Seamless steel tube plug and preparation method thereof

A technology of seamless steel pipes and seamless pipes, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of low hardness, poor wear performance, and poor temperature resistance of seamless steel pipe heads, and achieve stable chemical Effects of performance and physical properties, long service life, extended online use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

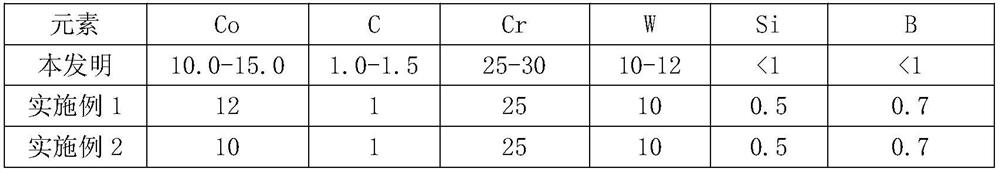

[0033] Below in conjunction with specific embodiment 1-5, the present invention is further described, as shown in table 1-3, table 1 is the chemical composition (by weight percentage) of the cobalt-based spray coating of the seamless steel pipe head of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0034] Table 1 The chemical composition of the cobalt-based spray coating on the head of the seamless steel pipe according to the embodiment of the present invention, unit: weight percent.

[0035]

[0036]

[0037] The preparation method of the above-mentioned seamless steel pipe plug includes:

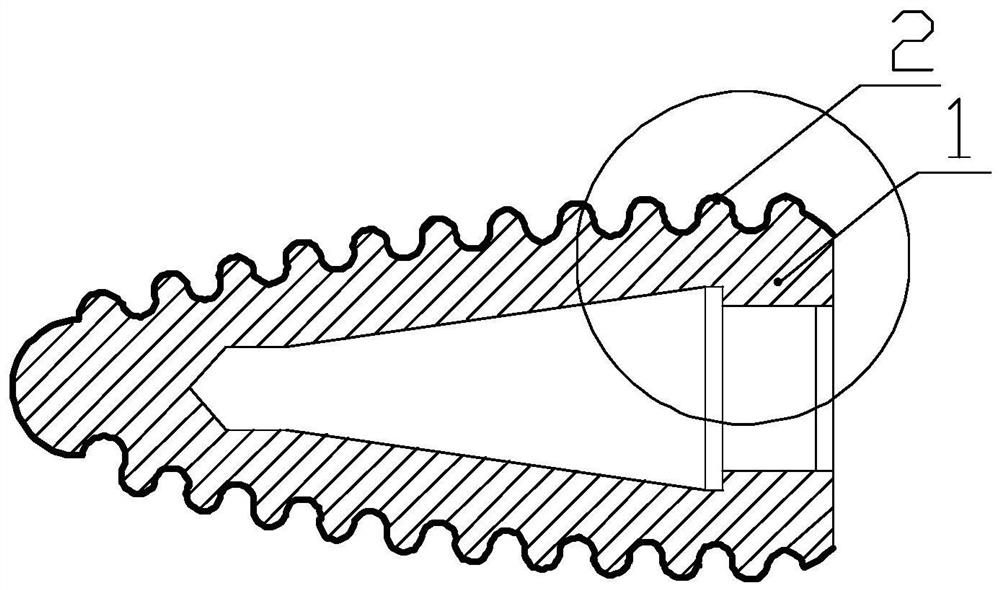

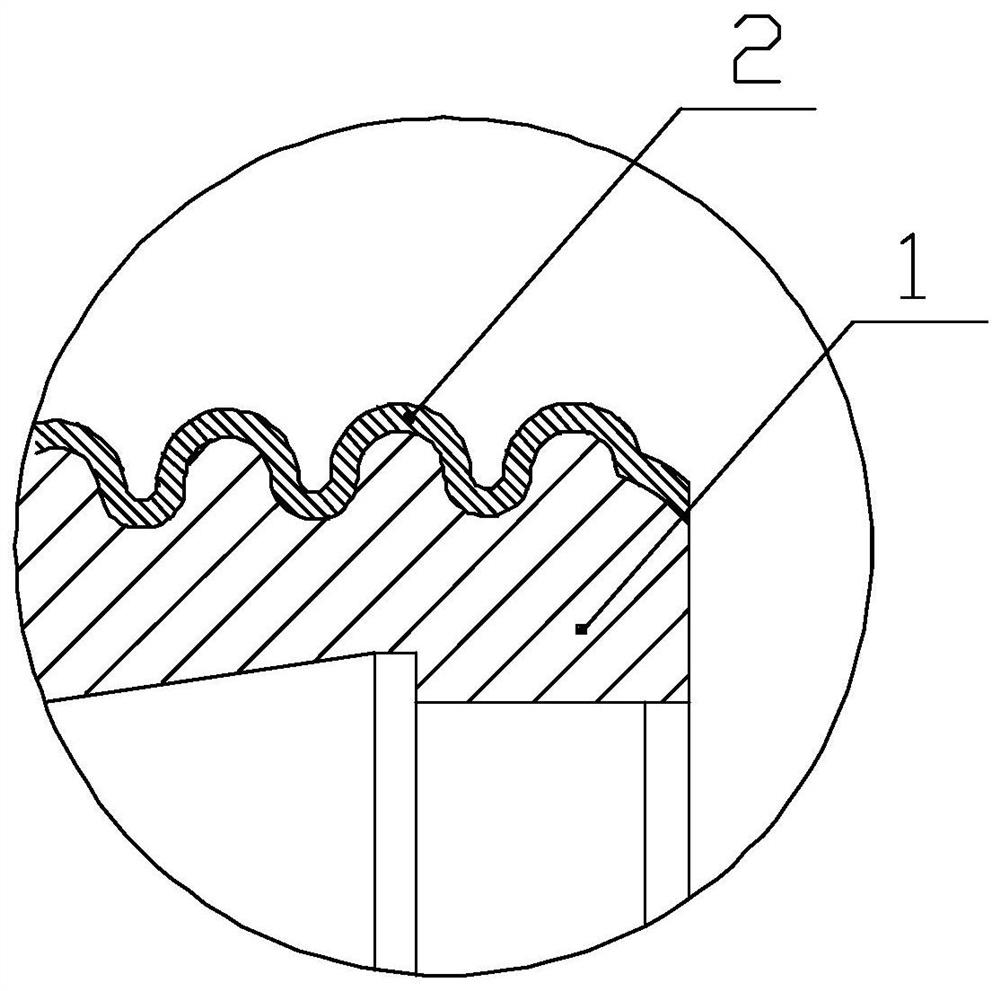

[0038] 1) Prepare the substrate of the seamless pipe plug, mechanically finish the 35CrMo substrate of the seamless pipe plug to the design size, the surface of the 35CrMo substrate is provided with a spiral groove, the groove depth is 4.0mm, and the pitch is 8.0mm;

[0039] 2) Preparation of cobalt-based spray coating materials, accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com