostics, and control

ActiveUS7581434B1Minimizes bandwidth requirementImprove performanceFlow propertiesLubrication indication devicesControl systemEngineering

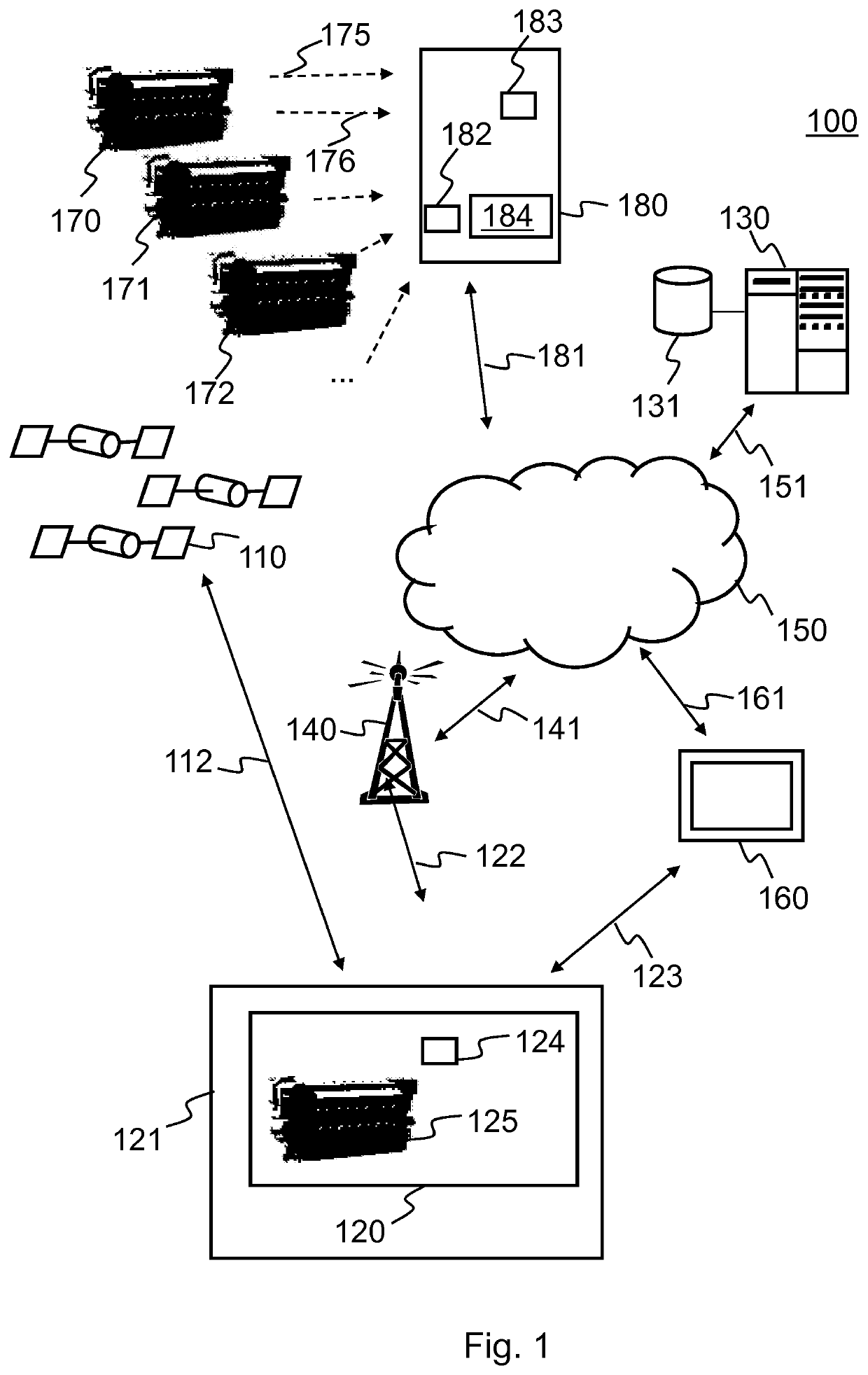

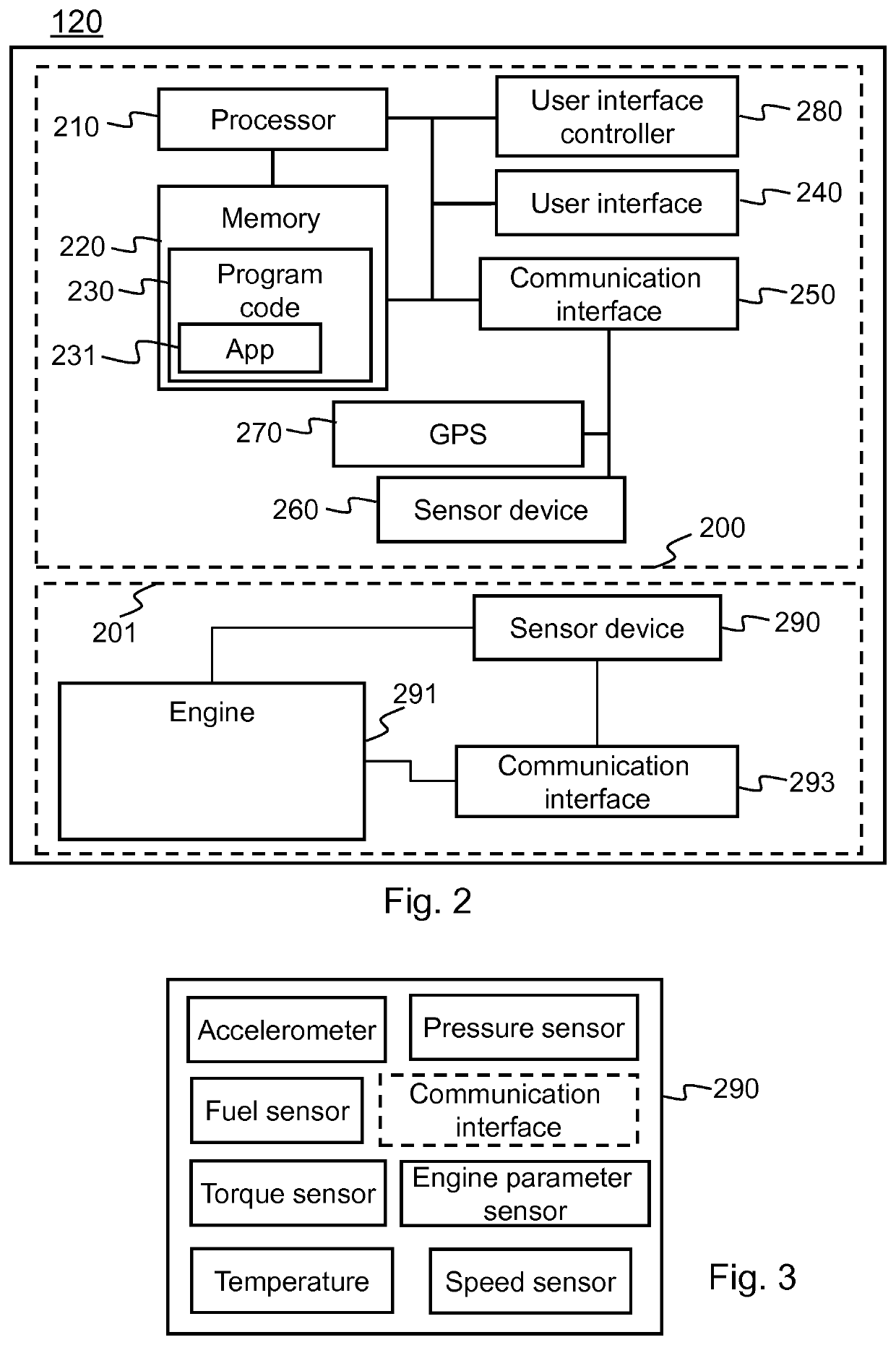

A system that facilitates device and / or machinery diagnostics, prognostics and control by way of condition sensing, such as sensing the condition of the device and / or a fluid of the device (e.g., fluid health indicators). The system can employ a plurality of sensors to determine a current state and estimate a future state of the fluid and / or device, as well as providing control of the device, e.g., in order to increase the remaining useful life of the fluid and / or operation of the device. The sensors can communicate wirelessly with each other, with the device, and / or with a central control system that provides, e.g., sensor fusion, prognostics and control integration. In addition, the sensors can be powered locally based upon the physical or chemical properties of the environment.

Owner:REXNORD IND LLC

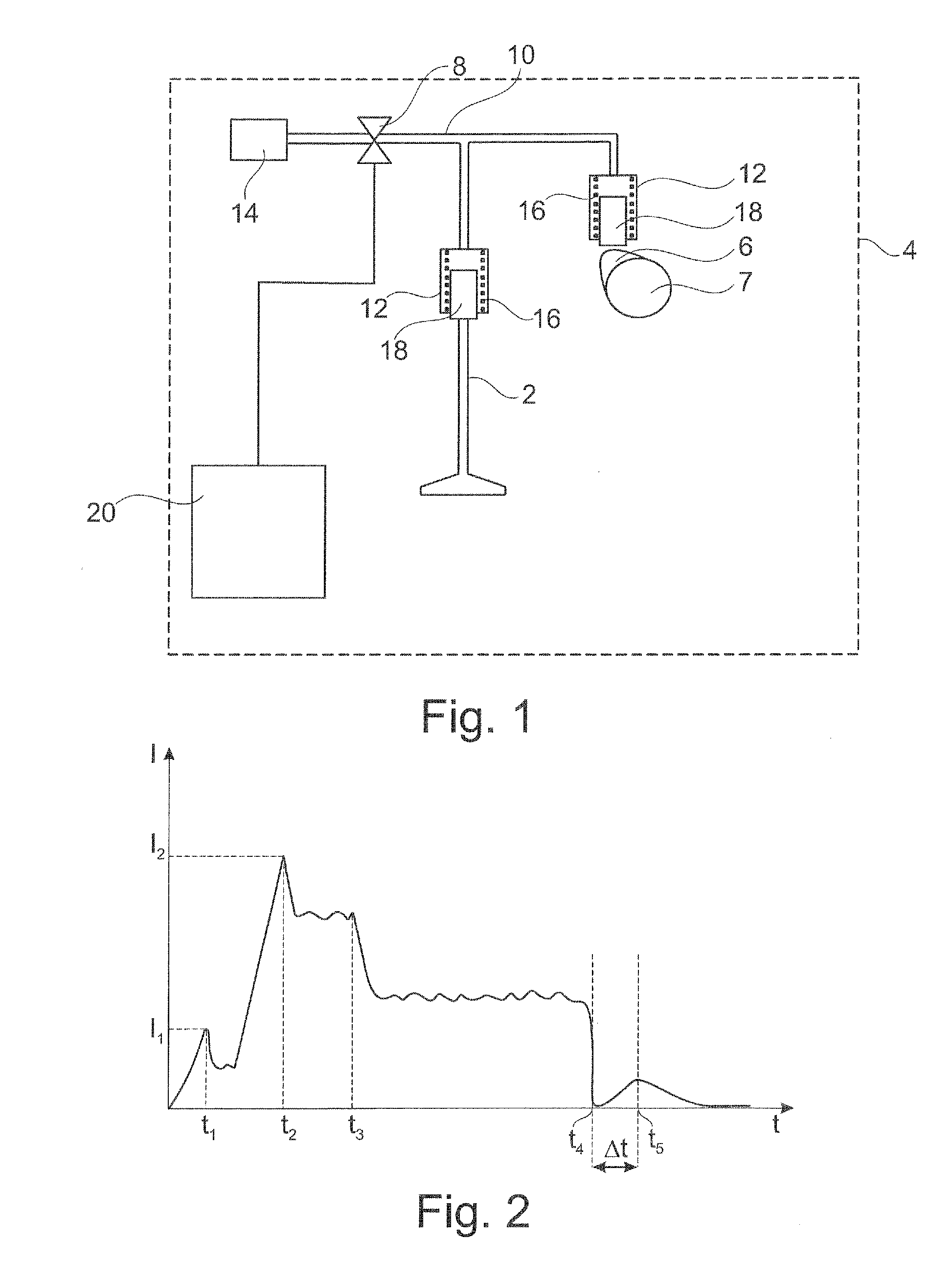

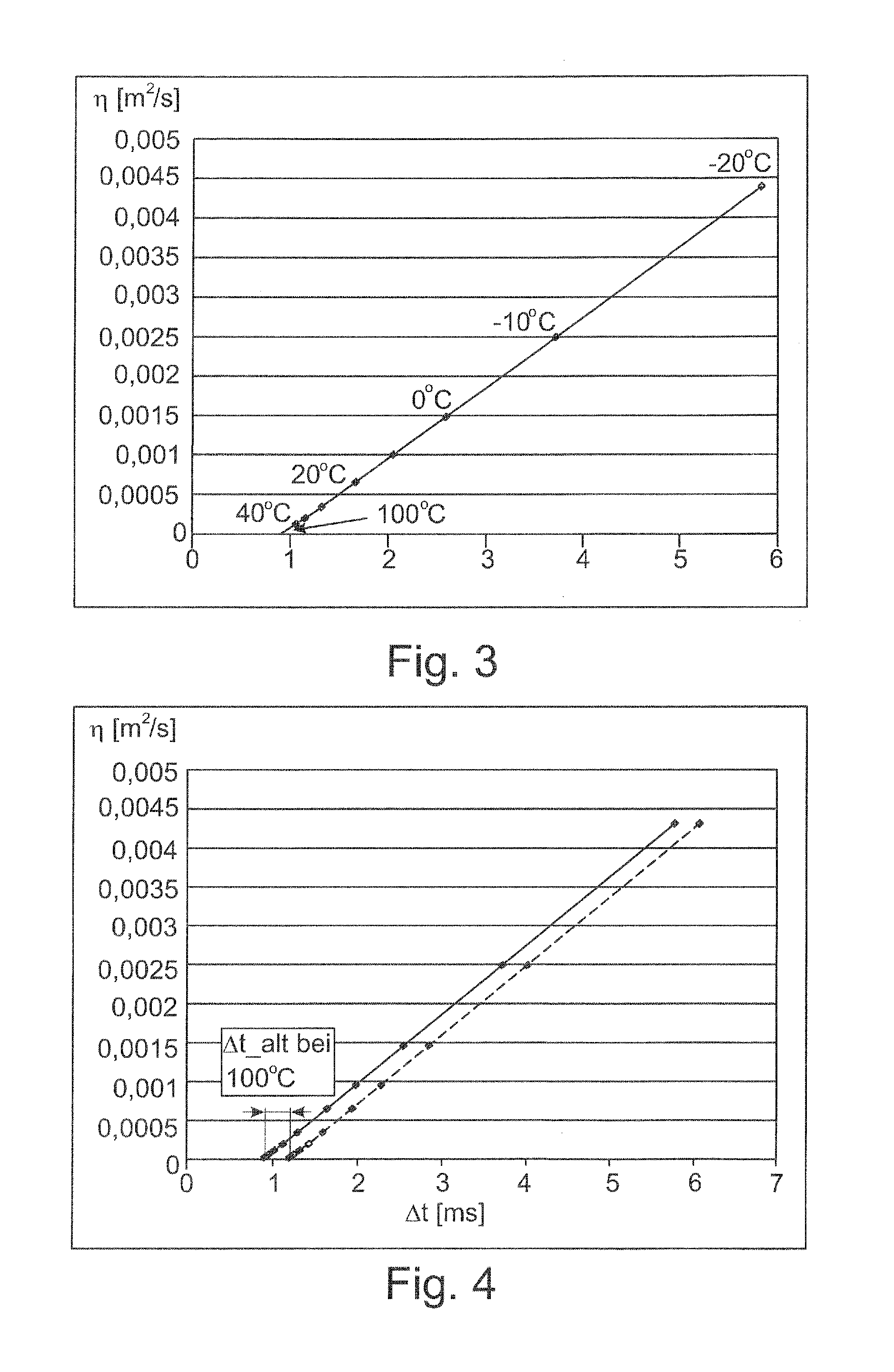

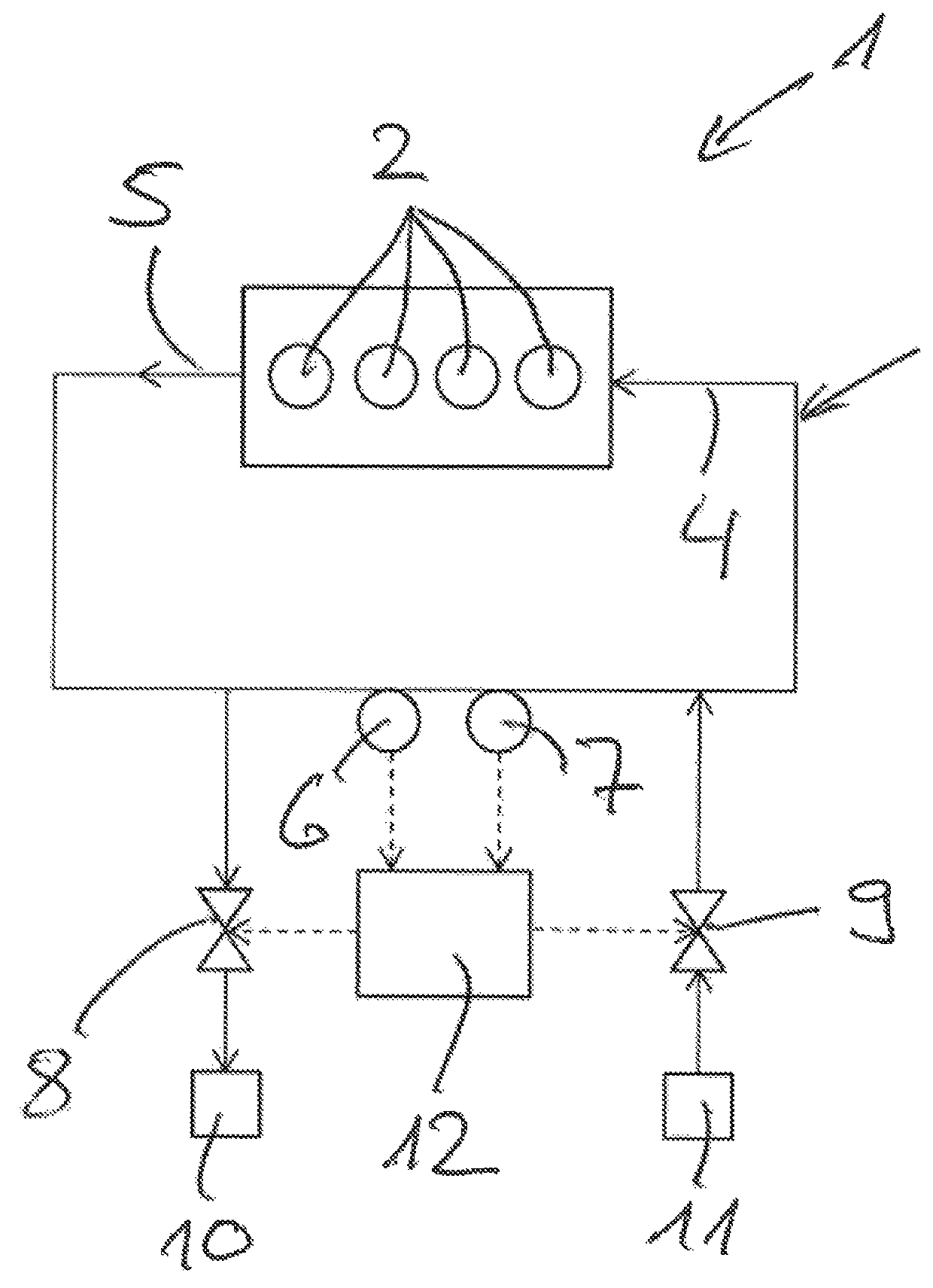

Method and control device for determining a characteristic viscosity variable of an oil

InactiveUS20120006289A1Avoid damageHigh viscosityElectrical controlInternal combustion piston enginesSolenoid valveElectrical control

In order for the viscosity of the engine oil to be determined as directly as possible, particularly in the case of a motor vehicle with hydraulic control of the gas exchange valves, provision is made for a time period which a hydraulic component, in particular a solenoid valve, requires to move from a first position to a second position to be used as a measure of the viscosity. In particular, an electrical control signal for the solenoid valve is evaluated in the process. An additional sensor arrangement is not required. The determined viscosity is preferably actively used for controlling the gas exchange valves.

Owner:SCHAEFFLER TECH AG & CO KG

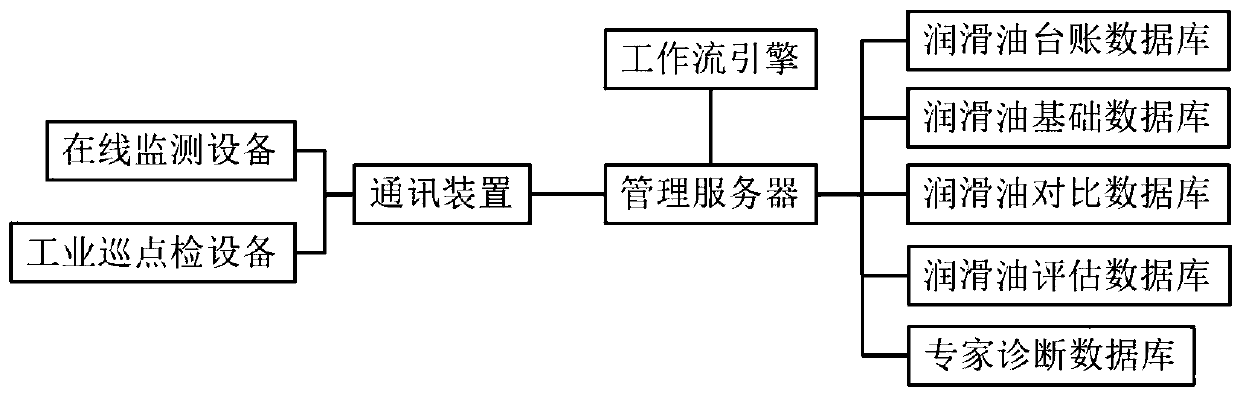

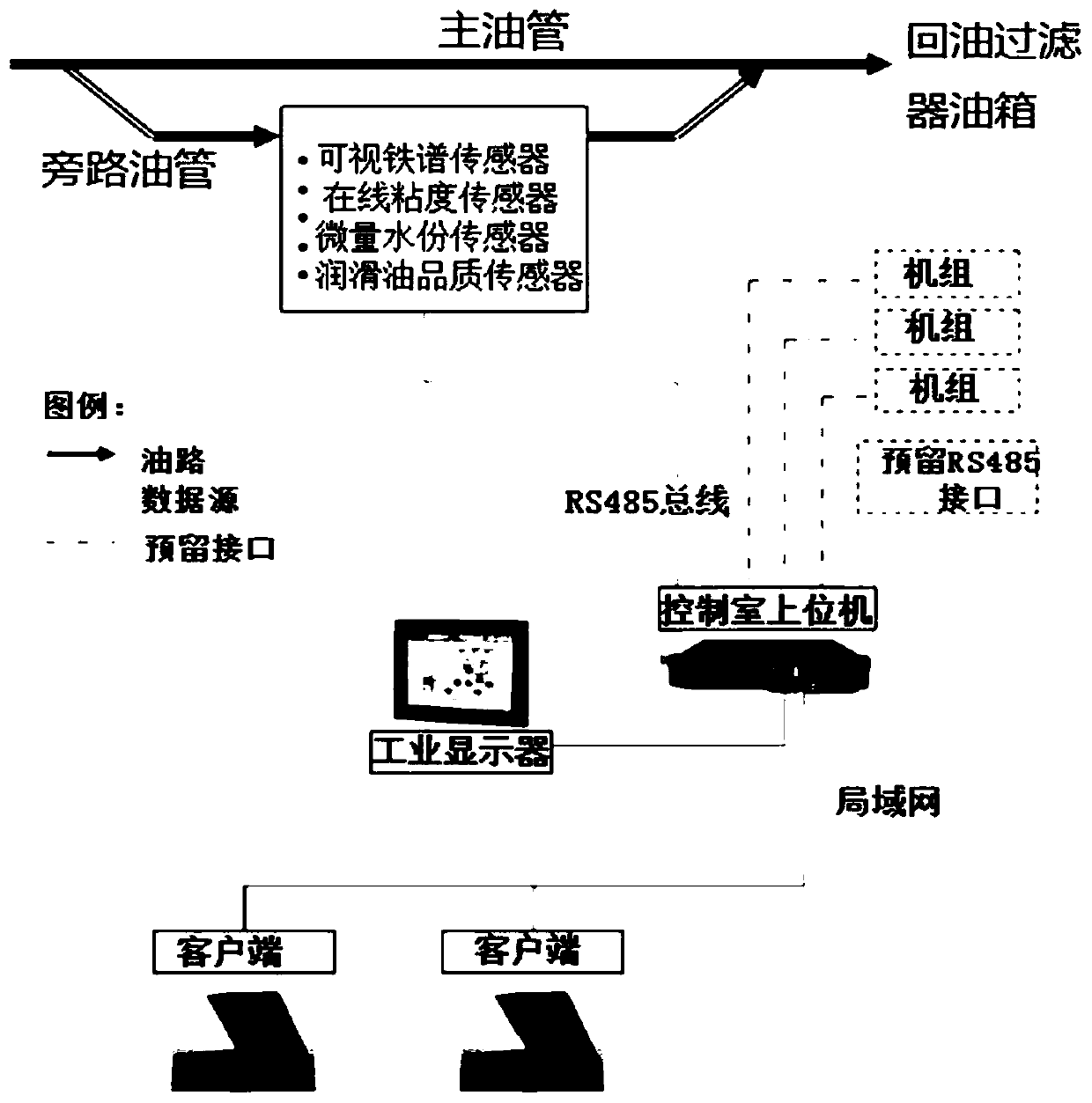

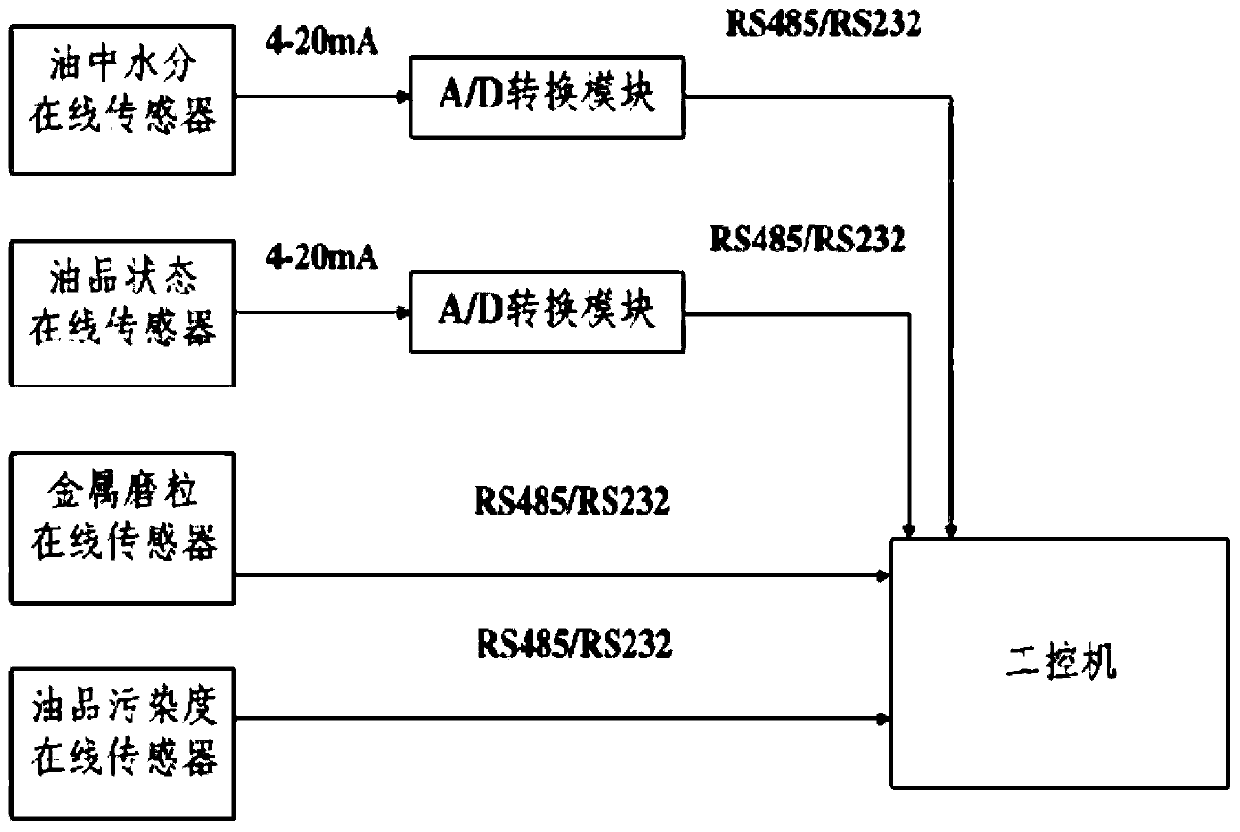

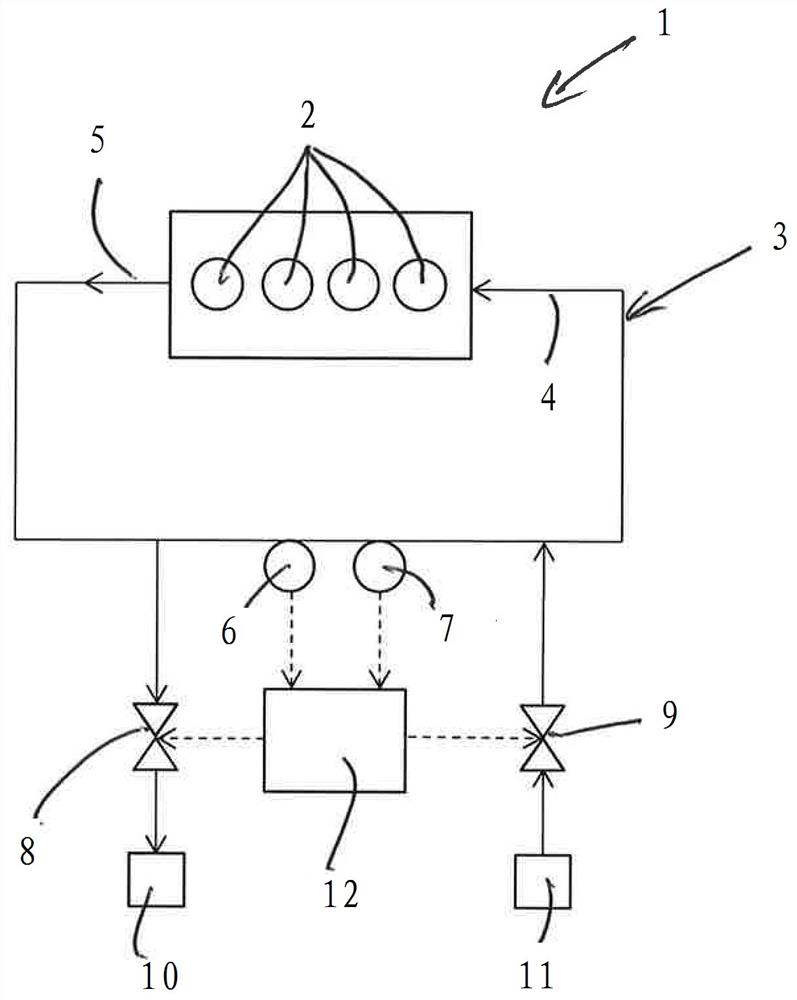

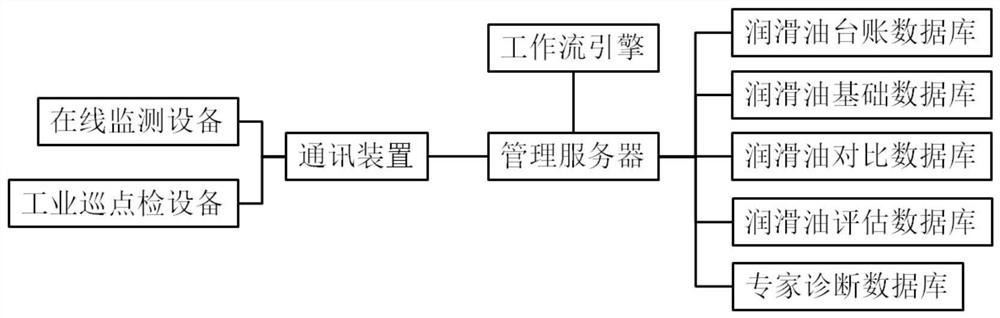

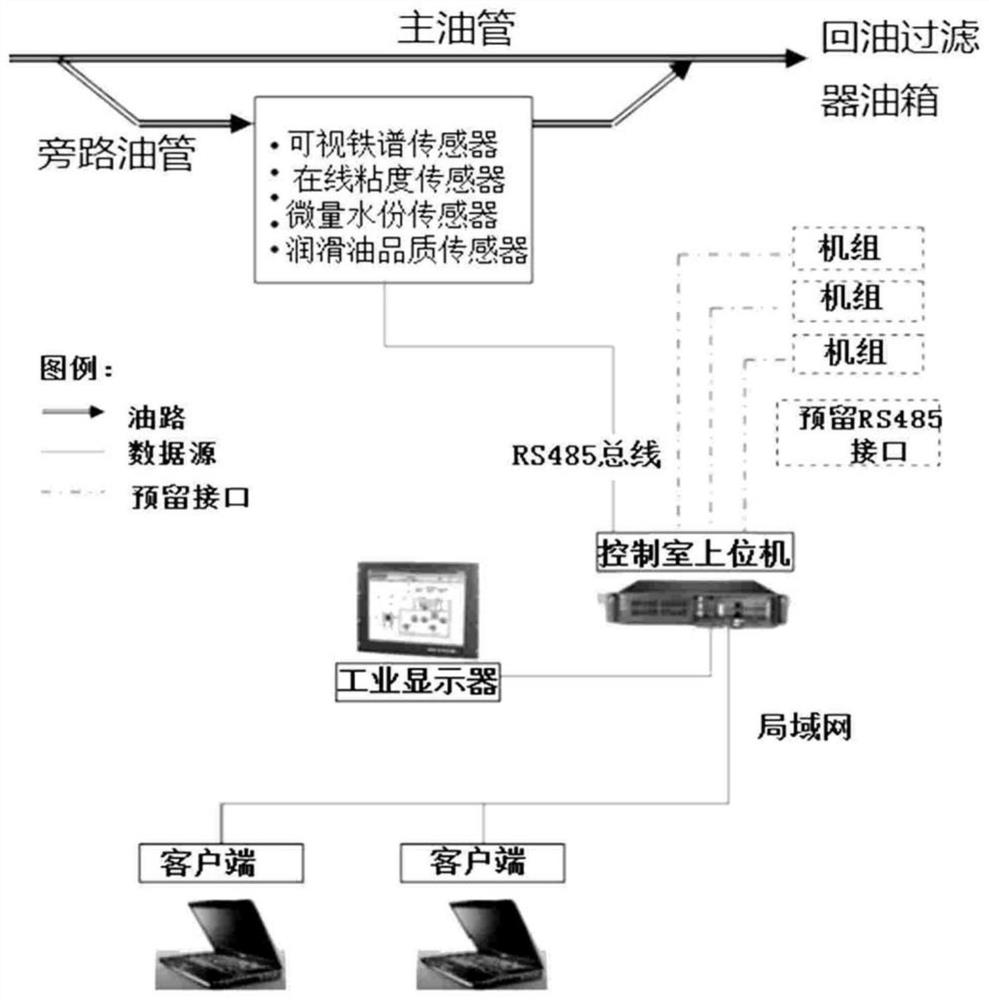

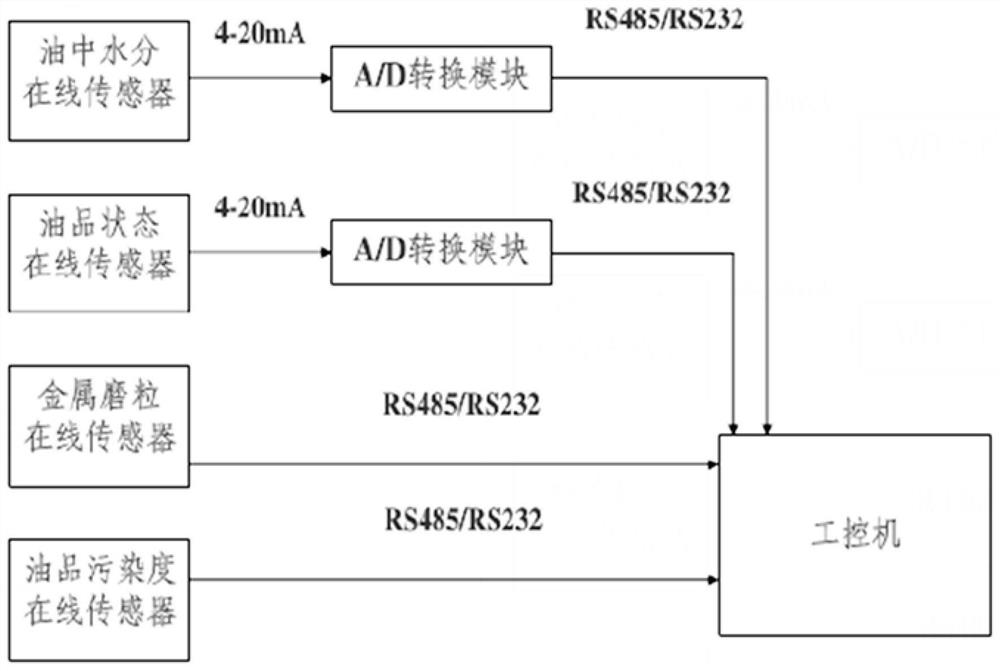

Online safety early warning system for phase adjusting machine oil liquid system

ActiveCN110906152AReduce operating and maintenance costsIncrease productivityBearing componentsLubrication elementsIndustrial equipmentEvaluation data

The invention discloses an online safety early warning system for a phase adjusting machine oil liquid system. The online safety early warning system comprises online monitoring equipment, a workflowengine, a management server, industrial patrol inspection equipment and a communication device. The workflow engine is used for establishing a workflow model, defining roles and realizing flow controlby adopting a flow controller. The online monitoring equipment is used for extracting partial oil samples from an oil liquid system for detection, and acquiring monitoring parameters. The managementserver processes the monitoring parameters collected by the online monitoring equipment according to the preset workflow model and stores original monitoring parameters and processed results into a lubricating oil ledger database, a lubricating oil base database, a lubricating oil comparison database, a lubricating oil evaluation database and an expert diagnosis database. By means of the online safety early warning system, visual intelligent safety pre-control can be carried out on lubricating oil from the four aspects of iron spectrum, viscosity, water and temperature, the operation and maintenance cost of industrial equipment of a factory is reduced, the production efficiency is improved, and serious lubricating failure and mechanical failure are avoided.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

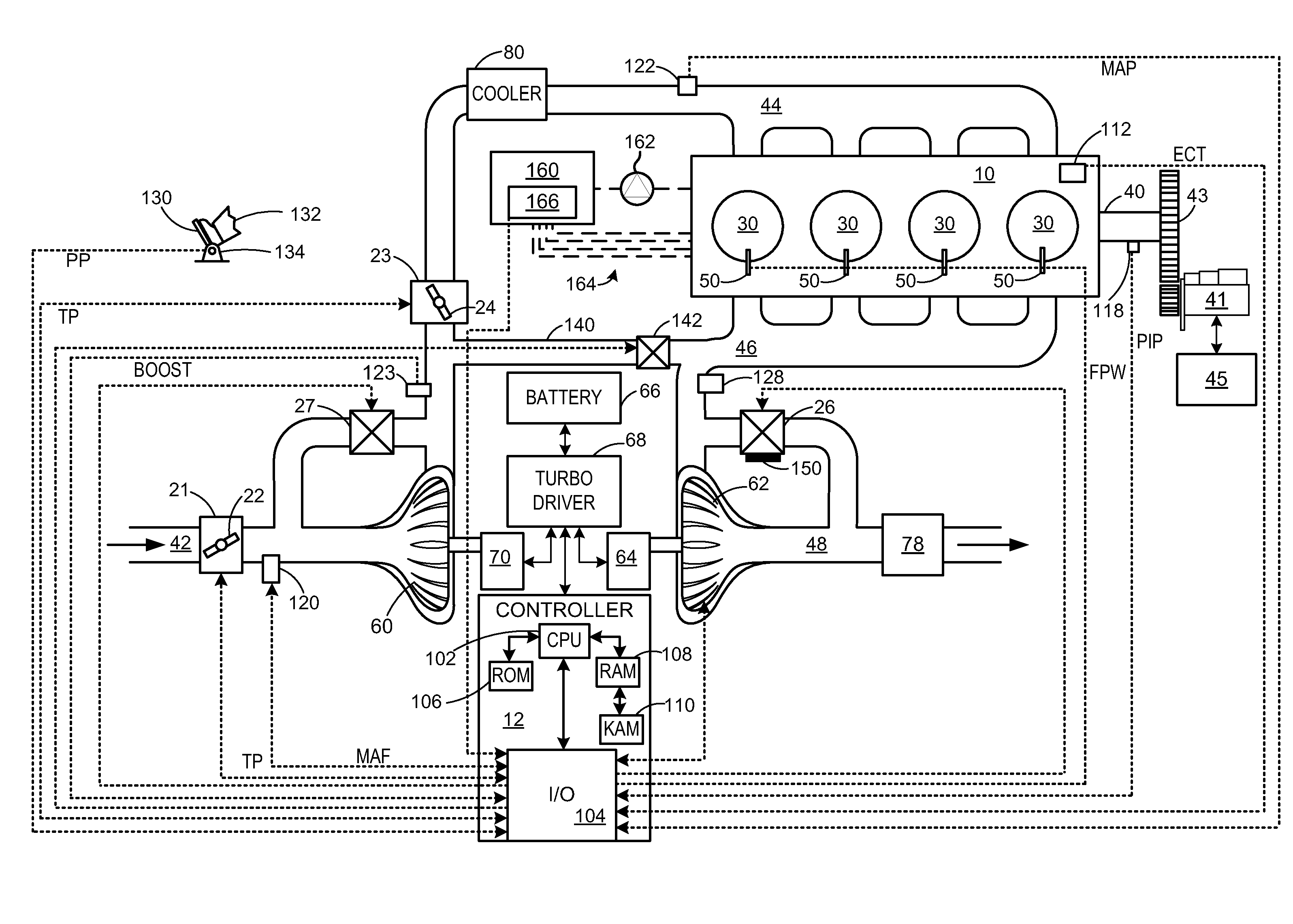

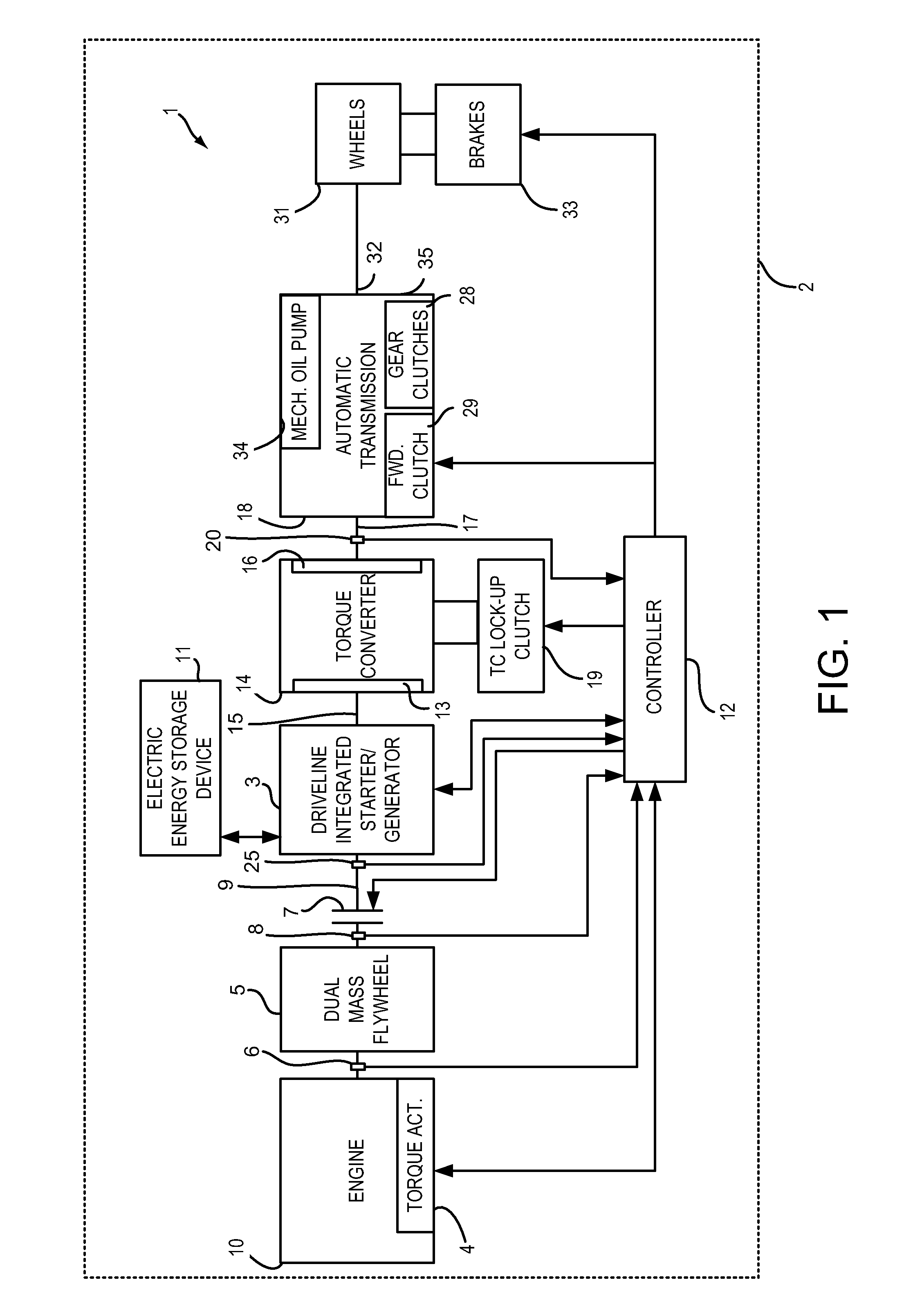

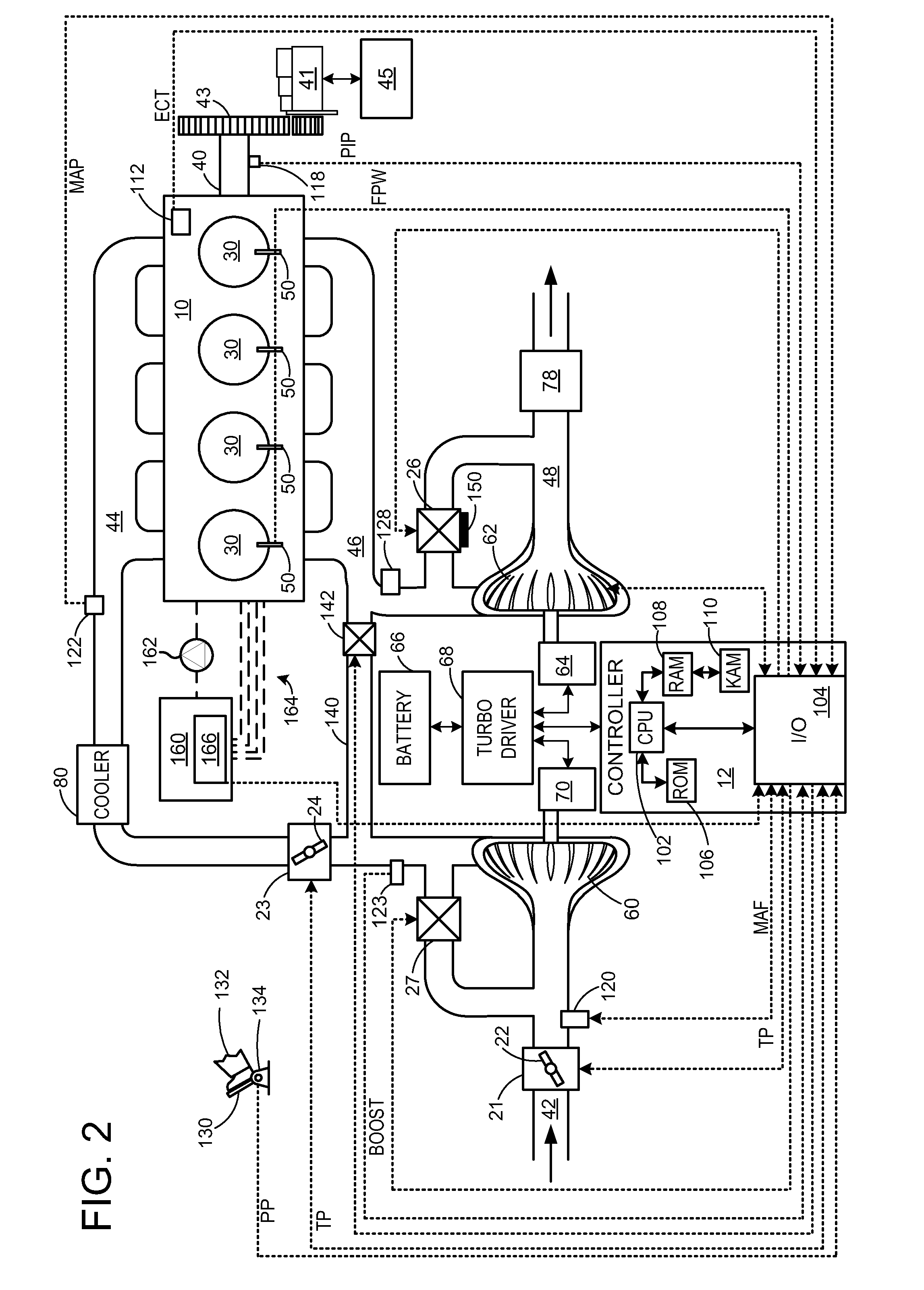

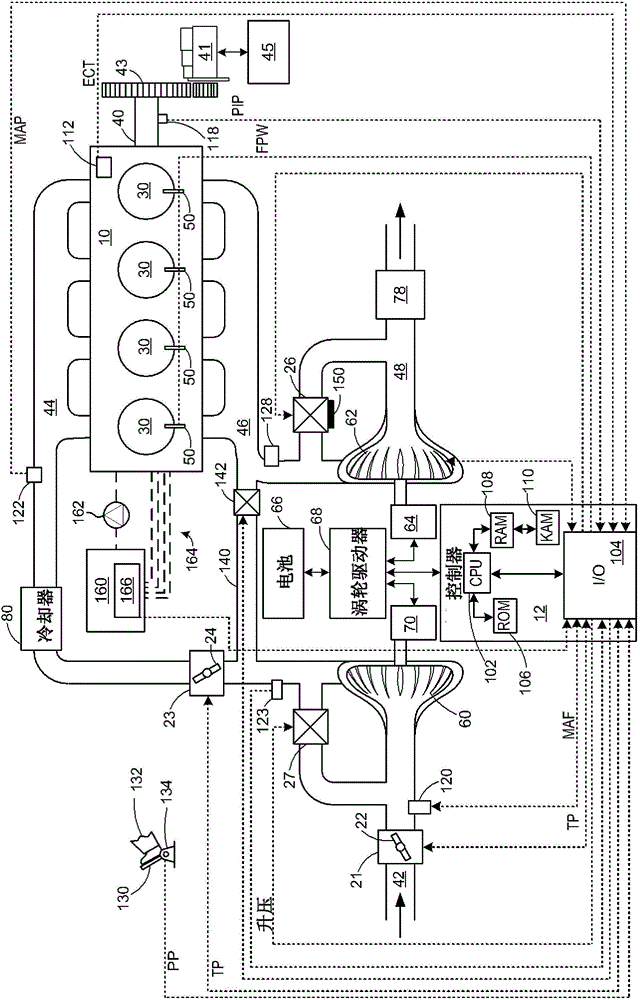

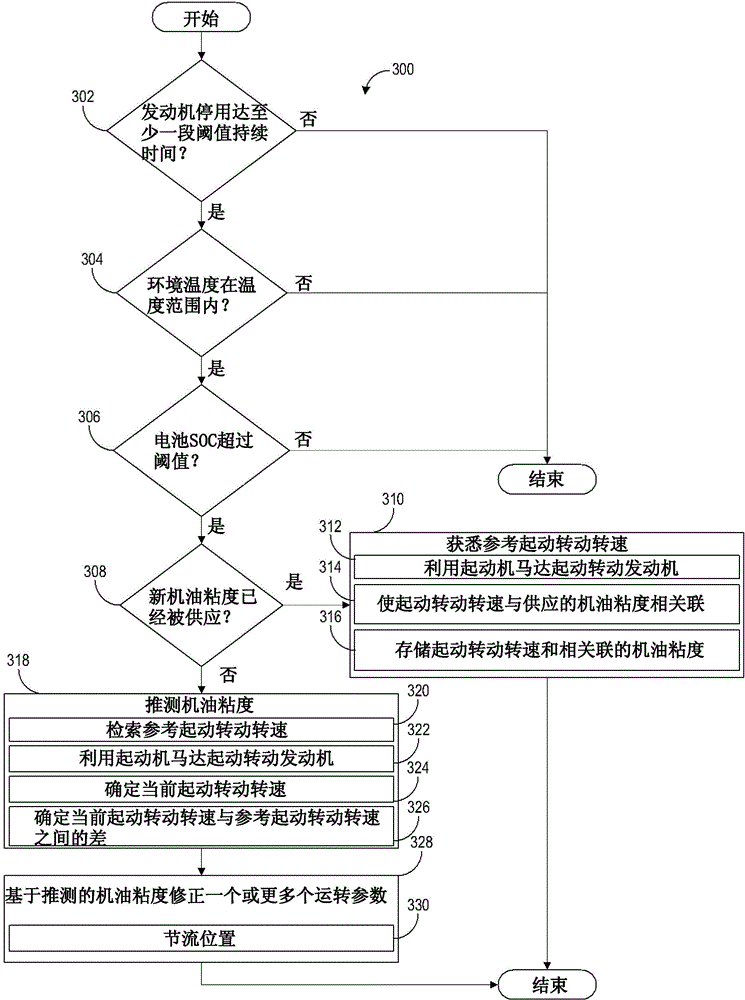

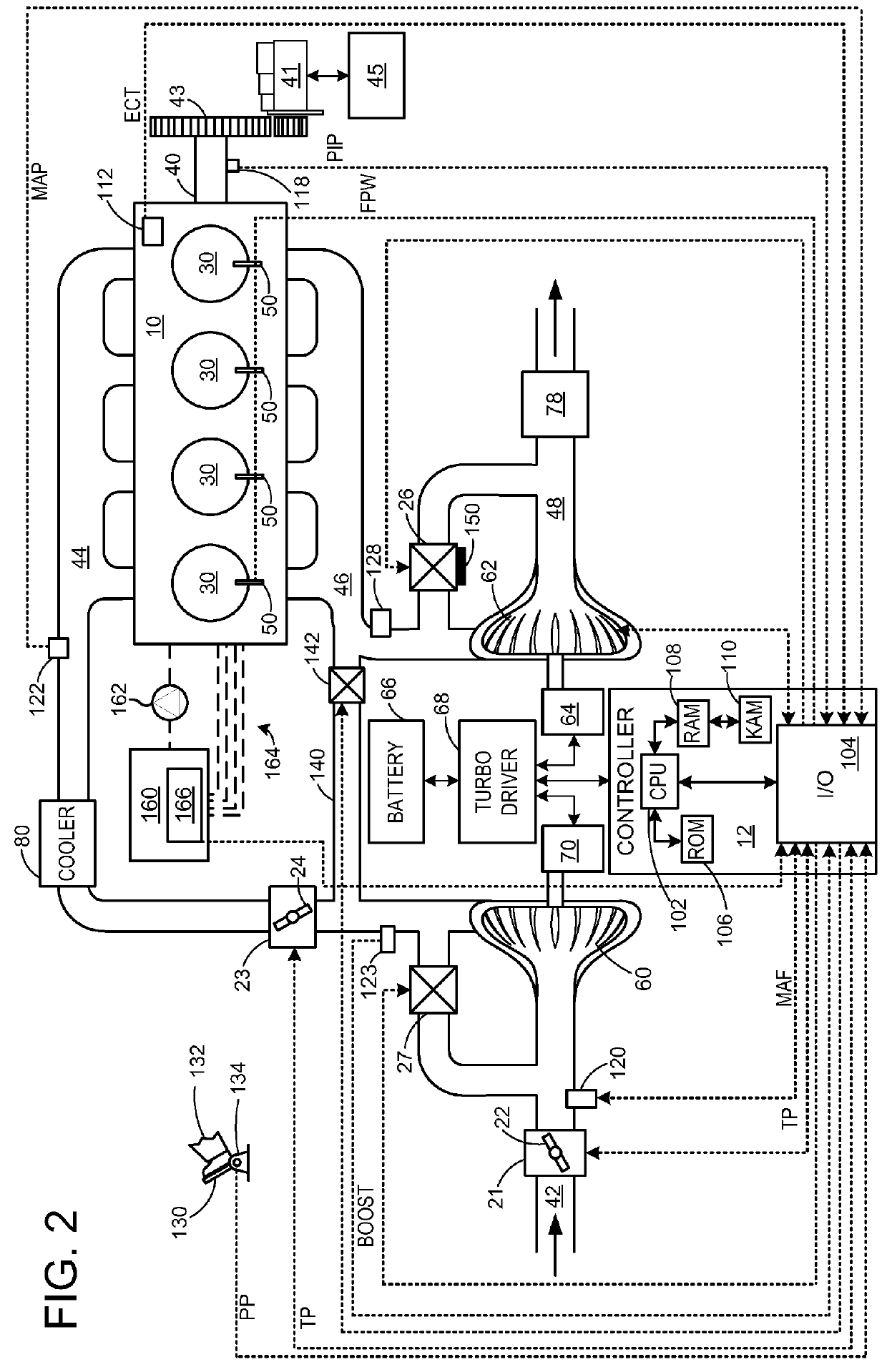

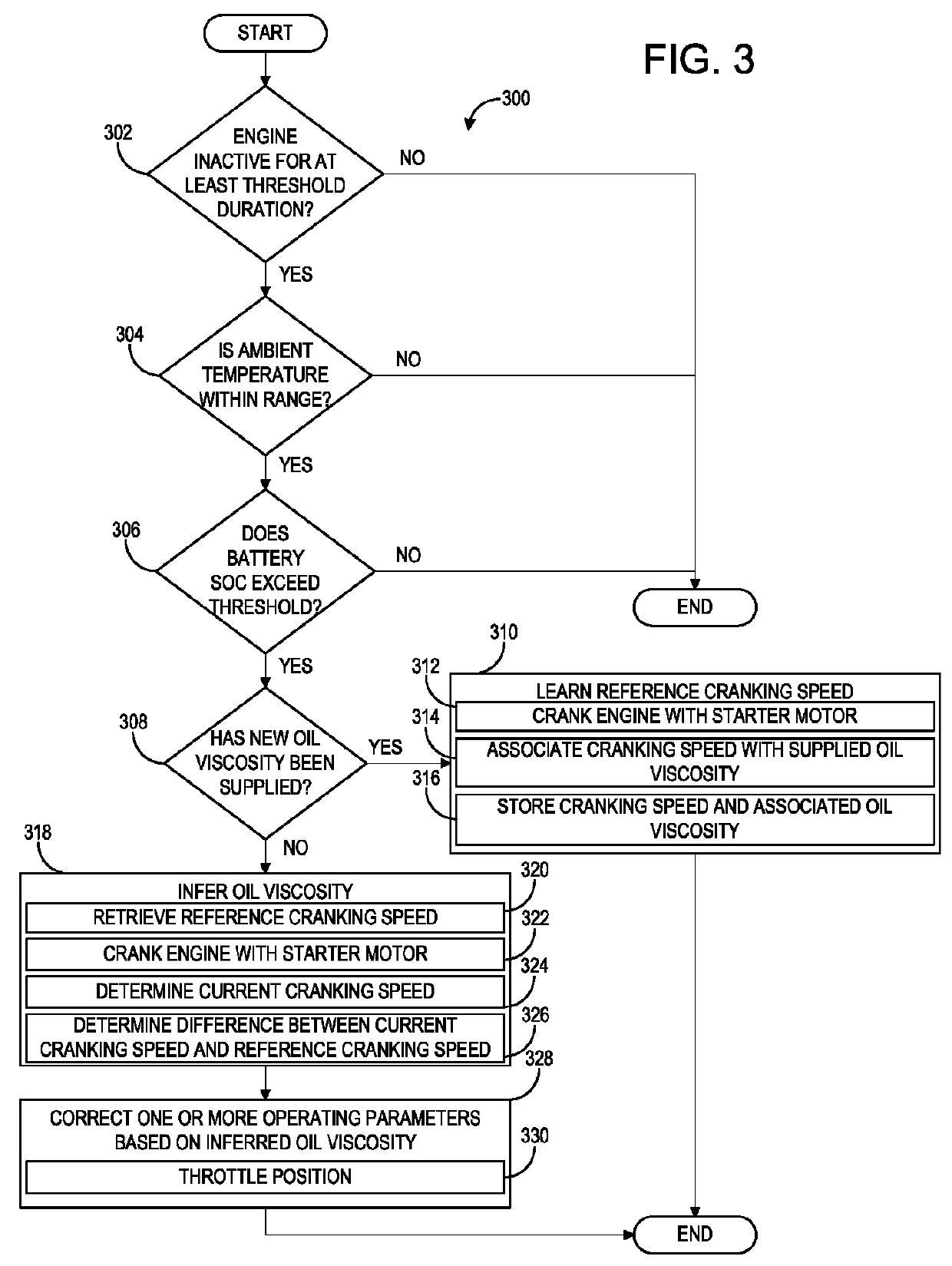

Viscosity detection using starter motor

ActiveUS20150105996A1High viscosityGreater throttle openingElectrical controlDigital data processing detailsExternal combustion engineOil viscosity

Various methods for inferring oil viscosity and / or oil viscosity index in an internal combustion engine are provided. In one example, a new control method comprises cranking the engine during a start mode with an electric motor connected to a substantially constant source of electrical power, inferring engine oil viscosity based at least on engine oil temperature and speed of the engine while being cranked by the electric motor during the start mode, and correcting an operating parameter of the engine based on the inferred engine oil viscosity.

Owner:FORD GLOBAL TECH LLC

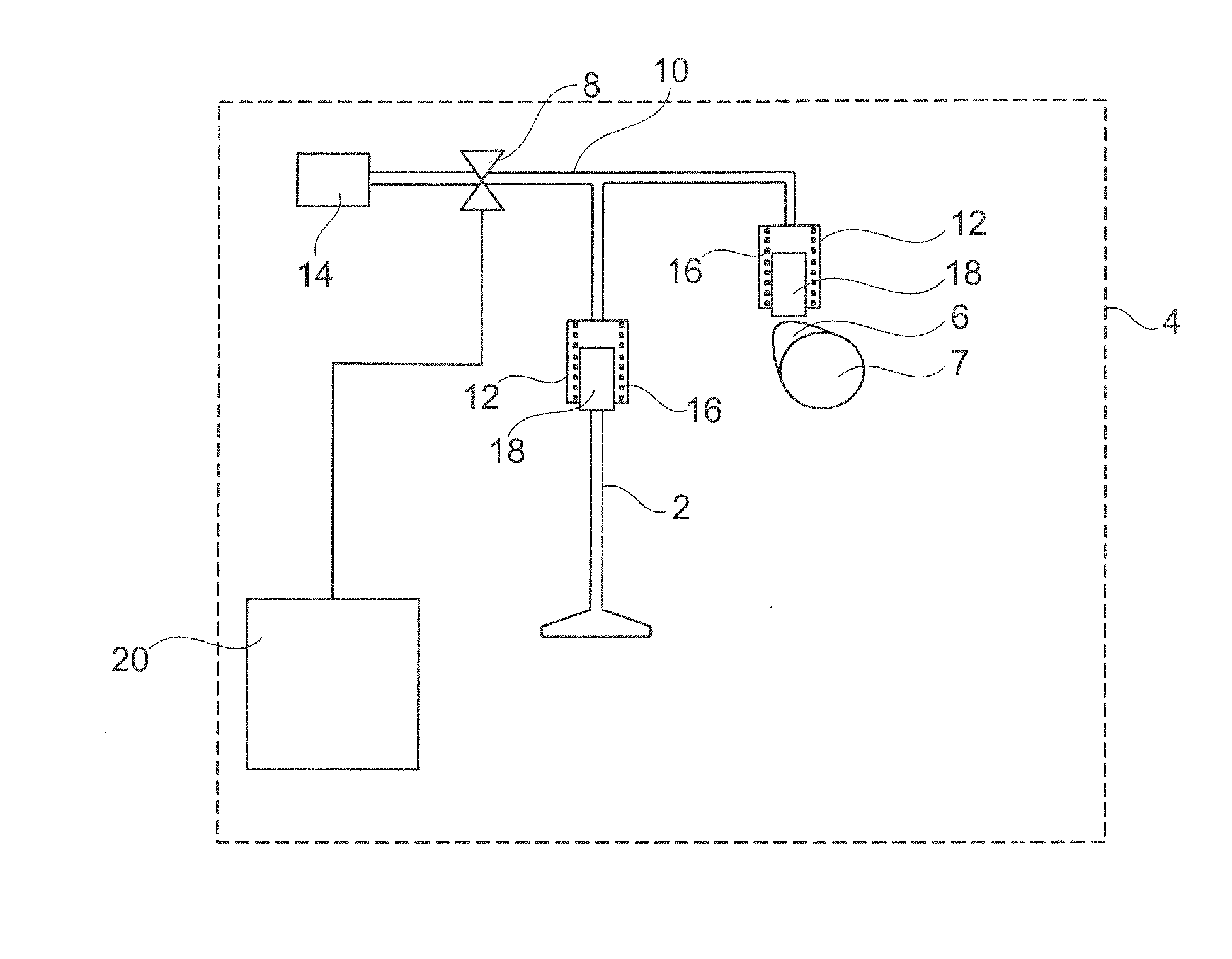

Device for supplying lubricant to a lubrication point in a machine

InactiveCN104006281AReduce lossesEngine pressureProportioning devicesTunnel boring machineEngineering

A device for supplying lubricant to a lubrication point in a machine, a tunnel boring machine, for example, includes a lubrication pump unit and a control unit. The lubrication pump unit is configured to supply a quantity of the lubricant to the lubrication point, and the control unit is configured to regulate the quantity of lubricant based on a sensor measurement signal. The sensor measurement signal may be based on a temperature measured in a region of the lubrication point, a pressure measured in a region of the lubrication point, a measured viscosity of the lubricant, a measured dielectricity of the lubricant, a measured water content of the lubricant, a vibration intensity measured at a part of the machine, or a measured rotational speed of a part of the machine.

Owner:SKF LUBRICATION SYST GERMANY

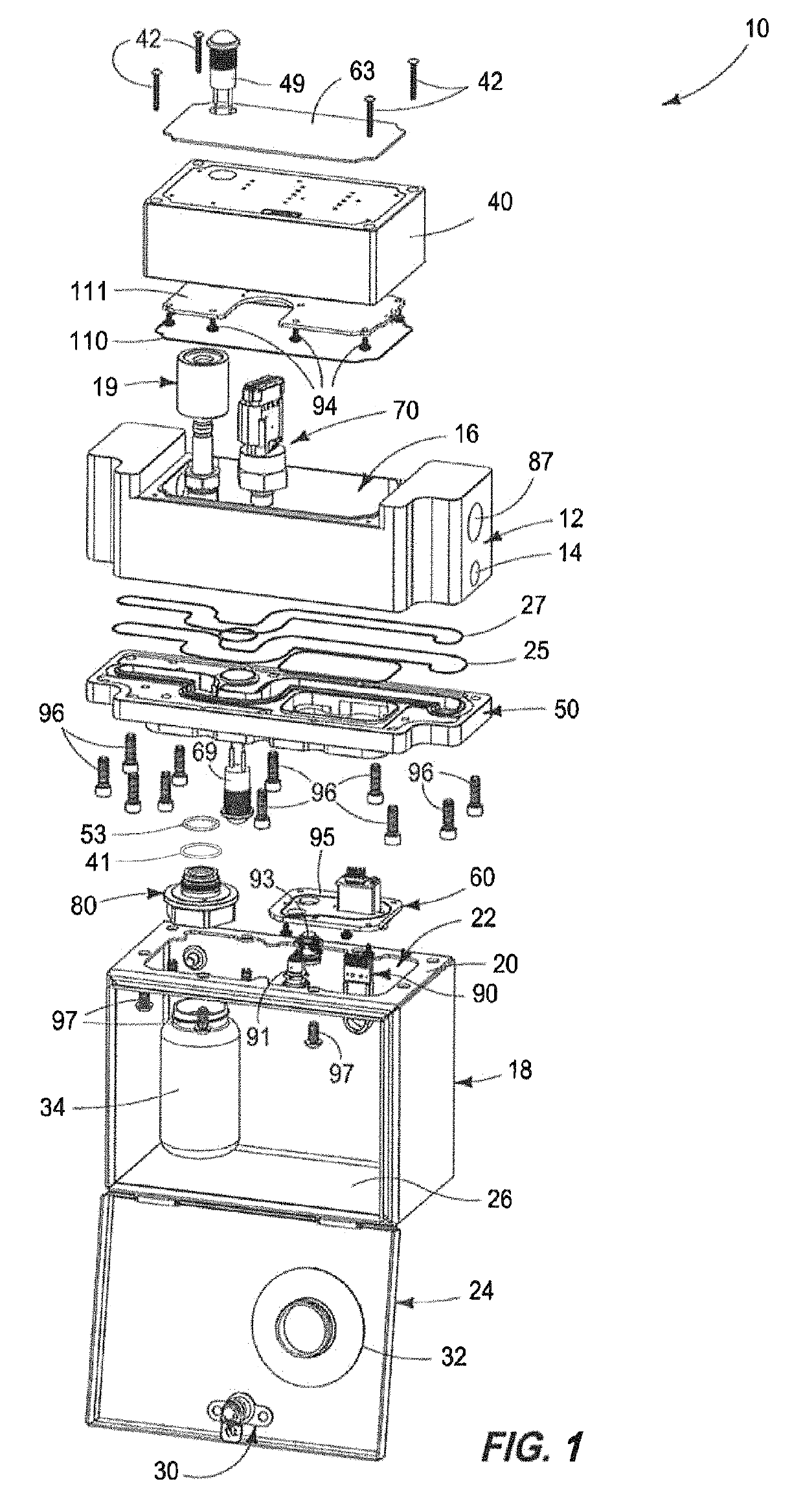

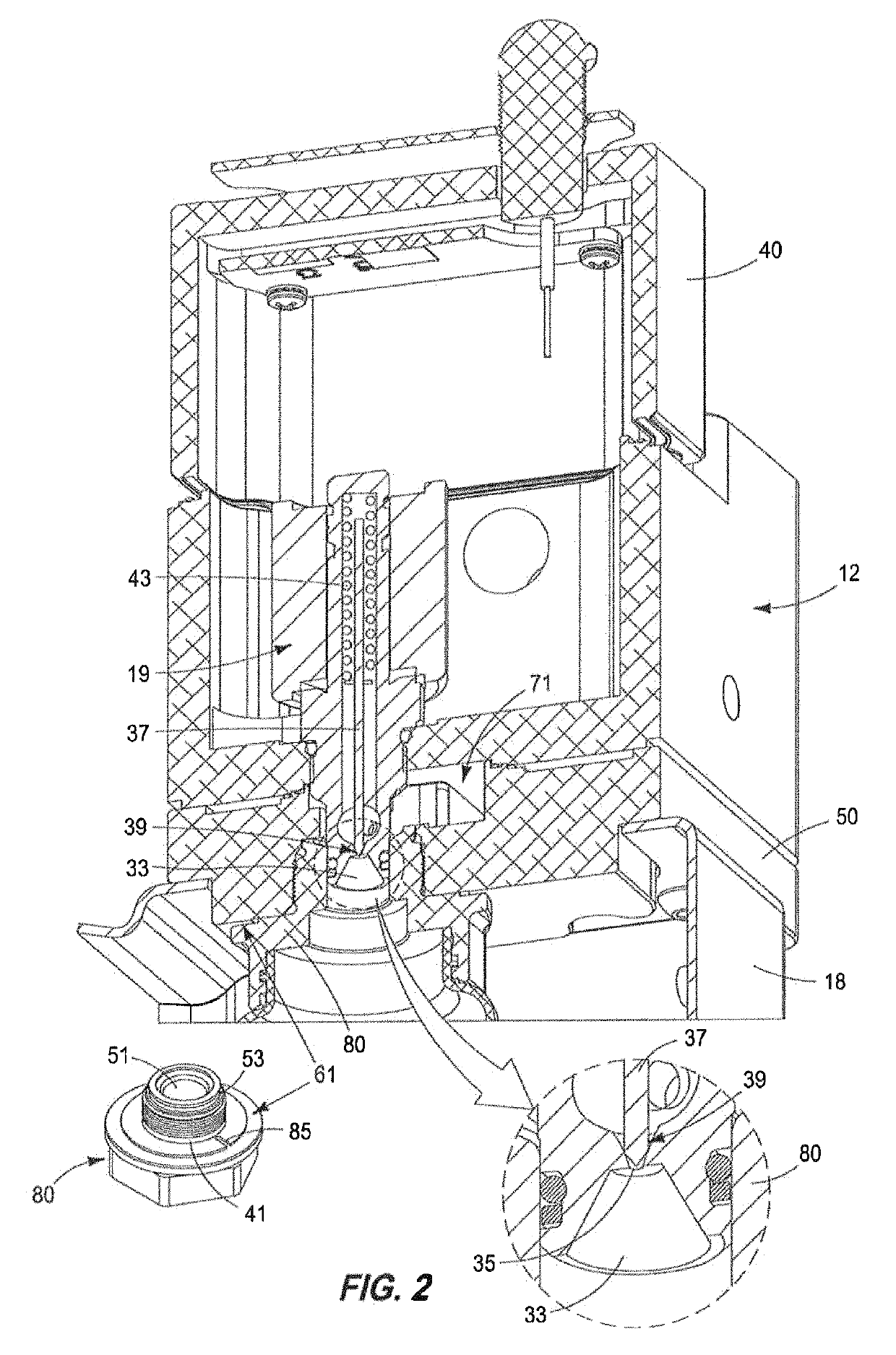

Fluid monitoring and management devices, fluid monitoring and management systems, and fluid monitoring and management methods

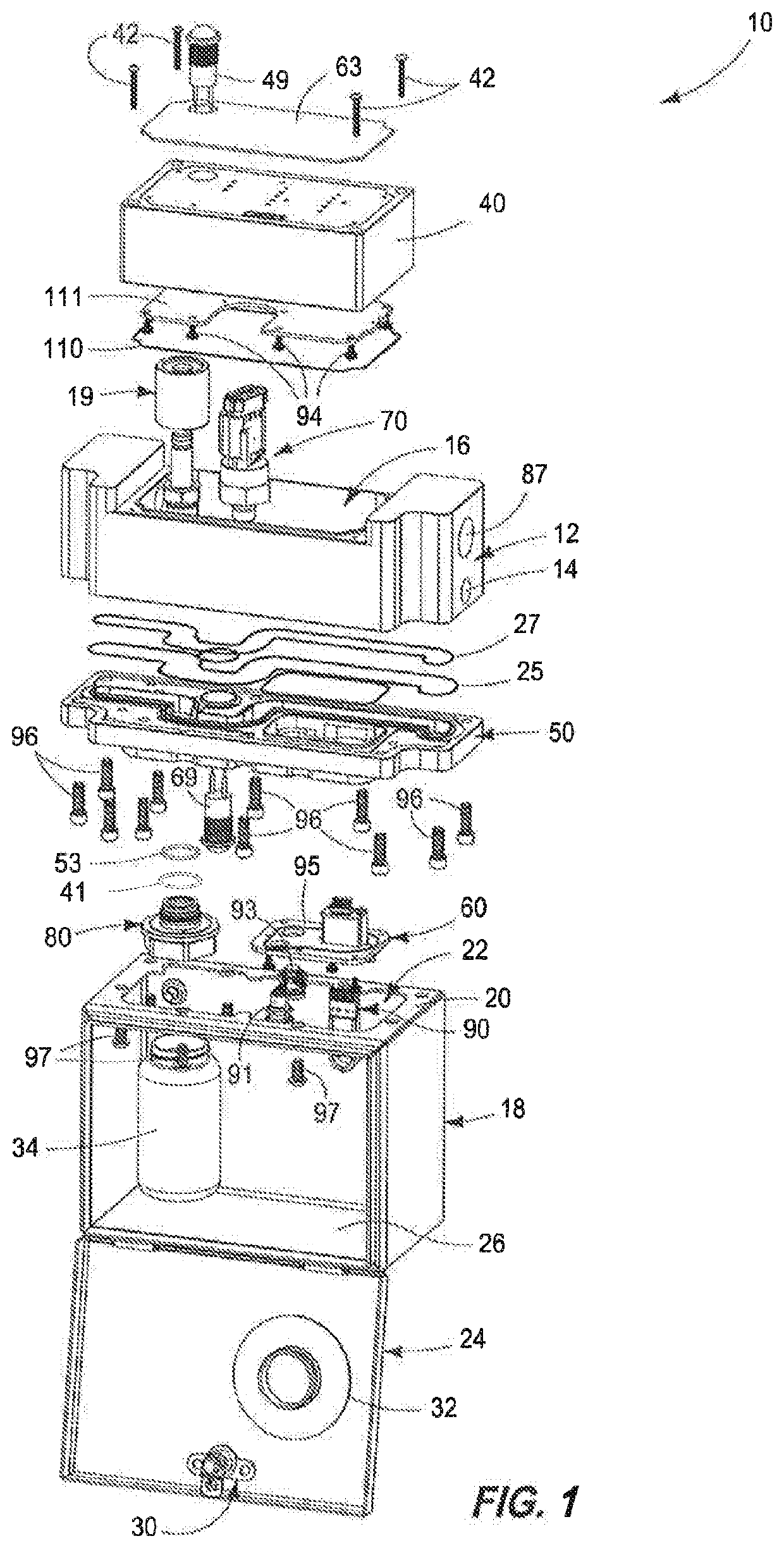

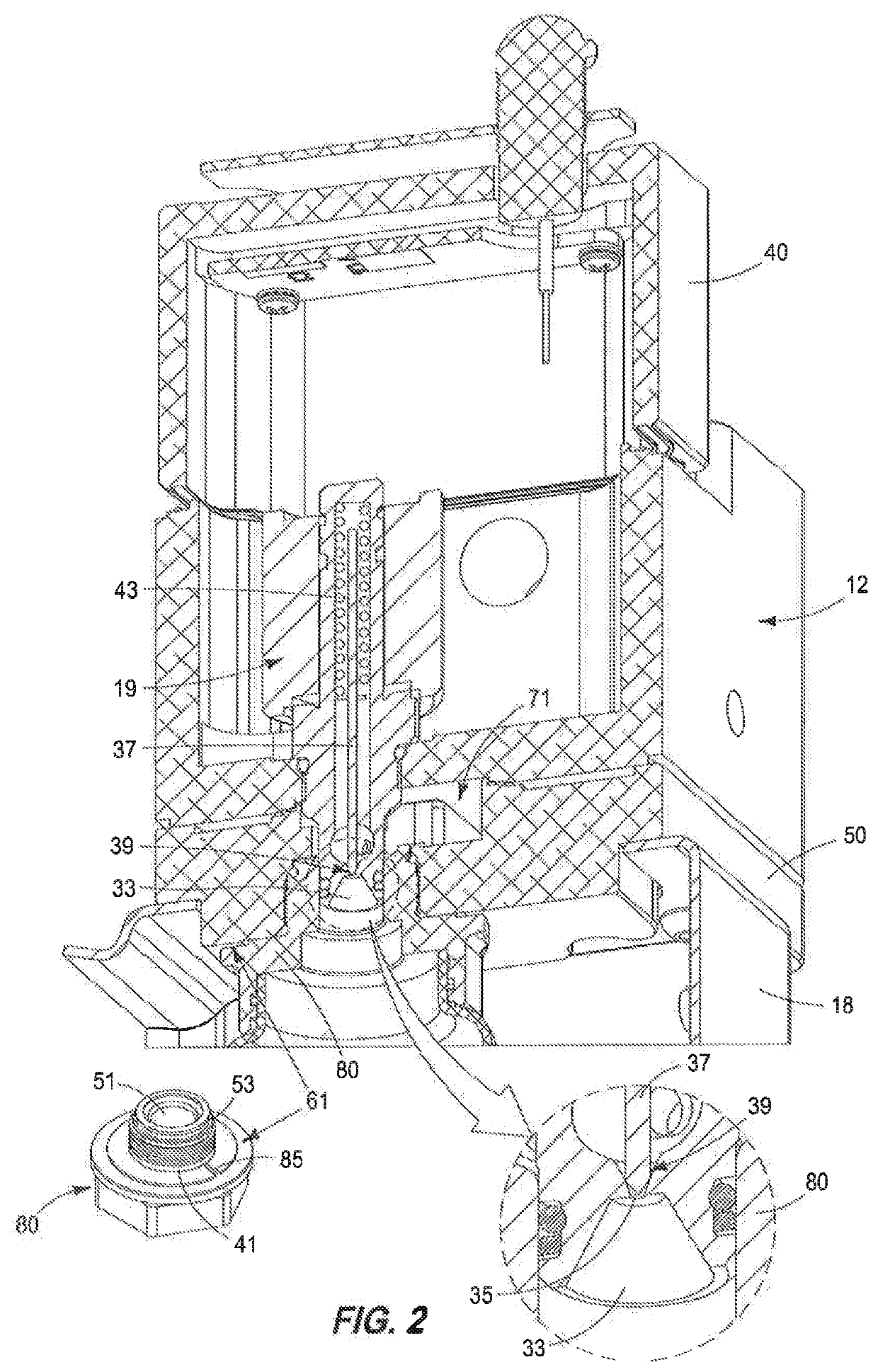

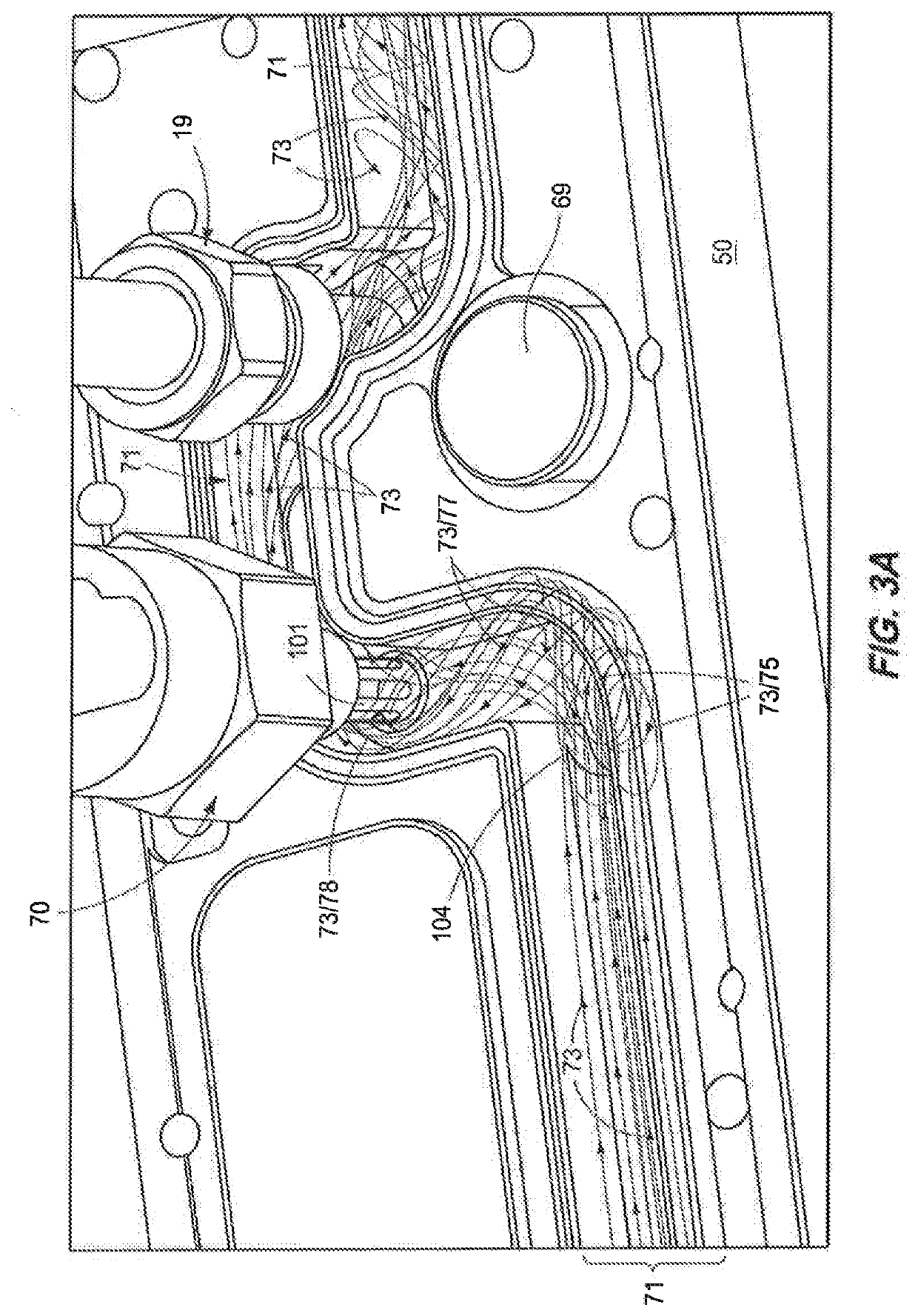

A fluid monitoring and management device that includes a housing with a fluid passageway. The fluid monitoring and management device further includes a fluid property sensor with a sensing element in the fluid passageway. A valve is in the fluid passageway of the fluid monitoring and management device. A removable bottle mount is aligned with the valve to be selectively in fluid communication with the fluid passageway.

Owner:LOGILUBE LLC

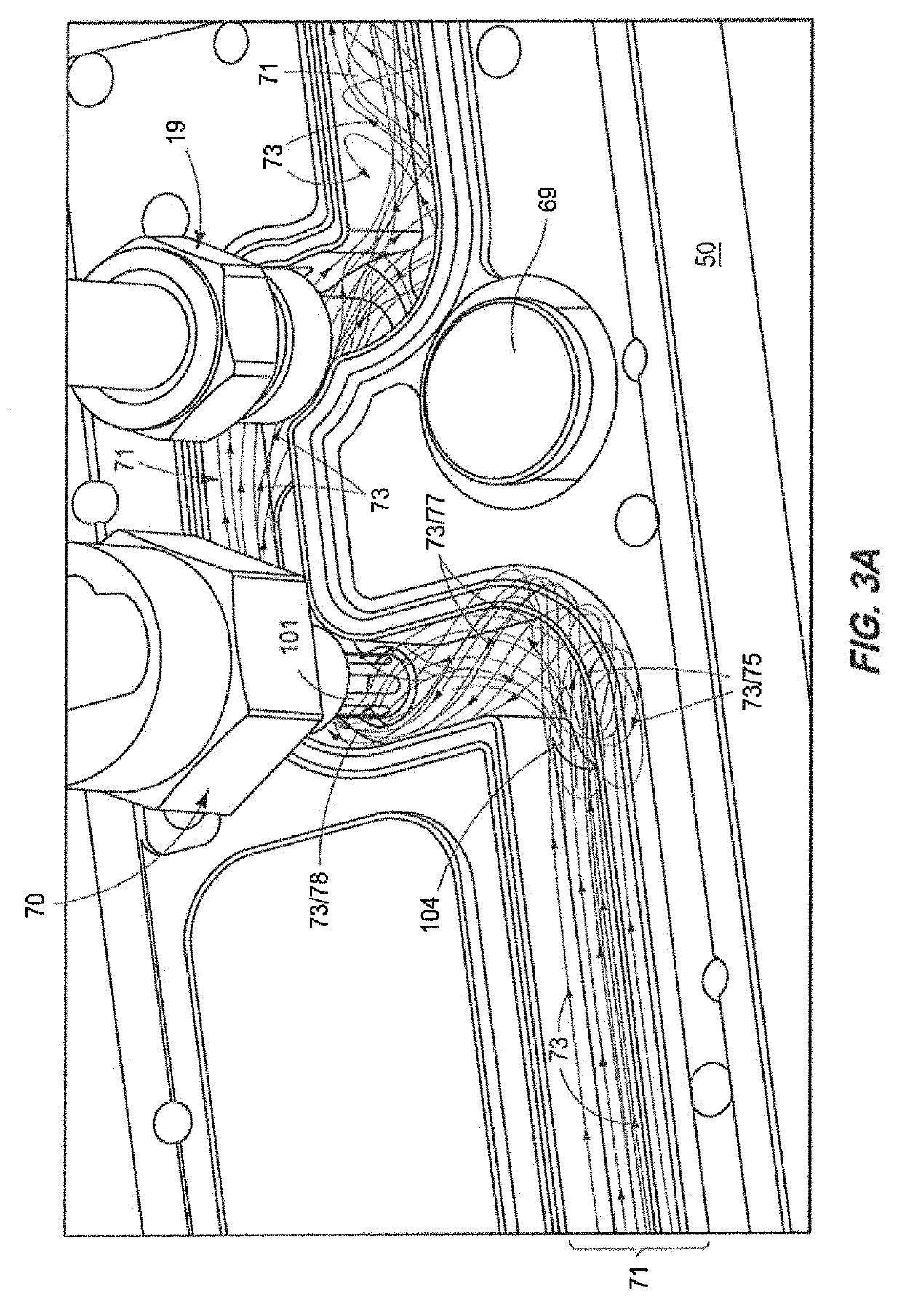

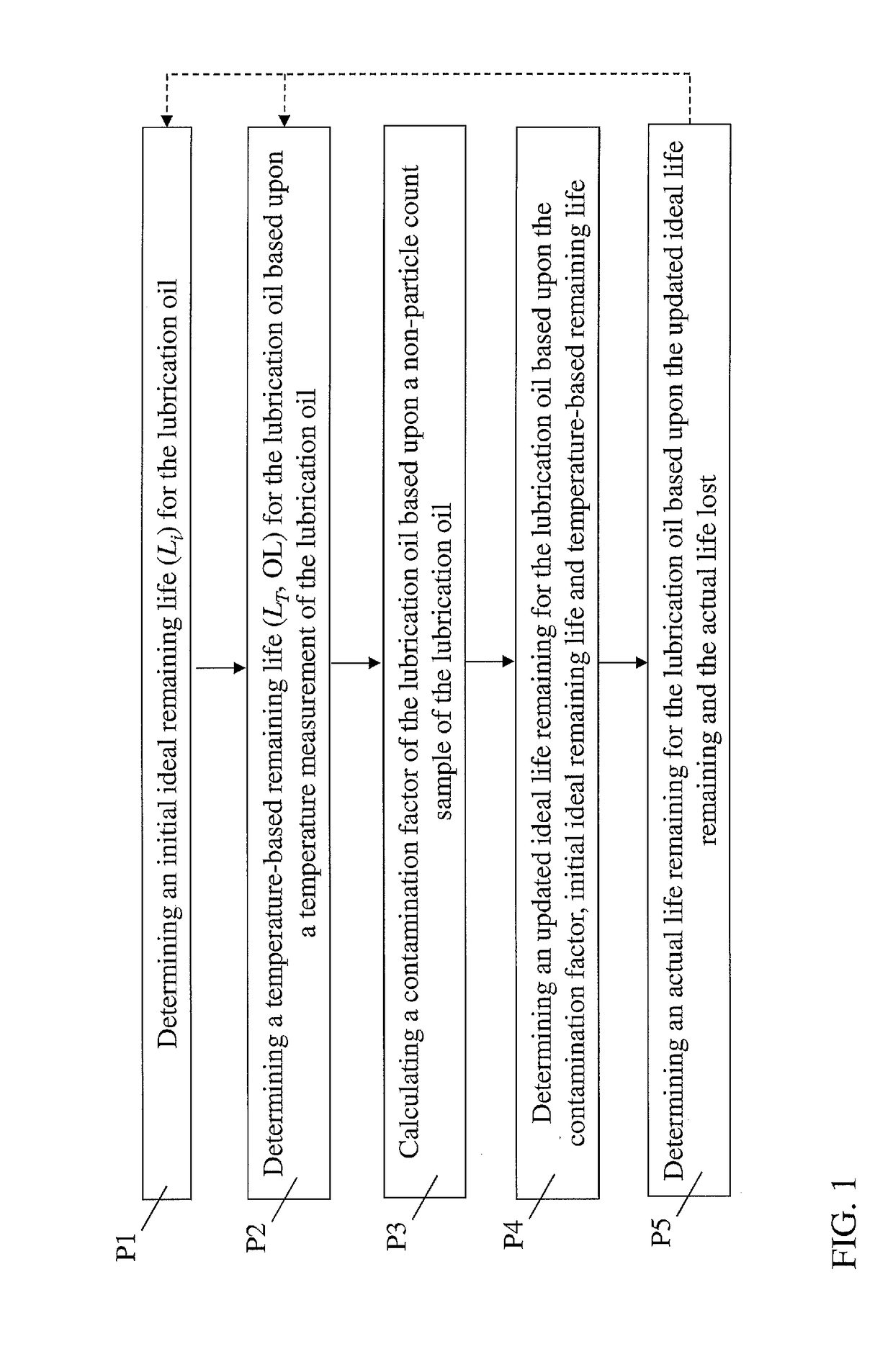

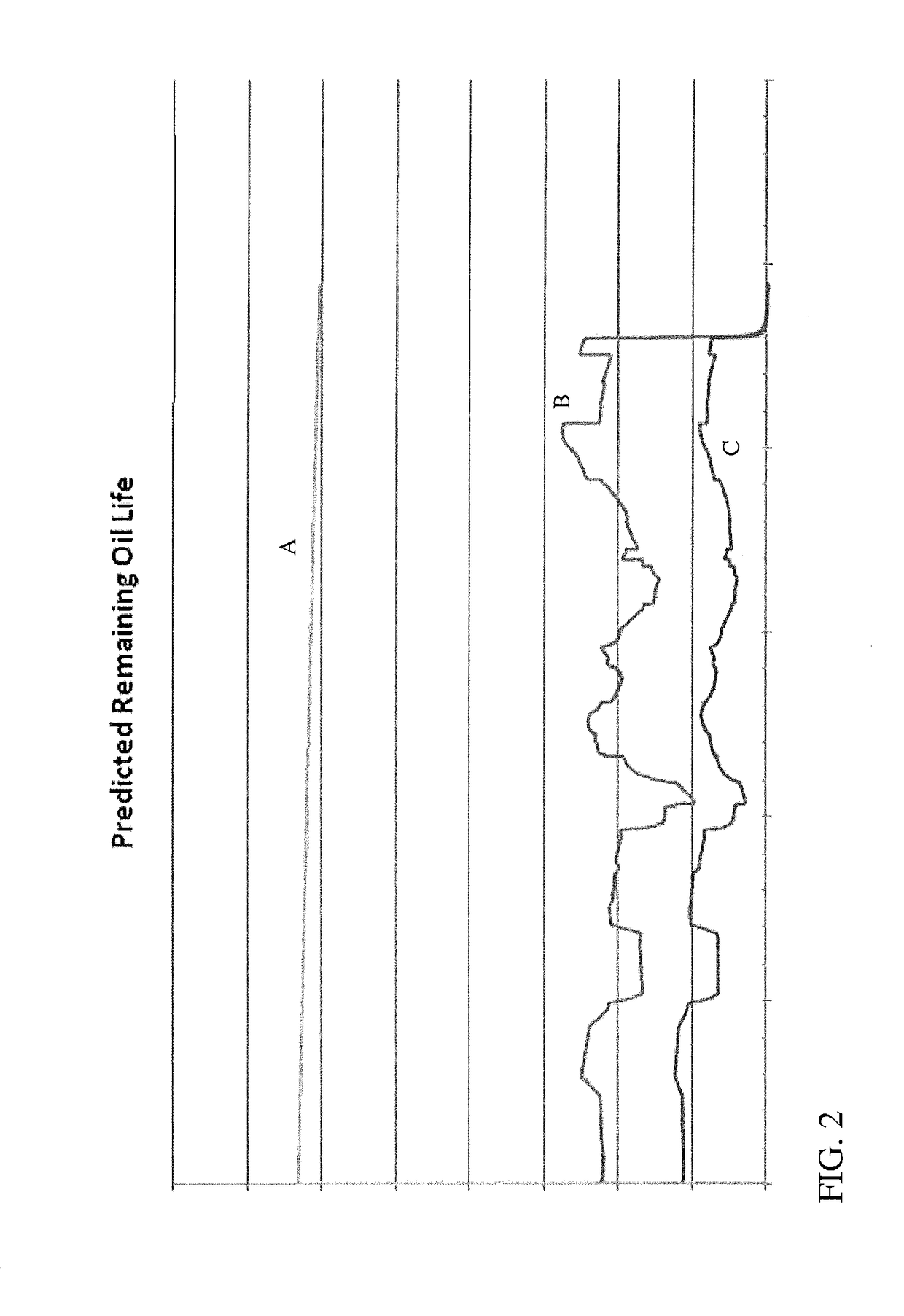

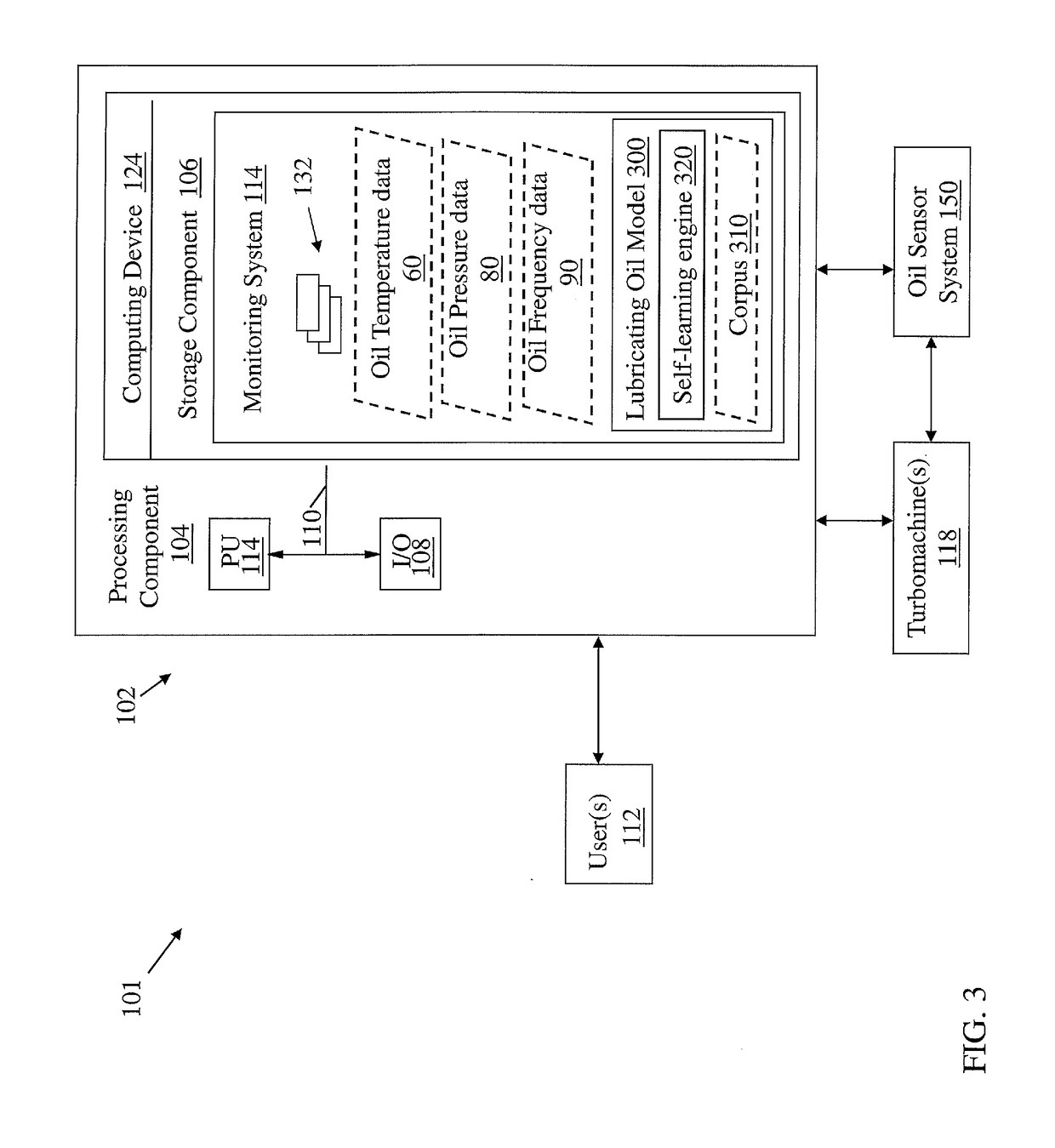

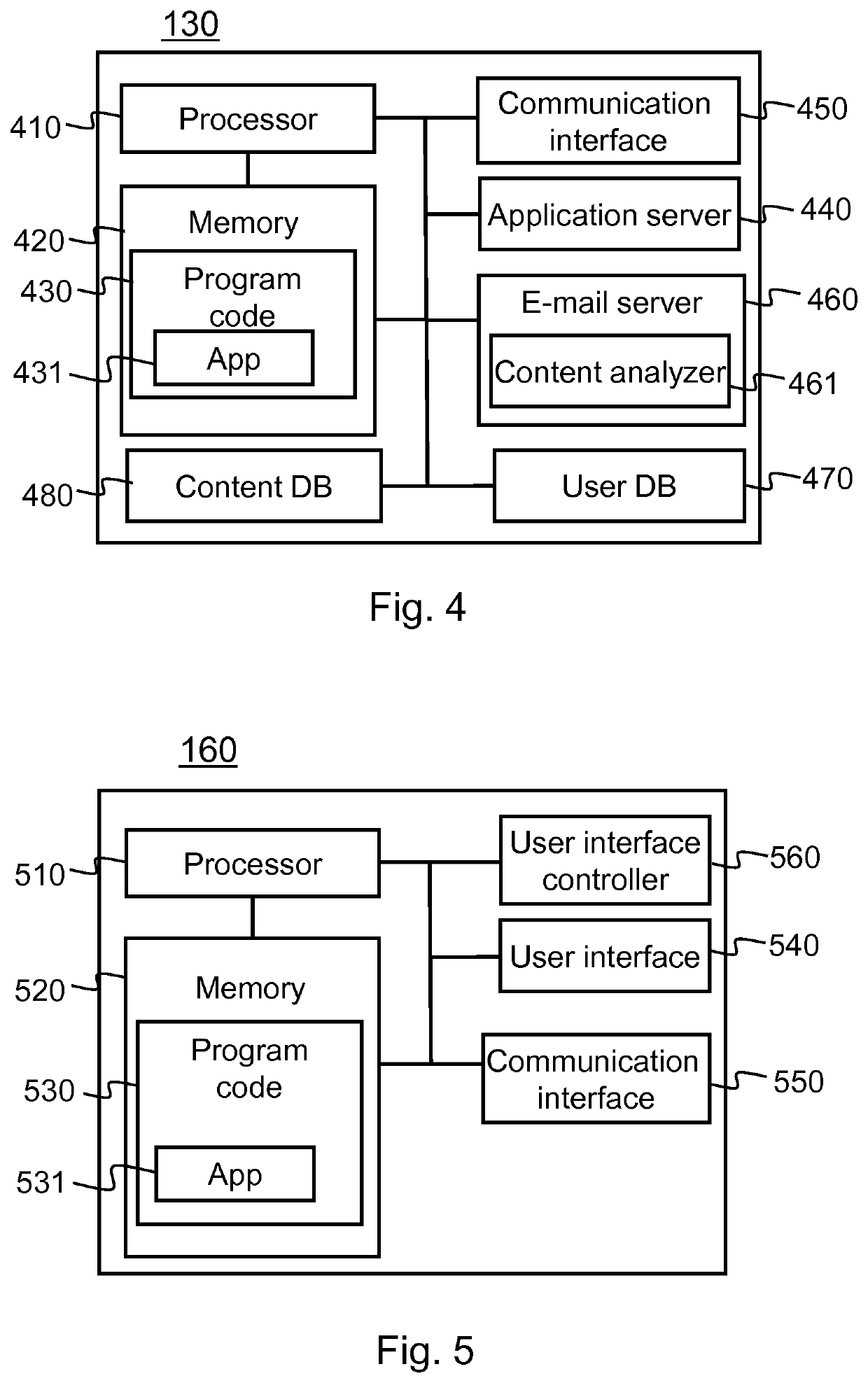

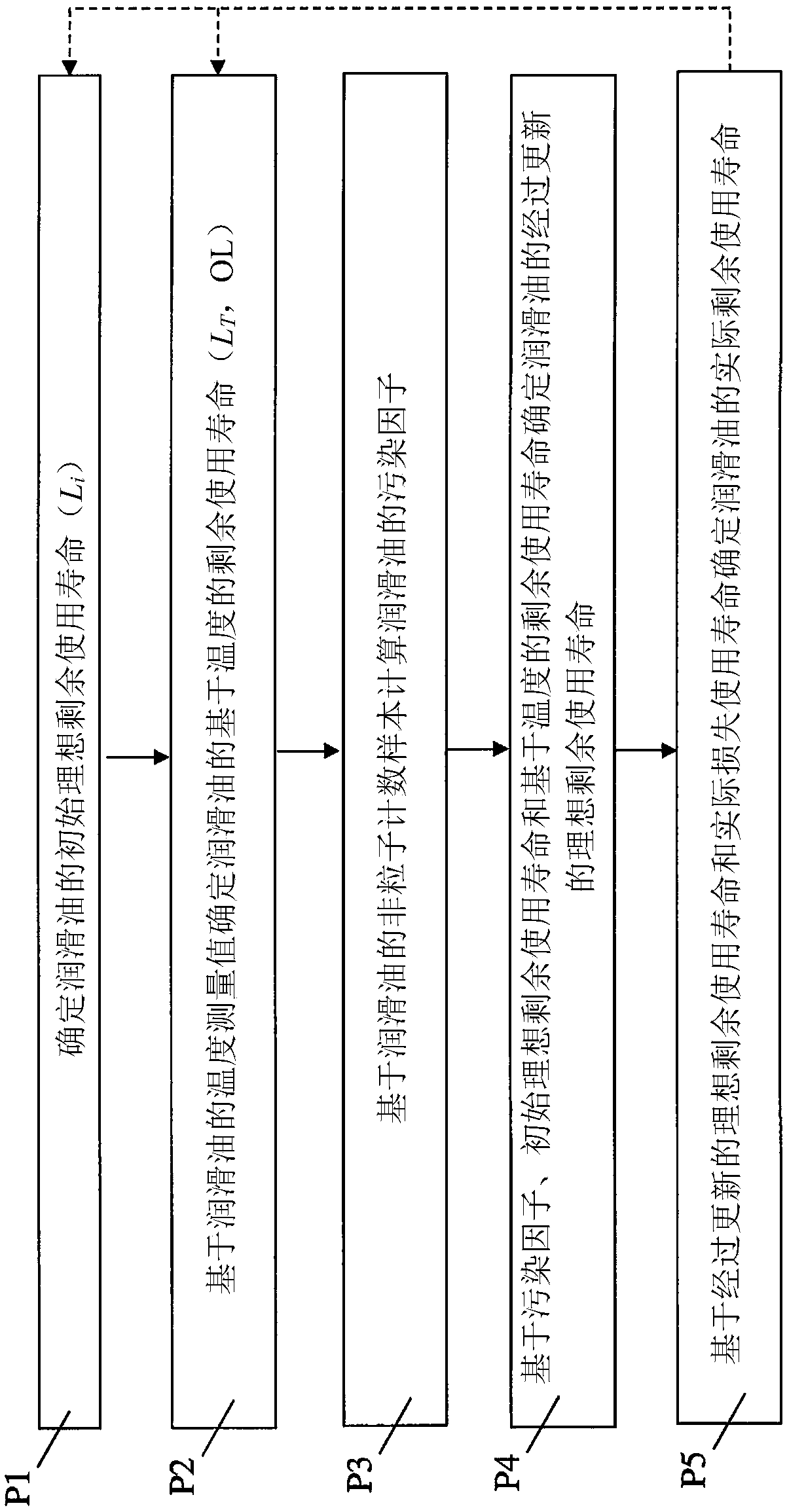

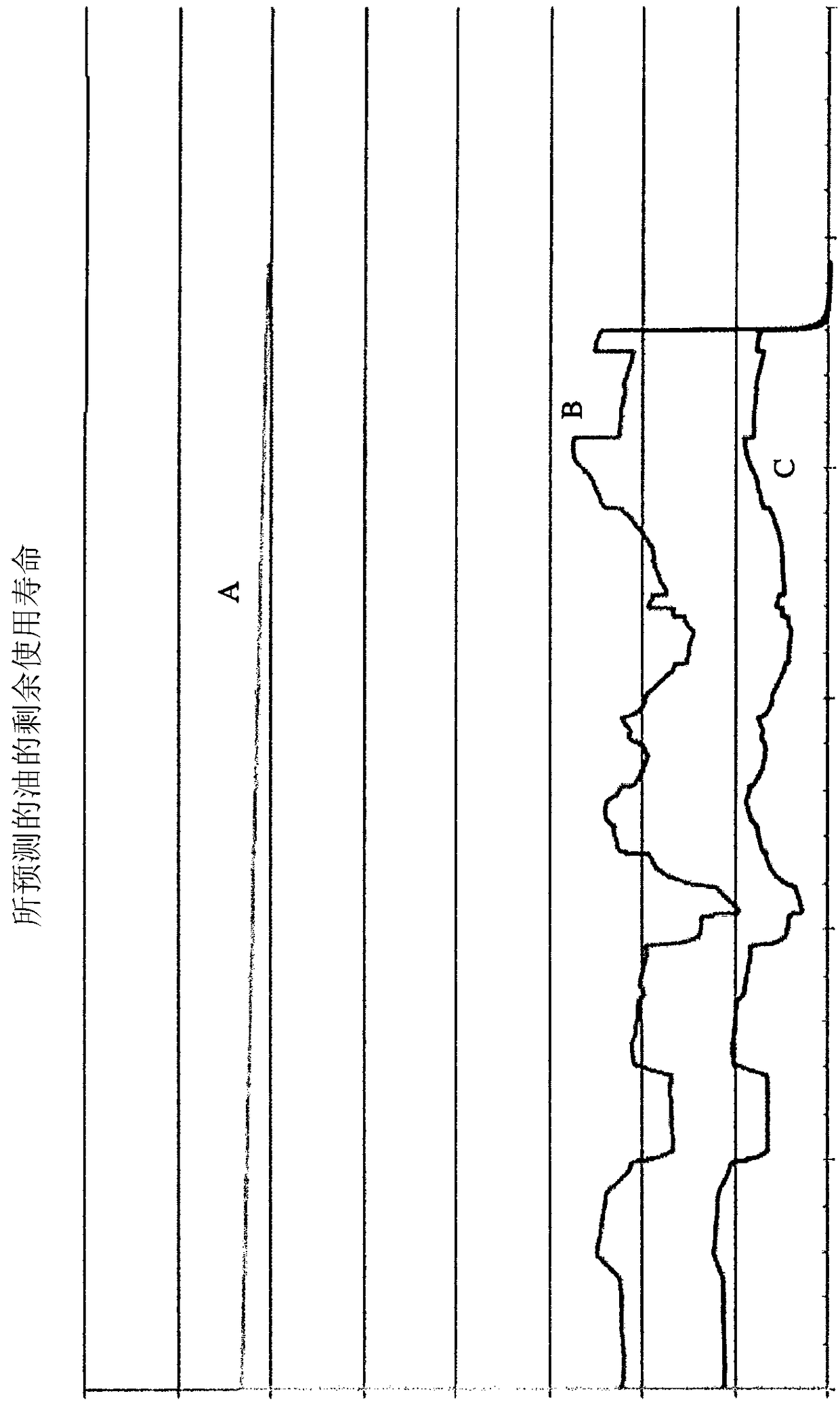

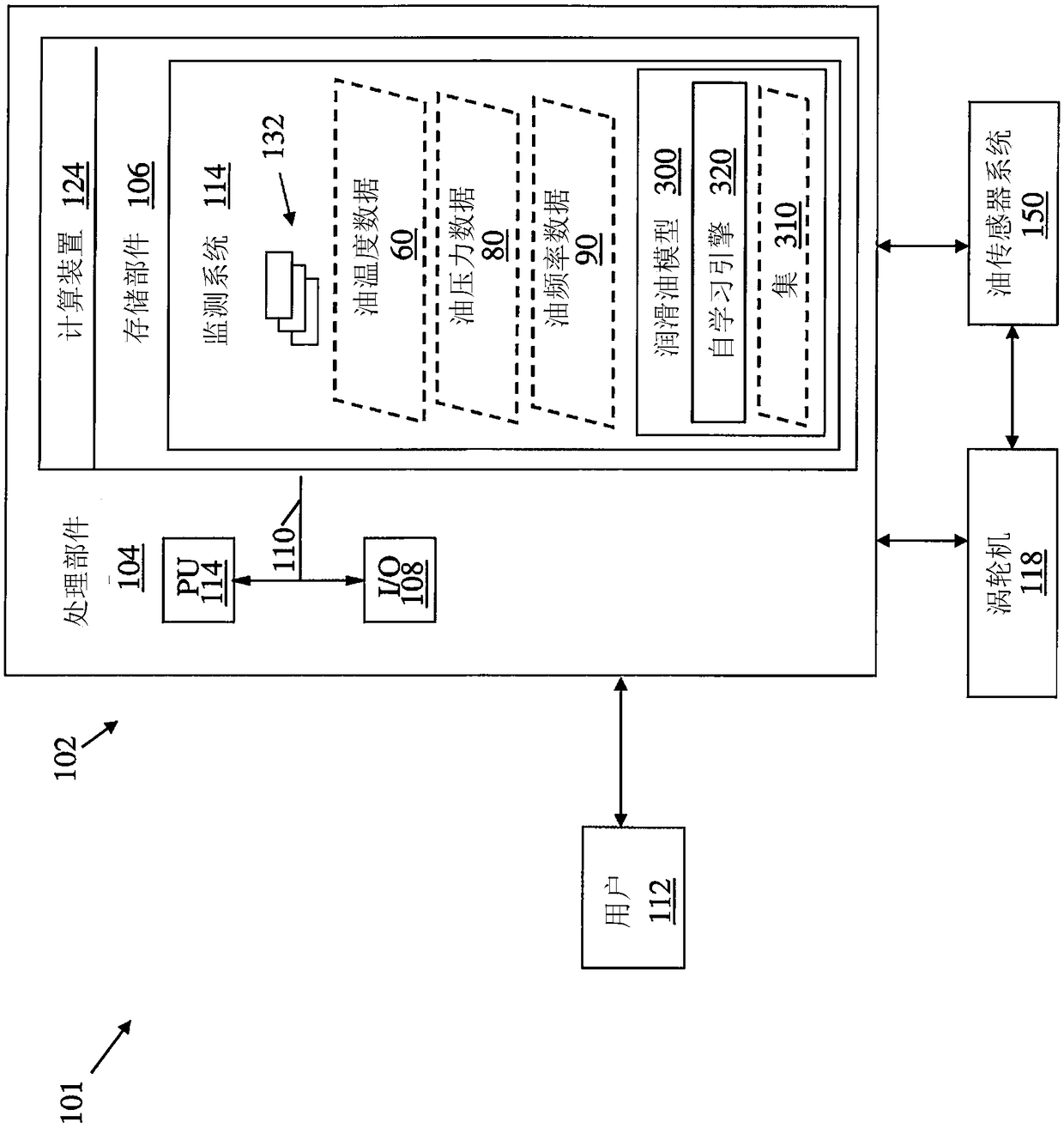

Turbomachine lubricating oil analyzer system, computer program product and related methods

Various embodiments of the invention include a system having: at least one computing device at least one computing device configured to monitor a lubrication oil by performing actions including: determining an initial ideal remaining life for the lubrication oil; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil; calculating a contamination factor of the lubrication oil based upon a non-particle count sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based upon the contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and an actual life lost for the lubrication oil.

Owner:GENERAL ELECTRIC CO

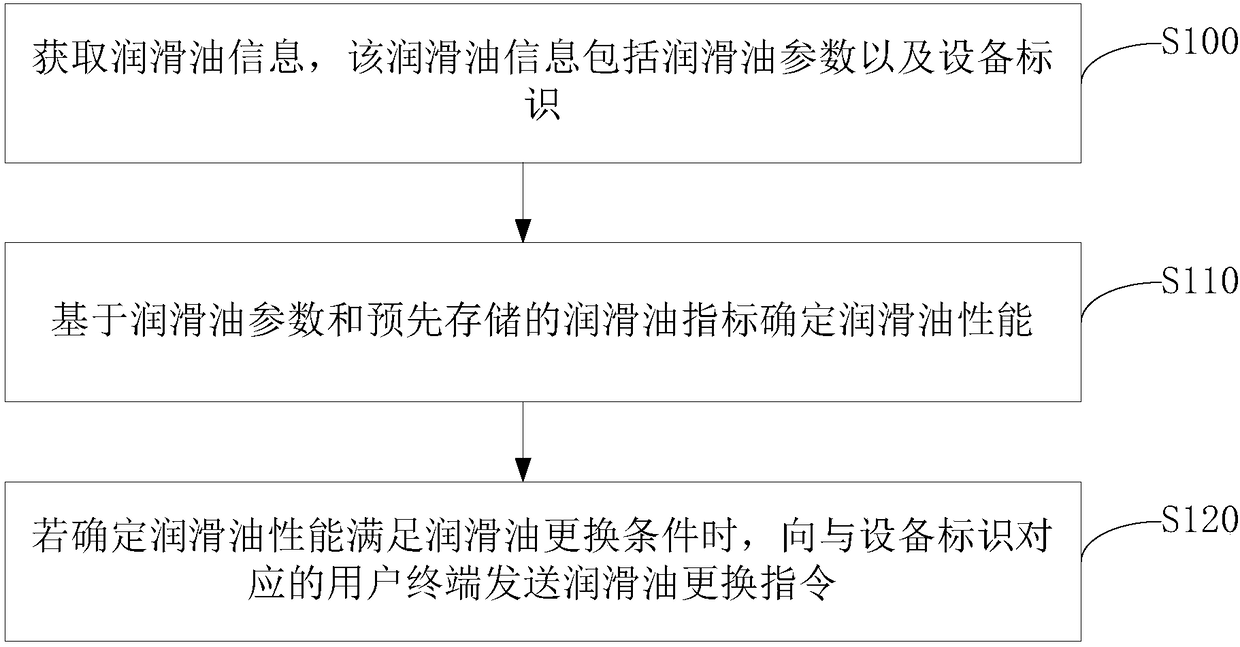

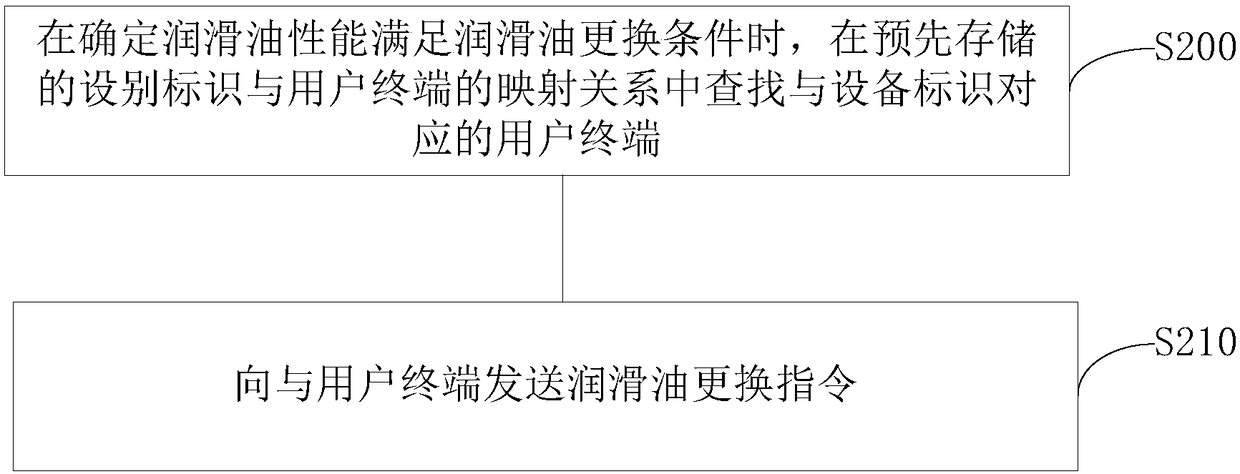

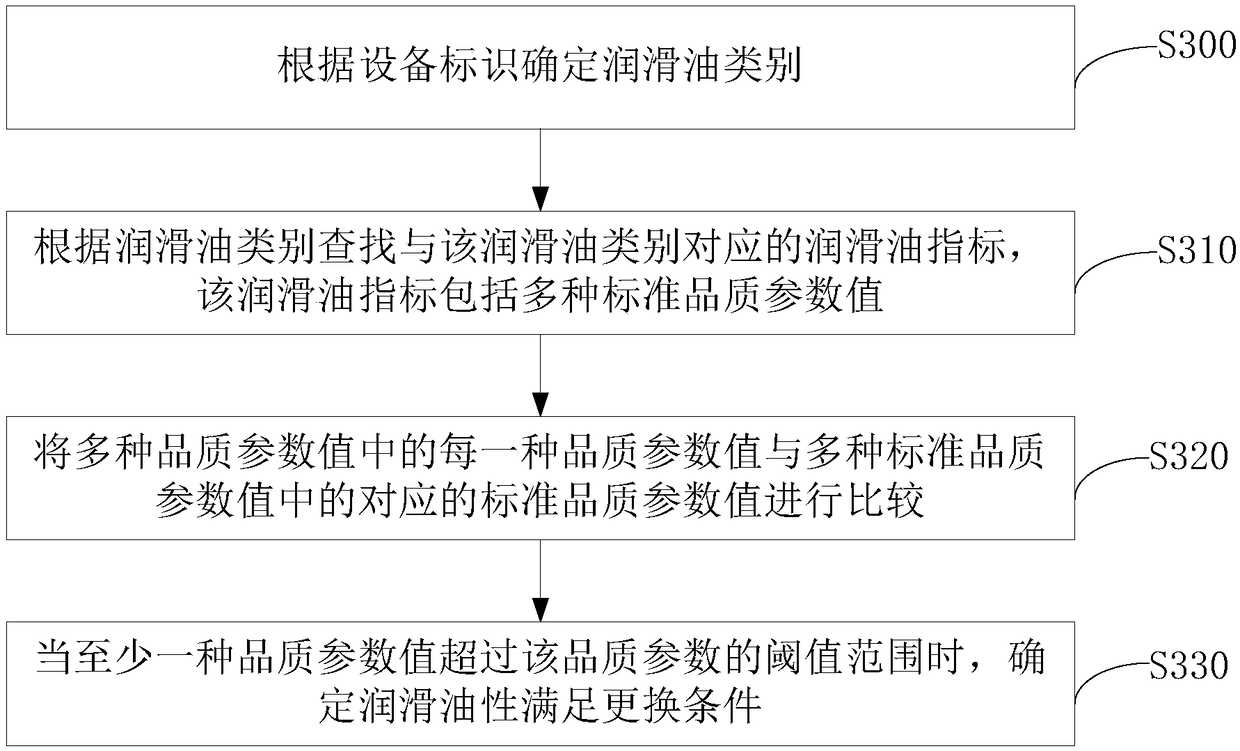

Equipment lubricating oil monitoring method and device and system

InactiveCN108150816AAvoid Equipment FailureAvoid failureLubrication elementsSafety/regulatory devicesComputer terminalDevice failure

The invention provides an equipment lubricating oil monitoring method and device and system. The equipment lubricating oil monitoring method comprises the steps that lubricating oil information is obtained, and the lubricating oil information includes lubricating oil parameters and device identification; lubricating oil performance is determined based on the lubricating oil parameters and pre-stored lubricating oil indicators; and if the lubricating oil performance is determined to satisfy a lubricating oil replacement condition, a lubricating oil replacement instruction is sent to a user terminal corresponding to the device identification. According to the equipment lubricating oil monitoring method and device and system, the problems of the equipment failure caused by untimely replacement of lubricating oil and the waste of resources caused by premature replacement of the lubricating oil are avoided.

Owner:金雪驰科技(马鞍山)有限公司

Viscosity detection using starter motor

InactiveCN104564396ACorrect idle speedElectrical controlFlow propertiesExternal combustion engineOil viscosity

Various methods for inferring oil viscosity and / or oil viscosity index in an internal combustion engine are provided. In one example, a new control method comprises cranking the engine during a start mode with an electric motor connected to a substantially constant source of electrical power, inferring engine oil viscosity based at least on engine oil temperature and speed of the engine while being cranked by the electric motor during the start mode, and correcting an operating parameter of the engine based on the inferred engine oil viscosity.

Owner:FORD GLOBAL TECH LLC

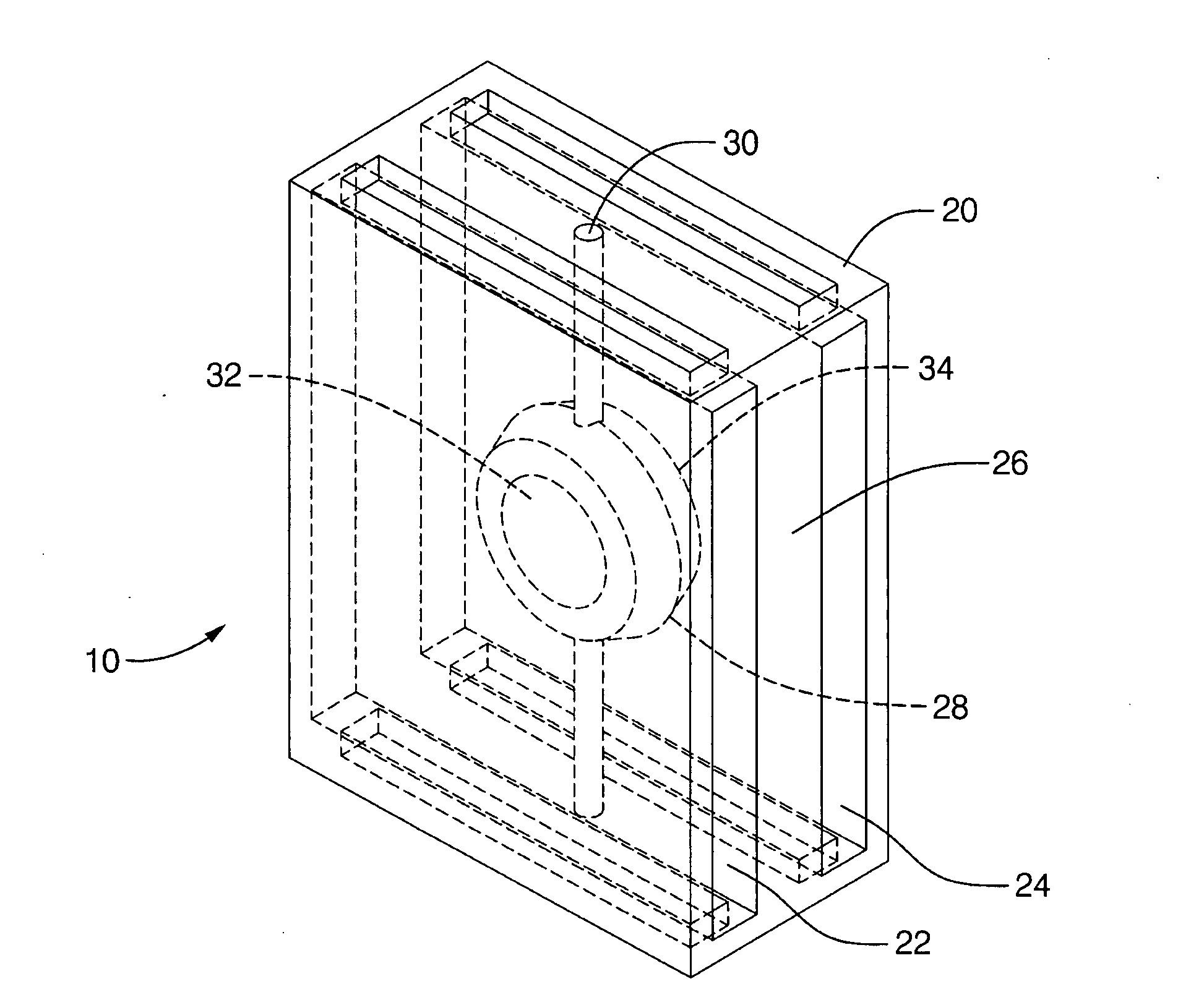

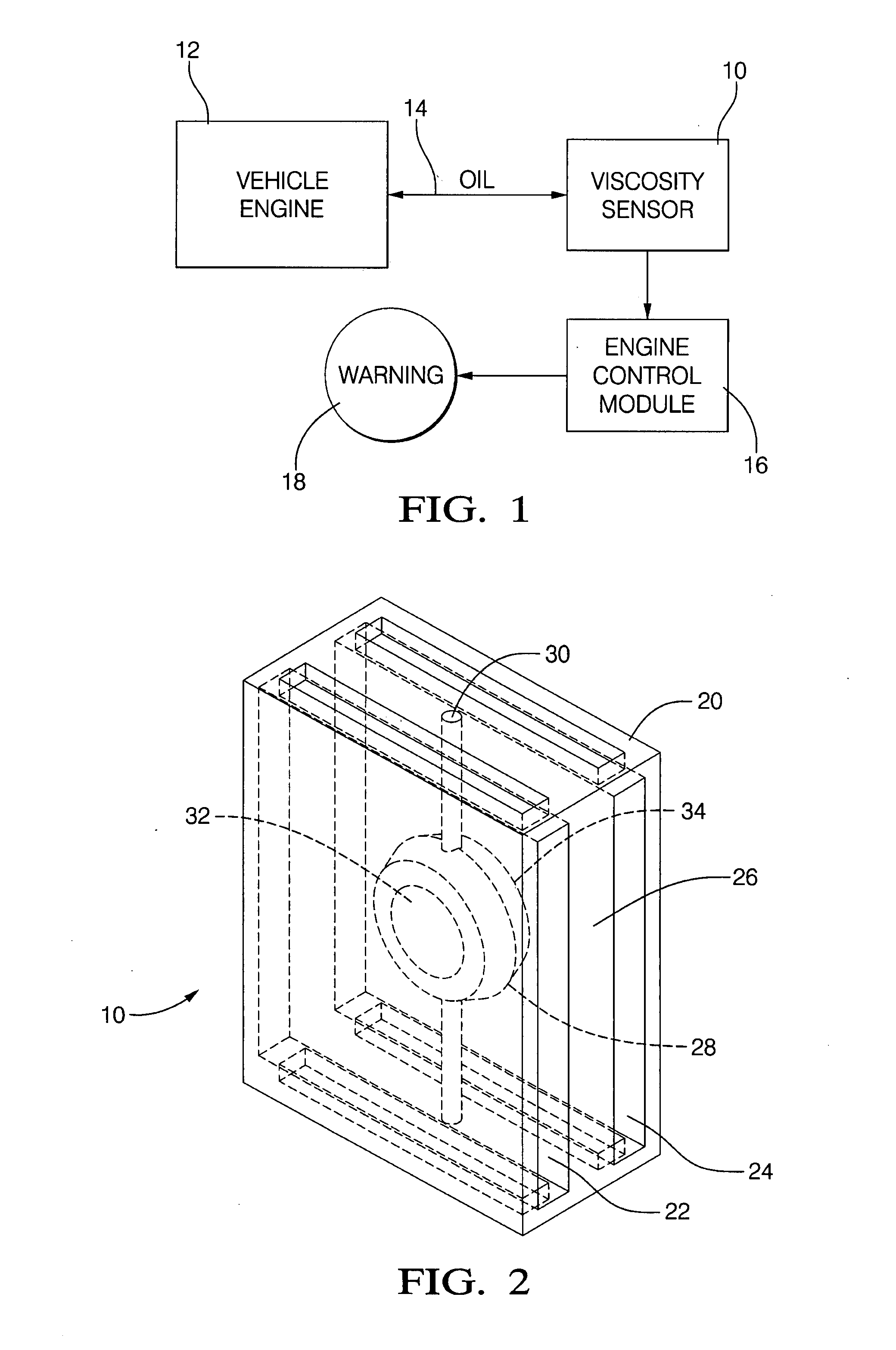

Viscosity sensor

A viscosity sensor for, e.g., outputting a signal representing the viscosity of engine oil has one or more piezoelectric diaphragms disposed in a fluid chamber of a housing. An elongated amplification channel is formed in the housing and extends away from the chamber. The diaphragm can be excited to induce fluid movement that in turn induces the diaphragm to output a sensor signal representative of the viscosity of the fluid.

Owner:DELPHI TECH INC

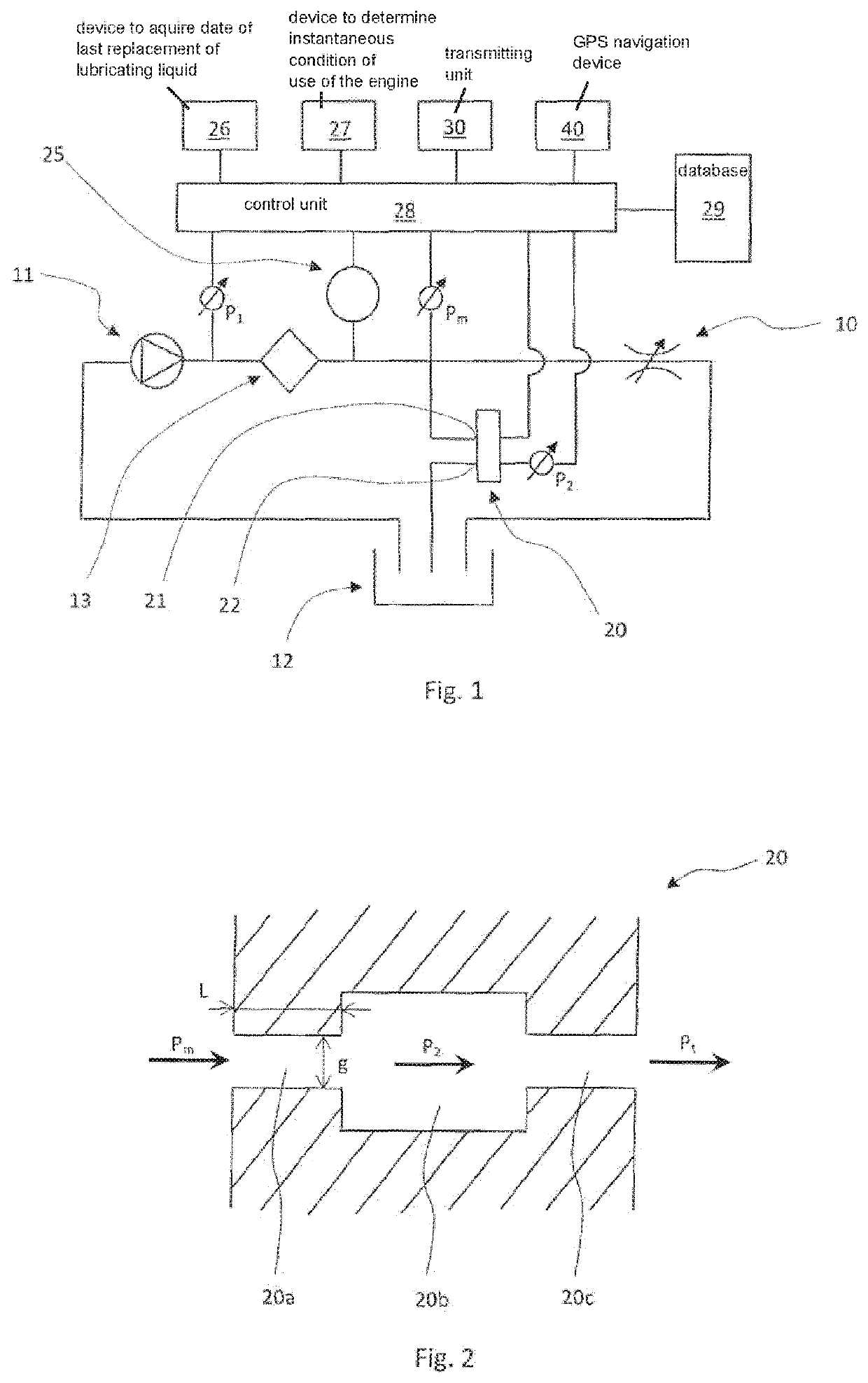

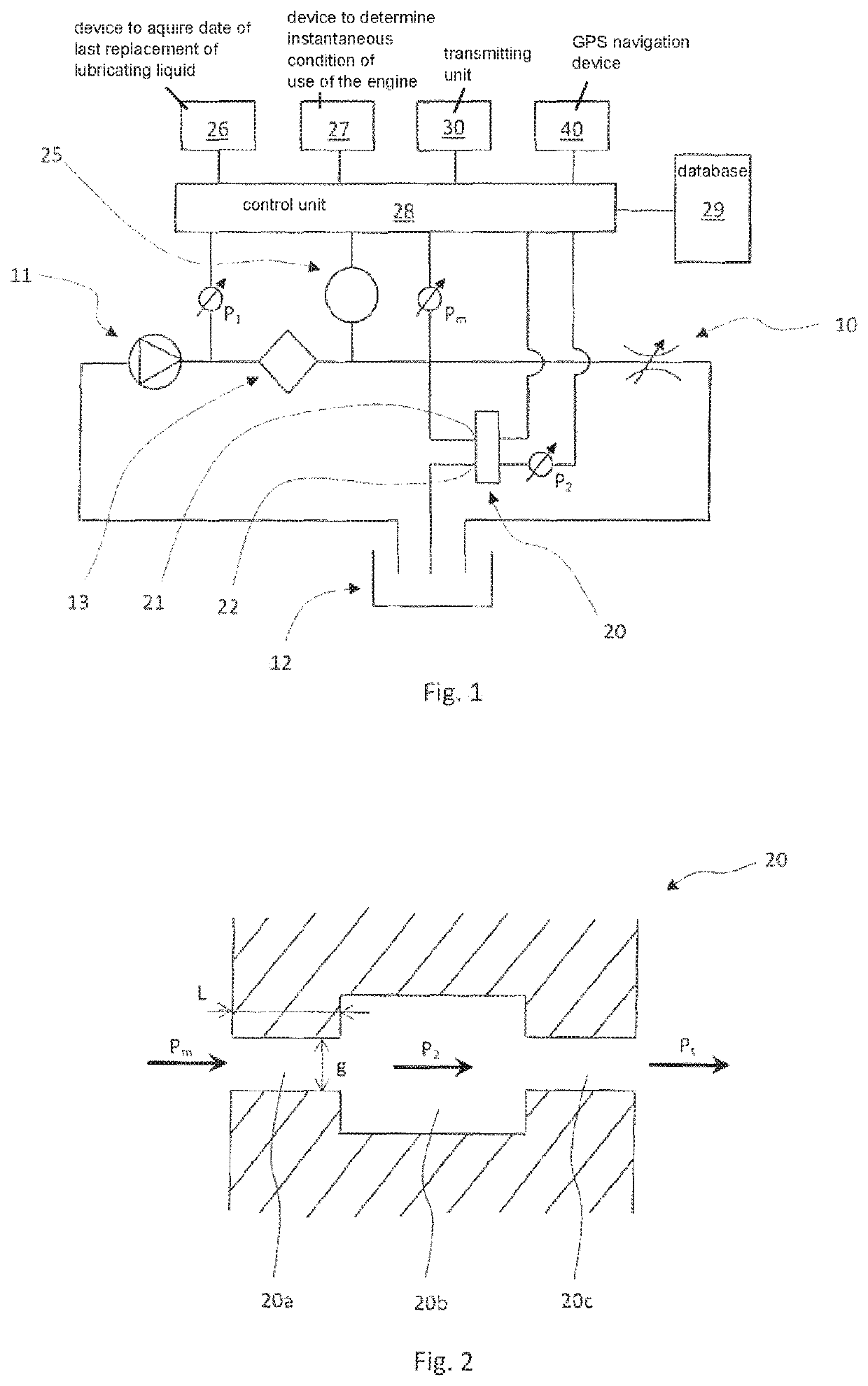

Diagnostic system for a lubrication circuit

A diagnostic system for a lubrication circuit of an internal combustion engine of a vehicle. The system includes a viscometer for detecting the viscosity of a lubricating liquid of the lubrication circuit, a temperature sensor for detecting the temperature of the lubricating liquid, and a control unit to acquire the state of the lubricating liquid, given by the viscosity detected for a given lubricating liquid condition, which includes the lubricating liquid temperature and the date of last replacement of the lubricating liquid, and for a given condition of use of the engine, and to assess the state of the lubricating liquid by comparing the detected viscosity of the lubricating liquid with the viscosity reference values stored in the database in the same or similar condition of lubricating liquid temperature, date of last replacement of the lubricating liquid and use of the engine.

Owner:VHIT SPA

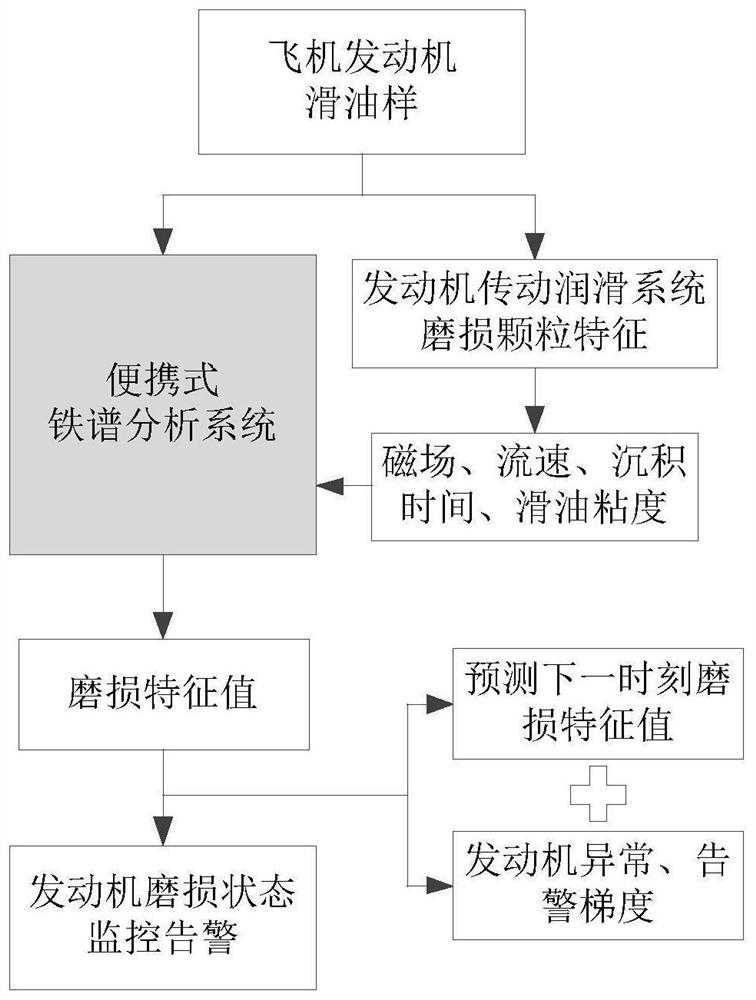

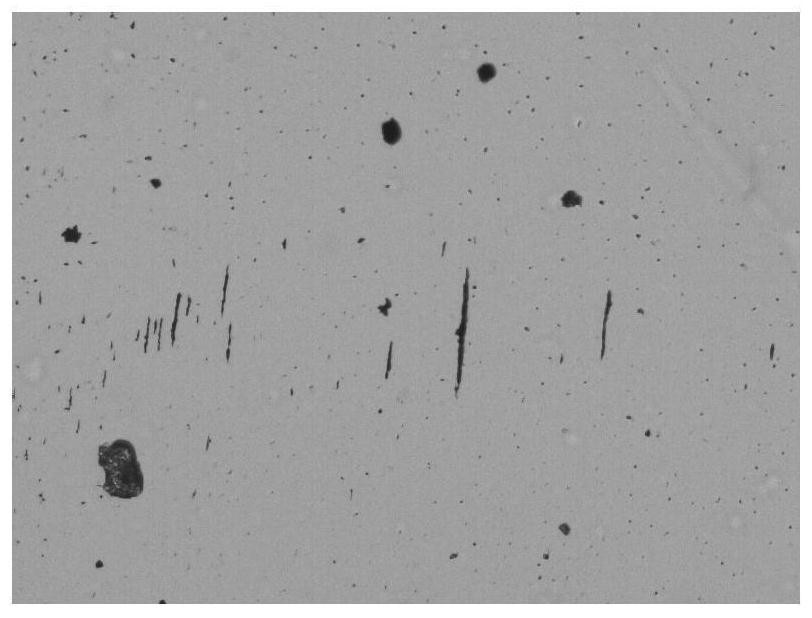

Novel wear monitoring method for transmission lubrication system of military aero-engine

ActiveCN113418126AImprove detection efficiencyImprove detection accuracyAircraft componentsColor/spectral properties measurementsWear particleLubrication

The invention relates to a novel wear monitoring method for a transmission lubrication system of a military aero-engine, which comprises the following steps of determining sensitive parameters of loss efficiency and configuration parameters of detection equipment by monitoring and researching the whole wear failure process of a transmission lubrication system of a typical active-service aero-engine, and establishing wear state initial judgment based on an abrasive particle ferrography quantized value. According to a comprehensive fault diagnosis method combining abrasive particle image special identification and spectral analysis, rapid fault detection and fault diagnosis of the transmission lubrication system of the military aero-engine can be realized, and the use safety of the military aero-engine is guaranteed.

Owner:中国人民解放军93208部队

Fluid Monitoring and Management Devices

A fluid monitoring and management device that includes a housing with a fluid passageway. The fluid monitoring and management device further includes a fluid property sensor with a sensing element in the fluid passageway. A valve is in the fluid passageway of the fluid monitoring and management device. A removable bottle mount is aligned with the valve to be selectively in fluid communication with the fluid passageway.

Owner:LOGILUBE LLC

Apparatus, device and computer implemented method for determining remaining life of engine oil in engine

ActiveUS20210270156A1Material testing goodsLubrication indication devicesReference modelControl engineering

A computer implemented method system and apparatus for determining remaining life of engine oil in an engine includes generating reference engine profile data by determining reference engine parameters of a reference engine; determining reference engine oil lubrication data based on mechanical testing of an oil sample from the reference engine; generating a reference model by associating the reference engine profile data with the reference engine oil lubrication data; receiving the reference model at an engine apparatus; measuring engine parameters relating to operation conditions of an engine of the engine apparatus; and determining remaining life of engine oil in the engine of the engine apparatus using the reference model and the engine parameters.

Owner:WARTSILA FINLAND OY

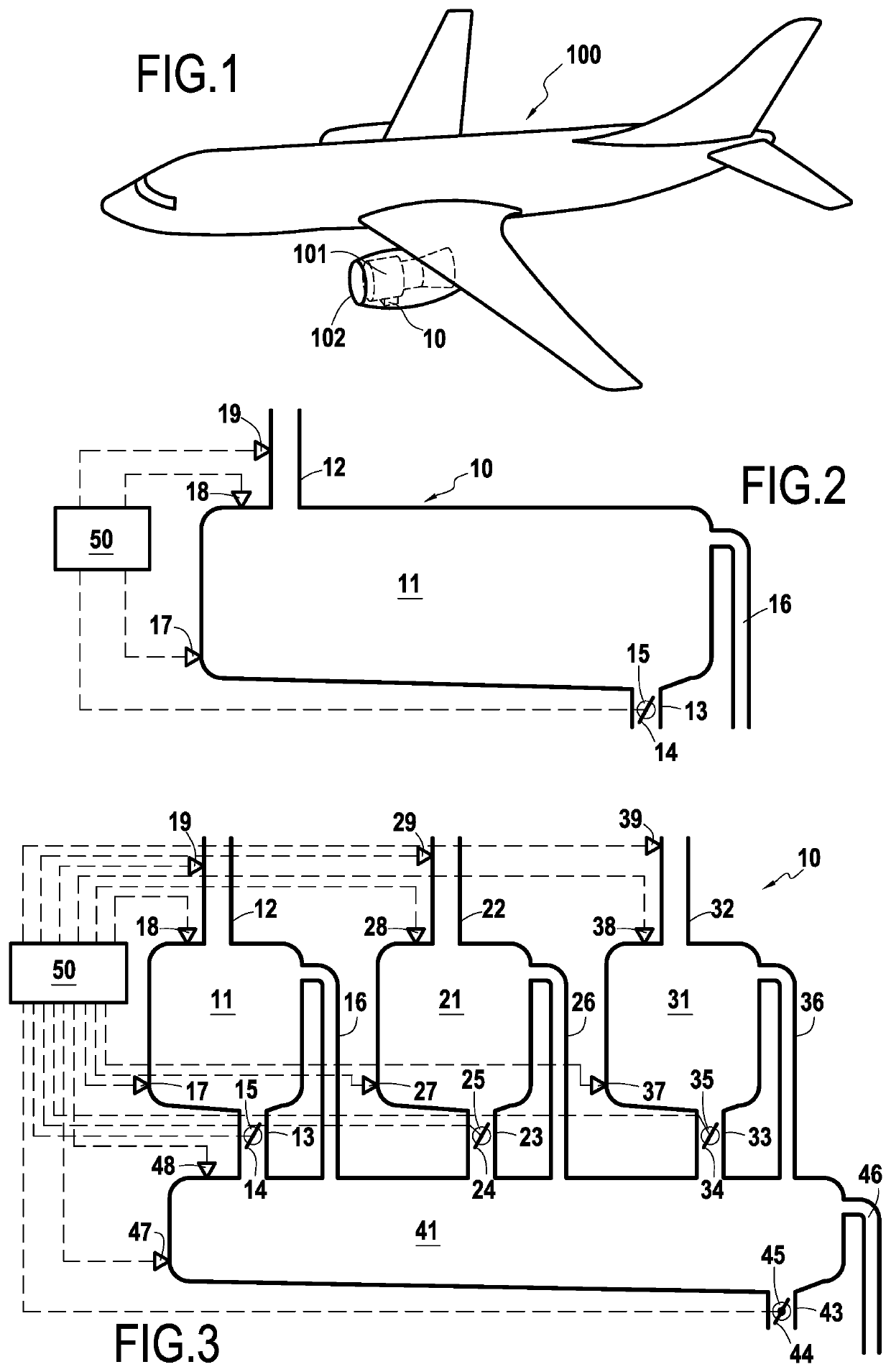

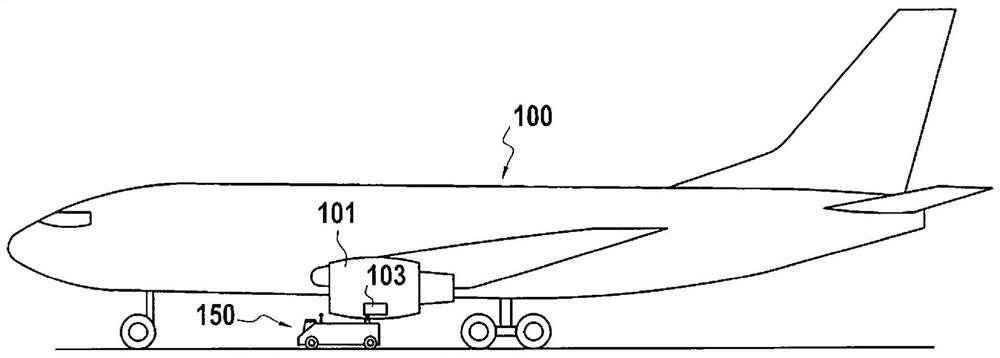

On-board tank for the drainage of an aircraft engine

The invention relates to the field of aeronautical propulsion, and more particularly an on-board drainage reservoir of an aircraft engine, the on-board reservoir including a first compartment with a first intake passage for receiving fluid drained from the engine, a first closeable emptying passage, and a first quality sensor assembly for detecting at least one quality parameter of the fluid drained from the engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

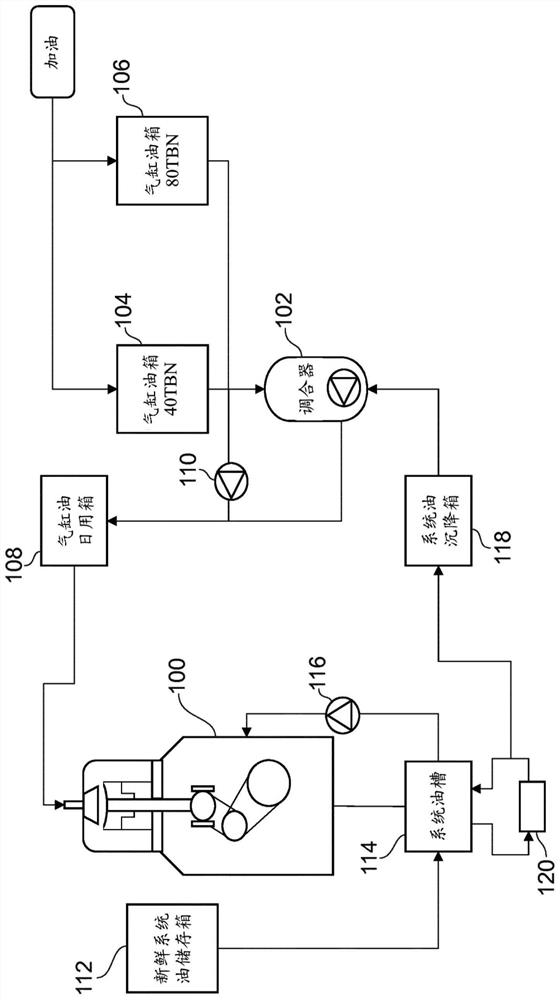

Method and control unit for operating diesel internal combustion engine or dual-fuel internal combustion engine operated in diesel mode

PendingCN111852610AWaterborne vesselsInternal combustion piston enginesTotal Base NumberInternal combustion engine

A method for operating an internal combustion engine wherein the internal combustion engine to be operated is supplied with lubricating oil via an oil circuit. A measurement value of a total base number and / or a measurement value of the viscosity of the lubricating oil currently used in the oil circuit for the lubrication is detected. Dependent on the established measurement value of the total base number and / or dependent on the established measurement value of the viscosity an exchange oil quantity for the oil circuit is determined. Currently used lubricating oil to an extent corresponding tothe exchange oil quantity is removed from the oil circuit. New lubricating oil to an extent corresponding to the exchange oil quantity is supplied to the oil circuit.

Owner:MAN ENERGY SOLUTIONS SA

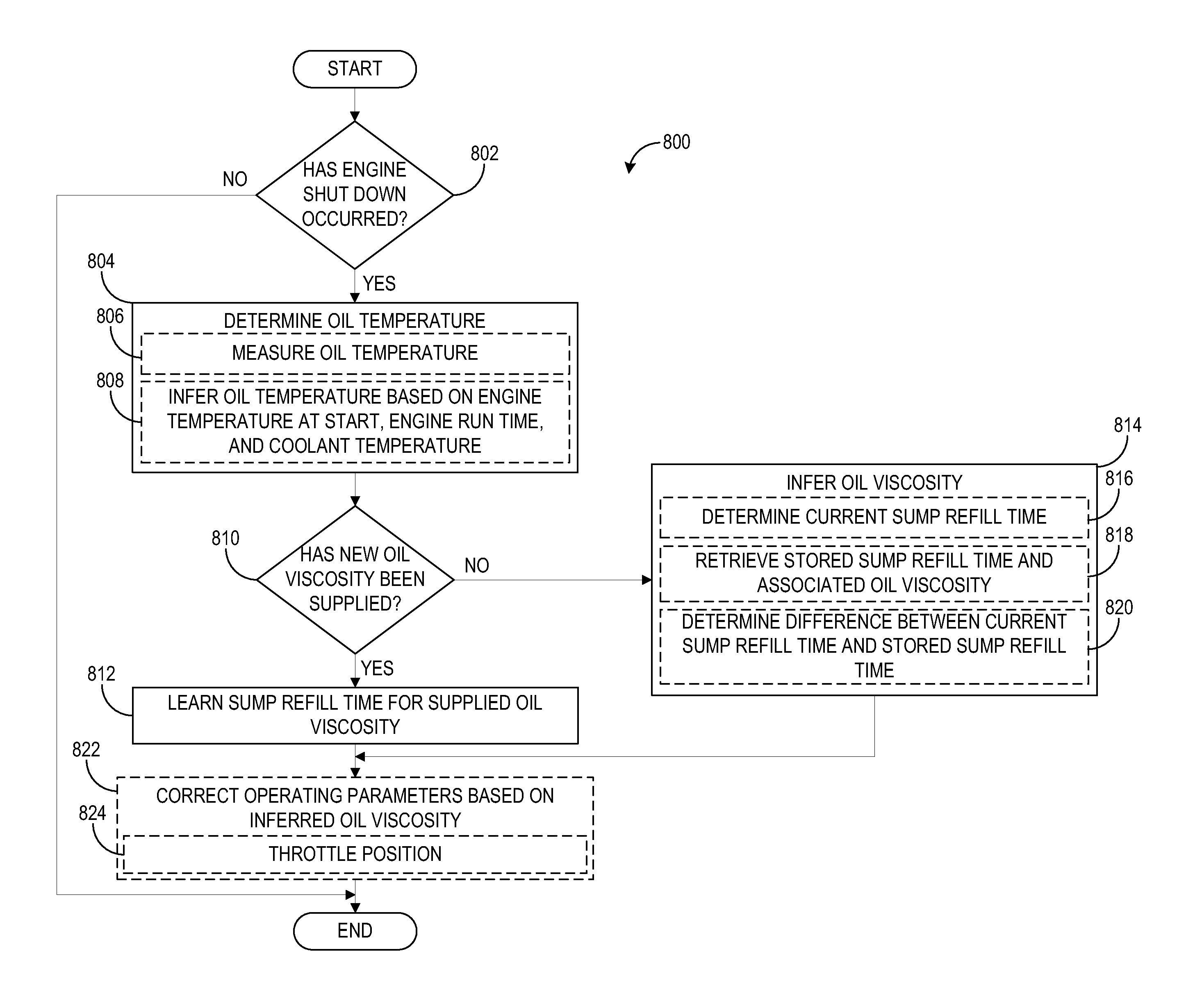

Viscosity detection using sump

InactiveUS9523320B2High viscosityGreater throttle openingElectrical controlMachines/enginesOil viscosityInternal combustion engine

Various methods for inferring oil viscosity and / or oil viscosity index in an internal combustion engine are provided. In one aspect, a new control method comprises: after engine shutdown, learning engine oil viscosity based on time to drain the oil back into an engine sump and oil temperature during the draining, and correcting an engine operating parameter based on the learned oil viscosity.

Owner:FORD GLOBAL TECH LLC

Method and system for reducing fuel consumption in a diesel engine

InactiveUS7444977B2Reduce fuel consumptionSimple and efficientLubrication of auxillariesLubricant conduit arrangementsDiesel engineViscosity

Owner:A P MOLLER AS

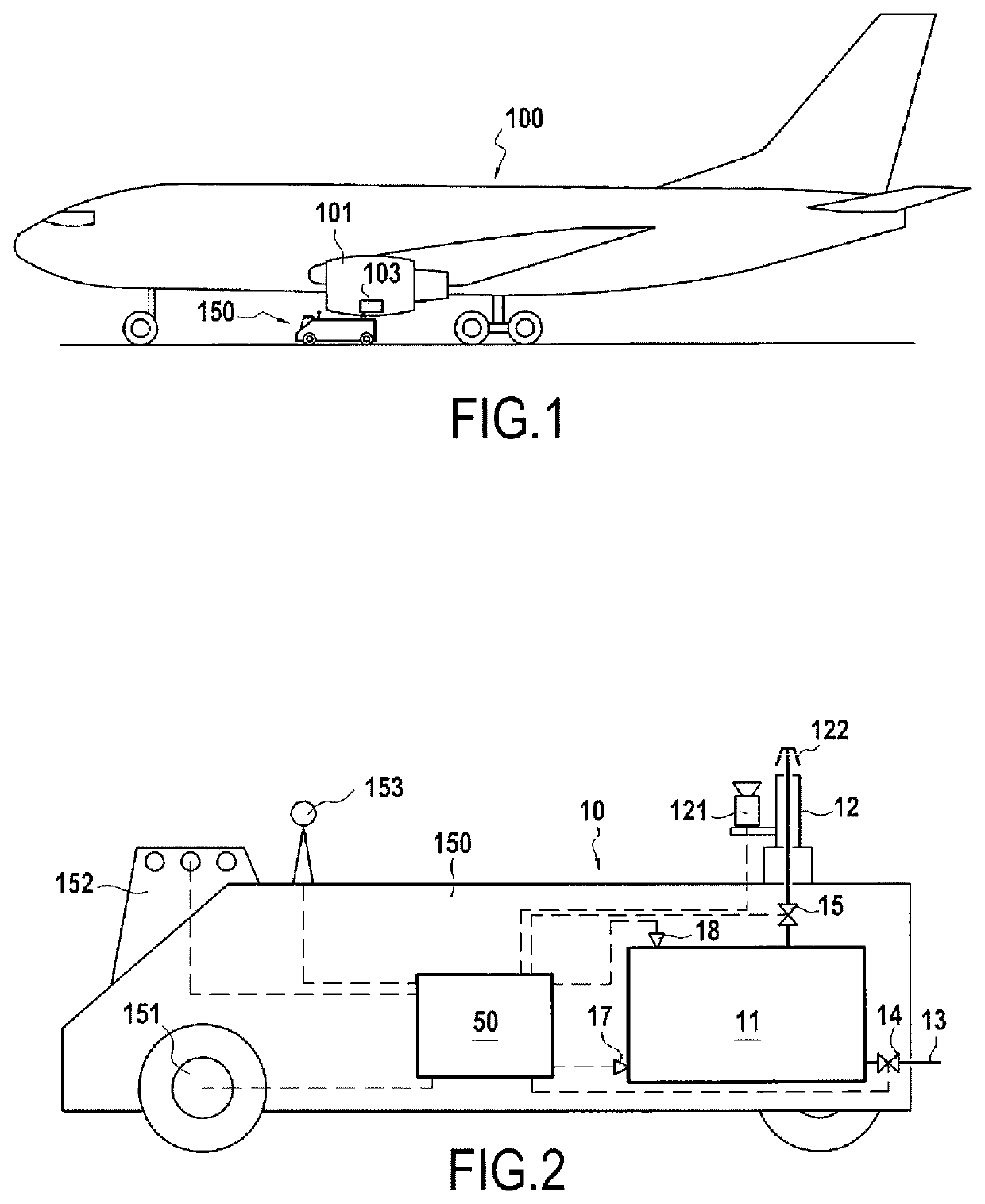

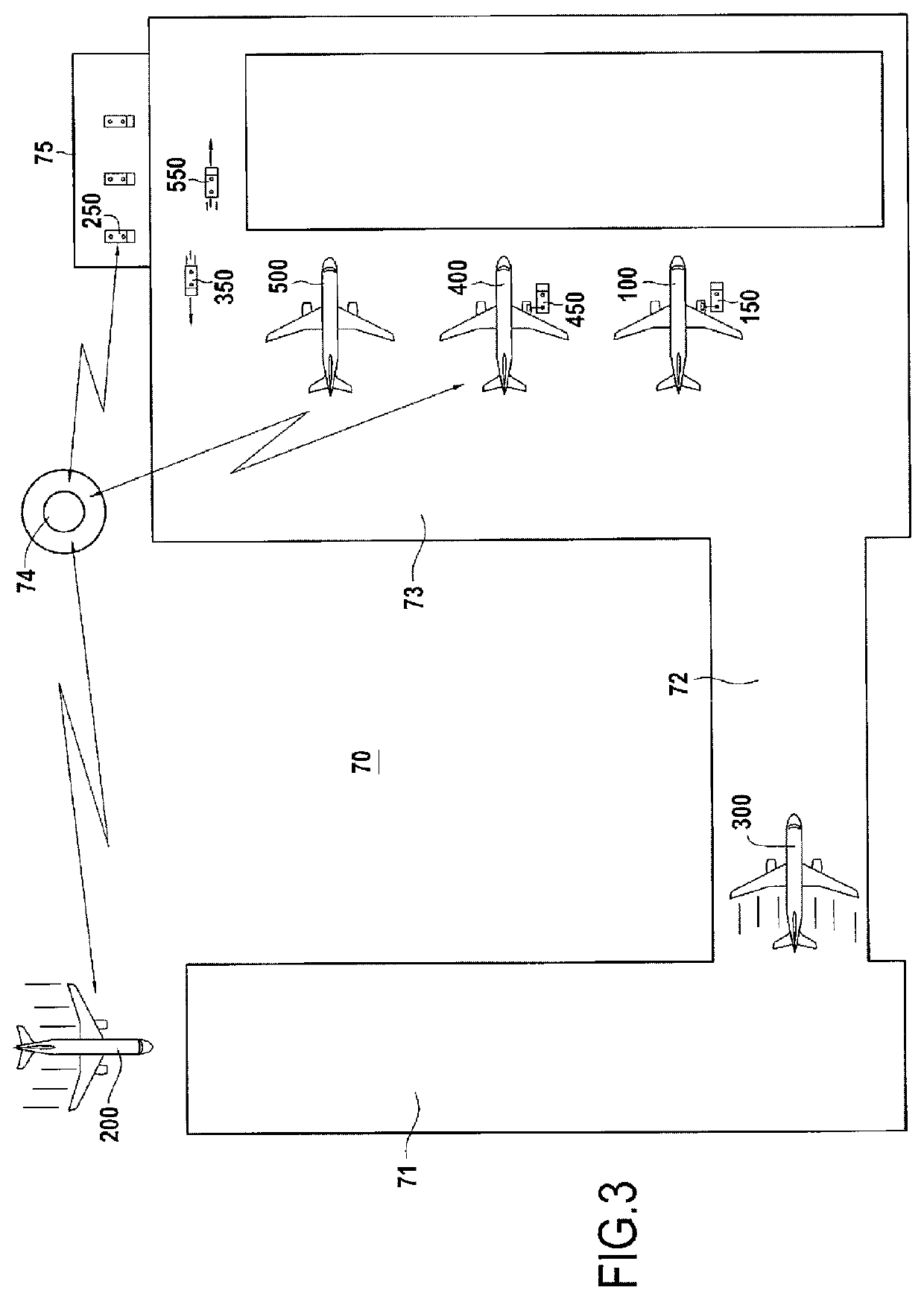

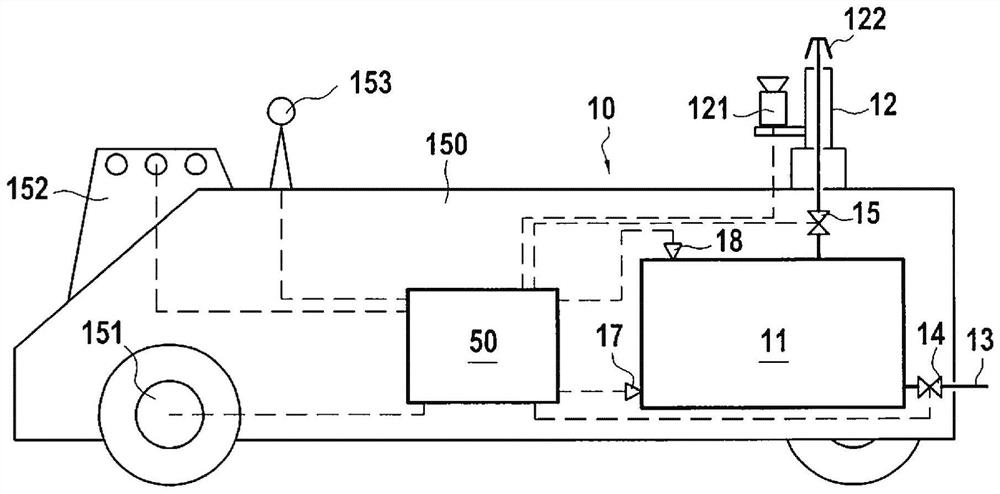

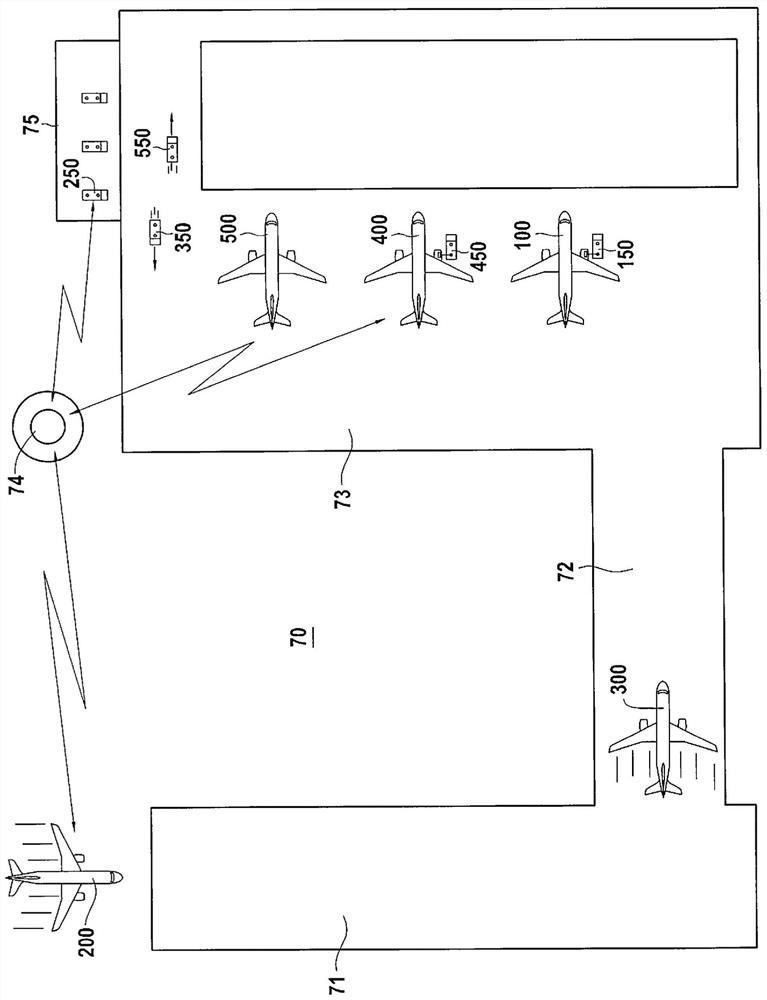

Device and method for emptying and monitoring fluid drained from an engine of an aircraft

PendingUS20210253274A1Rich relevant informationMonitor qualityTurbinesAutonomous decision making processAviationControl theory

The invention relates to the field of aeronautical propulsion, and more specifically to an emptying and monitoring device and method for emptying and monitoring a fluid drained from an aircraft engine. The emptying and monitoring device comprises at least one first intake passage for receiving, directly from the aircraft, fluid drained from the engine, and a first quality sensor assembly for detecting at least one quality parameter of the fluid drained from the engine, having been admitted through the first intake passage.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

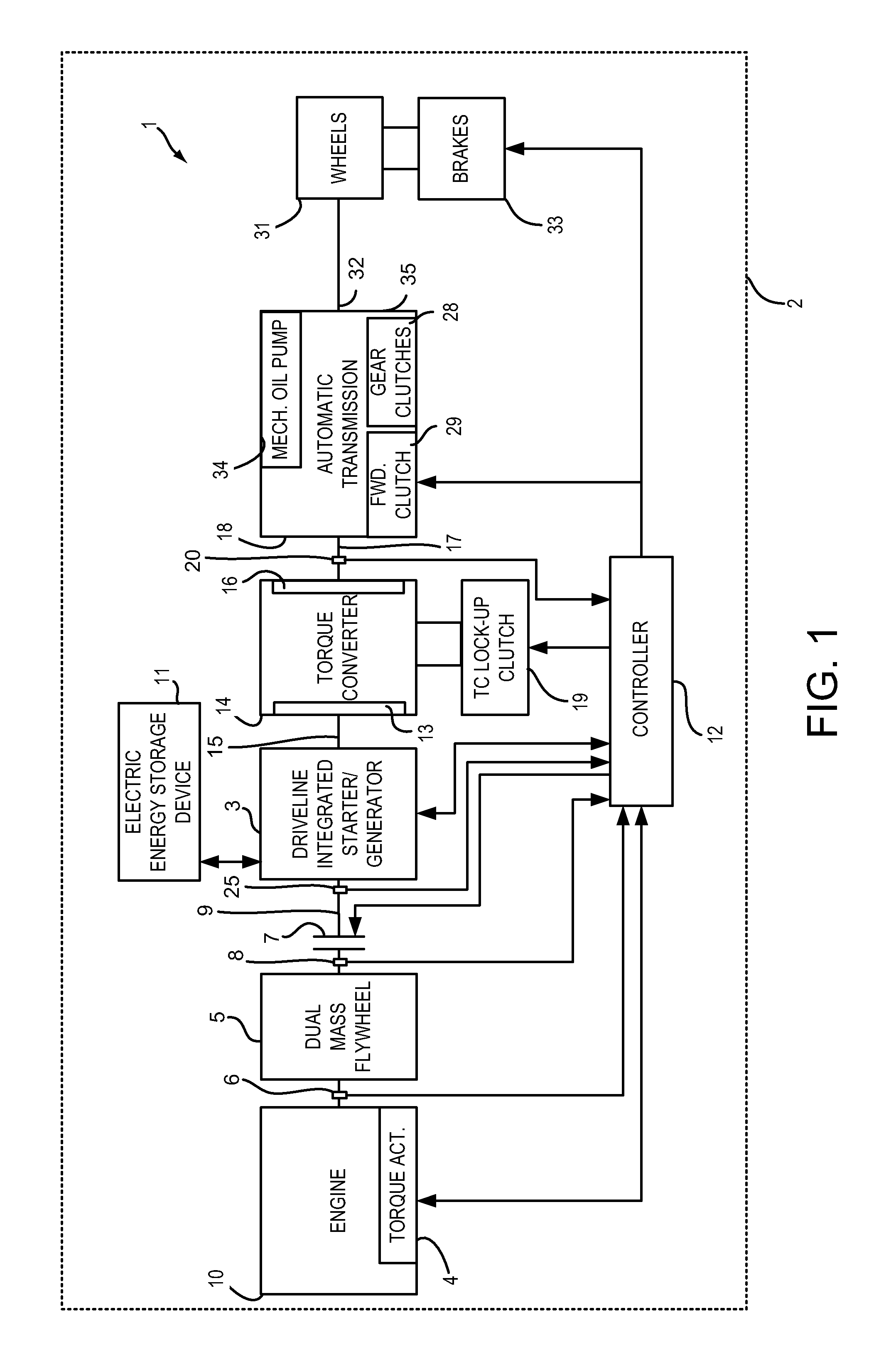

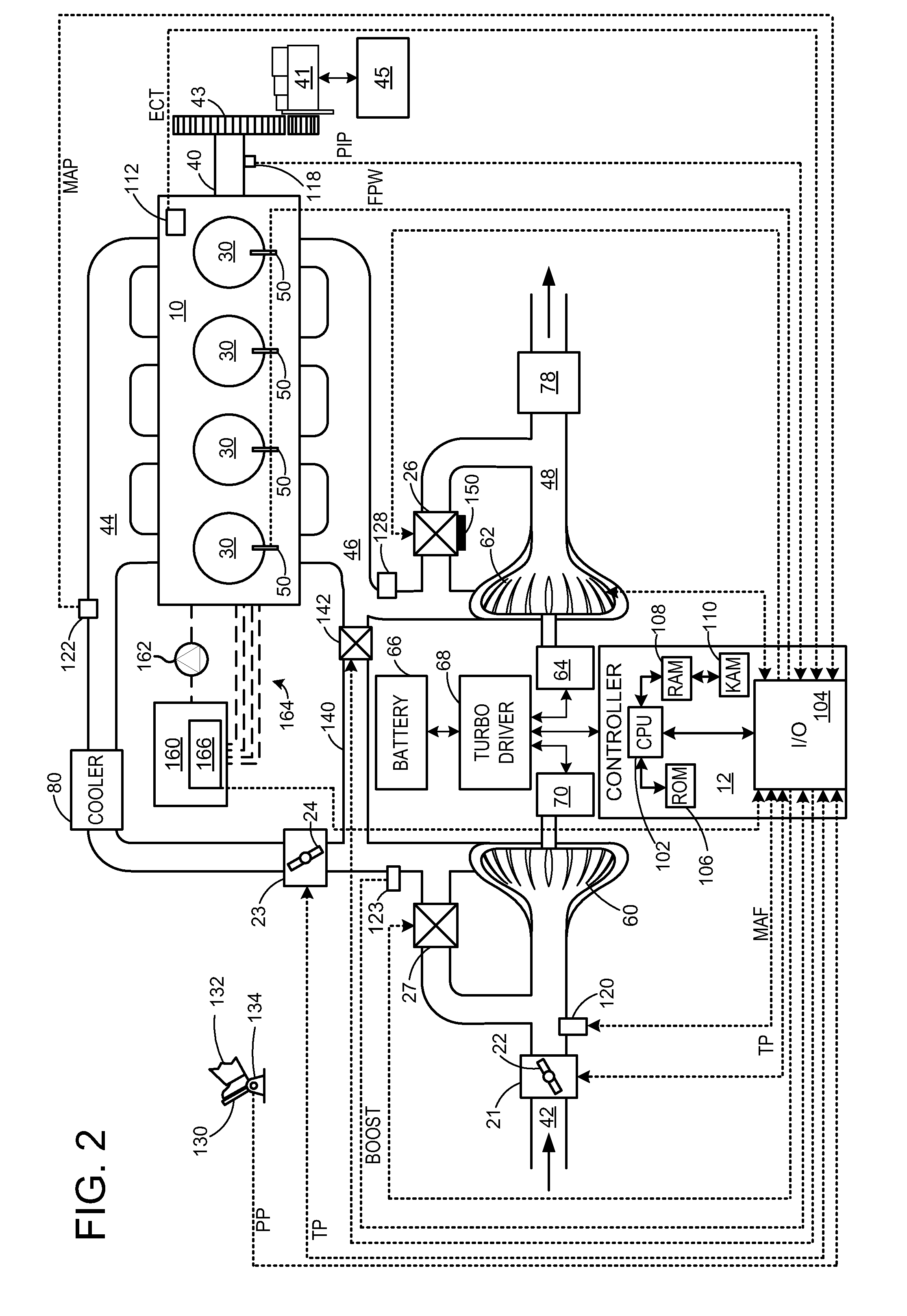

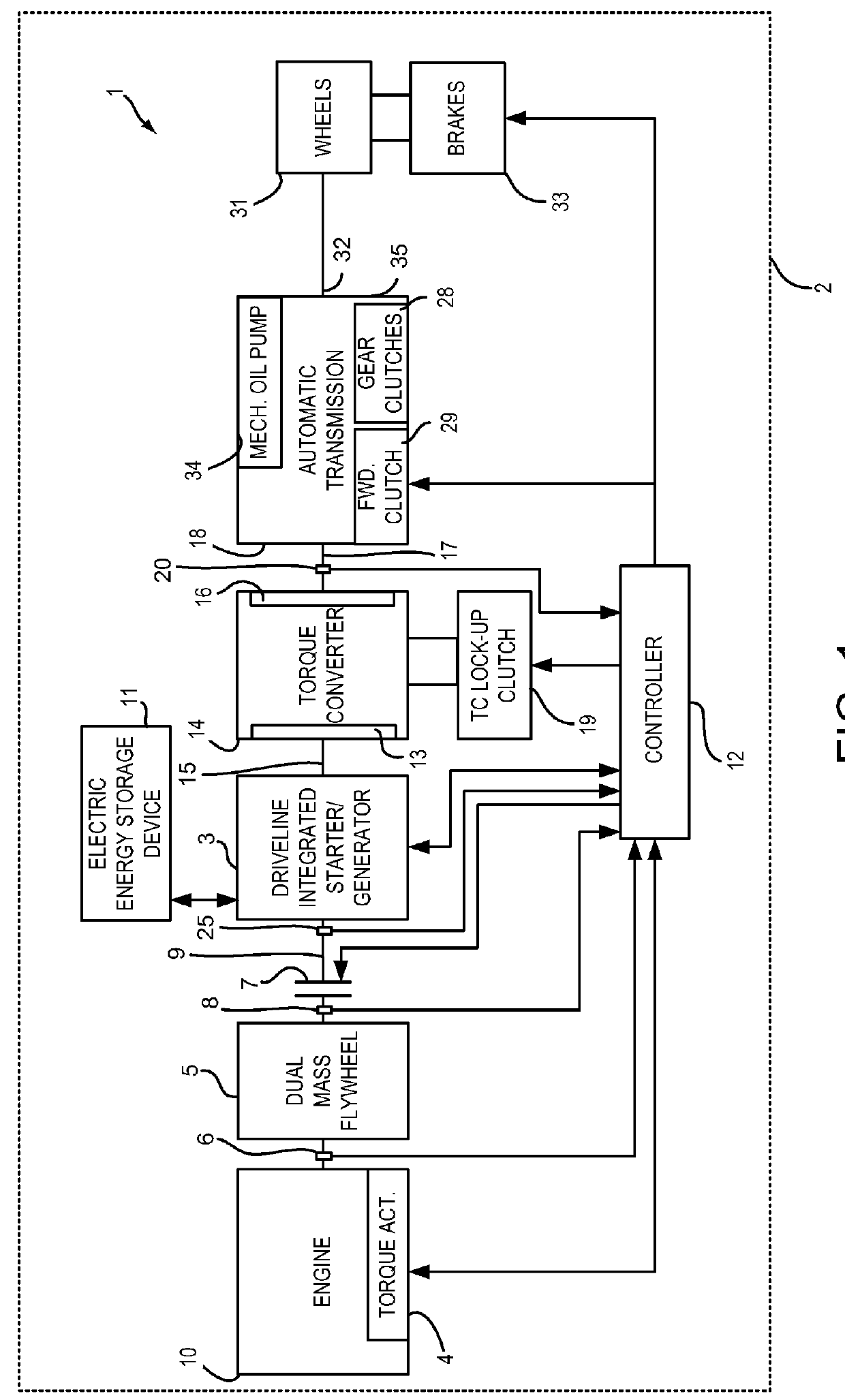

Viscosity detection using starter motor

ActiveUS9341129B2High viscosityGreater throttle openingElectrical controlElectric motor startersOil viscosityInternal combustion engine

Various methods for inferring oil viscosity and / or oil viscosity index in an internal combustion engine are provided. In one example, a new control method comprises cranking the engine during a start mode with an electric motor connected to a substantially constant source of electrical power, inferring engine oil viscosity based at least on engine oil temperature and speed of the engine while being cranked by the electric motor during the start mode, and correcting an operating parameter of the engine based on the inferred engine oil viscosity.

Owner:FORD GLOBAL TECH LLC

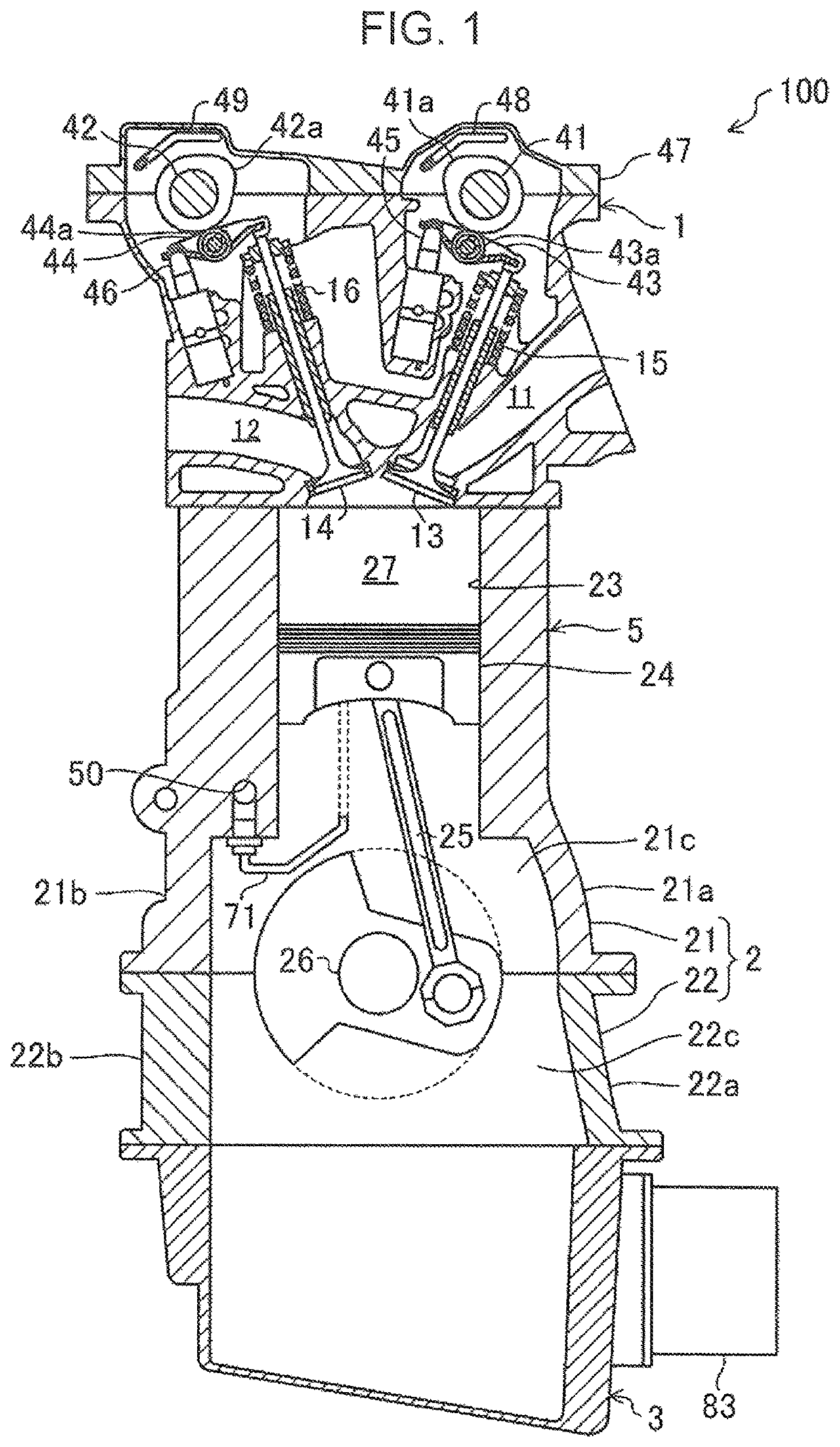

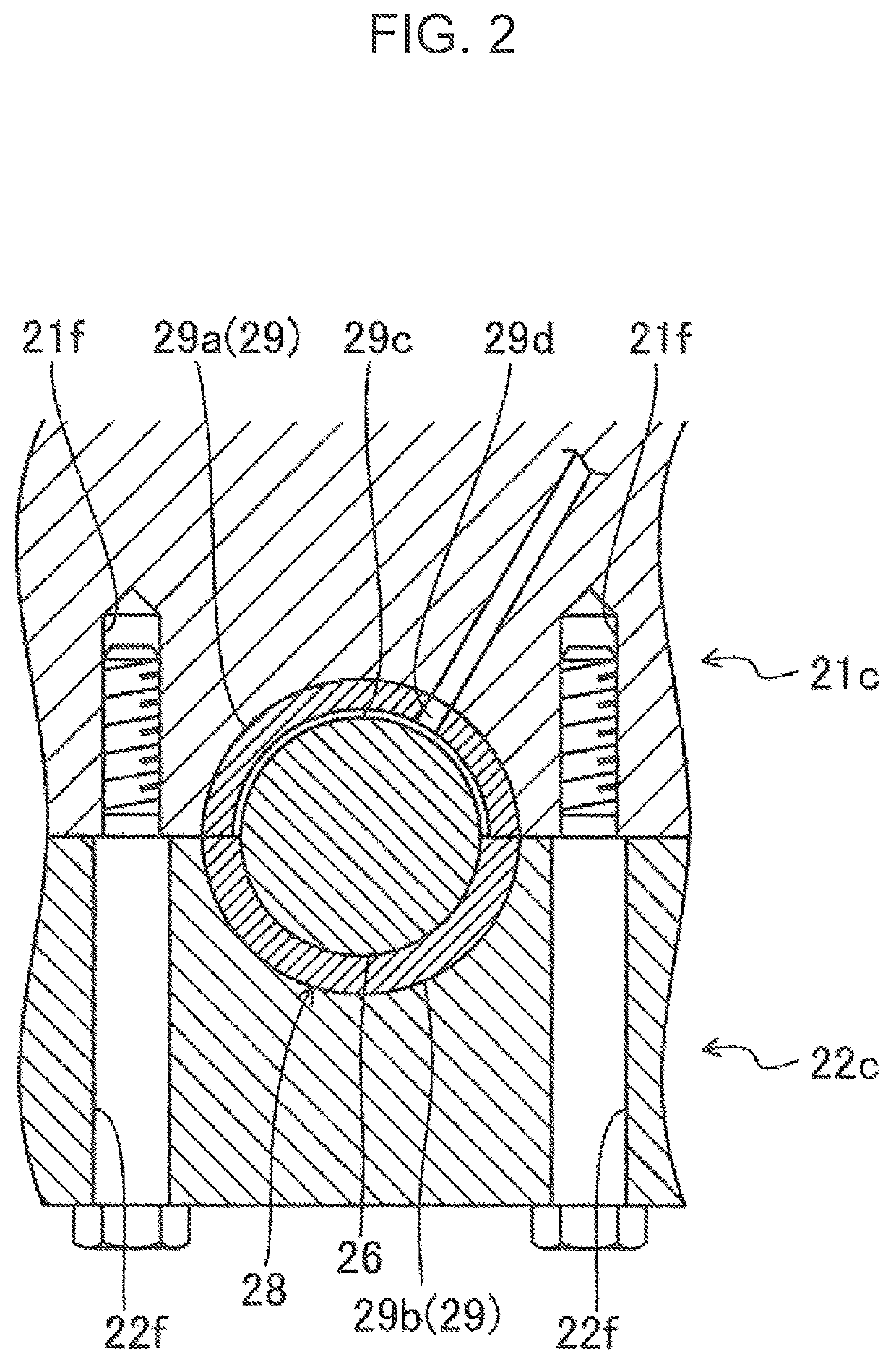

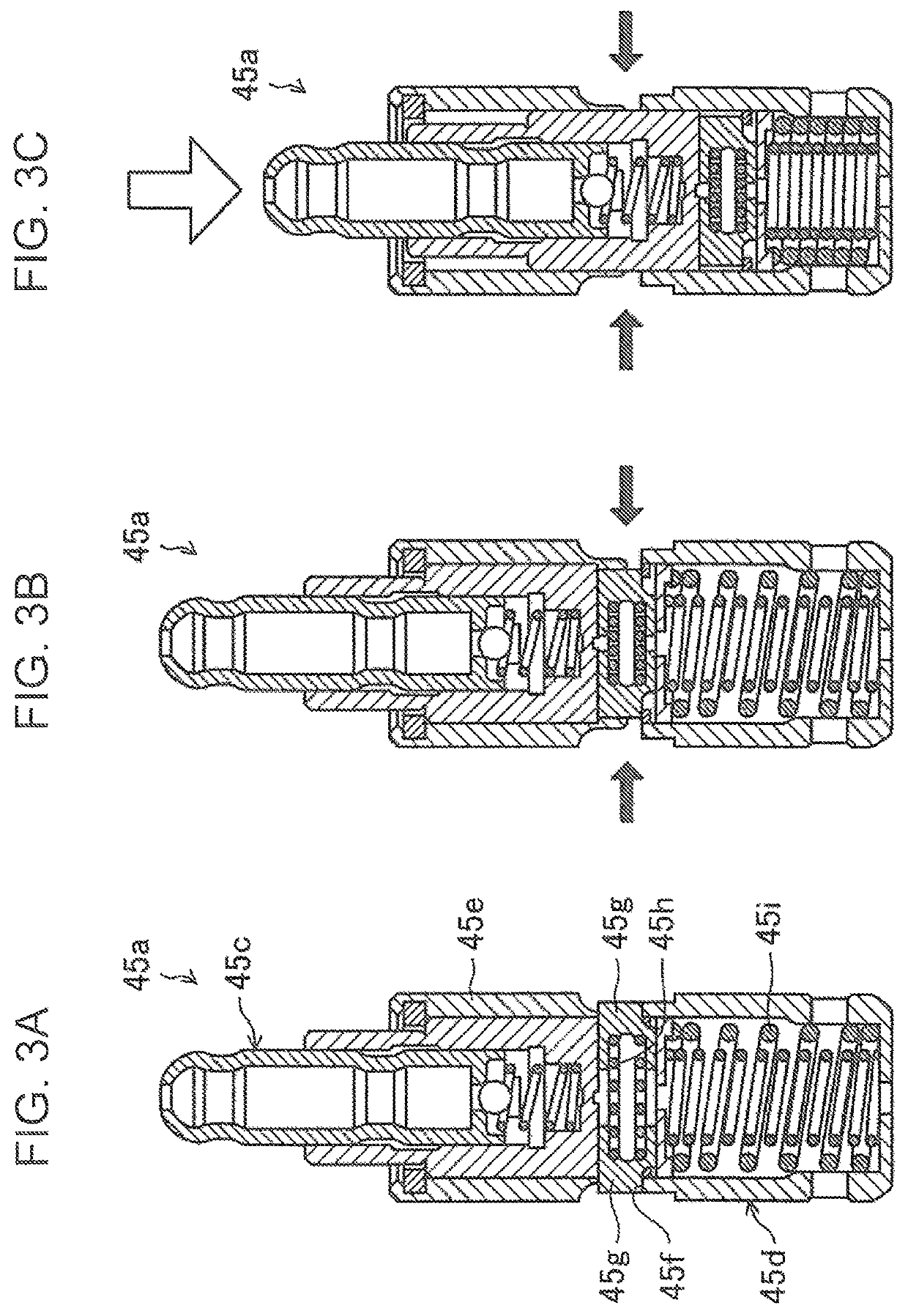

Oil supply device for engine

ActiveUS10738664B2Shorten the time periodStable controlCasingsMachines/enginesEngineeringControl valves

A controller sets a target hydraulic pressure from a required hydraulic pressure of a hydraulically operated device according to an operating condition of an engine. The controller causes an oil control valve to perform feedback control of the discharge amount of an oil pump in such a manner that an actual hydraulic pressure detected by a hydraulic pressure sensor coincides with the target hydraulic pressure. The controller executes feedback control after executing fixed duty control of setting a duty ratio of the oil control valve to a fixed duty ratio for a predetermined period of time from start of the engine.

Owner:MAZDA MOTOR CORP

Diagnostic system for a lubrication circuit

A diagnostic system for a lubrication circuit of an internal combustion engine of a vehicle. The system includes a viscometer for detecting the viscosity of a lubricating liquid of the lubrication circuit, a temperature sensor for detecting the temperature of the lubricating liquid, and a control unit to acquire the state of the lubricating liquid, given by the viscosity detected for a given lubricating liquid condition, which includes the lubricating liquid temperature and the date of last replacement of the lubricating liquid, and for a given condition of use of the engine, and to assess the state of the lubricating liquid by comparing the detected viscosity of the lubricating liquid with the viscosity reference values stored in the database in the same or similar condition of lubricating liquid temperature, date of last replacement of the lubricating liquid and use of the engine.

Owner:VHIT SPA

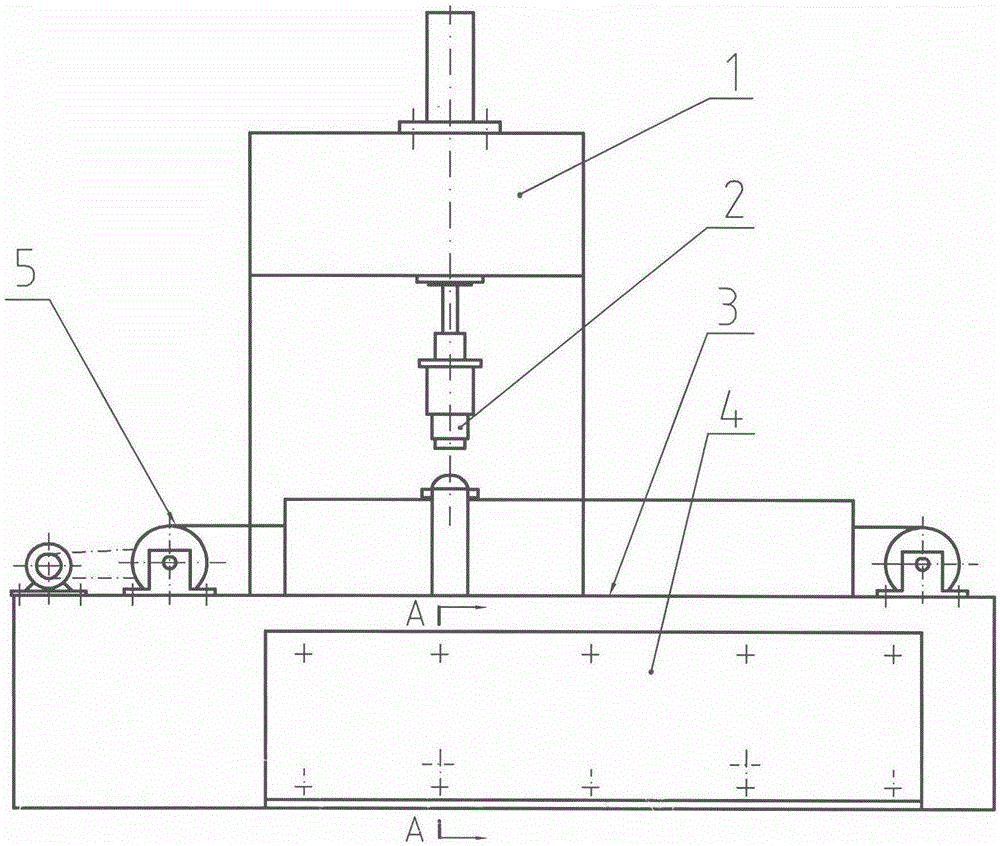

Multi-stage flywheel body oiling machine

InactiveCN105351721AOil injection achievedEasy to useLubrication elementsVehicle componentsBodies oilTemperature control

The invention discloses a multi-stage flywheel body oiling machine. The multi-stage flywheel body oiling machine comprises a transmission box, an oiling rod component, a conveying belt mechanism, a machine frame and an oil tank component. The multi-stage flywheel body oiling machine is characterized in that an electric heating and temperature control device is installed on the oil tank component, and a heat insulation layer is additionally arranged, so that the viscosity of an injected lubricant is reduced, the problem that the fluidity is poor due to the fact that the aperture of an oiling rod and the aperture of an injection head of the oiling rod are small is solved, and accordingly the adaptability and the oiling quality of the multi-stage flywheel body oiling machine are improved.

Owner:YANCHENG INST OF TECH

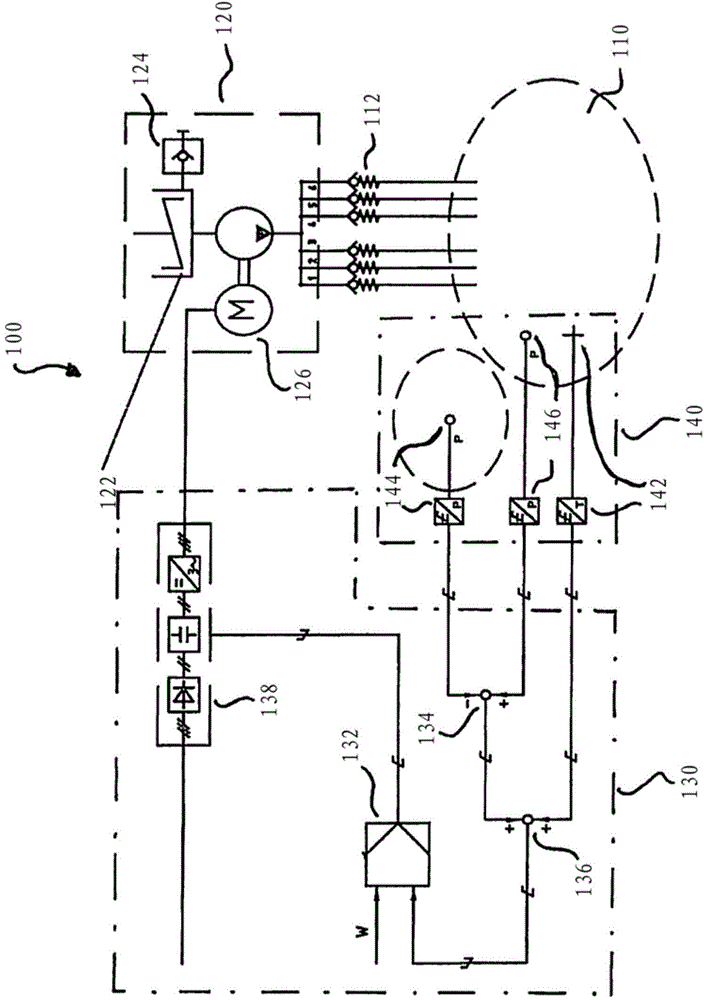

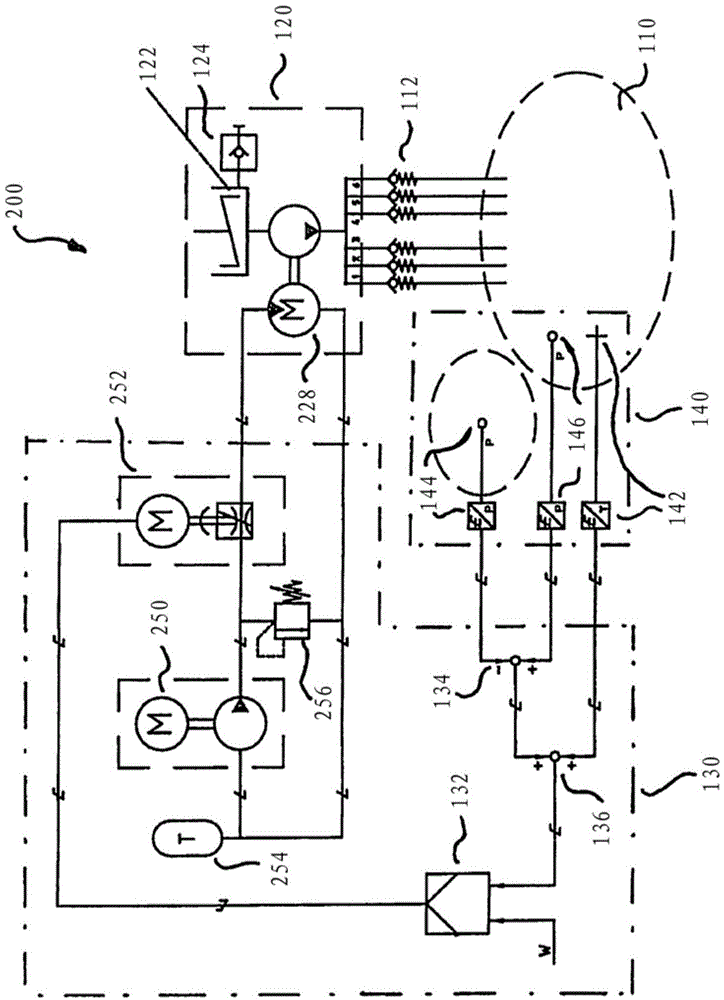

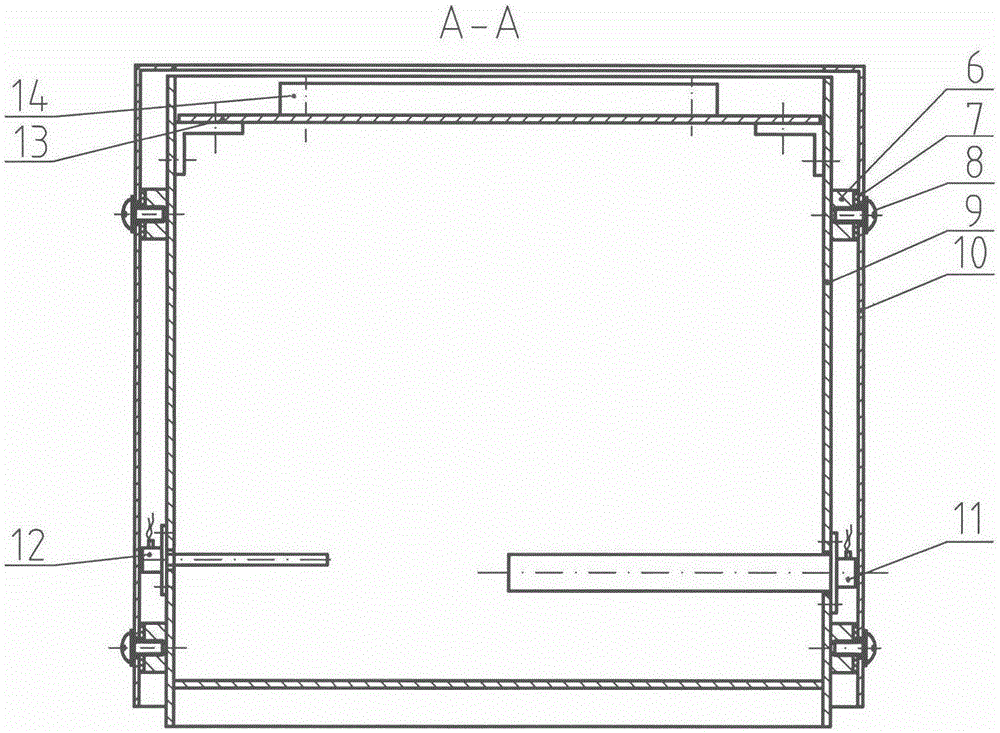

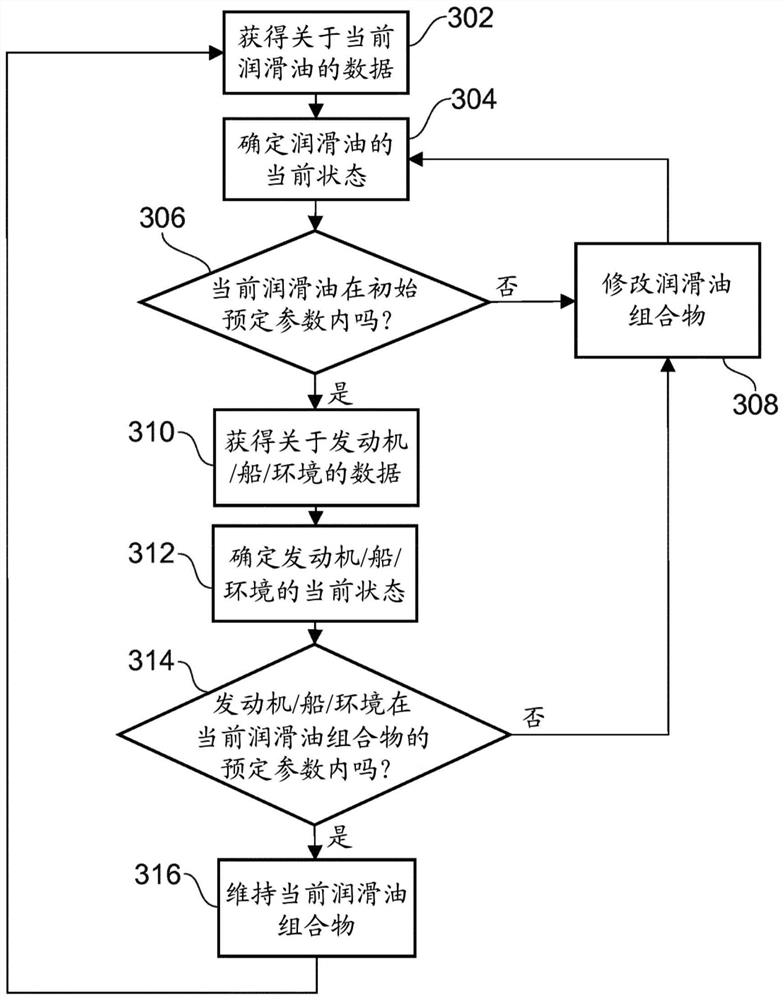

Apparatus and method for blending oil on a marine vessel

ActiveCN111542717BImprove performanceIncrease flexibilityEngine temperatureWaterborne vesselsProcess engineeringElectric generator

An oil blending system for a marine diesel two-stroke engine and / or generator comprising a blender having at least one inlet for receiving lubricating oil and at least one other ingredient and for mixing The lubricating oil composition is output to at least one outlet of the engine or generator. The blender controller is configured to receive parametric data regarding the current state of lubricating oil used in the engine or generator and to receive parametric data regarding the current engine and / or generator state. The blender controller is also configured to automatically determine whether the currently used lubricating oil is within predetermined parameters based on the current engine and / or generator state. If the current lubricating oil is outside a predetermined parameter threshold, the blender controller is configured to determine a new lubricating oil composition for the engine or generator.

Owner:马斯克公司

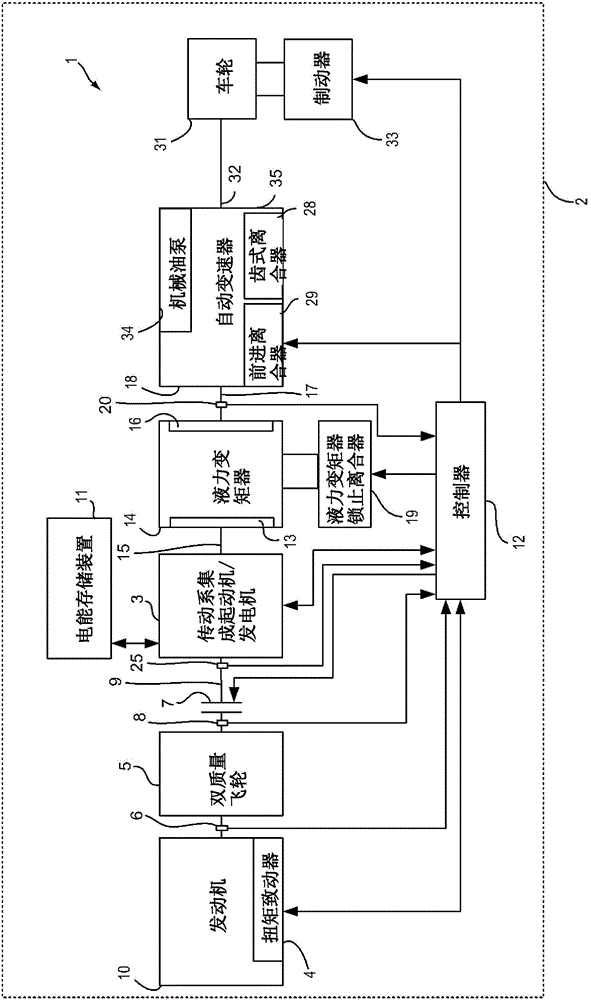

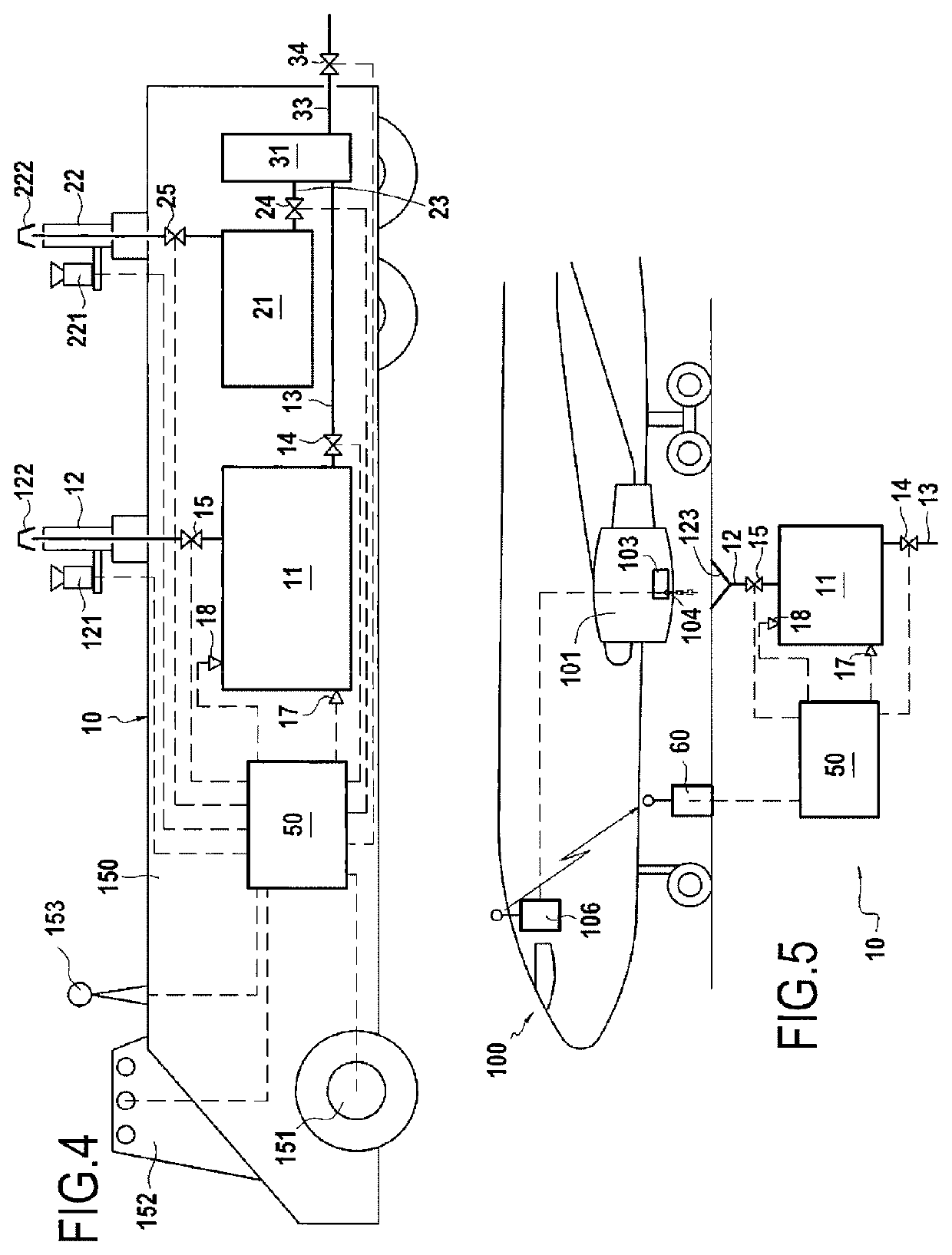

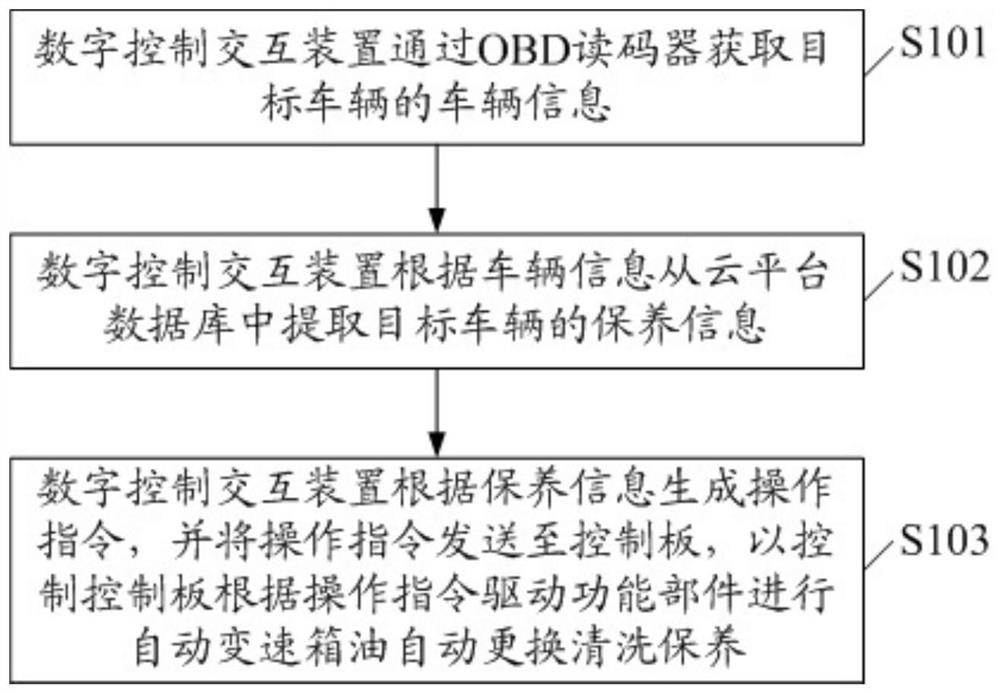

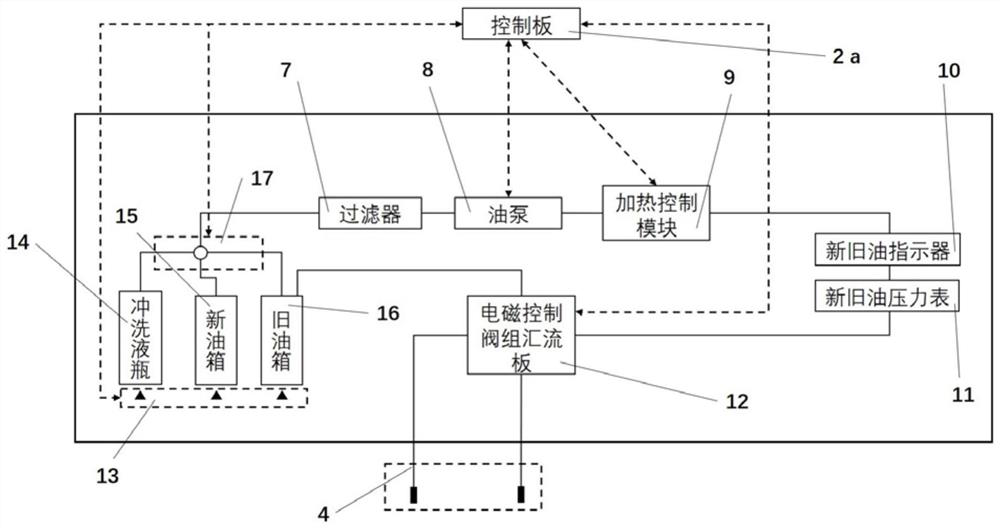

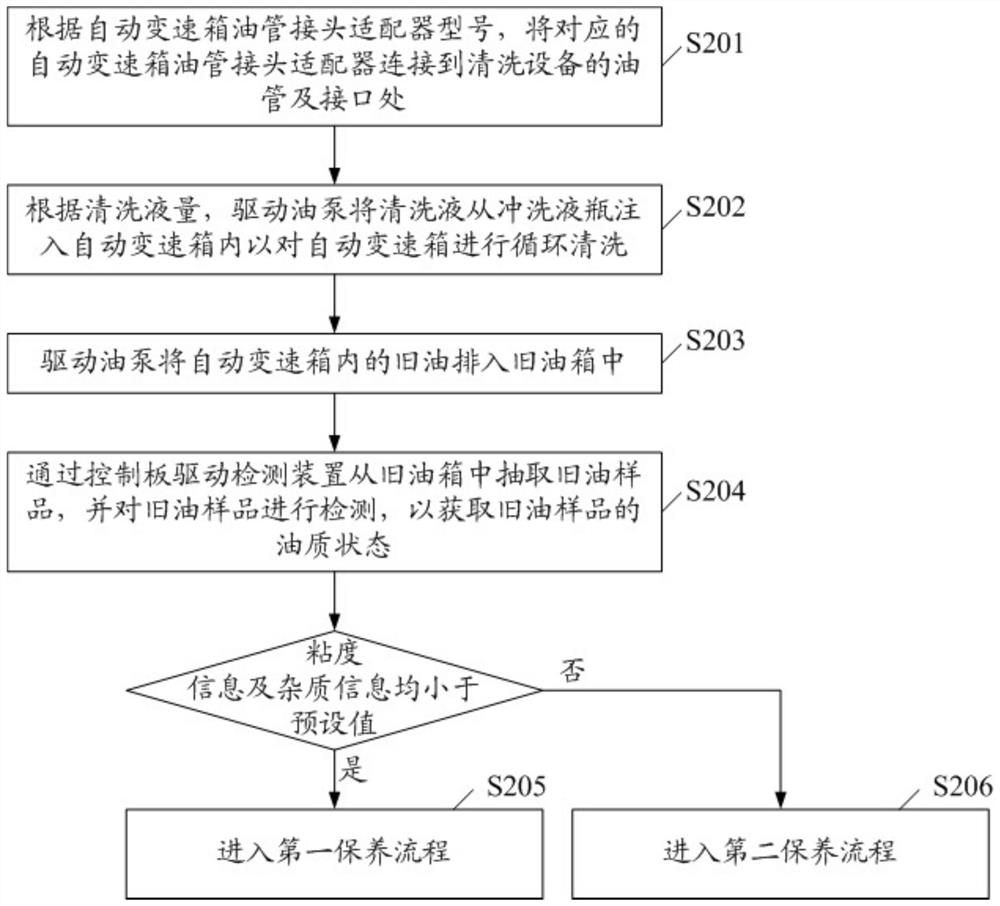

Automatic replacing, cleaning and maintaining method and system for automatic transmission oil

PendingCN112728055AAccurate extractionHigh degree of automationLubricant transferGear lubrication/coolingControl engineeringInteraction device

The invention discloses an automatic replacing, cleaning and maintaining method for automatic transmission oil. The method comprises the steps: acquiring vehicle information of a target vehicle by a digital control interaction device through an OBD code reader; extracting maintenance information of the target vehicle from a cloud platform database by the digital control interaction device according to the vehicle information; and generating an operation instruction according to the maintenance information and sending the operation instruction to the control panel by the digital control interaction device so as to control the control panel to drive the functional part to automatically replace, clean and maintain the automatic transmission oil according to the operation instruction. The invention further discloses an automatic transmission oil replacing, cleaning and maintaining method and system. According to the invention, the maintenance information can be automatically acquired in a networking manner, so that the automatic transmission oil of an automobile can be automatically replaced, cleaned and maintained, so that the automation degree is high, and the accuracy is high.

Owner:SHENZHEN COSBER IND CO LTD

An online safety warning system for oil system of condenser

ActiveCN110906152BLow operating and maintenance costsIncrease productivityBearing componentsLubrication elementsIndustrial equipmentLubrication

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

Device and method for emptying and monitoring fluid drained from an engine of an aircraft

PendingCN112351939AMonitoring statusHelp monitor statusTurbinesAutonomous decision making processAviationMarine engineering

The invention relates to the field of aeronautics propulsion, and more specifically to a device and a method for emptying and monitoring (10) for emptying and monitoring a fluid drained from an engine(101) of an aircraft (100). The emptying and monitoring device (10) comprises at least one first intake passage (12) for receiving, directly from the aircraft (100), fluid drained from the engine (101), and a first quality sensor assembly (17) for detecting at least one quality parameter of the fluid drained from the engine (101) that has been admitted through the first intake passage (12).

Owner:SAFRAN AIRCRAFT ENGINES SAS

Turbomachine lubricating oil analyzer system, computer program product and related methods

Various embodiments of the invention include a system having: at least one computing device, the at least one computing device configured to monitor a lubrication oil by performing actions including:determining an initial ideal remaining life for the lubrication oil; determining a temperature-based remaining life for the lubrication oil based upon a temperature measurement of the lubrication oil;calculating a contamination factor of the lubrication oil based upon a non-particle count sample of the lubrication oil; determining an updated ideal life remaining for the lubrication oil based uponthe contamination factor, the initial ideal remaining life, and the temperature-based remaining life; and determining an actual life remaining for the lubrication oil based upon the updated ideal life remaining and an actual life lost for the lubrication oil.

Owner:GENERAL ELECTRIC CO

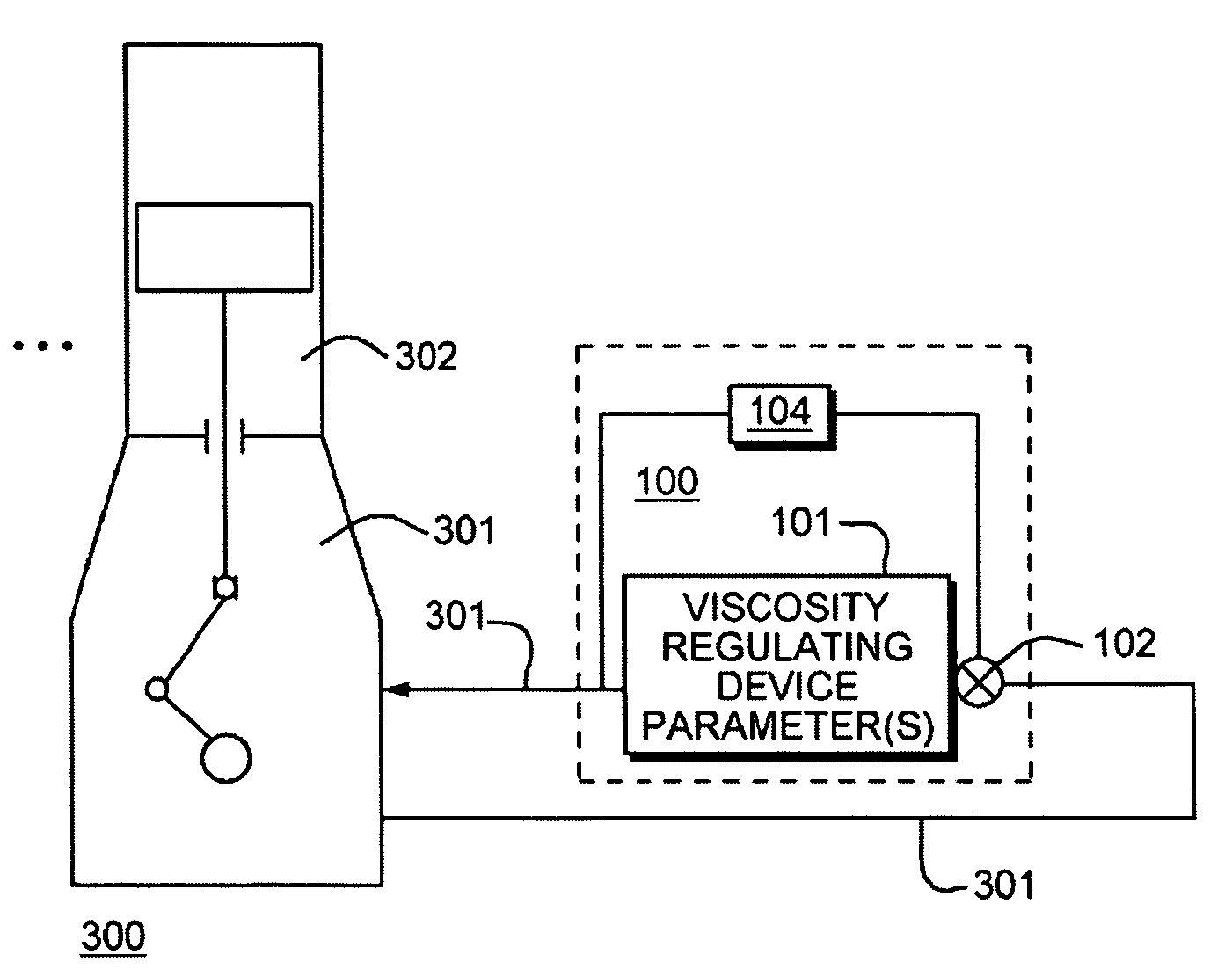

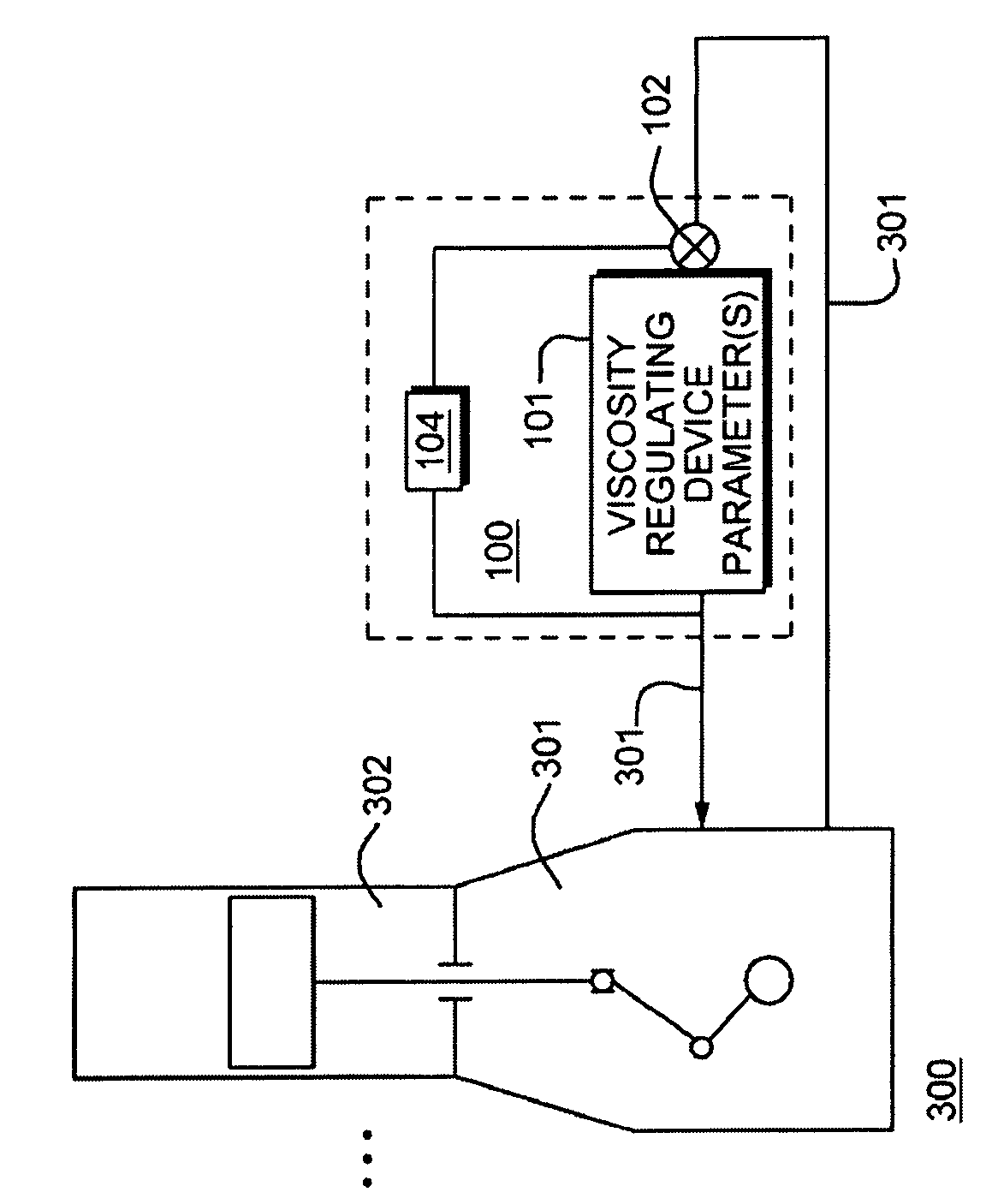

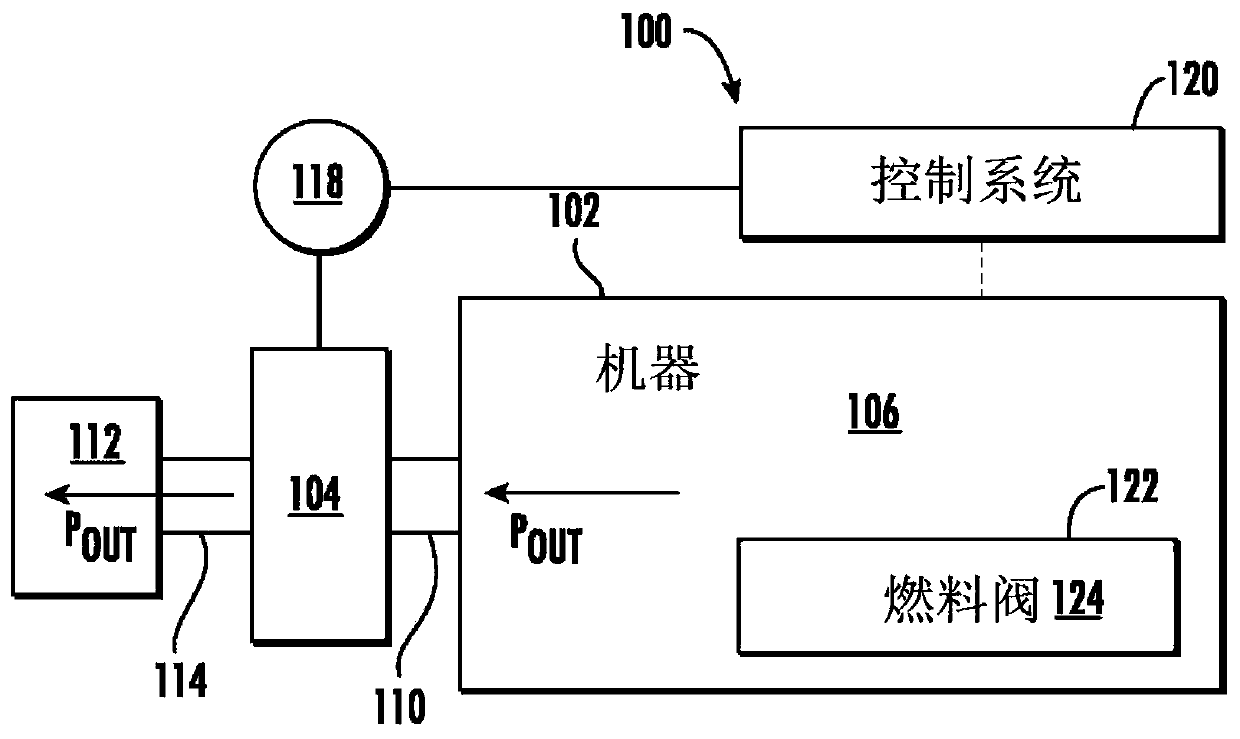

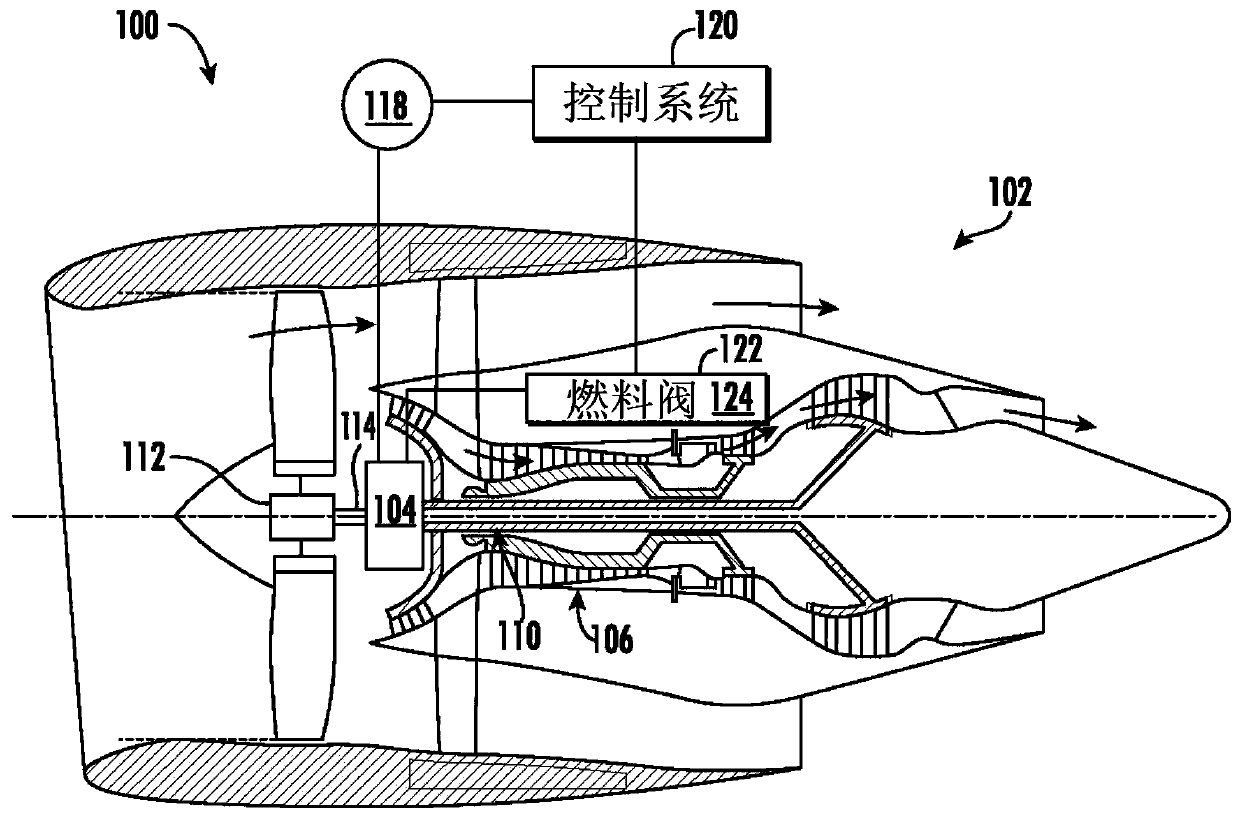

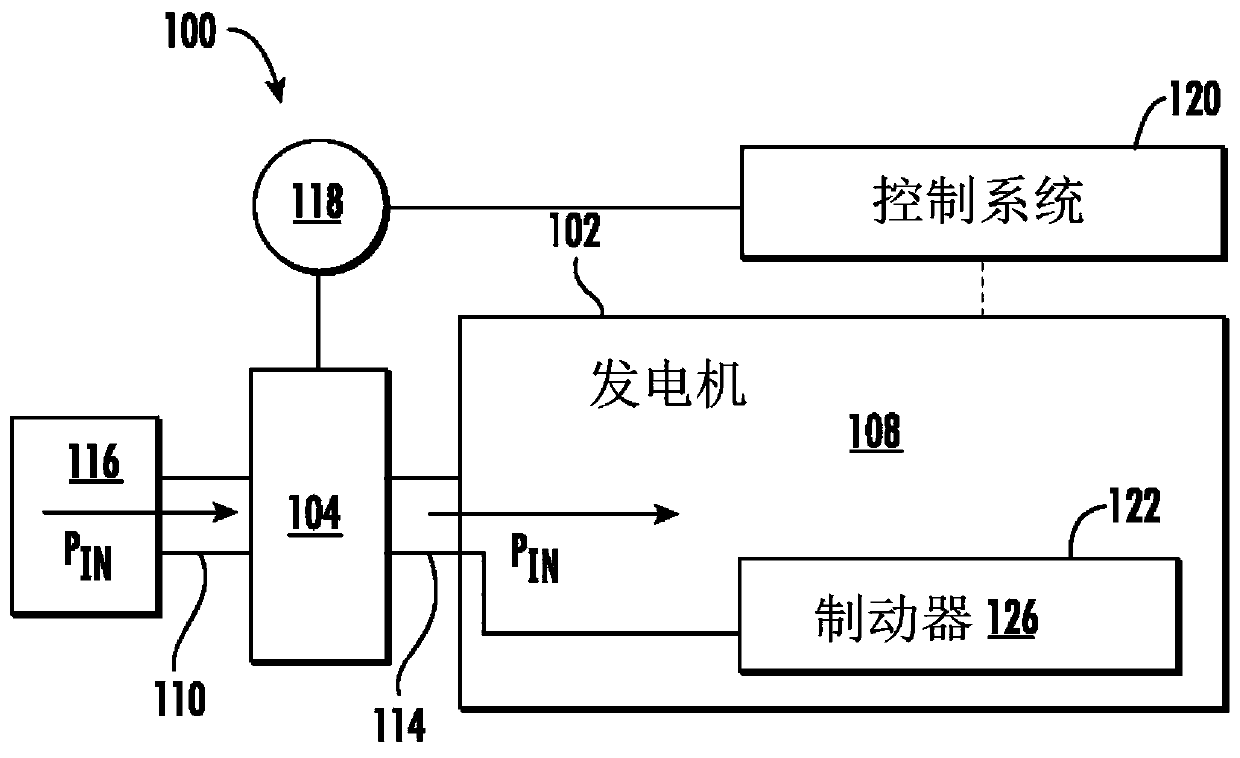

Systems and methods for monitoring lubrication of gear assembly

Systems and methods of monitoring lubrication of a gear assembly during operation of a machine (102) provide for receiving at a control system (120), a signal from a sensor (118) indicative of a valueobtained by the sensor (118) for an electrical property of a circuit (300) crossing the gear assembly (102) operably coupled to the machine (102), ascertaining whether the value for the electrical property corresponds to a warning level for a condition of the lubricant film (220), and outputting a control command (220) when the value for the electrical property corresponds to the warning level for the condition of the lubricant film.

Owner:通用电气阿维奥有限责任公司

Method and control unit for operating a diesel internal combustion engine or a dual-fuel internal combustion engine operated in the diesel mode

ActiveUS11187121B2Easy to implementInternal combustion piston enginesWaterborne vesselsTotal Base NumberInternal combustion engine

Owner:MAN ENERGY SOLUTIONS SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com