Multi-stage flywheel body oiling machine

A technology of oil injection machine and flywheel, which is applied in the field of bicycle multi-stage flywheel body oil injection machine, which can solve the problems of poor fluidity, poor effect, and influence on oil injection effect, and achieve good effect, improved performance, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

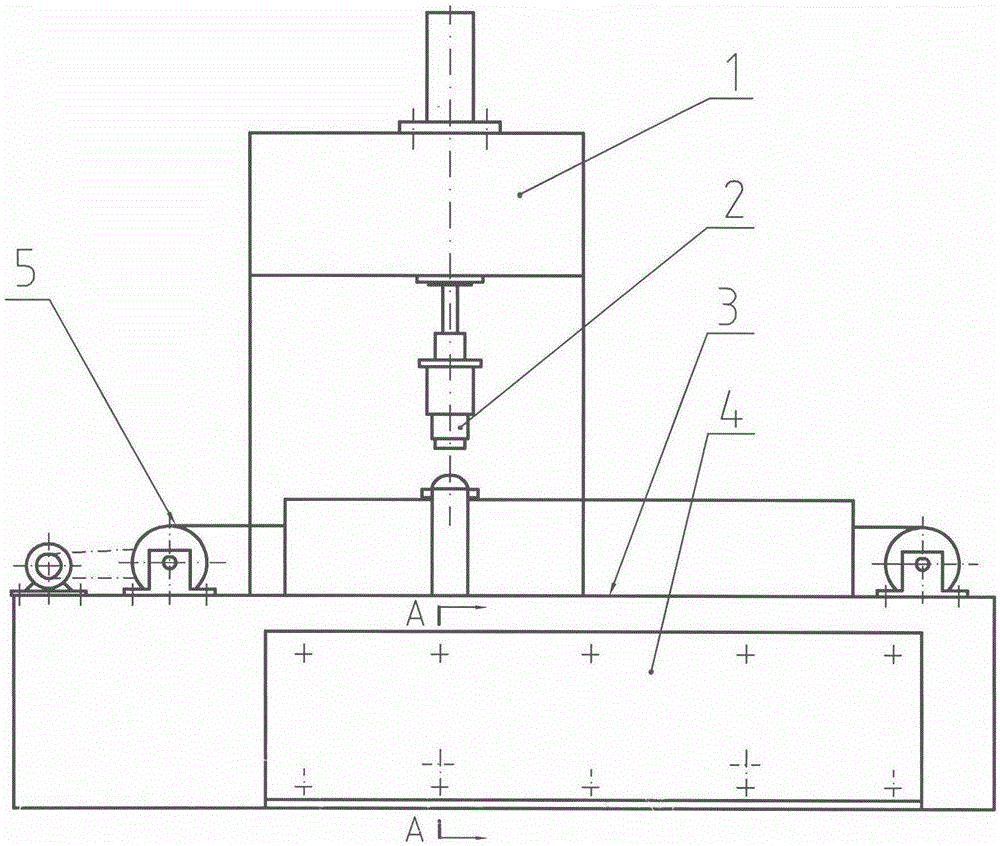

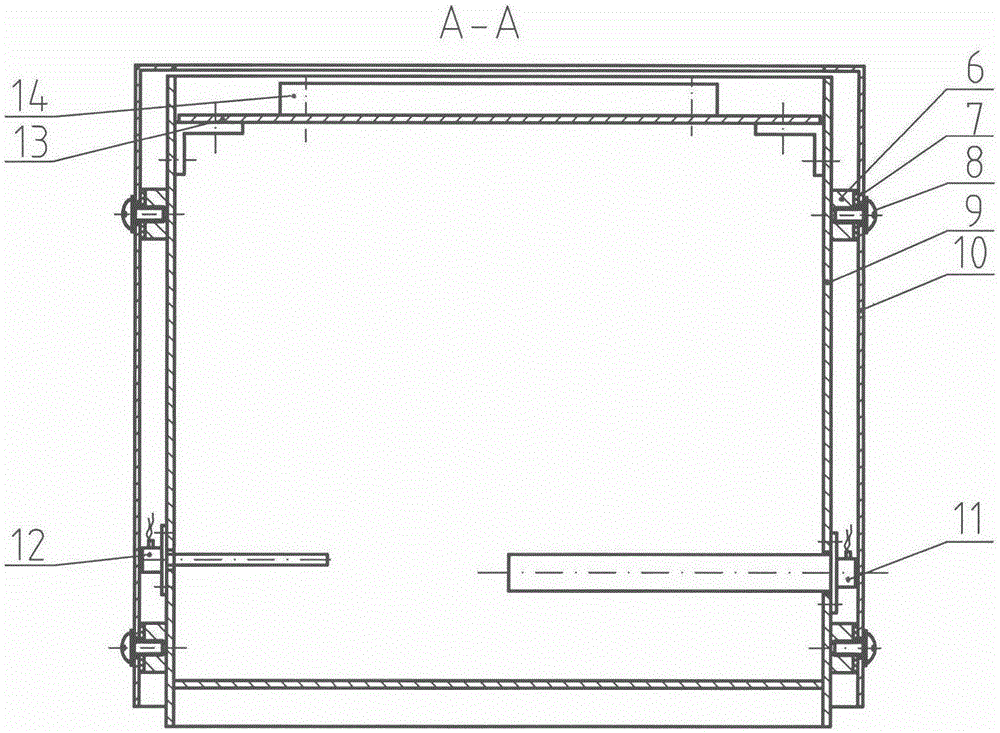

[0010] like figure 1 As shown, the present invention includes a transmission case 1, an oil injection rod part 2, a conveyor belt mechanism 5, a frame 3 and an oil tank part 4; such as figure 2 As shown, the above-mentioned fuel tank components are composed of a box body 9, a heat insulation plate 10, an electric heating pipe 11, a thermometer 12, a cover plate 13, an integrated block 14, a spacer block 6, a screw 8 and a heat insulation ring 7, wherein the electric heating pipe 11. The thermometers 12 are respectively fixedly connected to the lower part of the box body 9, the pads 6 are welded to the outer side of the box body 9, and the heat insulation plate 10 is fixedly connected to the pads 6 through the screws 8 and the heat insulation ring 7, so that the heat insulation is A gap insulation layer is formed between the plate 10 and the box body 9; the cover plate 13 is placed on the upper end of the box body 9 and is fixedly connected to the box body 9, and an integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com