Antistatic polyester false twisted yarn, process for its production, and antistatic special conjugated false twisted yarn comprising antistatic polyester false twisted yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

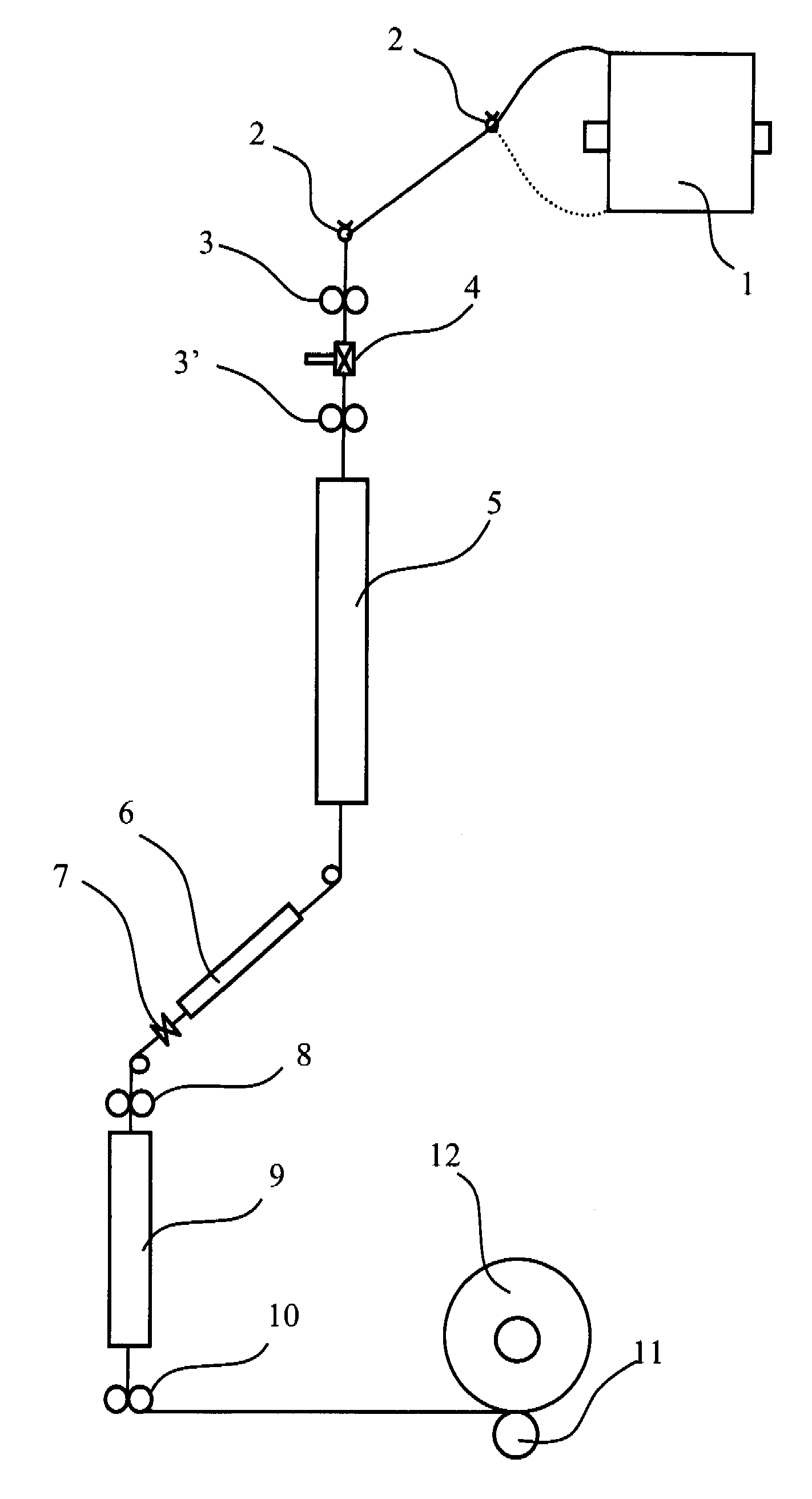

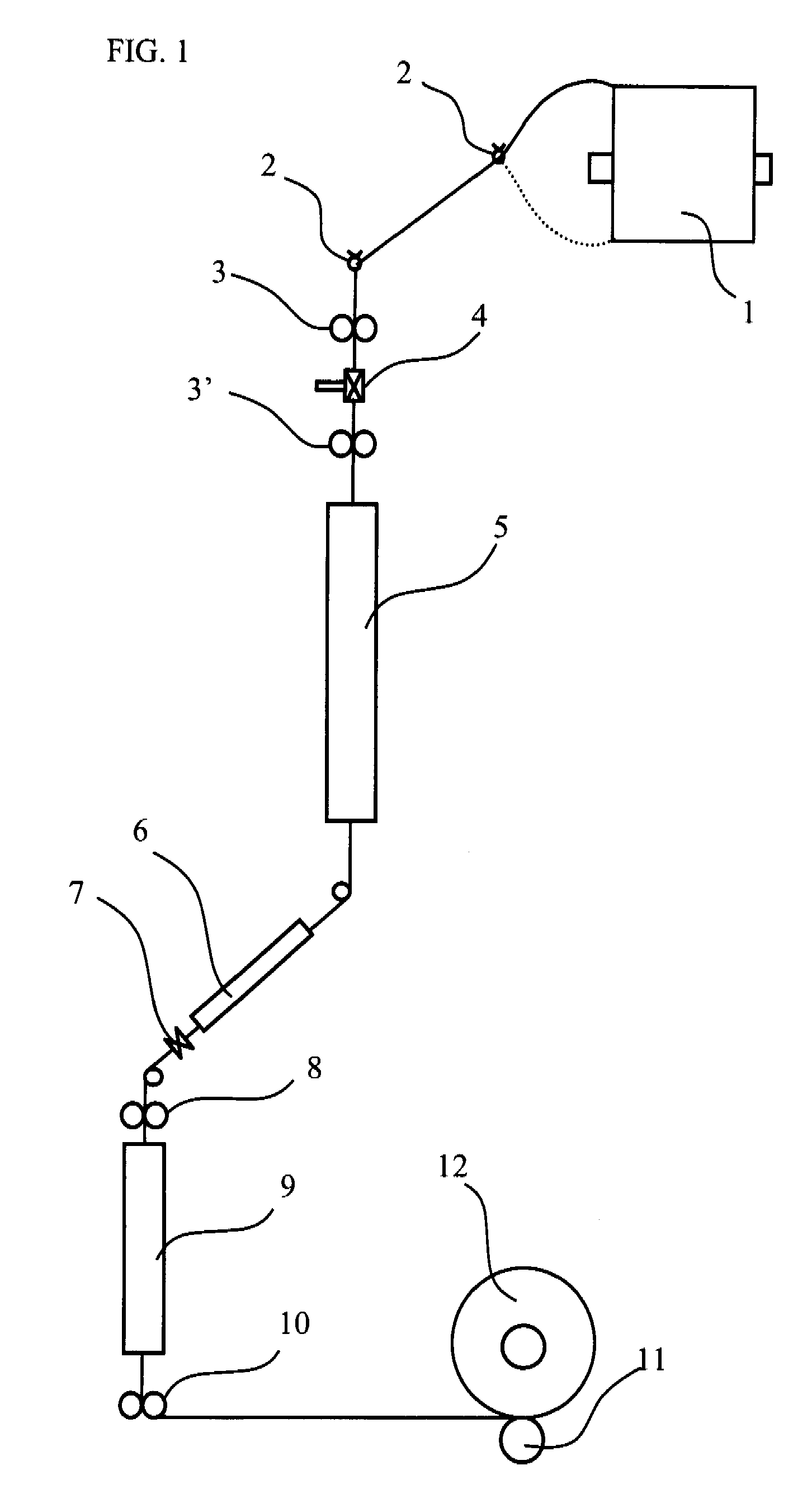

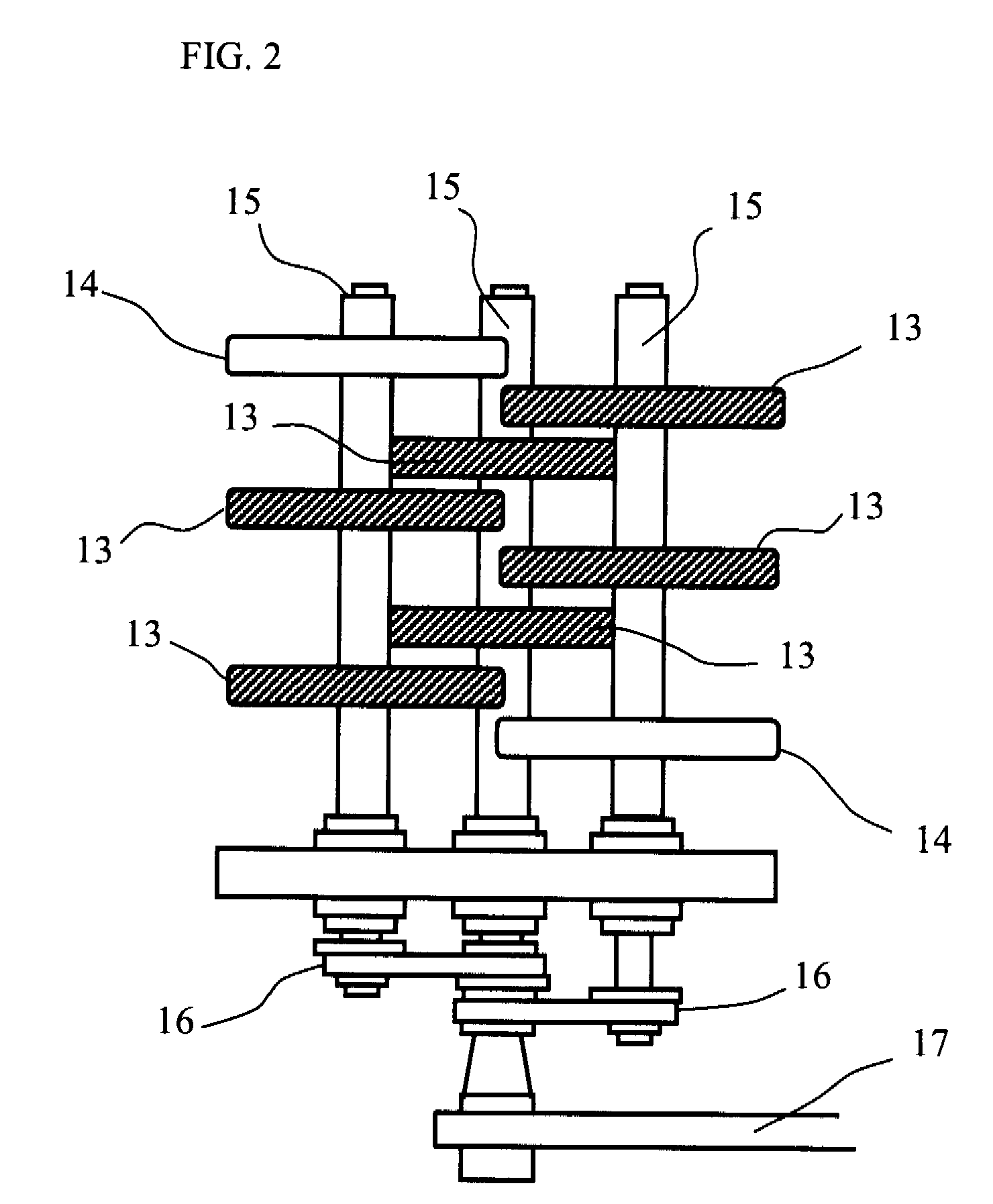

Image

Examples

examples

[0116]The present invention will now be explained in greater detail using examples and comparative examples. The measured values indicated in the examples were measured by the following methods. The term “parts” refers to “parts by weight” unless otherwise specified.

[0117]The aromatic polyester composition was dissolved in ortho-chlorophenol and measured at 35° C. using an Ubbellohde viscosity tube.

[0118]Melt spinning was carried out for one week with a melt spinning apparatus, and the number of yarn breaks was recorded for evaluation of the number of spinning yarn breaks per spindle per day. However, artificial or mechanical yarn breaks were excluded from the yarn breakage count.

(3) Birefringence

[0119]An optical microscope and compensator were used according to an ordinary method to determine the retardation of polarized light obtained on the surface of the fibers.

(4) Transit Angle

[0120]The yarn running on the false twisting disc was...

examples 1-3

, Comparative Examples 1-5

[0140]After charging 100 parts of dimethyl terephthalate, 60 parts of ethylene glycol, 0.06 part of calcium acetate monohydrate (0.066 mol % with respect to dimethyl terephthalate) and 0.013 part of cobalt acetate tetrahydrate (0.01 mol % with respect to dimethyl terephthalate) into a transesterification can, the temperature of the reaction product was raised from 140° C. to 220° C. over a period of 4 hours under a nitrogen gas atmosphere, and transesterification was carried out while removing from the system the methanol produced in the reaction can. Upon completion of transesterification, 0.058 part of trimethyl phosphate (0.080 mol % with respect to dimethyl terephthalate) was added as a stabilizer and 0.024 part of dimethylpolysiloxane was added as an antifoaming agent to the reaction mixture.

[0141]After 10 minutes, 0.041 part of antimony trioxide (0.027 mol % with respect to dimethyl terephthalate) was added to the reaction mixture, the temperature was...

examples 4-6

, Comparative Examples 6-7

[0152]The polyester unstretched filament obtained in Example 2 was subjected to stretching and false twisting under the conditions shown in Table 2, to obtain polyester false twisted yarns with the physical properties shown in Table 2. The stretching and false twisting yarn breakage and fluff generation are also shown in Table 2. The polyester false twisted yarns were evaluated for quality by the method described above, giving the results shown in Table 2.

TABLE 2ExampleExampleExampleComp.Comp.456Ex. 6Ex. 7Lowermost disc contact1.52.50.52.70.3length (mm)Spinning yarn breakage336351( / day)Stretching / false4575193twisting yarn breakage( / day)Textured yarn fluff35848151( / 104 m)Weaving property:Interruptions ( / day)2232863Percentage crimp (%)1415161715False twisted yarn3.33.43.02.82.4strength (cN / dtex)False twisted yarn2223211812ductility (%)Hand quality / soft feel11133(rankAntistatic property1528235851Method A (sec)Antistatic property11001090125018001900Method B (V)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com