Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Process instrumentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

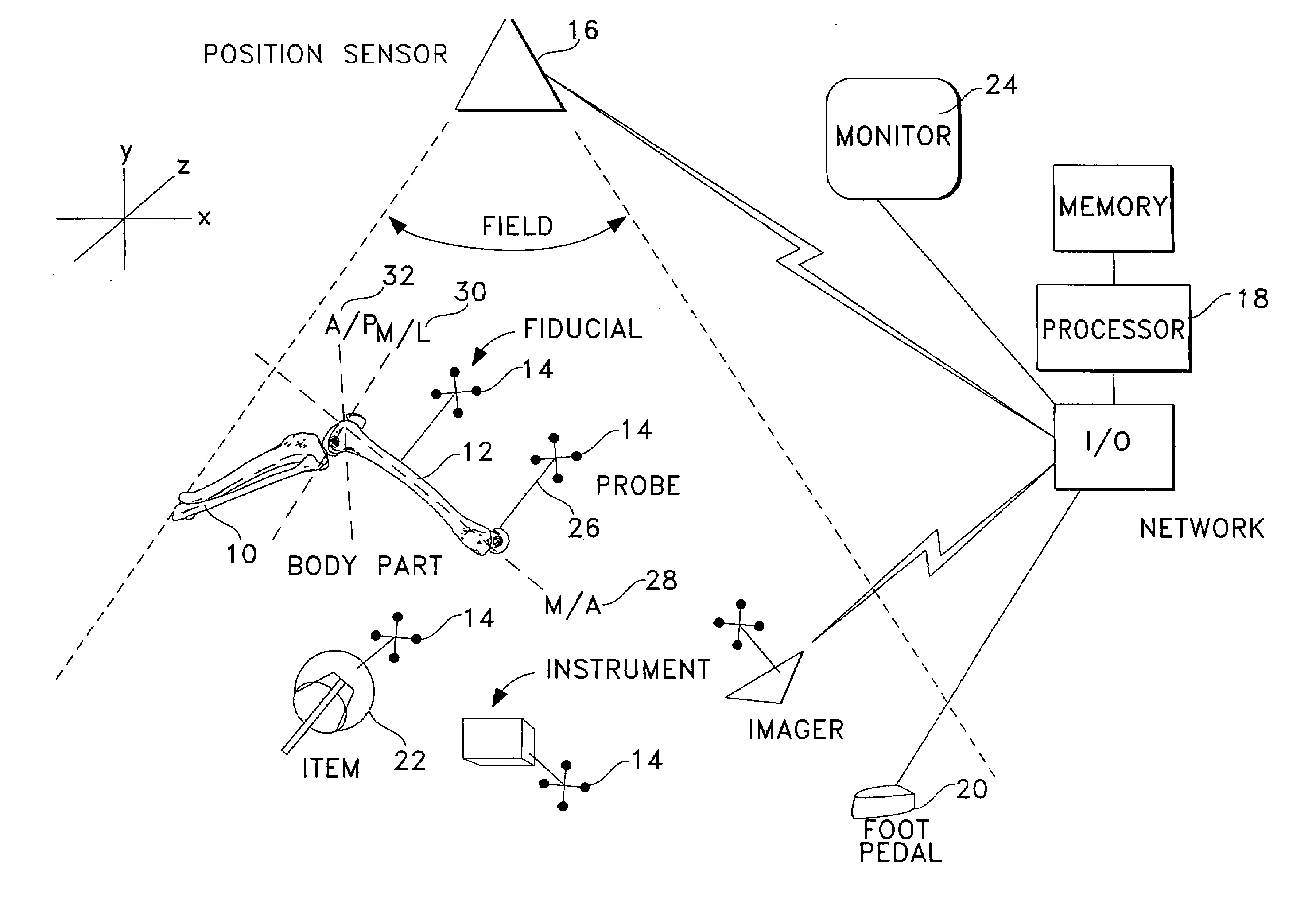

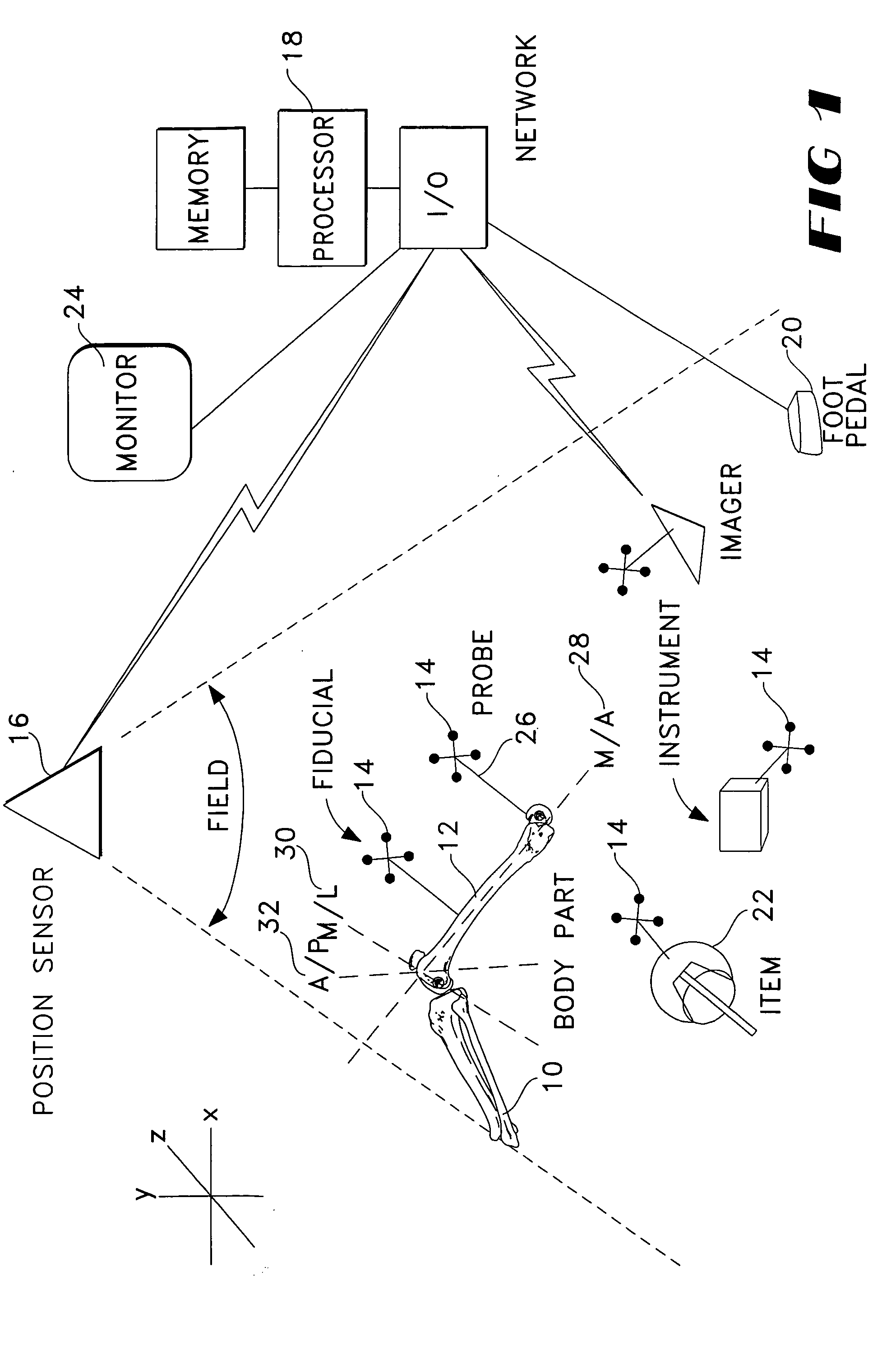

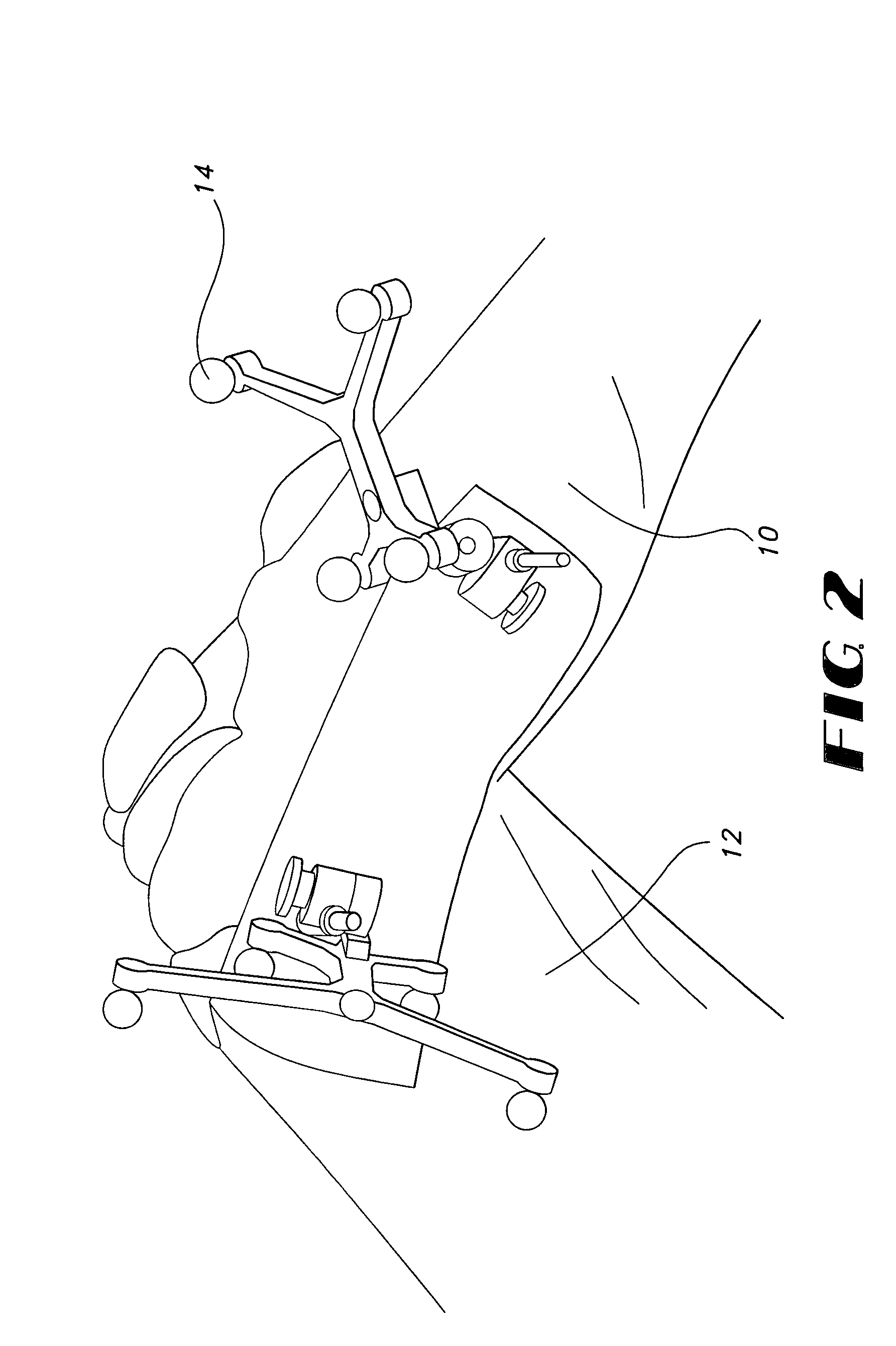

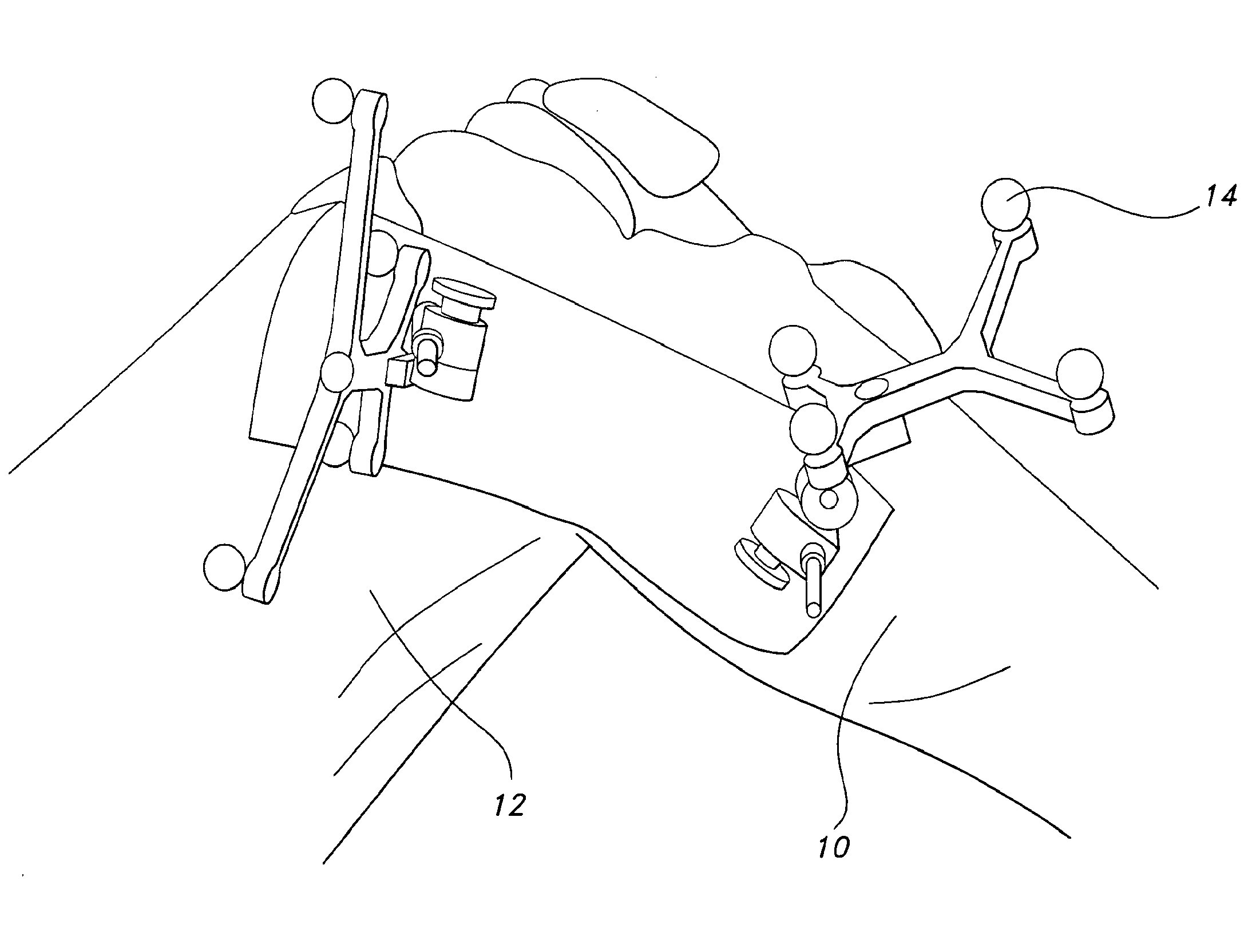

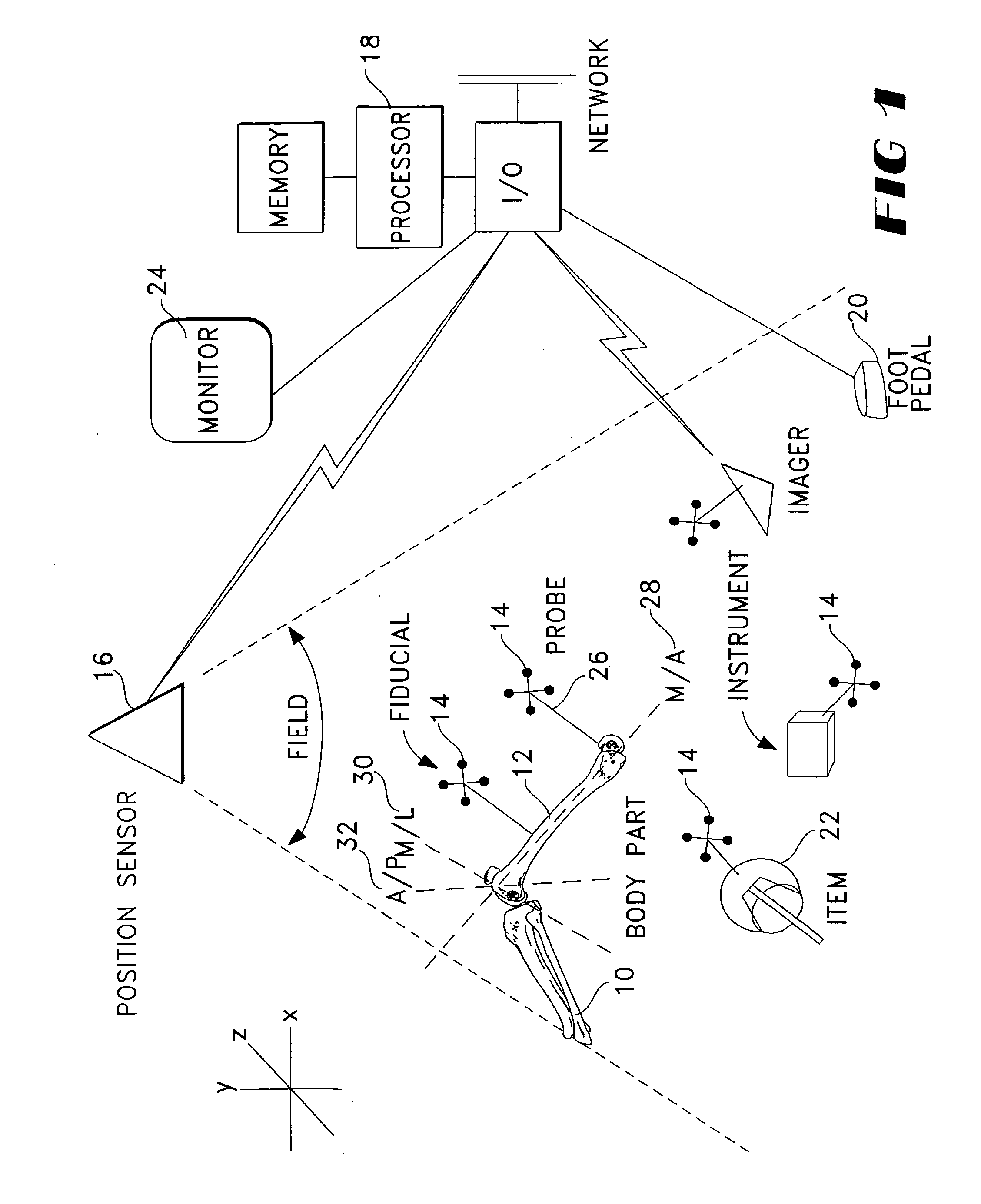

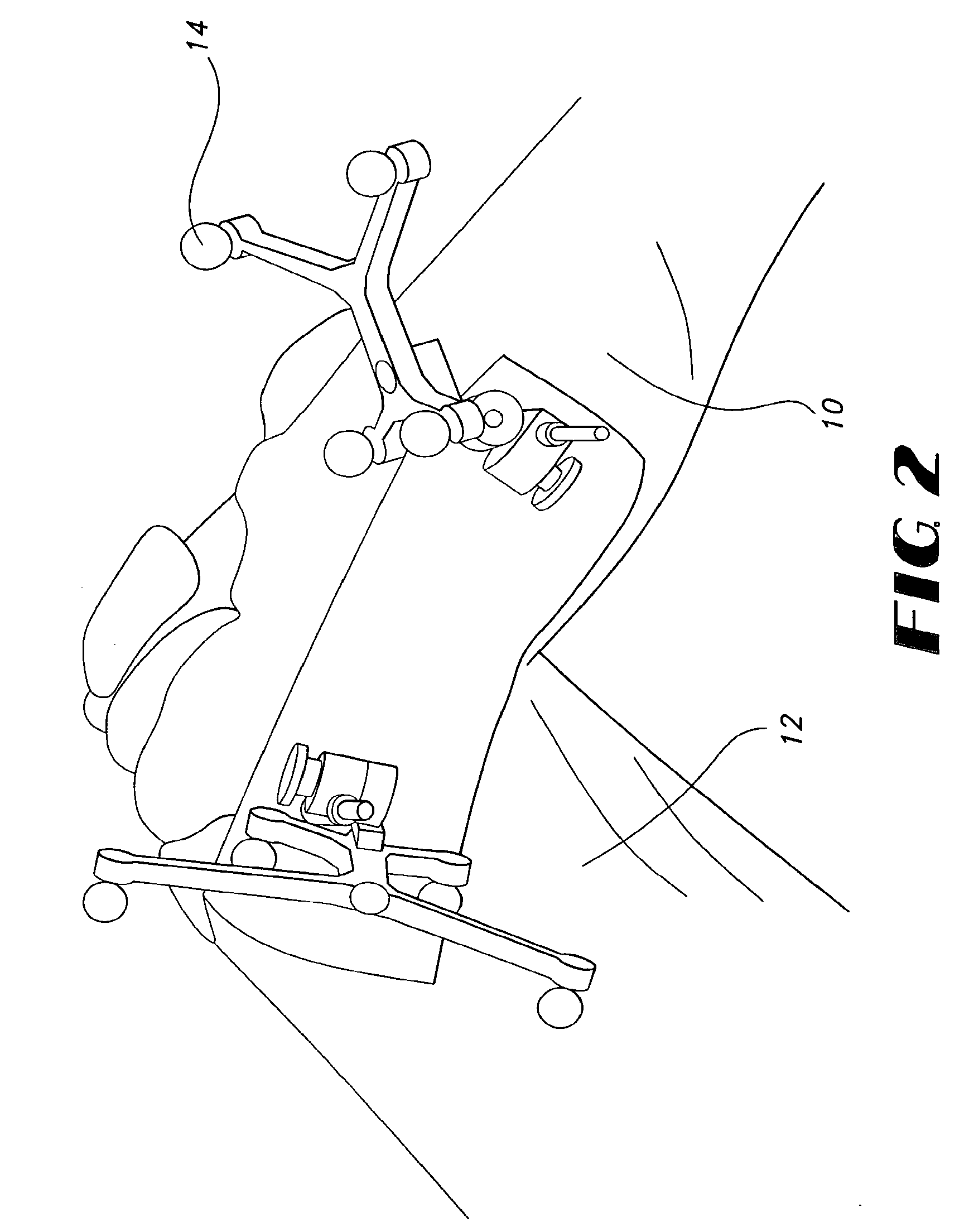

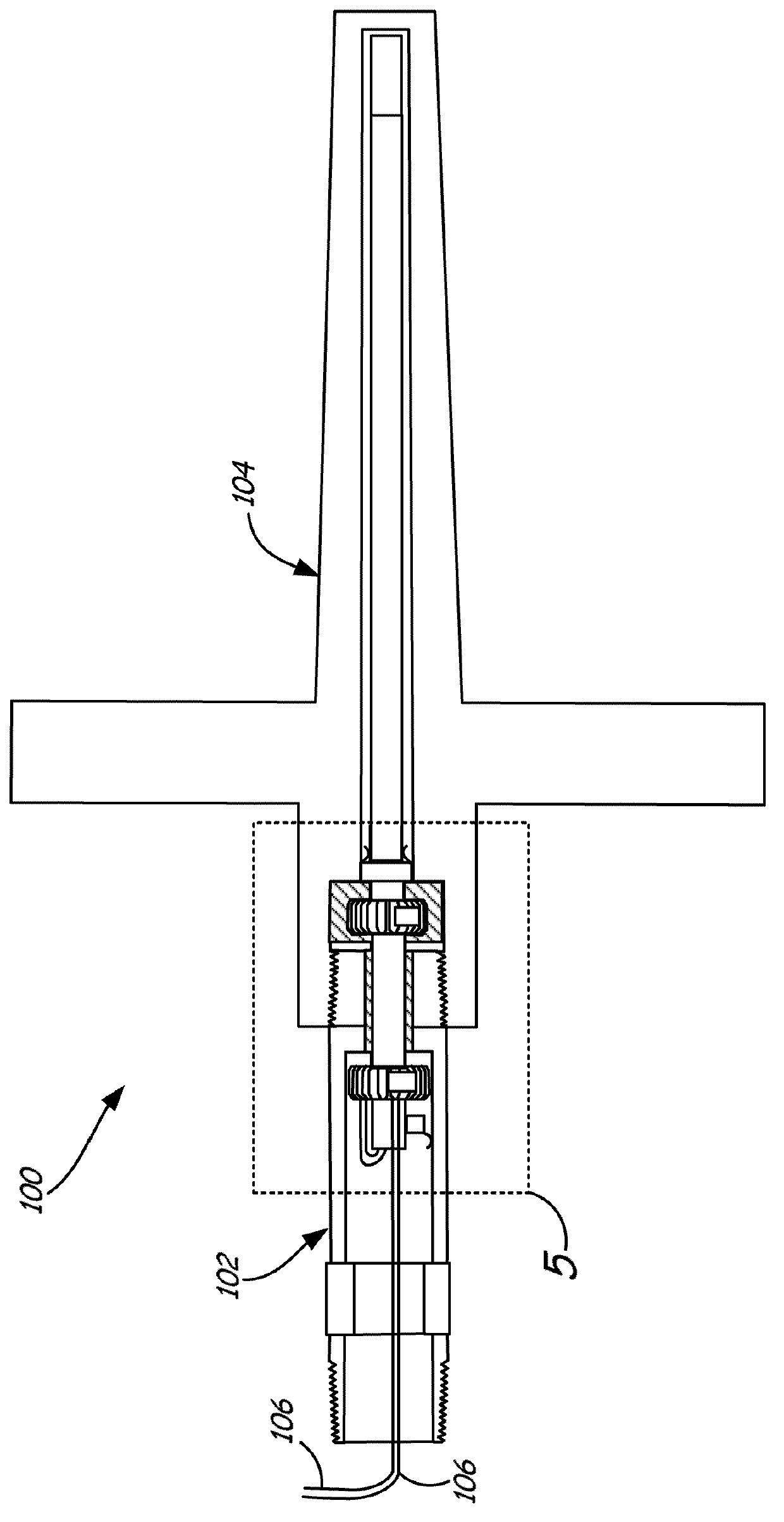

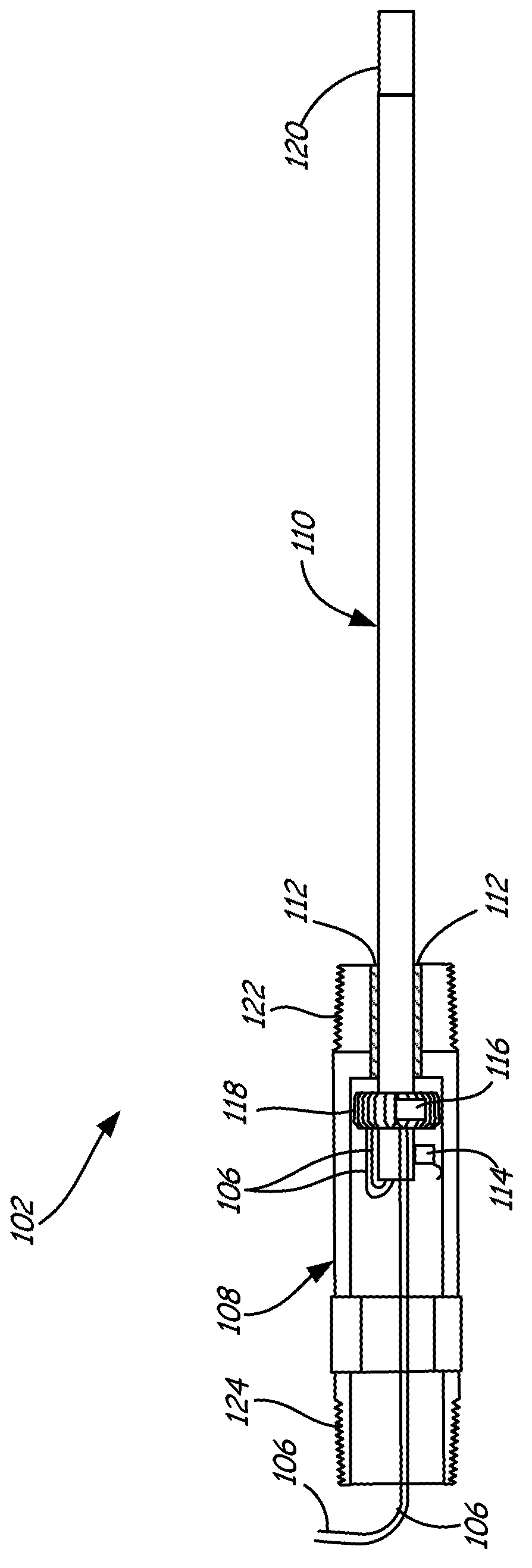

Computer assisted knee arthroplasty instrumentation, systems, and processes

ActiveUS7547307B2Performed efficiently and accuratelyImprove stabilityInternal osteosythesisDiagnosticsSurgical operationKnee Joint

Instrumentation, systems, and processes for tracking anatomy, instrumentation, trial implants, implants, and references, and rendering images and data related to them in connection with surgical operations, for example total knee arthroplasties (“TKA”). These instrumentation, systems, and processes are accomplished by using a computer to intraoperatively obtain images of body parts and to register, navigate, and track surgical instruments. Disclosed in this document are also alignment modules and other structures and processes which allow for coarse and fine alignment of instrumentation and other devices relative to bone for use in connection with the tracking systems of the present invention.

Owner:SMITH & NEPHEW INC

Computer Assisted Knee Arthroplasty Instrumentation, Systems, and Processes

InactiveUS20070233121A1Performed efficiently and accuratelyImprove stabilityInternal osteosythesisSurgical navigation systemsSurgical operationKnee Joint

Instrumentation, systems, and processes for tracking anatomy, instrumentation, trial implants, implants, and references, and rendering images and data related to them in connection with surgical operations, for example total knee arthroplasties (“TKA”). These instrumentation, systems, and processes are accomplished by using a computer to intraoperatively obtain images of body parts and to register, navigate, and track surgical instruments. Disclosed in this document are also alignment modules and other structures and processes which allow for coarse and fine alignment of instrumentation and other devices relative to bone for use in connection with the tracking systems of the present invention.

Owner:CARSON CHRISTOPHER PATRICK +2

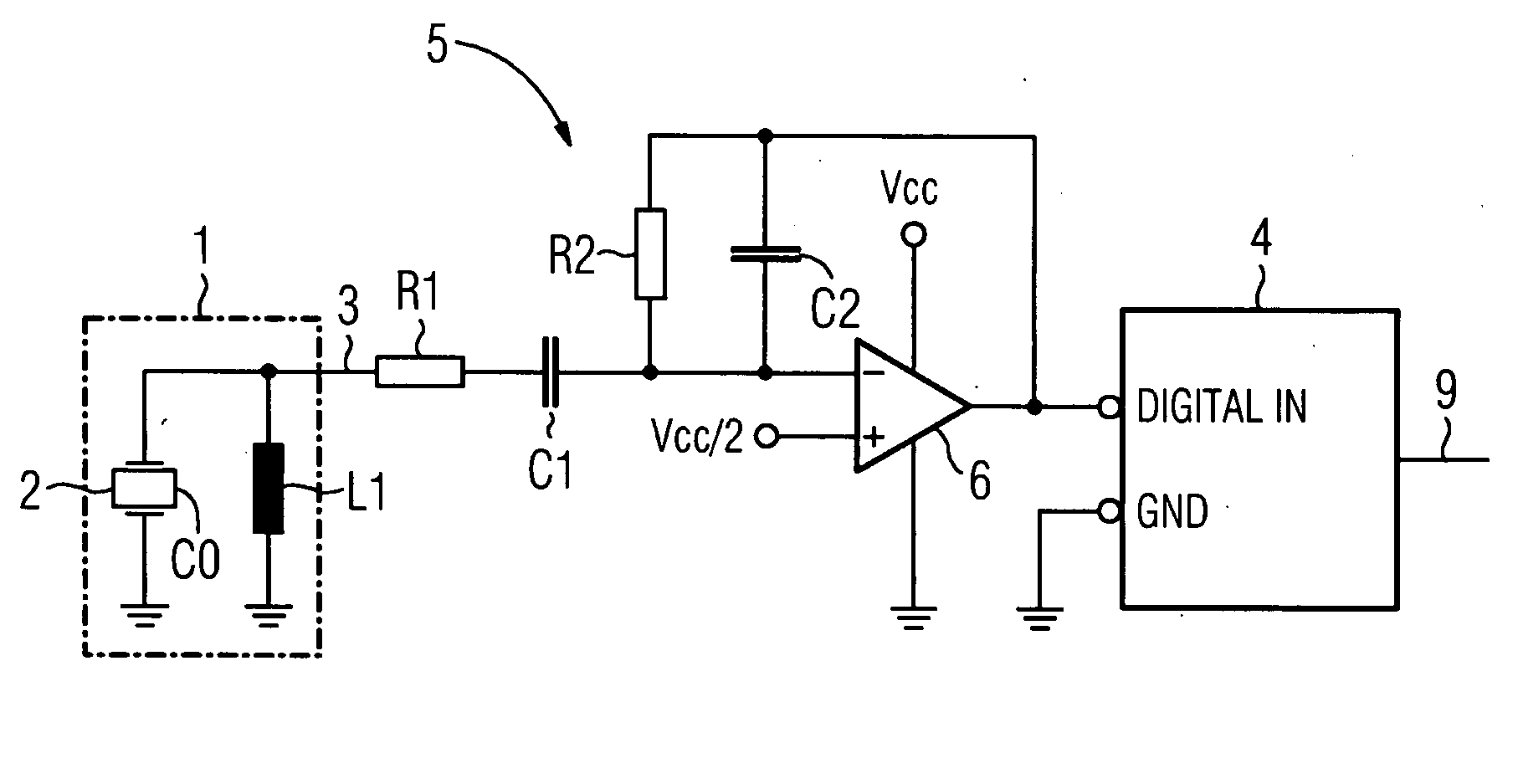

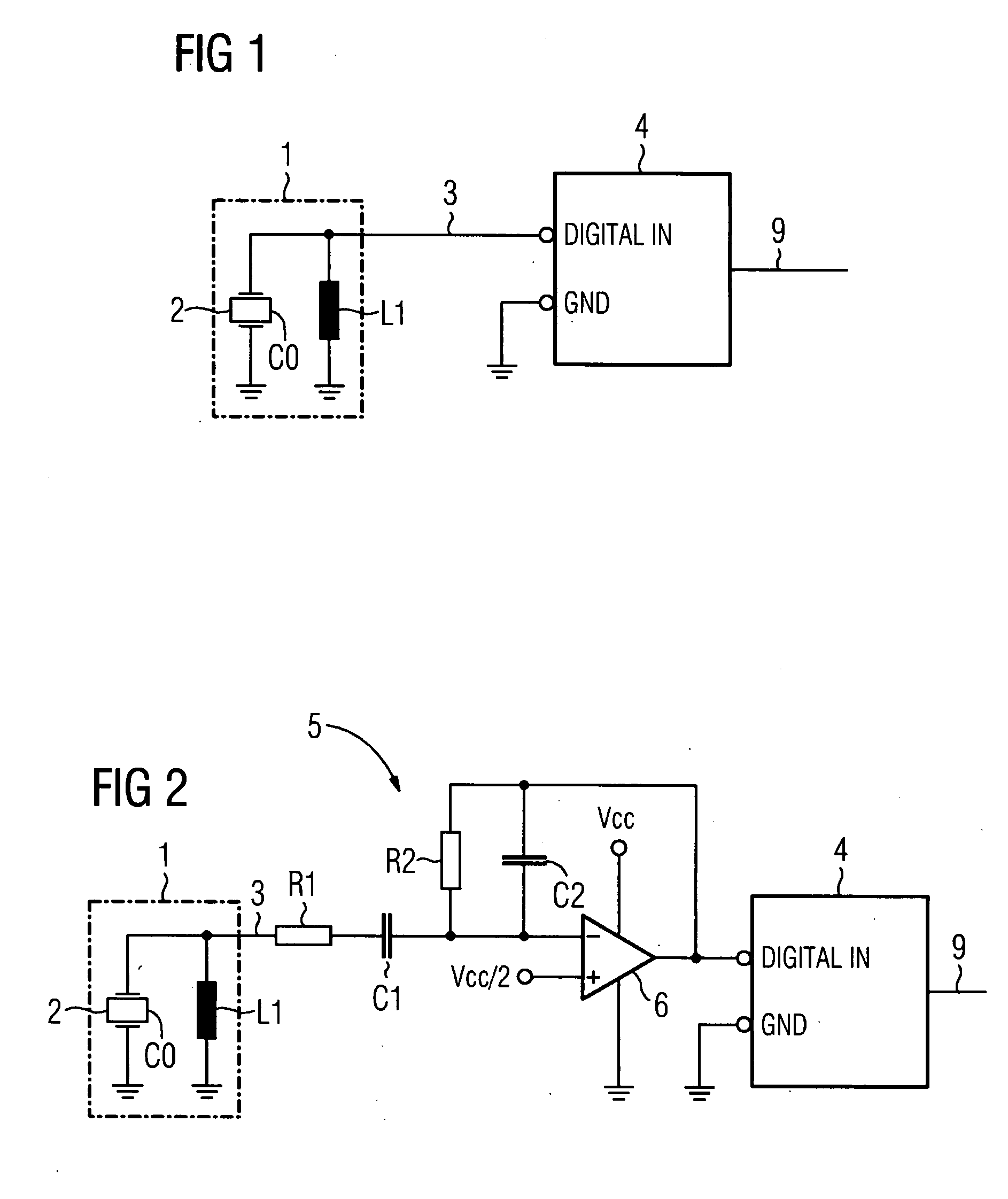

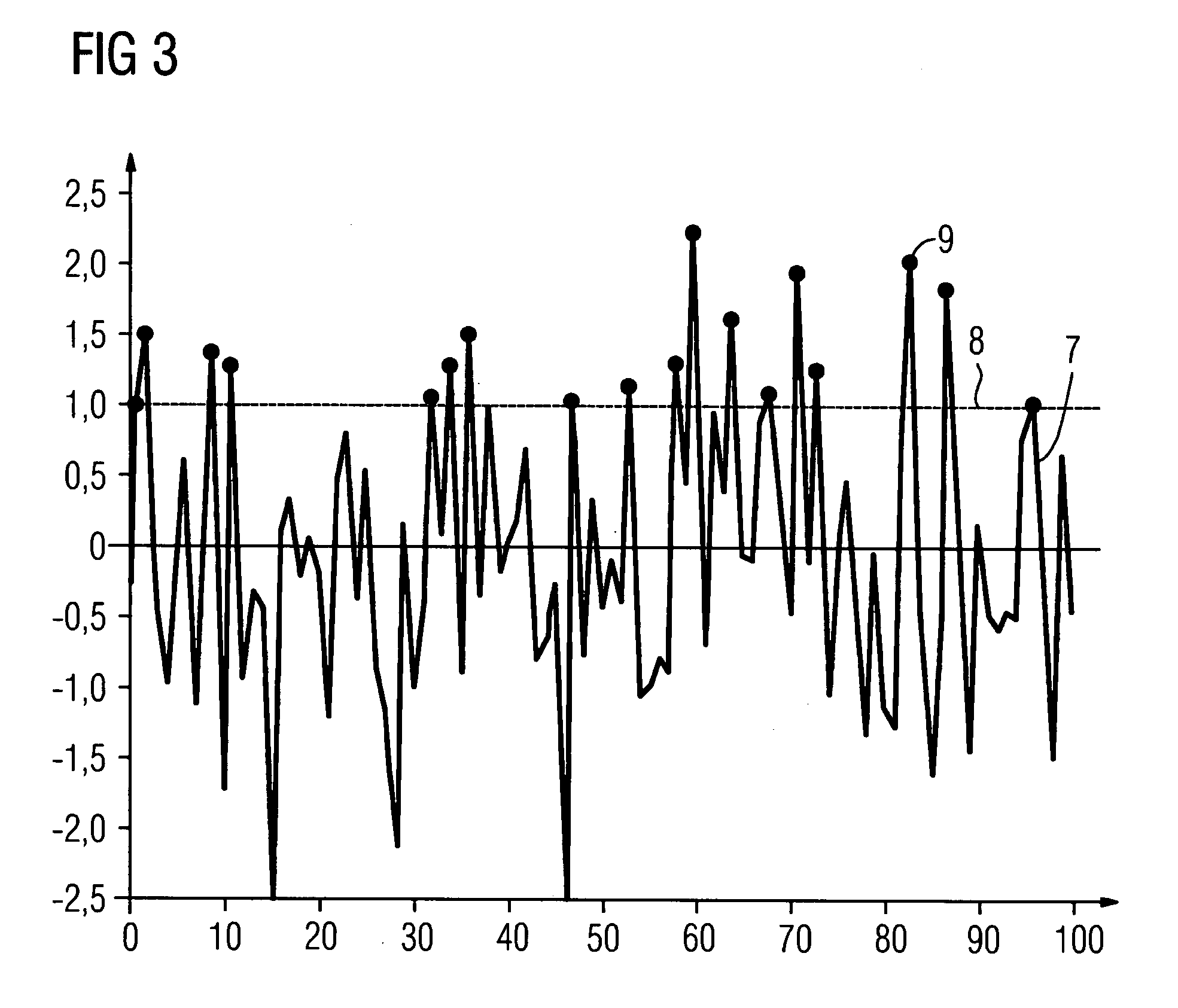

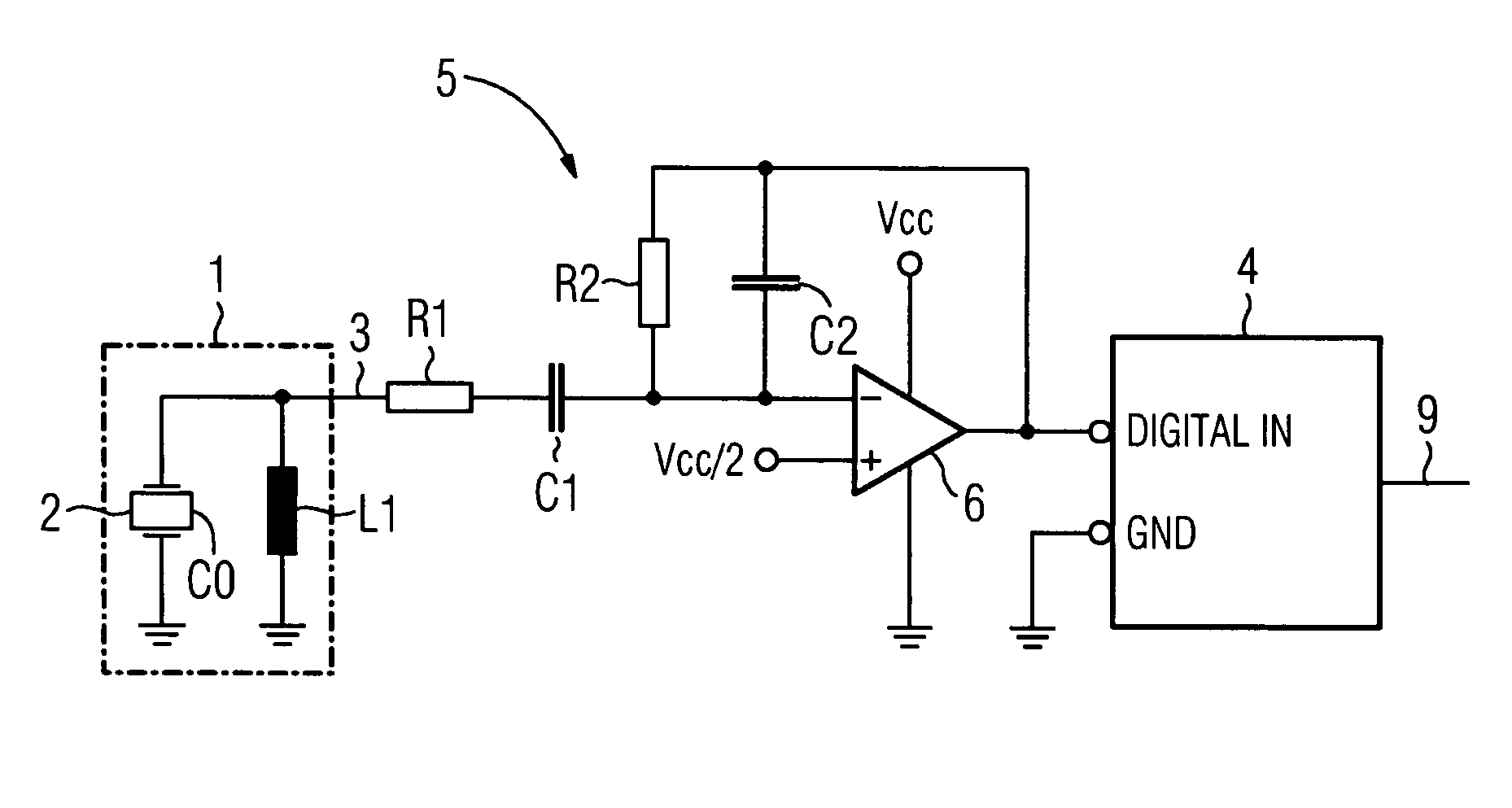

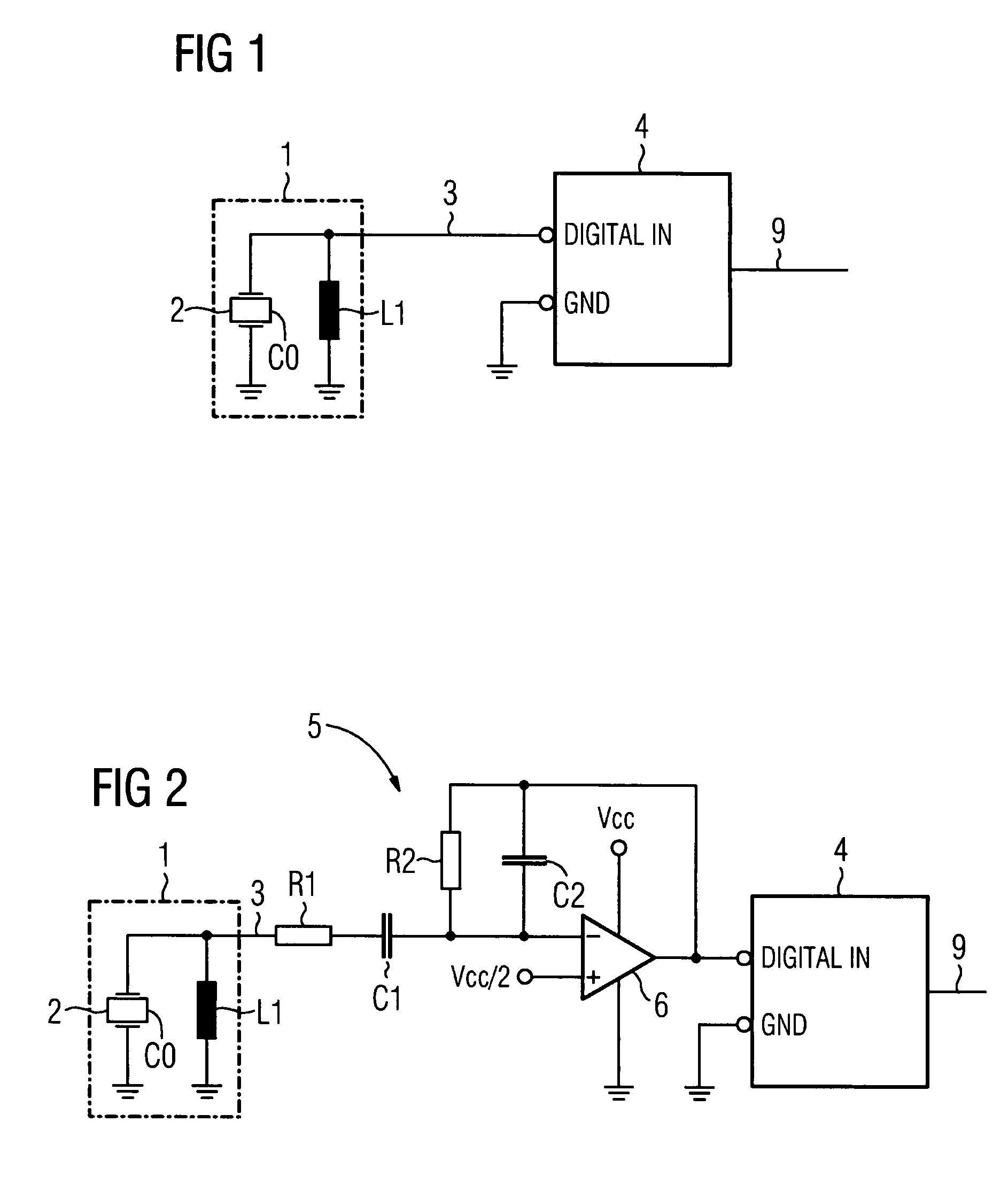

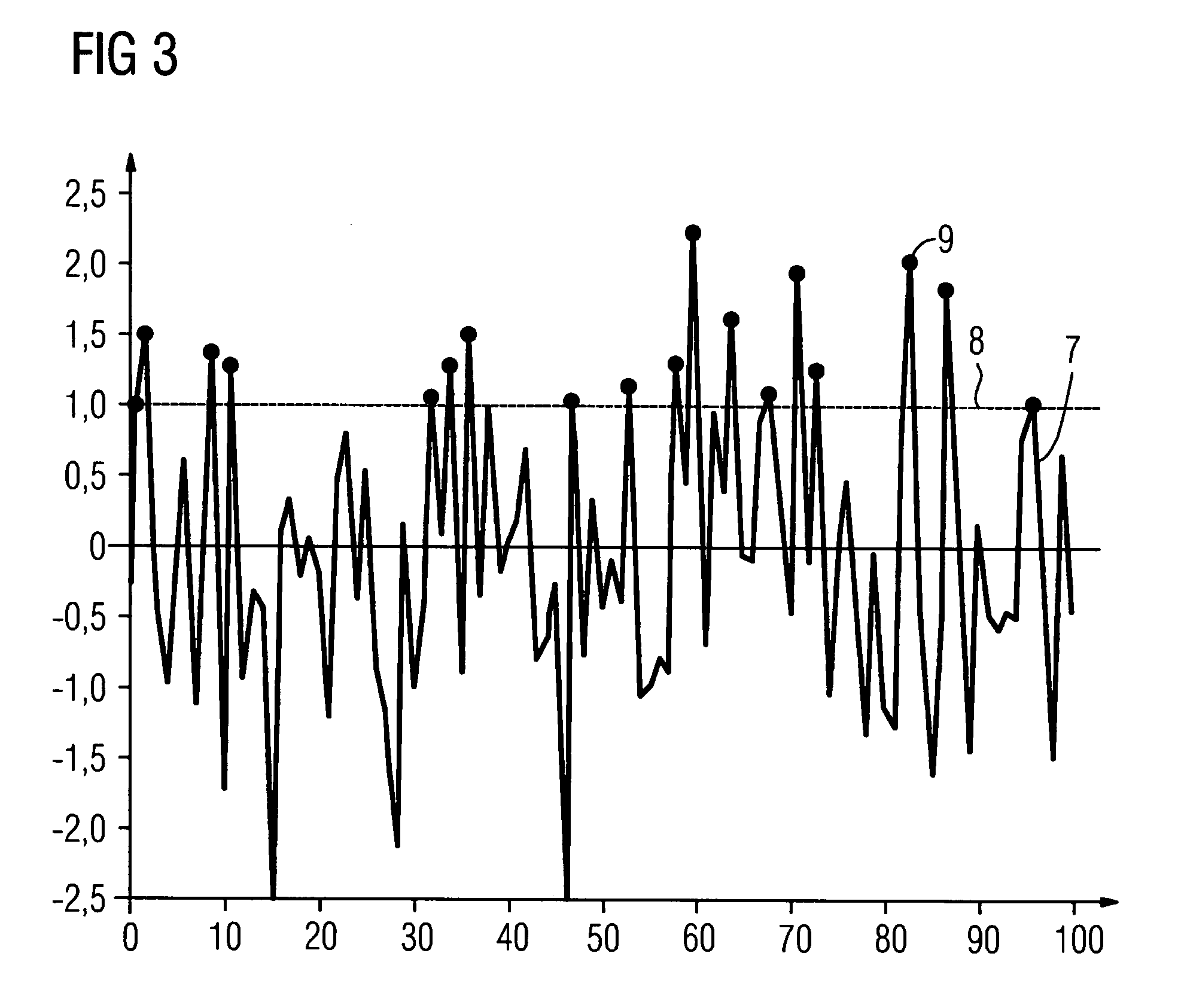

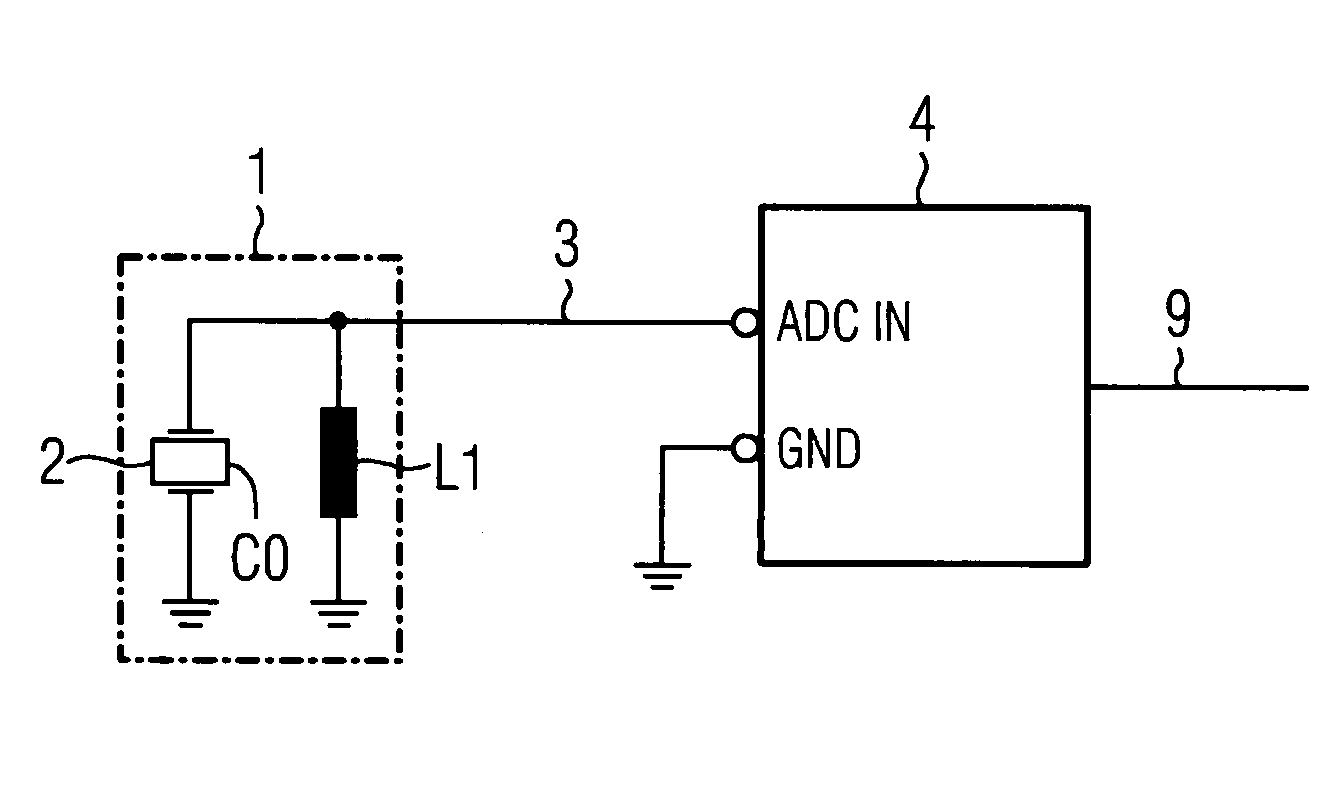

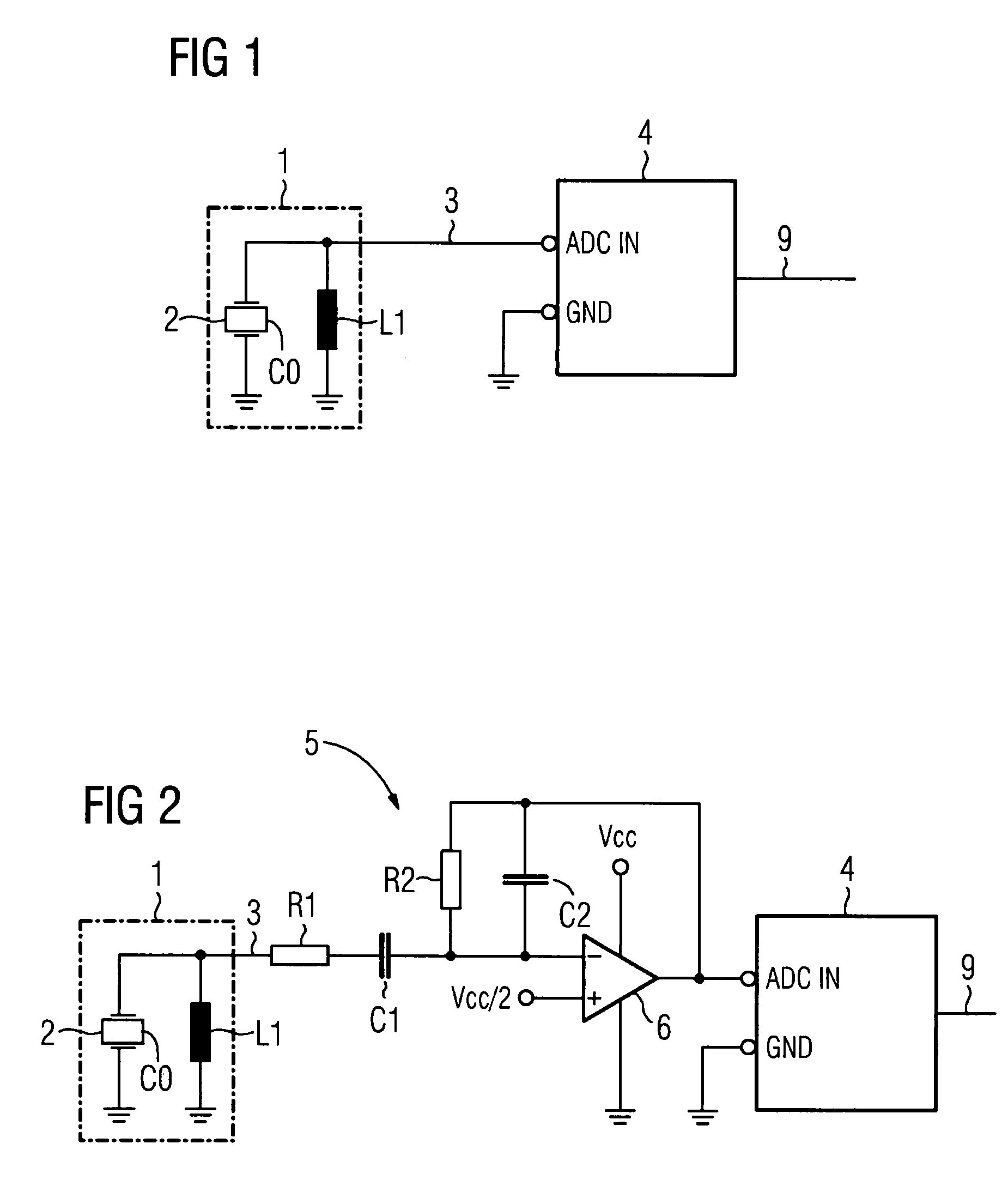

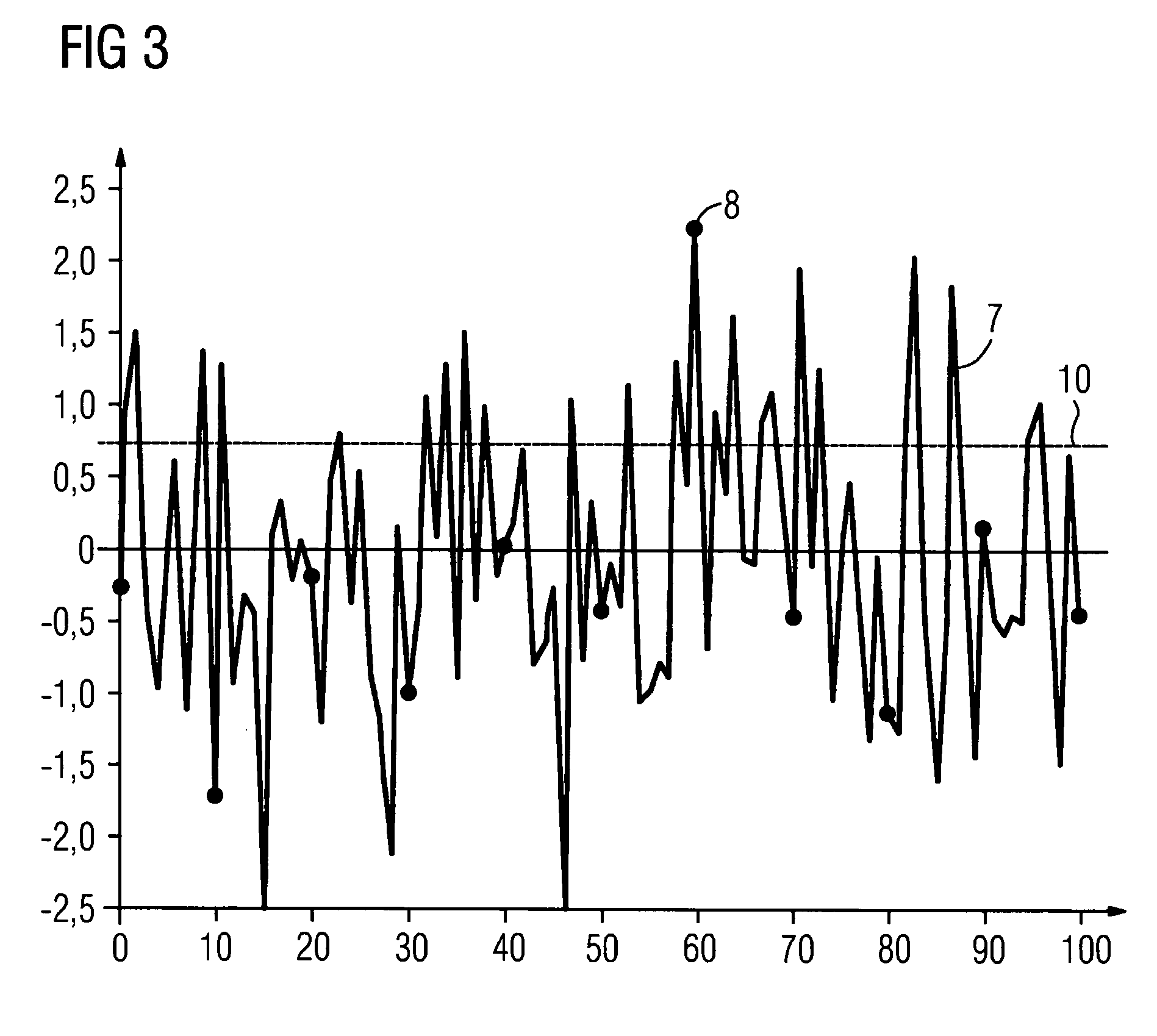

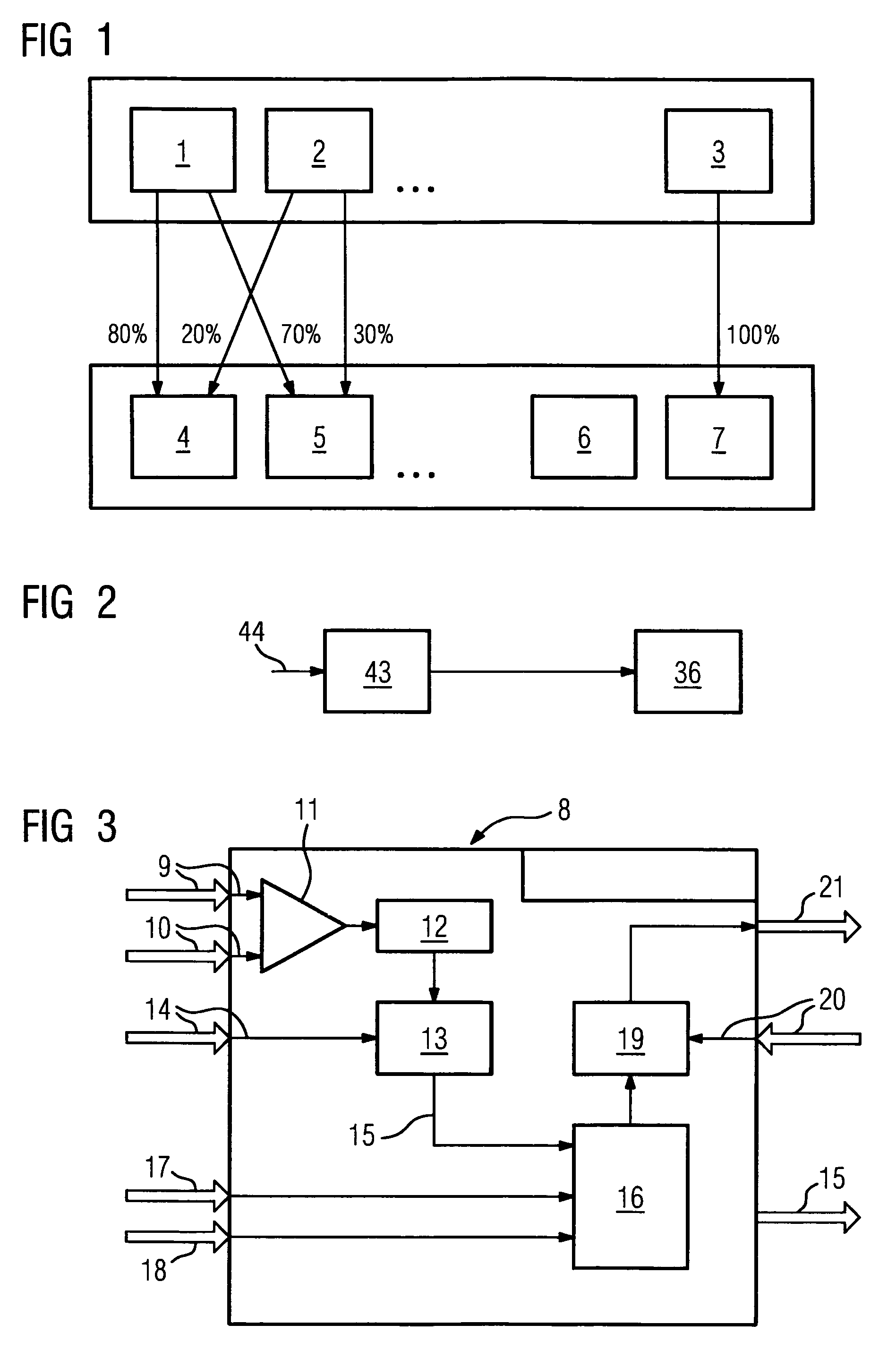

Method and system for diagnosing mechanical, electromechanical or fluidic components

InactiveUS20090090186A1Less switchingLess energy expenseVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesBandpass filteringEngineering

There is described a diagnosis method and a system comprising a structure-born noise sensor which transmits, in a bandpass filtered manner, a measuring signal based on the mechanical resonance frequency and capacity thereof and on an inductance and an evaluating device in which the frequency, at which the measuring signal level exceeds a predetermined threshold value, is defined and which is used for producing an error signal, when the frequency exceeds a second predetermined threshold value. As far as the diagnosis performance requires a small number of electronic components and a low power supply, the diagnostic can be integrated into existing devices, in particular into process instrumentation field devised for which a restricted quantity of operating power is available. The method and the system can be used for identifying a valve leakage with the aid of an electro-pneumatic positional regulator.

Owner:SIEMENS AG

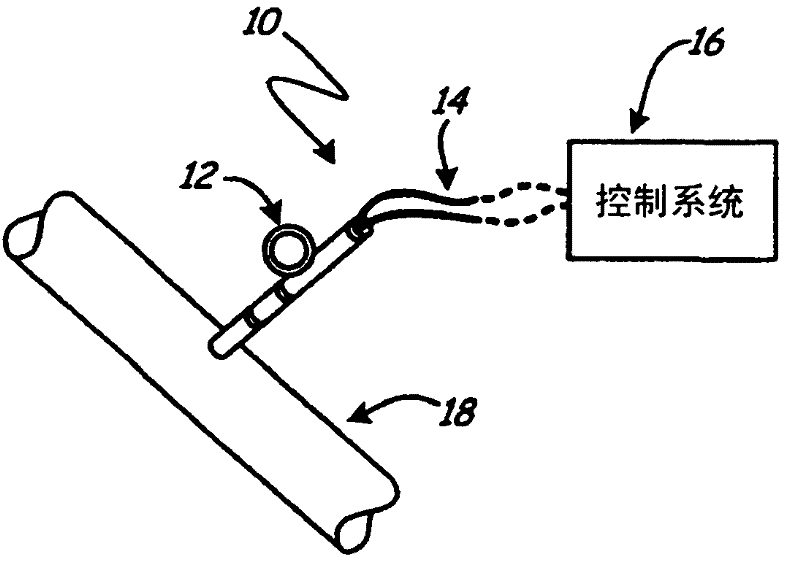

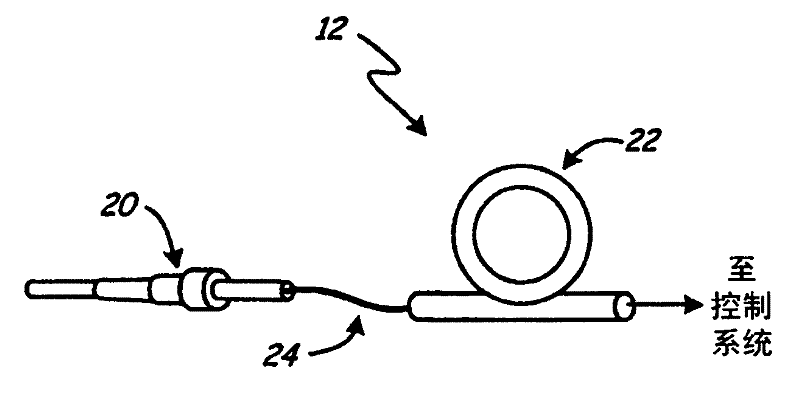

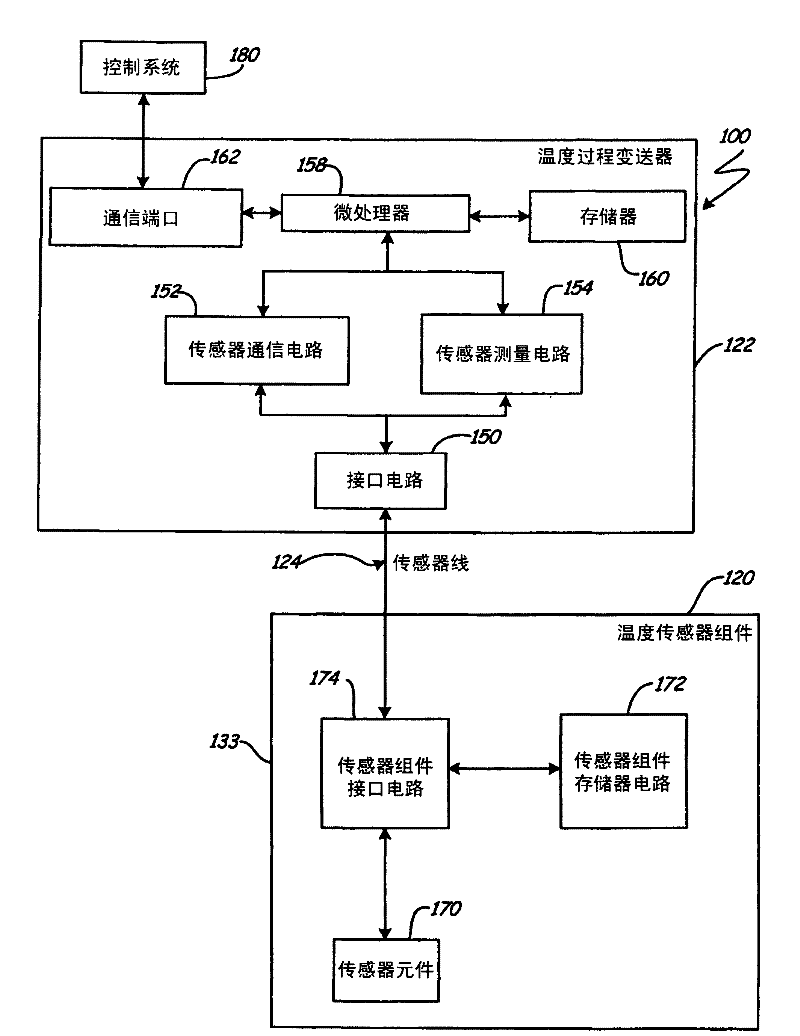

Sensor/transmitter plug-and-play for process instrumentation

ActiveCN102187179AThermometer detailsThermometers using electric/magnetic elementsEngineeringMemory circuits

A sensor assembly with a sensing element sends a sensor signal from the sensing element to attached process transmitter over sensor connection wires. The sensor assembly has memory circuitry for storing information related to the sensor assembly and interface circuitry that provides for digital communication of the stored information with the attached process transmitter. This digital communication is sent over the sensor connection wires.

Owner:ROSEMOUNT INC

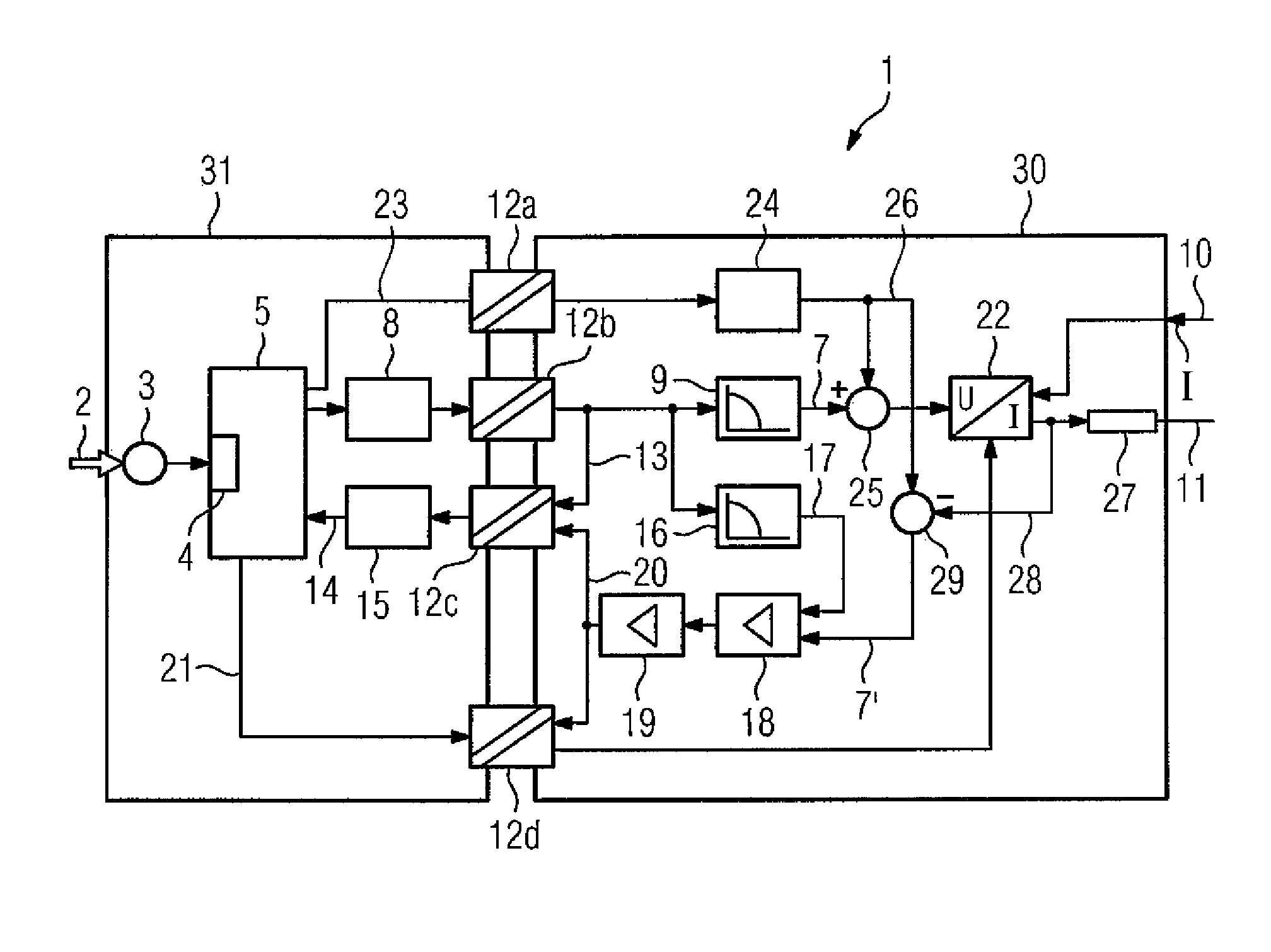

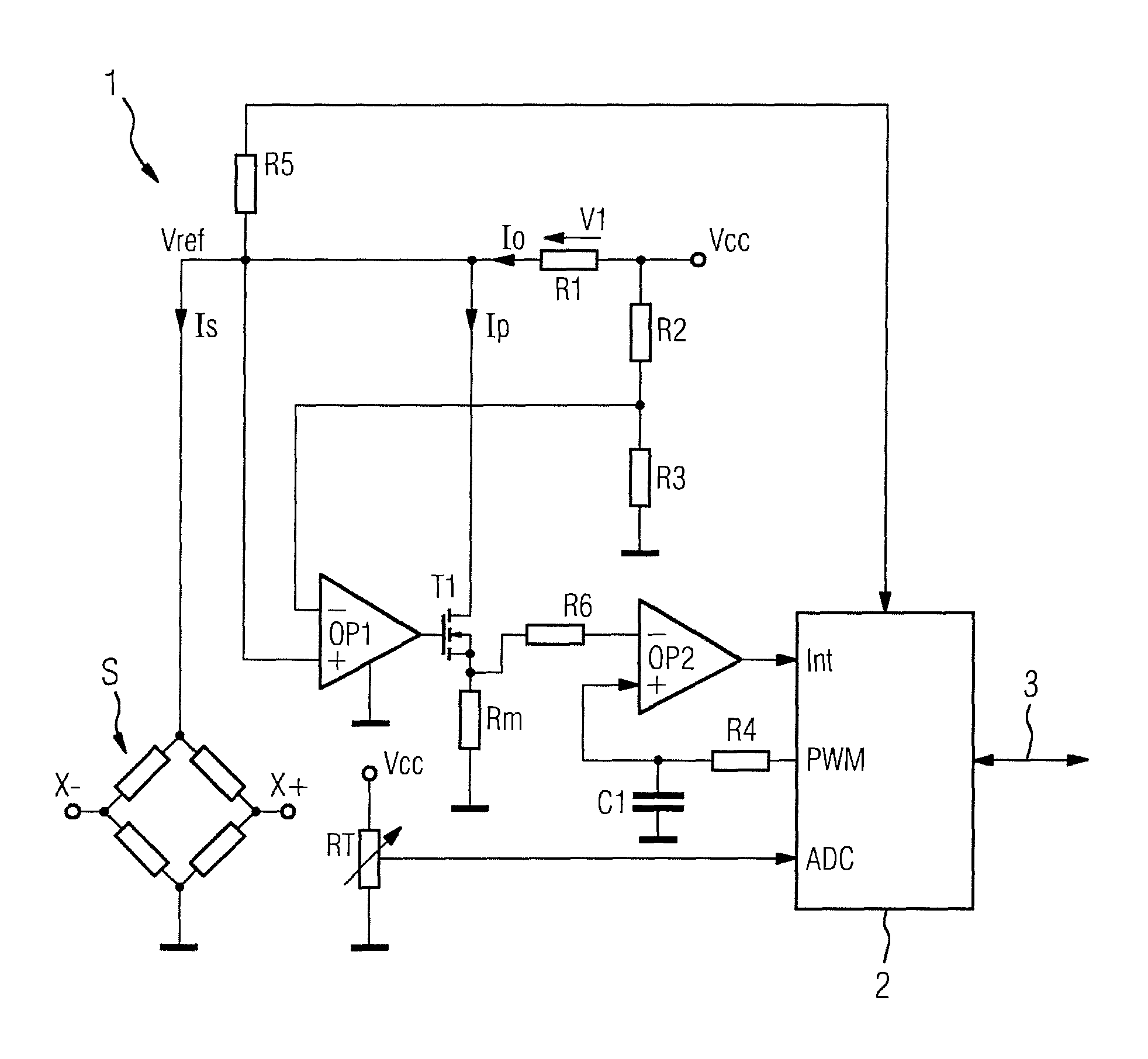

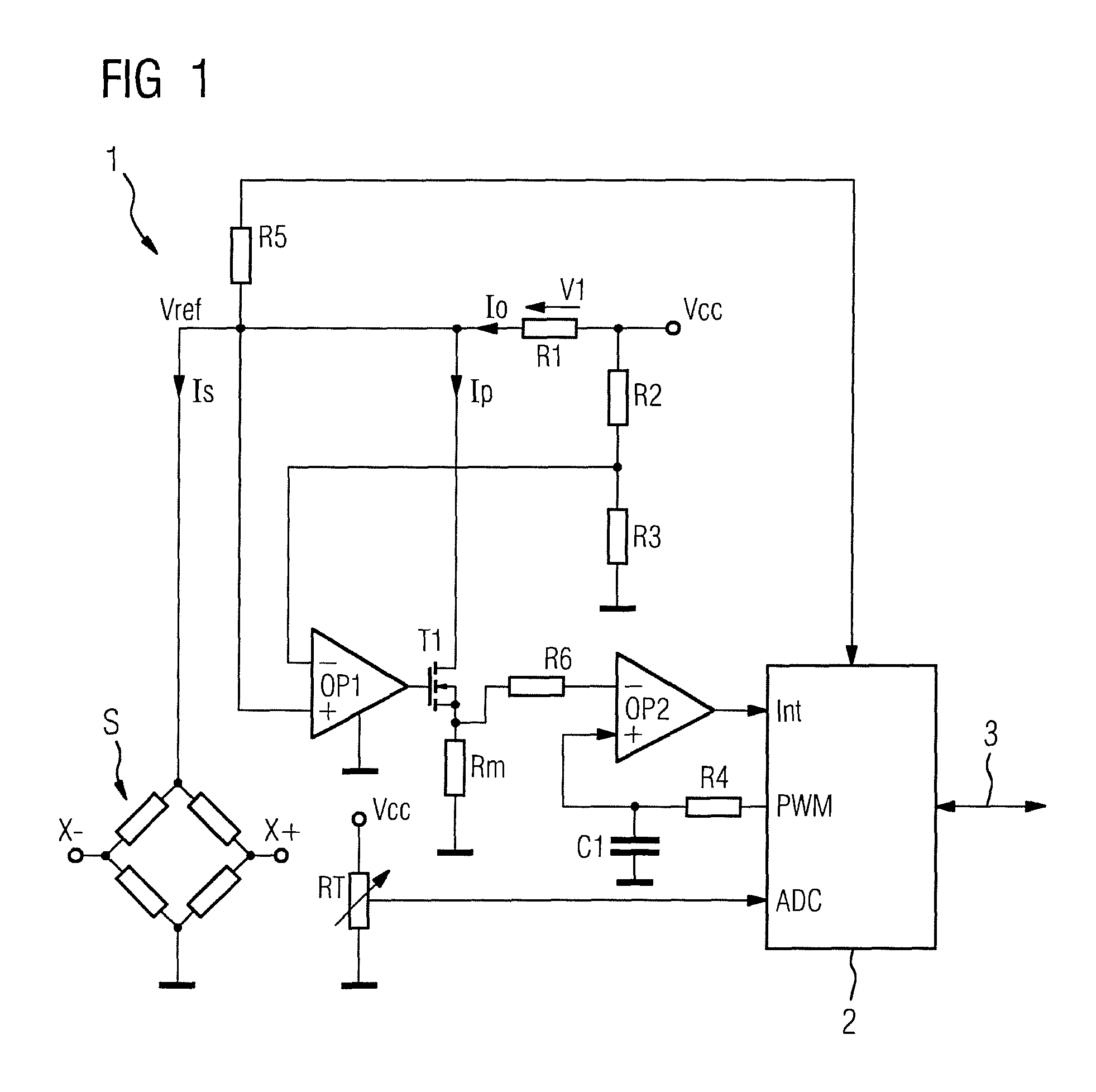

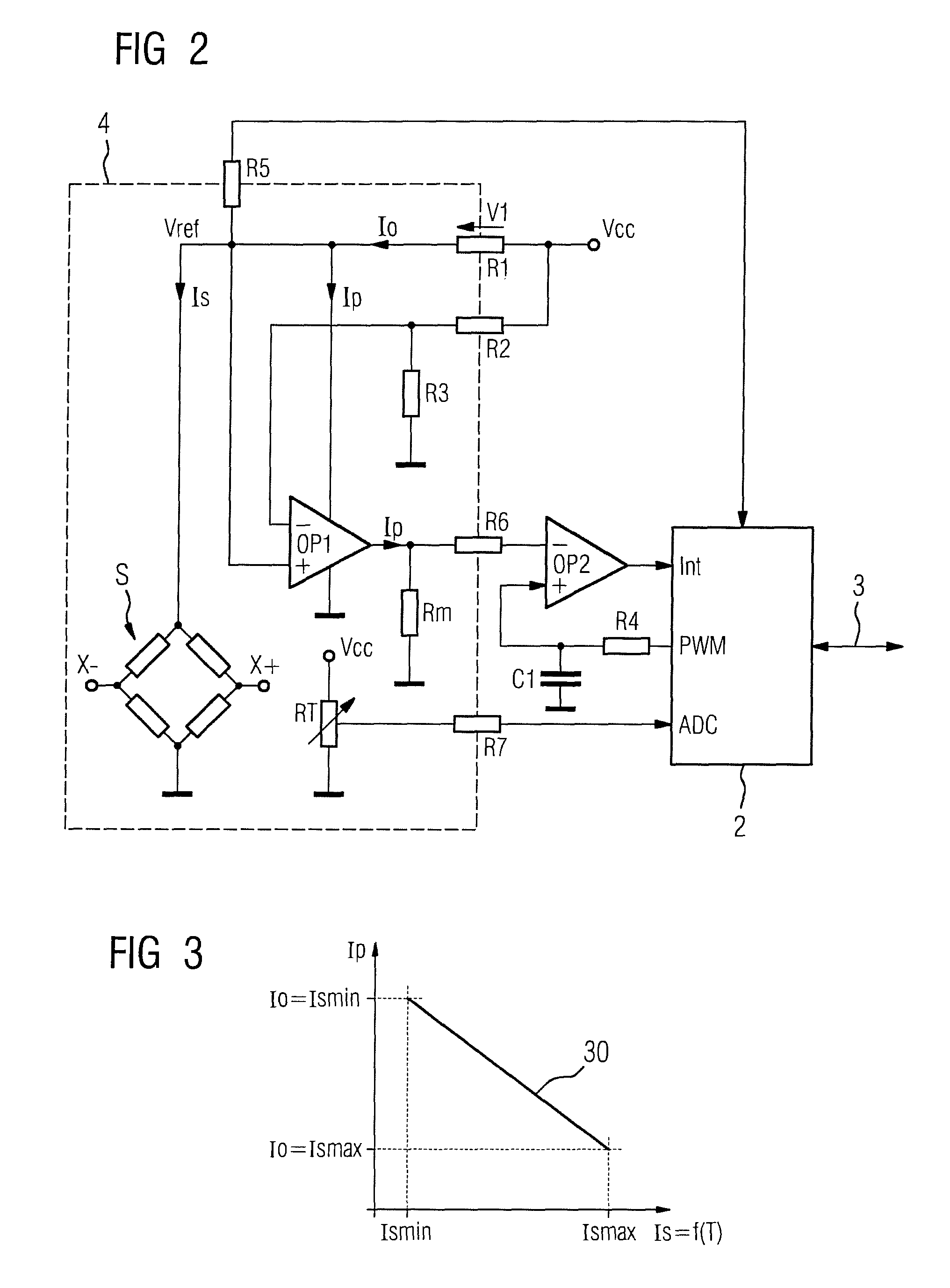

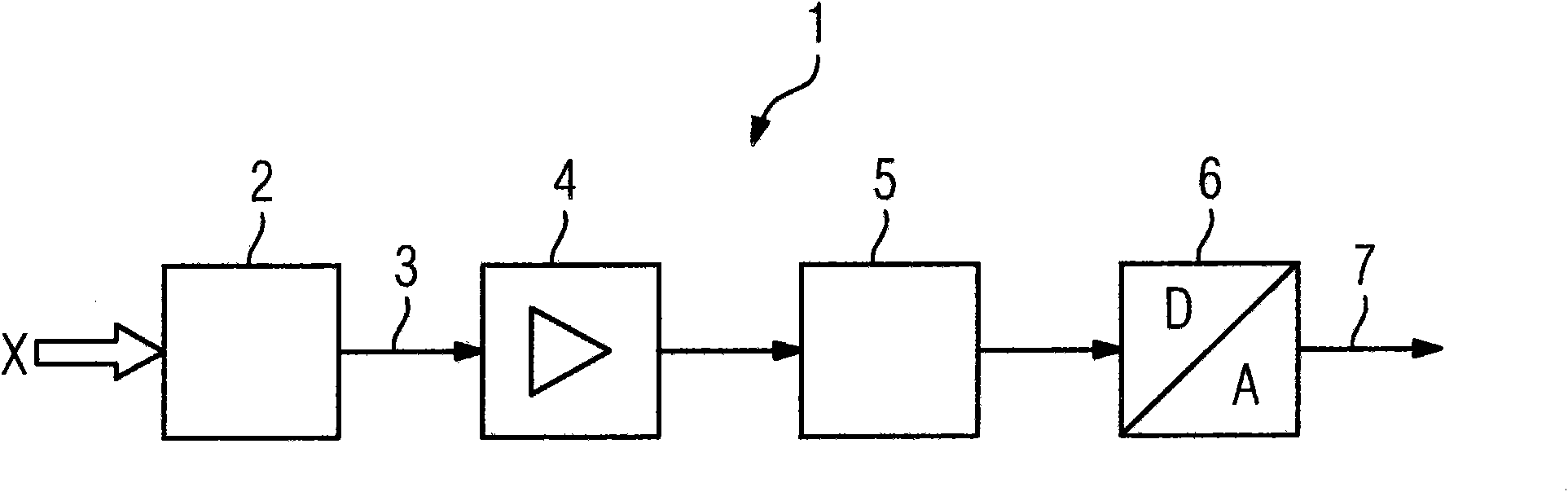

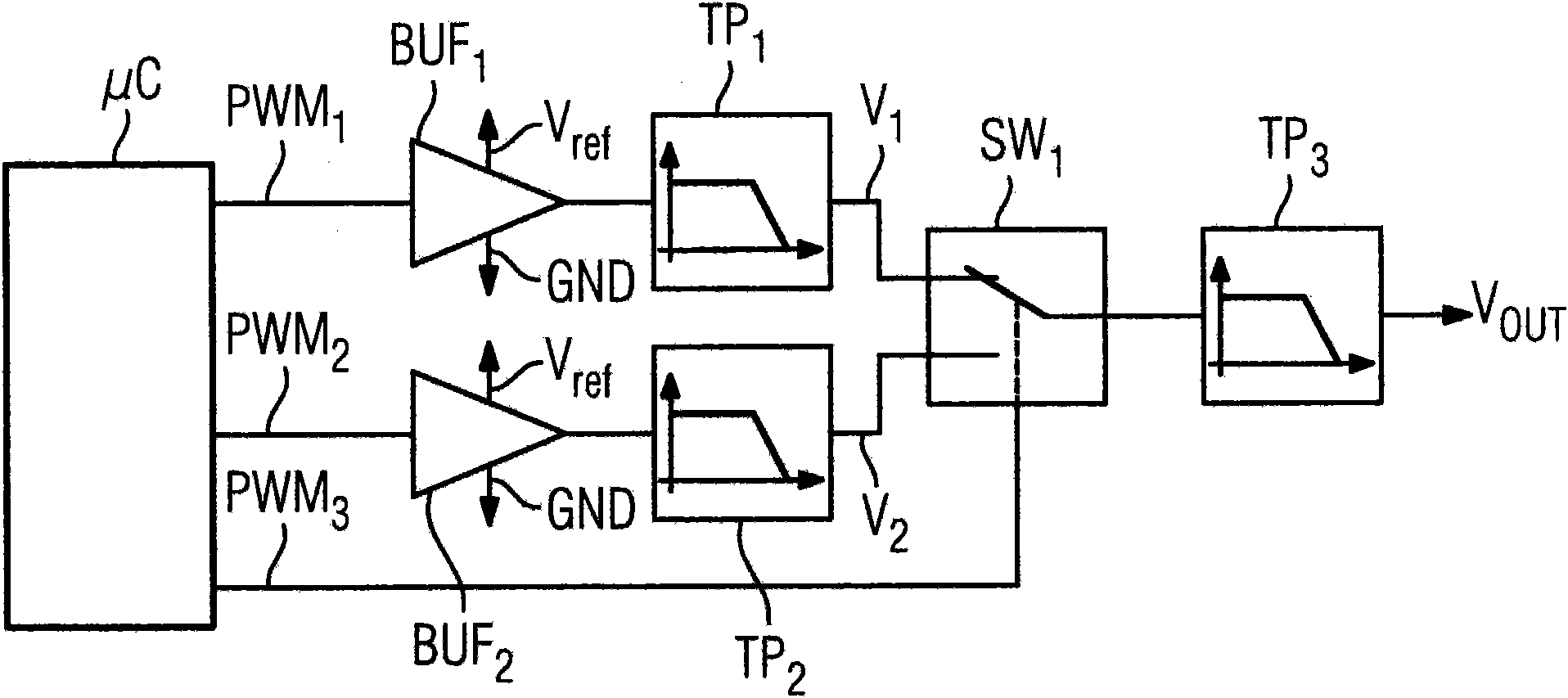

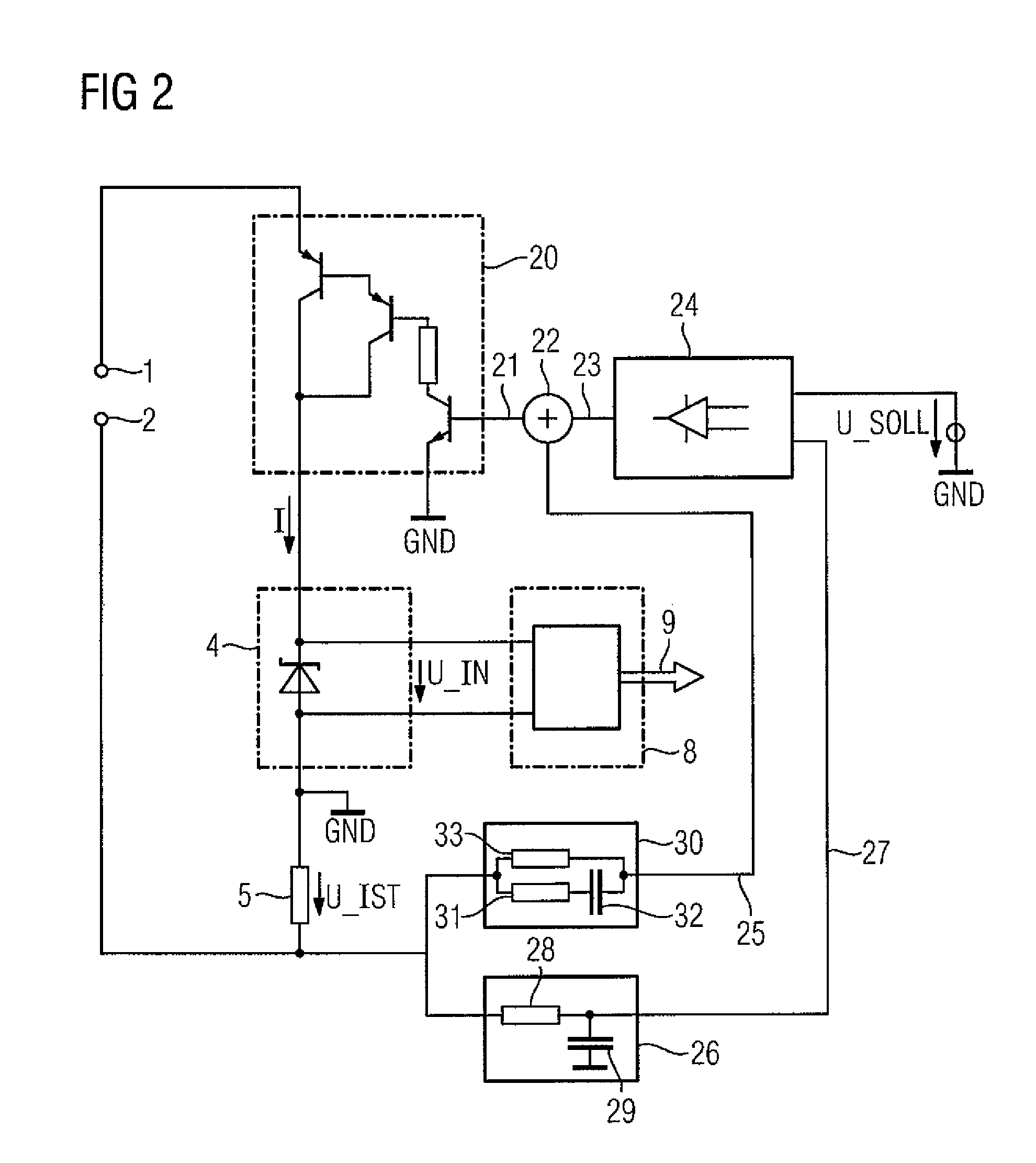

Field Device Having an Analog Output

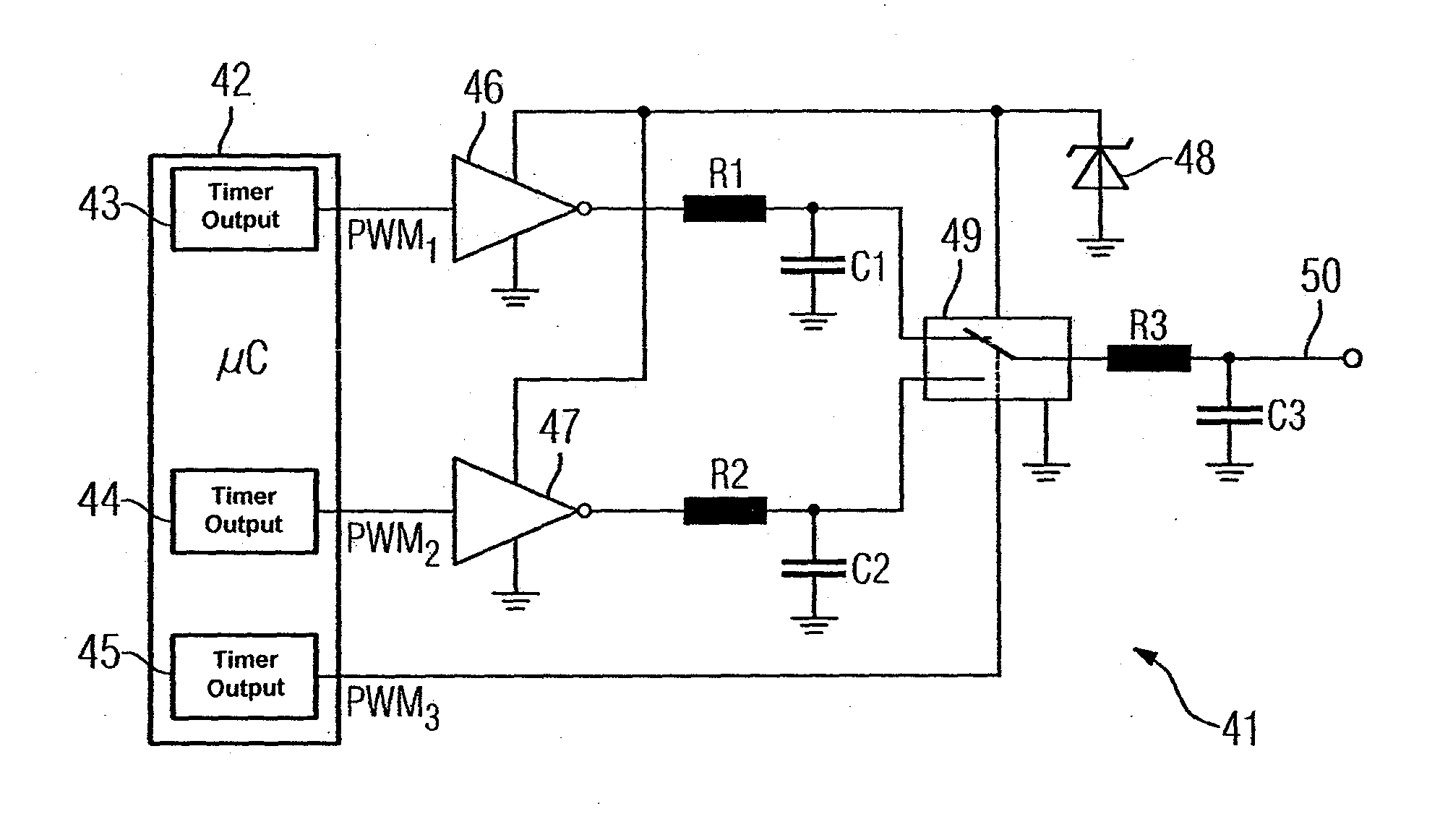

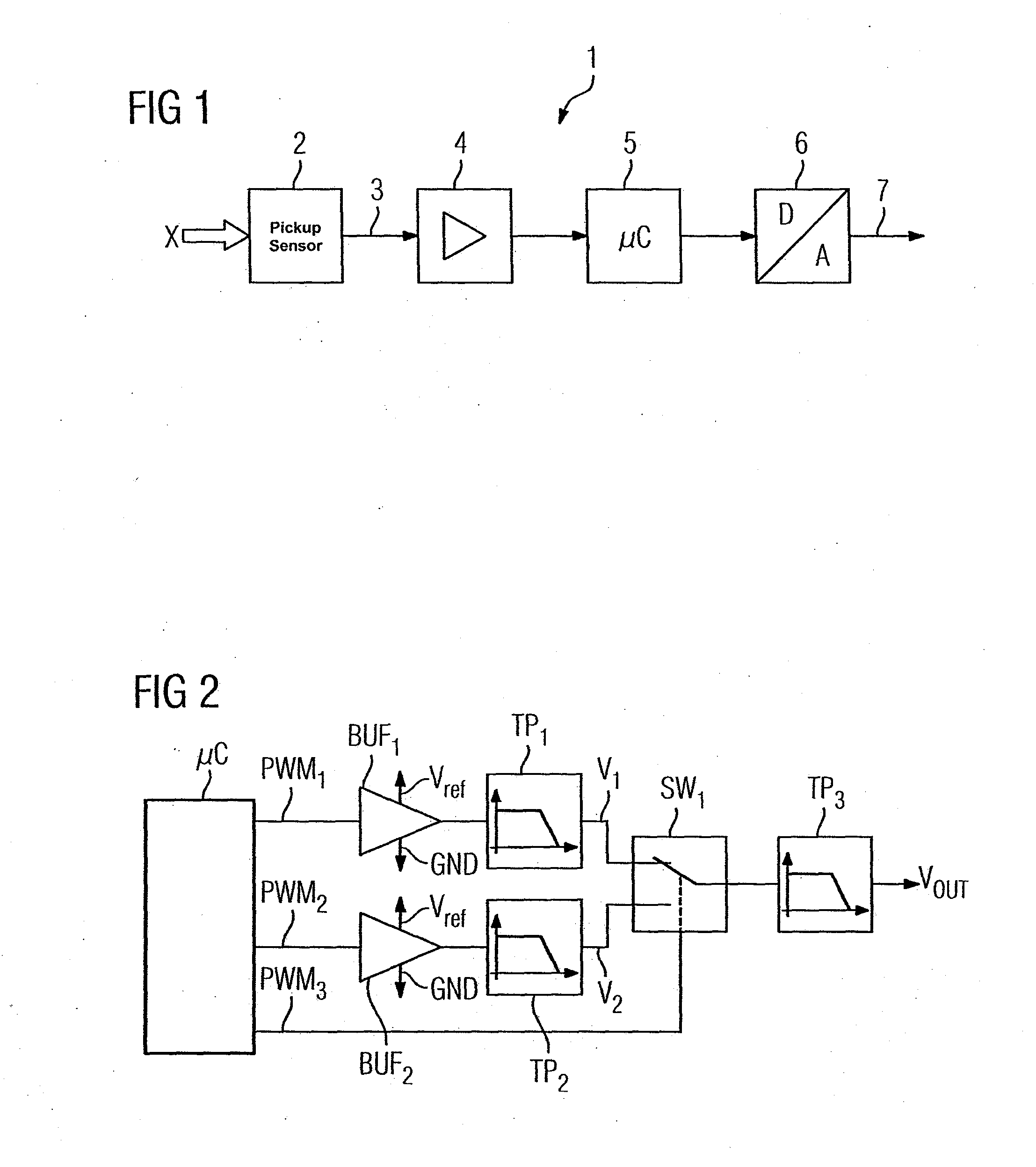

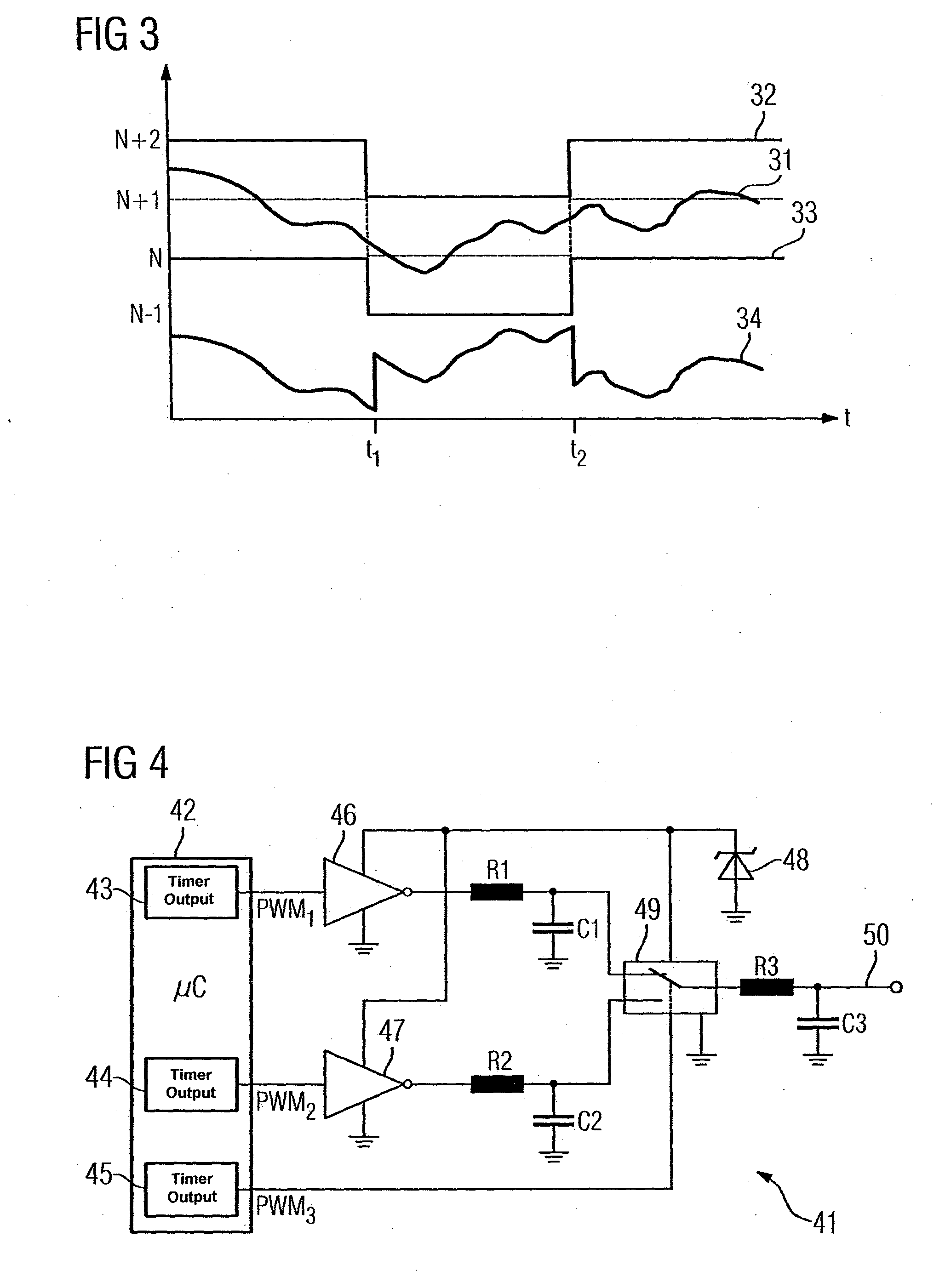

InactiveUS20100302085A1Reduce power consumptionLarge dynamic rangeElectric signal transmission systemsAltering/correcting law of variationLow-pass filterTransducer

A field device having an analog output, i.e., a measuring transducer, for process instrumentation having a 4-20 mA interface as the analog output. For digital-to-analog conversion, a digital value is split into a digital coarse portion and a digital fine portion. Depending on the digital coarse portion, a first analog signal is generated using a pulse width modulator having a downstream mounted low path filter and a signal above the analog output signal, and a second output signal using a pulse width modulator also having a downstream mounted low path filter with a signal below the analog output signal. The analog signals are supplied to a third pulse width modulator controlled with the digital fine portion, where a low-pass filter (TP3) is downstream mounted. As a result, an analog output signal is provided having a high resolution and good dynamic properties. In addition, the field device is provided with a digital-to-analog converter that can be produced having minimal complexity.

Owner:SIEMENS AG

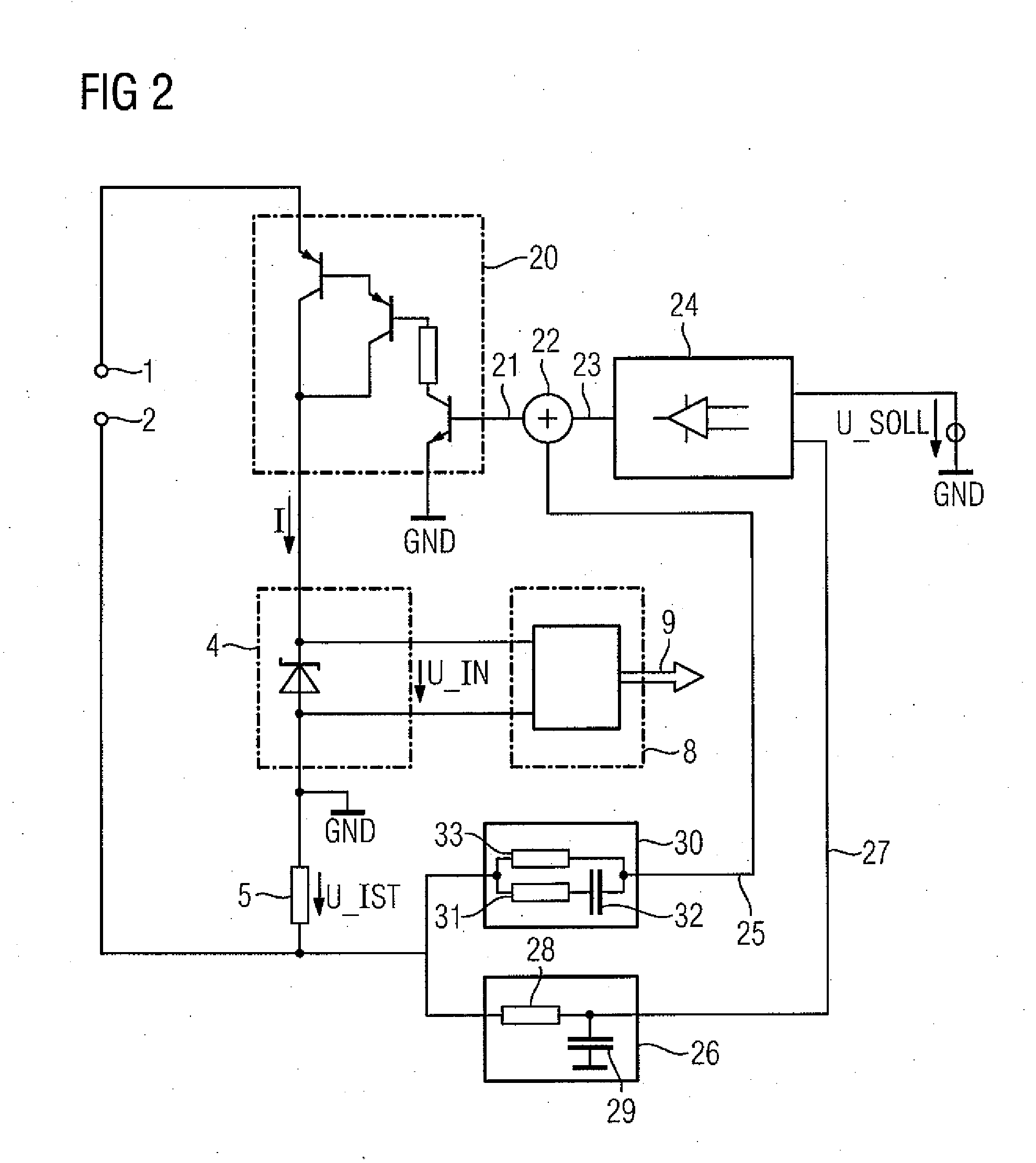

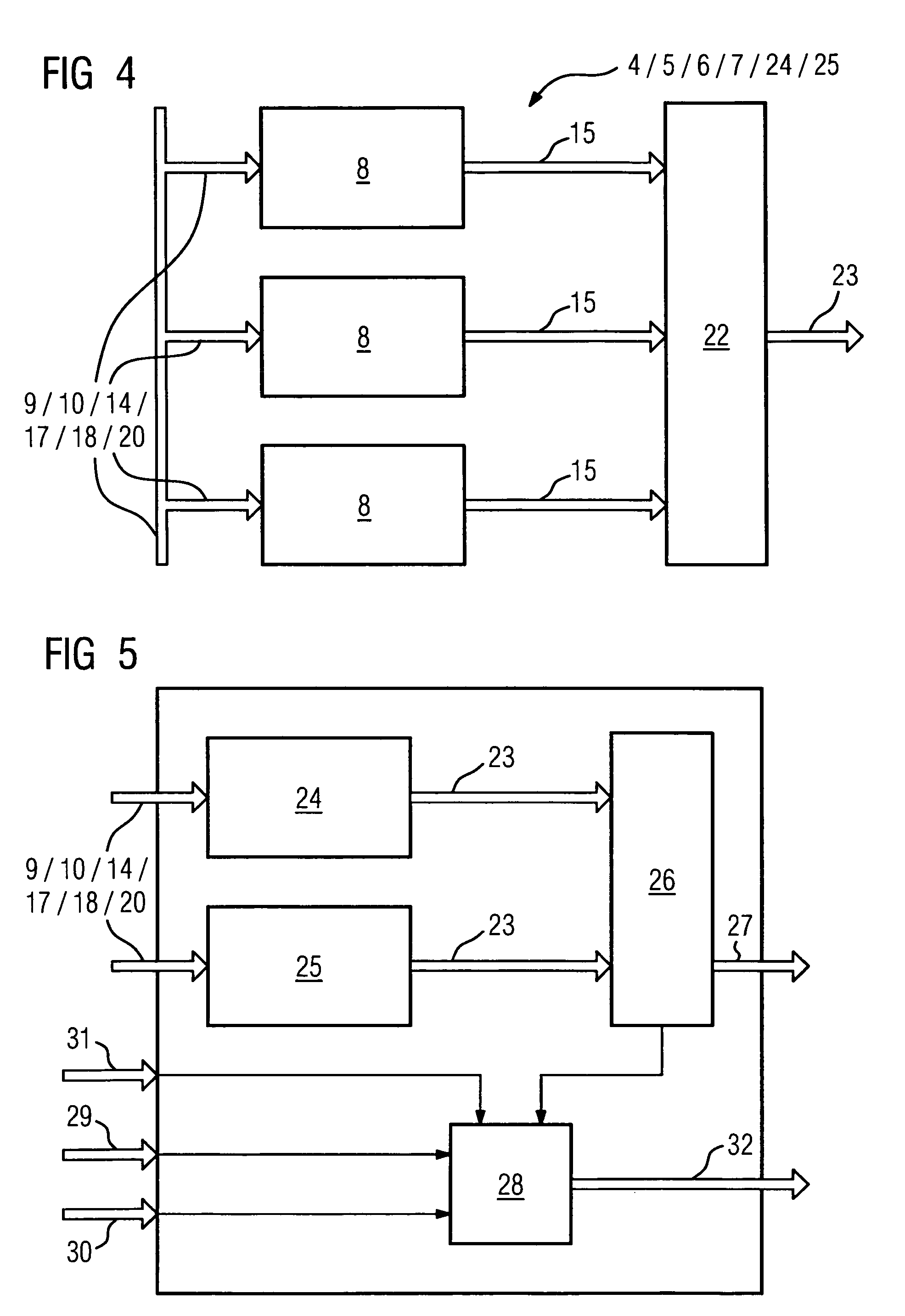

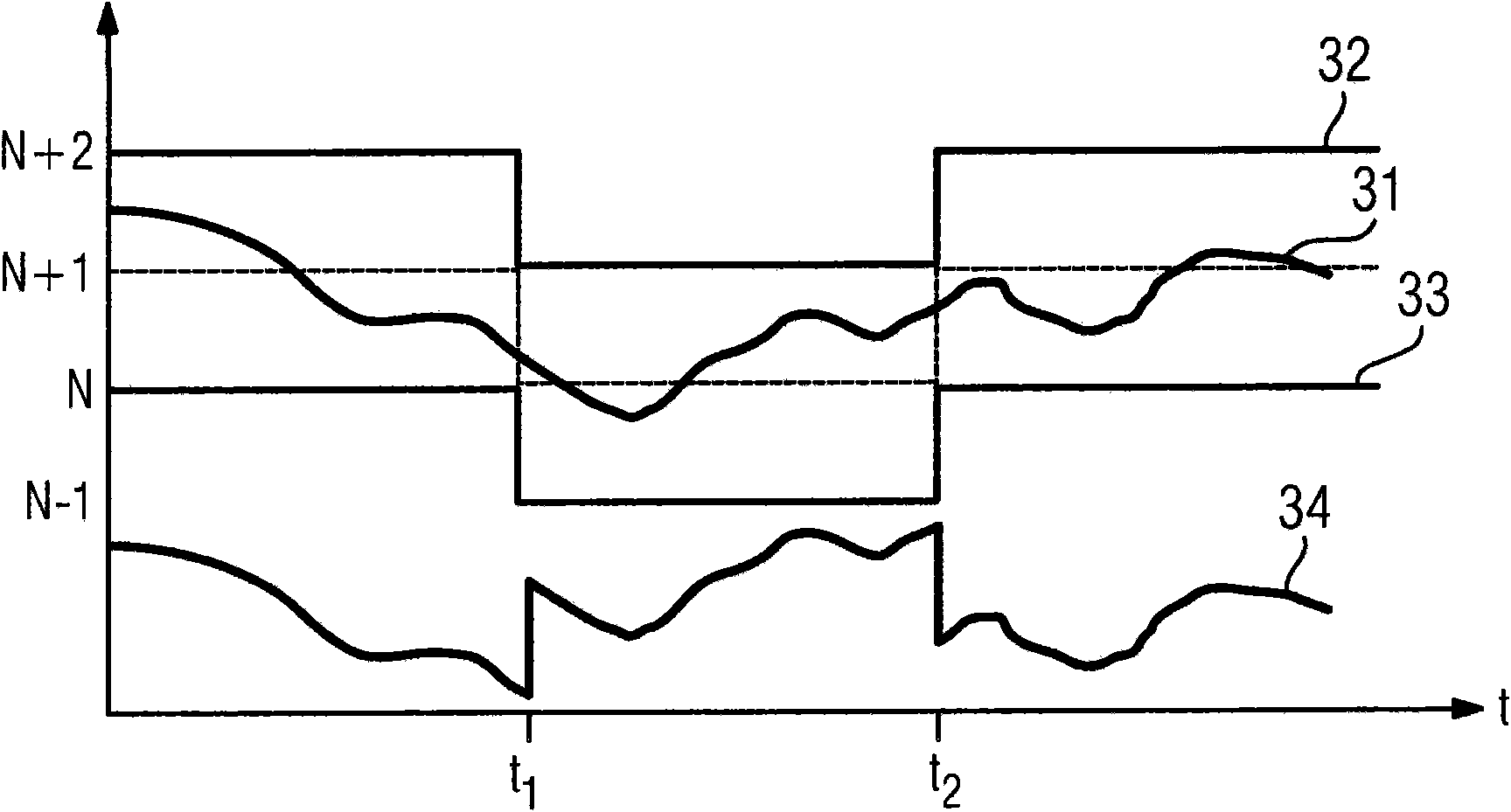

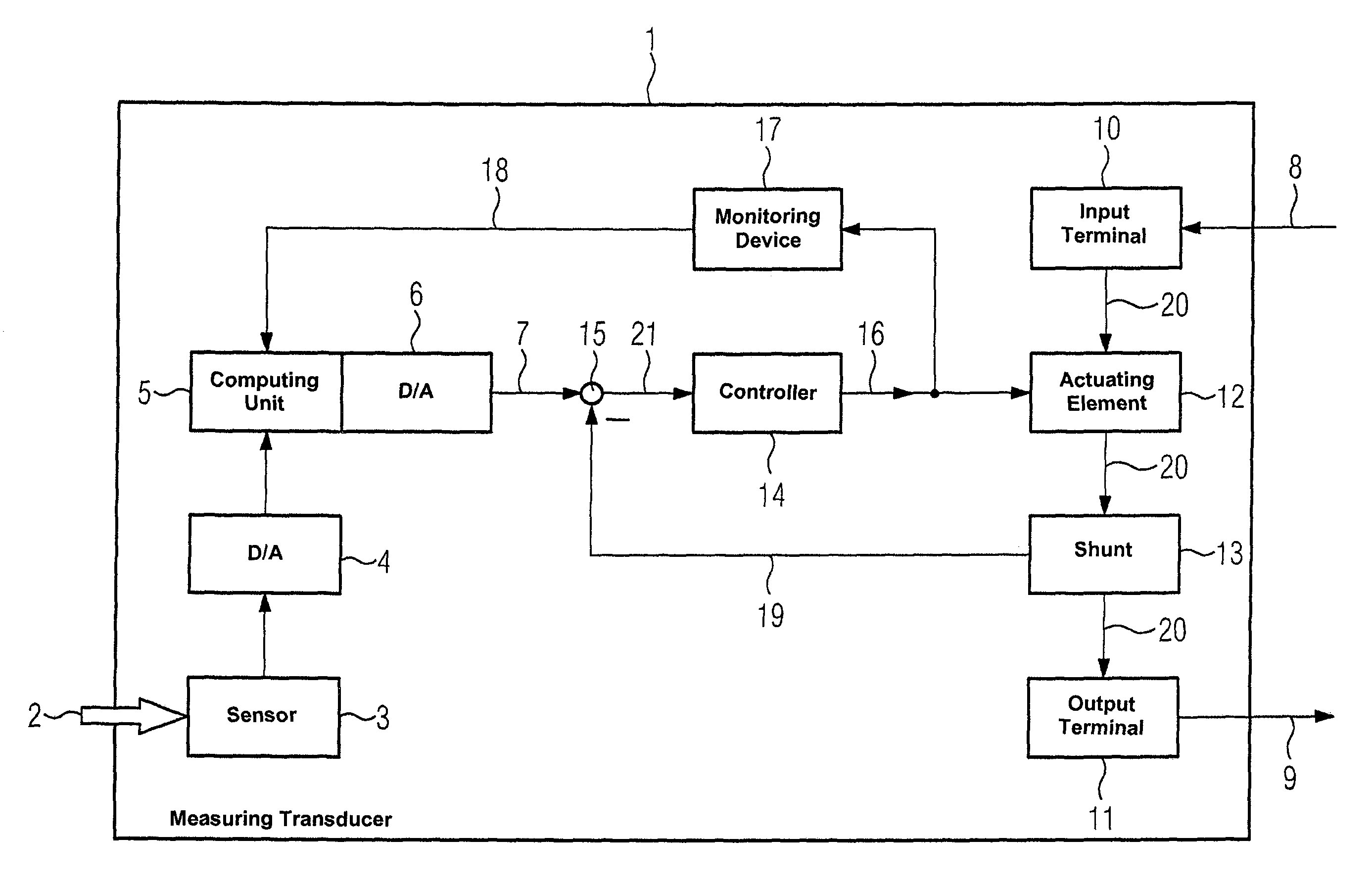

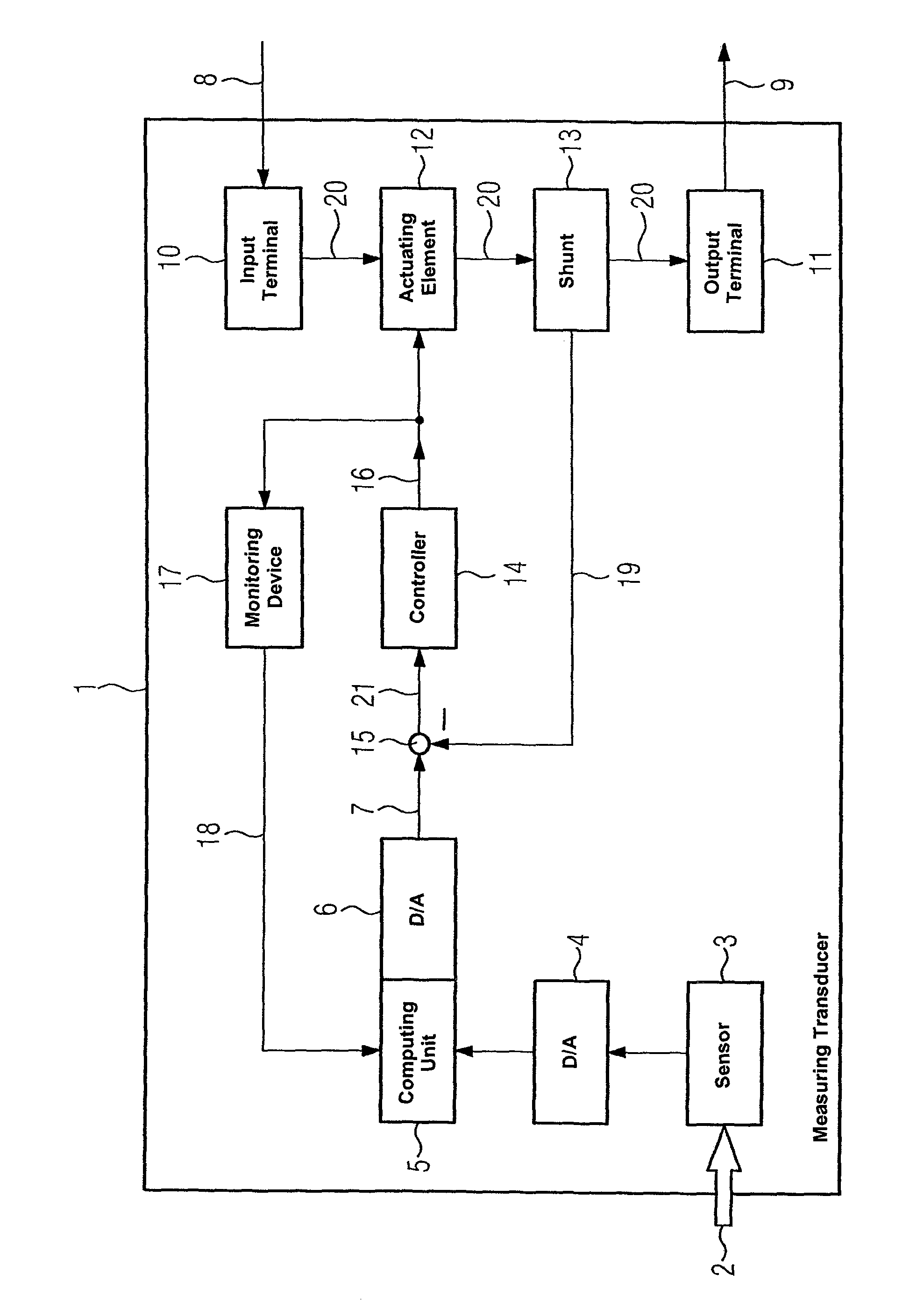

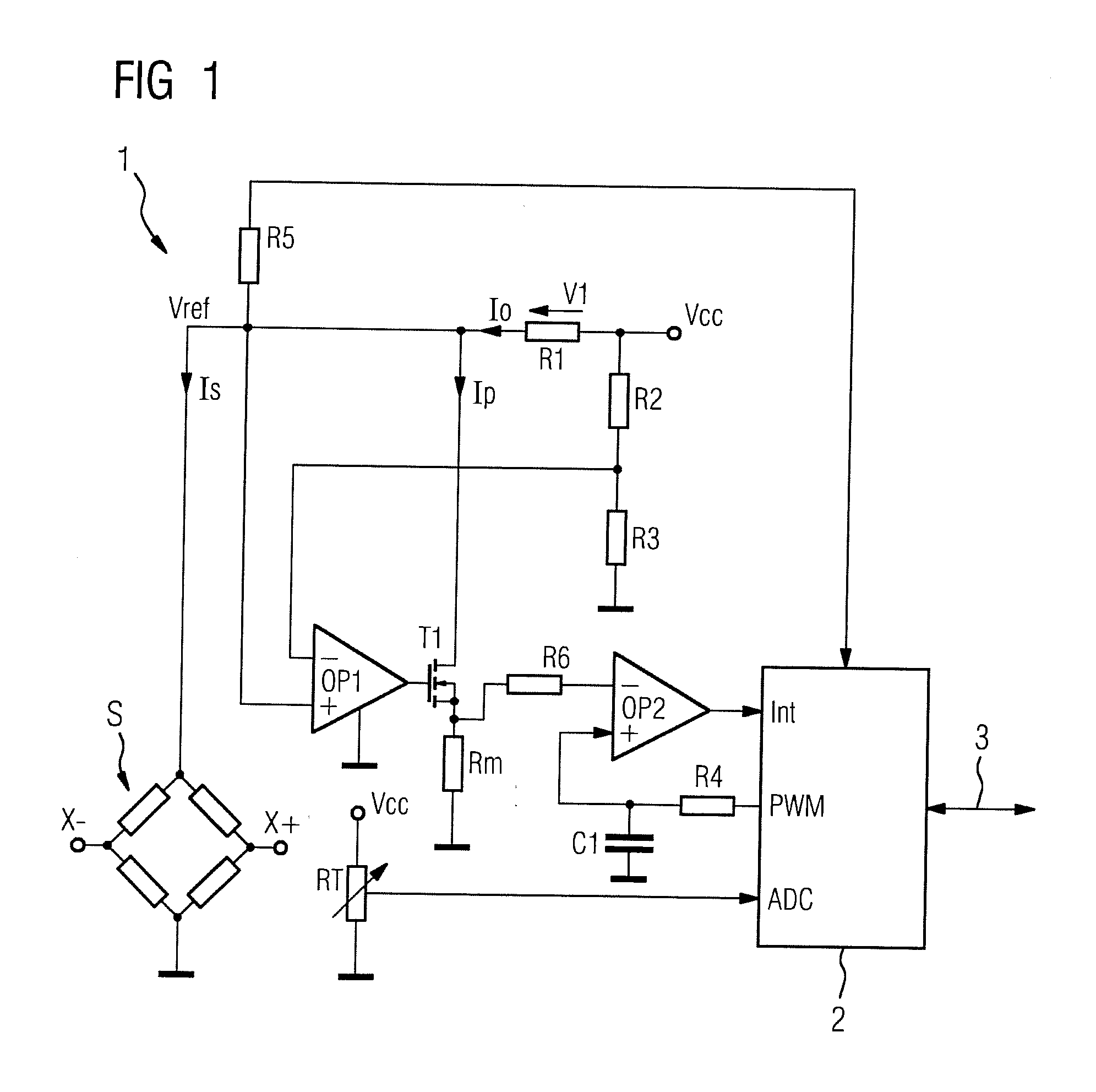

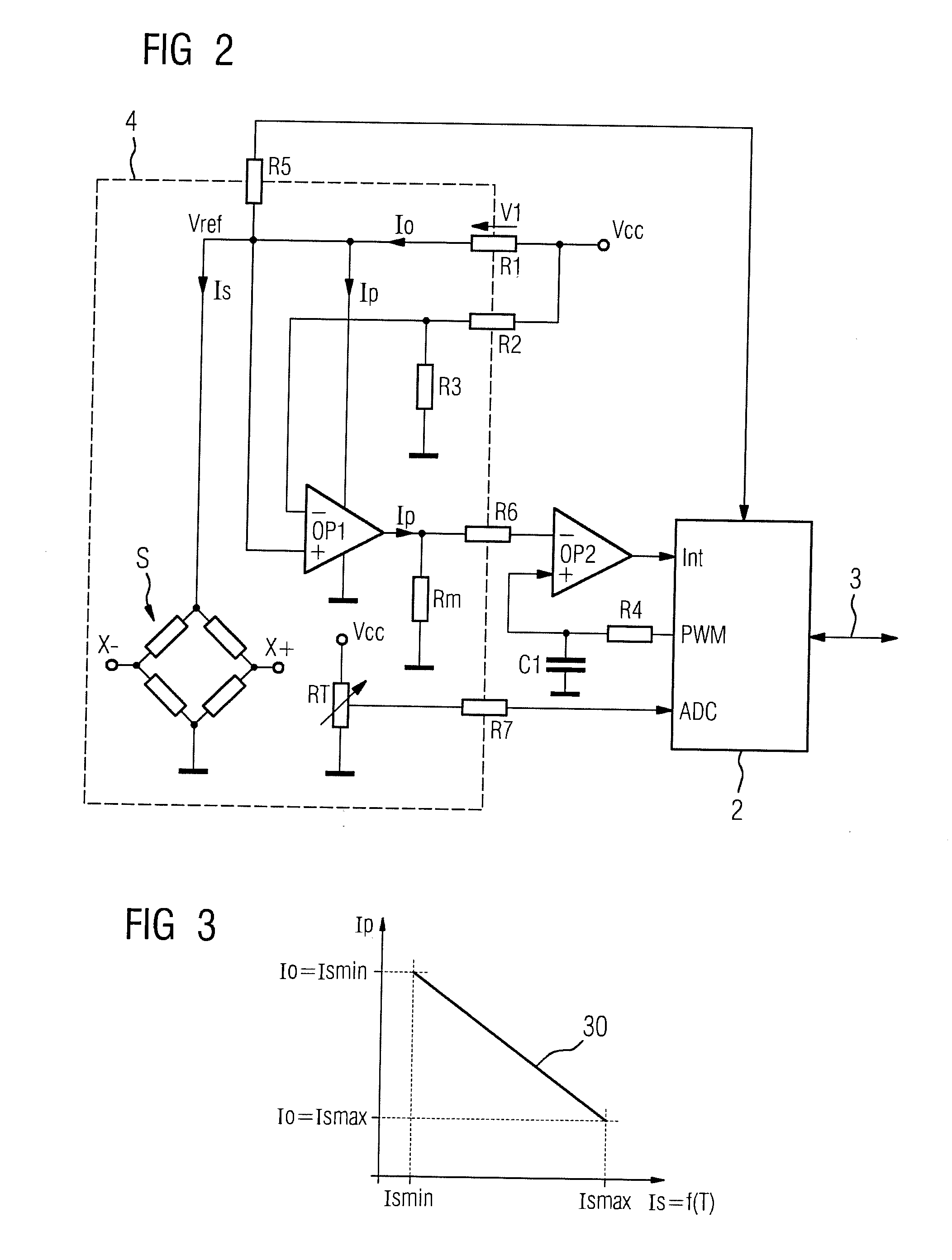

Field Device for Process Instrumentation

ActiveUS20120278042A1Improve accuracyReduce demandProgramme controlTesting/monitoring control systemsEngineeringField device

A field device for process instrumentation comprising a measurement transducer having an analog output to which a two-wire line can be connected for transmitting an analog output signal, wherein a unit galvanically separates the processor from an analog output circuit. A read-back channel for a pulse-width modulated digital signal, which is tapped behind an element for galvanic separation, is provided for monitoring generation of the analog output signal, and a unit is provided for monitoring the analog output signal to maintain a specifiable maximum deviation from a reference signal, which is generated in the same manner as the analog output signal by low-pass filtering from the pulse-width modulated digital signal. In the case of transient signals, the monitoring unit advantageously detects error states quickly and appropriate measures for reacting to the error states can therefore be implemented in less time.

Owner:SIEMENS AG

Field Device for Process Instrumentation

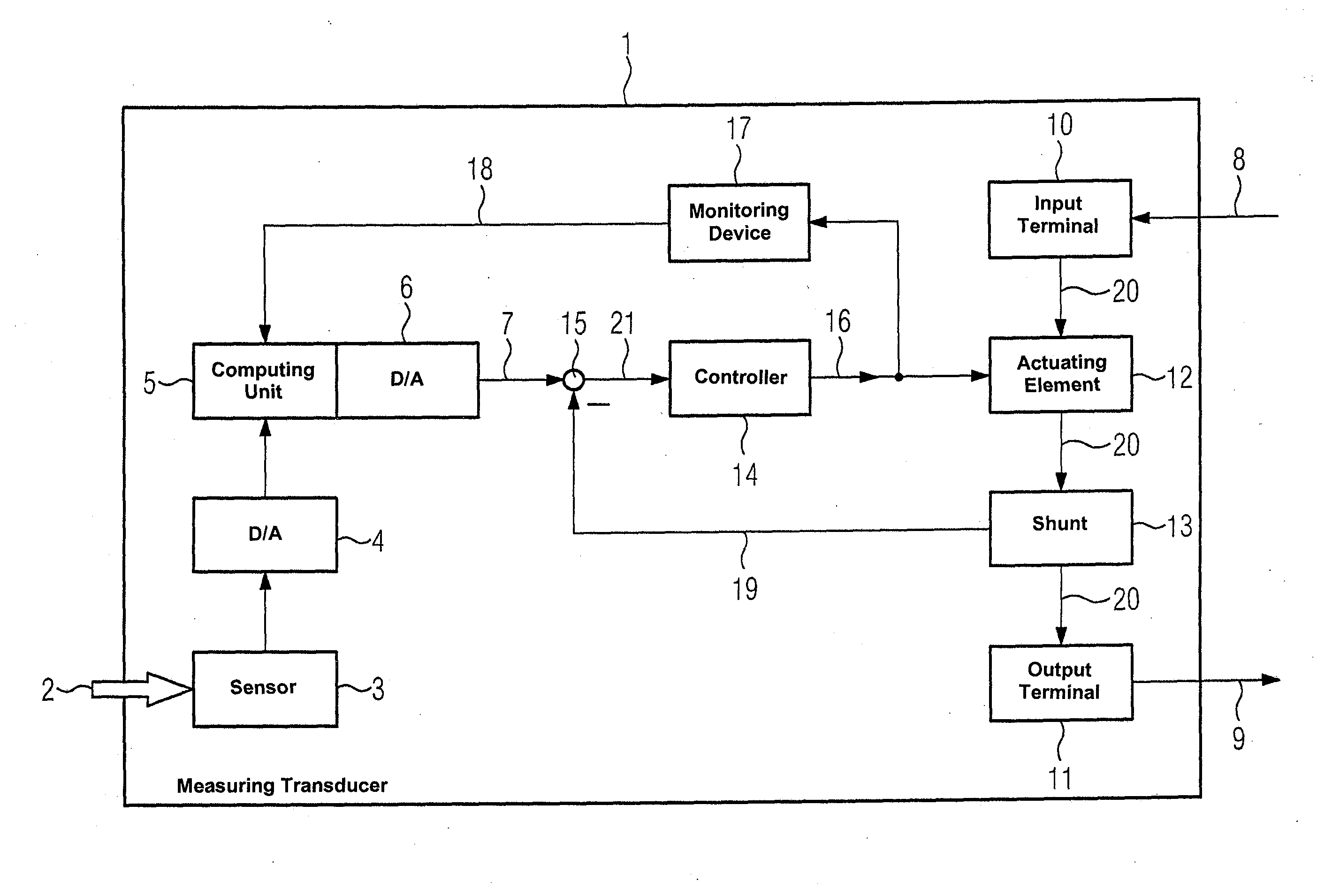

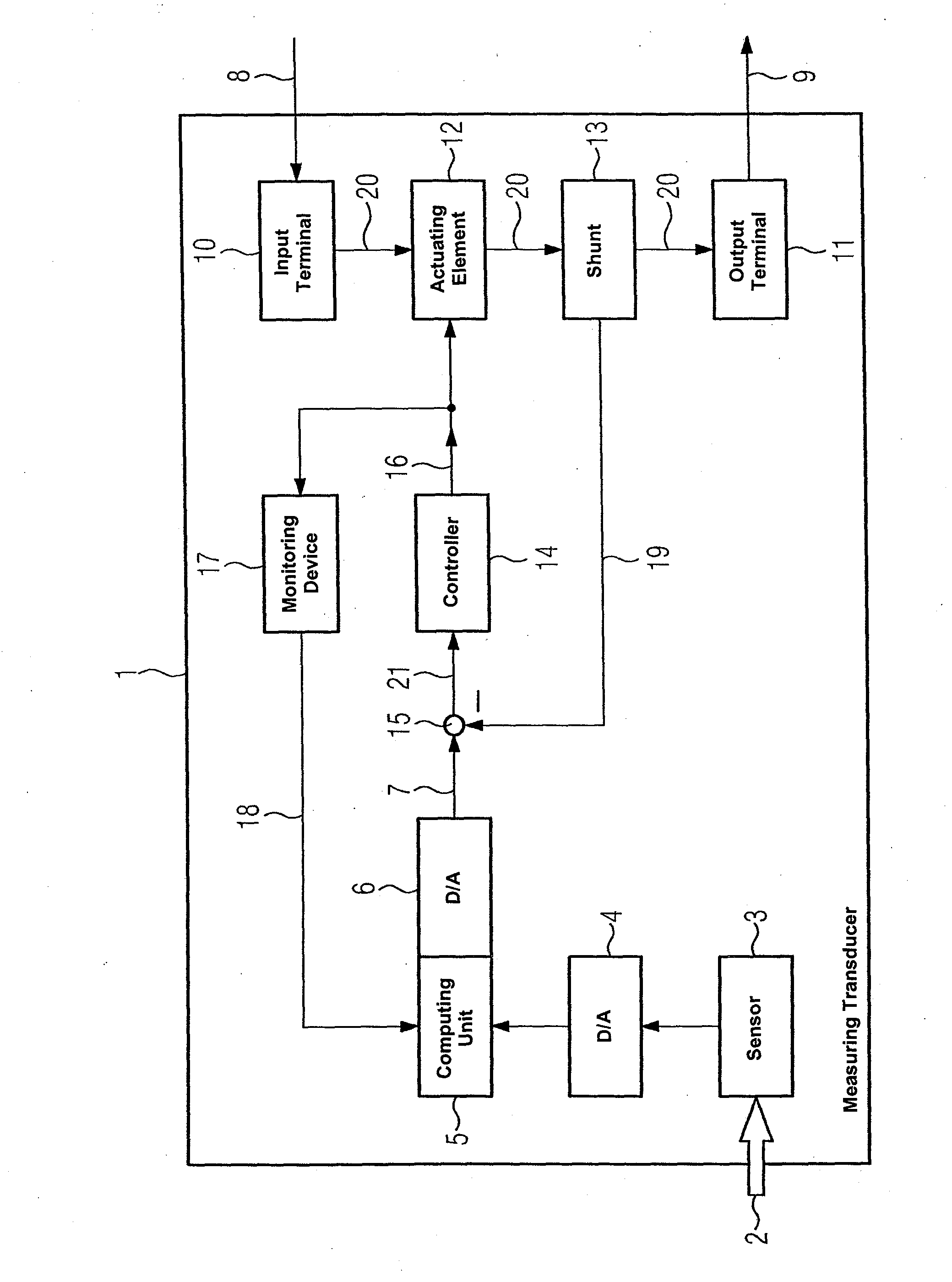

ActiveUS20100305896A1Simple wayMinimal effortTesting/monitoring control systemsElectrical measurementsTransducerEngineering

A field device for process instrumentation, in particular a measuring transducer, comprising an analogue output to which a two-wire line is connectable for transmitting an analogue output signal. The output circuit contains a controller with an actuator connected downstream for the analogue output signal. A monitoring unit monitors whether an actuating signal remains within a predeterminable value range to monitor the output circuit for correctly setting the loop current. If the actuating signal is outside the value range, an indicator signal is output to a computing unit so that suitable measures can be introduced in response to an error state that has thus been identified.

Owner:SIEMENS AG

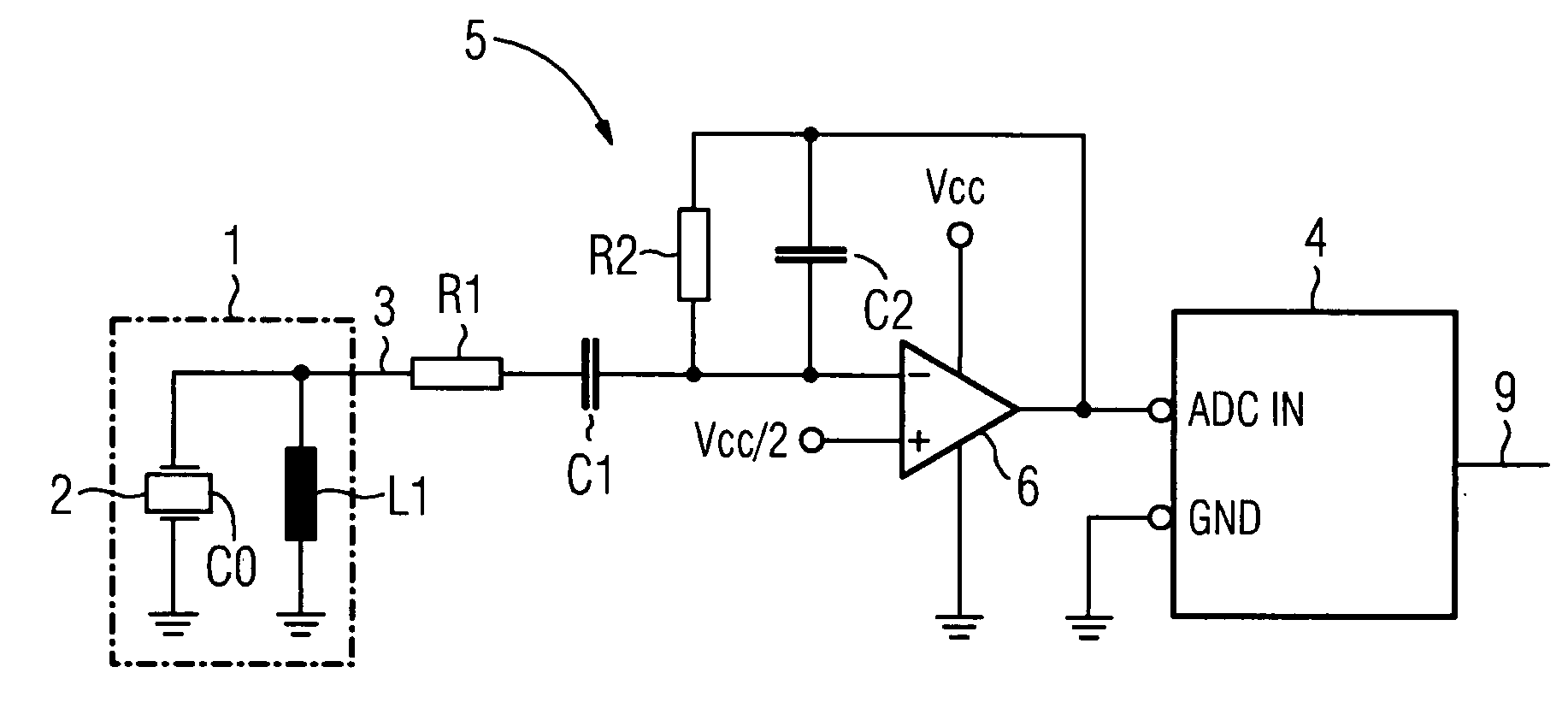

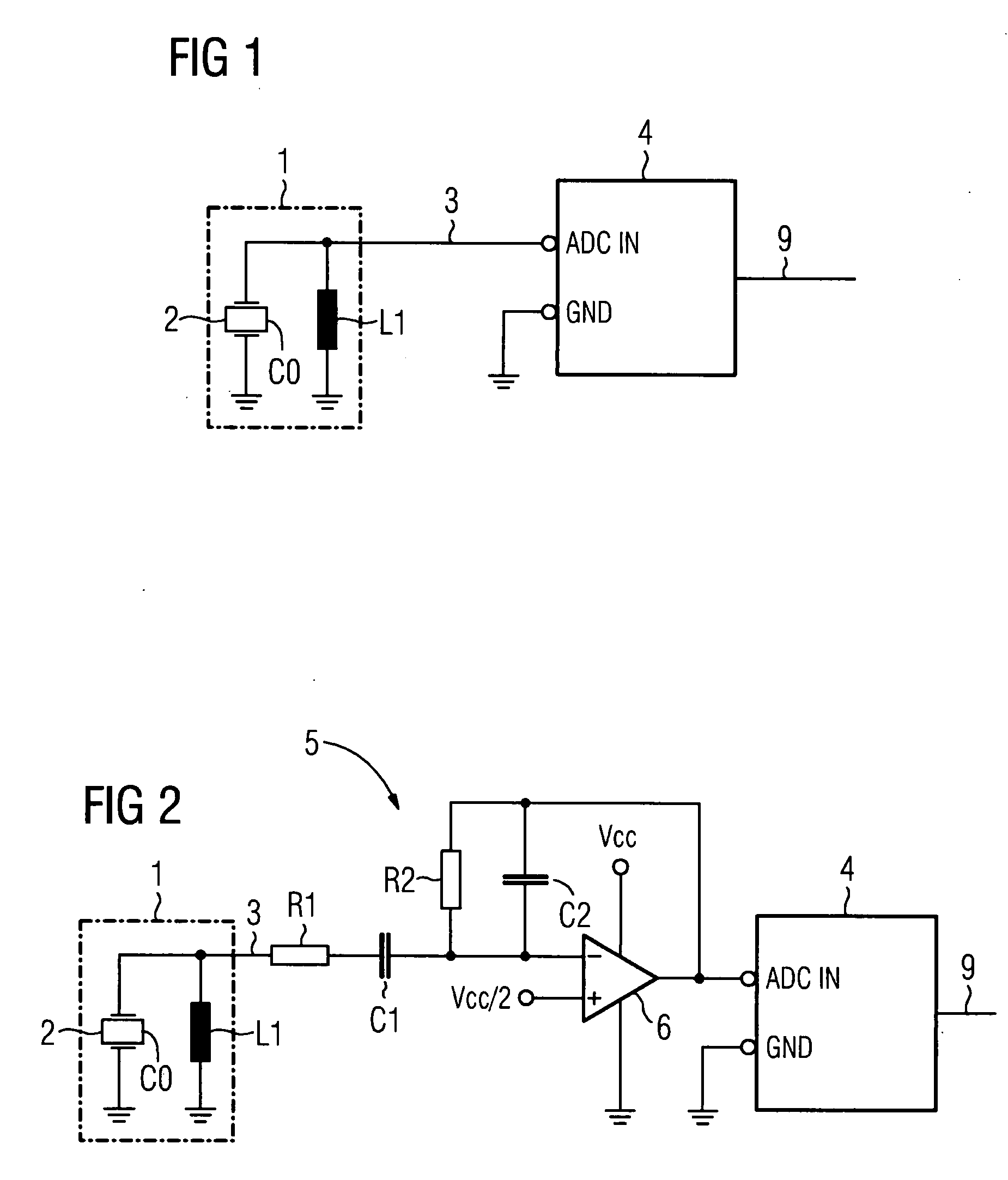

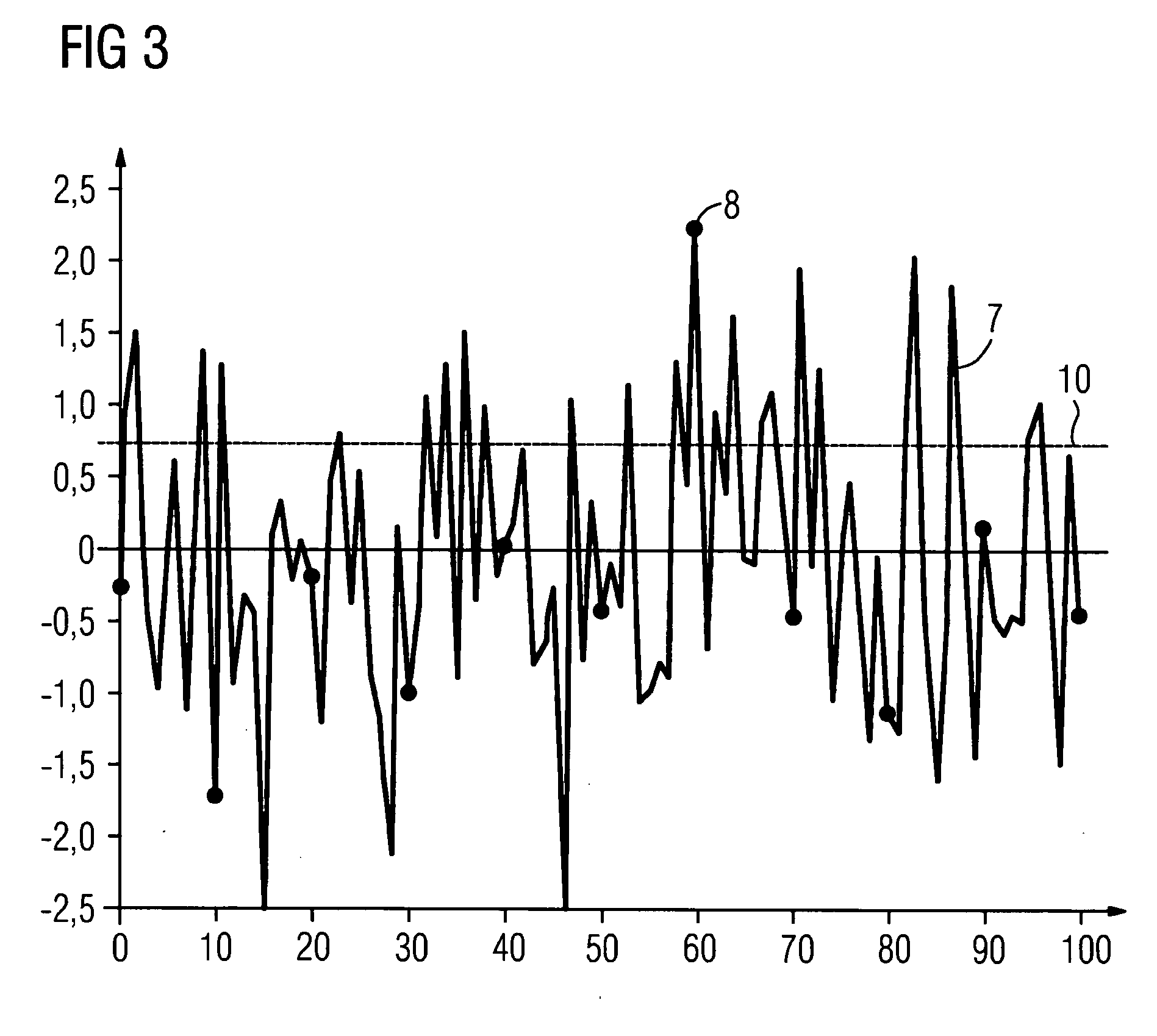

Method and system for diagnosing mechanical, electromechanical or fluidic components

InactiveUS20090090185A1Low costSolve excessive overheadVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringElectronic component

There is described a diagnosis method and system comprising a sensor for structure-borne noise which emits a measuring signal in a bandwidth-filtered manner due to its mechanical resonant frequency, its capacity and an inductance. The system also comprises an evaluation device in which the measuring signal is subsampled measuring signal exceeds a defined threshold value. The system requires only a small number of electronic components and only little power supply capacity, thereby allowing diagnosis to be carried out without complication in existing devices, especially in field devices of process instrumentation for which only a limited amount of operating power is available. The method and system are especially advantageous for the recognition of valve leakage with an electropneumatic position controller.

Owner:SIEMENS AG

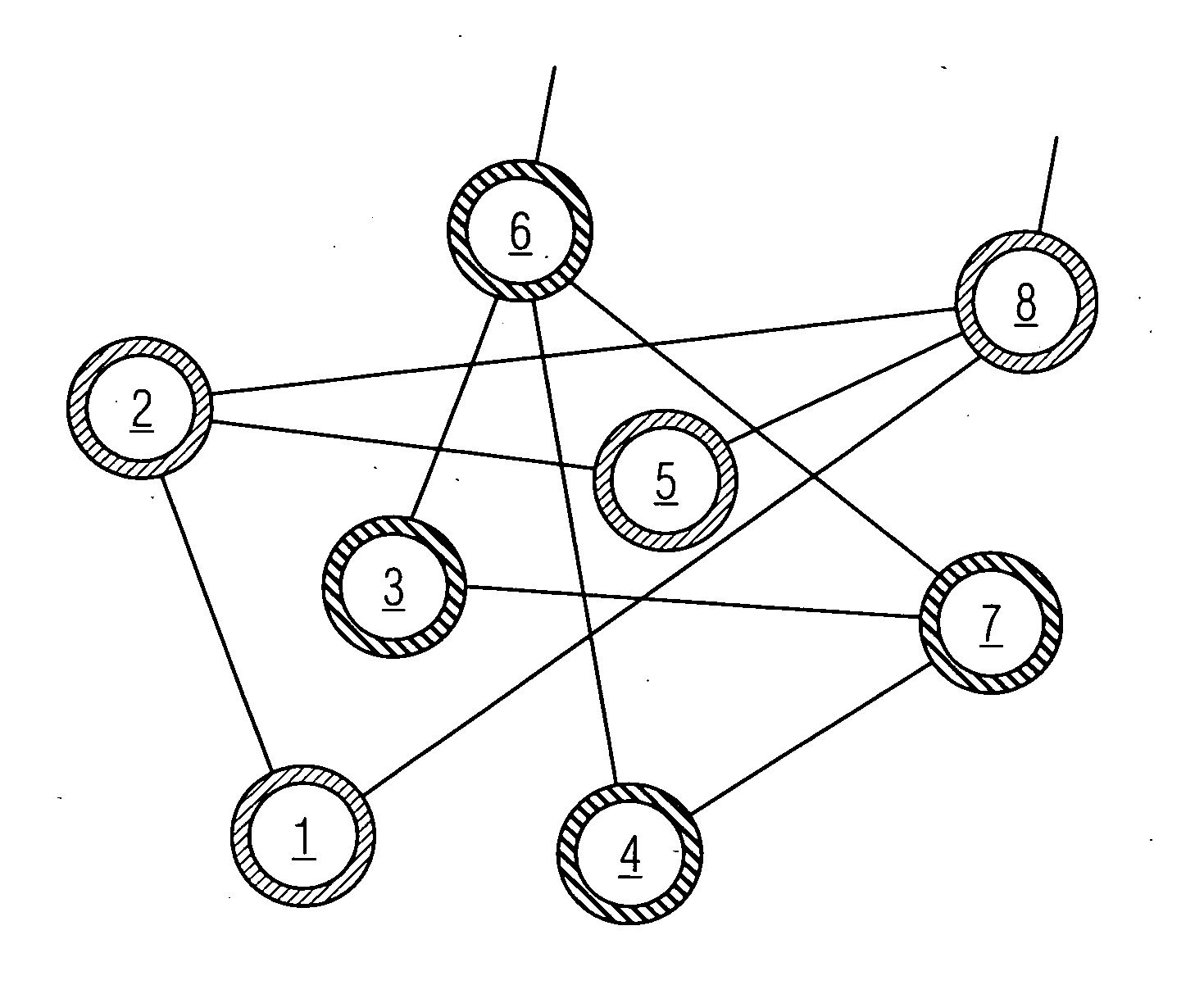

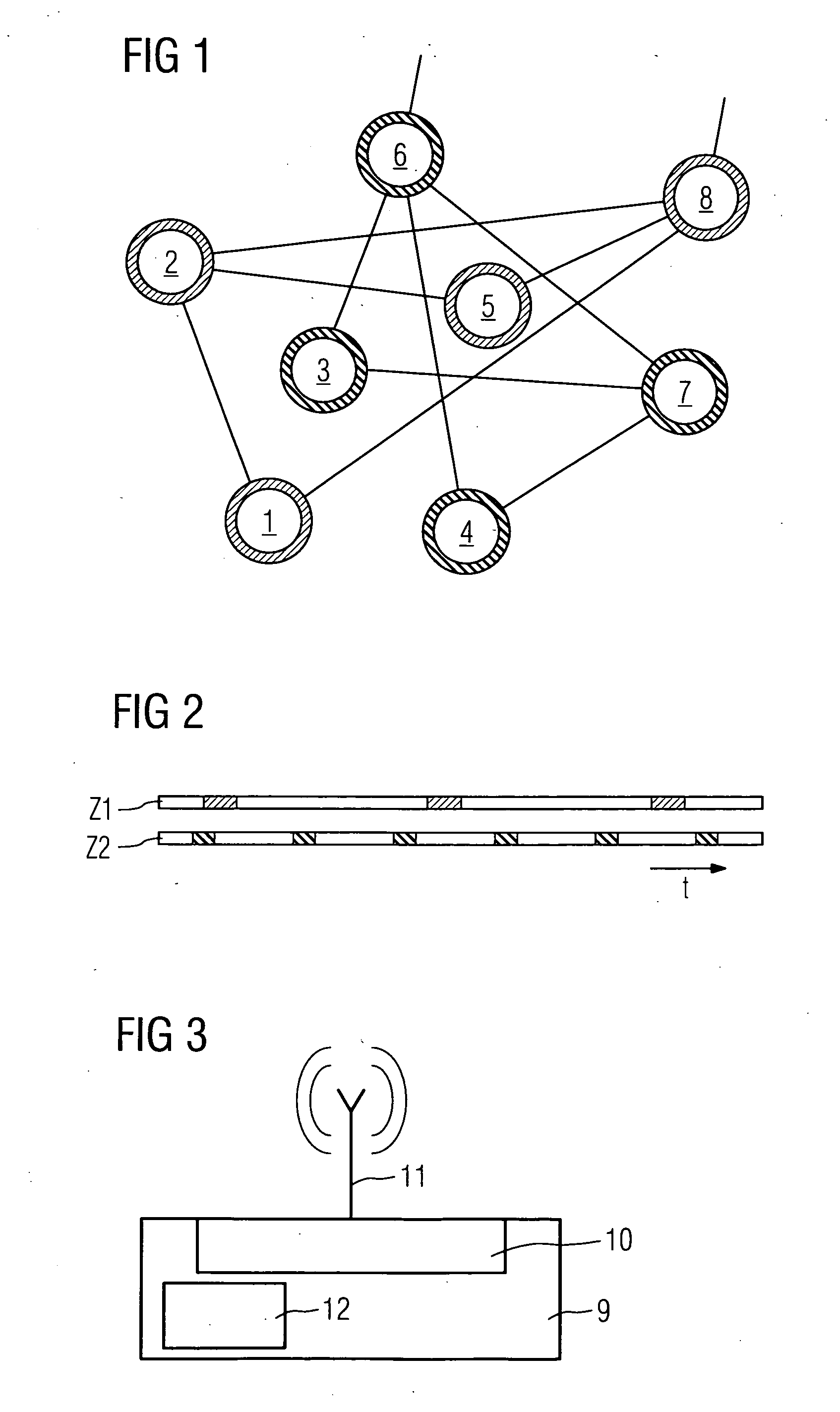

Method for Operating a Radio Network and Subscriber Device for Said Type of Network

InactiveUS20090047927A1Weaken energyPower managementEnergy efficient ICTCommunication interfaceRadio networks

Owner:SIEMENS AG

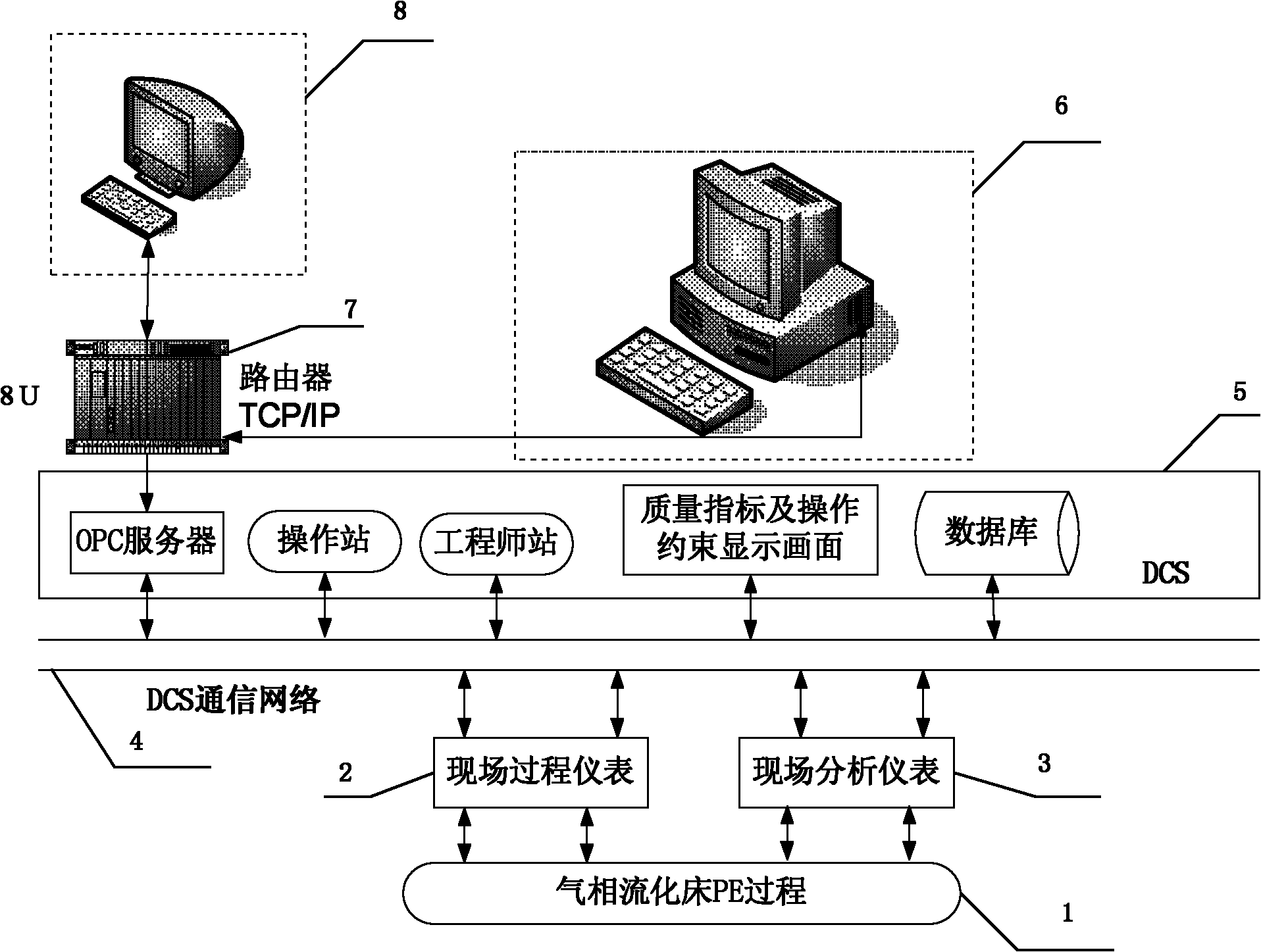

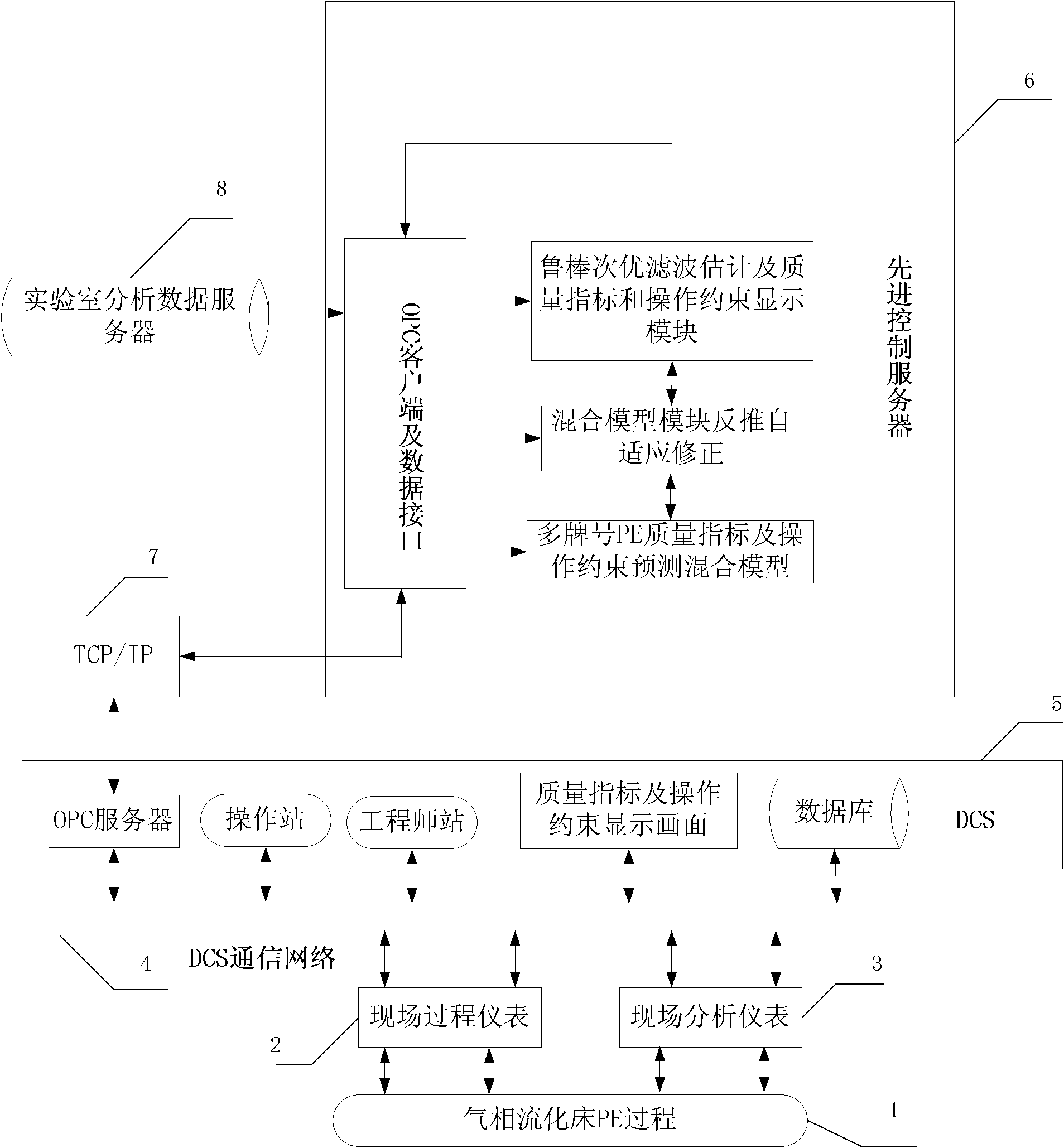

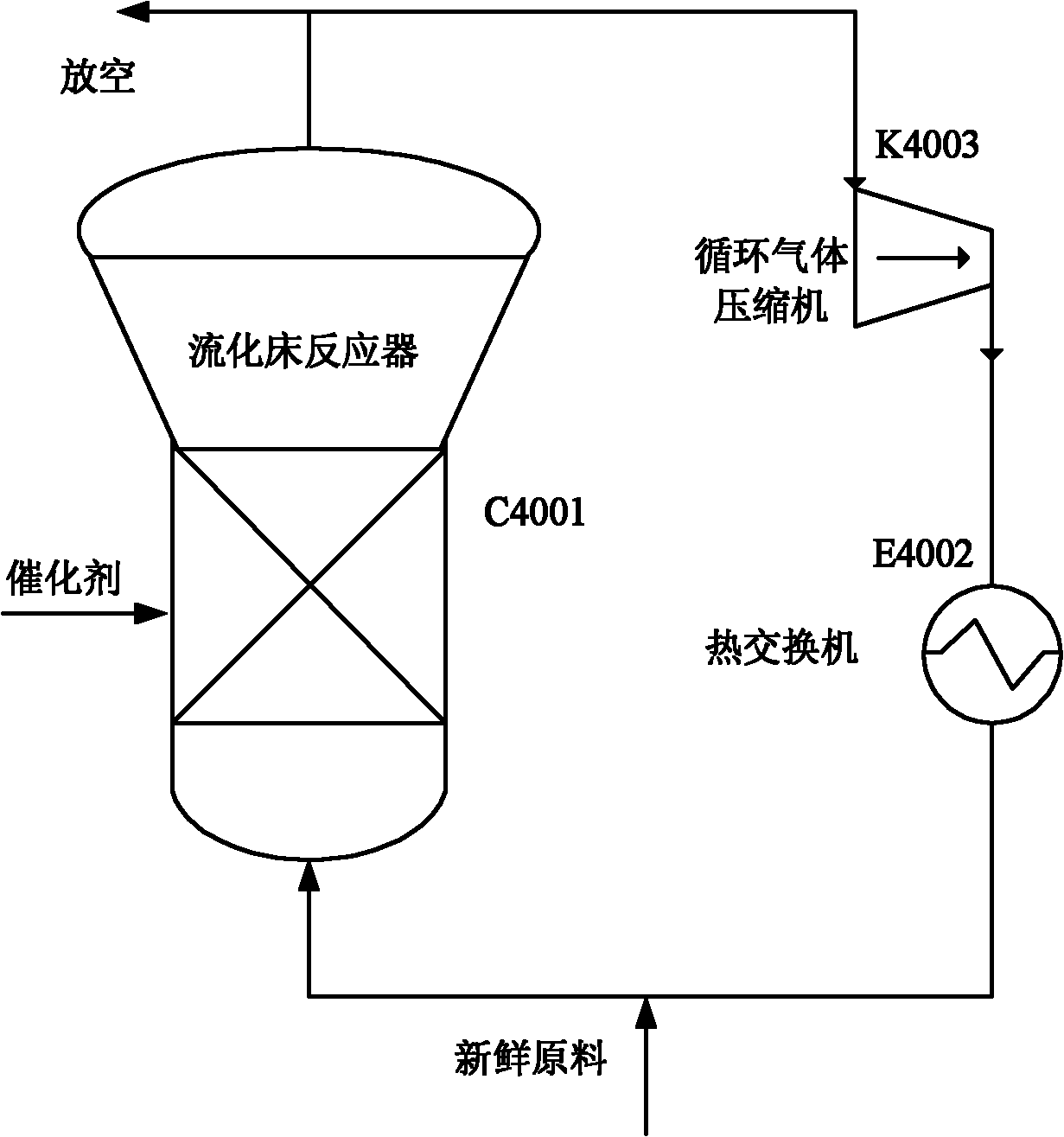

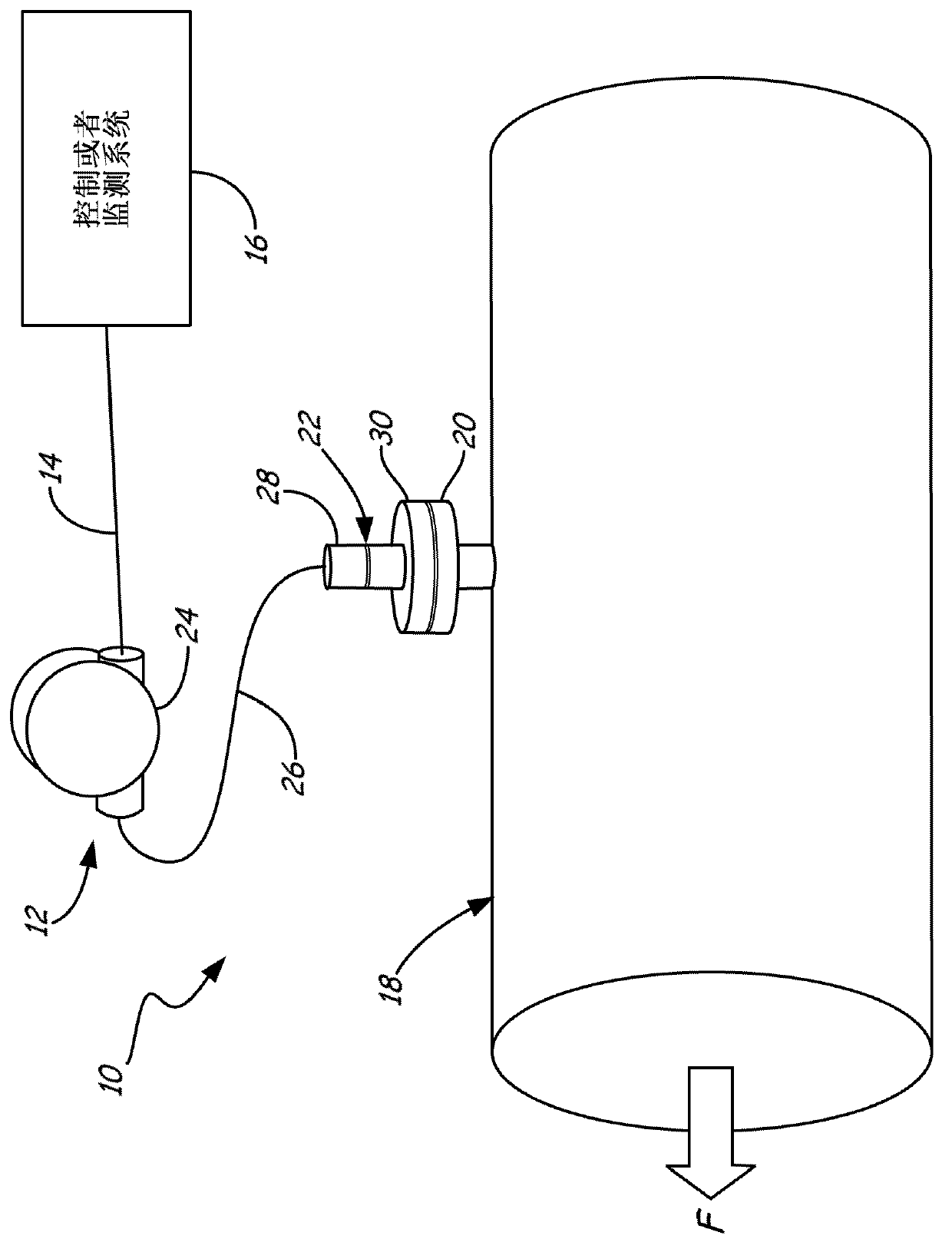

Gas phase polyethylene device quality index and operational constraint on-line estimation system and method thereof

ActiveCN102736570AEnable real-time estimationFully consider the impact of the estimateTotal factory controlProgramme total factory controlAnalysis dataProcess quality

The invention provides a polyethylene (PE) multi-trademark product quality index and operational constraint on-line estimation system for gas phase fluidized bed production technology. The system comprises a field process instrument which is connected with a gas phase PE object, a field analysis instrument, a distributed control system (DCS), a laboratory analysis data server and an advanced control server. The advanced control server includes an OPC client, a data interface module, a multi-trademark PE production process quality indicator and operational constraint model prediction module, a PE quality index prediction model parameter adaptive correction module, and a PE quality index robustness suboptimal filter estimation and quality indicator and operational constraint display module. The invention also provides a gas phase PE quality index and operational constraint on-line estimation method. The invention provides the real-time online estimation system and method of multi-trademark gas phase PE product quality index melt index and density, gas phase PE production operating constraint yield, and recycle gas dew point temperature.

Owner:BEIJING UNIV OF CHEM TECH

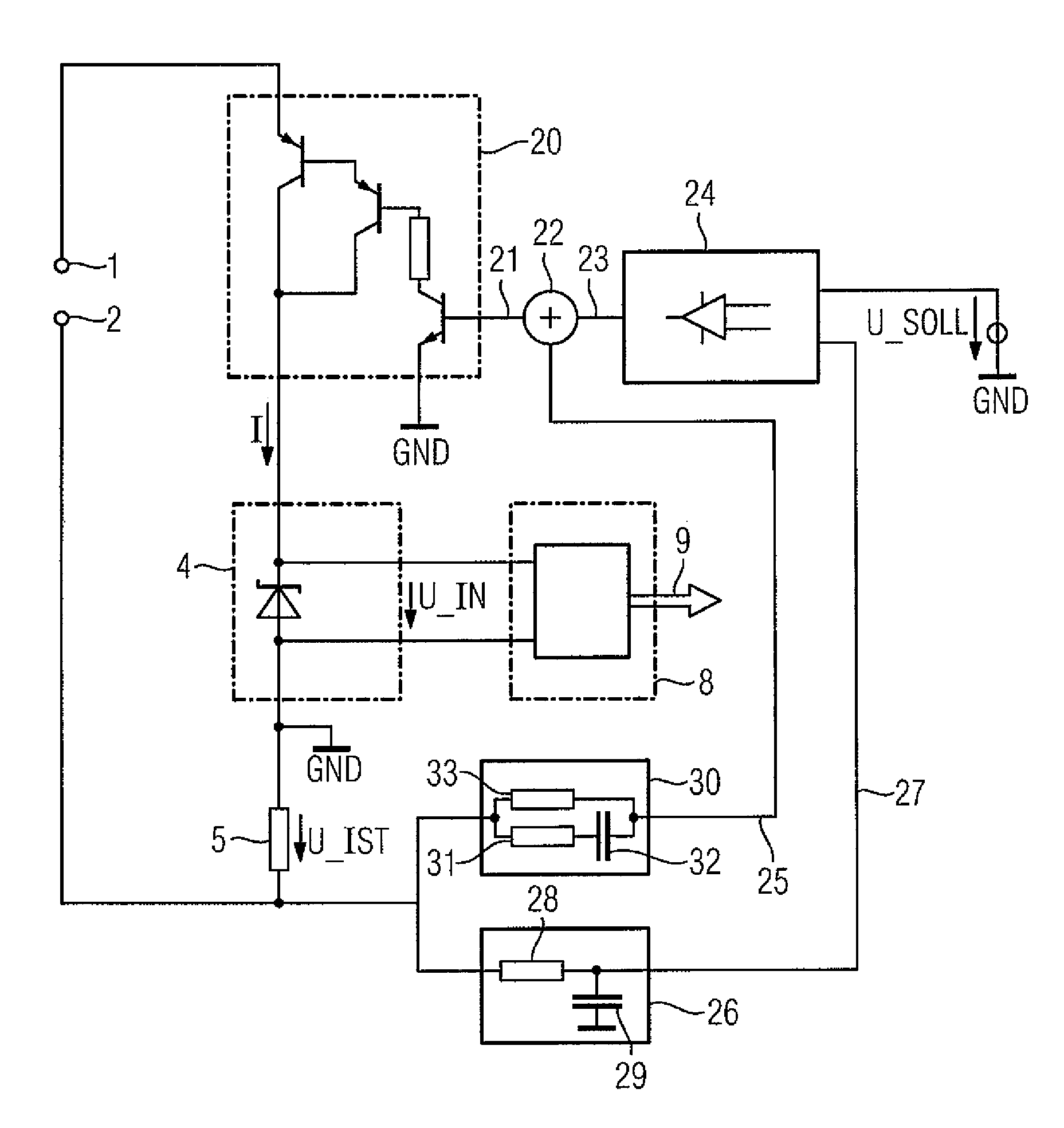

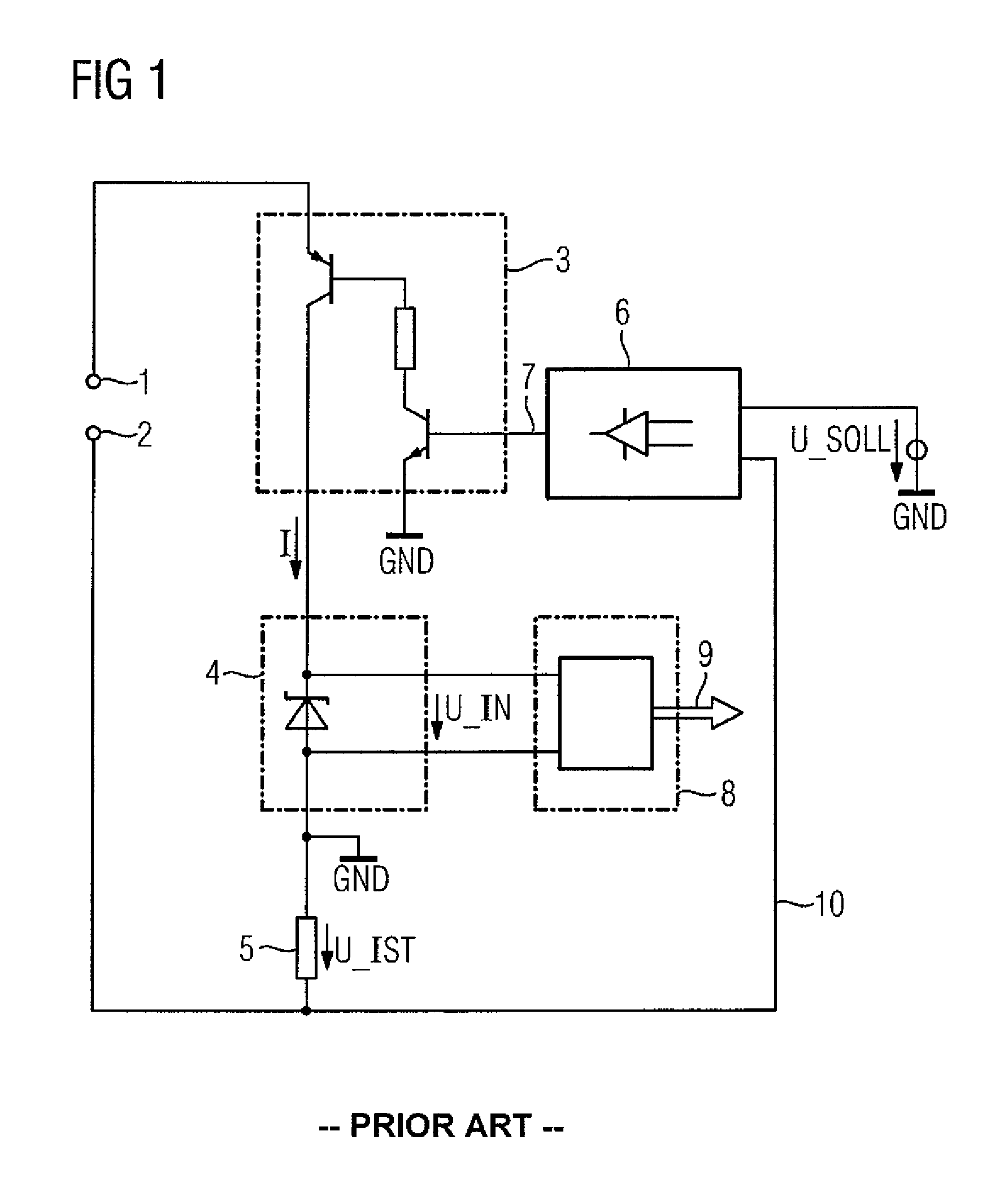

Field Device for Process Instrumentation

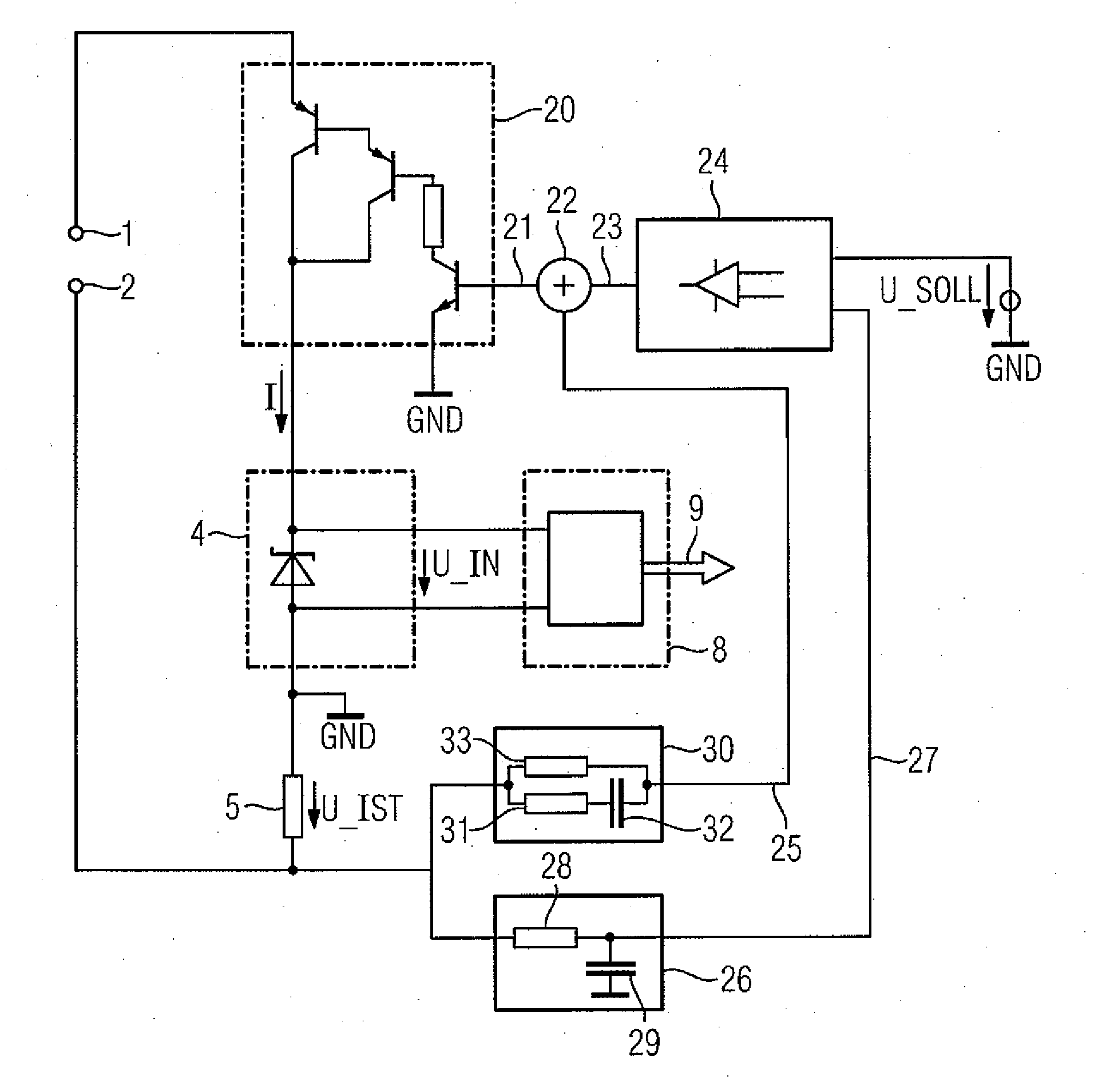

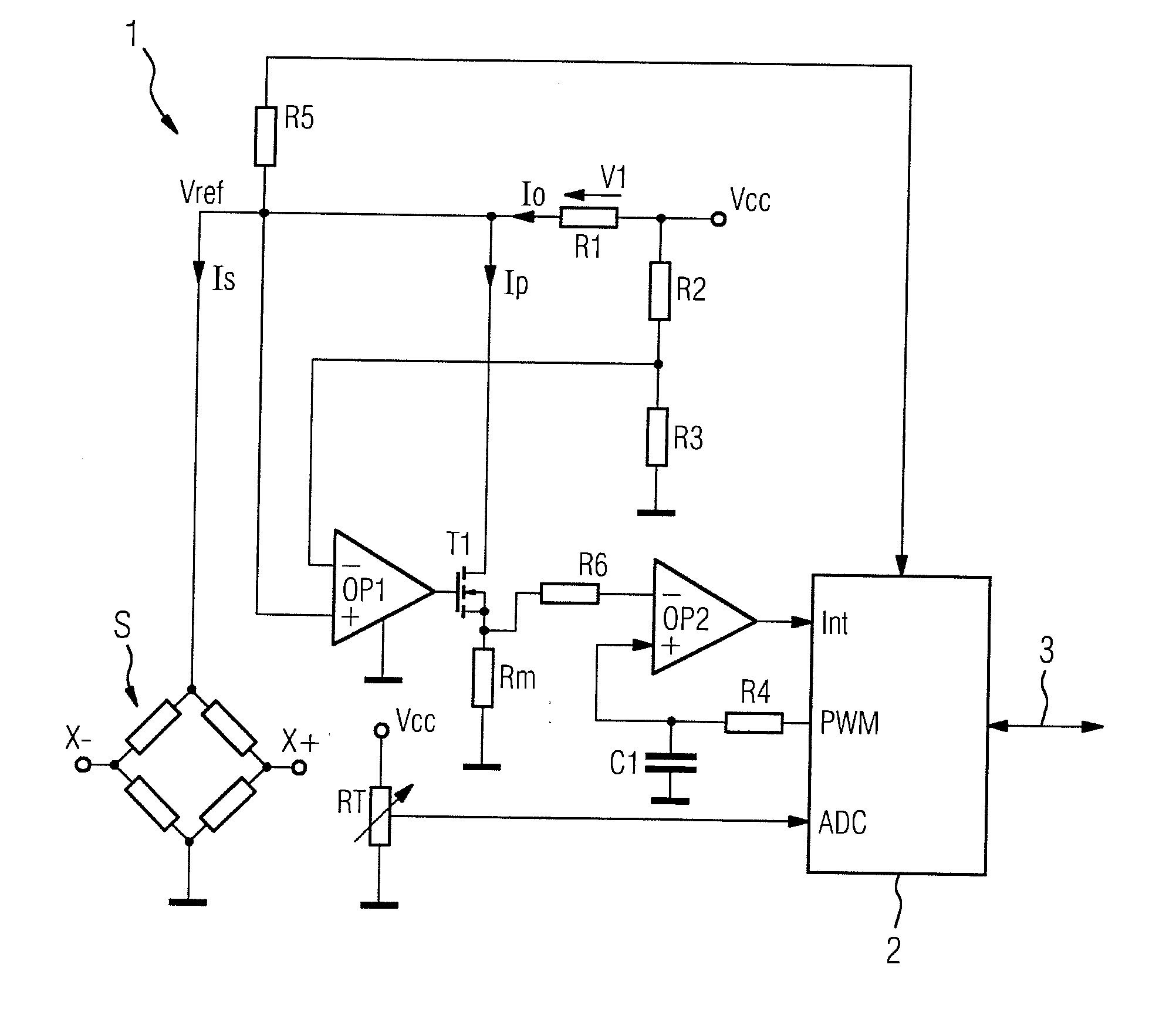

ActiveUS20120188005A1Reduce power consumptionAvoid excessive currentProgramme controlElectric variable regulationPower flowControl signal

A field device for process instrumentation having an interface for connecting a two-wire cable and for outputting measurement values, wherein the interface comprises a series circuit having a transistor circuit by which the loop current is adjustable as a function of a control signal, a power supply, and a device by which the loop current can be captured as an actual value that is fed by a first feedback coupling to a regulator having integrated behavior. The regulator compares the actual value to a target value, and generates a control signal for the transistor circuit. The actual value is fed by a second feedback coupling to a summation point as a compensation signal for generating an input signal for the transistor circuit as a function of the control signal and the compensation signal to suppress interference coupled into the two-conductor line.

Owner:SIEMENS AG

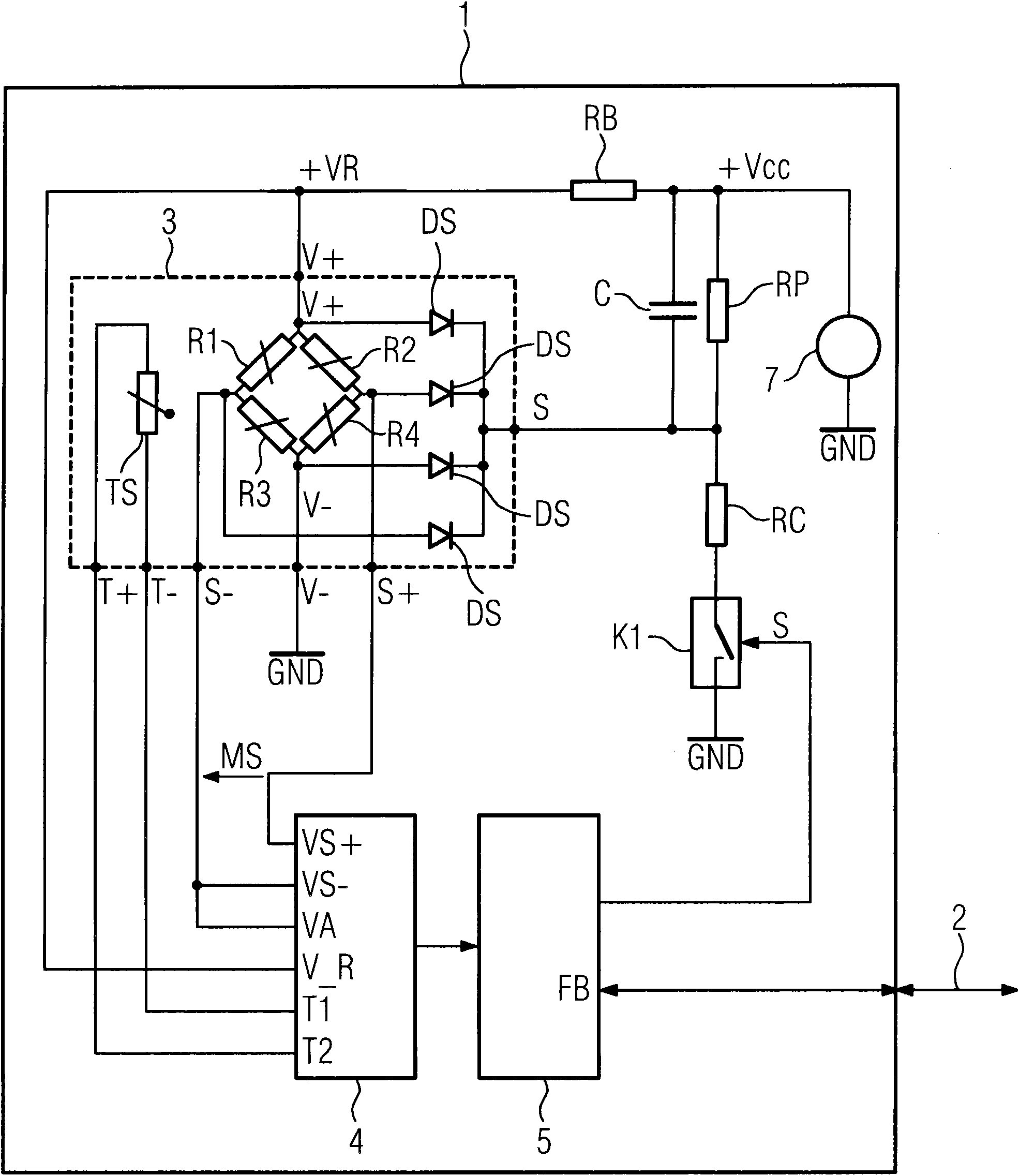

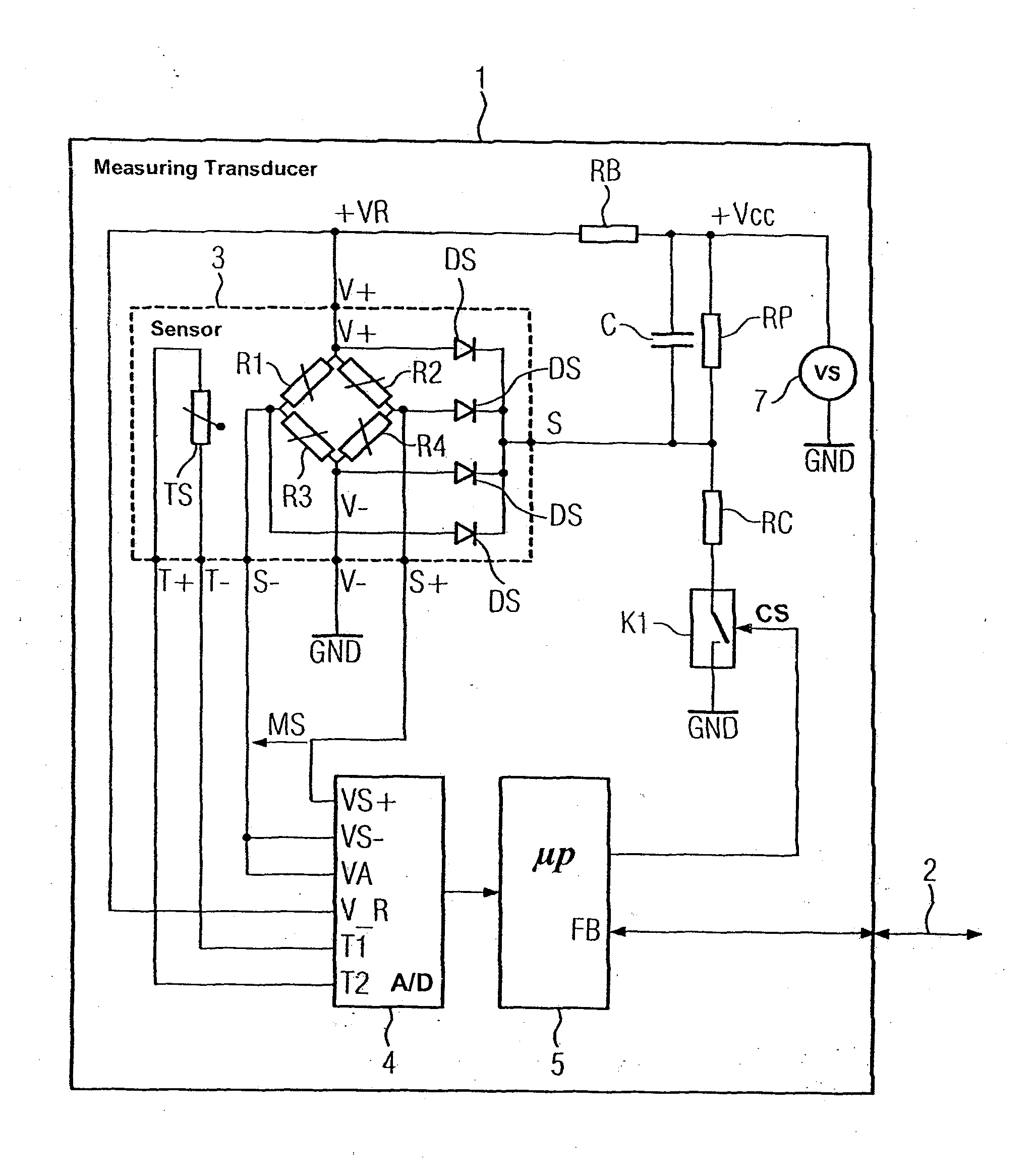

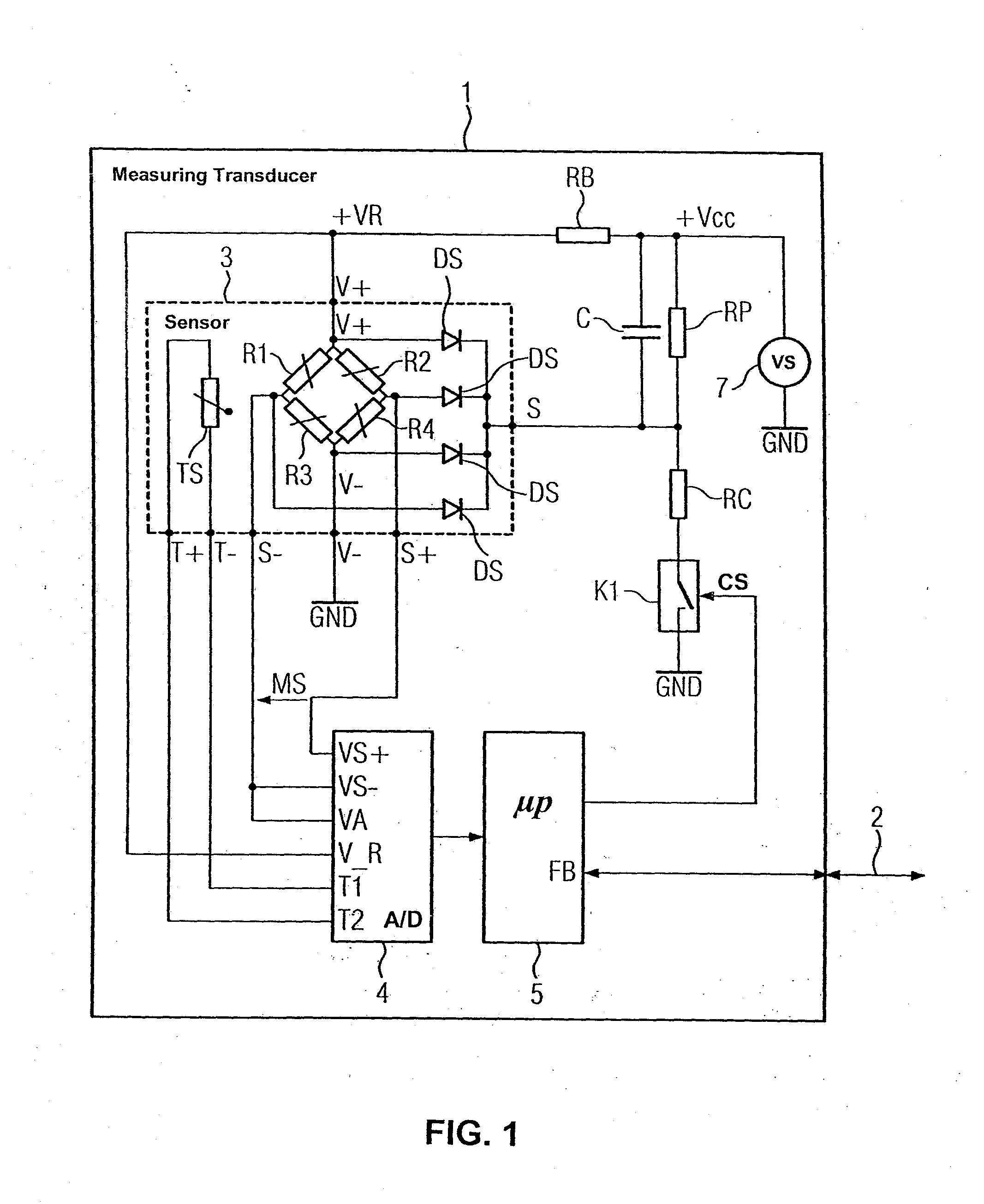

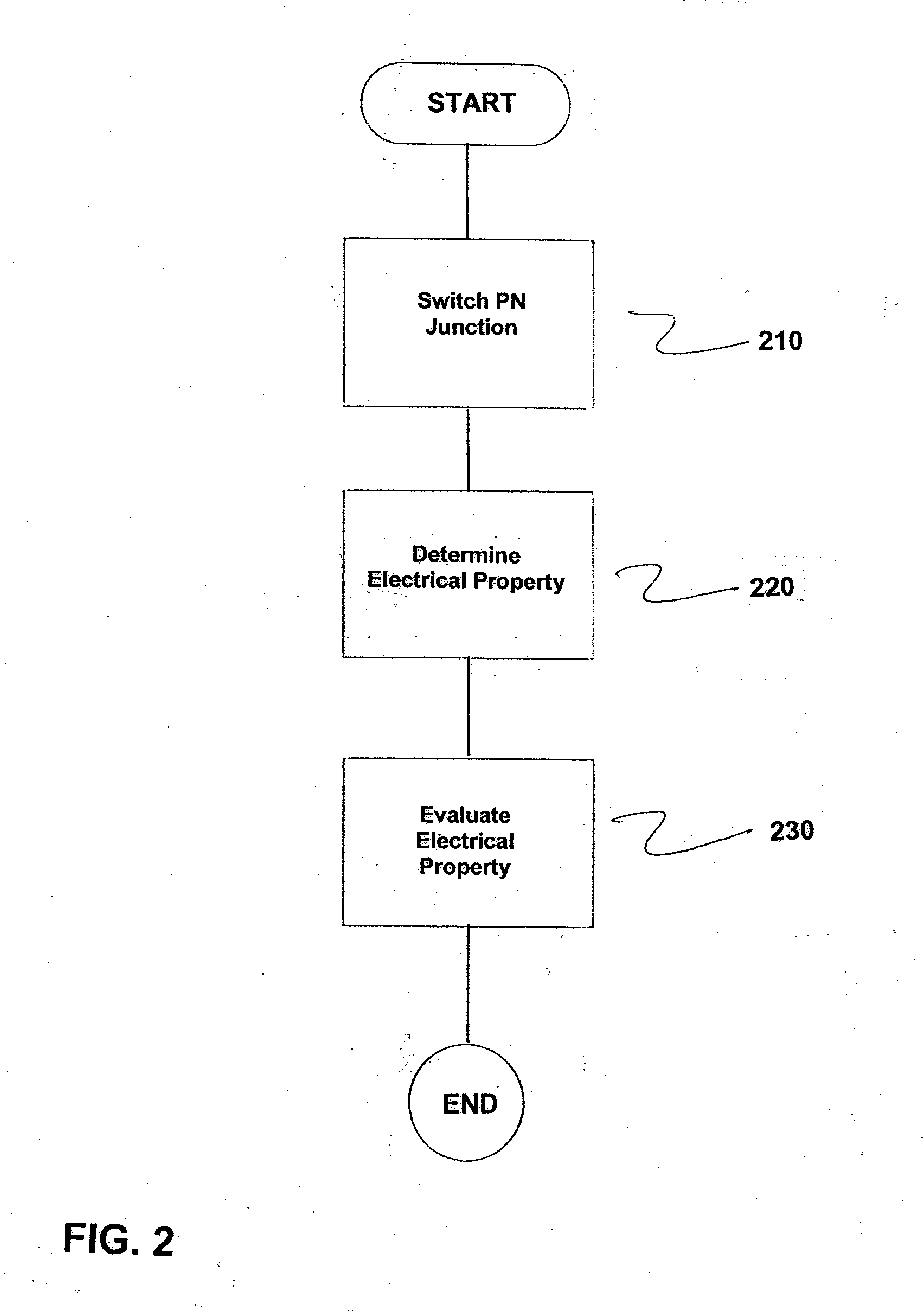

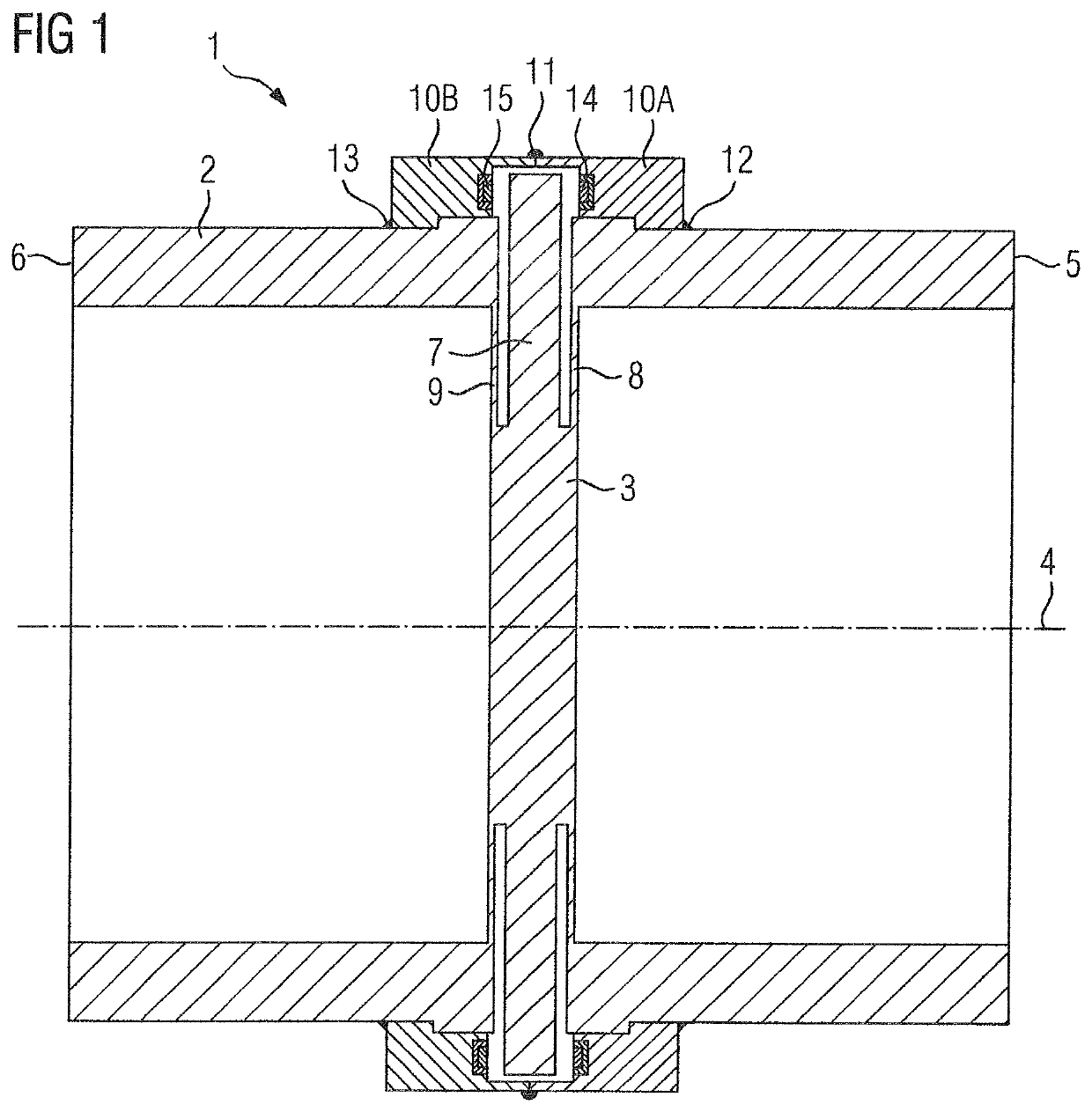

Measuring transducer for process instrumentation, and method for monitoring the condition of the sensor thereof

InactiveCN102016516AMeasurement apparatus componentsFluid pressure measurement by electric/magnetic elementsSemiconductor materialsEngineering

The invention relates to a measuring transducer for process instrumentation, comprising a sensor for sensing a physical or chemical variable. The sensor has at least one electrical element which is embedded in a substrate made of semiconducting material and is electrically separated therefrom by means of a blocked PN junction (DS) during normal operation. In order to monitor the condition of the sensor (3), the PN junction (DS) is connected in the conducting direction in a test mode, and the electrical property of the PN junction, in particular the forward voltage, is determined and is used for monitoring the condition. In addition, a temperature sensor (TS) mounted on the sensor (3) can be monitored by determining, on the basis of the dependence of the forward voltage on the temperature, a comparative value for the temperature sensed by the temperature sensor (TS). If major differences occur, it can be concluded that there is a failure of the sensor (3), and a corresponding error message can be output via a field bus (2).

Owner:SIEMENS AG

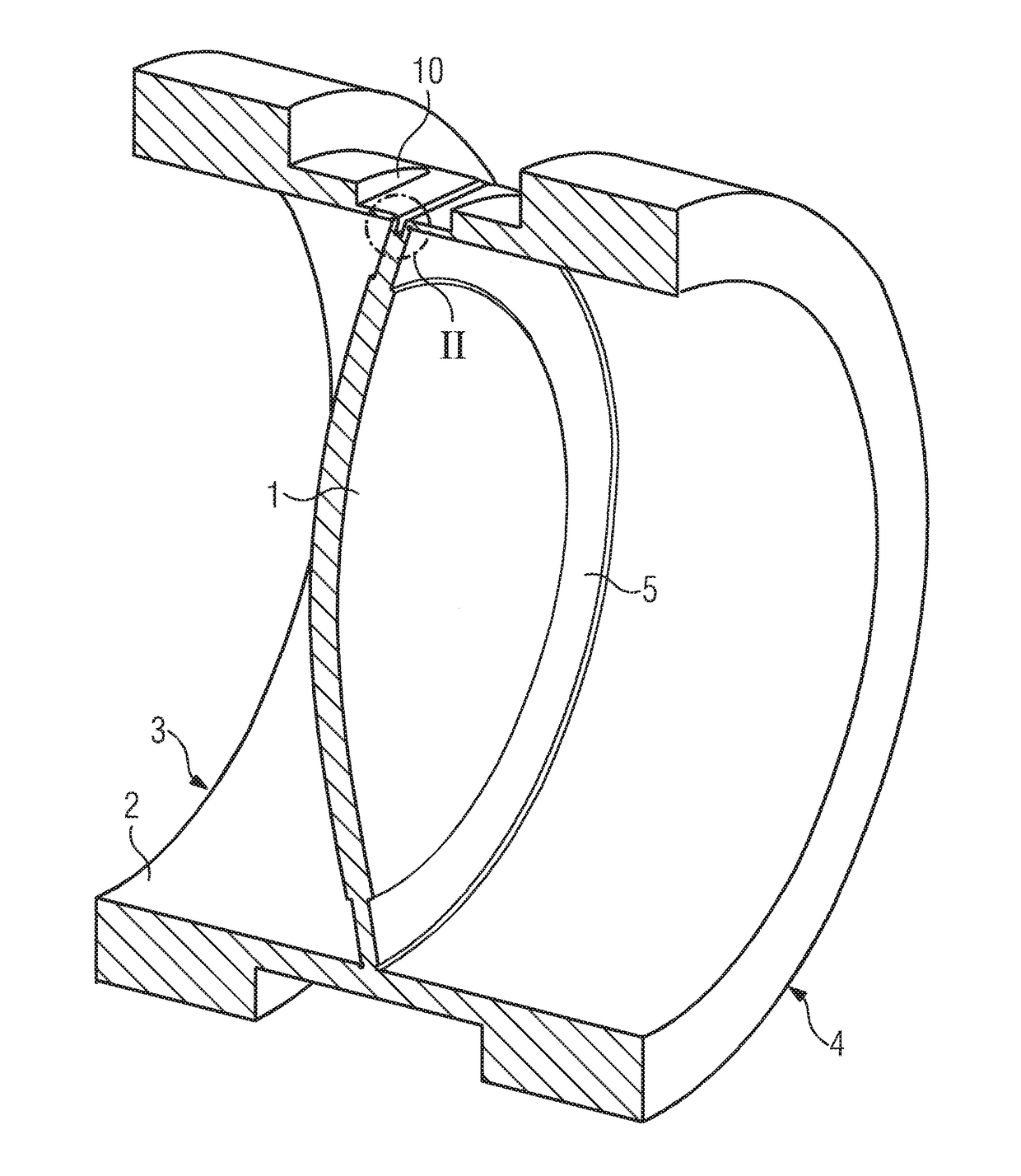

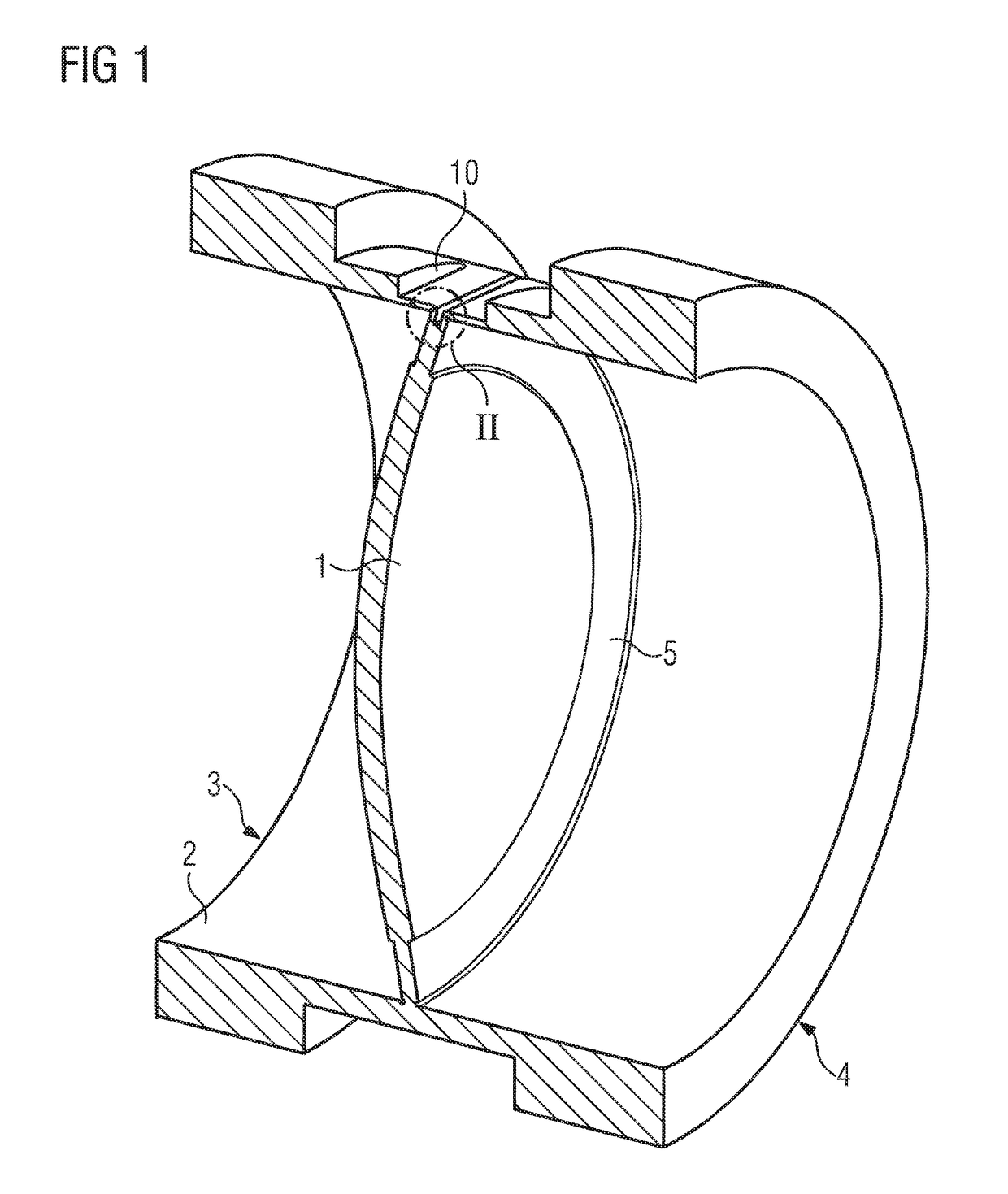

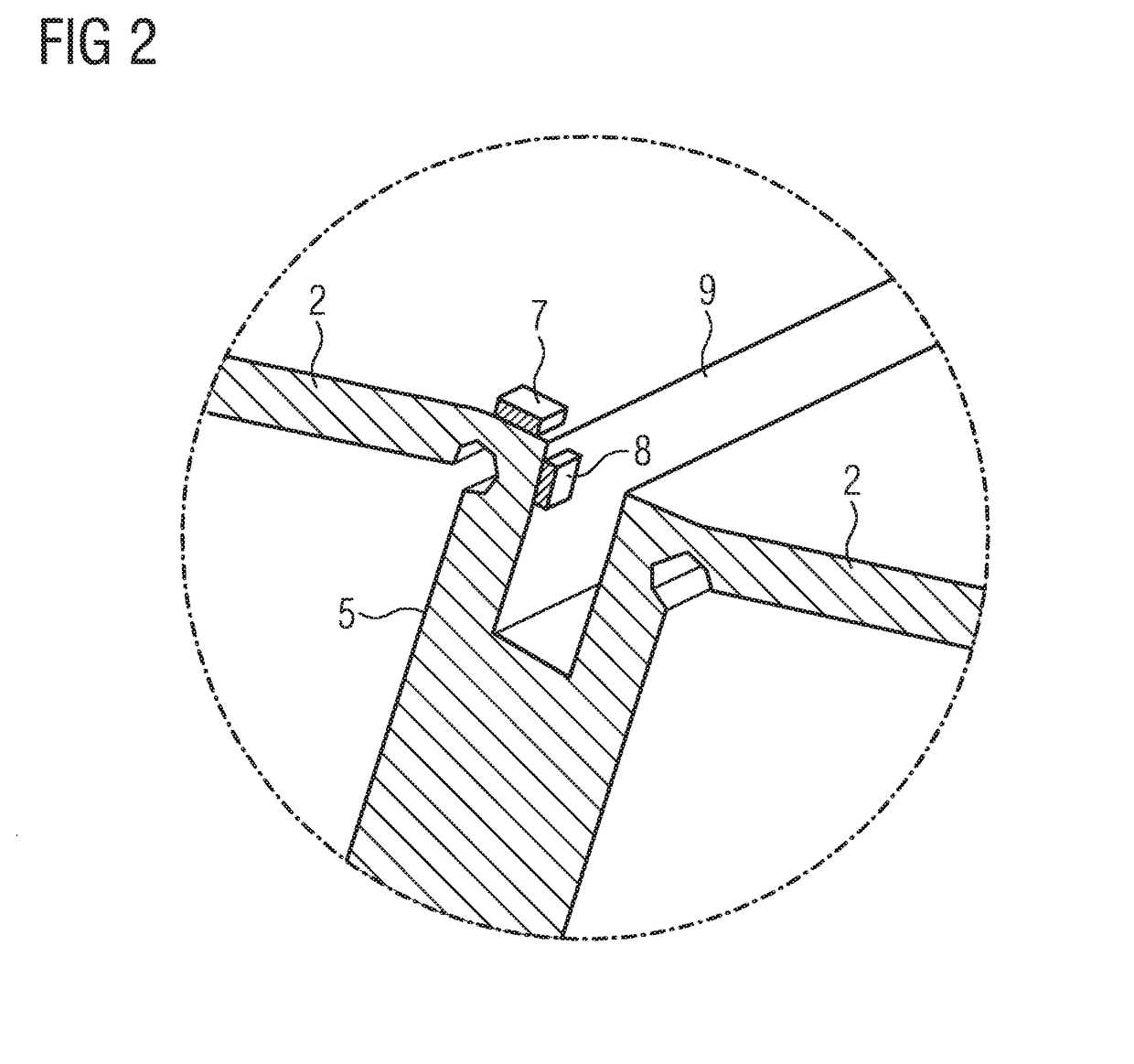

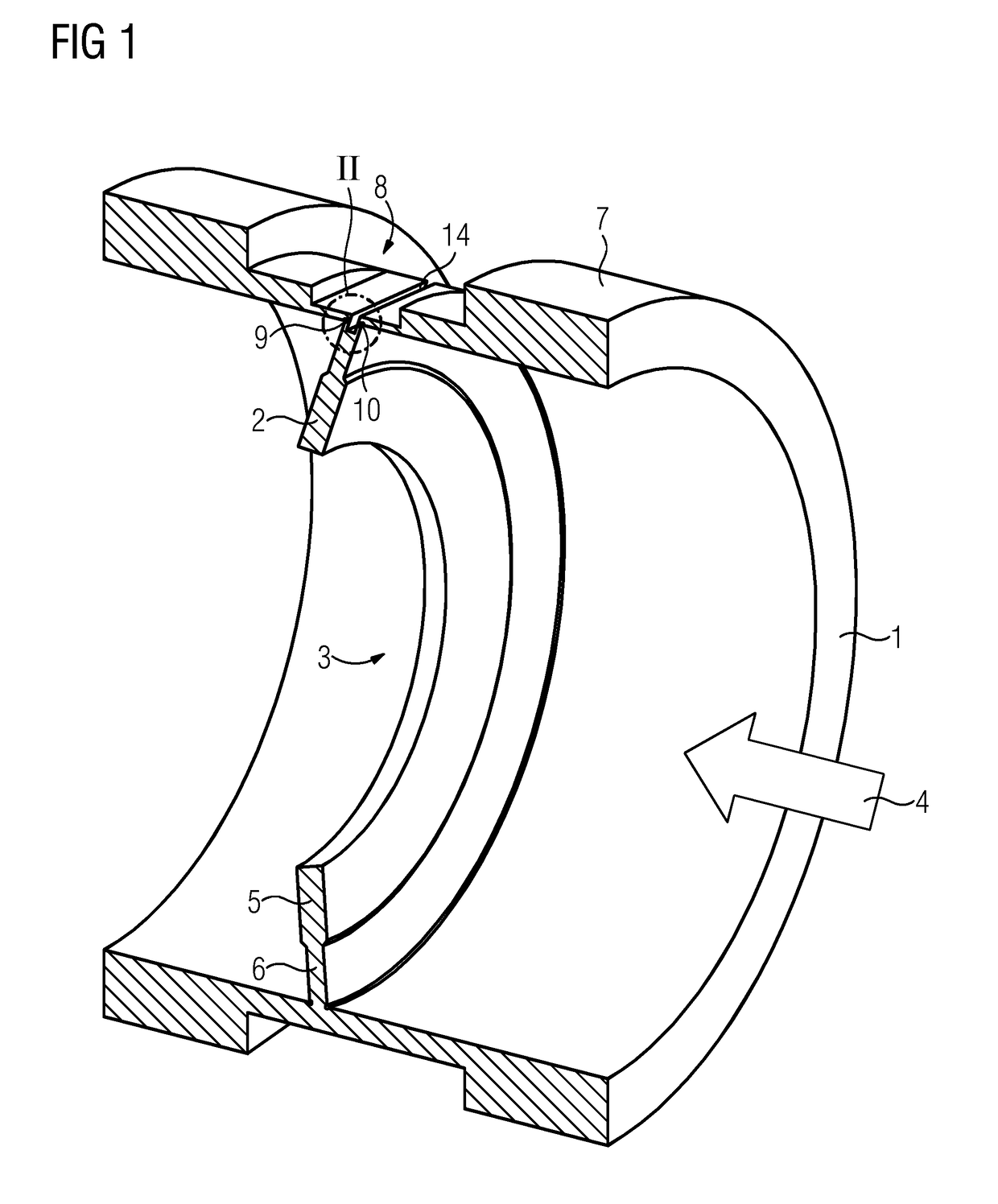

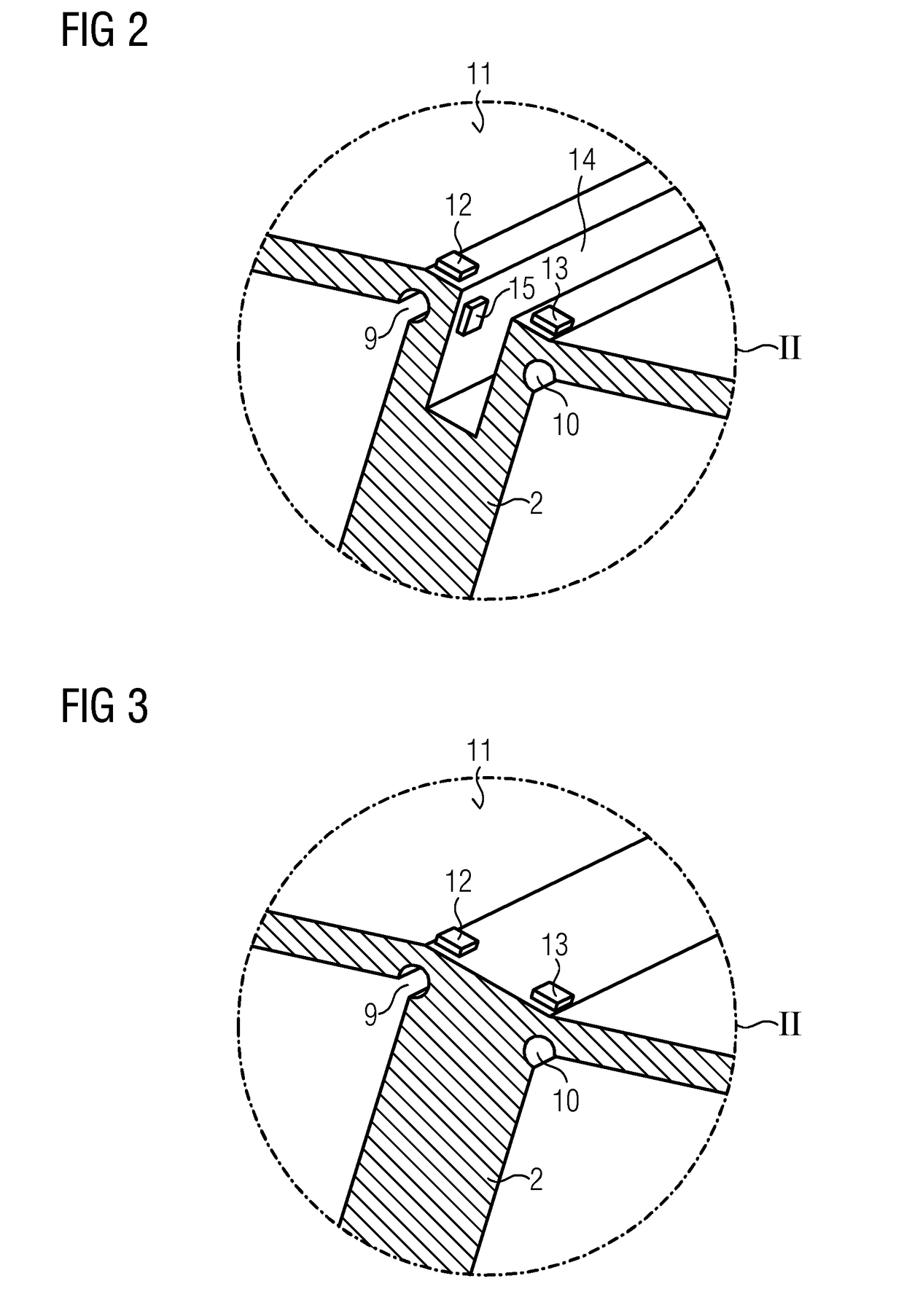

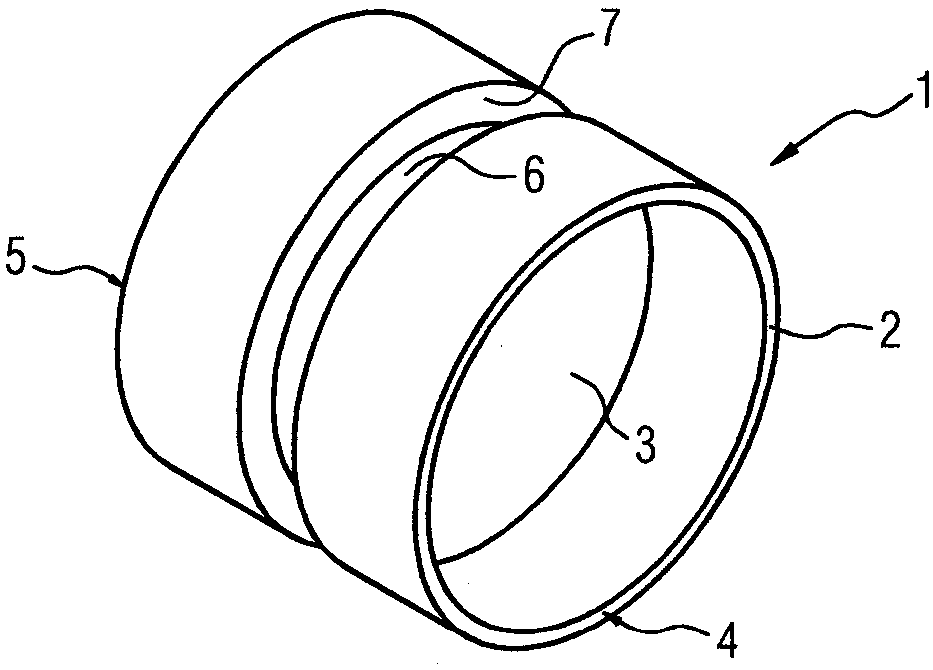

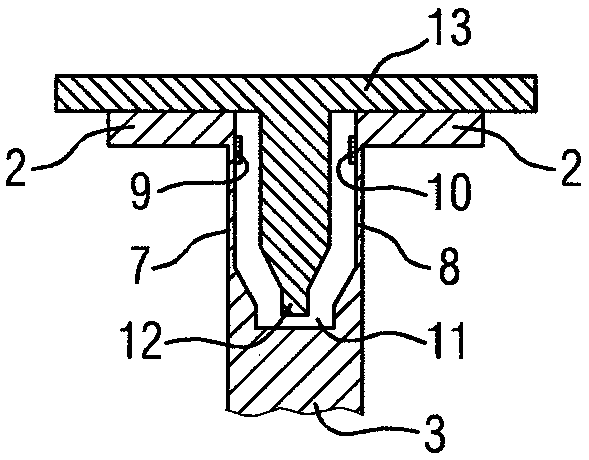

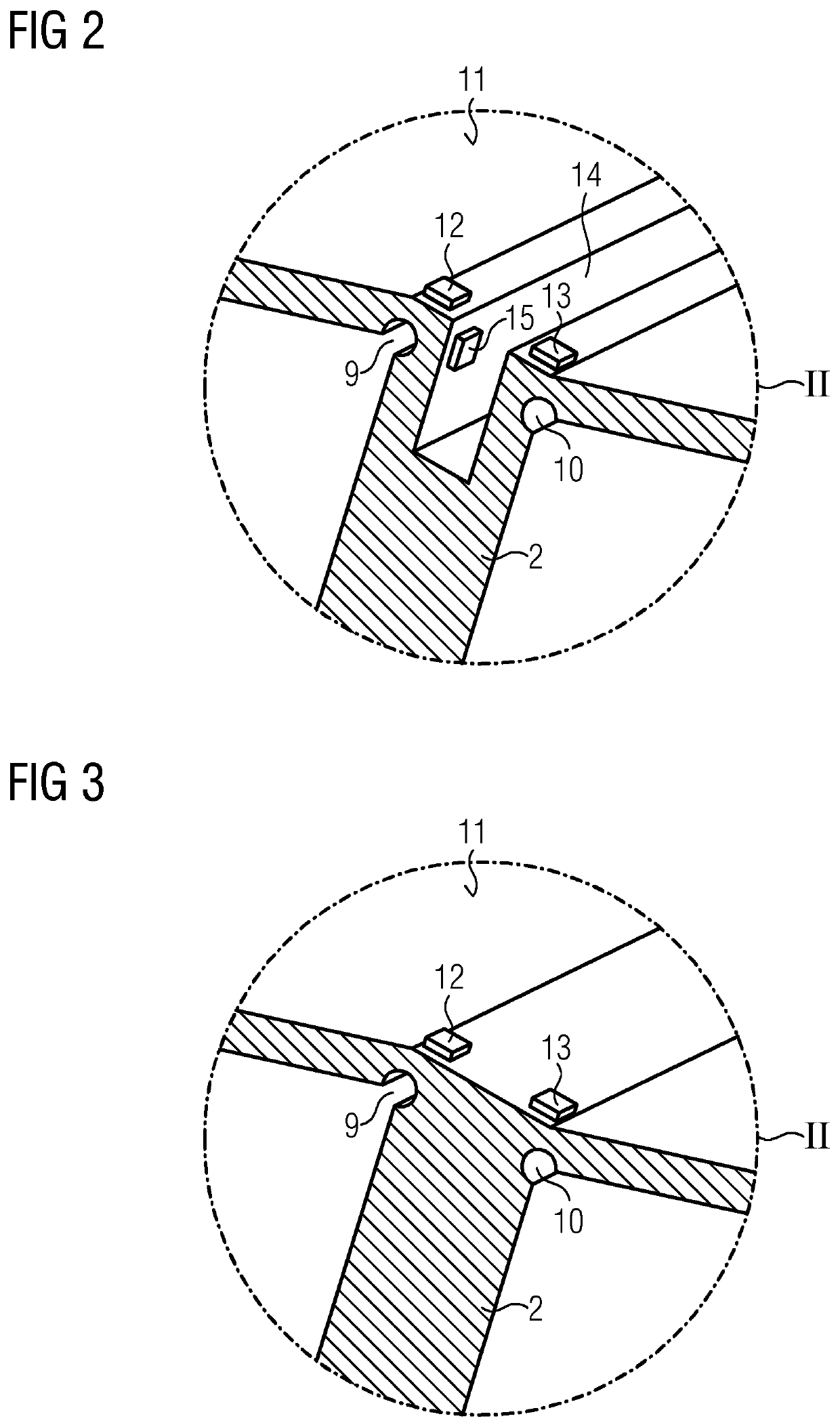

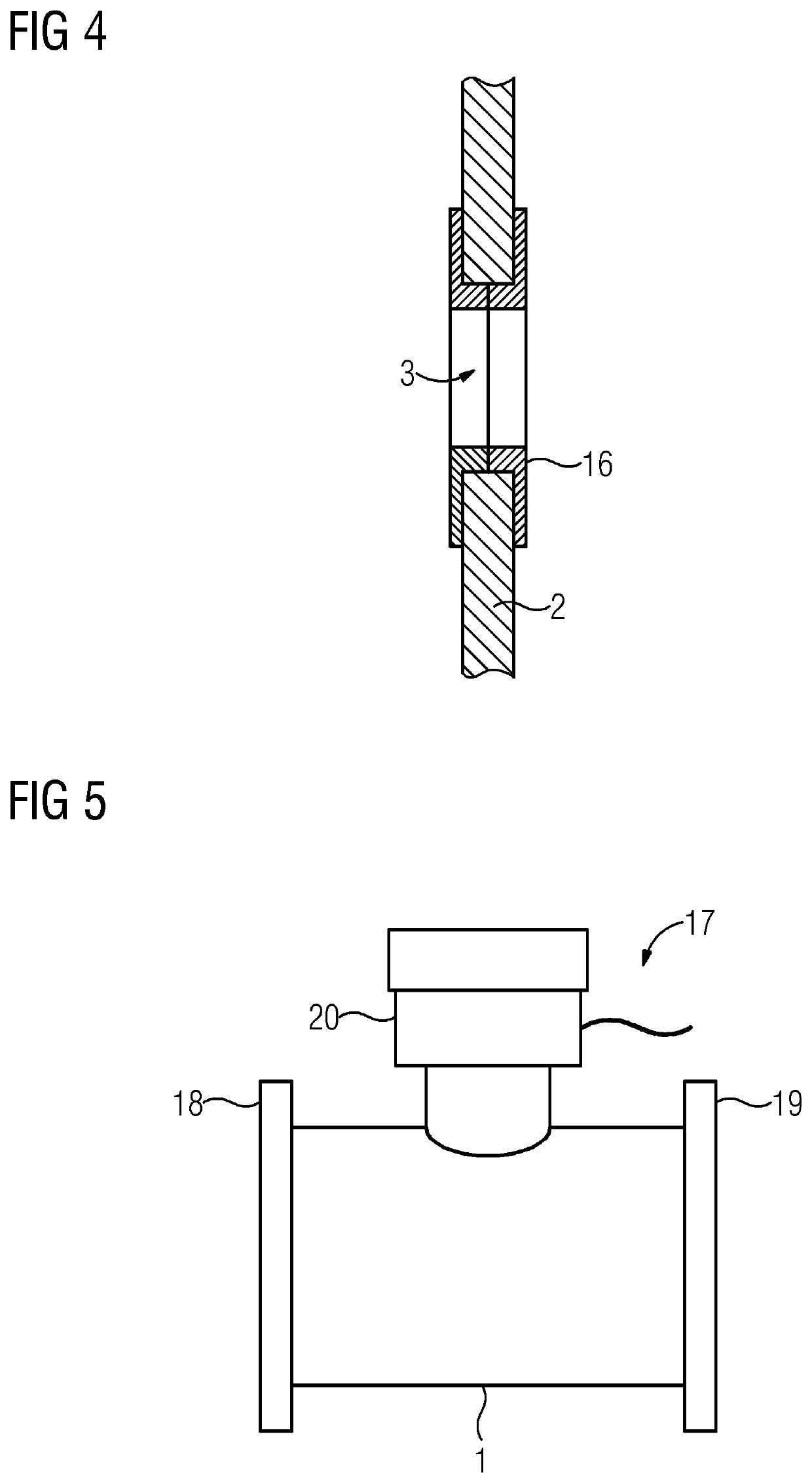

Pressure Sensor Arrangement and Measuring Transducer for Process Instrumentation Having Such a Pressure Sensor Arrangement

ActiveUS20180245999A1Improve long-term stabilityRugged designFluid pressure measurement by electric/magnetic elementsRapid change measurementTransducerEngineering

A pressure sensor arrangement includes a tube with a diaphragm to pressure to be measured is applied arranged in the cross-section of the tube, wherein the diaphragm is fastened to the tube inner wall via an articulation extending along the circumferential region of the diaphragm, where deformation of the diaphragm results in rotation of the articulation directly on the wall of the tube which can therefore be detected from the outside by suitable structure such that that strain sensors, for example, which can be used to detect deformation are advantageously not in contact with the process medium and there is advantageously no need for a pressure-tight bushing for electrical signals, and where the pressure sensor arrangement has a particularly simple structure and can be advantageously used in measuring transducers for process instrumentation.

Owner:SIEMENS AG

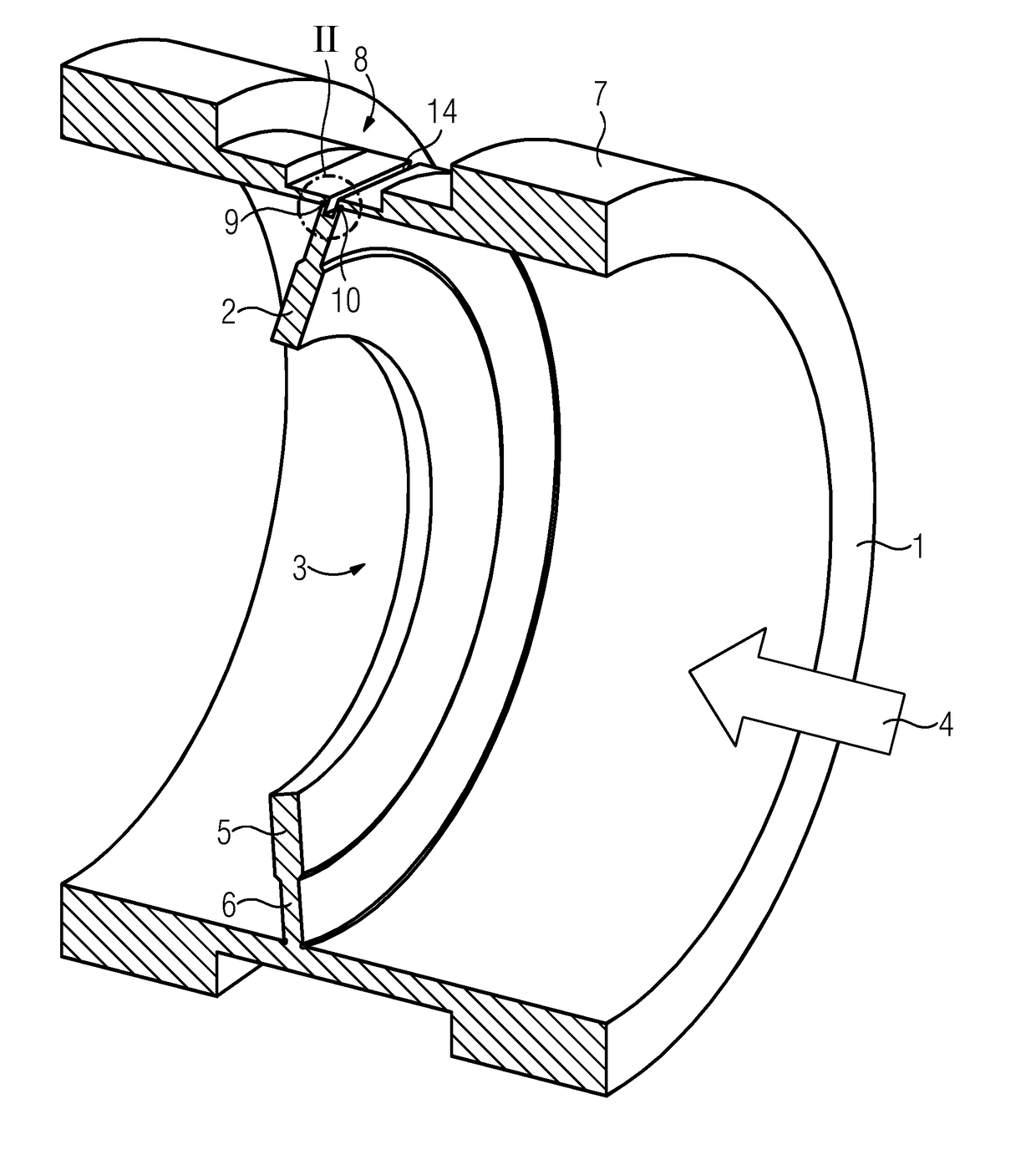

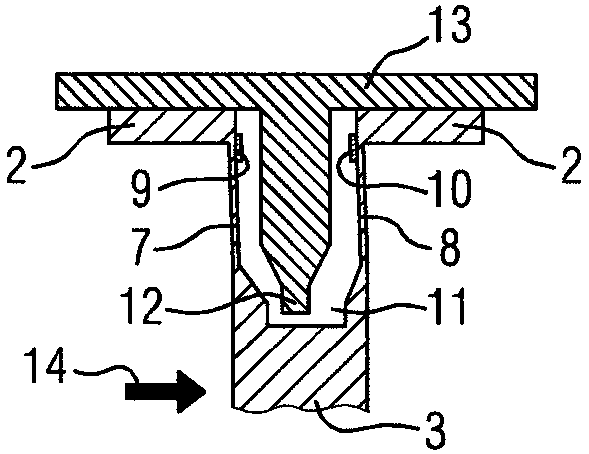

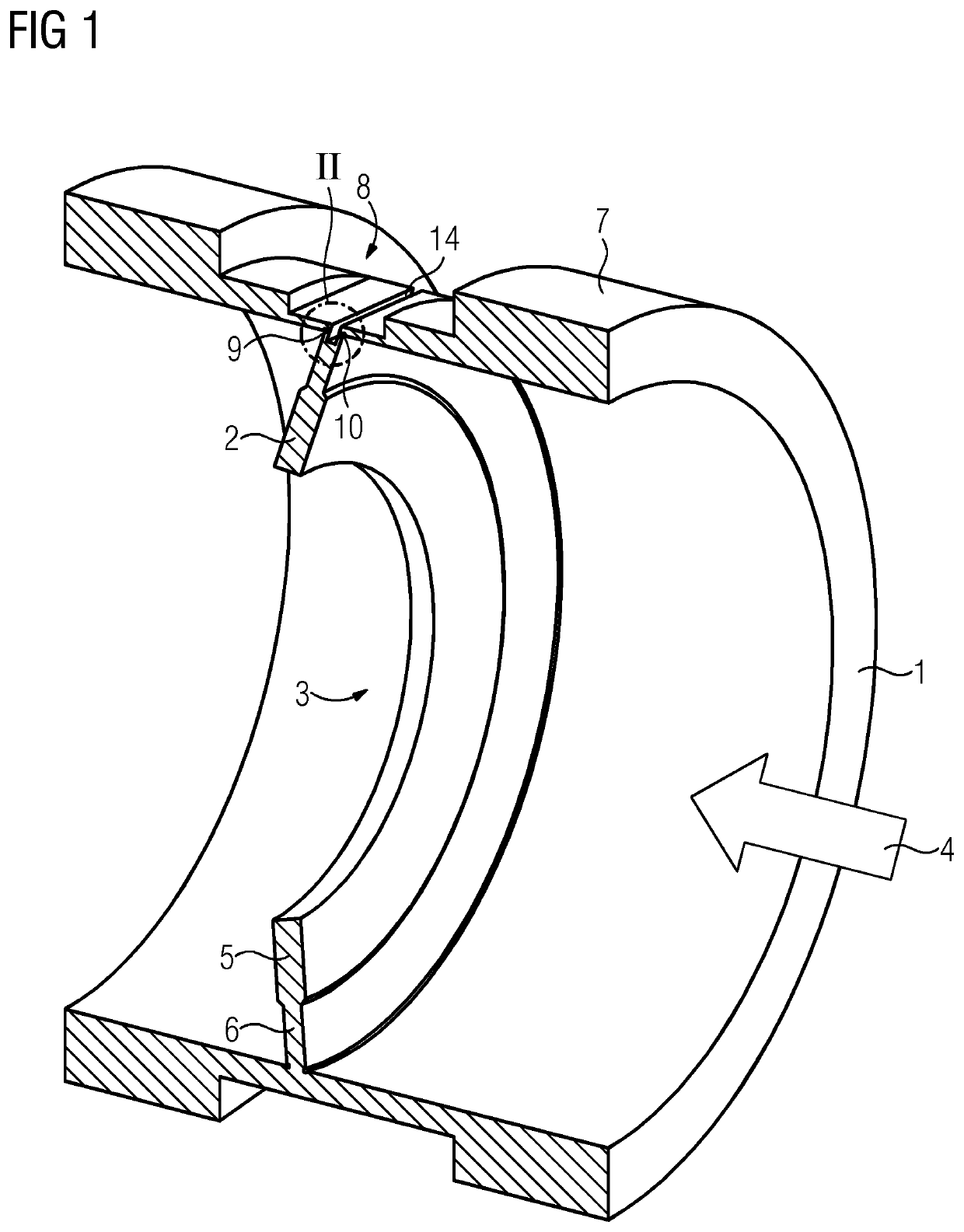

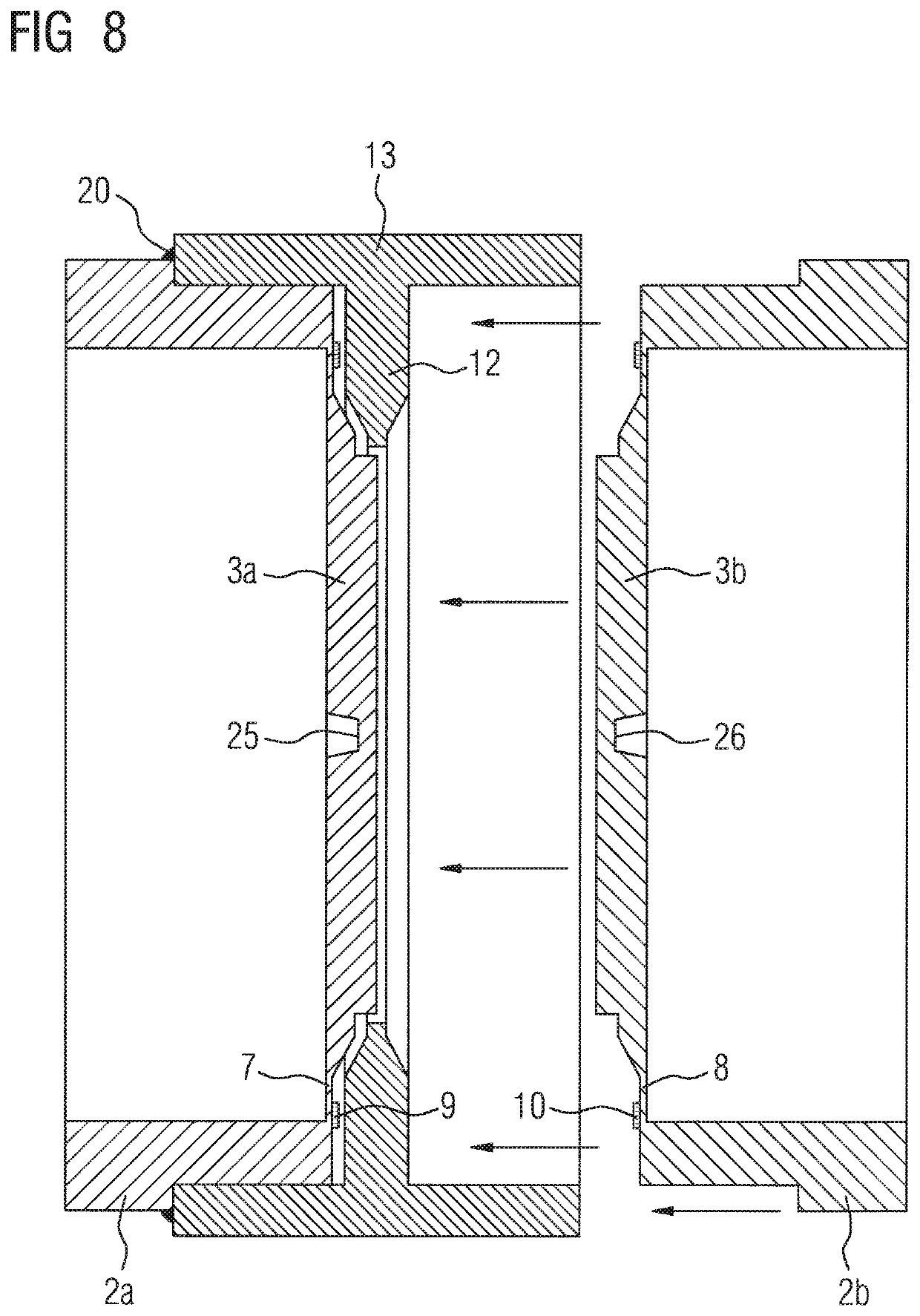

Through-flow Measurement Arrangement and Measuring Transducer for Process Instrumentation Having the Through-flow Measurement Arrangement

ActiveUS20180238722A1Easy to adaptImprove accuracyVolume/mass flow by differential pressureDifferential pressureTransducer

A through-flow measurement arrangement and measuring transducer for process instrumentation that includes the through-flow measurement arrangement, wherein the through-flow measurement arrangement operating in accordance with the differential-pressure method includes a tube and an elastically deformable measuring diaphragm arranged in the cross section of the tube and a strain sensor that detects the deformation and converts it into an electric signal, where the measuring diaphragm and the tube are formed in one piece from uniform material, and where both side of the measuring diaphragm each pass into the tube via a fillet groove and the at least one strain sensor is arranged on the circumferential side of the tube opposite the fillet groove.

Owner:SIEMENS AG

Method and system for diagnosing mechanical, electromechanical or fluidic components

InactiveUS7757556B2Less expense of energyFunction increaseVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementBandpass filteringMechanical resonance

There is described a diagnosis method and a system including a structure-born noise sensor which transmits, in a bandpass filtered manner, a measuring signal based on the mechanical resonance frequency and capacity thereof and on an inductance and an evaluating device in which the frequency, at which the measuring signal level exceeds a predetermined threshold value, is defined and which is used for producing an error signal, when the frequency exceeds a second predetermined threshold value. As far as the diagnosis performance requires a small number of electronic components and a low power supply, the diagnostic is integrated into existing devices, in particular into process instrumentation field devices for which a restricted quantity of operating power is available. The method and the system are used for identifying a valve leakage with the aid of an electro-pneumatic positional regulator.

Owner:SIEMENS AG

Plug-and-play sensor peripheral component for process instrumentation

A plug-and-play sensor peripheral component includes an electrically conductive physical connector; an electrical connector; a transformer; and an RF communication and data storage circuit. The electrical connector is electrically connected to the physical connector by a first conductive path. The transformer is electrically connected to the RF communication and data storage circuit. The transformer and the RF communication and data storage circuit are electrically isolated from the physical connector and the electrical connector. Electrically connecting the physical connector to the electrical connector by other than the first conductive path inductively couples the RF communication and data storage circuit to the first conductive path.

Owner:ROSEMOUNT INC

Method and system for diagnosing mechanical, electromechanical or fluidic components

InactiveUS7703326B2Low costSolve excessive overheadVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesCapacitanceEngineering

There is described a diagnosis method and system including a sensor for structure-borne noise which emits a measuring signal in a bandwidth-filtered manner due to its mechanical resonant frequency, capacitance and inductance. The system also includes an evaluation device in which the measuring signal is undersampled and which outputs an error signal should the undersampled measuring signal exceed a defined threshold value. The system requires only a small number of electronic components and only a little power supply capacity. The system thereby allows diagnosis to be carried out without complication in existing devices, especially in field devices of process instrumentation for which only a limited amount of operating power is available. The method and system are especially advantageous for the recognition of valve leakage with an electropneumatic position controller.

Owner:SIEMENS AG

Field device for process instrumentation

ActiveUS9194718B2Reduce demandImprove accuracyProgramme controlComputer controlEngineeringField device

A field device for process instrumentation comprising a measurement transducer having an analog output to which a two-wire line can be connected for transmitting an analog output signal, wherein a unit galvanically separates the processor from an analog output circuit. A read-back channel for a pulse-width modulated digital signal, which is tapped behind an element for galvanic separation, is provided for monitoring generation of the analog output signal, and a unit is provided for monitoring the analog output signal to maintain a specifiable maximum deviation from a reference signal, which is generated in the same manner as the analog output signal by low-pass filtering from the pulse-width modulated digital signal. In the case of transient signals, the monitoring unit advantageously detects error states quickly and appropriate measures for reacting to the error states can therefore be implemented in less time.

Owner:SIEMENS AG

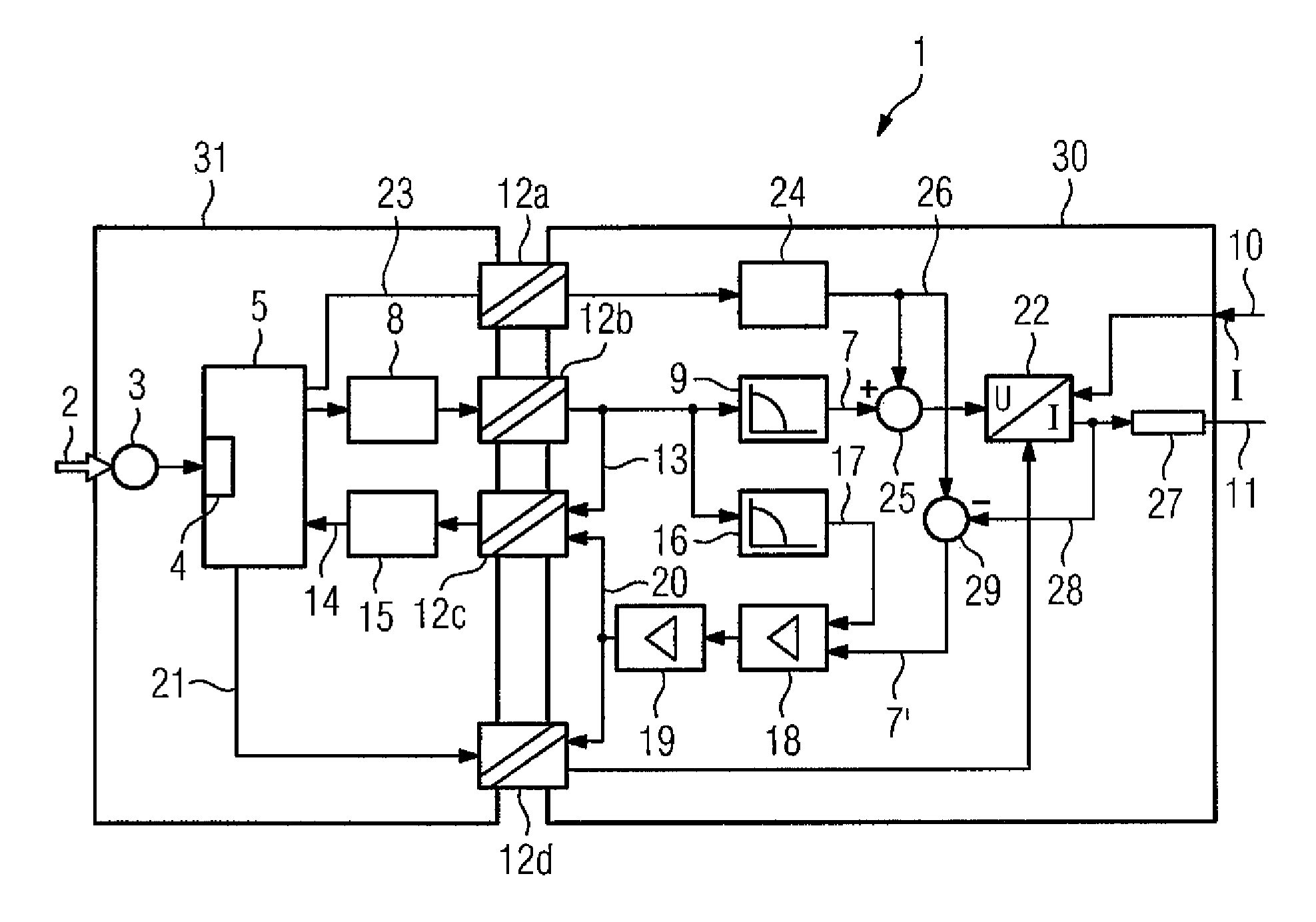

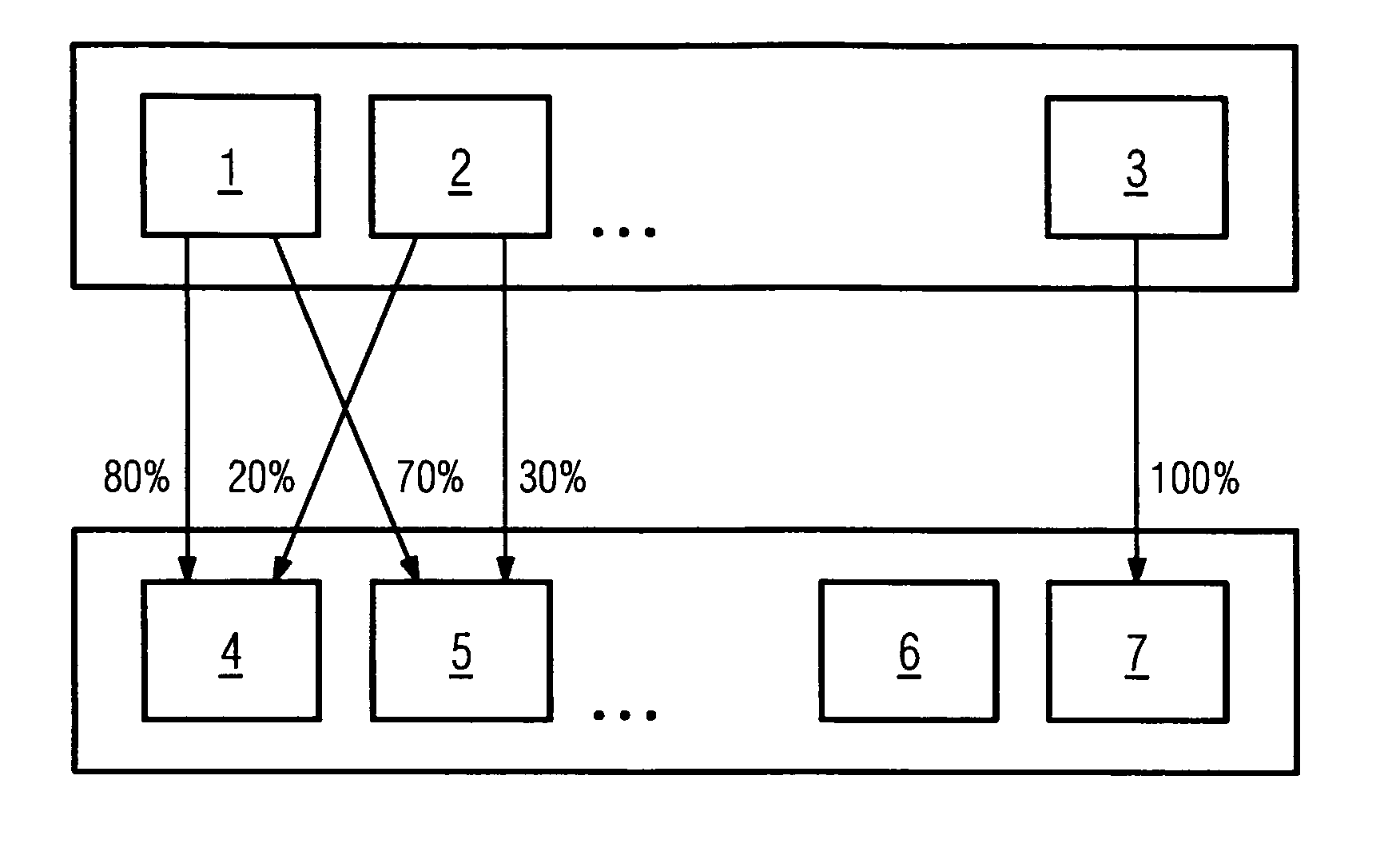

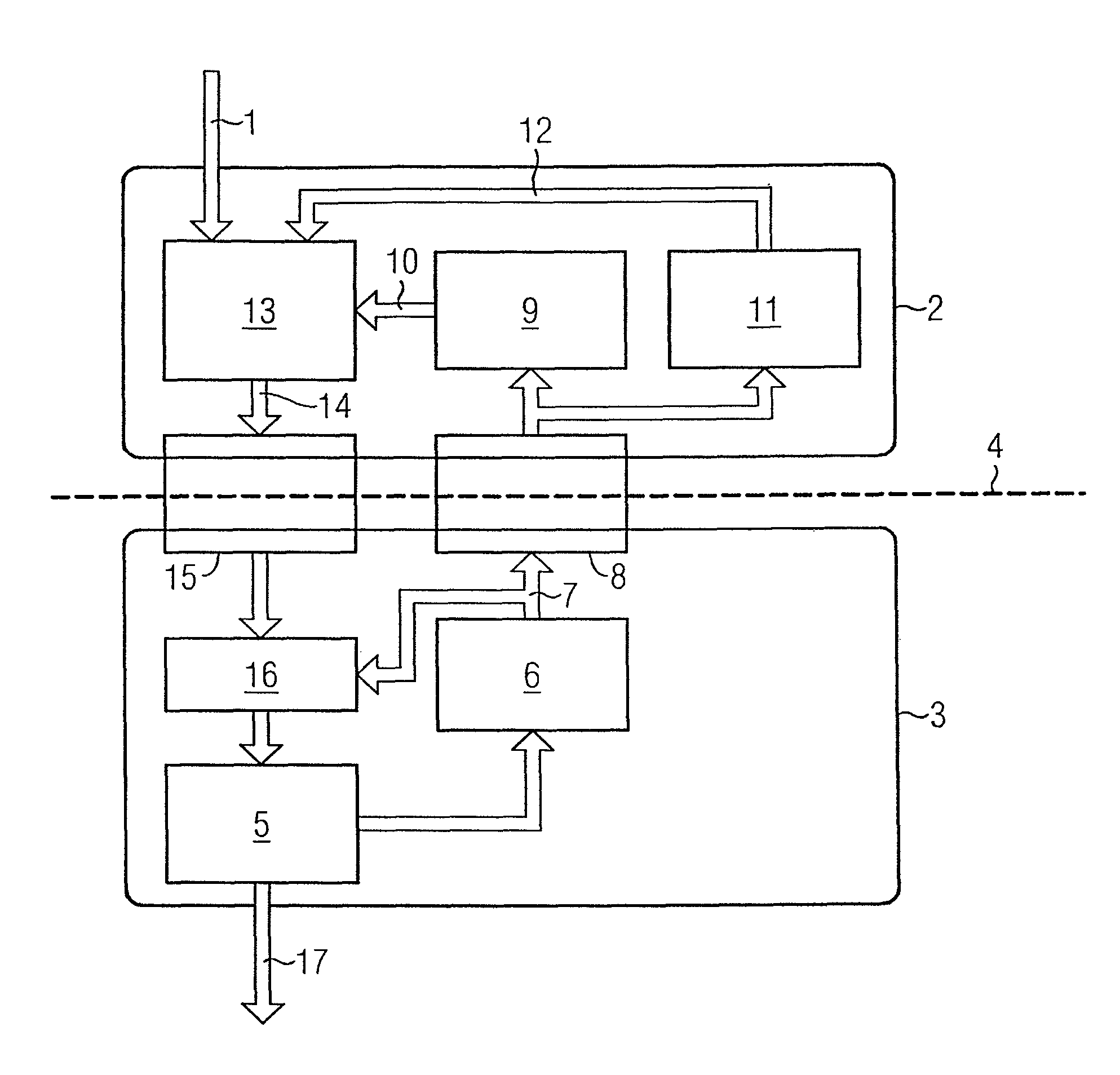

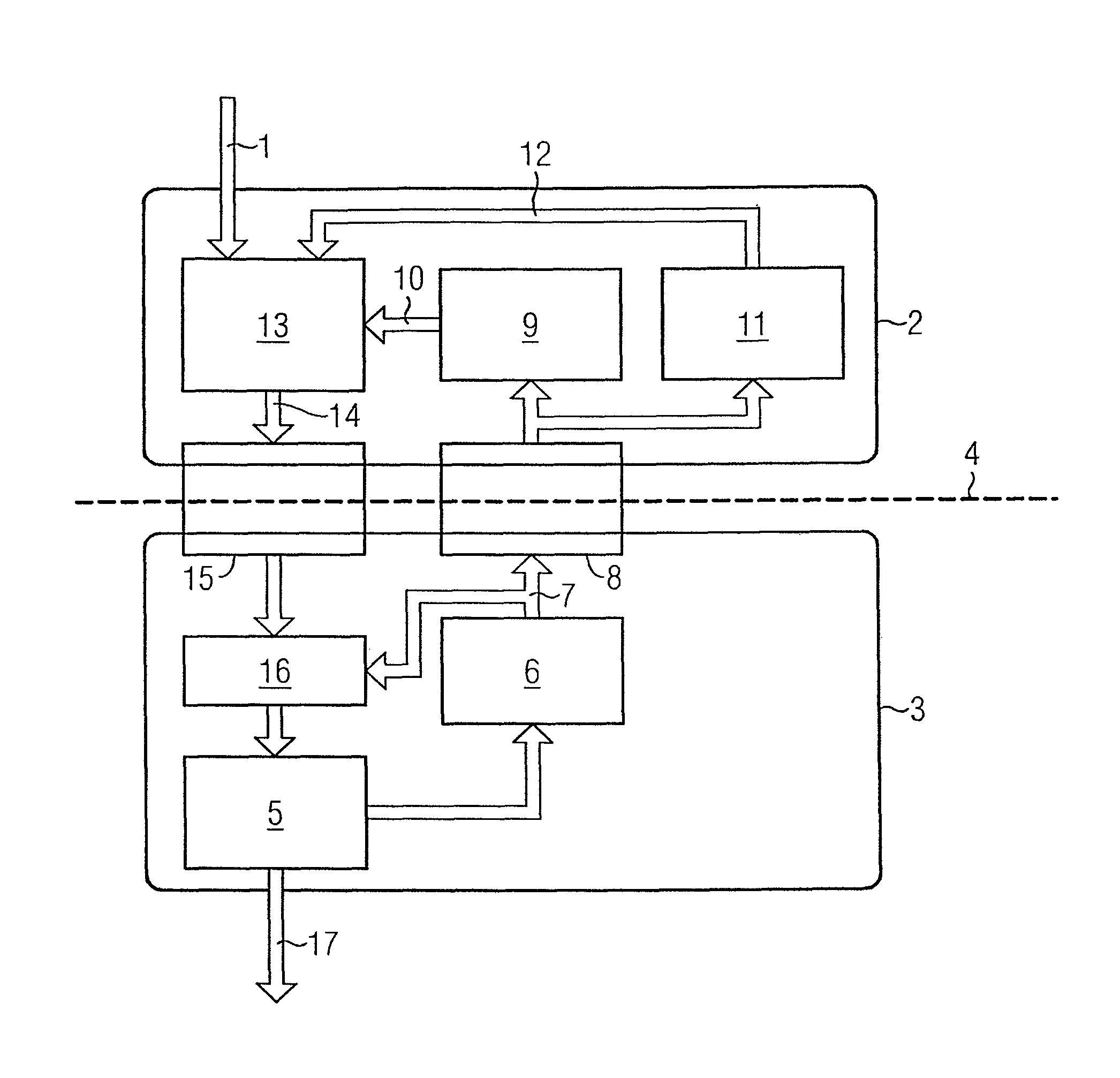

Method and device for optimizing processes

The invention relates to a process-optimizing device, particularly a manufacturing execution system device. Such a process-optimizing MES device is mounted between an enterprise production planning system, especially an enterprise resource planning device, and a control system, particularly a process instrumentation and control device. The inventive MES device comprises at least one optimization unit for influencing one or several process parameters of the control system, especially the PLT device, at least one data-determining unit for monitoring the process parameter / s, and at least one evaluation unit for automatically determining an optimization of the process parameter / s, which is created by the optimization unit / s.

Owner:SIEMENS AG

Measuring Transducer for Process Instrumentation, and Method for Monitoring the Condition of the Sensor Thereof

InactiveUS20110037456A1Improve reliabilityDetecting errorElectric devicesMeasurement apparatus componentsElectricitySemiconductor materials

A measuring transducer for process instrumentation that comprises a sensor for sensing a physical or chemical variable, wherein the sensor includes at least one electrical element embedded in a substrate comprising semiconducting material and is electrically separated therefrom by a blocked PN junction during normal operation. In order to monitor the condition of the sensor, the PN junction is connected in the conducting direction in a test mode, and the electrical property of the PN junction, i.e., the forward voltage, is determined and used to monitor the sensor condition. Additionally, a temperature sensor mounted on the sensor can be monitored by determining, based on the dependence of the forward voltage on the temperature, a comparative value for the temperature sensed by the temperature sensor. If major differences occur, a conclusion can be reached that there is a failure of the sensor, and a corresponding error message can be output over a field bus.

Owner:SIEMENS AG

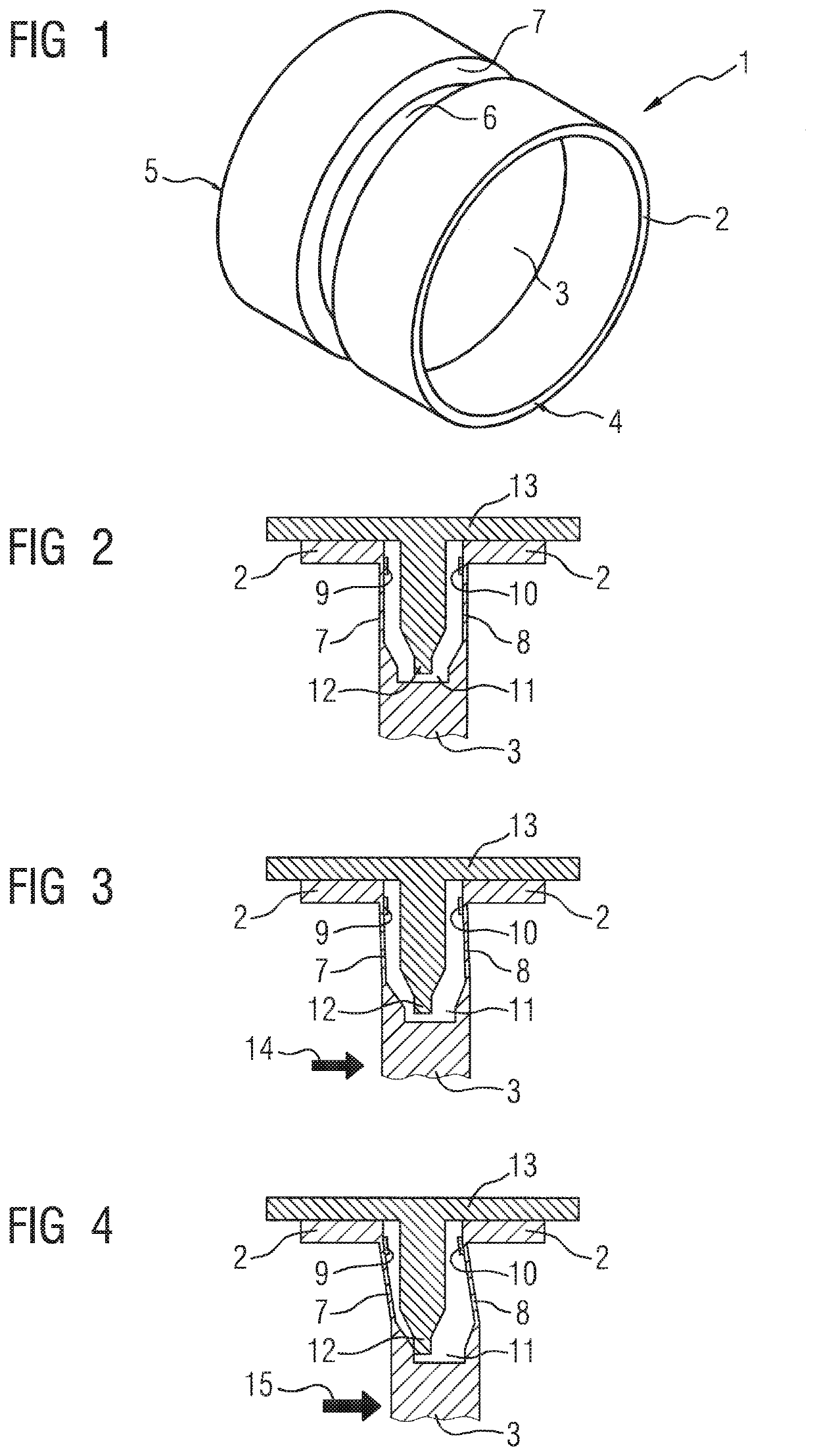

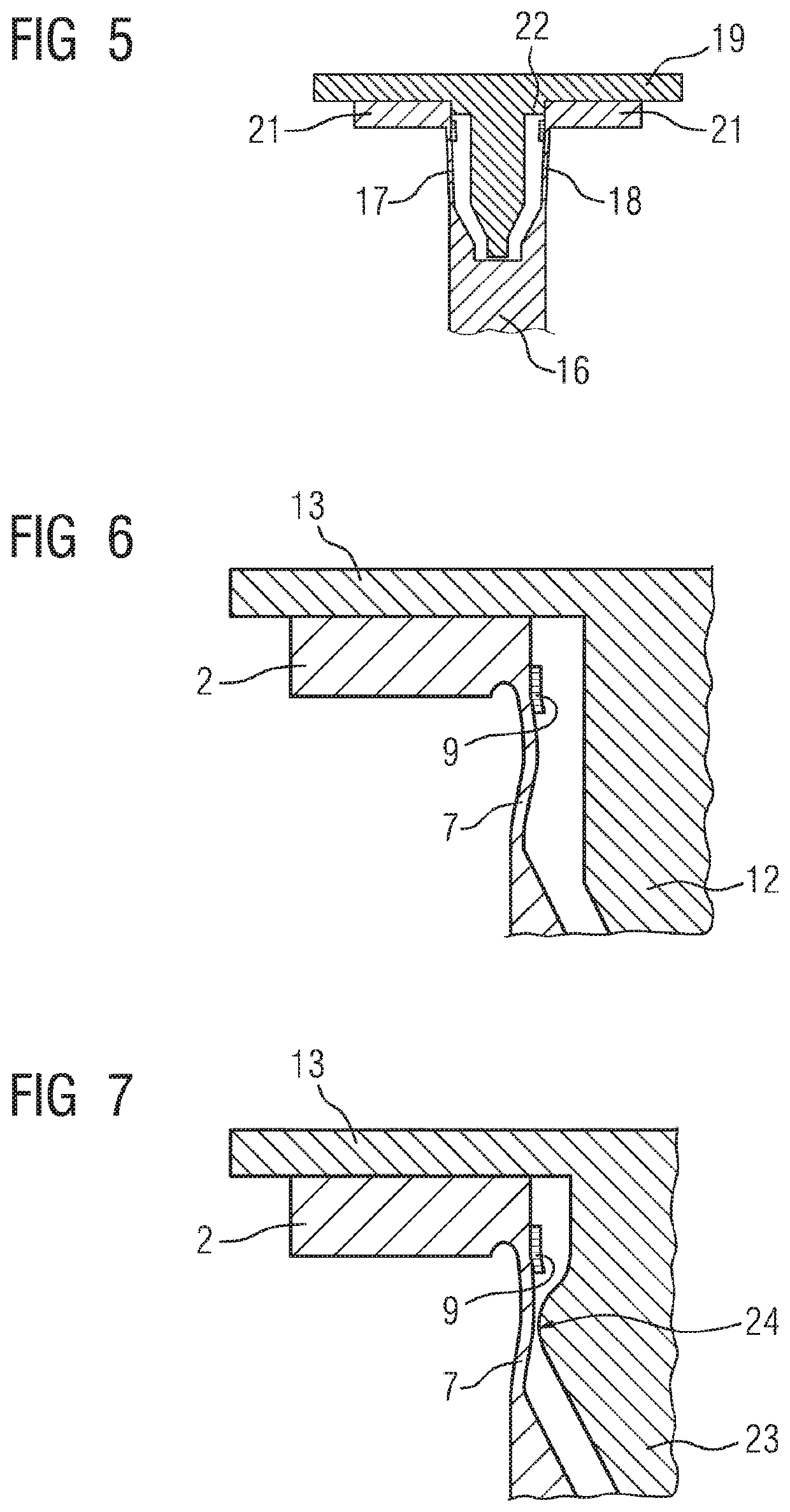

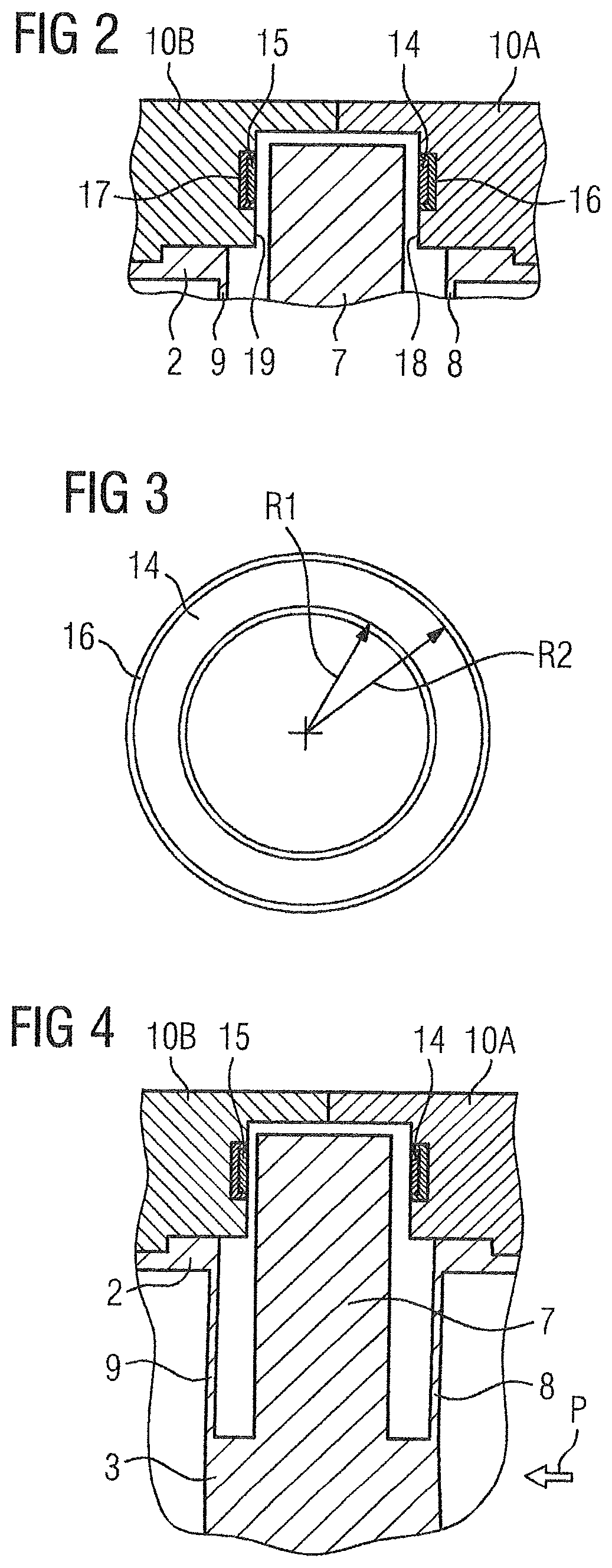

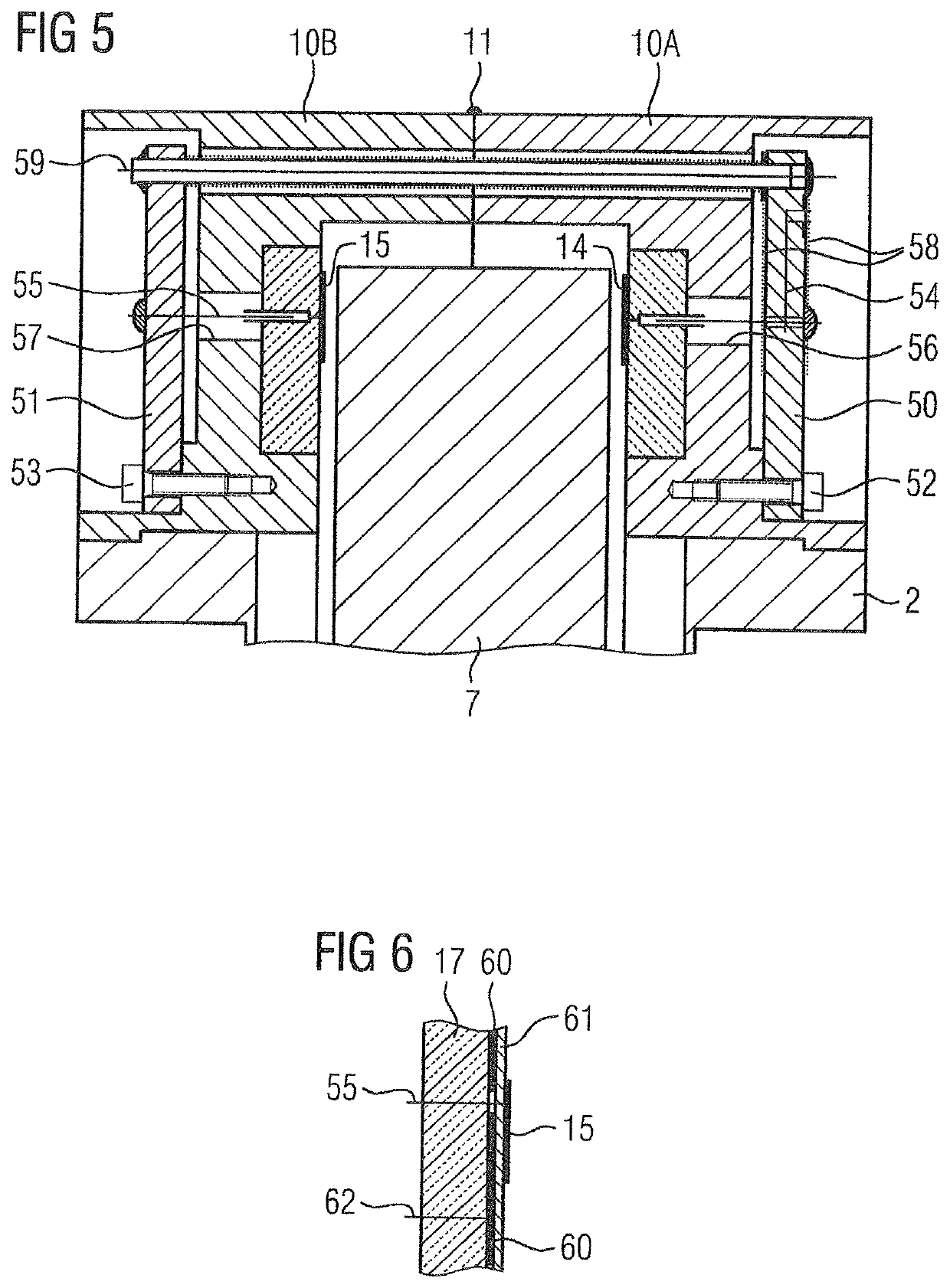

Pressure sensor assembly and measurement converter for process instrumentation, comprising such a pressure sensor assembly

ActiveCN107923808AImprove long-term stabilityStable designFluid pressure measurement by electric/magnetic elementsUltimate tensile strengthElectric signal

The invention relates to a pressure sensor assembly (1) comprising a tube (2), wherein a membrane (3) to which the pressure to be measured is applied is arranged in the cross-section of the tube. Themembrane (3) has a high flexural rigidity in the central region and is mounted in an elastic manner in the axial direction in the edge region (6) in the tube (2). In order to elastically mount the membrane, two limbs (7, 8; 17, 18) are used, the mutually facing sides of which are provided with elongation sensors (9, 10) for detecting an axial movement of the membrane (3), said movement depending on the pressure to be measured. Advantageously, the sensors (9, 10) do not contact the process medium and a pressure-tight feedthrough for electric signals is not required. The pressure sensor assembly(1) is characterized by a particularly simple structural design and can be used advantageously in measurement converters for process instrumentation.

Owner:SIEMENS AG

Measurement transducer for process instrumentation, and method for monitoring the state of its sensor

A measurement transducer for process instrumentation includes a sensor for detecting a physical or chemical quantity, where a supply voltage to the sensor is regulated by a cross regulator to a constant value, and the current intensity of the current adjusted by the cross regulator and flowing parallel to the sensor is determined and monitored to maintain a specified criterion in order to detect a sensor error such that error conditions of the sensor can be determined in a particularly simple and effective way.

Owner:SIEMENS AG

Flow measurement arrangement including a flow tube and an elastically deformable orifice plate with strain sensors

ActiveUS10571317B2Simple structural designSuitable for useVolume/mass flow by differential pressureEngineeringMechanical engineering

A flow measurement arrangement and measuring transmitter for process instrumentation that includes the flow measurement arrangement, wherein the flow measurement arrangement operating in accordance with the differential-pressure method includes a tube and an elastically deformable measuring diaphragm (orifice plate) arranged in the cross section of the tube and a strain sensor that detects the deformation and converts it into an electric signal, where the measuring diaphragm (orifice plate) and the tube are formed in one piece from uniform material, and where both side of the measuring diaphragm (orifice plate) each pass into the tube via a fillet groove and the at least one strain sensor is arranged on the circumferential side of the tube opposite the fillet groove.

Owner:SIEMENS AG

Circuit arrangement for detecting and digitizing an analog input signal, and field device for process instrumentation

ActiveUS8830108B2Without loss of accuracyLow costElectric signal transmission systemsElectrical testingAnalog signalOptical coupler

A circuit arrangement for detecting and digitizing an analog input signal and to a field device for process instrumentation, wherein the field device comprises such a circuit arrangement which includes a first electronics unit, a second electronics unit, and an interface by which the two electronics units are galvanically separated from each other. A first signal is generated at a first frequency in the second electronics unit. A voltage frequency converter, to which the analog input signal is routed, uses a reference frequency to generate a second signal at a second frequency that corresponds to the level of the analog input signal. After the second signal has been transmitted to the second electronics unit using an optical coupler, a ratiometric measurement of the second frequency is performed in the second electronics unit dependent on the first frequency using a capture timer.

Owner:SIEMENS AG

Pressure sensor assembly and measurement converter for process instrumentation comprising the pressure sensor assembly

ActiveUS10612990B2Simple structureSuitable for useFluid pressure measurement by electric/magnetic elementsConvertersMechanical engineering

A pressure sensor assembly that includes a tube, wherein a membrane to which the pressure to be measured is applied is arranged in the cross-section of the tube, where the membrane has a high flexural rigidity in its central region and is mounted in an elastic manner in the axial direction in the edge region in the tube, two limbs are used to elastically mount the membrane, the mutually facing sides of the two limbs being provided with elongation sensors for detecting an axial movement of the membrane, the movement depending on the pressure to be measured, and where the sensors advantageously do not contact the process medium and a pressure-tight feedthrough for electric signals is not required such that the pressure sensor assembly has a particularly simple structural design and can be used advantageously in measurement converters for process instrumentation.

Owner:SIEMENS AG

Field device having an analog output

InactiveCN101809413AAvoid noiseElectric signal transmission systemsDigital-analogue convertorsLow-pass filterImage resolution

The invention relates to a field device having an analog output, especially a measuring transducer (1) for process instrumentation having a 4-20 mA interface as the analog output (7). For digital-to-analog conversion, a digital value is split into a digital coarse portion and a digital fine portion. Depending on the digital coarse portion, a first analog signal (V1) is generated using a pulse width modulator (BUF1) having a low path filter (TP1) mounted downstream thereof, which signal is above the analog output signal (VOUT), and a second output signal (V2) using a pulse width modulator (BUF2) having a low path filter (TP2) mounted downstream thereof, which signal is below the analog output signal(VOUT). Both analog signals (V1, V2) are guided to a third pulse width modulator (SW1) which is controlled depending on the digital fine portion, a low-pass filter (TP3) being mounted downstream thereof. The invention allows provision of an analog output signal (VOUT) having high resolution and good dynamic properties. The field device is further characterized by a digital-to-analog converter that can be produced with especially little complication.

Owner:SIEMENS AG

Field device for process instrumentation

ActiveUS8825422B2Minimal effortRapidly and reliably signaledElectric testing/monitoringElectrical measurementsPower flowTransducer

A field device for process instrumentation, in particular a measuring transducer, comprising an analogue output to which a two-wire line is connectable for transmitting an analogue output signal. The output circuit contains a controller with an actuator connected downstream for the analogue output signal. A monitoring unit monitors whether an actuating signal remains within a predeterminable value range to monitor the output circuit for correctly setting the loop current. If the actuating signal is outside the value range, an indicator signal is output to a computing unit so that suitable measures can be introduced in response to an error state that has thus been identified.

Owner:SIEMENS AG

Field device for process instrumentation

ActiveUS8593214B2Reduce power consumptionAvoid excessive currentProgramme controlElectric variable regulationPower flowControl signal

Owner:SIEMENS AG

Measurement transducer for process instrumentation, and method for monitoring the state of its sensor

ActiveUS20160025528A1Reliable and low mannerReliable and low costWave based measurement systemsCalibration apparatusPower flowTransducer

A measurement transducer for process instrumentation includes a sensor for detecting a physical or chemical quantity, where a supply voltage to the sensor is regulated by a cross regulator to a constant value, and the current intensity of the current adjusted by the cross regulator and flowing parallel to the sensor is determined and monitored to maintain a specified criterion in order to detect a sensor error such that error conditions of the sensor can be determined in a particularly simple and effective way.

Owner:SIEMENS AG

Pressure sensor assembly and measurement transducer for process instrumentation with the pressure sensor assembly

ActiveUS10983023B2Simple configurationProcess can be usedFluid pressure measurement by electric/magnetic elementsPressure difference measurement between multiple valvesAxial displacementTransducer

A pressure sensor assembly includes a tube, wherein a membrane to which the pressure to be measured is applied is arranged in the cross-section of the tube, where the membrane has a high flexural rigidity in a central region and is mounted resiliently in the edge region in the tube via two limbs, and includes a device for detecting the axial displacement which is easily accessible from the outside on the outer side of the tube and is advantageously not in contact with the process medium, and where the pressure sensor assembly has a particularly simple structural configuration, and can be used advantageously in measurement transducers for process instrumentation.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com