Online safety early warning system for phase adjusting machine oil liquid system

A technology of safety early warning system and camera adjustment, applied in safety devices, mechanical equipment, engine viscosity, etc., can solve problems such as failure to predict failures in time, low efficiency, and ineffective use of data, so as to improve equipment monitoring efficiency, Improves accuracy, avoids lubrication failures and mechanical failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

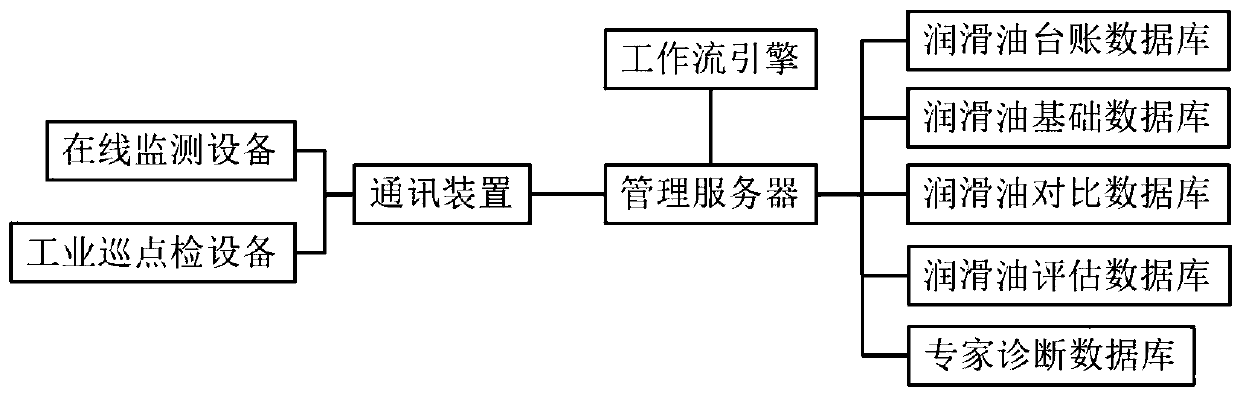

[0046] to combine figure 1 , The present invention refers to an online safety early warning system for the oil system of a condenser. The online safety early warning system includes online monitoring equipment, a workflow engine, a management server, industrial inspection equipment, and a communication device.

[0047] The workflow engine is built in the management server, and is used to establish a workflow model, define roles, and use a process controller to realize the online safety early warning process control of the oil system.

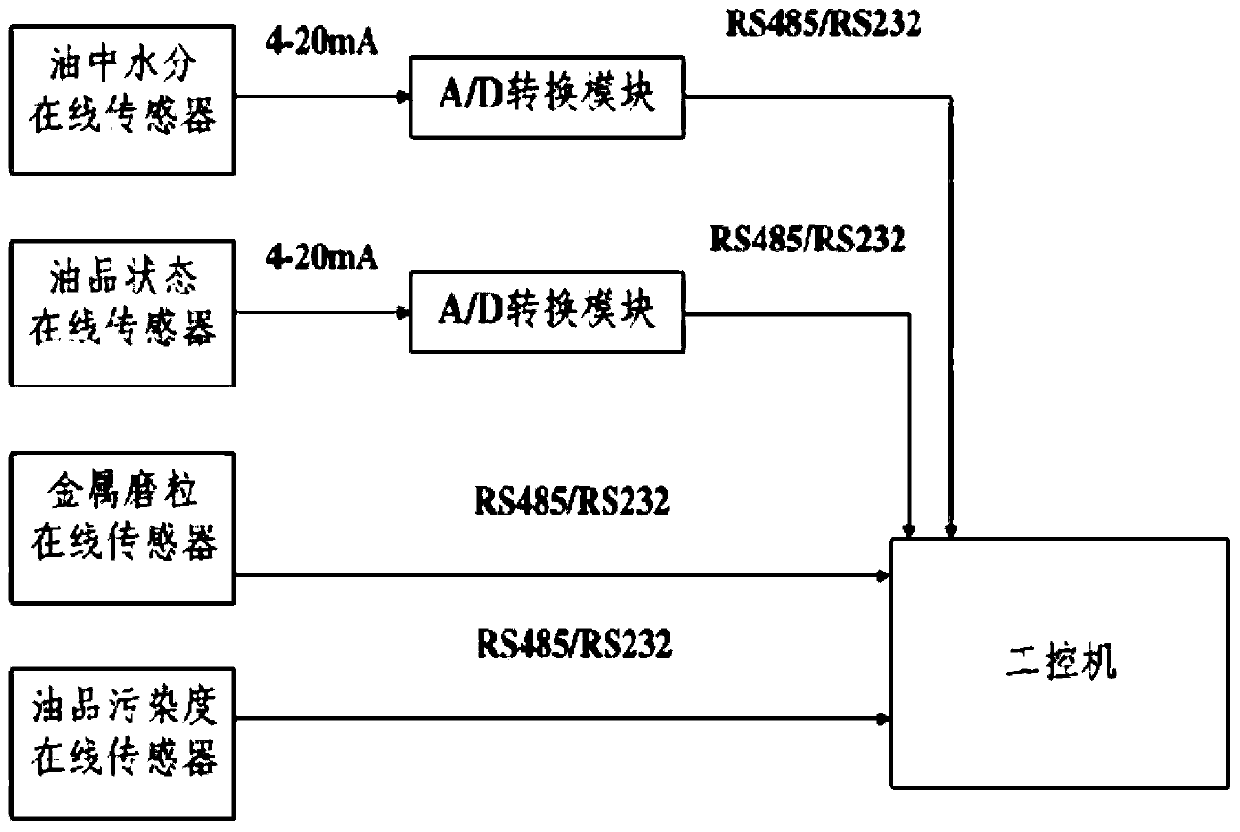

[0048] The online monitoring equipment is connected with the management server through a communication device, and is used to extract some oil samples from the oil system for detection and obtain various monitoring parameters, and the monitoring parameters include abrasive particle concentration, abrasive particle size, abrasive particle quantity, viscosity , moisture, temperature to realize multi-dimensional monitoring of equipment wear status ...

specific Embodiment 2

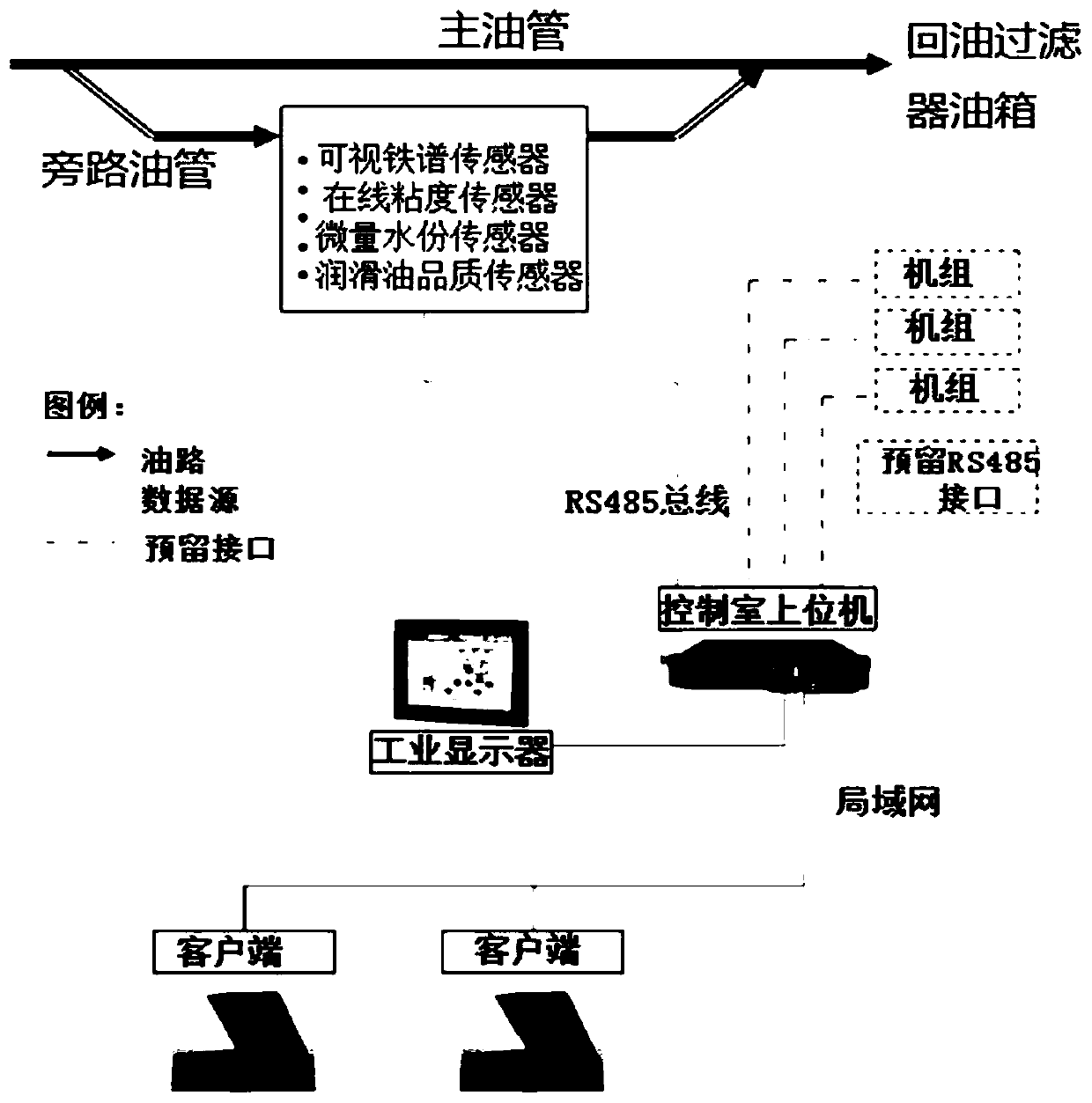

[0080] This embodiment refers to an online safety early warning system for the oil system of the condenser applied to power plant A. The built-in sensor is installed in the lubricating oil pipeline of the equipment to be tested. After the data acquisition terminal collects the parameters of the lubricating oil detected by the sensor, the The data transmission module transmits to the data storage device. The detection data is compared with the typical parameters and graphs in the lubricating oil comparison database, and the obtained lubricating oil state data and comparison results are sent to the lubricating oil evaluation database. The lubricating oil evaluation database stores the evaluation rules according to the established oil state data and gives the evaluation results. The expert diagnosis database is used to store the results corresponding to the lubricating oil state data, and perform parameter rating analysis, deterioration analysis, trend statistics, and maintenance...

specific Embodiment 3

[0082] This example mentions an online safety early warning system for the oil system of the condenser applied to power plant B. This system is used to monitor the installation of steam turbines in 2*330MW coal-fired units. During the experiment, it was found that No. 7 The temperature of the tile is higher than that of other tiles, and at this time the vibration has not been found to exceed the standard. Through the on-line safety warning system of the oil system of the condenser, a small amount of small abrasive particles were found in the lubricating oil. After a while, the abrasive particles rapidly became larger and the temperature also rose rapidly. When the value was long, the turbine was quickly warmed up at a low speed. Through timely adjustment, major accidents caused by large-scale wear of bearing bushes were avoided, and direct economic losses of more than 1.5 million yuan were avoided. At the same time, normal heating was ensured, and social honor was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com