Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Second moment of area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

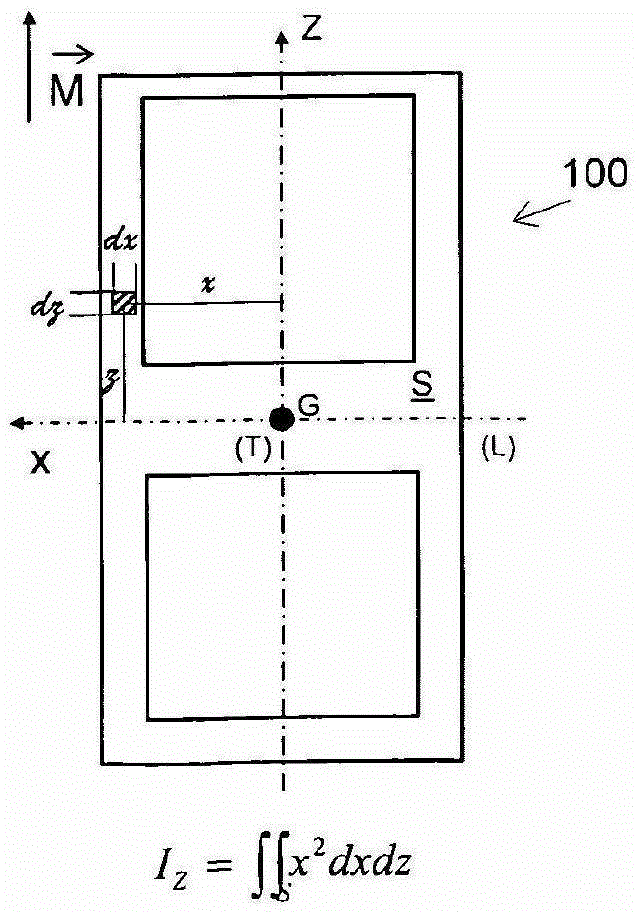

The 2nd moment of area, also known as the area moment of inertia, or second area moment, is a geometrical property of an area which reflects how its points are distributed with regard to an arbitrary axis. The second moment of area is typically denoted with either an I for an axis that lies in the plane or with a J for an axis perpendicular to the plane. In both cases, it is calculated with a multiple integral over the object in question.

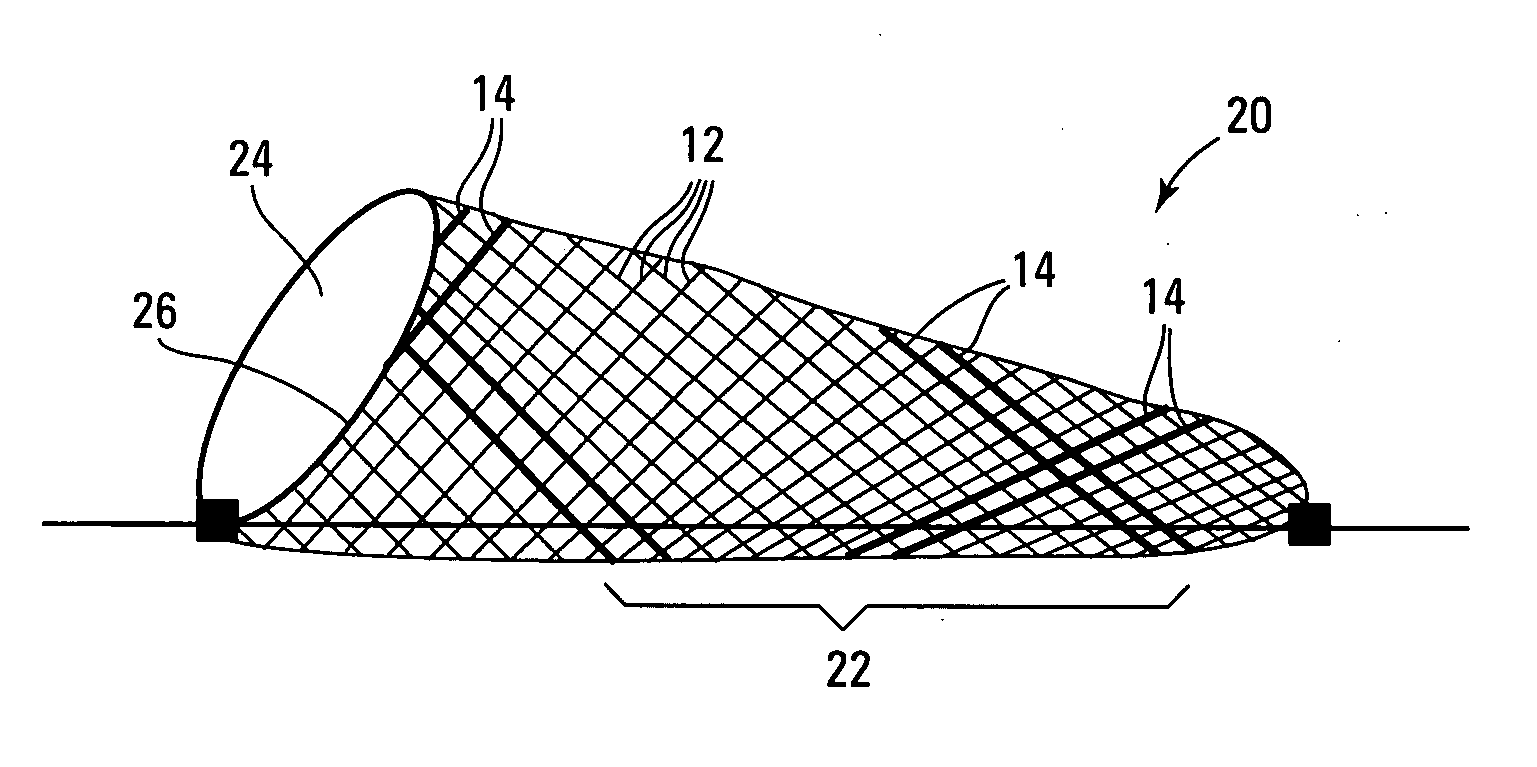

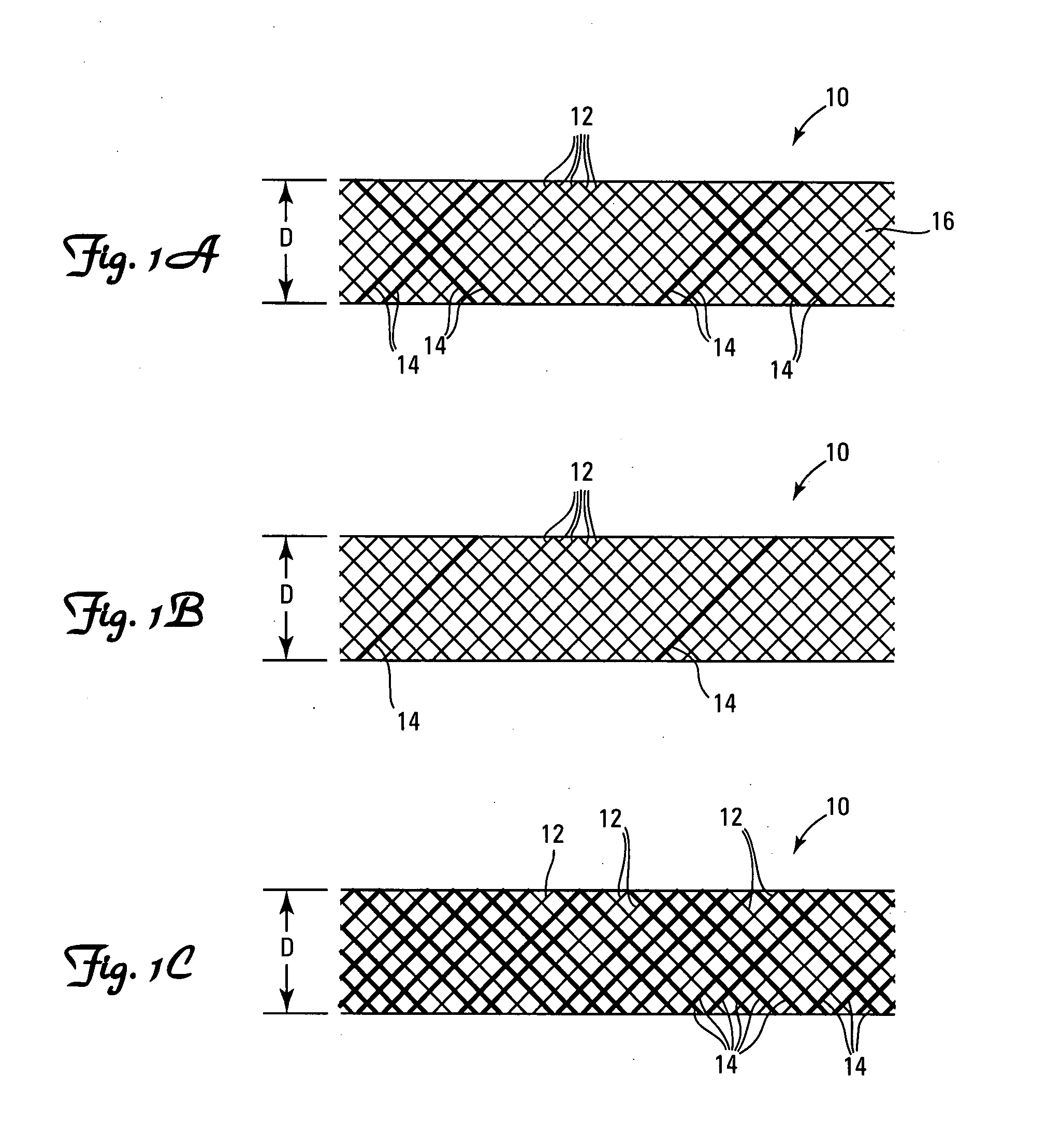

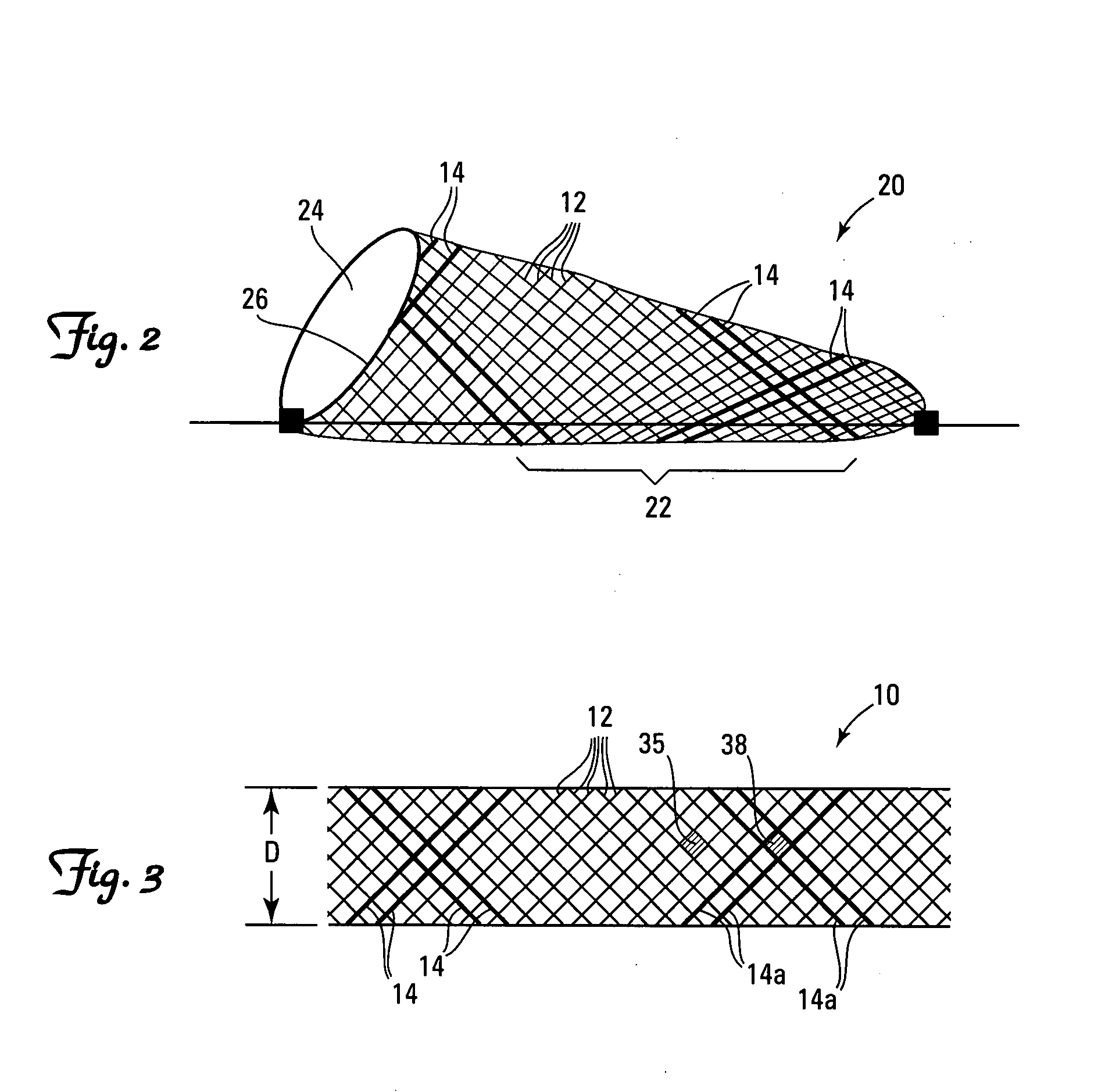

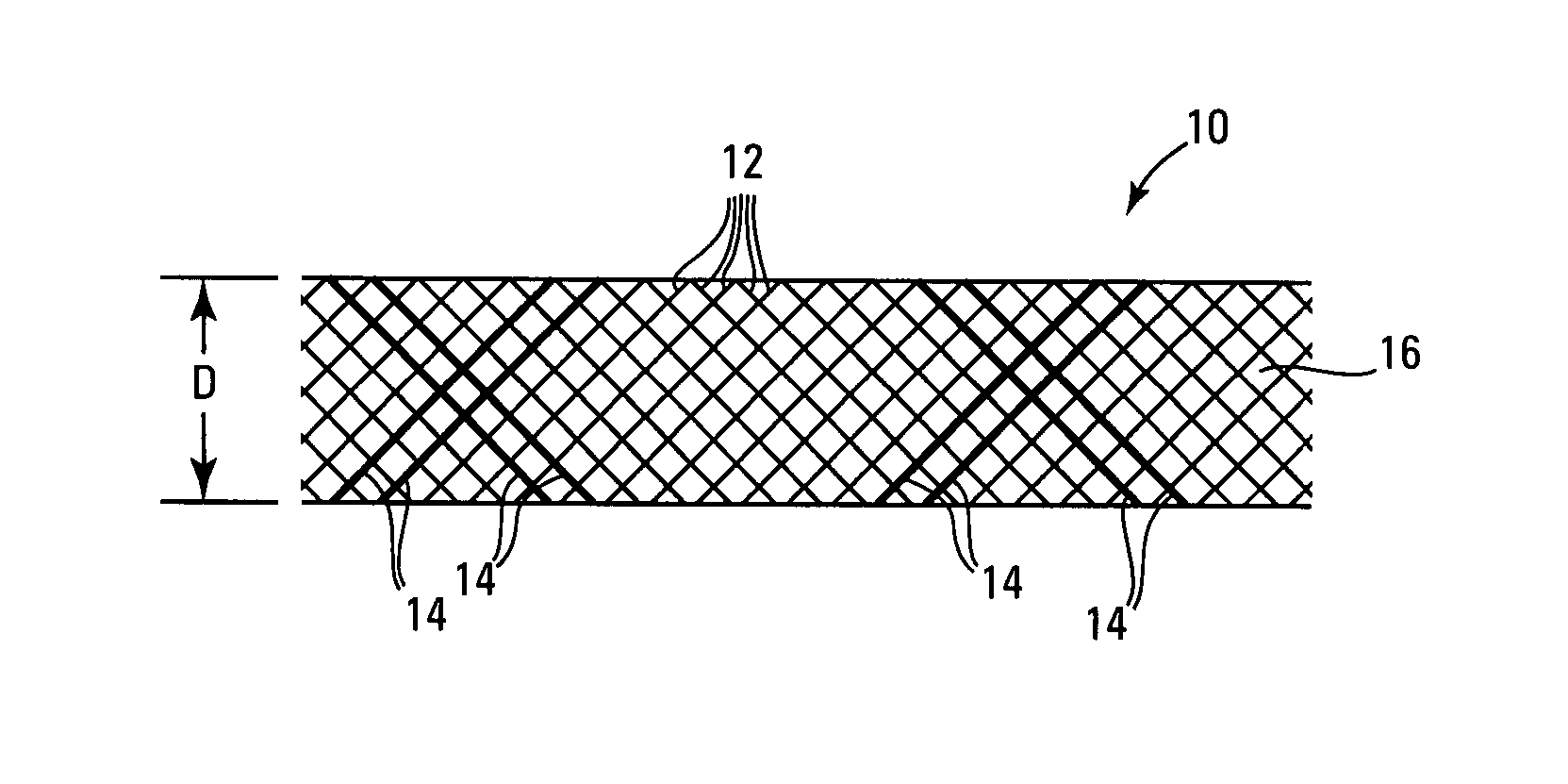

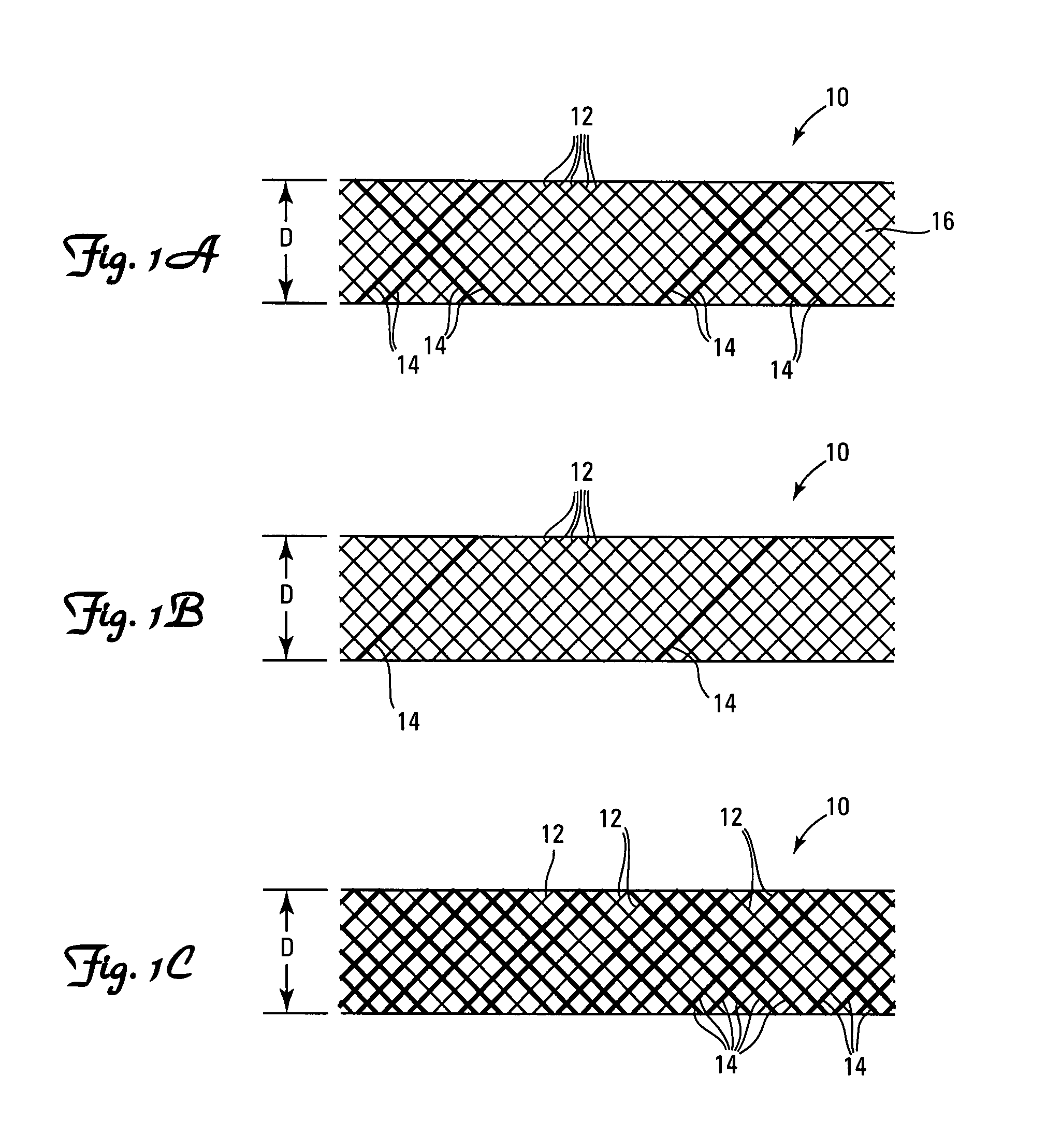

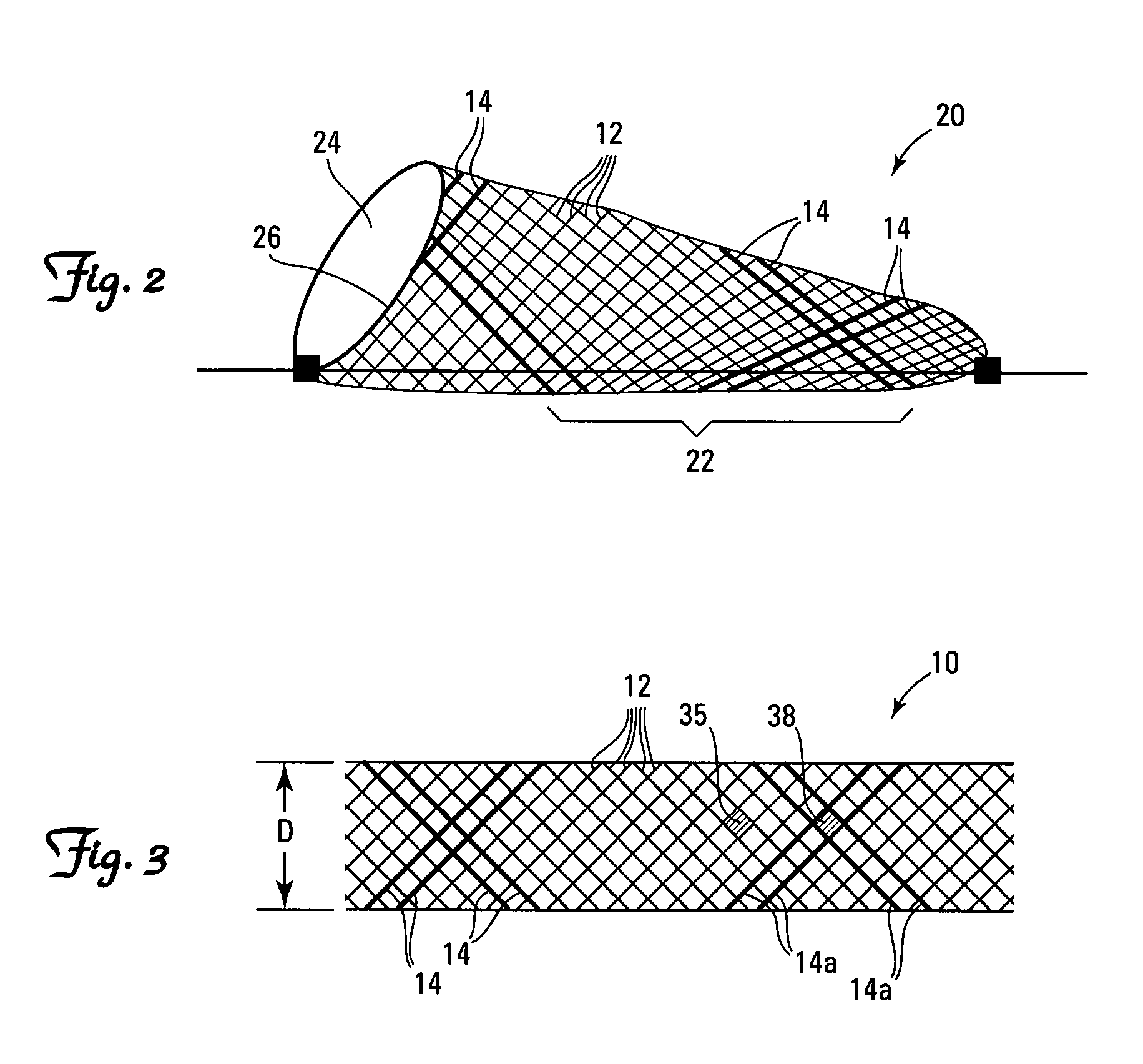

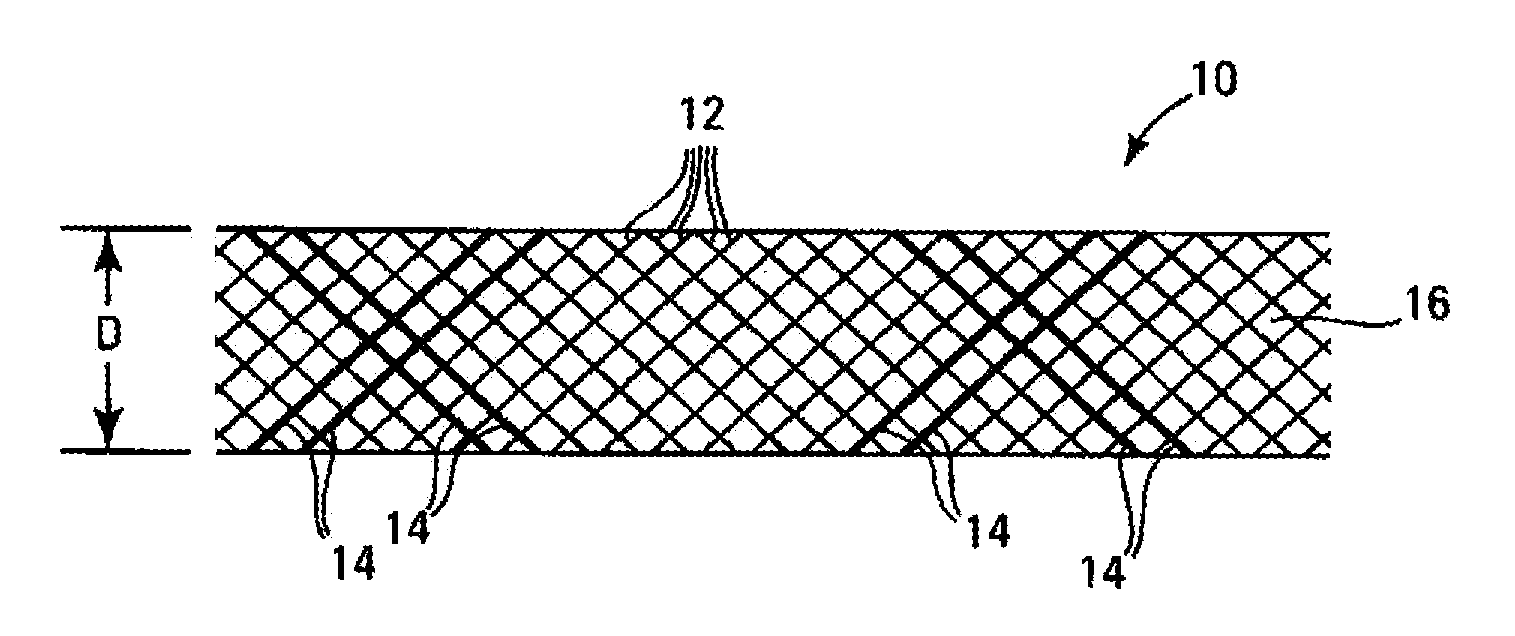

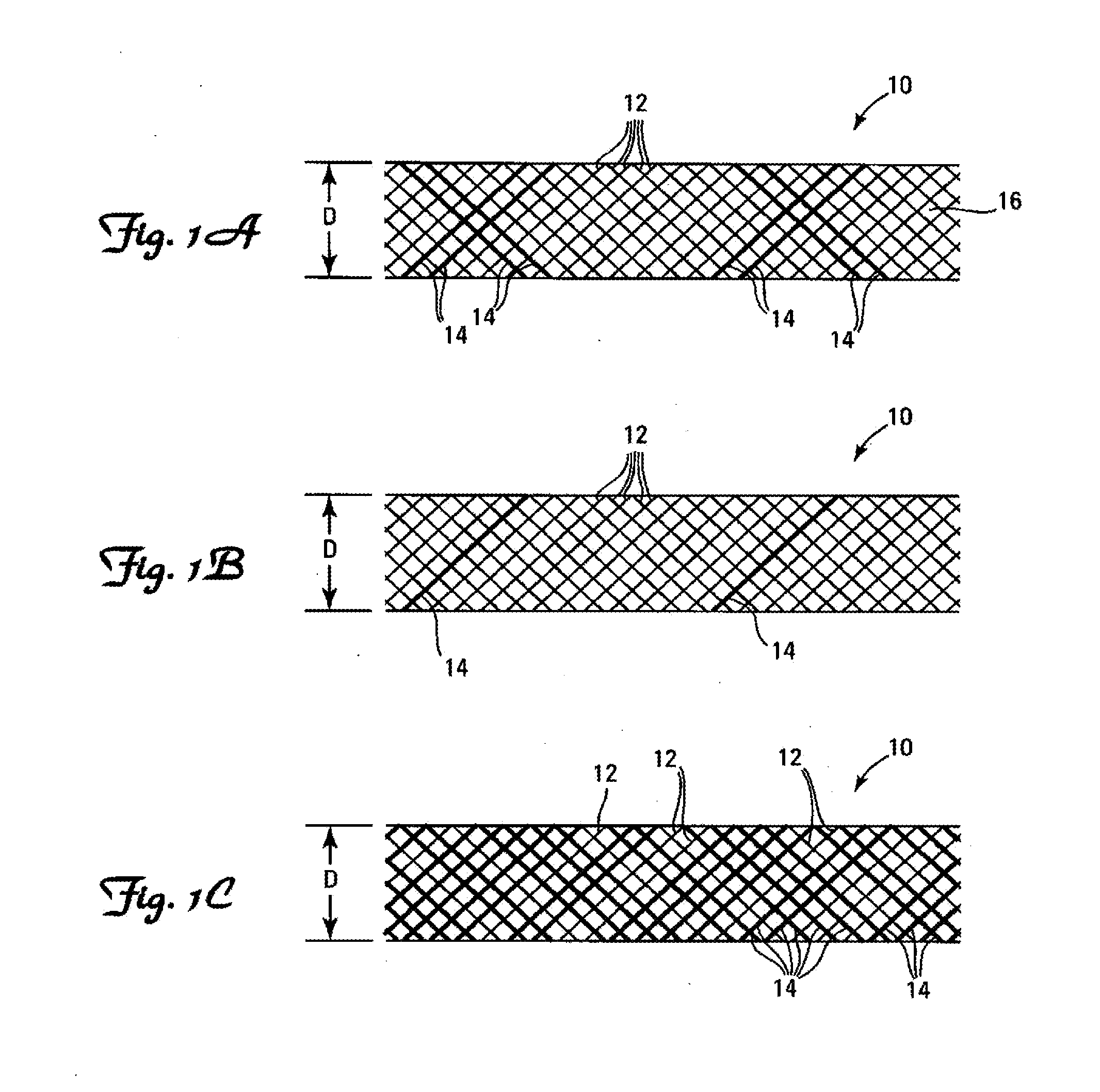

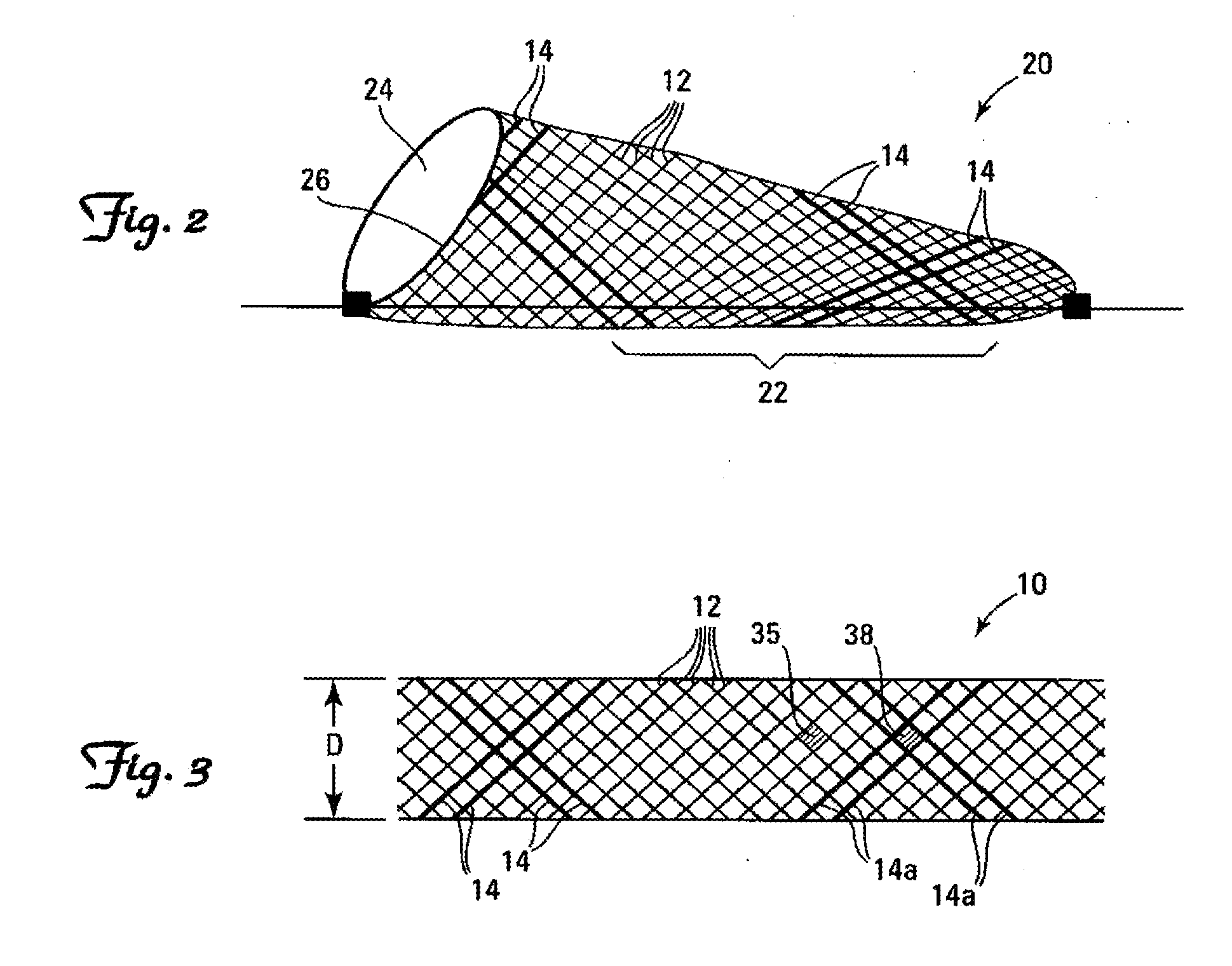

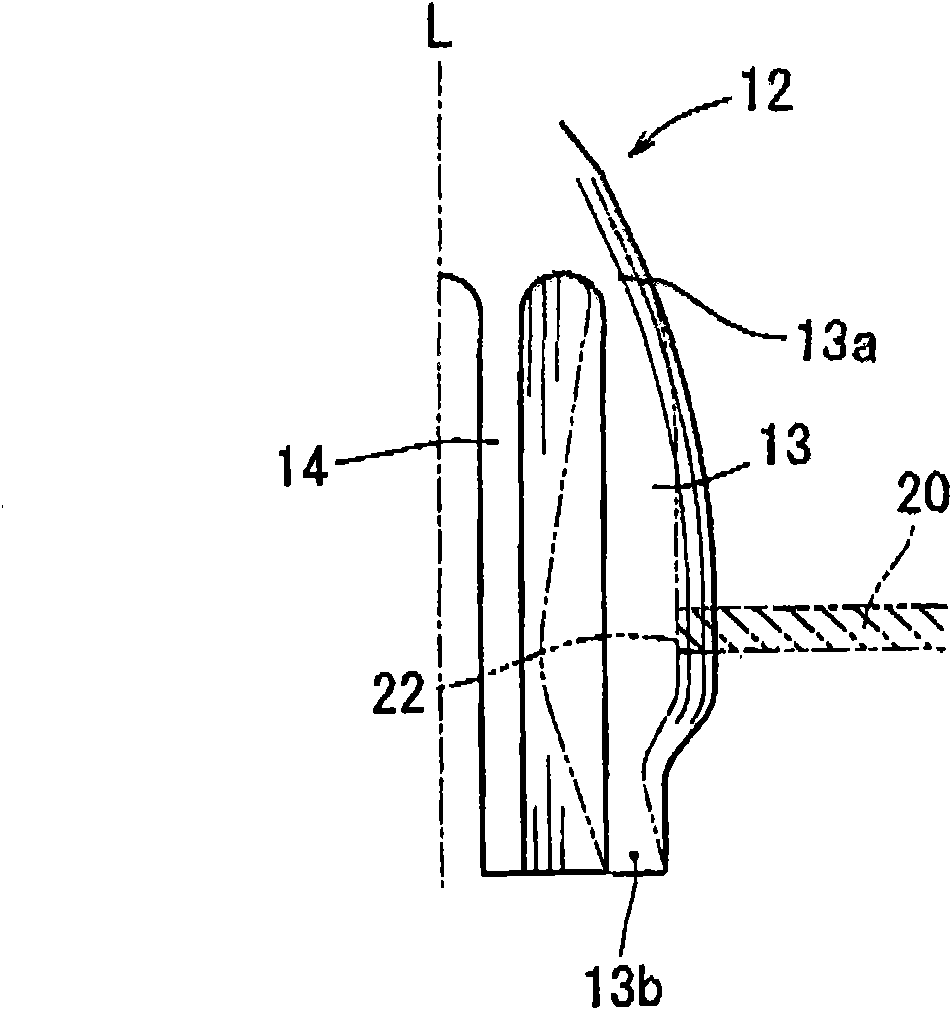

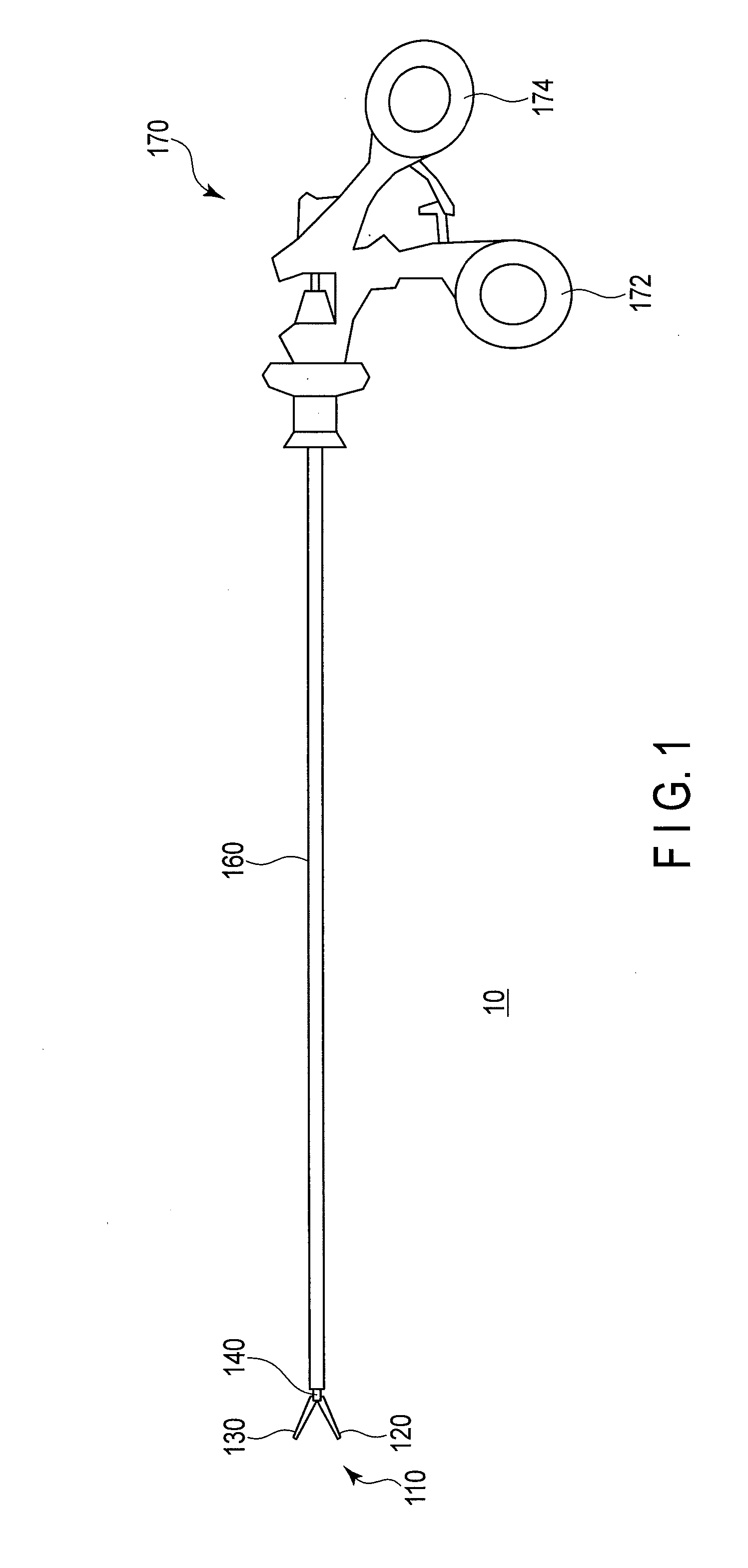

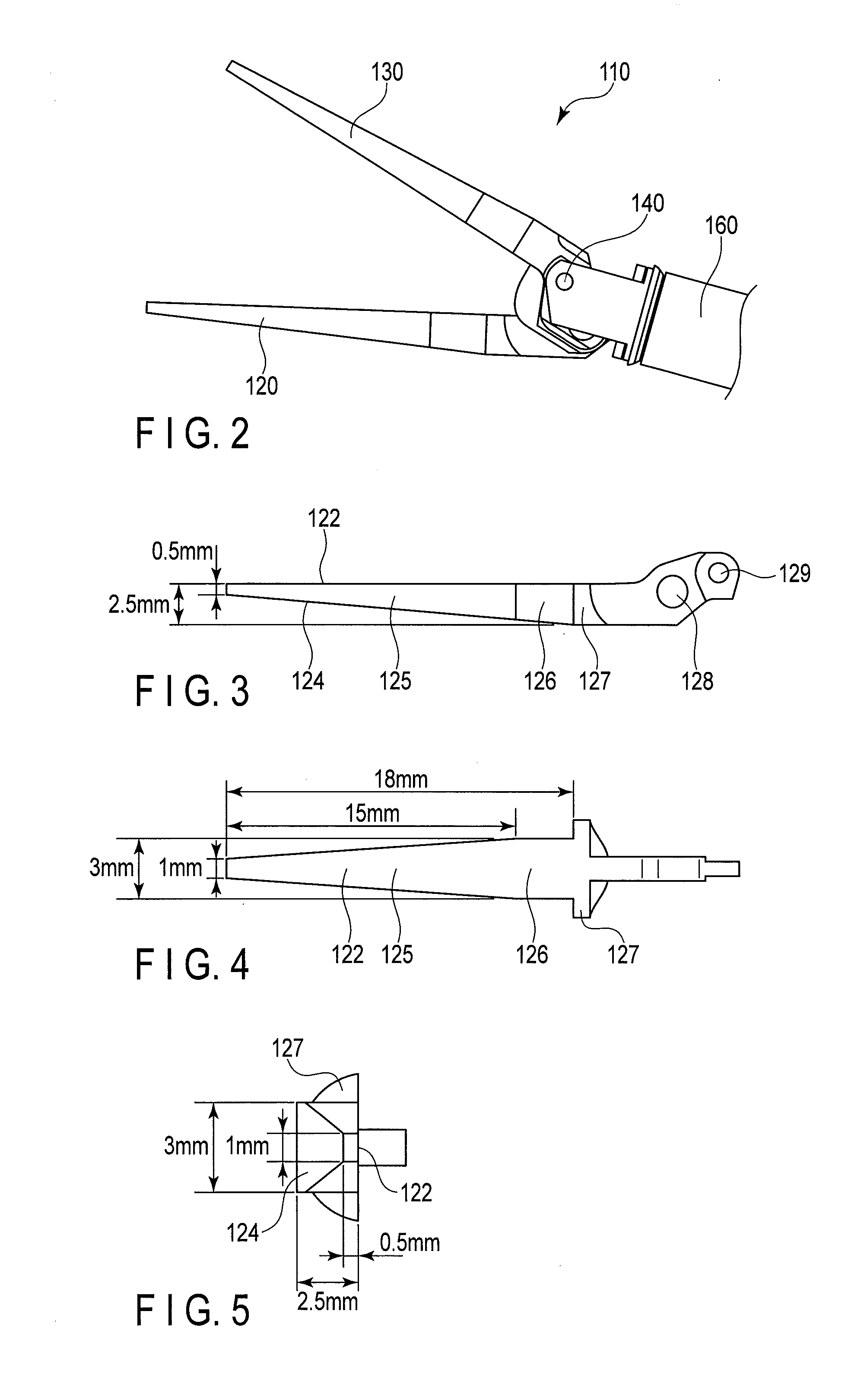

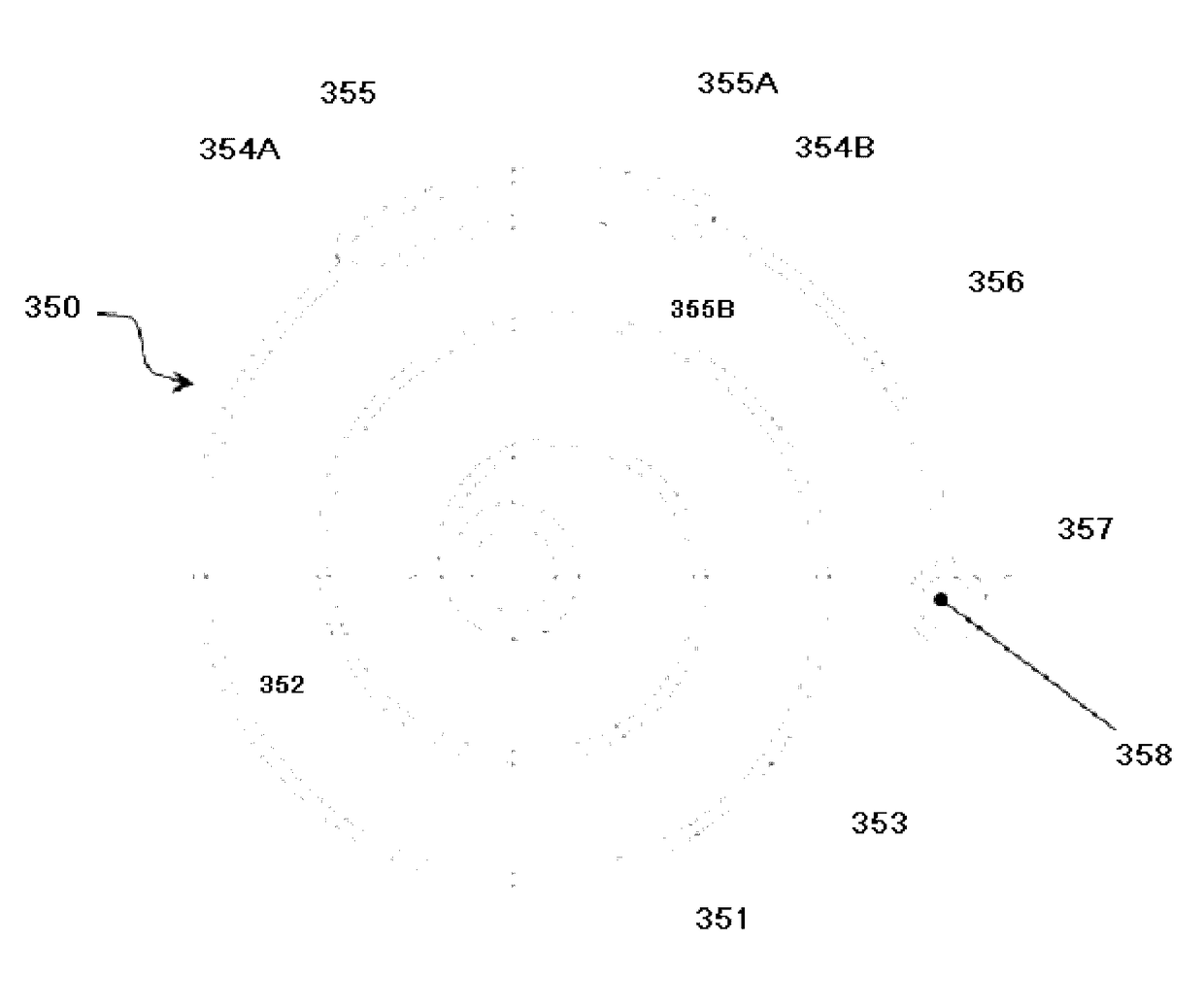

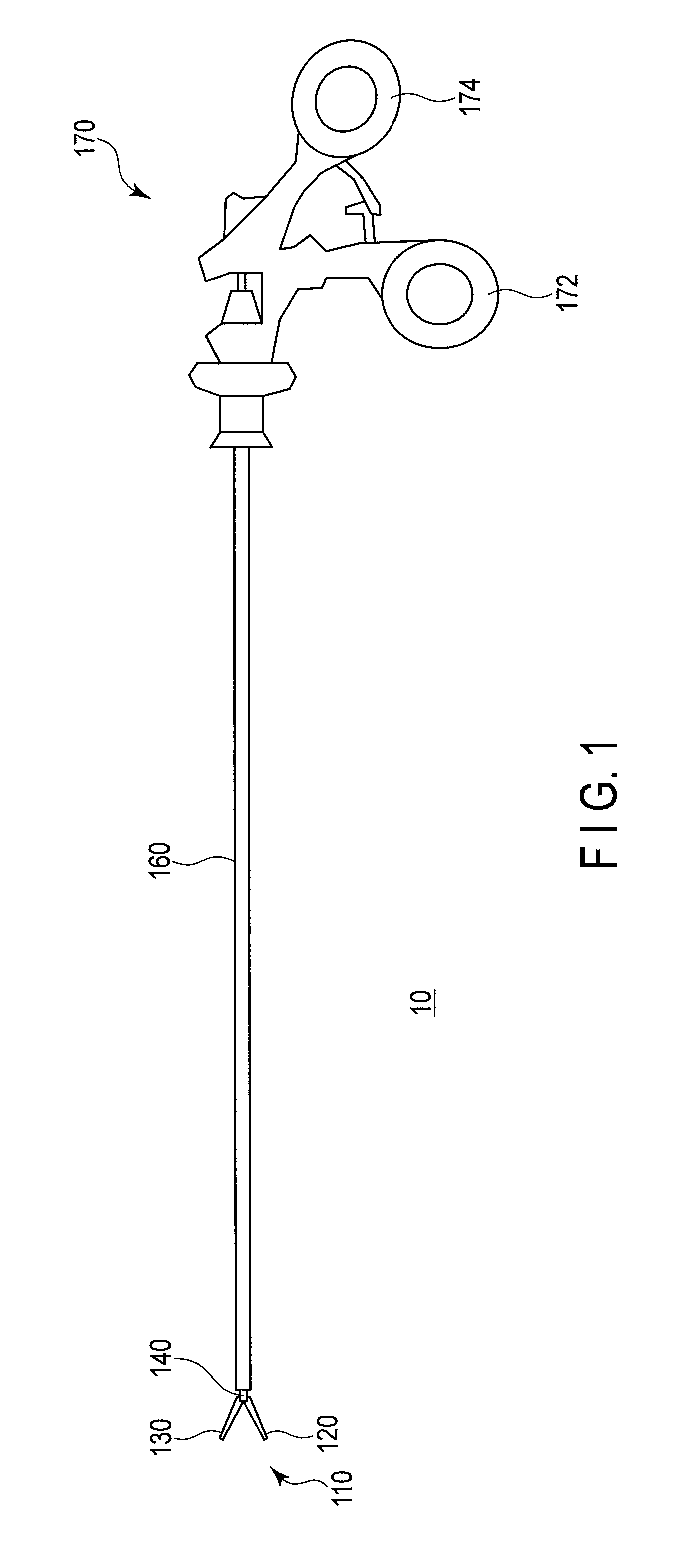

Embolic protection systems having radiopaque filter mesh

A device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body. The filter element is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained. The filter element includes a mesh including strands, each strand having a diameter. The mesh includes at least one radiopaque strand and at least one non-radiopaque strand, and wherein each strand has an index of wire stiffness EI, where EI is the mathematical product of the Young's modulus (E) and the second moment of area (I), and wherein the largest EI of a strand is no more than five times the smallest EI of a strand.

Owner:TYCO HEALTHCARE GRP LP

Embolic protection systems having radiopaque filter mesh

A device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body. The filter element is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained. The filter element includes a mesh including strands, each strand having a diameter. The mesh includes at least one radiopaque strand and at least one non-radiopaque strand, and wherein each strand has an index of wire stiffness EI, where EI is the mathematical product of the Young's modulus (E) and the second moment of area (I), and wherein the largest EI of a strand is no more than five times the smallest EI of a strand.

Owner:TYCO HEALTHCARE GRP LP

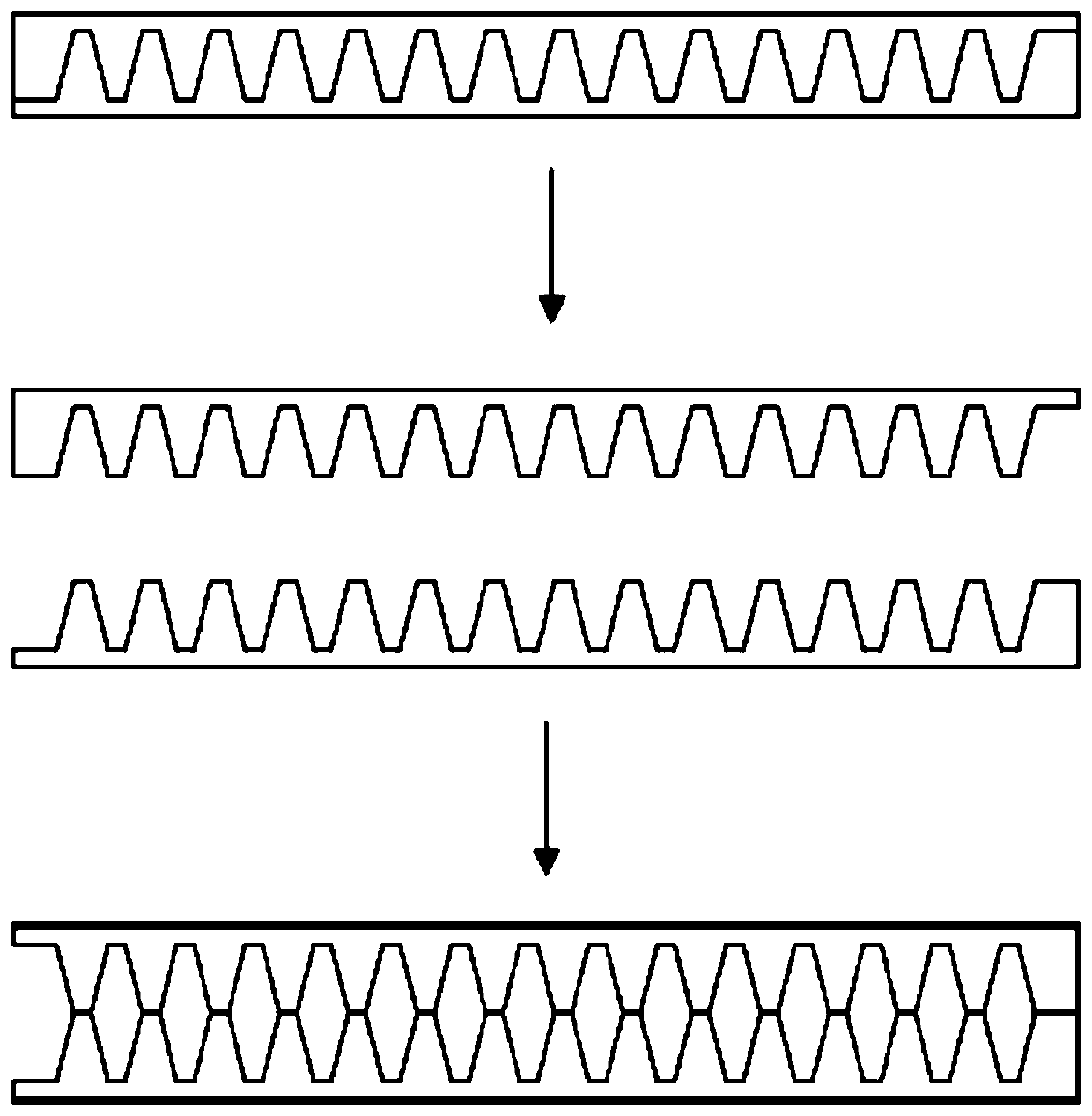

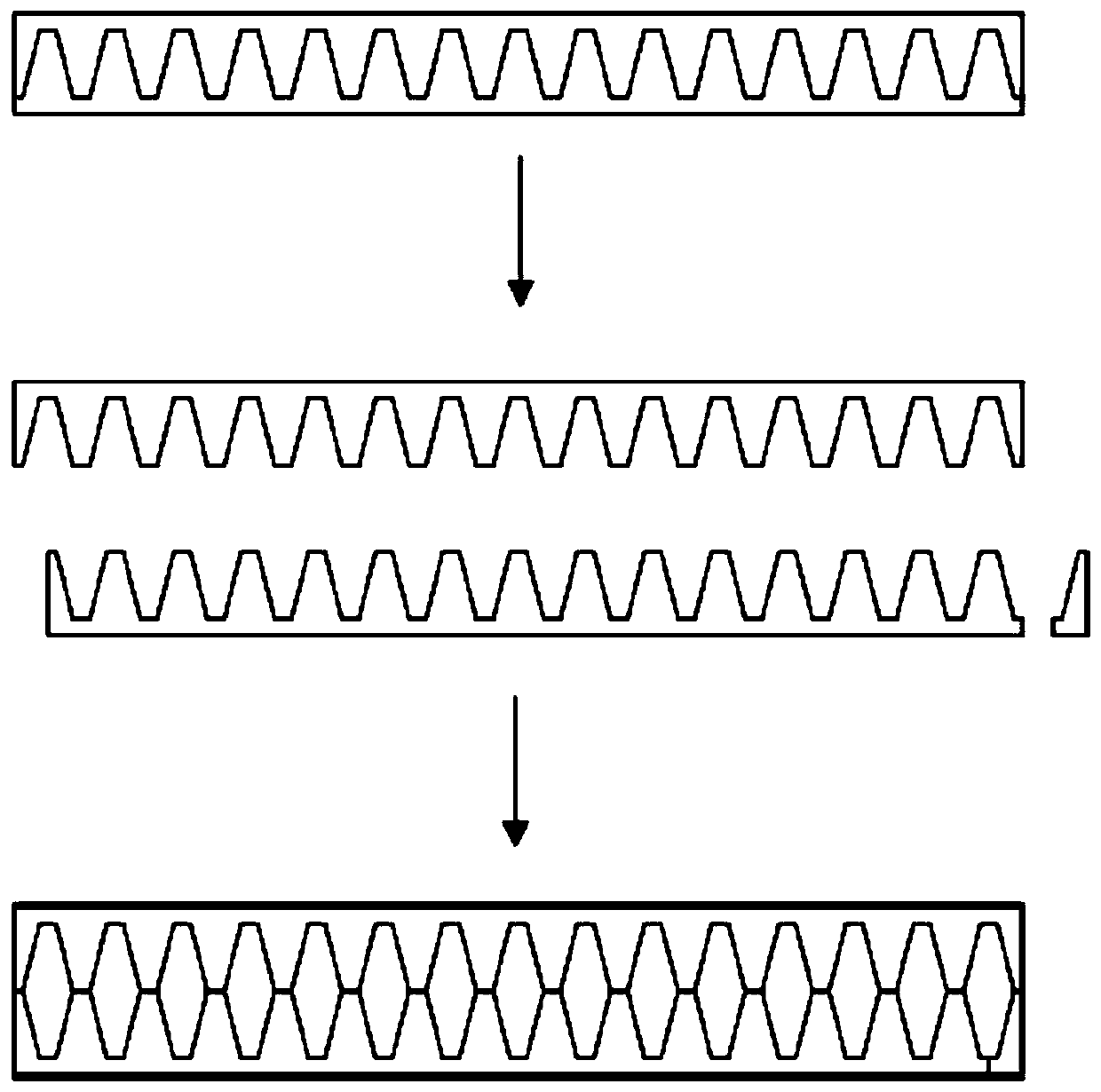

Stents having radiopaque mesh

A stent including a mesh made of strands. The mesh has at least one radiopaque strand and at least one non-radiopaque strand, and the at least one radiopaque strand and the at least one non-radiopaque strand each have different diameters. Each strand has an index of wire stiffness EI, where EI is the mathematical product of the Young's modulus (E) and the second moment of area (I). The EI of all strands in the mesh is no more than five times the EI of the strand having the smallest EI of any of the strands.

Owner:COVIDIEN LP

Structural insulator

ActiveUS20120205139A1Increased riskIncrease overheadOverhead installationSuspension/strain insulatorsElectrical conductorPower grid

An electrically insulating cross-arm for a tower for high-voltage power networks. The cross-arm includes an insulating structural member for attachment to the tower body and to support a conductor cable. The insulating structural member comprises a solid rigid spine extending along a long axis having cross sectional profile, normal to the long axis, having a second moment of area of its cross sectional profile about every axis normal to the long axis and dissecting its centroid has a value of A2 / 2π or more, where A is the area of the cross sectional profile. The structural member provides resistance to bending and compressive buckling and allows conductors to be safely supported at reduced tower height. T and Y shaped cross sections provide water run-off and inhibition of organic growth. The structural members are also generally useful as insulator members in high voltage power networks.

Owner:HUBBELL POWER SYST INC

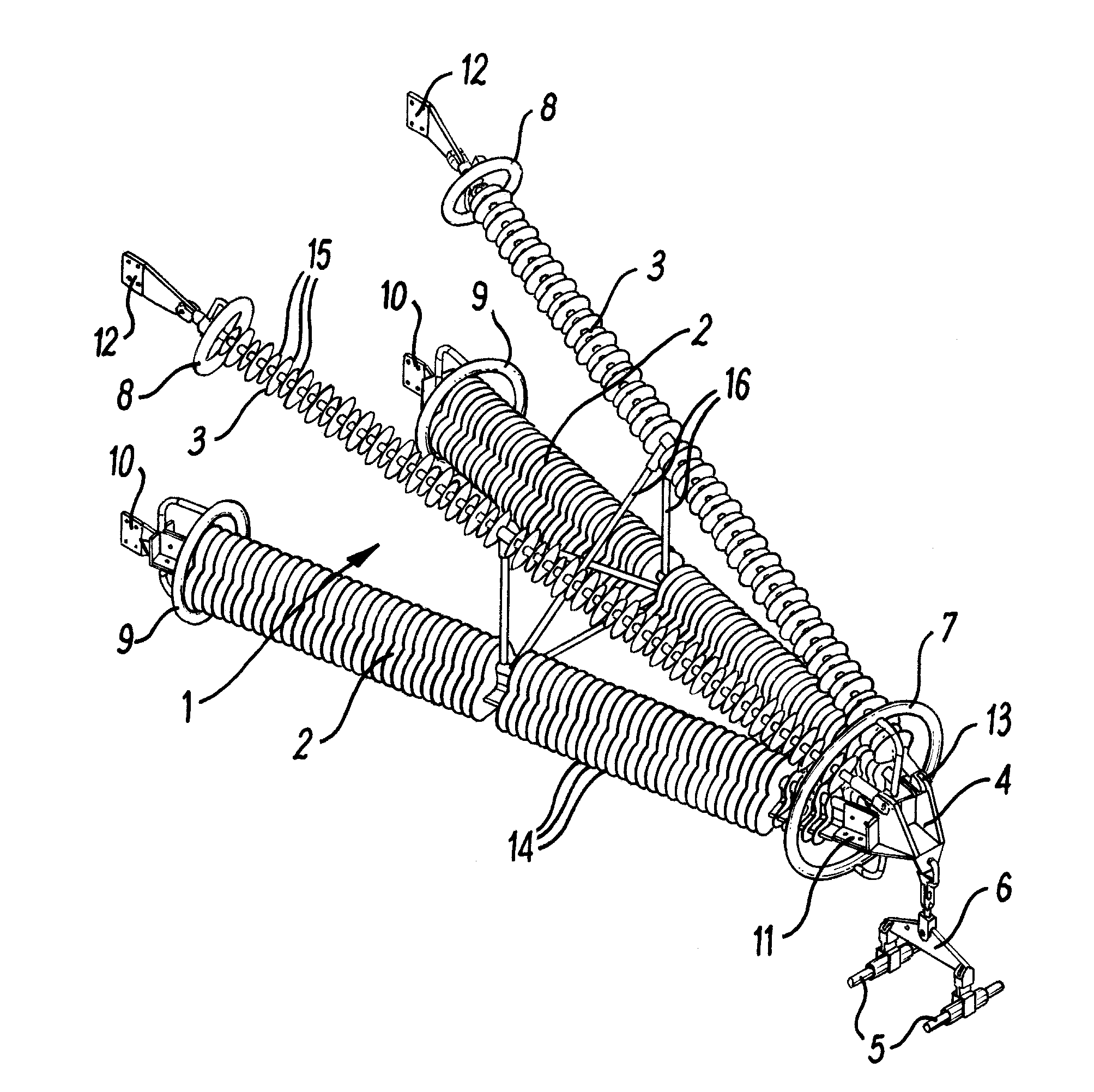

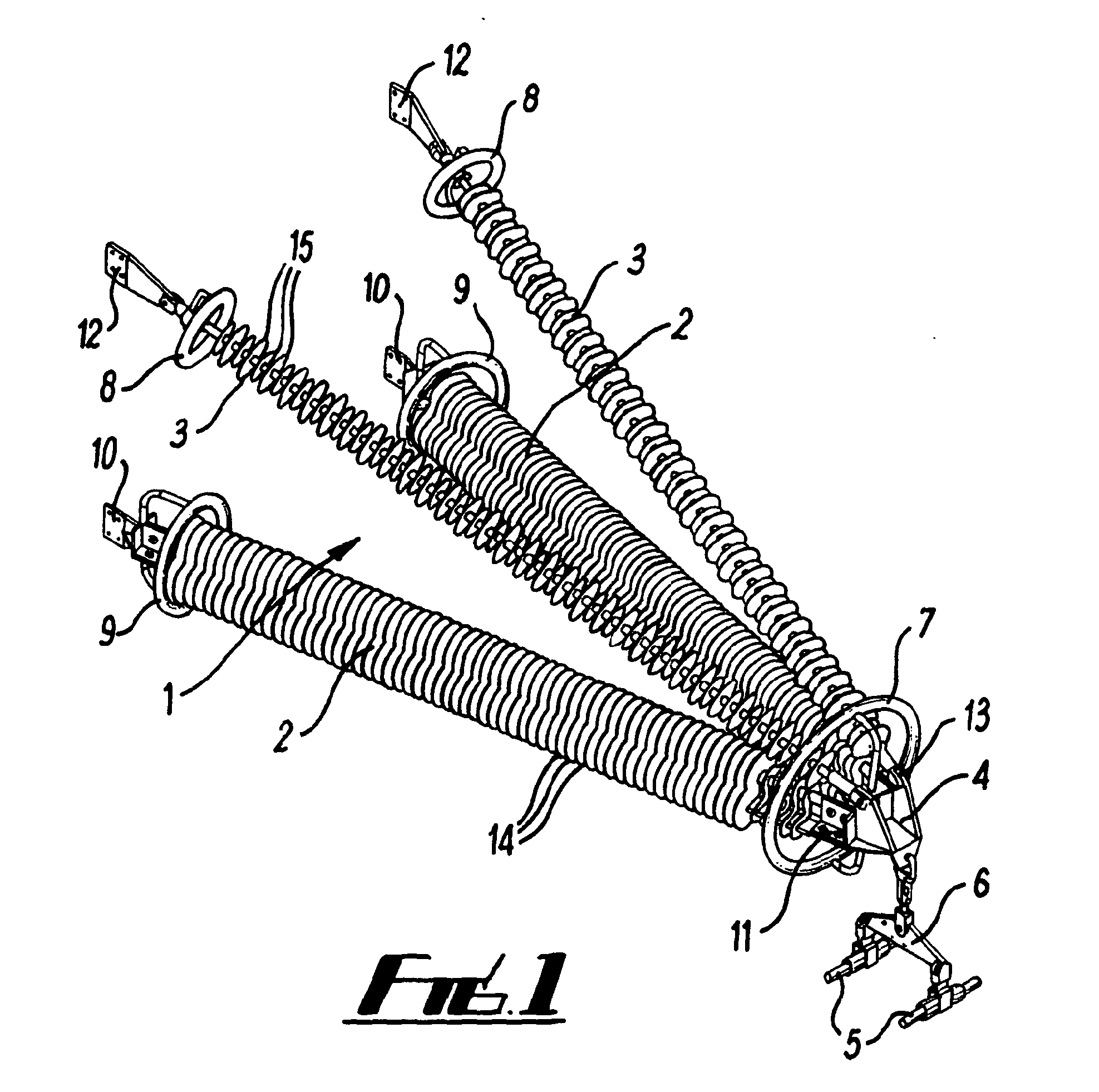

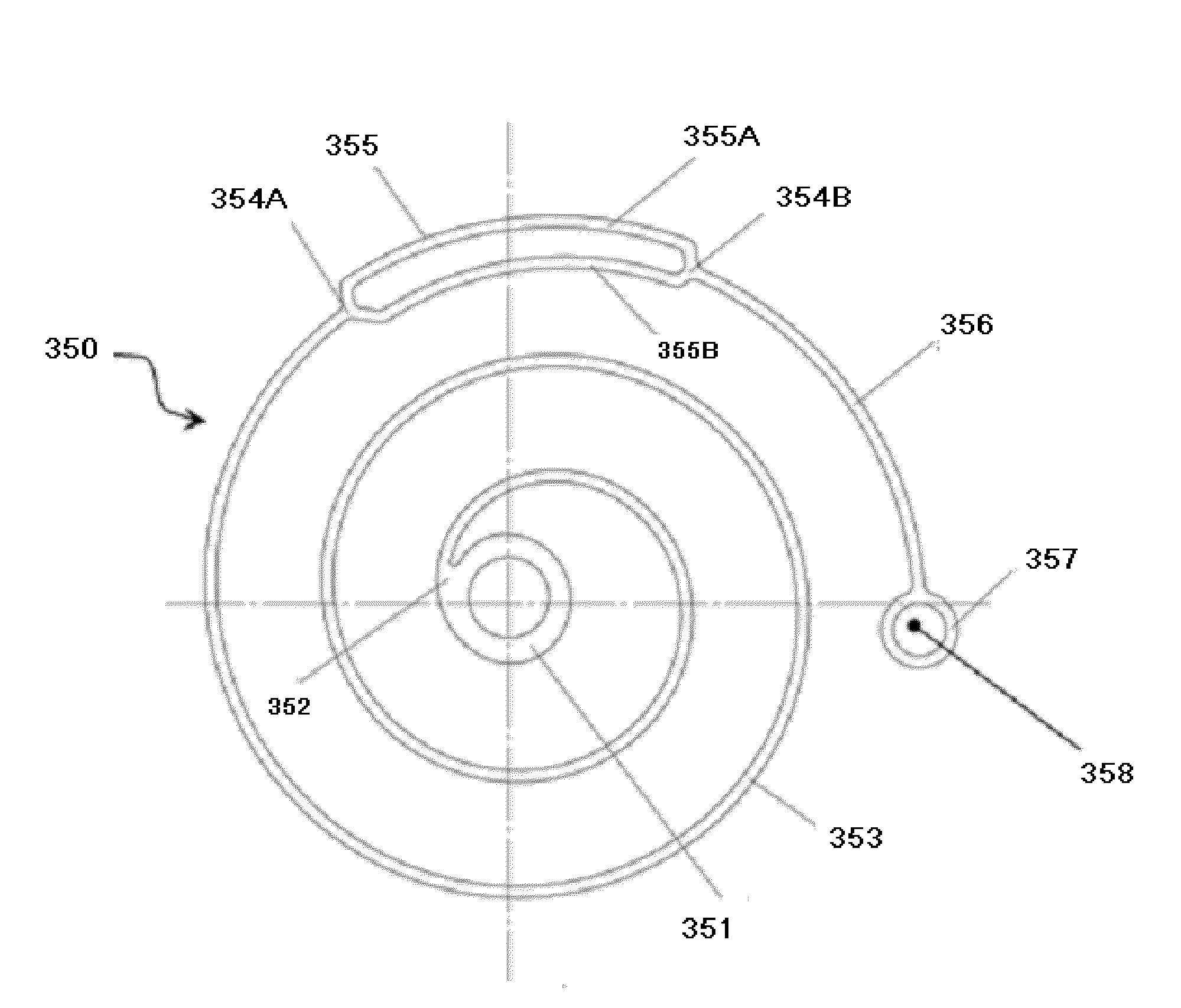

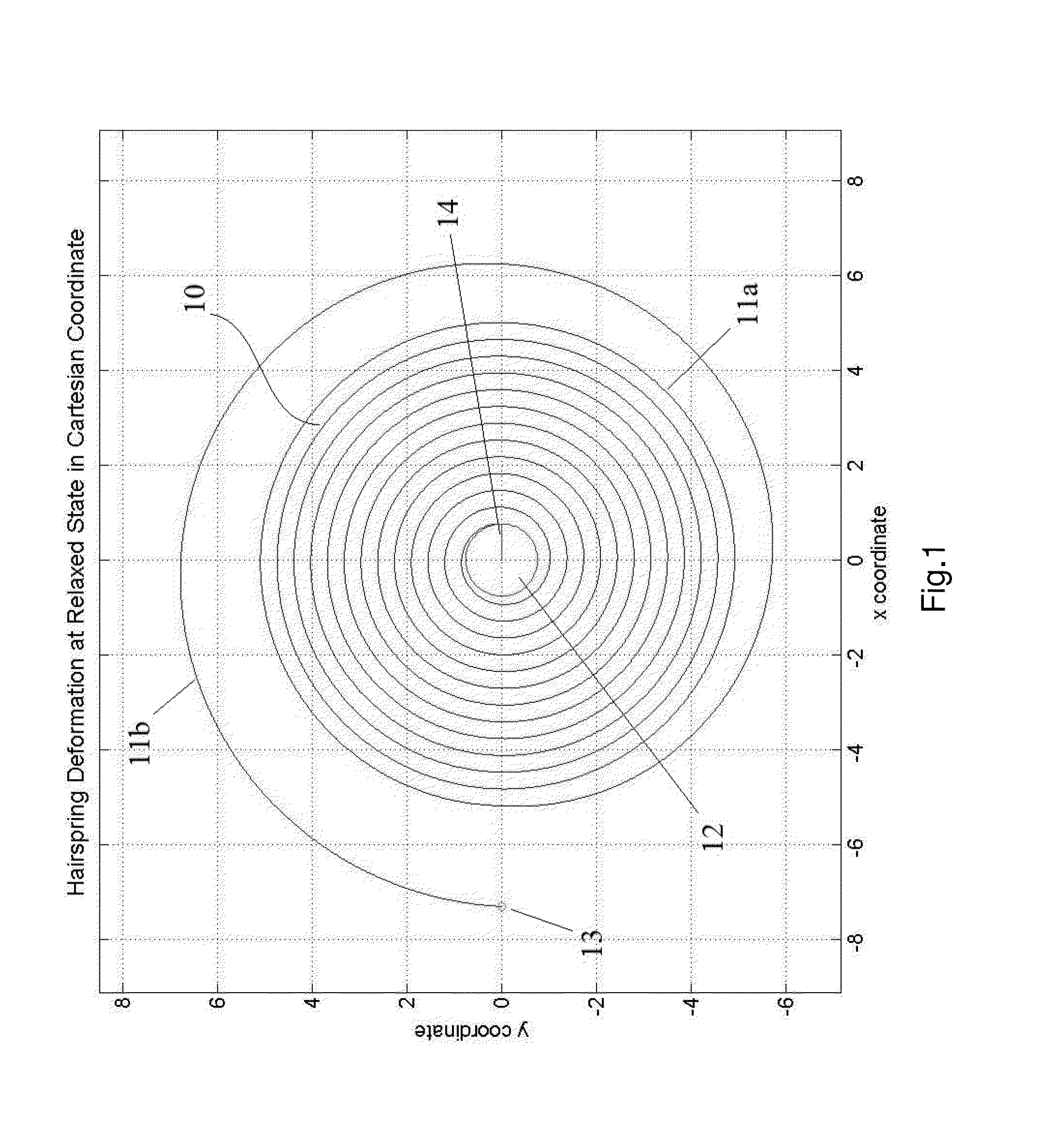

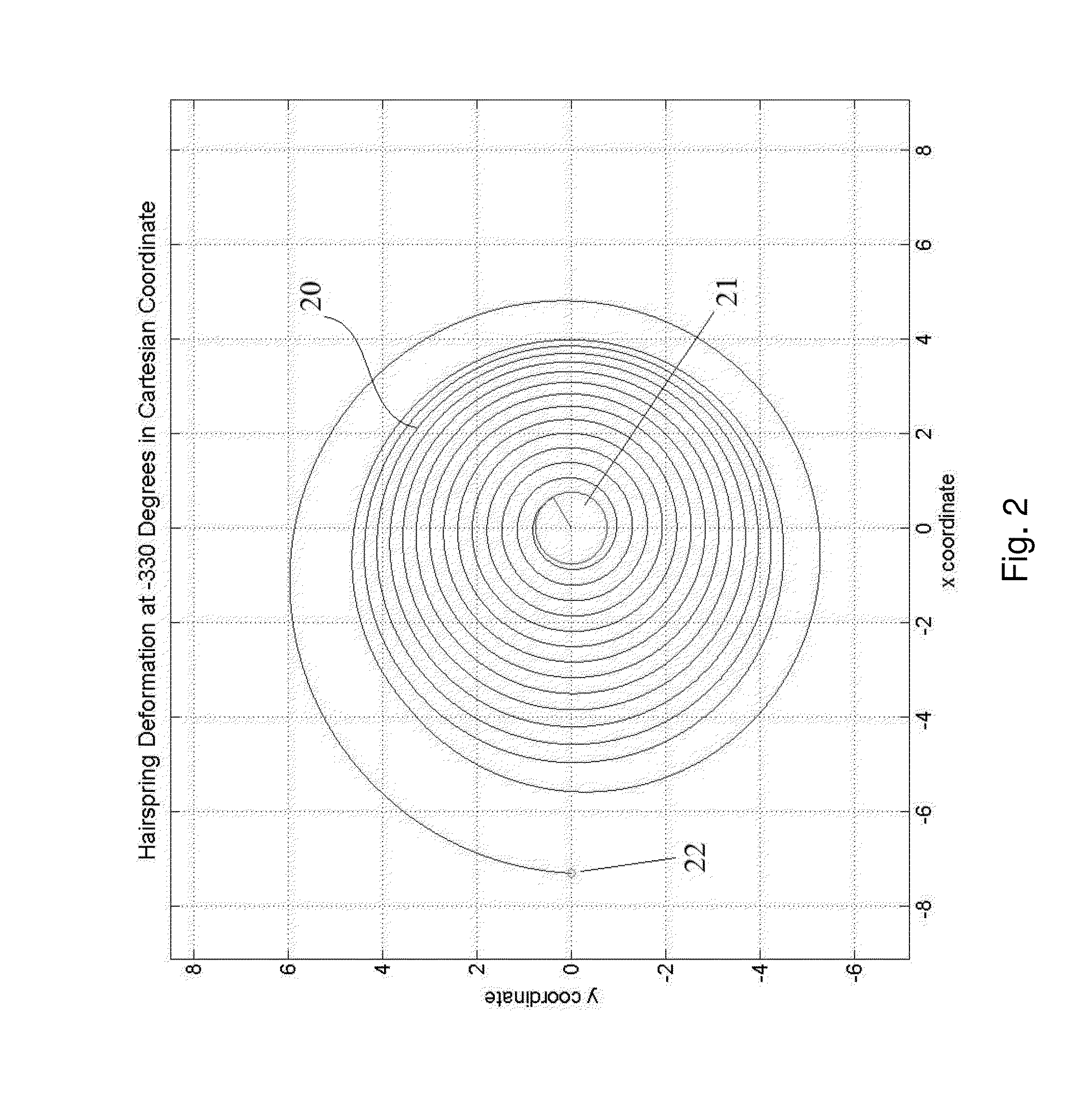

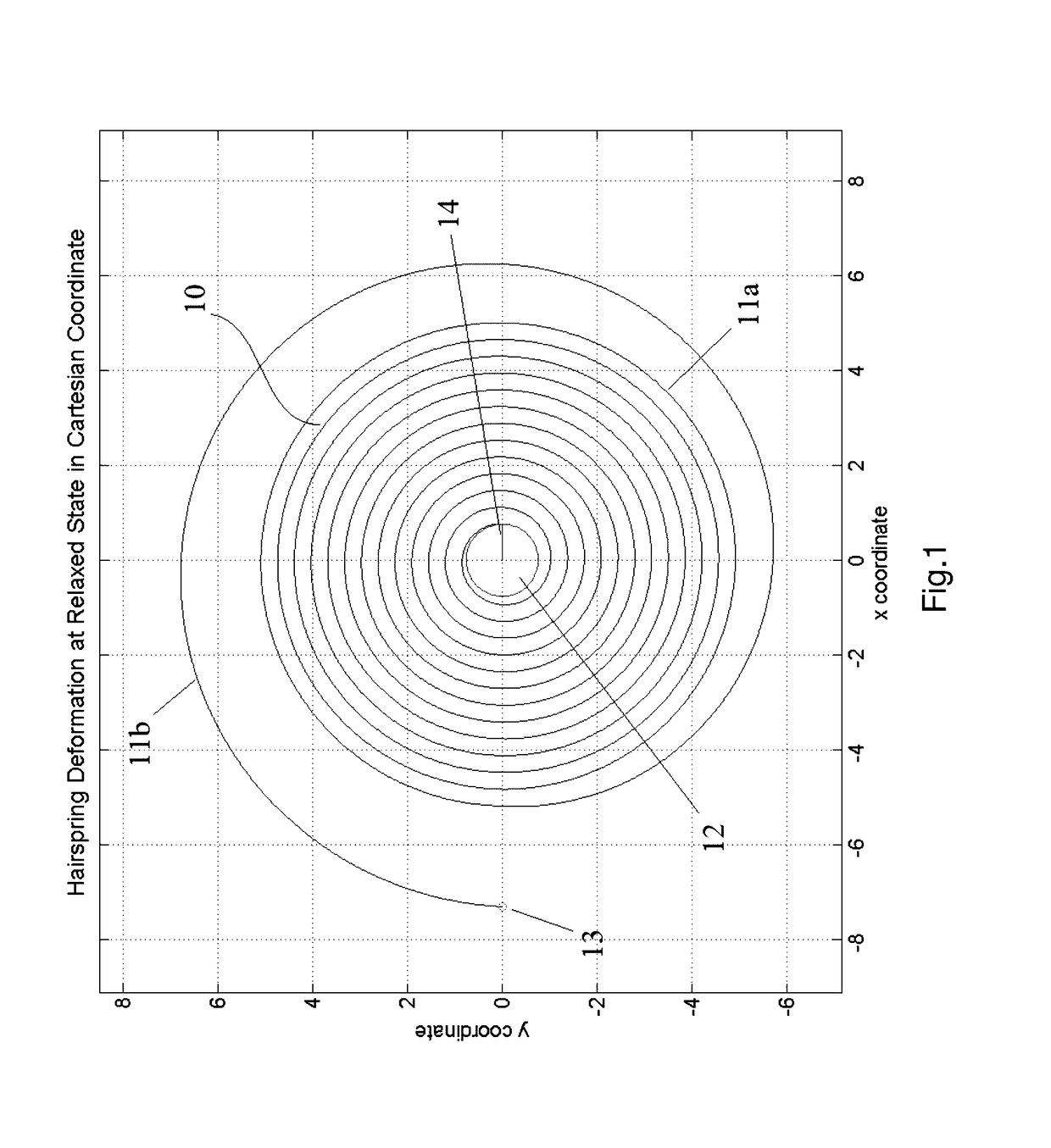

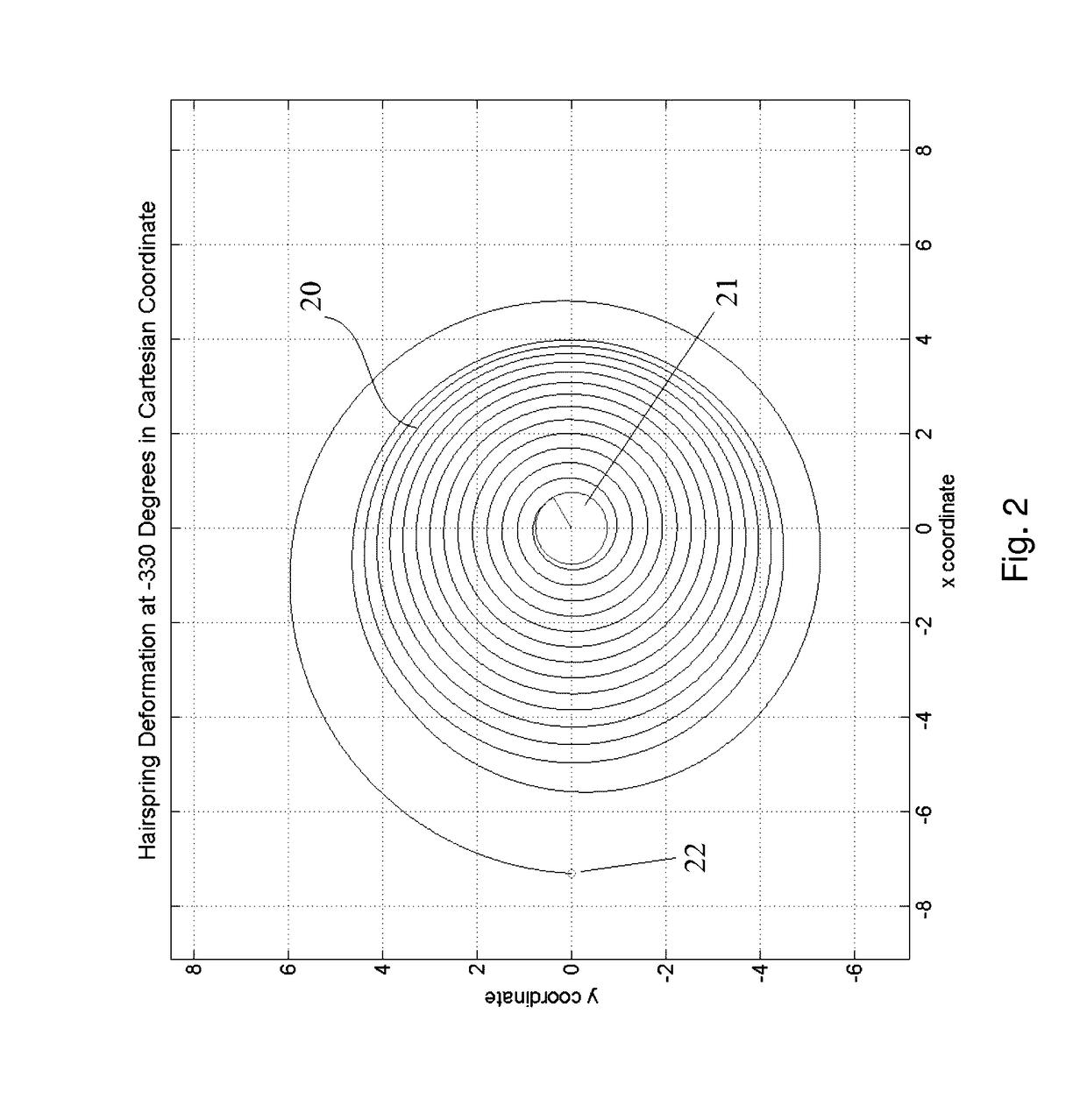

Hairspring for a time piece and hairspring design for concentricity

ActiveUS20140022873A1Easy to manufactureFrequency stabilisation mechanismRepair toolsEngineeringBending stiffness

A method of increasing concentricity in use of a spiral hairspring mechanical timepiece; the hairspring having an inner terminal end portion for engagement with a collet, an outer terminal end portion for engagement with a stud, a first limb portion extending from the inner terminal end portion towards the outer terminal end portion, and a stiffening portion positioned at the outer turn of the hairspring and having a cross-sectional second moment of area different to that of the first limb portion such that bending stiffness of the stiffening portion has a greater bending stiffness than the single limb portion. The method includes modifying cross-sectional second moments of an area of the first limb portion and the stiffening portion by minimizing a cost function throughout the amplitude of the rotation of hairspring in use, the cost function being correlated to the net concentricity of the hairspring.

Owner:MASTER DYNAMIC LTD

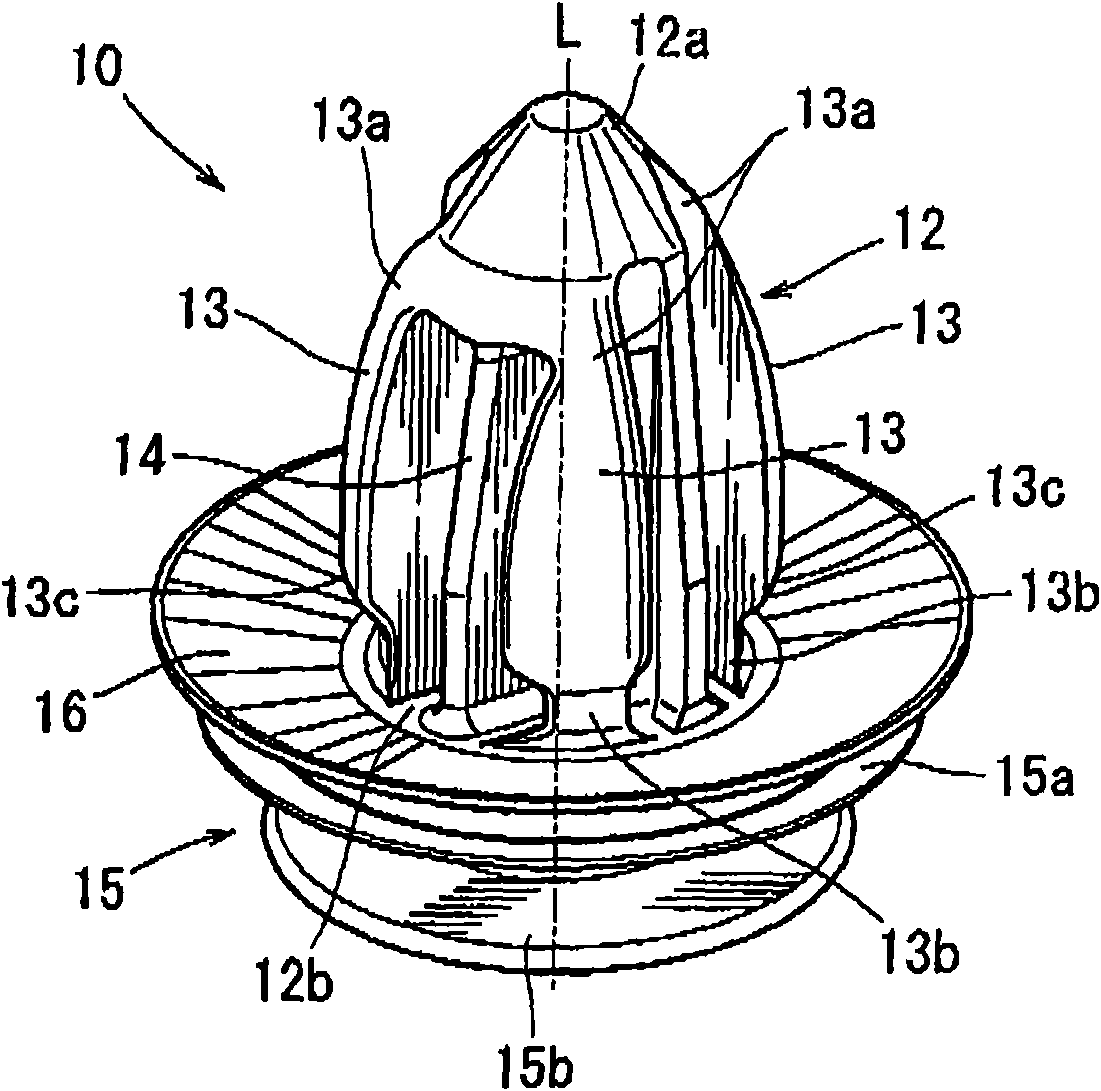

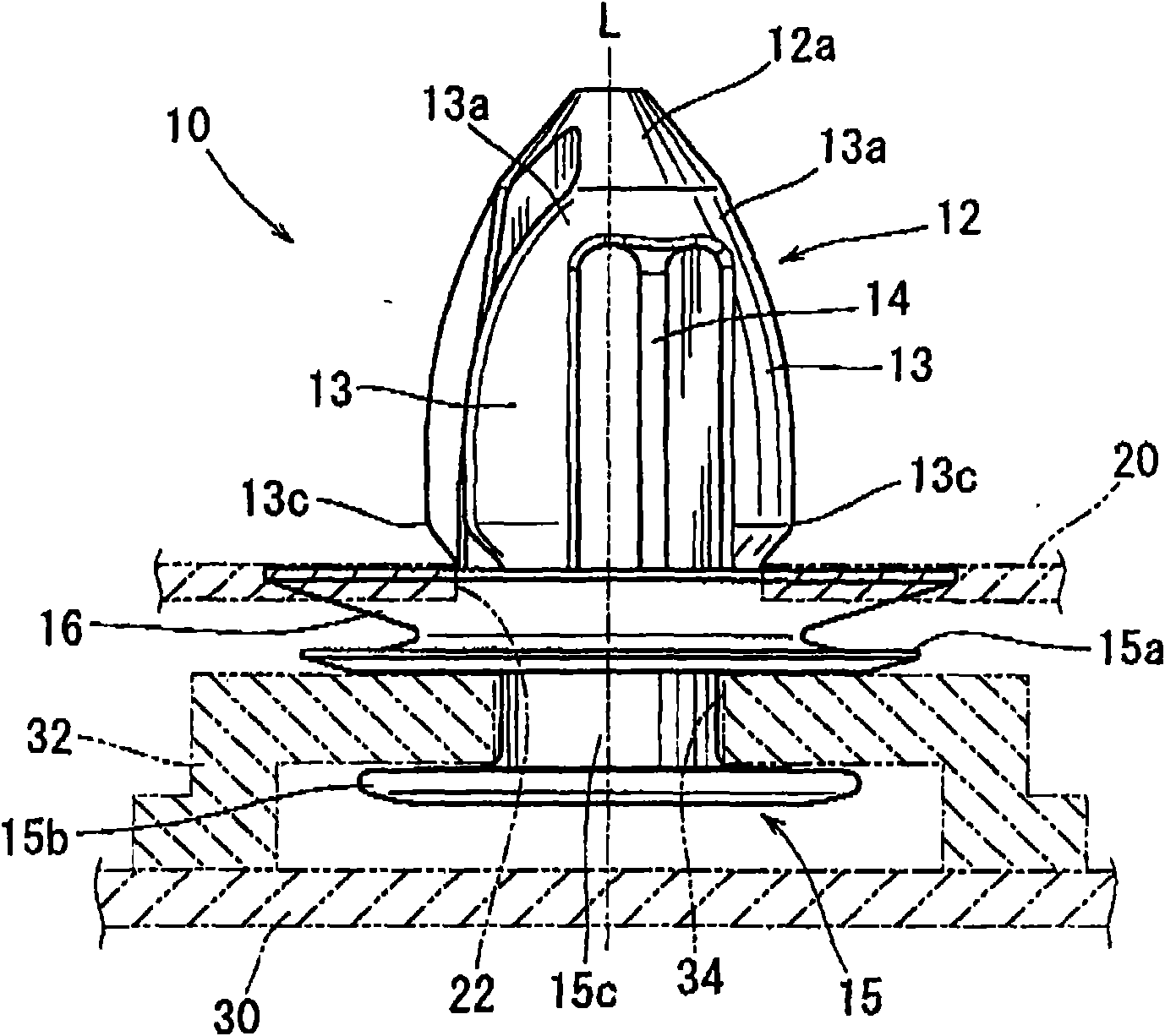

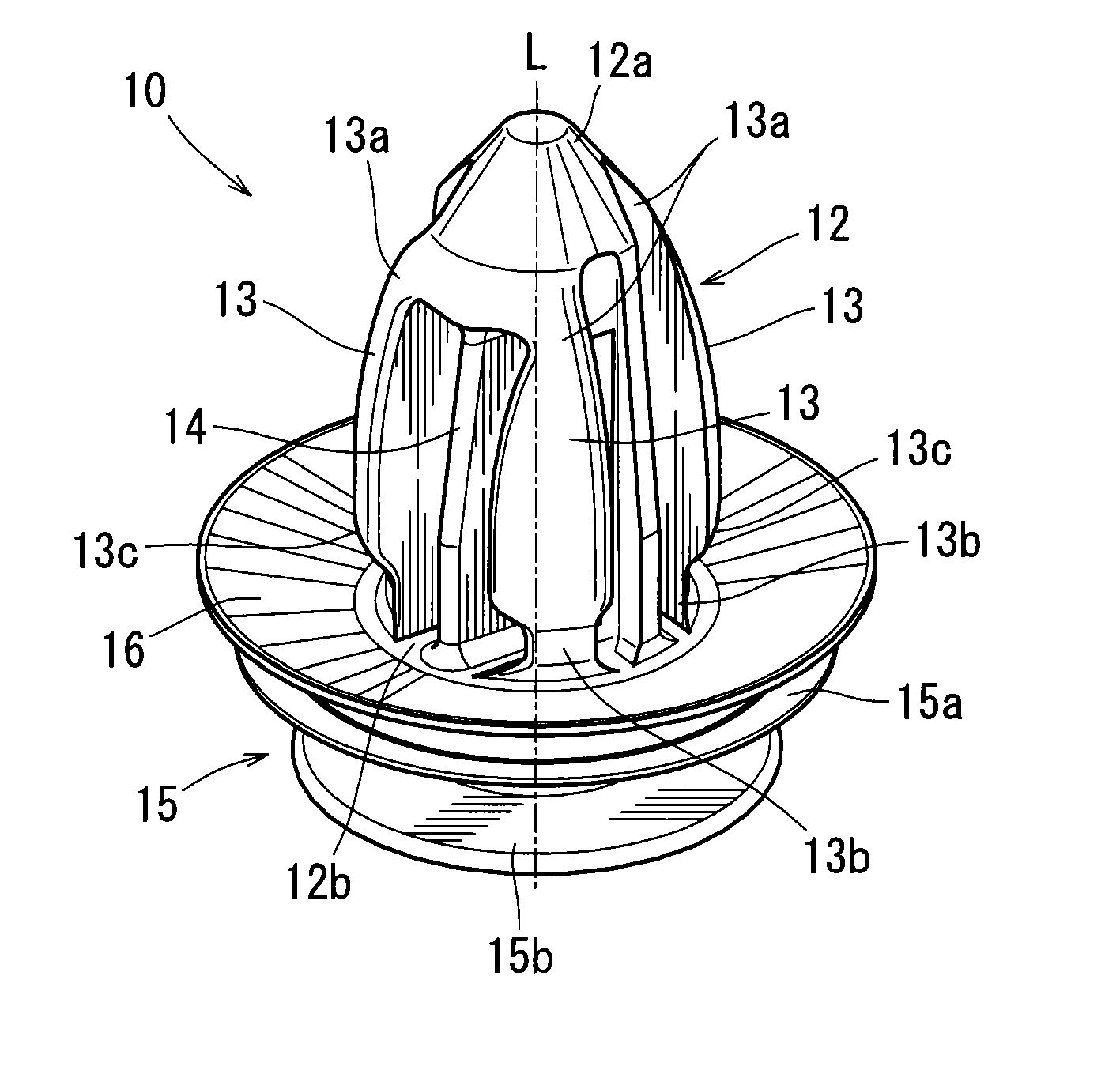

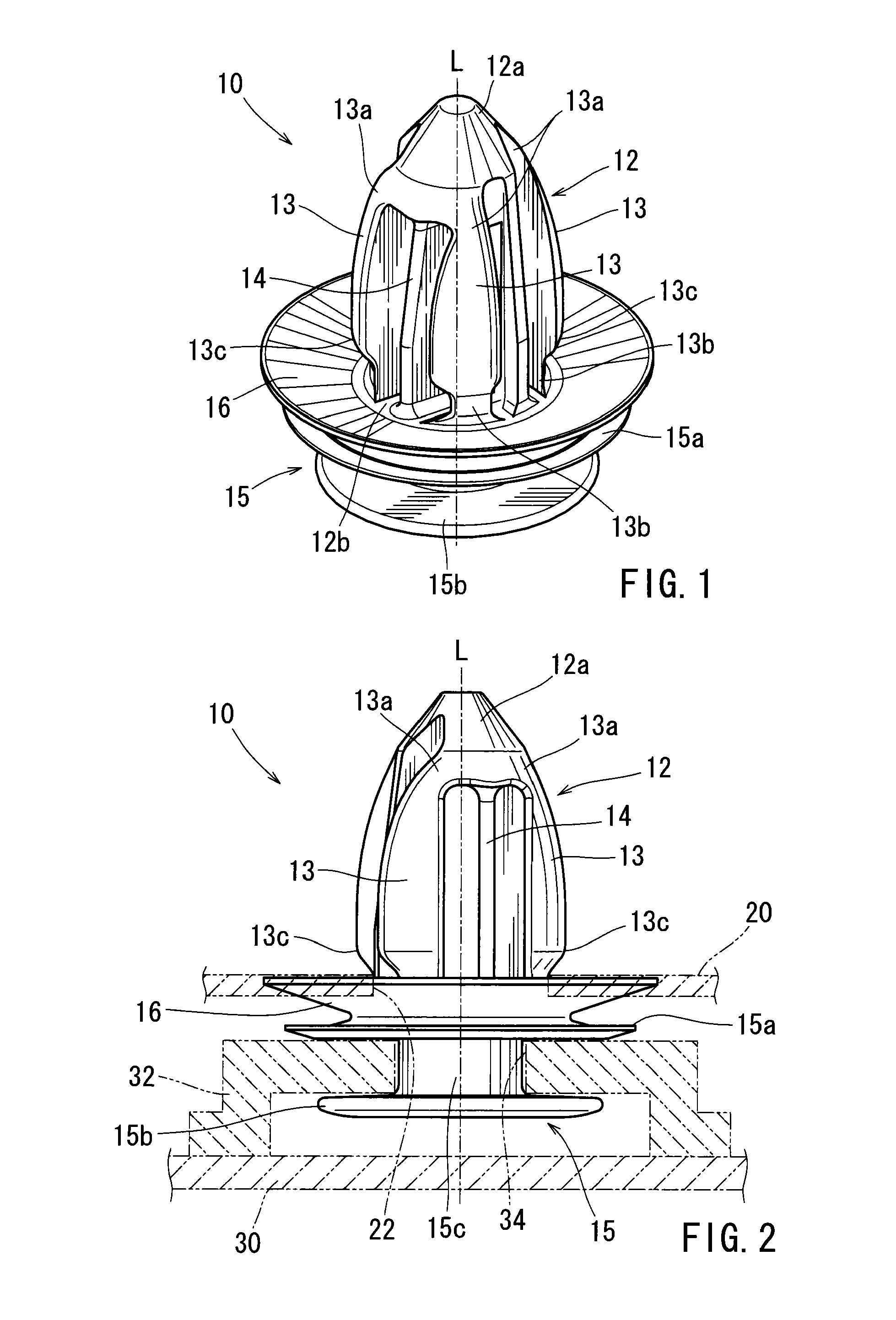

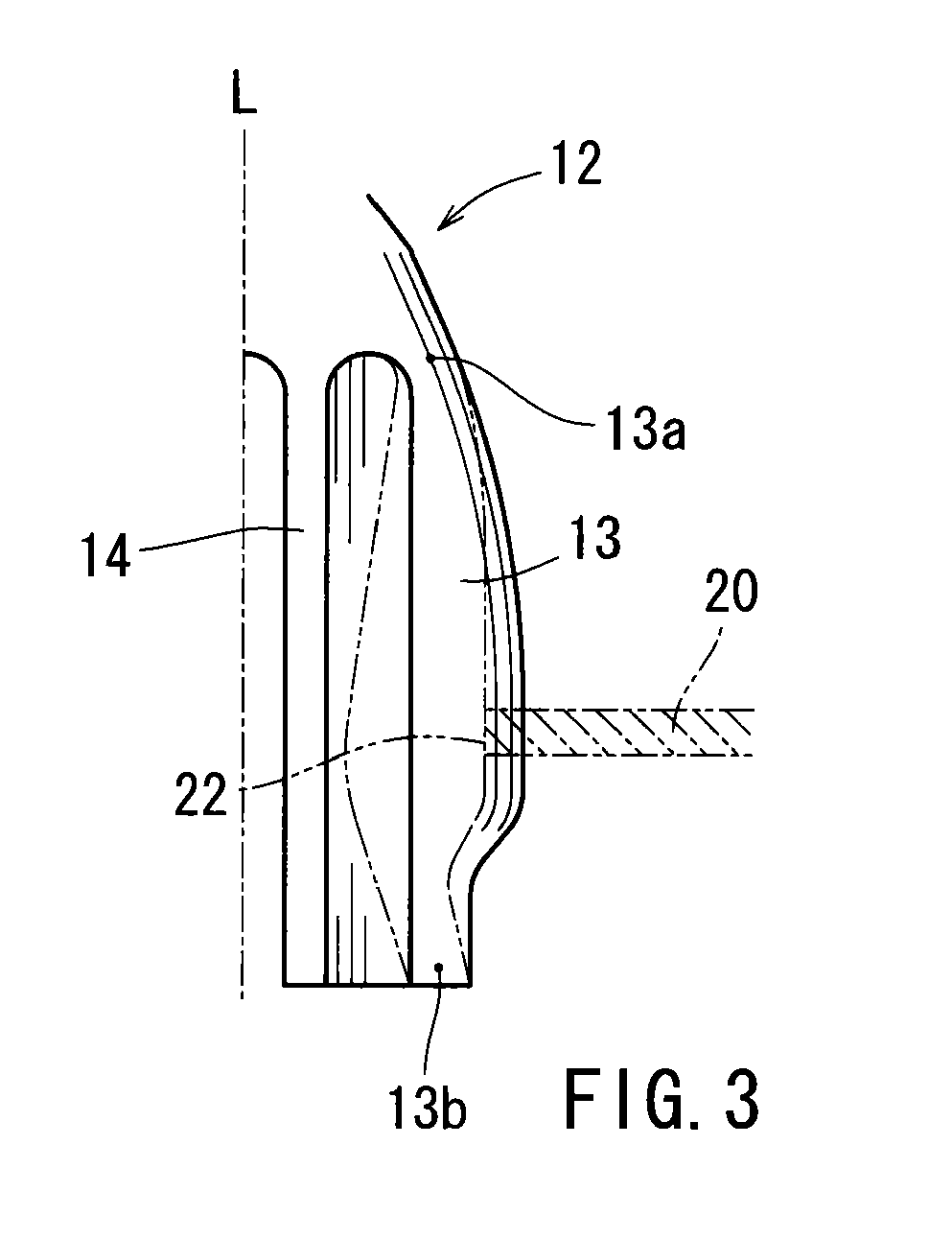

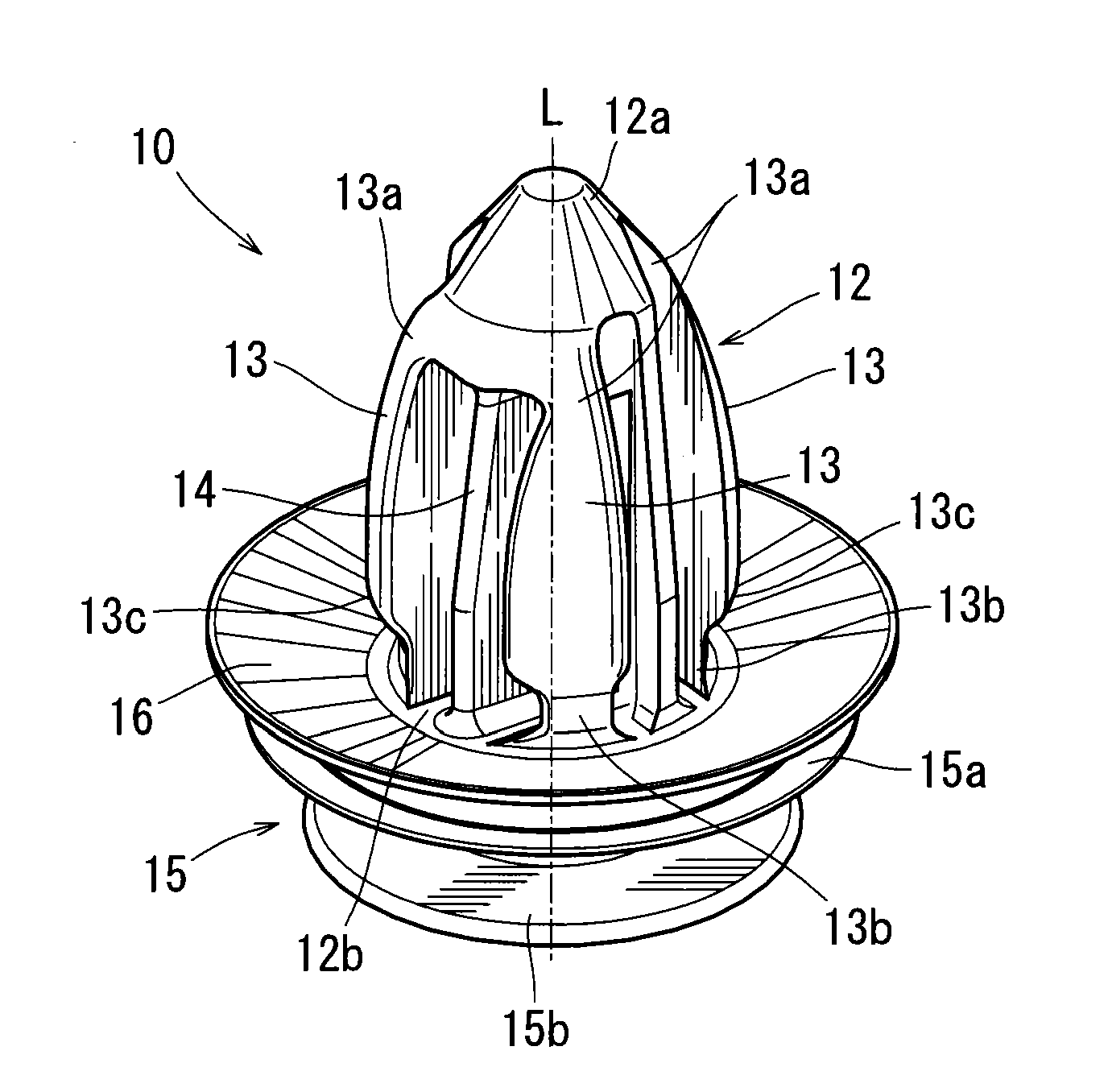

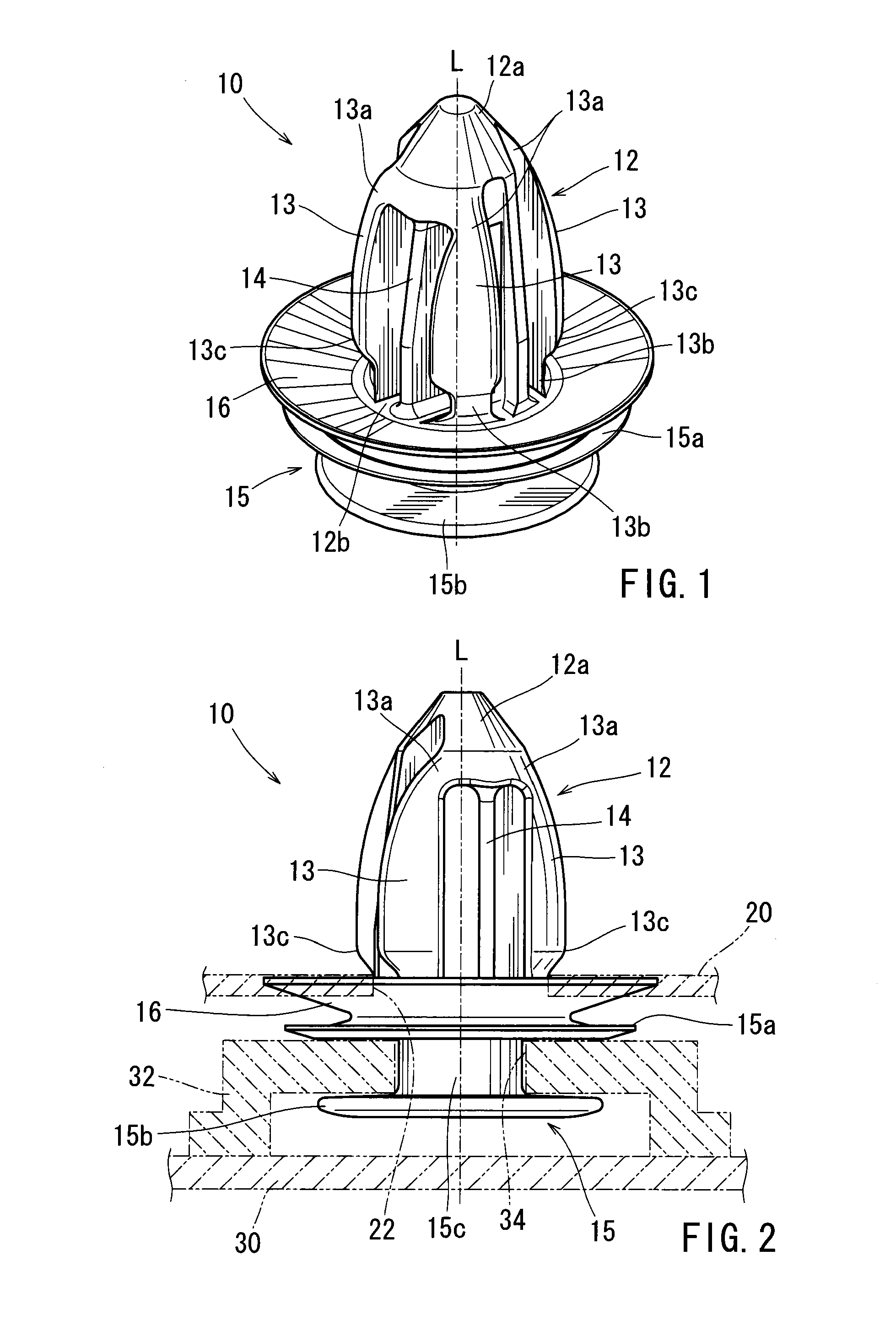

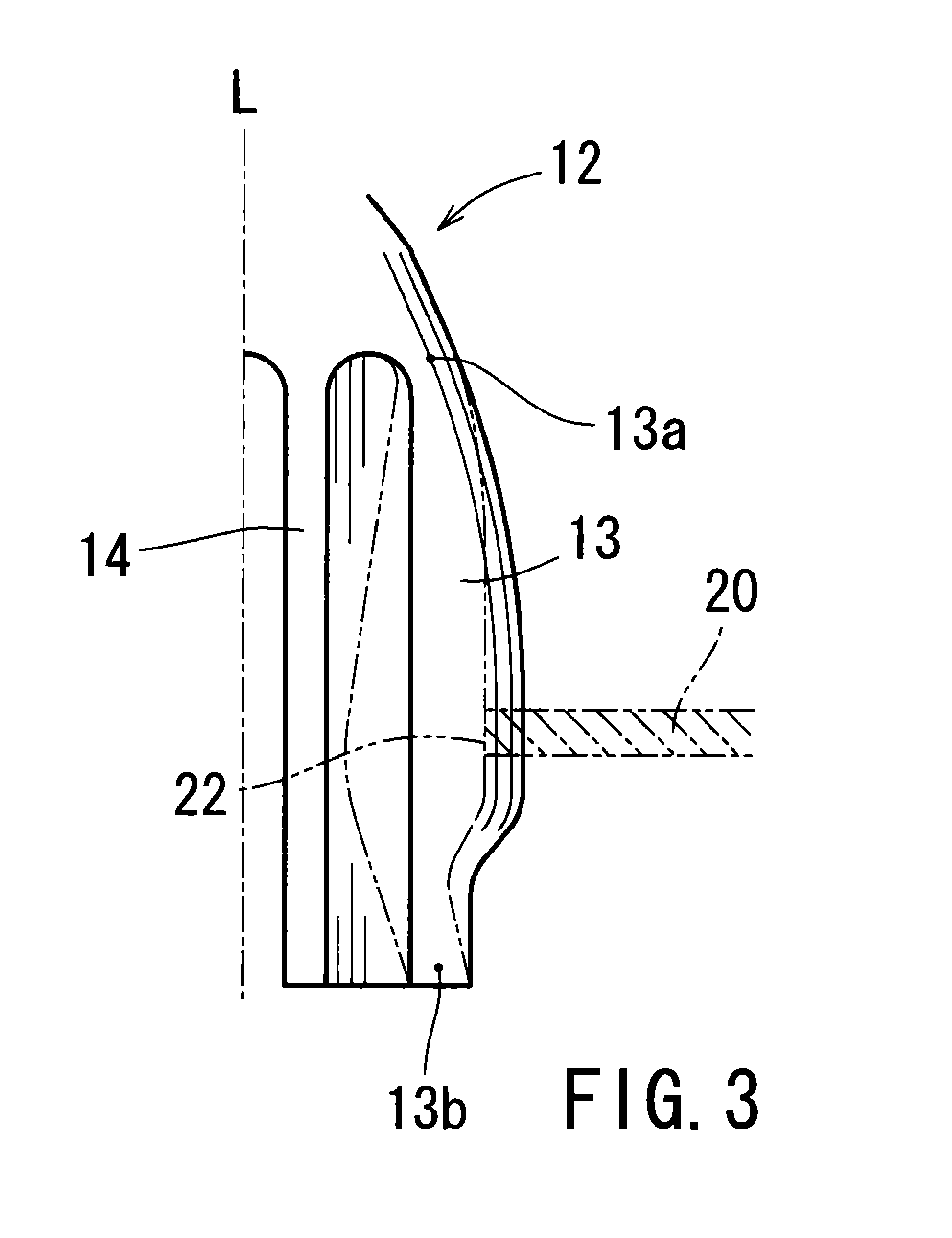

Clip

A clip may include an anchor portion having a plurality of flexible strips and at least one support strip. Each of the flexible strips is integrally connected to the at least one support strip only via a connecting portion corresponding to a distal end portion of the anchor portion and a connecting portion corresponding to a proximal end portion of the anchor portion. When the anchor portion is pushed into an insertion hole formed in a subject member, the anchor portion is inserted into the insertion hole while each of the flexible strips are flexed toward a longitudinal axis of the anchor portion. Each of the flexible strips is formed such that the difference between a second moment of area of the anchor distal end side connecting portion and a second moment of area of the anchor proximal end side connecting portion is 0-15%.

Owner:DAIWA KASEI IND CO LTD

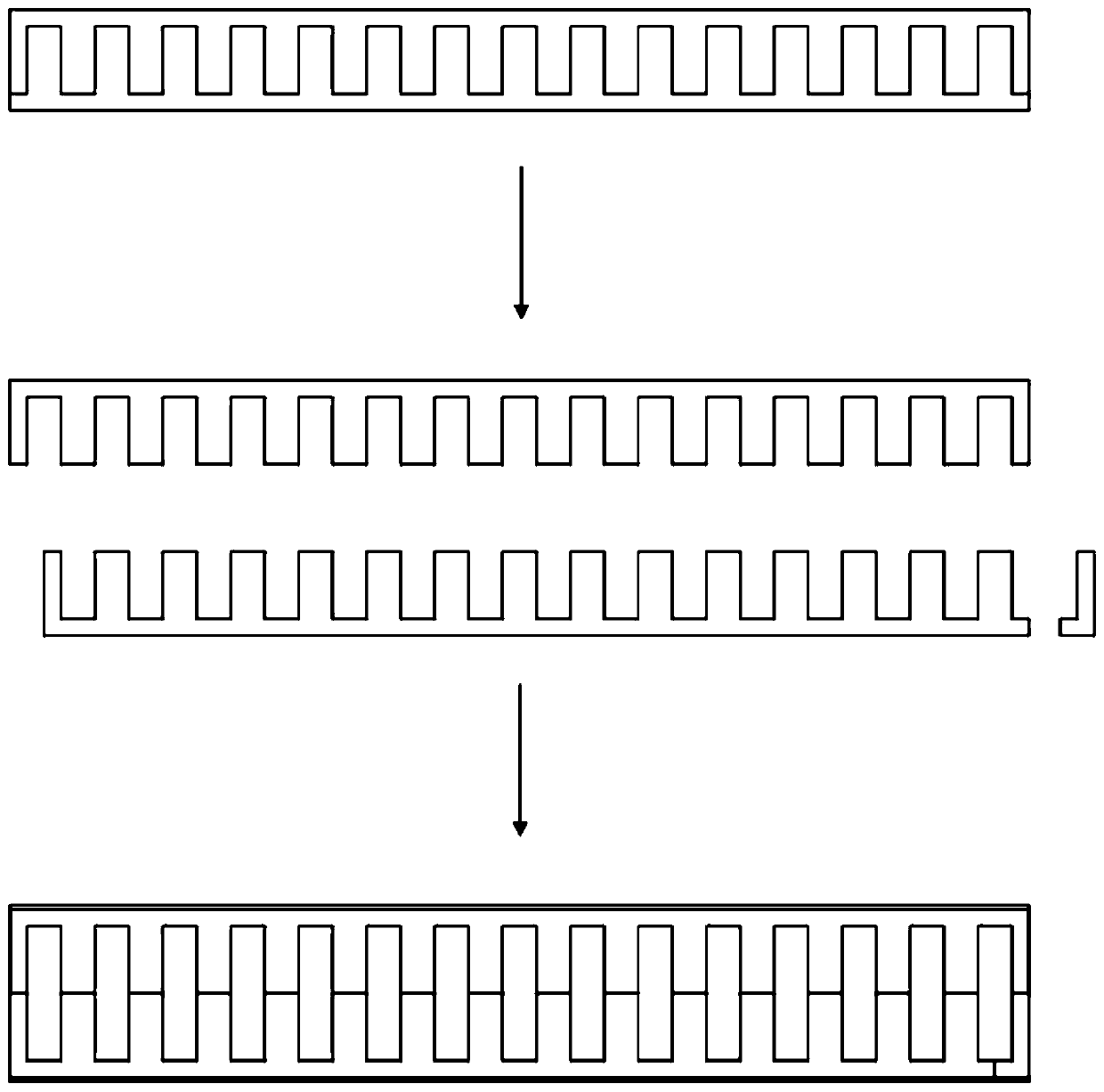

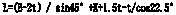

Opening method and device thereof

ActiveUS20150121985A1Controlled plastic deformationMetal-working feeding devicesFilament handlingYoung's modulusMetal sheet

An opening radial dimension is set as a radial direction permissible dimension K of the metal coil as expressed by the following equation or lower.K=Yp×Z2EIR2(Θ-sinΘcosΘ)Wherein: K is a radial direction permissible dimension at the load action point position in mm; Yp is a yield stress of the metal sheet, in kgf / mm2; Z is a section modulus of the metal sheet, in mm3; R=(a metal coil radius r)−½(the plate thickness t of the metal sheet), in mm; E is a Young's modulus of the metal sheet, in kgf / mm2; I is a second moment of area of the metal sheet in mm4; and Θ is an angle in radians about the axis of the metal coil from the load action point to the nearest restraining roll along a rewind direction of the metal coil.

Owner:NIPPON STEEL CORP

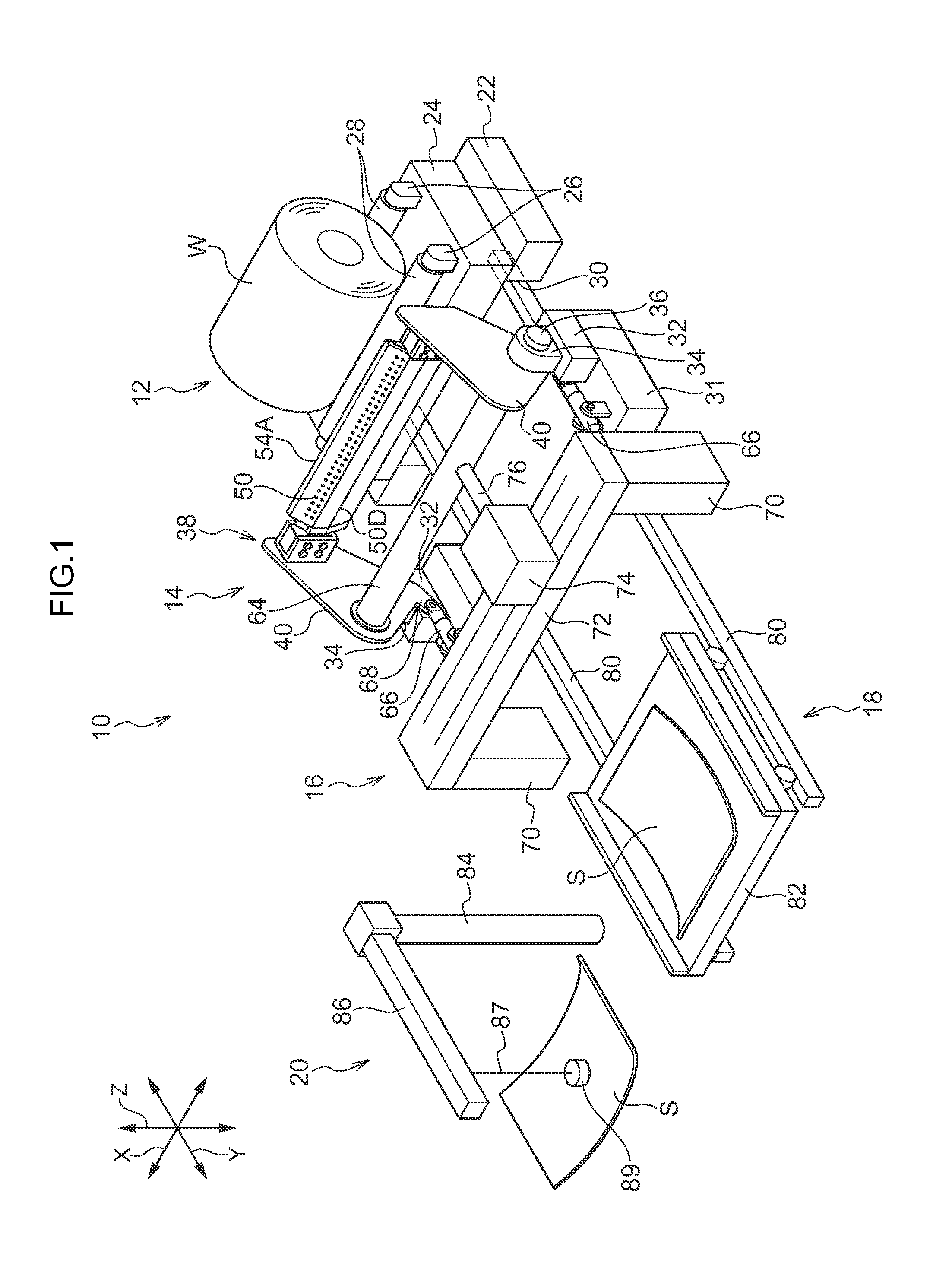

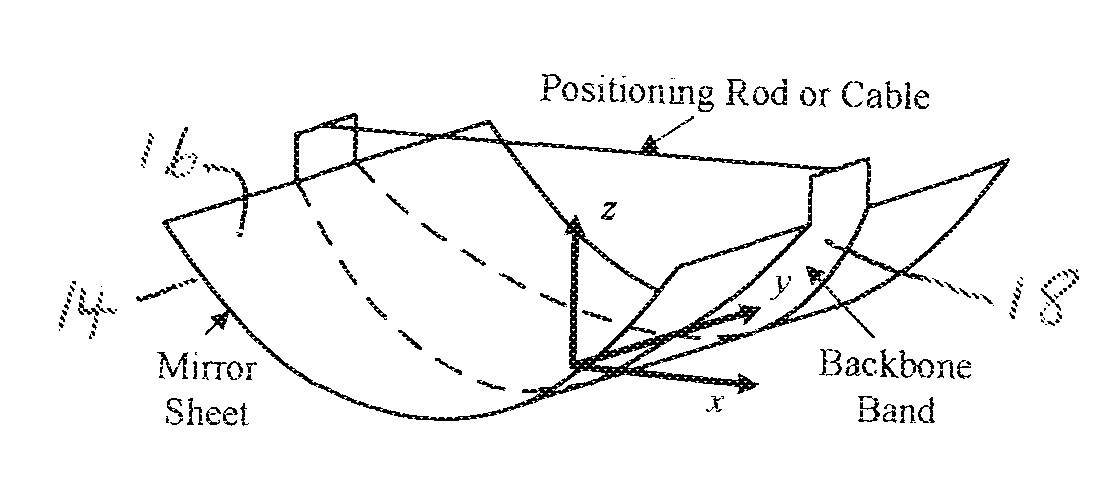

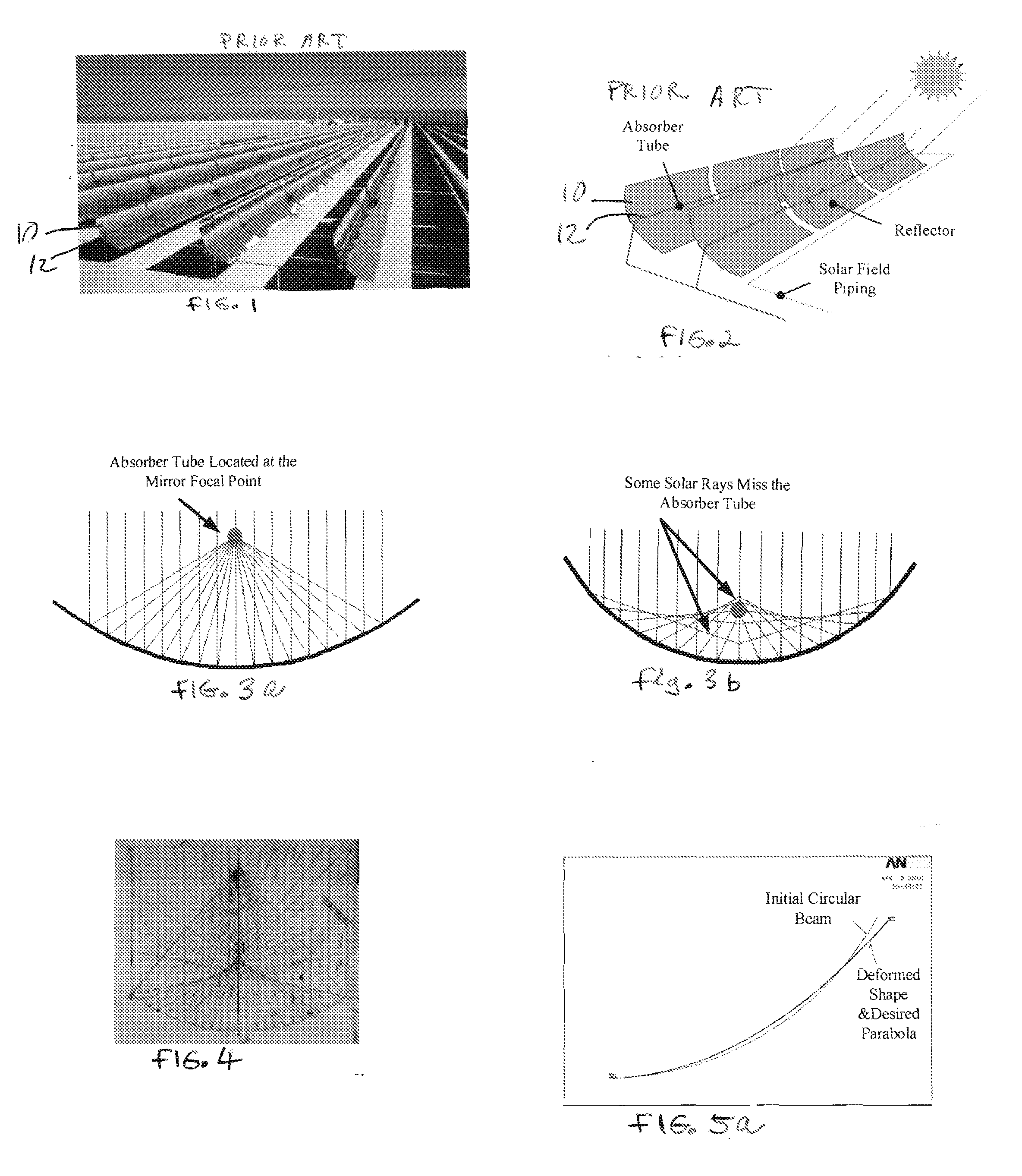

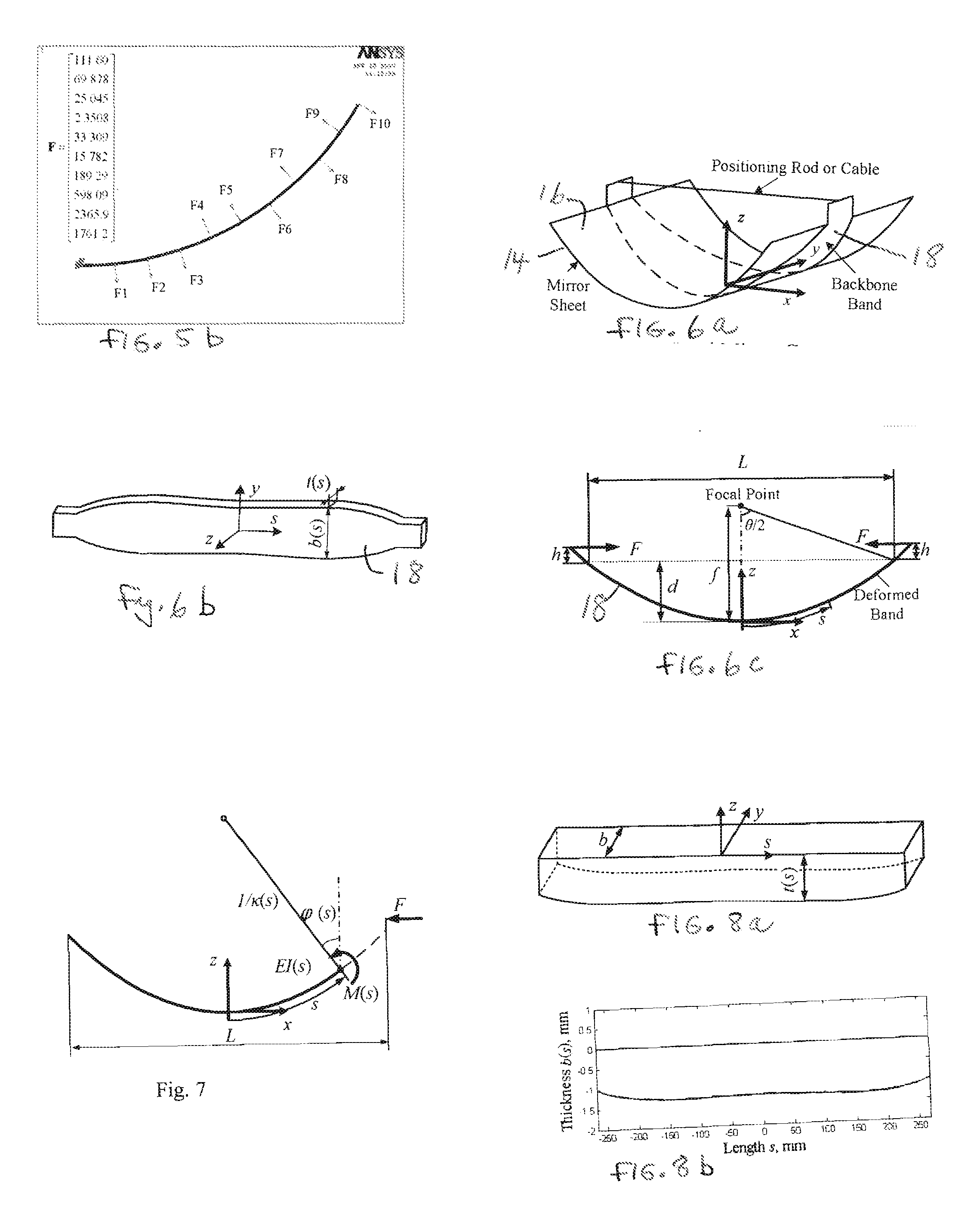

Precision parabolic mirror structures

Parabolic Mirror. The mirror includes a flexible material with a reflective surface and a rear surface. A flexible band is in contact with the rear surface of the flexible material. The bending stiffness of the band as a function of distance along its length is selected so that the band and the flexible material in contact therewith assume a parabolic shape when ends of the band are moved toward one another. In a preferred embodiment, the bending stiffness of the band is achieved by controlling the second moment of area of the band along its length. The second moment of area may be adjusted by altering the width of the band along its length or by altering the thickness of the band along its length, or a combination of the two.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

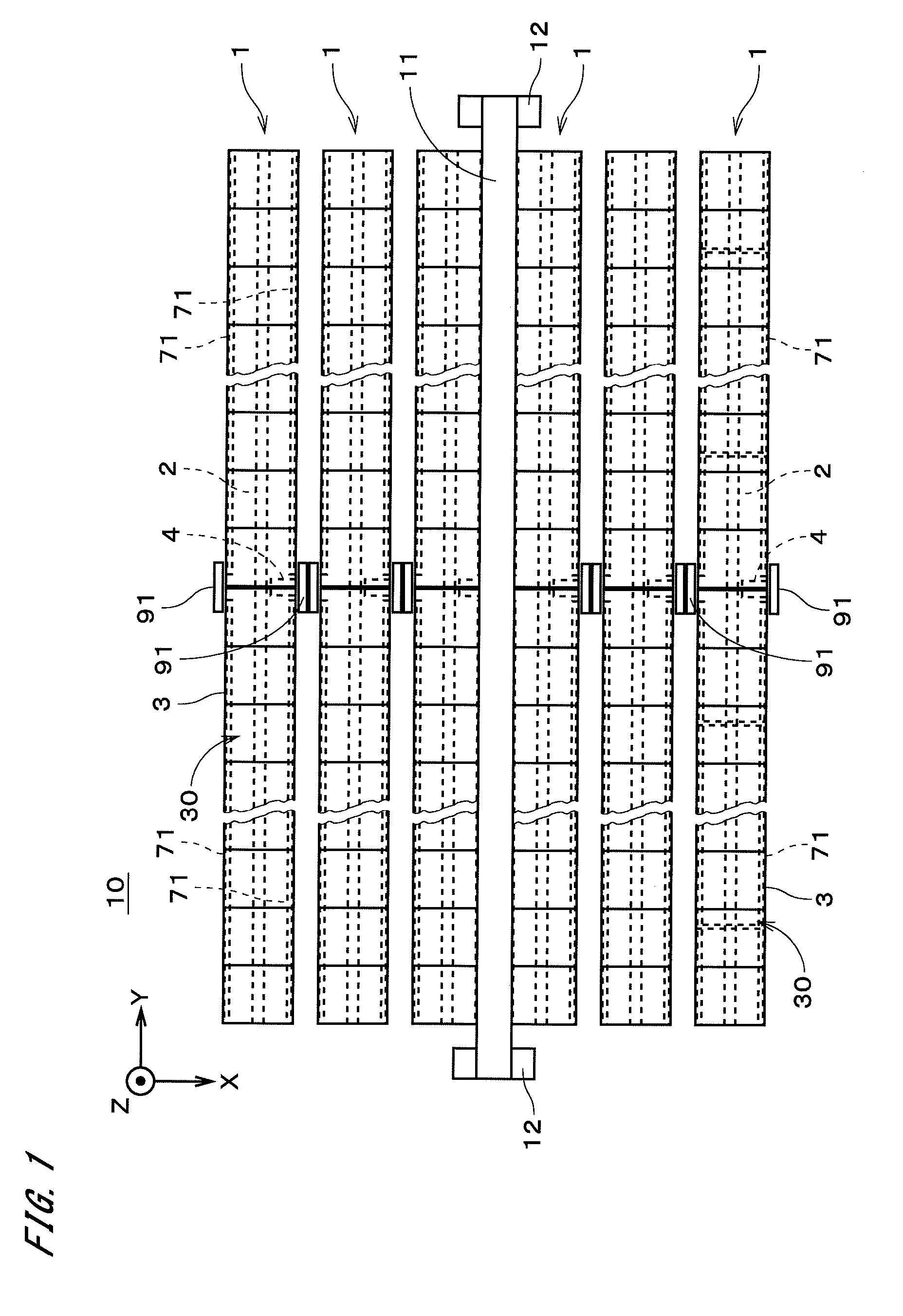

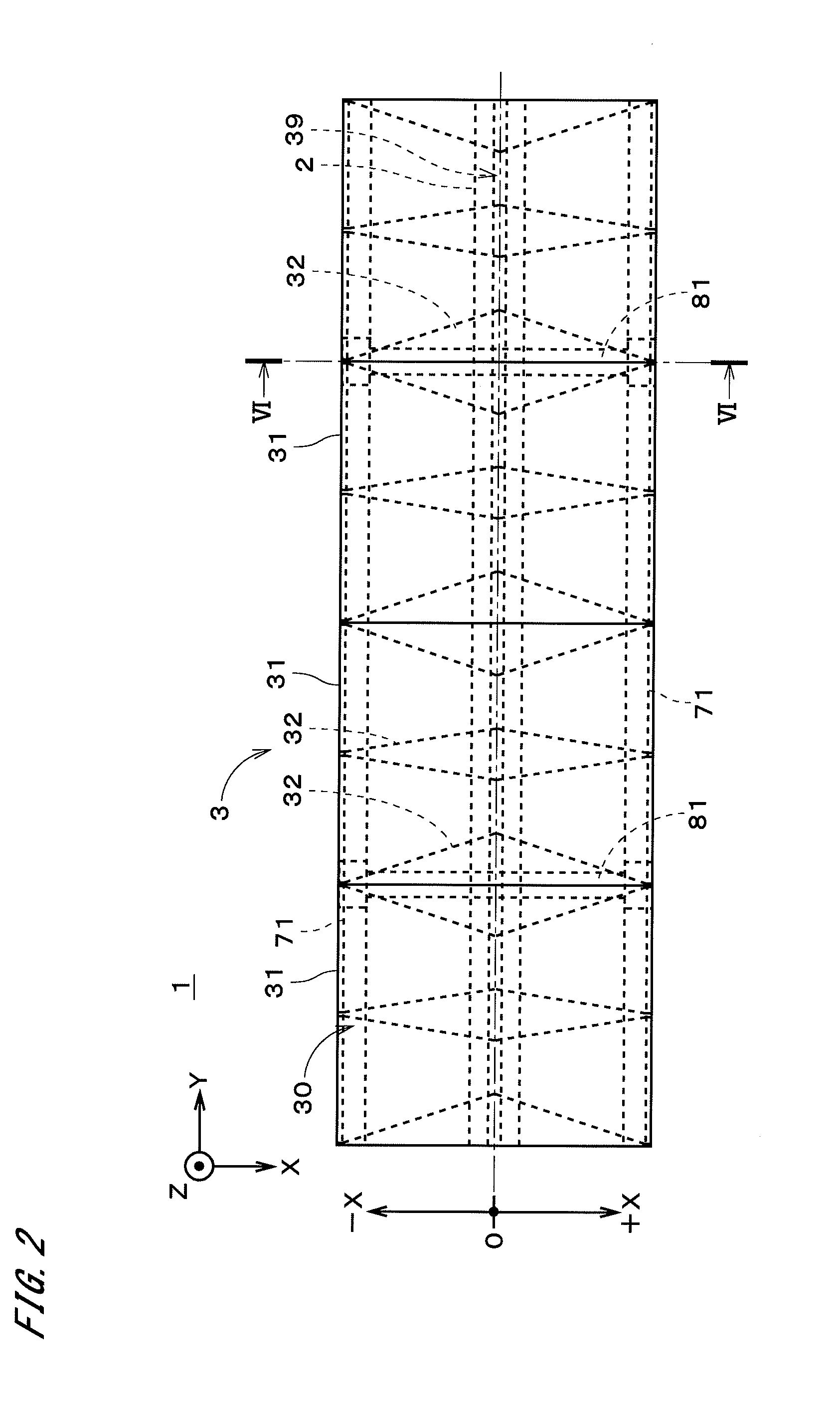

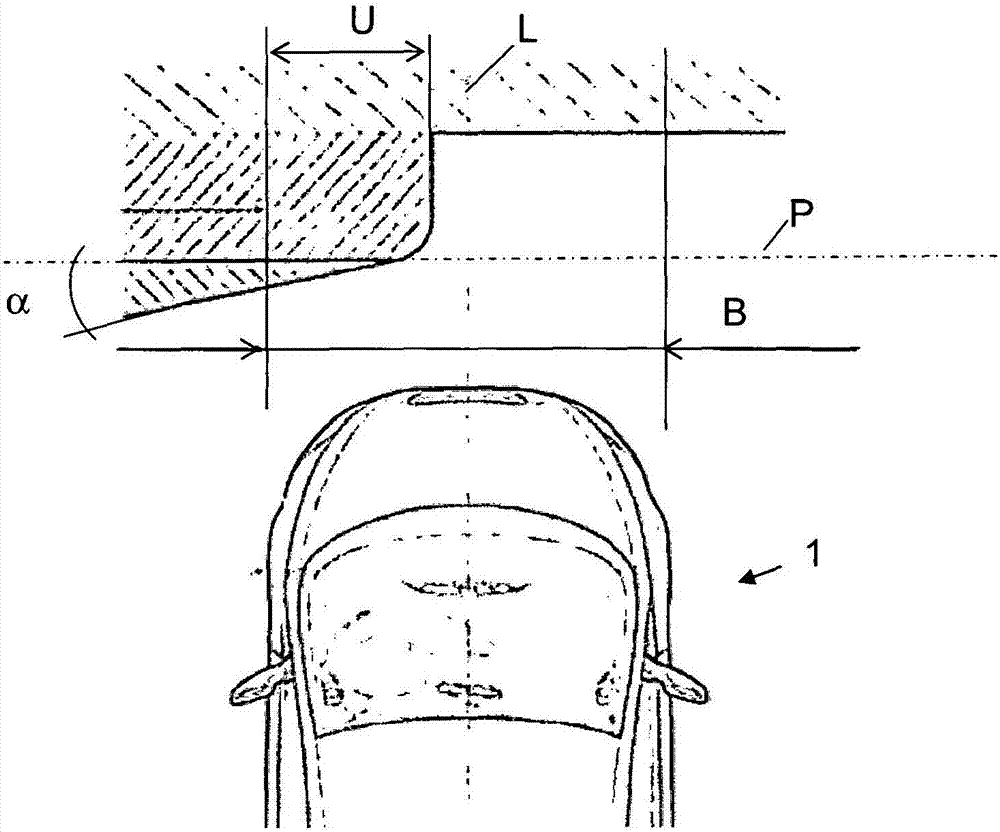

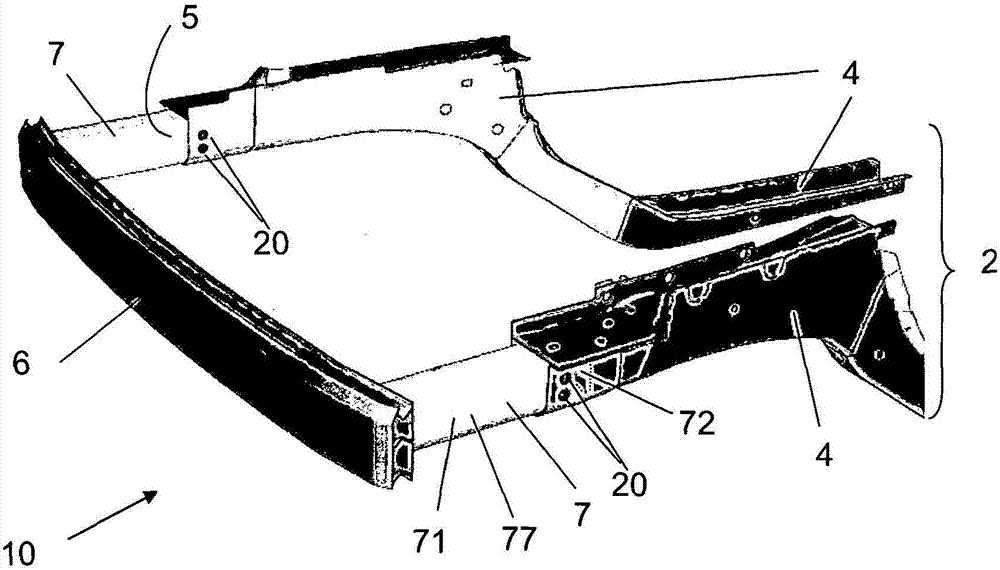

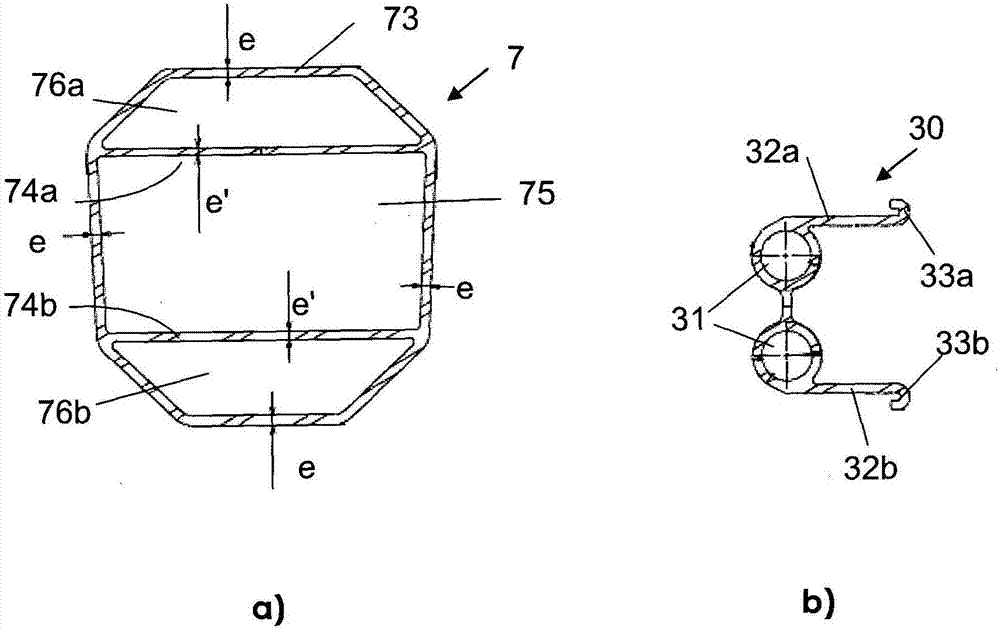

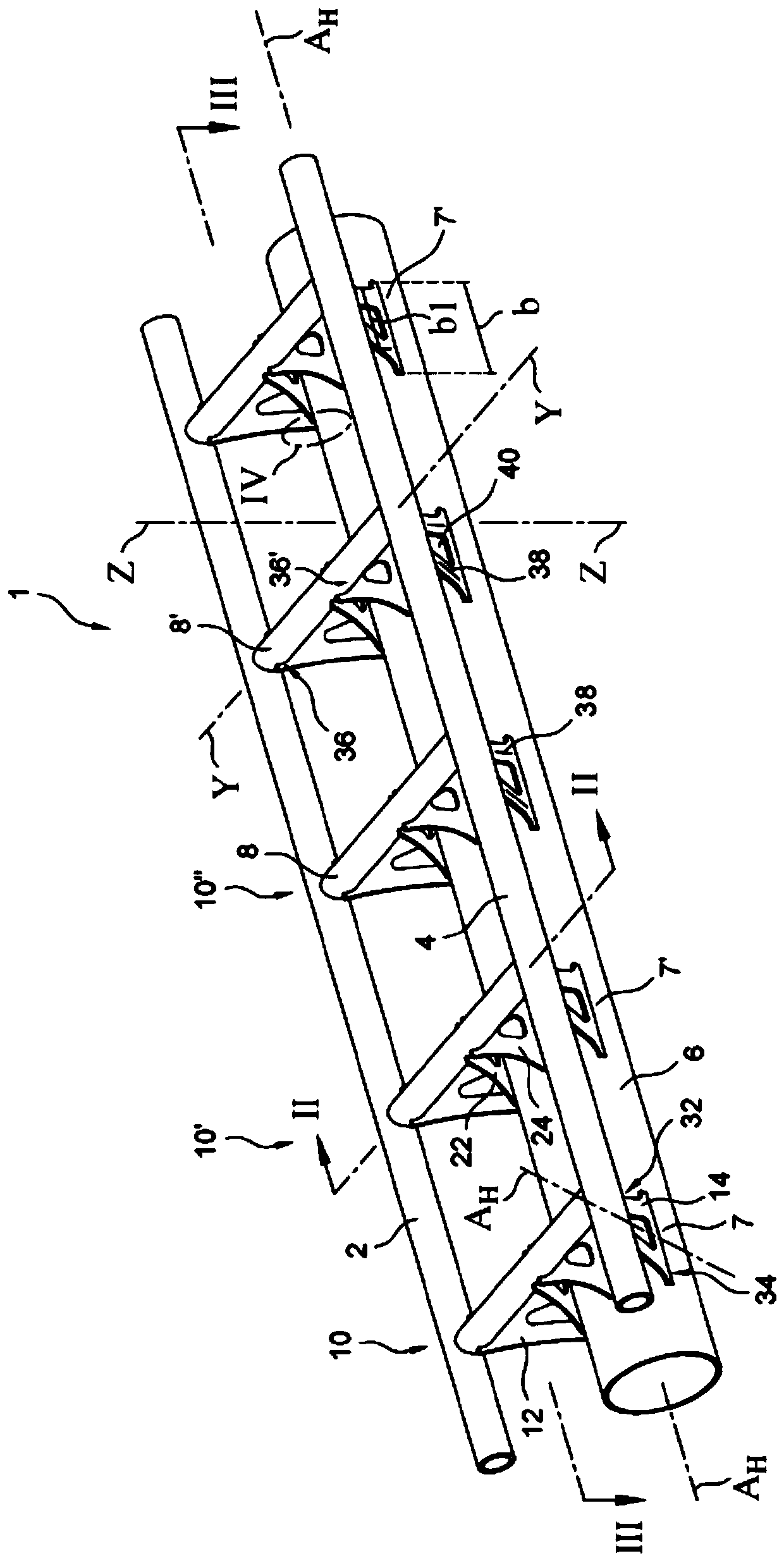

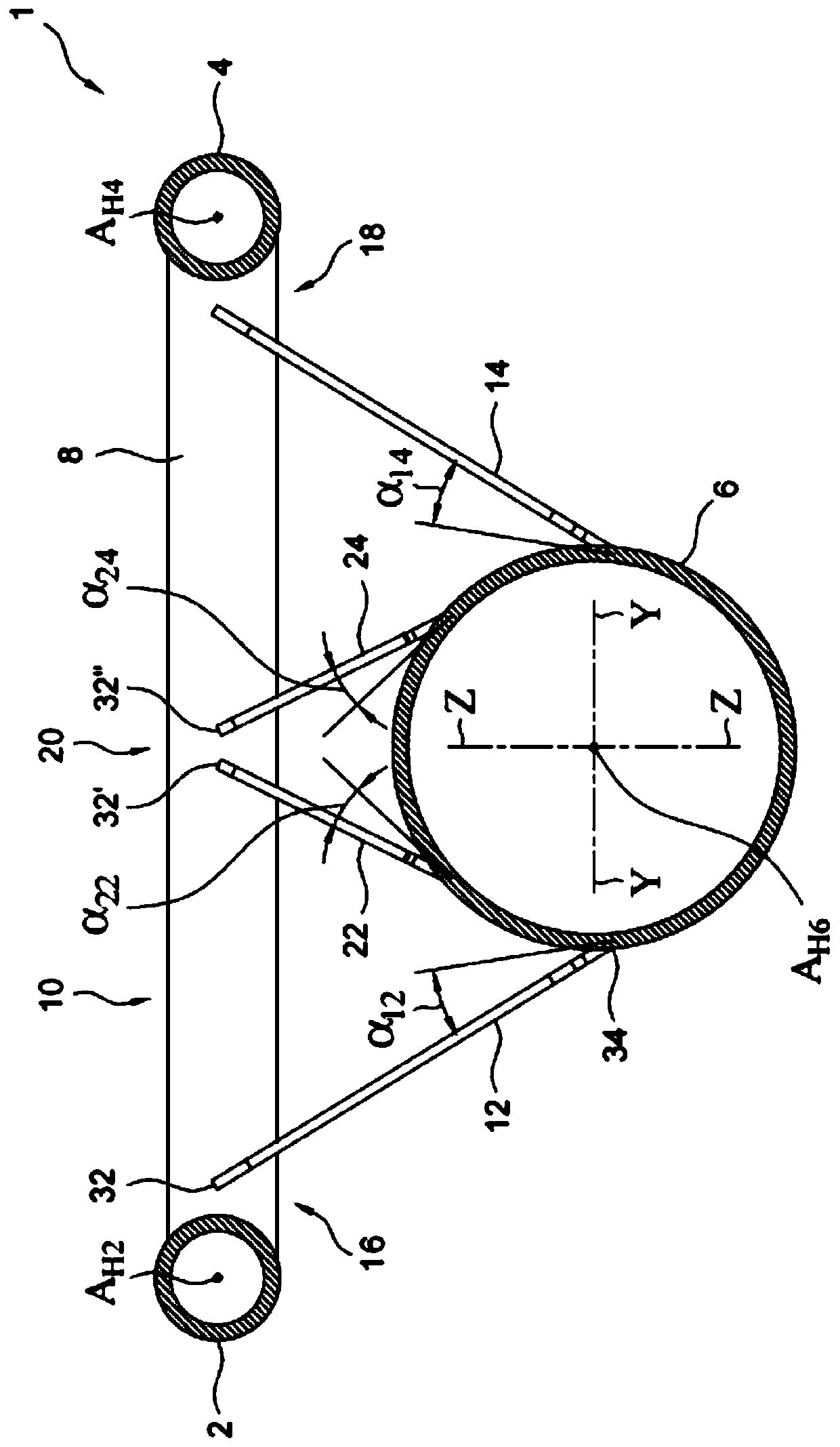

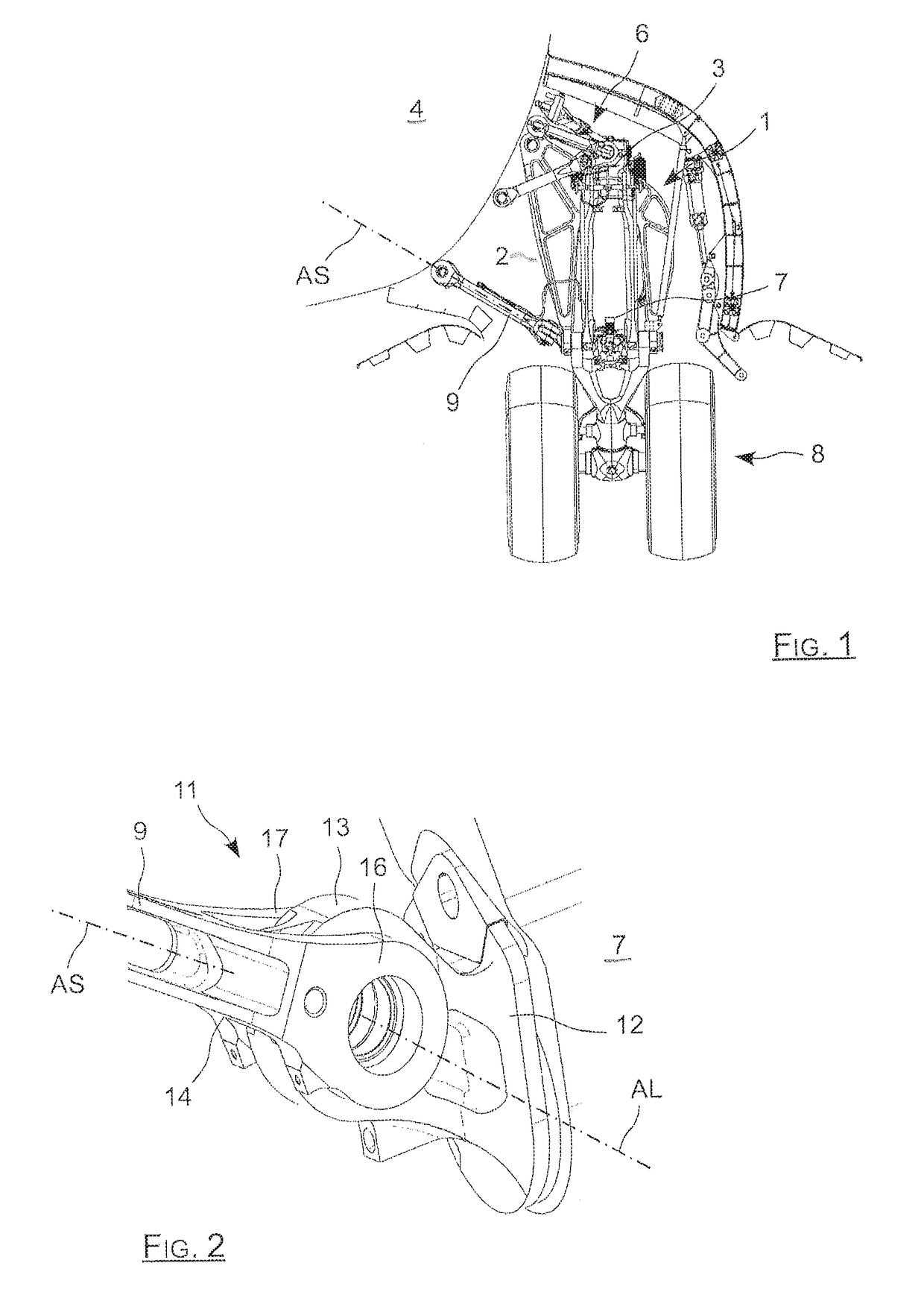

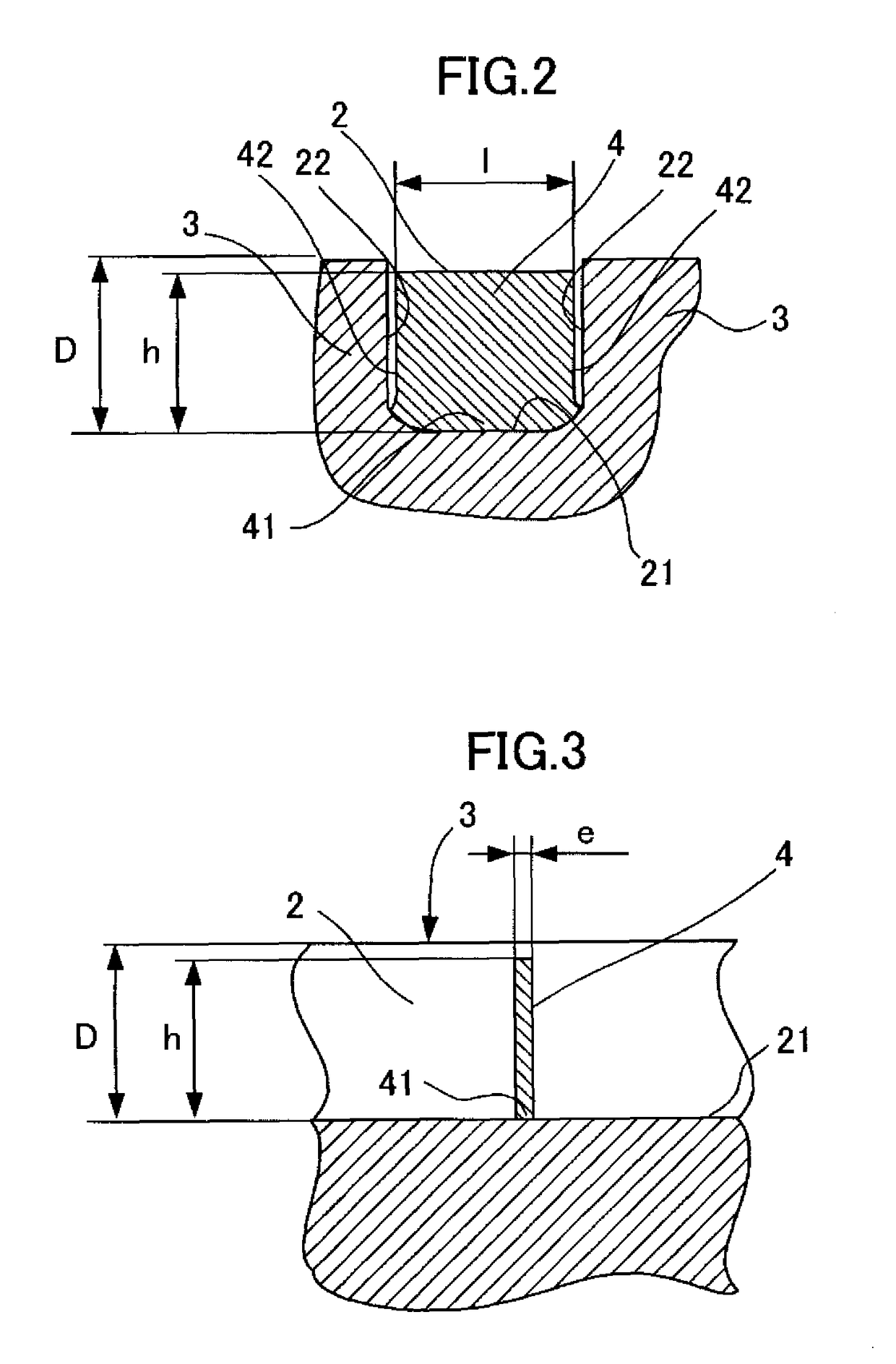

Shock absorbing device for the front or rear structure of a vehicle

ActiveCN105102276ADoes not increase strengthIncrease the lengthUnderstructuresElastic dampersEngineeringRadius of gyration

Shock absorbing structure (10, 10") for a vehicle comprising a side sill (2) comprising two chassis frame side members (4, 4") which together support a bumper beam (6, 6"), said shock absorbing structure comprising said bumper beam and an absorber (7, 7") interposed between each chassis frame side member and said bumper beam, said absorber having a working part (71) intended to deform in the event of an impact under the effect of a load below the limit load beyond which said chassis frame side member undergoes plastic deformation, said absorber being a section piece of which one end (72) is inserted inside the open end (5, 5") of said chassis frame side member and fixed thereto, characterized in that said absorber is an extruded aluminium alloy section piece of which the part not inserted inside said chassis frame side member or inside said bumper beam, which corresponds to said working part, has a length greater than 5 times its radius of gyration defined by formula (I), where I is the quadratic moment and S the cross-sectional area of said section piece, said cross section being such that, under the effect of a substantially frontal impact, said working part is able to deform in crumpling over a length such that the longitudinal crush distance is greater than 4 times said radius of gyration.

Owner:CONSTELLIUM SINGEN +1

Clip

InactiveUS8555469B2Reduce insertionConvenience to workSnap fastenersScrewsEngineeringSecond moment of area

A clip may include an anchor portion having a plurality of flexible strips and at least one support strip. Each of the flexible strips is integrally connected to the at least one support strip only via a connecting portion corresponding to a distal end portion of the anchor portion and a connecting portion corresponding to a proximal end portion of the anchor portion. When the anchor portion is pushed into an insertion hole formed in a subject member, the anchor portion is inserted into the insertion hole while each of the flexible strips are flexed toward a longitudinal axis of the anchor portion. Each of the flexible strips is formed such that the difference between a second moment of area of the anchor distal end side connecting portion and a second moment of area of the anchor proximal end side connecting portion is 0-15%.

Owner:DAIWA KASEI IND CO LTD

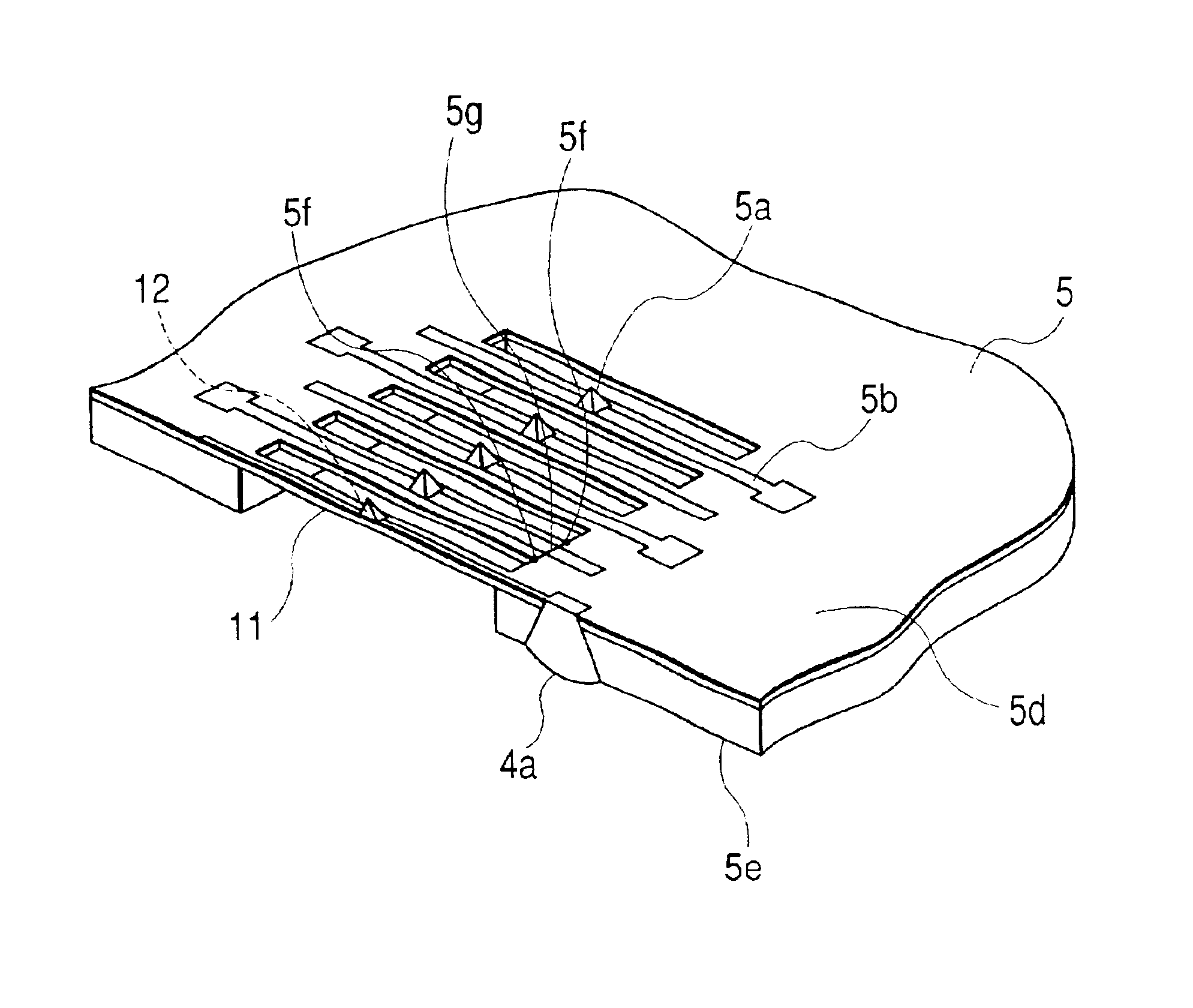

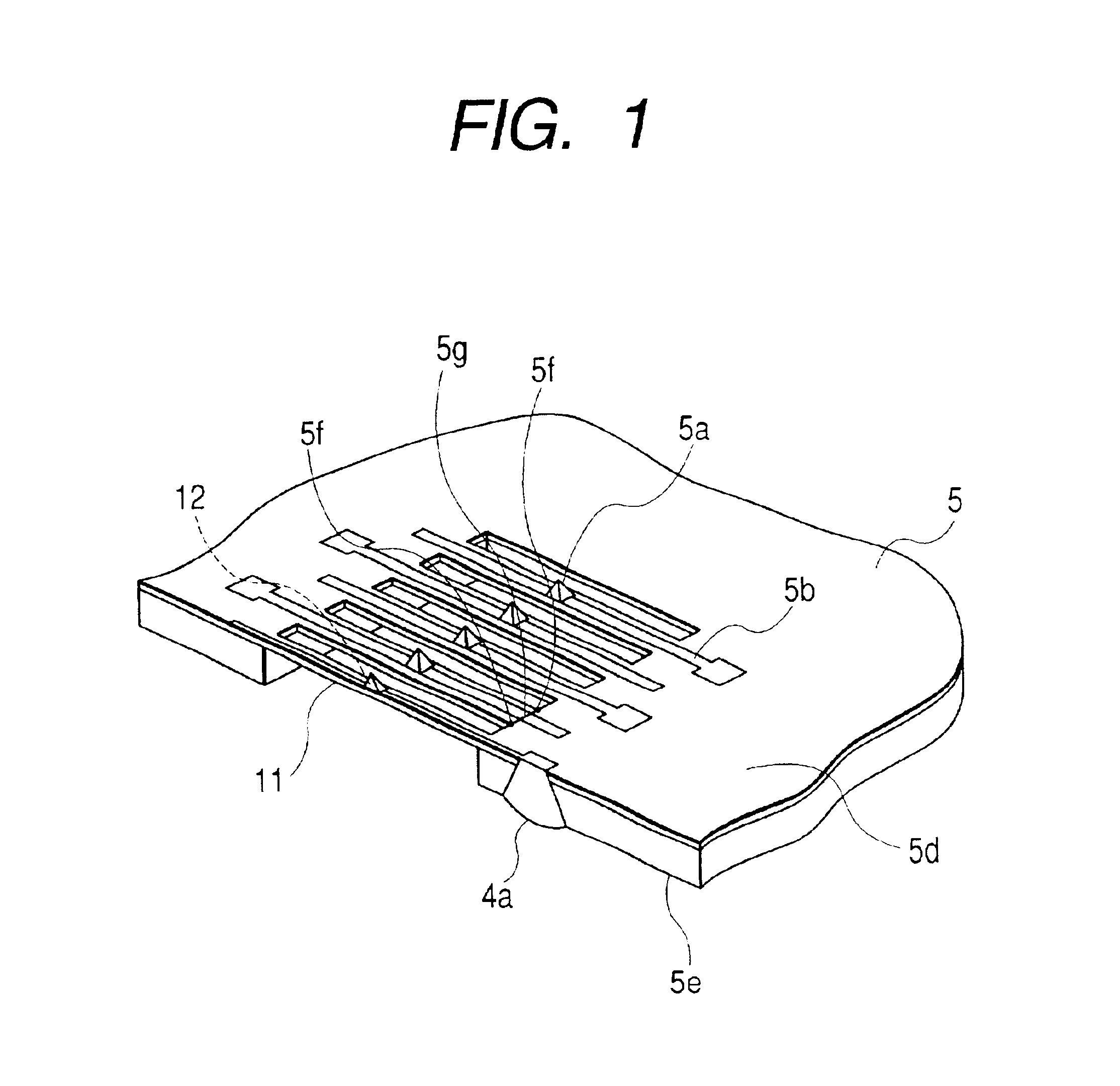

Semiconductor device testing apparatus and semiconductor device manufacturing method using it

InactiveUS6864695B2Avoid stress concentrationAvoid problemsSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsStress concentrationMiniaturization

Since each wiring line is formed on one surface of the associated beam at a prescribed width over the entire length of the beam, the beam has the same sectional shape taken in the width direction at any point along an arbitrary longitudinal direction of the beam. As a result, the second moment of area, which is determined by the shapes of the beam and the wiring line, is uniform. This prevents a problem of the curvature of a beam varying locally when the beam is bent by a prescribed amount due to contact of the probe with a pad of a subject body. This, in turn, prevents local concentration of stress in the beams and thereby prevents breakage of the beam. Therefore, the probe structure can be miniaturized while the strength of the beams is kept at a required level, whereby a semiconductor device testing apparatus capable of accommodating many probes can be realized.

Owner:RENESAS ELECTRONICS CORP

Structural insulator

ActiveUS8895861B2Resist buckling and compressive loadingImprove the immunitySuspension arrangements for electric cablesSuspension/strain insulatorsElectricityElectrical conductor

An electrically insulating cross-arm for a tower for high-voltage power networks. The cross-arm includes an insulating structural member for attachment to the tower body and to support a conductor cable. The insulating structural member comprises a solid rigid spine extending along a long axis having cross sectional profile, normal to the long axis, having a second moment of area of its cross sectional profile about every axis normal to the long axis and dissecting its centroid has a value of A2 / 2π or more, where A is the area of the cross sectional profile. The structural member provides resistance to bending and compressive buckling and allows conductors to be safely supported at reduced tower height. T and Y shaped cross sections provide water run-off and inhibition of organic growth. The structural members are also generally useful as insulator members in high voltage power networks.

Owner:HUBBELL POWER SYST INC

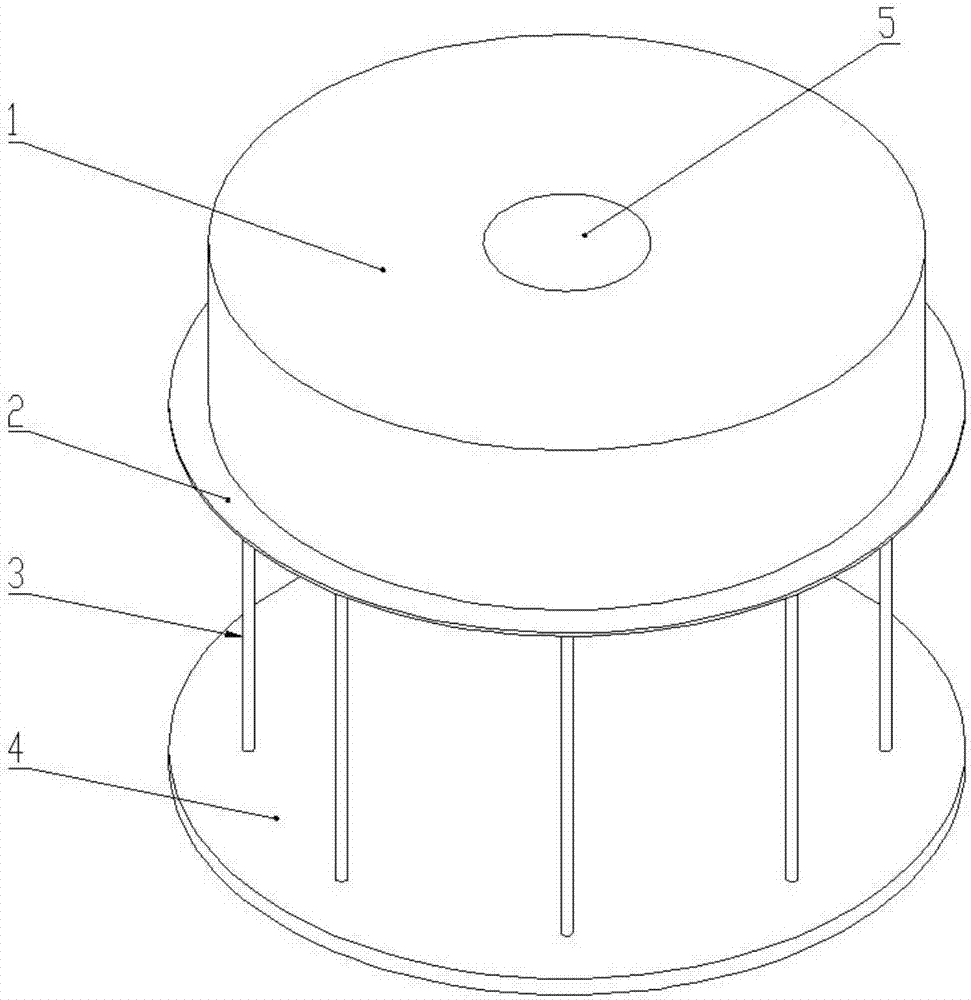

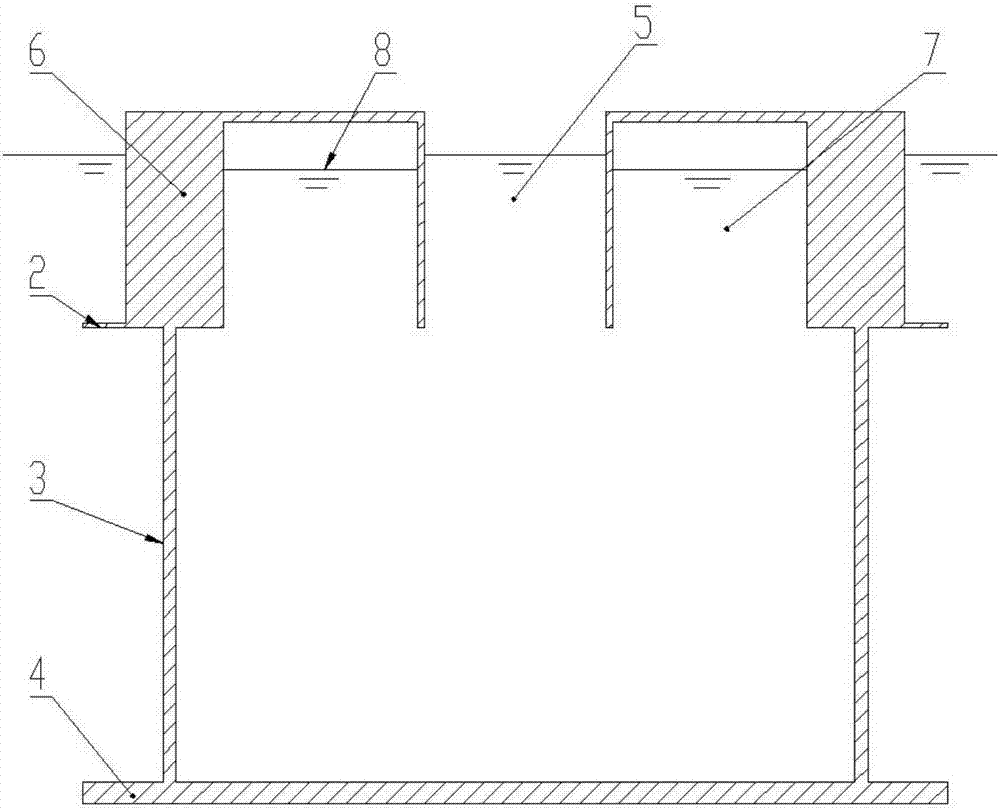

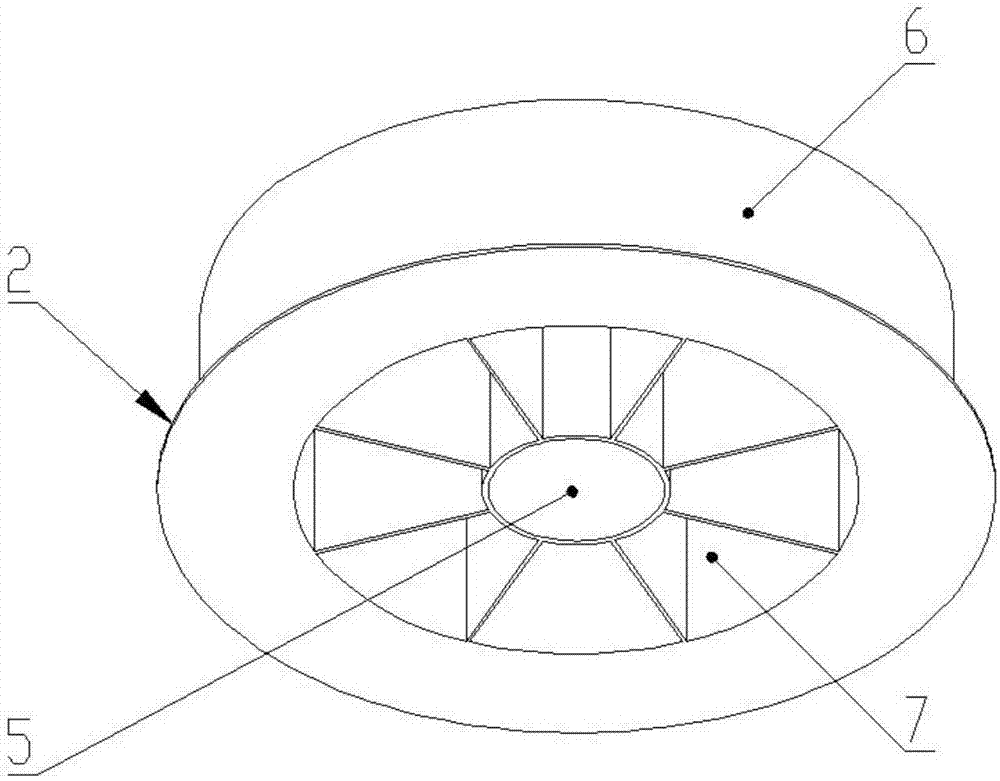

Floating air-cushion supporting platform

InactiveCN107200101AMotor responseReduced motor responseWaterborne vesselsFloating buildingsViscous dampingGravity center

The invention provides a floating air cushion support platform, which is mainly composed of a platform main body, a truss and ballast. The platform main body includes a buoyancy chamber, an air chamber, an air chamber partition, a central well and a damping apron. Below the platform, the main body of the platform and the ballast are connected by trusses, and the waterline is inside the main body of the platform. The buoyancy chamber provides the buoyancy required by the system, and increases the water surface area through the buoyancy chamber; the air chamber partition divides the air chamber into multiple independent units, and increases the section moment of inertia of the air chamber through the air chamber partition; the damping apron The viscous damping of the platform is increased; the ballast arranged below can lower the center of gravity of the system, and can also act as a heave plate, reducing the heave response of the system. Relying on the barge-type support platform, this platform has simple structure, convenient construction and low cost. By introducing the design of air cushion, it solves the problem of large motion response of ordinary barge-type floating structures under the action of waves.

Owner:HARBIN ENG UNIV

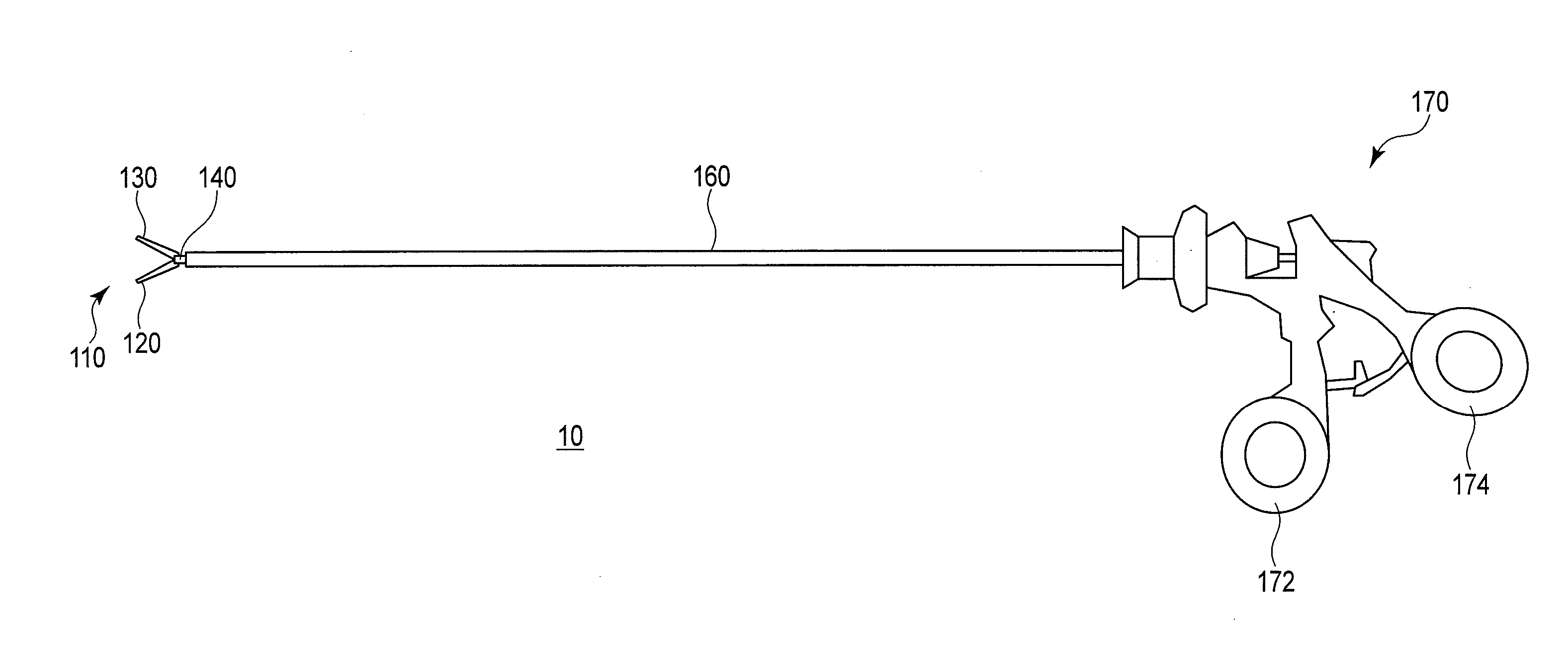

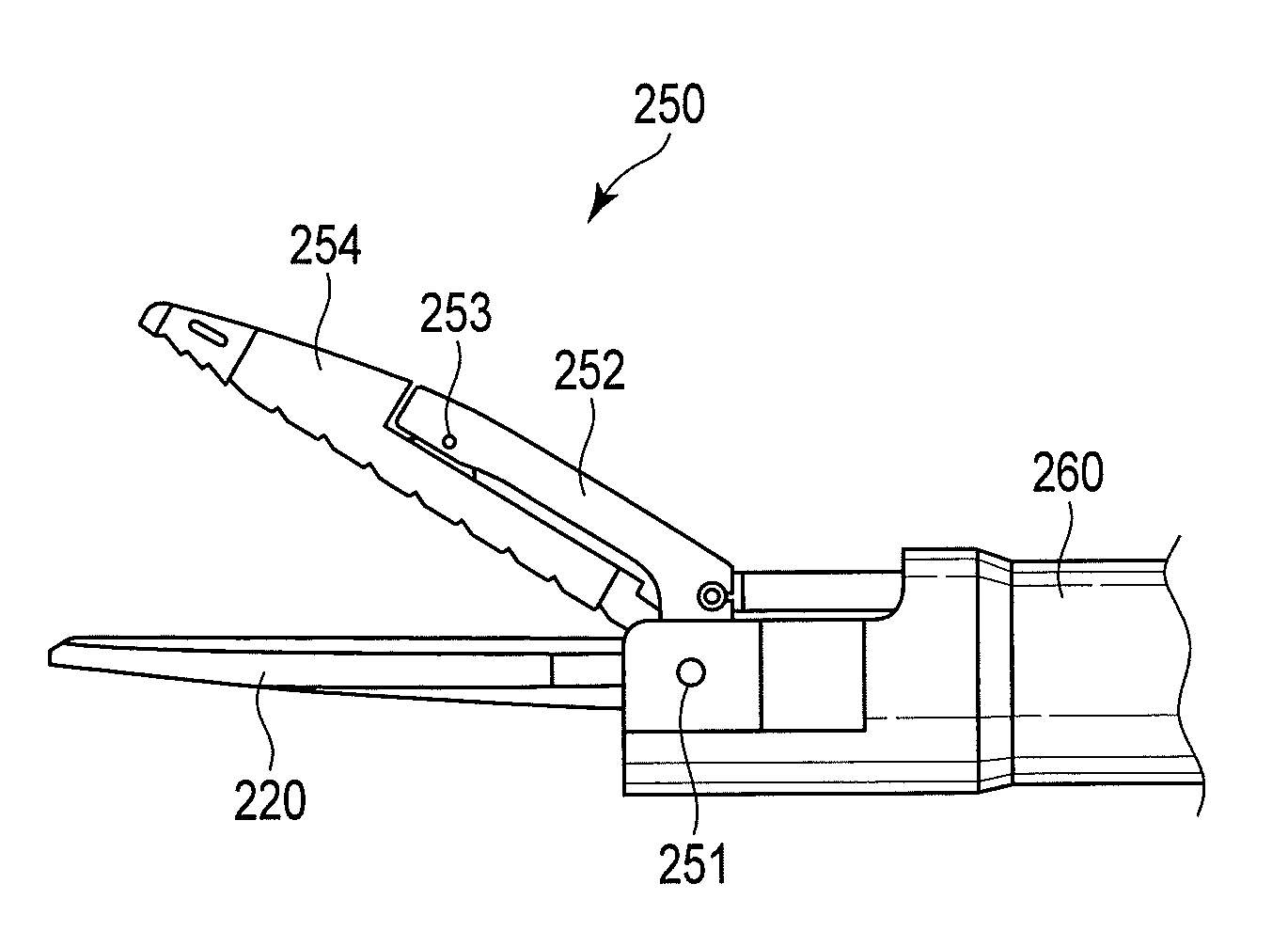

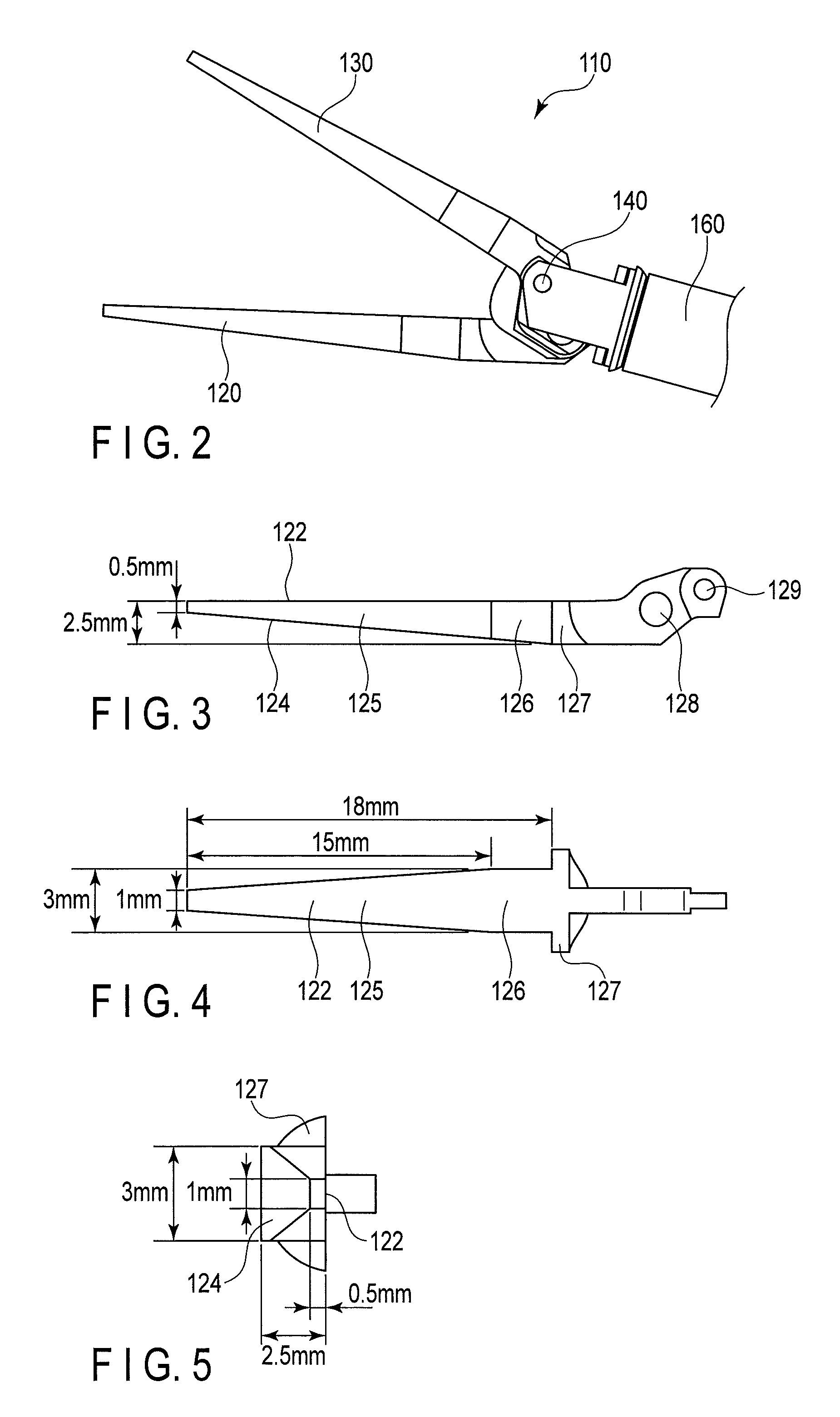

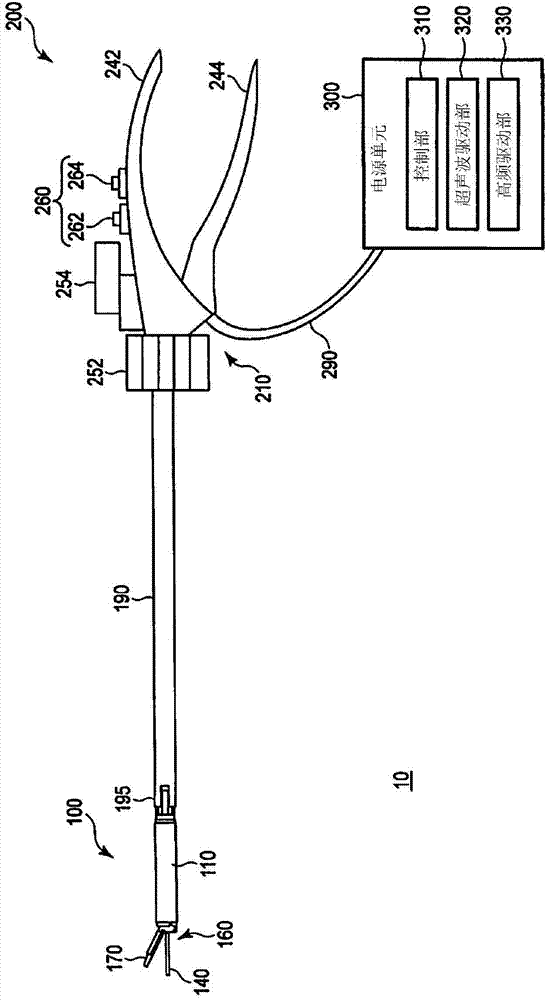

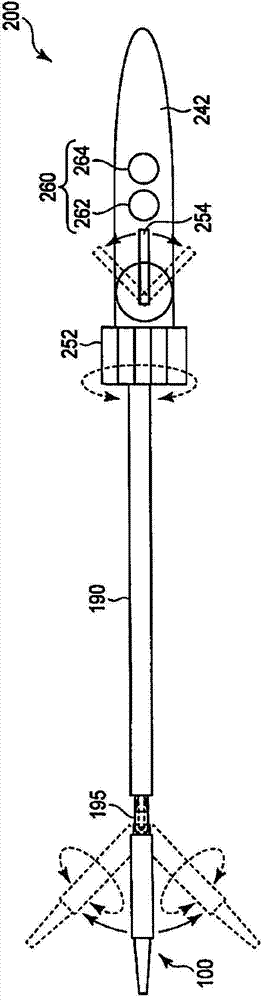

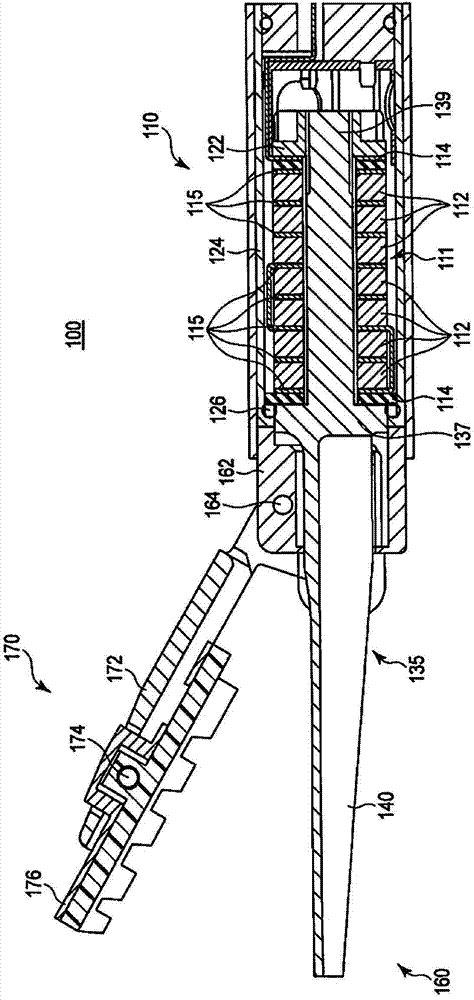

Treatment device

A treatment device includes a first grip member having an elongated shape, and a second grip member which is displaced with respect to the first grip member to grip the biological tissue between the first grip member and the second grip member. The second grip member includes a grip section that comes into contact with a biological tissue as a gripping target. I / A2 of the grip section is maximum at the proximal end, and / or Z / A3 / 2 of the grip section is maximum at the proximal end, where I is a second moment of area, Z is a section modulus, and A is a cross-sectional area calculated based on an axis perpendicular to a straight line passing through a center of gravity of the first grip member and a center of gravity of the second grip member in a cross section perpendicular to a longitudinal axis of the grip section.

Owner:OLYMPUS CORP

Staggered-welding type cast-in-place wrapped castellated beam with web openings

InactiveCN109930747ATake advantage ofIncreased beam heightLoad-supporting elementsPolygonal lineReinforced concrete

The invention discloses a staggered-welding type cast-in-place wrapped castellated beam with web openings. The castellated beam comprises a steel skeleton consisting of main beams and a secondary beam, wherein the main beams and the secondary beam are all produced by I-shaped beams, and the I-shaped beams comprises webs and top flanges and bottom flanges respectively arranged on the upper and lower sides of the webs; each I-shaped beam is cut along a preset fold line on the web of the I-shaped beam into two steel beams with a toothed side edge, and the toothed side edges of the two steel beamsare welded in a staggered way to form the main beam or the secondary beam with the web openings; after the steel skeleton is prefabricated, longitudinal reinforcements and pipelines are arranged on the steel skeleton, wherein lower longitudinal reinforcements and pipelines all penetrate the openings on the webs, upper longitudinal reinforcements pass through the upper parts of the top flanges, concrete is poured after the longitudinal reinforcements and the pipelines are arranged, the steel skeleton is wrapped by the concrete, so that a whole module is formed by the steel skeleton and a reinforced concrete floor. The castellated beam disclosed by the invention has large second moment of area and flexural capacity, and good energy-dissipating capacity under an earthquake load effect.

Owner:BEIJING UNIV OF TECH

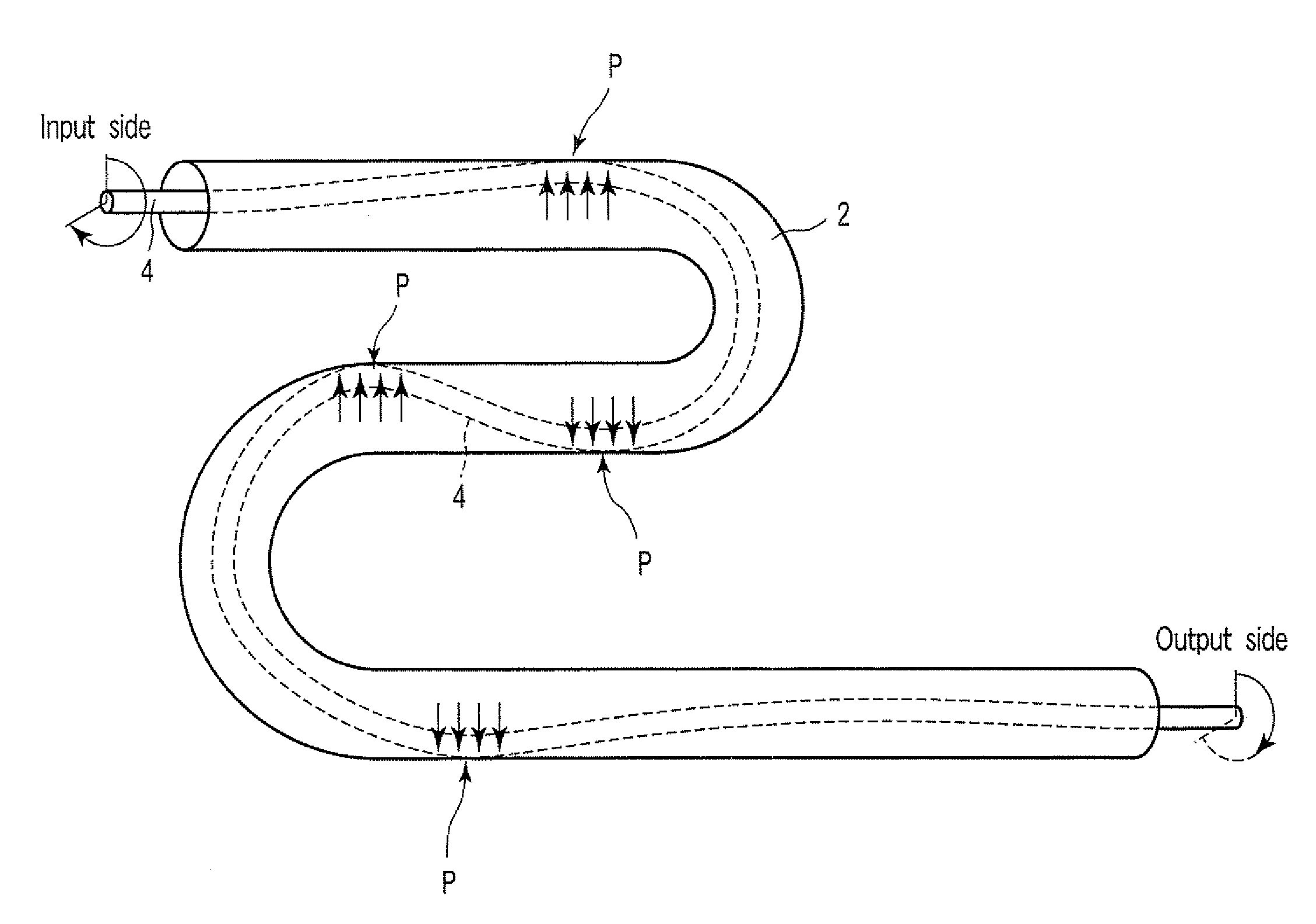

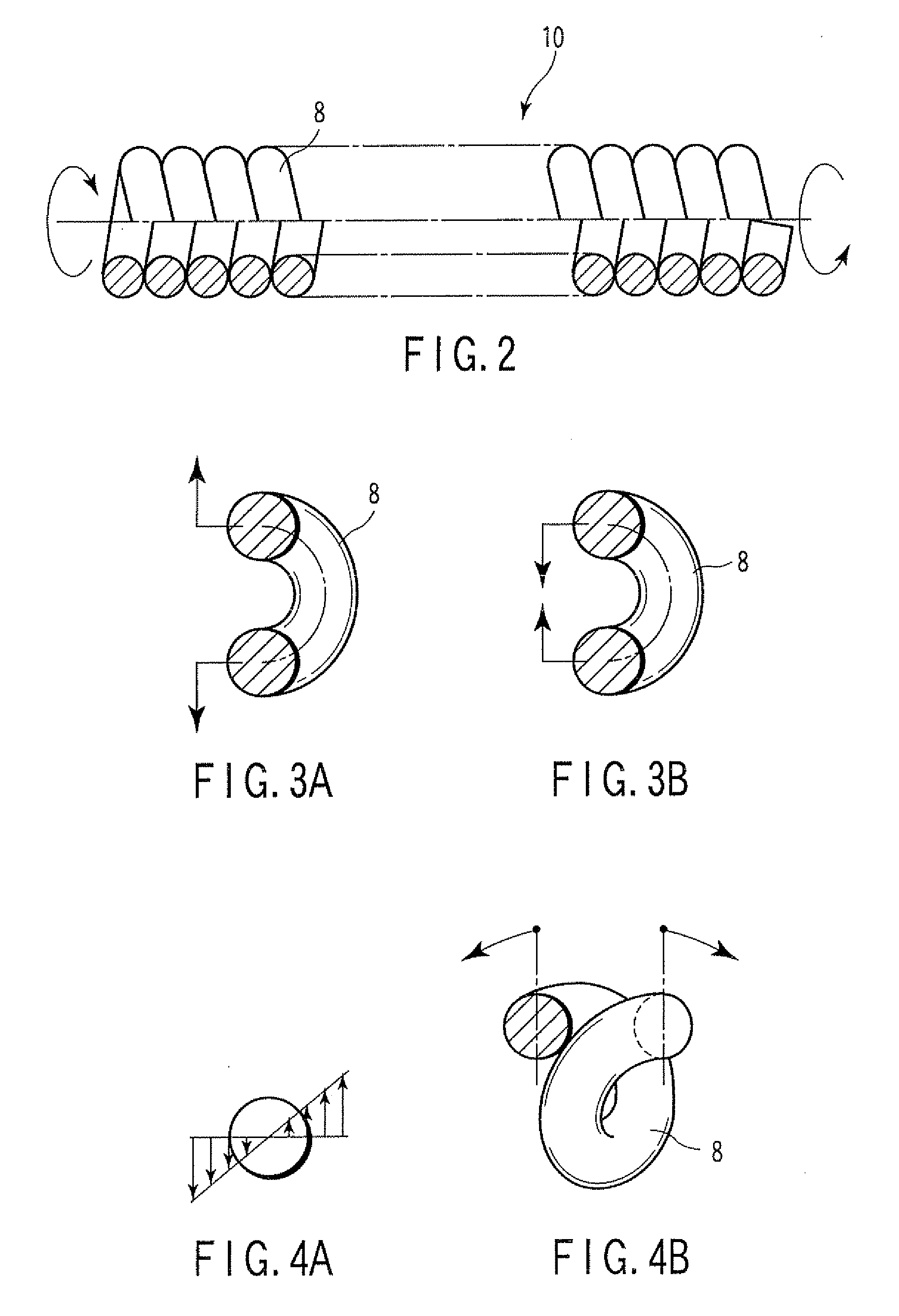

Close-wound coil and medical treatment tool using this coil

ActiveUS20090198103A1Good rotation transmission performanceSame flexural rigidityEndoscopesExcision instrumentsClose woundsClosing wound

A close-wound coil having a good rotation transmission performance, and a medical treatment tool using the close-wound coil. The close-wound coil is formed by winding a wire spirally and closely over a predetermined length around a predetermined first axis. The wire is formed, so that in the section vertical to a wire axis, the second moment of area concerning a second axis passing across the center of the section and vertical to the first axis is smaller than the second moment of area concerning a third axis passing across the center of the section and vertical to the second axis and parallel to the first axis.

Owner:OLYMPUS CORP

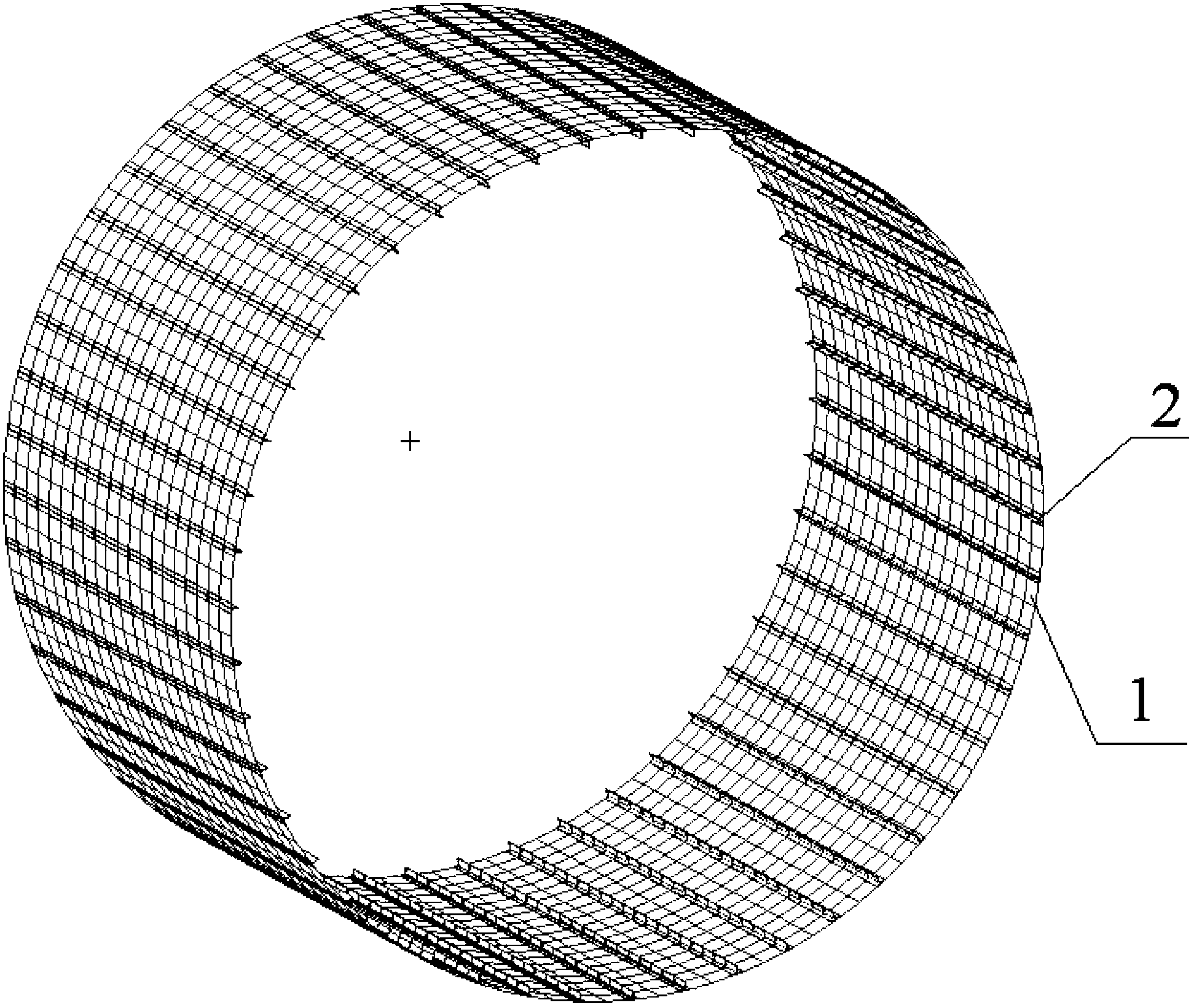

Method for obtaining bending equivalent stiffness of skin stiffened cylindrical shell structure

InactiveCN103454100AReasonable accessEasy to getStructural/machines measurementM categoryEquivalent stiffness

The invention relates to a method for obtaining the bending equivalent stiffness of a skin stiffened cylindrical shell structure. The method comprises the following steps: step 1, the skin elasticity modulus, stringer torsional elasticity modulus, skin shell diameter and skin thickness of the skin stiffened cylindrical shell structure are collected respectively, wherein collected stringers are of m categories totally, and then the number and sectional area of the stringers in each category are collected; step 2, the total equivalent thickness of the stringers is obtained; step 3, the total equivalent thickness and total area equivalent moment of inertia of the skin stiffened cylindrical shell structure are obtained; step 4, optimization factors of second moment of area are obtained; step 5, modified second moment of area is obtained; step 6, the total actual bending stiffness of the skin stiffened cylindrical shell structure is obtained. The method for obtaining the bending equivalent stiffness of the skin stiffened cylindrical shell structure solves the problem that the deviation of the bending stiffness causes the situation that errors of bending frequency are gradually increased along with the increase of orders, and can be used for obtaining the bending stiffness of the skin stiffened cylindrical shell structure reasonably, easily and quickly.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Hairspring for a time piece and hairspring design for concentricity

A method of increasing concentricity in use of a spiral hairspring mechanical timepiece; the hairspring having an inner terminal end portion for engagement with a collet, an outer terminal end portion for engagement with a stud, a first limb portion extending from the inner terminal end portion towards the outer terminal end portion, and a stiffening portion positioned at the outer turn of the hairspring and having a cross-sectional second moment of area different to that of the first limb portion such that bending stiffness of the stiffening portion has a greater bending stiffness than the single limb portion. The method includes modifying cross-sectional second moments of an area of the first limb portion and the stiffening portion by minimizing a cost function throughout the amplitude of the rotation of hairspring in use, the cost function being correlated to the net concentricity of the hairspring.

Owner:MASTER DYNAMIC LTD

Clip

InactiveUS20110072624A1Convenience to workGuaranteed to workSnap fastenersScrewsEngineeringSecond moment of area

A clip may include an anchor portion having a plurality of flexible strips and at least one support strip. Each of the flexible strips is integrally connected to the at least one support strip only via a connecting portion corresponding to a distal end portion of the anchor portion and a connecting portion corresponding to a proximal end portion of the anchor portion. When the anchor portion is pushed into an insertion hole formed in a subject member, the anchor portion is inserted into the insertion hole while each of the flexible strips are flexed toward a longitudinal axis of the anchor portion. Each of the flexible strips is formed such that the difference between a second moment of area of the anchor distal end side connecting portion and a second moment of area of the anchor proximal end side connecting portion is 0-15%.

Owner:DAIWA KASEI IND CO LTD

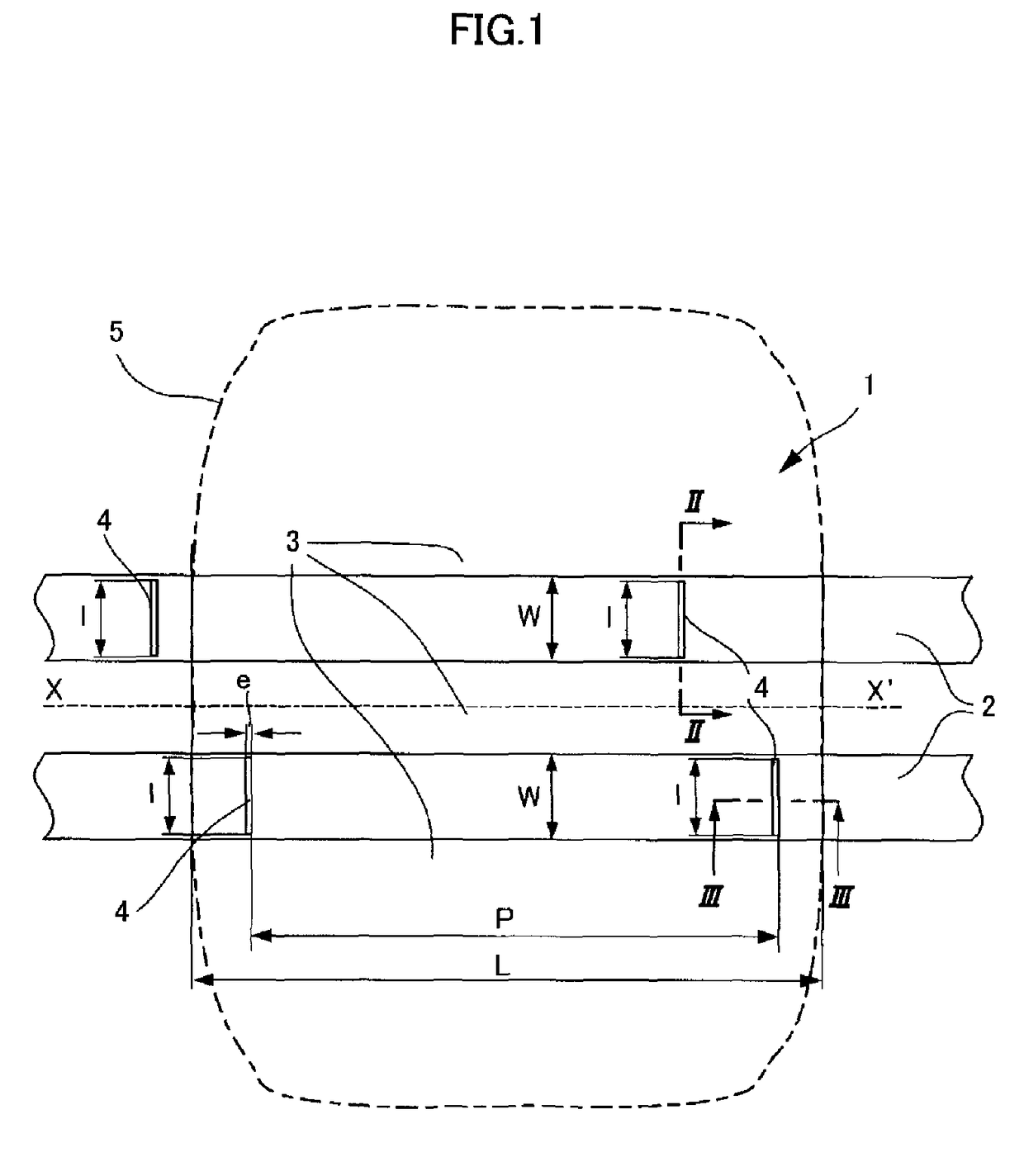

Tubular beams for automotive structures with improved crash performance

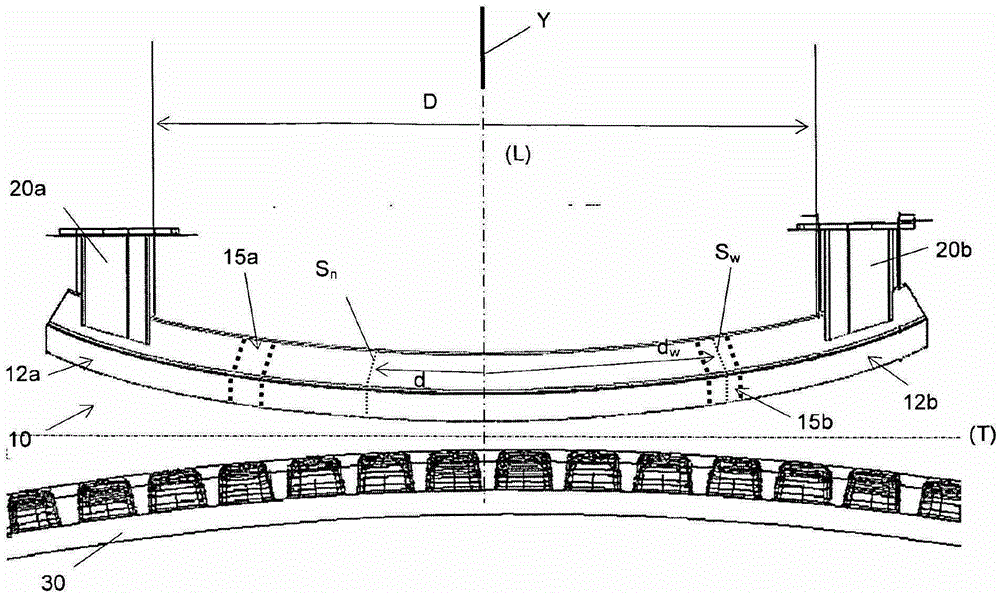

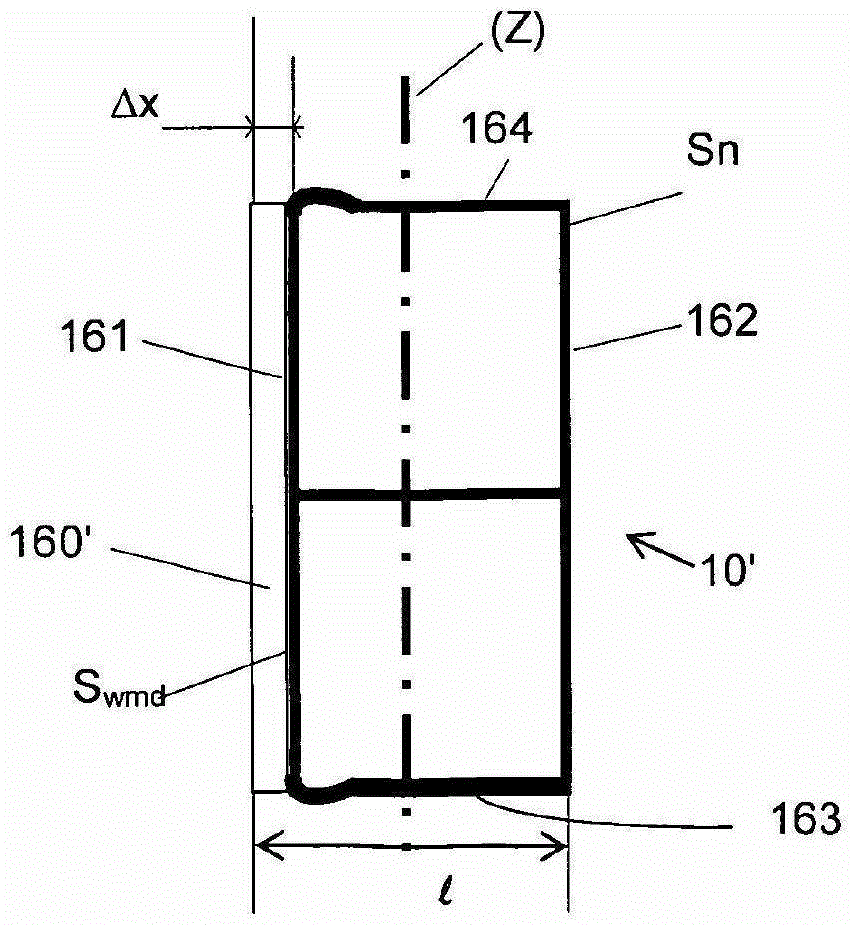

Bumper crossbeam (10, 10'), having a plane of symmetry (Y) and globally oriented in a direction (T) perpendicular to the plane of symmetry (Y), comprising two attachment areas (12a, 12b) symmetrically arranged with respect to the plane of symmetry (Y) and distant from each other by a distance D, said beam being designed to absorb the energy dissipated by a shock generated by a force substantially horizontal and oriented in a direction (L) perpendicular to said direction (T), made from a globally tubular body (11) with a monotonically varying nominal cross-section (Sn) over most of its length between said attachment areas (12a, 12b), except in two weakened areas (15a, 15b), which are symmetrical with respect to the plane of symmetry (Y), which are remote from the said plane of symmetry by a distance of between 0.10*D and 0.40*D, wherein the second moment of area about the axis (Z) perpendicular to the plane (L, T) is lower in the said weakened areas than expected from the nominal cross-section.

Owner:CONSTELLIUM SINGEN

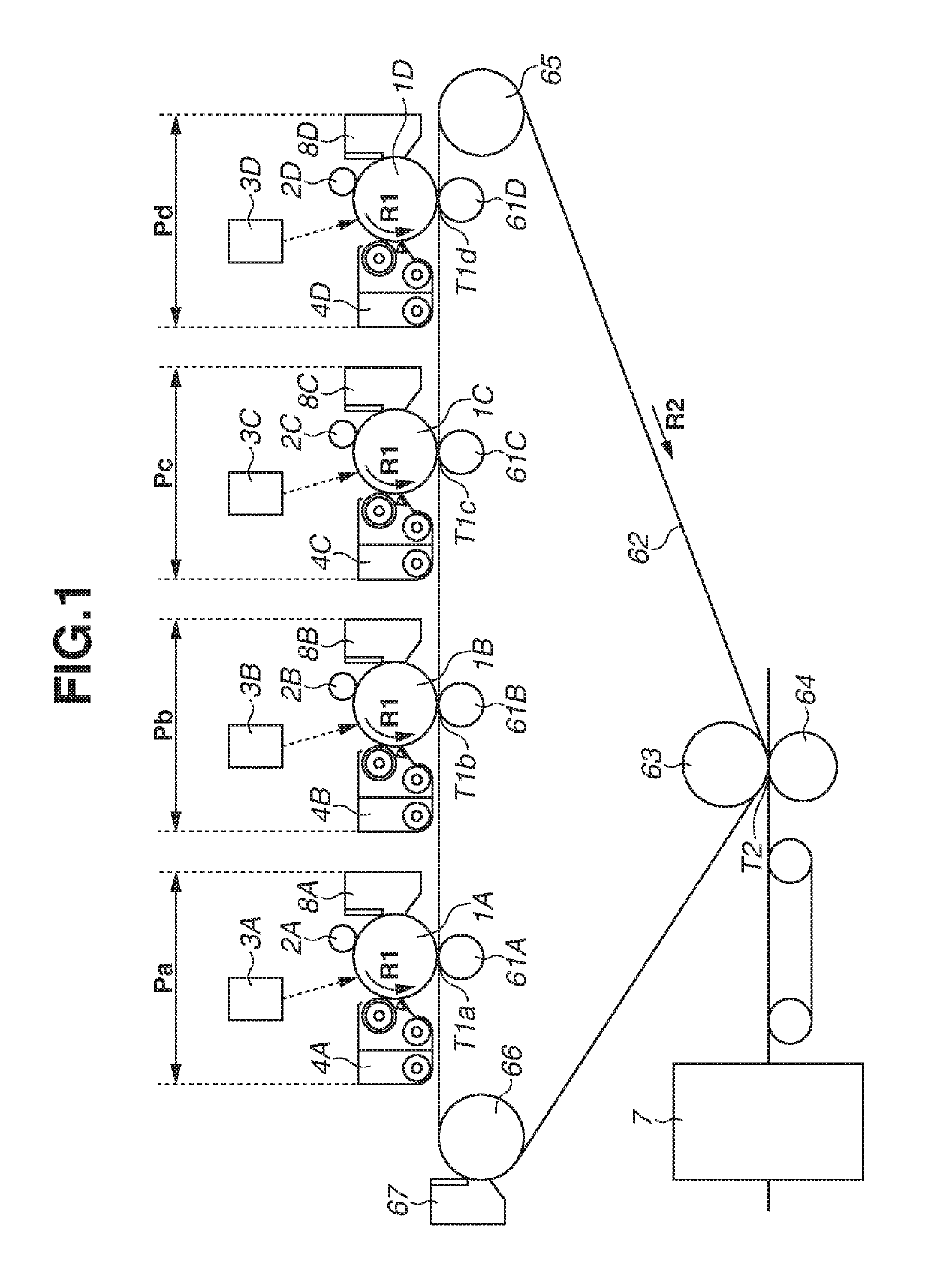

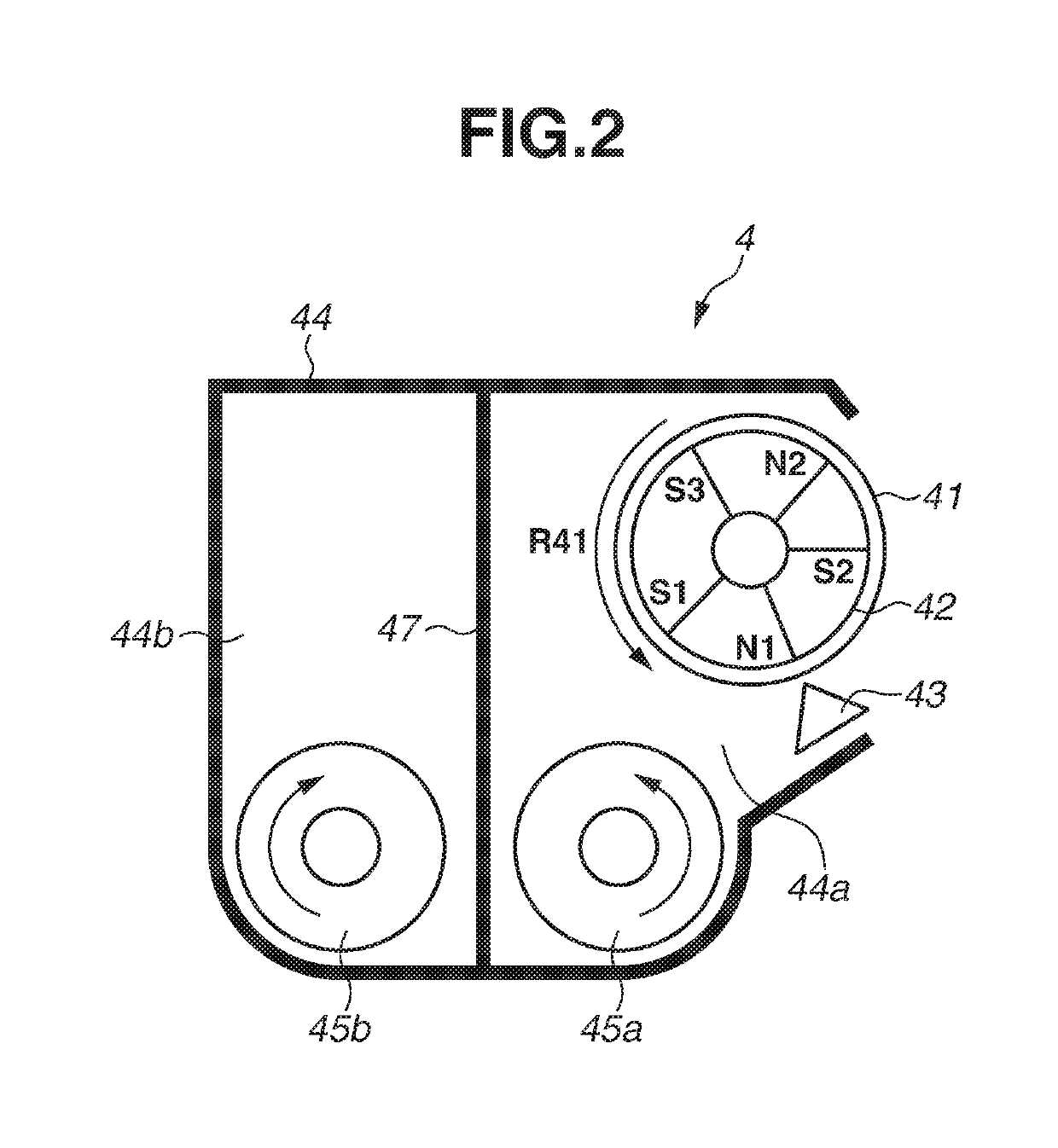

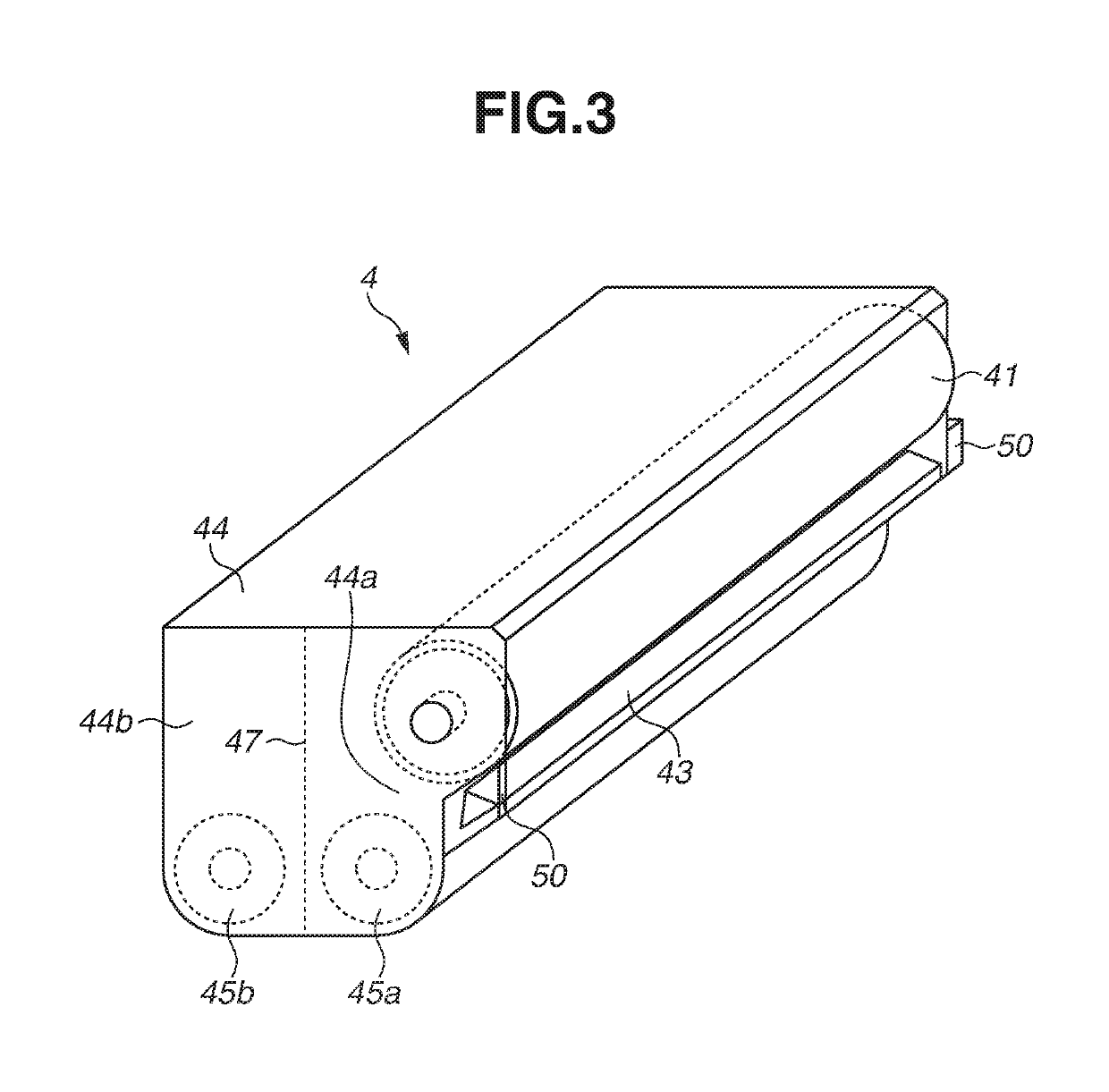

Developing device that reduces the bending of a developer regulating member when the developer regulating member receives developer pressure or magnetic force

InactiveUS10386743B2Less bendingElectrographic process apparatusRotational axisMagnetic tension force

Warpage of a developer regulating member formed of a magnetic material and unrotatably supported on only both end portions thereof caused when receiving pressure of developer or magnetic force is suppressed. In a cross section of the developer regulating member orthogonal to a rotational axis of the developer beading member, an area of the cross section of the developer regulating member is smaller than 28 mm2, a magnitude of a normal direction component of a second moment of area of the developer regulating member with respect to a centroid of the cross section is larger than 25 mm4, and a magnitude of a tangent direction component of the second moment of area is larger than 70 mm4. The normal direction component and the tangent direction component are respectively components in the normal direction and the tangent direction of the developer bearing member.

Owner:CANON KK

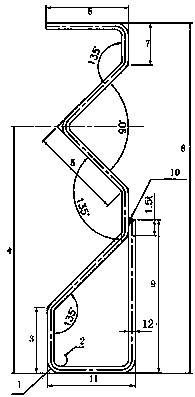

9-shaped pipe for supporting

The invention discloses a special-shaped rectangular pipe. The pipe with a function of supporting is applied to commercial vehicles and produced by means of online continuous cold-bending process and single-pipe bending process. The problems of simple structure, small second moment of area, limited section performance, excessive machining and welding procedures, low yield and complexity in installation process of existing normal sections are solved. The pipe comprises a steel plate integrally forming a 9 shape by cold bending, a weld seam (6) is reserved at the butt joint of the steel plate, and the cross section of the steel plate is in the 9 shape. A cold-bending pipe welding set is adopted for continuous roll bending, online welding shaping, online saw cutting, single-plate bending and offline welding shaping of a bending machine.

Owner:杜伟

Sunlight concentrating apparatus

InactiveUS20160040910A1Easy to bendEfficient ConcentrationSolar heating energySolar heat collector controllersLinear regionDaylight

A sunlight concentrating apparatus includes a plate-like reflecting part, with an upper reflection surface extending in an axial and a width direction, and a lower surface having a central linear region fixed to a main shaft part. A pair of bending mechanisms bend the reflection surface by moving opposite end portions in a central normal direction in accordance with a rotation of the main shaft part. The reflecting part includes a mirror plate and a support plate thereon. In the support plate, the ratio between the distance in the width direction from each end portion in the width direction and the second moment of area at this distance is constant between the end portion and the central linear region, allowing the reflection surface to be bent in an are shape.

Owner:HITACHI ZOSEN CORP

Treatment device

A treatment device includes a first grip member having an elongated shape, and a second grip member which is displaced with respect to the first grip member to grip the biological tissue between the first grip member and the second grip member. The second grip member includes a grip section that comes into contact with a biological tissue as a gripping target. I / A2 of the grip section is maximum at the proximal end, and / or Z / A3 / 2 of the grip section is maximum at the proximal end, where I is a second moment of area, Z is a section modulus, and A is a cross-sectional area calculated based on an axis perpendicular to a straight line passing through a center of gravity of the first grip member and a center of gravity of the second grip member in a cross section perpendicular to a longitudinal axis of the grip section.

Owner:OLYMPUS CORP

OM-shaped pipe for supporting

The invention discloses a special-shaped rectangular pipe. The pipe with a function of supporting is applied to commercial vehicles and produced by means of online continuous cold-bending process and single-pipe bending process. The problems of simple structure, small second moment of area, limited section performance, excessive machining and welding procedures, low yield and complexity in installation process of existing normal sections are solved. The pipe comprises a steel plate integrally forming an OM shape by cold bending, a weld seam (10) is reserved at the butt joint of the steel plate, and the cross section of the steel plate is in the OM shape. A cold-bending pipe welding set is adopted for continuous roll bending, online welding shaping, online saw cutting, single-plate bending and offline welding shaping of a bending machine.

Owner:宋宇光

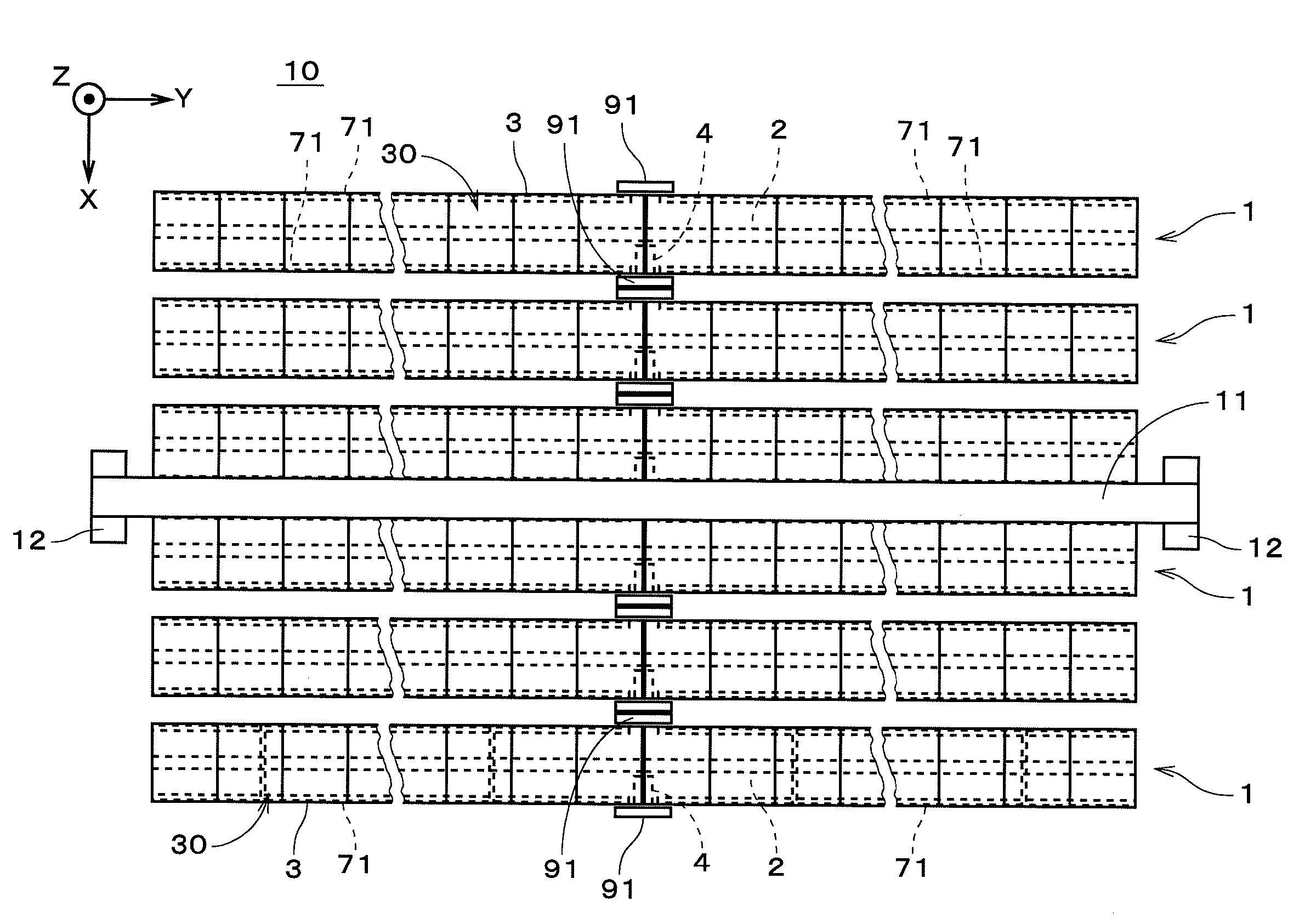

Impact absorbers for vehicle front or rear structures

ActiveCN105102276BDoes not increase strengthIncrease the lengthUnderstructuresElastic dampersRadius of gyrationSecond moment of area

Shock absorbing structure (10, 10") for a vehicle comprising a side sill (2) comprising two chassis frame side members (4, 4") which together support a bumper beam (6, 6"), said shock absorbing structure comprising said bumper beam and an absorber (7, 7") interposed between each chassis frame side member and said bumper beam, said absorber having a working part (71) intended to deform in the event of an impact under the effect of a load below the limit load beyond which said chassis frame side member undergoes plastic deformation, said absorber being a section piece of which one end (72) is inserted inside the open end (5, 5") of said chassis frame side member and fixed thereto, characterized in that said absorber is an extruded aluminium alloy section piece of which the part not inserted inside said chassis frame side member or inside said bumper beam, which corresponds to said working part, has a length greater than 5 times its radius of gyration defined by formula (I), where I is the quadratic moment and S the cross-sectional area of said section piece, said cross section being such that, under the effect of a substantially frontal impact, said working part is able to deform in crumpling over a length such that the longitudinal crush distance is greater than 4 times said radius of gyration.

Owner:CONSTELLIUM SINGEN GMBH +1

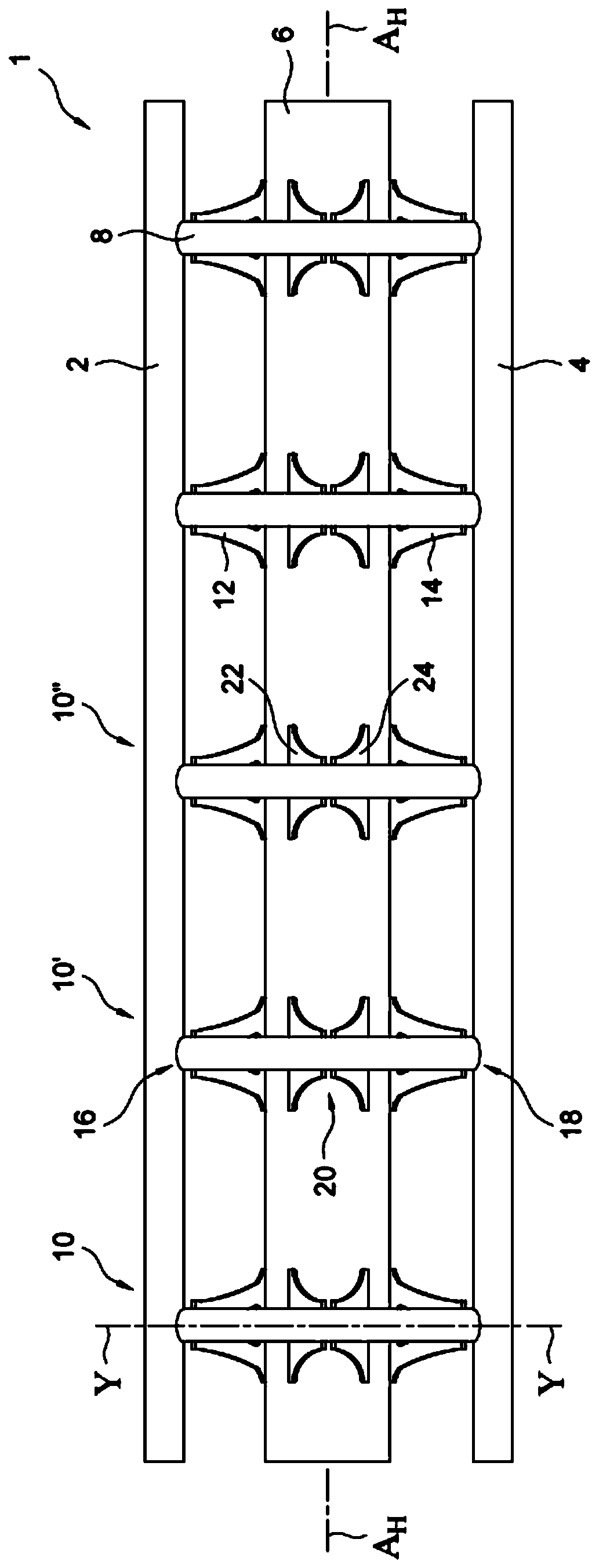

Backbone rail for a roller coaster and roller coaster arrangement

ActiveCN110198768AReduce manufacturing costImprove fatigue strengthRailway vehiclesLoad-supporting elementsRoller coasterEngineering

The invention relates to a backbone rail (1) for a roller coaster. The backbone rail (1) comprises two rail pipes (2, 4) designed for vehicles to travel upon, and at least one, particularly main load-bearing backbone pipe (6) not designed for vehicles to travel on, whose second moment of area is greater than the second moment of area of the rail pipes (2, 4), wherein rail pipes (2, 4) and backbonepipe (6) are connected to each other section- by-section by means of stiffening bulkheads (10), whereby at least one bulkhead (10) has the following features: A transverse cross member (8), which extends in the orthogonal direction and connects the rail pipes (2, 4) with each other, and bulkhead plates (12, 14), connecting at least one rail pipe (2, 4) with the backbone pipe (6), wherein at leastone bulkhead plate (12, 14) is designed as a longitudinal bulkhead plate, whose main plane of extension extends perpendicular to the bulk- head plane, and which is attached to the backbone pipe (6) in such a way that it runs tangentially into the backbone pipe (6). In addition, the invention relates to a roller coaster arrangement with such a backbone rail.

Owner:ING STENGEL

Treatment device

ActiveCN104853687AFull strengthUltrasound therapySurgical instrument detailsBiological bodyTherapeutic Devices

A treatment device includes a treatment portion, a transmission portion and a moment shift portion. The treatment portion transmits ultrasonic vibration. The length of the treatment portion is shorter than ¼ of a wavelength of the ultrasonic vibration. The transmission portion has one end at a node position where the first generated node from the distal end of the treatment portion appears, and is located closer to a proximal side than the node position. The length of the transmission portion is ¼ of the wavelength. The moment shift portion is located between the treatment portion and the transmission portion. An average of I1 / A12 is greater than an average of I2 / A22, where I1 is the second moment of area and A1 is a sectional area in the treatment portion, and I2 is the second moment of area and A2 is a sectional area in the transmission portion.

Owner:OLYMPUS CORP

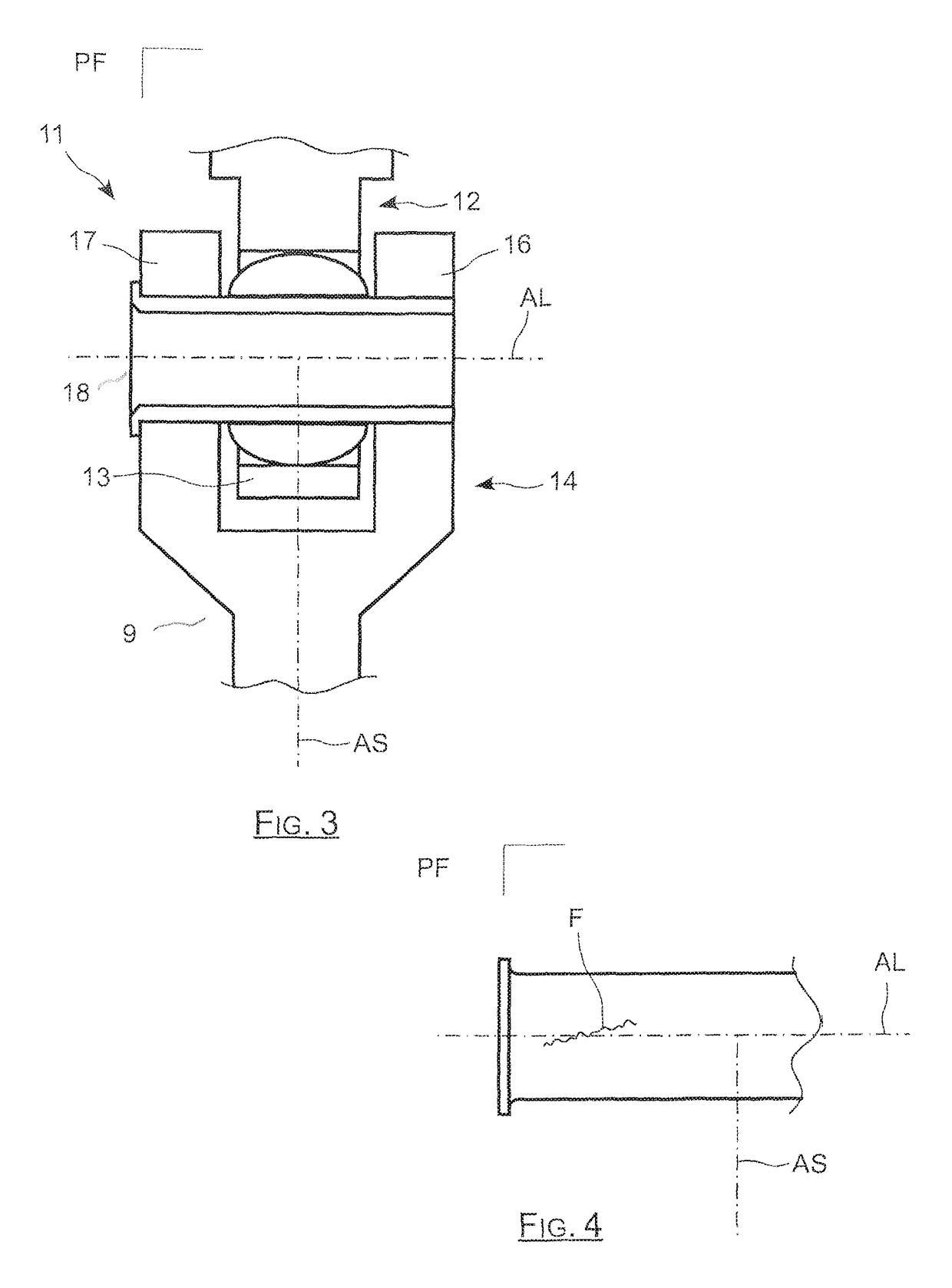

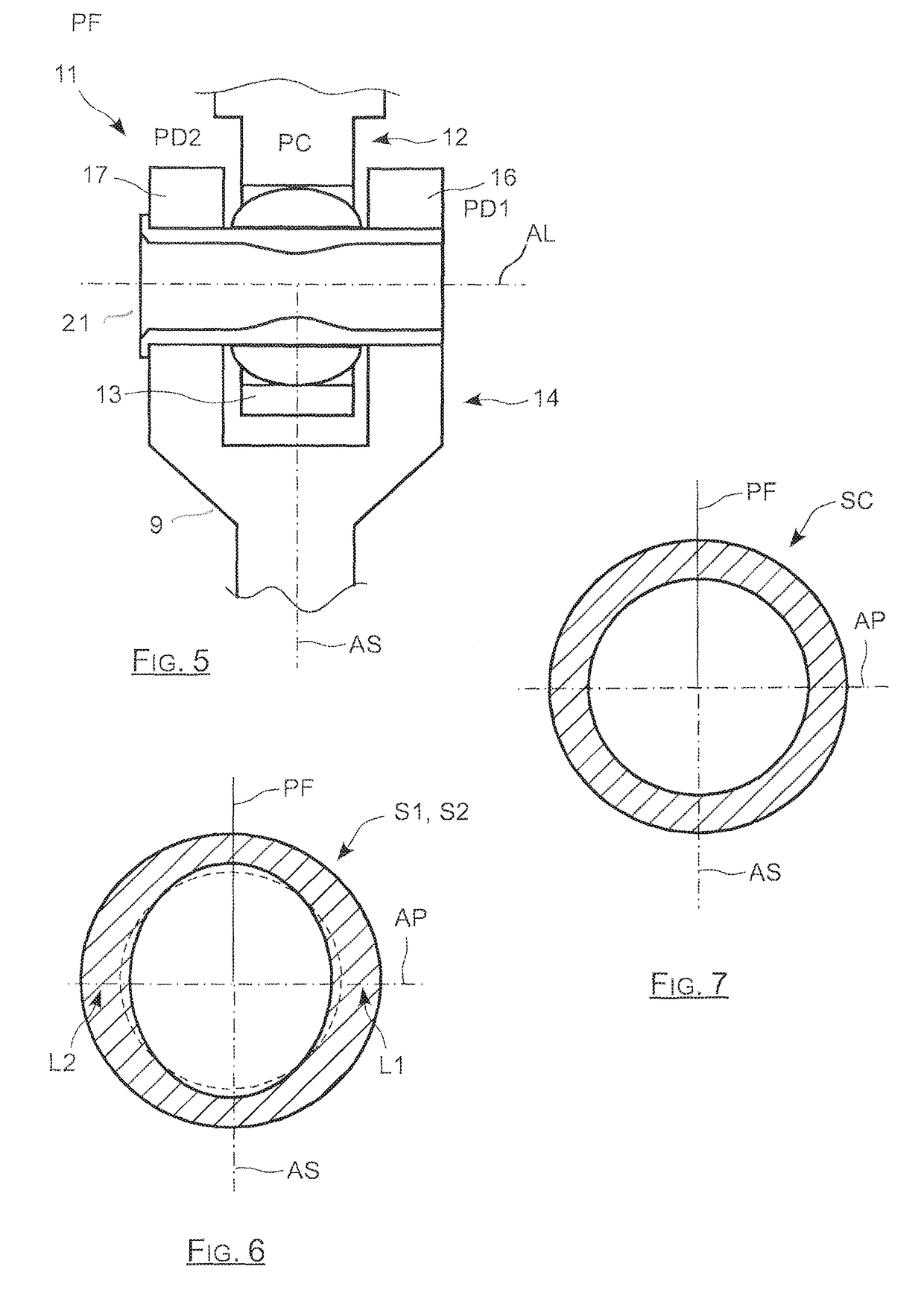

Fusible member intended to join two yokes to form a hinge

The invention relates to a tubular fusible member (21) extending along a longitudinal axis (AL) and for engaging in a two-lug clevis (14) and a single-lug clevis (12) in order to form a hinge (11). According to the invention, the fusible member (21) is constrained in rotation with one of the clevises (12, 14), and it presents a cross-section of shape that varies gradually between a central section and two distal sections, each distal section having reinforced thickness in its regions that extend parallel to the bending plane (PF) in which the fusible member (21) bends when it is stressed, the central section having a second moment of area relative to an axis normal to the bending plane (PF) that is greater than the second moment of area of the distal sections.

Owner:SAFRAN LANDING SYSTEMS

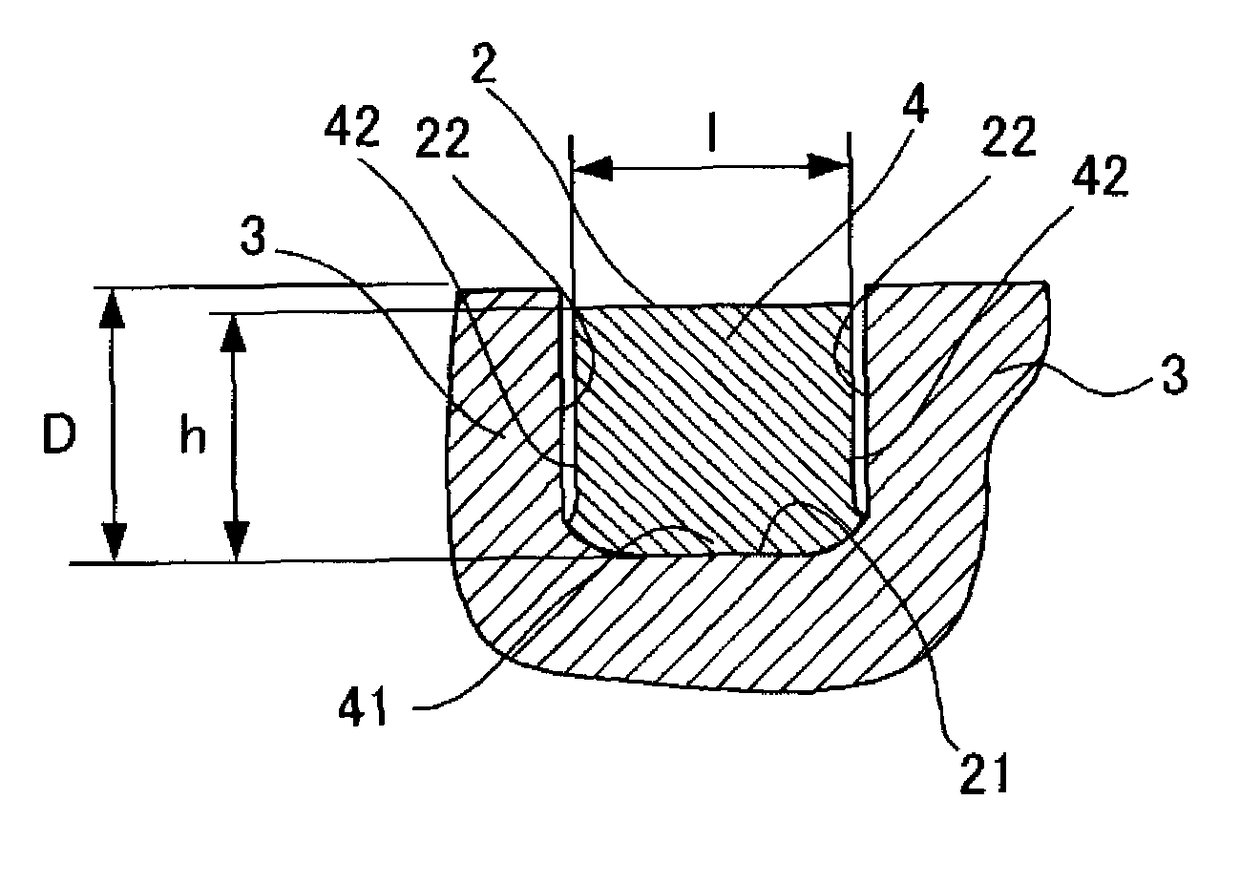

Pneumatic tire tread

ActiveUS9597930B2Reducing the air column resonance soundMaintain performanceTyre tread bands/patternsResonanceEngineering

A tread for a pneumatic tire in which air column resonance sound is reduced and wear of the groove fences and tread portion are caused to be approximately the same, while drainage performance is maintained, wherein a plurality of groove fences are formed and are installed within at least one circumferential groove, extending from the bottom of the circumferential groove, and block at least 70% of the cross-sectional area of the circumferential groove, and the bending parameter of the groove fences, defined as E·I / (h3l) (where E is the modulus at 10% elongation of the material used for the groove fences, I is the second moment of area of the groove fence, h is the height of the groove fence, and l is the width of the groove fence) is at least equal to 250 Pa and at most equal to 350 Pa.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com