Apparatus and method for blending oil on a marine vessel

A blender, marine technology, applied in the field of devices and methods for blending oil on marine vessels, capable of solving the problems of time-consuming, inflexible requirements, production and modification taking two to three days, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

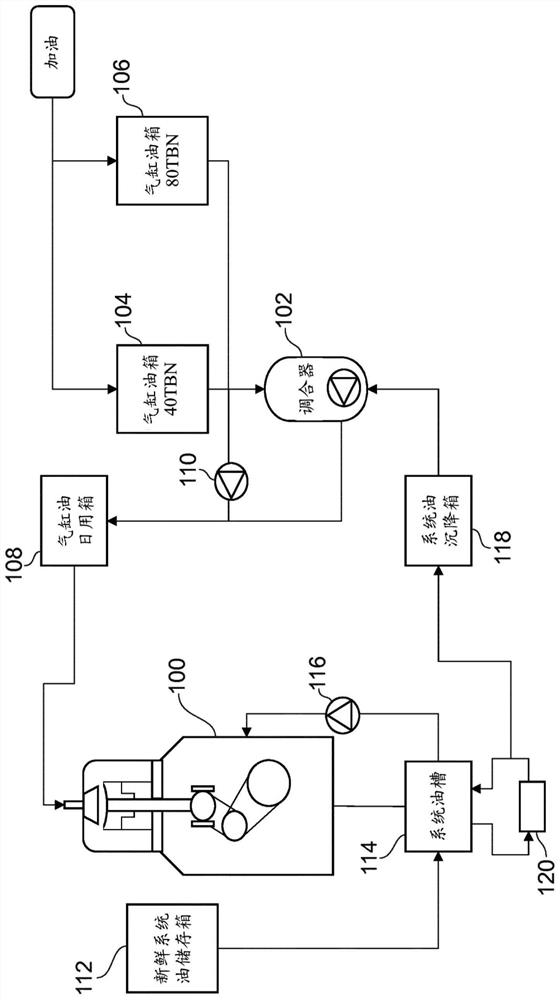

[0034] figure 1 A schematic diagram of the marine lube oil blending arrangement on board is shown. figure 1 Represents a known existing blending arrangement. The blender 102 is in fluid communication with the first cylinder tank 104 and the second cylinder tank 106 . The first cylinder tank typically holds 40TBN cylinder oil, and the second cylinder tank typically holds 100TBN to 320TBN. When the vessel is bunkered, the cylinder tanks 104, 106 are refilled. The term bunkering refers to the process of refueling a vessel, which includes refilling the respective cylinder tanks 104 , 106 . The cylinder oil tanks 104 , 106 may be in fluid communication and directly connected to the engine 100 via the cylinder oil service tank 108 . The cylinder oil daily tank 108 provides a buffer of pre-blended cylinder oil for use by the engine 100 . Cylinder oil from the first cylinder tank 104 and the second cylinder tank 106 is pumped directly to the cylinder oil day tank 108 via the pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com