A multi-degree-of-freedom motion branch chain resolution test platform and test method

A technology of motion branch chain and test platform, which is applied in the field of machinery, can solve the problems of shafting error measurement method useless Hooke hinge motion accuracy test, etc., and achieve the effect of simple, direct and efficient measurement method, high motion accuracy, and small friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

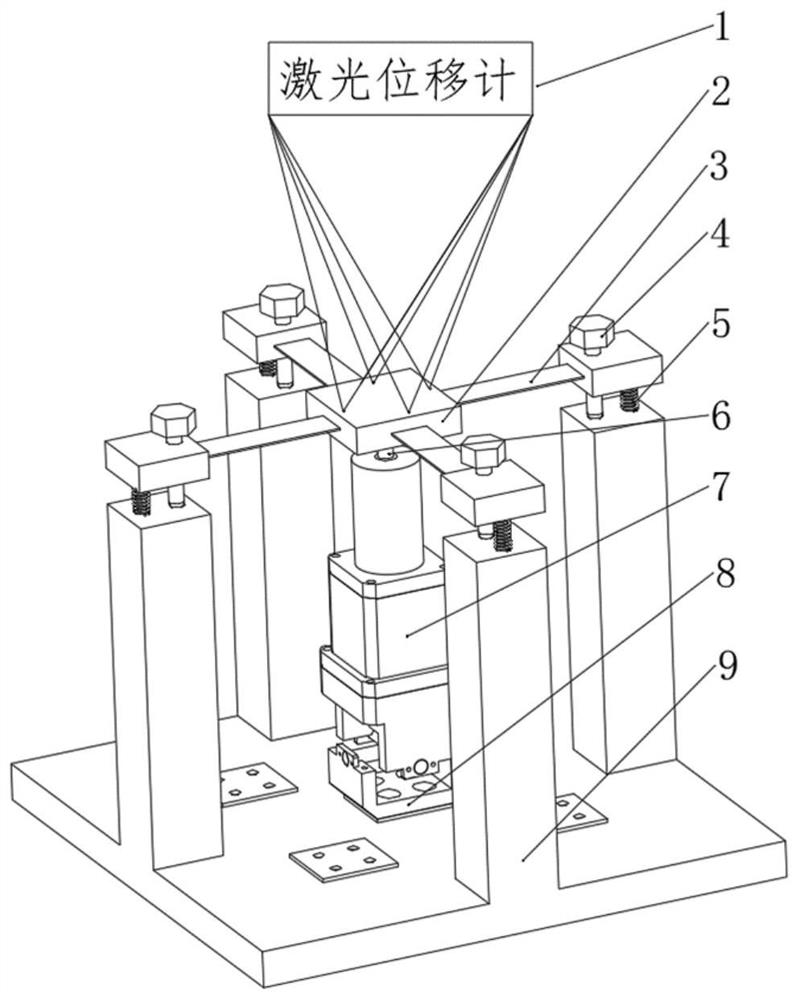

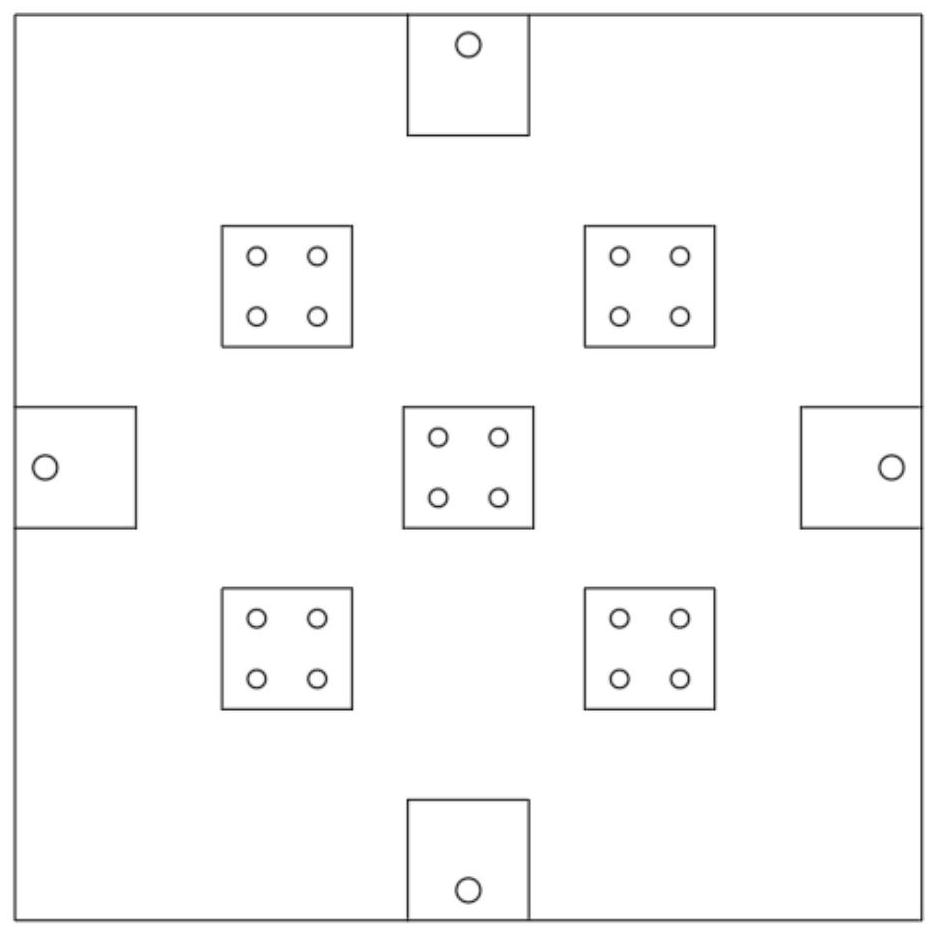

[0020] See attached figure 1 , the multi-degree-of-freedom motion branch chain resolution testing platform of the present invention includes: a laser displacement meter 1; a fixing device 9; a straight beam type flexible hinge 3 connected with the fixing device 9; Platform 2; and a linear drive assembly 7 arranged between the fixing device 9 and the moving platform 2, the upper end of the linear driving assembly 7 is connected to the lower end surface of the moving platform through a flexible ball hinge 6, and the lower end is connected to the fixing device 9 through a Hooke hinge 8; There are four straight beam-type flexible hinges 3, which are symmetrically and evenly distributed around the moving platform 2; the laser displacement gauge 1 is placed above the moving platform 2, and the test point is the center point of the moving platform; the fixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com