Method for stripping photoresist

a technology of photoresist and stripping technology, applied in the field of stripping a photoresist, can solve the problems of low yield in semiconductor production, poor resistance to ashing of low-k materials, and inability to withstand ashing, and achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0069] The invention is described in more detail with reference to the following Examples, to which, however, the invention should not be limited. Unless otherwise specifically indicated, the amount is in terms of % by mass.

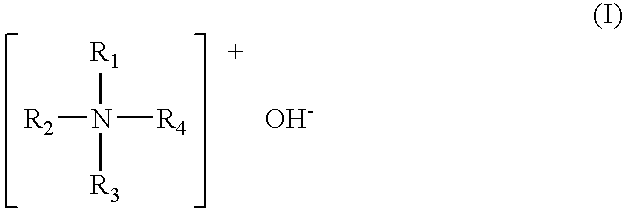

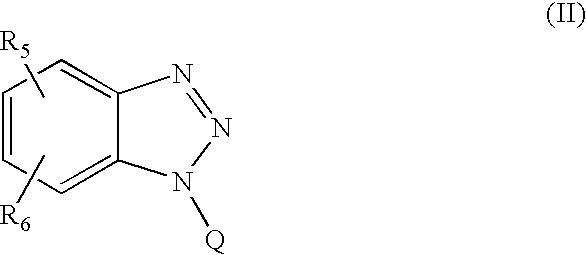

examples 1 to 6

[0070] A substrate having a Cu wiring thereon that is overlaid with an SiOC layer (carbon-doped oxide layer; low-k layer) was used. A positive photoresist, TDUR-P722 (by Tokyo Ohka Kogyo Co., Ltd.) was coated on the substrate, and heated at 140° C. for 90 seconds to form a photoresist layer, and then selectively exposed to light using S-203B (by Nikon Corp.), then further heated at 140° C. for 90 seconds (post-exposure baking treatment), and developed with an aqueous 2.38 mas. % tetraammonium hydroxide (TMAH) solution to form a photoresist pattern. Next, the SiOC layer was etched.

[0071] After thusly etched, the substrate was contacted with ozone water for 15 minutes. The ozone water had been prepared by bubbling ozone gas into pure water for 15 minutes. Subsequently, the substrate was dipped (at 60° C. for 30 seconds) in a photoresist stripping solution having the composition as in Table 1 below (stripping solutions A to F).

[0072] The surface of the thusly treated substrate was ob...

examples 7 to 12

[0073] The substrate that had been etched in the same manner as in Examples 1 to 6 was contacted with aqueous 30 mas. % hydrogen peroxide heated at 60° C., for 30 minutes, and then dipped (at 60° C. for 30 seconds) in a photoresist stripping solution having the composition as in Table 1 below (stripping solutions A to F).

[0074] The surface of the thusly treated substrate was observed with SEM (scanning electronic microscope), and it was found that the photoresist pattern and the etching residues had been completely removed. No corrosion was observed on the low-dielectric layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| water-soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com